Patents

Literature

271results about How to "High oil removal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

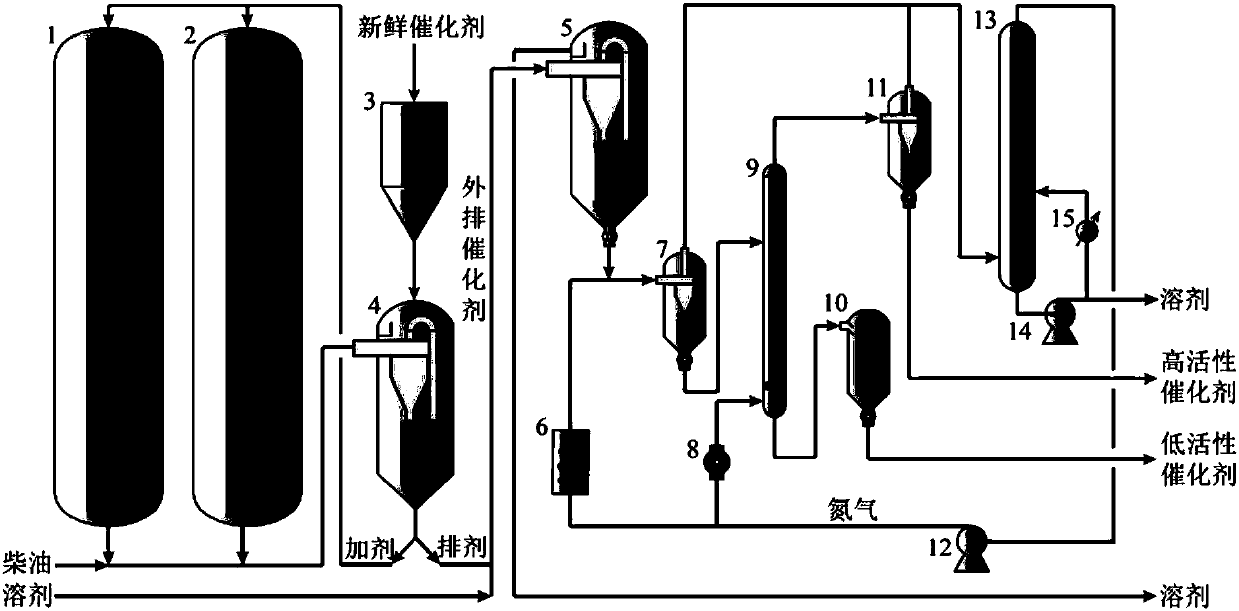

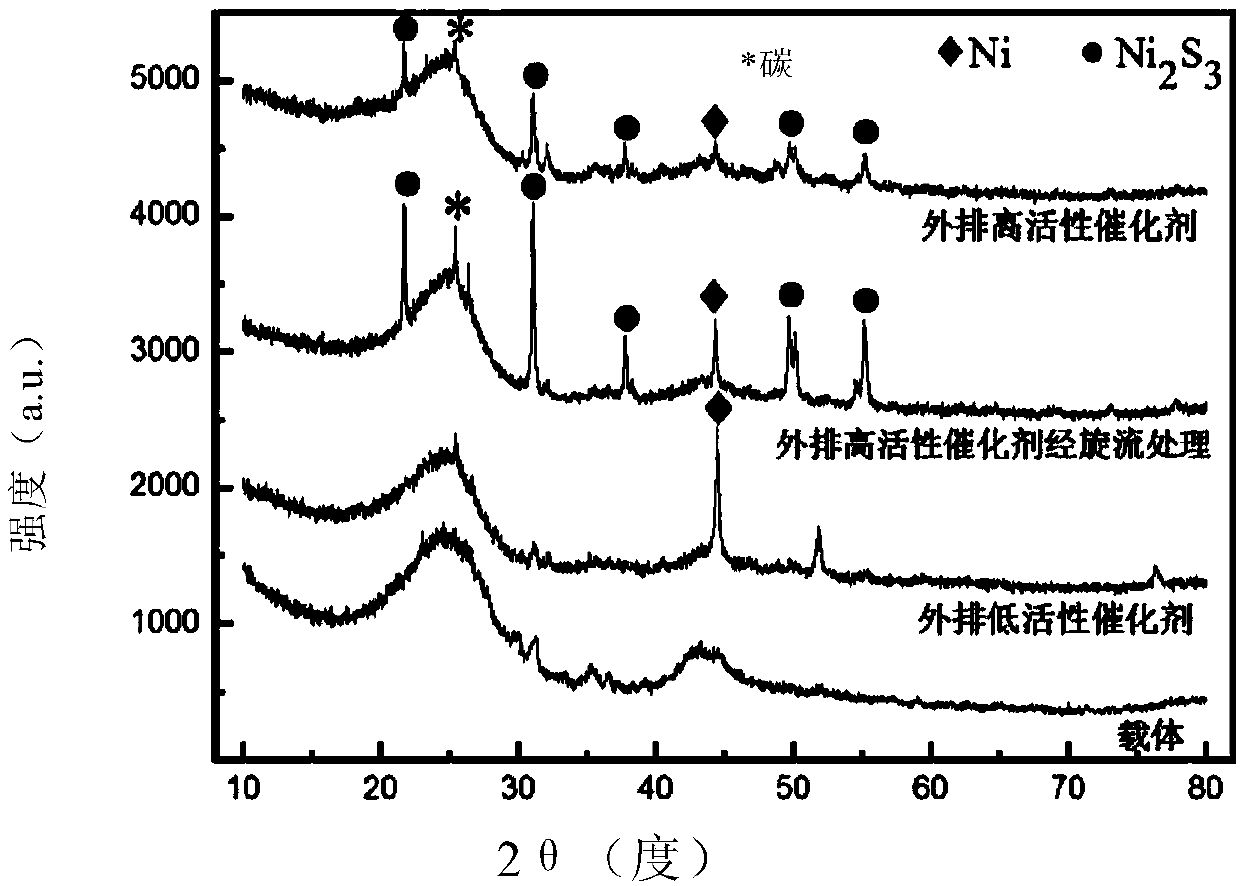

Method and apparatus for treating, sorting and recycling oil-containing discharged catalyst

ActiveCN107597201AHigh oil removal efficiencyIncrease update rateCatalytic crackingDispersed particle separationEngineeringProduct gas

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION +1

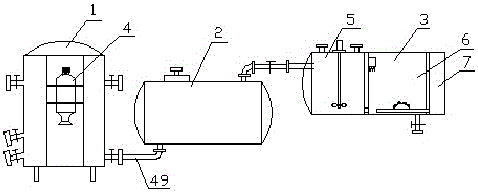

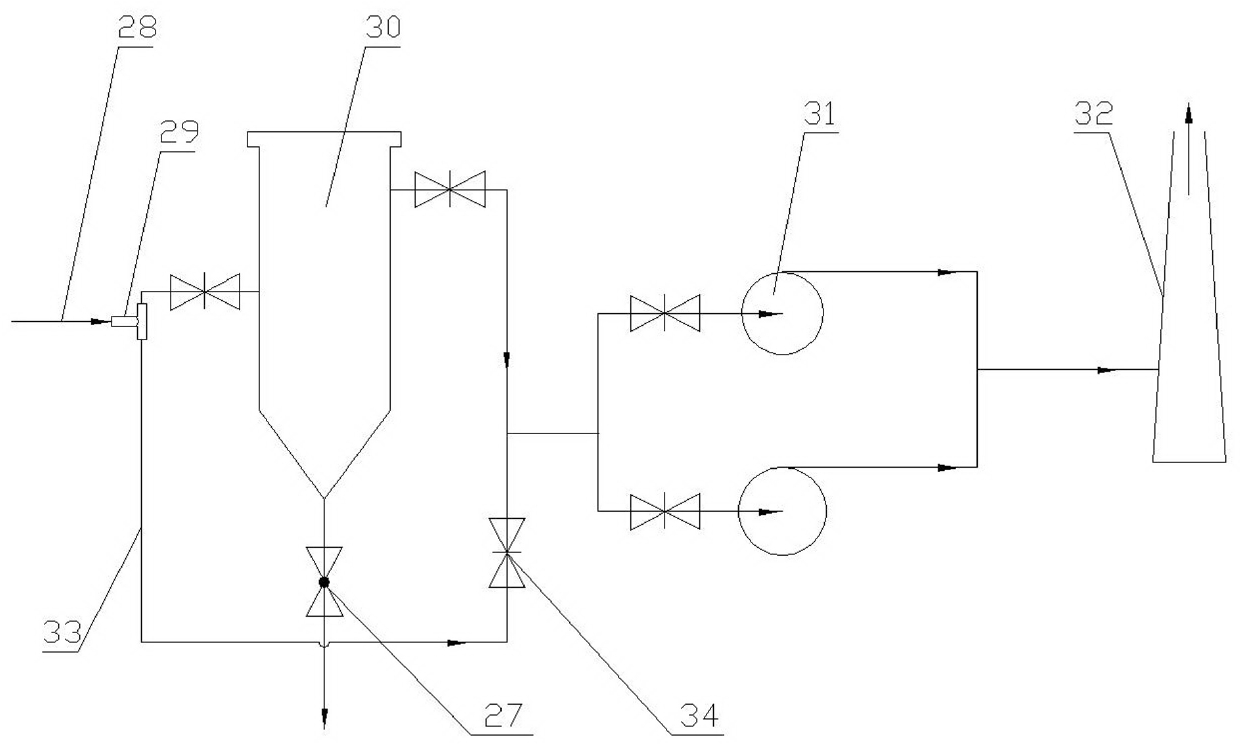

Oil removing pretreatment technology for petroleum oil refining wastewater

ActiveCN106007209AStructural scienceSimple processFatty/oily/floating substances removal devicesTreatment involving filtrationCycloneWater based

The invention discloses an oil removing pretreatment technology for petroleum oil refining wastewater. According to the oil removing pretreatment technology, a water collecting tank with gratings is used for separating sand and sludge; a three-phase cyclone liquid separation floating oil collecting and discharging adjusting tank is used for achieving separation of water, oil and residues; a cyclone oil coarse graining polymerization oil-water separator is used for removing fine oil grains; a dissolved air flotation device is used for demulsification and flocculation reaction, wherein air bubbles and suspended solids in wastewater make contact for adhesion and float upwards, and the standard is met through residue scraping. The technology is simple, the structure is scientific, the three-phase cyclone liquid separation floating oil collecting and discharging adjusting tank, the cyclone liquid coarse graining polymerization oil-water separator and the dissolved air flotation device jointly serve as the core treatment scheme, oily wastewater is pretreated through the density difference of oil and water based on the fluid dynamics principle, a physical method and a chemical method act jointly, and the oil content in the pretreated oily wastewater is smaller than or equal to 20 mg / L and reaches the standard. The oil removing pretreatment technology is large in daily treatment amount, high in oil removing efficiency, remarkable in oil collecting effect and considerable in economic benefit, and the water content of the recycled waste oil is 5% or lower.

Owner:江苏中嘉华新环保科技有限公司

Composite flocculation oil removal agent for treatment of oil-containing sewage

InactiveCN105314716AReduce dosageHigh oil removal efficiencyWater/sewage treatment by flocculation/precipitationFlocculationSodium Bentonite

A composite flocculation oil removal agent for treatment of oil-containing sewage is prepared by compounding the following components, by weight, 50-90% of aluminum sulfate, 5-20% of magnesium chloride, 4-20% of magnesium hydroxide, 0.5-5% of bentonite and 0.5-5% of polyacrylamide, wherein all the components are crushed and mixed together at normal temperature.

Owner:蒋寿悟

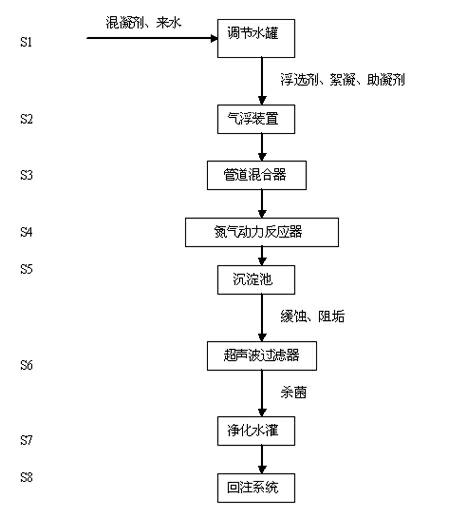

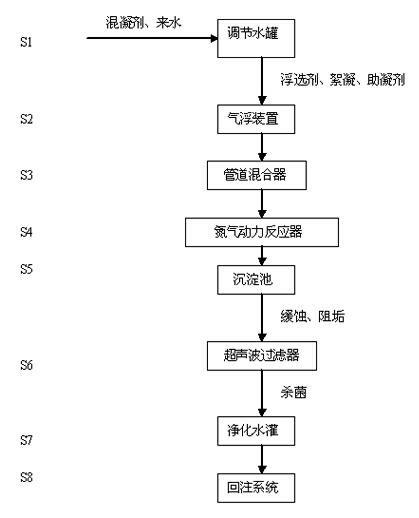

Process for treating oil field produced water

ActiveCN102153221AEasy to handleHigh degreasing efficiency at one timeWater/sewage treatment with mechanical oscillationsMultistage water/sewage treatmentFiltrationNitrogen

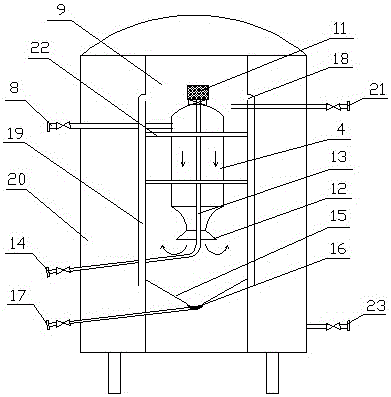

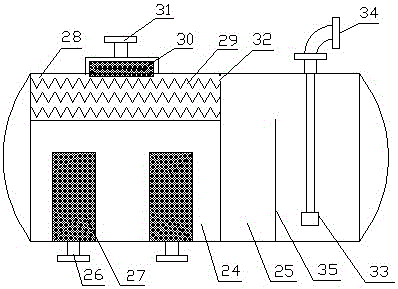

The invention belongs to a process for treating oil field produced water and belongs to the field of oil field produced water treatment, in particular relates to the process for treating the oil field produced water. In the process, at least a regulating water tank, an air flotation device, a pipeline mixer, a nitrogen power reactor, a sedimentation tank and an ultrasonic filter are adopted and the oil field produced water is treated by adopting a mode of combining air flotation oil and suspended matter removal, nitrogen preparation and ultrasonic filtration. The process for treating the oil field produced water has good treatment effect, high oil removing efficiency, corrosion resistance and low cost and has good effect in the actual application.

