Patents

Literature

267 results about "Batch reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low temperature silicon compound deposition

ActiveUS20060088985A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingReaction rateGas phase

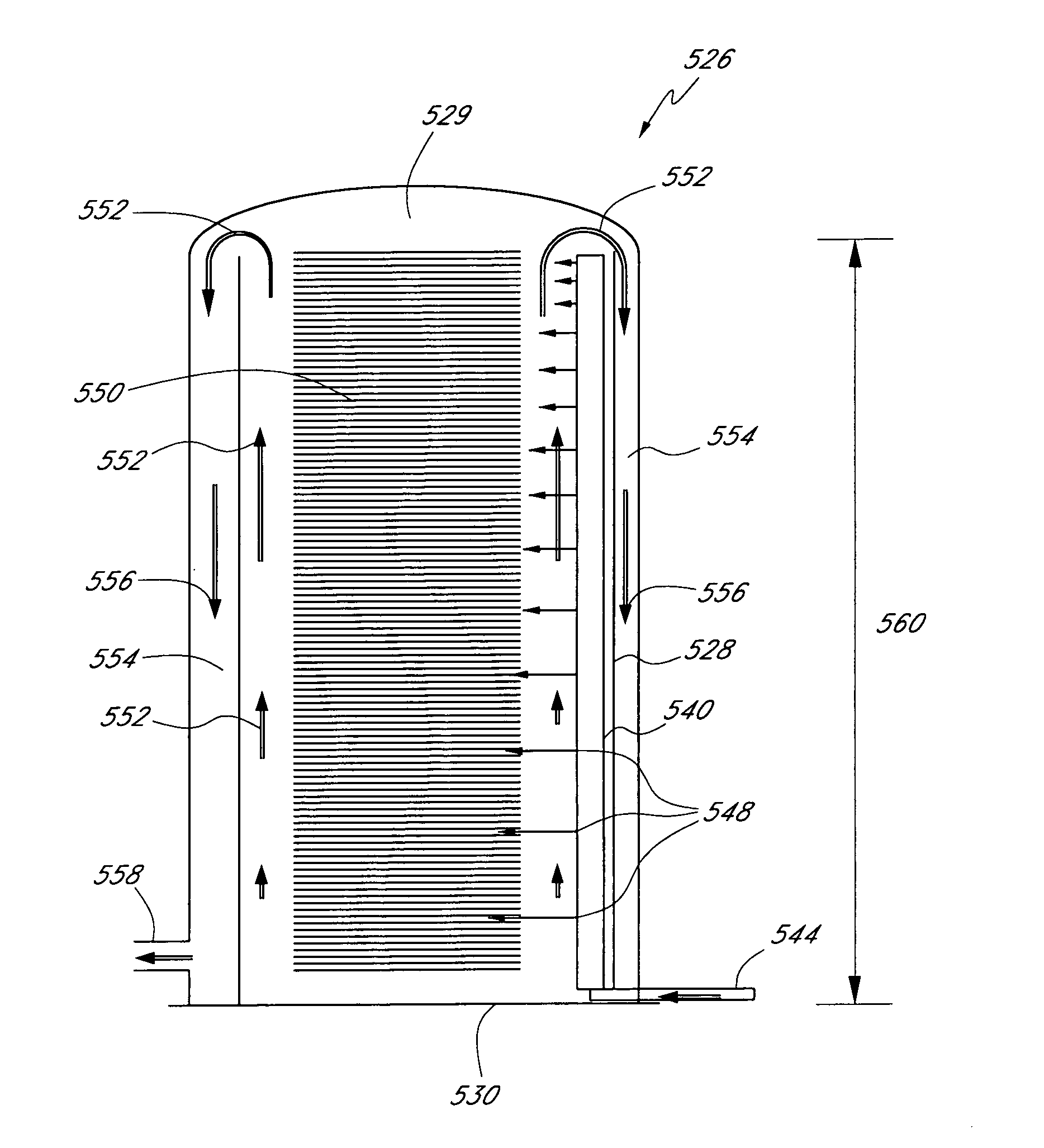

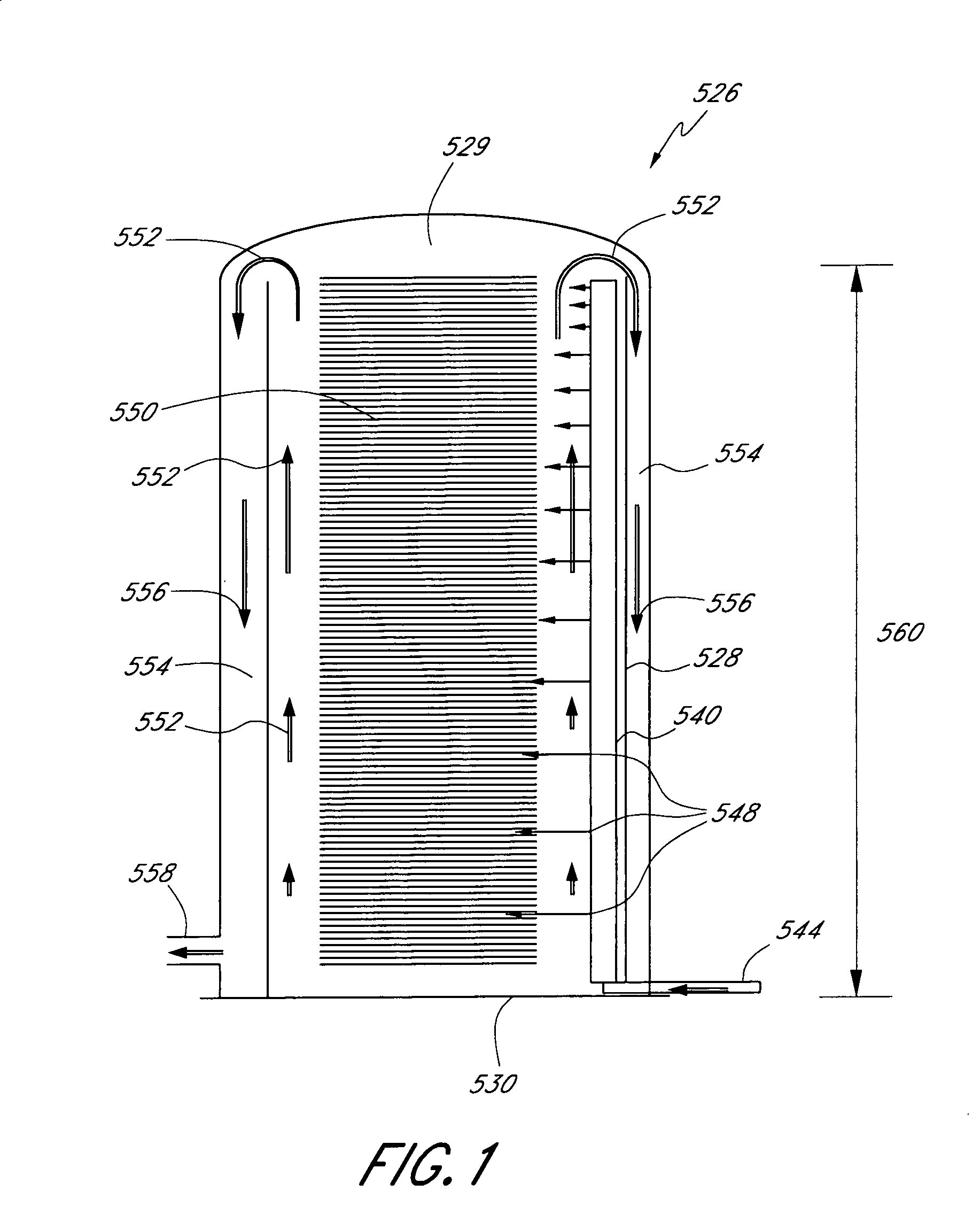

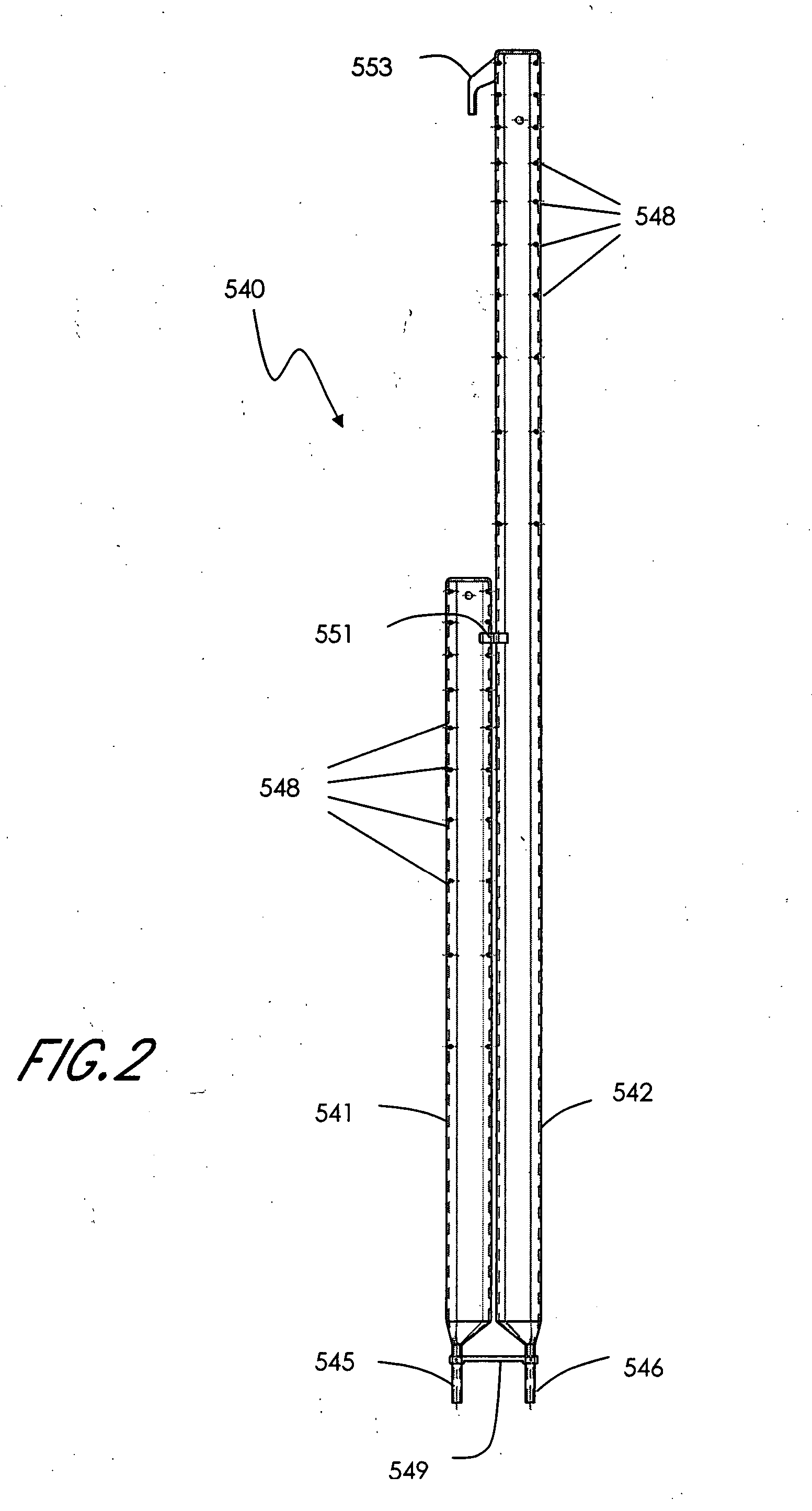

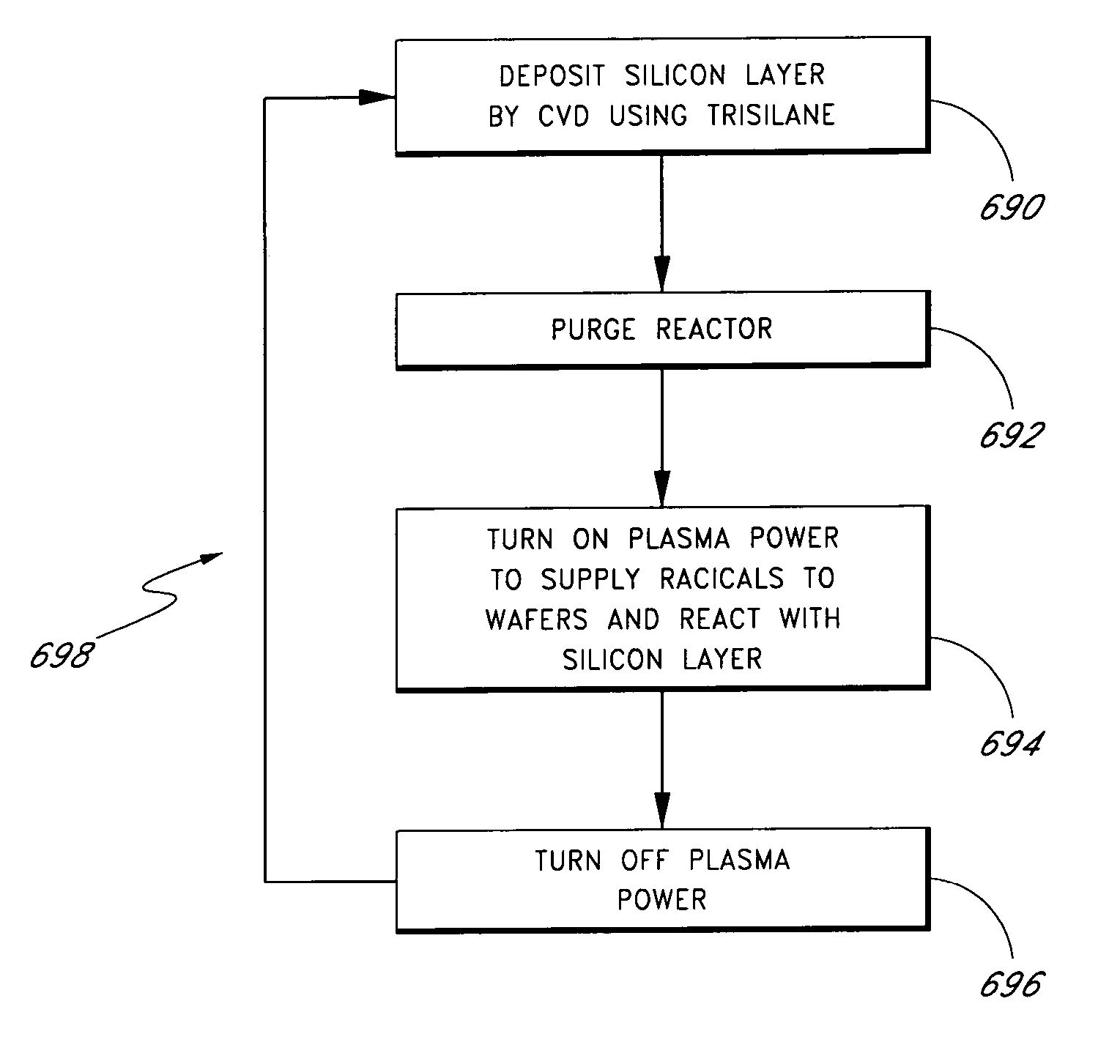

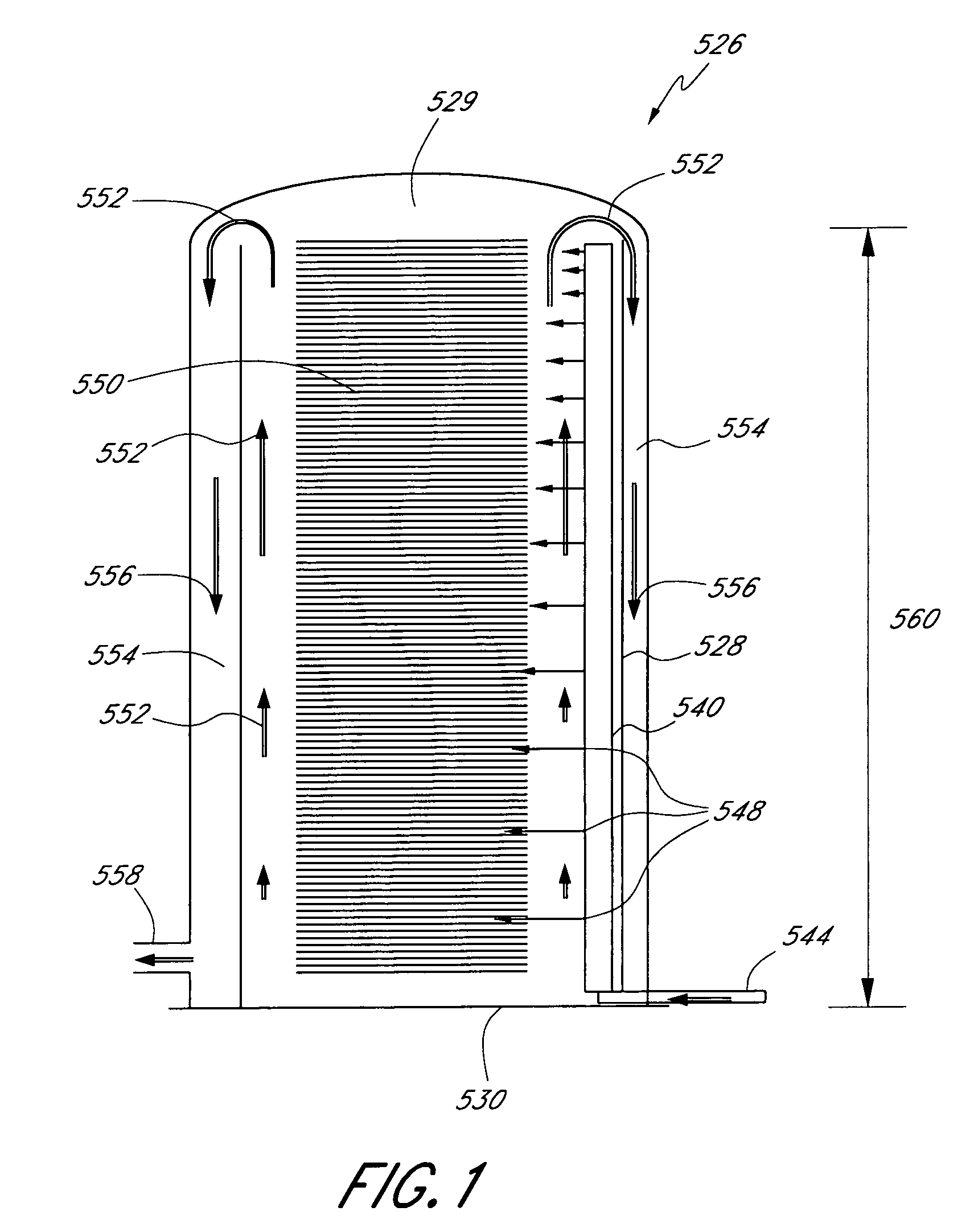

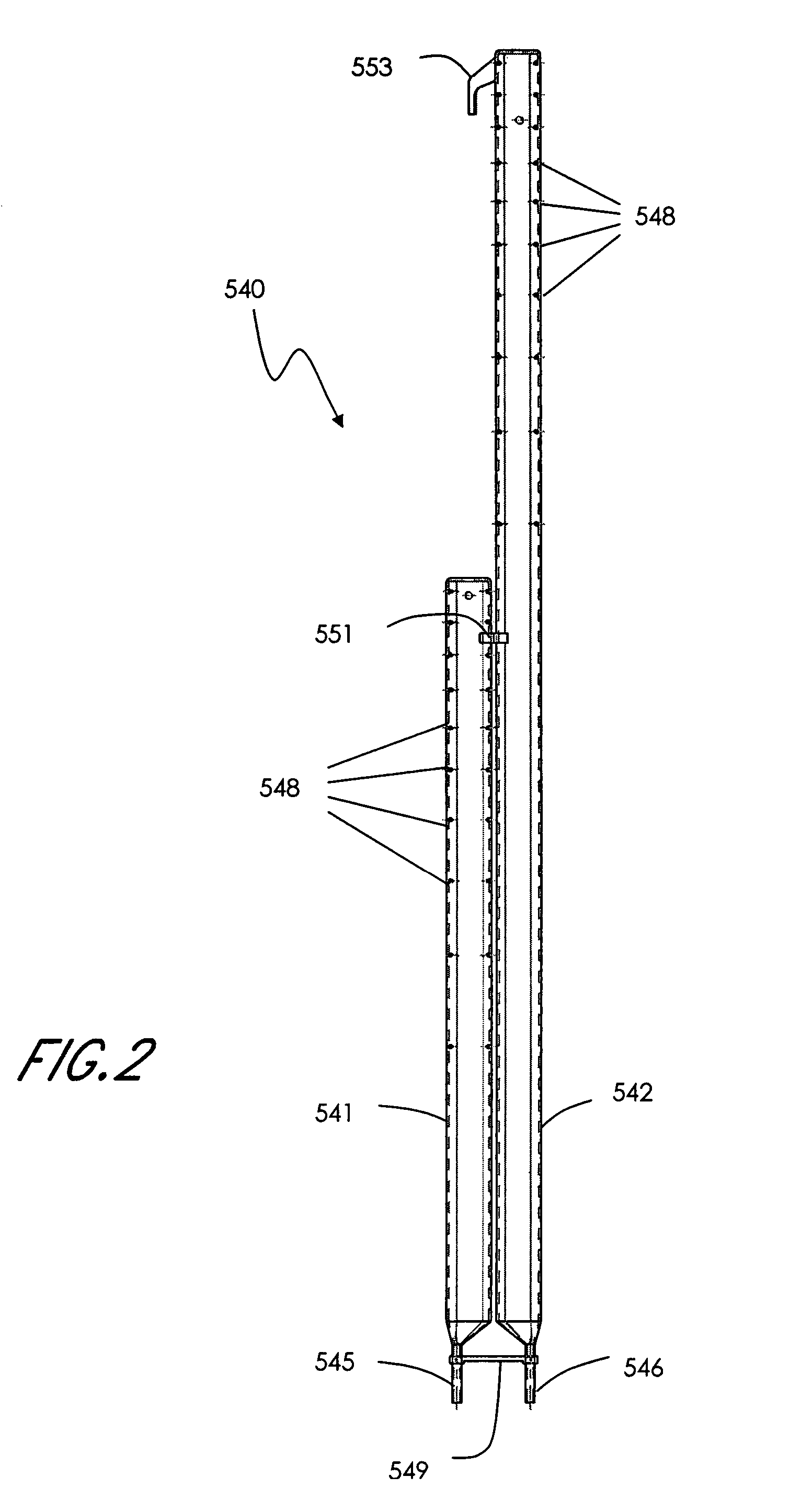

Sequential processes are conducted in a batch reaction chamber to form ultra high quality silicon-containing compound layers, e.g., silicon nitride layers, at low temperatures. Under reaction rate limited conditions, a silicon layer is deposited on a substrate using trisilane as the silicon precursor. Trisilane flow is interrupted. A silicon nitride layer is then formed by nitriding the silicon layer with nitrogen radicals, such as by pulsing the plasma power (remote or in situ) on after a trisilane step. The nitrogen radical supply is stopped. Optionally non-activated ammonia is also supplied, continuously or intermittently. If desired, the process is repeated for greater thickness, purging the reactor after each trisilane and silicon compounding step to avoid gas phase reactions, with each cycle producing about 5-7 angstroms of silicon nitride.

Owner:ASM INTERNATIONAL

Low temperature silicon compound deposition

InactiveUS7294582B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseSilanes

Sequential processes are conducted in a batch reaction chamber to form ultra high quality silicon-containing compound layers, e.g., silicon nitride layers, at low temperatures. Under reaction rate limited conditions, a silicon layer is deposited on a substrate using trisilane as the silicon precursor. Trisilane flow is interrupted. A silicon nitride layer is then formed by nitriding the silicon layer with nitrogen radicals, such as by pulsing the plasma power (remote or in situ) on after a trisilane step. The nitrogen radical supply is stopped. Optionally non-activated ammonia is also supplied, continuously or intermittently. If desired, the process is repeated for greater thickness, purging the reactor after each trisilane and silicon compounding step to avoid gas phase reactions, with each cycle producing about 5-7 angstroms of silicon nitride.

