Patents

Literature

112 results about "Methylcyclopentane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methylcyclopentane is an organic compound with the chemical formula CH₃C₅H₉. It is a colourless, flammable liquid with a faint odor. It is a component of the naphthene fraction of petroleum. It usually is obtained as a mixture with cyclohexane. It is mainly converted in naphthene reformers to benzene.. Methylcyclopentane is not perfectly planar and can pucker to alleviate stress in its structure.

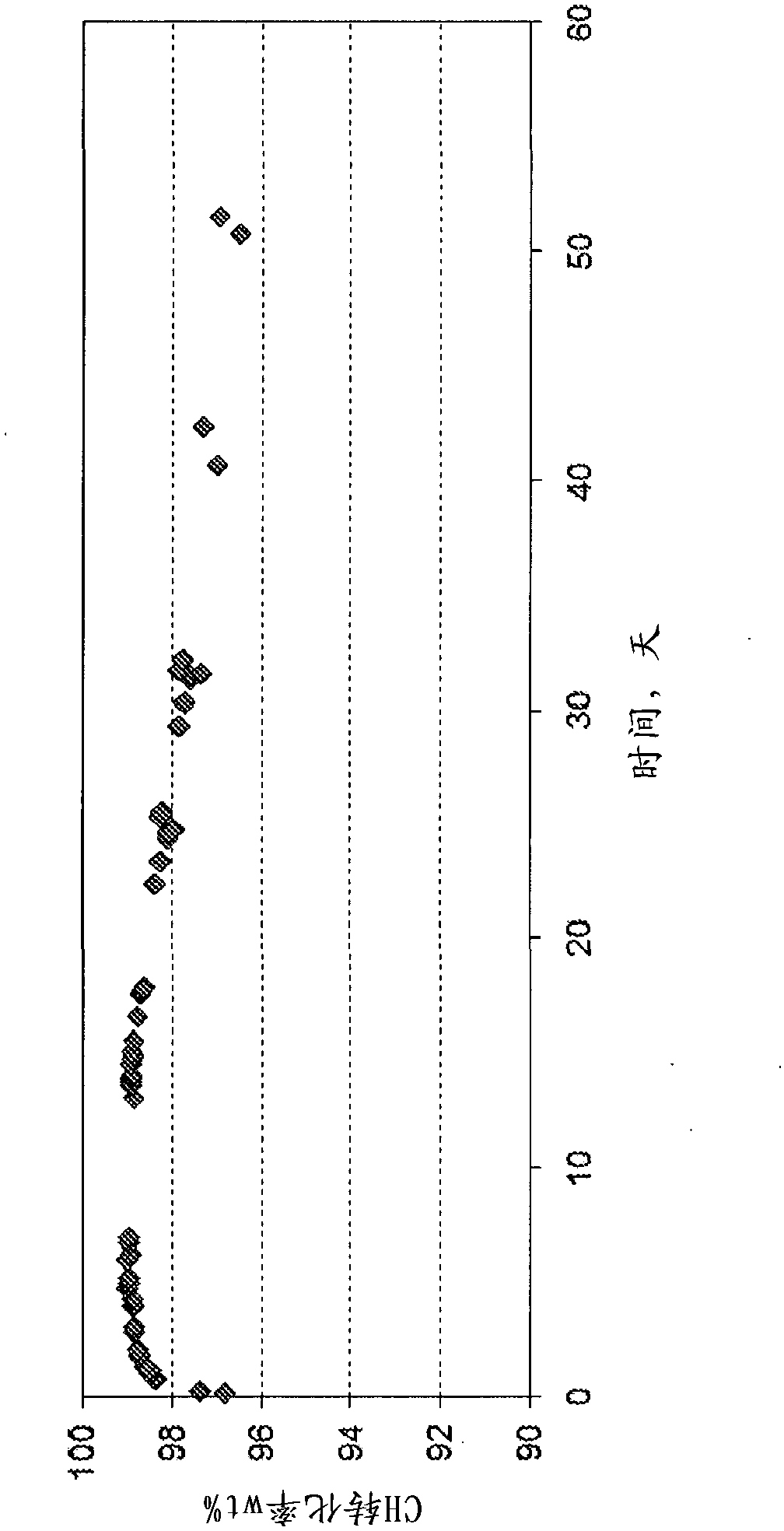

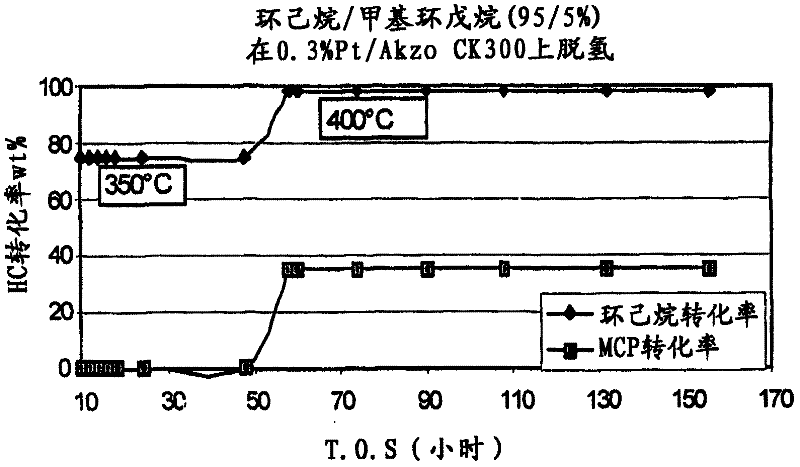

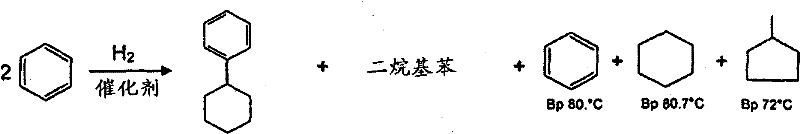

Process of producing cyclohexylbenzene

In a process for producing cyclohexylbenzene, benzene is contacted with hydrogen under hydroalkylation conditions effective to form a first effluent stream comprising cyclohexylbenzene, cyclohexane, methylcyclopentane, and unreacted benzene. At least a portion of the first effluent stream is contacted with a dehydrogenation catalyst under dehydrogenation conditions to convert at least a portion of the cyclohexane to benzene thereby forming a second effluent stream. The amount of methylcyclopentane in the second effluent stream is different by no more than 65% of the total amount of the portion of the first effluent stream, said amounts being on a weight basis. A methylcyclopentane-containing stream is removed from either the first or the second effluent stream and at least a portion of the second effluent stream containing benzene is recycled to the hydroalkylation step.

Owner:EXXONMOBIL CHEM PAT INC

Process for making cyclohexylbenzene

A process for making cyclohexylbenzene includes (a) contacting benzene and hydrogen in the presence of a first catalyst under hydroalkylation conditions sufficient to form a first effluent stream having cyclohexylbenzene, cyclohexane, methyl cyclopentane, and unreacted benzene, (b) supplying a portion of the first effluent stream to a first separation system to divide the first effluent stream part into (i) a C6-rich stream comppsing benzene, cyclohexane, and methylcyclopentane and (II) a cyclohexylbenzene-rich stream, (c) contacting a portion of the C6-rich stream with a second catalyst that catalyzes dehydrogenation and exhibits low acidity under conditions sufficient to convert a portion of the cyclohexane to benzene and a portion of the methylcyclopentane to linear and / or branched paraffins to form a second effluent stream, and (d); recycling a portion of the second effluent stream to the contacting step (a).

Owner:EXXONMOBIL CHEM PAT INC

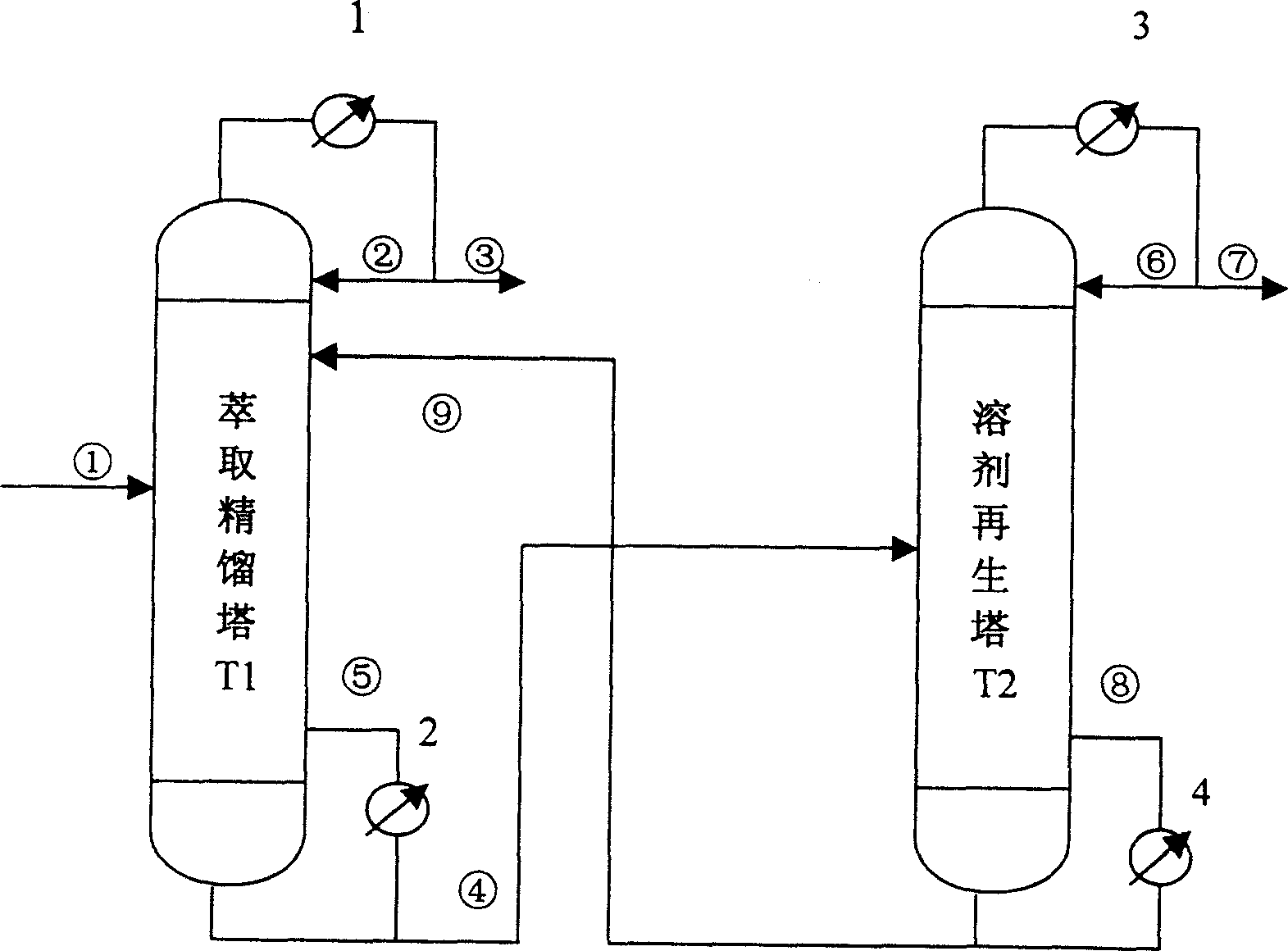

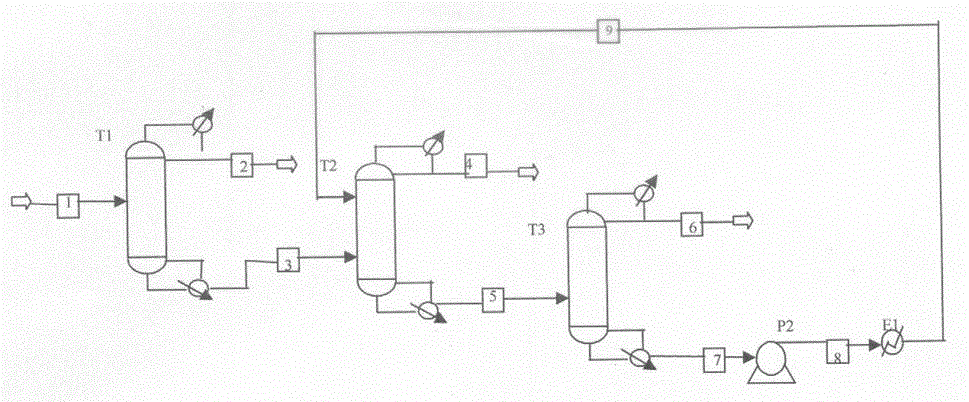

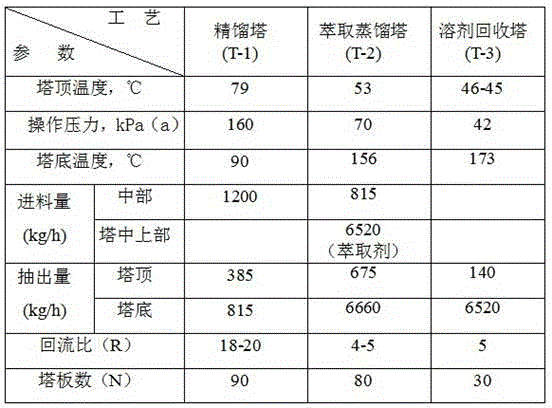

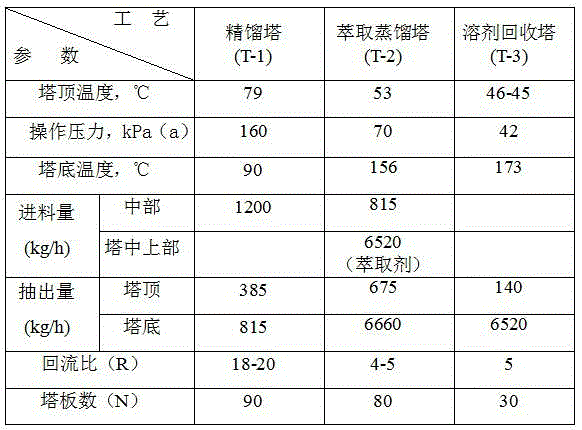

Extraction and rectification separation method for normal hexane and methyl cyclopentane

The extraction rectification separation method for normal hexane and methyl cyclopentane comprises: adding the industrial hexane and dimethyl phthalate into the tower with given ratio; after separation, there is high-purity normal hexane on tower top, solution and methyl cyclopentane on tower kettle; putting the material in kettle to solution for distillation with methyl cyclopentane on tower top for further refine; recycling the solution. Wherein, the ratio is 1:3~5. This invention has recycle ratio more than 90% with purity more than 98%, and has no pollution.