Owner:XIAN CHANGQING TECH ENG

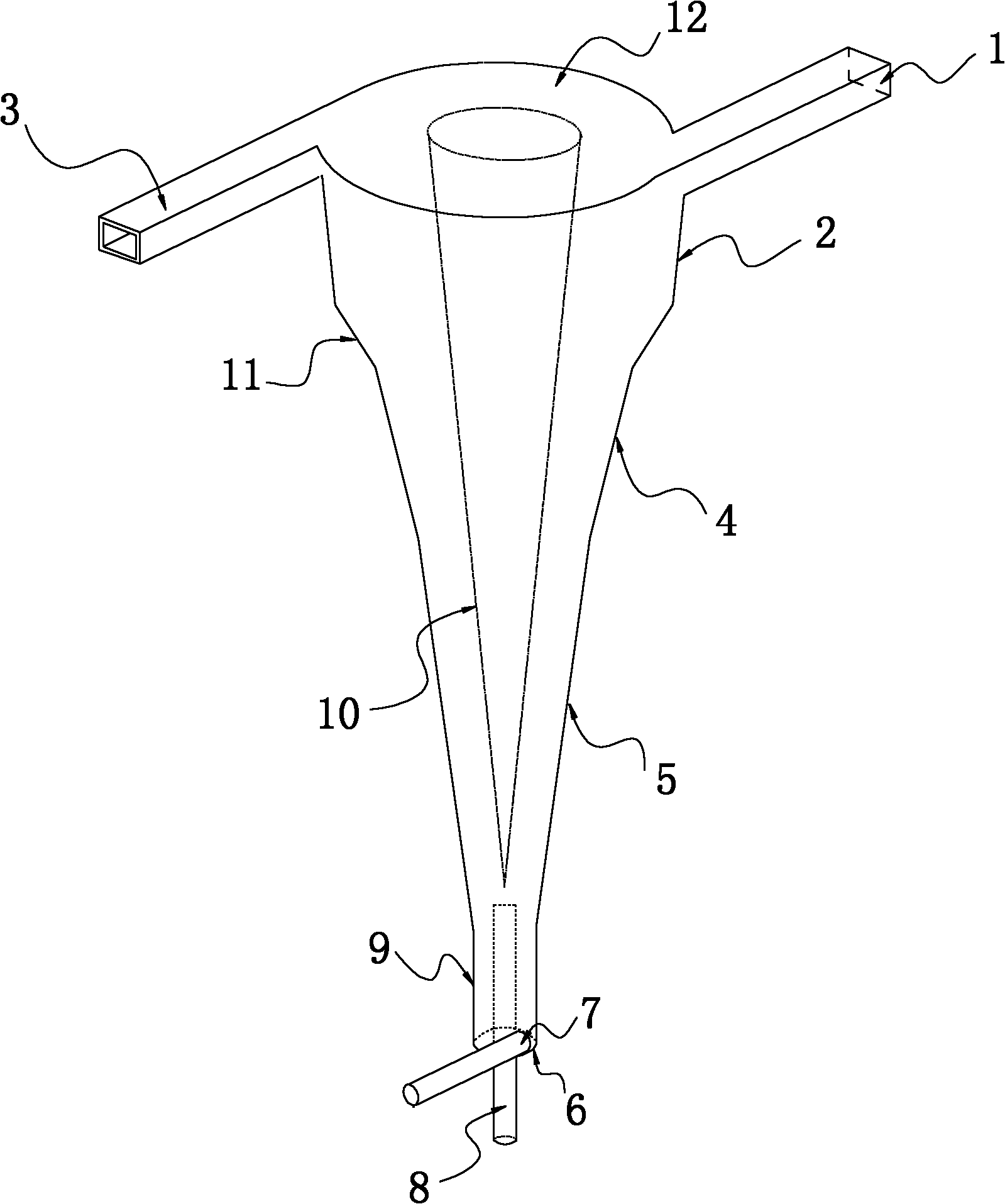

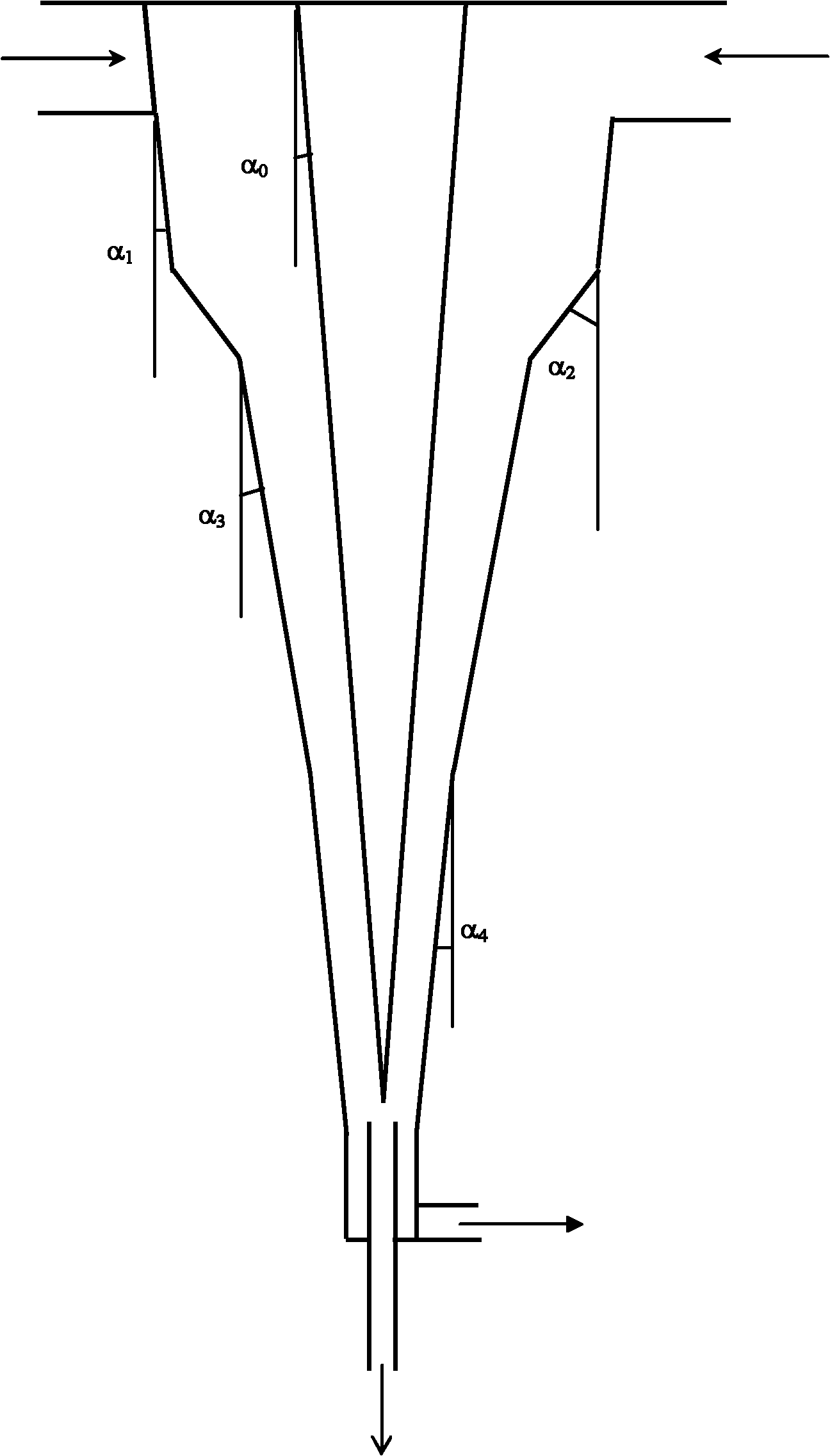

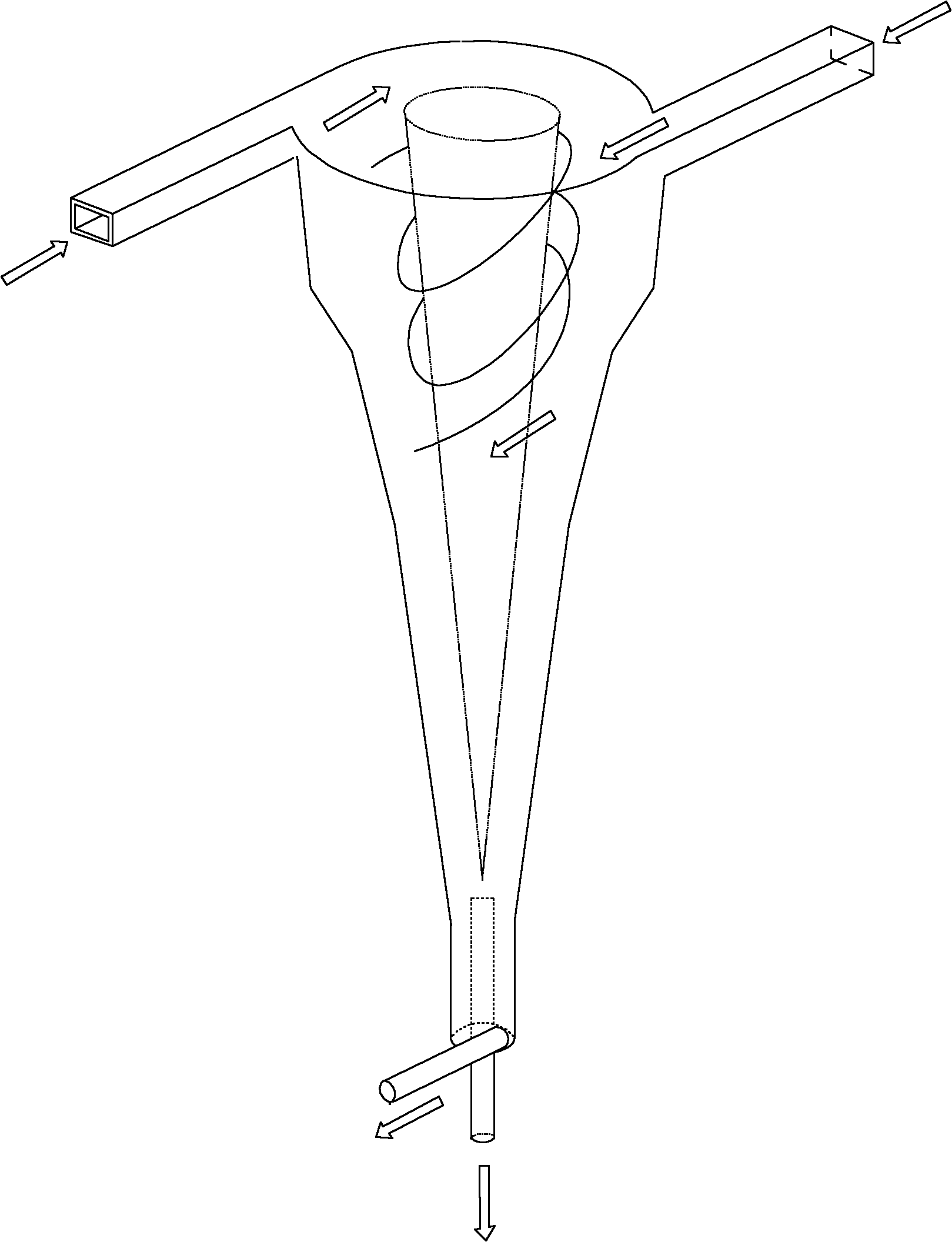

Equidirectional drainage reverse taper type high-efficiency rotational flow separator

InactiveCN101983779AReduce volumeSmall footprintReversed direction vortexPetroleum engineeringHydrocyclone

The invention relates to an equidirectional drainage reverse taper type high-efficiency rotational flow separator, which mainly solves the problems of poor separation effect of tiny oil drops, large volume and inconvenient installation of the traditional hydraulic cyclone separator. The invention is mainly characterized in that a rotational flow cavity section, a large taper section, a small taper section, a tail pipe section and an outlet section are successively distributed between upper and lower sealing faces; the components form a rotational flow cavity body gradually converged towards the central axis after being successively connected; a tapered thimble in the rotational flow cavity body is fixed on inner side surface of the upper sealing face; the taper top of the tapered thimble points to one side of the lower sealing face; an oil outlet pipe is vertically and fixedly connected to the lower sealing face through the center of the lower sealing face; the pipe orifice of the oil outlet pipe is positioned on the lower part of the taper top of the tapered thimble; and a water outlet pipe is horizontally connected to the bottom end of the outlet section along the tangential direction of a cycle. The rotational flow separator has the characteristics of good elimination effect on the tiny oil drops. Compared with the traditional hydraulic rotational flow separator, the rotational flow separator has the advantages of stable flow field and high separation efficiency, and is convenient for technological installation.

Owner:NORTHEAST GASOLINEEUM UNIV

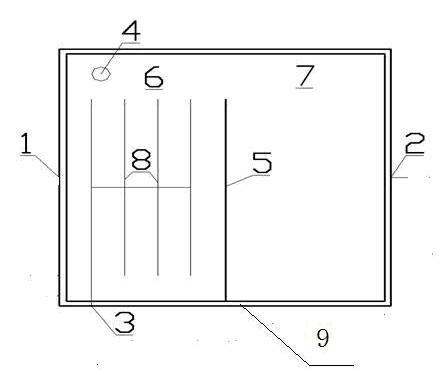

Gas-oil-water three-phase separator

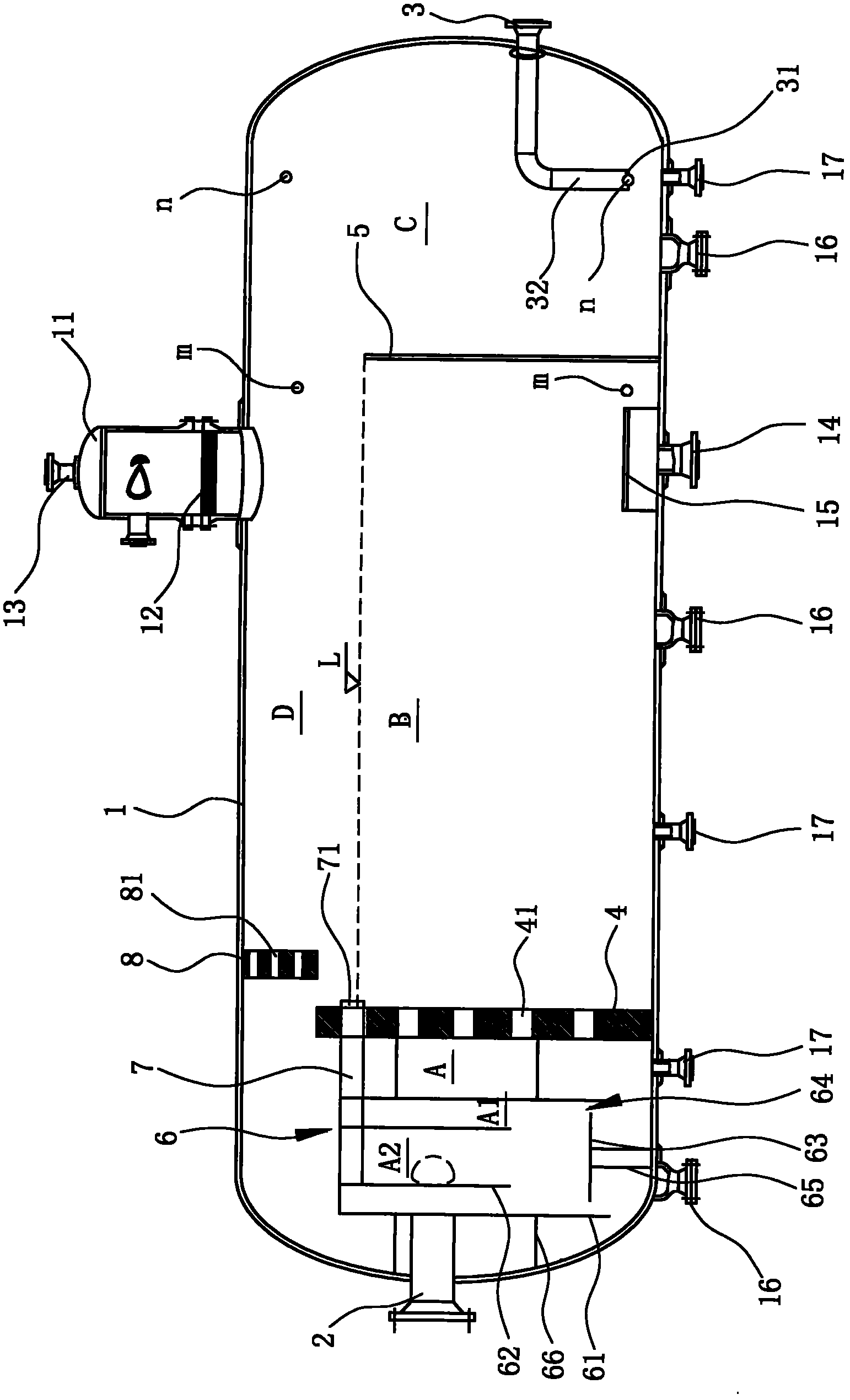

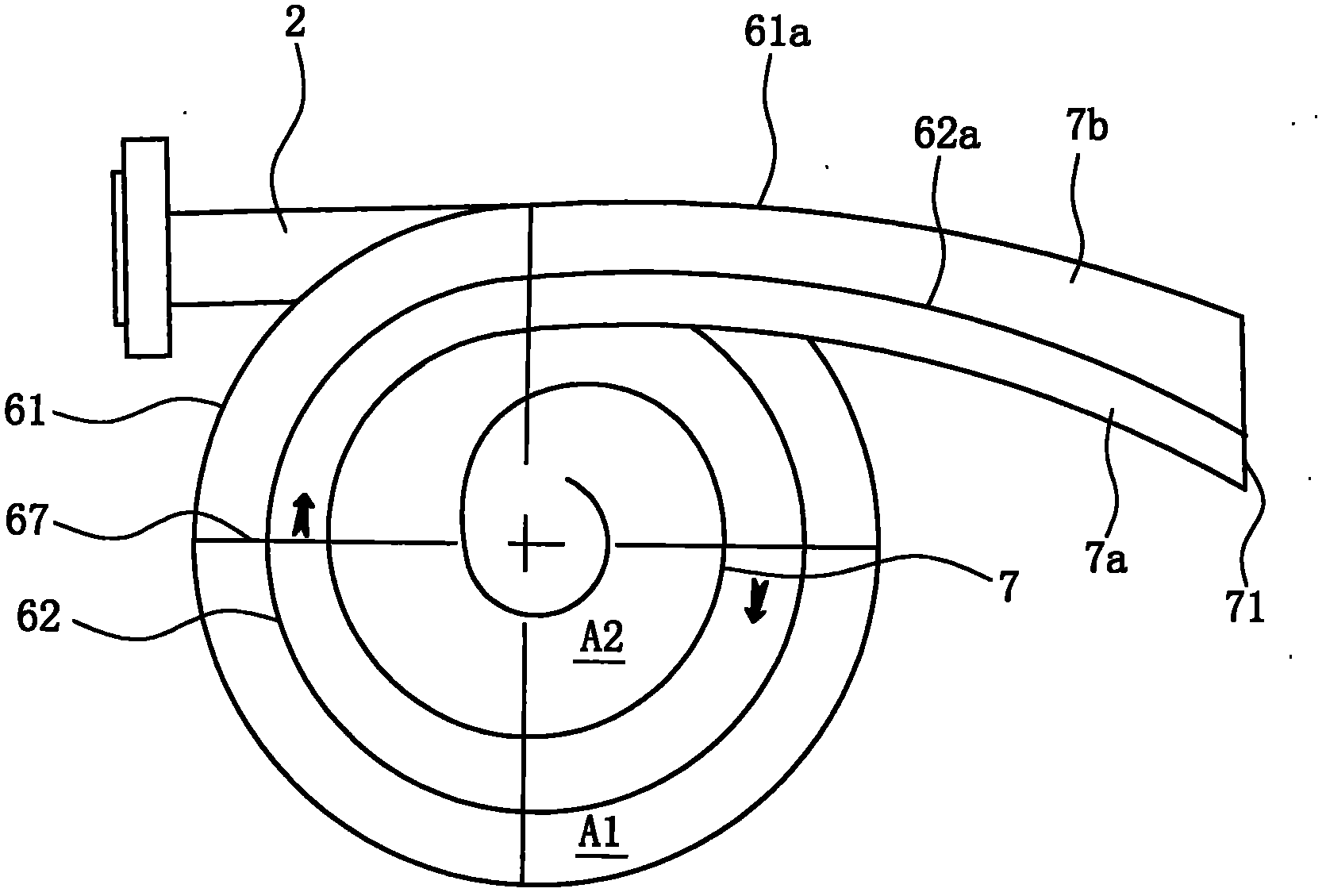

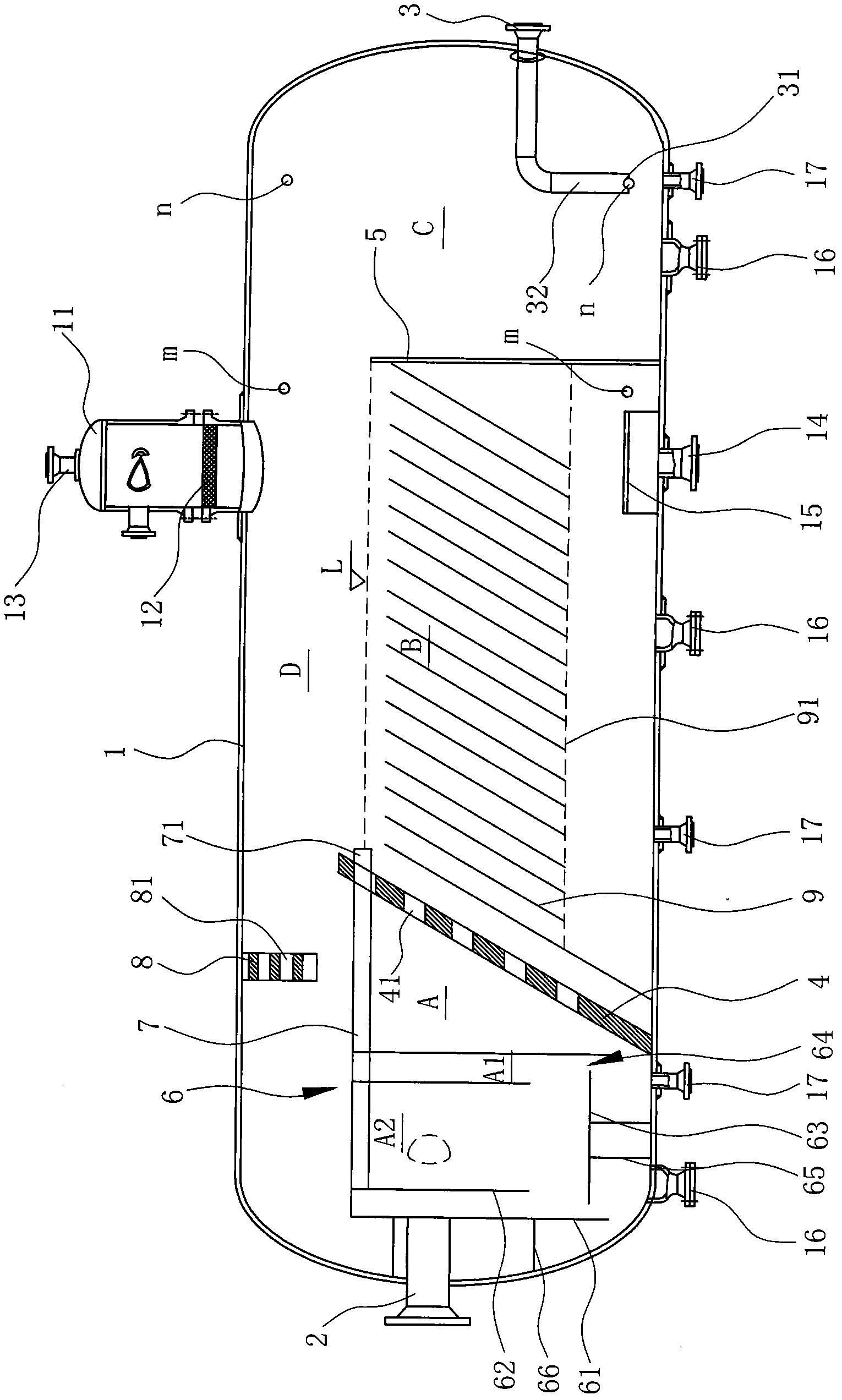

ActiveCN102120103ALabor-saving maintenance workConvenient inspection and maintenance workLiquid degasificationLiquid separationCycloneDraining tube

The invention discloses a gas-oil-water three-phase separator which comprises a horizontal tank body (1) and a crude oil input tube (2), wherein a liquid steady flow plate (4) and a baffle (5) are sequentially erected in the tank body (1) from left to right so as to sequentially divide the interior of the tank body (1) into a separating area (A), a liquid collecting area (B) and an oil collectingarea (C); a gas collecting area (D) is arranged above the baffle (5); the bottom of the tank body (1) is provided with a drain tube (14), the top of the tank body (1) is provided with a convex gas collecting bag (11), and the right side end of the tank body (1) is provided with an oil drain tube (3); moreover, a sleeve-type cyclone separator (6) is arranged in the separating area (A) and comprises an outer sleeve (61) and an inner sleeve (62) which are concentrically arranged and parallel and level at the top; a gas-liquid separating area (A1) is arranged between the outer sleeve (61) and theinner sleeve (62); and a gas-water mixing area (A2) is arranged in the inner sleeve (62). Compared with the prior art, the gas-oil-water three-phase separator provided by the invention has the advantages that the repair and maintenance are labor-saving and convenient; for the same crude oil throughput, the volume of the horizontal tank body can be reduced, the gas-oil-water separating efficiency is obviously improved, and the separating effect is more ideal.

Owner:浙江海牛海洋工程有限公司

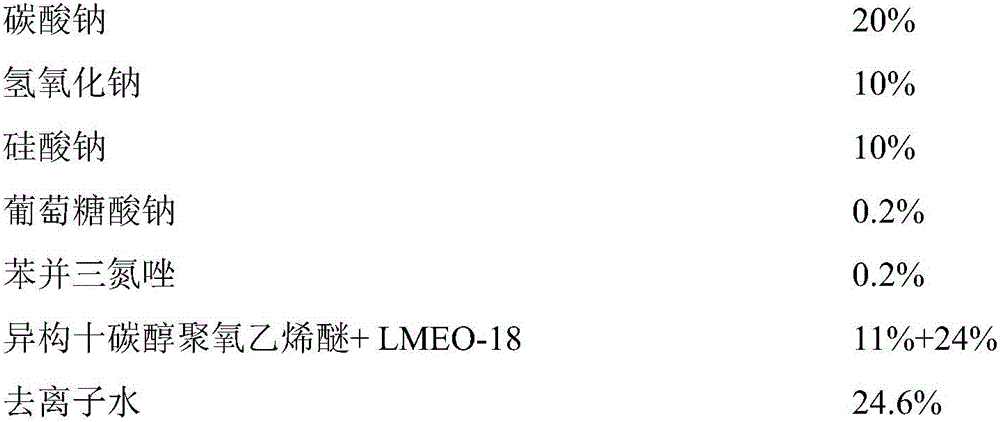

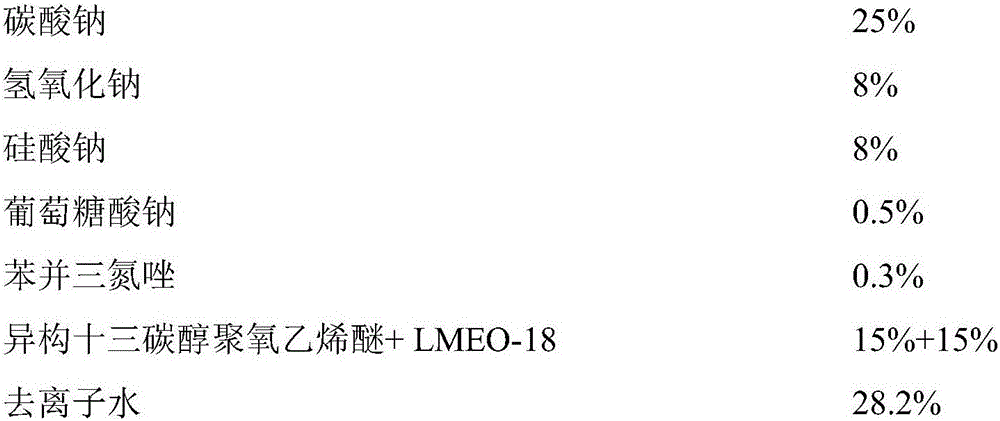

Environmentally friendly industrial heavy oil cleaning agent

The invention discloses an environmentally friendly industrial heavy oil cleaning agent. The environmentally friendly industrial heavy oil cleaning agent mainly comprises the following raw materials of 20-35% of sodium carbonate, 5-10% of sodium hydroxide, 5-10% of sodium silicate, 0.2-1% of sodium gluconate, 0.2-0.5% of benzotriazole, 15-35% of a composite surface active agent and the balance water. The composite surface active agent is at least one of alcohol alkoxylate, LMEO-18 and a low-foam type emulgator. The heavy oil cleaning agent is excellent in cleaning effect, capable of cleaning up heavy oil on various surfaces of machining equipment, machine tools, steel materials and the like, low in use amount and high in oil removal efficiency, and the cleaning rate for oil stains is up to 99% or above.

