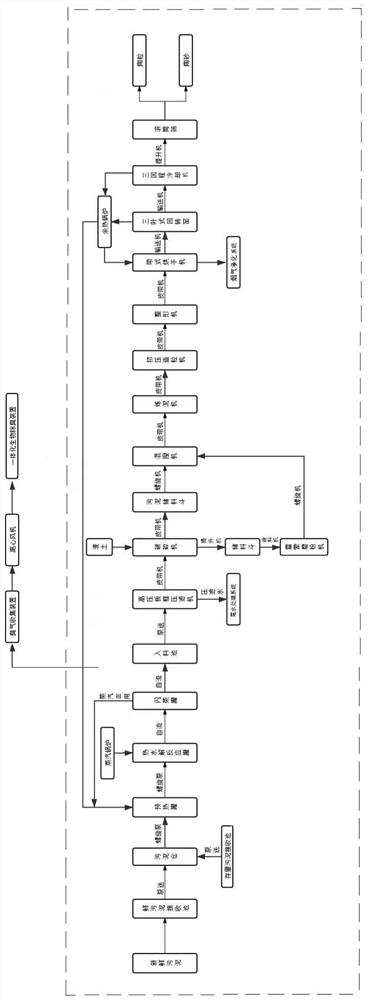

Patents

Literature

38results about How to "Achieve capacity reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

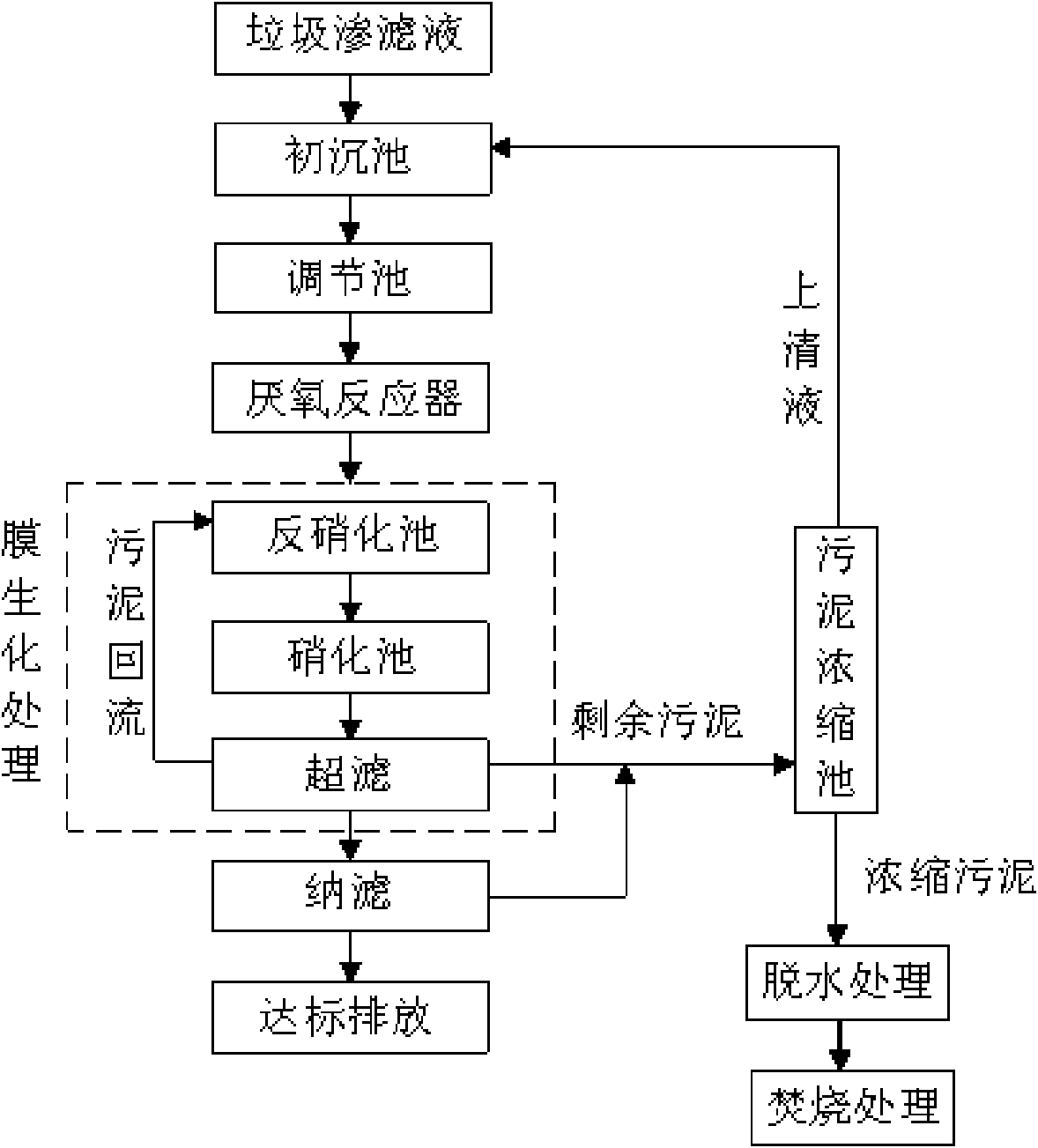

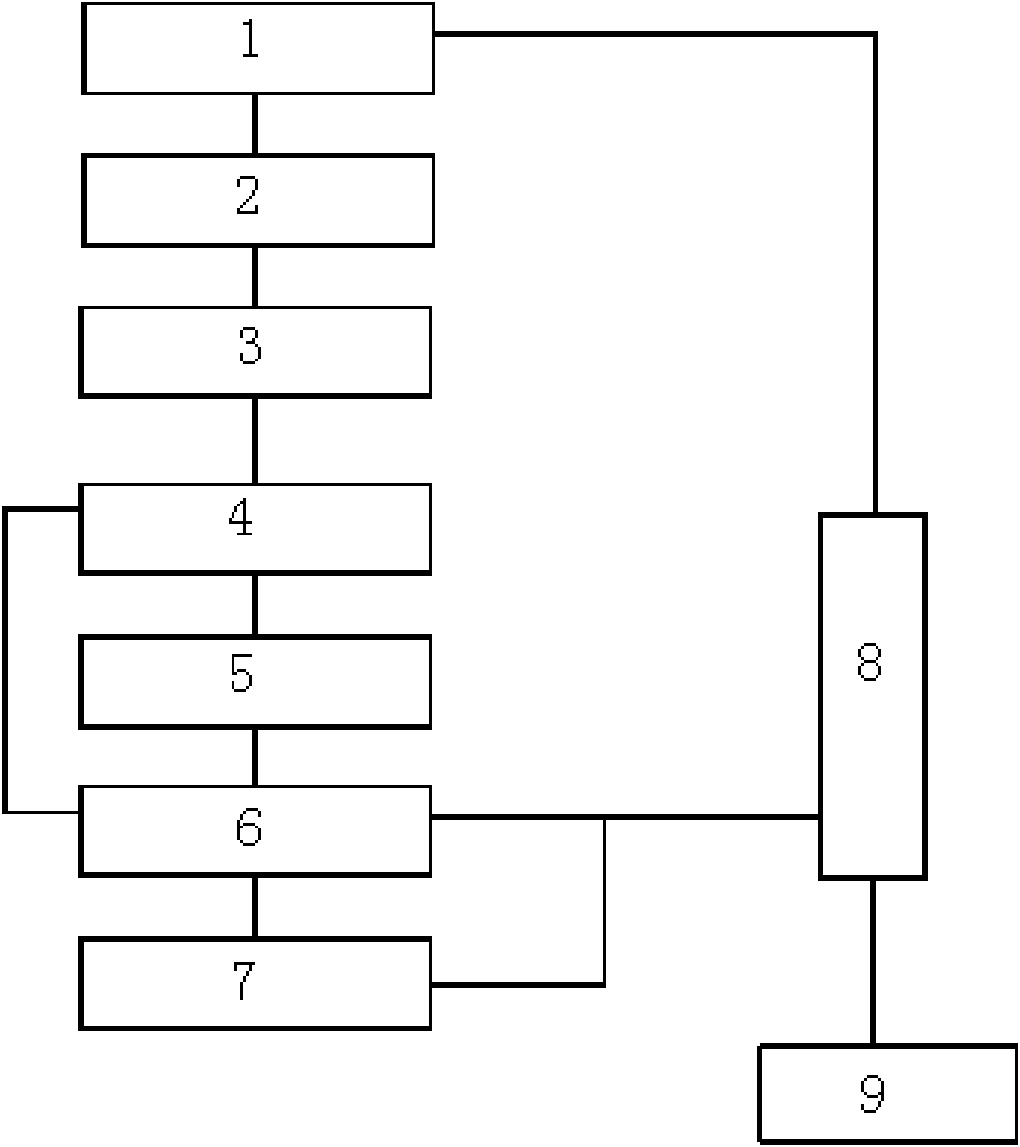

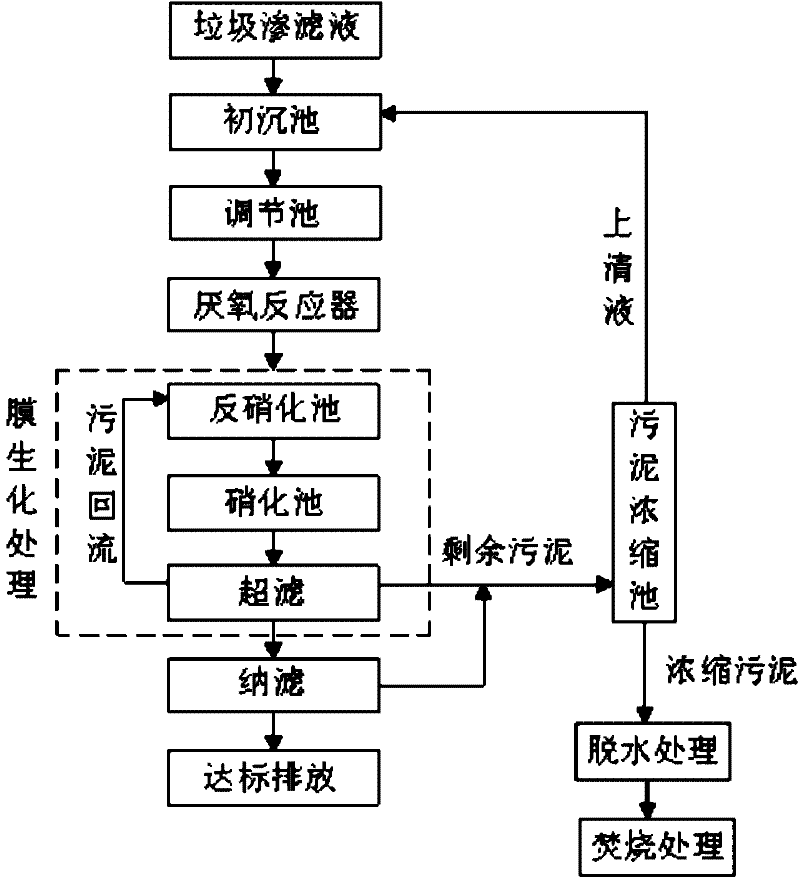

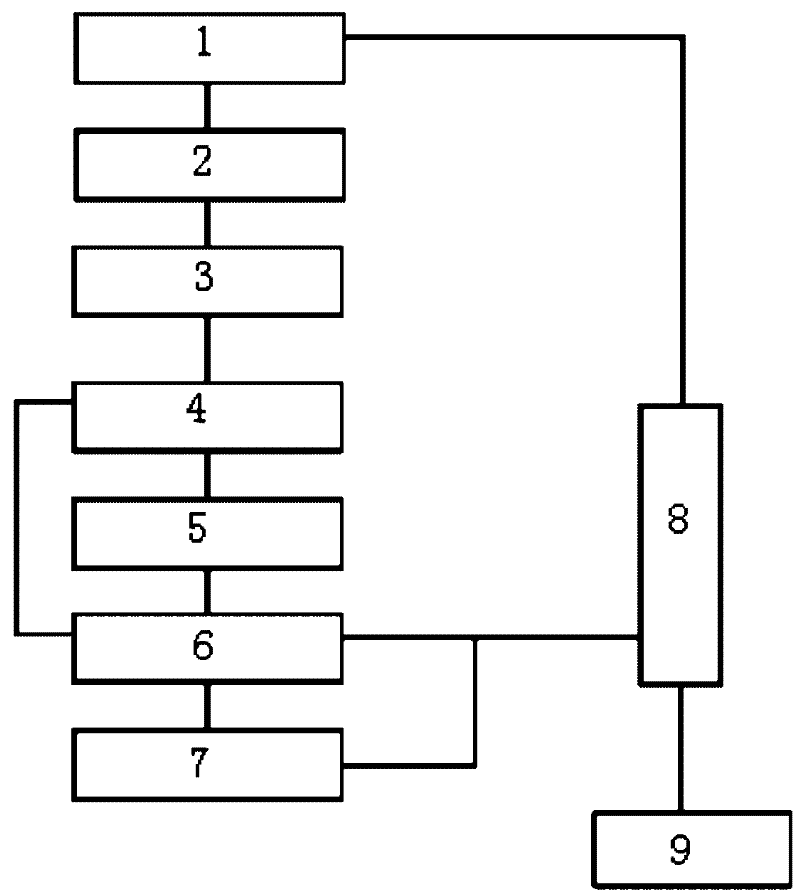

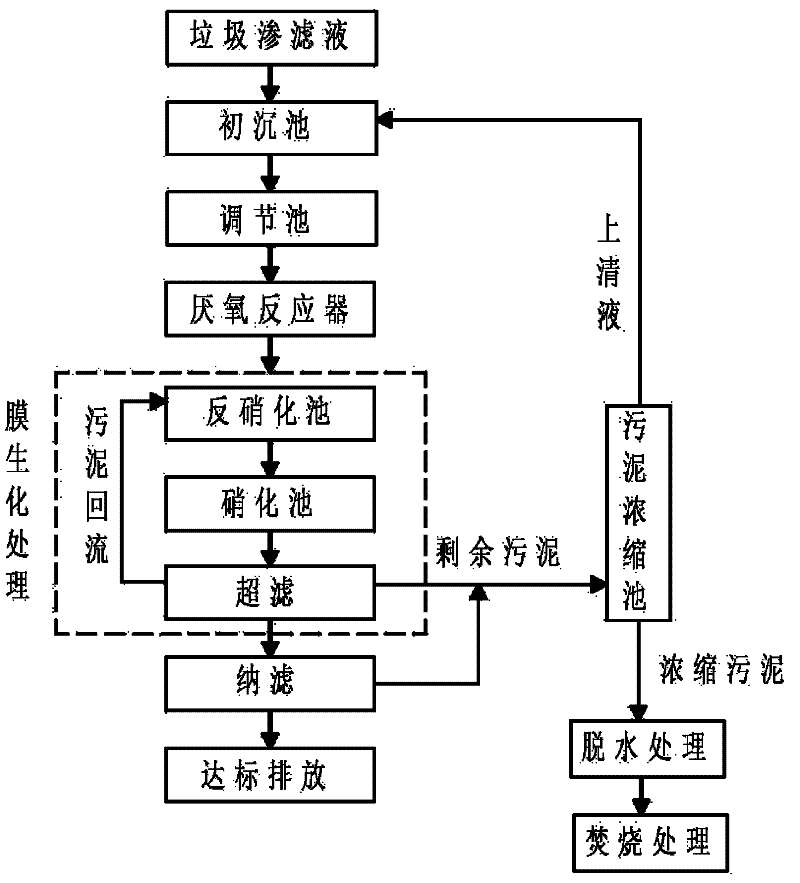

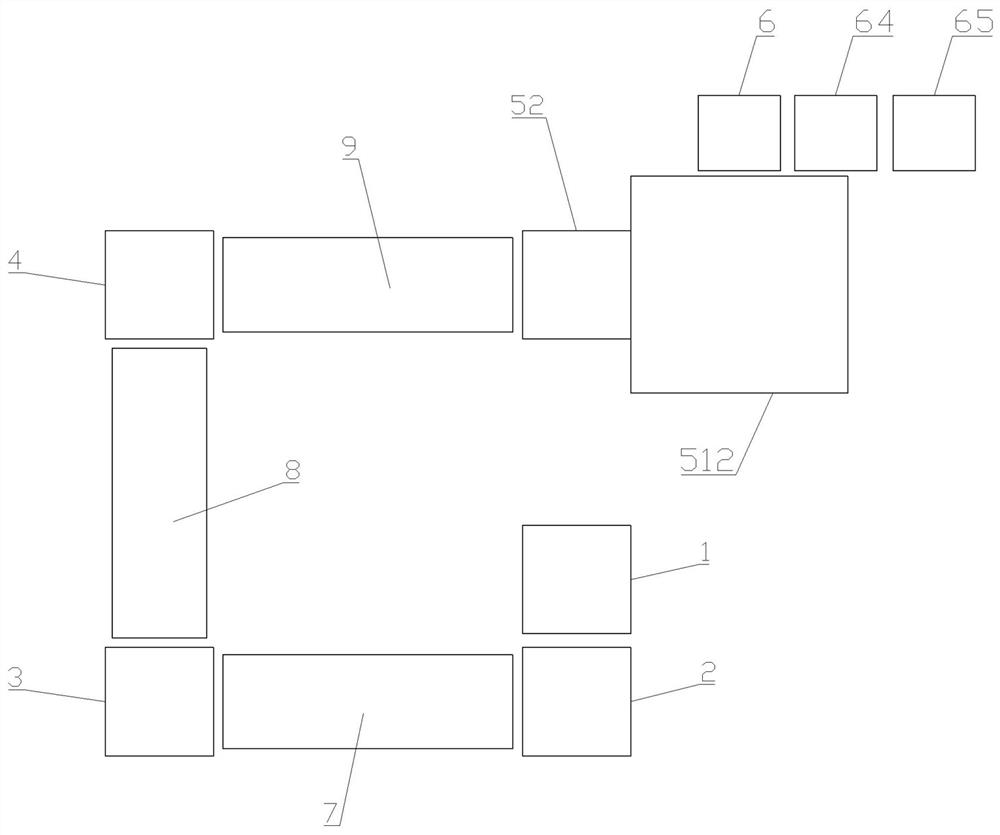

Method and device for treating garbage percolate

ActiveCN101597131AAchieving zero emissionsRelieve stressSludge treatment by de-watering/drying/thickeningTreatment with aerobic and anaerobic processesHigh concentrationAfter treatment

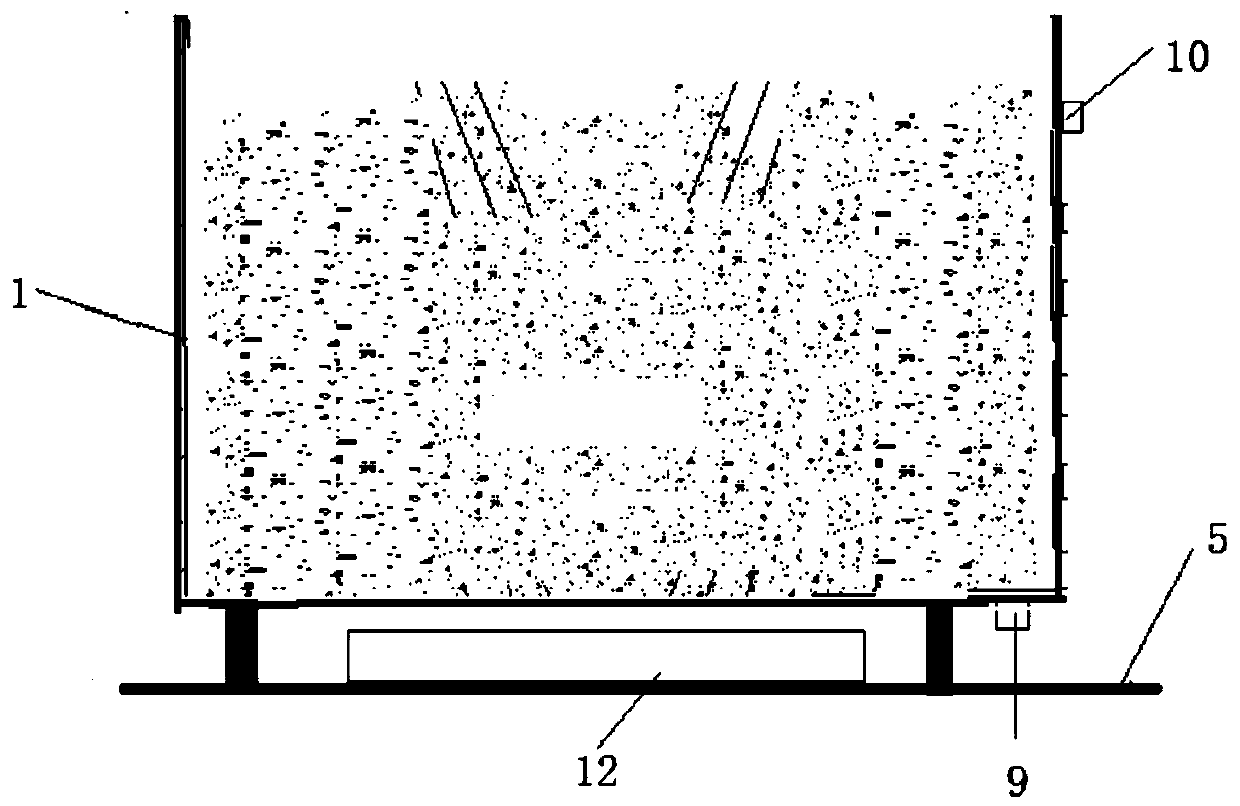

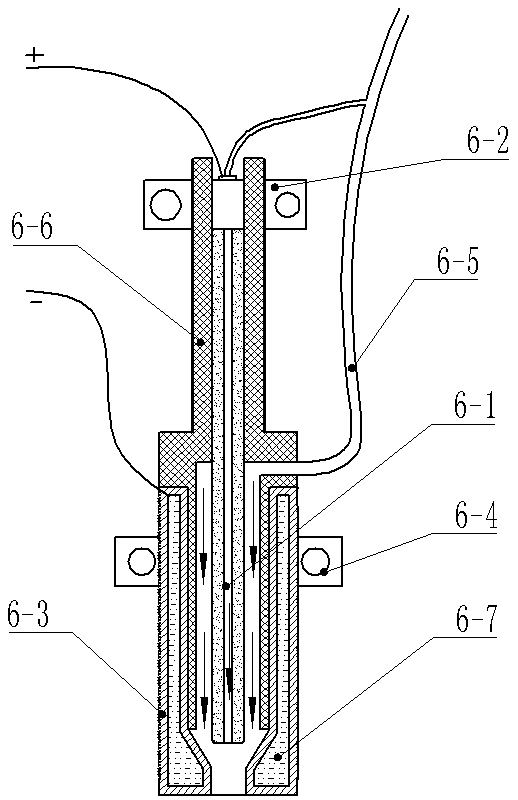

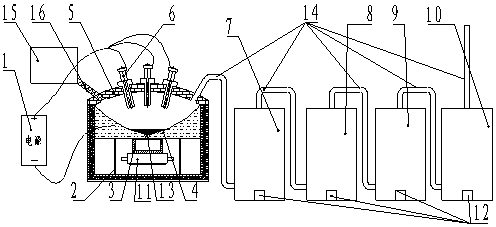

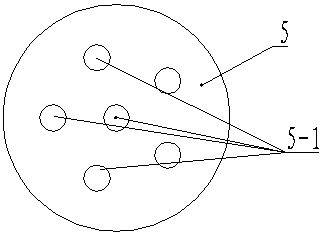

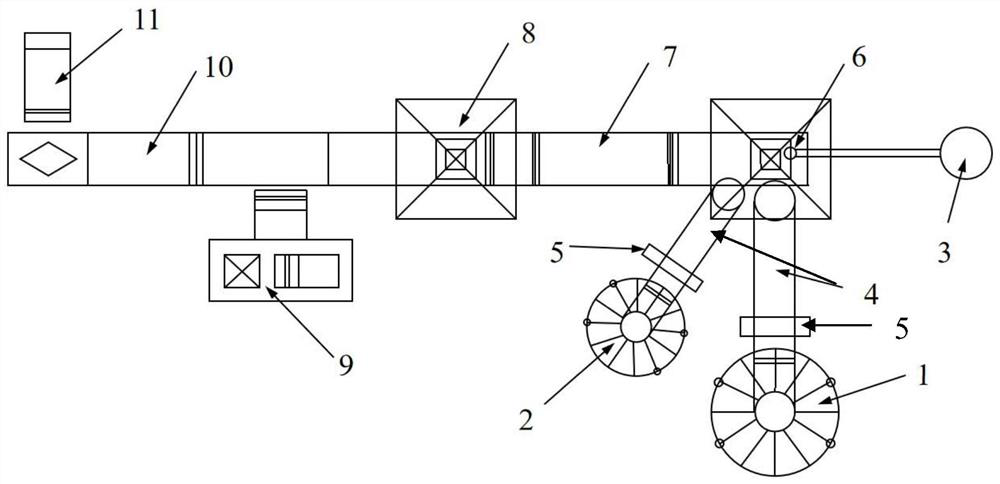

The invention discloses a method and a device for treating garbage percolate, wherein the method comprises the steps of pretreatment, anaerobic treatment, membrane biochemical treatment, nanofiltration treatment, sludge treatment and the like; the device comprises a primary sedimentation tank (1) and an adjusting tank (2), the adjusting tank (2) is connected with an anaerobic reactor (3), the anaerobic reactor (3) is connected with a denitrification tank (4), and the denitrification tank (4) is communicated with a nitrification tank (5); and the nitrification tank (5) is connected with an ultrafiltration apparatus (6), and the ultrafiltration apparatus (6) is connected with a nanofiltration device (7). The method and the device achieve COD degradation of high-concentration wastewater so that the COD of high-concentration COD of 50,000 reaches about 50 after treatment and reaches the standard of industrial reuse water, thus the method and the device achieve zero discharge of the percolate, initiate a new attempt to treat high-concentration percolate, and fill up the domestic blank.