Owner:NANJING UNIV OF TECH

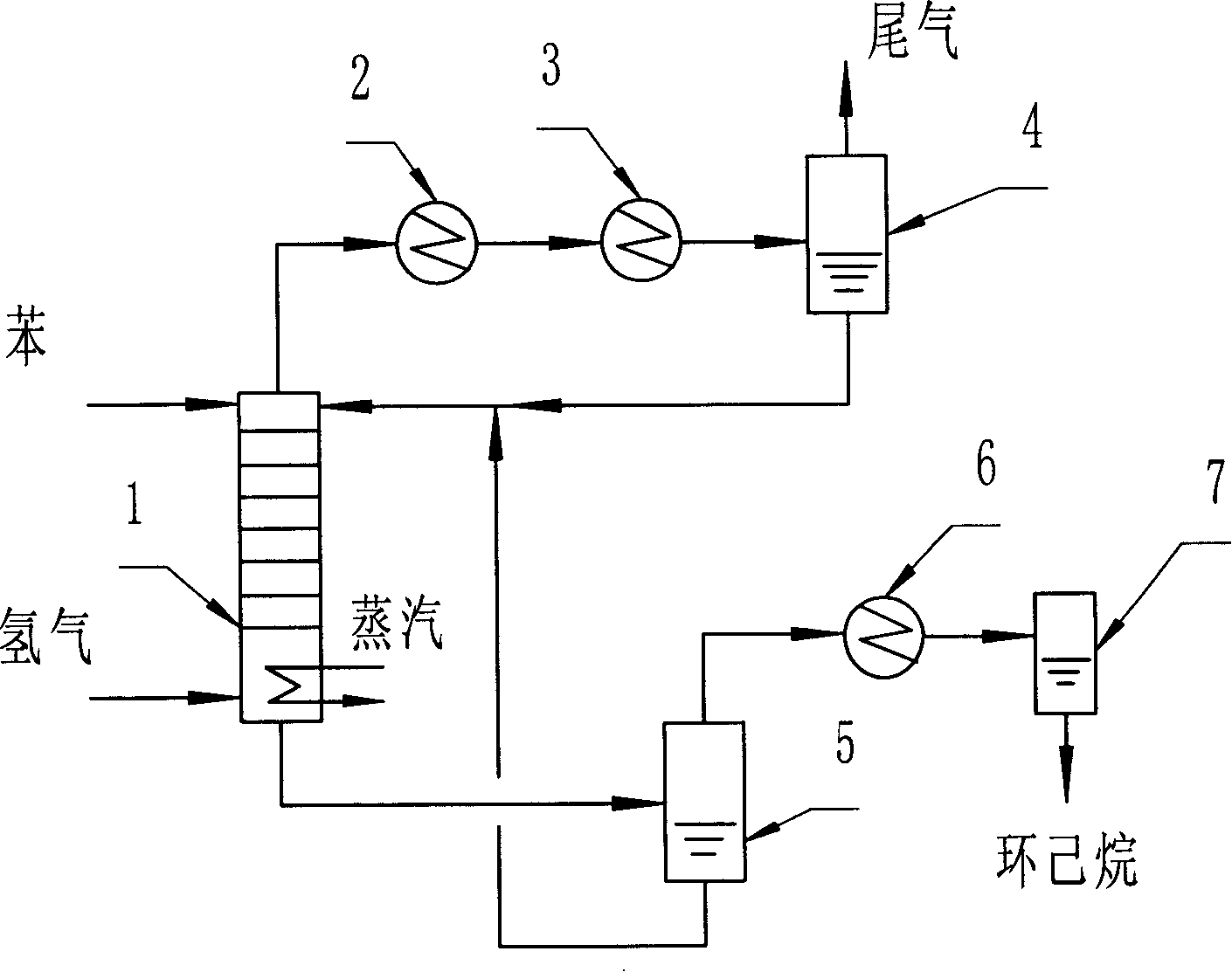

Preparation method of cyclohexane

ActiveCN101205163ASolve the problem of heat transferStable reaction temperatureHydrocarbon by hydrogenationBenzeneHydrogen

A method for preparing a cyclohexane comprises the following steps: a benzene and a hydrogenation catalyst are driven to enter a distillation tower from the tower top and the hydrogen goes into the distillation tower from the tower bottom; the tower bottom is heated by the steam and a reaction in which the benzene hydrogenation is used for generating the cyclohexane is conducted in the tower; the condensate at the tower top refluxes and the discharged materials from the tower bottom are subject to the flash separation so as to obtain the cyclohexane. The method of the invention can lower the content of the methyl cyclopentane in the products and is beneficial to the stabilized operation and the enhancement of the hydrogen utilization ratio and the effective reaction volume of the tower.

Owner:CHINA PETROLEUM & CHEM CORP +1

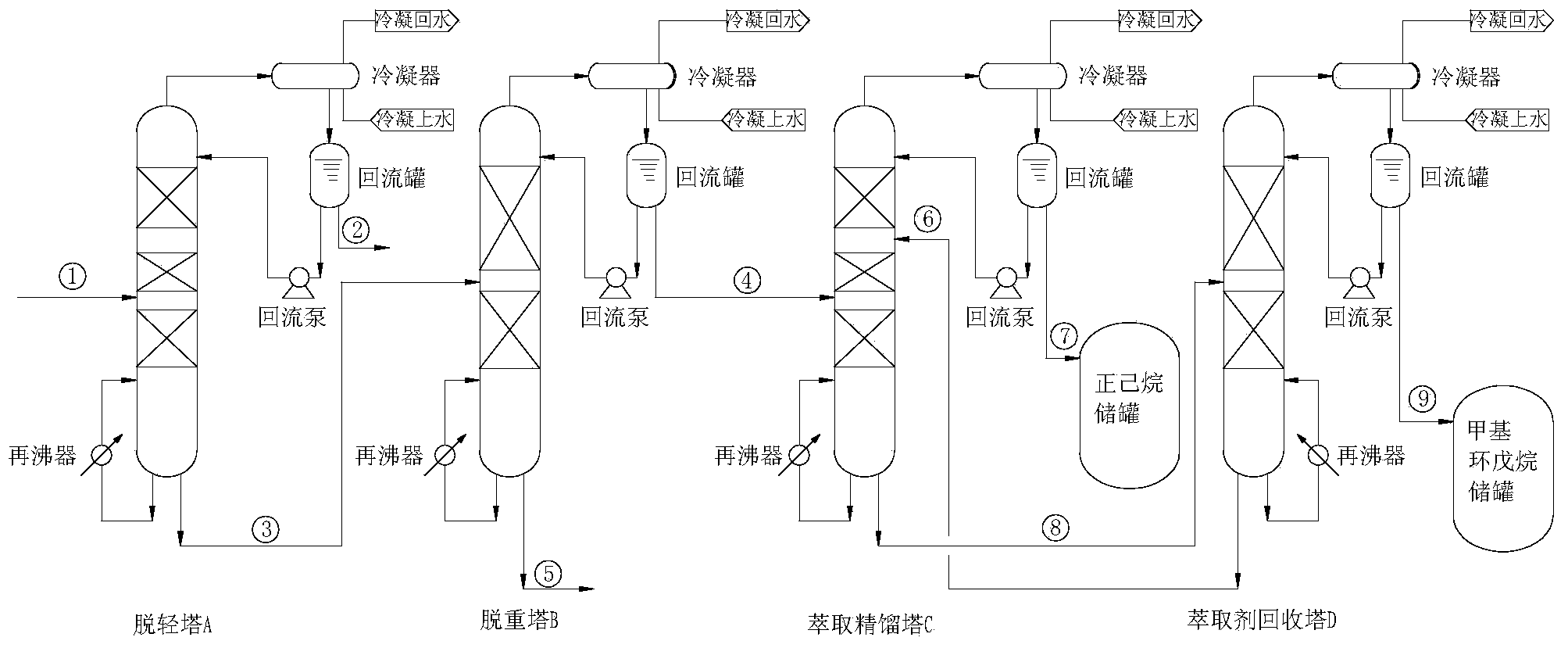

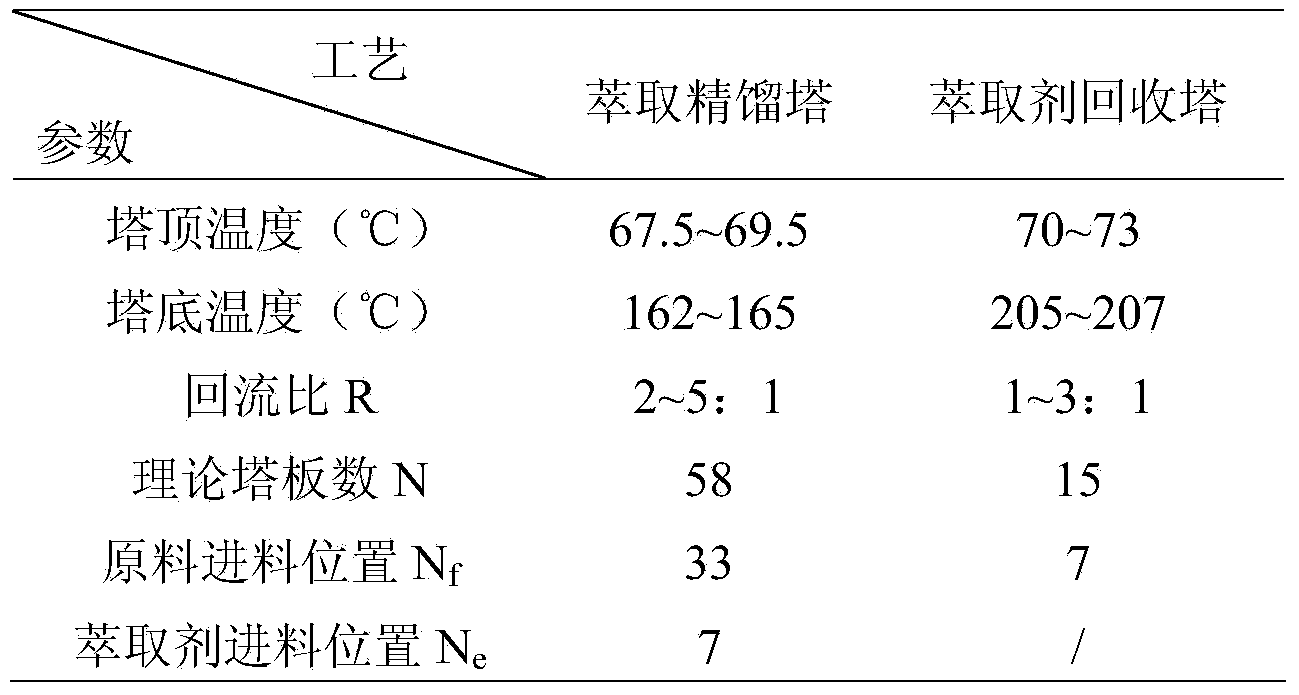

Technology for separating n-hexane-methylcyclopentane through extractive distillation

InactiveCN103664446ANo pollution in the processSimple processDistillation purification/separationExtractive distillationReactive distillation

A technology for separating n-hexane-methylcyclopentane through extractive distillation comprises the steps as follows: light components are removed from industrial raw materials containing n-hexane and methylcyclopentane in a light component removal column, the materials without light components enter a heavy component removal column for separation to obtain heavy components and the material without the heavy components, and the materials without the heavy components enter an extractive distillation column for separation of n-hexane and methylcyclopentane; n-hexane flows out of the column top, and a mixed solution of an extraction agent and methylcyclopentane is extracted from a column kettle; and the mixed solution is subjected to regeneration treatment in an extraction agent recovery tower to realize recycling of the extraction agent. The technology has the advantages of simple technological process, low extraction agent price, recycling, high product purity, high yield, lower energy consumption and environmental friendliness.

