Microwave method for processing reverse osmosis concentrated water

A technology of reverse osmosis concentrated water and microwave treatment, which is applied in illumination water/sewage treatment, osmosis/dialysis water/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. RO concentrated water treatment effect is not ideal and other problems, to achieve the effect of reducing operating costs, good technical and economic indicators, and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

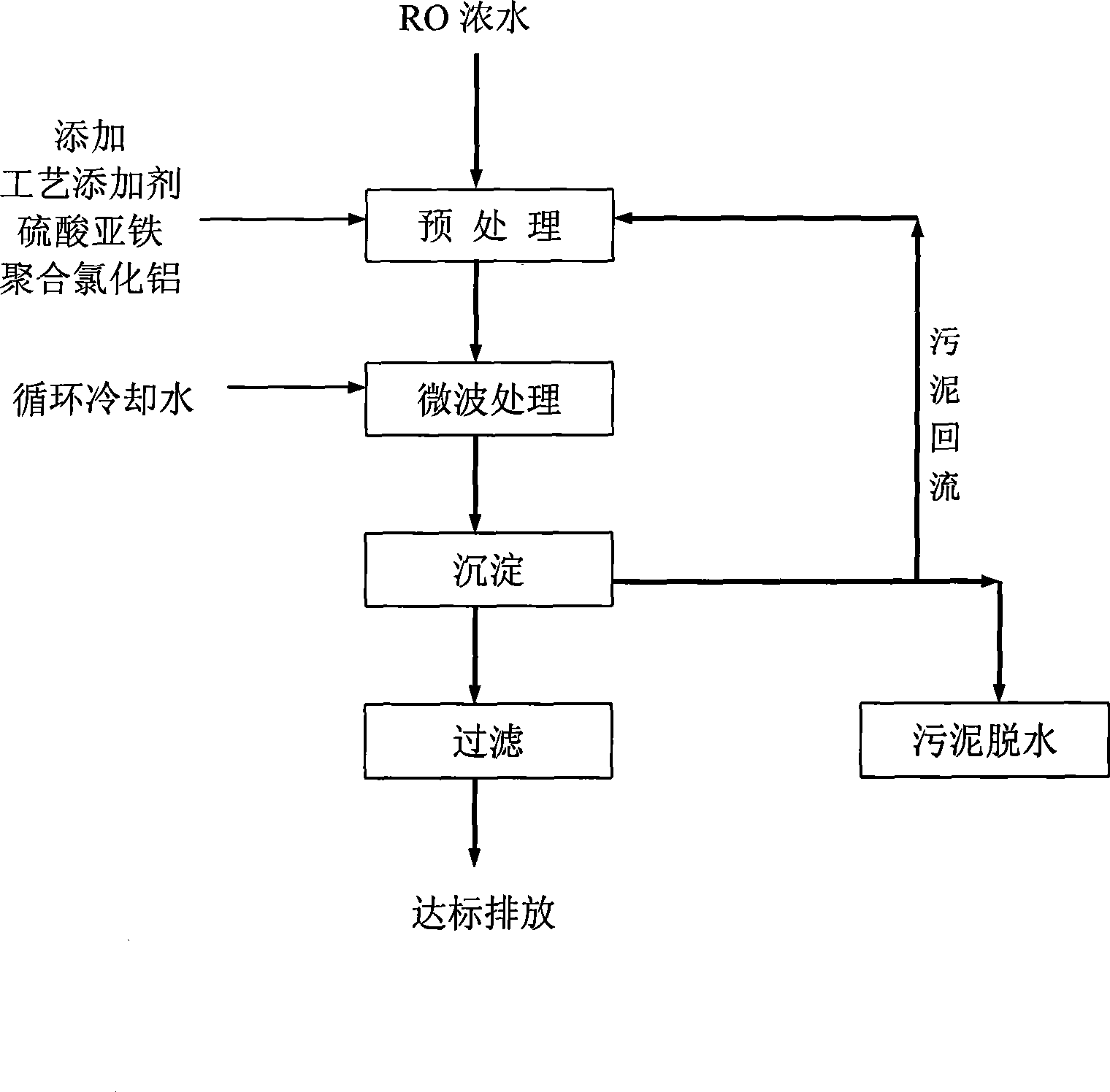

[0038] Take a landfill leachate after biological and membrane treatment, the waste water is: 1000mL, and the water temperature is 21°C. According to the present invention through following technological process:

[0039]waste water mixed reaction 1 mixed reaction 2 mixed reaction 3 microwave treatment sediment filtration out of water

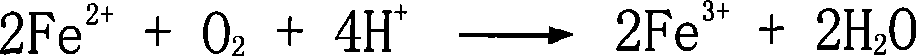

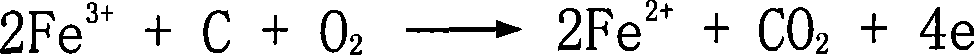

[0040] The process and parameters are as follows: the RO concentrated water self-regulating tank is pumped into the first-stage mixed reaction 1 and stirred and reacted therein for 5 minutes, and 450 ppm of process additives (composed of Al 2 o 3 4SiO2 2 ·3H 2 O: Na 2 Ca[AlSi 5 o 12 ] 4 12H 2 O:+modified carbon fiber=1.5:2.0:6.5) and ferrous sulfate of 130ppm; the effluent of mixed reaction 1 enters into mixed reaction 2 by gravity, depending on the pH value of concentrated water, a pH value regulator is added therein to make Its pH value is 6.5-9.0; 90ppm of polyaluminum chloride is added to the mixed reaction 3. The mixed...

Embodiment 2

[0046] Reverse osmosis (RO) concentrated water is reused in the electroplating plant, and is processed through the following technological process according to the present invention:

[0047] RO concentrated water mixed reaction 1 mixed reaction 2 mixed reaction 3 microwave processor sediment filtration out of water

[0048] The test process and parameters are as follows:

[0049] Take 1000mL of concentrated RO water in a beaker, and add 250ppm of process additives (composition of Al 2 o 3 4SiO2 2 ·3H 2 O: Na 2 Ca[AlSi 5 o 12 ] 4 12H 2 O: + modified carbon fiber = 3.5:3.0:3.5), 220ppm of ferrous sulfate, stirring continuously for 5 minutes; adding lime to adjust the pH value to 8.5, adding 110ppm of polyaluminum chloride; running in the microwave test processor for 15 Second, the effluent water quality after sedimentation and filtration is 1; take another 1000mL of RO concentrated water, add all the sludge in the first test (no need to dry) and add 50ppm o...

Embodiment 3

[0054] The reverse osmosis (RO) concentrated water of certain large-scale paper mill passes through following technological process according to the present invention:

[0055] RO concentrated water mixed reaction 1 mixed reaction 2 mixed reaction 3 microwave treatment sediment filtration out of water

[0056] The process and parameters are as follows:

[0057] The flow rate of RO concentrated water is: 1000L / h, the water temperature is 34°C, it enters the mixed reaction 1 with an effective volume of 120 liters, and 500ppm of process additives are added to it (the composition of Al 2 o 3 4SiO2 2 ·3H 2 O: Na 2 Ca[AlSi 5 o 12 ] 4 12H 2 O: + modified carbon fiber = 1:2.0:7.0), 220ppm ferrous sulfate and continuous stirring; the effluent enters the mixed reaction 2 with an effective volume of 60 liters, and 90ppm of PAC is added to it; the effluent is pumped into the microwave The processor runs the wave for 20 seconds, and the effluent water after microwave t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com