Owner:汕头市澄海洁源垃圾发电厂有限公司

Method for applying integrated technology of combination of membrane biochemistry and nanofiltration membrane to high-density leachate advanced treatment and recycling

InactiveCN102190400ARelieve stressSolve pollutionSludge treatment by pyrolysisTreatment with aerobic and anaerobic processesHigh densityUltrafiltration

The invention discloses a processing method and a processing apparatus of landfill leachate. The processing method comprises steps of pretreatment, anaerobic treatment, membrane biochemical treatment, nanofiltration treatment, and sludge treatment and the like. And the processing apparatus includes a primary settling tank (1) and a regulating tank (2). The regulating tank (2) is connected with an anaerobic reactor (3) which is connected with a denitrifying tank (4); the denitrifying tank (4) is communicated with a nitration tank (5), which is connected with ultrafiltration equipment (6); and the ultrafiltration equipment (6) is connected with nanofiltration equipment (7). According to the invention, COD of the high-density wastewater is degraded. After processing, high-density COD of 50,000 to 60,000mg / L is degraded to COD of about 50 mg / L, which reaches the standard of industrial reused water. Moreover, zero discharge of leachate is realized. Therefore, a new attempt to treat the high-density leachate is initiated and the domestic blank is filled.

Owner:HUZHOU NANTAIHU ENVIRONMENTAL PROTECTION ENERGY

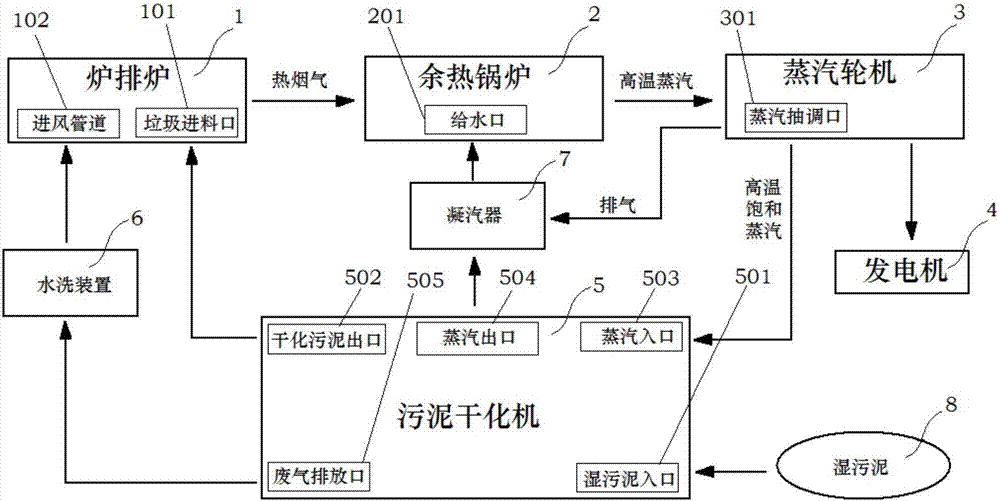

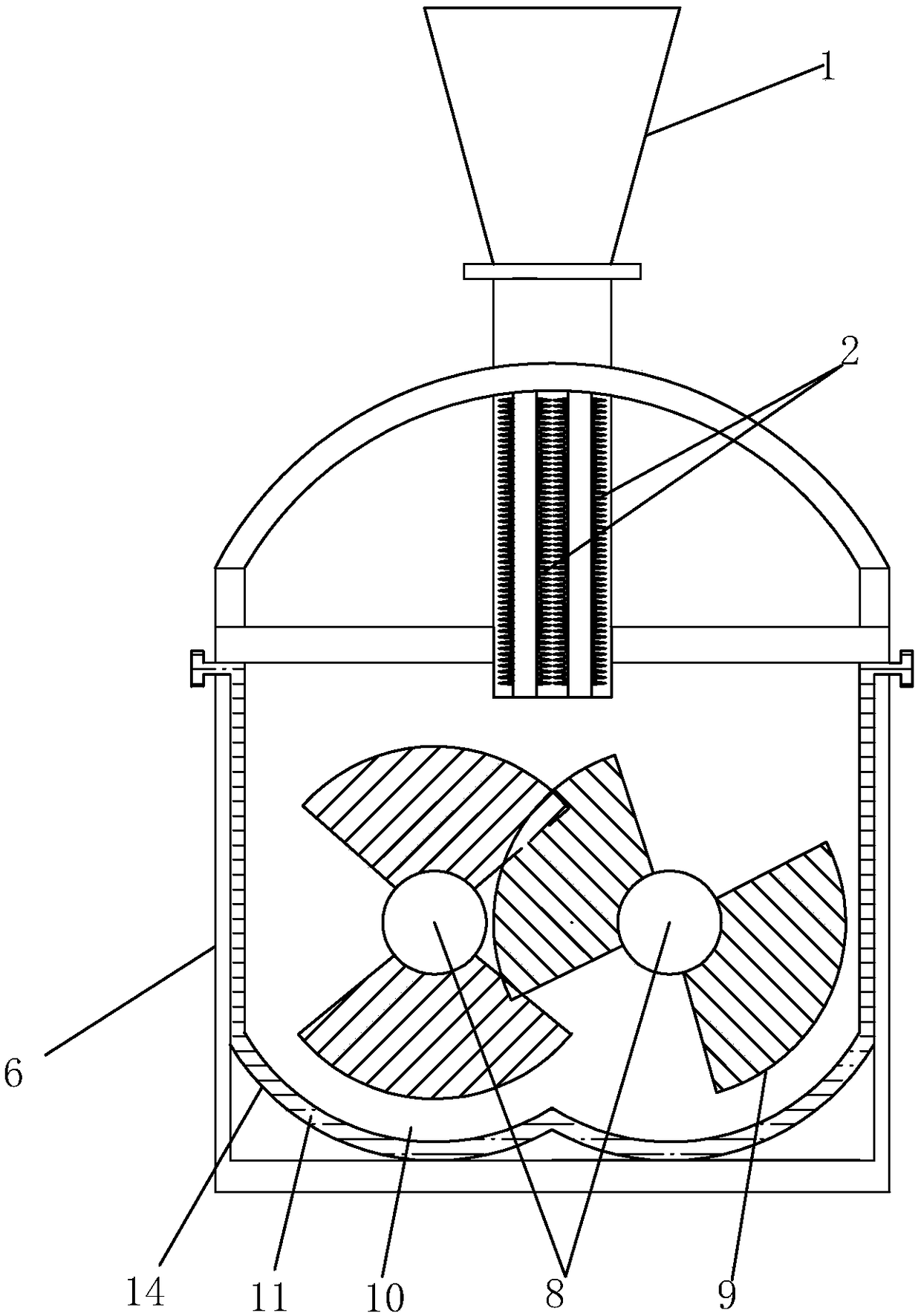

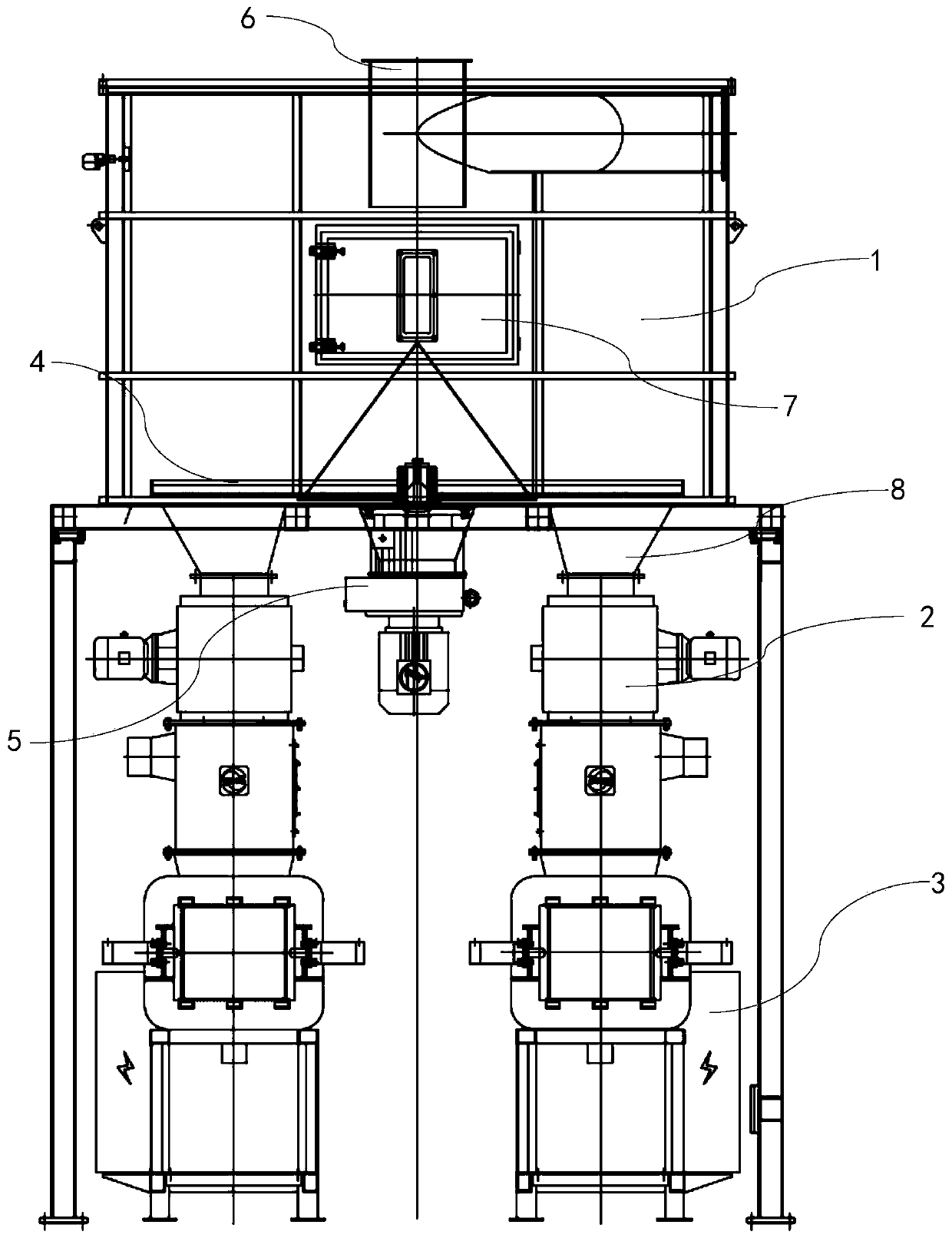

Method and system for cooperatively treating sludge through grate furnace waste incineration

PendingCN107013928AEasy to handleTechnically feasibleSludge treatment by de-watering/drying/thickeningIncinerator apparatusSludgeProcess engineering

The invention discloses a method and system for cooperatively treating sludge through grate furnace waste incineration, and belongs to the field of sludge treatment. Steam generated by grate furnace waste incineration is firstly utilized for carrying out indirect heat exchange drying on the sludge, and then the sludge dried to a certain degree and in-furnace waste are mixed and incinerated in a grate furnace according to a certain proportion. According to the method and system, the existing and mature grate furnace waste incineration technology is utilized for achieving effective drying and cooperative incineration on the sludge, the sludge independent drying cost and the building and operating cost of an incineration treatment project can be greatly reduced, and harmlessness, reduction and recycling of sludge treatment are achieved.

Owner:CHONGQING SANFENG COVANTA ENVIRONMENTAL IND

Recycling method of house refuse

InactiveCN102671925AEfficient separationRealize resourcesConstruction waste recoverySolid waste disposalBrickTower

The invention relates to a method for sorting and recycling municipal solid waste. The municipal solid waste can be sorted into two types, namely, combustible wastes and incombustible wastes. The combustible waste cracking treatment is as follows: directly introducing a cracking gas to a rectifying tower to separate to obtain aromatic hydrocarbon, oil, asphalt and the like; and sending difficultly-condensed gas to a cracking device as cracking energy, wherein the building garage in the incombustible waste can be used for manufacturing bricks or can be buried directly; and the crushed and separated substances such as kitchen garbage and the like can be used as compost or buried directly, therefore, the reduction, harmlessness and recycling of garbage treatment can be achieved. With the adoption of the treatment method, not only the oil and energy needed by cracking can be obtained from the garbage, but also the high-temperature cracking tail gas can be used for refining oil products after passing through steam produced by a residual heat boiler, thereby the energy consumption can be satisfied during the garbage recycling in a maximum manner.

Owner:庞金钊

Biodegradable dinner ware and its preparation method

InactiveCN1651494AReduce pollutionAchieve capacity reductionTable equipmentsPolymer sciencePolyolefin

A biodegradable dining set is prepared from biodegradable starch-base mother material, polyolefin resin, plastic filler, pigment, lubricating disperser, degradating aid, and moisture absorbent through proportionally mixing, heating, extruding to become sheet, moulding, and cooling.

Owner:陈明忠

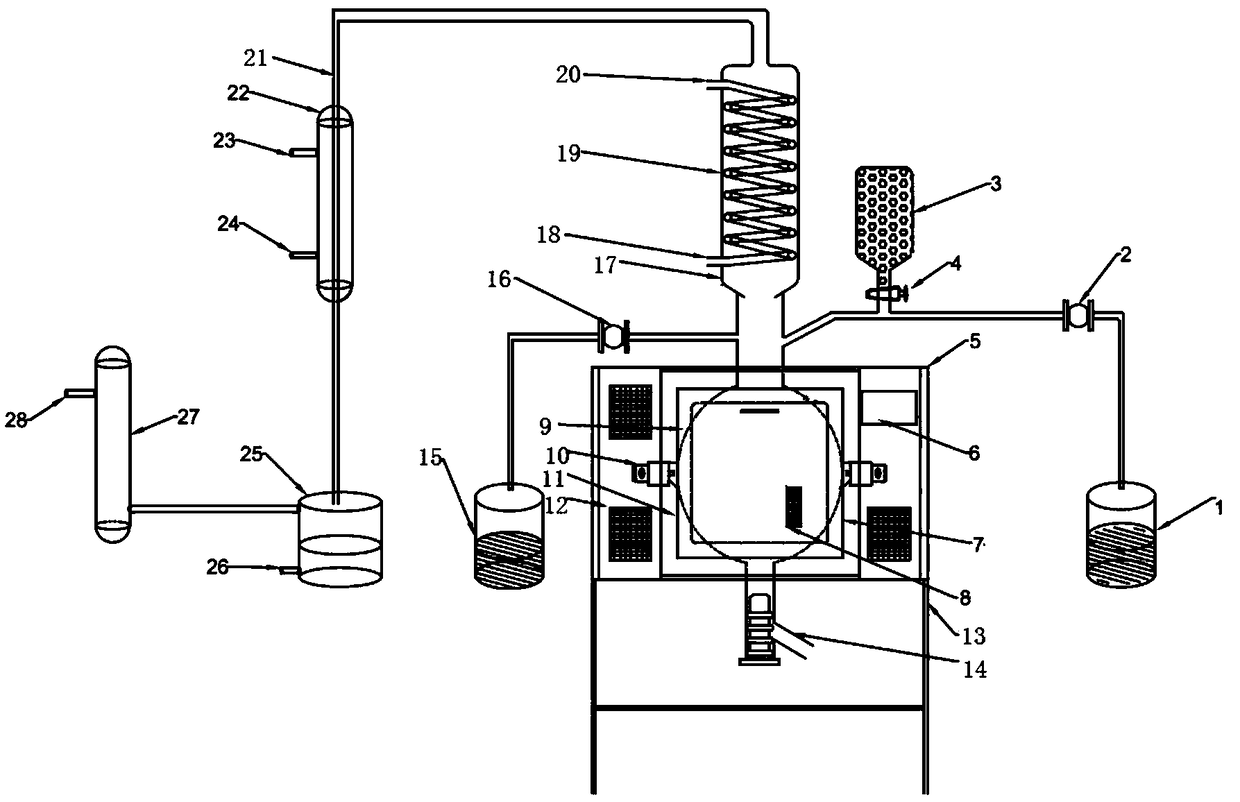

Radioactive waste ion exchange resin rapid degradation device

PendingCN109215825AIncrease outputImprove degradation efficiencyRadioactive decontaminationExhaust gasVolume reduction

The invention relates to the radioactive waste processing technology field and especially relates to a radioactive waste ion exchange resin rapid degradation device. The device comprises a feeding system, a reaction system and a tail gas processing system. The reaction system comprises a reaction kettle and a microwave heating device which is installed on the outer side of the reaction kettle andis used for microwave heating. The reaction kettle is provided with a discharge port and an exhaust port. The feeding system comprises a catalyst feeding tank which is connected with the reaction kettle and supplies a material in an internal portion, a radioactive waste ion exchange resin feeding tank, and an oxidant feeding tank. The tail gas processing system comprises a first condensation pipeused for reflux condensation and a second condensation pipe used for vapor condensation which are successively connected. The air inlet of the first condensation pipe is connected to the upper end exhaust port of the reaction kettle. Compared with the prior art, by using the degradation device, a degradation speed is fast, volume reduction discharging can be realized, degradation and later periodcost is low, work efficiency is high, performance is stable and economic benefits are good.