Owner:SEDIN ENG

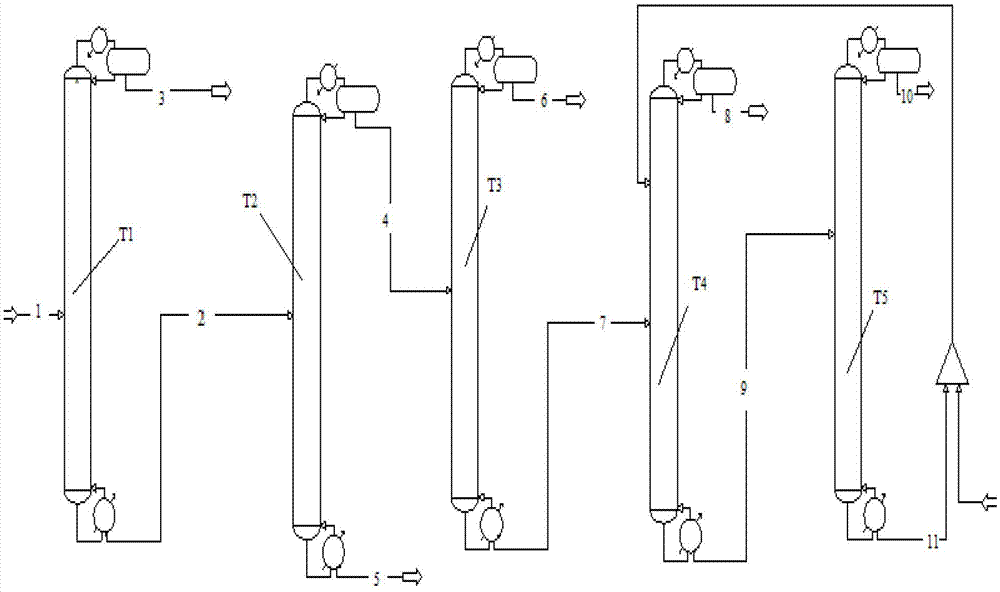

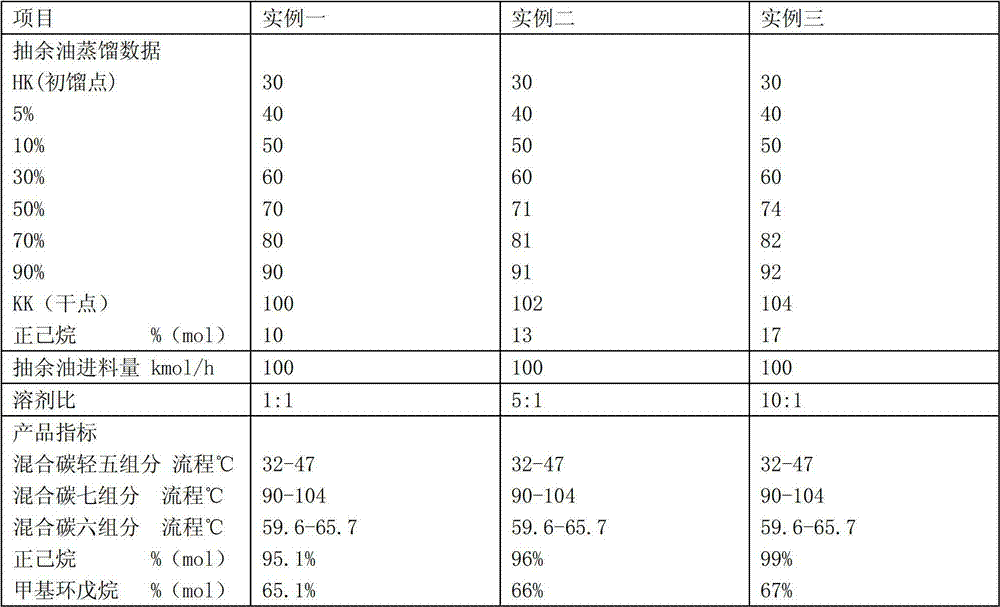

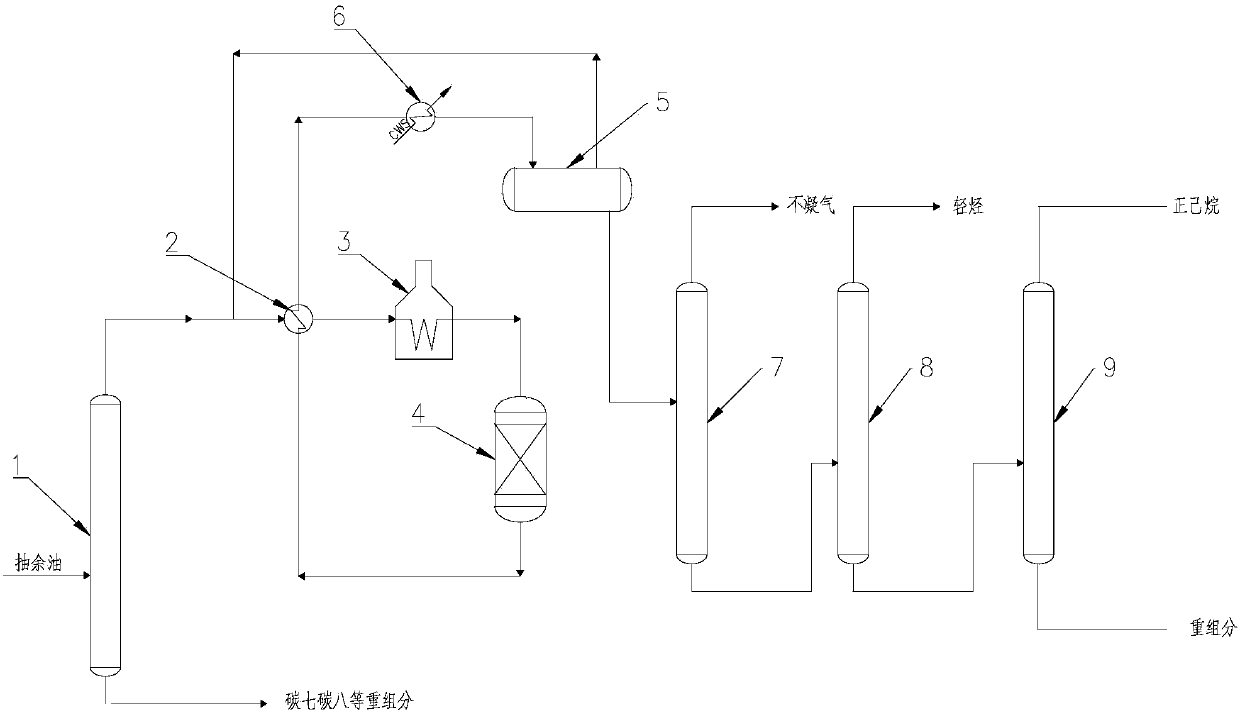

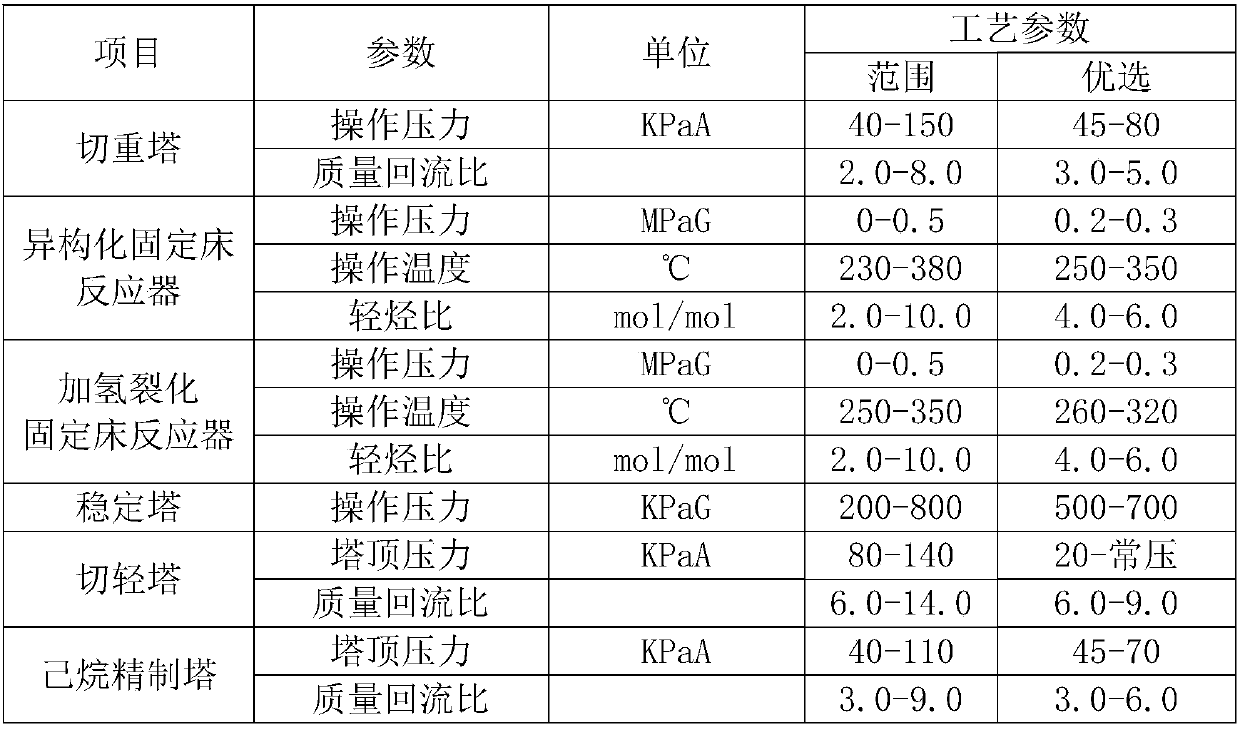

Process for producing n-hexane by using reformate raffinate oil

ActiveCN103588603ASolve the problem of comprehensive utilization of reforming raffinate oilIncrease concentrationDistillation purification/separationAfter treatmentExtractive distillation

The invention relates to a process for producing n-hexane by using reformate raffinate oil. After the raffinate oil is pre-treated in a C5 decarbonization tower, low-boiling mixed C5 light components are distilled from the top of the C5 decarbonization tower; mixed C6 and C7 components at the bottom of the C75 decarbonization tower enter into a C7 decarbonization tower; after the mixed C6 and C7 components are treated in the C7 decarbonization tower, mixed C7 components are discharged from the bottom of the C7 decarbonization tower; unseparated mixed components enter into a C6 decarbonization tower from the top of the tower; after treatment in the C6 decarbonization tower, distillates at the top of the C6 decarbonization tower are mixed C6 components, a mixture at the bottom of the C6 decarbonization tower enters into an extractive distillation tower; a fraction at the top of the extractive distillation tower is high pure n-hexane, a mixture at the bottom of the extractive distillation tower enters into a solvent recovery tower; a distillate at the top of the solvent recovery tower is methylcyclopentane and a distillate at the bottom of the solvent recovery tower is an extraction agent which can be reused. The process solves the problems of comprehensive utilization of the reformate raffinate oil of an oil refinery, and increases deep processing level of oil products. A concentration of n-hexane can reach over 95%; and simultaneously, the mixed C5, mixed C6 and mixed C7 components are recycled.

Owner:PETROCHINA CO LTD

Method extracting high purity n-hexane by integrating rectification and extraction

InactiveCN102942434AWide variety of sourcesImprove thermal stabilityDistillation purification/separationExtractive distillationReactive distillation

The invention relates to a method extracting high purity n-hexane by integrating rectification and extraction. The method utilizes aromatic hydrocarbon raffinate oil as a raw material and adopts a three-tower technological process which combines continuous rectification and extractive distillation. Firstly, distillate lighter than n-hexane is removed in a rectifying tower, and n-hexane distillate which is around 80% in content is obtained at the bottom of the tower. The distillate at the bottom of the tower is adopted as the raw material of an extractive distillation tower, N-methyl pyrrolidone is adopted as an extracting solvent to be delivered into the extractive distillation tower, and the proportion of the N-methyl pyrrolidone and raw oil is 8:1, after extractive distillation, high purity n-hexane is extracted at the top of the tower by integrating rectification and extraction, and heavy components which are rich in methylcyclopentane and the extracting solvent are at the bottom of the tower. Materials at the bottom of the tower are delivered into a solvent recovery tower, distillate oil which is rich in methylcyclopentane is separated at the top of the tower, and N-methyl pyrrolidone solvent is at the bottom of the tower and sent back to the extractive distillation tower to be recycled. By means of the method, n-hexane content can achieve 99%, no extracting solvent is contained in products, solvent consumption is smaller than 0.1%, one-off yield of n-hexane is larger than 95%, and compared with traditional rectification, energy consumption can be saved over 50%.

Owner:广州赫尔普化工有限公司

Normal hexane and benzene extractive distillation operating method

The invention relates to a normal hexane and benzene extractive distillation operating method. The device comprises a normal hexane separation extraction and rectification and purification system and a benzene extractive distillation rectification and purification system. The compounded N-methylpyrrolidone solvent or N-formyl morpholine solvent serves as an extraction agent, so that the relative volatility of aromatic hydrocarbon and non-aromatic hydrocarbon is improved, and the relative volatility of methyl cyclopentane and normal hexane is improved; two extracting agent recovery towers are in negative pressure operation, and the tower kettle temperature is relatively low; liquid-liquid phase does not occur in the two extracting agent recovery towers in the operation process, and the operation is stable; the compounded N-methylpyrrolidone or N-formyl morpholine extracting is recovered and cooled and enters the extraction and rectification tower; and the benzene, toluene and non-aromatic mixtures are heated and enter the benzene extraction and rectification tower. The benzene content in the normal hexane product obtained by the operation method is lower than 100ppm, the purity of the normal hexane product is over 99.0 weight percent, and the purity of benzene product is over 99.9 weight percent.

Owner:TIANJIN UNIV

Methanol diesel

InactiveCN104498110AImprove stabilitySolve the difficulty of starting at low temperatureLiquid carbonaceous fuelsIsobutanolKetone

The invention relates to a methanol diesel. The methanol diesel is characterized by comprising the following components in percentage by weight: 60-80% of diesel, 15-25% of methanol and 5-15% of additives, wherein the additives are composed of the following components in percentage by weight: 0.1-7% of cyclopentyl ferrocene, 2-30% of isopropyl-ketone, 0.2-16% of dimethyl carbonate, 0.1-18% of isobutanol, 0.2-10% of methylbenzene, 0.5-15% of n-butyl alcohol, 6-20% of methyl tertiary-butyl ether, 3-15% of octane, 15% of methyl cyclopentane, 0.2-10% of oleic acid, 0.05-15% of ethyl nitrate, 0.05-10% of 12 carbons, 0.02-1% of castor oil, 2-20% of petroleum ether, 0.5-15% of ethyl acetate, 0.1-20% of n-octyl alcohol, 0.3-30% of isoamyl alcohol, 5-10% of fatty acid, 2-15% of ethanol amine, 1-9% of butanediamide, 0.05-0.4% of benzotriazole, 0.05-1% of Twain and 0.03-2% of span 80. The methanol diesel provided by the invention can be widely used in a vehicle fuel.

Owner:崔天豪

Aromatic hydrocarbon liquid phase alkylation method

ActiveCN103539600AImprove stabilityReduce olefin contentHydrocarbonsBulk chemical productionAlkaneAlkylation unit

The invention relates to an aromatic hydrocarbon liquid phase alkylation method, for mainly solving the problem that a catalyst is easily inactivated and poor in stability in the prior art. According to the technical scheme, a mixture containing saturated alkane, aromatic hydrocarbon and olefin is taken as a raw material, silicon-aluminum crystal zeolite is taken as a catalyst, and the raw material comes into contact with the catalyst to react to generate an alkylation liquid containing alkylbenzene and polyalkylbenzene under the conditions that the reaction temperature is 100-210 DEG C, the reaction pressure is 1.5-5.0MPa, the mole ratio of aromatic hydrocarbon to olefin is 1:10 and the weight space velocity of olefin is 0.1-1.0 hour<-1>, wherein the saturated alkane is at least one of ethane, propane, n-butane, iso-butane, pentane, cyclopentane, methylcyclopentane, hexane or cyclohexane, and the content of the saturated alkane is 1-80% of the weight of the reaction mixture. Due to adoption of the technical scheme, the problem in the prior art is well solved. The aromatic hydrocarbon liquid phase alkylation method can be applied to industrial production of aromatic hydrocarbon liquid phase alkylation.

