Patents

Literature

51results about How to "Good volume reduction effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

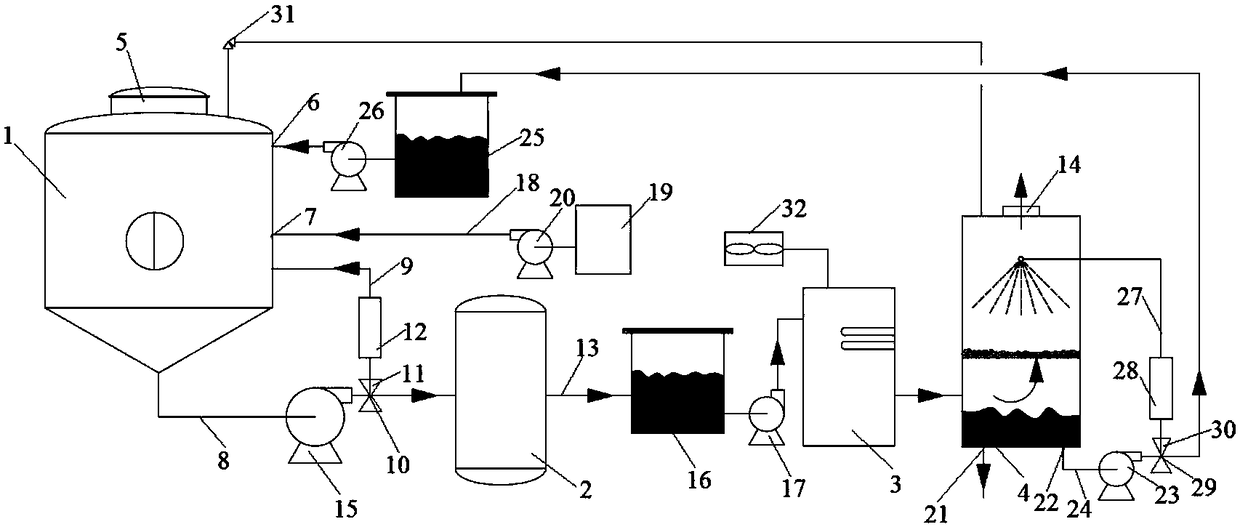

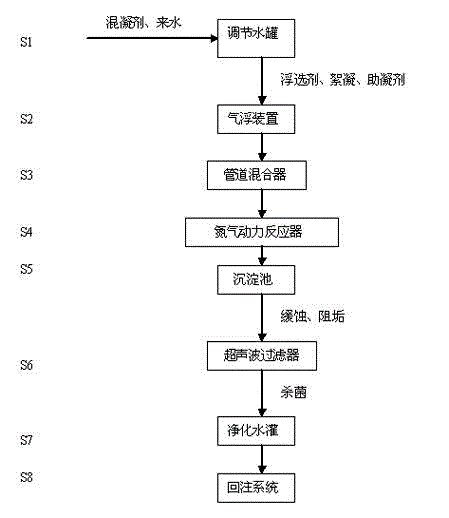

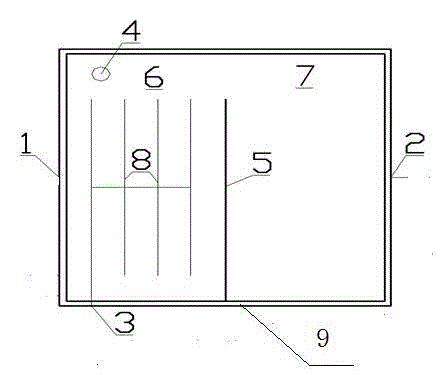

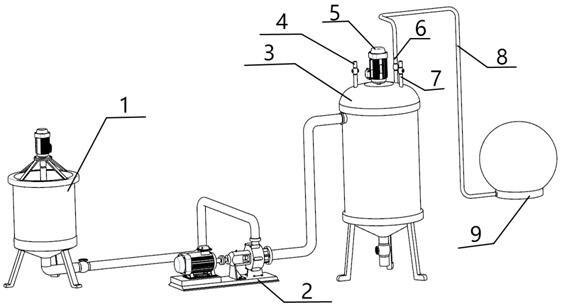

Process for treating oil field produced water

ActiveCN102153221AEasy to handleHigh degreasing efficiency at one timeWater/sewage treatment with mechanical oscillationsMultistage water/sewage treatmentFiltrationNitrogen

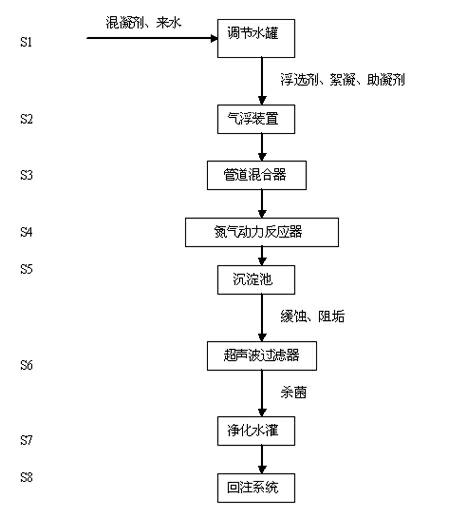

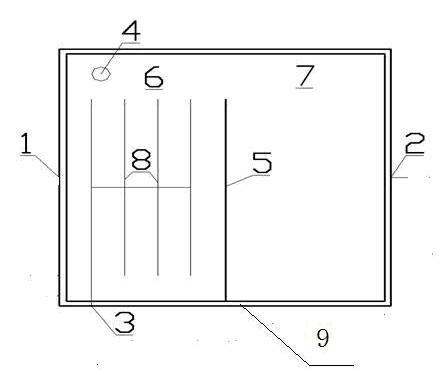

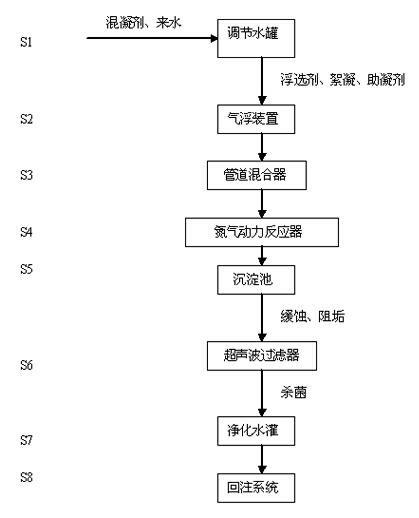

The invention belongs to a process for treating oil field produced water and belongs to the field of oil field produced water treatment, in particular relates to the process for treating the oil field produced water. In the process, at least a regulating water tank, an air flotation device, a pipeline mixer, a nitrogen power reactor, a sedimentation tank and an ultrasonic filter are adopted and the oil field produced water is treated by adopting a mode of combining air flotation oil and suspended matter removal, nitrogen preparation and ultrasonic filtration. The process for treating the oil field produced water has good treatment effect, high oil removing efficiency, corrosion resistance and low cost and has good effect in the actual application.

Owner:XIAN CHANGQING TECH ENG

A treatment method for dewatered sludge in a domestic sewage treatment plant

InactiveCN102276128AHigh activityShort curing timeSludge treatment by de-watering/drying/thickeningSewageSewage treatment

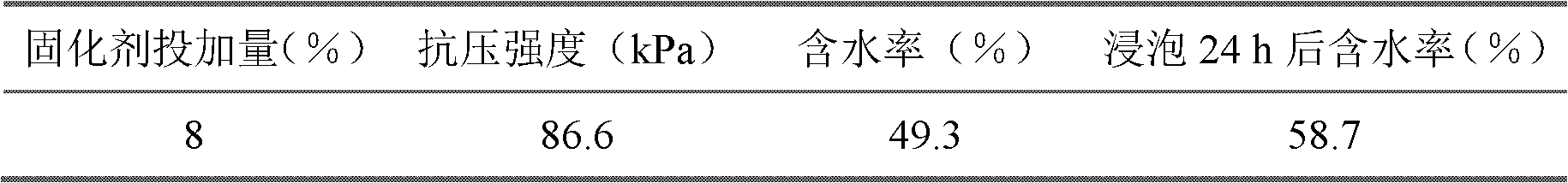

The invention relates to a treatment method of dehydrated sludge in a domestic sewage treatment plant. The treatment method comprises the following steps: evenly mixing limestone, magnesia and bauxite which are weighed in a ratio of (40%-60%):(20%-30%):(20%-30%) by weight percent and then firing for 1-2 hours at the temperature of 900 DEG C-1200 DEG C so as to obtain a sludge solidifying agent; adding the sludge solidifying agent in the dehydrated sludge in the ratio of dehydrated sludge to sludge solidifying agent of (90%-95%):(5%-10%) by weight percent, and then stirring; after evenly mixing, paving the mixture obtained in the former step to the thickness of 20-30 cm in the open air, and placing for 48 hours so as to obtain a sludge solidifying body; and finally, performing landfill treatment. According to the invention, the solidifying time is short, and the adding amount of the sludge solidifying agent is less; by using the treatment method, sludge can be modified, and the stabilization of sludge is promoted; the bulking of the sludge solidifying body is small, the stability and mechanical strength of the sludge solidifying body are high, and secondary pollution can not be caused; and the solidifying technological process is simple and convenient for operation, and the investment and treatment costs are low, thus the treatment method in the invention can be widely applied to stabilization, reduction and innocent treatments of dehydrated sludge in a sewage plant.

Owner:SHANGHAI TONGJI CONSTR CO LTD

Garbage cracking purification device and garbage cracking purification treatment process

InactiveCN102433139AReduce energy consumptionObvious disfigurementSolid waste disposalGas purification with selectively adsorptive solidsPollutant emissionsTherapeutic effect

The invention discloses a garbage cracking purification device and a garbage cracking purification treatment process and aims at providing the garbage cracking purification device, which is lower in running cost, good in purification treatment effect and lower in energy consumption and has no emission of pollutants, and the garbage cracking purification treatment process. According to the garbage cracking purification device and the garbage cracking purification treatment process, disclosed by the invention, garbage is dried and cracked mainly under a totally-enclosed, negative-pressure and oxygen-deficient high-temperature environment so as to oxidize or decompose organic matters in the garbage into inorganic matters and further facilitate the treatment of the garbage. The whole treatment process and the treatment environment for implementing the device and the process, disclosed by the invention, can be realized in a total enclosure manner, so that air pollution can be avoided and the zero emission of the pollutants can be basically realized in a real sense. The device and the process, disclosed by the invention, can be widely applied to the field of garbage purification treatment processes and equipment.

Owner:胡昀

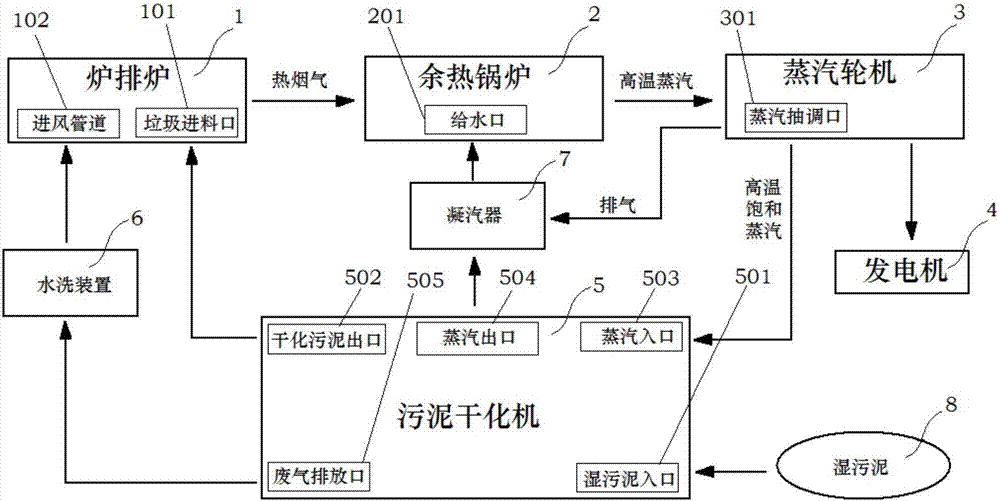

Method and system for cooperatively treating sludge through grate furnace waste incineration

PendingCN107013928AEasy to handleTechnically feasibleSludge treatment by de-watering/drying/thickeningIncinerator apparatusSludgeProcess engineering

The invention discloses a method and system for cooperatively treating sludge through grate furnace waste incineration, and belongs to the field of sludge treatment. Steam generated by grate furnace waste incineration is firstly utilized for carrying out indirect heat exchange drying on the sludge, and then the sludge dried to a certain degree and in-furnace waste are mixed and incinerated in a grate furnace according to a certain proportion. According to the method and system, the existing and mature grate furnace waste incineration technology is utilized for achieving effective drying and cooperative incineration on the sludge, the sludge independent drying cost and the building and operating cost of an incineration treatment project can be greatly reduced, and harmlessness, reduction and recycling of sludge treatment are achieved.