Owner:SOUTHWEAT UNIV OF SCI & TECH

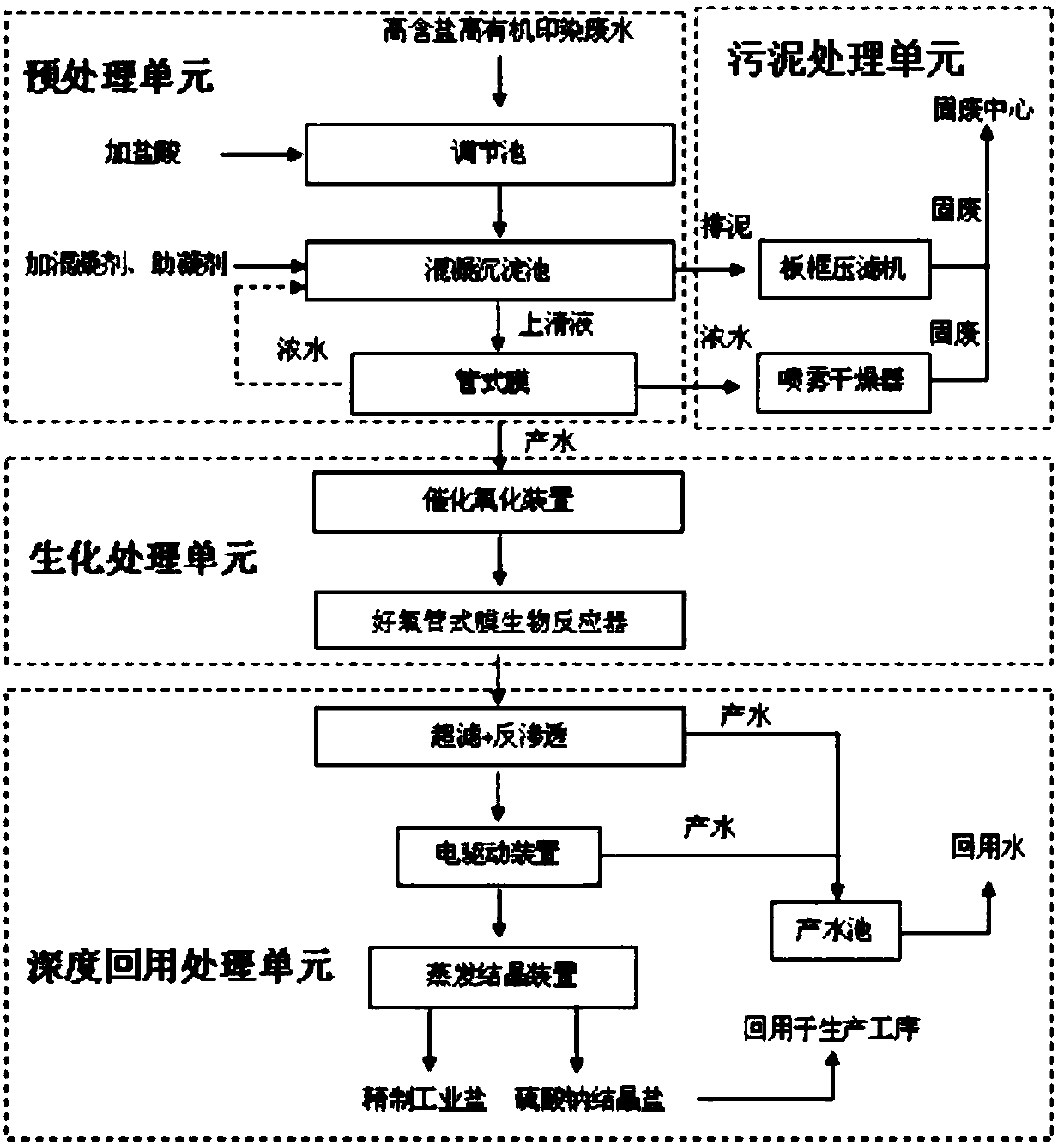

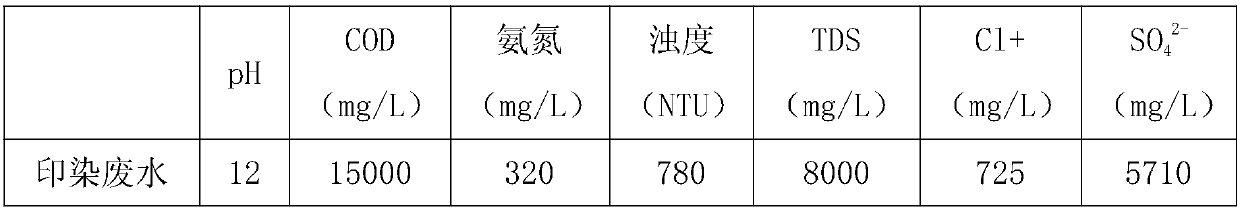

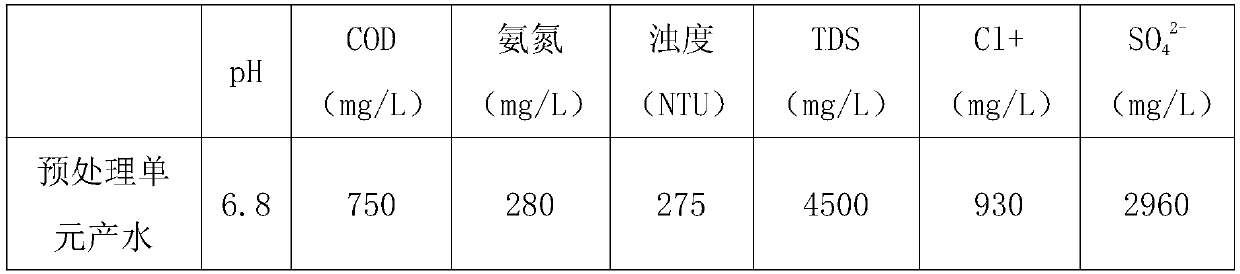

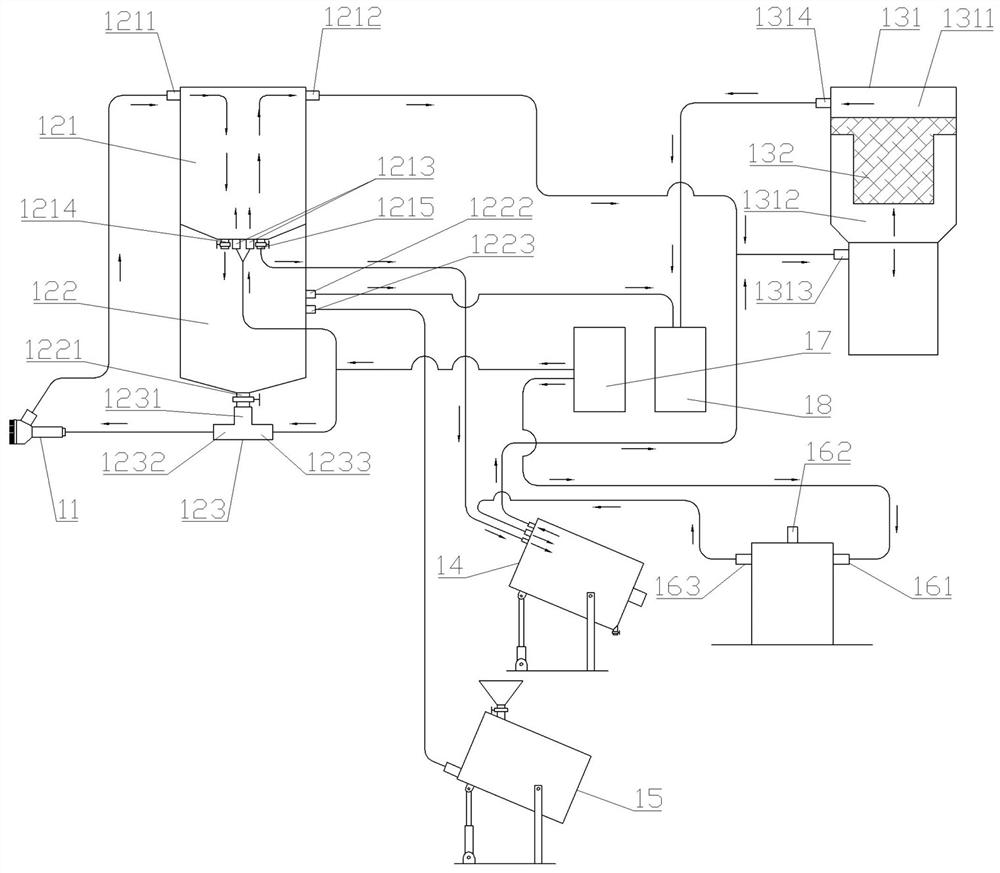

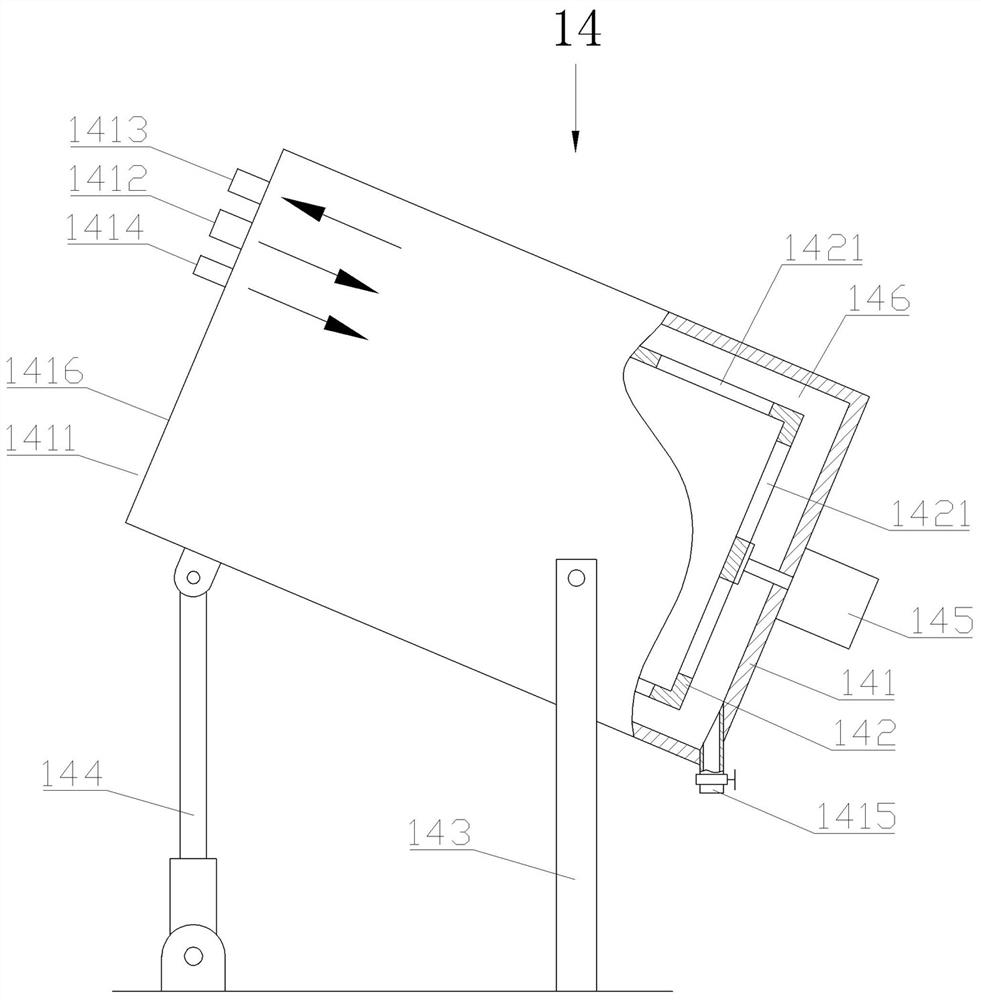

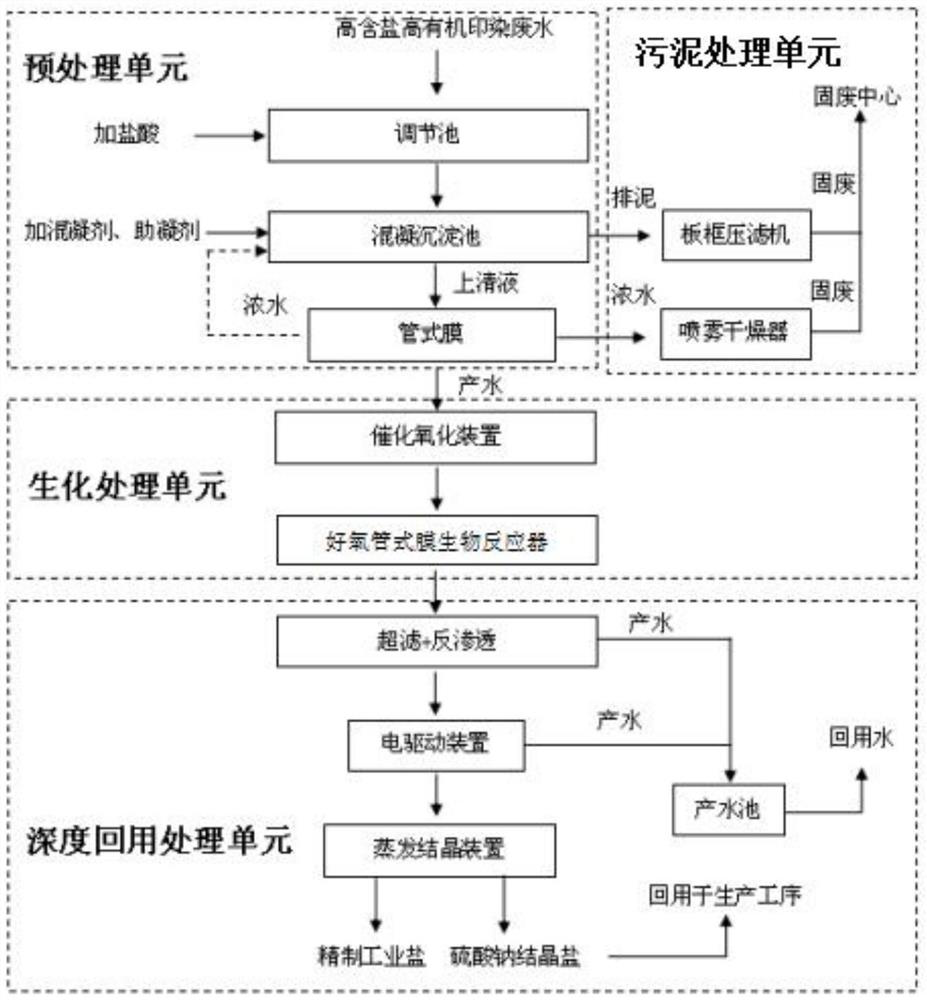

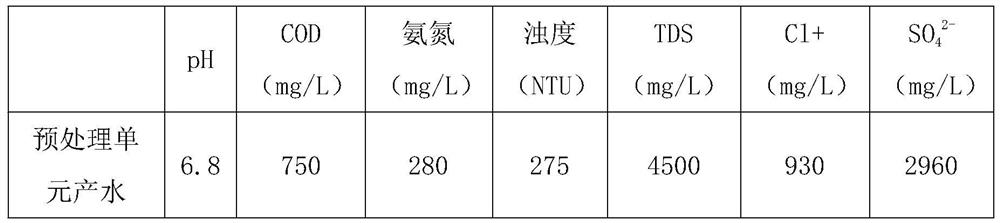

Tubular membrane based high concentration printing and dyeing waste water pretreatment integrated method

ActiveCN110156249AIncrease permeate fluxReduce COD valueSludge treatment by de-watering/drying/thickeningWater contaminantsHigh concentrationUltrafiltration

The invention discloses a tubular membrane based high concentration printing and dyeing waste water pretreatment integrated method. A device of the tubular membrane based high concentration printing and dyeing waste water pretreatment integrated method comprises a pretreatment unit, a biochemical treatment unit, a deep recycling treatment unit, and a sludge treatment unit; the pretreatment unit comprises an adjusting tank, a coagulation sedimentation basin, and a tubular membrane; the biochemical treatment unit comprises a catalytic oxidation device and an aerobic tubular membrane bioreactor;the deep recycling treatment unit comprises an ultrafiltration device, an reverse osmosis device, an electric driving device, an evaporation crystallization device, and a water production tank; the sludge treatment unit comprises a plate and frame filter press and a spray drying device. According to the tubular membrane based high concentration printing and dyeing waste water pretreatment integrated method, the tubular membrane is adopted for pretreatment to remove refractory high pollution organic matters, reduce waste water COD, shortening treatment process, reducing civil engineering operation cost, recycling sodium sulfate crystalloid salt in weaving printing and dyeing industry, realizing recycling of industrial salt, and realizing weaving enterprise printing and dyeing printing anddyeing waste water zero discharge.

Owner:新疆水处理工程技术研究中心有限公司

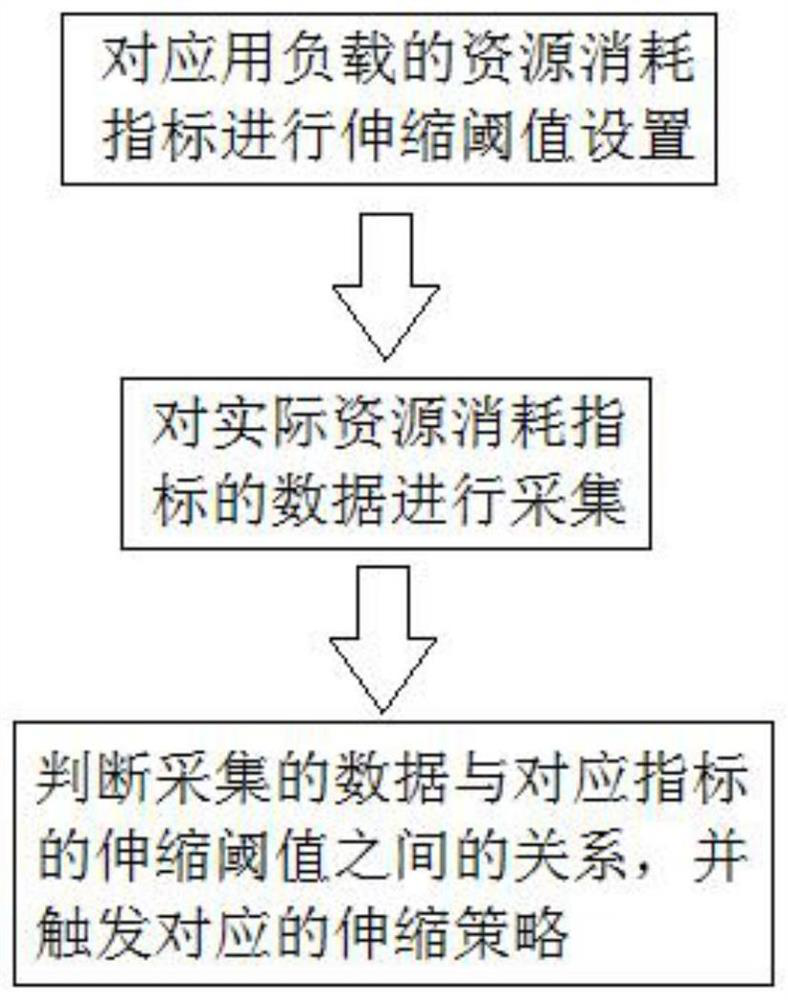

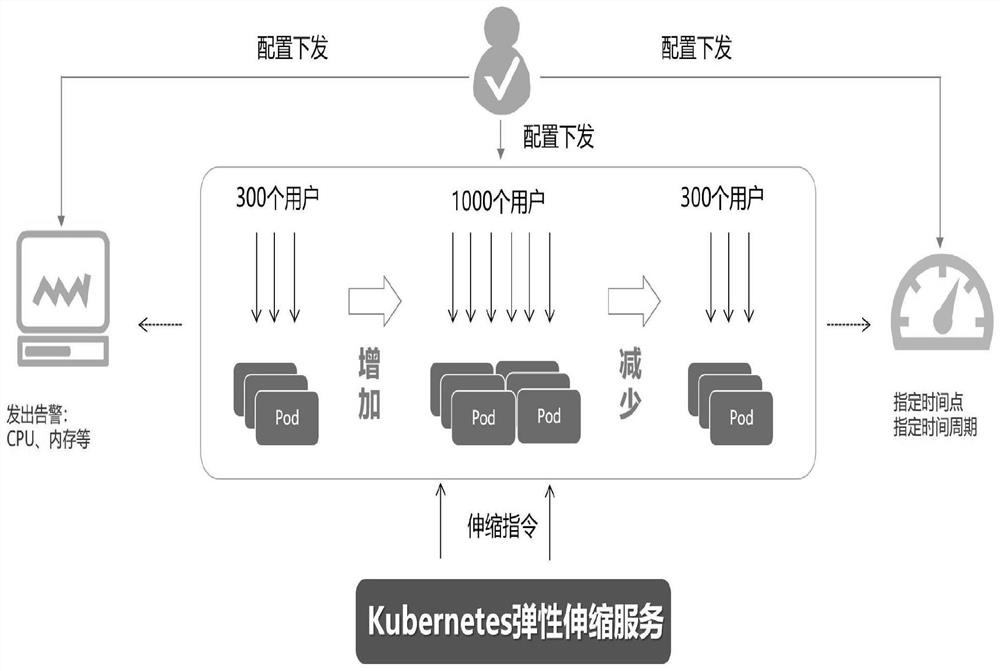

Docker elastic scaling-based big data platform resource scheduling method

PendingCN112380009AIncrease or decrease the number of PodsAchieve expansionResource allocationAutoscalingResource consumption

The invention provides a docker elastic scaling-based big data platform resource scheduling method, relates to the technical field of big data resource scheduling, and aims to realize automatic capacity expansion and capacity reduction of an application system, remarkably improve the resource utilization rate and save the cost. The method comprises the following steps: S1, setting a threshold value for a resource consumption index of an application load; S2, collecting data of actual resource consumption indexes; S3, judging a relationship between the acquired data and a threshold value of a corresponding index, and triggering a corresponding scaling strategy; when the collected data exceeds the threshold value of the corresponding index, automatic expansion is carried out; and when the collected data is lower than the threshold value of the corresponding index, automatic capacity reduction is carried out. The technical scheme provided by the invention is suitable for a big data resource scheduling process.