Owner:GUANGDONG UNIV OF TECH

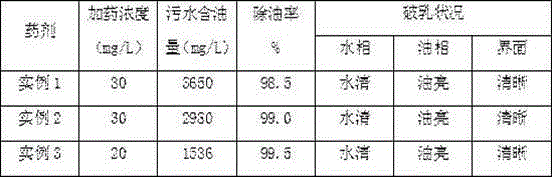

Oil-in-water type emulsion demulsifying agent and preparation method thereof

ActiveCN105384927ANo lumpsFast separationWaste water treatment from quariesFatty/oily/floating substances removal devicesDemulsifierWastewater

The present invention discloses an oil-in-water type emulsion demulsifying agent and a preparation method thereof. Firstly, bisamide is prepared, then chlorinated polyether is prepared, and finally cationic polyether is obtained, namely the oil-in-water emulsion demulsifying agent. The preparation method has readily available raw materials, is simple in operation, and has low equipment requirements. The prepared demulsifying agent is a cationic polymer with a network structure formed by the reaction of bisamide and epichlorohydrin, has a special network structure and a very strong surface activity, has a good demulsification function, is a reverse demulsifying agent suitable for chemical flooding produced liquid, can be used in oilfield produced wastewater treatment, can break the emulsion interfacial energy, and has an oil removal rate of more than 98% in a use amount of 20-30 mg / L. The prepared demulsifying agent is not layered, has no caking and no mechanical impurities, and has characteristics of being fast in oil and water separating speed and being low in oil content of water, and a good demulsifying effect for a three compound combination flooding O / W emulsion and high oil removal efficiency.

Owner:克拉玛依新科澳石油天然气技术股份有限公司

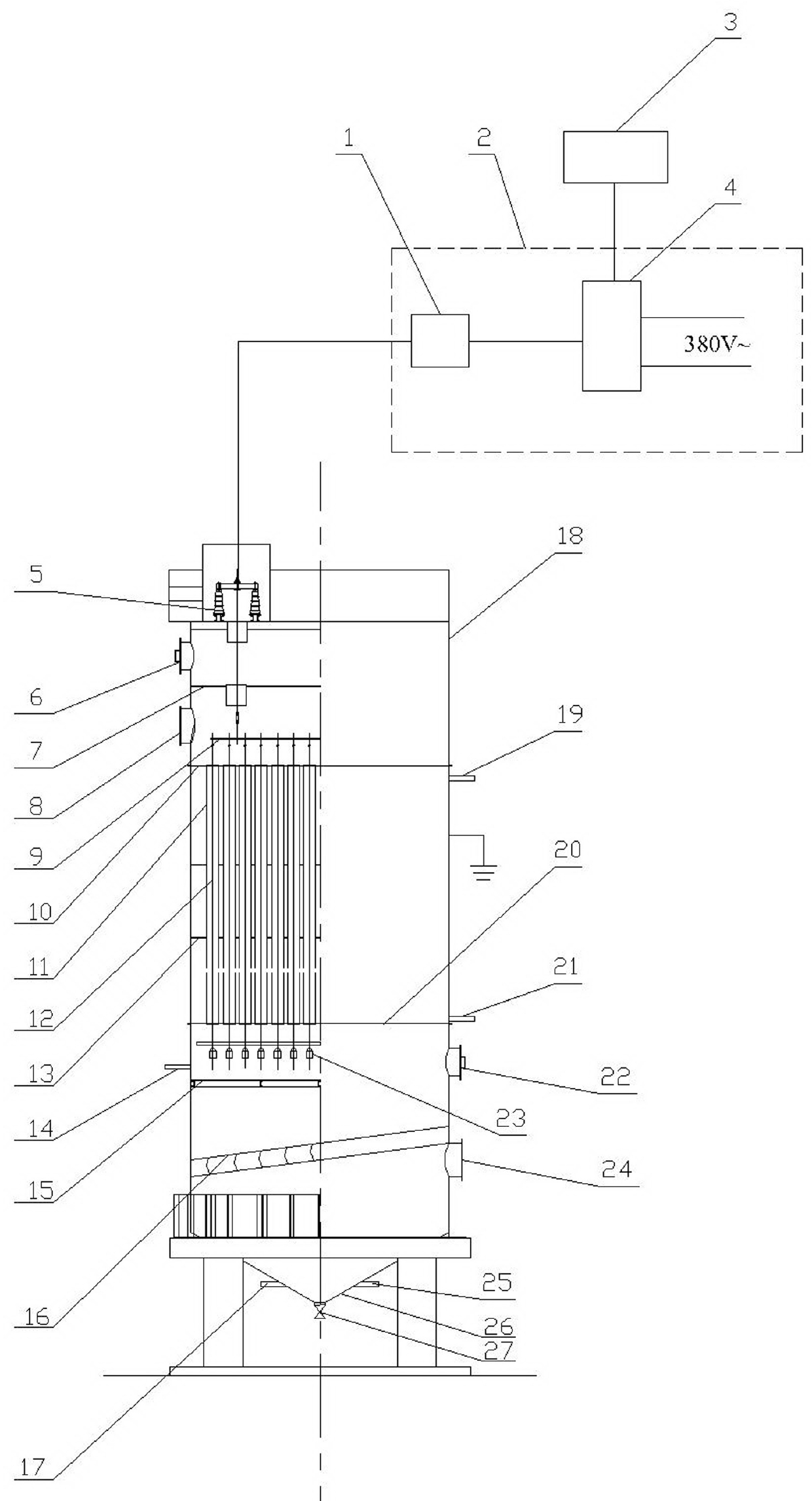

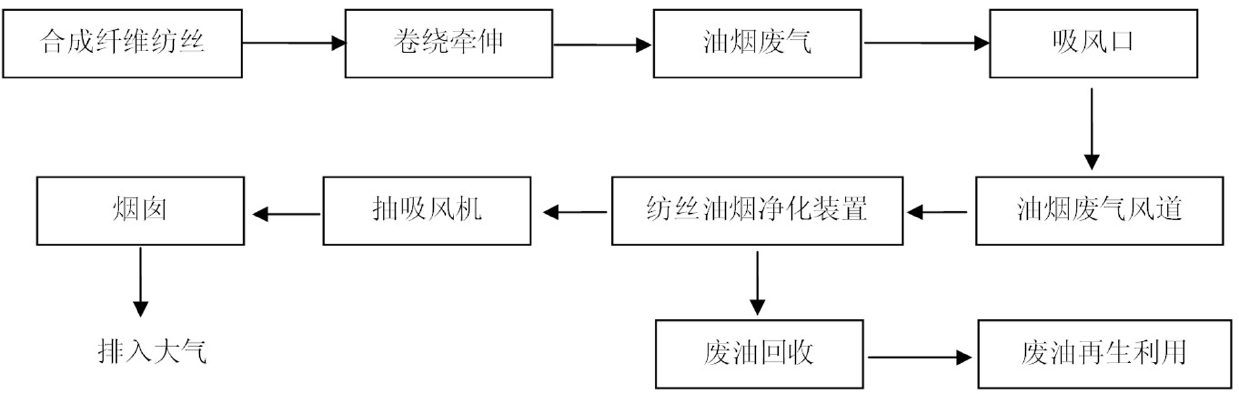

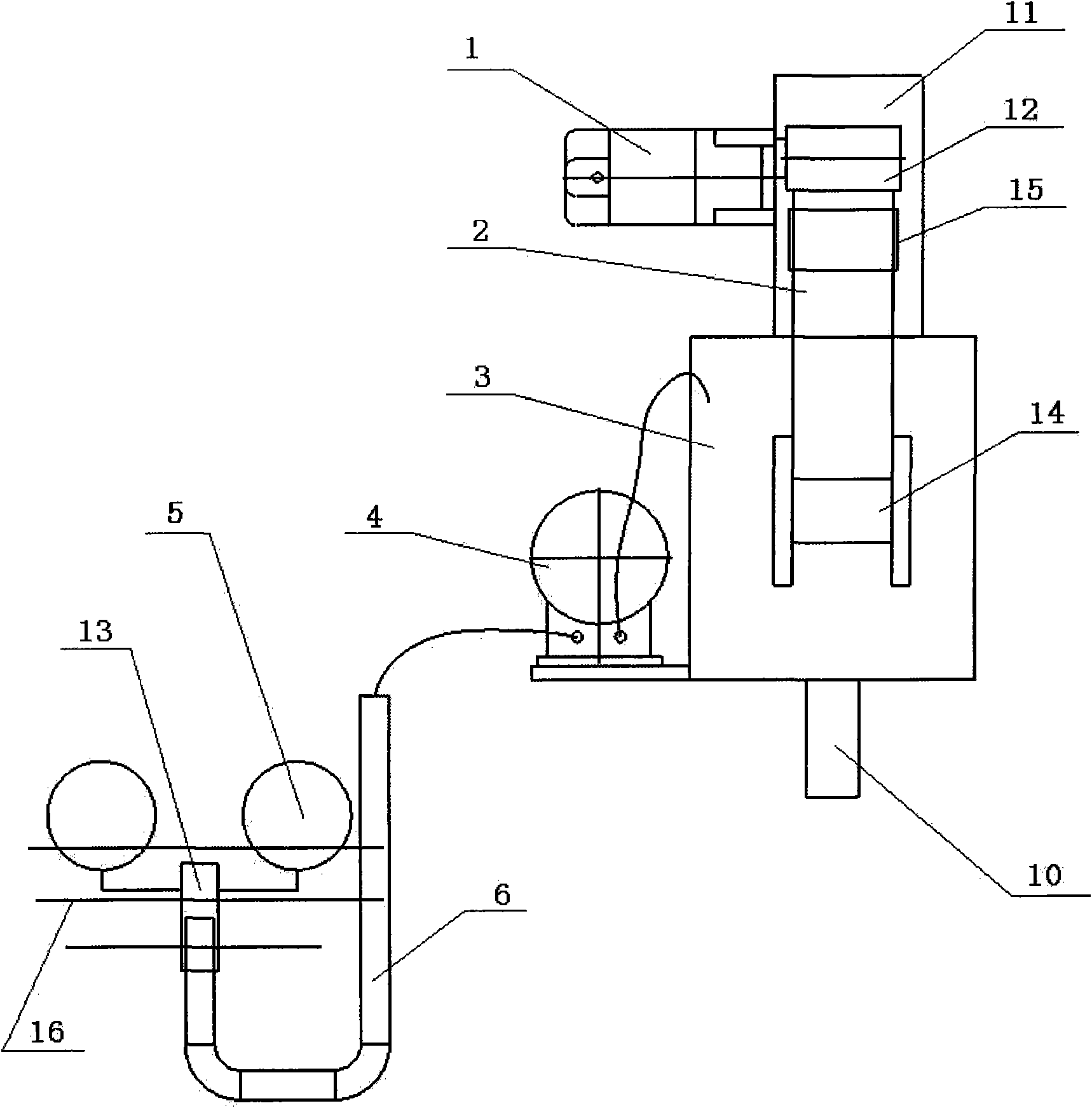

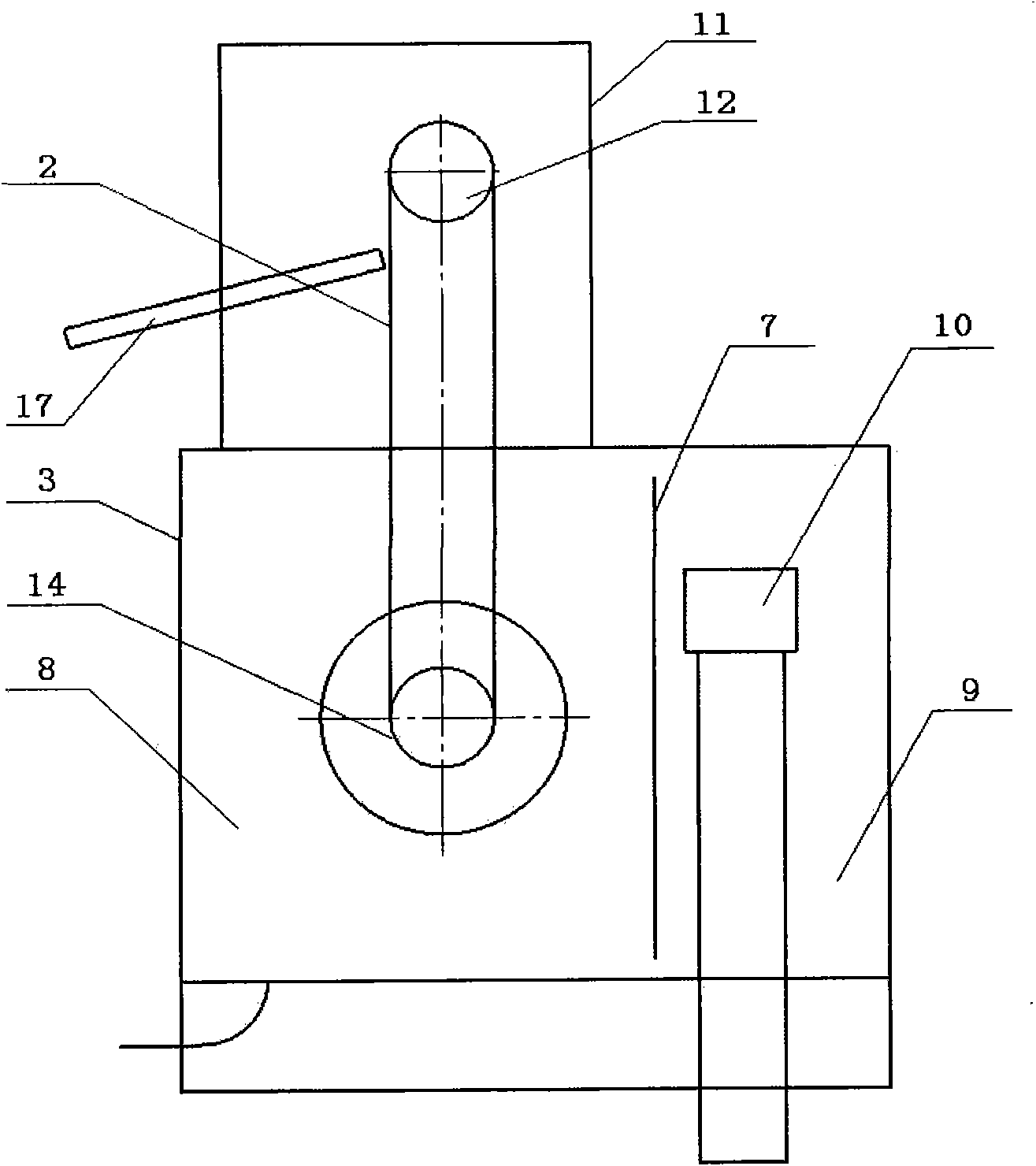

Spinning oil fume purifying device

InactiveCN102000631AImprove purification effectWith automatic processExternal electric electrostatic seperatorElectrostatic separation detailsEngineeringWaste oil

The invention discloses a spinning oil fume purifying device, which belongs to the technical field of synthetic fiber. The spinning oil fume purifying device comprises a shell; multiple anode tubes are vertically arranged in the shell; a cathode line is vertically hung in the centre of each anode tube; the upper part of each anode tube is inserted into an upper card, and the lower part of each anode tube is inserted into a lower card; the upper and lower cards, the outer walls of the anode tubes and the inner wall of the shell surround a closed cavity; the upper part of the cavity is communicated with a heat tracing steam inlet on the side wall of the shell; and the lower part of the cavity is communicated with a heat tracing condensed water outlet on the side wall of the shell. When oil fume passes through the anode tube, the oil fume particles mixed in the fume are charged under the action of an electric field and then adsorbed on a cathode and an anode. Through the invention, the accumulated oil stains are heated to 70-120 DEG C by the steam heat tracing so that the fluidity of the waste oil stains is maintained and the oil stains can smoothly flow into an oil collector on the bottom of the device,thereby guaranteeing the operation stability of the equipment and laying a good foundation for the collection of waste oil. The purifying device of the invention has notably good purifying effect and ensures that 95% of the oil fume in the waste gas can be removed.

Owner:SHEN MA INDUSTRY CO LTD

Double-stage oil-water separator

InactiveCN101601939AImprove cleaning qualityEliminate the effects of gravityNon-miscible liquid separationOil waterDouble stage

The invention relates to a double-stage oil-water separator, comprising an oil-water separation chamber, wherein a water outlet pipe of a pump is communicated with the oil-water separation chamber, an oil suction floater is communicated with a water inlet pipe of the pump by an oil suction pipeline, an oil baffle plate is arranged in the oil-water separation chamber separating the oil-water separation chamber into a clear water chamber and a polluted water chamber, an overflow device is installed in the clear water chamber, and an oil scraping mechanism is connected with the oil-water separation chamber by an installing support. The double-stage oil-water separator of the invention combines the working principles of the existing two one-stage oil-water separators so that after an oil-water mixture extracted by the pump is primarily separated in the oil-water separation chamber, concentrated floating oil can be processed by secondary separation by the oil scraping mechanism. The double-stage oil-water separator has simple structure and high oil removal efficiency, and can greatly improve the quality of cleaning workpieces; the oil suction floater is transformed to be a sliding structure, thereby eliminating the influence of the oil suction pipeline on the weight of the floater and increasing the efficiency; and the invention also has the advantages of small volume, low manufacturing cost and convenient operation.

Owner:YICHANG ENHANCE ULTRASONIC ELECTRIC

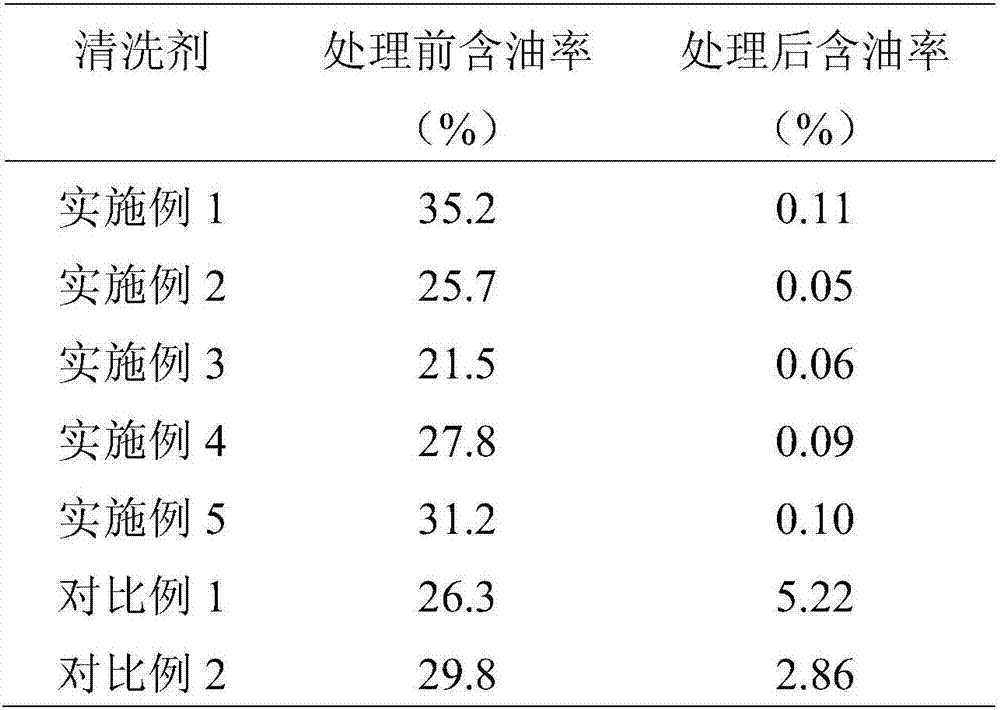

Oil base drilling cuttings cleaning agent and cleaning method thereof

InactiveCN107881025AGood degreasing effectHigh oil removal efficiencyInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsAlcoholSulfate

The invention belongs to the field of cleaning of oil base drilling cuttings, and particularly relates to an oil base drilling cuttings cleaning agent and a cleaning method thereof. The oil base drilling cuttings cleanings agent contains an epoxypropane or ethylene oxide nonionic surfactant, a sulfate or sulphosalt negative ion surfactant, short chain alcohol, sodium silicate, sodium salt except sodium silicate and water. The invention provides an oil base drilling cuttings cleaning agent which is high in oil removal efficiency, convenient in operation and low in cost and can be used repeatedly and a cleaning method thereof.