Owner:CHONGQING SANFENG COVANTA ENVIRONMENTAL IND

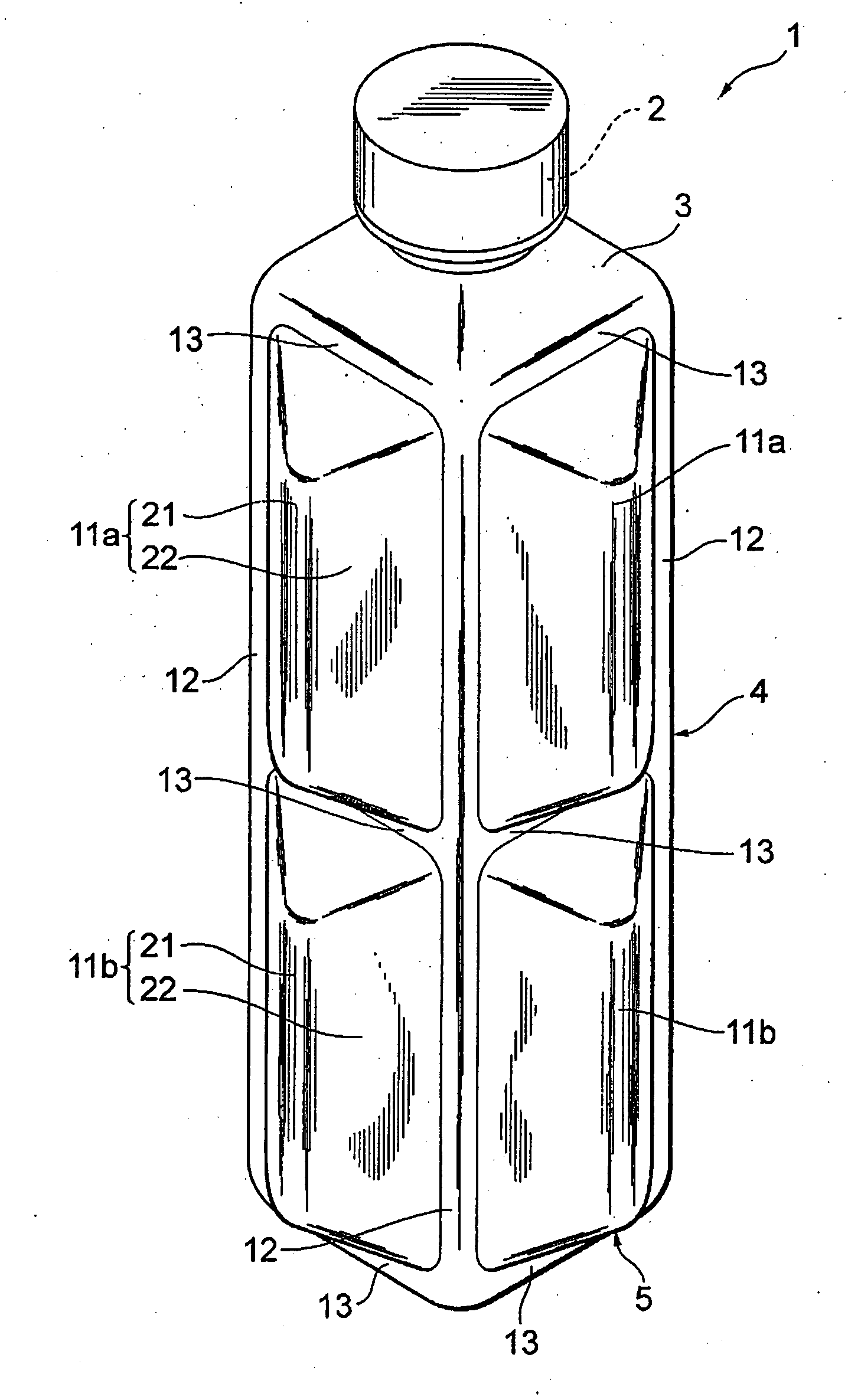

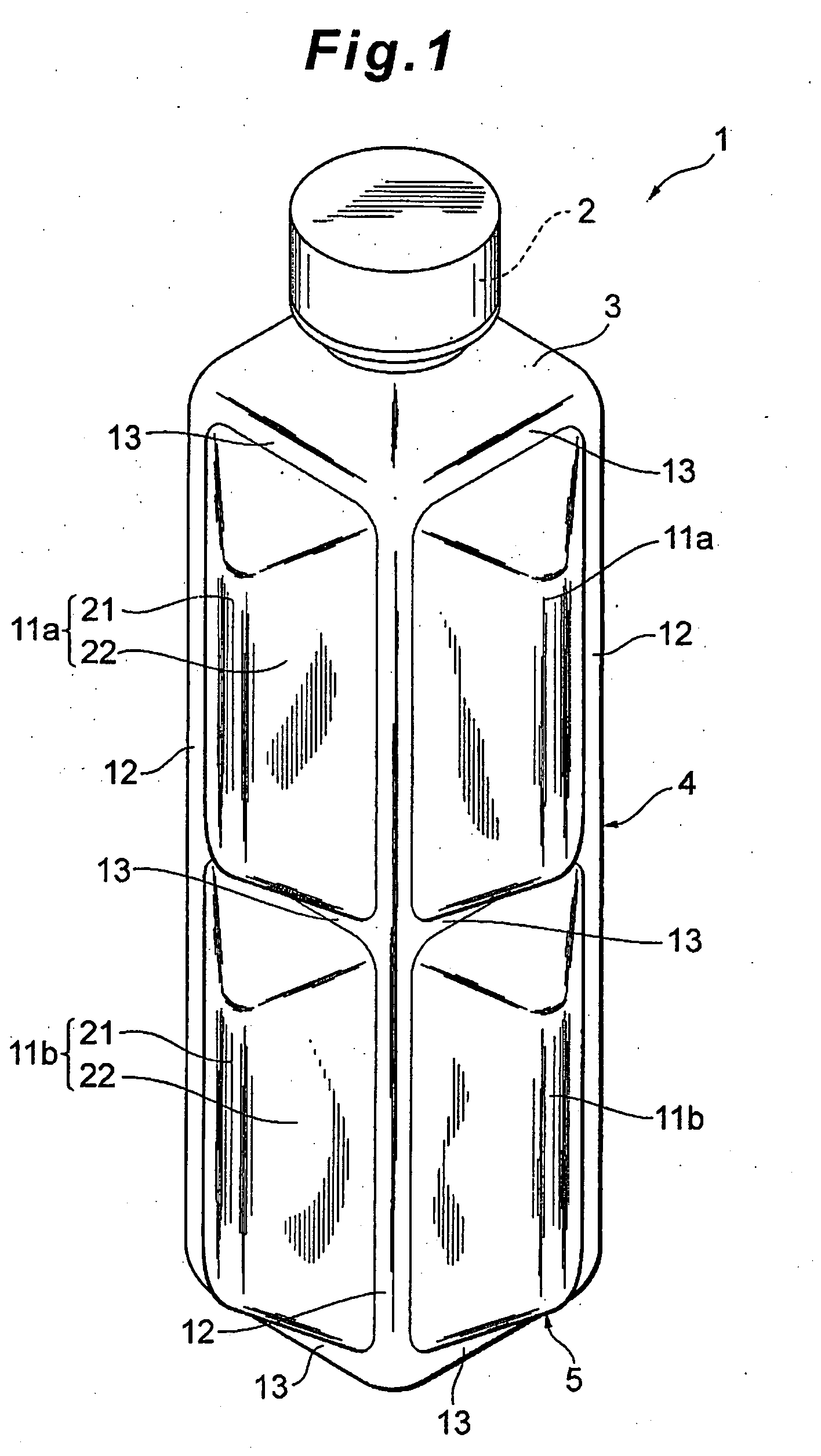

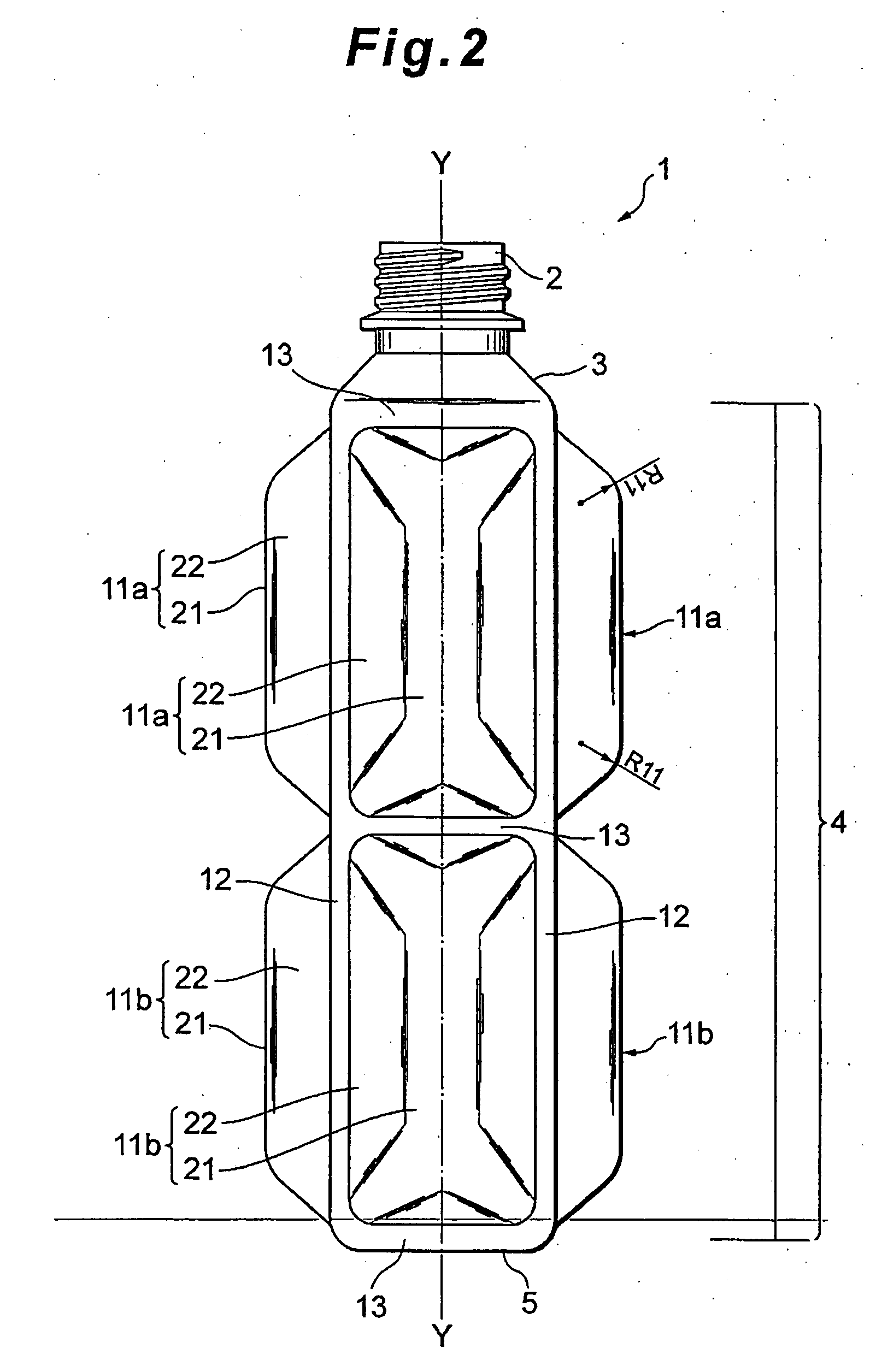

Plastic bottle

ActiveUS20090114617A1Reduce space volumeGood volume reduction effectBottlesLarge containersBiomedical engineeringPlastic bottle

A plastic bottle that can easily be collapsed after used is provided.The plastic bottle has a body portion that is depressed internally by applying external force, and a depressible portion formed on a circumferential wall of the body portion to protrude externally. The depressible portion is depressed internally by applying external force. Plural depressible portions and plural depression-resistant portions may be formed alternately on the circumferential wall of the body portion in the circumferential direction of the body portion.

Owner:THE COCA-COLA CO

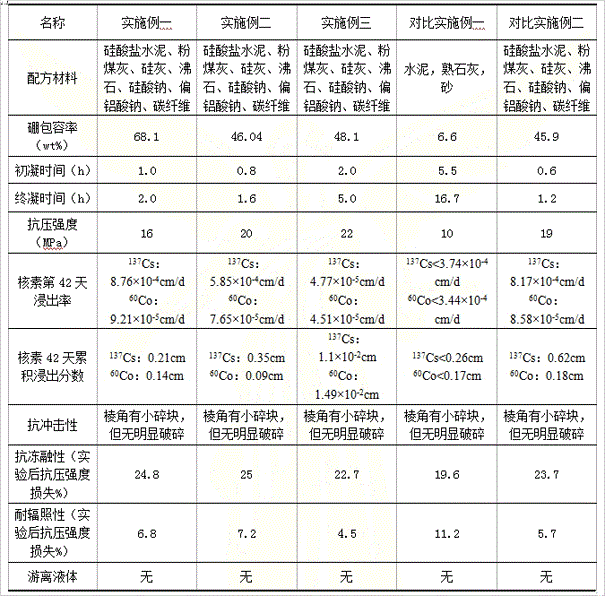

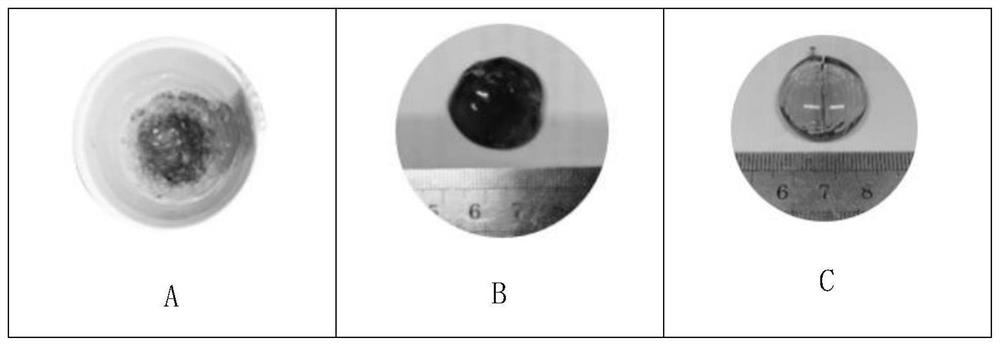

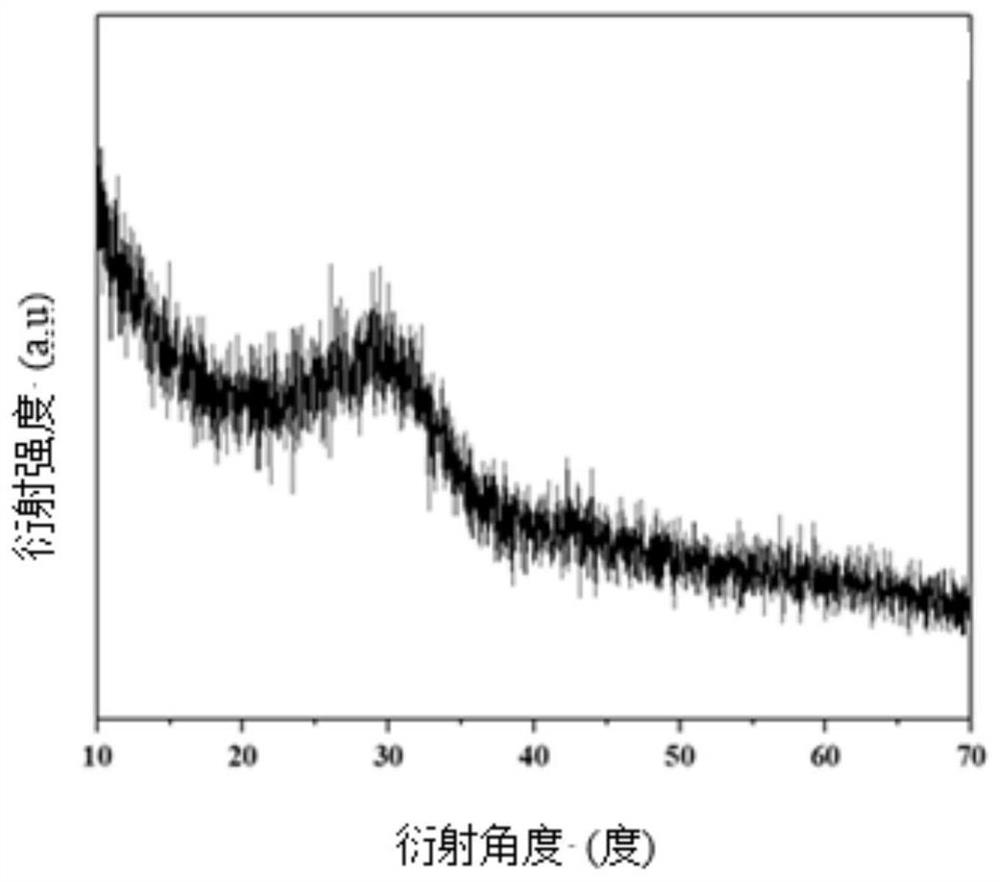

Solidification treatment additive, solidification formula and solidification process for radioactive boron-containing waste liquor

ActiveCN105741899AGood volume reduction effectReduce leakageRadioactive decontaminationFiberCarbon fibers

The invention discloses a solidification treatment additive, a solidification formula and a solidification process for radioactive boron-containing waste liquor.The solidification treatment entrapment rate of radioactive boron-containing waste liquor can be greatly increased.According to the additive, cement is adopted as a solidification base material, coal ash is used for reducing hydration heat, zeolite powder is used for reducing cesium leaching and promoting hydration, silica fume is used for reducing strontium and cesium leaching, sodium metaaluminate is used for accelerating cement hardening and setting, sodium silicate is used for improving strength, and carbon fiber power is used for improving strength.By means of the method that borate is prepared into condensed borate and then a solidification agent is added for solidification, the entrapment rate of prepared solidified boric acid can reach 49.5%.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

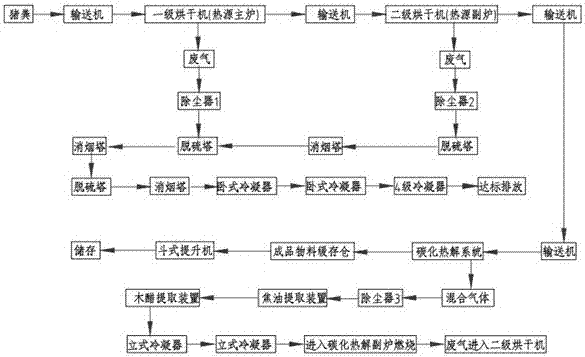

Comprehensive utilization method of pig manure on the basis of carbonization pyrolysis technology

InactiveCN107162373ARealize "three modernizations" processingImprove thermal efficiencySludge treatment by pyrolysisByproduct vaporizationHazardous substanceRetention time

The invention provides a comprehensive utilization method of pig manure on the basis of carbonization pyrolysis technology. Through steps including multi-stage drying to the pig manure, carbonization pyrolysis to the pig manure, flue gas treatment and the like, the pig manure is subjected to dry pyrolysis in a furnace, high-temperature pyrolysis gasification, and re-pyrolysis gasification to flue gas (outlet flue gas temperature is higher than 850 DEG C), wherein retention time of flue gas in the furnace is prolonged to more than 2 sec. In the whole pyrolysis process, generation of PCDDs / PCDFs harmful substances is effectively inhibited. Through quenching cooling to high-temperature flue gas, re-synthesis of dioxin is effectively avoided. Main measurements, such as a desulfurization column, adsorption in a smoke removal column, liquefaction in a condenser and the like, are all employed in the technology, so that national smoke and dust discharge standard at present can be satisfied.

Owner:FUJIAN YUYI ENVIRONMENT TECH CO LTD

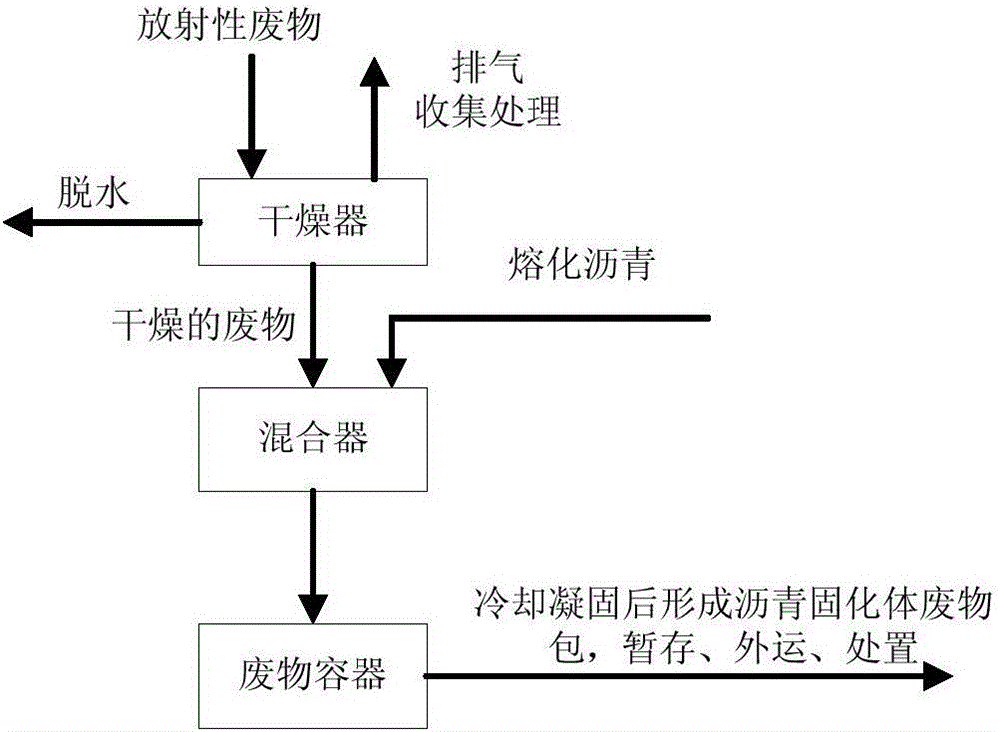

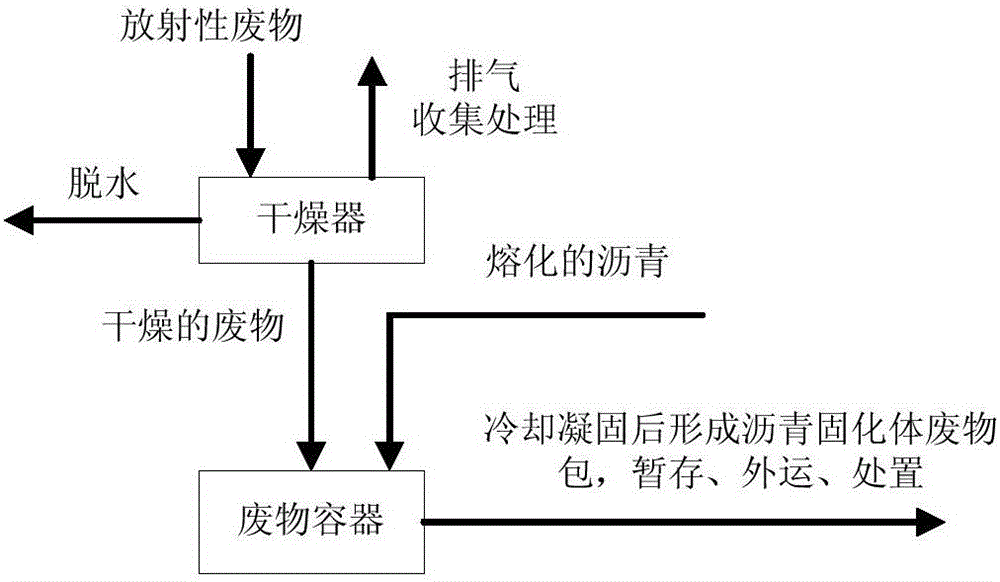

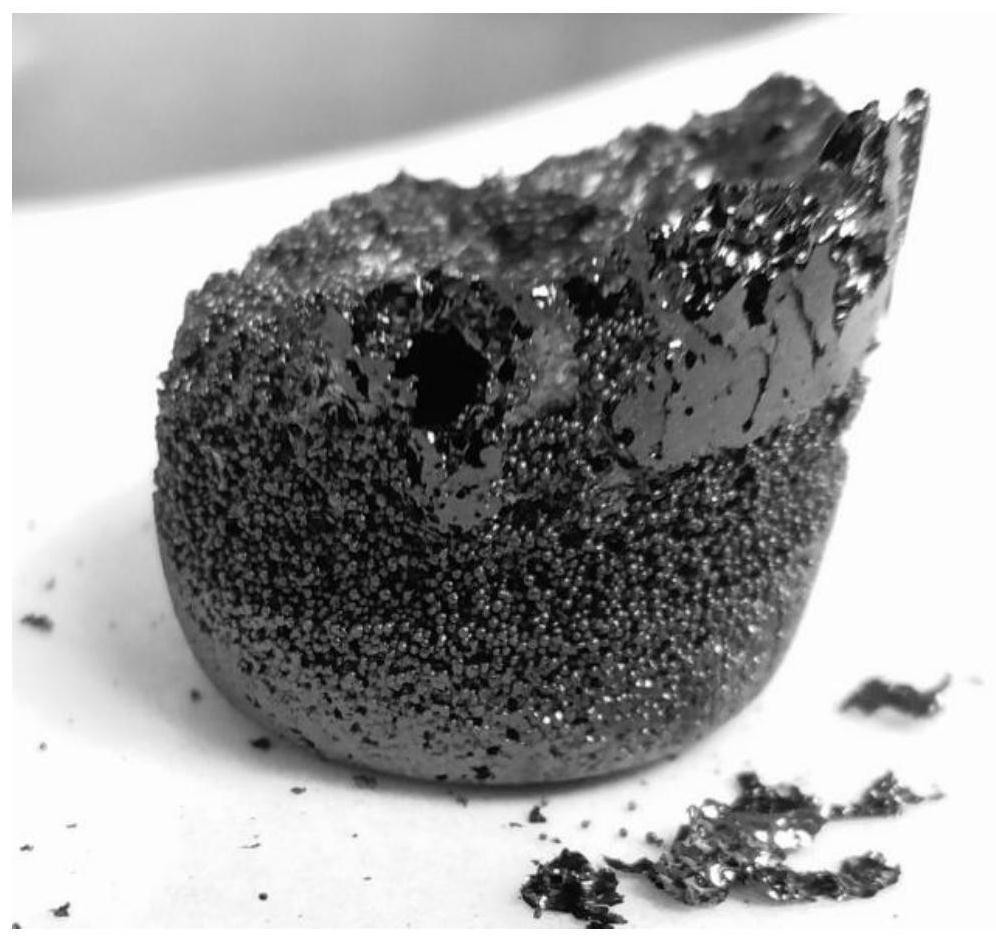

Radioactive waste curing method

PendingCN105976886ALarge inclusive rateContainer fee reductionRadioactive decontaminationRadioactive wasteEngineering

The invention relates to a radioactive waste curing method carried out in a ventilating condition; the method comprises the following steps: waste drying, i.e., drying to-be-processed radioactive waste; asphalt fusing, i.e., heating to fuse the selected asphalt; mixing, i.e., evenly mixing dried radioactive waste with fused asphalt; cooling solidification, i.e., cooling the mixture of dried radioactive waste and fused asphalt for solidification, thus forming an asphalt firming body waste bag. The curing method is simple and easy, high in volume reduction ratio, and the formed asphalt firming body is good in stability, thus satisfying GB 14569.3 <low and medium level radioactivity firming body performance requirement-asphalt firming body> requirements, and the asphalt firming body waste bag can satisfy our country radioactive waste near-surface disposal standard requirements.

