Swirl-type oil removal machine

A technology of degreasing machine and swirling flow, which is applied in the field of cleaning large-area oil leakage accidents, can solve the problems of low degreasing efficiency, untimely degreasing, enlarged polluted area, inconvenient cleaning work, etc., and achieve the effect of improving degreasing efficiency

Inactive Publication Date: 2010-03-31

北京市八荣科技有限责任公司

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the process of industrial production and waterway transportation of oil, due to sudden leakage accidents, the oil enters the water body and causes pollution accidents. The oil efficiency is too low, which expands the polluted area, especially the large amount of oil slicks leaked on rivers and seas, resulting in the continuous expansion of the polluted area due to untimely removal, which brings inconvenience to the cleaning work

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

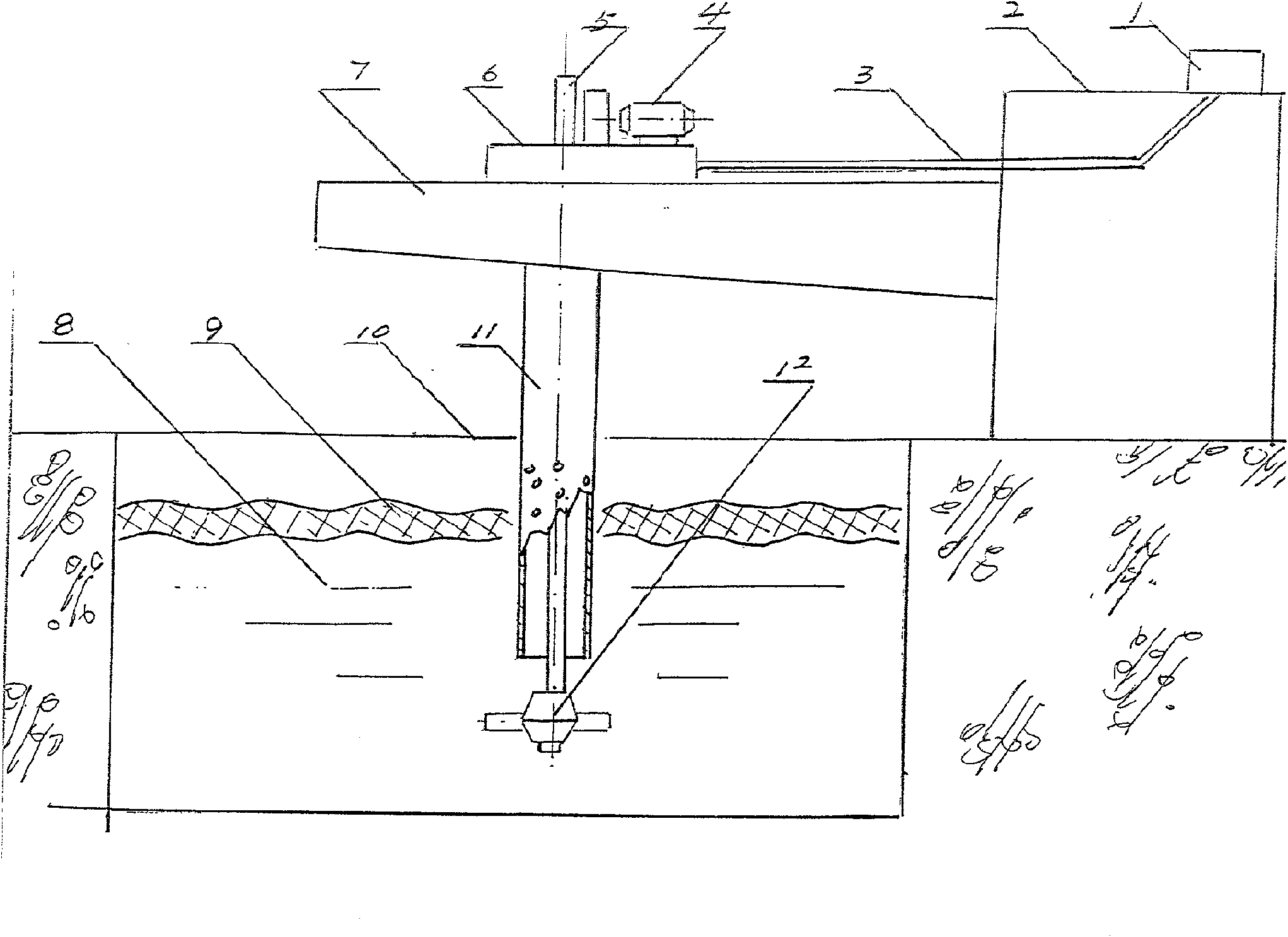

[0014] In Figure (1), (5) the liftable main shaft is installed on (6) the mobile positioning frame and is driven by (4) driving motor to do dragging motion. (12) helical blade is fixed on (5) bottom end of liftable main shaft. (11) Sleeve type oil suction pipe is connected with (3) oil suction hose through (10) oil suction pump to suck the accumulated oil into (2) cantilever bracket attached oil tank.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a swirl-type oil removal machine for removing grease in water body. The technical characteristics of the oil removal machine are as follows: utilizing different specific gravity of oil molecule and water molecule, a mechanism of endured different centrifugal forces and a gravity potential difference mechanism, adopting high-speed rotation of a helical blade in the water body to enable the water body to generate whirl and form swirl to lead the floating oil floating on the surface of the water body to rapidly concentrate in the center of the swirl under the action of gravity potential difference and centrifugal force, and utilizing an oil suction pipe to suck the concentrated floating oil. The structure of the oil removing machine is as follows: a lifting main shaftis installed on a mobile main-shaft positioning frame to drive the main shaft to rotate by driving a motor, the helical blade fixed at the tip of the main shaft rotates with the main shaft, a cantilever for supporting the above device is integrated with a cantilever shalving deposition oil box into a whole, a sleeve-type oil suction pipe is connected with an oil suction hose, and grease aggregating at the center of the swirling center is sucked into the deposition oil box by an oil suction pump.

Description

1. Technical field: [0001] The invention relates to a swirl type degreasing machine capable of removing dirty oil in a water body. The helical blade rotates at a high speed in the water body so that the water body generates a swirl and forms a vortex. The slick oil on the surface of the water body quickly gathers in the center of the vortex and is sucked away through the oil suction pipe. This technology is especially suitable for cleaning up large-scale oil spill accidents. 2. Background technology: [0002] In the process of industrial production and waterway transportation of oil, due to sudden leakage accidents, the oil enters the water body and causes pollution accidents. The oil efficiency is too low, so that the pollution area is enlarged, especially a large amount of oil slicks leaked on rivers and seas cause the pollution area to continue to expand due to untimely removal, which brings inconvenience to the removal work. 3. Contents of the invention: [0003] The...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F1/40

Inventor 韩涛

Owner 北京市八荣科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com