System and method for processing PVA product in nuclear power station

A processing system and technology for nuclear power plants, applied in the field of PVA product processing systems in nuclear power plants, can solve the problems of backward processing methods and unsatisfactory volume reduction effect, and achieve the effect of reducing the amount of accumulation and disposal, obvious volume reduction effect and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

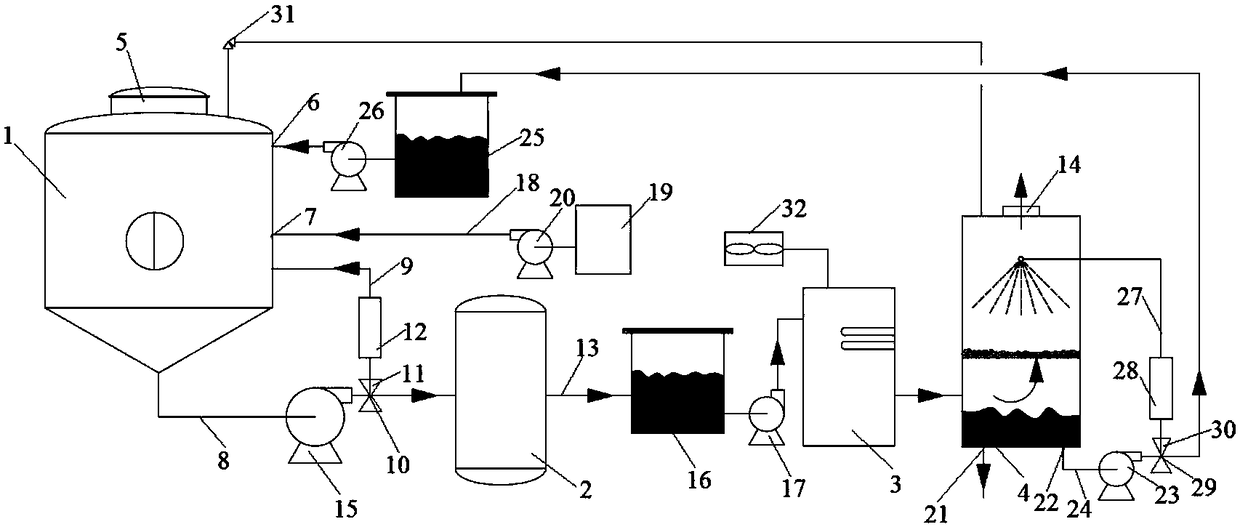

[0043] Embodiment 1 A kind of nuclear power plant PVA product processing system

[0044] A nuclear power plant PVA product processing system, which: includes a dissolution tank 1, a filter 2, a thermal oxidizer 3 and a quenching tank 4;

[0045]The dissolving 1 is provided with a PVA product input port 5, a dissolved water inlet 6 and a chemical addition port 7;

[0046] The outlet of the solution of the dissolution tank 1 is connected to the inlet of the filter 2 through the first connecting pipe 8. There is a branch 9 on the first connecting pipe 8 and forms a first junction 10 with the branch 9. At the first junction A first reversing valve 11 is provided at 10, a first cooler 12 is provided on the branch 9, and the outlet of the first cooler 12 is connected to an inlet of the dissolution tank 1;

[0047] The filtrate outlet of the filter 2 is connected with the inlet of the thermal oxidizer 3 through the second connecting pipe 13, and the outlet of the thermal oxidizer 3 ...

Embodiment 2

[0059] Embodiment 2 A kind of nuclear power plant PVA product processing method

[0060] The present invention further provides a method for processing PVA products in nuclear power plants, comprising the steps of:

[0061] (1) Dissolving and cooling: Put the PVA protective clothing into the dissolving tank 1, start the solution delivery pump 26 to transport water from the solution tank 25 to the dissolving tank 1, and the dissolving tank 1 is equipped with a level detection system, and the output is equivalent to that of the PLC system Then, when the predetermined liquid level is reached, stop adding liquid. After the water in the dissolving tank 1 is heated to 110° C., the PVA product can be completely dissolved into about 8% PVA solution. During the dissolving process, the continuous operation of the first delivery pump 15 ensures that the mixture is evenly mixed. Once the PVA material dissolves completely, start the metering pump 20, from the chemical storage tank 19, qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com