Owner:CHINA NUCLEAR POWER ENG CO LTD

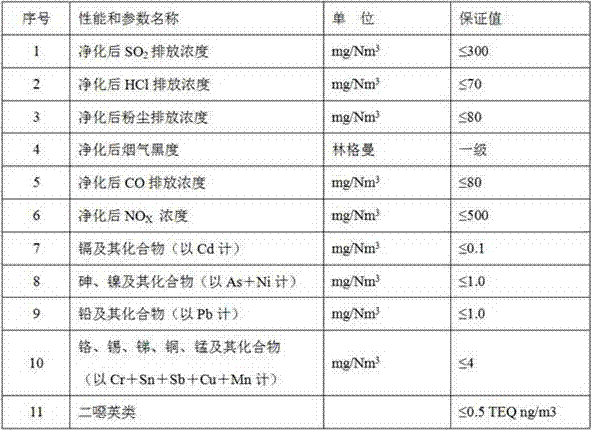

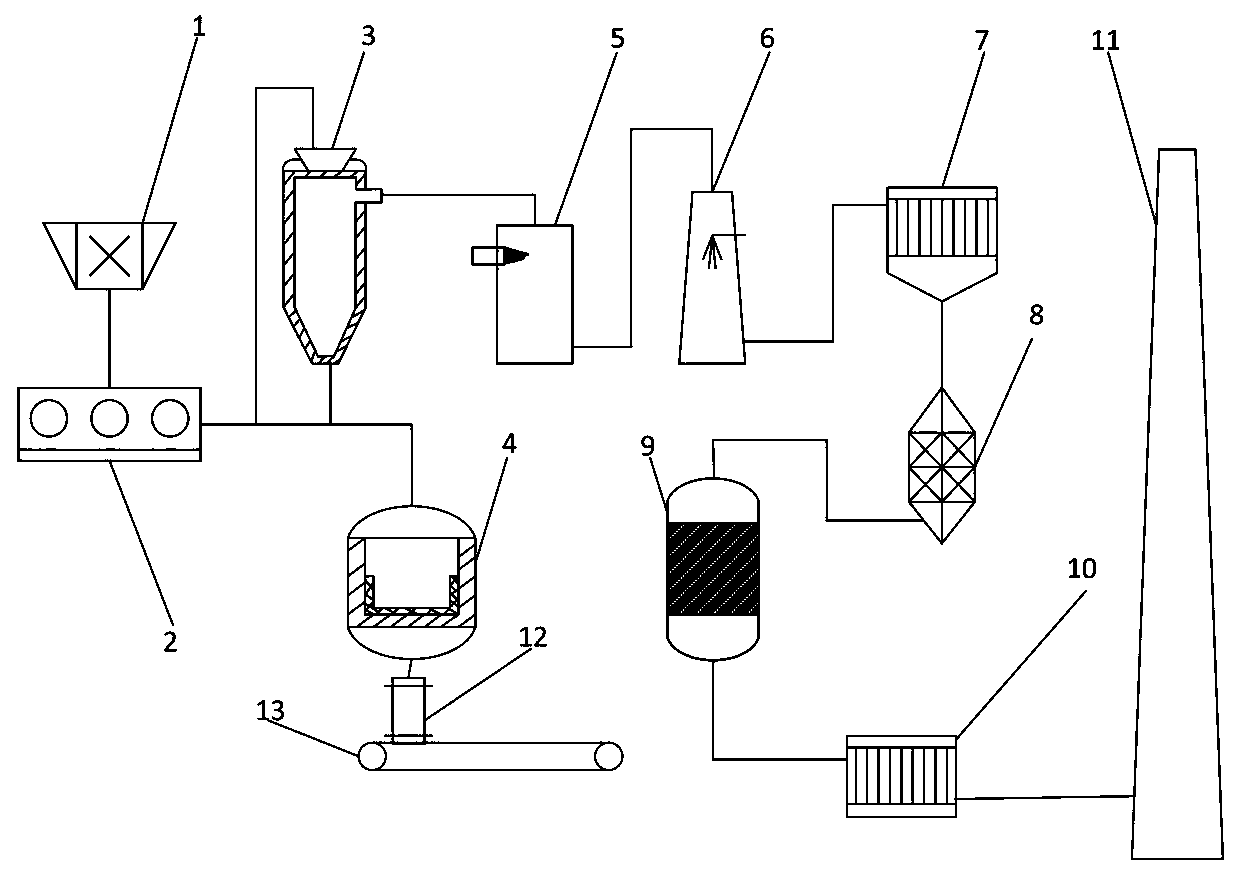

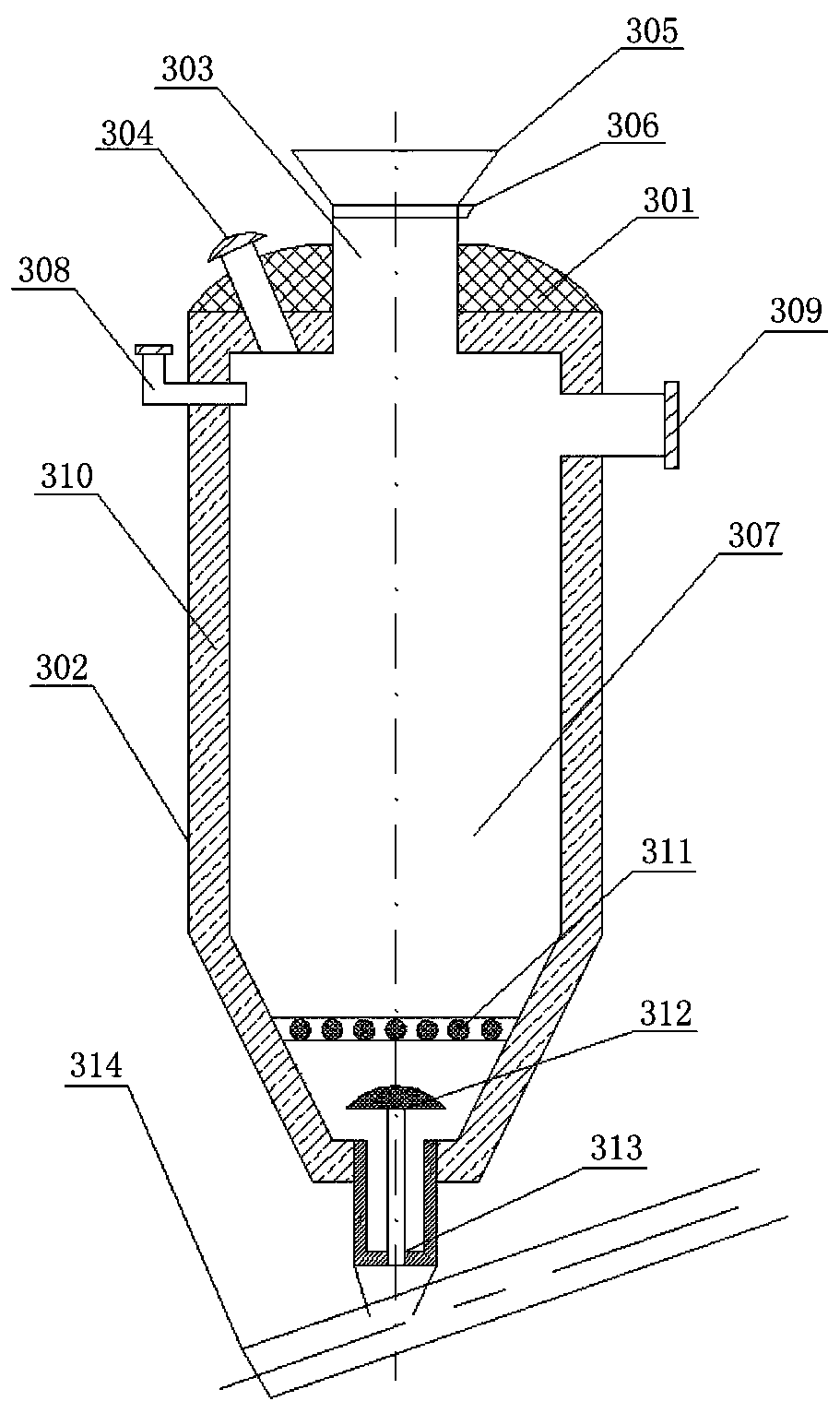

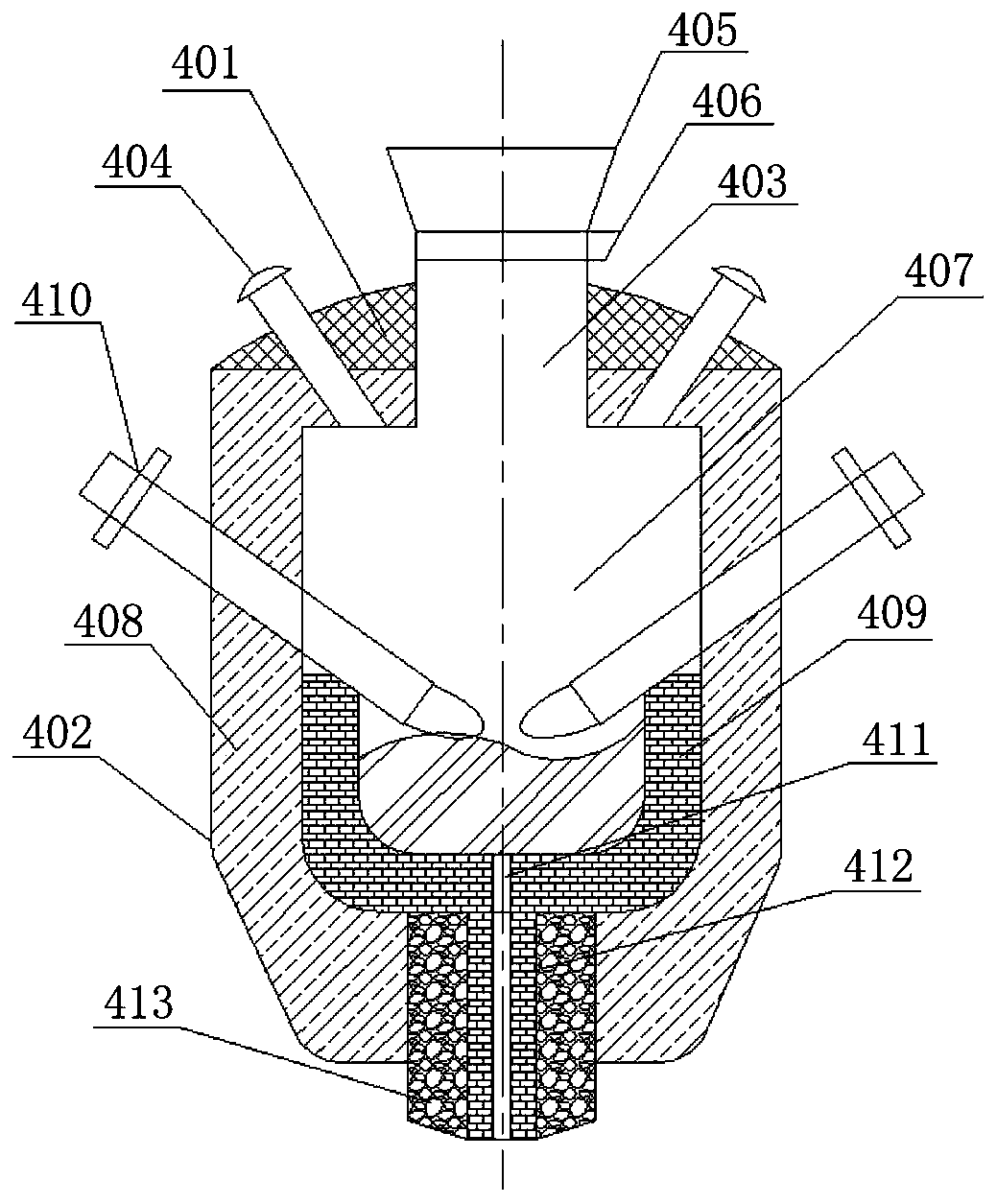

Capacity reduction treatment system and method for medium-low radioactive solid waste

PendingCN110176322AReduce disposal storage spaceReduce disposal costsRadioactive decontaminationReduction treatmentAir filter

The invention discloses a capacity reduction treatment system and method for medium-low radioactive solid waste. The system comprises a crusher, a sorting box, a plasma gasifier, a plasma fusion furnace, a burning chamber, a quench tower, a ceramic filter, an activated carbon adsorption tower, a deacidification washing tower, an efficient air filter, a chimney, a fused vitreous body receiver and aconveyor. Firstly, the medium-low radioactive solid waste is crushed by using a crushing device and then conveyed to the sorting device for sorting, the combustible waste is conveyed into the gasifier, organic components are subjected to a gasification reaction, and generated ash and noncombustible waste are collected and conveyed into the fusion furnace for vitreous fusion treatment, so that radioactive nuclide is fixed into the fused vitreous body; the vitreous body is cooled, barreled and stored by an automatic receiving system, and generated smoke is purified and then reaches the comprehensive emission standard of atmospheric pollutants, so that up-to-standard emission is achieved. The capacity reduction treatment system has a good capacity reduction effect and is high in safety reliability and nuclide stability.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

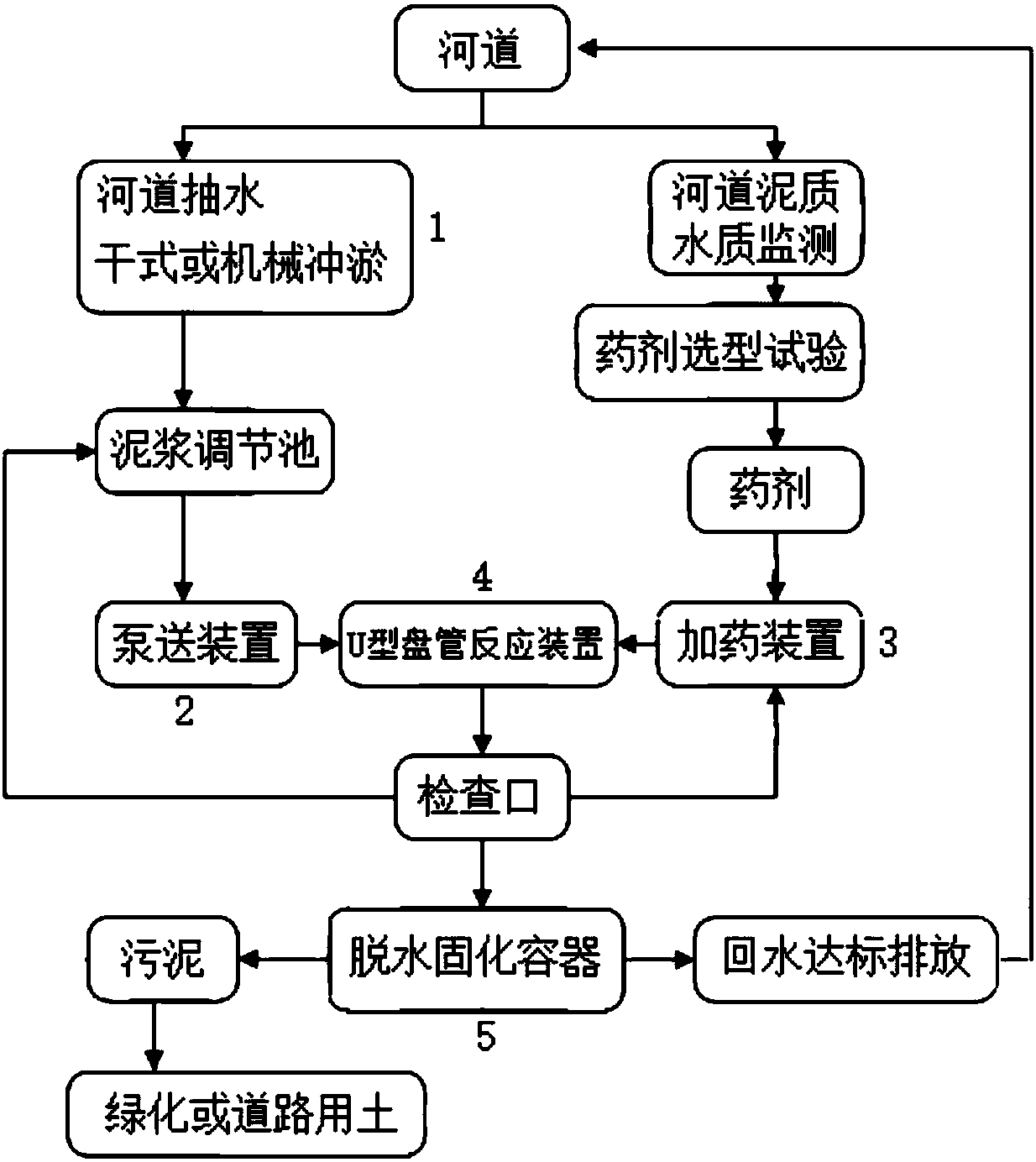

City and town medium-and-small river sludge ecological treatment system

InactiveCN107915392AAvoid secondary pollutionSecondary pollution is not easy to causeSludge treatment by de-watering/drying/thickeningMechanical machines/dredgersSludgeEngineering

The invention discloses a city and town medium-and-small river sludge ecological treatment system. The system comprises five subsidiary modules of a river dredging subsidiary module, a slurry pumpingsubsidiary module, an agent adding device subsidiary module, a reaction device subsidiary module and a slurry dehydration and solidification subsidiary module; the city and town medium-and-small riverdredging subsidiary module is connected with the slurry pumping subsidiary module and the agent adding device subsidiary module, macromolecular flocculation agent for water treatment is selected according to analysis of river sediment properties, the agent is put into the slurry pumping subsidiary module through the agent adding device subsidiary module, slurry is fully reacted with the agent inthe reaction device subsidiary module, and finally solidification is conducted in a dehydration container of the slurry dehydration and solidification subsidiary module to achieve slurry-water separation. The sludge is subjected to reduction, stabilization, hazard-free treatment and resourceful treatment; the construction noise is low, secondary pollution is not easily caused, the treatment and volume reduction effect of the wastewater and the slurry is good, the treatment and volume reduction efficiency of the wastewater and the slurry is high, the size of the sludge can basically be reducedby 50% or above within one month, a fixed plant is not needed, the treatment cost is low, the treatment capability can be flexibly adjusted, and the application range is wide.