Owner:北京开物数智科技有限公司

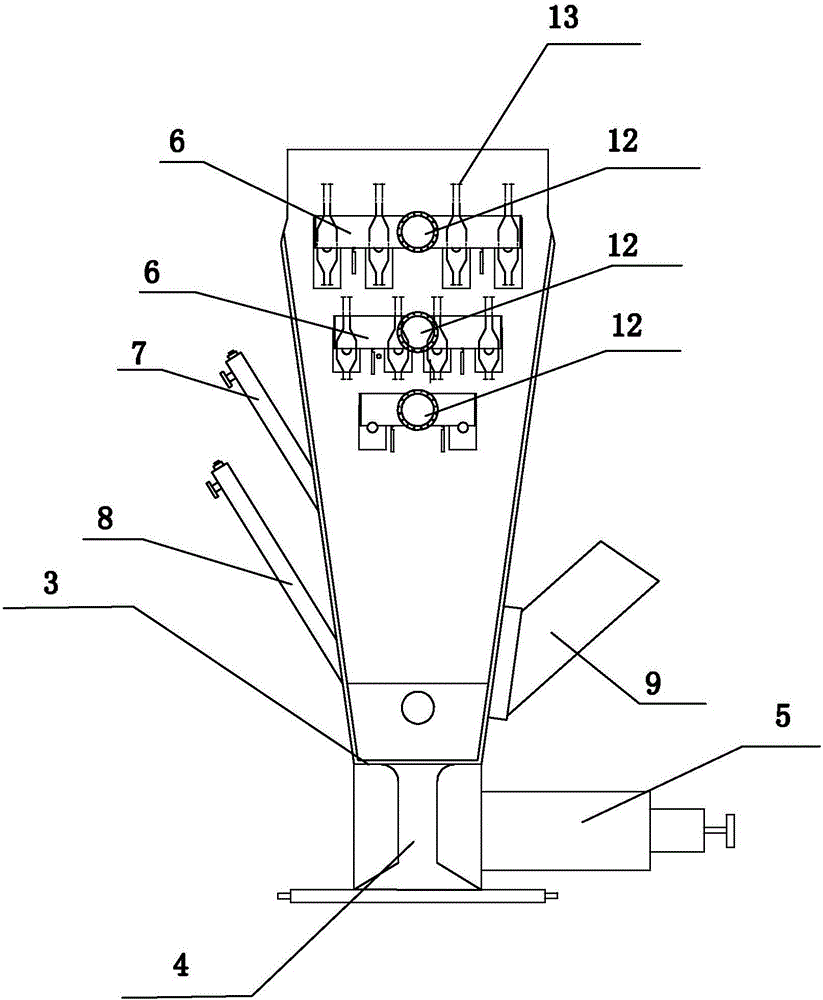

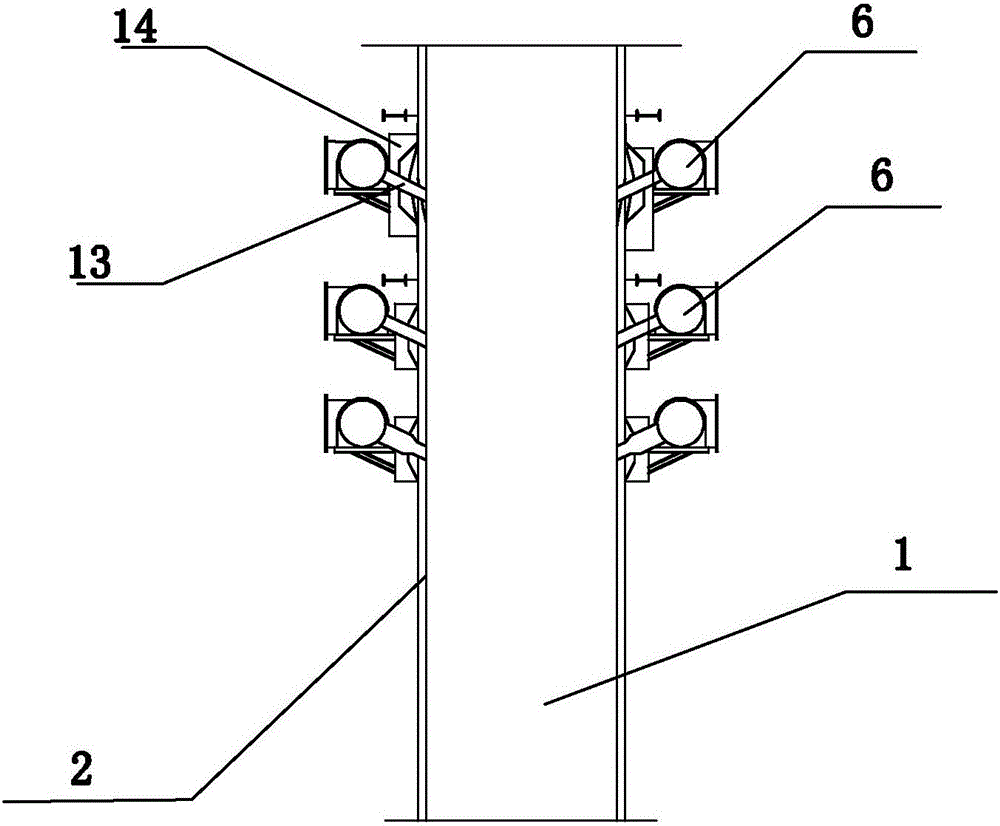

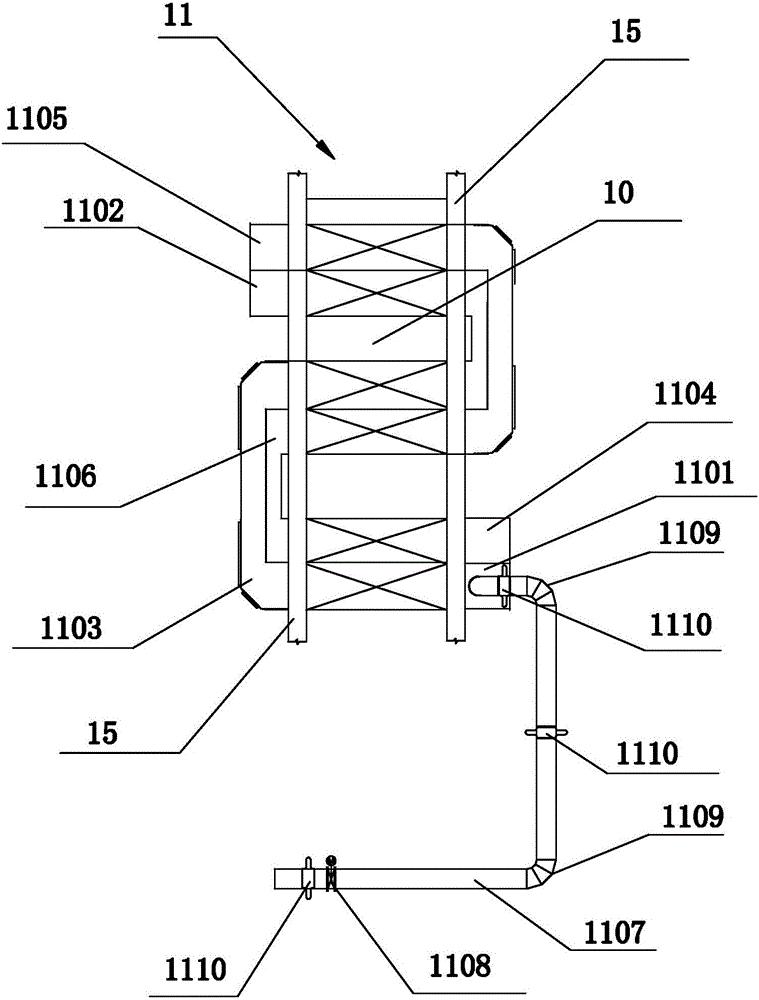

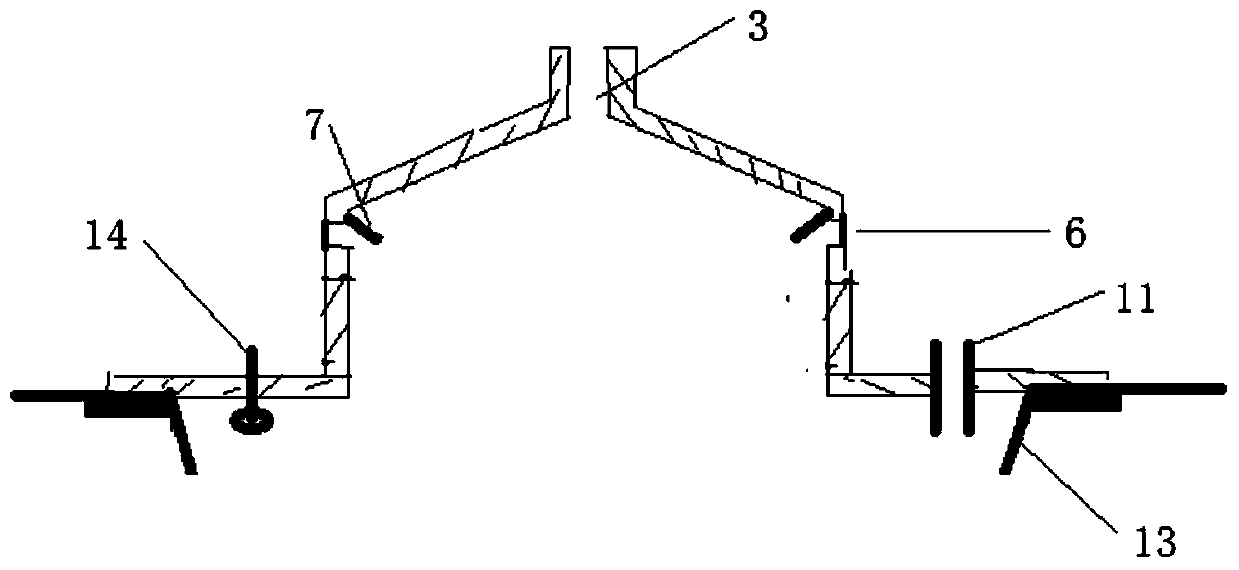

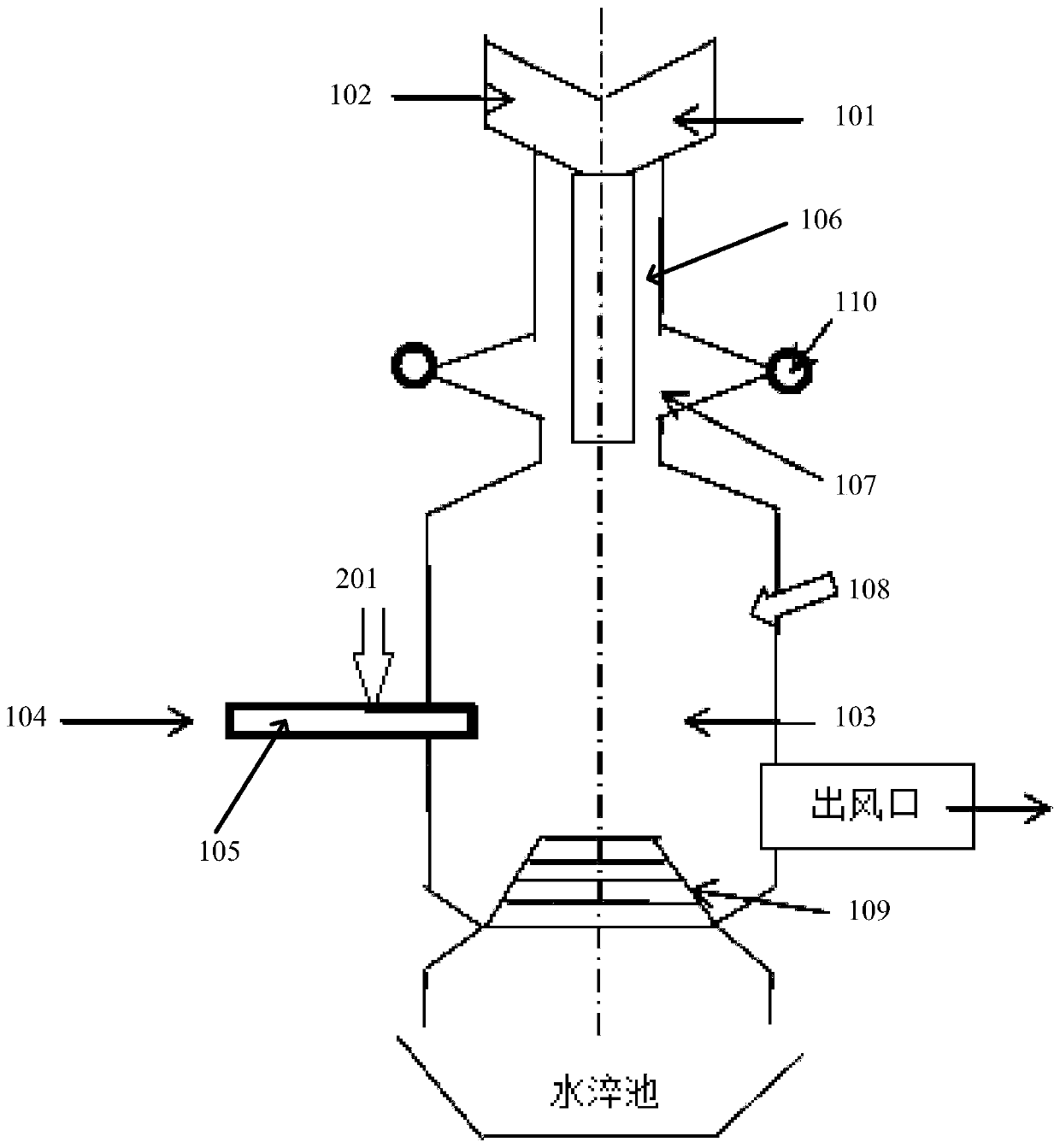

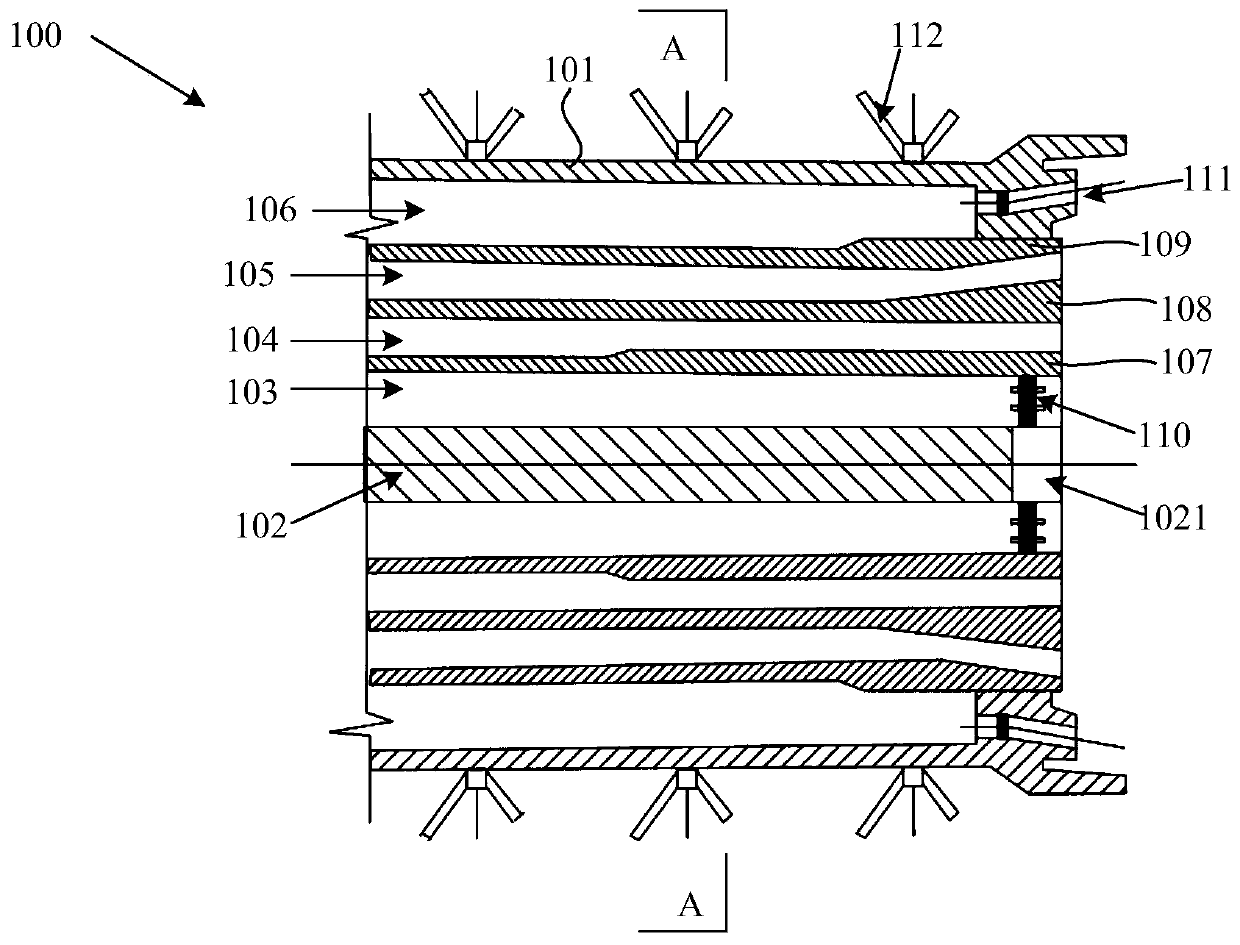

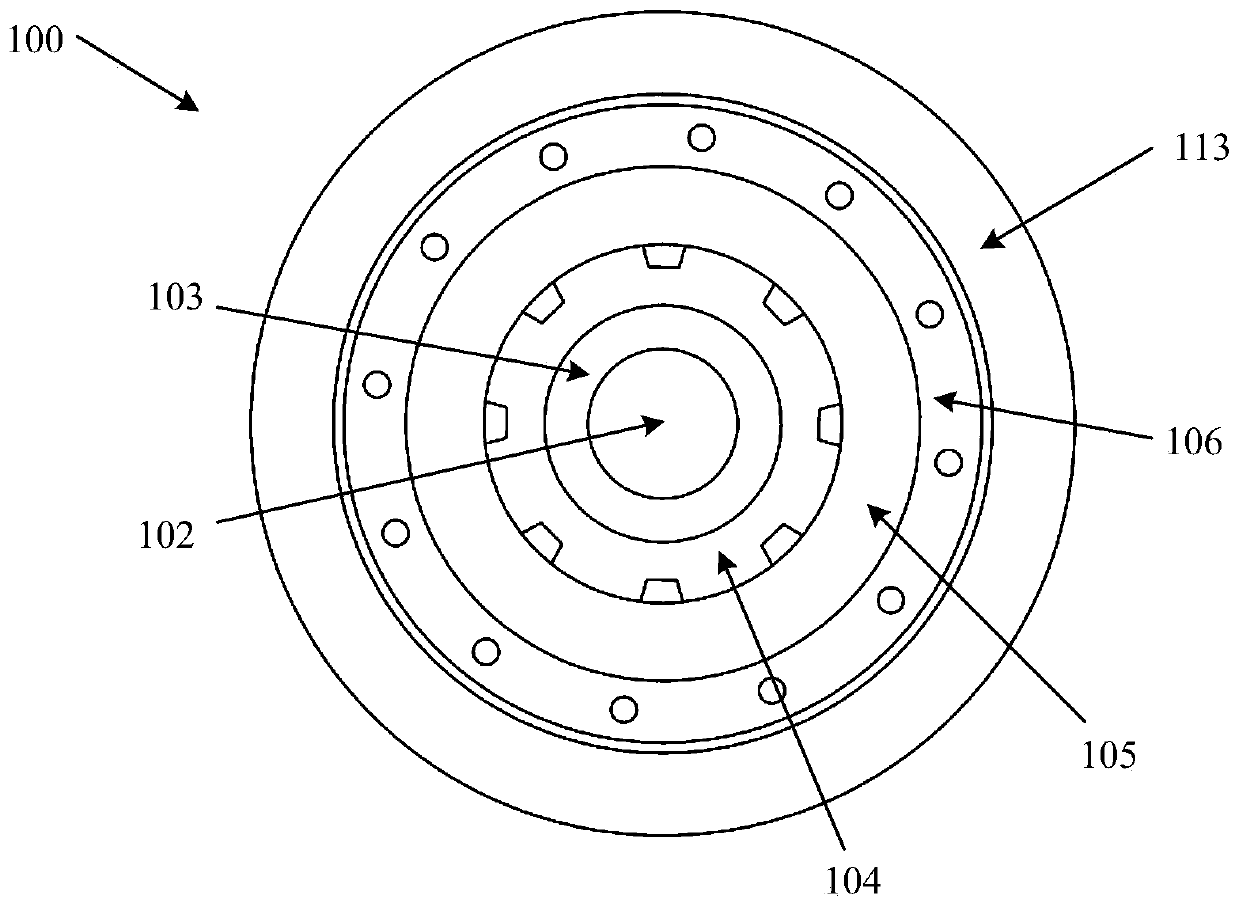

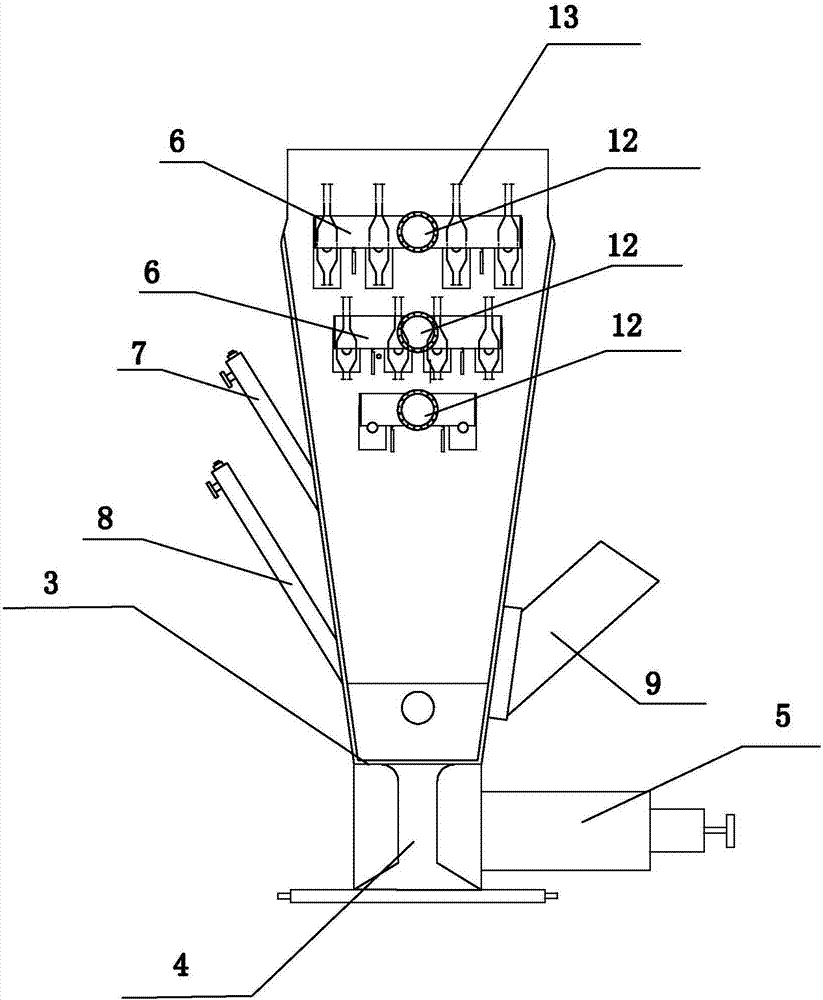

Intake method of garbage incineration boiler hearth and garbage incineration boiler equipment thereof

ActiveCN105782989ABurn fullyReduce production efficiencyFluidized bed combustionIndirect carbon-dioxide mitigationElectricityCombustion

The invention discloses an intake method of a garbage incineration boiler hearth and garbage incineration boiler equipment thereof, and belongs to the technical field of garbage incineration boiler operation methods and equipment thereof. The intake method comprises the following steps: a) a primary intake temperature of an air chamber is reduced; and b) the position of an intake pipe on a secondary intake furnace wall is raised. The garbage incineration boiler equipment comprises an air preheating device, a direct connecting pipe, an electric circular air door and a DCS distributed control system; the air preheating device includes a preheating pipe, an air inlet and an air outlet; the direct connecting pipe includes multiple sections of straight pipes and multiple 90-degree shrimp elbows; one end of the direct connecting pipe is connected with a primary intake port of the air preheating device, and the other end is directly communicated with an air chamber intake port below the hearth; the electric circular air door is arranged on one section of straight pipe; the DCS distributed control system can be disconnected or electrically connected with the electric circular air door; and three sets of furnace wall intake pipes are respectively arranged on the front and back walls of the upper and middle parts of the hearth. The Intake method of the garbage incineration boiler hearth and the garbage incineration boiler equipment thereof have the following beneficial effects: the furnace slag caking phenomenon and the furnace slag blockage cannot be generated; and the outlet temperature of the hearth is high, so that the combustion is sufficient.