Owner:中海石油环保服务(天津)有限公司

Method for preparing composite flocculant

InactiveCN1880239ARapid flocculation separationReduce turbidityWater/sewage treatment by flocculation/precipitationAcetic acidTurbidity

A preparing method of composite flocculating agent includes that substitute amine A produced by the reaction of amine and epoxypropane reacts with adduct B produced by the reaction of carbowax molecular weight of which is 500-1000 and epichlorohydrin with inverse flow, the product of which can be used for flocculating agent directly after neutralization of commercial alcaine or acetic acid, wherein inorganic flocculants account for 5-40 mass%, that has strong demulsifying effect for oily wastewater of oil-in-water or water-in-oil, and rapid flocculating separation effect for oily wastewater contained more fatlute, after that the wastewater with low turbidity and little scum contains much oil.

Owner:PETROCHINA CO LTD

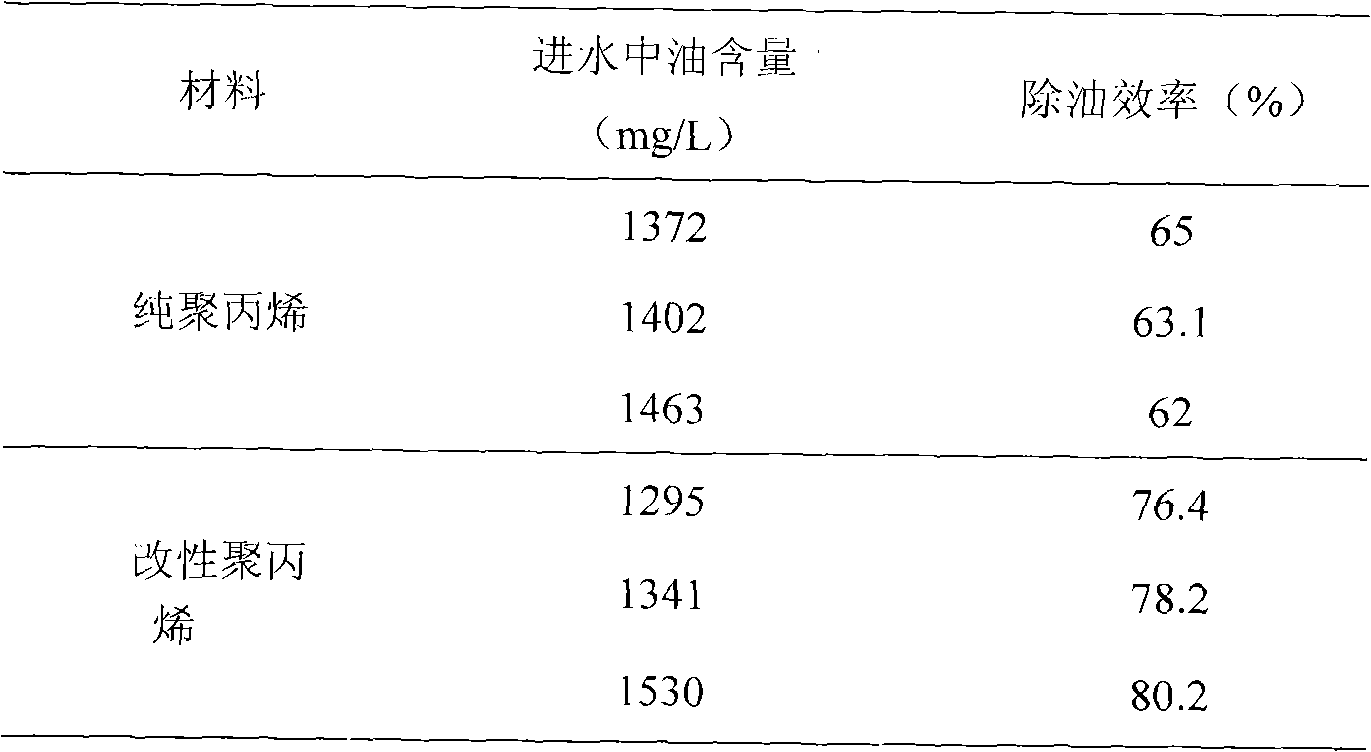

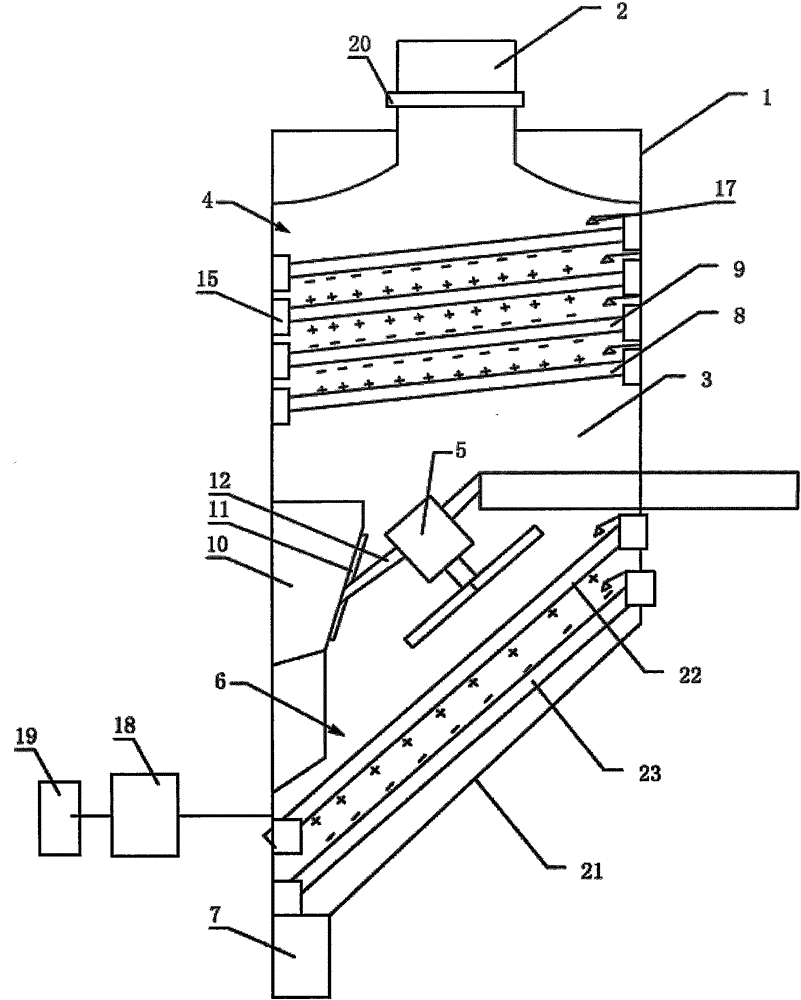

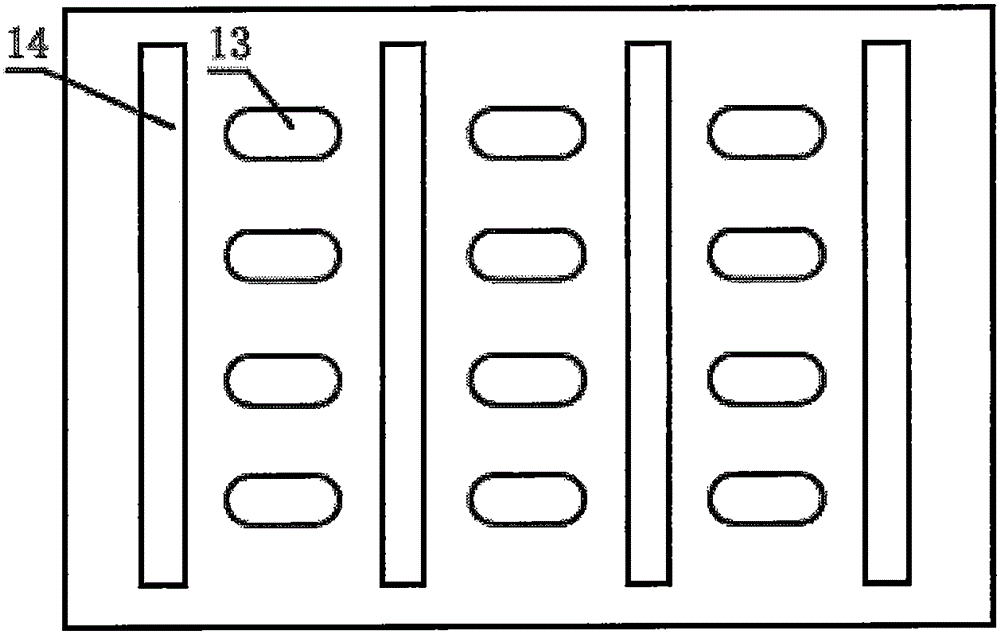

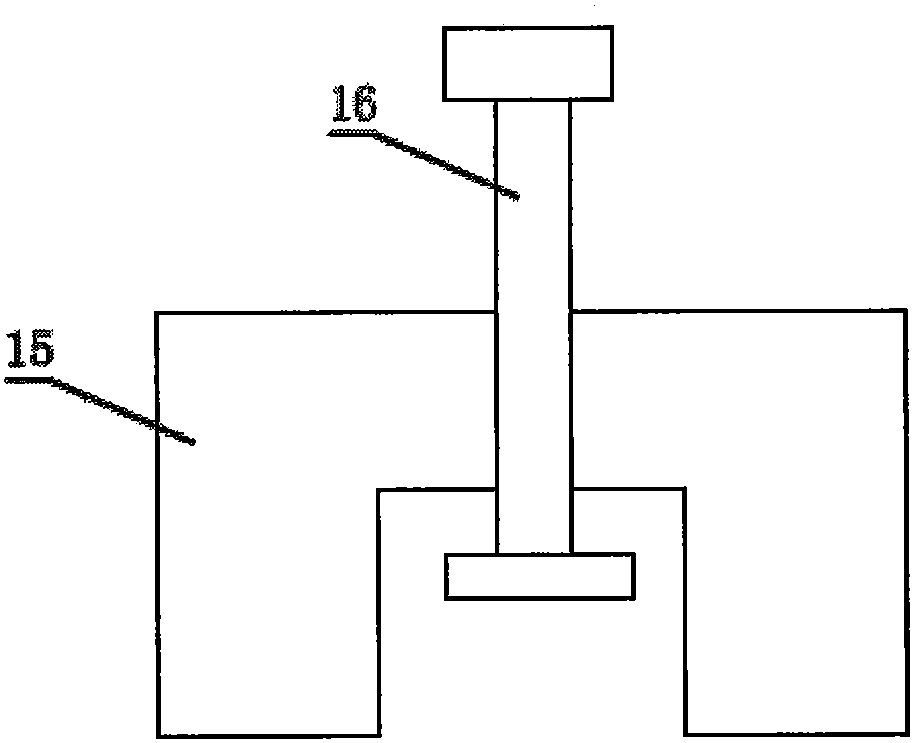

Coalescence material and preparation method

ActiveCN101838419AImprove lipophilic and hydrophilic balanceImprove coalescenceFatty/oily/floating substances removal devicesLiquid separationGlass fiberPolymer science

The invention relates to a coalescence material. The technical scheme is that: a polypropylene coalescence material is modified by polyvinylidene fluoride, nano-calcium carbonate, glass fibers and a 1010-antioxidant and the modified formula is formula a or formula b. According to the formula a, the mass part ratio of polypropylene, polyvinylidene fluoride, nano-calcium carbonate, glass fibers and 1010-antioxidant is 71.5%: 4%: 3%: 20%: 1.5%. According to the formula b, the mass part ratio of polypropylene, polyvinylidene fluoride, nano-calcium carbonate, glass fibers and 1010-antioxidant is 77.5%: 6%: 5%: 10%: 1.5%. According to the above formula a or formula b, the coalescence material is prepared by the steps of mixing the above components according the mass part ratio in the above formula a or formula b; mixing the raw materials uniformly at the temperature of between 50 and 80 DEG C; granulating the raw materials in a granulation machine; and drying at the temperature of between 50 and 95 DEG C after granulating so as to prepare a granular master batch of a polypropylene-modified coalescence material, wherein the working temperature of the granulation machine is between 165 and 185 DEG C; and the grain size is less than 3 mm. The coalescence material is better in balance between hydrophilic and lipophilic performances and is beneficial to the coalesce separation of oil droplets in the water.

Owner:CHINA PETROCHEMICAL CORP +2

Range hood

ActiveCN105042661ASatisfy purificationFulfil requirementsDomestic stoves or rangesLighting and heating apparatusEngineeringHigh pressure

The invention discloses a range hood. The range hood comprises a case. An air duct allowing smoke to pass through is formed in the case. A second high-voltage static lampblack removing device, a draught fan, a first high-voltage static lampblack removing device and an oil collecting box are mounted in the air duct in sequence from top to bottom. The first high-voltage static lampblack removing device comprises a set of positive plate electrode and negative plate electrode, wherein the positive plate electrode and the negative plate electrode are matched with each other and arranged oppositely. The draught fan is mounted in the air duct by means of a draught fan box, and an oil collection belt is arranged on the inner wall of the draught fan box. The second high-voltage static lampblack removing device comprises at least one positive plate electrode and at least one negative plate electrode, and each positive plate electrode and the corresponding negative plate electrode opposite to the positive plate electrode form an electric field. The oil collecting box is located below the bottommost negative plate electrode of the first high-voltage static lampblack removing device. The lampblack removing rate of the range hood can reach 98.5%, and the range hood is convenient to clean and maintain.

Owner:李峰

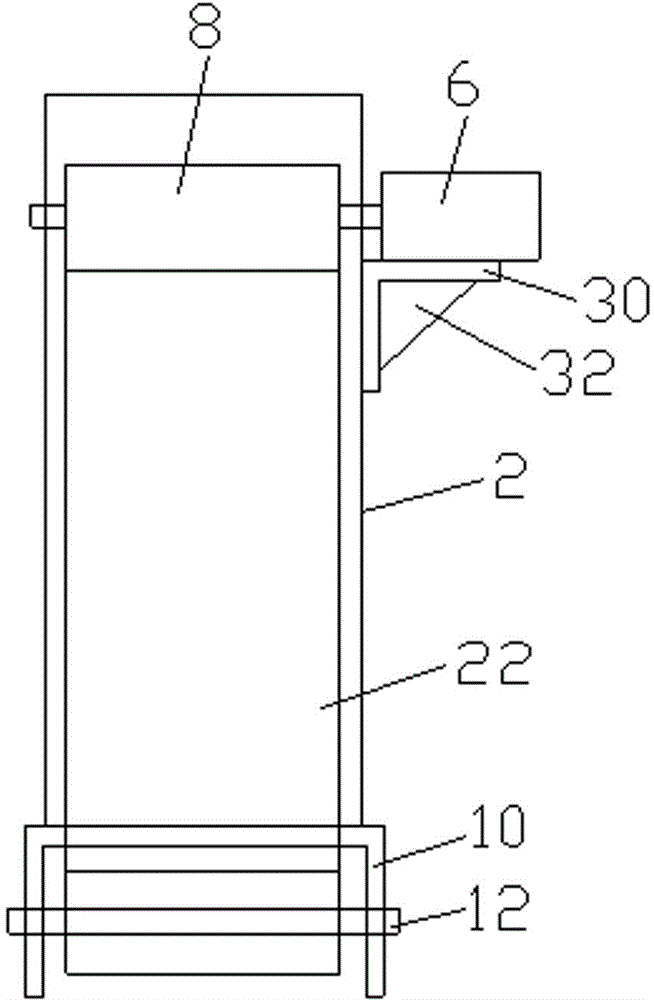

Efficient oil removal device for rare earth material liquid

ActiveCN107164645AGood degreasingHigh oil removal efficiencyProcess efficiency improvementRare earthBilateral symmetry

The invention relates to an oil removal device, in particular to an efficient oil removal device for rare earth material liquid. The efficient oil removal device for the rare earth material liquid comprises large L-shaped supports, a material liquid conveying device, a rotating device, a top pipe, a connecting pipe and the like, wherein the material liquid conveying device is arranged on one large L-shaped support, the rotating device is arranged between the large L-shaped supports in bilateral symmetry, the top pipe is arranged above the rotating device, the left end of the connecting pipe is connected with the right side wall of the top pipe in a welding mode, and the connecting pipe communicates with the top pipe. According to the efficient oil removal device for the rare earth material liquid, by combining the material liquid conveying device and the rotating device, high-efficiency oil removal can be carried out on the rare-earth material liquid, and the oil removal work efficiency is high.