Owner:上海市水利工程集团有限公司

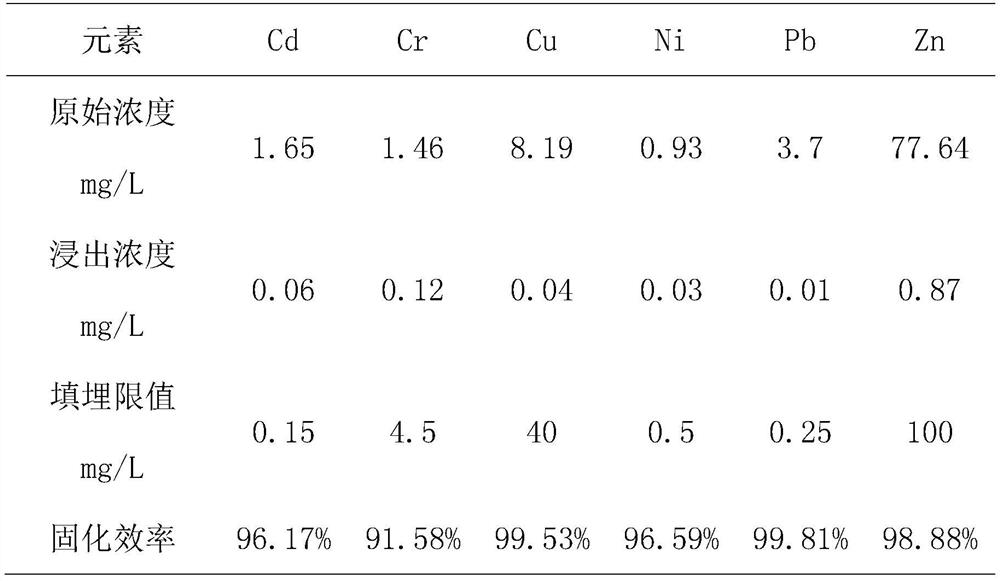

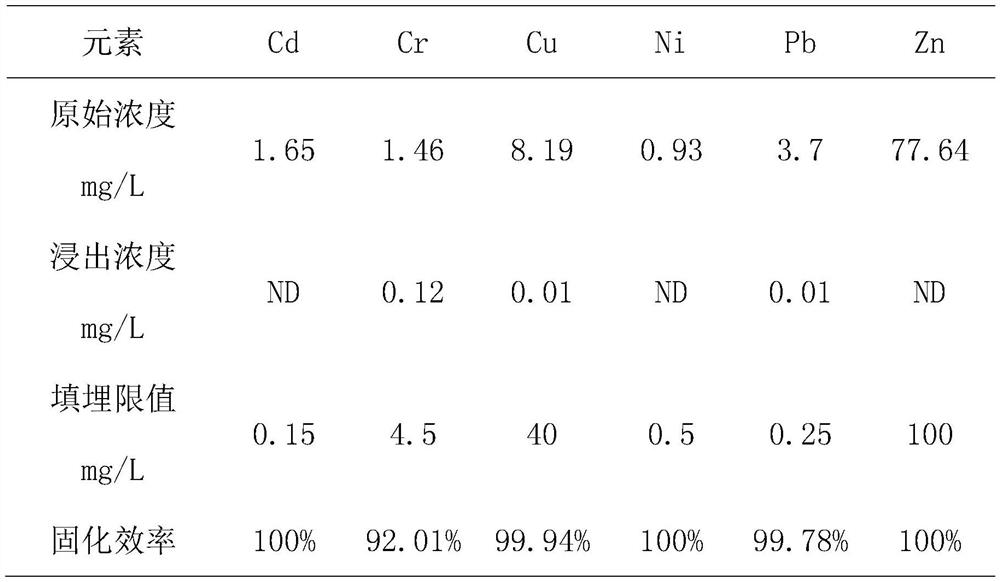

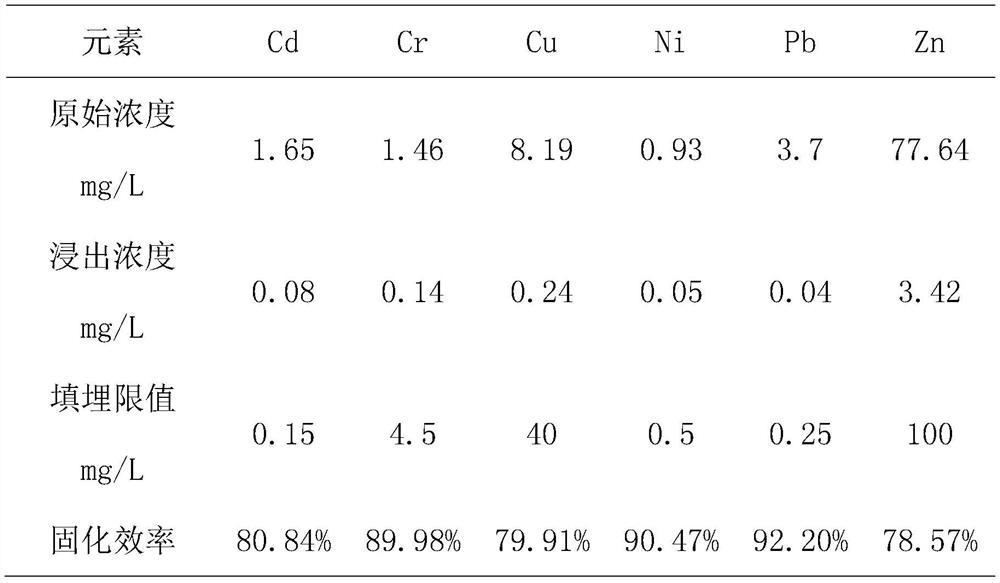

Method for stabilizing heavy metals in waste incineration fly ash through combination of coal gangue and calcium oxide

ActiveCN113441526ASave stacking costLow raw material costSolid waste disposalCement productionCalcium silicateIon exchange

The invention discloses a method for stabilizing heavy metals in waste incineration fly ash through combination of coal gangue and calcium oxide, and belongs to the field of household waste incineration fly ash treatment. Coal gangue and amorphous SiO2 and Al2O3 in household waste incineration fly ash are subjected to a geological polymerization reaction under the condition of an alkali activator, an inorganic polymer of a three-dimensional net structure is formed, meanwhile, calcium oxide is added, a large quantity of hydrated calcium silicate, hydrated calcium aluminosilicate and hydrated sodium aluminosilicate gel are formed in a cured body during maintenance and react with the heavy metals in manners of physical encapsulation, physical adsorption and ion exchange, so that the heavy metals in the fly ash are harmlessly treated, and it is guaranteed that the heavy metal leaching concentration of the fly ash-coal gangue-calcium oxide polymerization cured body meets the landfill safety standard. The heavy metals in the waste incineration fly ash are stabilized and produced though combination of coal gangue and calcium oxide, the curing efficiency of the heavy metals in the fly ash is further improved, the curing cost is reduced, and the environment-friendly concept of treating wastes with wastes is met.

Owner:POWERCHINA HEBEI ELECTRIC POWER SURVEY & DESIGN INST CO LTD +1

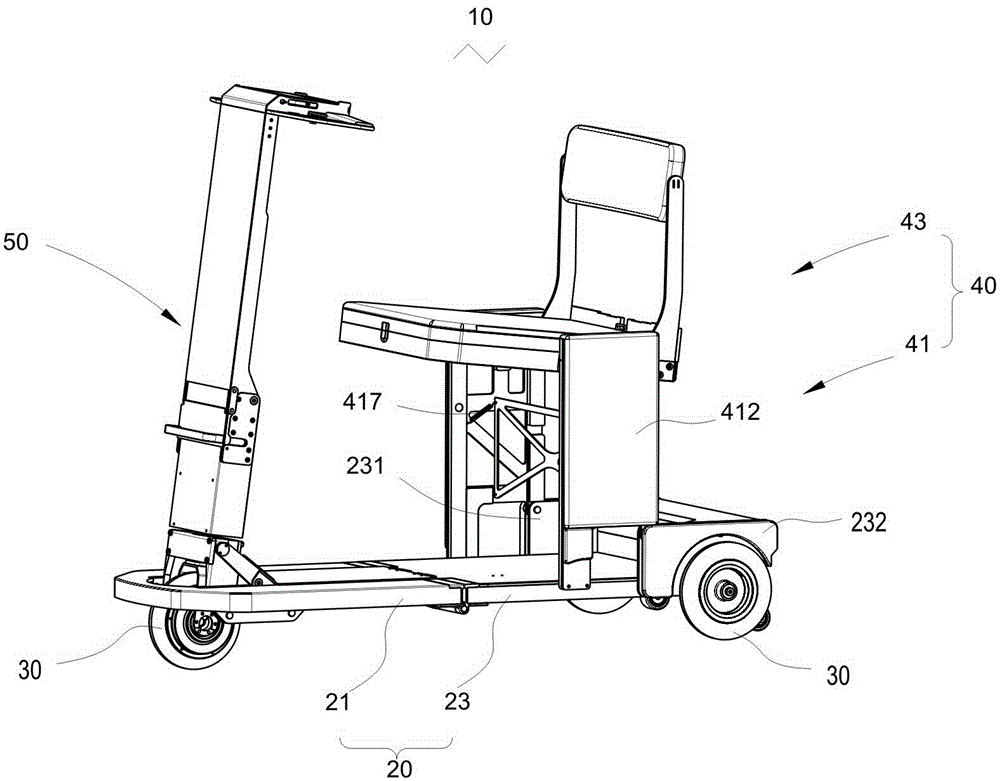

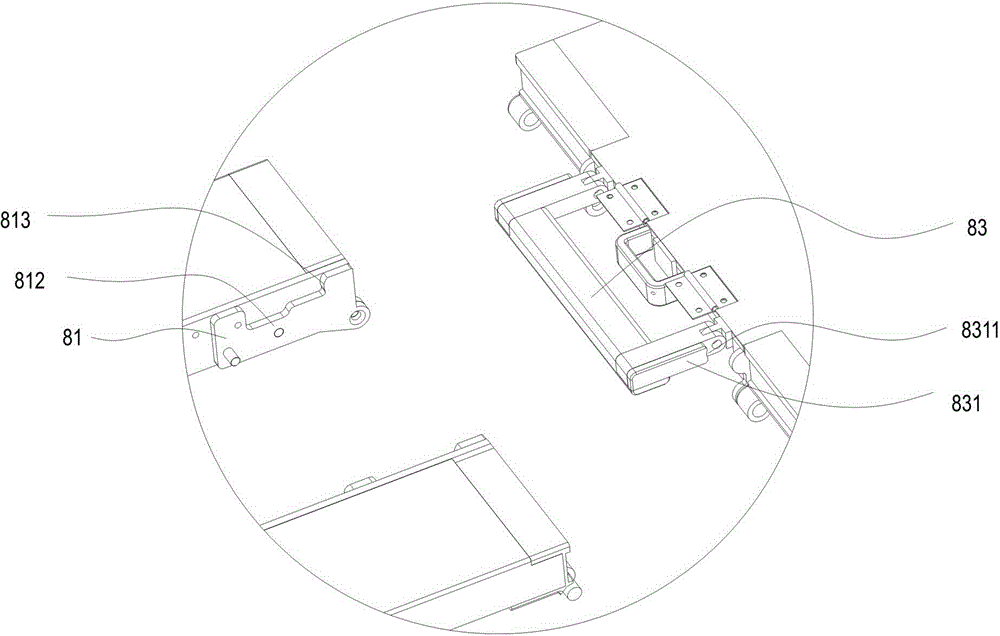

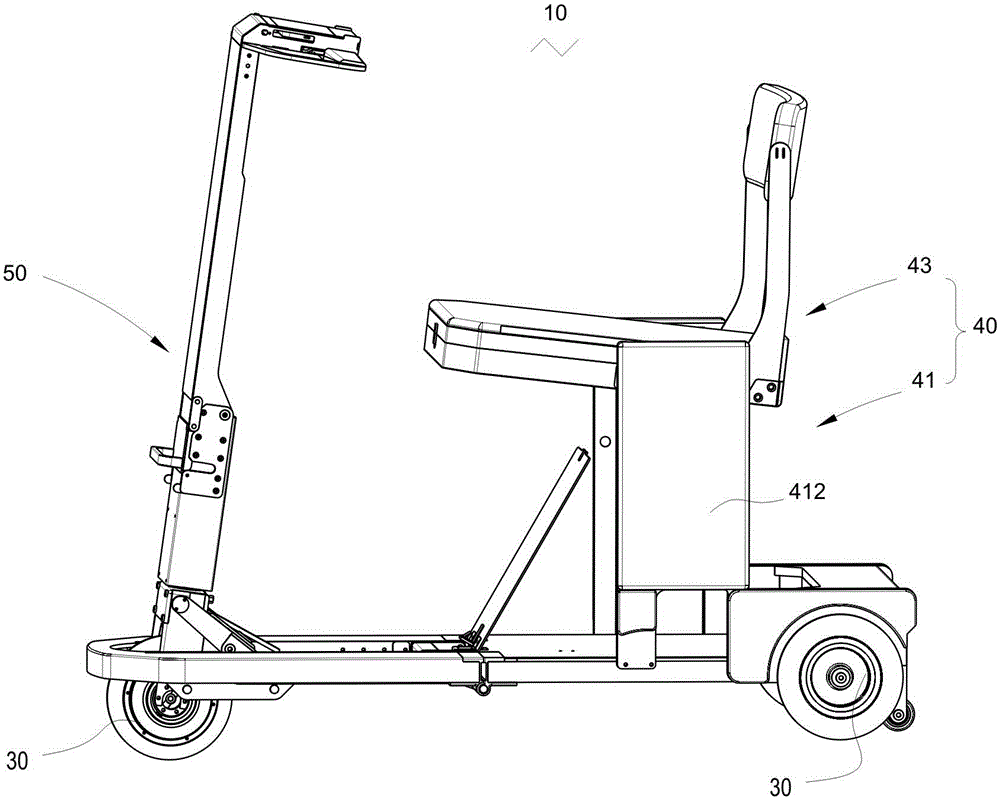

Folding vehicle

The invention provides a folding vehicle which comprises a front chassis, a rear chassis and a chair arranged at the rear chassis, wherein the front chassis is articulated at the rear chassis; the chair comprises a connection positioning component and a seat component; the connection positioning component comprises two connecting frameworks respectively and rotatably connected to two sides of the rear chassis and a reinforced supporting piece fixedly connected between the two connecting frameworks; the seat component is rotatably connected to the connecting frameworks of the connection positioning component. When the folding vehicle is in an unfolded state, the front chassis and the rear chassis are unfolded, the chair is arranged on the rear chassis, the connection positioning component of the chair is arranged between the rear chassis and the seat component and is used for supporting the seat component; when the folding vehicle is in a folded state, the seat component is arranged between the two connecting frameworks of the connection positioning component and stacked on the reinforced supporting piece of the connection positioning component; the front chassis and the seat component of the chair are stacked on two opposite surfaces of the rear chassis. The folding vehicle is convenient to fold; the folding vehicle has regular appearance and a favorable volume reduction effect after being folded.

Owner:SHENZHEN RELYNC TECH LTD

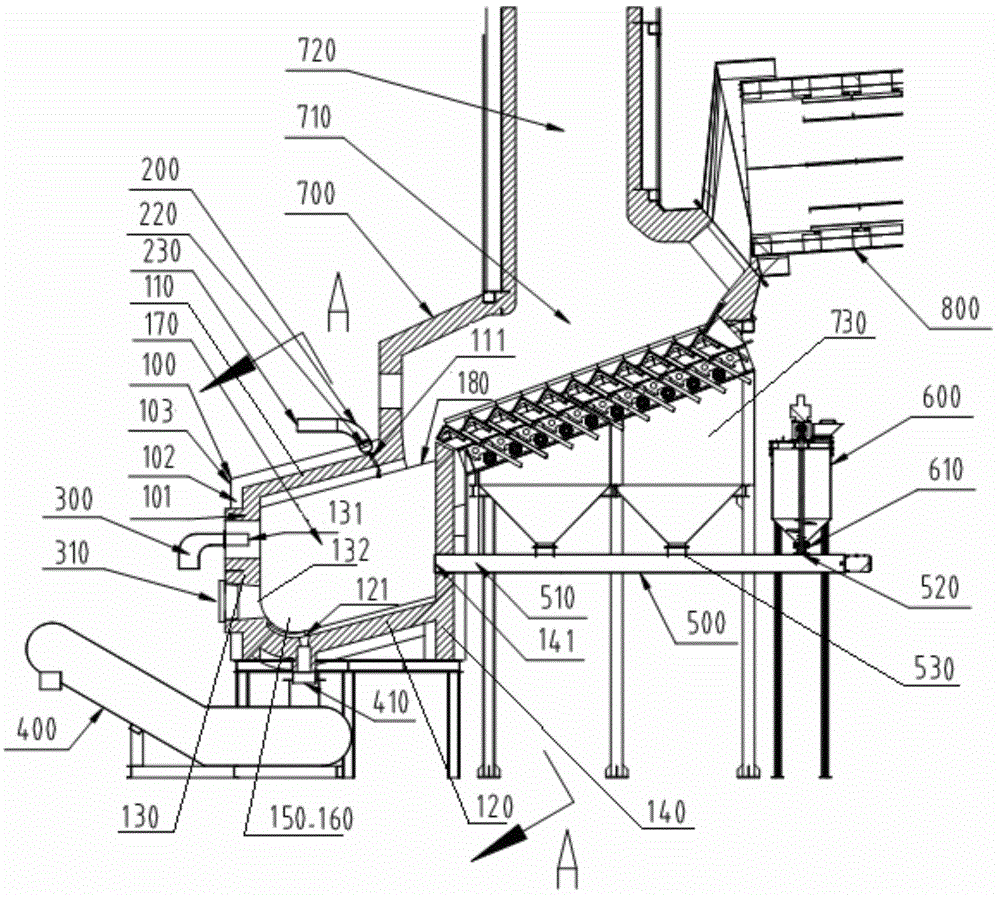

Waste disposal device realizing thermolysis, incineration and melting integration

The invention discloses a waste disposal device realizing thermolysis, incineration and melting integration. The waste disposal device comprises an ash melting furnace arranged at the back end of an incineration furnace and a rotary thermolysis furnace arranged at the front end of the incineration furnace. The ash melting furnace comprises an oxygen supply device, a furnace starting and heat insulation burner, a water cooling slag discharging machine, a spiral material conveying device and a feeding device, the oxygen supply device is arranged above the furnace top, the furnace starting and heat insulation burner is arranged at the back furnace wall, the water cooling slag discharging machine is arranged under the groove-shaped furnace bottom of the ash melting furnace, the spiral material conveying device is arranged outside the front furnace wall of the ash melting furnace, and the feeding device is arranged at the upper side, near the front end, of the spiral material conveying device. The waste disposal device realizing thermolysis, incineration and melting integration belongs to a set of waste disposal system integrating the advantages of thermolysis, incineration and melting. The waste disposal device has the advantages that the particular structure features of the ash melting furnace are expounded in an emphasis way, and the prominent advantages of the waste disposal combing three kinds of technologies of the rotary thermolysis furnace, the incineration furnace and the ash melting furnace are briefly introduced in operation characteristics.

