Fermentation method of water hyacinth

A fermentation method and technology of water hyacinth, applied in the direction of fertilizers made from biological waste, applications, organic fertilizers, etc., can solve the problems of cumbersome operations, pollution, and large space occupation, and achieve simplified processes, efficient collection, and site construction simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

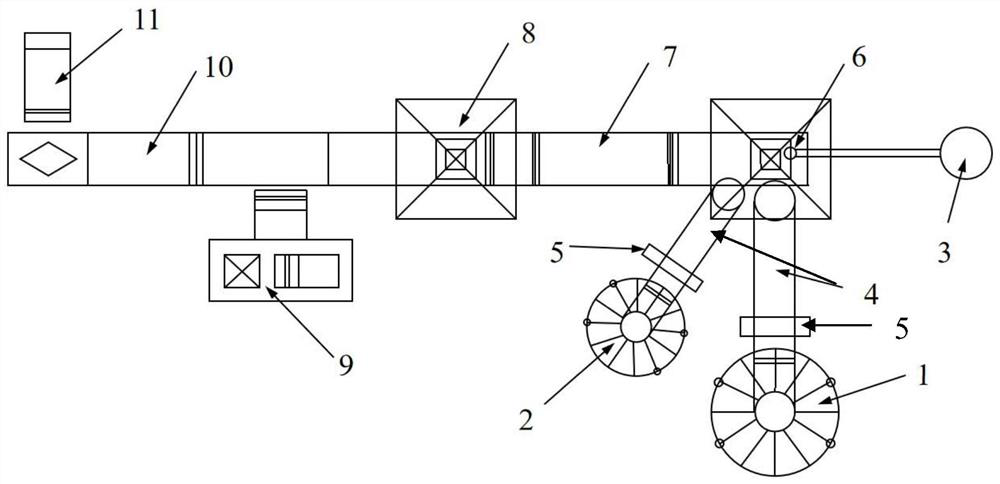

[0030] Below in conjunction with accompanying drawing, the fermentation method of water hyacinth of the present invention is described in detail.

[0031] see figure 1 , the method includes the following steps:

[0032] S1. After the water hyacinth in the water hyacinth storage tank 1 and the auxiliary materials in the auxiliary material storage tank 2 are measured by the metering device 5, they are sent to the feeding bin of the packaging equipment through the conveying device 4, and a pipeline and a spray are arranged at the upper end of the feeding bin. The shower head is used to spray the composite bacterial agent in the bacterial agent bucket 3 on the water hyacinth;

[0033] S2, sending the water hyacinth and auxiliary materials sprayed with the compound bacterial agent into the compression packing machine 7 through the screw conveying device;

[0034] S3, the material is subjected to high-pressure compression by the compression baler 7, and the compressed bales are bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com