Owner:CHINA PETROLEUM & CHEM CORP +1

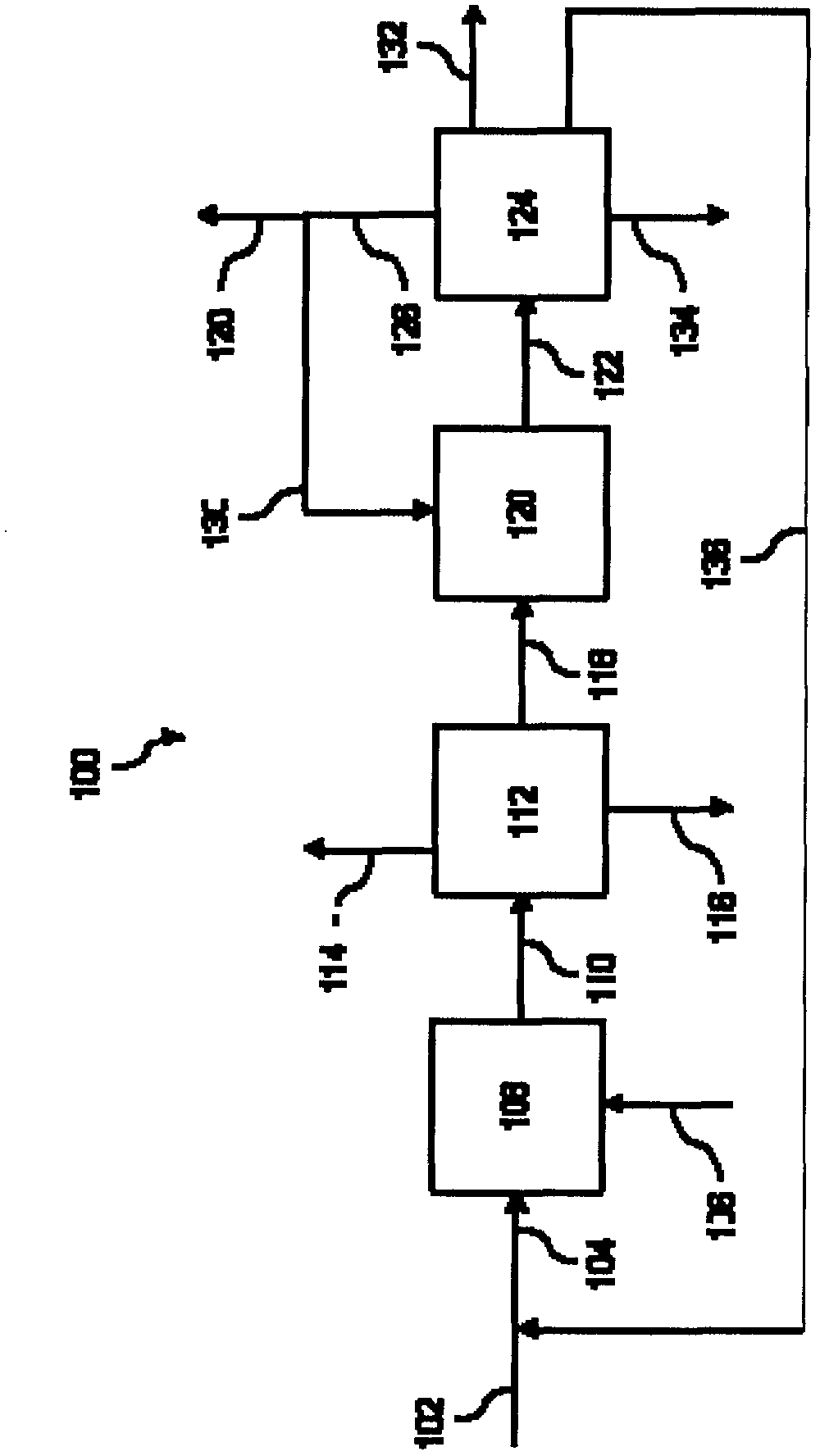

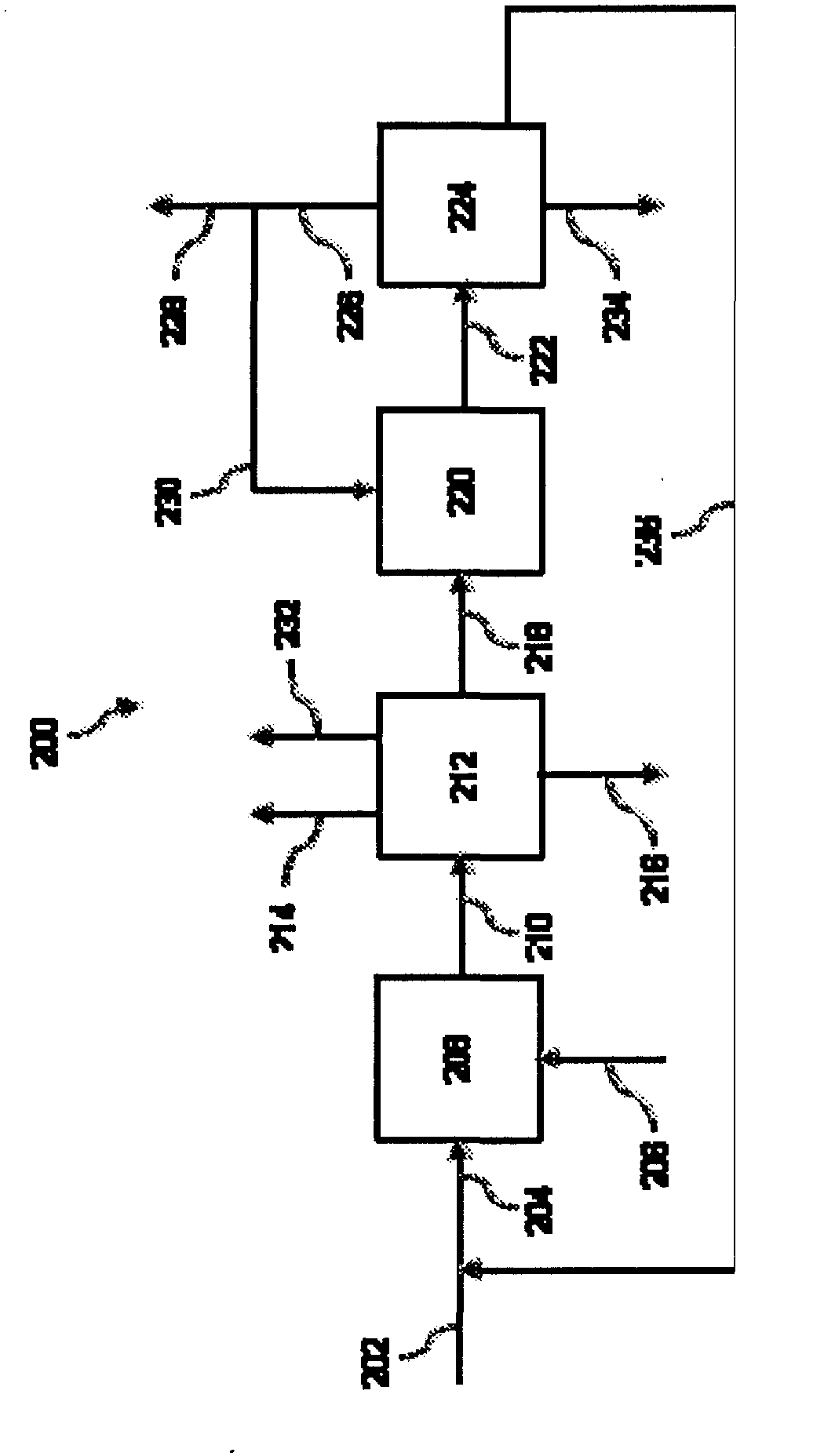

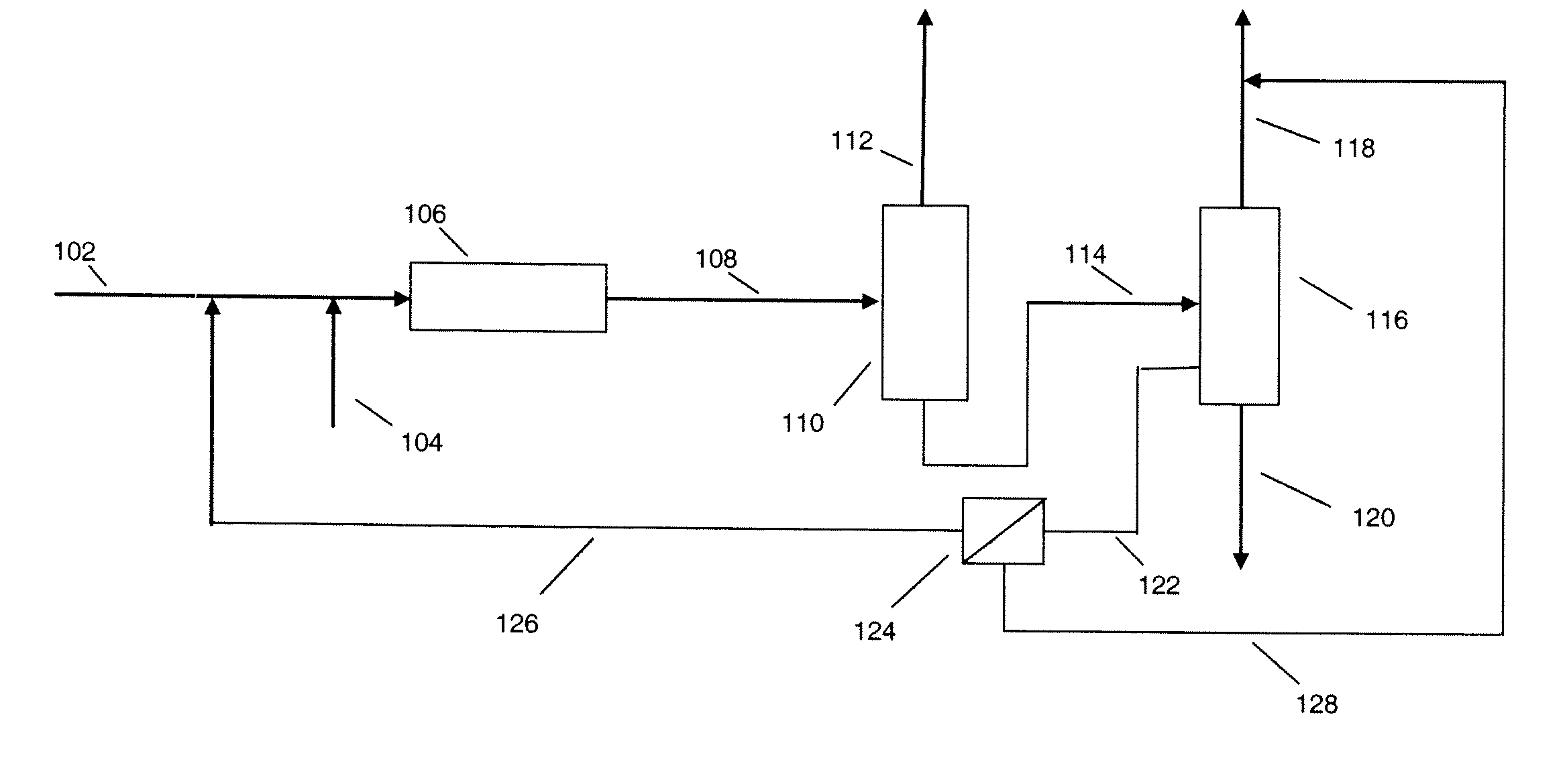

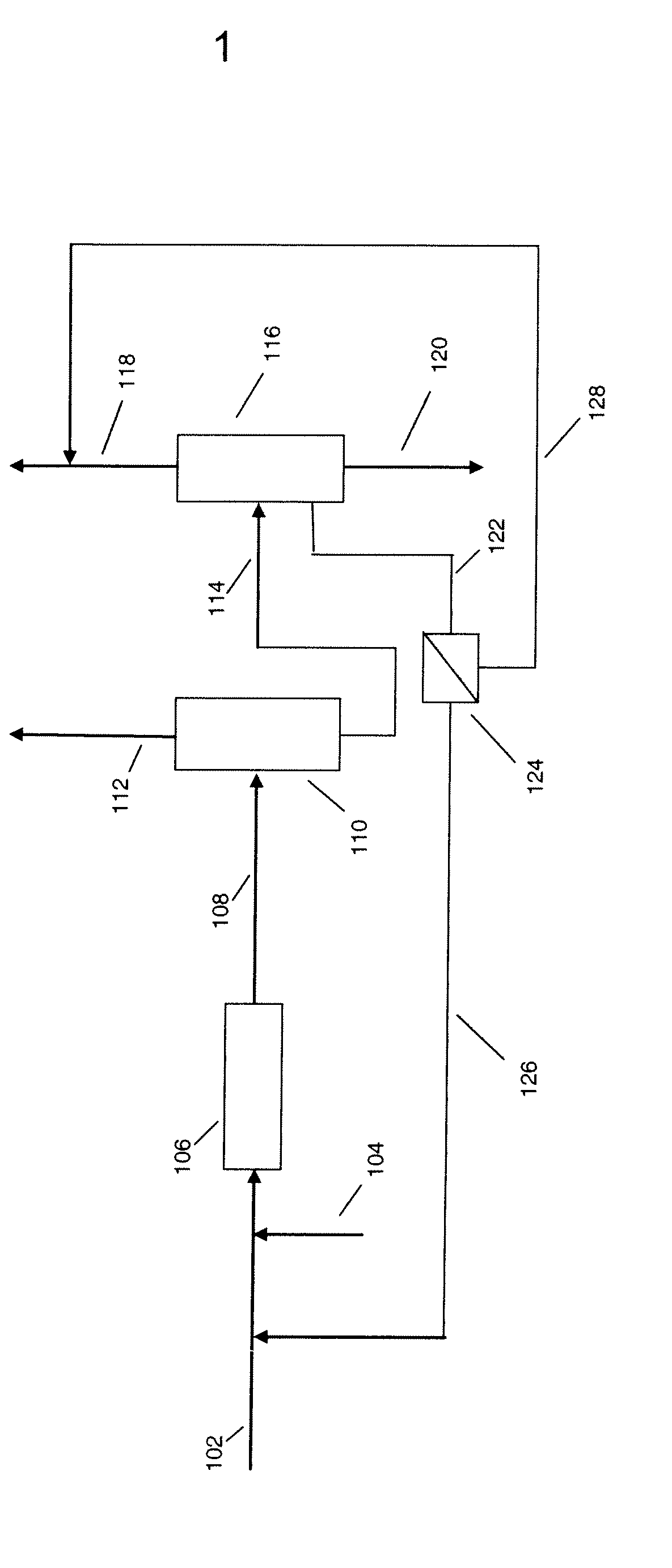

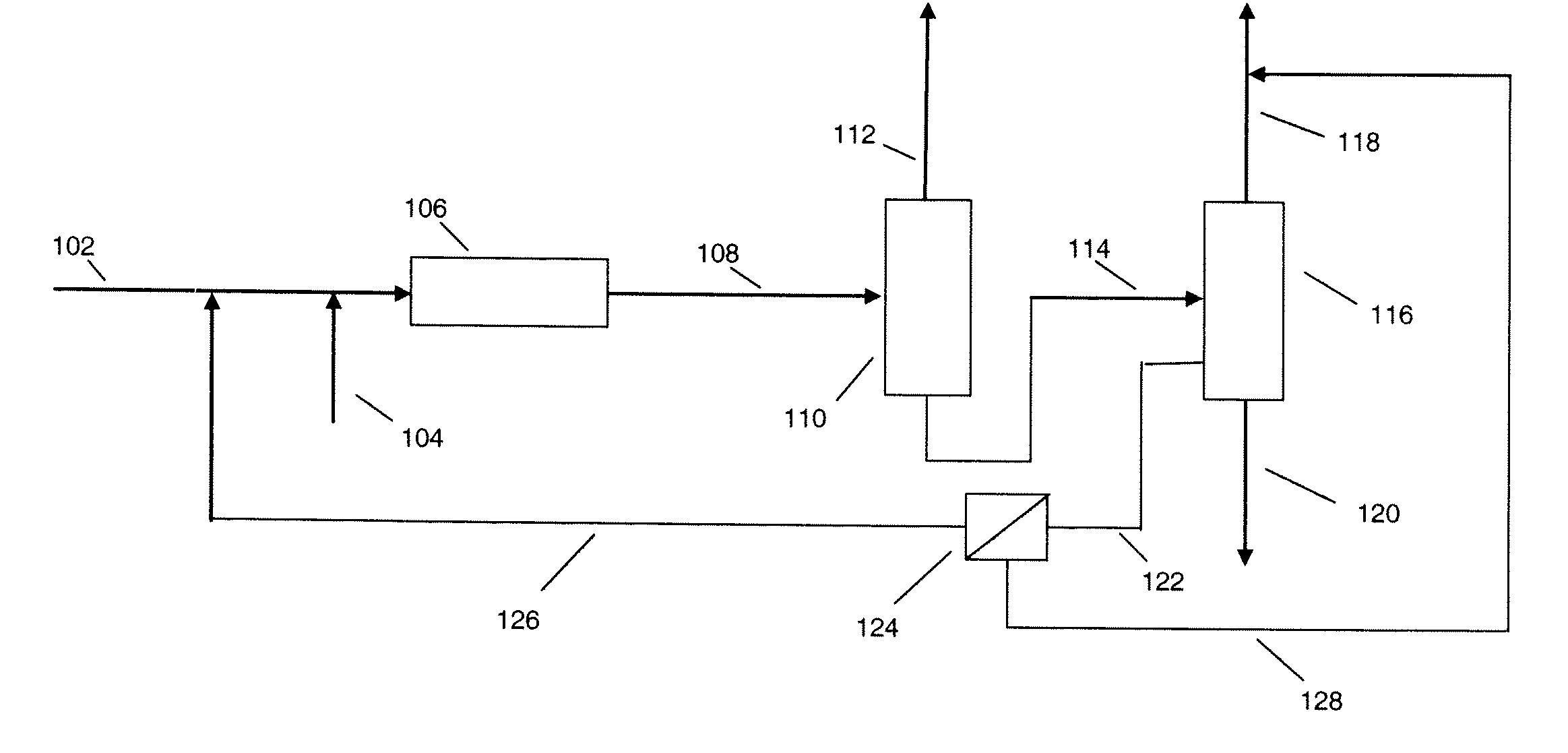

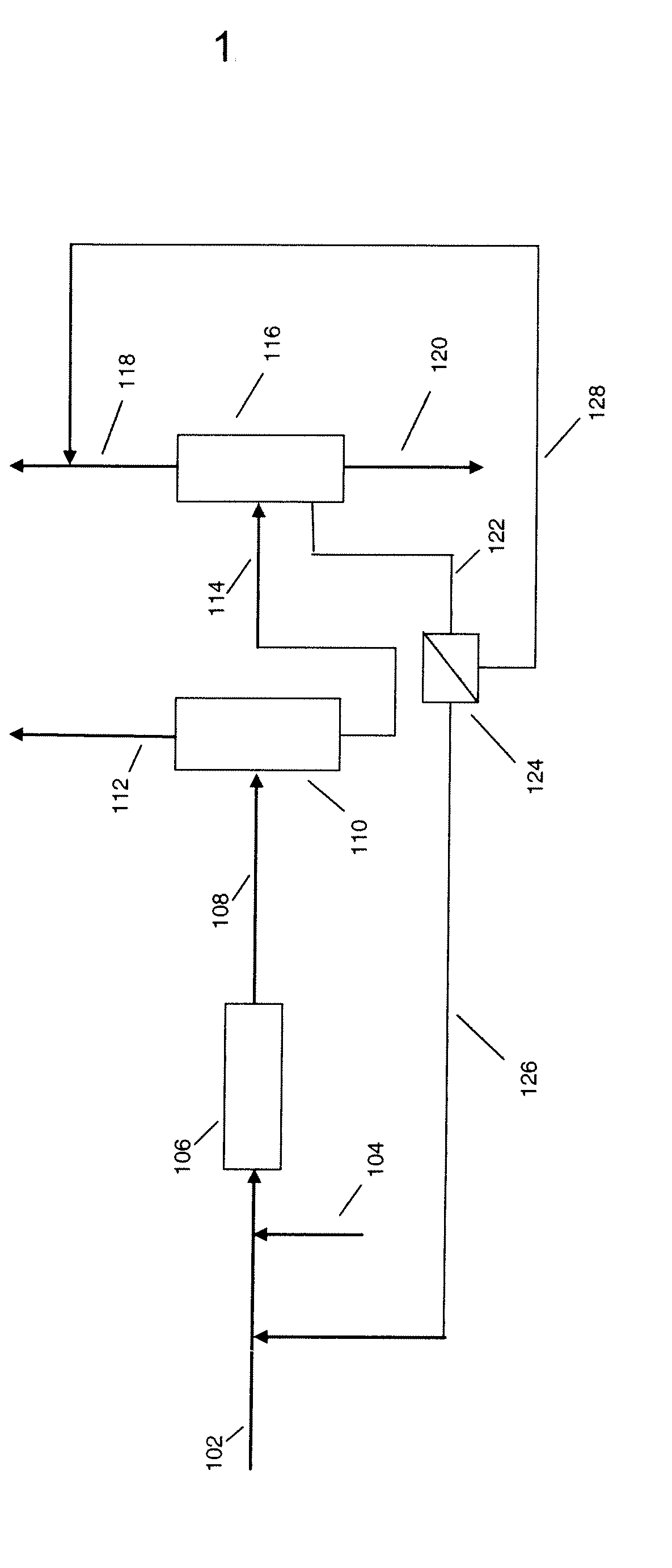

Processes for the isomerization of paraffins of 5 and 6 carbon atoms with methylcyclopentane recovery

InactiveUS7638674B2Enhances their economic viabilitySmall surface areaHydrocarbon by isomerisationHydrocarbon by hydrogenationBoiling pointPermselective membrane

In an isomerization process where the isomerization effluent (108) is fractionated in a deisohexanizer (116) to provide an overhead (118) containing dimethylbutanes and a higher boiling fraction (122) containing normal hexane, the higher boiling is contacted with a selectively permeable membrane (124) to provide a retentate containing methylcyclopentane (128). If desired, the normal hexane-containing permeate can be recycled for isomerization. The preferred membranes are sieving membranes having a C6 Permeate Flow Index of at least 0.01 and a C6 Permeate Flow Ratio of at least 1.25:1.

