Liquid-state hydrocarbon waste alkali liquid treatment method

A technology of liquid hydrocarbon waste lye and treatment method, which is applied in chemical instruments and methods, flotation water/sewage treatment, neutralized water/sewage treatment, etc. Efficiency-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

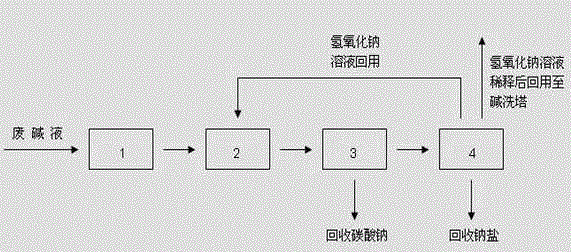

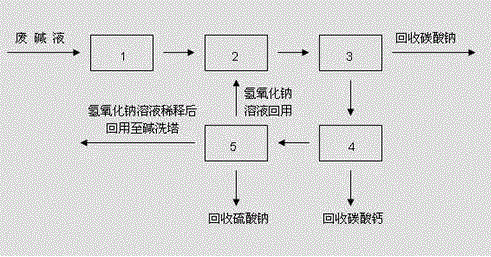

Image

Examples

Embodiment 1

[0032] A stream of liquid hydrocarbon waste lye, its COD is 298000mg / L, S 2-The concentration is 37500mg / l, the concentration of phenol is 23850mg / L, the concentration of sodium carbonate is 25670mg / L, the concentration of sodium hydroxide is 0.5wt%, and the concentration of oil is 190mg / L. Adopt the inventive method to process under the following conditions:

[0033] (1) Air flotation degreasing: Air is introduced into the waste lye to generate air bubbles in the waste lye, and a small amount of light oil entrained in the waste lye sticks to the air bubbles, and is removed by floating on the water surface with the gas. The oil content in the waste lye drops to 17mg / L.

[0034] (2) High-temperature wet oxidation treatment: the reaction temperature of wet oxidation treatment is 290°C, the reaction pressure is 12.0MPa, and the reaction residence time is 60min. Add dilution water and the 50wt% sodium hydroxide solution obtained in step (4) to the solution. Add 1.7m3 of diluted...

Embodiment 2

[0039] A stream of liquid hydrocarbon waste lye, its COD is 367600mg / L, S 2- The concentration is 72900mg / l, the concentration of phenol is 43820mg / L, the concentration of sodium carbonate is 31271mg / L, the concentration of sodium hydroxide is 0.6wt%, and the concentration of oil is 210mg / L. Adopt the inventive method to process under the following conditions:

[0040] (1) Air flotation degreasing: Air is introduced into the waste lye to generate air bubbles in the waste lye, and a small amount of light oil entrained in the waste lye sticks to the air bubbles, and is removed by floating on the water surface with the gas. The oil content in the waste lye drops to 20mg / L.

[0041] (2) High-temperature wet oxidation treatment: the reaction temperature of wet oxidation treatment is 290°C, the reaction pressure is 12.0MPa, and the reaction residence time is 60min. Dilution water and 40 wt% sodium hydroxide solution were added to the solution. Add 2.45m3 of diluted water and 550L...

Embodiment 3

[0046] A stream of liquid hydrocarbon waste lye, its COD is 256800mg / L, S 2- The concentration is 29400mg / L, the concentration of phenol is 19860mg / L, the concentration of sodium carbonate is 21750mg / L, the concentration of sodium hydroxide is 0.6wt%, and the concentration of oil is 176mg / L. Adopt the inventive method to process under the following conditions:

[0047] (1) Air flotation degreasing: Air is introduced into the waste lye to generate air bubbles in the waste lye, and a small amount of light oil entrained in the waste lye sticks to the air bubbles, and is removed by floating on the water surface with the gas. The oil content in the waste lye drops to 13mg / L.

[0048] (2) High-temperature wet oxidation treatment: the reaction temperature of wet oxidation treatment is 290°C, the reaction pressure is 12.0MPa, and the reaction residence time is 60min. Dilution water and 50 wt% sodium hydroxide solution were added to the solution. Add 1.7 m3 of dilution water and 300...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com