Deoiling-dephenolization combined treatment method for high-concentration phenol ammonia wastewater and system

A combined treatment and high-concentration technology, applied in the direction of flotation water/sewage treatment, extraction water/sewage treatment, neutralization water/sewage treatment, etc. Chemical industry and other problems, to achieve the effect of improving wastewater treatment efficiency, improving extraction efficiency, and improving distribution coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

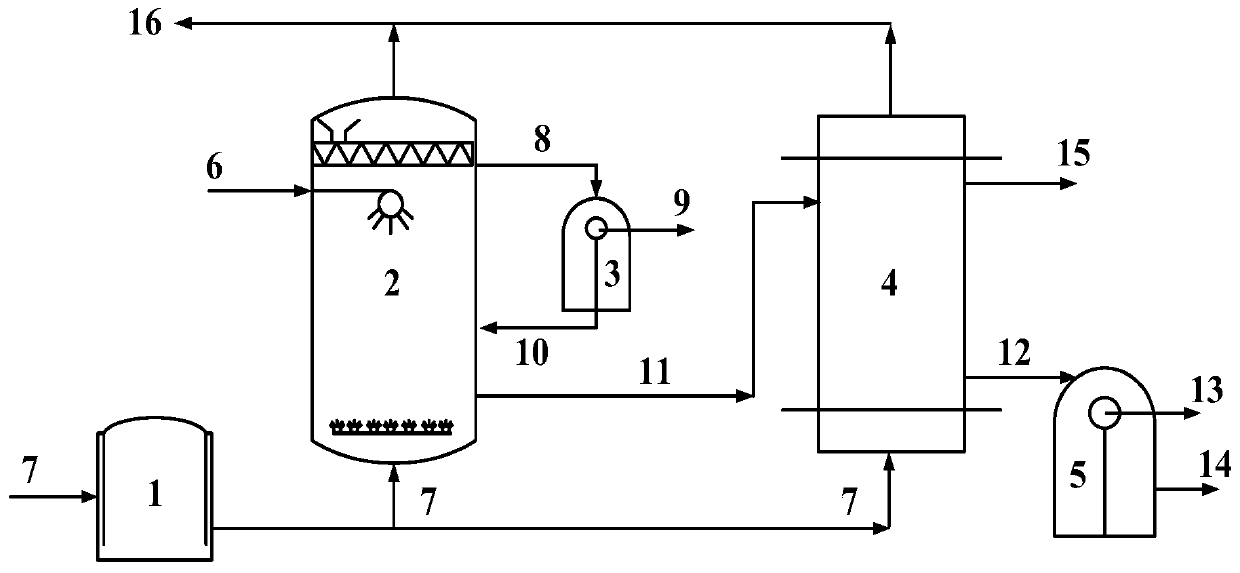

[0037] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0038] The combined treatment method of oil removal and dephenolization of a kind of high-concentration phenolic ammonia wastewater of the present invention, the index of described high-concentration phenolic ammonia wastewater is: COD=10000~30000mg / L, volatile phenol=2000~10000mg / L, oil= 500~3000mg / L, ammonia nitrogen=2000~8000mg / L; pH value=7~14;

[0039] Such as figure 1 Shown, described deoiling and dephenolizing combined treatment method comprises the following steps:

[0040] (1) Air flotation and oil removal of coke oven flue gas;

[0041] High-concentration phenol ammonia waste water 6 enters from the upper part of the air flotation tank 2, and coke oven flue gas 7 enters from the gas collection chamber at the bottom of the air flotation tank 2 as foaming gas; carbon dioxide, nitrogen and waste heat in the coke oven flue gas are used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com