Owner:XUZHOU NANFANG YONGCI MATERIAL

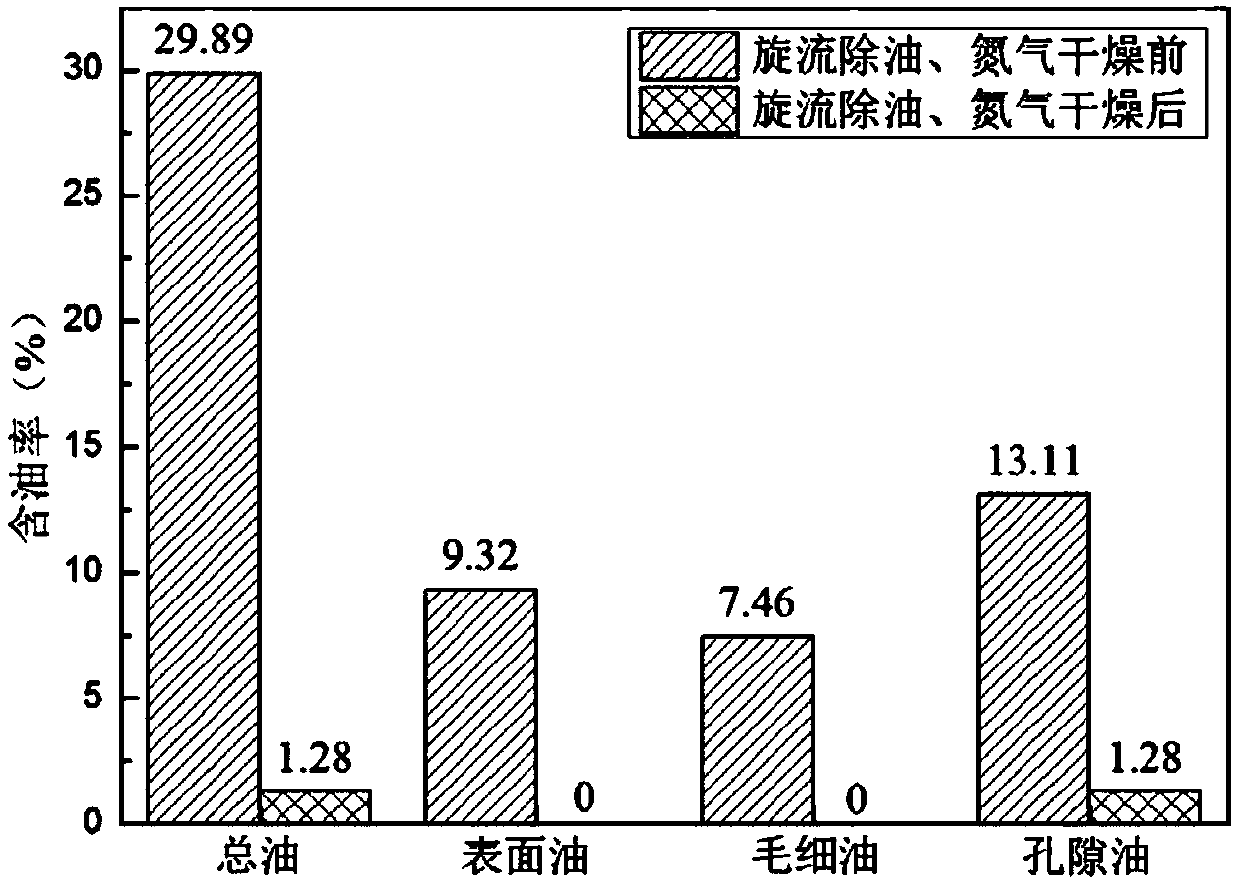

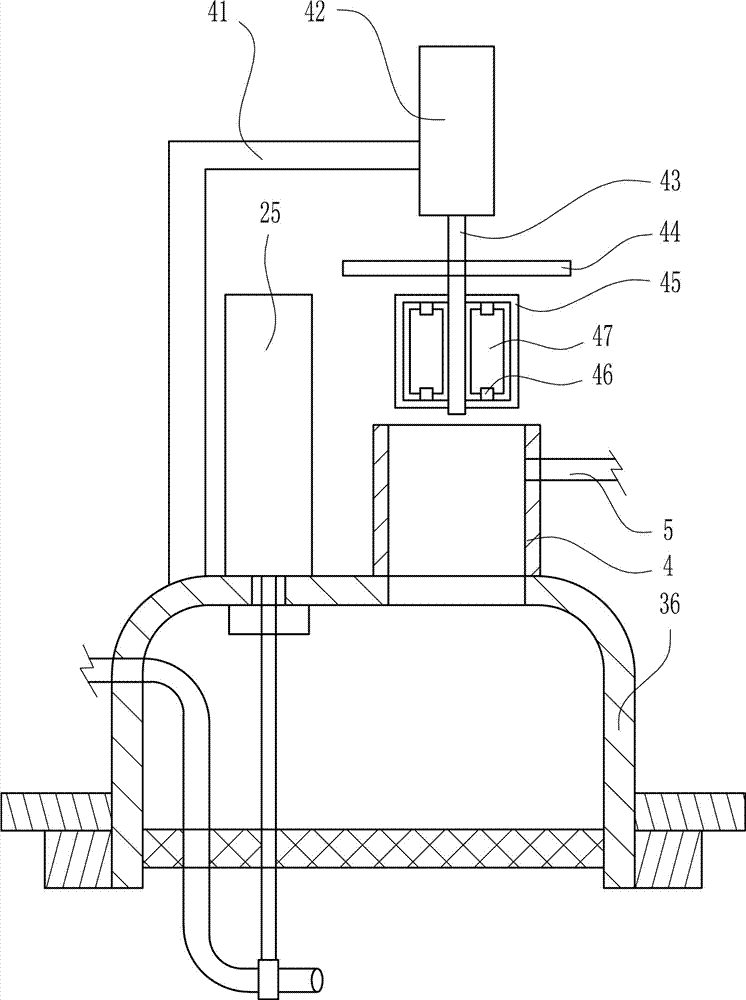

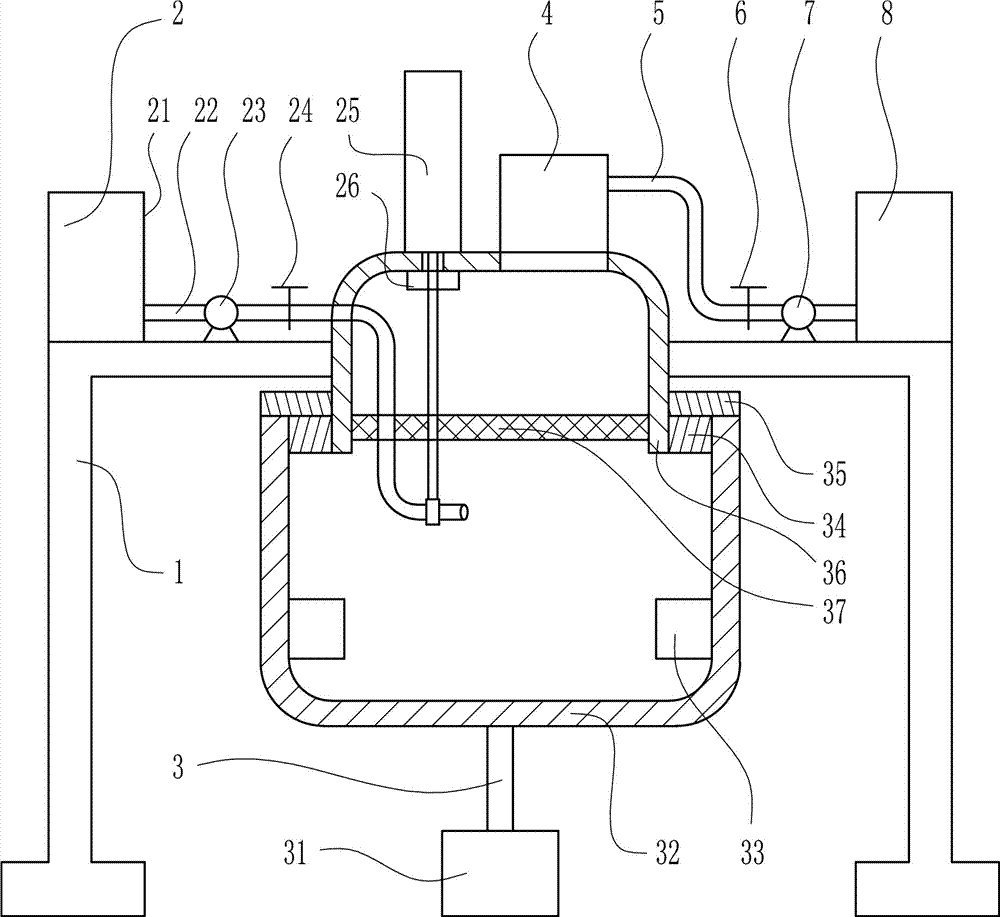

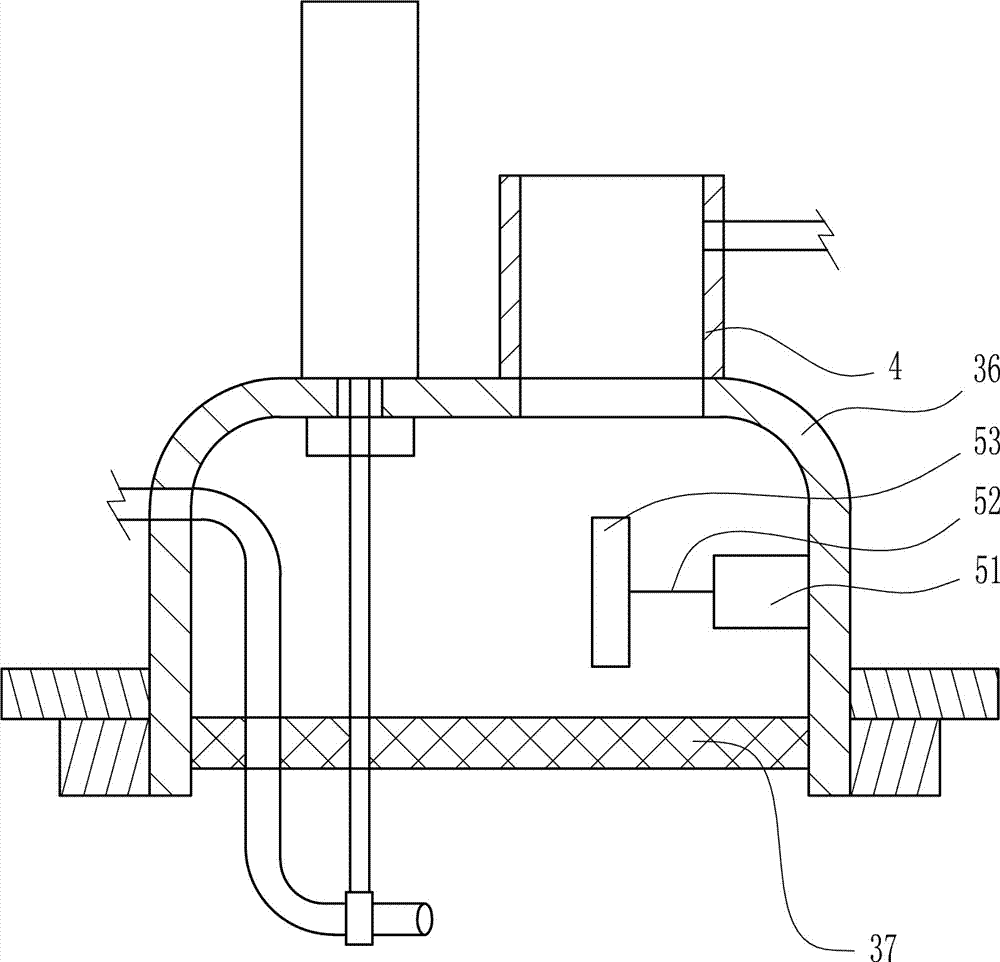

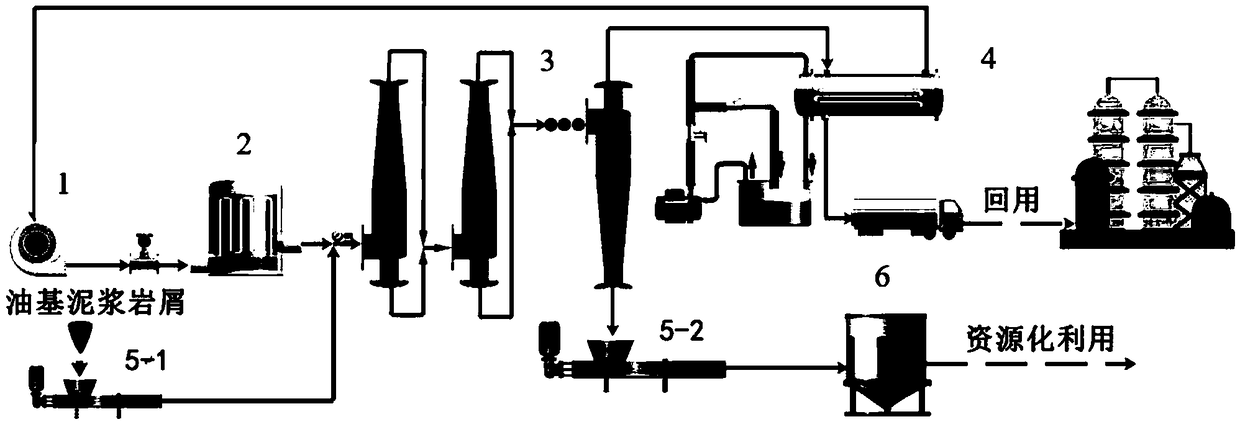

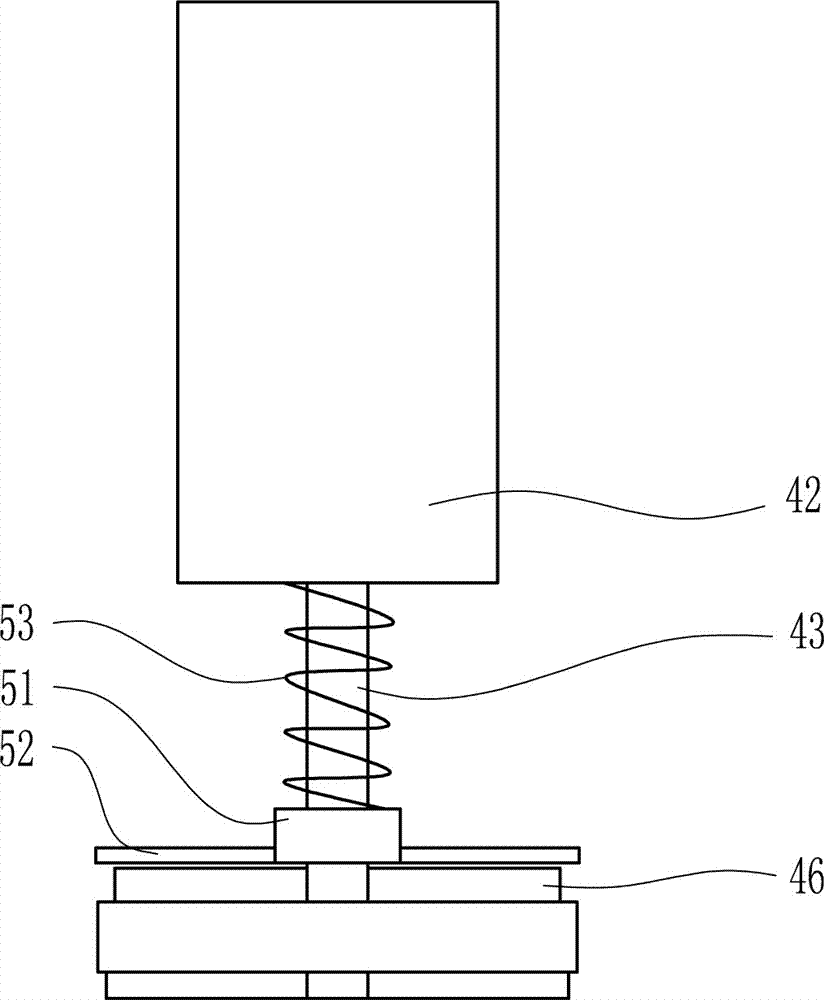

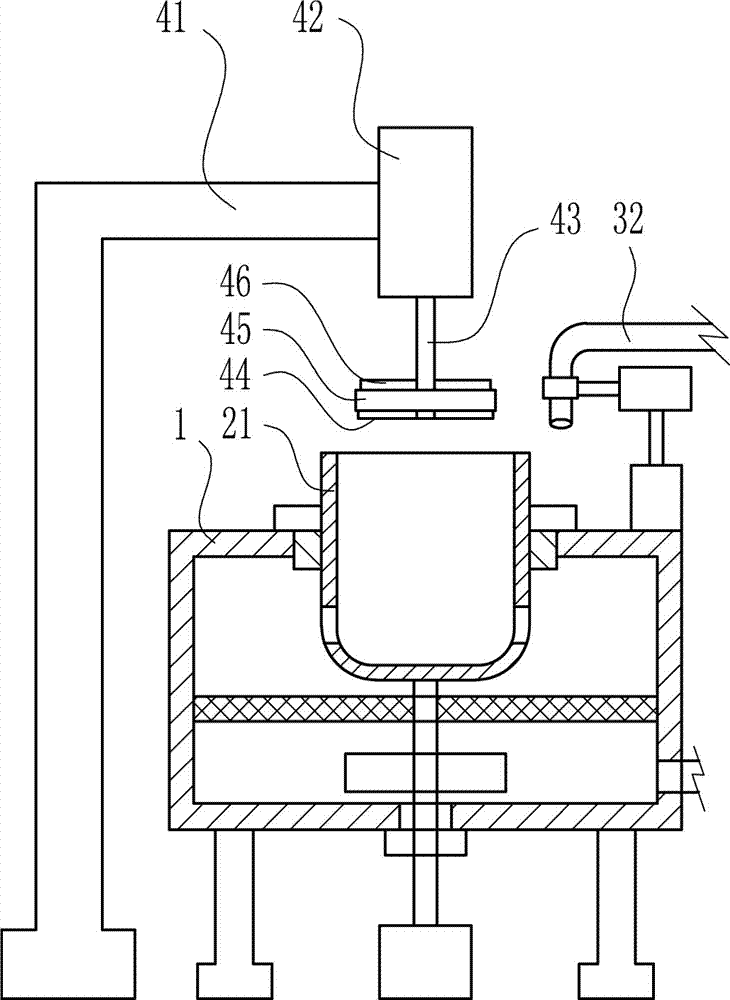

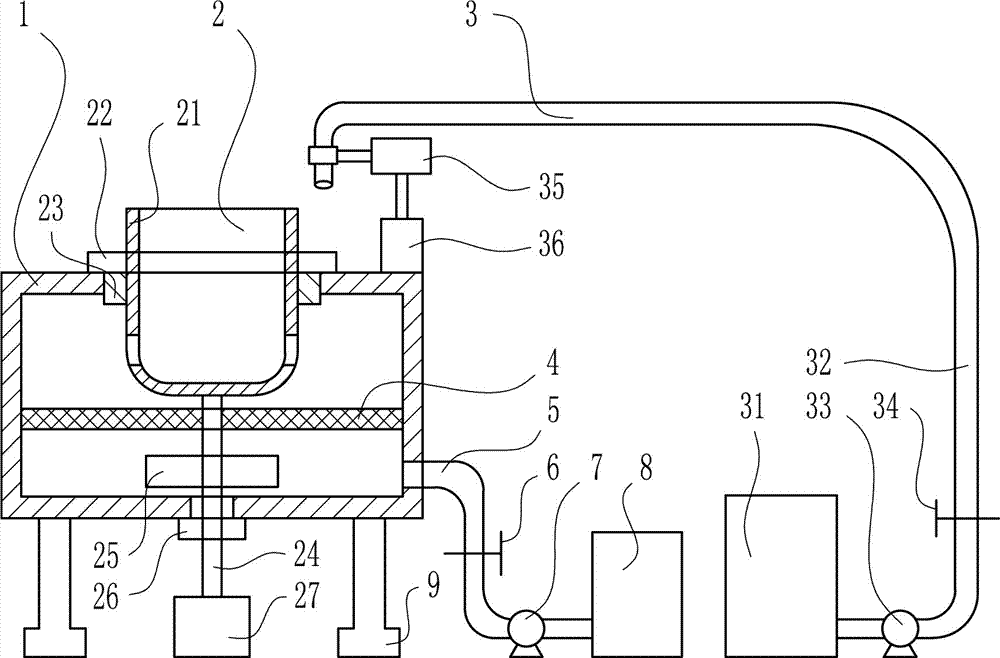

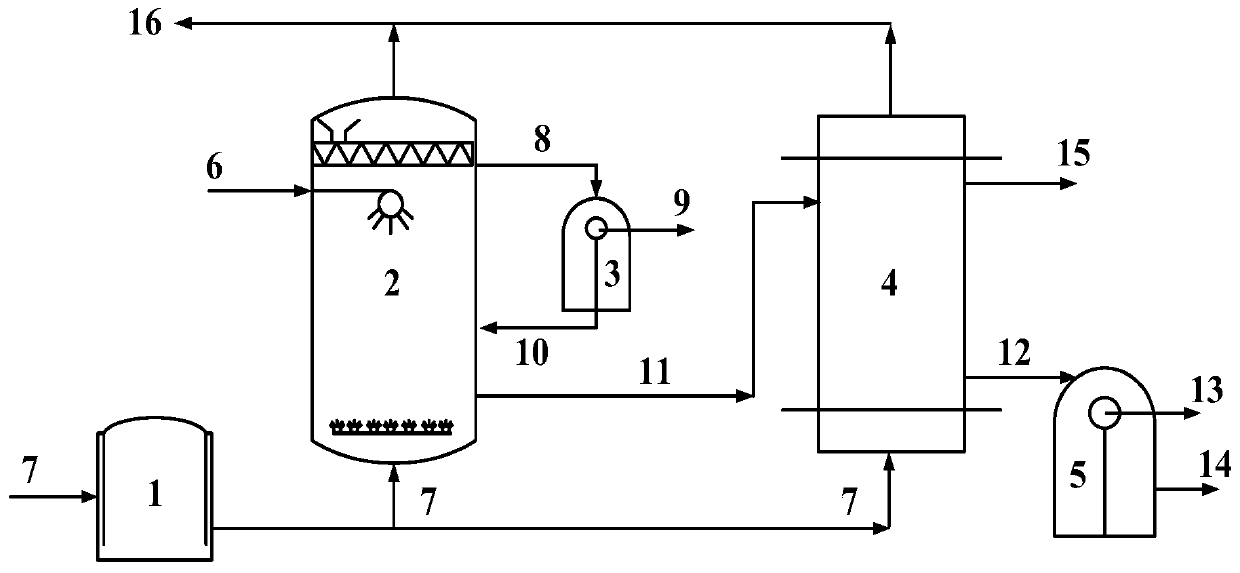

Method and device for de-oiling oil-based mud rock debris through rotation by rotary flow

PendingCN109052881AFully removedHigh oil removal efficiencySludge treatment by de-watering/drying/thickeningFlushingGas phaseDesorption

The invention relates to a method and a device for de-oiling oil-based mud rock debris through rotation by a rotary flow, and provides a method for de-oiling oil-based mud rock debris through rotationby a rotary flow. The method comprises the following steps: (1) system viscosity regulating: through heat exchange between gas media and rock debris, lowering the viscosity of the oil-based mud rockdebris to reduce the interaction between the oil and water and the surface and pore passage of solid particles, thereby facilitating separation in a rotary flow field; (2) de-oiling through rotation by a rotary flow: as a coupling movement of rotation and revolution of oil-based mud rock debris particles exists in a rotary flow field, strengthening the centrifugal desorption of solid-phase surfaceoil, capillary oil and pore oil through the rotation of the rock debris particles, and completing the oil-phase, gas-phase and solid-phase separation and enrichment through a centrifugal force of theperiodic oscillation generated by revolution, so as to realize the oil-phase removal in the pore passages of the rock debris; and (3) gas-phase separating and recycling: conducting gas-liquid separation of the oil-bearing mixture generated in step (2) to realize the recycling of base oil, the circulation of gas media and the harmless treatment of rock debris. The invention also provides a devicefor de-oiling oil-based mud rock debris through rotation by a rotary flow.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION +1