Owner:上海煜工环保科技有限公司

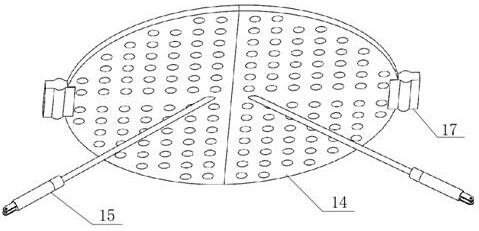

Sewage treatment sludge recycling device and method

ActiveCN109205977ASolve multiple and difficult problemsReduce processing costsExcrement fertilisersInvertebrate treatmentSludgeEngineering

The invention provides a sewage treatment sludge recycling device and method. The device comprises a supporting frame and an earthworm breeding cabin, wherein the earthworm breeding cabin is fixed above the supporting frame; the earthworm breeding cabin comprises a cabin body, a cabin cover, a lighting assembly and a discharging assembly; the discharging assembly comprises a metal screen, a vibrating motor used for driving the metal screen to swing and a discharging bottom plate; nail-shaped protrusions are evenly distributed on the upper surface of the metal screen, cylinders are evenly distributed on the lower surface of the metal screen, round holes for the cylinders to be inserted into are evenly distributed on the discharging bottom plate, a steam channel is arranged in the discharging bottom plate, and a stirring device is arranged below the earthworm breeding cabin. According to the sewage treatment sludge recycling device disclosed by the invention, the characteristics of photophoby and heat intolerance of earthworms are utilized, and the earthworms are utilized to treat sludge and heavy metal in the sludge; furthermore, heating of the discharging bottom plate is utilized to kill germs and eliminate peculiar smell; after the sludge is treated by the earthworms, the sludge is mixed with other useable waste to be applied to agricultural fertilizers; thus, sludge resourcesare recycled, environmental protection is achieved, and the cost is low.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

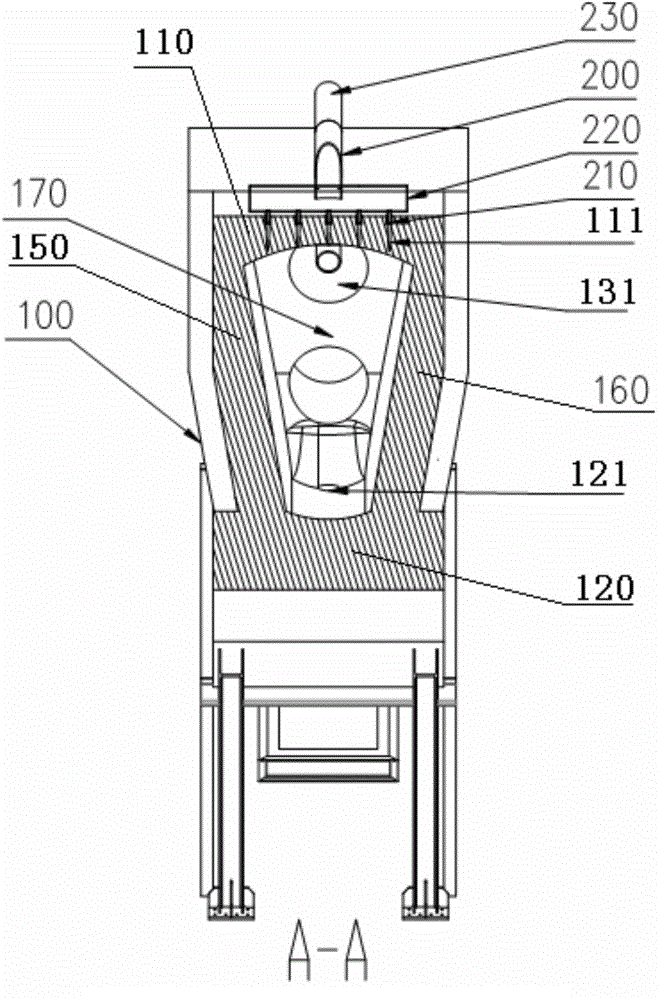

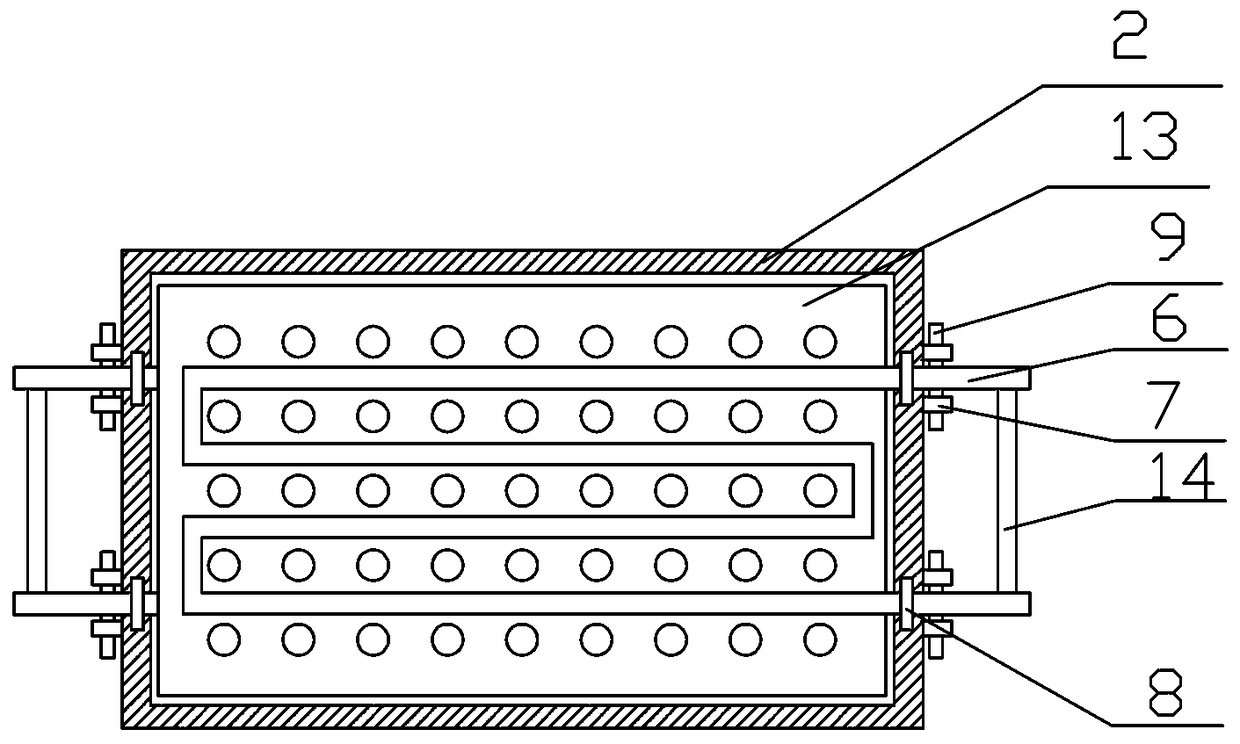

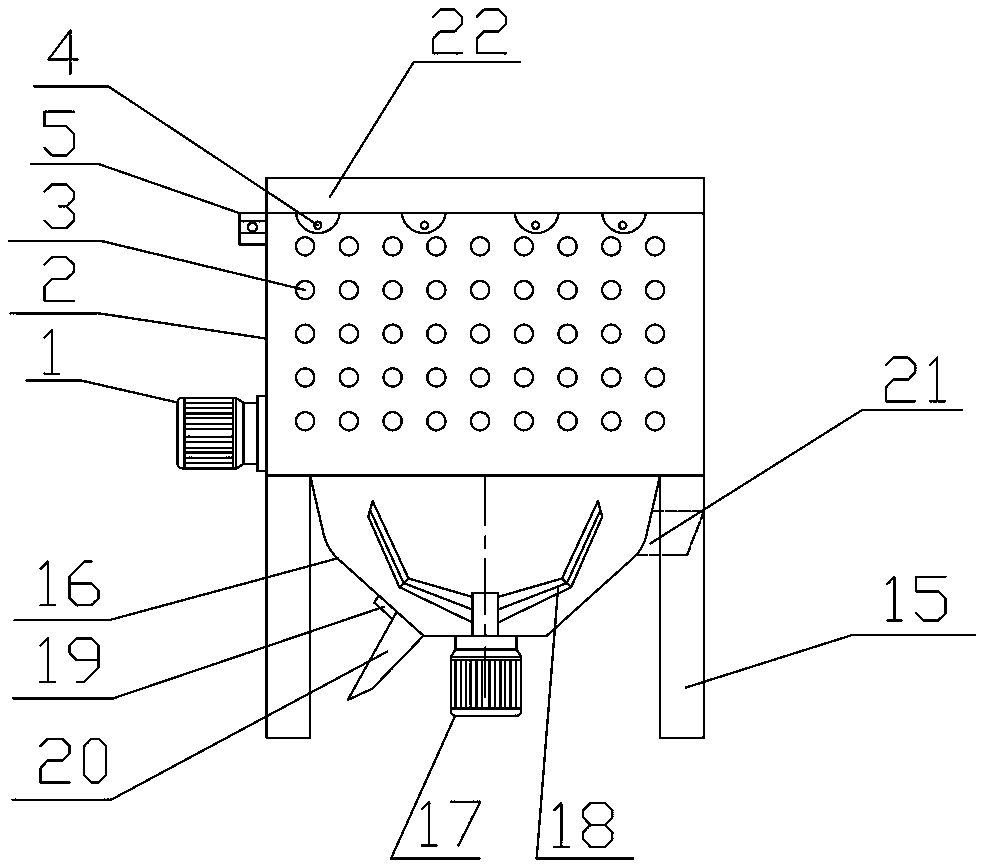

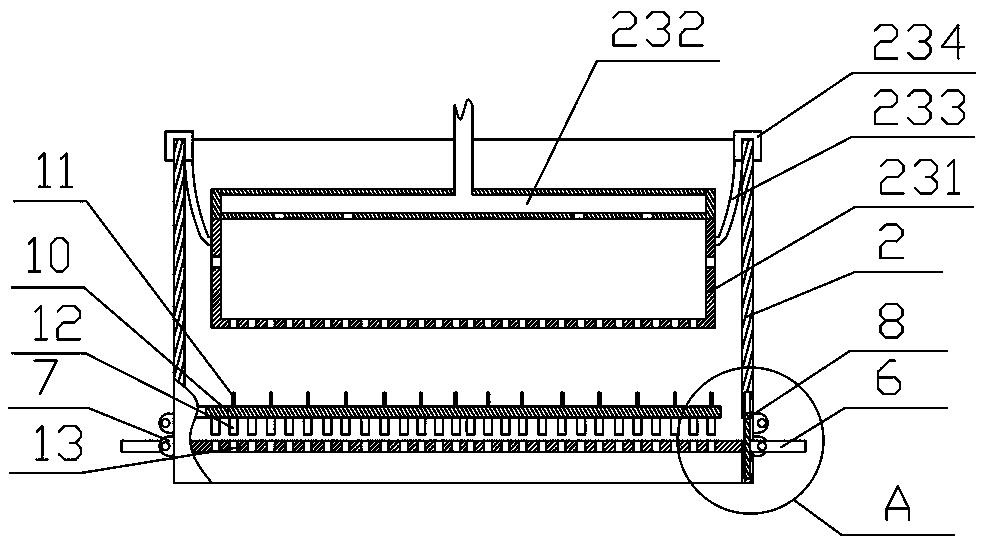

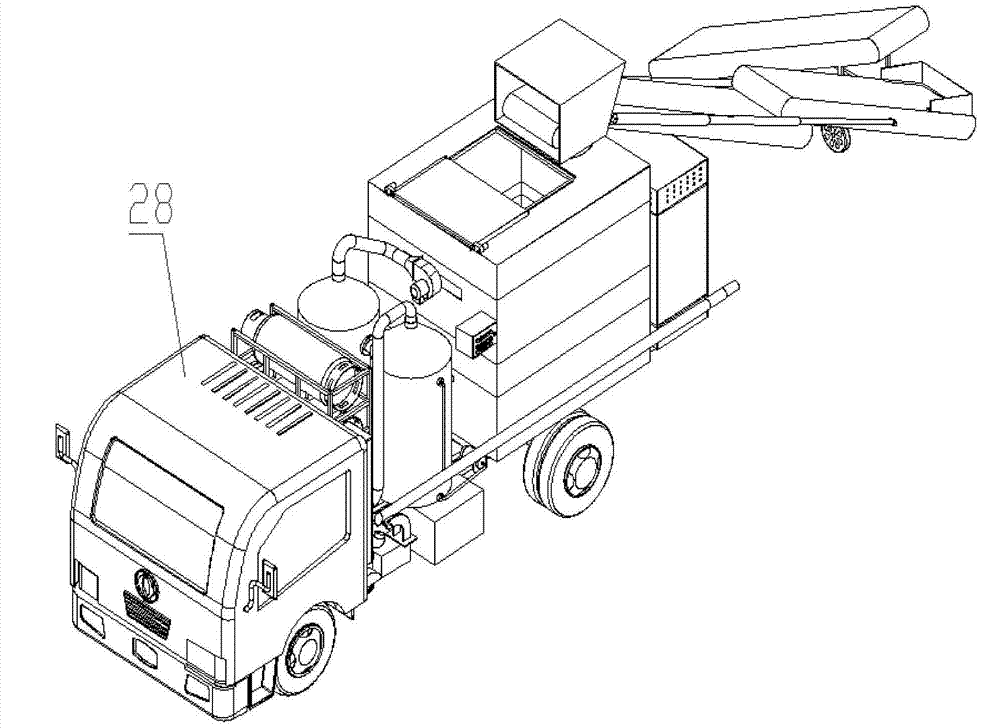

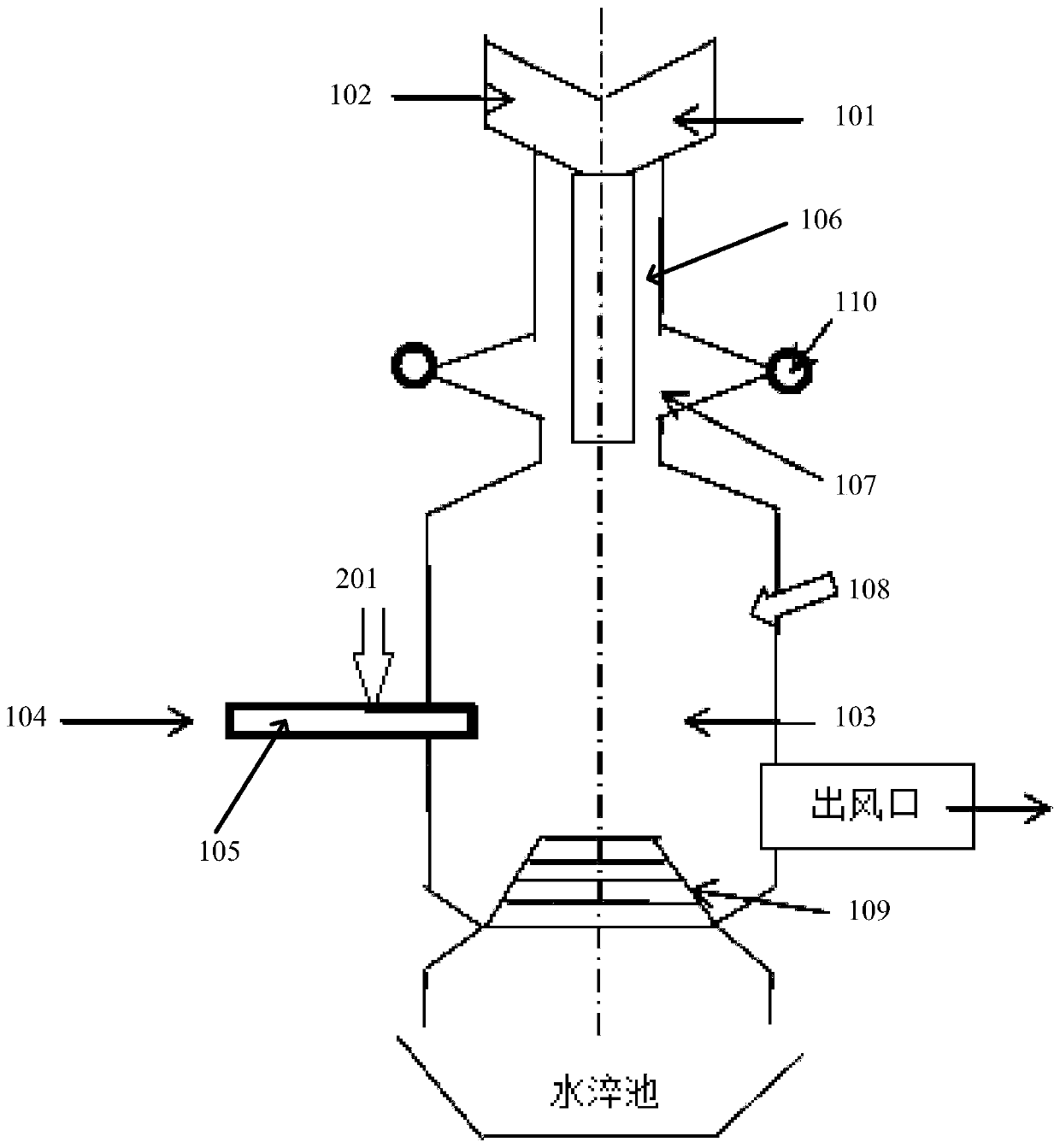

Incinerator and movable type incinerating station

InactiveCN104748127AImprove incineration effectSave energyIncinerator apparatusCombustionAdditive ingredient

The invention relates to an incinerator and a movable type incinerating station. The incinerator comprises an incinerator body, wherein a drying area, a medium-temperature area and a high-temperature area are sequentially arranged in the incinerator body from top to bottom, a first partition discharging mechanism used for partitioning the two areas and used for materials to pass through is arranged between the drying area and the medium-temperature area, a second partition discharging mechanism used for partitioning the two areas and used for materials to pass through is arranged between the medium-temperature area and the high-temperature area, and a heat exchange device and a desulfurization and dust removal mechanism are further arranged outside the incinerator body. High-temperature incineration at 1,100 DEG C is carried out, and Dioxin cannot be generated. The incinerator is installed on a movable type vehicle body to form the movable type incinerating station. According to the incinerator, the volume and amount of combustible ingredients in rubbish can be generally reduced by 80% or higher after the combustible ingredients in the rubbish are decomposed at a high temperature, the volume and amount reducing effect is good, and a large amount of landfill occupied land can be saved; heat generated by incinerating the rubbish is returned to the incinerator through the heat exchange device to fully preheat rubbish which is just thrown into the incinerator, the effect of combustion supporting is achieved, the combustion effect is good, and energy is saved.

