Automobile manufacturer wastewater treatment method

A wastewater treatment and manufacturing plant technology, applied in flotation water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of waste of resources, limited adsorption capacity of activated carbon, and high treatment costs , to achieve strong impact load resistance, good comprehensive treatment effect, and high microbial concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

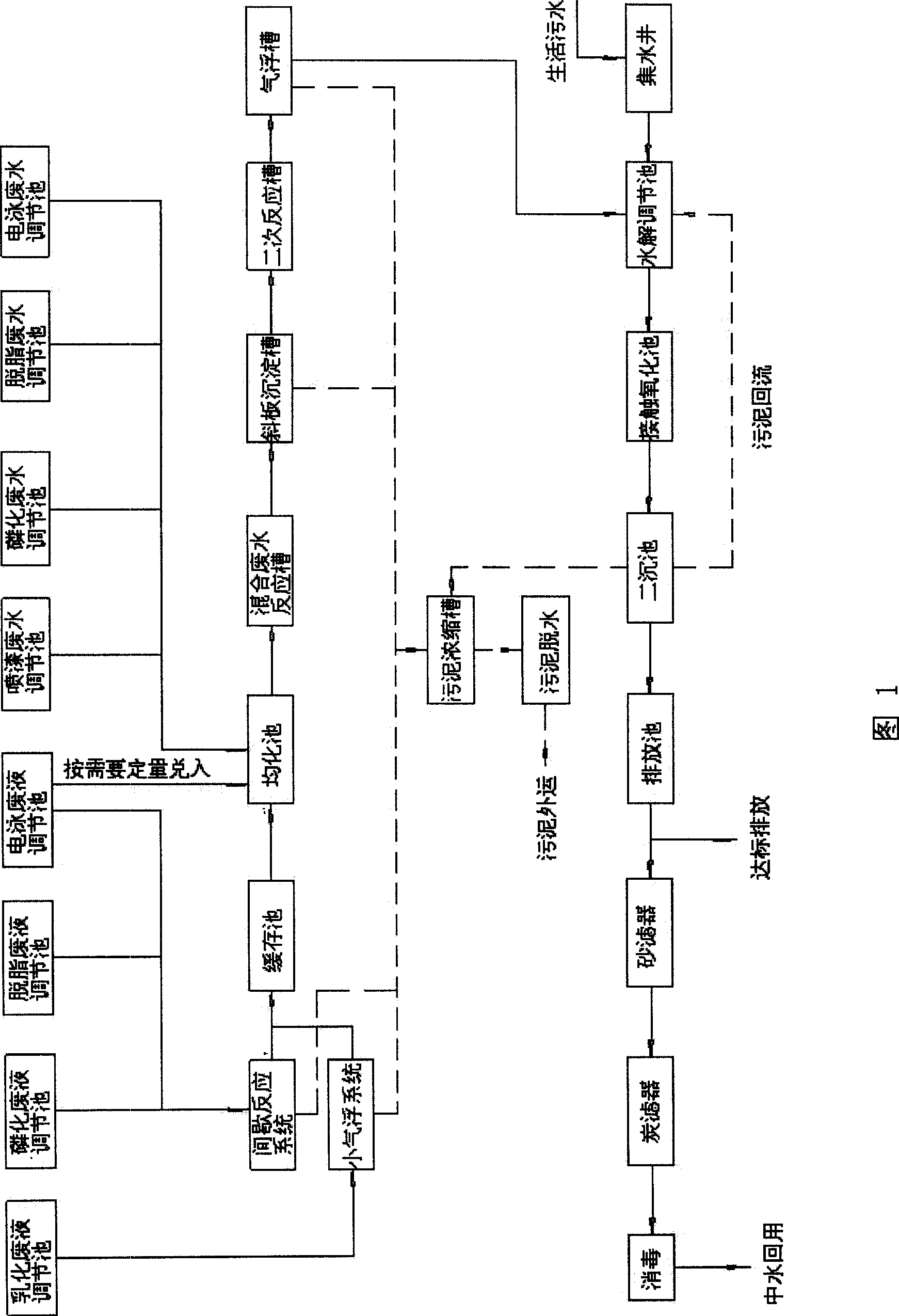

[0047] The process flow chart is shown in Figure 1.

[0048] All kinds of waste water and waste liquid generated in the workshop are collected through pipelines and input into the corresponding waste water regulating pool or waste liquid regulating pool, and the air is stirred evenly. Domestic sewage is collected through pipes into the sump well.

[0049] Enter the emulsified waste liquid (COD3 / h. Add PAC and PAM (dosage: PAC 450-800mg / L, PAM 17-26mg / L), and control the pH value of the reaction to 6.0-8.0. The air flotation water is discharged into the buffer pool.

[0050] Phosphating waste liquid 40m 3 (COD4 3- : 425mg / L, SS: 250mg / L, Zn: 35mg / L, Ni: 35mg / L, Mn: 35mg / L, PH: 1.5) Enter the batch reaction tank, start stirring at the same time, add 30% NaOH to adjust the pH to 4.0 ~8.0 range, add CaCl 2 250mg / L, polyiron 200mg / L. Continue to add alkali to adjust the pH to 10.5~11.2, add PAM 1~3mg / L, stir evenly, let it stand for 48 hours, then discharge the mud, and pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com