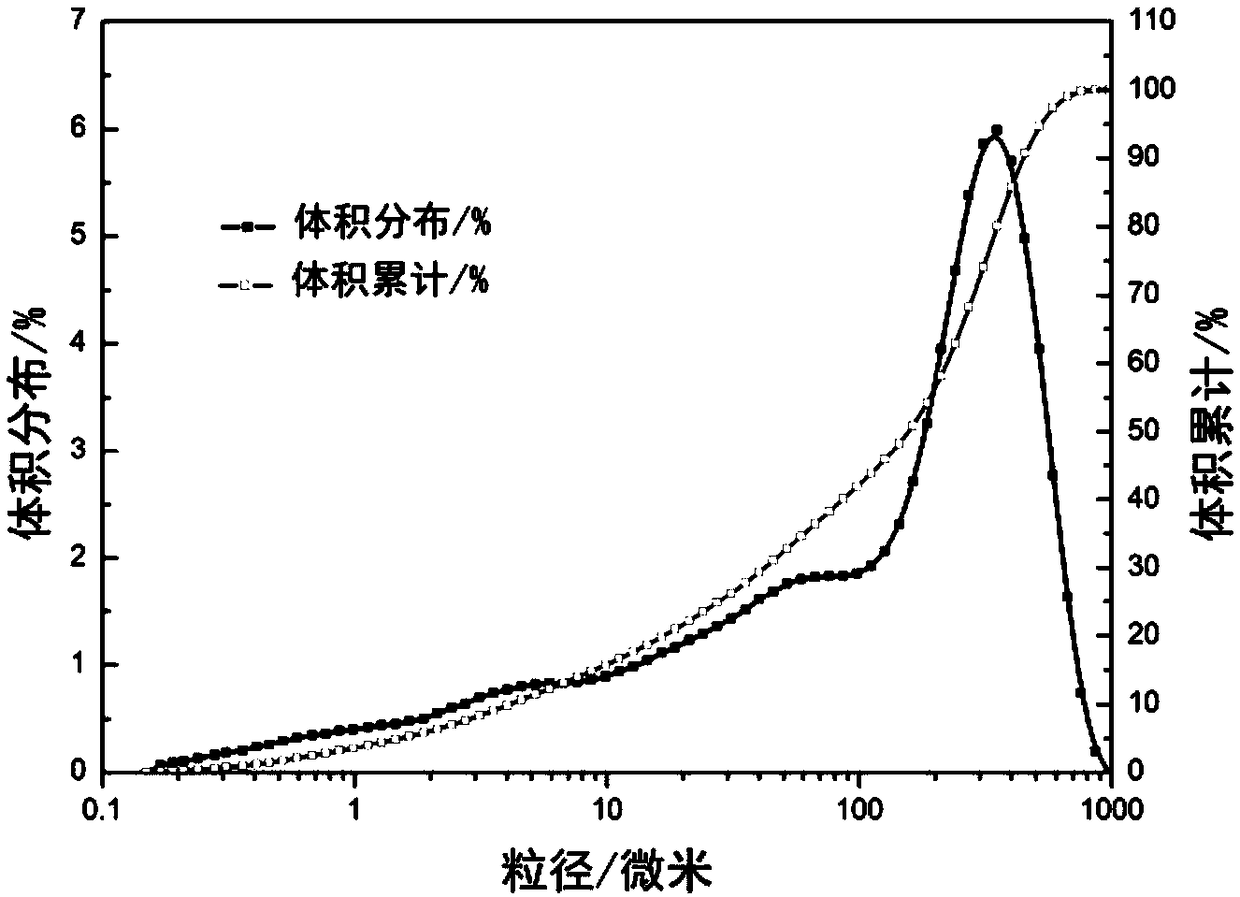

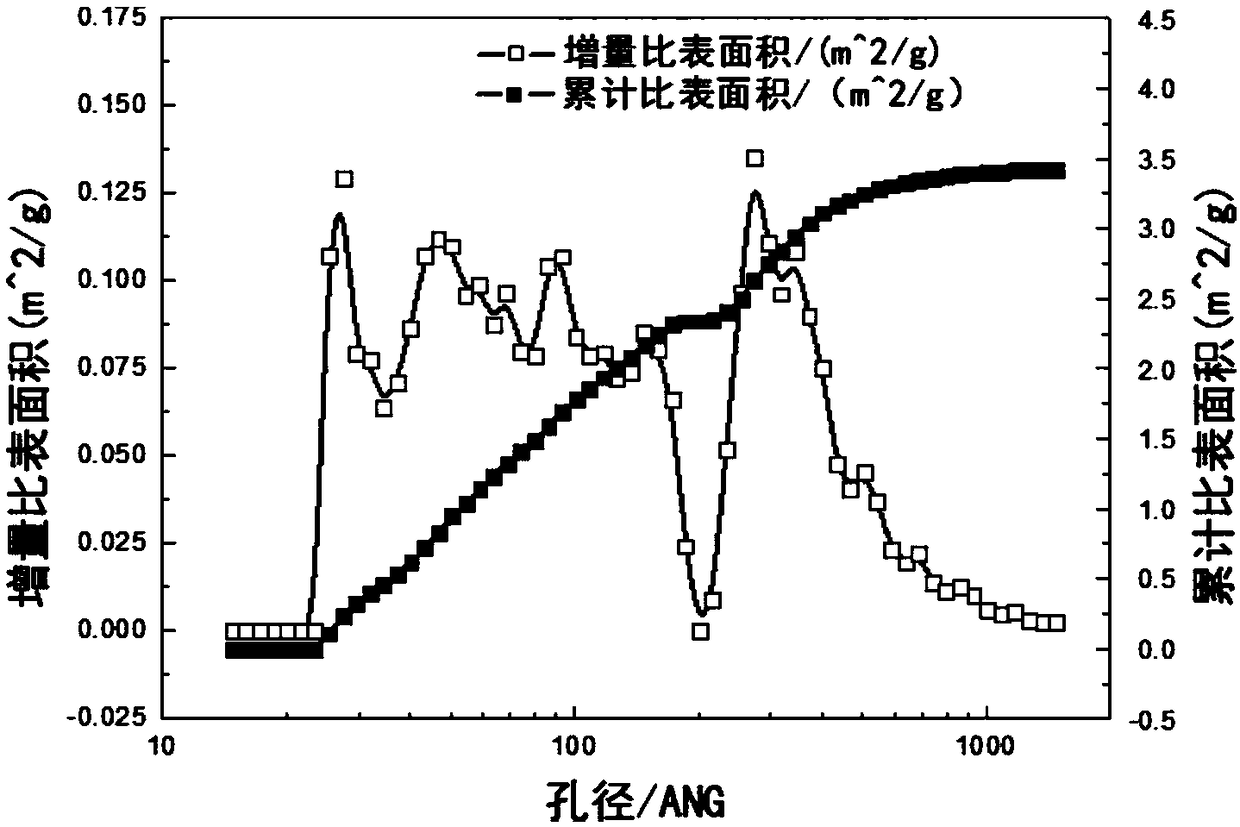

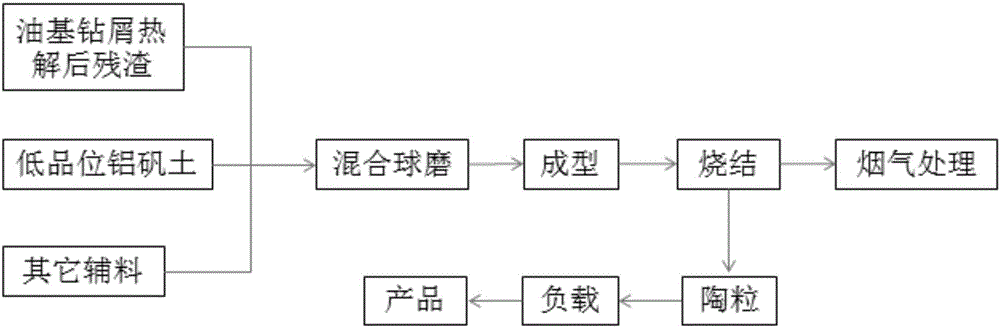

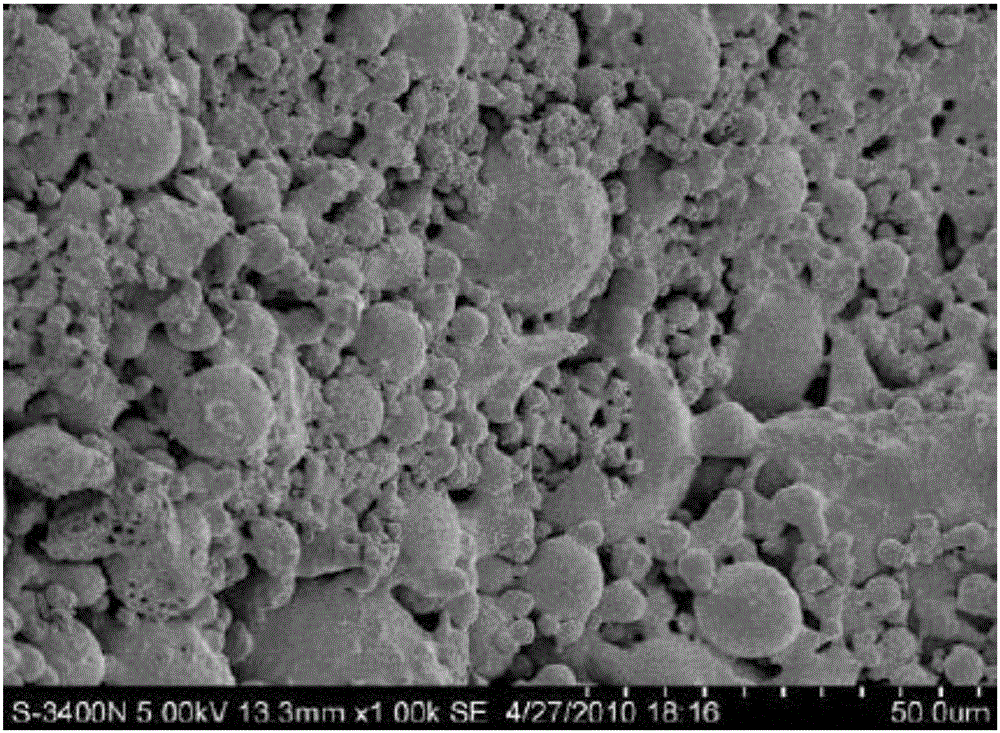

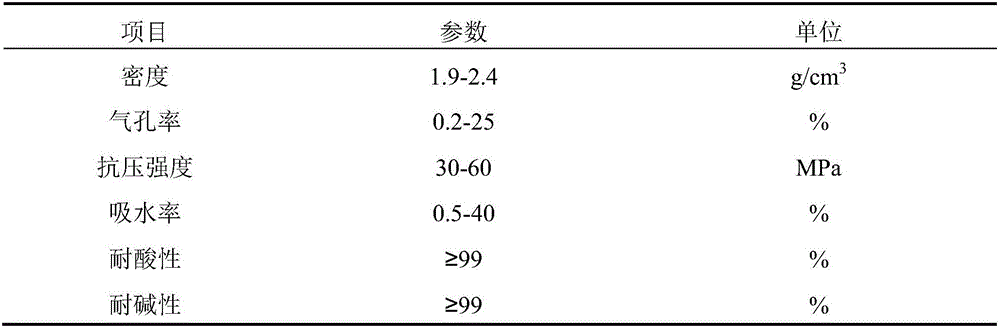

Oleophylic ceramsite adopting oil-based drilling cutting residues obtained after thermal decomposition and preparation method of oleophylic ceramsite

InactiveCN106518147AHigh compressive strengthImprove acid and alkali corrosion resistanceCeramic materials productionCeramicwarePotassiumDyeing wastewater

The invention discloses ceramsite with an oleophylic property. The different proportions of oil-based drilling cutting residues obtained after thermal decomposition, potassium feldspar, bauxite and bentonite are utilized, the performance of the ceramsite can be improved by adding a small amount of waste glass powder, and the prepared ceramsite has the oleophylic property through loading of an aluminic acid ester coupling agent. The ceramsite with the oleophylic property is large in compressive strength and good in acid and alkali corrosion resistance, and has the oleophylic property, powder is not likely to fall off, backflushing regeneration of the ceramsite is easy, hardening is avoided, and a good effect can be achieved when the ceramsite serves as a filtering medium. The ceramsite can be used for treating oily sewage and production sewage or printing and dyeing wastewater; when the ceramsite is used for treating the oily sewage, the oil removal rate is 85% or above, and the suspended solid removal rate is 80% or above.

Owner:SINOPEC ENERGY & ENVIRONMENTAL ENG CO LTD +1

Rapid deoiling device for rare earth feed liquid

ActiveCN107217160AFast degreasingReduce manufacturing costProcess efficiency improvementFuel tankRare earth

The invention relates to a deoiling device, in particular to a rapid deoiling device for rare earth feed liquid. The rapid deoiling device for rare earth feed liquid for solving technical problems comprises a deoiling box, a rotating device, a feed liquid collection device, a filter cloth, a connection pipe, a first valve and the like. The rotating device is installed on the deoiling box, the feed liquid collection device is arranged on the right side of the deoiling box, the filter cloth is in screw connection with the lower portion of the inner side wall of the deoiling box, the lower portion of the right side wall of the deoiling box is in welded connection with the left end of the connection pipe, and the connection pipe communicates with the deoiling box. According to the rapid deoiling device for rare earth feed liquid, by combining the filter cloth, the rotating device and the feed liquid collection device, rare earth feed liquid can be rapidly deoiled.

Owner:徐玉玉

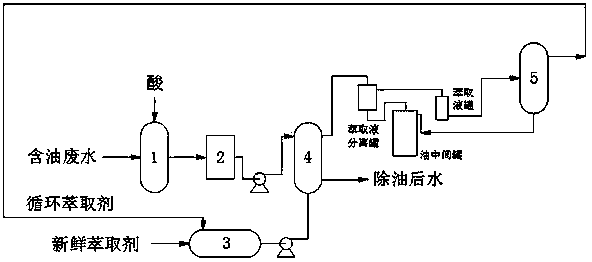

Diesel-oil-based drilling cutting processing method based on solvent extracting

ActiveCN105969418AHigh oil removal efficiencyImprove recycling efficiencyLiquid hydrocarbon mixture productionHydrocarbon oils treatmentKetoneSolvent

The invention discloses a diesel-oil-based drilling cutting processing method based on solvent extracting, and particularly relates to a method for processing shale-gas diesel-oil-based drilling-fluid drilling cuttings. A solvent for processing shale-gas diesel-oil-based drilling cuttings is prepared from, by weight, 20-40 parts of normal hexane, 20-40 parts of acetone, 20-40 parts of methyl ethyl ketone, 10 parts of ethyl acetate and 10 parts of ethyl alcohol. According to the solvent, the crude oil recycling rate for diesel-oil-based drilling cuttings can be about 99.7%, and the optimal extracting conditions are that the solvent-to-mud ratio (volume unit (ml) : mass unit (g)) is 3:1, extracting temperature is 45 DEG C, the stirring speed is 500 r / min, extracting time is 20 min, and the water-washing-three-grade cross-flow extracting technology is adopted. After extracting is completed, the recycling rate of an extracting agent can be about 98.5%, and the prepared extracting agent has the advantages that the effect is good, the crude oil recycling rate is high, the recycling rate of the extracting agent is high, the technology is simple, cleaning and pollution-free effects are achieved, and cost is saved.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

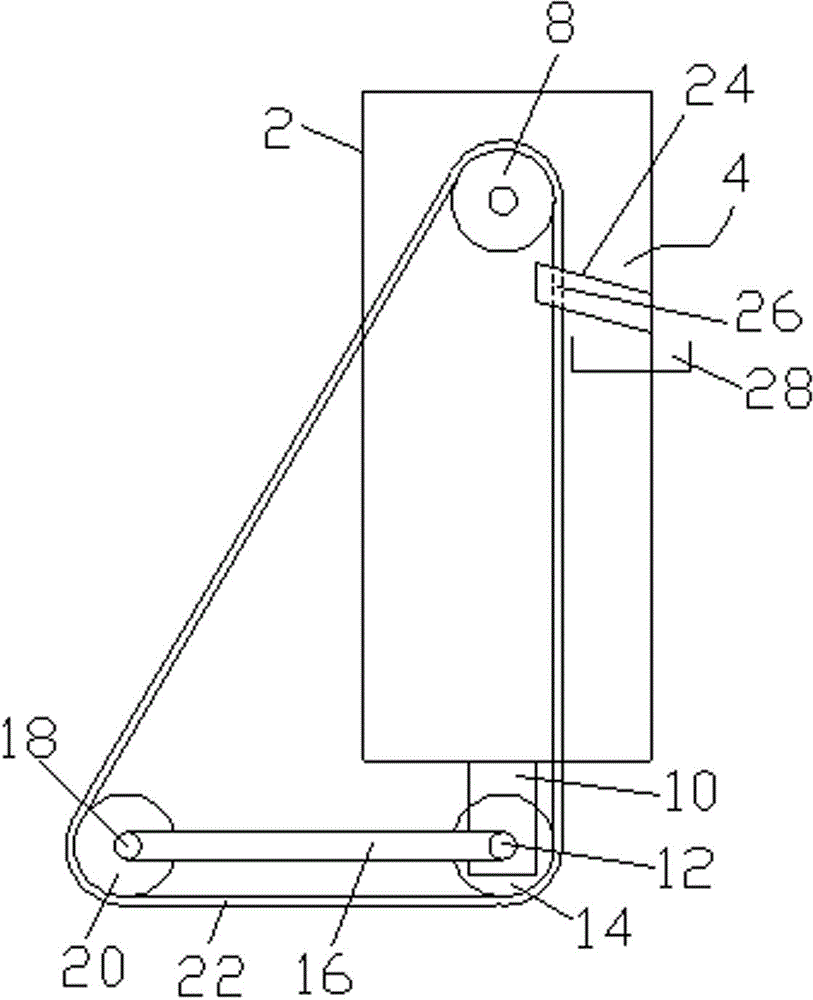

Band type oil removal device

InactiveCN103949090AIncrease contact timeIncrease forceLiquid separationContact timeEconomic benefits

The invention relates to a band type oil removal device. The band type oil removal device comprises a stander, wherein a scraping plate, a motor and a driving drum are mounted at the upper end of the stander, the driving drum is connected with the motor, a portal frame is mounted at the lower end of the stander, a first support shaft is arranged on the portal frame in a penetrating manner, the first support shaft is sleeved with a first driven drum, transverse rods are respectively fixed at two ends of the first support shaft, a second support shaft is fixed between the two transverse rods, the second support shaft is sleeved with a second driven drum, and an oil absorption band is arranged among the driving drum, the first driven drum and the second driven drum. The band type oil removal device has the advantages that the structure is simple, the use is convenient, the cost is low, the contact time between the oil absorption band and the oil is long, the oil absorption quantity is large, the side end of the oil absorption band has a support force, an action force between the scraping plate and the oil absorption band is large, and the oil removal efficiency is high; the band type oil removal device has excellent social and economic benefits.

Owner:石家庄永潮机械科技有限公司

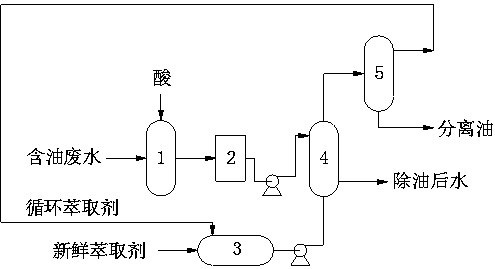

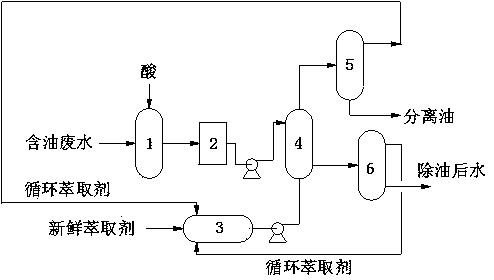

Method for oil removal from wastewater in field of coal chemical industry

InactiveCN103964544ASimplify timeLow costFatty/oily/floating substances removal devicesLiquid separationChemical industryWastewater

The invention discloses a method for oil removal from wastewater in the field of coal chemical industry, which is characterized in that oil contains soluble oil; and the method comprises the following steps: wastewater pretreatment, extraction and oil removal, and extraction agent recovery. Through the method, the oil contained in the wastewater, in particular to the soluble oil can be effectively removed. The invention further provides normal hexane and / or petroleum ether as an extraction agent; and through a practical application experiment, after the method is adopted, the oil contained in the treated wastewater is the soluble oil basically, the removal rate of the oil reaches 95.31-97.91 percent, and the removal rate of the soluble oil reaches 87.08-94.17 percent, so that a good oil removal effect is reached, and particularly, the effect of removing the soluble oil is good.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

Composite flocculation deoiling agent for oil-containing sewage

InactiveCN101058451AReduce dosageHigh oil removal efficiencyWater/sewage treatment by flocculation/precipitationChemistryPolyacrylamide

The invention discloses an allocating method of composite flocculating degreaser for disposing the effluent with oil, which comprises the following parts: 50%-90% aluminium sulfate, 5%-20% magnesium chloride, 4%-20% magnesium hydroxide, 0. 5%-5% alta-mud and 0. 5%-5% polyacrylamide, wherein the materials are grinded and blended under normal temperature. The invention uses little raw material with high degreasing efficiency, simple preparation and low cost, which is especially for disposing the effluent with kinds of oil and predisposing the effluent of oil field.