Owner:CHANGSHA WEINUO ELECTROMECHANICAL

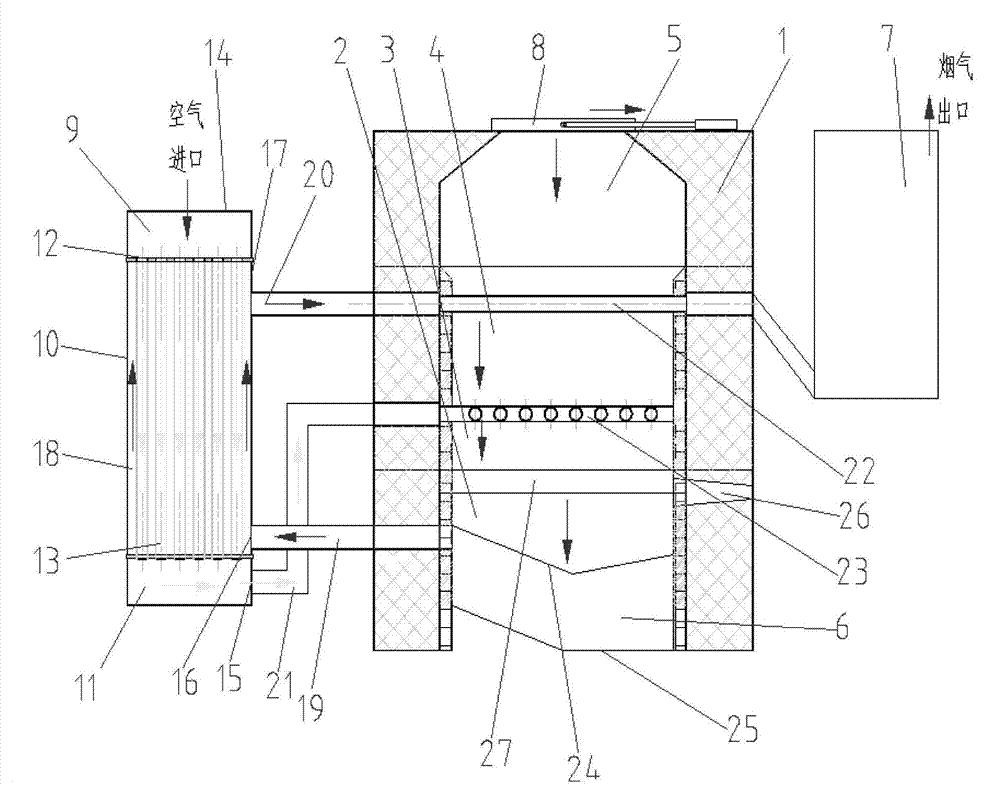

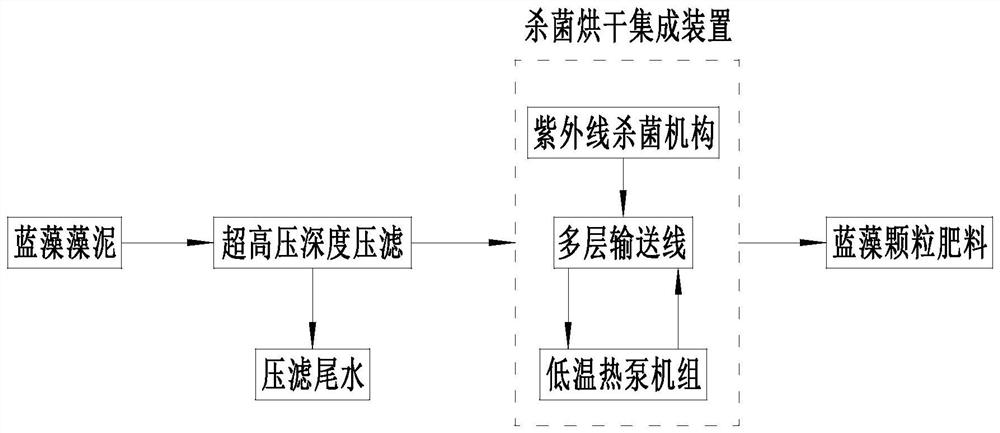

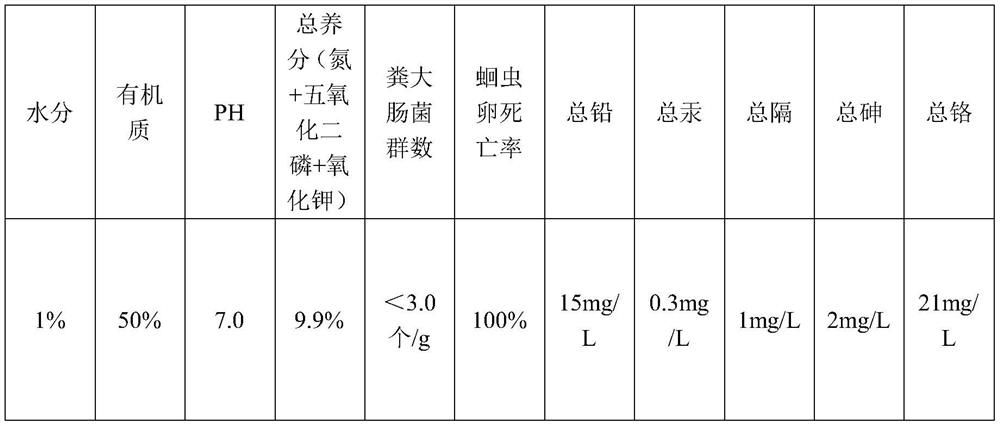

Cyanobacteria dehydrated algal mud waste treatment process

PendingCN111995445AImprove efficiencyImproved efficiency of algal toxin removalBio-organic fraction processingIrradiation based treatmentFertilizerAlgae

The invention relates to a cyanobacteria dehydrated algal mud waste treatment process. The process comprises the following steps: 1) ultrahigh-pressure deep filter pressing is carried out; 2) sterilizing and drying are carried out; 3) a blue algae granular fertilizer is produced, no conditioner is added, and the blue algae granular fertilizer can be produced after dehydration, sterilization and disinfection, so that harmless treatment and resource utilization of the blue algae mud are realized, and the blue algae granular fertilizer prepared from the blue algae mud is low in water content, remarkable in volume reduction effect, low in process energy consumption and high in sterilization and drying efficiency.

Owner:无锡东方船研水环境科技有限公司 +1

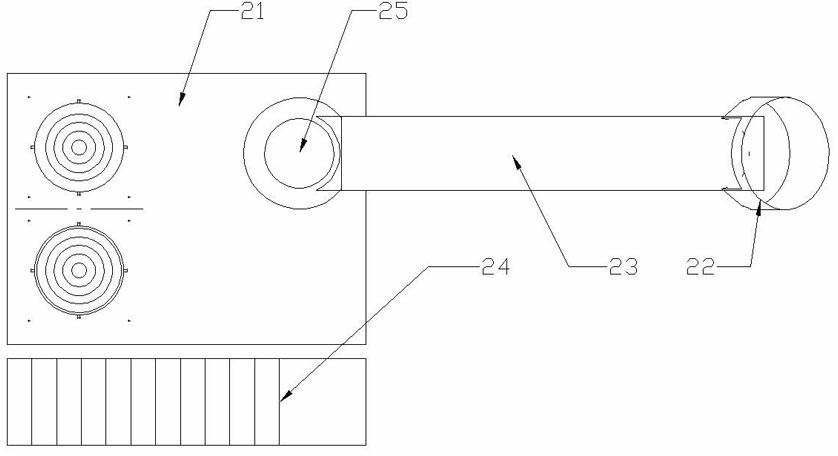

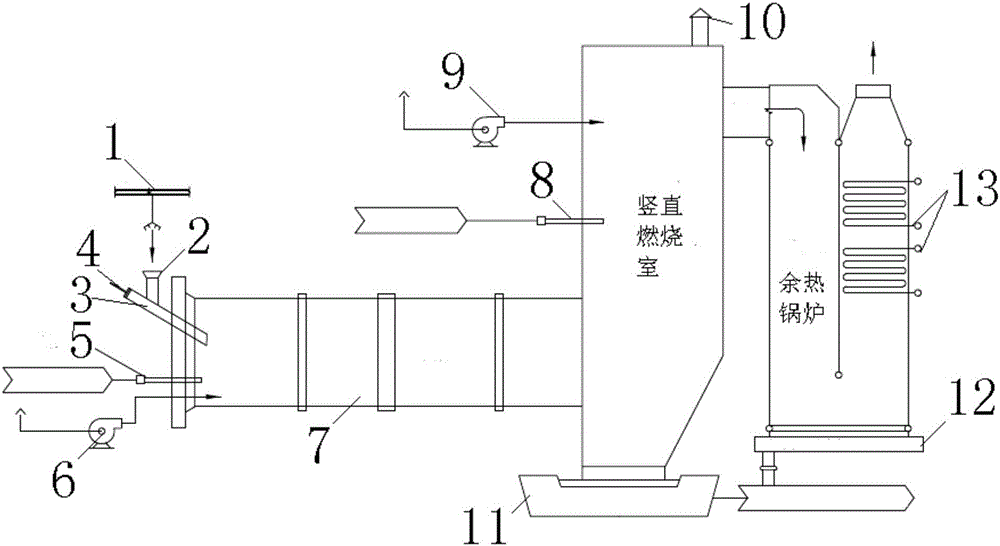

Oil sludge incineration boiler

The invention discloses an oil sludge incineration boiler comprising a combustion chamber and also comprising a top feeding mechanism and a waste heat boiler; the combustion chamber comprises a horizontally-arranged rotary kiln and a vertical combustion chamber; the top feeding mechanism is arranged at one end of the rotary kiln; the other end of the rotary kiln communicates with the lower part of the vertical combustion chamber; the top of the vertical combustion chamber communicates with the waste heat boiler; the top feeding mechanism comprises an inclined feeding pipe communicating with the rotary kiln; the inclined feeding pipe is connected with a vertical feeding hopper; and the outer end of the inclined feeding pipe is correspondingly provided with a rod pusher. The oil sludge incineration boiler is reasonable in structural design; rapid feeding can be realized due to the coordination of the inclined feeding pipe and the rod pusher; harmful substances in oil sludge are removed almost, so that environment hazards are reduced; and the oil sludge incineration boiler is good in waste volume reduction effect, relatively safe in treatment, efficient in oil sludge treatment and low in cost.

Owner:ANHUI JINDING BOILER

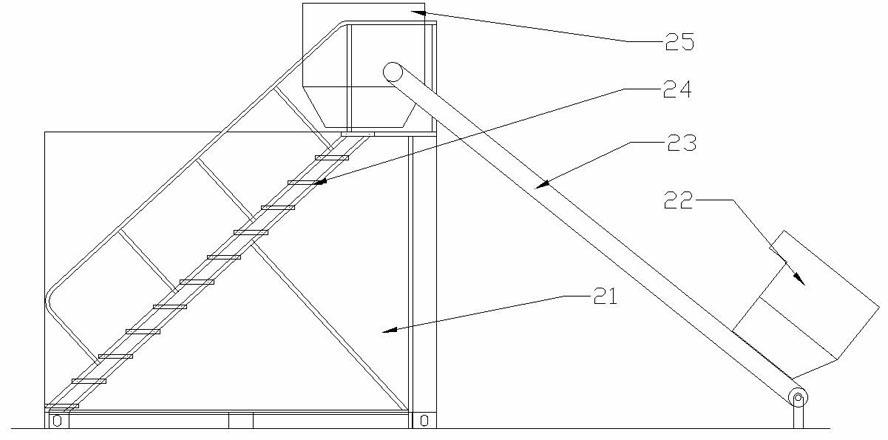

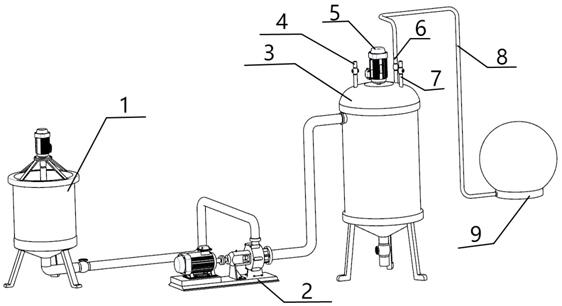

System and method for processing PVA product in nuclear power station

InactiveCN108806815AReduce accumulationReduce the number of disposalsRadioactive decontaminationNuclear powerSmall footprint

The invention discloses a system and method for processing a PVA product in a nuclear power station, wherein the system comprises a dissolving tank, a filter, a thermal oxidizer and a quenching tank;the dissolving tank is provided with a PVA product feeding port, a dissolving water inlet and a chemicals feeding port; the solution outlet of the dissolving tank is connected with the filter inlet through a first connecting pipe, a branch is arranged on the first connecting pipe and forms a first connecting point with the connecting pipe, a first reversing valve is arranged at the first connecting point, a first cooler is arranged on the branch, the outlet of the first cooler is connected with one inlet of the dissolving tank; the filter filtrate outlet is connected with the inlet of the thermal oxidizer through a second connecting pipe, the outlet of the thermal oxidizer is connected with the inlet of the quenching tank, and a gas outlet and a liquid outlet are arranged on the quenchingtank. By using the system and method for processing the PVA product, solid radioactive waste accumulation in the nuclear power plant can be effectively reduced, the method has the advantages of simpleprocess and equipment, small occupied area, convenient operation and wide application prospect.

Owner:北京中安吉泰科技有限公司

Oily silt honeycomb briquet

InactiveCN101280238AGood volume reduction effectReduce pollutionSolid fuelsWaste based fuelCombustionSulfur

The invention provides oil sediment honeycomb briquette which is part by weight composed of 45% of oil sediment, 20% of forming material, 20% of combustion support material, 5% of sulfur fixative material and 10% of crude oil absorption material, and is prepared through the steps of grinding, stirring, formation, discharge and drying; the oil sediment honeycomb briquette has the advantages of simple operation, low cost, convenient application, good waste volume reduction effect, safe treatment, reducing the pollution of the environment and saving the energy through recovery utilization.

Owner:李新

Method and device for stabilizing heavy metals in sludge by electrically promoting enhanced anaerobic fermentation

ActiveCN111762986AHigh activityWell formedSludge treatment by de-watering/drying/thickeningWater contaminantsPulsed DCHumin

The invention discloses a method and device for stabilizing heavy metals in sludge by electrically promoting enhanced anaerobic fermentation. According to the method and device for stabilizing heavy metals in the sludge by electrically promoting enhanced anaerobic fermentation, magnetized water, humus, nano-iron and acclimated microbial liquid are stirred and uniformly mixed with municipal dewatered sludge treated by an A2 / O process in an adjusting tank, the water content and pH of the sludge are adjusted, and the uniformly mixed sludge slurry is conveyed to a fermentation tank through a pump;a positive electrode and a negative electrode are arranged in the sludge of the fermentation tank, pulse direct current is introduced into the positive electrode in the fermentation tank in a mannerof continuously applying an electric field; the sludge is subjected to medium-temperature anaerobic fermentation, biogas is collected, heavy metal stabilization is achieved; in the fermentation process, fermentation liquor is periodically discharged, exchangeable heavy metal is discharged from the bottom along with the fermentation liquor, the separation of the heavy metal and the sludge is achieved, and meanwhile the purpose of sludge reduction is achieved. The method increases the contents of heavy metal organic states and residue states in the sludge and has high stabilization efficiency and good stabilization effect; the separation of solid, liquid and gas in a sludge fermentation process is realized, and the biogas generation efficiency is high.

Owner:KUNMING UNIV OF SCI & TECH

Three-waste integrated reactor and method for treating nitrite gas

PendingCN109974009AAvoid cloggingEffective destruction and decompositionIncinerator apparatusGratingCombustion chamber

The invention provides a three-waste integrated reactor. The three-waste integrated reactor and method for treating nitrite gas is vertically arranged and comprises a first combustion chamber arrangedat the top, the first combustion chamber is provided with a primary air inlet which is formed in the tangential direction and is used for spraying mixed air of waste solid and primary fuel gas into the first combustion chamber; the reactor further comprises a second combustion chamber, the second combustion chamber is provided with a secondary air inlet which is tangential to the second combustion chamber and is used for spraying mixed air of waste solid and secondary fuel gas into the second combustion chamber; a waste liquid filling port is formed in the second combustion chamber and is used for filling waste liquid into the second combustion chamber; a combustion descending channel is formed between the first combustion chamber and the second combustion chamber, and the combustion descending channel protrudes outwards to form a mixing chamber; and a grating tower is arranged at the bottom of the reactor, and a water quenching tank is arranged below the grating tower. According to the three-waste integrated reactor, the blockage of the dangerous waste incineration device can be effectively avoided, and meanwhile, the nitrite gas generated in the adipic acid production process can be sufficiently recovered.