Owner:UOP LLC

Weather-resistance and low-temperature-resistance chloroprene rubber adhesive

ActiveCN105238299AGood compatibilityGood weather resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesBenzoic acidPolymer science

The present invention discloses a weather-resistance and low-temperature-resistance chloroprene rubber adhesive, wherein the raw materials comprise a chloroprene rubber, a natural rubber, an alkyl benzoic acid resin, a phenolic resin, an epoxy resin, a terpene resins, a trans-1,4-polyisoprene rubber, active magnesium oxide, nanometer silicon dioxide, ethylene thiourea, zinc oxide, ethyl acetate, cyclohexane, acetone, propylene glycol, methyl cyclopentane, dimethyl carbonate, an anti-aging agent, cerium oxide, 3-aminopropyl trimethoxy silane, a silane coupling agent KH-560, and a plasticizer. The weather-resistance and low-temperature-resistance chloroprene rubber adhesive of the present invention has characteristics of high bonding strength, good low-temperature resistance, good weather resistance, and excellent storage stability.

Owner:安徽大松树脂有限公司

Production method of polyvinylidene fluoride with thermal stability

The invention discloses a production method of polyvinylidene fluoride with thermal stability. The production method comprises the following steps of (1)adding 1.7 parts of hydrogen peroxide and 3.1 parts of an inorganic alkaline solution into a reaction kettle, uniformly mixing, then, adding 14.3 parts of a dichlorofluoroethane solvent and 1.5 parts of a sulfonyl chloride solution, and reacting while stirring at the temperature of 2 DEG C below zero for 28 minutes; (2) introducing 5.8 parts of a sodium pyrophosphate solution, 93 parts of vinylidene fluoride monomers and 0.9 part of 1, 2-dimethylcyclopentane, reacting while stirring at the temperature of 18 DEG C, and stopping reacting when the pressure is reduced to less than 0.25MPa; and (3) filtering, washing and drying to obtain the powdery polyvinylidene fluoride. The polyvinylidene fluoride prepared by using the production method is favorable in thermal stability and processability and capable of meeting the requirements of production processes such as injection molding, extrusion and film drawing.

Owner:CHANGSHU LIYUAN MEMBRANE TECH

Method for increasing pepper red pigment yield

The invention discloses a method for increasing the pepper red pigment yield, which comprises the following steps: extracting the pepper particle raw materials with organic solvents, and carrying out sedimentation-filtration and solvent evaporation to obtain primary pepper oil resin. The method is characterized in that the organic solvents are prepared by adding methylcyclopentane into a 6# solvent, and based on a volume ratio, the methylcyclopentane addition volume is 5-10% of the 6# solvent dosage. The invention uses the 6# solvent as extracting agents, and the moderate methylcyclopentane is added to enhance the extraction property of the hexane to the pepper red pigment in the 6# solvent, to increase the yield of the pepper red pigment product, such as increasing the pepper red pigmentyield to more than 98.2%. Moreover, the addition volume of the above methylcyclopentane has little influence on the production cost of the pepper red pigment product.

Owner:青岛赛特生物科技有限公司

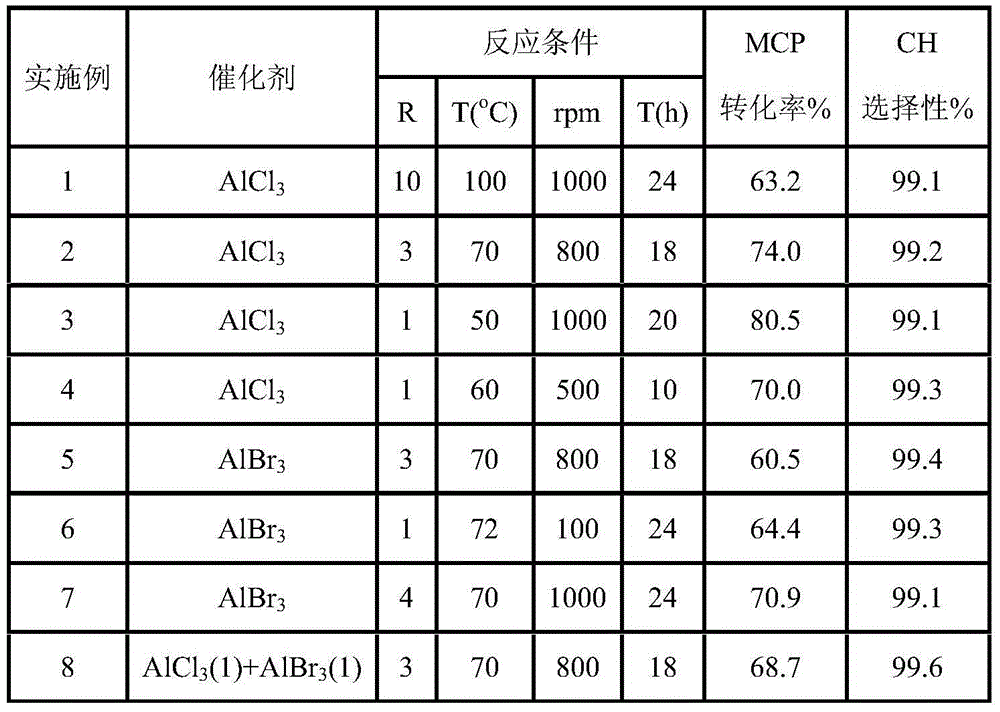

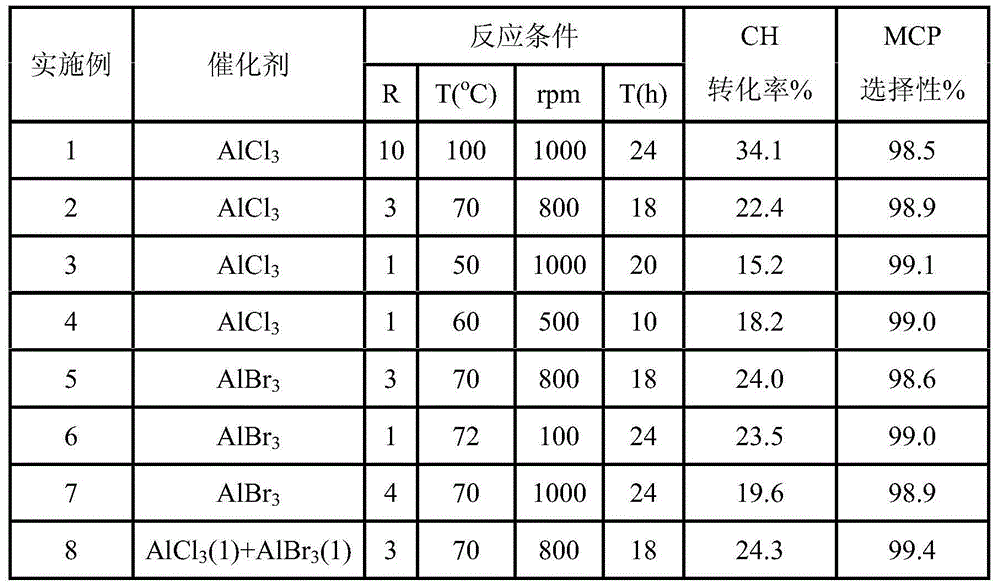

A preparing method of cyclohexane

The invention relates to a preparing method of cyclohexane, and mainly overcomes technical problems of cyclohexane production by benzene hydrogenation in the prior art, namely severe operation conditions and long procedures. According to a technical scheme adopted by the method, a material rich in methylcyclopentane is adopted as a raw material and is brought into contact with a catalyst at 50-100 DEG C to produce cyclohexane, the catalyst is at least one of anhydrous aluminum halides, and the weight ratio of the raw material to the catalyst is 1-10. The problems are overcome by adoption of the technical scheme. The method can be used for industrial production of the cyclohexane.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of polyvinylidene fluoride

InactiveCN104403033AImprove thermal stabilityEasy to processPolyethylene glycol1,1,2-Trichloroethane

The invention discloses a preparation method of polyvinylidene fluoride. The preparation method comprises the following steps: (1) putting 1.3 parts of hydrogen peroxide and 2.1 parts of inorganic alkali solution by weight in a reaction kettle, uniformly mixing, then putting 8.9 parts of 1,2,2-trifluoro-1,1,2-trichloroethane solvent and 1.3 parts of undecafluoro-hexanoyl fluoride solution by weight, and stirring at 8 DEG C below zero for 35-minute reaction; (2) then introducing 5.5 parts of a polyglycol solution, 83 parts of vinylidene fluoride monomers and 3.1 parts of methylcyclopentane by weight, stirring at 32 DEG C for reaction, and ending the reaction when the pressure is reduced below 0.27 MPa; (3) filtering, washing and drying to obtain powered polyvinylidene fluoride. The prepared polyvinylidene fluoride has good heat stability and machinability, and can meet the production technology such as injection molding, extrusion and film drawing.

Owner:CHANGSHU LIYUAN MEMBRANE TECH

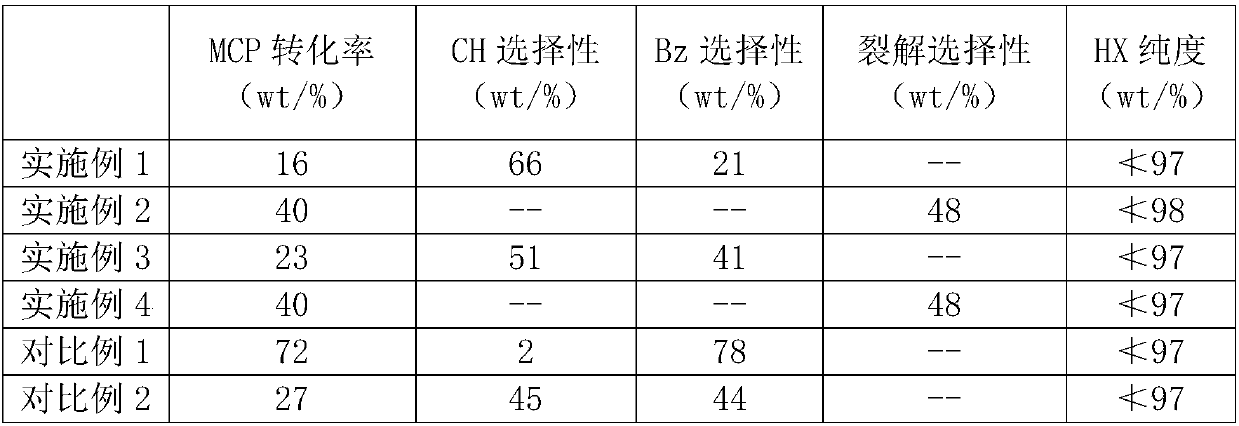

Method for producing n-hexane through raffinate oil

ActiveCN108033869AReduce energy consumptionWide adaptabilityDistillation purification/separationHydrocarbonsGas phaseFixed bed

The invention provides a method for producing n-hexane through raffinate oil. The method comprises the following steps: (1) rectifying raffinate oil through a de-heavy fractionator; distilling off C5and C6 components in raffinate oil from the top of the de-heavy fractionator; and extracting mixed C7 and C8 heavy components from the bottom of the de-heavy fractionator; (2) preheating the C5 and C6components obtained in step (1); feeding into a fixed bed reactor; and performing isomerization reaction or hydrocracking reaction through methyl cyclopentane in the presence of a bifunctional catalyst under hydrogen service condition; and (3) conveying the reaction product obtained in step (2) to a gas-liquid separator; returning the separated gas phase product as circulating hydrogen to the fixed bed reactor for recycling; conveying the liquid phase product to a stabilizing tower; and distilling off little hydrogen and little cracking small molecule light dydrocarbon from the top of the de-heavy fractionator after processing. According to the method, methyl cyclopentane in raffinate oil is converted into a chemical substance of which the boiling point is highly different from n-hexane,so that the energy consumption in purification of n-hexane is greatly decreased.

Owner:山东海成石化工程设计有限公司

Processes for the Isomerization of Paraffins of 5 and 6 Carbon Atoms with Methylcyclopentane Recovery

InactiveUS20090069613A1Enhances their economic viabilitySmall surface areaHydrocarbon by isomerisationHydrocarbon by hydrogenationBoiling pointFlow ratio

In an isomerization process where the isomerization effluent (108) is fractionated in a deisohexanizer (116) to provide an overhead (118) containing dimethylbutanes and a higher boiling fraction (122) containing normal hexane, the higher boiling is contacted with a selectively permeable membrane (124) to provide a retentate containing methylcyclopentane (128). If desired, the normal hexane-containing permeate can be recycled for isomerization. The preferred membranes are sieving membranes having a C6 Permeate Flow Index of at least 0.01 and a C6 Permeate Flow Ratio of at least 1.25:1.

Owner:UOP LLC

Preparation method of polyvinylidene fluoride separation membrane

InactiveCN105435650AImprove corrosion resistanceImprove heat resistanceSemi-permeable membranesMembranesDichlorodifluoromethaneHexyldecanol

The invention discloses a preparation method of a polyvinylidene fluoride separation membrane. Polyvinylidene fluoride is taken as a membrane raw material; and the preparation method comprises following steps: 1) by weight, 1 to 2 parts of hexyldecanol, 0.8 part of hydrogen peroxide, and 1.1 parts of an inorganic base solution are delivered into a reaction vessel for uniform mixing, 1.6 parts of poly(ethylene glycol) monooleate, 14.5 parts of dichlorodifluoromethane solvent, and 1.8 parts of phenylmethylsulfonyl fluoride solution are subjected to 25min of reaction at -6 DEG C with stirring; 2) 1.3 parts of sodium oleoyl amino fatty acid, 2.2 parts of a hexyldecanol solution, 59 parts of vinylidene fluoride monomer, and 1.8 parts of methylcyclopentane are delivered into the reaction vessel, an obtained mixture is subjected to reaction at 18 DEG C with stirring, and reaction is stopped when pressure is reduced to be lower than 0.23MPa; and 3) an obtained product is filtered, washed, and dried so as to obtain polyvinylidene fluoride powder. The polyvinylidene fluoride separation membrane possesses corrosion resistance, heat resistance, cold resistance, oxidation resistance, and weather resistance.

