Complete device and method for enhancing oil-water separation by combining fiber particles and double bubbles

A fiber particle, oil-water separation technology, applied in chemical instruments and methods, centrifugal separation water/sewage treatment, multi-stage water treatment, etc. High-efficiency separation, high-efficiency device, and accelerated floating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

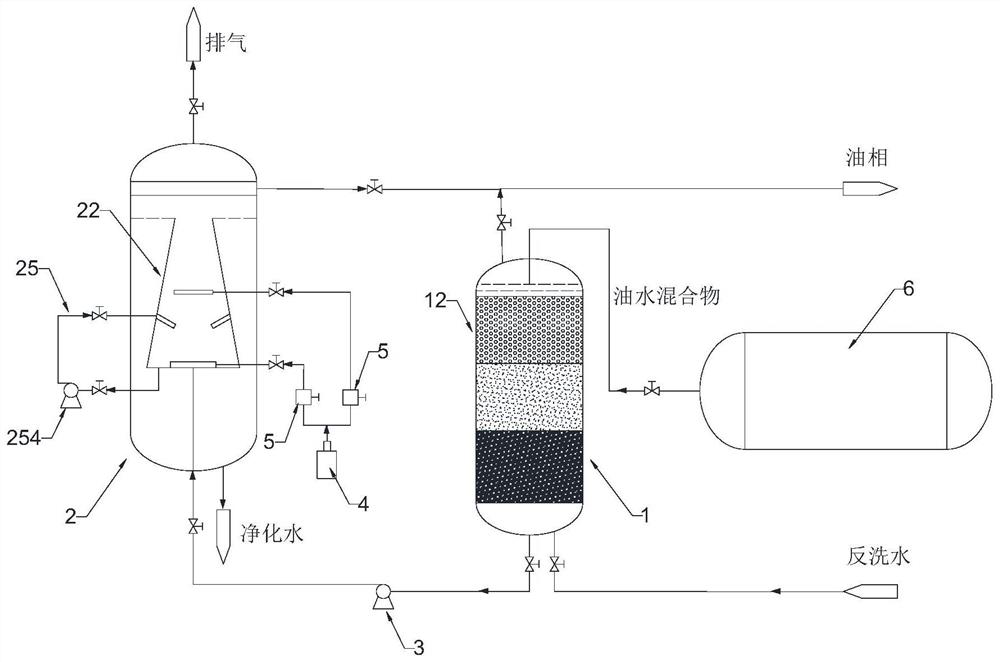

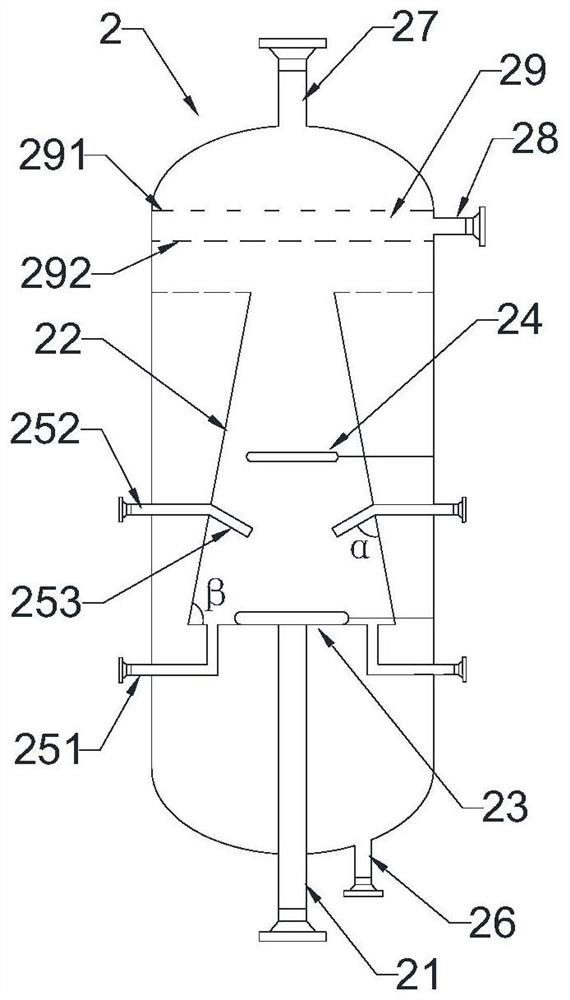

[0036] The invention provides a complete set of equipment for strengthening oil-water separation with fiber particles combined with double bubbles, such as figure 1 As shown, the complete set of equipment for strengthening oil-water separation includes a demulsification filter unit 1 and a cyclone air flotation unit 2, wherein:

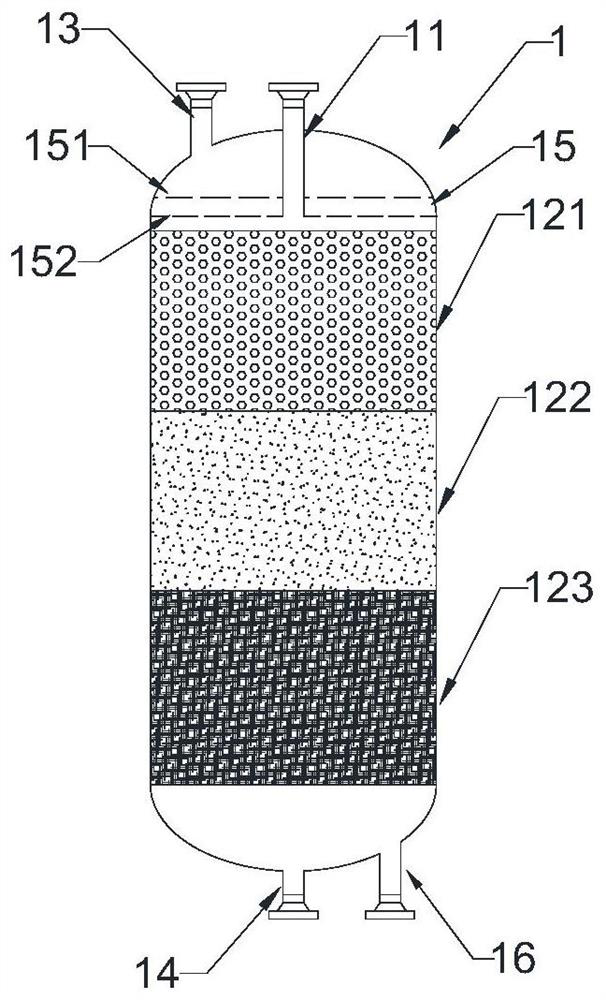

[0037] combine figure 2 As shown, the demulsification filter unit 1 is a hydrophilic and hydrophobic fiber filter, the top of the filter 1 is provided with a feed inlet pipeline 11, and the filter 1 includes several stages of fiber particle beds 12 from top to bottom, The surroundings of the fiber particle bed 12 are connected to the inner wall of the filter 1 and the feed inlet pipeline 11 communicates with the uppermost fiber particle bed 12, so that the oil-water mixture entering the filter 1 is directly connected to the filter 1. The fiber particle bed 12 contacts, coalesces and separates under the action of the fiber particles, the top wall of ...

Embodiment 2

[0059] A petrochemical company utilizes the complete set of equipment described in Embodiment 1 to strengthen oil-water separation, and the flow rate of the inlet pipeline of the filter is 12m 3 / h, the oil content is 10000mg / L, and the solid content is 0.05%.

[0060] The nominal diameter of the filter is 300mm, the tangent length of the container is 1327mm, and the thickness of the primary fiber particle bed, the secondary fiber particle bed and the tertiary fiber particle bed are all 260mm; the nominal diameter of the air flotation device is 377mm, The tangent length of the container is 1457mm.

[0061]The water content of the oil phase in the oil phase outlet of the filter after the oil-water separation of the complete set of equipment is 4.6%, and the oil content of the water phase in the water phase outlet of the filter is 1720mg / L; the oil in the oil phase outlet of the air flotation device The water content of the phase is 3.9%, and the oil content of the water phase ...

Embodiment 3

[0064] A petrochemical company utilizes the complete set of equipment described in Embodiment 1 to strengthen oil-water separation, and the flow rate of the inlet pipeline of the filter is 8m 3 / h, the oil content is 10350mg / L, and the solid content is 0.08%.

[0065] The nominal diameter of the filter is 300 mm, the tangent length of the container is 1327 mm, and the thickness of the primary fiber particle bed, the secondary fiber particle bed and the tertiary fiber particle bed are all 260 mm; the nominal diameter of the air flotation device is 377 mm, The tangent length of the container is 1457mm.

[0066] After the oil-water separation of the complete set of equipment, the water content of the oil phase in the oil phase outlet of the filter is 3.8%, and the oil content of the water phase in the water phase outlet of the filter is 1481mg / L; the oil phase in the oil phase outlet of the air flotation device The water content is 3.2%, and the oil content of the water phase in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com