Owner:ASM INTERNATIONAL

Method for preparing acrolein through catalysis of glycerol liquid phase dehydration by using imidazole ion liquid

InactiveCN102936190ALow priceIn line with the sustainable development strategyOrganic compound preparationCarbonyl compound preparationPtru catalystFluid phase

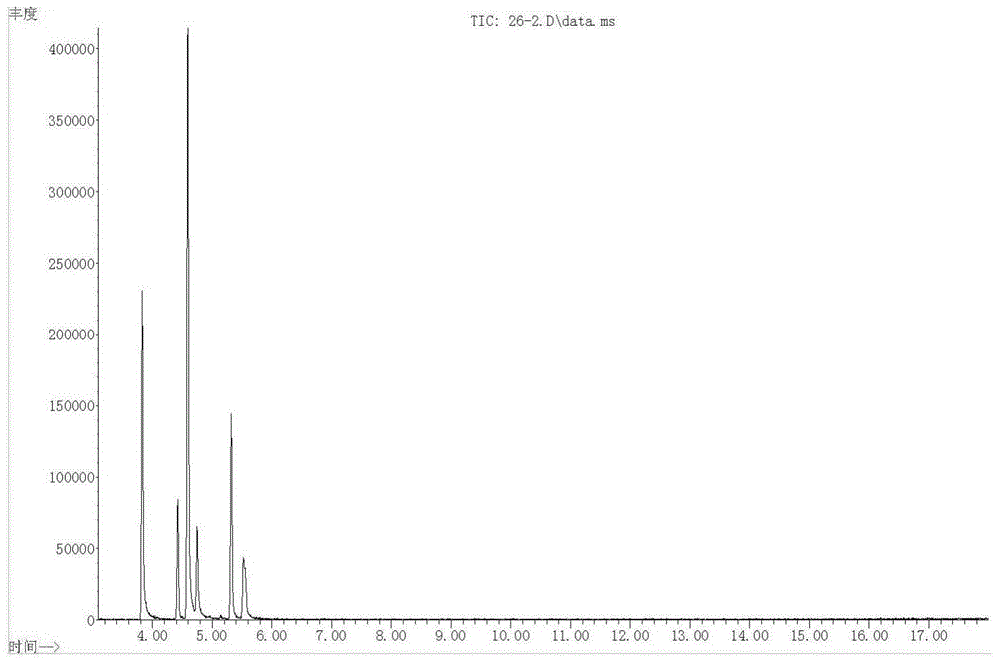

The present invention relates to the field of organic chemistry, particularly to a method for preparing acrolein through catalysis of glycerol liquid phase dehydration by using an imidazole ion liquid. According to the method, an imidazole ion liquid is adopted as a catalyst, a semi-batch reaction is adopted, and glycerol liquid phase dehydration is performed at a reaction temperature of 250-350 DEG C and a molar ratio of the ion liquid to the glycerol of 0.1:100-1.5:100 to prepare the acrolein, wherein a glycerol conversion rate is 100%, and an acrolein yield is 30.5-68.2%. According to the present invention, the biomass glycerol is adopted to prepare the high added value acrolein, raw material cost is low, raw material sources are wide, acidity of the catalyst can be adjusted, catalytic activity is high, and the process has characteristics of fast reaction, high selectivity, simple product system separation, safe and environmental protection process, and industrial production.

Owner:JIANGSU UNIV

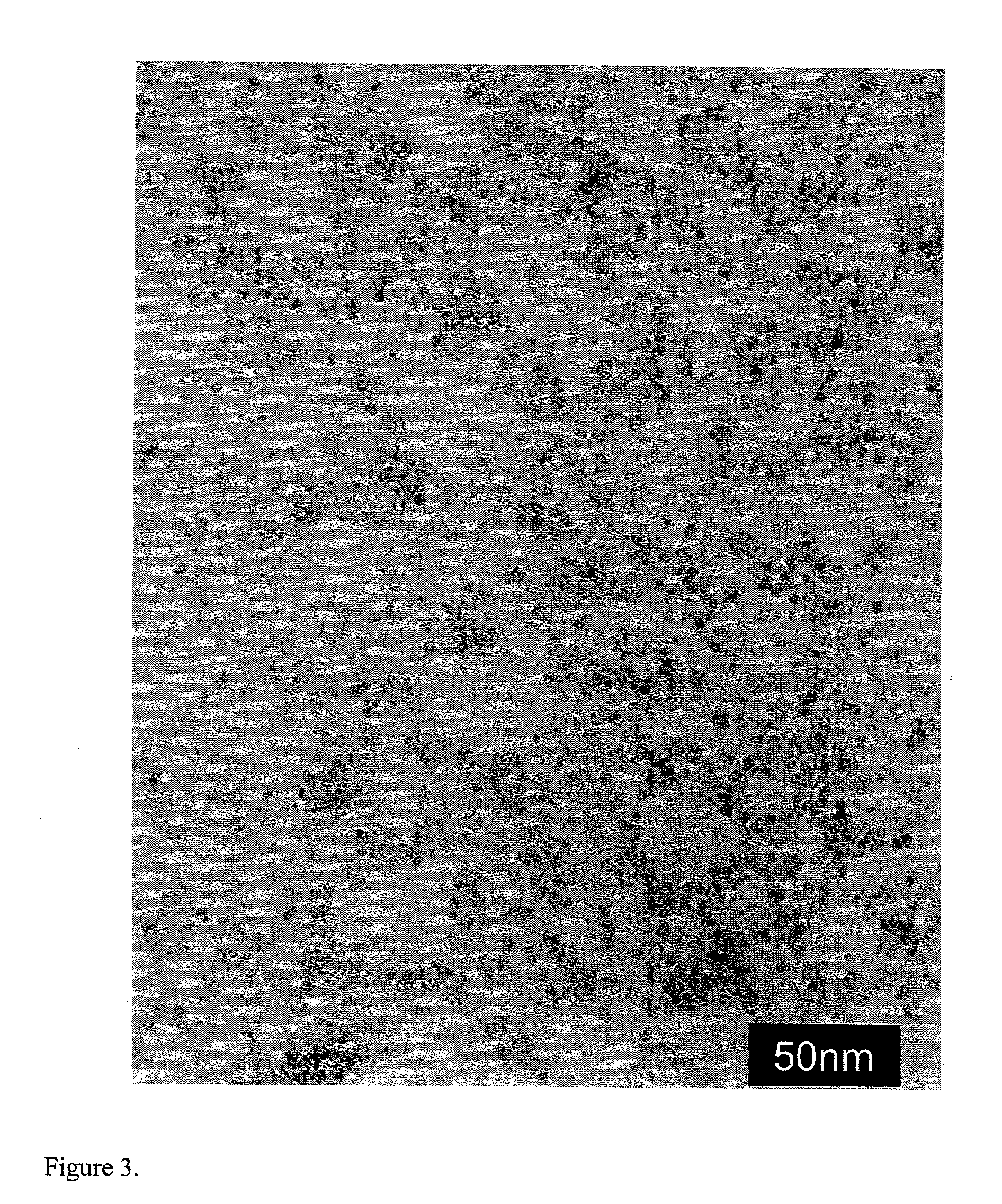

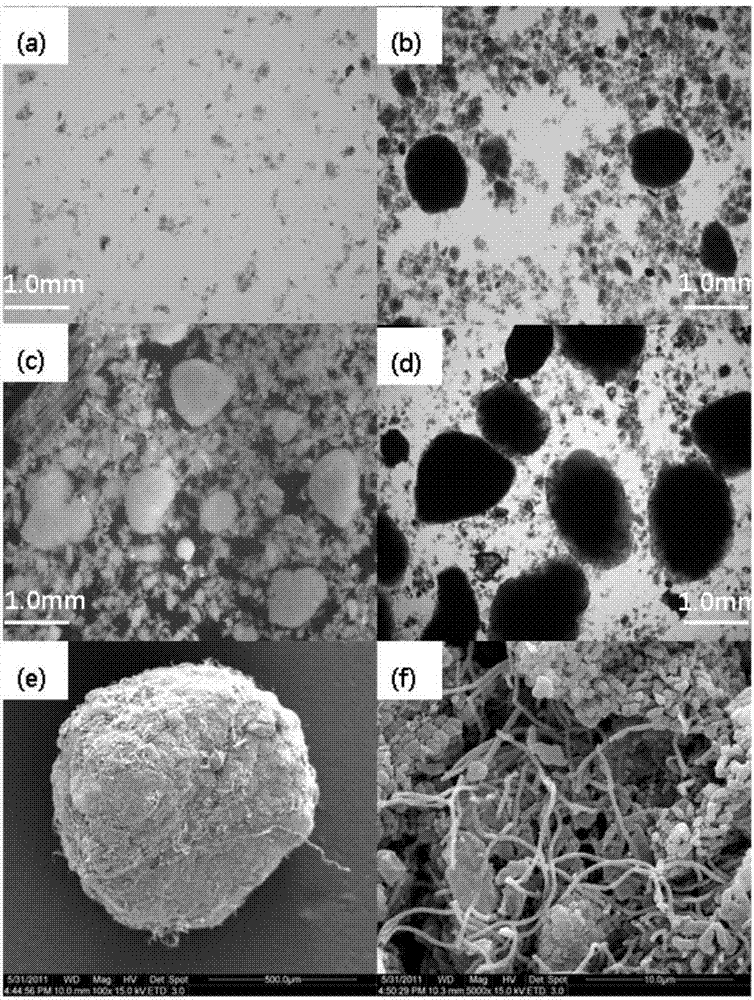

Method for preparation of nanometer cerium-based oxide particles

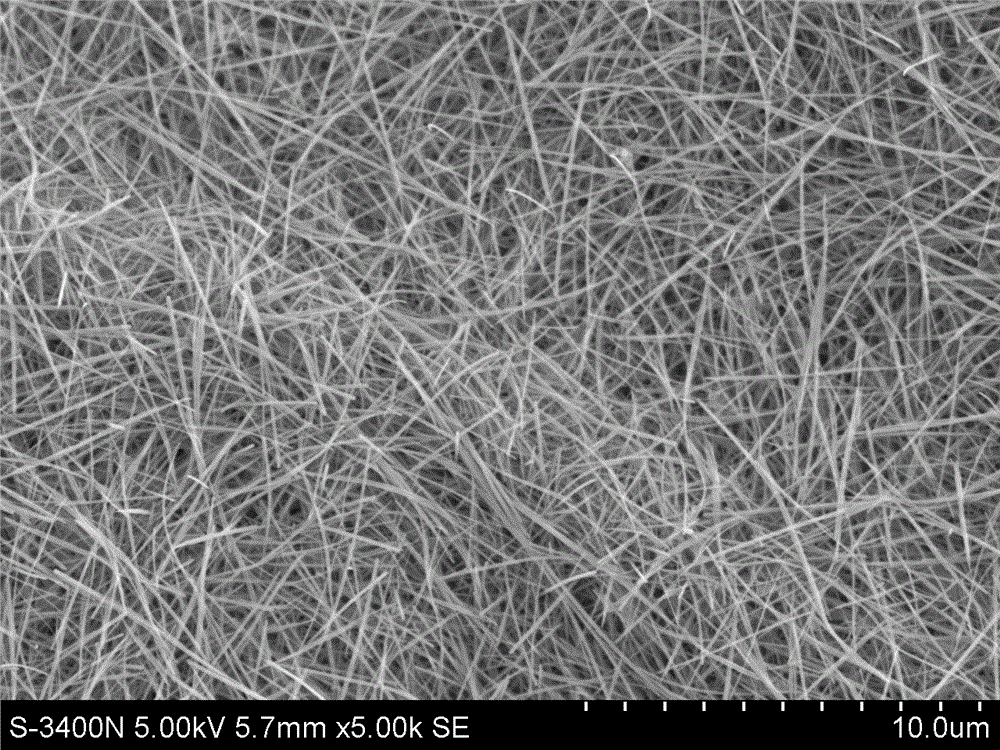

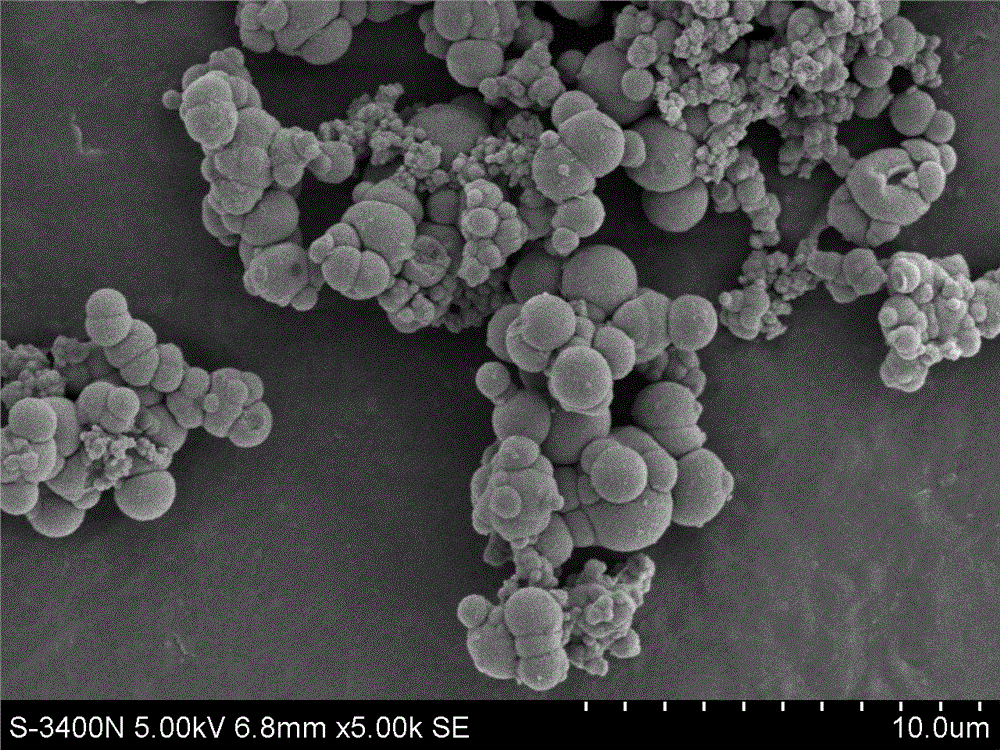

InactiveUS7025943B2Small particle sizeUniform shapeMaterial nanotechnologyCerium oxides/hydroxidesRoom temperatureCerium

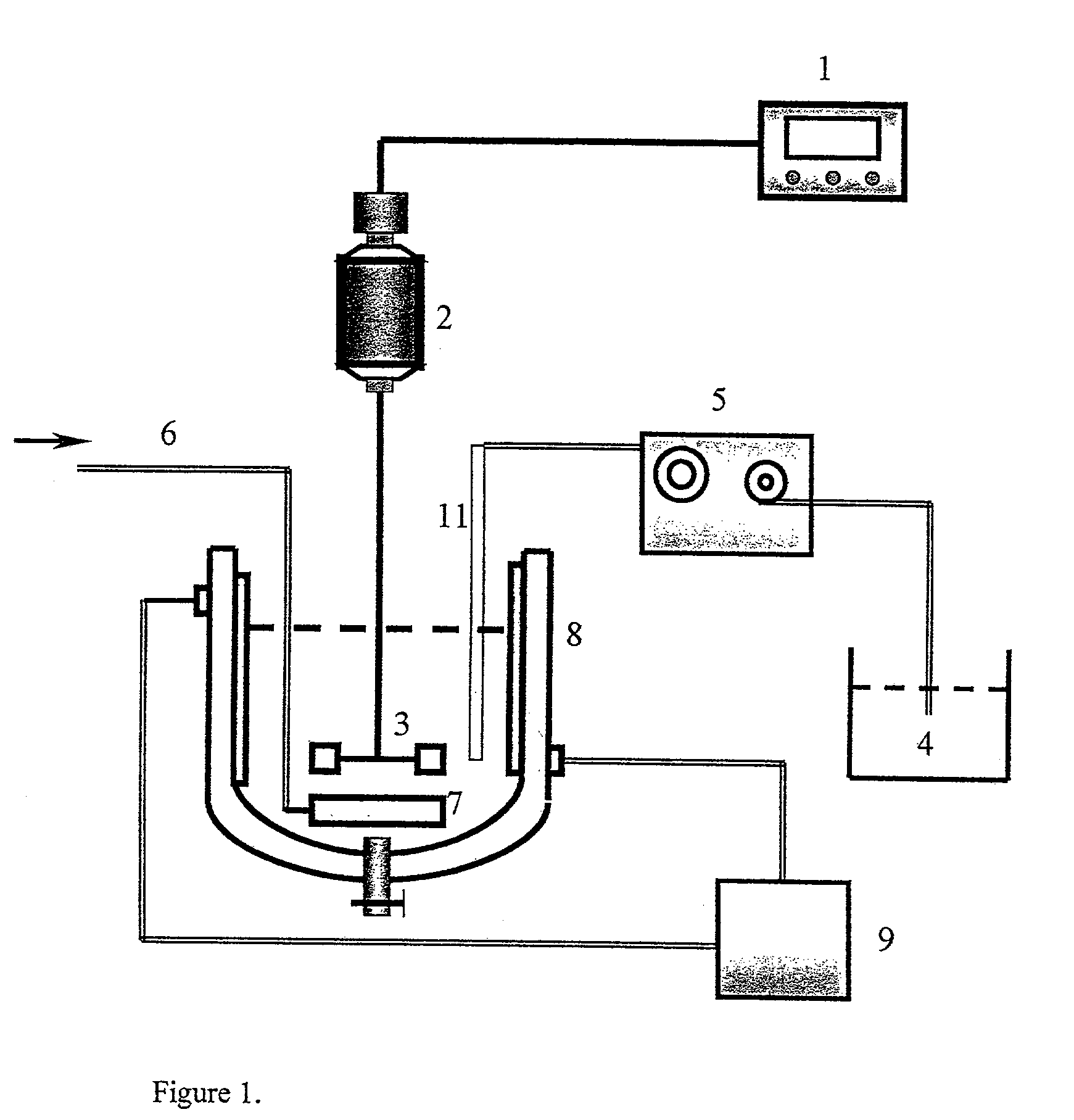

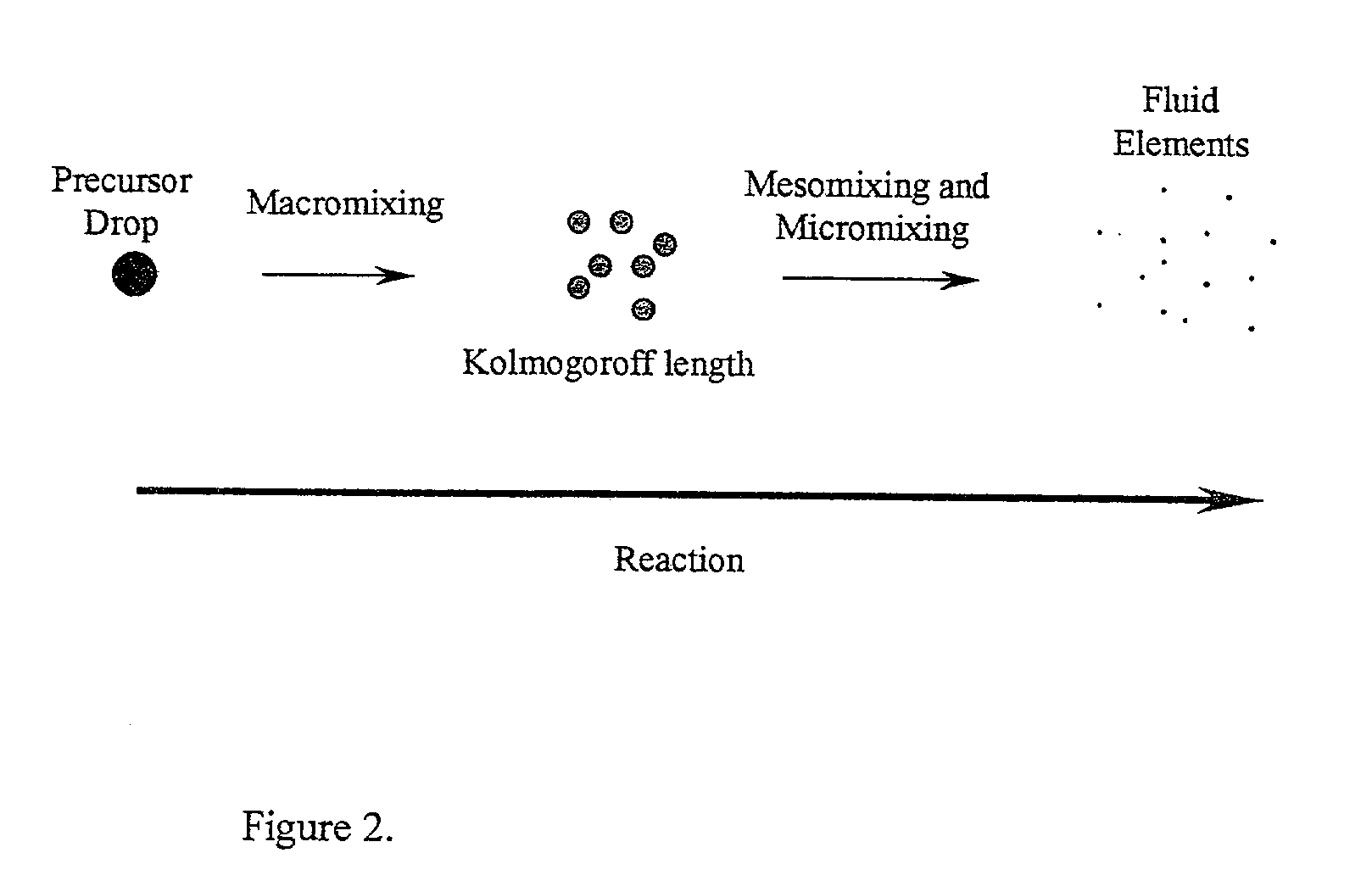

The invention comprises novel undoped and doped nanometer-scale CeO2 particles as well as a novel semi-batch reactor method for directly synthesizing the novel particles at room temperature. The powders exhibited a surface area of approximately 170 m2 / g with a particle size of about 3–5 nm, and are formed of single crystal particles that are of uniform size and shape. The particles' surface area could be decreased down to 5 m2 / g, which corresponds to a particle size of 100 nm, by thermal annealing at temperatures up to 1000° C. Control over the particle size, size distribution and state of agglomeration could be achieved through variation of the mixing conditions such as the feeding method, stirrer rate, amount of O2 gas that is bubbled through the reactor, the temperature the reaction is carried out at, as well as heating the final product at temperatures ranging from 150° to 1000° C.

Owner:UNIVERSITY OF MISSOURI

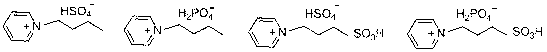

Method for preparing acrolein through catalysis of glycerol liquid phase dehydration by using pyridine ion liquid

InactiveCN102936189ALow priceIn line with the sustainable development strategyOrganic compound preparationCarbonyl compound preparationPtru catalystReaction rate

The present invention relates to the field of organic chemistry, particularly to a method for preparing acrolein through catalysis of glycerol liquid phase dehydration by using a pyridine ion liquid. According to the method, a pyridine ion liquid is adopted, a semi-batch reaction is adopted, and glycerol liquid phase dehydration is performed at a reaction temperature of 250-350 DEG C and a molar ratio of the ion liquid to the glycerol of 0.5:100-1.2:100 to prepare the acrolein, wherein a glycerol conversion rate is 100%, and an acrolein yield is 32.0-67.9%. According to the present invention, the biomass glycerol is adopted to prepare the high added value acrolein, raw material cost is low, raw material sources are wide, acidity of the catalyst can be adjusted, catalytic activity is high, and the process has characteristics of fast reaction, high selectivity, simple product system separation, safe and environmental protection process, and industrial production.