Owner:NINGBO ZHONGMAO YAOBEI THERMAL POWER CO LTD

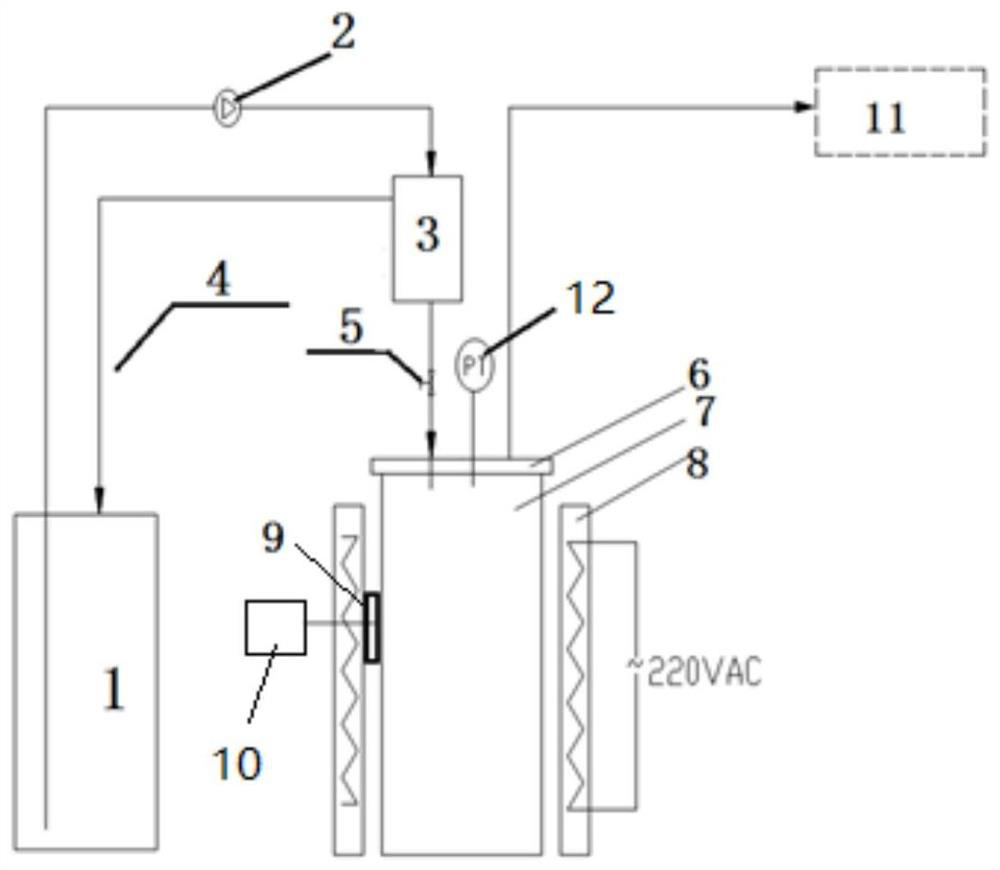

Microwave-based drying device and drying method for treating reactor core waste water

PendingCN110211721AAchieve dryingAchieve capacity reductionRadioactive decontaminationMicrowaveWater vapor

The invention relates to a microwave-based drying device and a drying method for treating reactor core waste water, belonging to the technical field of reactor core waste water treatment during nuclear power operation. The drying device comprises a drying area and a microwave feeding area, the drying area is used for containing reactor core waste water to be treated; microwaves are fed from the side surface of the microwave feeding area and irradiate the liquid level of the reactor core waste water; non-contact heating is carried out on the reactor core waste water. Meanwhile, a vapor outlet is arranged above the microwave feeding area for discharging water vapor. According to the invention, water in the reactor core waste water is discharged in an evaporation mode; meanwhile, NaNO3 in thereactor core waste water is solidified, and the solidified NaNO3 is greatly smaller than the volume of the original reactor core waste water, so that drying, volume reduction and solidification of the reactor core waste water are realized. The reactor core waste water is continuously supplemented through a fluid supplement port, so that multiple barrels of reactor core waste water can be concentrated in one drying barrel, centralized treatment is realized, curing treatment is not required, and the reactor core waste water can be directly fed into a disposal field.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

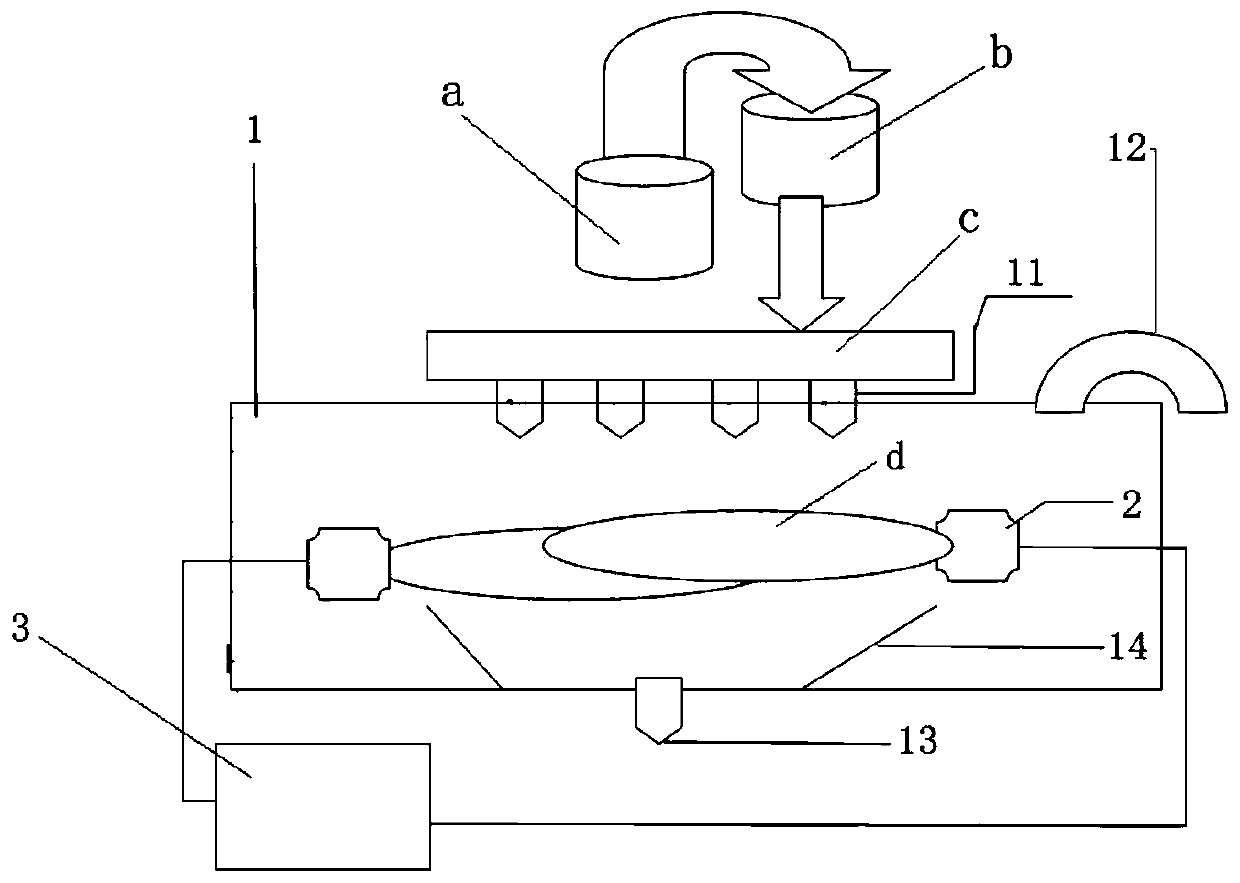

Plasma melting and cracking furnace

PendingCN108692314ADehydration fastPromote pyrolysisElectric discharge heatingIncinerator apparatusPlasma torchScrap

The invention discloses a plasma melting and cracking furnace. The plasma melting and cracking furnace comprises a power supply, a bracket, a receiving mould, a crucible, a furnace lid, plasma torch generating devices, a heat exchanger, a first-stage settling and purifying room, a second-stage electrostatic purifying room and a third-stage filtering and purifying room, wherein the plasma torch generating devices are arranged on the furnace lid. According to the plasma melting and cracking furnace disclosed by the invention, industrial garbage can be effectively melted and cracked, waste gas generated by combustion is recycled after being purified, waste is taken as a building raw material, pollution on environment is greatly reduced, and waste of resources is reduced, so that the plasma melting and cracking furnace saves more energy and is environmentally friendlier.

Owner:蔡永辉

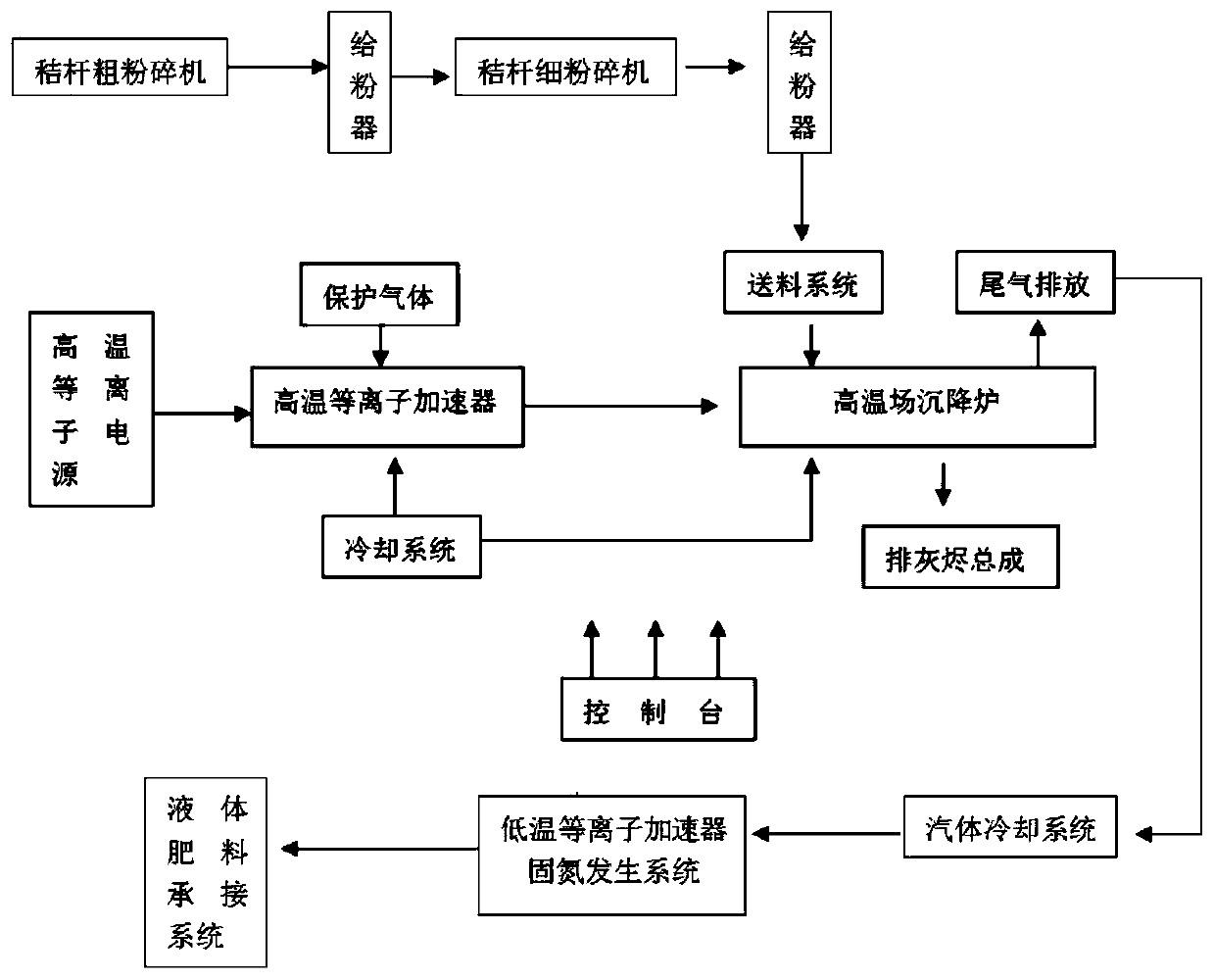

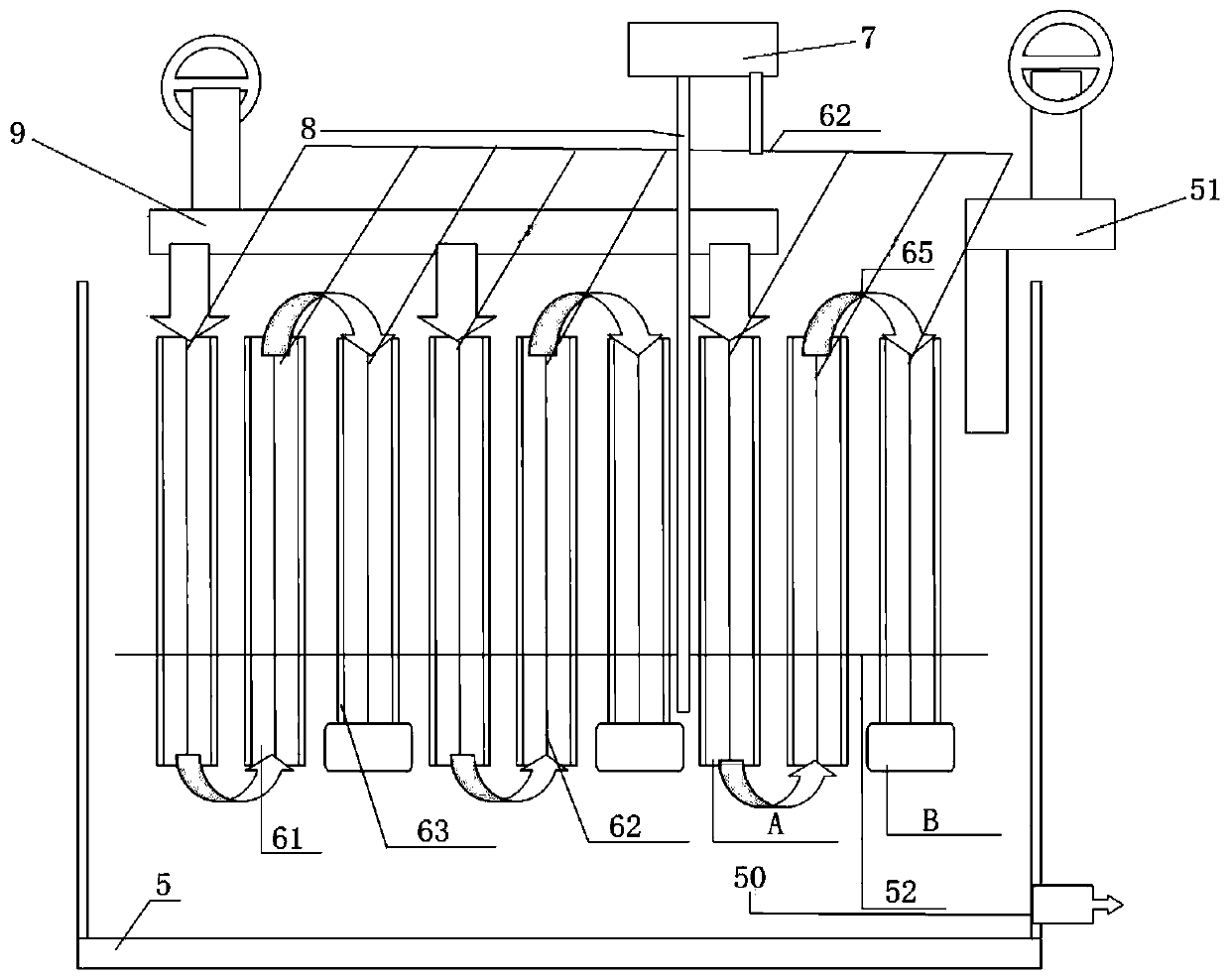

Distributed low-temperature plasma tubular accelerator straw fertilizer manufacturing machine

PendingCN111089302AEliminate the stubble effectAchieve capacity reductionIncinerator apparatusPotassium fertilisersAgricultural engineeringEnvironmental engineering

The invention relates to a distributed low-temperature plasma tubular accelerator straw fertilizer manufacturing machine, which comprises a high-temperature field sedimentation furnace, high-temperature plasma accelerators, a sealed water tank and a distributed low-temperature plasma tubular accelerator, wherein the high-temperature field sedimentation furnace is provided with a straw powder feeding hole, a tail gas discharging hole and an ash discharging hole; the flame nozzle of each high-temperature plasma accelerator communicates with the hearth of the high-temperature field sedimentationfurnace; the sealed water tank is provided with a liquid feeding and discharging valve and an air outlet and is filled with a preset water level of aqueous solution; the distributed low-temperature plasma tubular accelerator is used for manufacturing the tail gas of the high-temperature field sedimentation furnace into soluble fertilizers, and the soluble fertilizers are dissolved in the aqueous solution in the sealed water tank; and a condenser is arranged between the tail gas discharging hole and the sealed water tank. The hearth of the high-temperature field sedimentation furnace formed bythe high-temperature plasma accelerators generates a high-temperature even thermal force field; when straw powder particles fall to the high-temperature even thermal force field, the straw powder particles are instantaneously gasified, ashes sink to form soluble macroelement, medium element and trace element fertilizers, the tail gas is processed by the distributed low-temperature plasma tubular accelerator, nitrogen and sulfur gases condense and fall into water, and macroelement and medium element fertilizers are formed.

