Environmentally friendly industrial heavy oil cleaning agent

A heavy oil pollution cleaning agent and a technology for oil pollution cleaning agent are applied in the field of environmentally friendly industrial heavy oil pollution cleaning agents, which can solve the problems that surfactants cannot be cleaned, surfactants are difficult to degrade, and surfactants are not environmentally friendly, and achieve excellent Detergent performance, good biodegradation performance, environmental friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the environment-friendly industrial heavy oil stain cleaning agent of the present invention comprises the steps:

[0027] S1. Mix sodium carbonate, sodium hydroxide, sodium silicate, sodium gluconate and benzotriazole in proportion, add deionized water, stir and dissolve at room temperature, and obtain mixed solution A;

[0028] S2. Add the surfactant into the mixed solution A and stir evenly to obtain the heavy oil stain cleaning agent. Example 1

Embodiment 1

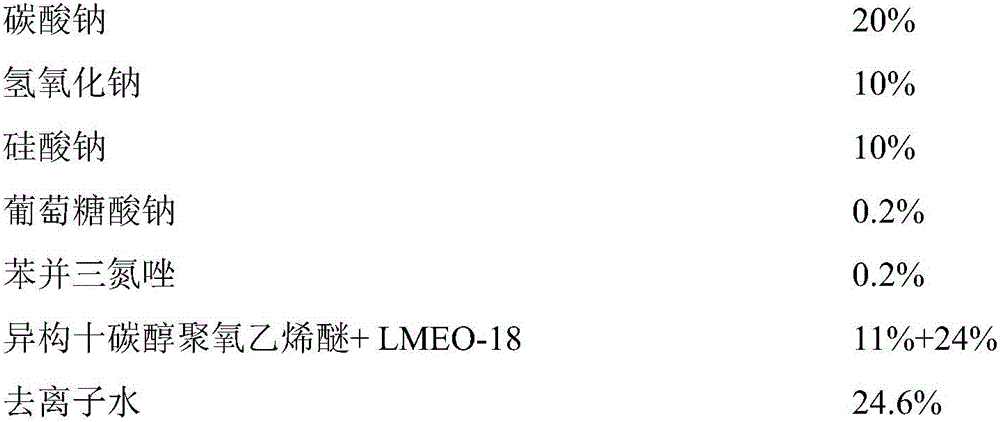

[0029] An environment-friendly industrial heavy oil stain cleaning agent, calculated by mass percentage, its raw material composition and content are as follows:

[0030]

[0031] Remarks: 11%+24% in the above formula means that the mass fractions of isomeric decanol polyoxyethylene ether and LMEO-18 are 11% and 24%, respectively, and the following examples refer to the same.

Embodiment 2

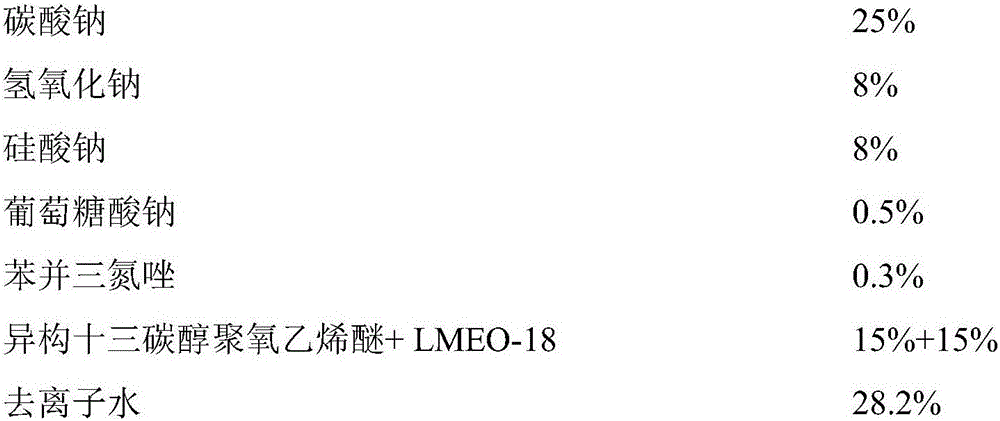

[0033] An environment-friendly industrial heavy oil stain cleaning agent, calculated by mass percentage, its raw material composition and content are as follows:

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com