Owner:JIANGSU UNIV

Method for preparing acraldehyde from liquid-phase dehydration of glycerin catalyzed by quaternary ammonium salt ionic liquid

InactiveCN102942462AHigh activityHigh selectivityOrganic compound preparationCarbonyl compound preparationPtru catalystFluid phase

The invention relates to the field of organic chemistry, and particularly relates to a method for preparing acraldehyde from liquid-phase dehydration of glycerin catalyzed by quaternary ammonium salt ionic liquid. In the method, the quaternary ammonium salt ionic liquid is used as a catalyst; a semi-batch reaction technology is employed; a reaction temperature is 280-350 DEG C; the molar ratio of the ionic liquid to glycerin is 1.0 : 100-2.5 : 100; acraldehyde is prepared from the liquid-phase dehydration of glycerin; the conversion rate of glycerin is 100%; and the yield of the product acraldehyde is 37.8-70.3%. High added-value acraldehyde is prepared by using biomass glycerin. The raw materials are low in cost and wide in resources. The acidity of the catalyst is adjustable; and the catalyst has high catalytic activity. The method has the characteristics of fast reaction rate and high selectivity. The product system is simple in separation; the process is safe and environment-friendly, and can realize industrialized production.

Owner:JIANGSU UNIV

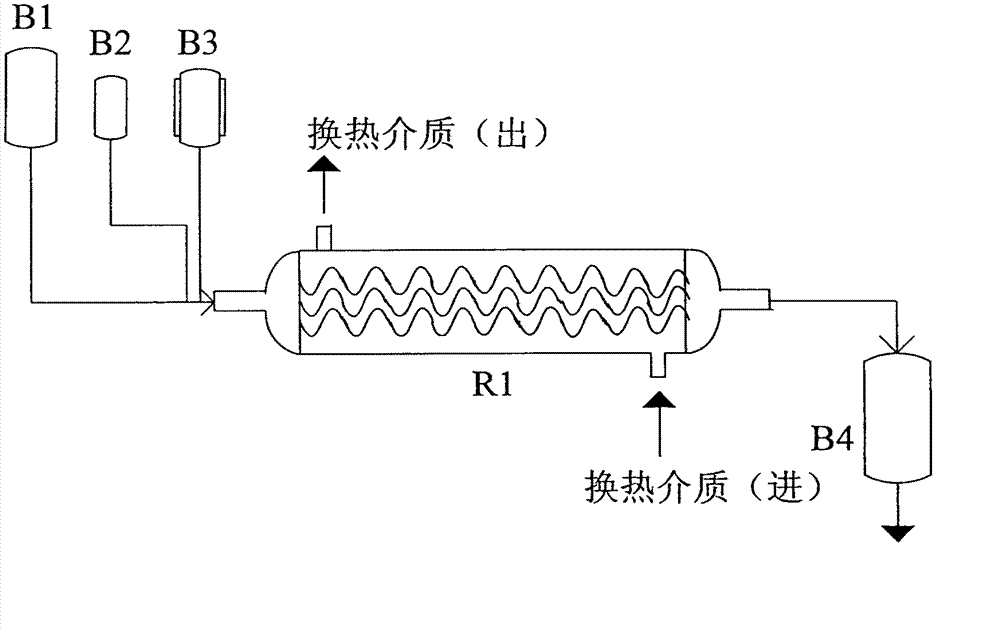

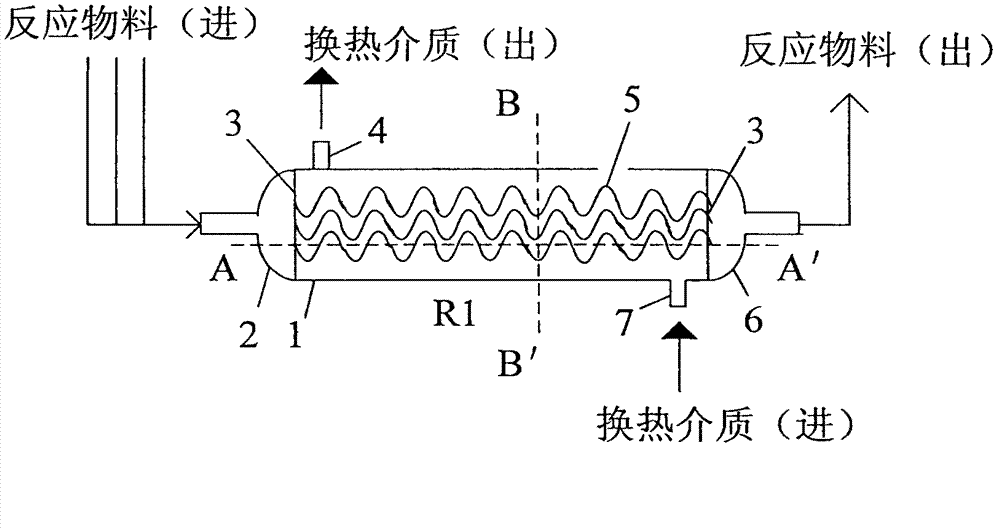

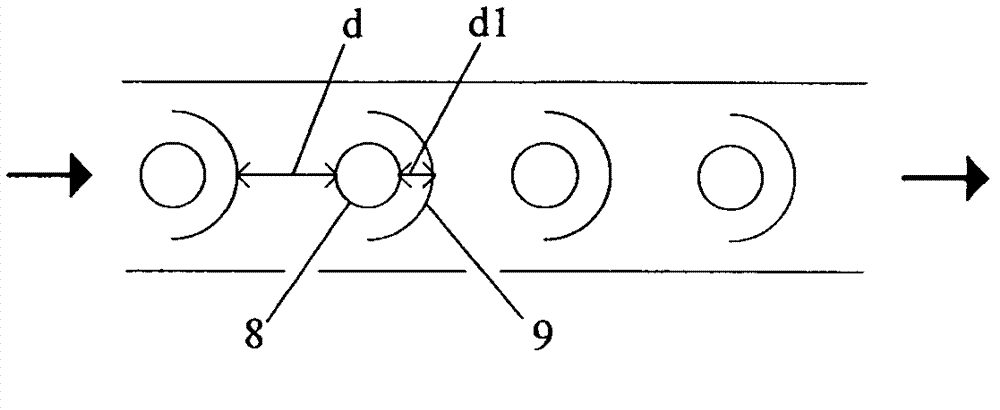

Reactor for preparing isophorone nitrile and method for continuously preparing isophorone nitrile by adopting reactor

ActiveCN103301799AImprove heat transfer efficiencyImprove mass transfer efficiencyChemical/physical/physico-chemical stationary reactorsPreparation by hydrogen cyanide additionMicron scaleIsophorone

The invention provides a reactor for preparing isophorone nitrile and a method for continuously preparing the isophorone nitrile by adopting the reactor. A plurality of millimeter to micron-sized narrow regular reaction channels which are arranged in parallel are arranged in the reactor, and inner members are arranged in the reaction channels, so that the reactor has good heat and mass transfer effects, and the dwell time can be accurately controlled, thereby obtaining a high reaction conversion rate and a high product yield. Compared with a traditional batch reactor or a common continuous tubular reactor, the method has obvious advantages on many aspects of improvement in the reaction effect in preparation of the isophorone nitrile, safety in production, energy conservation, consumption reduction and the like.

Owner:WANHUA CHEM GRP CO LTD +1

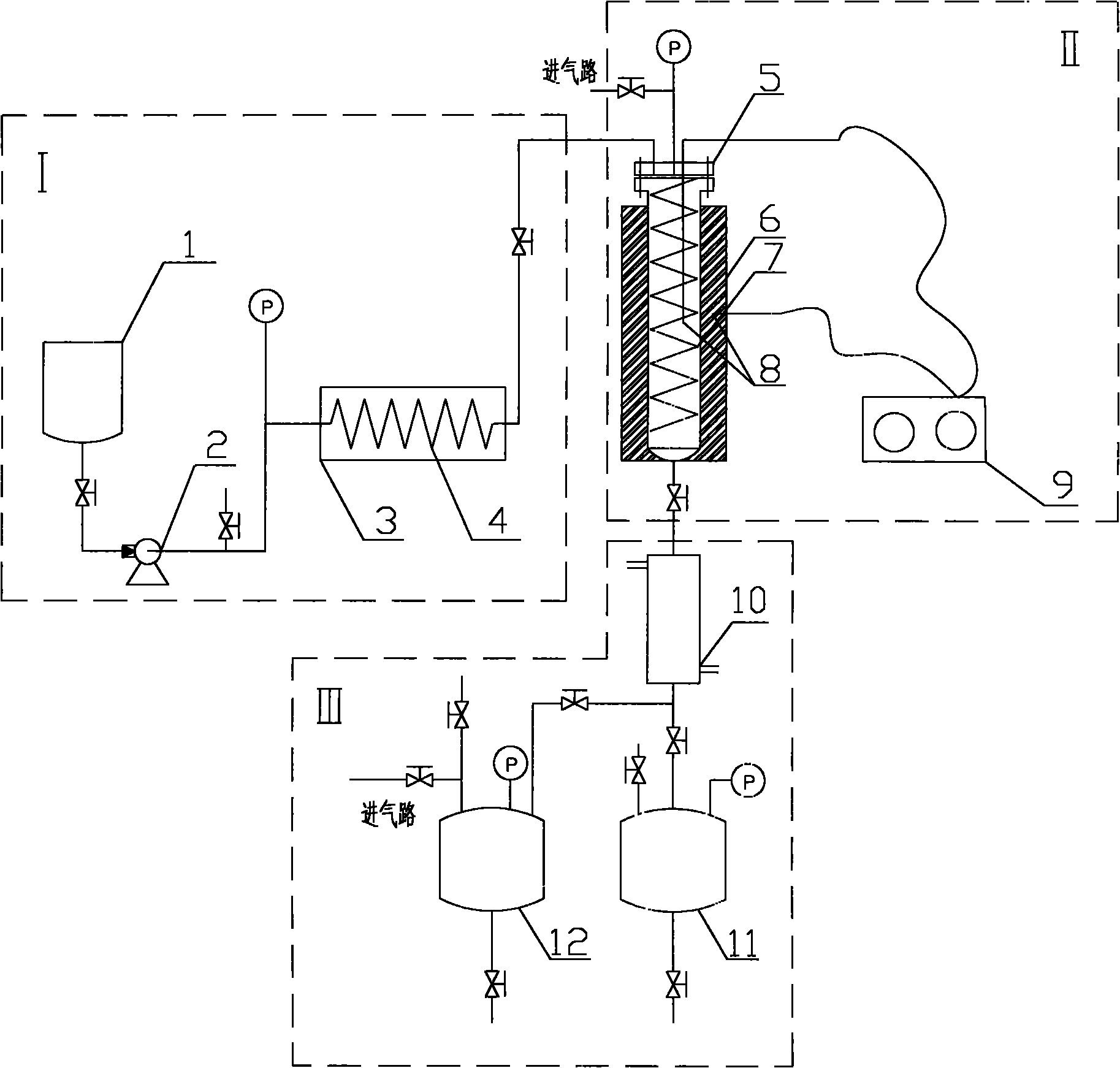

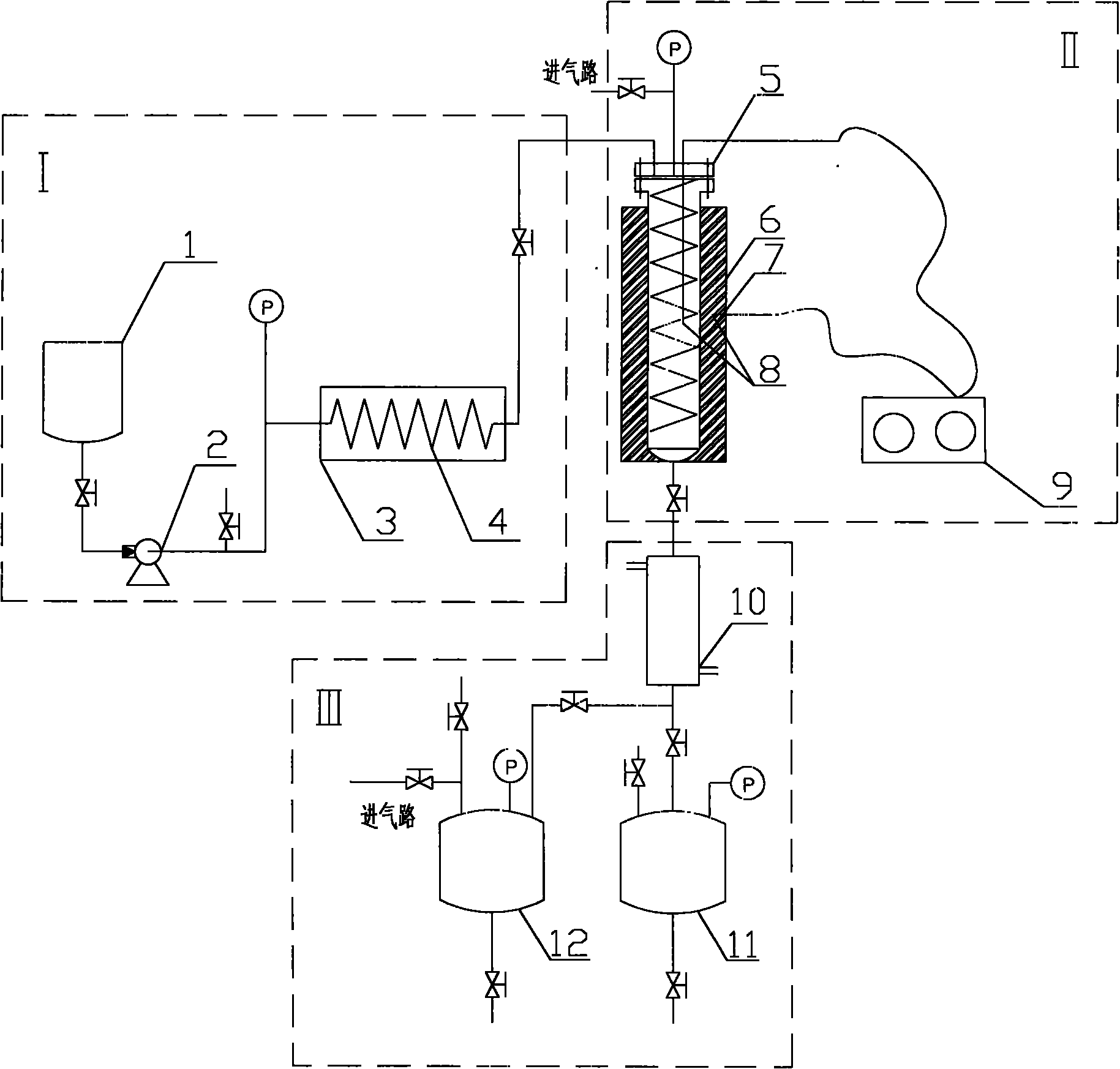

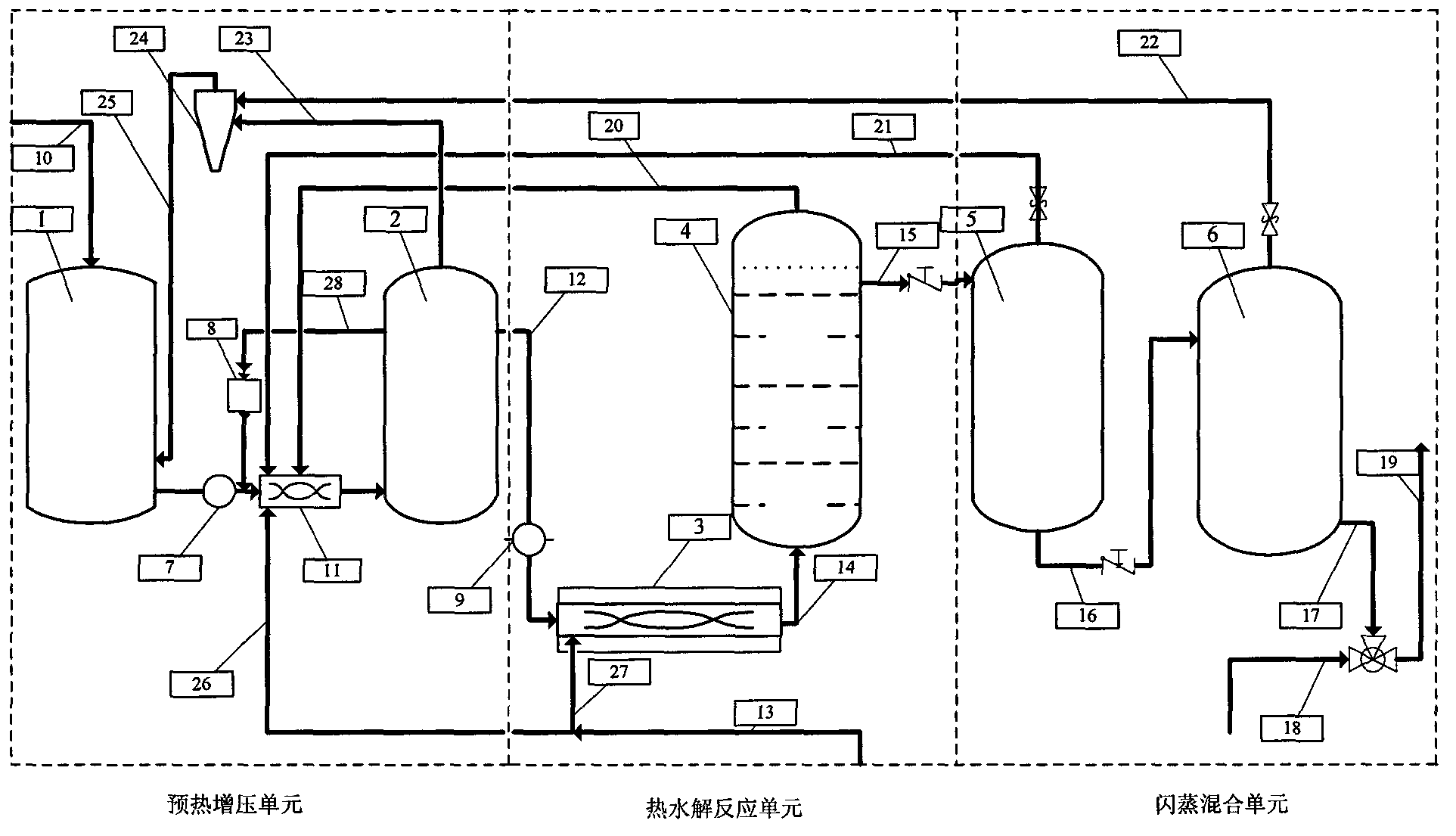

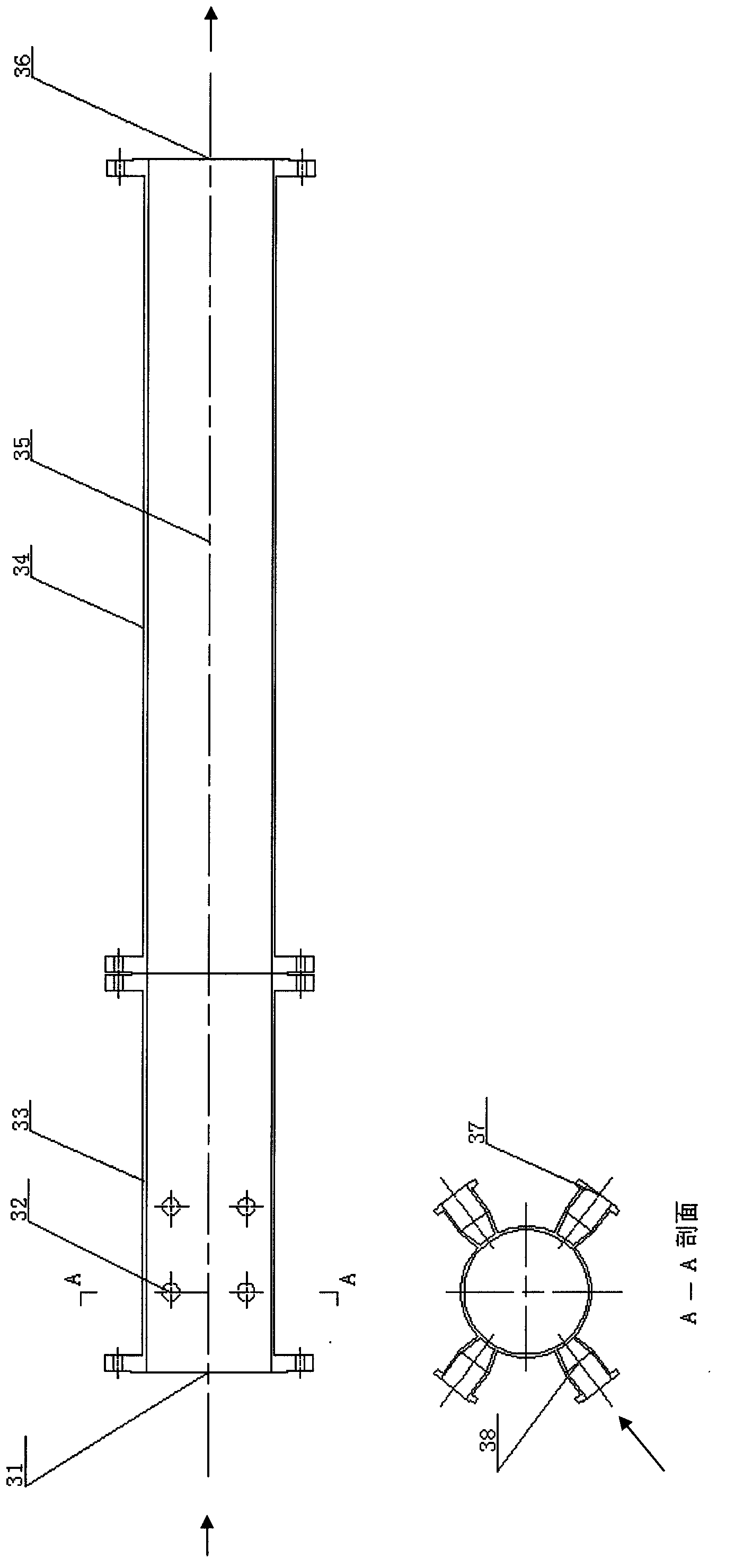

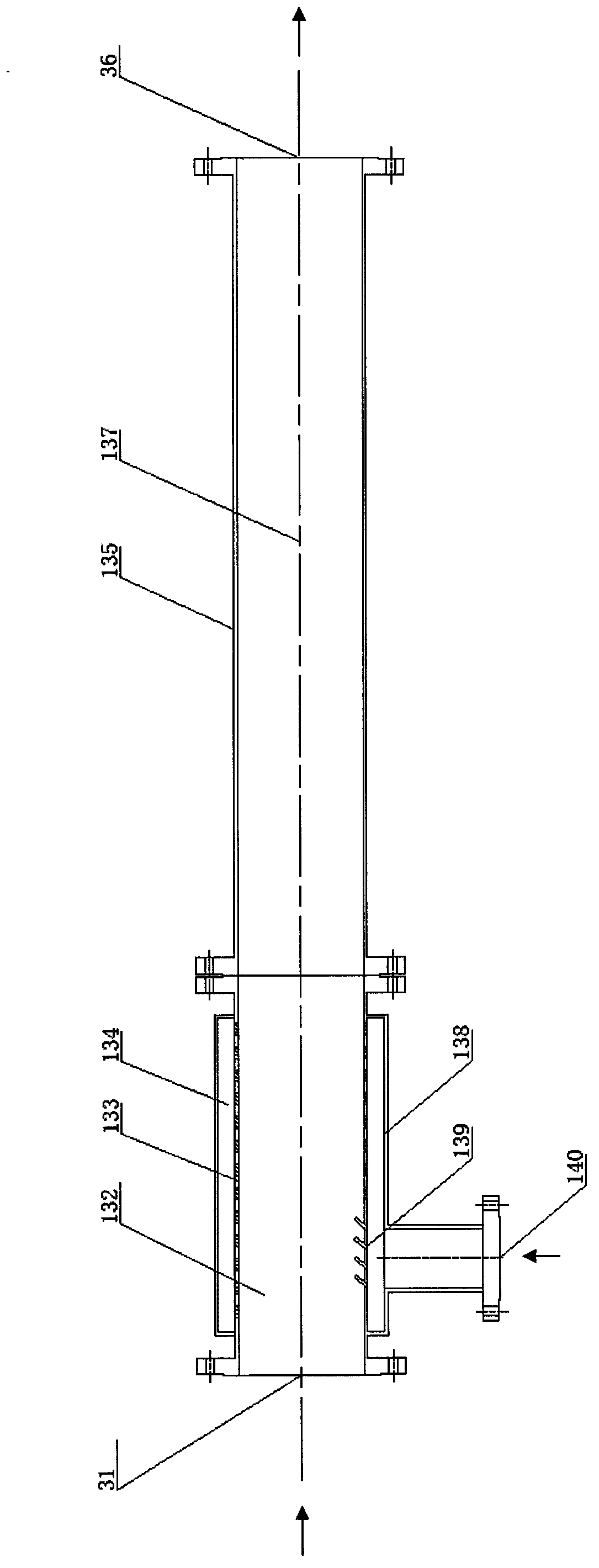

Method and device for pretreatment of high-temperature liquid water of cellulosic biomass