Owner:杭州三得农业科技有限公司

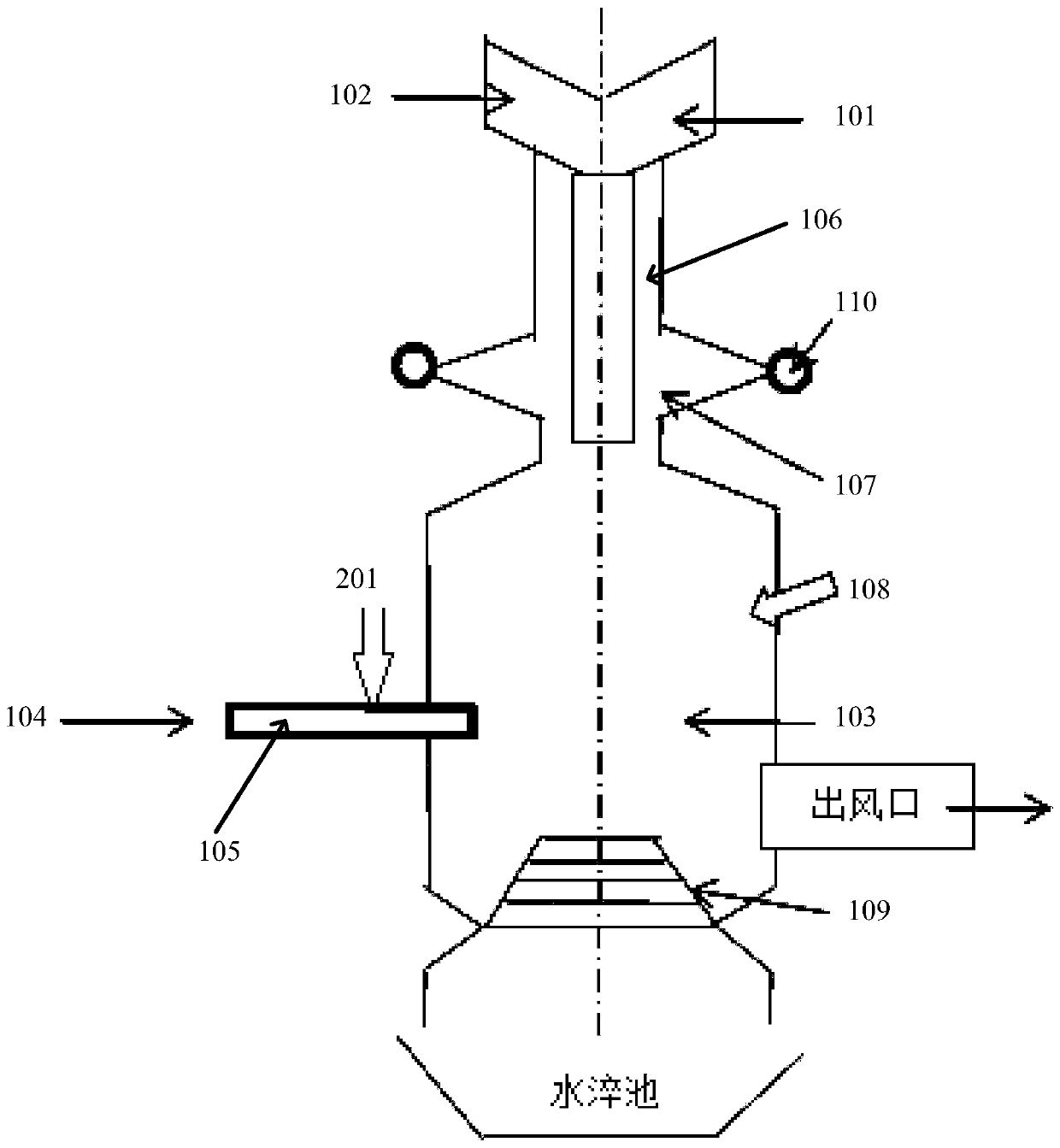

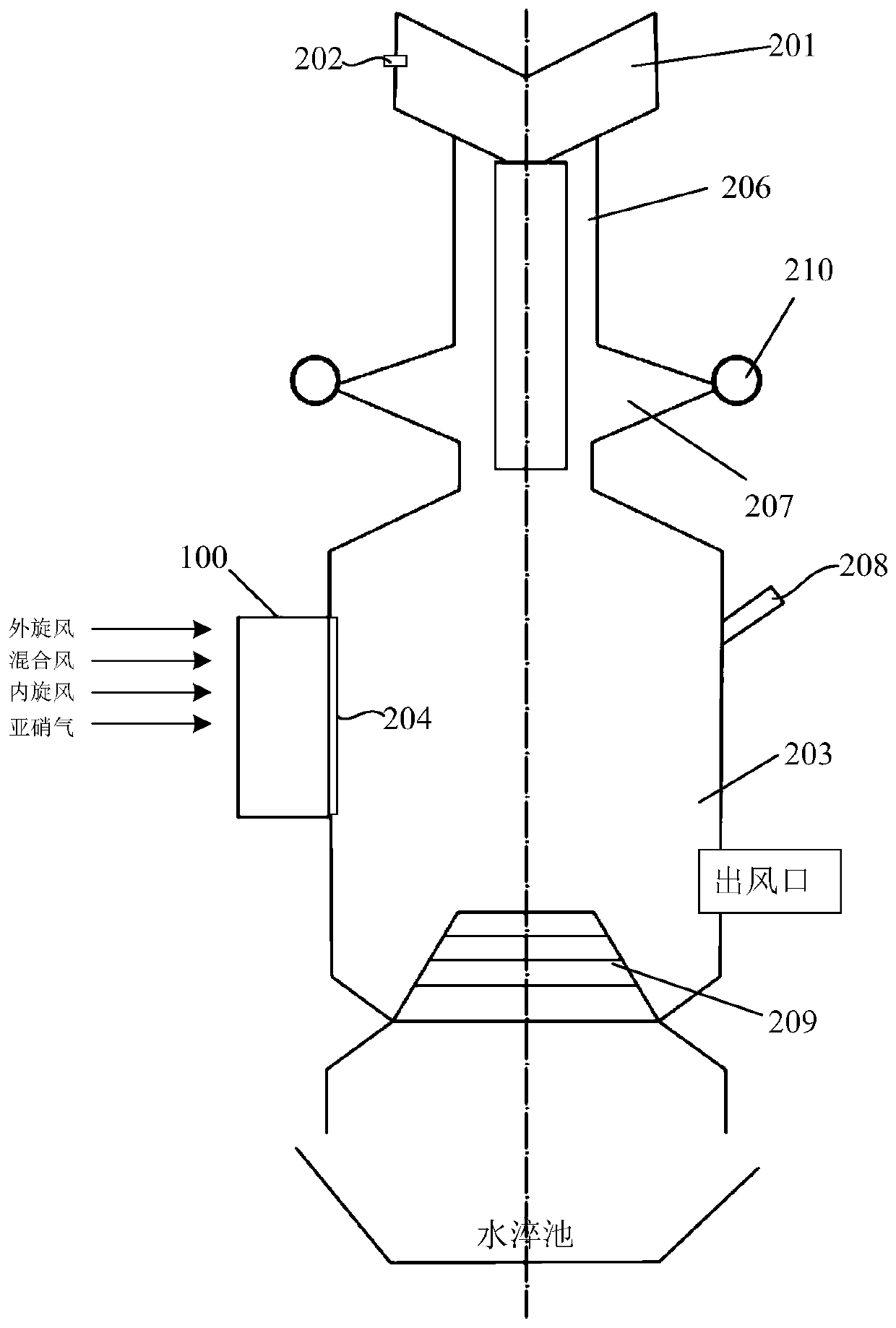

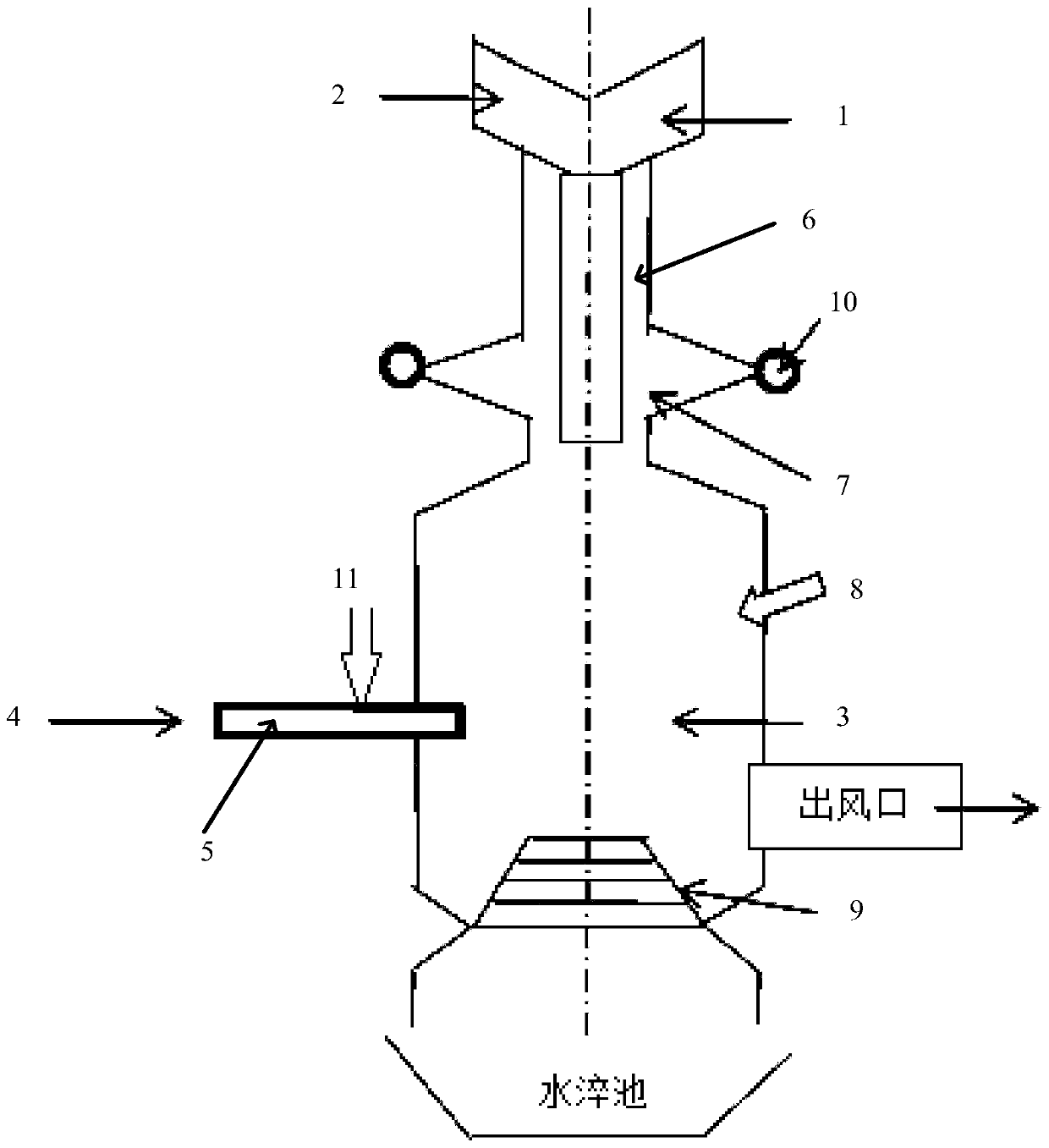

Three-waste integrated reactor and method for treating nitrite gas

PendingCN109974009AAvoid cloggingEffective destruction and decompositionIncinerator apparatusGratingCombustion chamber

The invention provides a three-waste integrated reactor. The three-waste integrated reactor and method for treating nitrite gas is vertically arranged and comprises a first combustion chamber arrangedat the top, the first combustion chamber is provided with a primary air inlet which is formed in the tangential direction and is used for spraying mixed air of waste solid and primary fuel gas into the first combustion chamber; the reactor further comprises a second combustion chamber, the second combustion chamber is provided with a secondary air inlet which is tangential to the second combustion chamber and is used for spraying mixed air of waste solid and secondary fuel gas into the second combustion chamber; a waste liquid filling port is formed in the second combustion chamber and is used for filling waste liquid into the second combustion chamber; a combustion descending channel is formed between the first combustion chamber and the second combustion chamber, and the combustion descending channel protrudes outwards to form a mixing chamber; and a grating tower is arranged at the bottom of the reactor, and a water quenching tank is arranged below the grating tower. According to the three-waste integrated reactor, the blockage of the dangerous waste incineration device can be effectively avoided, and meanwhile, the nitrite gas generated in the adipic acid production process can be sufficiently recovered.

Owner:北京科太亚洲生态科技股份有限公司

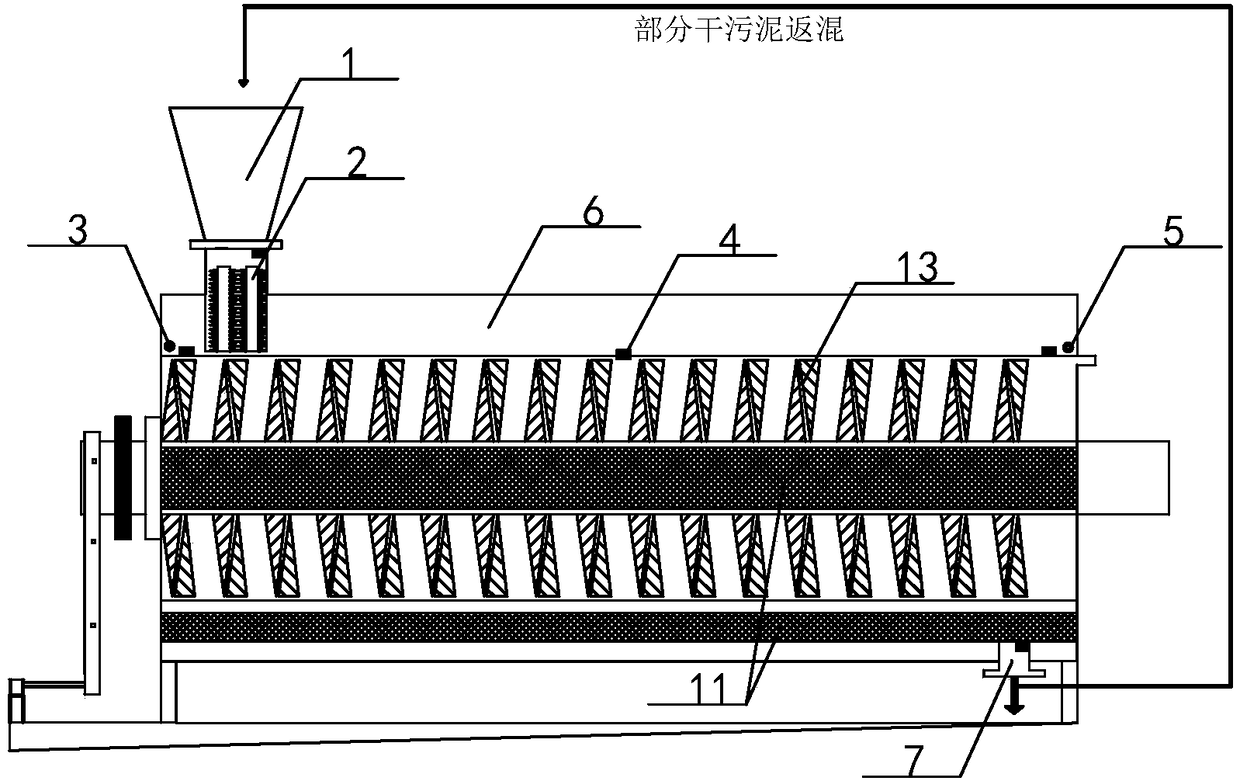

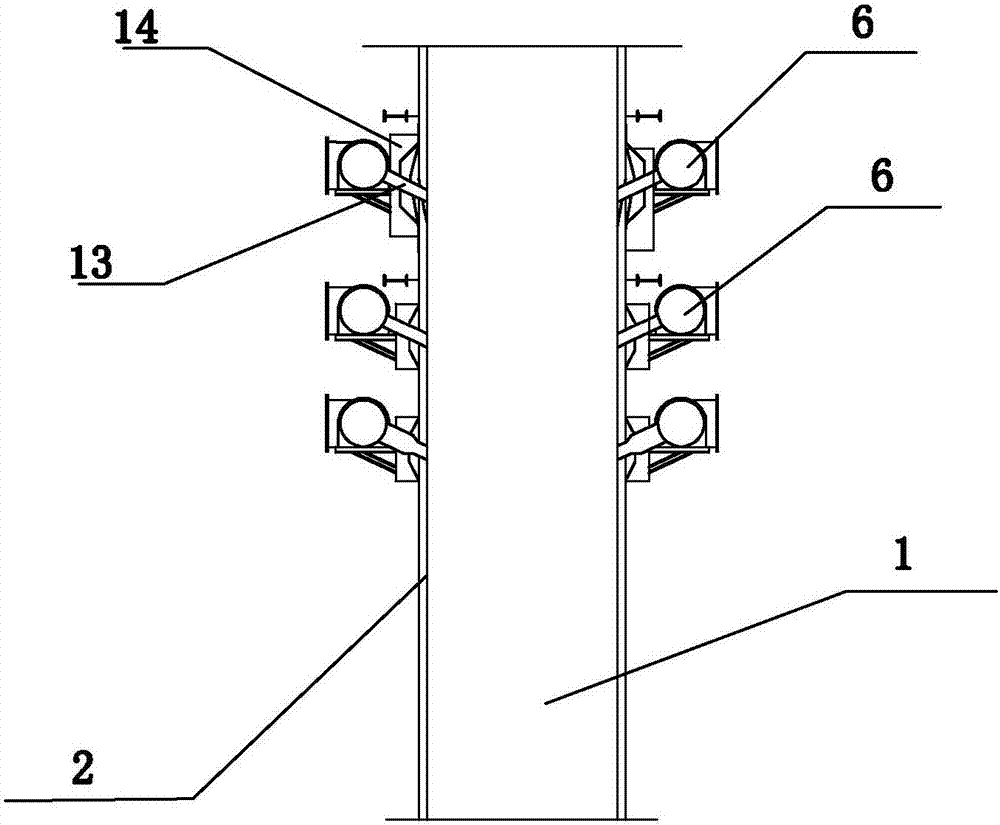

Sludge drying device

InactiveCN108117241AReduce moisture contentReduce volumeSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgePulp and paper industry

The invention relates to a sludge drying device. The sludge drying device comprises a feeding hopper, a feeding screw rod group, a tank body, a discharging hole and the like, wherein the feeding hopper is fixed on the tank body, the discharging hole is formed in the tank body, the feeding screw rod group is located at the bottom of the feeding hopper and is used for assisting feeding; a steam jacket, steam inlets and condensed water outlets are formed in the periphery of the tank body, and the steam jacket forms a steam channel; a drying cavity is formed in the tank body and is communicated with the feeding hopper and the discharging hole, and a sufficient space is formed in the drying cavity for dispersing moisture produced during the hydration of the sludge; and a pushing screw rod groupis located in the drying cavity, is of a hollow structure and forms another steam channel. According to the sludge drying device, partial dried sludge is returned to the feeding hole during the feeding and is premixed with to-be-treated wet sludge, so that the total water content of the fed sludge is controlled to be 40% or below 40%, and the sticking problem of the sludge is avoided; and the water content of the discharged sludge treated by the sludge drying device can be generally decreased to about 5%, so that the volume of the sludge is greatly reduced, the purposes of water reduction, volume reduction and harmlessness are achieved, and the sludge can be conveniently stored and transported.

Owner:XIAMEN UNIV

Method for preparing high-strength lightweight aggregate from municipal sludge

PendingCN112960966AImprove dehydration effectHigh compressive strengthCeramic materials productionClaywaresSludgeExpanded clay aggregate

The invention provides a method for preparing high-strength lightweight aggregate by using municipal sludge. The method comprises the following steps: firstly, mixing and stirring the sludge to generate slurry; conducting pyrohydrolysis to enable the properties of the slurry to be fundamentally changed in a high-temperature hydrolysis reaction and the dehydration performance of the slurry to be greatly improved; dehydrating the slurry through a high-pressure plate-and-frame filter press; subjecting a ceramsite blank to granulation and balling through a ceramic preparation process, carrying out high-temperature roasting and conducting ceramsite screening so as to obtain the high-strength lightweight aggregate; and conducting resource treatment and recycling on the whole ceramic preparation process through tail water treatment, flue gas purification and deodorization processes and the assistance of a waste heat boiler, thereby achieving low-energy and environment-friendly process effects. According to the method for preparing the high-strength lightweight aggregate, defects in the prior art are overcome, and the method is high in sludge mixing amount, low in admixture requirement, compact in ceramsite structure, high in ceramsite strength, wide in application range, high in economic benefit, friendly to environmentally and low in energy consumption.

Owner:BEAUTIFUL ORIENTAL ENVIRONMENTAL PROTECTION CO LTD

Fermentation method of water hyacinth

PendingCN114368990ASimple processSave on mixing costsBio-organic fraction processingBioloigcal waste fertilisersAgricultural engineeringEnvironmental engineering

The invention discloses a water hyacinth fermentation method which comprises the following steps: feeding water hyacinth and auxiliary materials into a feeding bin, and spraying a complex microbial inoculant on the water hyacinth, the water hyacinth mixed with the complex microbial inoculants and the auxiliary materials are conveyed into packaging equipment; performing high-pressure packaging on the water hyacinth and the auxiliary materials through packaging equipment, and immediately sealing and baling by using a degradable film to obtain a sealed bag; drilling a plurality of holes in the bottom of the sealing bag, transferring, and piling in a fermentation field; the sealing bags are erected on ventilation ducts of the fermentation field at intervals; the fermentation field is covered with a film, and then aerobic fermentation is conducted; and crushing the fermented water hyacinth, and drying to obtain the fertilizer. According to the method, the process is simple, the material mixing cost is saved, the added complex microbial inoculant can treat tail water obtained after water hyacinth is compressed and leachate generated through fermentation, organic matter in a water body is decomposed into non-toxic and harmless carbon dioxide and water, and the virtuous cycle of environmental protection and comprehensive development of fertilizer is achieved.

Owner:CCCC TIANJIN ECO ENVIRONMENTAL PROTECTION DESIGN & RES INST CO LTD

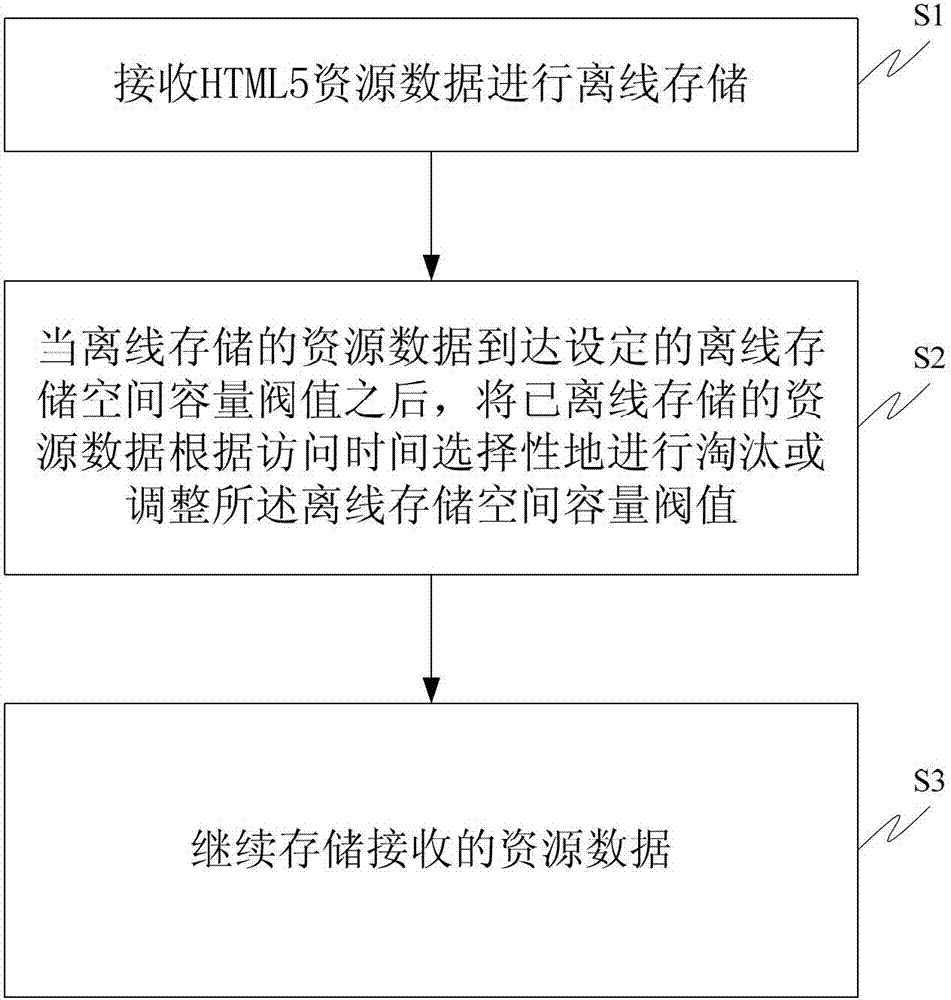

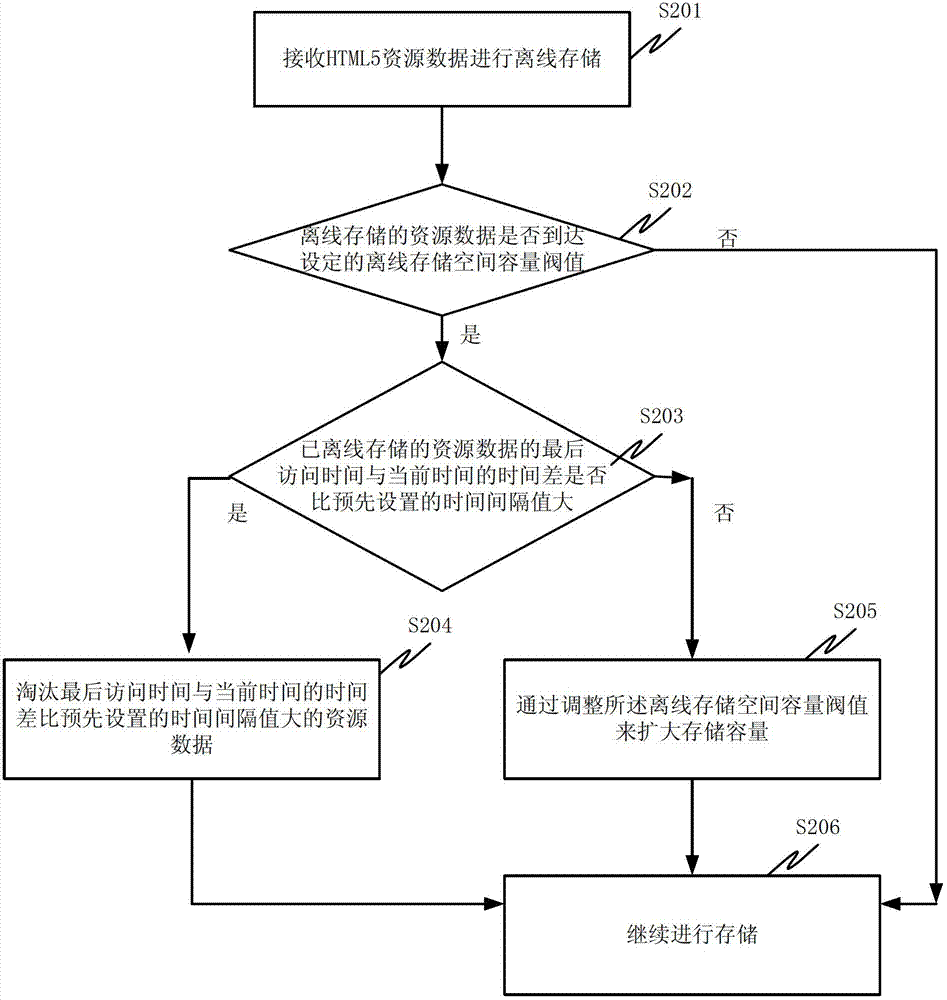

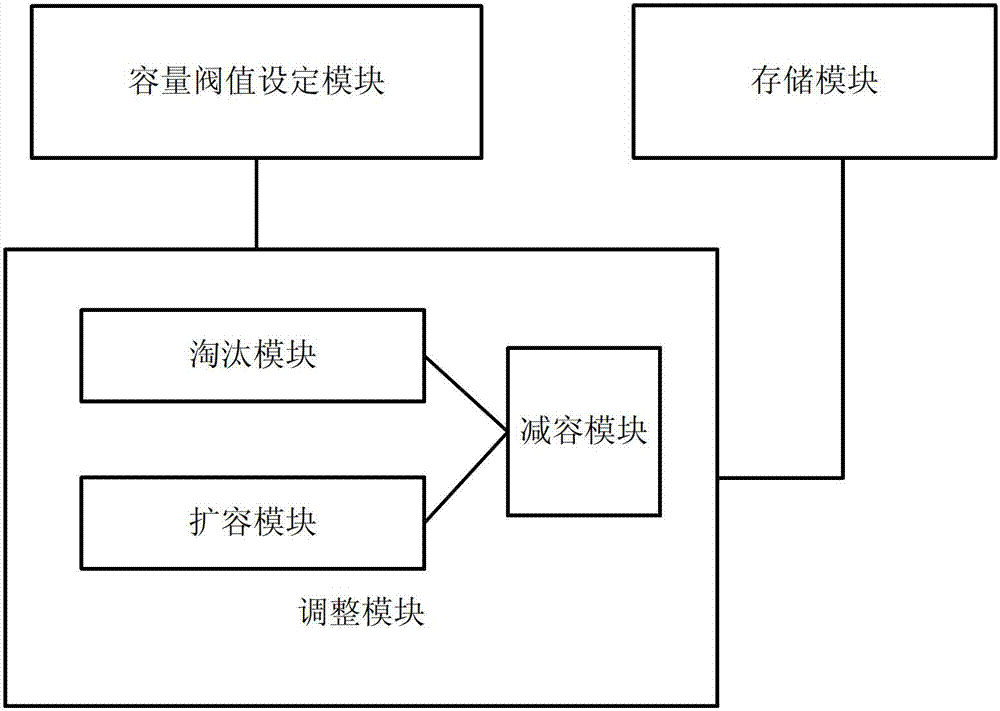

Browser off-line storage data processing method based on hypertext markup language (HTML) 5 and browser

ActiveCN102779181BEfficient use ofImprove experienceSpecial data processing applicationsAccess timePersonal computer

The invention provides a browser off-line storage data processing method based on hypertext markup language (HTML) 5 and a corresponding browser. The browser off-line storage data processing method includes the following steps: receiving HTML 5 resource data and performing off-line storage for the HTML 5 resource data; selectively eliminating or adjusting off-line storage space capacity threshold value of off-line storage data according to access time when off-line storage resource data reach the set off-line storage space capacity threshold value; and continuing to store received resource data. The browser is applicable to cell phones and personal computers (PCs), storage space can be effectively released and adjusted, browsing speed is improved, and user experience is improved.

