Preparation method of metal-organic framework porous adsorption material for normal paraffin and isoparaffin adsorption separation

A metal-organic framework and porous adsorption material technology, applied in the direction of adsorption purification/separation, organic chemistry, alkali metal compounds, etc., can solve the problems of low yield per unit adsorbent, low adsorption capacity, etc., and achieve controllable surface potential energy, adsorption The effect of large capacity and excellent selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

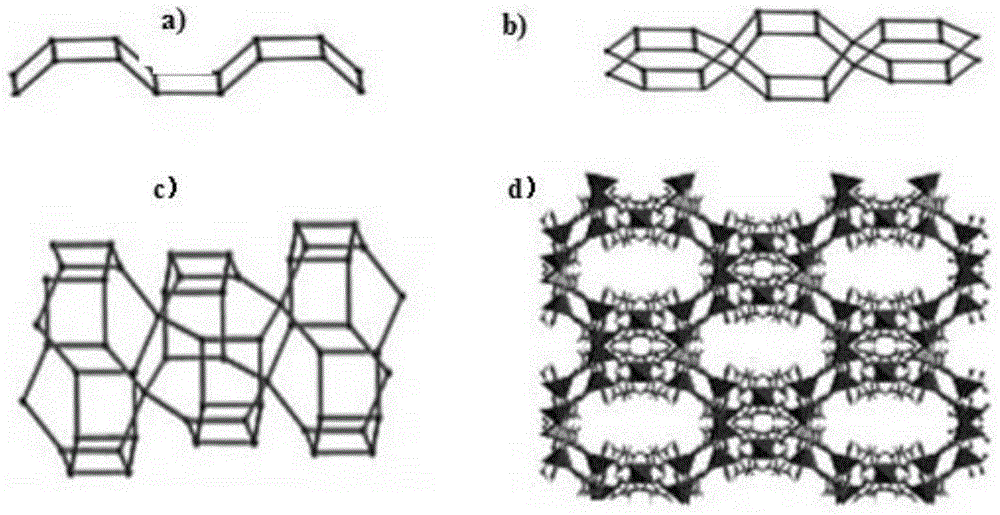

Embodiment 1

[0030] 1.0g of 2-methylimidazole and 1.0g of zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O) Dissolve in a mixed solvent prepared by 50ml N,N-dimethylformamide and 50ml N,N-diethylformamide, mix evenly and pour into a polytetrafluoroethylene reactor, the reaction temperature is 150°C, and the reaction time is 12h , to synthesize three-dimensional cage-like metal-organic frameworks by hydrothermal synthesis. Its three-dimensional structure is as figure 1 As shown, the framework structure consists of dodecahedral Zn(ClbIm) 2 and polycyclic rings. At a temperature of 180°C and a pressure of 0.5Mpa, the binary mixture components n-hexane and 2,2-dimethylbutane are completely separated, 2,2-dimethylbutane is hardly adsorbed, and the adsorption capacity of n-hexane reaches 15.6g / 100g ads , showing excellent selectivity and high adsorption capacity of the adsorbent.

Embodiment 2

[0032]2.0g nickel nitrate (Ni(NO 3 ) 2 6H2O), 4.0g 1,3,5-triethyl benzenetricarboxylate (C 15 h 18 o 6 ) and 8.0g imidazole mixed components were dissolved in 200ml N,N-dimethylformamide and 250ml N,N-diethylformamide solvent, stirred at 30°C for 30min, kept the reaction temperature at 80°C for 24h, passed Synthesis of three-dimensional metal-organic frameworks by hydrothermal synthesis. The three-dimensional structure of the adsorbent described in Example 2 is composed of 1,3,5-triethyl benzenetricarboxylate, imidazole, nickel atoms and oxygen atoms, such as figure 2 shown. At a temperature of 110°C and a pressure of 0.15Mpa, the ternary mixed components of n-pentane, 2-methylbutane and methylcyclopentane were successfully separated, and the adsorbent in Example 2 hardly adsorbed isoparaffins , The adsorption capacity for n-pentane reaches 18.5g / 100gads.