InactiveCN101818217AEfficient hydrolysisSave reaction mediumSaccharides productionLiquid productHydrolysate

The invention provides a method and a device for performing hydrolysis on hemicellulose in lignocellulose biomass. The method comprises the following steps of: adding lignocellulose biomass of which the granularity is less than 1 centimeter into an internal cylinder of a compression percolation reactor; allowing high-temperature liquid water with low-concentration metal ions serving as a reactionmedium to continuously flow through biomass raw materials in the internal cylinder of the compression percolation reactor in a mode of subsection and variable flow, wherein the temperature of the high-temperature liquid water is between 150 and 200 DEG C, and the pressure is within the saturated vapor pressure of the corresponding temperature to 5 MPa; and simultaneously, recovering xylose after cooling and liquid products taking oligosaccharide of the xylose as predominant matters. The device consists of three parts, namely a reaction medium fed-batch system I for preheating and realizing variable fed-batch reaction media, a compression percolation reactor component II with the compression percolation reactor and a split reactor heating device and a liquid product collecting device III. The method and the device can realize the high-efficiency hydrolysis of hemicellulose components in the lignocellulose biomass, and can realize the continuous and stable collection of hydrolysate.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

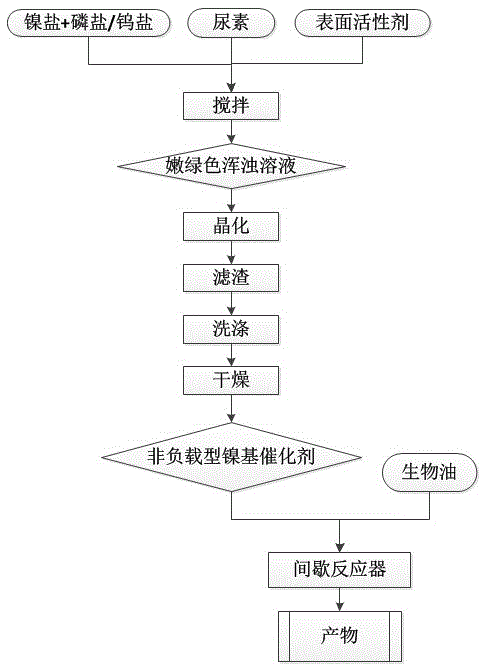

Non-loading type nickel-based bio-oil hydrodeoxygenation catalyst and preparation method thereof

InactiveCN105413723AThe synthesis method is simpleLow equipment requirementsOrganic compound preparationHydrocarbon from oxygen organic compoundsNickel saltSynthesis methods

The invention provides a preparation method of a non-loading type nickel-based bio-oil hydrodeoxygenation catalyst, and belongs to the technical field of catalyst synthesis. The method includes the steps of firstly, dissolving a surface active agent in water, dissolving urea in water, dissolving soluble nickel salt, soluble phosphor salt or (and) soluble tungsten salt in water, and conducting crystallization for 2-16 h at a temperature of 100-300 DEG C; secondly, washing filtered-out filter residues with water and absolute ethyl alcohol, obtaining a non-loading type nickel-based catalyst after drying is conducted; thirdly, placing the non-loading type nickel-based catalyst and bio-oil in an intermittent reactor, and conducting the hydrodeoxygenation reaction for 1-10 h under the condition of the hydrogen pressure of 2-4 MPa and the temperature of 100-250 DEG C to obtain a bio-oil hydrodeoxygenation product. The synthesis method is easy, convenient to use, efficient and gentle in reaction condition, the metal content of the unit volume of obtained non-loading type nickel-based catalyst is high, the number of hydrogenation activity sites is large, and the catalysis efficiency of the catalyst is improved by dozens of times compared with that of a traditional catalyst.

Owner:BEIJING FORESTRY UNIVERSITY

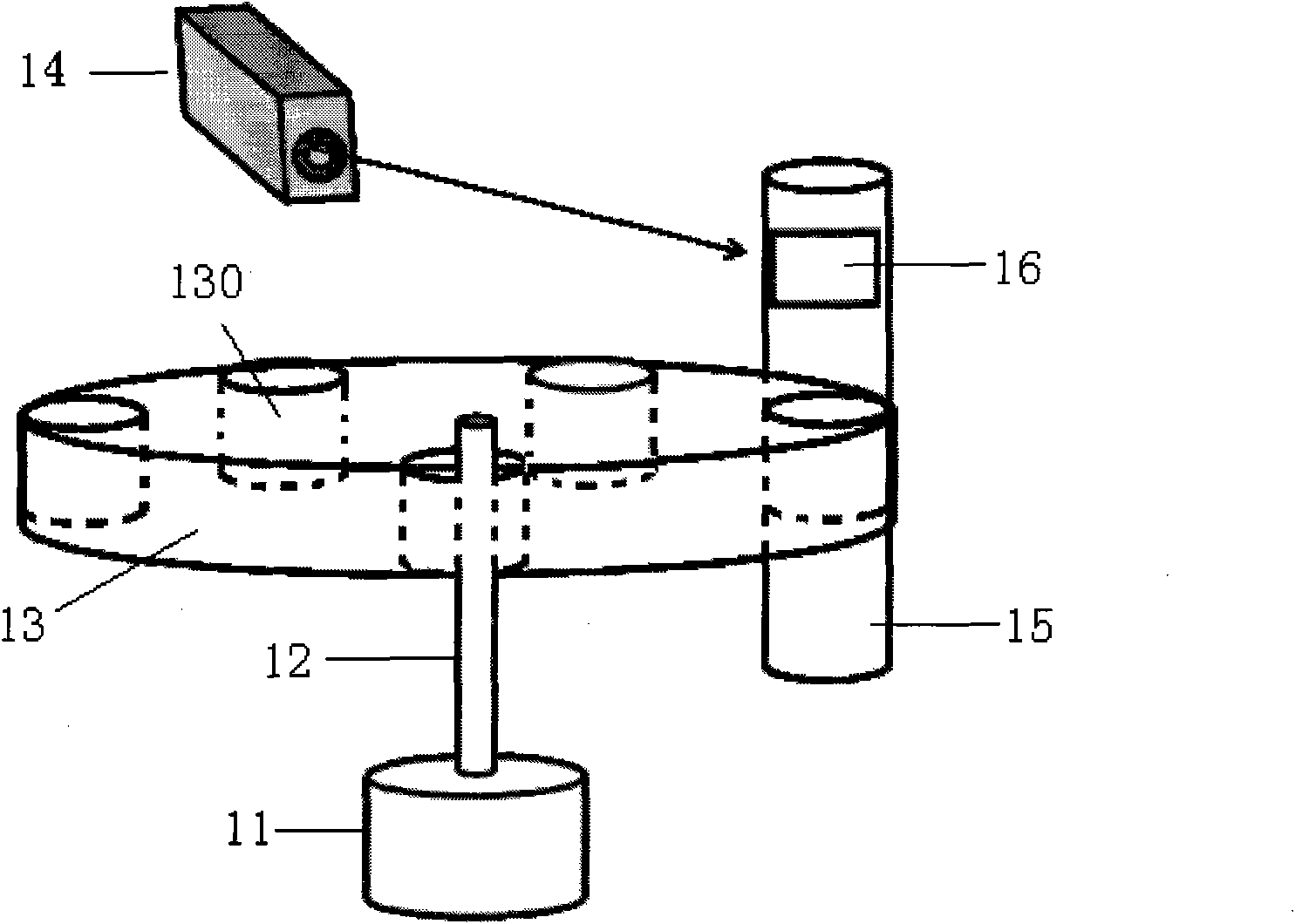

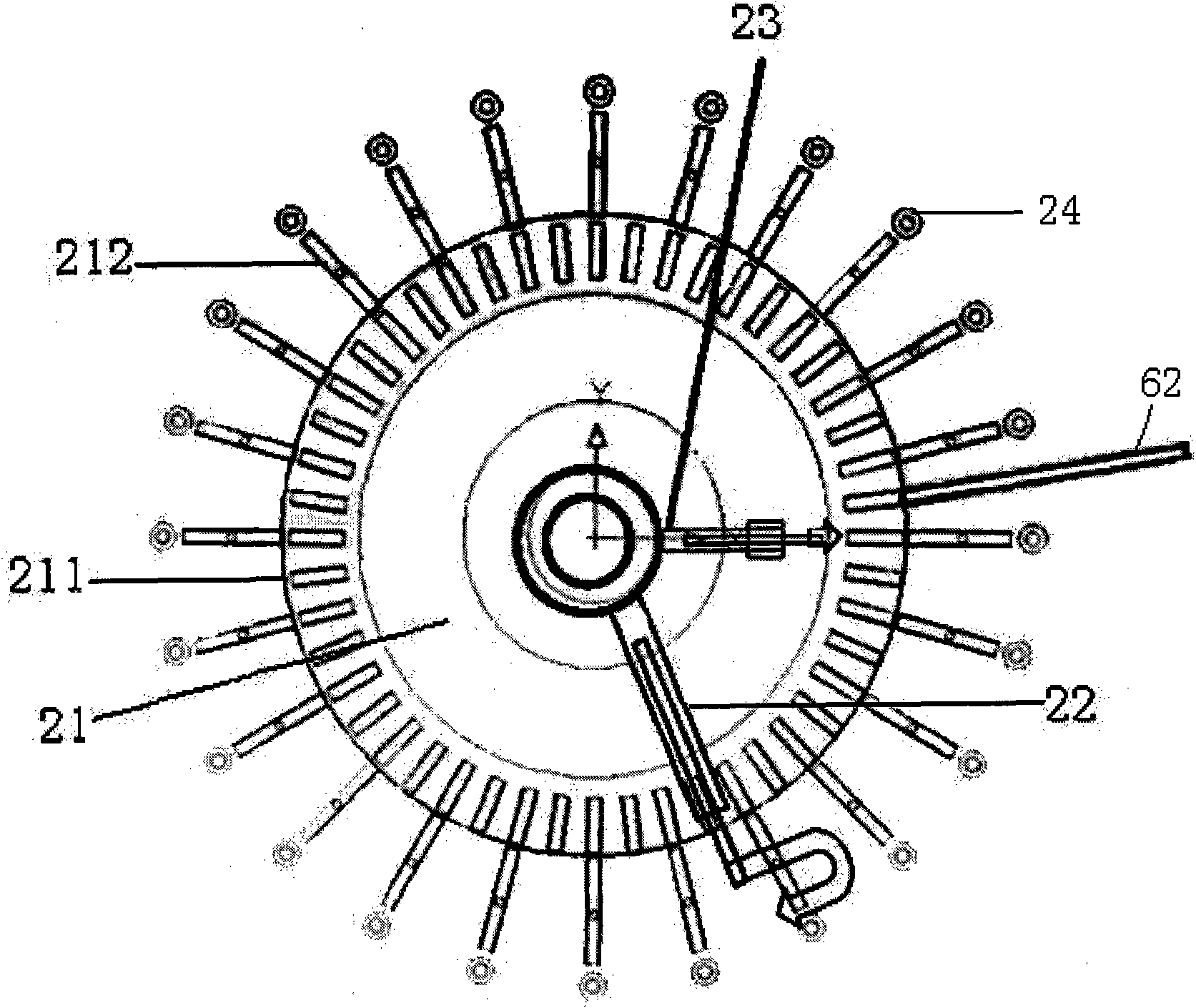

Full-automatic serial fluorescence PCR detection system

InactiveCN101613663ARealize separate collectionIncrease usageBioreactor/fermenter combinationsBiological substance pretreatmentsFluorescenceInformation design

The invention discloses a full-automatic serial fluorescence PCR detection system, comprising a photoelectric reader, a sample device to be detected, a nucleic acid processing unit, a reaction unit, a manipulator and a guide rail; wherein the photoelectric reader is connected with the sample device to be detected, the guide rail and the manipulator are arranged between the sample device to be detected and the nucleic acid processing unit, and the manipulator is arranged between the nucleic acid processing unit and the reaction unit. The full-automatic serial fluorescence PCR detection system of the invention is a device which is variable in temperature and acquires fluorescence information designed for realizing full-automatic PCR reaction process, innovatively improves the traditional PCR amplifier and changes the batch reaction mode of the traditional PCR amplifier, flow line PCR operating mode is provided, utilization rate of PCR devices is improved, full automation without human intervention of the whole detection process is realized, labour force is saved, working efficiency is improved, and meanwhile influence caused by human factor is also reduced.

Owner:GUANGZHOU INST OF RESPIRATORY DISEASE +1

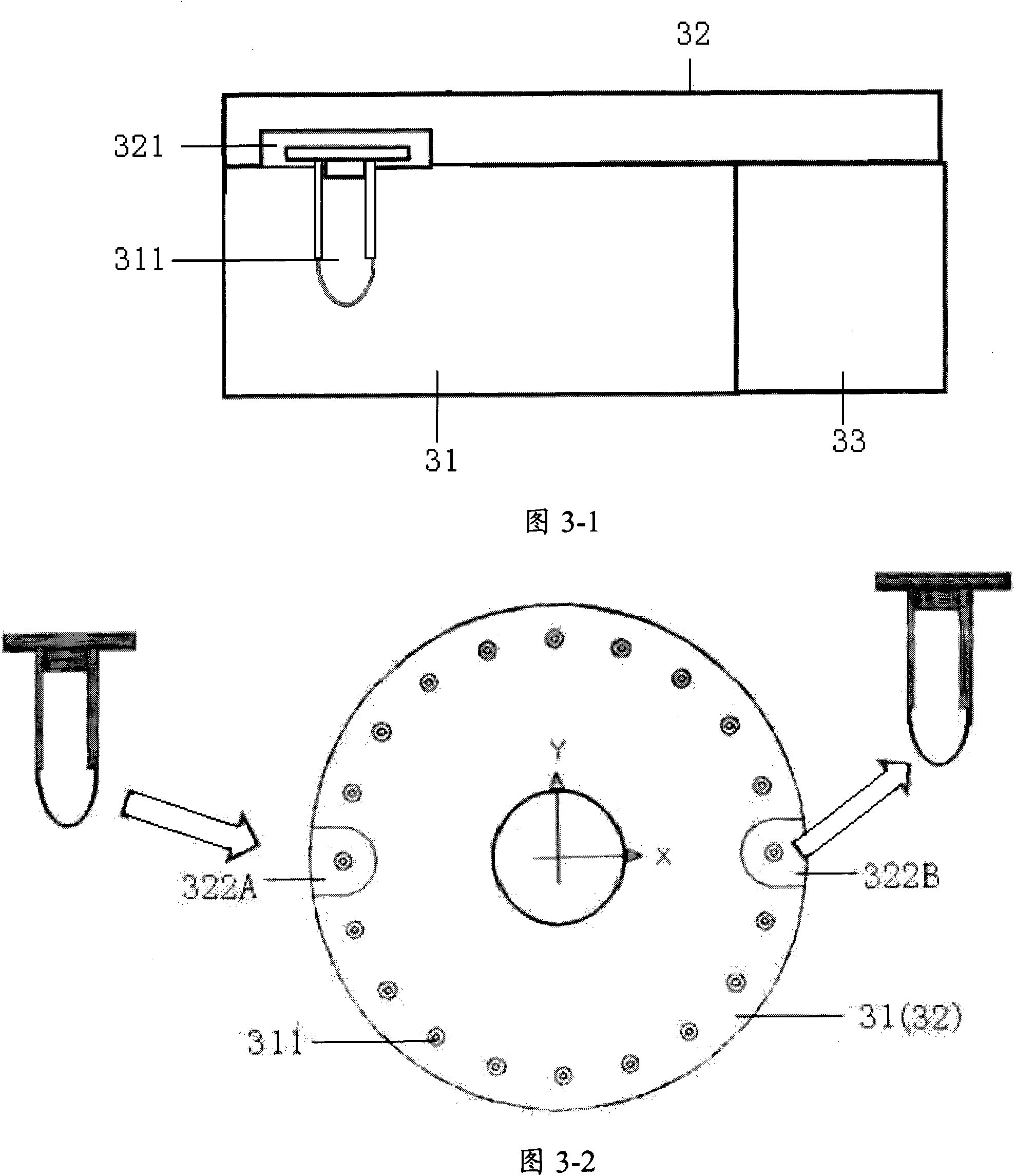

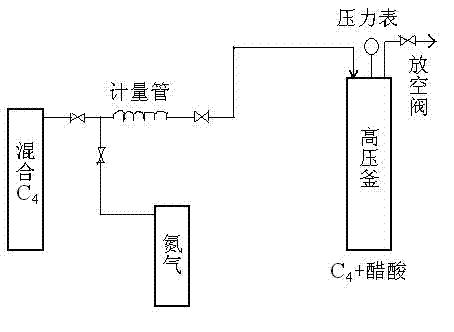

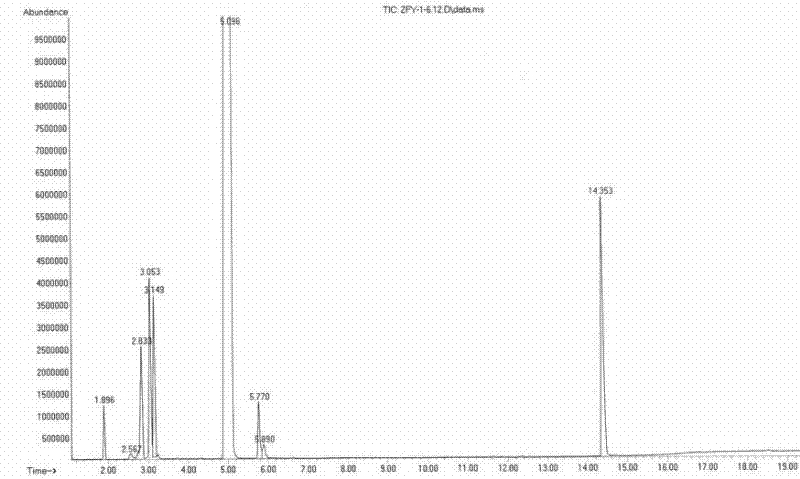

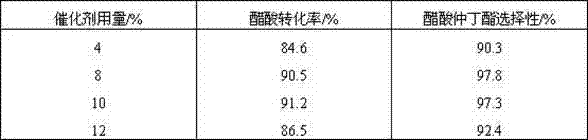

Method for producing sec-butyl acetate by synthesizing acetic acid and mixed C4

InactiveCN102344364AHigh activityHigh selectivityOrganic compound preparationCarboxylic acid esters preparationPtru catalystReaction temperature

The invention relates to a method for producing sec-butyl acetate by synthesizing acetic acid and mixed C4, which belongs to the chemical field. The invention aims to provide the method for producing the sec-butyl acetate by synthesizing the acetic acid and the mixed C4, which is used for fully and reasonably utilizing byproduct mixed C4 resources of petrochemical enterprises, broadening the way to comprehensively utilize C4 hydrocarbon, and producing fine chemical products with high added value. According to the invention, a kettle type batch reactor is adopted, strong-acid cation exchange resin is adopted as solid catalyst, the acetic acid and the mixed C4 are used as the raw materials to synthesize the sec-butyl acetate, the reaction pressure is 2.0-6.0MPa, the reaction temperature is 80-160 DEG C, the reaction time is 5-15h, the molar ratio of olefine acid is 0.2-1.5, and the catalyst amount is 4-12 percent of the acetic acid. According to the synthetic process of the sec-butyl acetate, the acetic acid and butane (refinery byproduct mixed C4 contains 1-butane and 2-butane) are adopted as the raw materials to be directly synthesized through addition reaction under the action of acid catalysts, an olefin resource is directly utilized, and ethanol is unnecessary to be an intermediate, so that the production cost of the sec-butyl acetate is reduced, the obvious economic advantage is achieved, the refinery mixed C4 resource is effectively utilized, and the method is an effective way to improve chemical utilization of C4 hydrocarbon.