Owner:UNIV OF SCI & TECH BEIJING

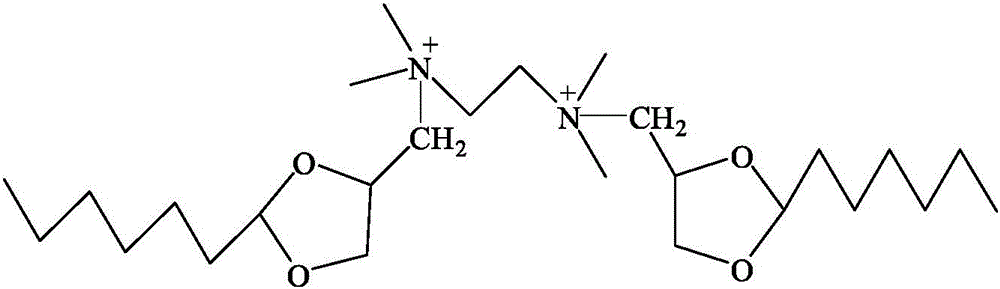

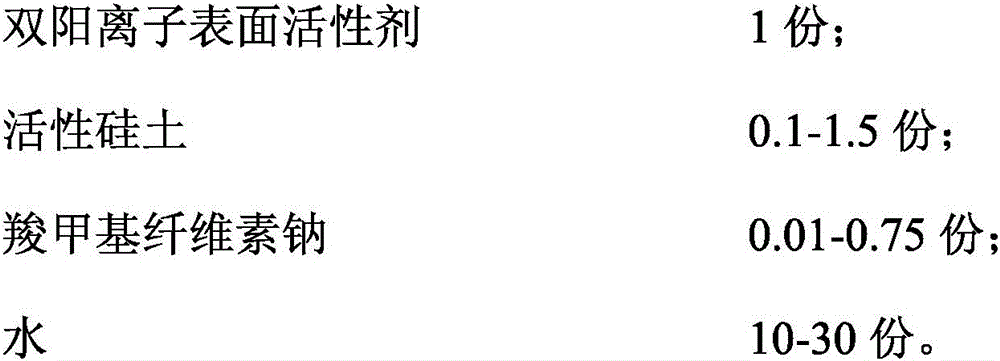

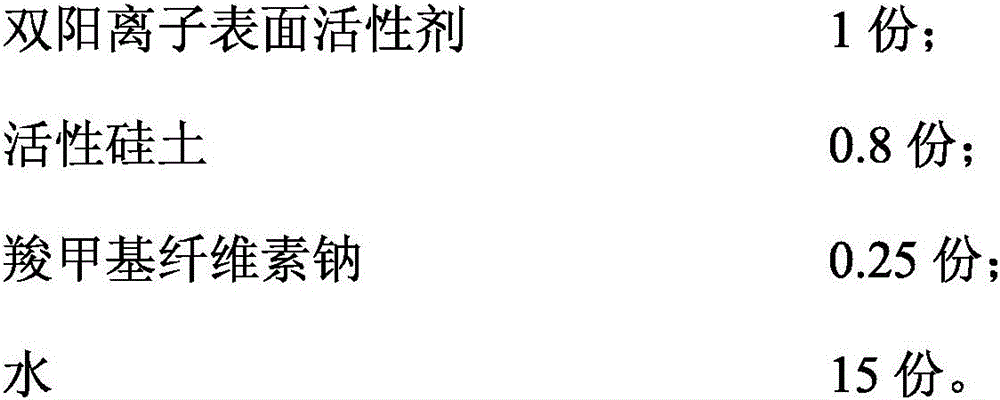

High-temperature high-salt resistant thick oil thermal recovery sewage degreasing agent and preparation method thereof

ActiveCN106348362AGood flocculation effectHigh activityWaste water treatment from quariesWater treatment compoundsSalt resistanceSewage

The invention belongs to the technical filed of oil field sewage treatment, and in particular relates to a high-temperature high-salt resistant thick oil thermal recovery sewage degreasing agent which is compounded from a dication surfactant, activated silica, sodium carboxymethylcellulose and water, wherein the dication surfactant is a symmetric molecule with long-carbon-chain alkyl and biquaternary ammonium salt cation polar groups. The degreasing agent provided by the invention has the characteristics of simple preparation process, low cost and good temperature and salt resistance, the mineralization resistance degree of the degreasing agent can be up to 250000mg / L, the temperature resistance of the degreasing agent is up to 250 DEG C, and a good degreasing effect can be achieved; the degreasing rate of thick oil thermal recovery sewage can be greater than 96%, and compared with that of a conventional agent, the degreasing rate of the degreasing agent is increased by more than 40%. Therefore, the degreasing agent can be widely applied to degreasing processes of thick oil thermal recovery sewage.

Owner:深圳市亿歌润滑科技有限公司

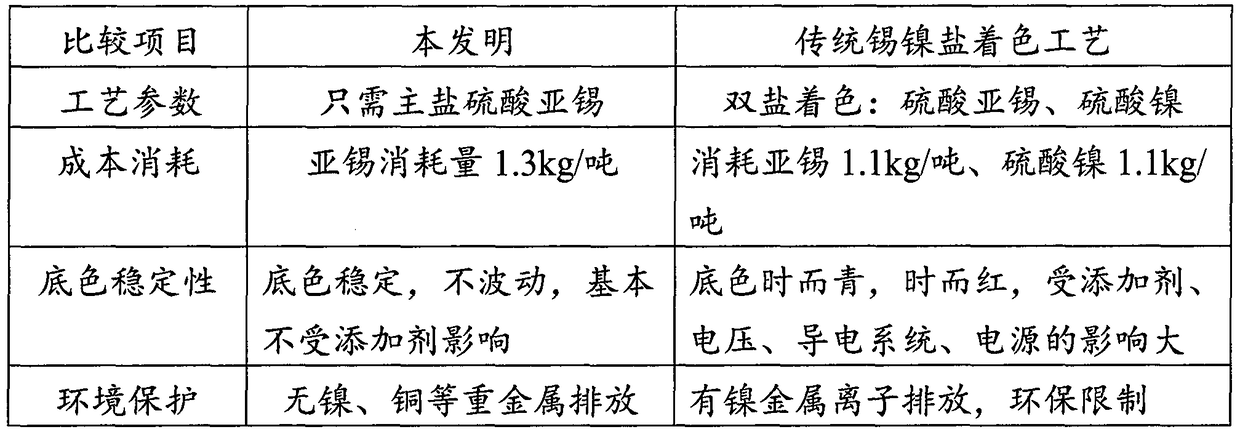

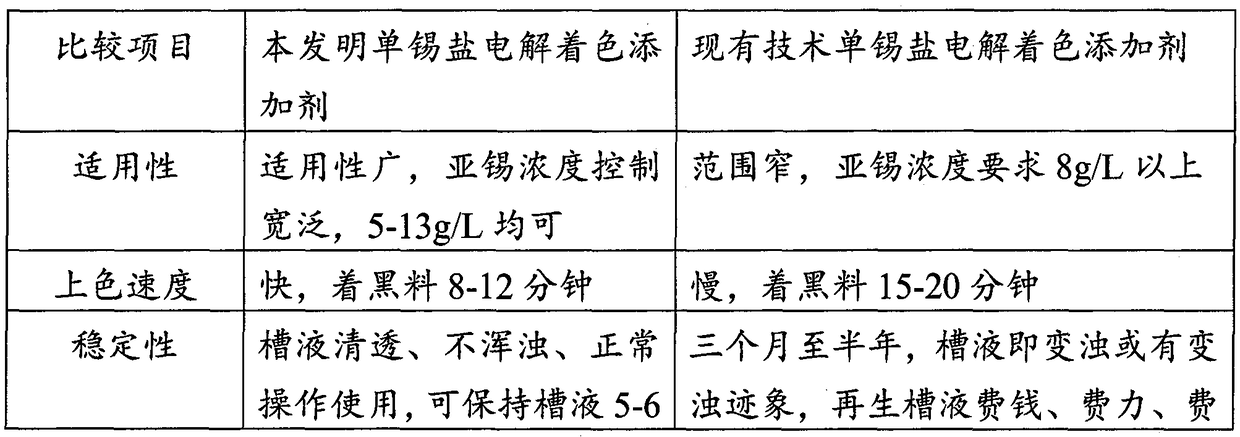

Single tin salt electrolytic coloring additive and application thereof

InactiveCN108342763AAntioxidantProtection stabilitySurface reaction electrolytic coatingZinc phosphateElectrolysis

The invention discloses a single tin salt electrolytic coloring additive. The single tin salt electrolytic coloring additive comprises a complexing agent, a buffer agent, an antioxidant and a surfactant, wherein the antioxidant comprises ferrous sulfate; the single tin salt electrolytic coloring additive also comprises an auxiliary agent containing ferrous sulfate; the auxiliary agent comprises modified amino amide zinc phosphate. The single tin salt electrolytic coloring additive disclosed by the invention has good comprehensive performances, solves the problem that nickel must take part in the reaction in an electrolytic coloring process, and is stable in groove liquid and quick and uniform to color, and the cost can be lowered effectively. Moreover, the single tin salt electrolytic coloring additive is low-carbon, energy-saving and green and environment-friendly, and process and product quality consistent to those of a double salt system can be obtained.

Owner:FOSHAN HAIHUA SURFACE TREATMENT TECH CO LTD

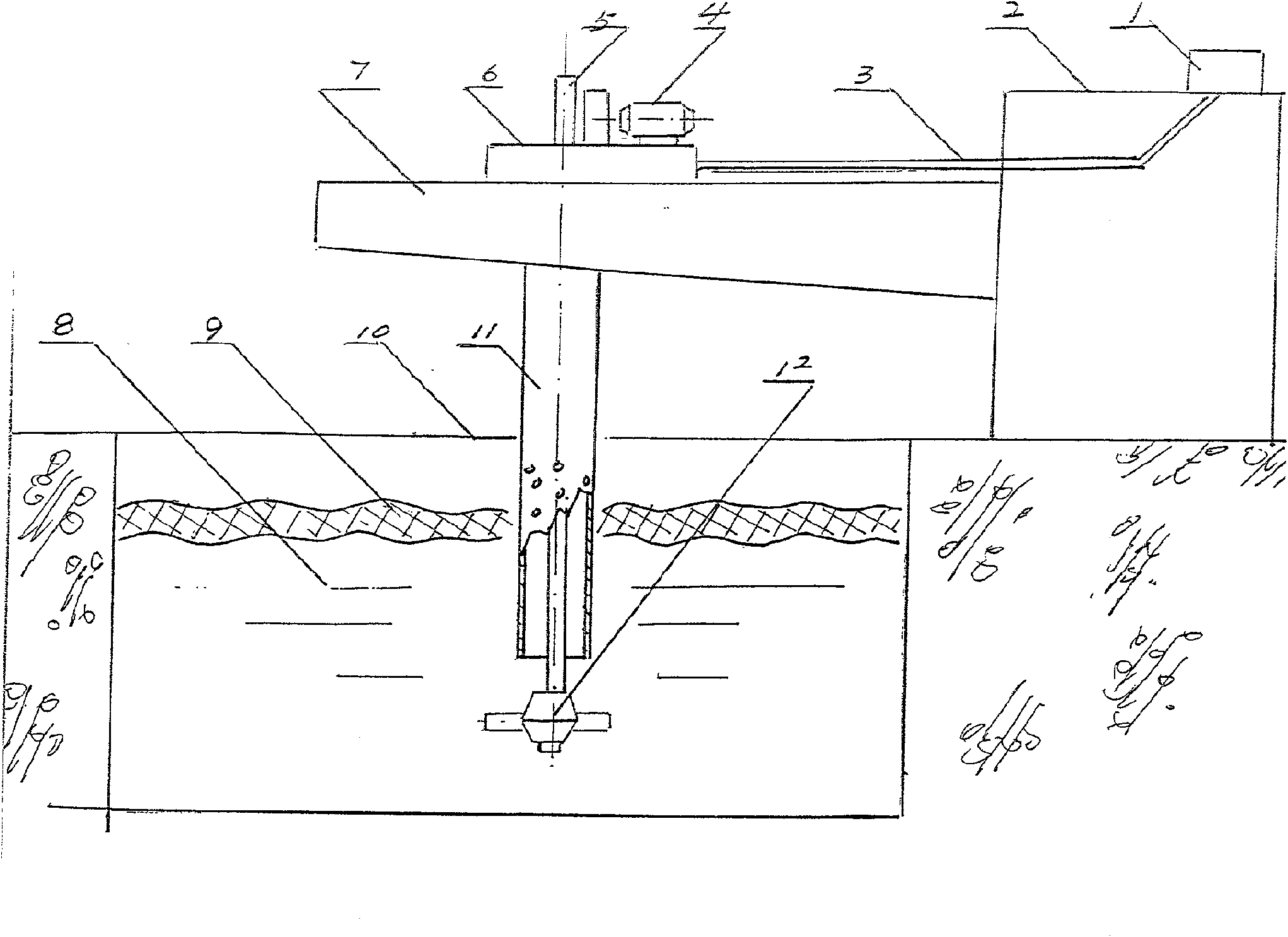

Swirl-type oil removal machine

InactiveCN101684012AEasy to separateHigh oil removal efficiencyFatty/oily/floating substances removal devicesLiquid separationOil and greasePotential difference

The invention discloses a swirl-type oil removal machine for removing grease in water body. The technical characteristics of the oil removal machine are as follows: utilizing different specific gravity of oil molecule and water molecule, a mechanism of endured different centrifugal forces and a gravity potential difference mechanism, adopting high-speed rotation of a helical blade in the water body to enable the water body to generate whirl and form swirl to lead the floating oil floating on the surface of the water body to rapidly concentrate in the center of the swirl under the action of gravity potential difference and centrifugal force, and utilizing an oil suction pipe to suck the concentrated floating oil. The structure of the oil removing machine is as follows: a lifting main shaftis installed on a mobile main-shaft positioning frame to drive the main shaft to rotate by driving a motor, the helical blade fixed at the tip of the main shaft rotates with the main shaft, a cantilever for supporting the above device is integrated with a cantilever shalving deposition oil box into a whole, a sleeve-type oil suction pipe is connected with an oil suction hose, and grease aggregating at the center of the swirling center is sucked into the deposition oil box by an oil suction pump.

Owner:北京市八荣科技有限责任公司

Deoiling-dephenolization combined treatment method for high-concentration phenol ammonia wastewater and system

ActiveCN110002629AHigh oil removal efficiencyImprove processing efficiencyFatty/oily/floating substances removal devicesWater contaminantsHigh concentrationRisk stroke

The invention relates to a deoiling-dephenolization combined treatment method for high-concentration phenol ammonia wastewater and a system. The treatment method comprises the following steps: (1) carrying out gas floating deoiling on a coke oven flue gas; (2) carrying out oil-water separation; (3) carrying out pressurized extraction dephenolization. A treatment system comprises a gas floating tank, an oil-water separator, an extraction device, a recycling tank and a flue gas buffer tank. As the coke oven flue gas is adopted as a foaming gas, the deoiling efficiency can be improved by virtue of nonpolar characteristics of carbon dioxide in the coke oven flue gas and the waste heat of the coke oven flue gas, and the acid gas carbon dioxide can be subjected to saturated absorption while deoiling is carried out; by changing the pH value of a solution, phenolate in wastewater can be induced to release phenolic substances of rich molecule modes, the allocation coefficient of the phenolic substances in an extraction agent can be increased, and the extraction efficiency can be improved; finally, through synergetic effects of gas floating deoiling and acidification and extraction procedures, the wastewater treatment efficiency is greatly improved, and three purposes can be achieved with one stroke.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD +1

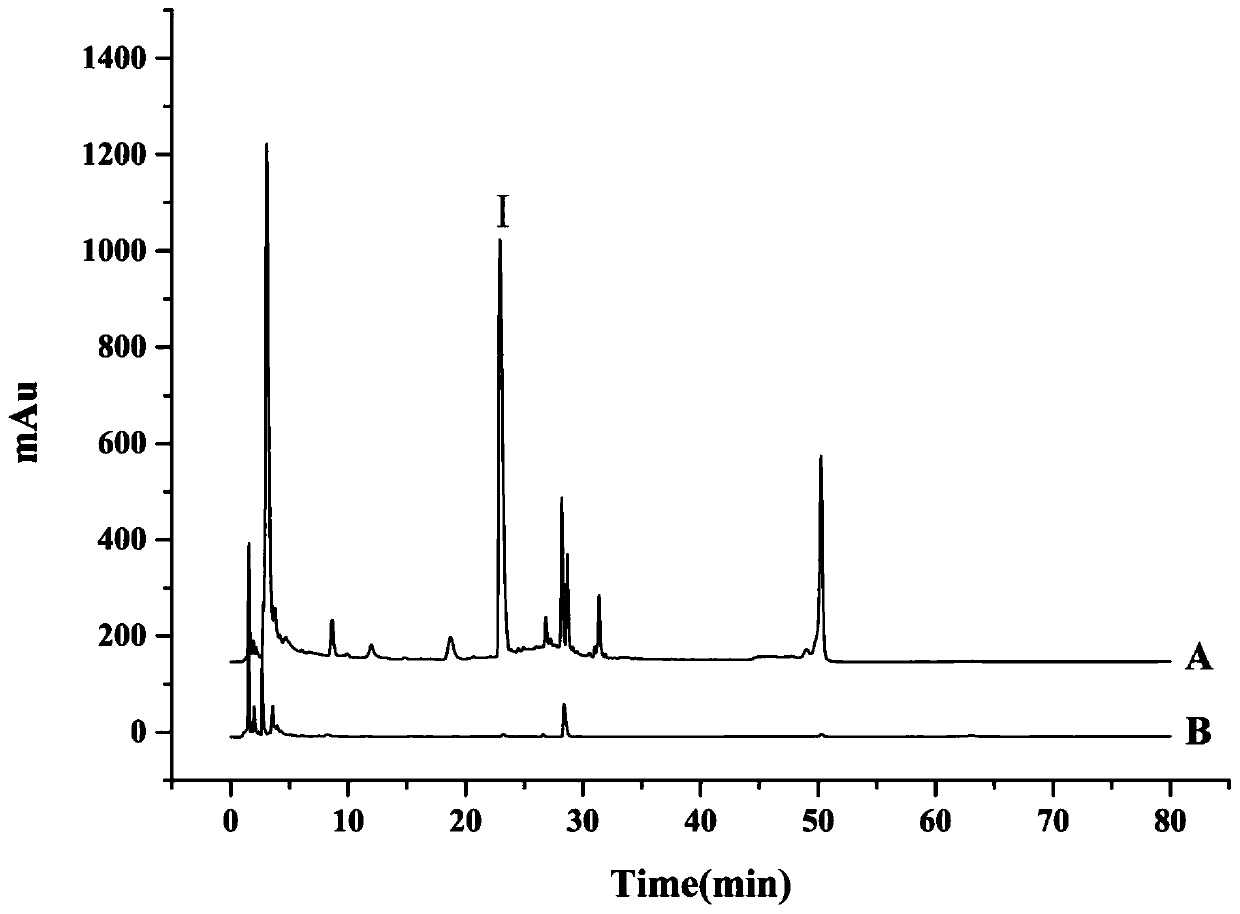

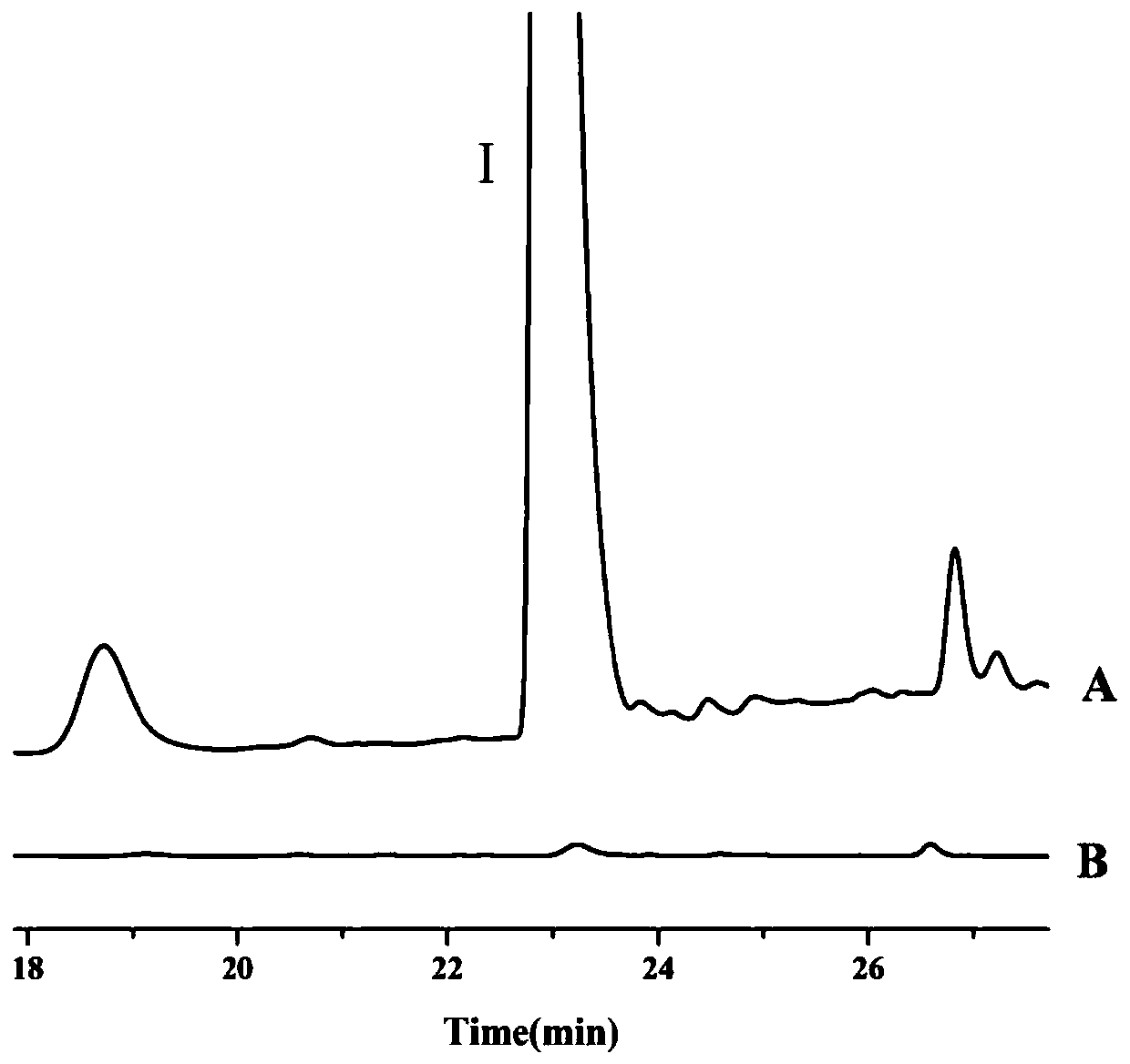

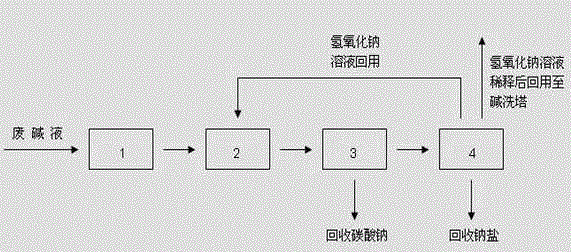

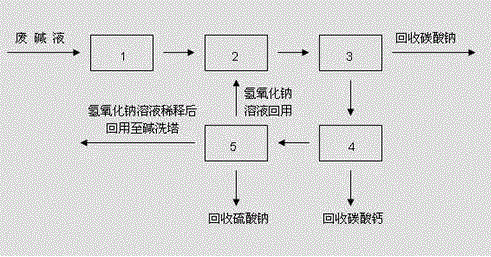

Liquid-state hydrocarbon waste alkali liquid treatment method

ActiveCN104609626AHigh oil removal efficiencySatisfy the requirement of oil content in waterMultistage water/sewage treatmentWater/sewage treatment by neutralisationLiquid stateEvaporation

The present invention discloses a liquid-state hydrocarbon waste alkali liquid treatment method, which comprises: removing oil substances from a waste alkali liquid, carrying out a high temperature wet oxidation treatment, adjusting the alkali concentration of the waste alkali liquid, recovering sodium carbonate, carrying out evaporation concentration so as to further improve the alkali concentration in the solution and recover the remaining sodium salt, and reusing the treated waste alkali liquid. With the method of the present invention, the COD and the sulfides in the waste alkali liquid can be efficiently removed, the concentration difference of the sodium carbonate and the sodium sulfate in the solution being subjected to the high temperature wet oxidation treatment is utilized to recover the sodium salt in two times, the sodium hydroxide solution obtained after treating the waste alkali liquid is recycled, and the zero emission of the liquid-state hydrocarbon waste alkali liquid is achieved.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

Dissolved air flotation tank

PendingCN107324432ASmall footprintLow costWaste water treatment from quariesWater/sewage treatment by centrifugal separationSeparation technologyEnvironmental engineering

A dissolved air flotation tank comprises a tank body, an upper head, a lower head, a pack mounting rack and a conical barrel, wherein coalescent pack and a taper tube are arranged on the pack mounting rack, a blowdown pipe is arranged on the lower side of the taper tube, an outer barrel is arranged on the upper side of the taper tube, an inner barrel is arranged in the outer barrel, a cyclone water inlet pipe is welded tangentially on the side wall of the inner barrel, an insertion pipe is inserted in the cyclone water inlet pipe and connected with a static mixer and a water inlet, a dross outlet is formed in the upper head of the tank body, and the blowdown pipe is arranged on the lower head of the tank body; a closed water purification area is formed between the conical barrel and the lower head, a plurality of water distribution square tubes communicating the tank body with the water purification area are arranged uniformly on the lower surface of the conical barrel; the water purification area is provided with a water outlet in the side wall of the tank body. An air flotation technology, a cyclone separation technology and a coalescence-separation technology are combined, and the dissolved air flotation tank further has the advantages of occupying small area and being low in cost, high in oil removal efficiency, simple and convenient to operate and high in reliability.