Owner:ALIBABA (CHINA) CO LTD

A combustor for treating nitrous gas and a three-waste integrated reactor

ActiveCN110081442BImprove combustion efficiencyEasy to stir and mixIncinerator apparatusCombustionEngineering

Owner:北京科太亚洲生态科技股份有限公司 +1

Special steel shot preparation system for removing radioactivity of nuclear scrap metal

PendingCN114131032AMeet the requirement of minimizingAchieve capacity reductionBlast gunsRadioactive decontaminationDust controlDry ice

The special steel shot preparation system is used for removing radioactivity of the nuclear scrap metal and is used for preparing steel shots; the device comprises a shot blasting decontamination device, a metal smelting feeding assembly and a shot making equipment assembly, the shot blasting decontamination device, the metal smelting feeding assembly and the shot making equipment assembly are sequentially used in the steel shot preparation process. The shot blasting decontamination device comprises a spray gun, a sand and dust separator, a sand and dust collector, a steel shot cleaning machine, a steel shot repriatrix, a dry ice supply device, a high-pressure air source and a negative-pressure exhaust device. The metal smelting feeding assembly comprises a main frame, a vertical elevator, a smelting furnace assembly, a trolley assembly, a feeding butt joint mechanism, a negative pressure dust removal mechanism and a material conveying mechanism. According to the method, the nuclear waste metal serves as the raw material, the steel shot special for metal core decontamination is prepared, radioactive waste is not additionally generated in the steel shot preparation process, multiple times of cyclic utilization can be achieved through the cleaning process in the steel shot using process, and the requirement of radioactive waste minimization is fully met.

Owner:NANHUA UNIV

Foam distributing device

PendingCN110203653AUniform dischargeAchieve capacity reductionConveyorsConveyor partsImpellerReducer

The invention discloses a foam distributing device. The foam distributing device comprises a storage hopper, multiple air closing machines and multiple volume reduction machines, wherein the storage hopper, the air closing machines and the volume reduction machines are sequentially connected from top to bottom. At least two discharge ports are formed in the lower end of the storage hopper, the multiple discharge ports are connected with the air closing machines, and the multiple air closing machines are connected with the volume reduction machines. A speed reducer and an impeller connected with the speed reducer are arranged in the storage hopper. The impeller is arranged in the middles of the multiple discharge ports. By means of the foam distributing device, materials can be evenly distributed.

Owner:GUANGZHOU 3E MACHINERY

An integrated method for the pretreatment of high-concentration printing and dyeing wastewater based on tubular membranes

ActiveCN110156249BIncrease permeate fluxReduce COD valueSludge treatmentWater contaminantsTextile printerCatalytic oxidation

The invention discloses an integrated method for pretreatment of high-concentration printing and dyeing wastewater based on tubular membranes, including a pretreatment unit, a biochemical treatment unit, a deep reuse treatment unit, and a sludge treatment unit. The pretreatment unit includes a regulating tank, Coagulation sedimentation tank and tubular membrane, the biochemical treatment unit includes a catalytic oxidation device and an aerobic tubular membrane bioreactor, and the deep reuse treatment unit includes ultrafiltration, reverse osmosis, electric drive device, evaporation crystallization device and A water production tank, and the sludge treatment unit includes a plate and frame filter press and a spray dryer. The invention can remove highly polluting organic matter that is difficult to degrade in raw water by using tubular membrane as pretreatment, reduce COD of wastewater, shorten the process chain at the same time, reduce civil engineering and operating costs, and can reuse sodium sulfate crystalline salt in the textile printing and dyeing industry At the same time, it realizes the recycling of industrial salt and realizes zero discharge of printing and dyeing wastewater in textile enterprises.

Owner:新疆水处理工程技术研究中心有限公司

A kind of municipal domestic sludge treatment process

ActiveCN105693058BReduced dehydration equipment requirementsAchieve capacity reductionSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSlurryMethane gas

The invention discloses an urban domestic sludge treatment process.The process includes the following steps of 1 preparation of dewatered sludge, wherein sludge which is concentrated and dewatered by an urban sewage treatment plant is adopted; 2, conditioning of sludge, the dewatered sludge is conveyed to a slurry regulating pool, a chemical conditioning agent is added, and the mixture is stirred and mixed to be uniform through a stirrer in the regulating pool; 3, slurry radiation treatment, wherein slurry obtained after chemical conditioning is conveyed to a radiation workshop through a conveyor belt for radiation treatment; 4, slurry low-temperature pyrohydrolysis; slurry obtained after radiation treatment is beaten into a reaction kettle through a slurry conveying pump, a reaction kettle keeps closed in the work period, after slurry enters the reaction kettle, the temperature is raised continuously in the continuous stirring process, when the temperature is raised to 85-95 DEG C, timing is started, and the temperature is maintained at 90 + / -5 DEG C for 30-35 minutes; 5, slurry obtained after low-temperature pyrohydrolysis can be directly dewatered through a membrane filter press, the moisture content is lowered to 60% or below, the number of fecal coliform groups is smaller than or equal to 100 / g (mL), the slurry obtained after low-temperature pyrohydrolysis can also be combined with anaerobic digestion which has been developed and matured for stabilizing treatment, and methane gas utilization is achieved.

Owner:CGN DASHENG ELECTRON ACCELERATOR TECH

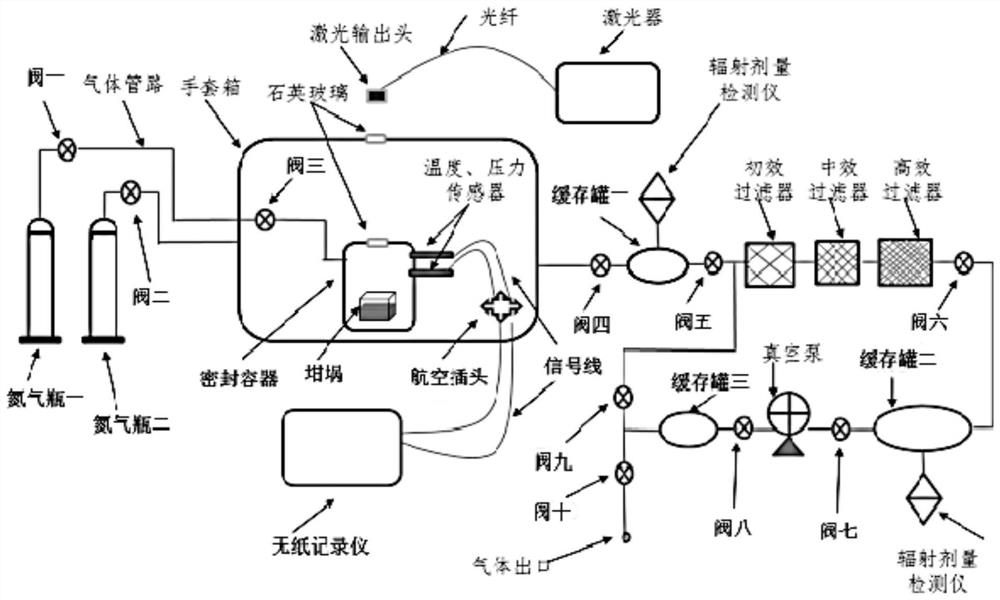

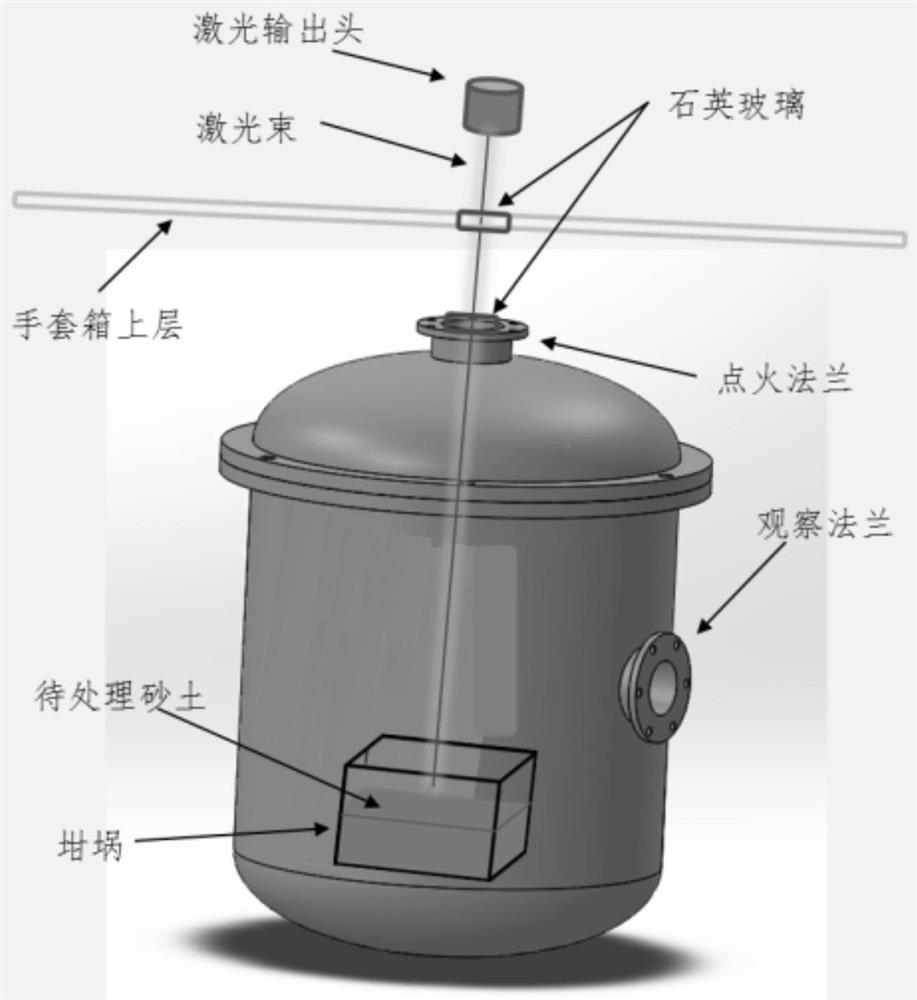

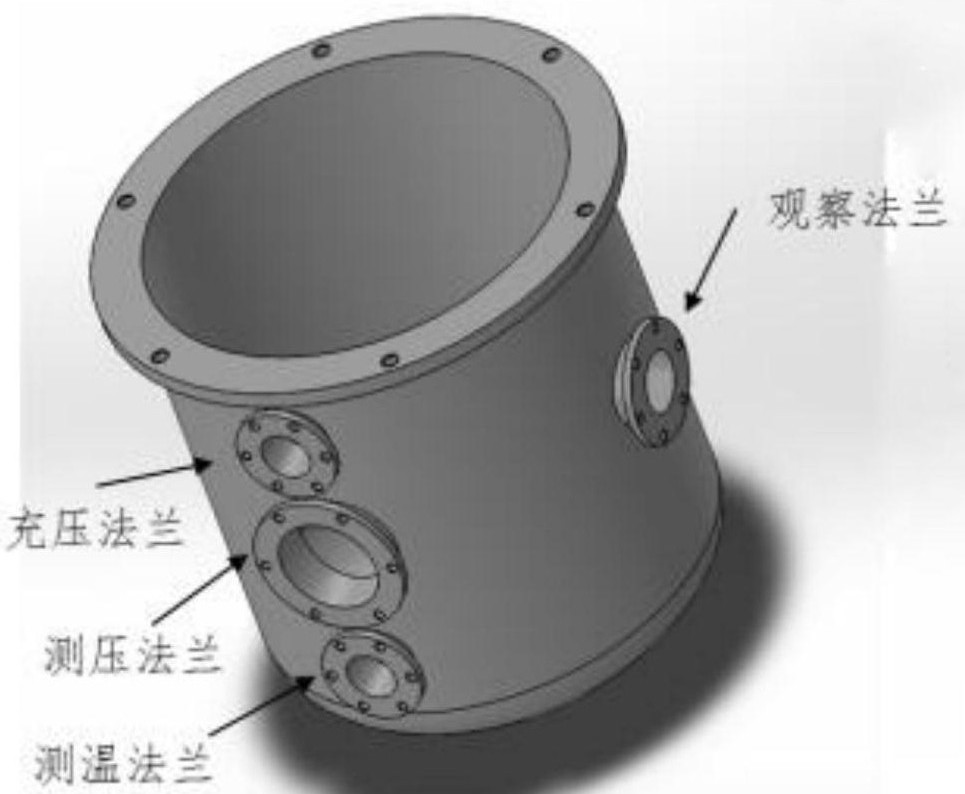

A self-propagating high-temperature synthesis system capable of solidifying radioactively contaminated sand

ActiveCN111992160BReduce disturbanceTemperature monitoringDispersed particle filtrationTransportation and packagingSelf-propagating high-temperature synthesisAviation

The invention discloses a self-propagating high-temperature synthesis system capable of solidifying radioactively polluted sand, which includes a glove box, a laser generator, a sealed container, a paperless recorder and an exhaust gas treatment part. The outer wall of the glove box is provided with an aviation plug. The outer wall of the glove box is provided with an air inlet and a booster port, and the inlet ends of the air inlet and the booster port are respectively connected with a nitrogen cylinder through a pipeline, and the gas outlet of the glove box is connected with the exhaust gas through a pipeline. The processing part is sealed and connected, the top of the glove box is sealed with quartz glass, and the sealed container is located in the glove box. The patent of the present invention uses a specially customized glove box to isolate radioactive sand and protect experimental operators; The generator ignites the self-propagating material in the sealed container, which can realize non-contact ignition and reduce disturbance to polluted sand.

Owner:63653 FORCES PLA

Radioactive waste resin Fenton oxidation waste liquid drying and volume-reducing treatment device and method

PendingCN111681799AReduce volumeAchieve continuous dryingRadioactive decontaminationProcess engineeringEnvironmental engineering

The invention discloses a radioactive waste resin Fenton oxidation waste liquid drying and volume-reducing treatment device and method. The device comprises a waste liquid conveying and metering unit,a drying unit and a tail gas treatment unit, the waste liquid conveying and metering unit comprises a waste liquid temporary storage tank, a conveying pump and a constant-volume metering tank; and the drying unit comprises an electric heater, a drying barrel, a sealing top cover, a temperature sensor, a temperature controller and a pressure sensor. The provided radioactive waste resin Fenton oxidation waste liquid drying and volume-reducing treatment device and method can minimize the radioactive wastes generated in Fenton oxidation process of waste resin, and the subsequent processing cost is reduced.

Owner:CHINA INST FOR RADIATION PROTECTION

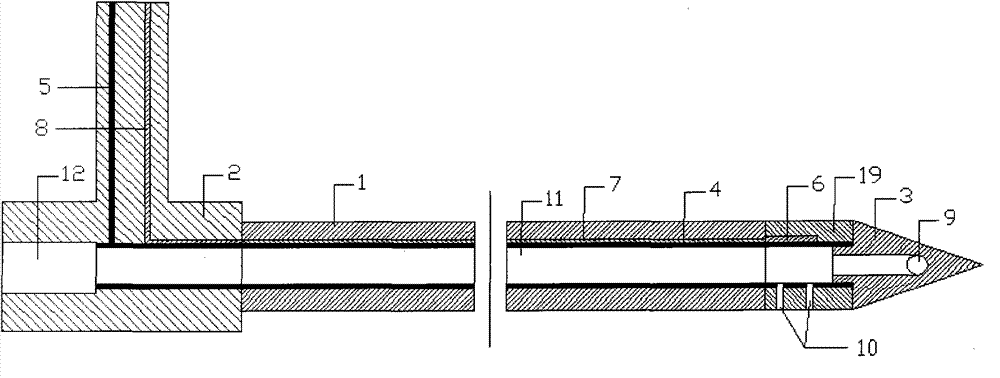

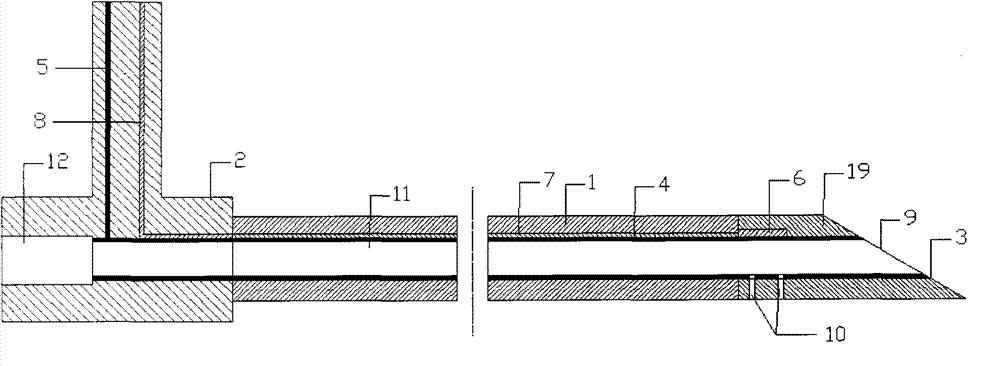

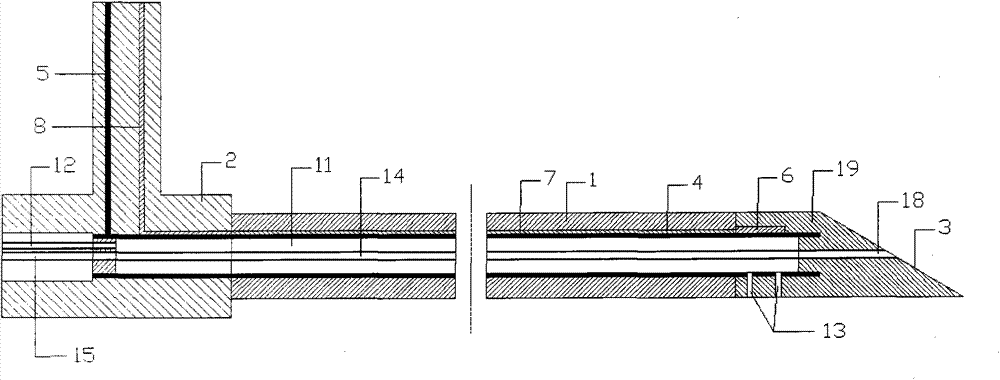

Radiofrequency ablation volume reduction electrode capable of leading out waste gas in liver

ActiveCN103876833AAchieve capacity reductionTraumaWound drainsSurgical instruments for heatingRadiofrequency ablationEngineering

The invention relates to a medical apparatus, in particular to a radiofrequency ablation volume reduction electrode capable of leading out waste gas in the liver. The radiofrequency ablation volume reduction electrode comprises a radiofrequency electrode tip, a temperature measurement resistor and a liver waste gas draw-out assembly. The radiofrequency electrode tip is connected with a radiofrequency transmission hole arranged in an outer pipe to give out a radiofrequency current, and is used for conducting radiofrequency ablation on lesion tissue of alveolus pulmonis. The temperature measurement resistor is connected with a temperature measurement resistor cable and used for collecting the temperature of an ablation area and regulating the temperature released by a radiofrequency electrode. The liver waste gas draw-out assembly comprises a gas draw-out hole and a gas draw-out passageway connected with the gas draw-out hole, and is used for drawing out waste gas in the liver. The radiofrequency ablation volume reduction electrode can conduct radiofrequency ablation treatment on the lesion tissue of the alveolus pulmonis and can meanwhile draw out a large amount of gas detained in the alveolus pulmonis which loses the function, and therefore the aims of reducing the volume of the liver and treating pulmonary emphysema are achieved.