Owner:CHANGCHUN UNIV OF TECH

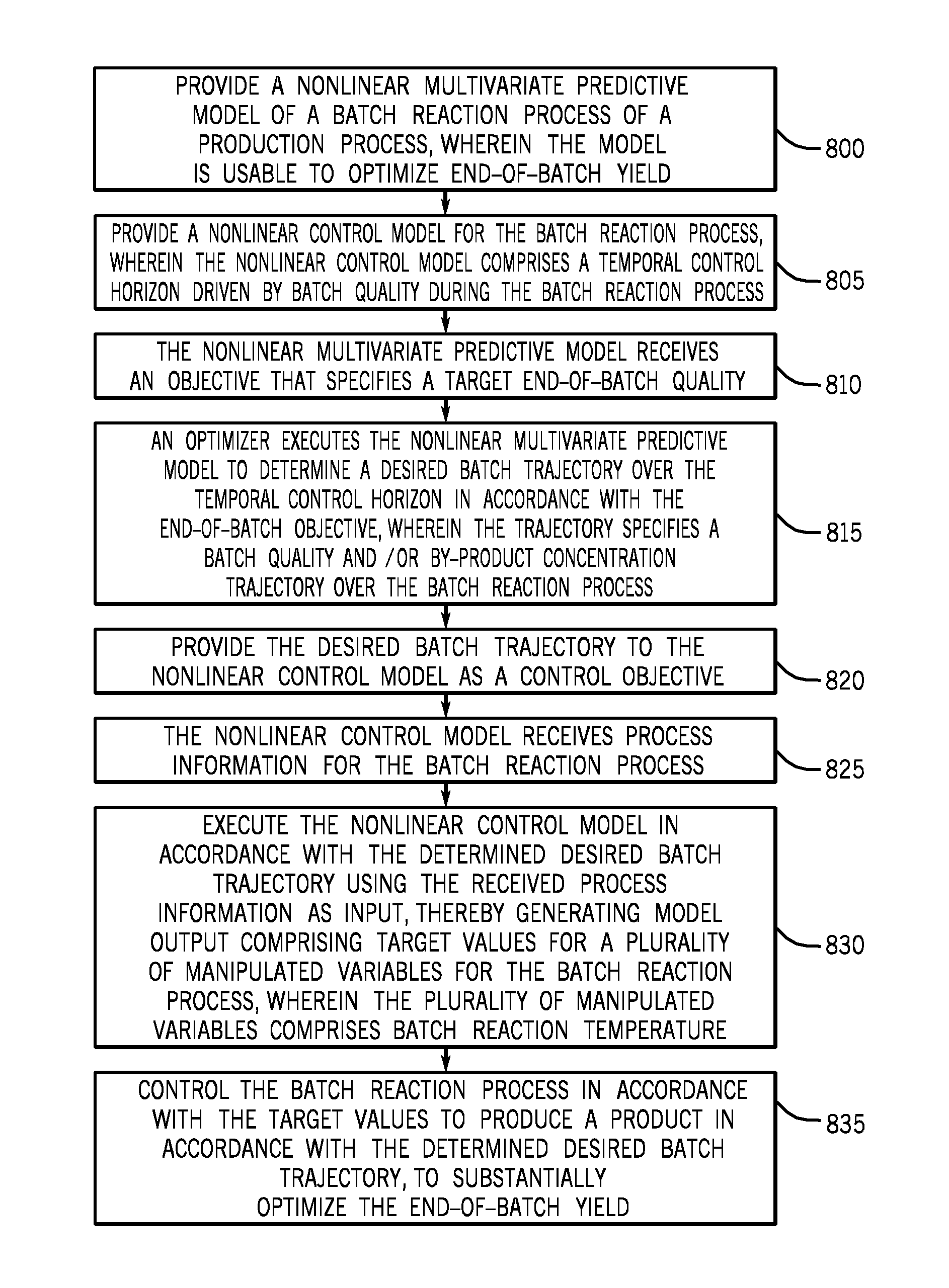

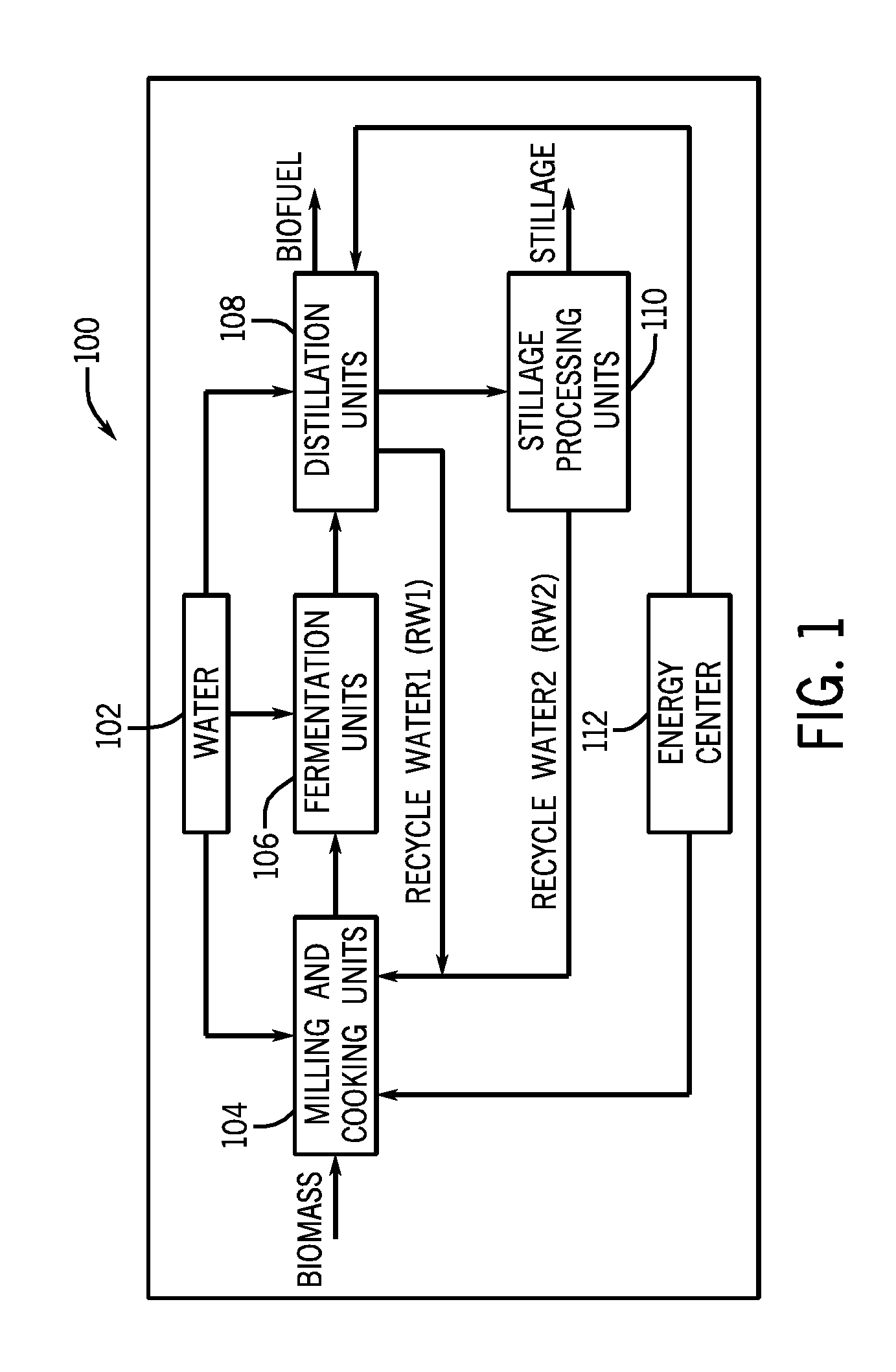

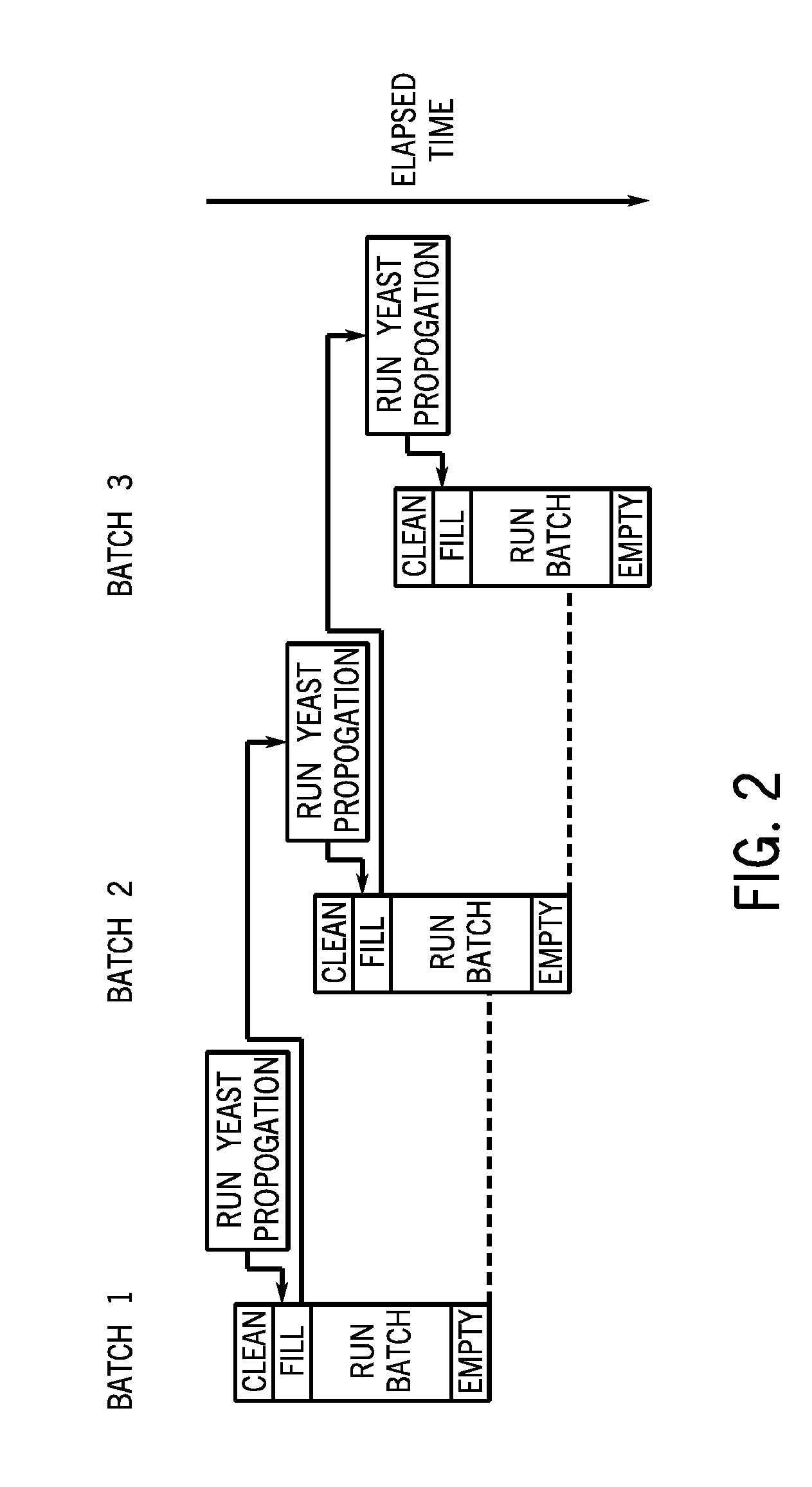

Nonlinear model predictive control of a batch reaction system

ActiveUS9046882B2Sampled-variable control systemsBioreactor/fermenter combinationsDynamic modelsBatch operation

The present invention provides novel techniques for controlling batch reaction processes. In particular, a parametric hybrid model may be used to parameterize inputs and outputs of batch reaction processes. The parametric hybrid model may include an empirical model, a parameter model, and a dynamic model. Critical quality parameters, which are correlated with, but not the same as, end-of-batch quality values for the batch reaction processes may be monitored during cycles of the batch reaction processes. The quality parameters may be used to generate desired batch trajectories, which may be used to control the batch reaction processes during the cycles of the batch reaction processes.

Owner:ROCKWELL AUTOMATION TECH

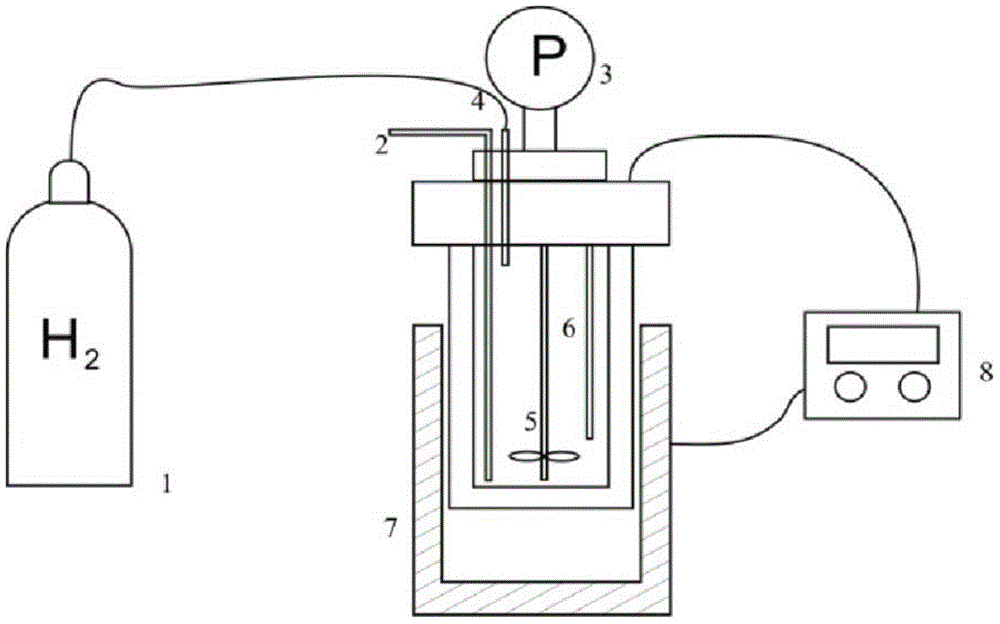

Method for performing hydrogenation on liquid-state organic hydrogen storage carrier through batch reaction kettle

ActiveCN105129728ASignificant improvementHydrogenMetal/metal-oxides/metal-hydroxide catalystsMetal catalystLiquid state

The invention discloses a method for performing catalytic hydrogenation reaction on a liquid-state organic hydrogen storage carrier through a batch high-temperature high-pressure reaction kettle. According to the method, a certain proportion of a supported metal catalyst and selected solvent are added into the batch high-temperature high-pressure reaction kettle to perform catalyst activation; then the liquid-state organic hydrogen storage carrier is added, sealing is performed, and hydrogen is injected three times in sequence to drain air inside the kettle; temperature is increased to a set hydrogenation working temperature, hydrogen is injected, stirring is performed, and hydrogen injection is stopped after reaction is performed for 2-10 h to obtain all-hydrogenated liquid-state hydrogen source materials. By the adoption of the method, the all-hydrogenated rate of the liquid-state hydrogen storage carrier ranges from 85% to 100%.

Owner:WUHAN HYNERTECH CO LTD

Device and method for realizing continuous pyrohydrolysis treatment of organic material

ActiveCN103449699AEasy to adjust processing loadReasonable useSludge treatment by pyrolysisProcess engineeringHigh pressure

The invention discloses a device and a method for realizing continuous pyrohydrolysis treatment of an organic material. According to the method, the organic material is preheated to below 100 DEG C by utilizing flash-off steam, the temperature and the pressure in a booster jar are increased with the flash-off steam, reactants after boosting enter a two-stage reaction unit with tubular mixing heat exchange and pyrohydrolysis reaction, heat fully exchanges with high-temperature and high-pressure steam to perform pyrohydrolysis reaction, one-stage flash-off and two-stage flash-off are continuously performed on the material after reaction, the produced flash-off steam enters the booster jar and a preheating tank respectively as preheating mediums, and the reactants after the flash-off are thrown into a digestion tank after cooling mixing for fermentation to produce marsh gas or directly drying compost. The device comprises the preheating tank, a two-stage continuous pyrohydrolysis reactor consisting of a tubular mixing heat exchanger and a continuous reaction tank, and a flash-off cooling part. The device and the method fully realize the cascade efficient utilization of the system waste heat; compared with the traditional sequencing batch reaction technology, the equipment and the running control of the equipment are simplified, and the continuous pyrohydrolysis reaction of the organic material is realized.

Owner:JIAOZUO KAITAI POWER EQUIP MFG

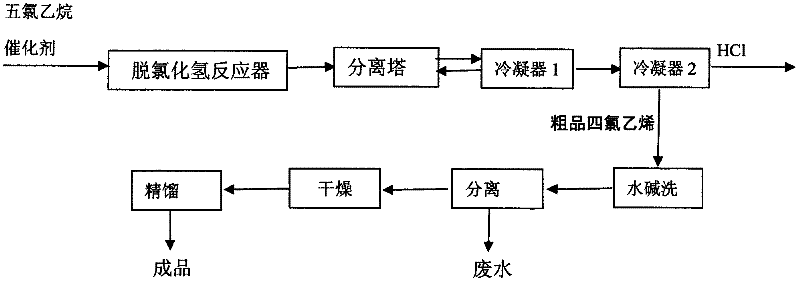

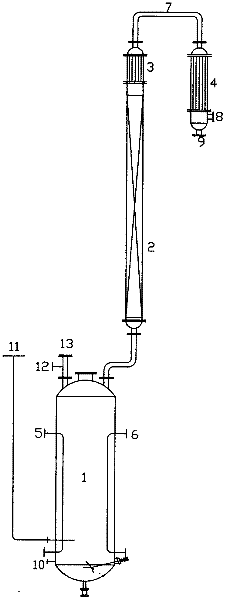

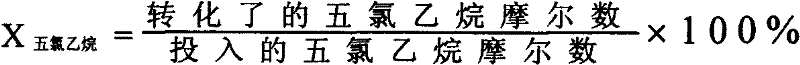

Method for preparing tetrachloroethylene by liquid-phase catalysis of pentachloroethane

ActiveCN102295521ASolve the environmental problems of serious pollutionIncrease profitPreparation by hydrogen halide split-offCalcium hydroxideTetrachloroethylene

The invention relates to a method for preparing tetrachloroethylene through pentachloroethane liquid-phase catalysis, which comprises the following steps of: an intermittent method: by using high-purity pentachloroethane as a raw material, adding a metal halide as a catalyst according to the percentage by weight, stirring and heating in a reactor, and intermittently reacting and distilling under a normal pressure to obtain a crude tetrachloroethylene product; or a continuous method: by using the prepared crude tetrachloroethylene product as a mother solution, adding the metal halide as the catalyst, stirring, heating, then adding the high-purity pentachloroethane, maintaining the reaction, then heating to prepare the crude tetrachloroethylene product, and continuously adding the high-purity pentachloroethane to continuously produce the crude tetrachloroethylene products with the same volume; and carrying out water-alkali washing for the crude products prepared by the two methods to be neutral, separating, drying and rectifying to obtain a tetrachloroethylene finished product. The environmental-protection difficult problem of serious environmental pollution brought by traditional calcium-hydroxide saponification is radically solved, particularly the usage amount of the catalyst is small in the continuous method, materials are continuously fed and produced, the method is simpler and more labor-saving to operate, the cost is low, the method is suitable for large-batch production, the utilization ratio of the materials is high, and the purity of the prepared product reaches up to more than 99.8 percent.

Owner:江西国宏化工有限公司

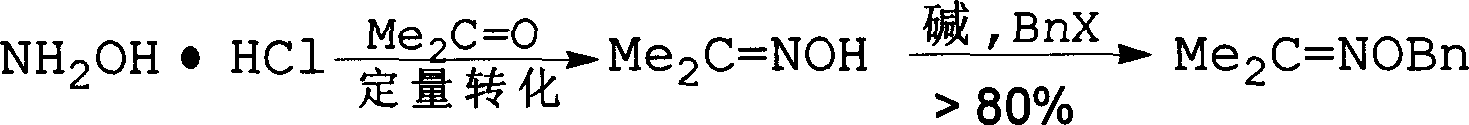

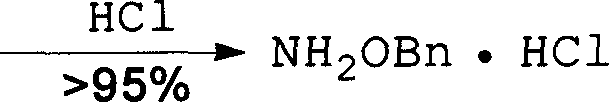

Method for synthesizing benzyloxy amine hydrochloride

The invention refers to a manufacturing method of an important medicine and the organic synthesis midbody-benzyl oxide amine hydrochlorate. The invention starts from hydroxylamine hydrochlorate and gets acetoxime through batching reaction. There obtains the product by the liquor hydrochloric acid under the controlled temperature. The increasing of midbody molecular is little, and the reaction efficiency is high, the whole line atom economic is good. The cost is low.

Owner:XIAMEN UNIV

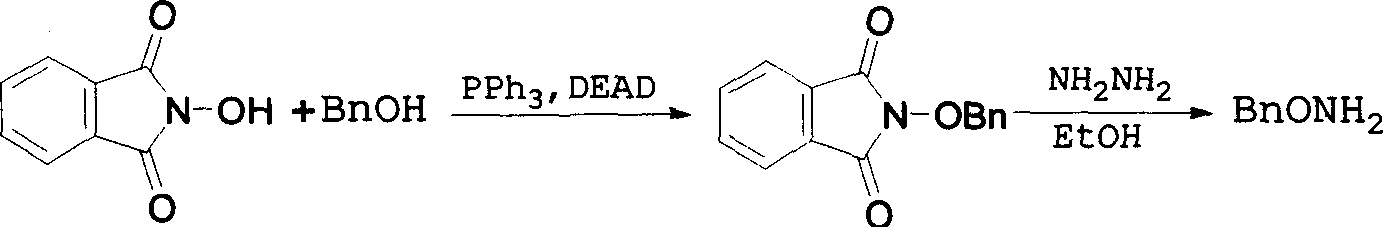

Process for synthesizing 3,4-difluorobenzonitrile

ActiveCN103539699AProcess raw materials are easy to getShort reaction timeCarboxylic acid nitrile preparationOrganic compound preparationPotassium fluorideChloride

The invention discloses a process for synthesizing 3,4-difluorobenzonitrile. According to the process, 3,4-difluorobenzonitrile with the purity of over 99% is obtained through taking 3,4-dichlorobenzonitrile as a raw material, taking potassium fluoride as a fluorination reagent, taking 1,3-dimethyl-2-imidazolidinone as a reaction solvent, taking bis-(N-bis(dimethylamino)methylene)-iminium chloride as a catalyst, enabling reactants to react for 2-3 hours at the temperature of 130-150 DEG C and react for 5-6 hours at the temperature of 180-200 DEG C, then ending reaction, filtering a reaction solution and then rectifying under reduced pressure, and the yield can reach 85%. Rectification mother liquor (containing the catalyst) is mechanically applied to next-batch reaction directly. According to the process disclosed by the invention, the raw material is easy to obtain, the reaction conditions are mild, the reaction time is short, the operation is simple, the yield is high, the reaction solvent (containing the catalyst) can be repeatedly applied mechanically, the cost is low, and the emission of waste gases, waste water and waste residues is little, so that the process is applicable to industrial production.

Owner:SHANGHAI HUAYI GRP CO

Method for synthesizing methyl ethyl carbonate

ActiveCN101863771AHigh activityEasy to separatePreparation from organic carbonatesMetal/metal-oxides/metal-hydroxide catalystsMethyl carbonateDistillation

The invention discloses a preparation method of hydrotalcite-like solid catalyst for synthesizing methyl ethyl carbonate. The invention relates to a preparation method for hydrotalcite-like solid catalyst, which solves the problem that the low activity in present solid base catalyst result in low yield in methyl ethyl carbonate. In the method, dimethyl carbonate and diethyl carbonate are used as raw materials, a batch kettle is used as a reactor, and a catalyst used is a hydrotalcite-like solid catalyst. The preparation method of the catalyst comprises: preparing nitrate mixed solution of copper, zinc, magnesium and aluminum respectively and preparing mixed solution of NaOH and a carbonate or bicarbonate; mixing the two kinds of solution together by dripping and stirring the mixed solution; performing crystallization, filtration, distillation and washing; drying filter cakes; roasting the filter cakes; and cooling the filter cakes. The catalyst has high activity, is easy to separate, can be recycled, and is long in service life and free from pollution; the reaction time is short; and the cost is low. The catalyst is used in the batch reaction kettle for catalyzing the reaction of the dimethyl carbonate and the diethyl carbonate to synthesize the methyl ethyl carbonate; the raw materials and product of the reaction can be used as electrolyte solvents for lithium ion batteries and can be used directly by controlling water content without separation; and a large part of separation and purification cost can be reduced.

Owner:QIQIHAR UNIVERSITY

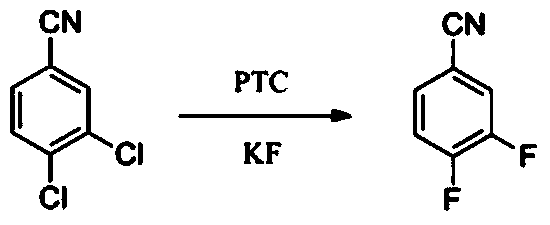

Method for preparing 16-dehydropregnenolone acetate by multistage filtration and recrystallization

The invention relates to a method for preparing 16-dehydropregnenolone acetate by multistage filtration and recrystallization, comprising the following steps of: high-pressure ring-opening (cracking), oxidizing, hydrolyzing and extracting, multistage filtering after posttreatment, recrystallizing and refining, recovering and applying mother liquor, and the like. In the method, by multistage filtration and recrystallization technologies the contents of most 16-dehydropregnenolone acetate product with low content and low-polarity impurities in the reaction processes of high-pressure ring-opening, oxidizing and hydrolyzing in the finished product and the mother liquor are reduced, therefore, the posttreatment difficulty is reduced, the stability of the next-batch reaction is increased, and the product quality and the product yield are improved.

