Method for applying integrated technology of combination of membrane biochemistry and nanofiltration membrane to high-density leachate advanced treatment and recycling

A nanofiltration membrane and membrane biochemical technology, applied in chemical instruments and methods, permeation/dialysis water/sewage treatment, pyrolysis treatment of sludge, etc., can solve the problems of environmental pollution, difficult treatment, high SS content, etc. Environmental pollution problems, the effect of relieving environmental pressure, and protecting land resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

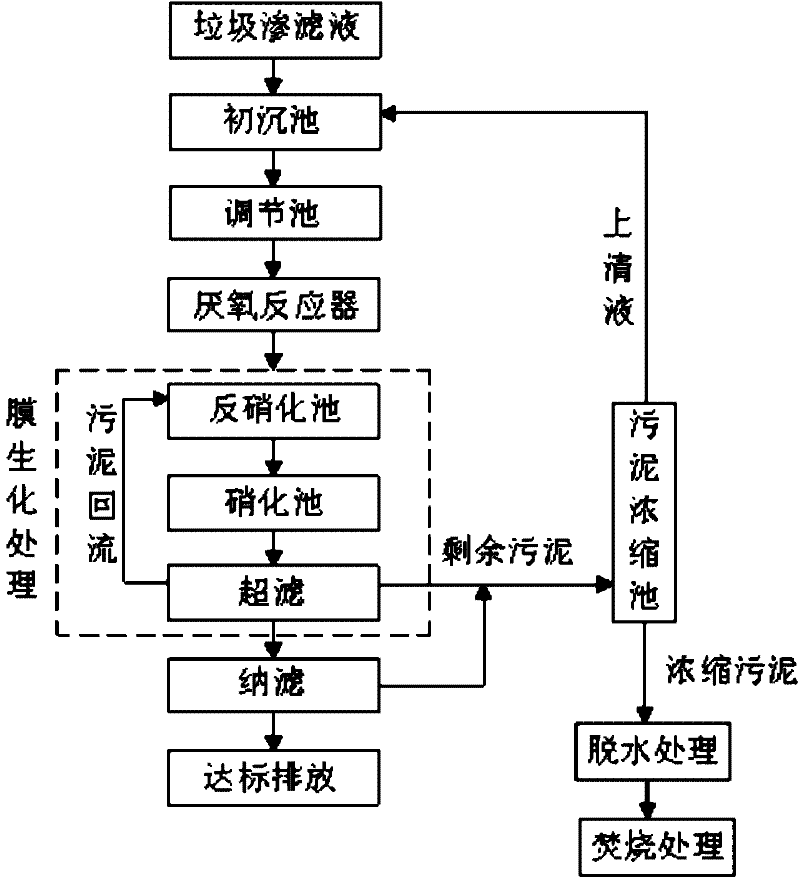

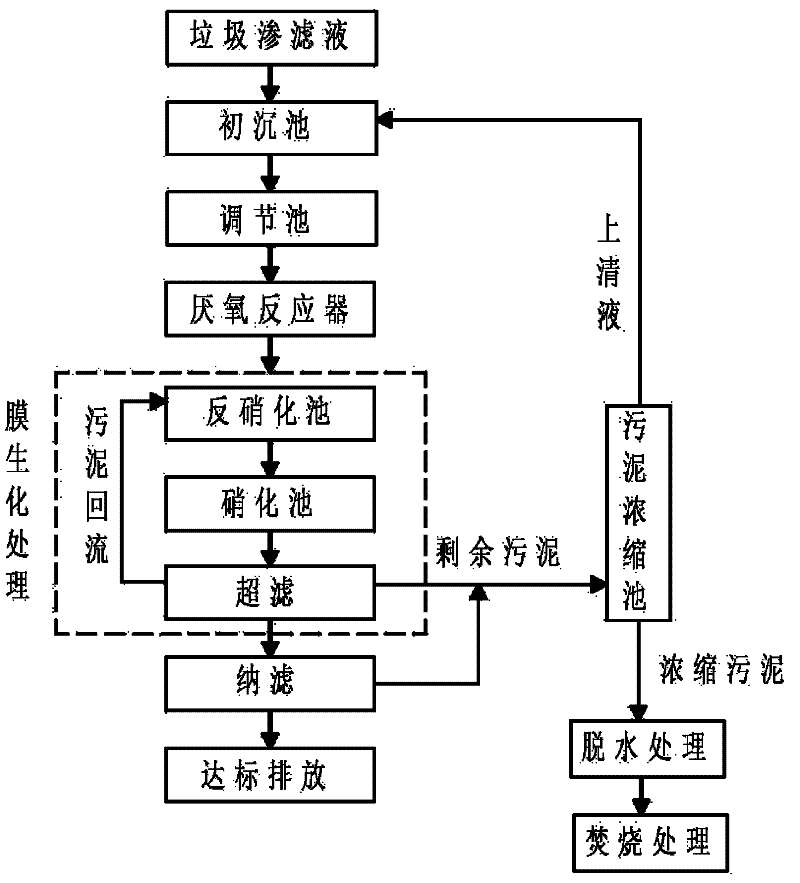

[0027] Example 1. Such as figure 1 As shown, the landfill leachate is processed according to the following steps: a. Pretreatment, the landfill leachate from the waste storage pit is collected and then enters the primary sedimentation tank for precipitation. The leachate enters the primary sedimentation tank from the central pipe of the primary sedimentation tank. At the bottom of the tank, most of the impurities and sludge are deposited and then pumped back to the garbage storage pit by the sludge pump, which plays a role in reducing water quality and protecting the subsequent system (especially ultrafiltration). The clarified garbage leachate overflows to the regulating tank. Stay in the pool for 7 days to adjust and store the flow, which not only plays a role of homogenization, but also plays a buffer role for the rainy season or the maintenance of the treatment system;

[0028] b. Anaerobic treatment. The landfill leachate is lifted by the pump into the bottom of the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com