MSBR (Modified SBR) nitrogen and phosphorus removal technique based on MBBR (Moving Bed Biofilm Reactor)

A denitrification and dephosphorization technology, which is applied in the field of MBBR-based MSBR denitrification and dephosphorization process, can solve the problems of weak system impact resistance, large system area, long sewage residence time, etc., and achieves great adjustability. , The effect of high volume load and simple transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

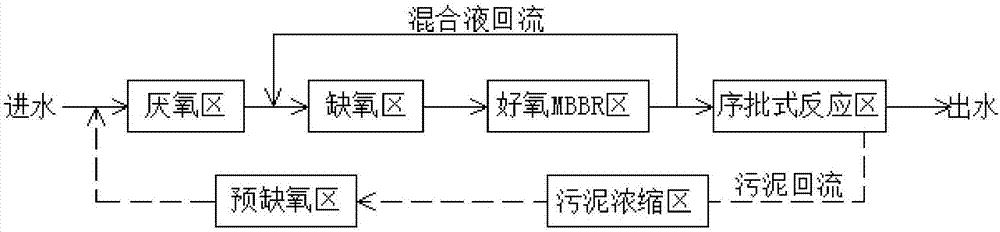

[0024] The invention provides an MBBR-based MSBR nitrogen and phosphorus removal process. By setting an aerobic MBBR zone and using the biofilm effect on the suspended filler, the volume load and impact resistance of the system are greatly improved. It is convenient to upgrade the MSBR process, improve the processing capacity and stability of the existing process, and meet the improvement of the treatment water volume or effluent water quality standards. For new projects, it can greatly save the occupied area.

[0025] In order to make the advantages and technical solutions of the present invention clearer and more specific, the present invention will be described in detail below in conjunction with specific embodiments. Before describing the denitrification and phosphorus removal process of the present invention, the system based on the process of the present invention will be described first.

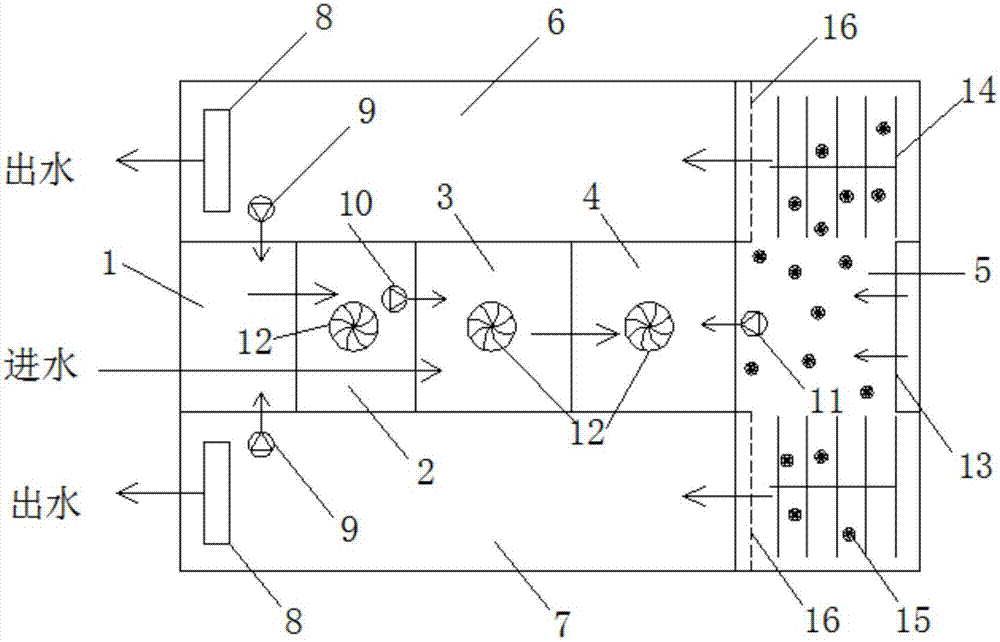

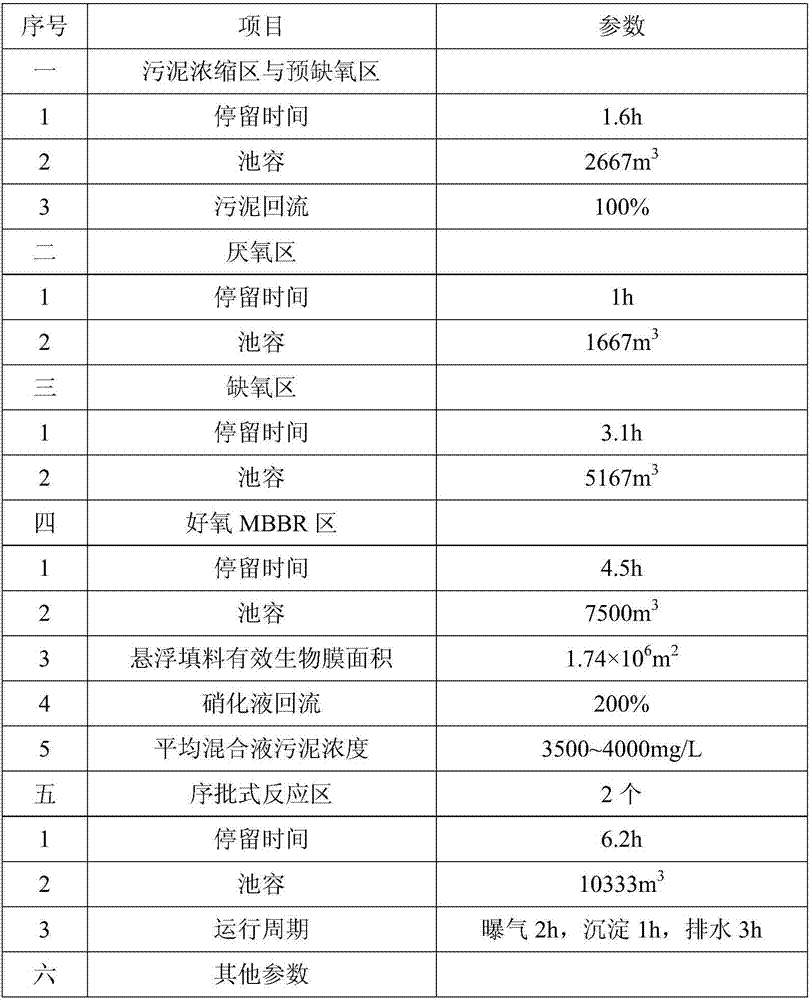

[0026] Such as figure 2 As shown, a MBBR-based MSBR nitrogen and phosphorus rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com