Owner:湖北民生生物医药有限公司

Cerium-containing hydrodesulfurization catalysts and uses

PendingUS20200290023A1Reduce sulfur contentMolecular sieve catalystsCatalyst activation/preparationPtru catalystHydrodesulfurization

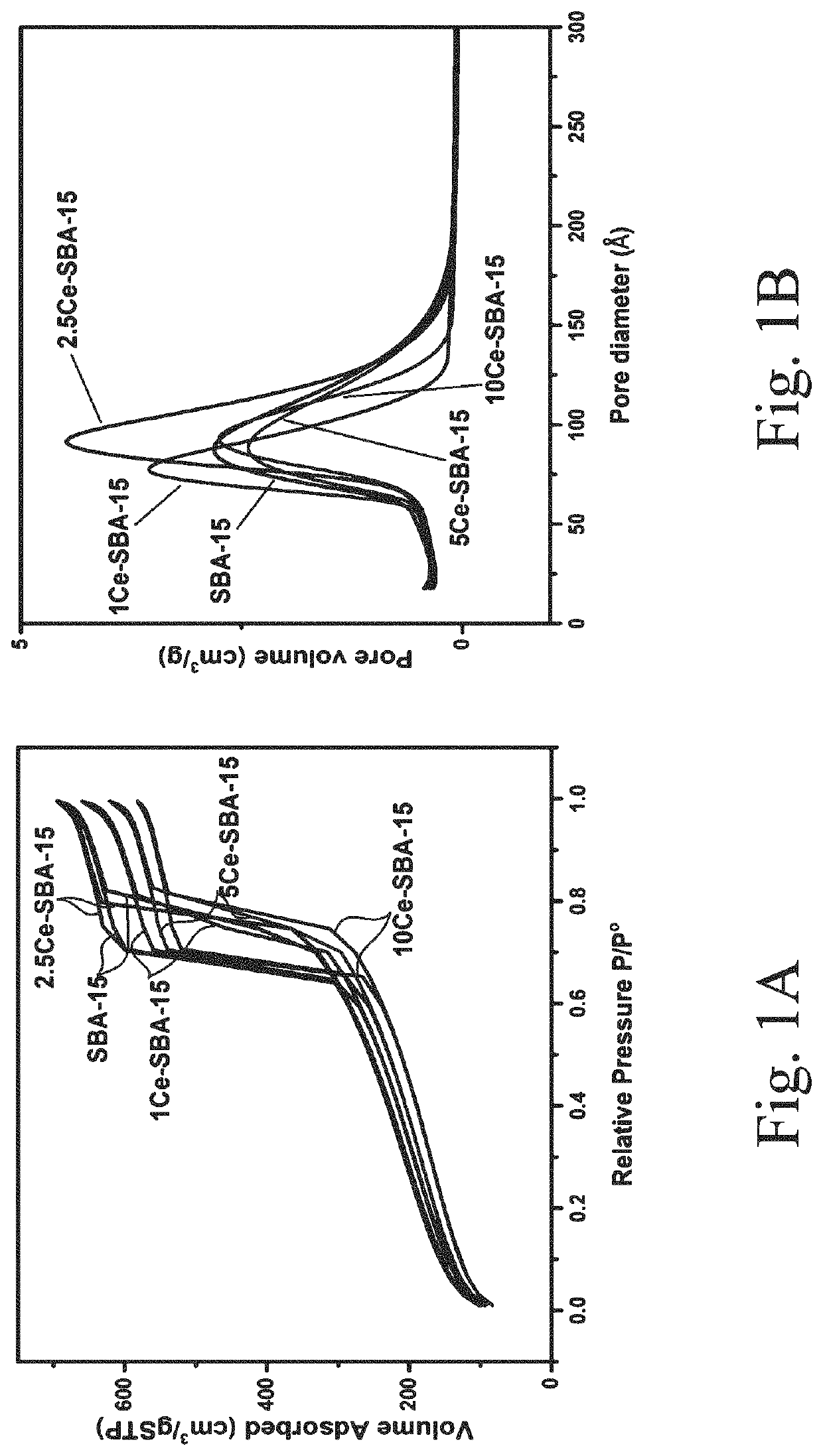

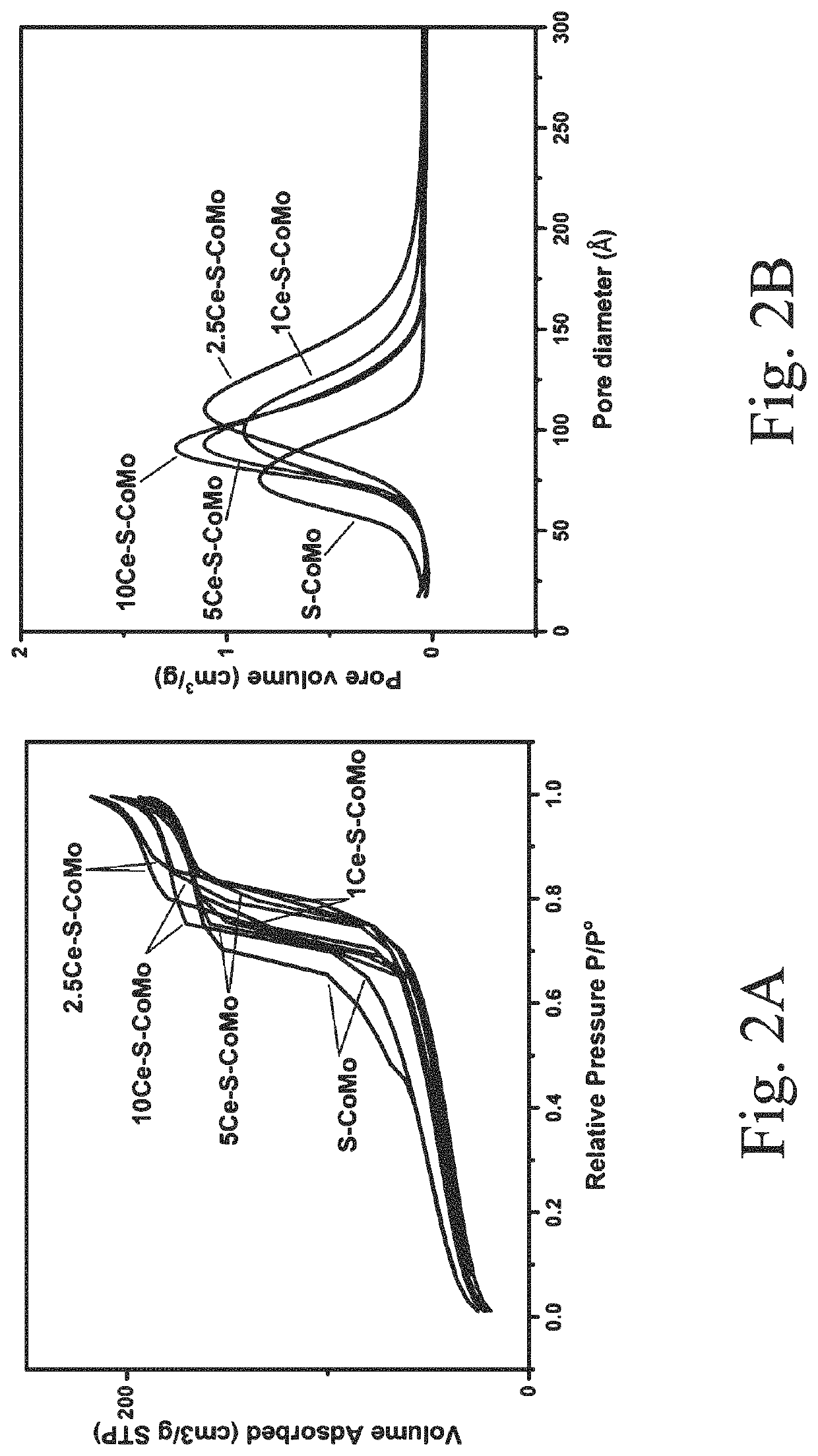

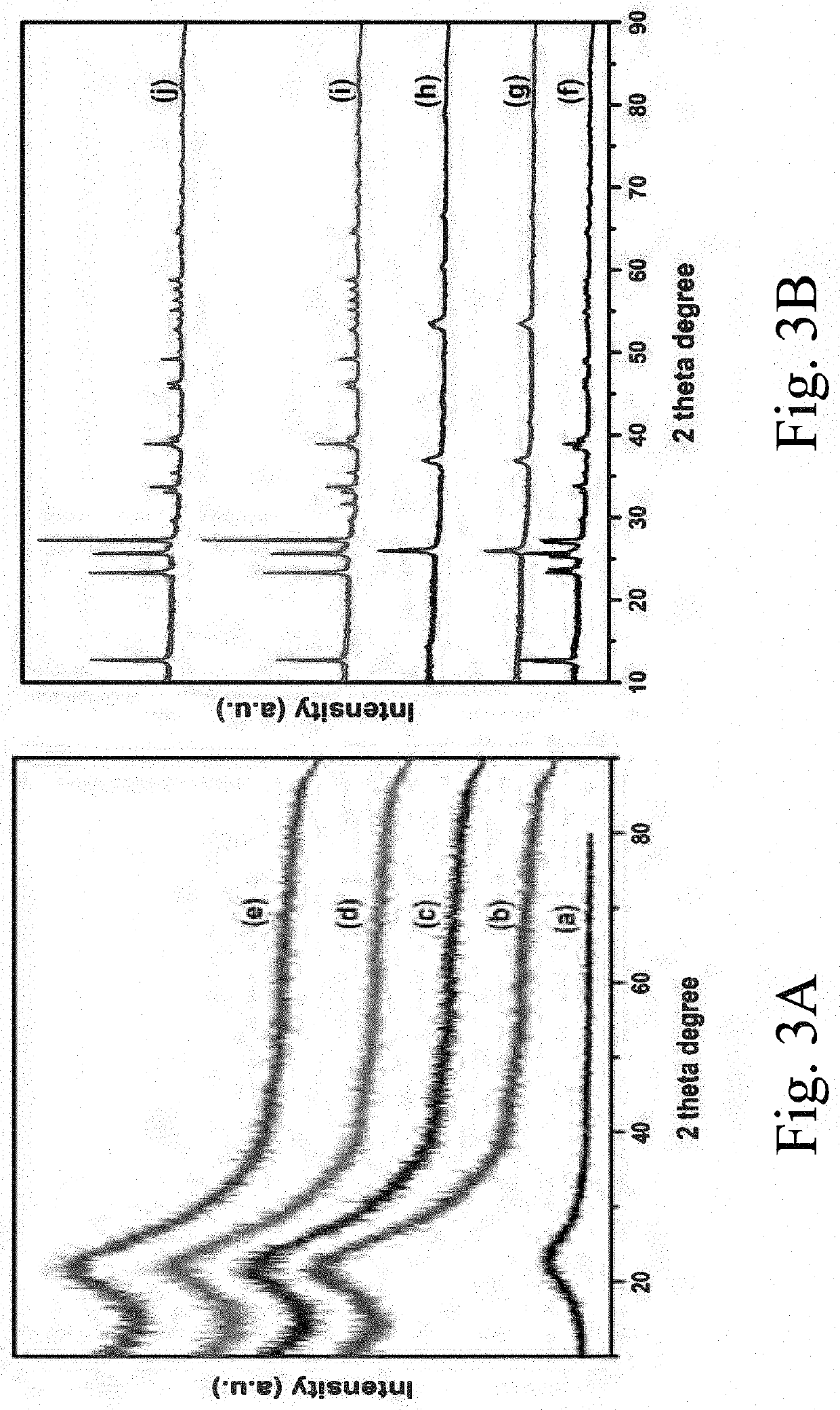

Catalysts for hydrodesulfurization (HDS), e.g., of fuel such DBT in a batch reactor, may include Ce-modified SBA CoMo-sulfided catalysts. The dispersion and catalytic activity of the active species (CoMoS2) may be influenced by the Ce—Si network in the support. The physico-chemical properties of such catalysts—textural properties, crystallinity, metal oxide reducibility, and Mo phases—were established, and BET surface area, X-ray diffraction (XRD), and Raman spectroscopy analysis showed up to 2.5 wt. % Ce incorporation into the Si-network in SBA-15. Up to 2.5 wt. % Ce loading on the SBA-15 support can provide large BET surface area and total pore volume. The metal oxide reducibility and MoS2 phase in the sulfided 2.5Ce—S—CoMo catalyst indicate moderate metal-support interaction at 2.5Ce wt. %. Improved HDS activity was shown with Ce loading up to 2.5 wt. %, possibly due to Ce's facilitation of metal oxide reduction and dispersion of the MoS2 active phase via metal-support interaction.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

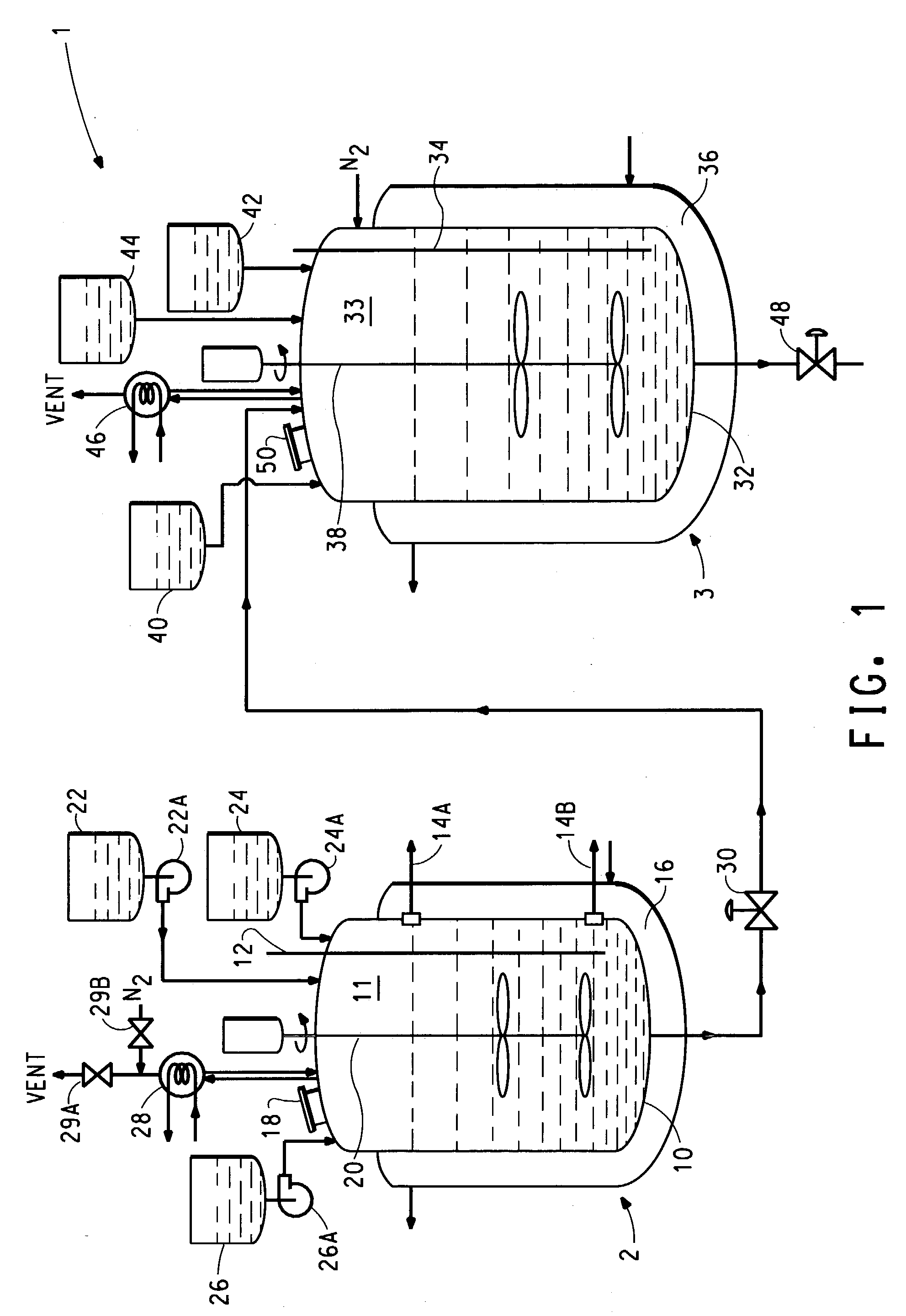

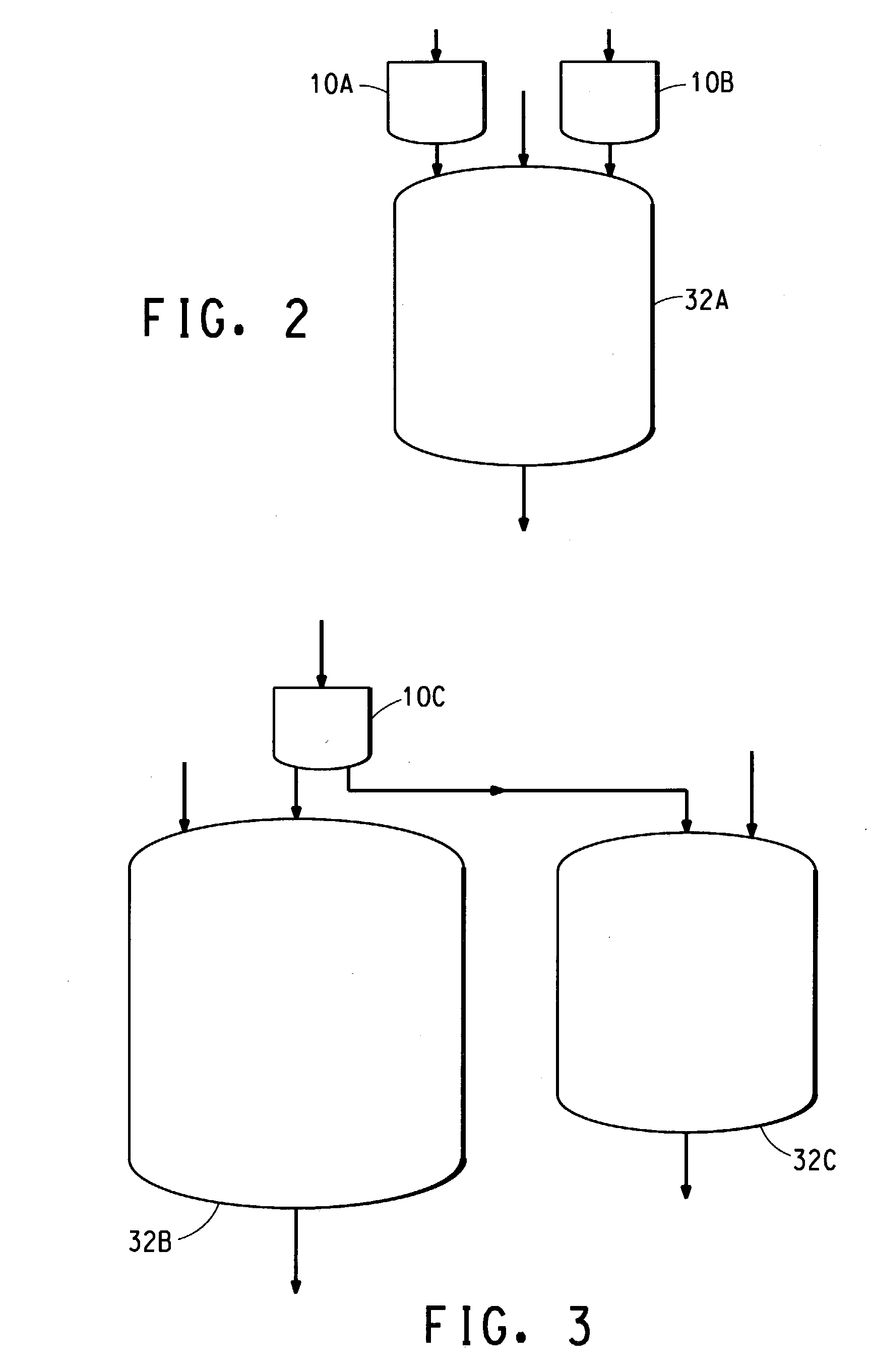

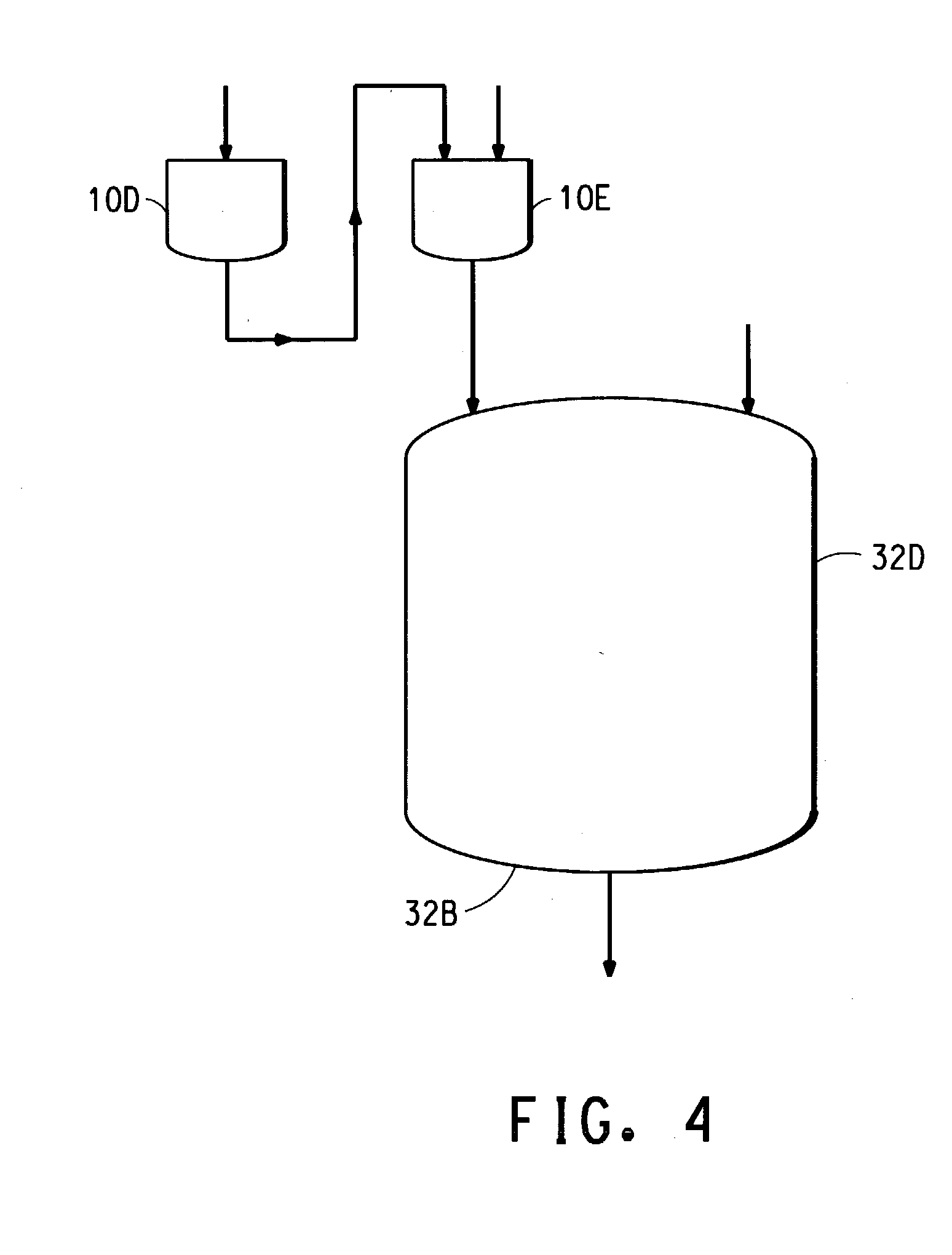

Pressurized high temperature polymerization process and polymerization system used therein

The present invention is directed to a novel high temperature polymerization process operating at high pressures for producing a polymer. The process includes conveying hybrid reactor mixtures, which include one or more hybrid reactor monomers and one or more hybrid reactor initiators to one or more hybrid reactors. The hybrid reactors are maintained at effective hybrid polymerization temperatures and sub-reflux polymerization gage pressures to cause polymerization of a portion of the hybrid reactor monomers into the polymer. The process further includes conveying hybrid reactor contents from. the hybrid reactors to one or more batch reactors maintained at effective batch polymerization temperatures and reflux polymerization pressures to cause polymerization of a remaining portion of the hybrid reactor monomers into the polymer. The hybrid reactors are smaller in volume than the batch reactors. By utilizing the hybrid / batch reactor combination, the process of the present invention can be operated under safe working conditions. The process of the present invention also allows control of the polydispersity and molecular weight of the resulting polymers. As a result, the polymers made therefrom can be used as binders in compositions, such as coating compositions used in the automotive refinish and OEM applications having desired coating properties. The present invention is also directed to a polymerization system used in the process of the present invention.