Embodiment 3

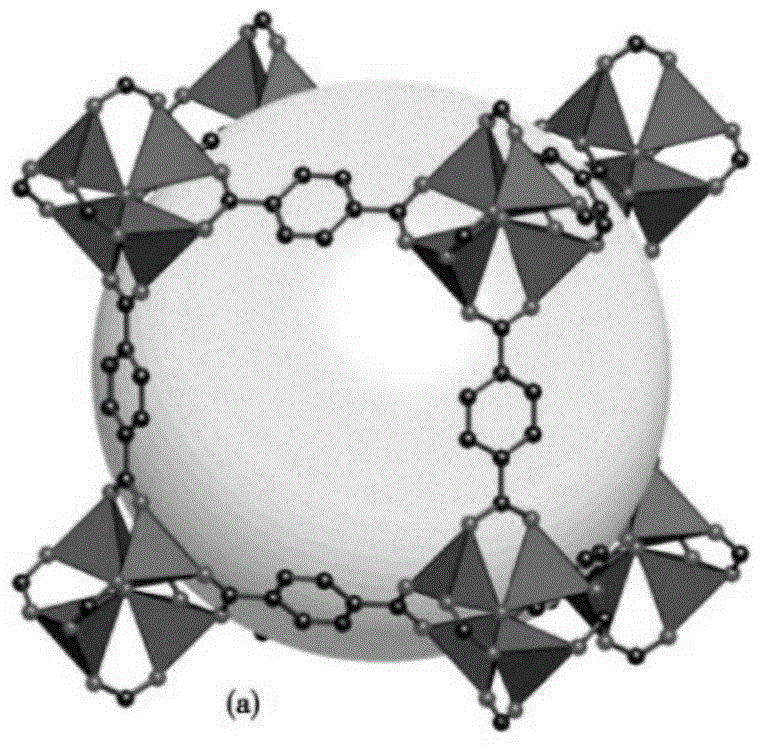

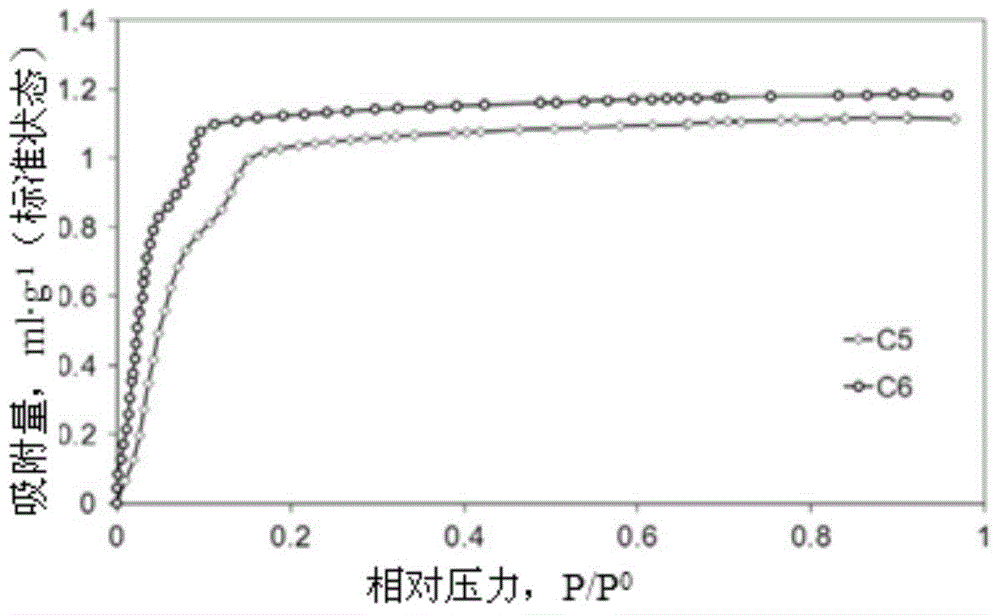

[0034] 2.0g aluminum nitrate (Al(NO 3 ) 3 ) and 30g of 1,4-benzenedicarboxylate, add solvent 40mllN,N-dimethylformamide and 200mlN,N-diethylformamide mixed solution, stir for 12h, mix well and pour into polytetrafluoroethylene to react In the kettle, keep the reaction temperature at 215°C, and react for 120h. Through the hydrothermal synthesis method, the three-dimensional network topology structure is obtained, and the adsorption isotherms of the three-dimensional organic framework material to n-pentane and n-hexane in Example 3 are as follows image 3 shown. The synthesized MOFs have an adsorption capacity of 20.0g / 100gads for the mixed component of n-pentane and n-hexane at a certain temperature and pressure, and have almost no adsorption capacity for multi-branched isoparaffins.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com