Owner:王昌惠 +3

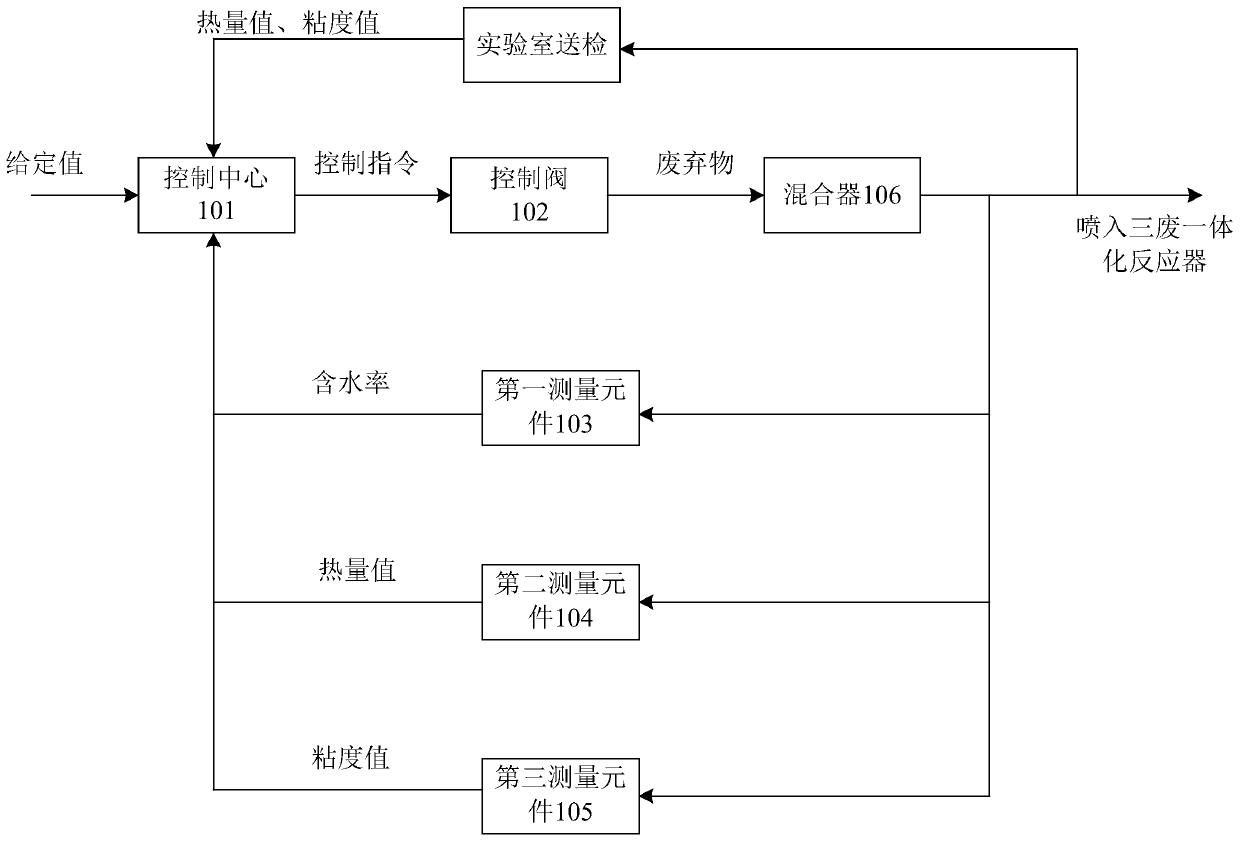

Control system and control method for wastes in three-waste integrated reactor

ActiveCN110107901ASolve the problem of incorrect calculation of filling ratioResolve Insufficient CombustionIncinerator apparatusControl systemEngineering

The invention provides a control system for wastes in a three-waste integrated reactor. The control system for the wastes in the three-waste integrated reactor comprises a control center, a first measurement component, a second measurement component, a third measurement component and a mixer, wherein the control center calculates a control quantity according to a given value and a variable elementfed back by a measurement component, adjusts the opening degree of a control valve through the control quantity, and adjusts the ratio of the different wastes; the first measurement component is usedfor measuring the moisture content of the wastes, and feeding back the measured moisture content to the control center; the second measurement component is used for measuring a heat value of the wastes, and feeding back the measured heat value to the control center; the third measurement component is used for measuring a viscosity value of the wastes, and feeding back the measured viscosity valueto the control center; and the mixer is used for mixing the different wastes in a ratio, and mixing the wastes with fuel gas. The control system for the wastes in the three-waste integrated reactor is capable of effectively solving the problems of wrong calculation of waste filling and proportioning, insufficient waste combustion, structure blockage, and the like.

Owner:北京科太亚洲生态科技股份有限公司 +1

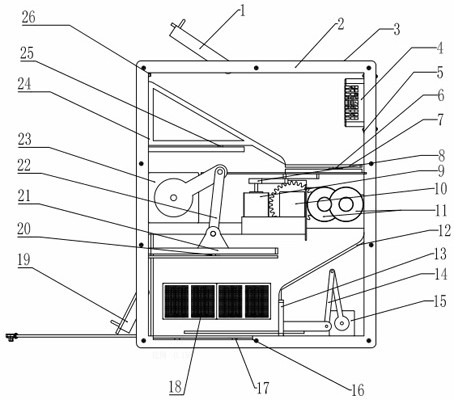

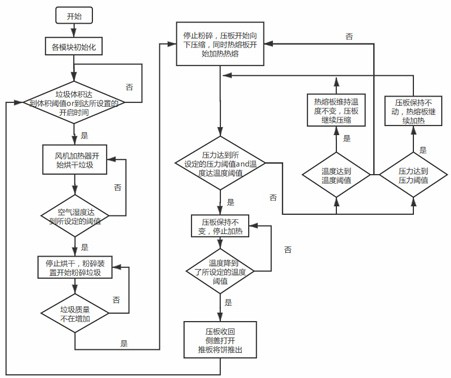

Automatic garbage can for treating rural domestic garbage

PendingCN113277241AIncrease profitIncrease power generationWaste collection and transferRefuse receptaclesEnvironmental geologySystems engineering

The invention discloses an automatic garbage can for treating rural domestic garbage. A hot air drying unit, a garbage crushing unit, a hot melting compression unit and a garbage pushing unit are integrated, and the hot air drying unit comprises a fan heater, a humidity sensor and an ultrasonic sensor. The garbage crushing unit comprises a motor and a crushing device. The hot melting compression unit comprises a motor, a pressure sensor, a temperature sensor, a pressing plate, a pressing plate movement connecting rod and a hot melting plate. Various built-in sensors are used for sensing the garbage condition in a cavity, data are gathered in a control center, the control center controls all modules of a system to work according to the obtained data, the thrown garbage is crushed, heated and compressed into cakes in order, volume reduction and deodorization of the garbage are achieved, the utilization rate of space resources is increased, the collection and transportation cost is reduced, and an APP and a data statistics intelligent system are correspondingly designed for subsequent operation management.

Owner:XIANGTAN UNIV

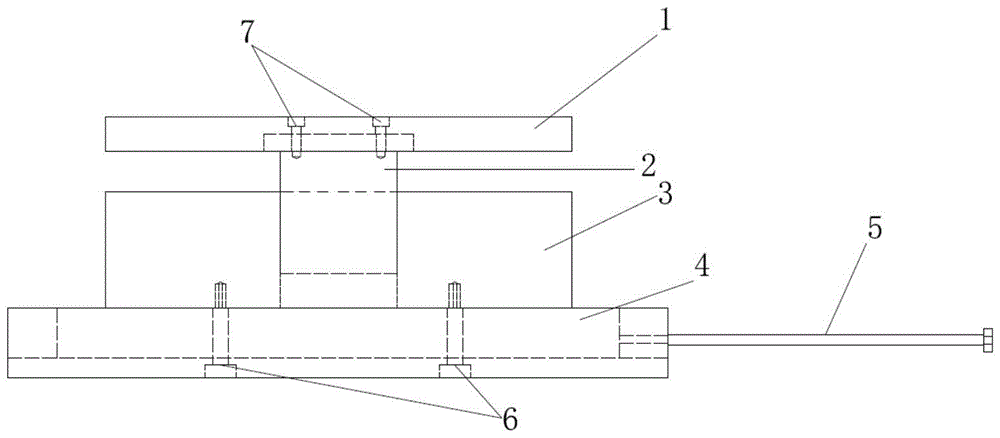

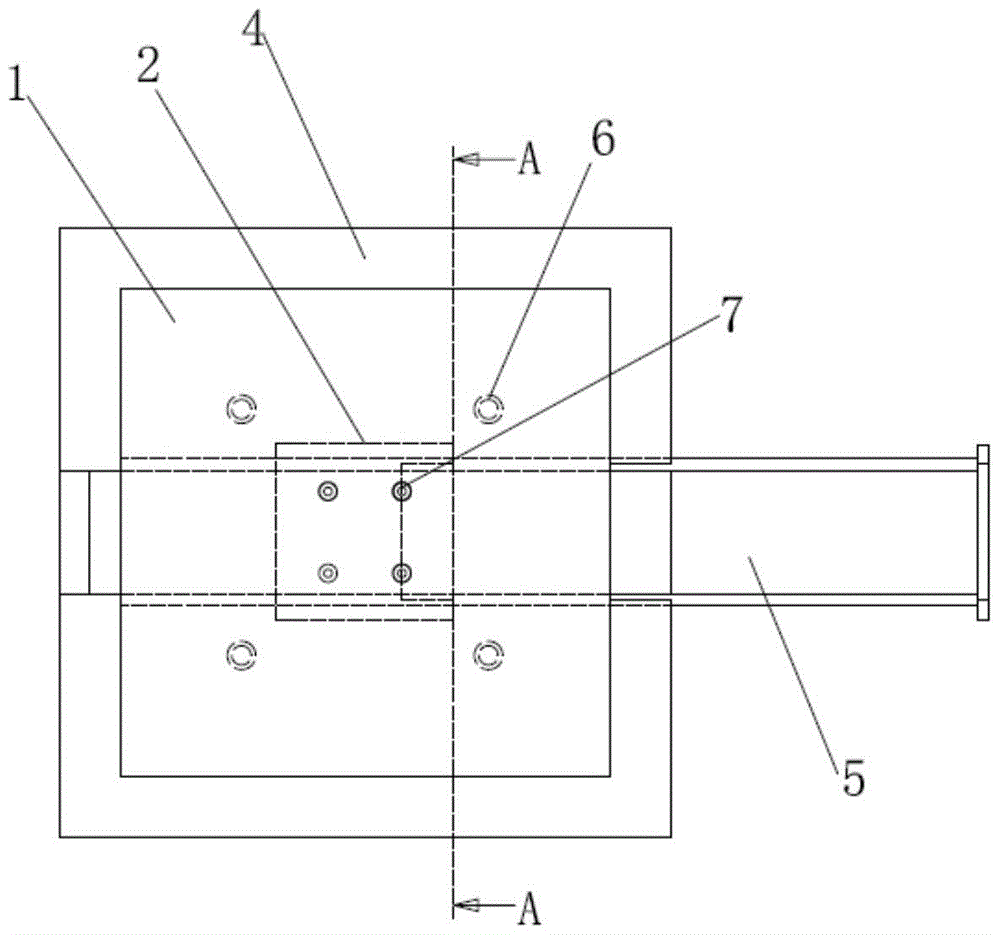

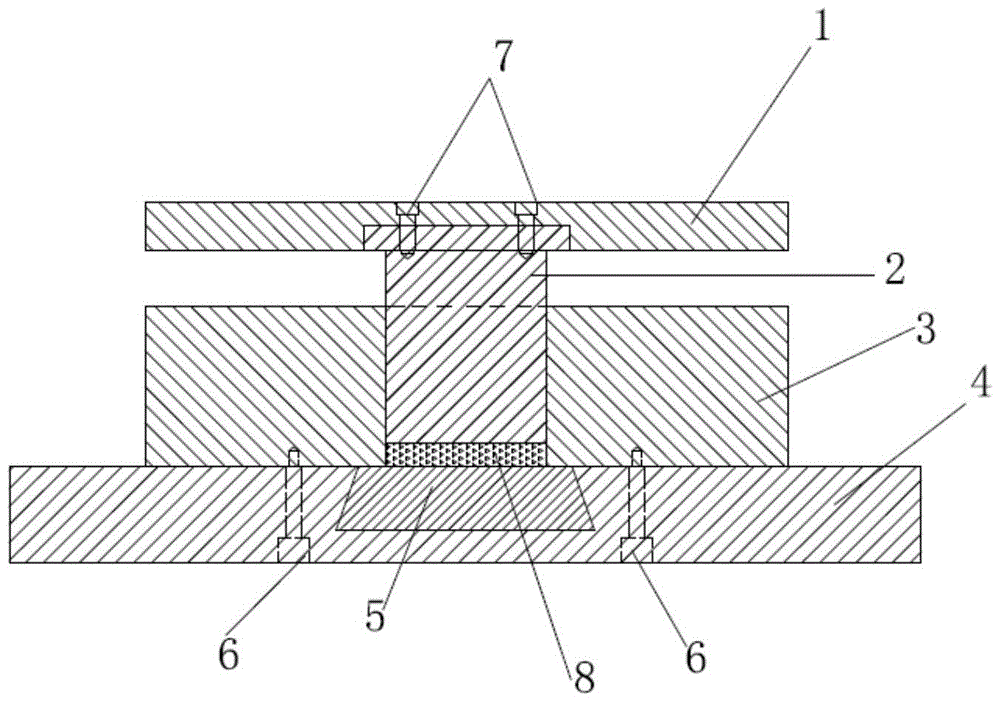

A mold for ultra-high pressure hydraulically pressing hazardous waste into high-density modules

The invention relates to a die for pressing hazardous waste to be a high-density module in an ultrahigh-pressure hydraulic mode. The die is composed of an upper pressure-bearing module (1), an upper die puncher pin (2), a middle module (3), a lower pressure-bearing base (4), a sliding block (5), a large hexagonal screw (6) and a small hexagonal screw (7). The upper pressure-bearing module (1) connected with a hydraulic machine is fixedly connected with the upper die puncher pin (2) through the small hexagonal screw (7). The center of the middle module (3) is provided with a vertical-through die cavity matched with the upper die puncher pin (2). The middle module (3) is fixedly connected with the lower pressure-bearing base (4) through the large hexagonal screw (6). The lower pressure-bearing base (4) is provided with a slot, and the slot corresponds to the die cavity and horizontally penetrates through the lower pressure-bearing base (4). A sliding block (5) which moves horizontally is arranged in the slot. The die can ensure that pressed material density meets requirements and facilitate die removal, can avoid corner breakage, and can be widely used for processing solid hazardous waste such as fly ash, slag and waste catalysts.

Owner:TONGJI UNIV

Air intake method for furnace of waste incineration boiler and waste incineration boiler equipment

ActiveCN105782989BBurn fullyReduce production efficiencyFluidized bed combustionIndirect carbon-dioxide mitigationElectricityShrimp

The invention discloses an intake method of a garbage incineration boiler hearth and garbage incineration boiler equipment thereof, and belongs to the technical field of garbage incineration boiler operation methods and equipment thereof. The intake method comprises the following steps: a) a primary intake temperature of an air chamber is reduced; and b) the position of an intake pipe on a secondary intake furnace wall is raised. The garbage incineration boiler equipment comprises an air preheating device, a direct connecting pipe, an electric circular air door and a DCS distributed control system; the air preheating device includes a preheating pipe, an air inlet and an air outlet; the direct connecting pipe includes multiple sections of straight pipes and multiple 90-degree shrimp elbows; one end of the direct connecting pipe is connected with a primary intake port of the air preheating device, and the other end is directly communicated with an air chamber intake port below the hearth; the electric circular air door is arranged on one section of straight pipe; the DCS distributed control system can be disconnected or electrically connected with the electric circular air door; and three sets of furnace wall intake pipes are respectively arranged on the front and back walls of the upper and middle parts of the hearth. The Intake method of the garbage incineration boiler hearth and the garbage incineration boiler equipment thereof have the following beneficial effects: the furnace slag caking phenomenon and the furnace slag blockage cannot be generated; and the outlet temperature of the hearth is high, so that the combustion is sufficient.

Owner:NINGBO ZHONGMAO YAOBEI THERMAL POWER CO LTD

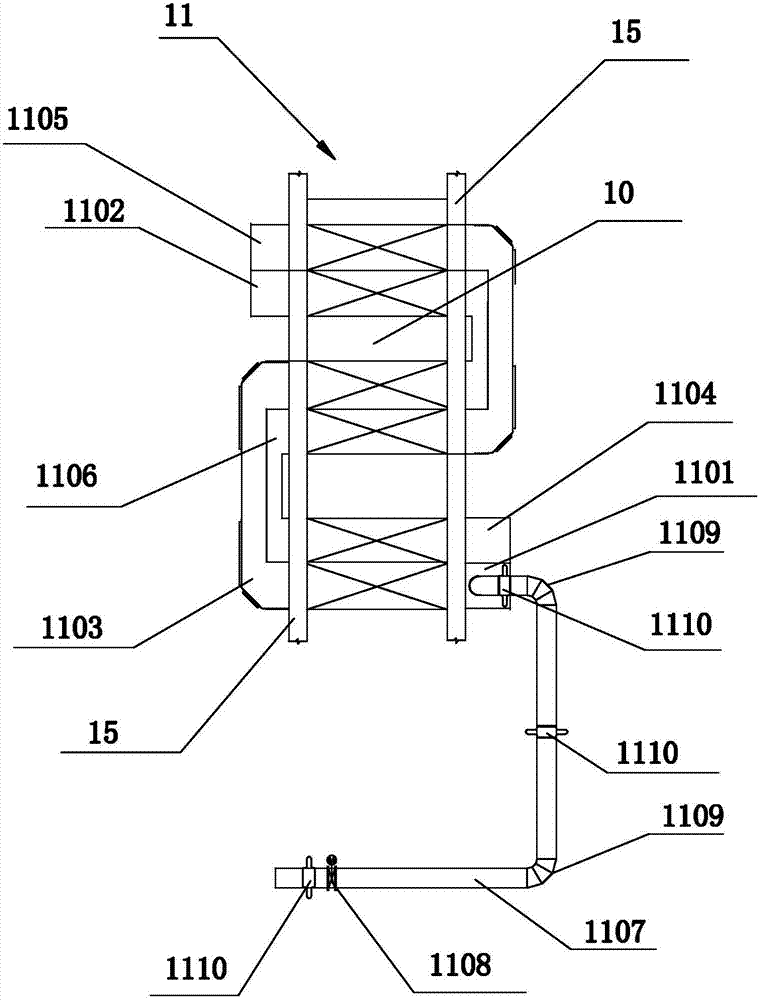

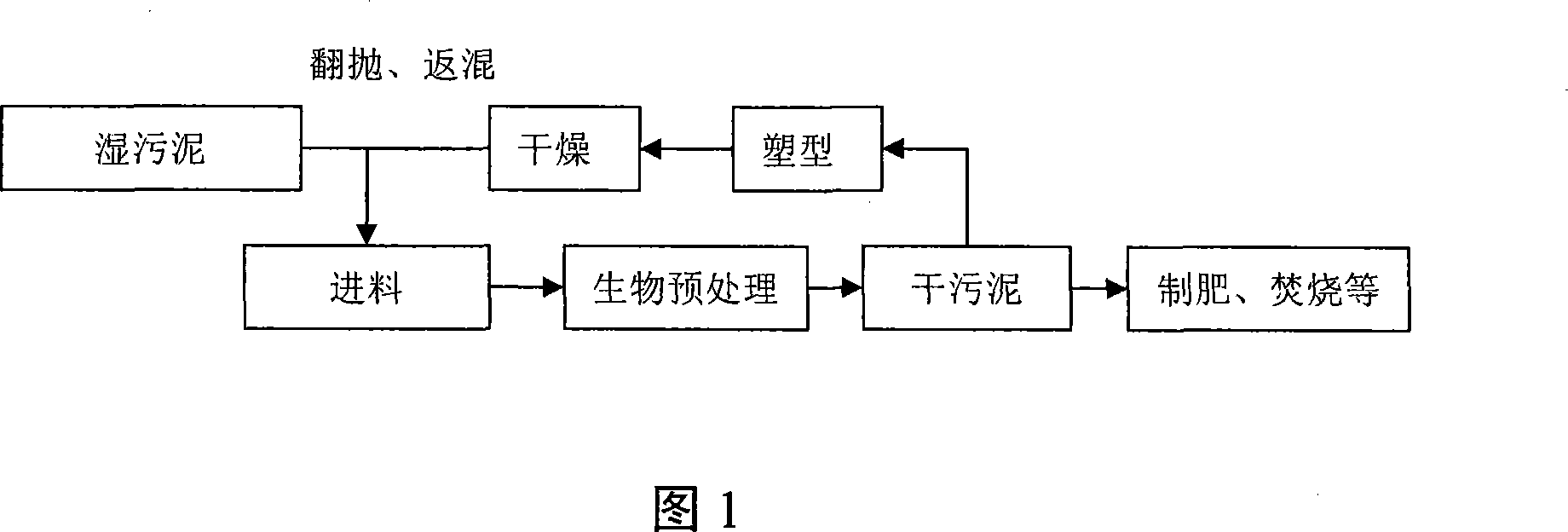

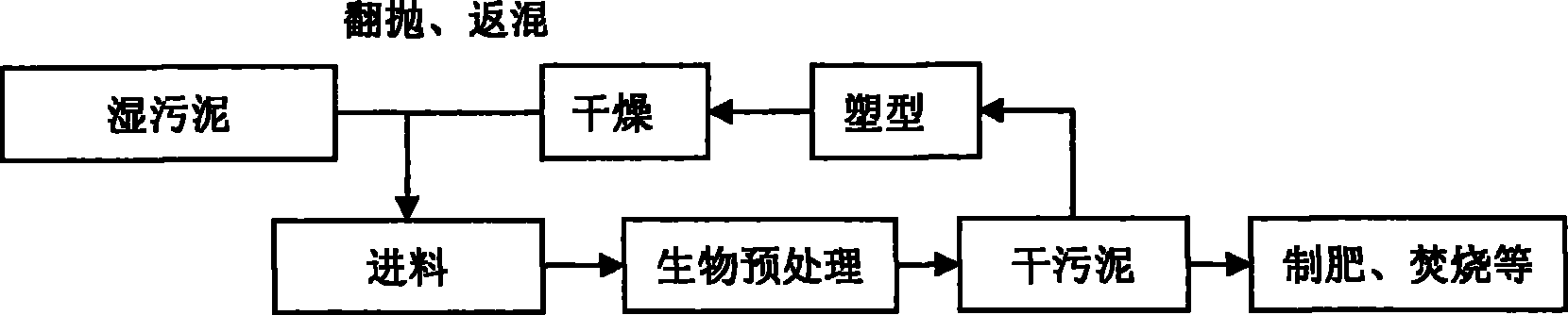

Back mixing method for pretreatment of sludge

InactiveCN101407367BIncrease dosageReduce processing costsBiological sludge treatmentSludgePretreatment Period

A back mixing method in the biological pretreatment of sludge comprises the steps: a) the dry sludge plastotype with the water ratio being 35 percent to 37 percent is processed into cylindrical granular dry sludge A and striping dry sludge B, which are dried until the water ratio reduces to 20-25 percent; b) the dry sludge A and B prepared in step a are mixed as per the mass ratio of 8-10:1 to bemade into back mixing dry sludge; c) the back mixing dry sludge is mixed with wet sludge and accounts for 25-35 percent of the mass of the total materials, and the turn and throw are carried out for 3-7 times per week, with ventilation and oxygen supply, the temperature is maintained between 45-60 DEG C, when the water ratio reaches 35 percent to 37 percent, fertilizer manufacture and incineration and other subsequent disposals are conducted. Through the back mixing of the dry sludge A and B of different shapes, the invention can reach the aims of improving the space structure of sludge and shortening the pretreatment period; and the final pretreatment product dry sludge is of granular structure, which is more beneficial to the execution of further disposals such as fertilizer manufactureand incineration.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com