Owner:AXALTA COATING SYST IP CO LLC

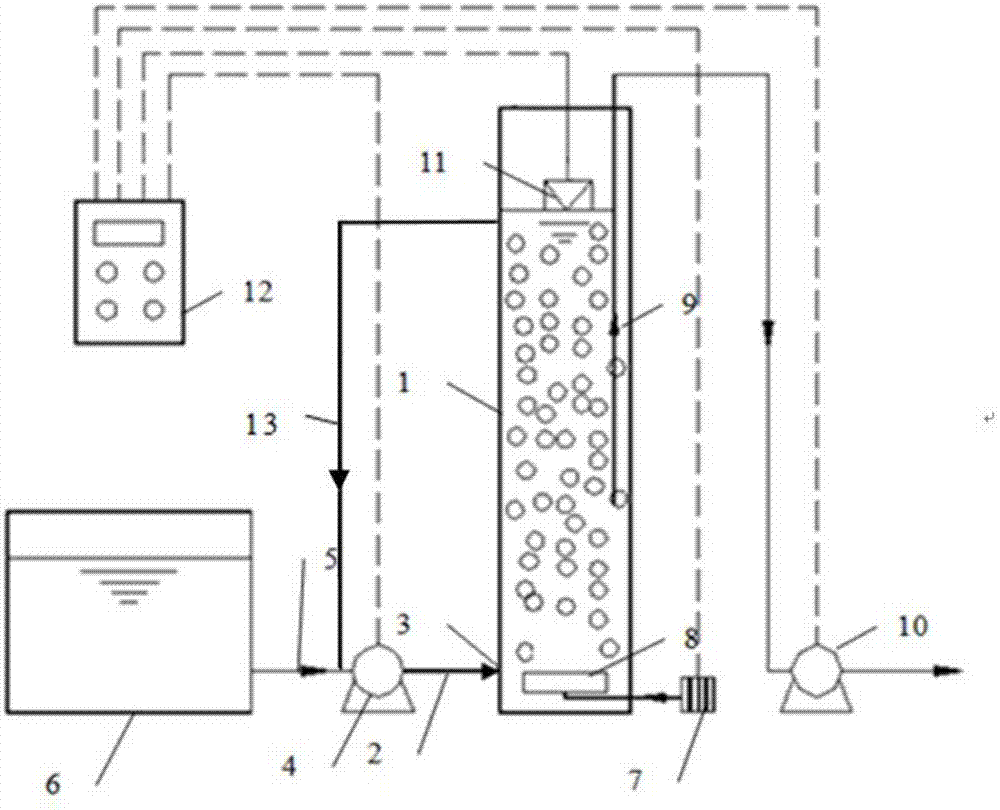

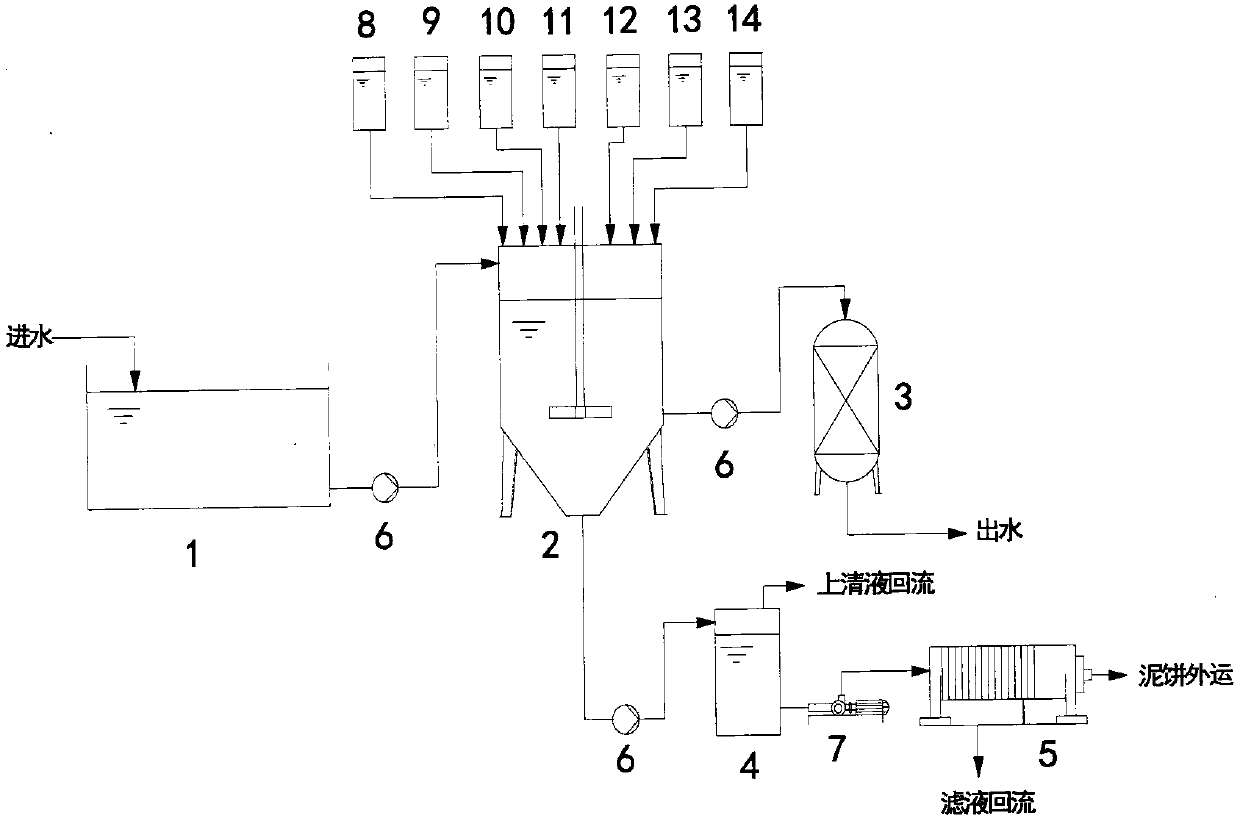

Method for quickly culturing aerobic granular sludge and sequencing batch reaction device

InactiveCN107364956AAccelerated and optimized formation of fully granulatedImprove the coagulation effectSustainable biological treatmentBiological water/sewage treatmentSequencing batch reactorHigh concentration

The invention discloses a method for quickly culturing aerobic granular sludge and a sequencing batch reaction device. The method includes that in an alternate anaerobic / aerobic sequencing batch reactor, municipal sewage is used as incoming water, and anaerobic digestion sludge and aerobic sludge (mixing ratio being 1:1) are used as inoculating sludge; at the early stage of starting, enhancing of sludge settling performance improvement and initial aerobic granular crystal nucleus formation and accelerating and optimizing of aerobic granular sludge formation and thorough granulation are realized by inoculating high-concentration sludge (20g / L) and adopting a low sludge load (0.056kgCOD / kgSS d) running mode. The method has the advantages that granules are formed quickly, so that the problem that aerobic sludge granules are difficult to form and too long in forming time is solved; an aerobic granular sludge 'crystal nucleus hypothesis' quick mode is realized; cultured aerobic granular sludge is compact in structure, high in stability and faint yellow in appearance, average grain diameter is 750um, sludge volume index (SVI) is 20-35mL / g, and removal rates of COD, TN and TP can reach 92%, 81% and 85% respectively; the method is simple in process, convenient in operation and low in cost.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing methylal

InactiveCN101628860AImprove conversion rateEasy to separateOrganic chemistryOrganic compound preparationOrganic solventReaction speed

The invention provides a method for preparing methylal. The method comprises the following steps of: taking methanol and paraformaldehyde as raw materials and acid as a catalyst; putting the raw materials and the catalyst in an organic solvent for reaction; reacting with stirring in a mode of batch reaction to prepare methylal; and by separating the methylal, obtaining an azeotrope of methanol and methylal or high-purity methylal. The method has the advantages of high reaction speed and high conversion rate, and can be applied in the field of organic chemical engineering.

Owner:CHINA PETROLEUM & CHEM CORP +1

MSBR (Modified SBR) nitrogen and phosphorus removal technique based on MBBR (Moving Bed Biofilm Reactor)

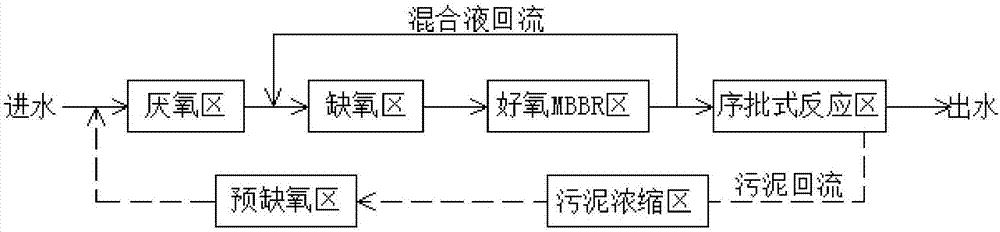

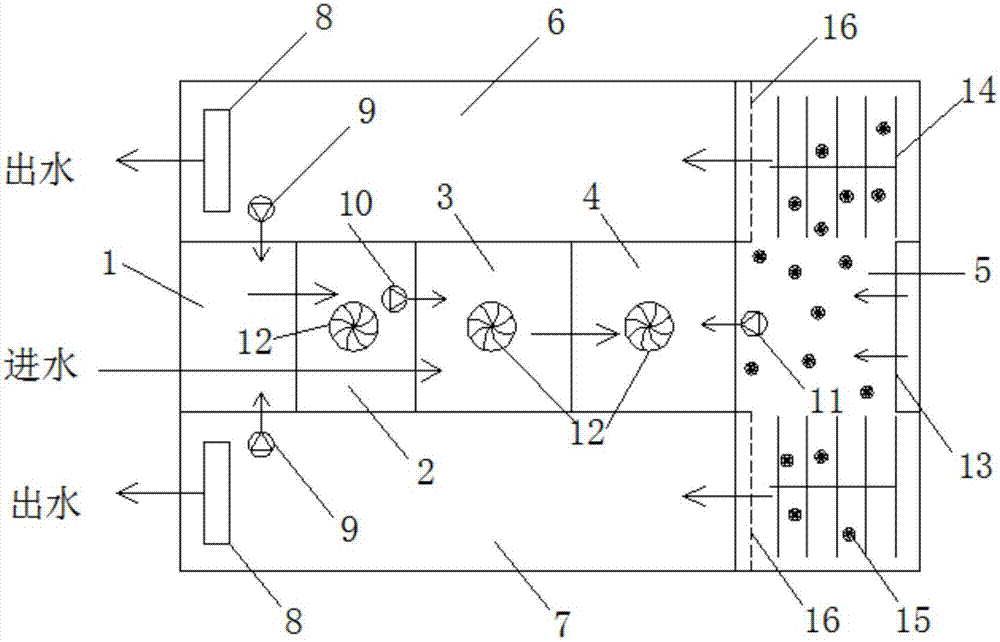

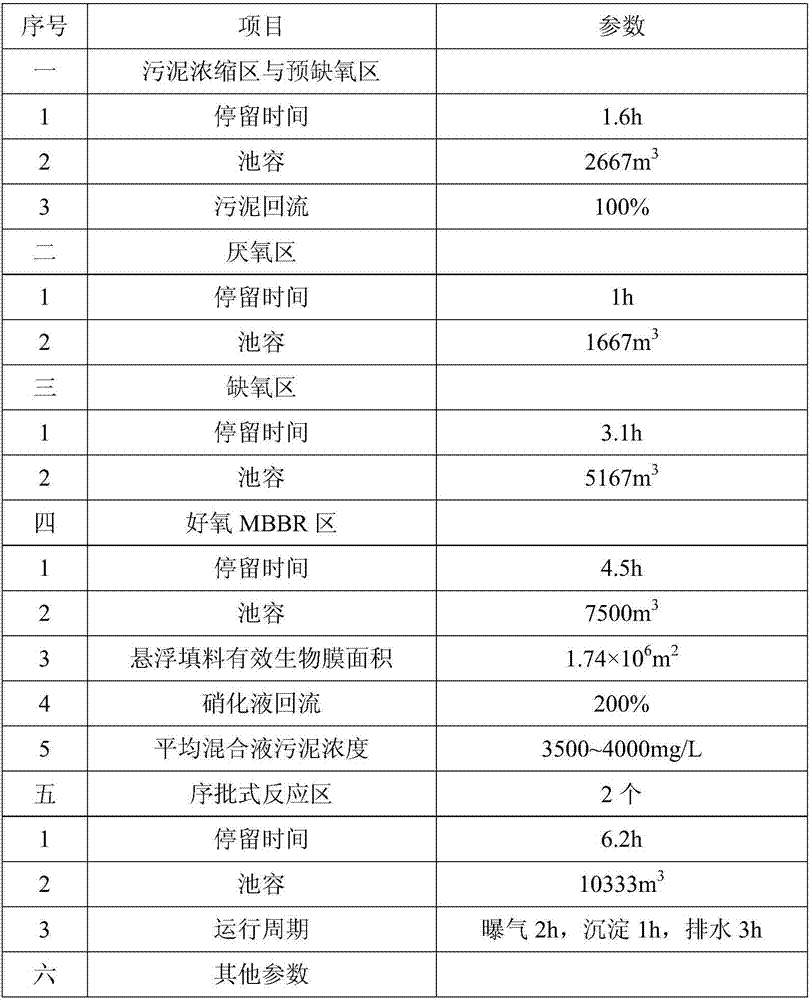

InactiveCN107285463AHigh volume loadImprove adjustabilityWater contaminantsTreatment with aerobic and anaerobic processesHypoxic preconditioningMoving bed biofilm reactor

The invention discloses an MSBR (Modified SBR) nitrogen and phosphorus removal technique based on an MBBR, and belongs to the technical field of sewage treatment. The technique is based on a system consisting of seven units, including a sludge concentration area, a hypoxic preconditioning area, an anaerobic area, an anoxic zone, an aerobic MBBR area, a sequencing batch reaction I area and a sequencing batch reaction II area, wherein suspended packing is all dropped into the aerobic MBBR area, a medium hole perforating aeration system is arranged at the bottom of the aerobic MBBR area, a water distribution system is arranged at a water inlet, and an interception screening system is arranged at a water outlet. According to the MSBR nitrogen and phosphorus removal technique based on the MBBR disclosed by the invention, the advantages of an MSBR technique and the MBBR technique are combined, the technique has the advantages of high volume load and stable effluent effect, and is suitable for carrying out update or capacity increasing transformation on the original MSBR technique, so that the treatment capability of the existing technique is promoted, and meanwhile, the technique is applied to new construction items, so that the occupied area can be greatly reduced.

Owner:QINGDAO SPRING WATER TREATMENT

Process for treating and recycling alkaline wastewater containing zinc and chromium ions

InactiveCN103771631ACompliance with emission requirementsSolubility product constant is smallMultistage water/sewage treatmentActivated carbonSludge

The invention discloses a process for treating and recycling alkaline wastewater containing zinc and chromium ions. The process comprises the steps: introducing wastewater to an integrated sequencing batch reaction tank; then, finishing dosing, stirring, reacting, flocculating and settling processes; treating a supernatant liquid in the reaction tank by using activated carbon, and then, recycling the supernatant liquid as cleaning water; and concentrating the sludge slurry at the lower part of the reaction tank, and then, preparing the sludge slurry into mud cakes to be outwards transported and treated. The alkaline wastewater containing the zinc and chromium ions can be recycled as water after being treated by using the process provided by the invention. The process has the advantages of high efficiency, simplicity, convenience, economy, practicability and the like and can be used for simultaneously realizing economic, societal and environmental benefits.

Owner:HANGZHOU SHUANGBO ENVIRONMENTAL PROTECTION TECH

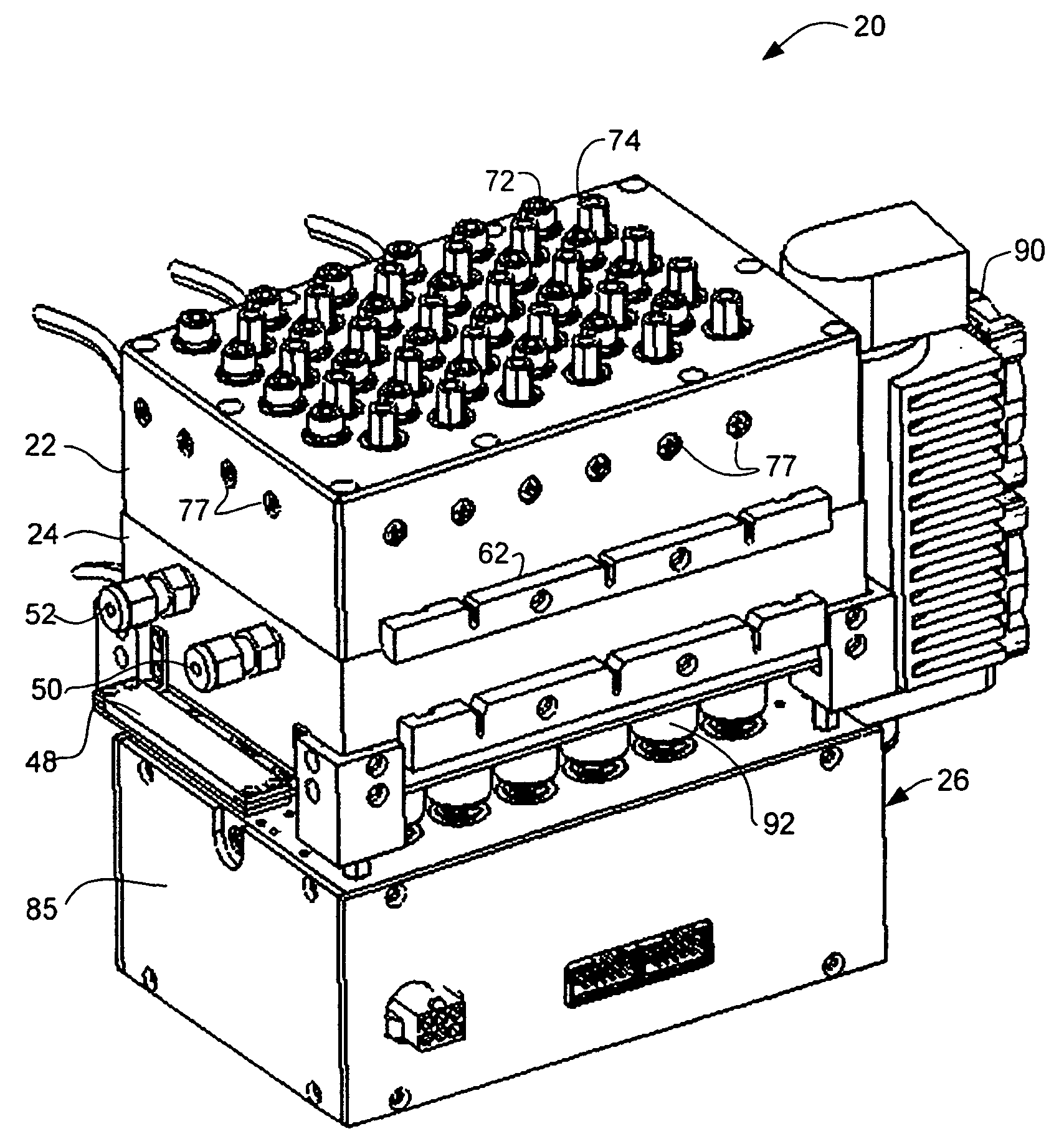

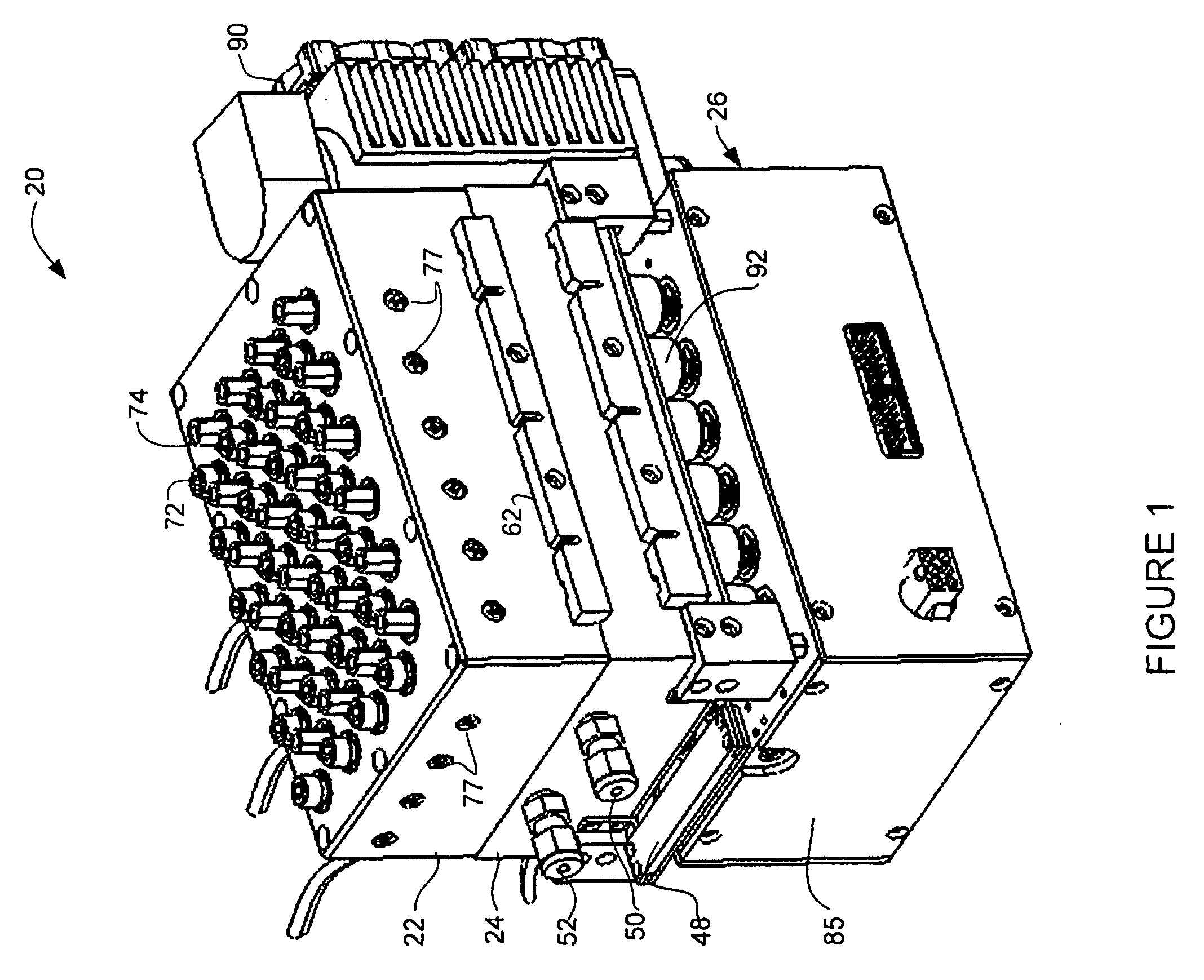

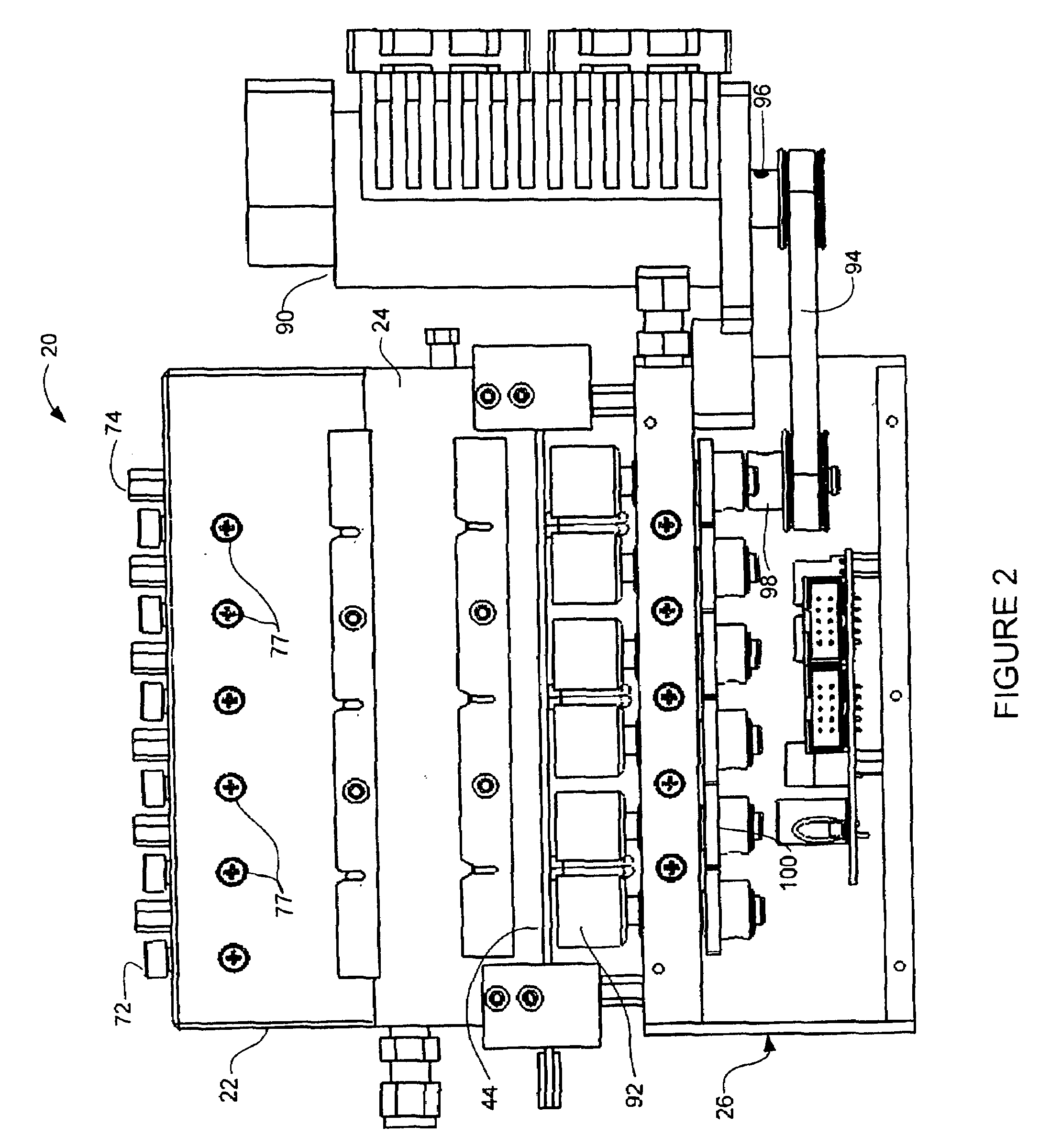

Parallel batch reactor with pressure monitoring

ActiveUS20080286171A1Sequential/parallel process reactionsChemical/physical/physico-chemical stationary reactorsChemical reactionNuclear engineering

In one embodiment, a parallel batch reactor for effecting chemical reactions includes a plurality of reactor vessels for receiving components of a reaction, an inlet port for receiving pressurized fluid, and a plurality of valves configured to transfer fluid from the inlet port to the reactor vessels and fluidically isolate one or more of the reactor vessels from at least one of the other reactor vessels. The reactor further includes a pressure monitoring system comprising an array of pressure sensors configured to sense pressure in the reactor vessels. Each of the pressure sensors is aligned with one of the plurality of reactor vessels and located external to the reactor vessels and fluid passageways in fluid communication with the reactor vessels.