Owner:北京科太亚洲生态科技股份有限公司

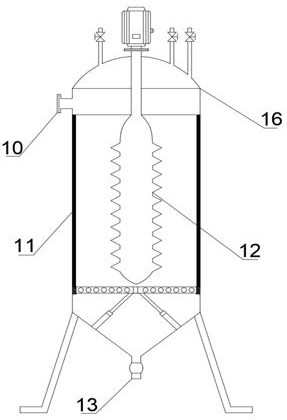

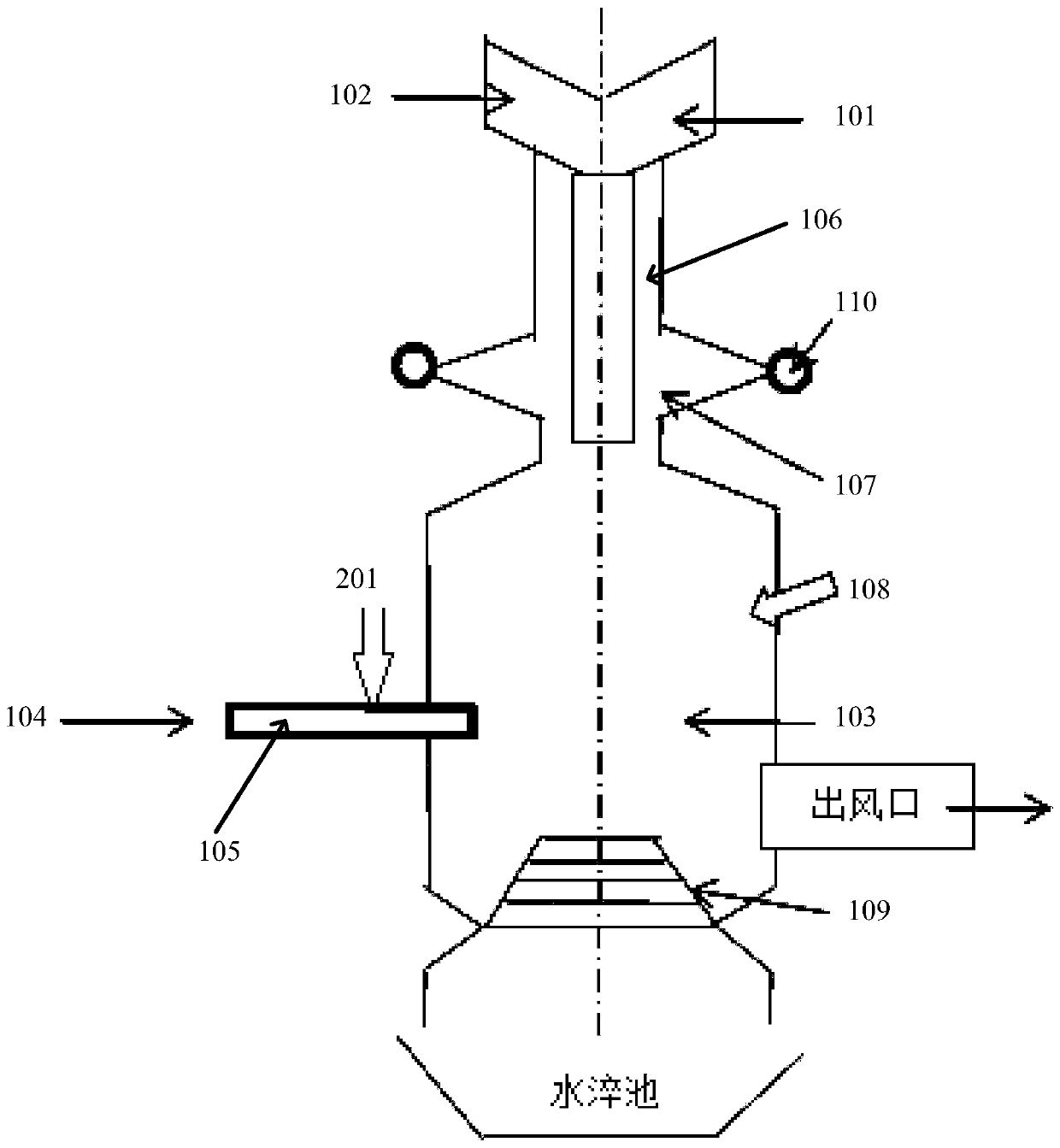

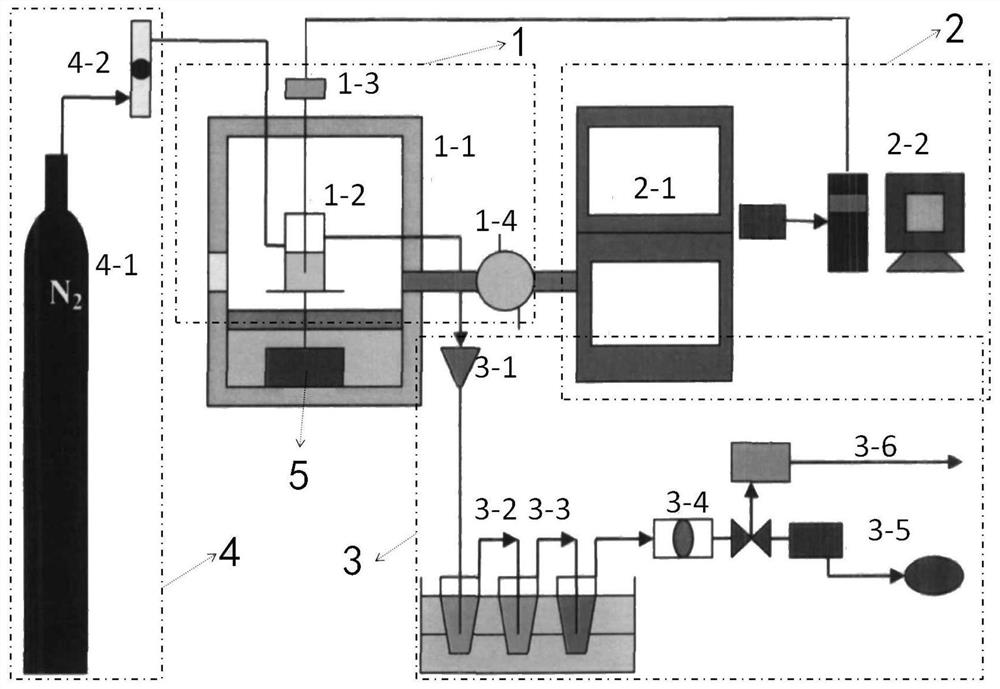

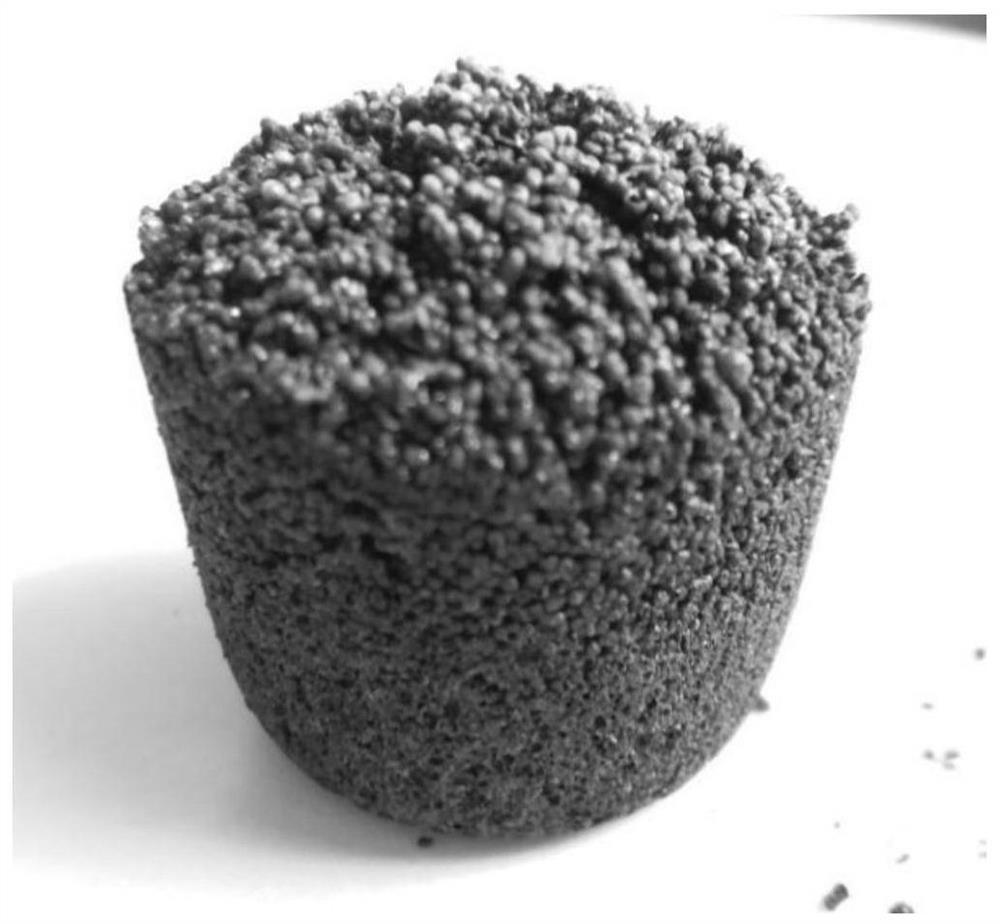

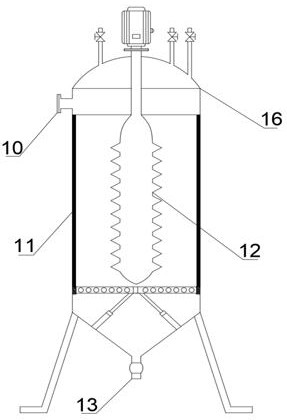

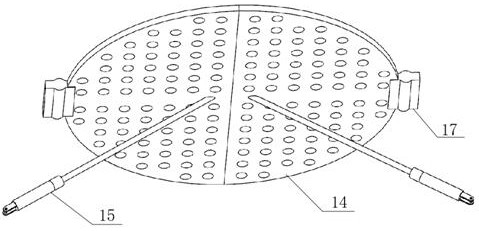

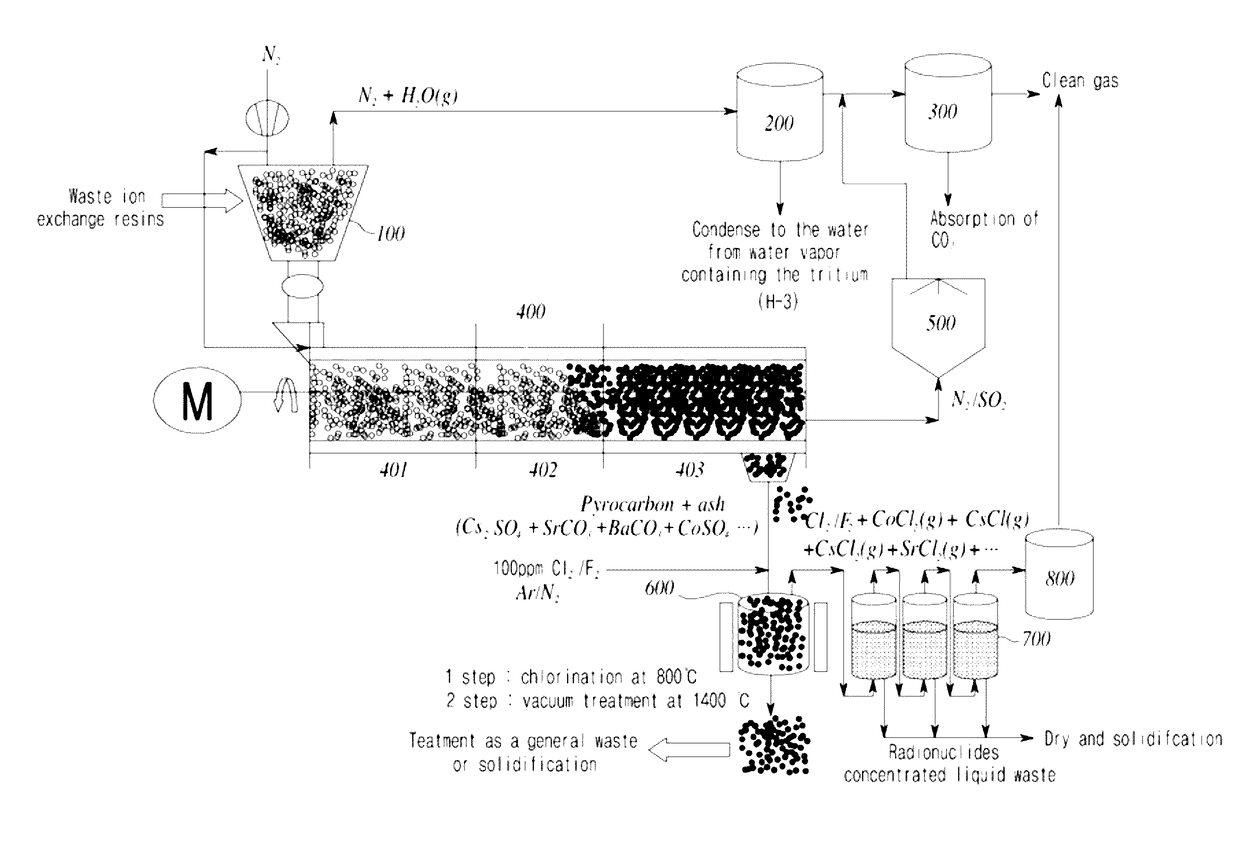

Thermal cracking treatment device and method for radioactive waste resin

ActiveCN111849529ACracking is effectiveWill not polluteProductsReagentsNitrogen gasHeating efficiency

The invention provides a thermal cracking treatment device and method for radioactive waste resin, and belongs to the technical field of nuclear industry. The thermal cracking treatment device comprises a microwave resonance and heating system 1, a microwave generation and control system 2, a thermal cracking gas treatment system 3, a nitrogen input system 4 and a residual carbon collection cavity5. According to the method, the radioactive waste resin is heated through microwaves, the method has the advantages of being safe, clean and efficient, dehydration and thermal cracking of the radioactive waste resin can be achieved within a short time, on one hand, organic matters in the resin are cracked into gases, the size of the waste resin is greatly reduced, and radionuclide is enriched inresidual carbon; on the other hand, the residual carbon obtained after resin pyrolysis is a microwave absorbing material, and the heating efficiency in the microwave pyrolysis process can be effectively improved. According to the present invention, the thermal cracking gas treatment system 3 can treat the gas generated by thermal cracking so as to avoid the emission of radionuclide-containing solid particles and harmful gases.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Process for treating oil field produced water

ActiveCN102153221BEasy to handleHigh degreasing efficiency at one timeWater/sewage treatment with mechanical oscillationsMultistage water/sewage treatmentFiltrationOil field

The invention belongs to a process for treating oil field produced water and belongs to the field of oil field produced water treatment, in particular relates to the process for treating the oil field produced water. In the process, at least a regulating water tank, an air flotation device, a pipeline mixer, a nitrogen power reactor, a sedimentation tank and an ultrasonic filter are adopted and the oil field produced water is treated by adopting a mode of combining air flotation oil and suspended matter removal, nitrogen preparation and ultrasonic filtration. The process for treating the oil field produced water has good treatment effect, high oil removing efficiency, corrosion resistance and low cost and has good effect in the actual application.

Owner:XIAN CHANGQING TECH ENG

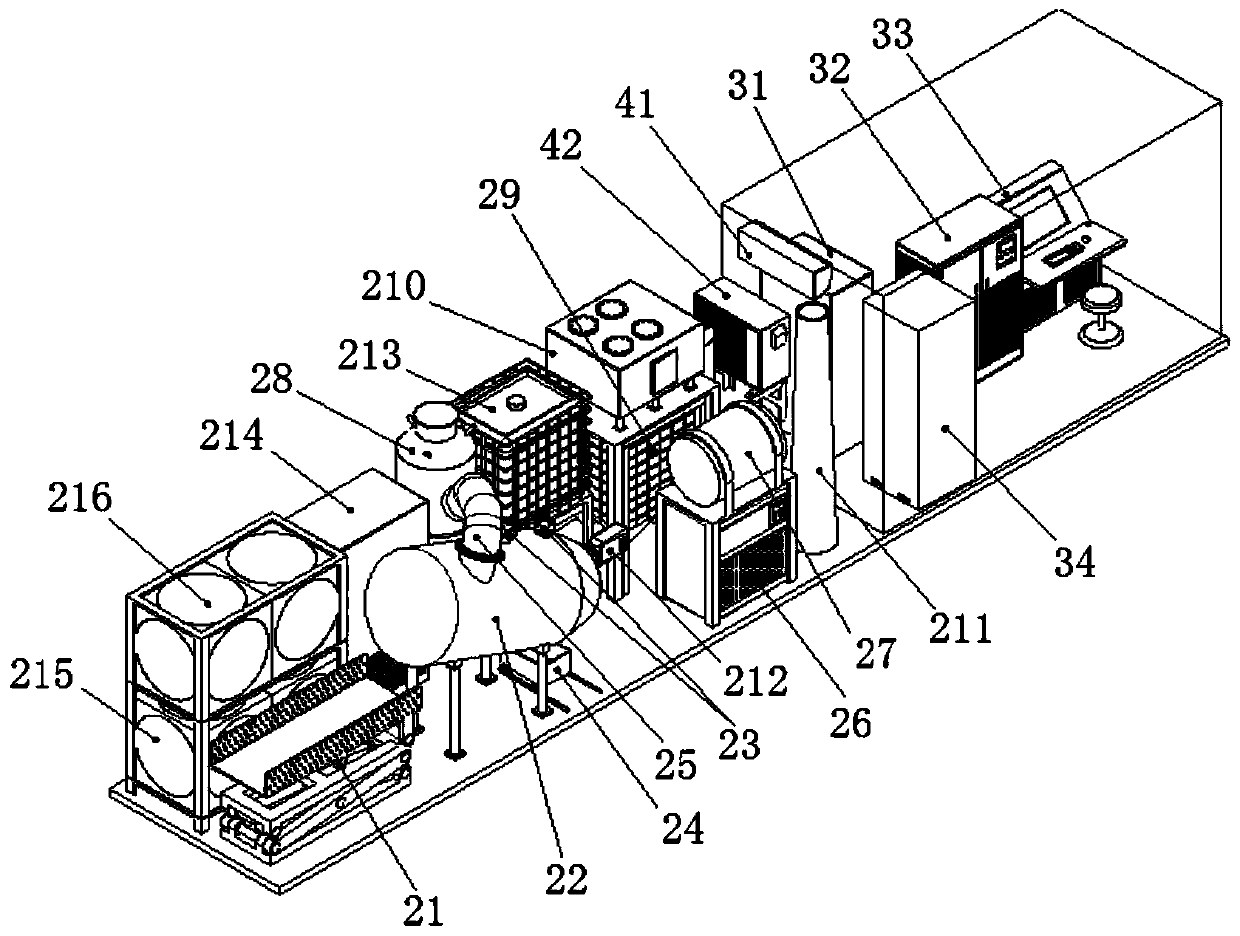

High-temperature plasma organism disposal shelter and disposal method

PendingCN111536521AIncrease gasification melting rateHigh gasification melting decomposition efficiencyIncinerator apparatusCombustion chamberFlue gas

The invention discloses a high-temperature plasma organism disposal shelter and a disposal method. The shelter comprises a shelter body and a disposal system, wherein a disposal area is arranged in the shelter body, and the disposal system is arranged in the disposal area of the shelter body; and the disposal system comprises a plasma gasification melting furnace, a slag fishing device, a secondary combustion chamber section, a quenching deacidification tower, a dust remover, a hydroxyl generator and a chimney, wherein the plasma gasification melting furnace is used for carrying out gasification decomposition treatment on organisms, the slag fishing device is arranged at a slag discharge port of the plasma gasification melting furnace, and a flue gas outlet of the plasma gasification melting furnace is connected with a flue gas inlet of the secondary combustion chamber section. According to the disposal shelter, gasification decomposition is carried out on the organisms in a high-temperature reducing atmosphere, and dioxin is not generated in the gasification decomposition process; and by arranging the secondary combustion chamber section, the quenching deacidification tower, the dust remover and the hydroxyl generator, deacidification, denitrification and salinity treatment on flue gas generated by gasification and decomposition are achieved, secondary pollution is avoided, complete harmless treatment of organisms is achieved, the volume reduction effect is remarkable, harmless treatment is thorough, and the organic matter burn-down rate is high.

Owner:西安太乙鼎生航天环保科技有限公司

A method and device for stabilizing heavy metals in anaerobic fermentation sludge by electrocatalysis

ActiveCN111762986BImprove stability efficiencyImprove stabilitySludge treatment by de-watering/drying/thickeningWater contaminantsPulsed DCHumin

The invention discloses a method and device for stabilizing heavy metals in electroenhanced anaerobic fermentation sludge. Magnetized water, humus, nano-iron, and domesticated microbial liquid are mixed with A in a regulating tank. 2 The urban dewatered sludge treated by the / O process is stirred and mixed evenly, the water content and pH of the sludge are adjusted, and the mixed sludge slurry is transported to the fermenter by a pump; an anode and a cathode are set in the sludge of the fermenter to Continuously apply an electric field to the anode electrode in the fermenter to feed pulsed direct current, the sludge undergoes mesophilic anaerobic fermentation, collects biogas, and realizes the stabilization of heavy metals. During the fermentation process, the fermented liquid is regularly discharged. The bottom is removed to realize the separation of heavy metals and sludge, and at the same time achieve the purpose of sludge reduction; this method increases the content of heavy metals in the organic state and residue state of the sludge, and has high stabilization efficiency and good stabilization effect; Three-phase separation of solid, liquid and gas, high biogasification efficiency.

Owner:KUNMING UNIV OF SCI & TECH

Glass solidification body of incombustible radioactive waste and synergistic glass solidification method

PendingCN113979642AProcessing is not limitedHigh inclusion rateGlass furnace apparatusGlass shaping apparatusGlass fiberCompressive resistance

The invention relates to a glass solidification body of incombustible radioactive waste and a synergistic glass solidification method. The raw materials of the glass solidified body are derived from non-combustible wastes such as radioactive glass fibers, soil, concrete and the like, and the glass fibers, the soil and the concrete can be arbitrarily combined into two elements and three elements according to actual conditions. A used glass substrate is simple in composition and small in dosage. The glass solidified body obtained through synergistic glass solidification has high chemical stability, the leaching resistance rate, the compressive strength, the impact resistance and the like all meet the geological disposal requirements, the waste containing capacity is high, the obvious volume reduction effect is achieved, and the follow-up landfill cost can be reduced.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

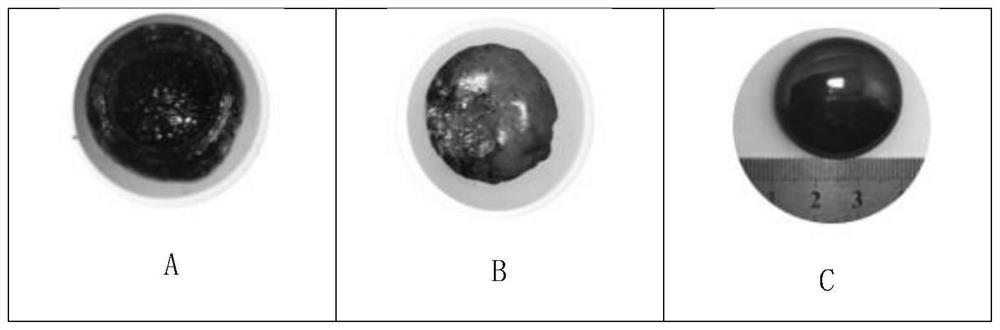

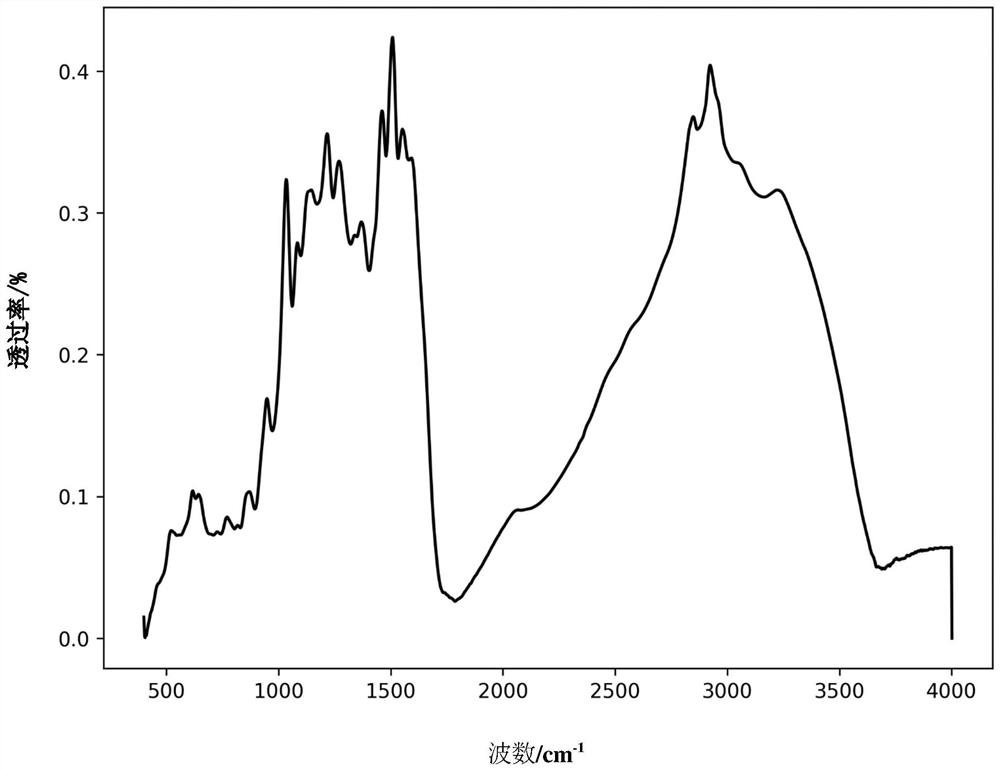

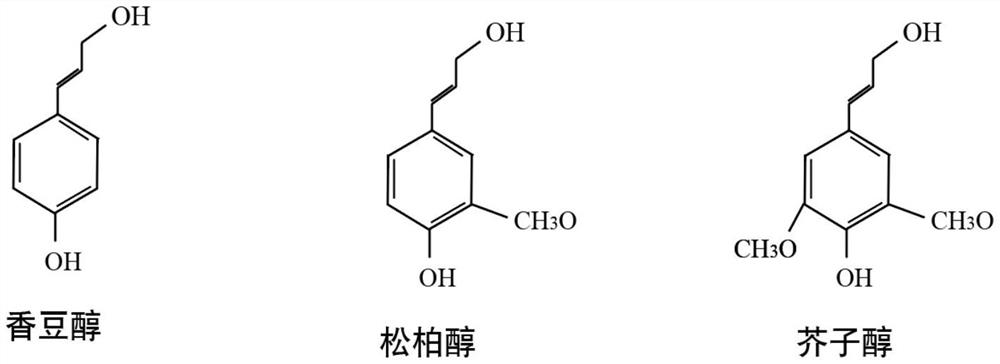

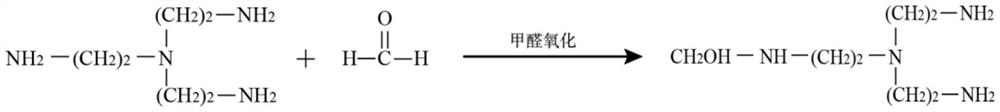

Lignin-based triaminotriethylamine salt waste incineration fly ash heavy metal stabilizer and preparation method and application thereof