Owner:CHANGSHU 3F ZHENFU NEW MATERIALS CO LTD

Hollow fiber ultrafilter membrane

InactiveCN105536557AImprove corrosion resistanceImprove heat resistanceSemi-permeable membranesMembranesHollow fibreFiber

The invention discloses a hollow fiber ultrafilter membrane. Polyvinylidene fluoride is used as a raw material of the membrane, and the preparation of polyvinylidene fluoride comprises the following steps: 1) 1-2 parts by weight of hydroxypropyl methyl cellulose, 2.7 parts by weight of hydrogen peroxide and 4.1 parts by weight of an inorganic alkali solution are added into a reaction vessel and are mixed uniformly, 1.4 parts by weight of N-acylamino acid salt, 14.3 parts by weight of a dichlorofluoroethane solvent and 1.5 parts by weight of a bromodifluoroacetyl fluoride solution are added, and a reaction is carried out for 28 minutes with stirring at -3.5 DEG C; 2) 3.7 parts by weight of polyethylene glycol monolaurate, 4.8 parts by weight of a sodium pyrophosphate solution, 83 parts by weight of a vinylidene fluoride monomer, and 0.9 parts by weight of 1,2,3-trimethylcyclopentane are added, a reaction is carried out with stirring at 19 DEG C, and when the pressure reduces to 0.25MPa, the reaction is terminated; 3) filtering, washing and drying are carried out, and powdery polyvinylidene fluoride is obtained. The hollow fiber ultrafilter membrane has the advantages of corrosion resistance, heat resistance, cold resistance, oxidation resistance, and weatherability.

Owner:CHANGSHU LIYUAN MEMBRANE TECH

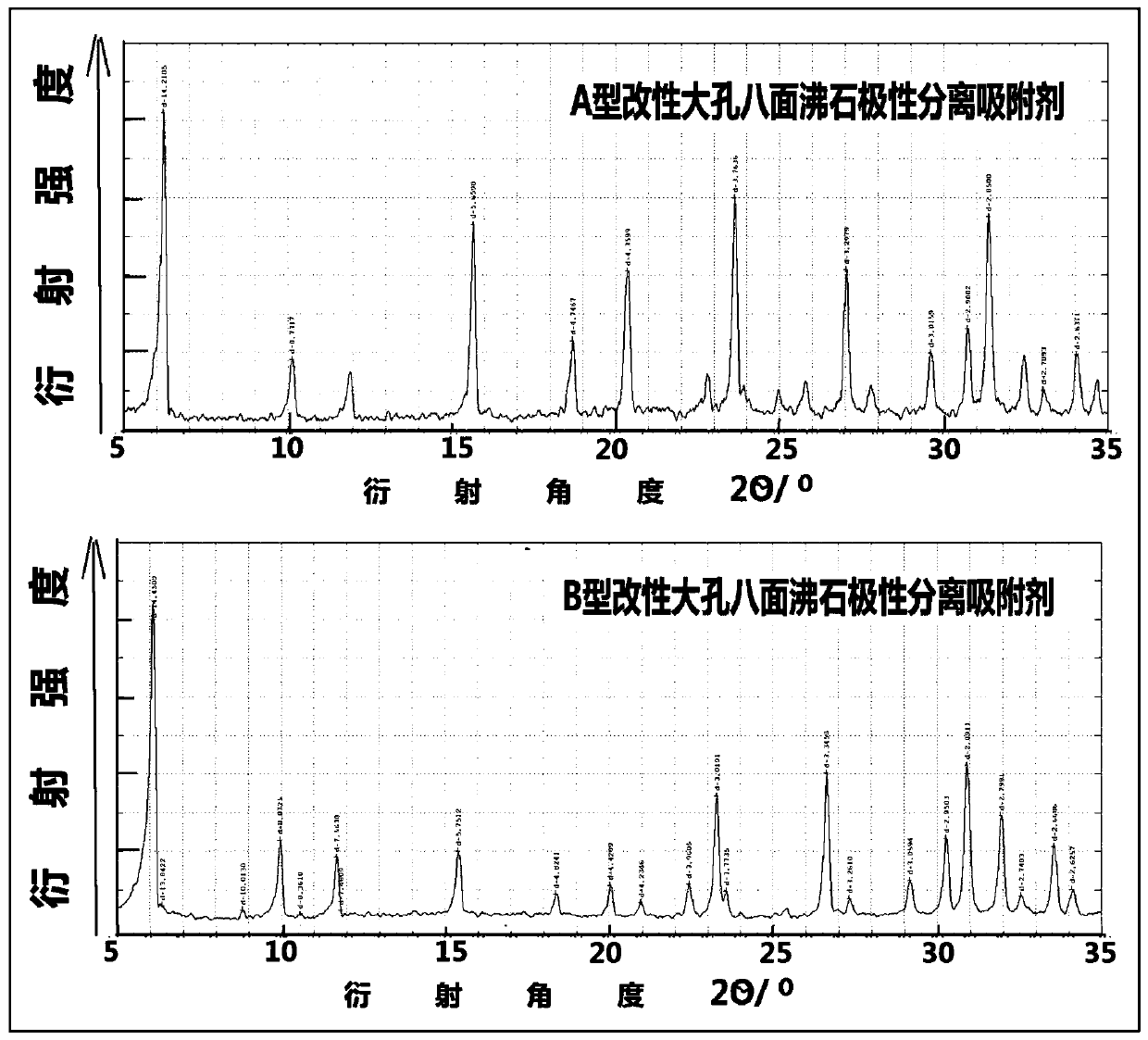

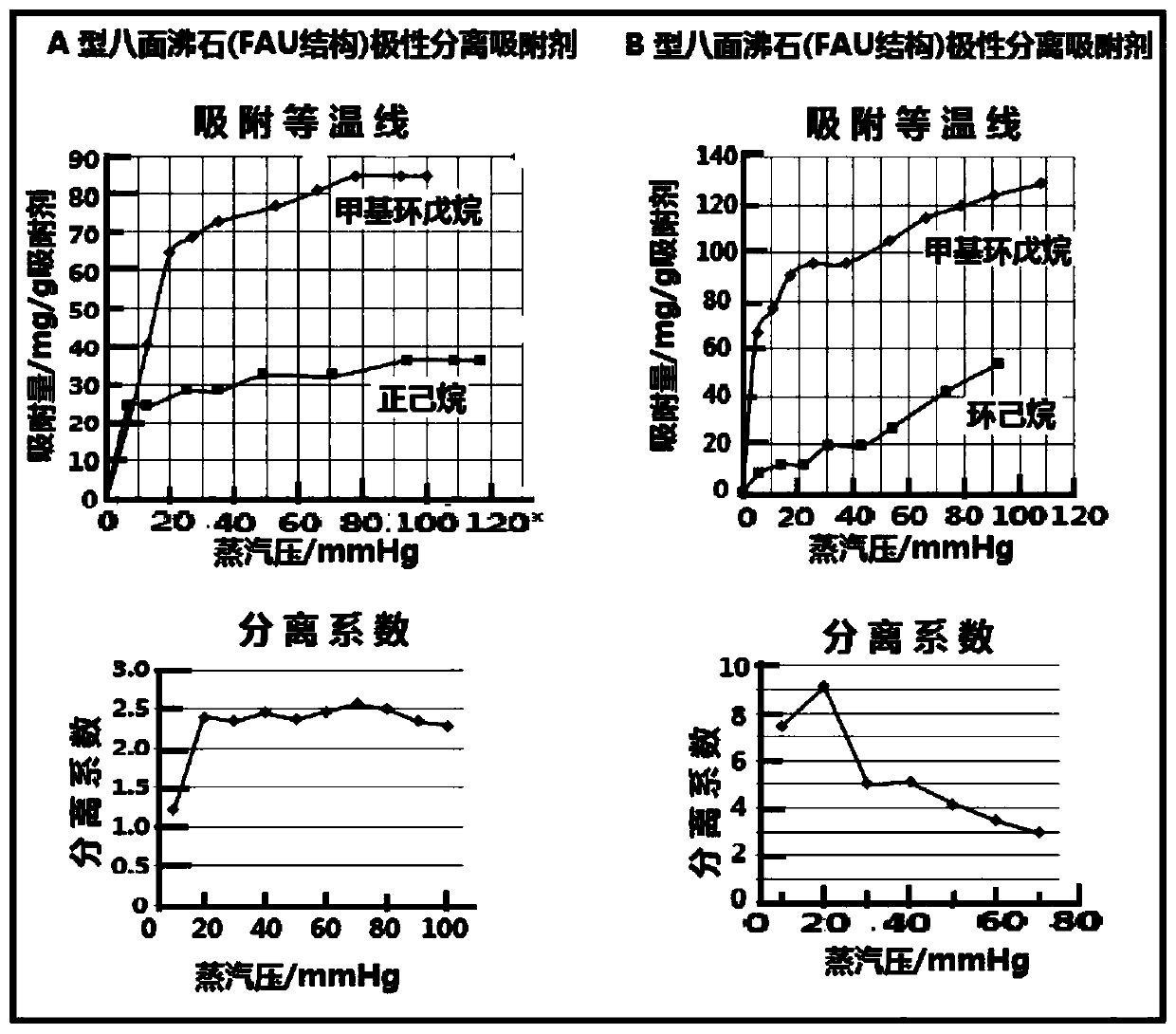

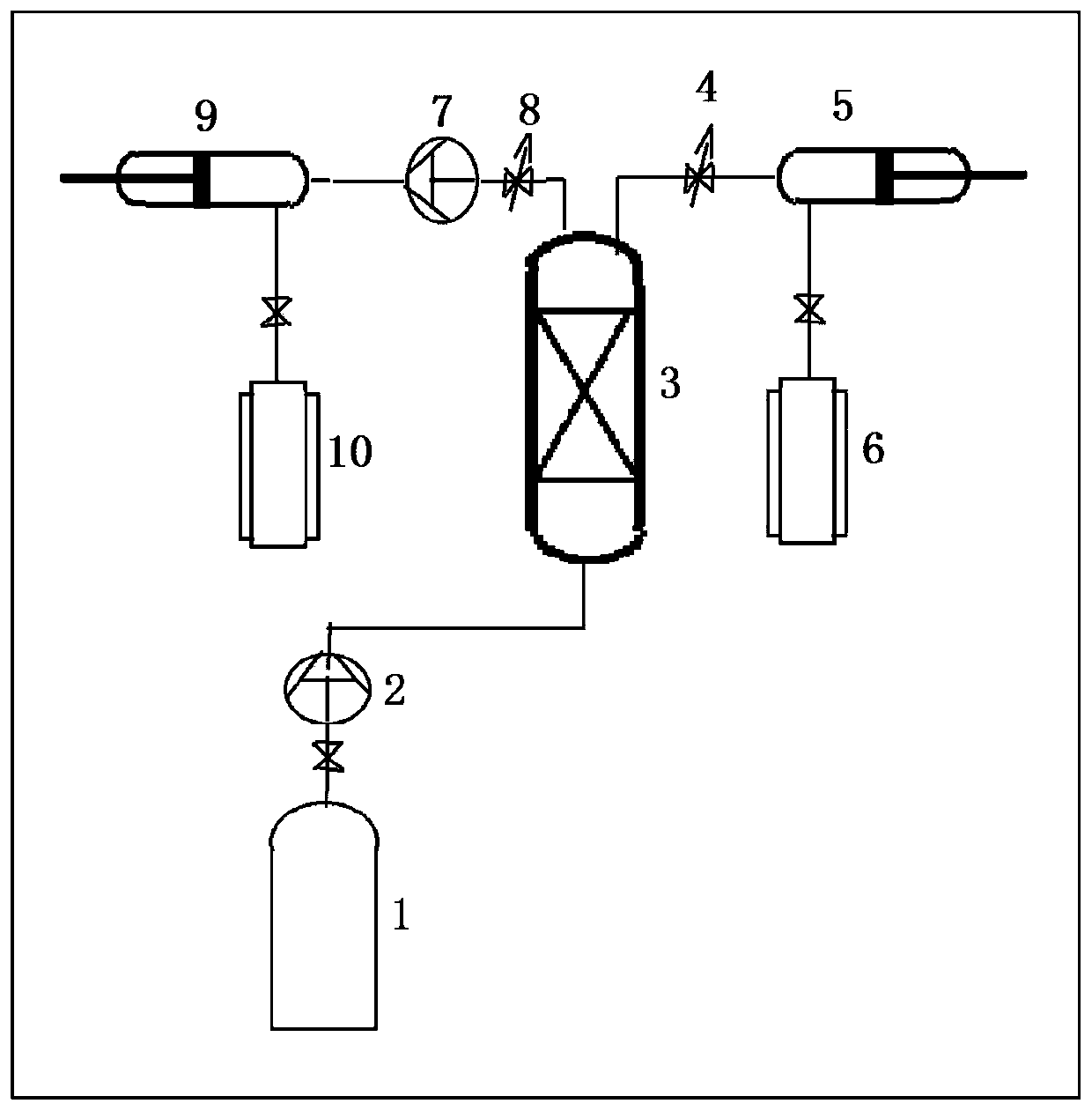

Method for separating C6 mixed hydrocarbon by two-stage PSA

ActiveCN111099956AReduce adsorptionLow heat of desorptionDispersed particle separationAdsorption purification/separationHydrocarbon mixturesSorbent

The invention relates to a method for separating C6 mixed hydrocarbon by two-stage PSA (Pressure Swing Adsorption). Methyl cyclopentane, n-hexane and cyclohexane with the purity higher than 99.0% arerespectively extracted from C6 mixed hydrocarbon with different sources. The method comprises a two-stage PSA separation process, wherein the first-stage PSA separation process comprises the followingsteps: mixing a polar separation adsorbent with C6 hydrocarbon mixture steam, adsorbing and separating a component A under a first pressure condition to obtain a high-purity component B, and desorbing and liquefying the component A adsorbed by the adsorbent under a second pressure condition to obtain a first-stage desorbed substance A-rich mixed hydrocarbon. In the second-stage PSA separation process, a selective separation adsorbent is mixed with A-rich mixed hydrocarbon steam of a first-stage desorbed substance, a component B is adsorbed and separated under a first pressure condition to obtain a high-purity component A, and the component B adsorbed by the adsorbent is desorbed and liquefied under a second pressure condition to obtain a second-stage desorbed substance. And the second-stage desorbed substance is mixed with the original C6 hydrocarbon mixture, and the two-stage PSA separation and adsorption separation process is repeated.

