Method and system for cooperatively treating sludge through grate furnace waste incineration

A waste incineration and co-processing technology, applied in the direction of combustion methods, dehydration/drying/thickened sludge treatment, incinerators, etc., can solve the problems of high sludge construction and operation costs, and achieve obvious results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

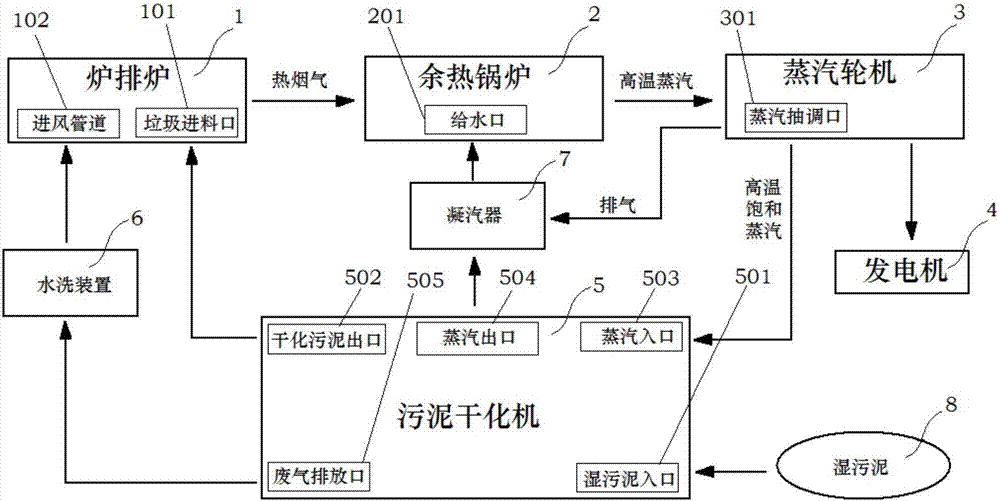

[0027] Such as figure 1 As shown, grate furnace 1, garbage feed port 101, air intake pipe 102, waste heat boiler 2, water supply port 201, steam turbine 3, steam extraction port 301, generator 4, sludge dryer 5, wet sludge Inlet 501 , dried sludge outlet 502 , steam inlet 503 , steam outlet 504 , waste gas outlet 505 , water washing device 6 , condenser 7 , and wet sludge 8 .

[0028] A method for synergistically treating sludge with grate furnace waste incineration provided by the invention comprises:

[0029] Extract the high-temperature steam in the grate furnace 1 waste incineration power generation;

[0030] Using the high-temperature steam to dry the wet sludge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com