PendingCN111635538ALower synthesis costHigh molecular weightChemical protectionMannich reactionEnvironmental engineering

The invention discloses a lignin-based triaminotriethylamine salt waste incineration fly ash heavy metal stabilizer and a preparation method and application thereof, and belongs to the technical fieldof environmental protection technologies and municipal solid waste incineration fly ash treatment. The relative molecular weight of the stabilizer is 3000-20000, and the stabilizer is specifically lignin-based triaminotriethylamine sodium salt or lignin-based triamino triethylamine potassium salt. The method comprises the following steps: firstly, carrying out oxidative degradation on alkaline lignin, exposing a reaction site, carrying out a Mannich reaction on an oxidized aminating agent and the lignin, inoculating amido to the lignin, wherein a condensation reaction increases the molecularweight and enlarges the chelate ring, and introducing C=S double bonds through an esterifying agent to obtain the lignin-based triaminotriethylamine derivative. The method can effectively reduce the leaching concentration of heavy metals such as Pb and Cd in the fly ash, promotes the conversion of the heavy metals into a form with low biotoxicity, is low in energy consumption, high in heavy metalstabilization efficiency and good in volume reduction effect, and is suitable for industrial application of harmless treatment on municipal solid waste incineration fly ash.

Owner:POWERCHINA HEBEI ELECTRIC POWER SURVEY & DESIGN INST CO LTD +1

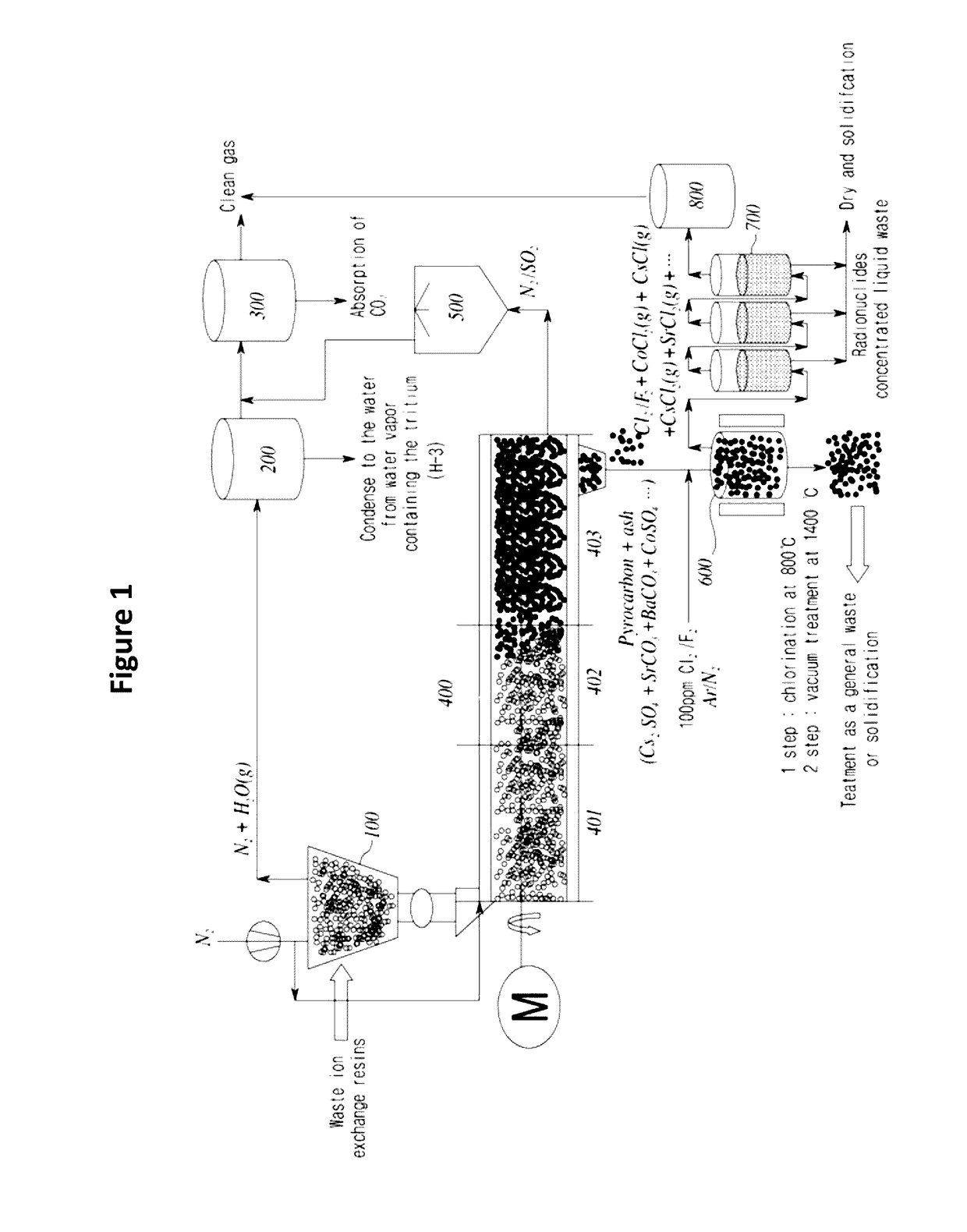

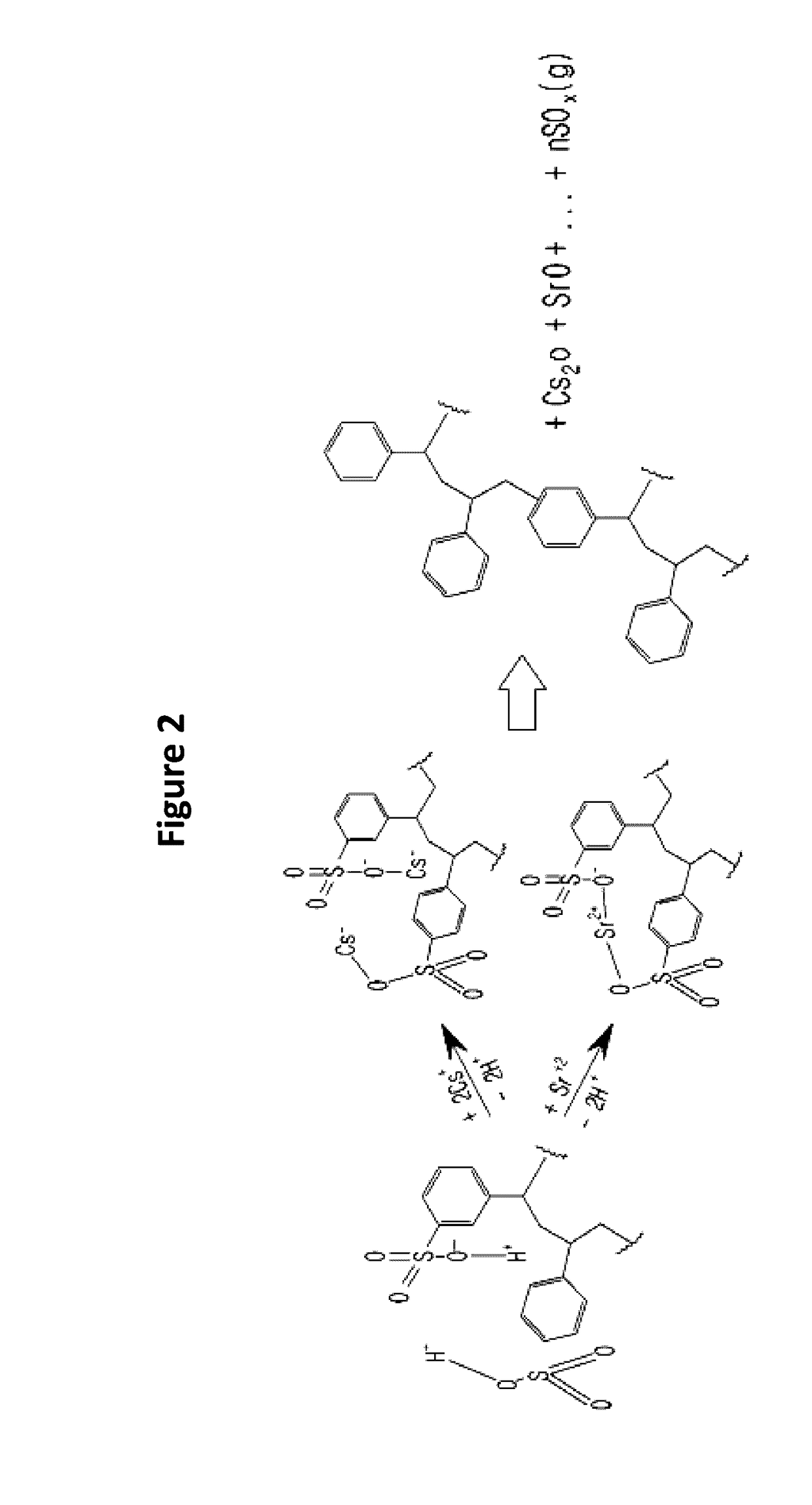

Method for treatment of spent radioactive ion exchange resins, and the apparatus thereof

ActiveUS20170148535A1Good volume reduction effectWater/sewage treatment by ion-exchangeRadioactive contaminantsIon exchangeIon-exchange resin

Owner:KOREA ATOMIC ENERGY RES INST

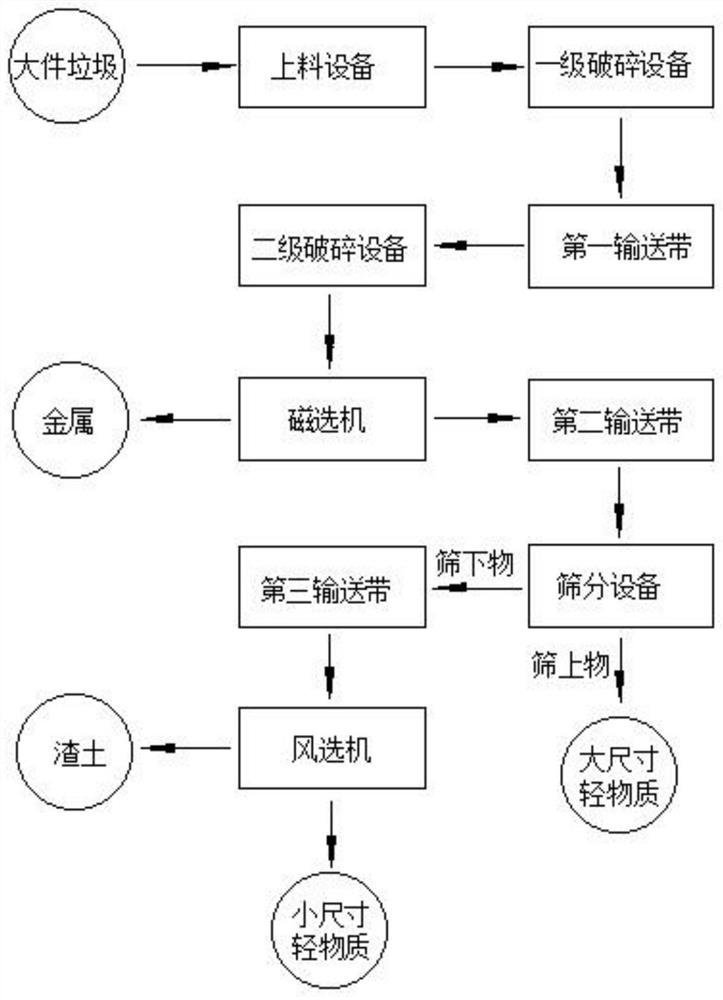

Automatic crushing and separating treatment device and process method for large garbage

PendingCN111632729ASmall sizeGood volume reduction effectMagnetic separationGrain treatmentsMagnetic separatorBulky waste

The invention discloses an automatic crushing and separating treatment device and process method for large garbage. The automatic crushing and separating treatment device comprises a feeding device, aprimary crushing device, a secondary crushing device, a magnetic separator, screening device and a winnowing machine, wherein the feeding device is used for receiving put materials and conveying thematerials; the primary crushing device is used for primarily crushing the materials; the secondary crushing device is used for finely crushing the materials; the magnetic separator is used for separating out metal materials; the screening device is used for separating large-size light substances; and the winnowing machine is used for separating small-size light substances. According to the automatic crushing and separating treatment device and process method for the large garbage, the large garbage can be efficiently and safely converted into metal products, large-size light material productsand small-size light material products, sorting is efficient, and the cost performance is excellent.

Owner:江苏隽诺环保工程技术有限公司

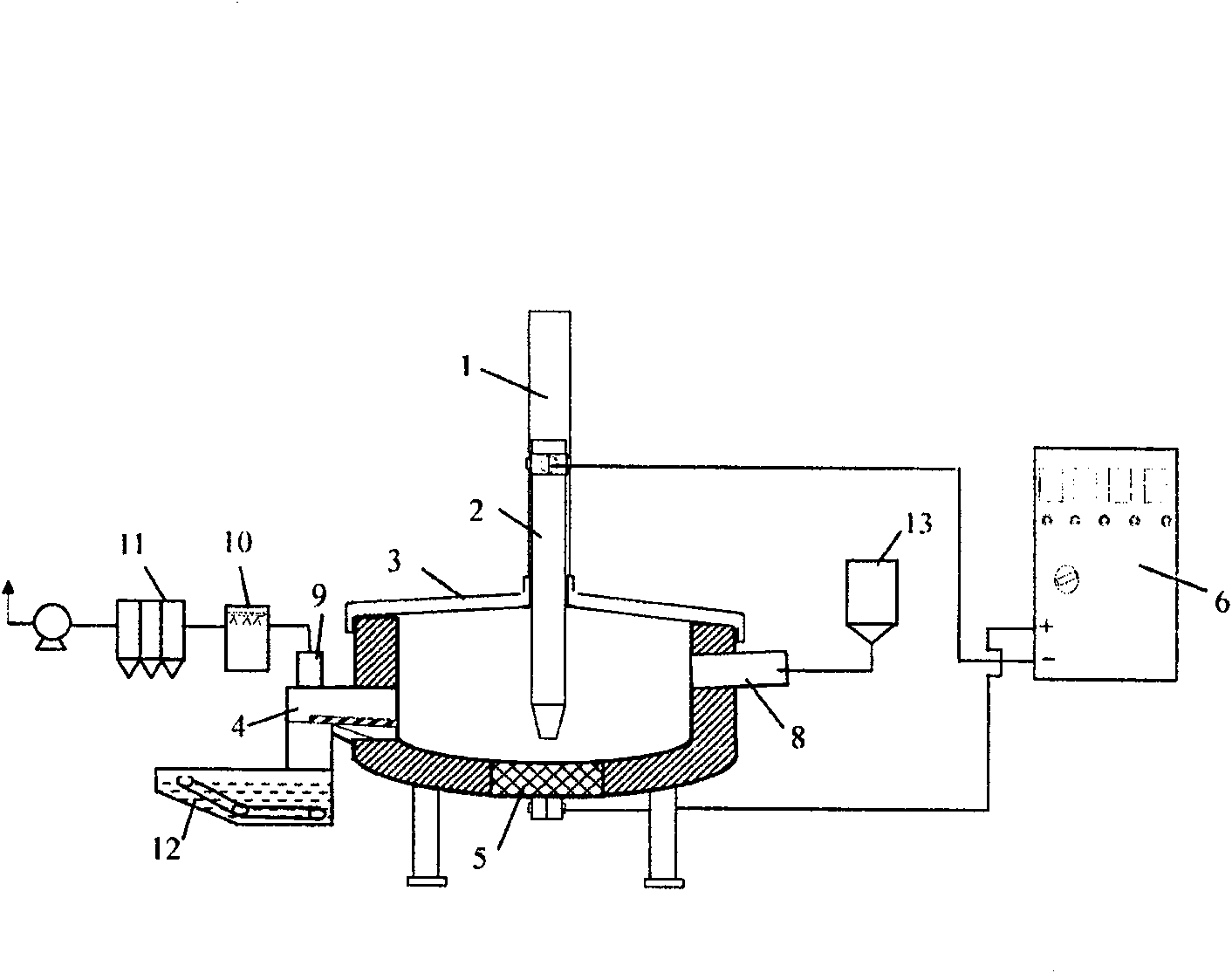

Electric arc molten processing system and method for processing rubbish combustion ash

InactiveCN100552296CIncrease temperatureLarge electrothermal conversion abilityIncinerator apparatusElectric arc furnaceCombustion

The present invention relates to an electric arc molten processing system and method for processing rubbish combustion ash, which includes: a feeding system, a fume emission control system, a slag cold system and an arc furnace. The arc furnace structure is as follows: a furnace body as the melten pool; a water cooled cover covering on the furnace body; a bracket arranged on the water cooled cover; a top electrode in the bracket, whose discharge end passes through the water cooled cover into the inside of the furnace body; a bottom electrode in the bottom of the furnace body corresponding to the discharge end of the top electrode, respectively connecting to the output electrode of the power with the top electrode; a feed port disposed on one side of the furnace body; a slag eye arranged on the bottom of the furnace body; an exhaust port mounted on the furnace body. The processing method is: 1. a material processing procedure; 2. a loading procedure; 3. an electric arc molten procedure; 4. an exhaust purification processing procedure; 5. slag cooling procedure. The invention reduces the molten markedly to decompose the dioxin in the ash and melt the heavy metal in the slag. The generated slag can be recycled directly and reduce the environmental pollution.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com