Owner:FUYU ZHANGJIAGANG NEW MATERIALS TECH CO LTD

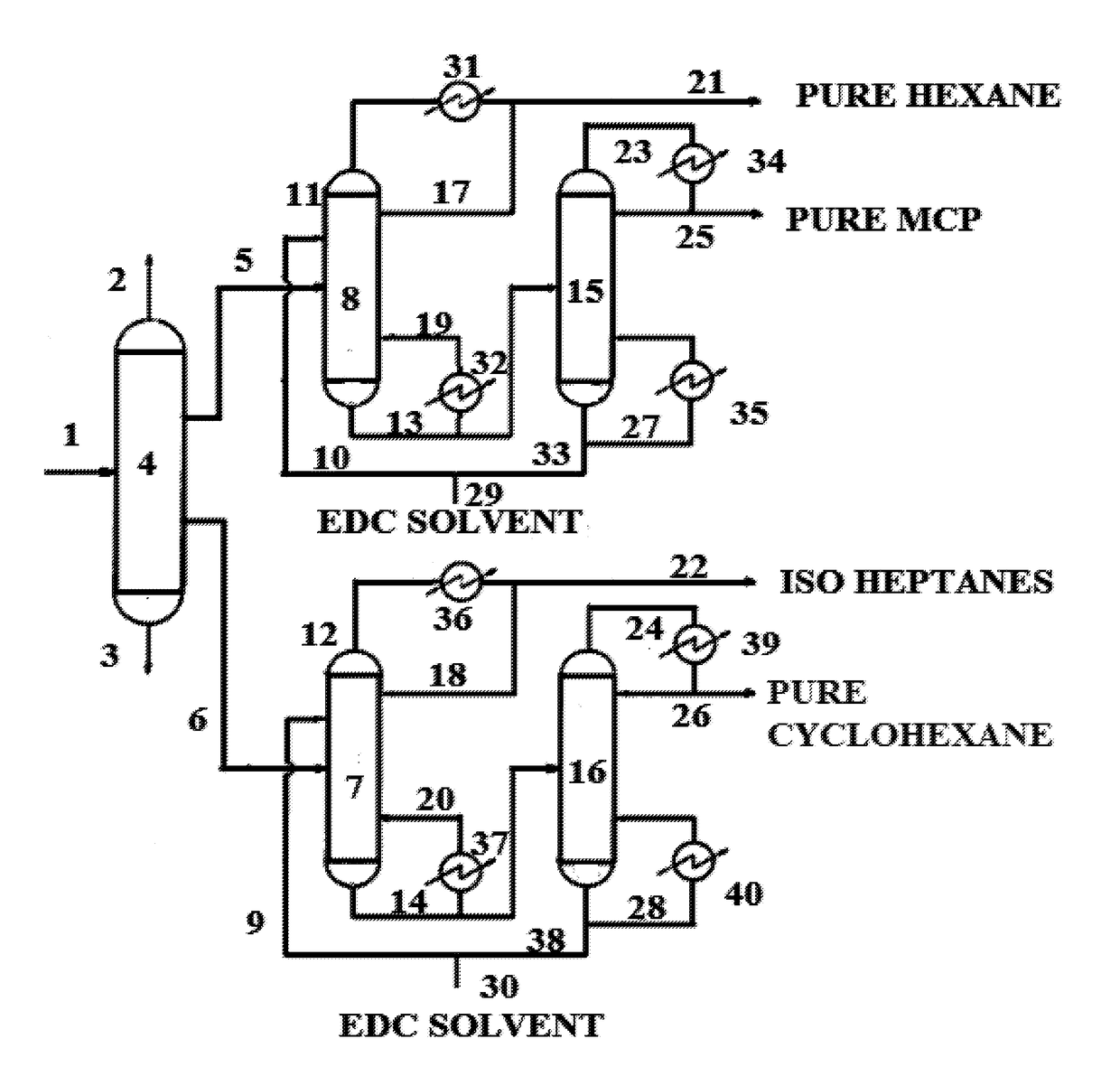

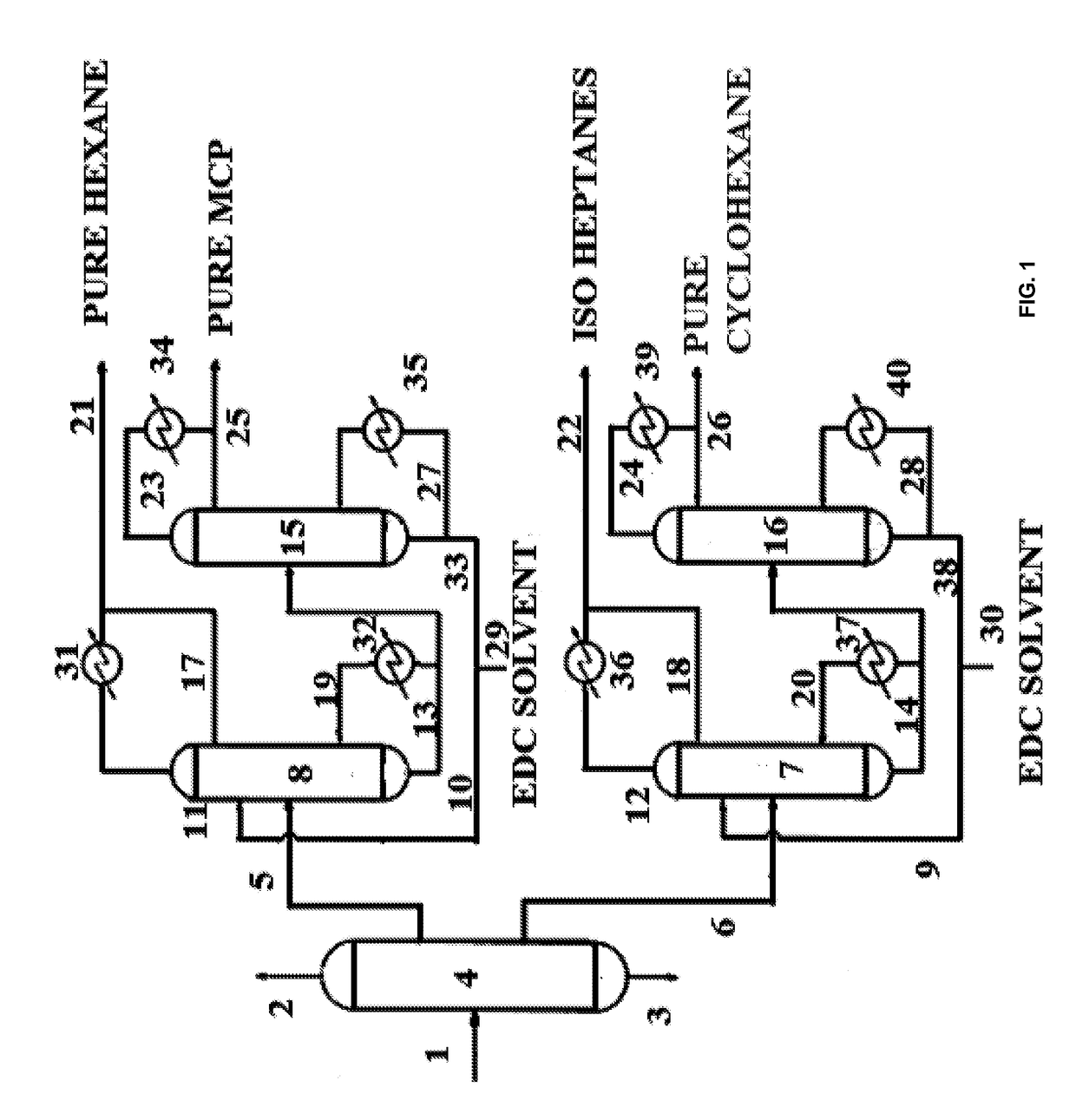

Process for high purity hexane and production thereof

ActiveUS20170203231A1Distillation purification/separationFractional condensation purification/separationBenzeneOrganic solvent

The invention relates to the production of High purity n-hexane from low value stream such as raffinate from benzene extraction unit in crude oil refineries employing extractive distillation. The present invention further related to an extractive distillation employing an organic solvent having comparable or same Hansen dispersive force parameter (δd) of that of the key component of to be separated through extractive distillation. The present invention is useful for separating and isolating pure cyclohexane, pure methylcyclopentane and pure iso-heptane along with the pure n-hexane.

Owner:INDIAN OIL CORPORATION

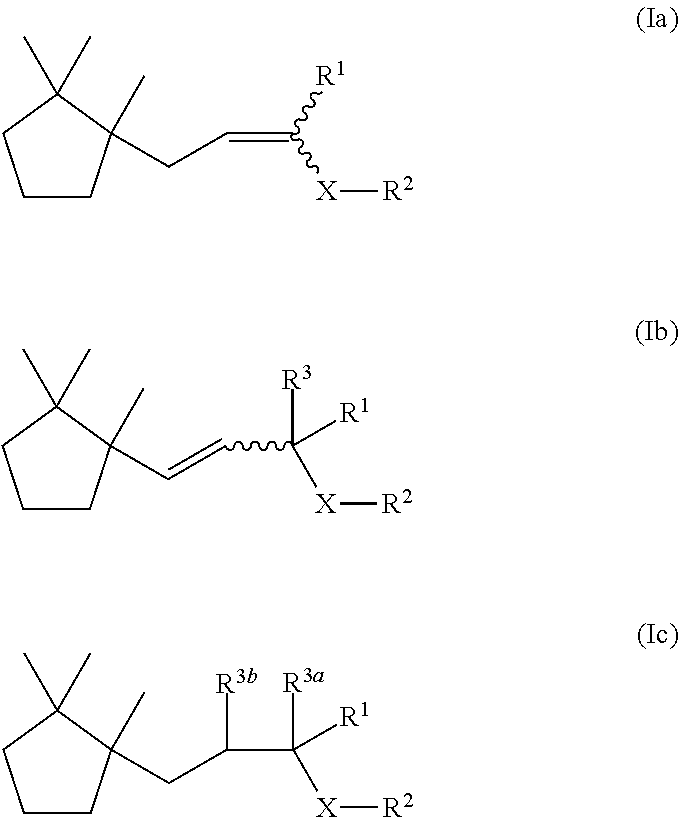

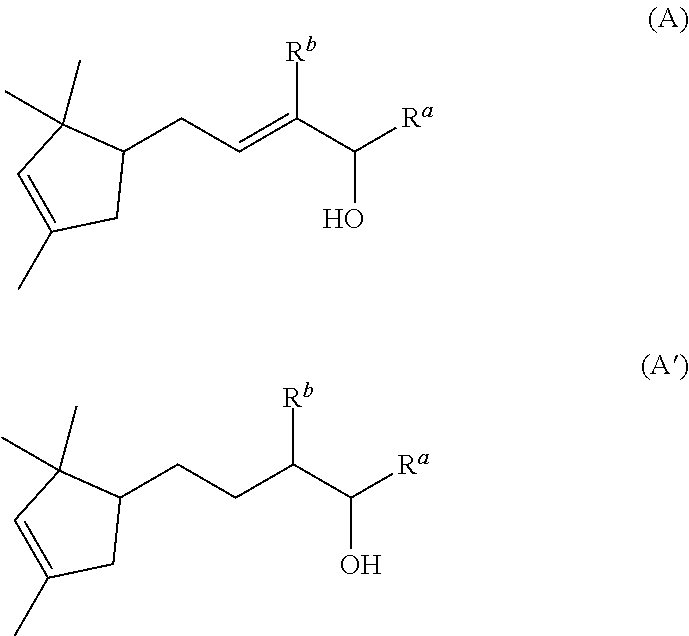

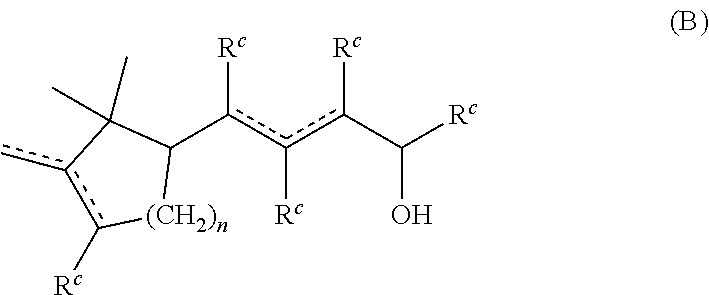

Novel aroma chemicals having a 1,2,2-trimethylcyclopentan-1-yl moiety

InactiveUS20180171262A1Pleasant odorOrganic compound preparationEssential-oils/perfumesHydrogenCompound (substance)

The present invention relates to novel compounds of general formulae (la), (lb) and (Ic) and to the stereoisomers thereof. The compounds are useful as a fragrance or as flavor as they have a sandalwood like scent. The invention also relates to a method for imparting or modifying a scent or a flavor to a composition by including said compounds into such composition, to a fragrance containing composition and / or a fragrance material containing said compound and to a process for preparing these compounds. X is C(R4)—OH or C═O; R1 is selected from the group consisting of hydrogen, C1-C4-alkyl, C2-C4-alkenyl and C3-C4-cycloalkyl, R2 is selected from the group consisting of hydrogen, C1-C4-alkyl, C2-C4-alkenyl and C3-C4-cycloalkyl, R3 is C1-C4-alkyl, R3a is selected from the group consisting of hydrogen and C1-C4-alkyl, R3b is hydrogen or together with R3a is CH2; R4 is selected from the group consisting of hydrogen and C1-C4-alkyl.

Owner:BASF AG +1

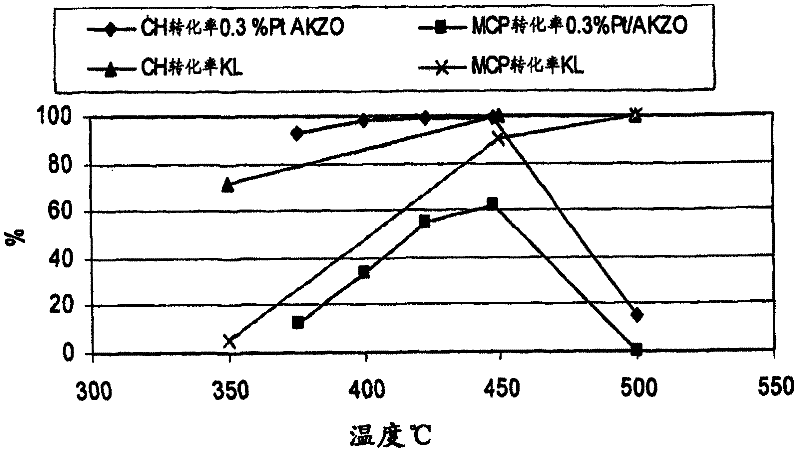

A preparing method of methylcyclopentane

ActiveCN105439791AMild reaction conditionsGood technical effectHydrocarbon by isomerisationRaw materialCyclohexane

The invention relates to a preparing method of methylcyclopentane, and mainly overcomes technical problems of methylcyclopentane production by hydrogenation in the prior art, namely severe operation conditions and long procedures. According to a technical scheme adopted by the method, a material rich in cyclohexane is adopted as a raw material and is brought into contact with a catalyst at 50-100 DEG C to produce the methylcyclopentane, the catalyst is at least one of anhydrous aluminum halides, and the weight ratio of the raw material to the catalyst is 1-10. The problems are overcome by adoption of the technical scheme. The method can be used for industrial production of the methylcyclopentane.