Owner:UNCHAINED LABS

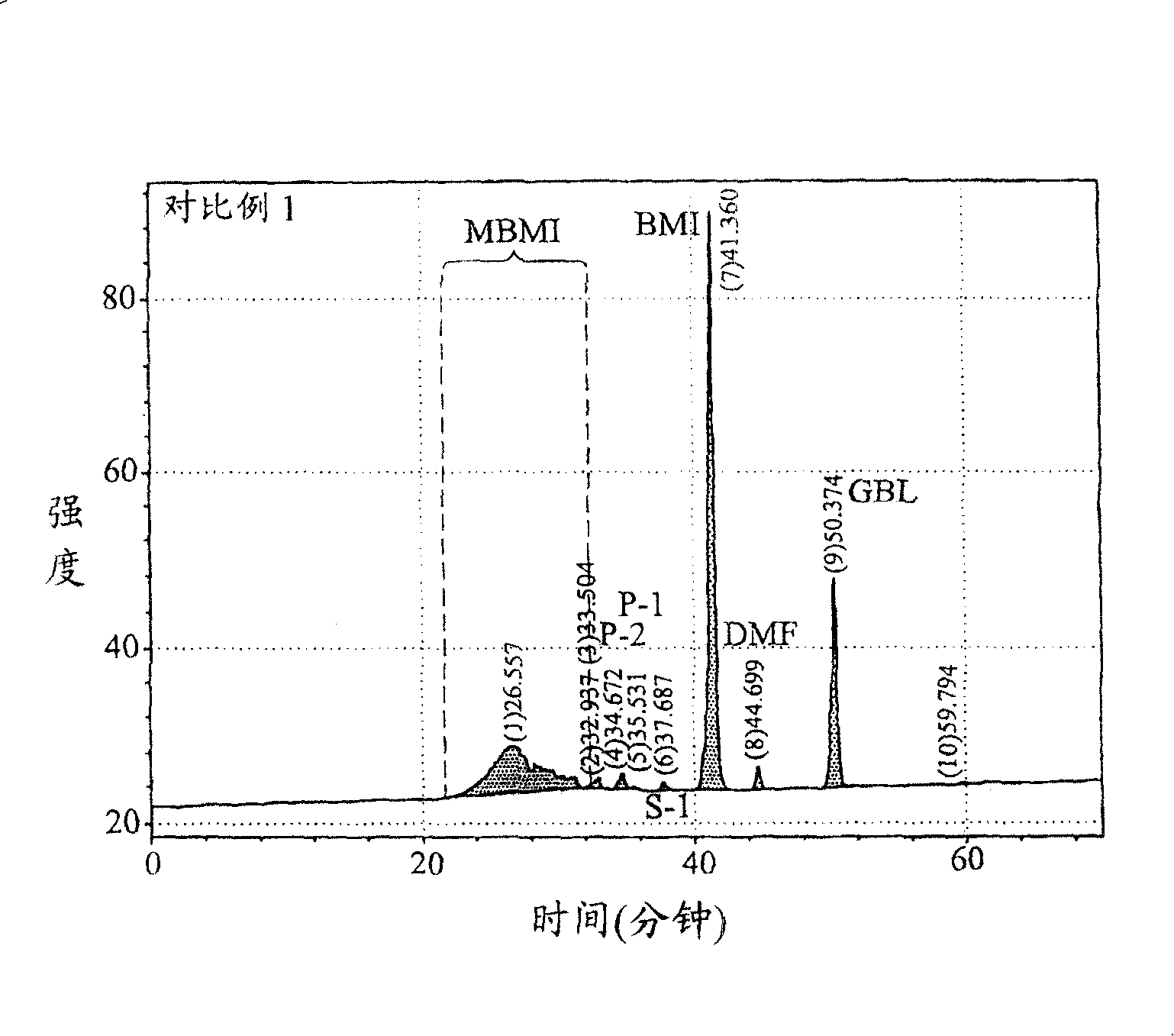

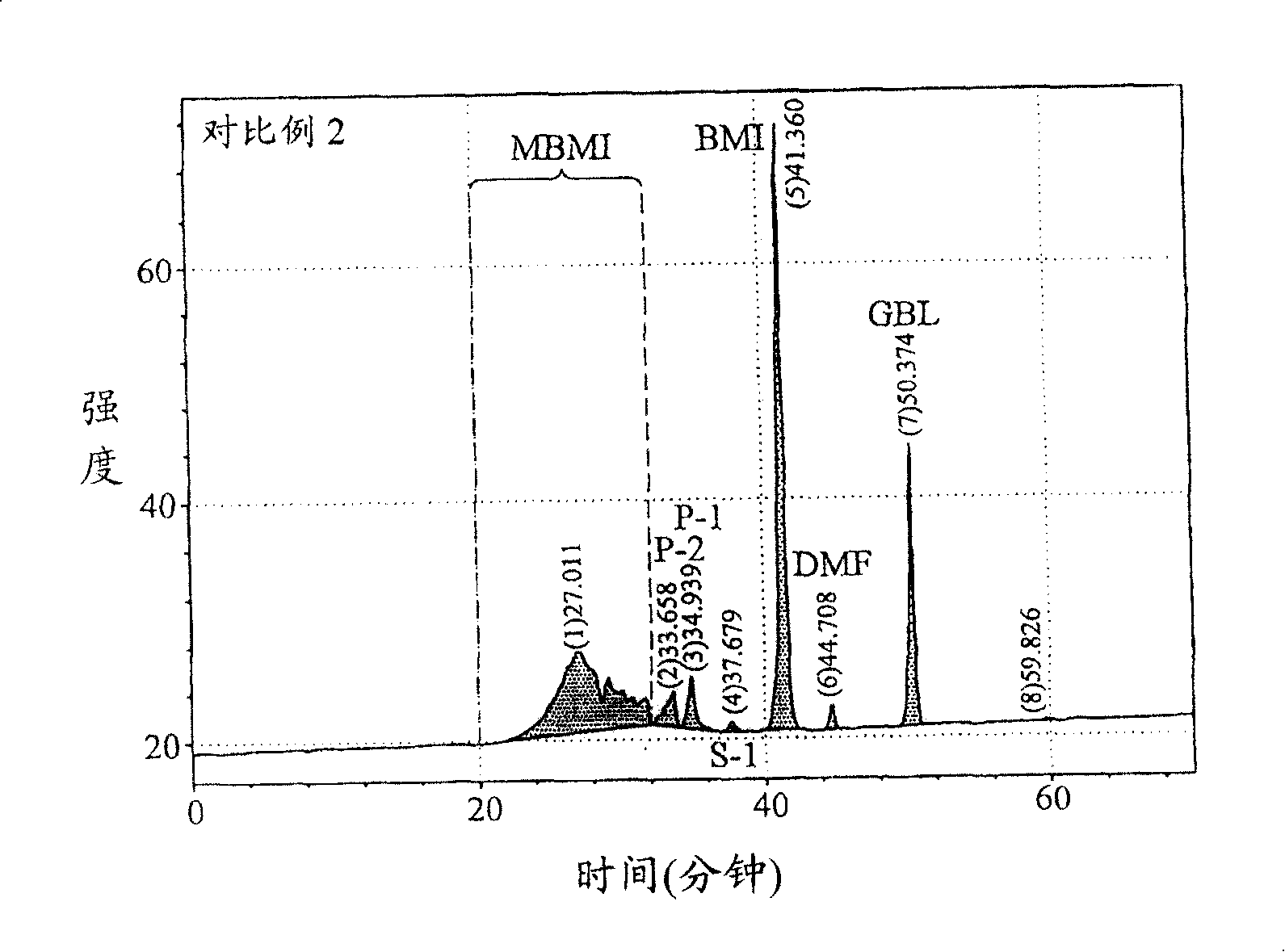

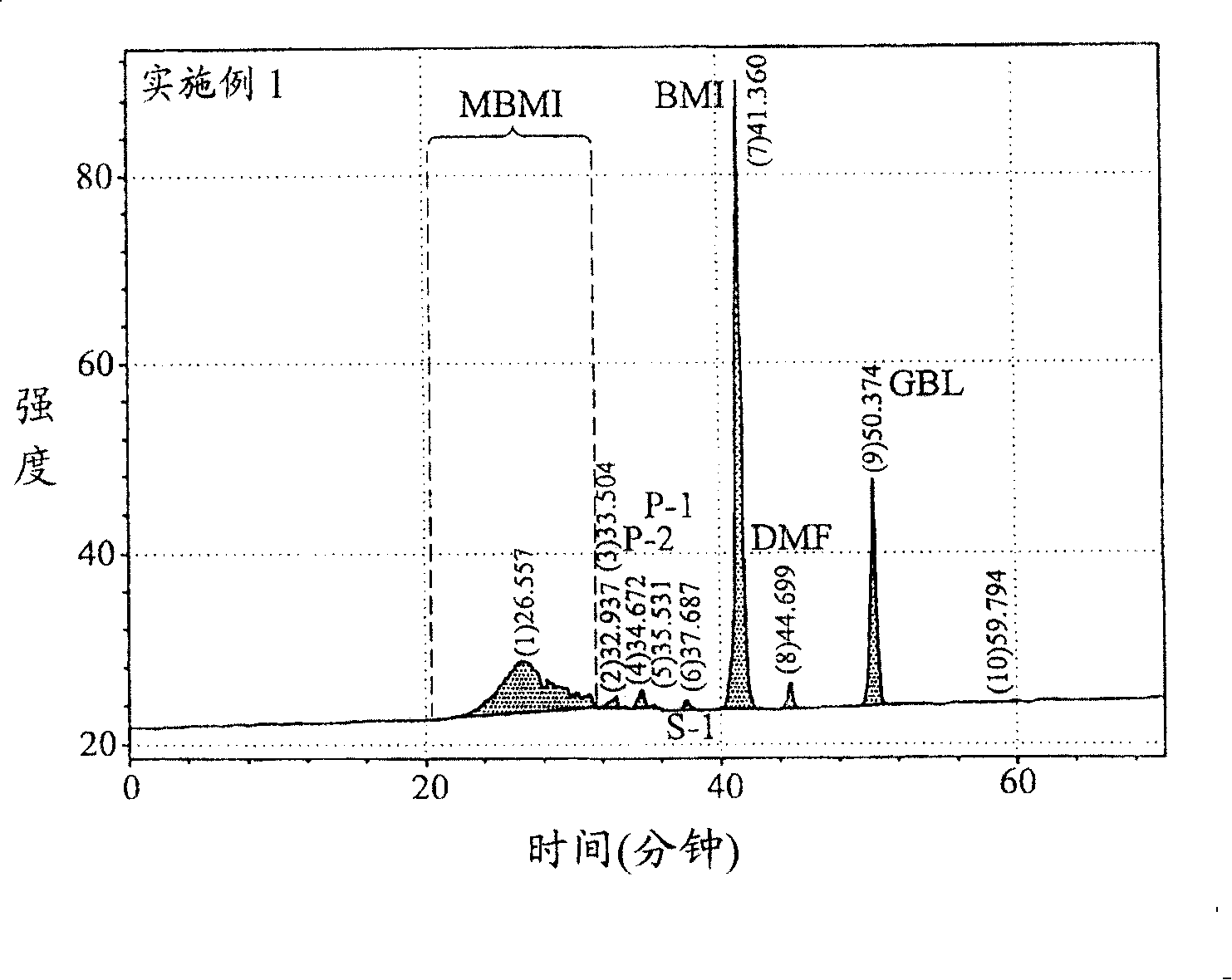

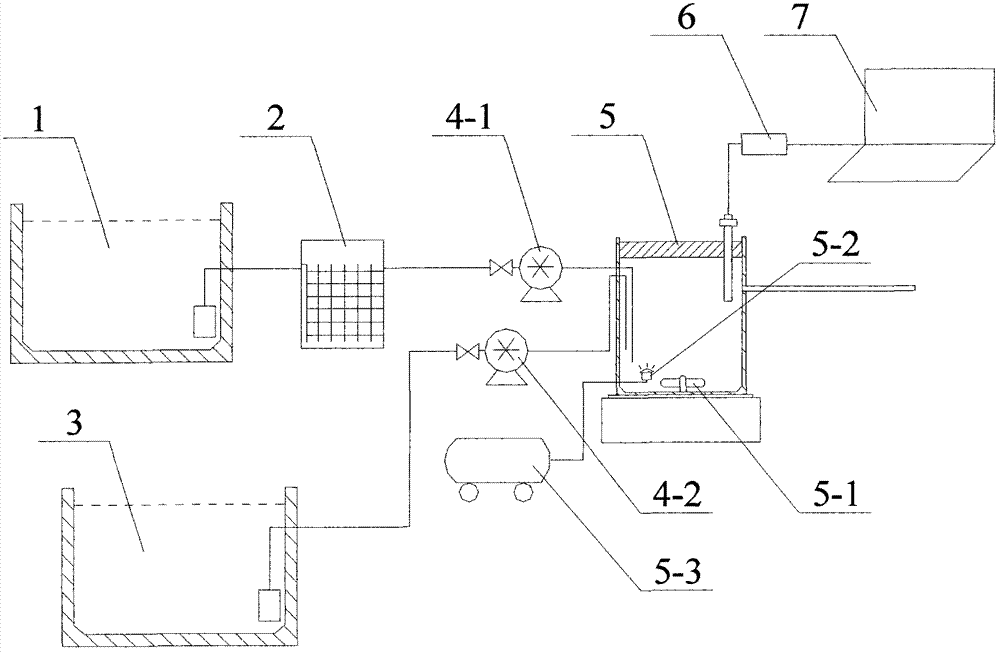

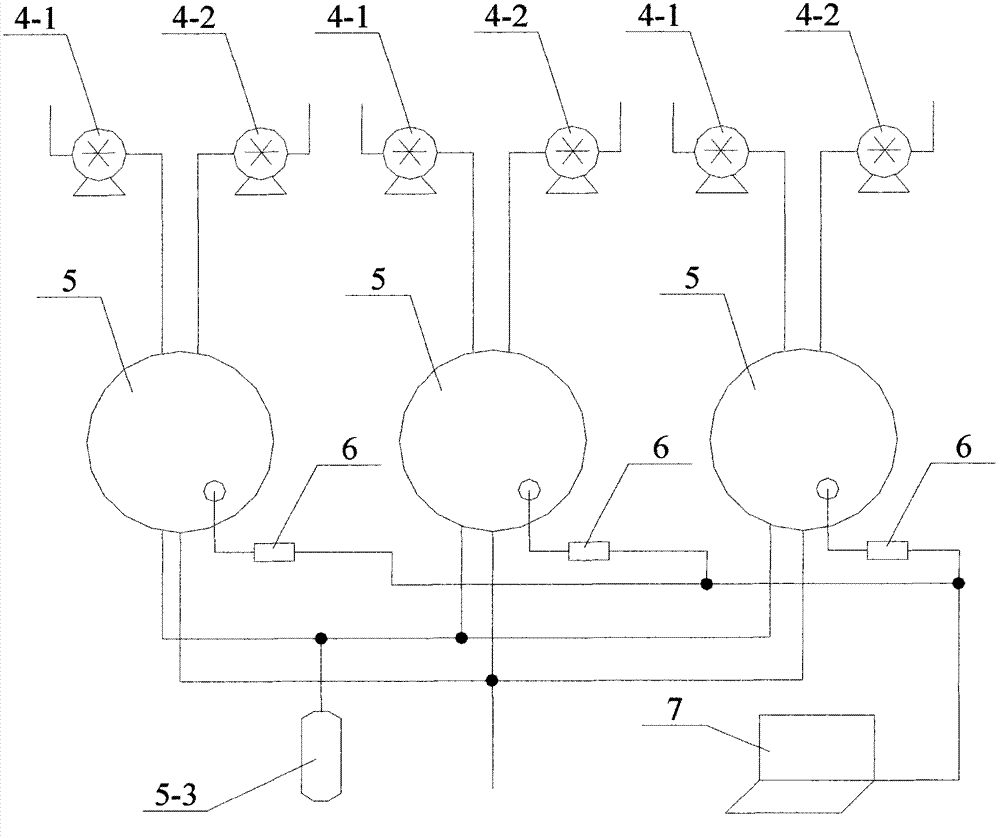

Composition containing bismaleimide oligomer and preparing method thereof

The invention relates to a combination containing bismaleimide oligomer and a preparation method thereof. The combination containing bismaleimide oligomer comprises the bismaleimide oligomer accounting for more than 75 percent of the total solid content of the combination, wherein, the combination containing bismaleimide oligomer is obtained from the batch reaction between bismaleimide monomer and barbituric acid.

Owner:IND TECH RES INST

Process for producing(methyl) propenoic acid hydroxyalkyl ester

The present invention provides a novel production process for a hydroxyalkyl (meth)acrylate, in which it is possible that: in a batch reaction system, the amount of the hydroxyalkyl (meth)acrylate (which is the objective product) as produced is kept nearly on the same level as conventional and further, at the same time, there is suppressed the side production of the alkylene oxide's diaddition product (dialkylene glycol mono(meth)acrylate) that lowers the purity of the product to thus give a bad influence upon its quality. The present invention production process comprises the step of carrying out a batch reaction between (meth)acrylic acid and an alkylene oxide in the presence of a catalyst in order to produce the hydroxyalkyl (meth)acrylate; with the production process being characterized by arranging that the reaction should be initiated in a state of a catalyst concentration of more than 1, wherein the catalyst concentration is defined as the amount of the catalyst as used relative to the integrated amount of the (meth)acrylic acid as supplied and is assumed to be 1 in terms of the amount of the entire catalyst to be used relative to the amount of the entire (meth)acrylic acid to be supplied.

Owner:NIPPON SHOKUBAI CO LTD

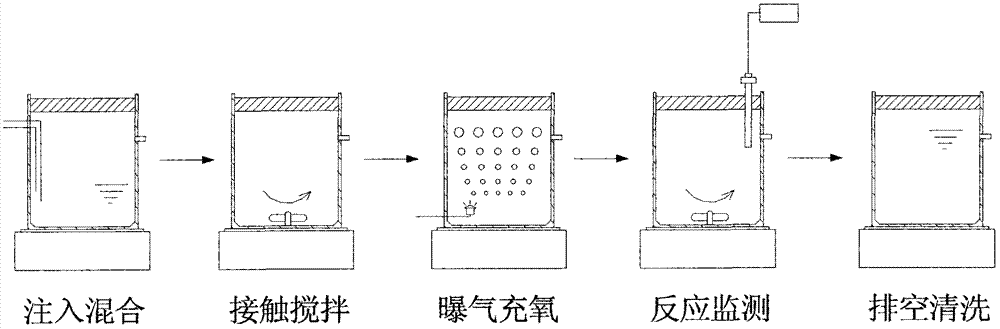

Sequencing batch-based biotoxicity monitoring and early warning system and monitoring method

InactiveCN103592334AWell mixedImprove anti-interference abilityMaterial analysis by electric/magnetic meansSequencing batch reactorEngineering

The invention provides a sequencing batch-based biotoxicity monitoring and early warning system and a monitoring method. The early warning system comprises a sewage system, a security filter, an active sludge system, a sewage injection pump, a sludge injection pump, a sequencing batch reactor, a dissolved oxygen electrode and a PLC (Programmable Logic Controller) system. The monitoring method comprises five stages: injection and mixing; contacting and stirring; aerating and oxygenating; reaction monitoring; and emptying and cleaning. The early warning system provided by the invention is best in reaction and mixing effects by adopting the principle of the sequencing batch reactor, and the devices are in a full closed state, so that the antijamming capability is strong. Therefore, the reaction is more efficient and the result is more accurate. Through the sequencing batch reaction method, the respiratory rate of the active sludge is measured and calculated in a same reactor by using a same dissolved oxygen electrode. Compared with reactors continuous in operation, the system is more efficient and accurate and avoids system errors by using a plurality of dissolved oxygen electrodes to monitor in conventional continuous operation, so that the system can be widely applied to online monitoring early warning of sewage toxicity.

Owner:陈亚松

Compound immobilization method for fructosyl transferase

InactiveCN104560936ANovel cracking methodNovel methodMicroorganism based processesOn/in organic carrierCalcium alginateBatch reaction

The invention discloses a compound immobilization method for fructosyl transferase, and belongs to the field of biotechnologies. The technology has the advantages that fructosyl transferase extraction technological equipment is simple; the fructosyl transferase is embedded by calcium alginate after chitosan covalence immobilization; the problems of forming and integer of chitosan covalence immobilized enzyme can be solved; the immobilization efficiency of the enzyme is high (enzyme activity recovery rate reaches above 70%); the enzyme can be used repeatedly for more than 85 times during batch reaction.

Owner:BAOLINGBAO BIOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com