Owner:ZHEJIANG JINLONG AUTOMATIC CONTROL EQUIP

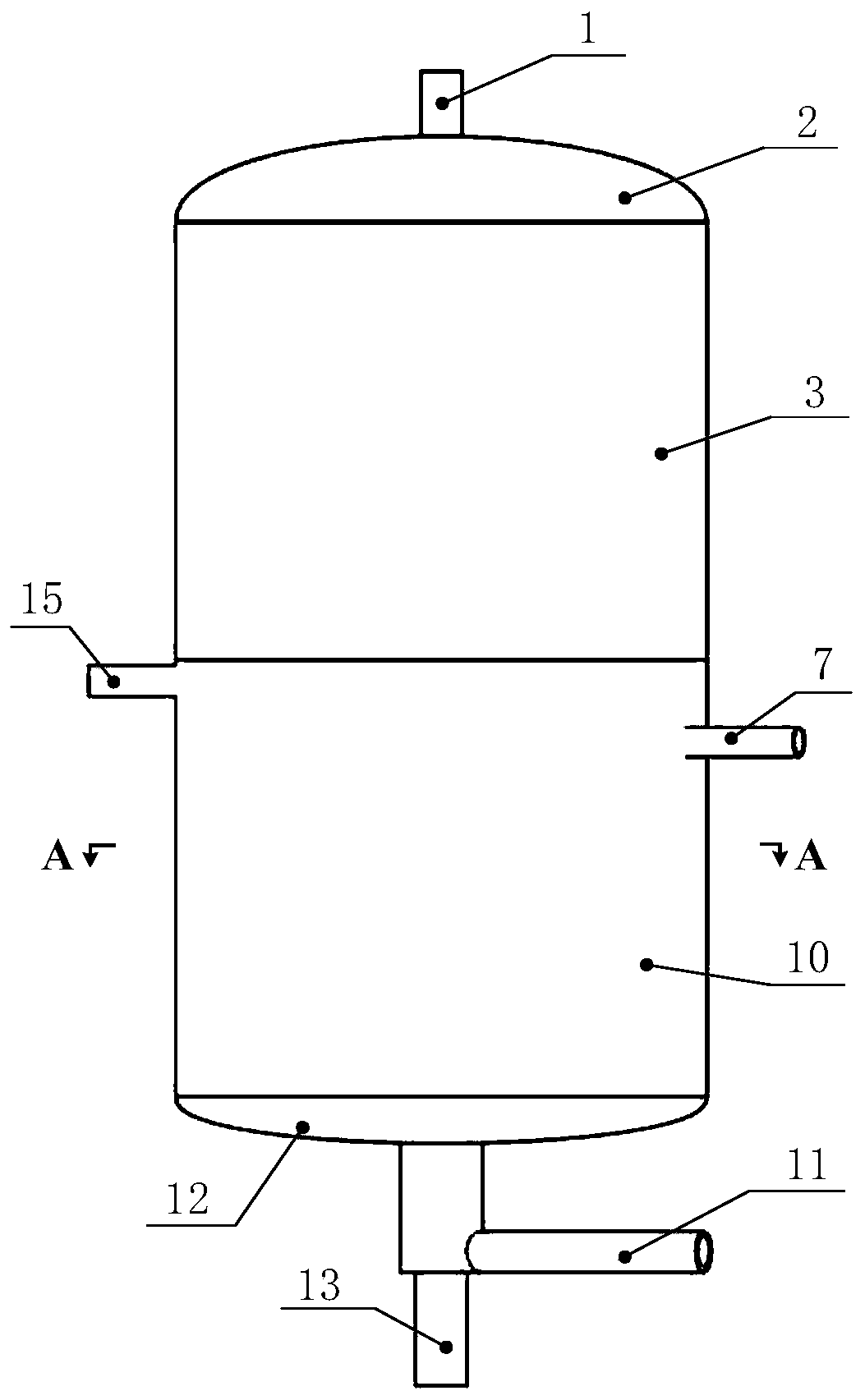

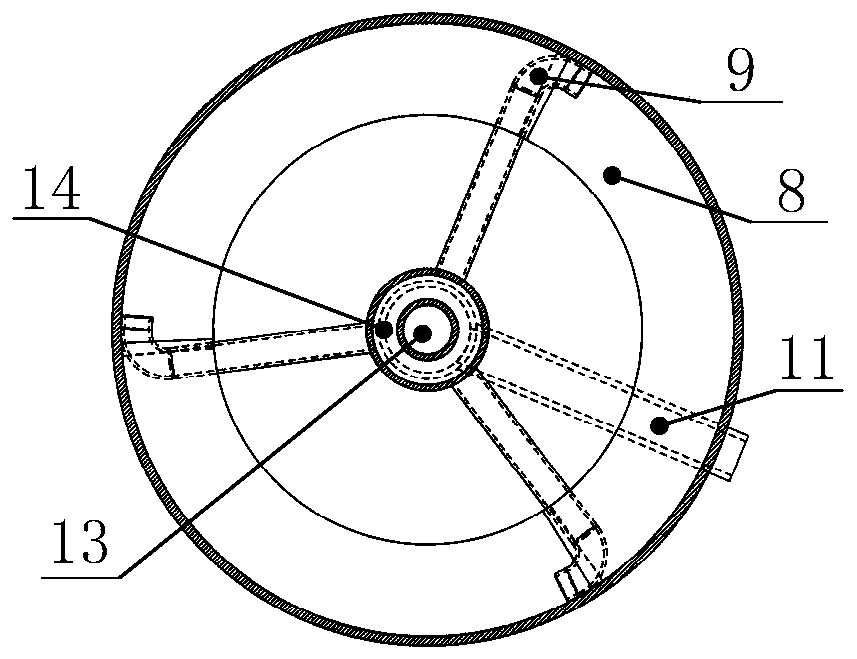

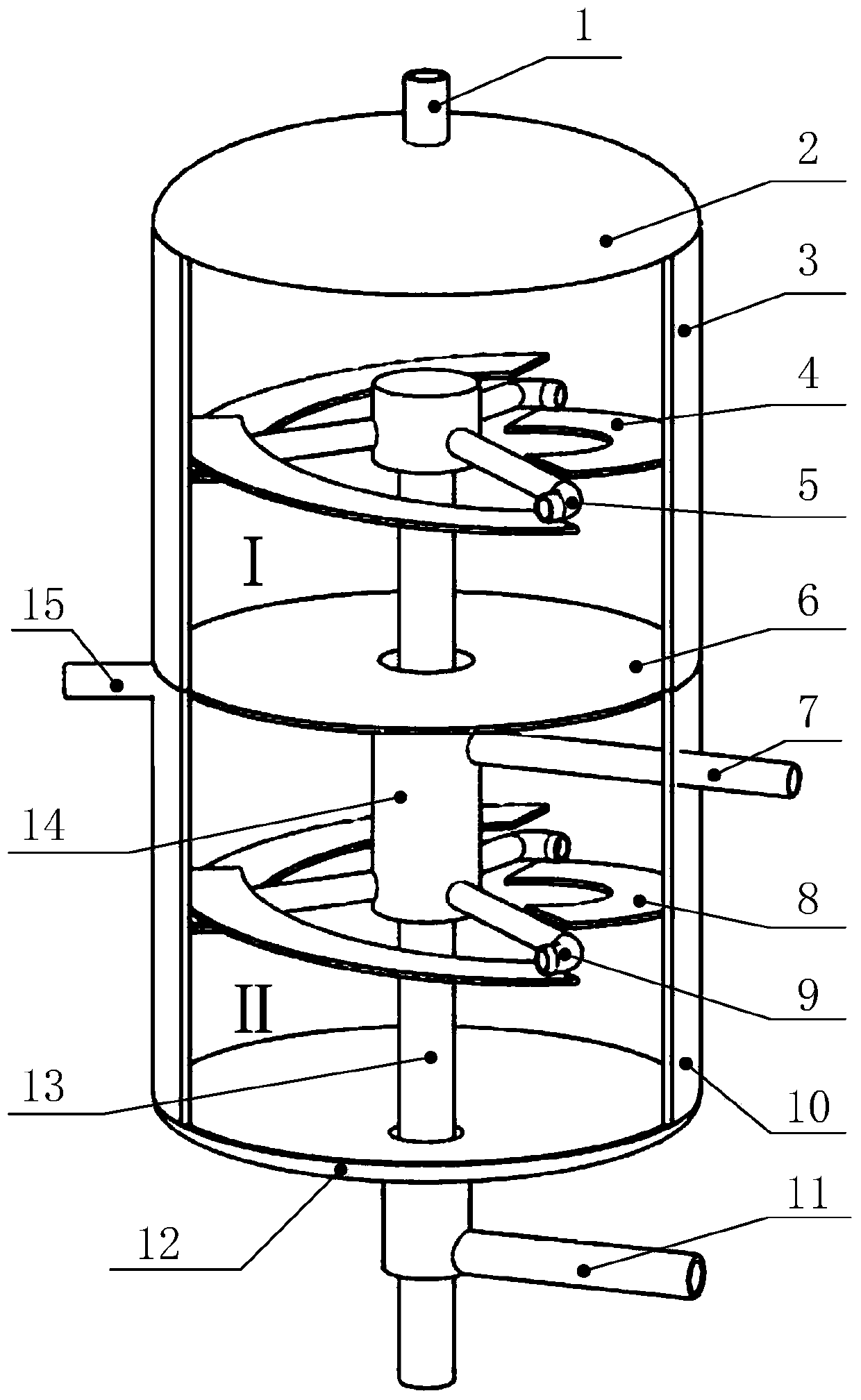

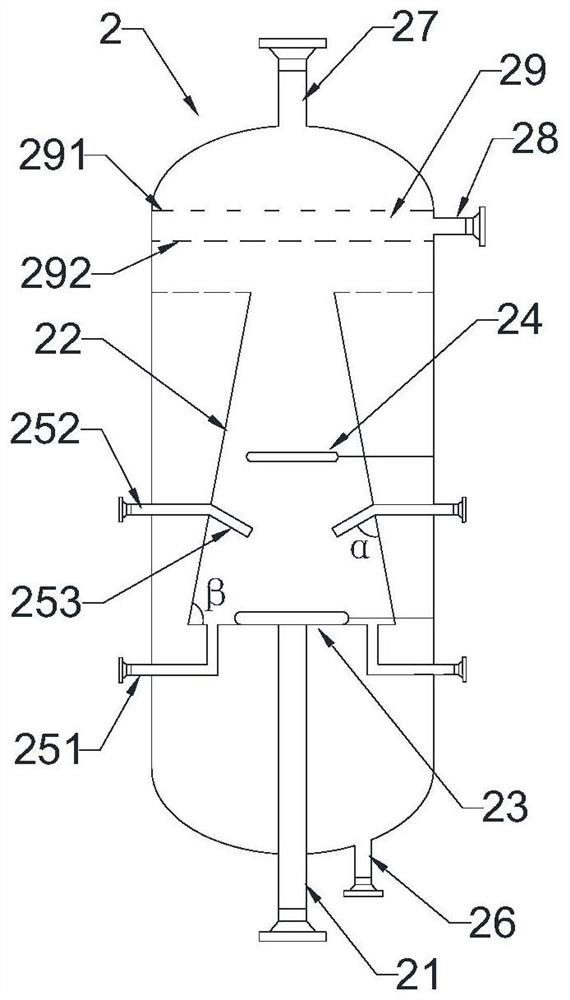

Single-stage, multi-stage and variable-stage rotational flow air floatation oil-containing sewage treatment device

ActiveCN110902758AFacilitates collision adhesionEasy to separateWaste water treatment from quariesFatty/oily/floating substances removal devicesSewage treatmentTreated water

The invention discloses a single-stage, multi-stage and variable-stage rotational flow air floatation oil-containing sewage treatment device, which comprises an outer shell comprising all stages of cylinder bodies, an upper seal head and a lower seal head, an inlet and outlet pipeline part comprising all stages of overflow pipes, all stages of reflux pipes, an underflow pipe and a central verticalpipe, and an internal structure comprising all stages of water distribution pipes, all stages of flow guide plates, annular channels and treated water collecting plates, wherein the first-stage overflow pipe is positioned at the top of the upper seal head, other overflow pipes are positioned on the upper side surfaces of various stages of the cylinder bodies, the underflow pipe is positioned at the lower seal head, various stages of the reflux pipes penetrate through various stages of the cylinder bodies and are communicated with various stages of the annular channels, the central vertical pipe is located on the axis of the cylinder bodies and penetrates through the lower seal head, the annular channels and various stages of the cylinder bodies, the first-stage water distribution pipe ispositioned at the top of the central vertical pipe, other water distribution pipes are positioned at the bottoms of the annular channels, various stages of the flow guide plates spirally incline upwards and are fixed on the inner walls of various stages of the cylinder bodies, and the treated water collecting plate is positioned between the two cylinder bodies. The device of the invention is compact in structure, easy and convenient to operate, wide in applicability and good in oil removal effect, wherein the single-body multi-stage design meets the requirements of different effluent qualitiesand treatment capacities.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

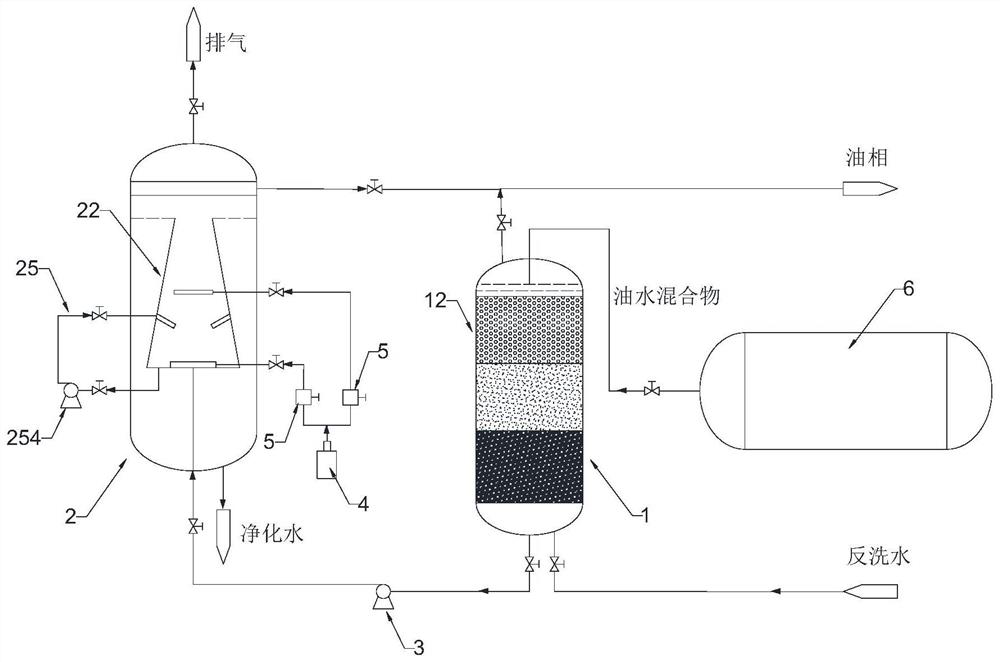

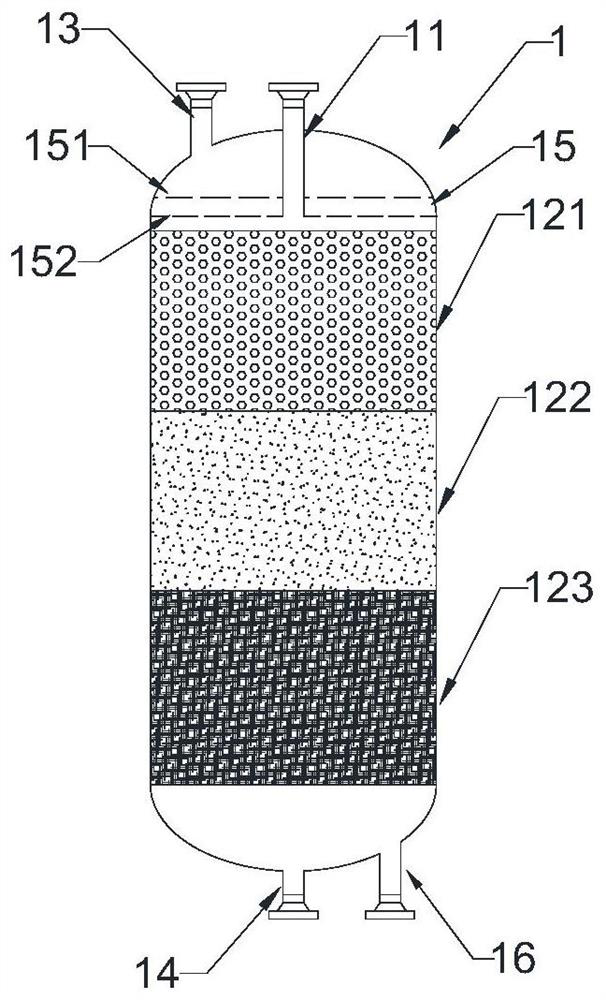

Complete device and method for enhancing oil-water separation by combining fiber particles and double bubbles

ActiveCN113461196AImprove separation efficiencyHigh oil removal efficiencyWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesFiberThermodynamics

The invention provides a complete device and method for enhancing oil-water separation by combining fiber particles and double bubbles, and the complete device comprises a demulsification filtering unit and a rotational flow air flotation unit; the demulsification filtering unit is an oleophylic and hydrophobic fiber filter, and the interior of the demulsification filtering unit comprises a plurality of stages of fiber particle beds from top to bottom, and the demulsification filtering unit is used for coalescing, demulsifying and separating emulsion; the rotational flow air flotation unit is a double-bubble jet rotational flow type air flotation device, an air flotation inner cylinder is arranged in the air flotation device, and a first-stage bubble generator and a second-stage bubble generator are sequentially arranged in the air flotation inner cylinder from bottom to top and used for generating bubble groups and separating oil and water under the air flotation effect; a circulating injection mechanism comprising an entrainment nozzle is arranged on the air floatation inner cylinder, a swirling flow field is formed in the air floatation inner cylinder, and liquid drop collision and separation are accelerated; oil-water separation is enhanced through coupling of the circulating injection mechanism, the first-stage bubble generator and the second-stage bubble generator. The complete device and the method have the advantages of stable operation, wide adaptability, high oil-water separation efficiency and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com