Owner:CHINA PETROLEUM & CHEM CORP +1

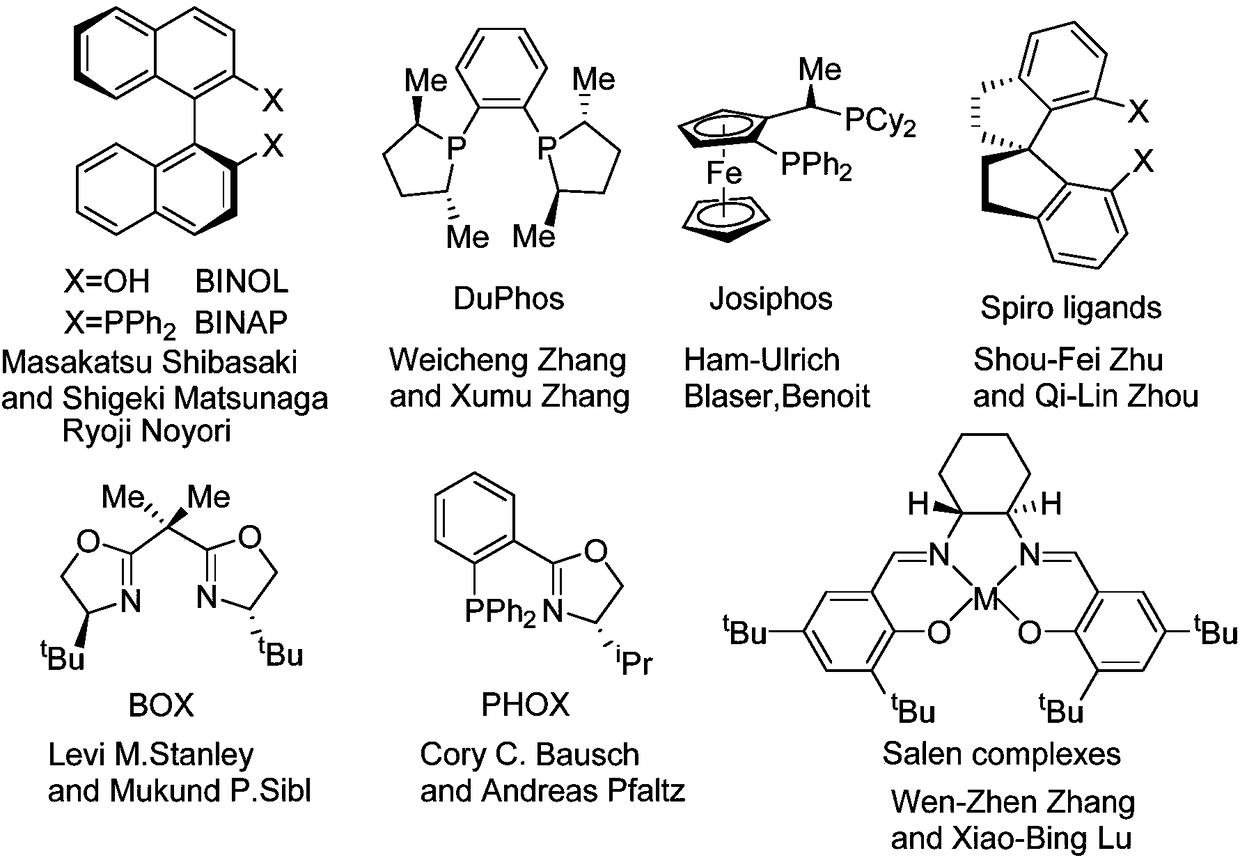

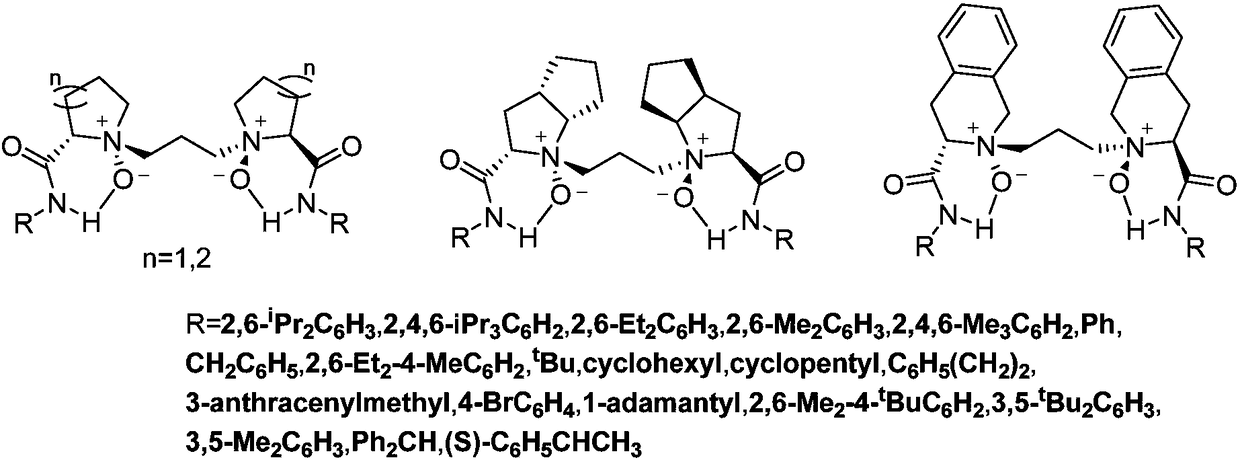

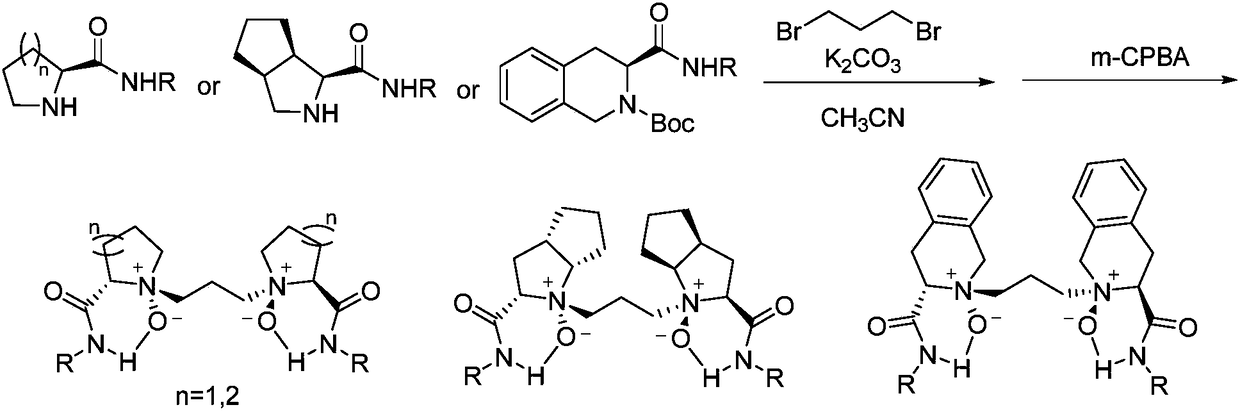

Novel chiral nitrogen oxygen ligands and synthesis method thereof

InactiveCN108084079AThe synthesis method is simpleHigh enantioselectivityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsSynthesis methodsCyclobutane

The invention discloses a series of novel chiral nitrogen oxygen ligands and a synthesis method thereof. According to the invention, simple amino acids, amino acid derivatives proline and Leimi acid,4-aminobutyric acid and tetrahydroisoquiline acid are adopted as raw materials, and a series of key processes are adopted, so that 4-carbon, 6-carbon, 7-carbon and 8-carbon novel chiral nitrogen oxygen ligands, 2-A-propane 3-carbon novel chiral nitrogen oxygen ligands, 2,2-di(B)-propane 3-carbon novel chiral nitrogen oxygen ligands, 1,1-dimethyl cyclopropane 3-carbon novel chiral nitrogen oxygen ligands, 1,1-dimethyl cyclobutane 3-carbon novel chiral nitrogen oxygen ligands, 1,1-dimethyl cyclopentane 3-carbon novel chiral nitrogen oxygen ligands and 1,1-dimethyl cyclohexane 3-carbon novel chiral nitrogen oxygen ligands, p-xylene and m-xylene and o-xylene novel chiral nitrogen oxygen ligands, and p-diethylbenzene, m-diethylbenzene and o-diethylbenzene novel chiral nitrogen oxygen ligands, and other novel chiral nitrogen oxygen ligands are finally synthesized. The above novel chiral nitrogen oxygen molecules can realize high enantioselectivity and high reaction activity in a variety of asymmetric reactions, and have great significance in solving reactions which cannot be completed by existing nitrogen oxygen ligands.

Owner:SICHUAN UNIV

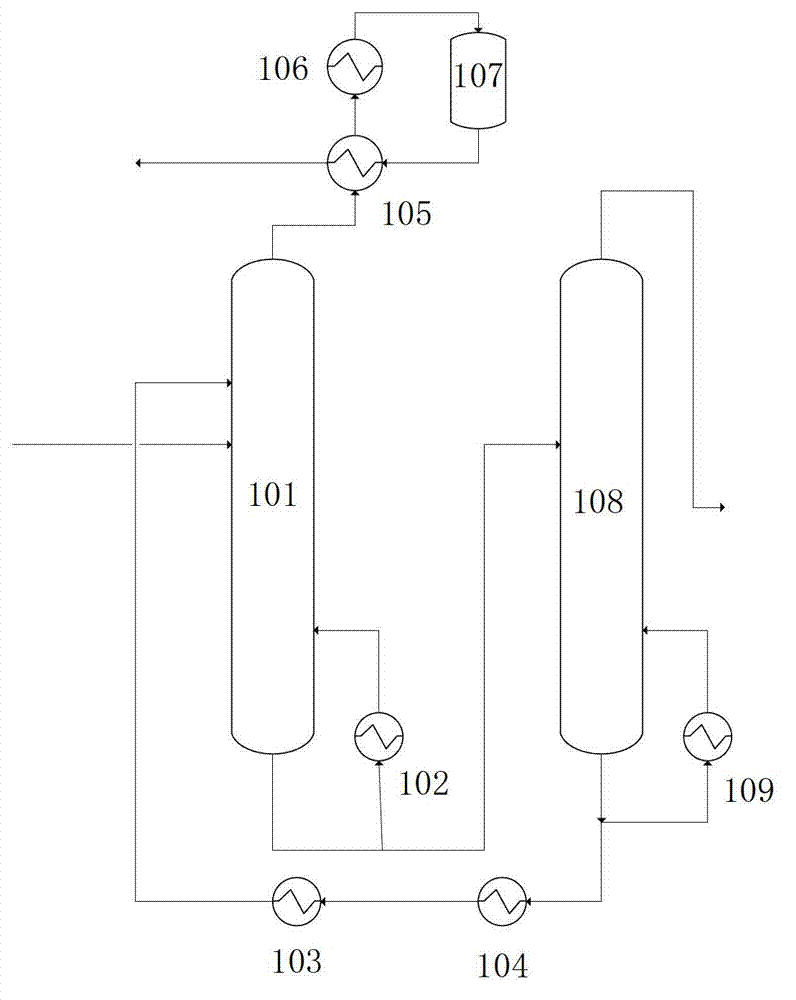

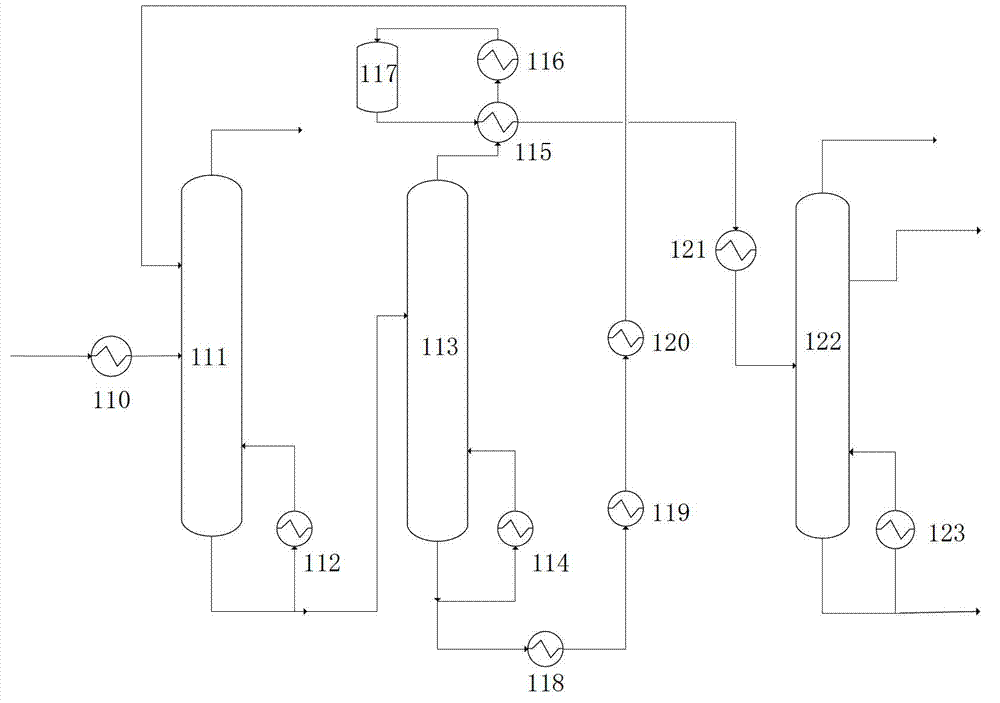

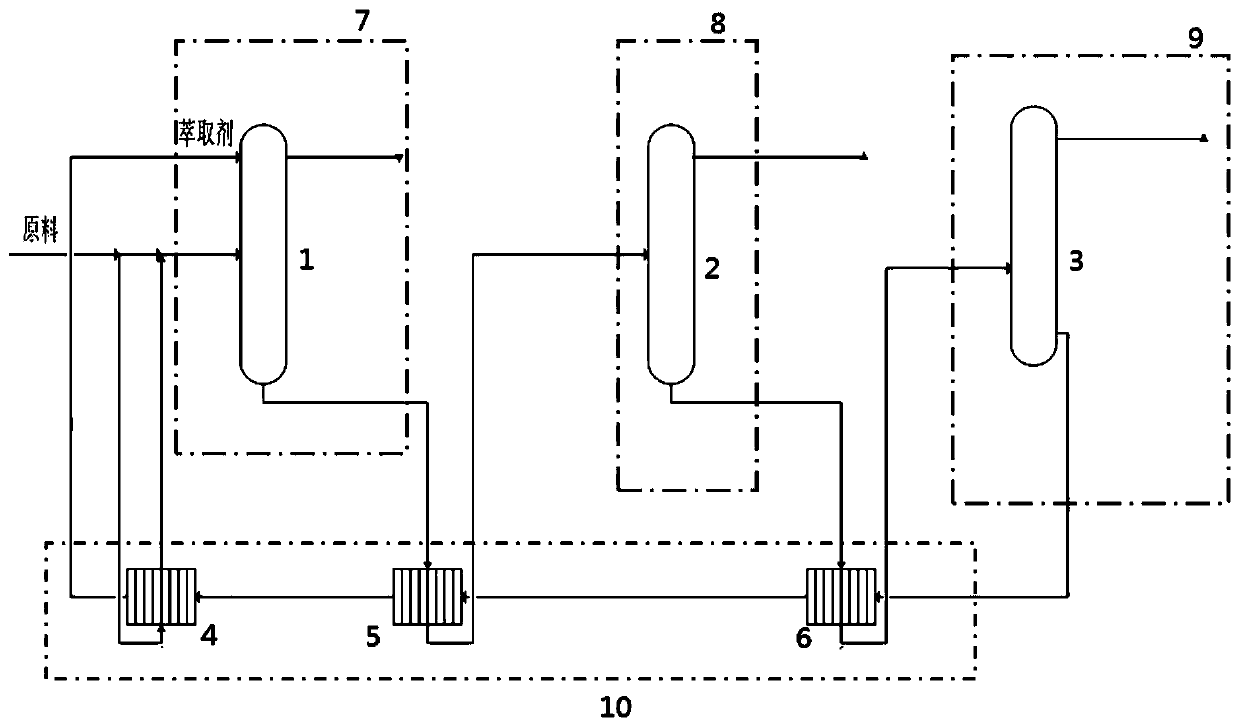

A system and method for recovering refined methylcyclopentane and its application

ActiveCN107935807BEasy extractionEasy to prepareChemical industryDistillation purification/separationSulfolaneDistillation

The invention relates to a system and a method for recycling refined methyl cyclopentane and application of the system and the method. The system comprises a dehydrogenation unit, a purification unit,a solvent recycling unit as well as a heat exchange unit, wherein the dehydrogenation unit, the purification unit and the solvent recycling unit are sequentially connected; the dehydrogenation unit is a first extraction distillation column; the purification unit is a second extraction rectification unit; the heat exchange unit comprises a first heat exchanger, a second heat exchanger and a thirdheat exchanger which are independent from one another; a raw material input pipeline penetrates through the first heat exchanger and then is connected with a raw material inlet in the first extractiondistillation column; a first pipeline is arranged at the bottom of the first extraction distillation column, and so on in a similar manner. An extraction agent used in the method is a mixed solvent which is composed of one or a combination of at least two of sulfolane, ethylene glycol, glycerin, NMF (N-Formylmorpholine), NMP (N-Methyl Pyrrolidone) and DMF (Dimethyl Formamide), and a deep-eutecticsolvent in a compounded manner. By adopting the system and the method, a methyl cyclopentane product of which the purity is greater than 99.95wt% can be purified at one time, and the recycling rate of methyl cyclopentane is greater than 99%.

Owner:JIANGXI INST OF RARE EARTHS CHINESE ACAD OF SCI

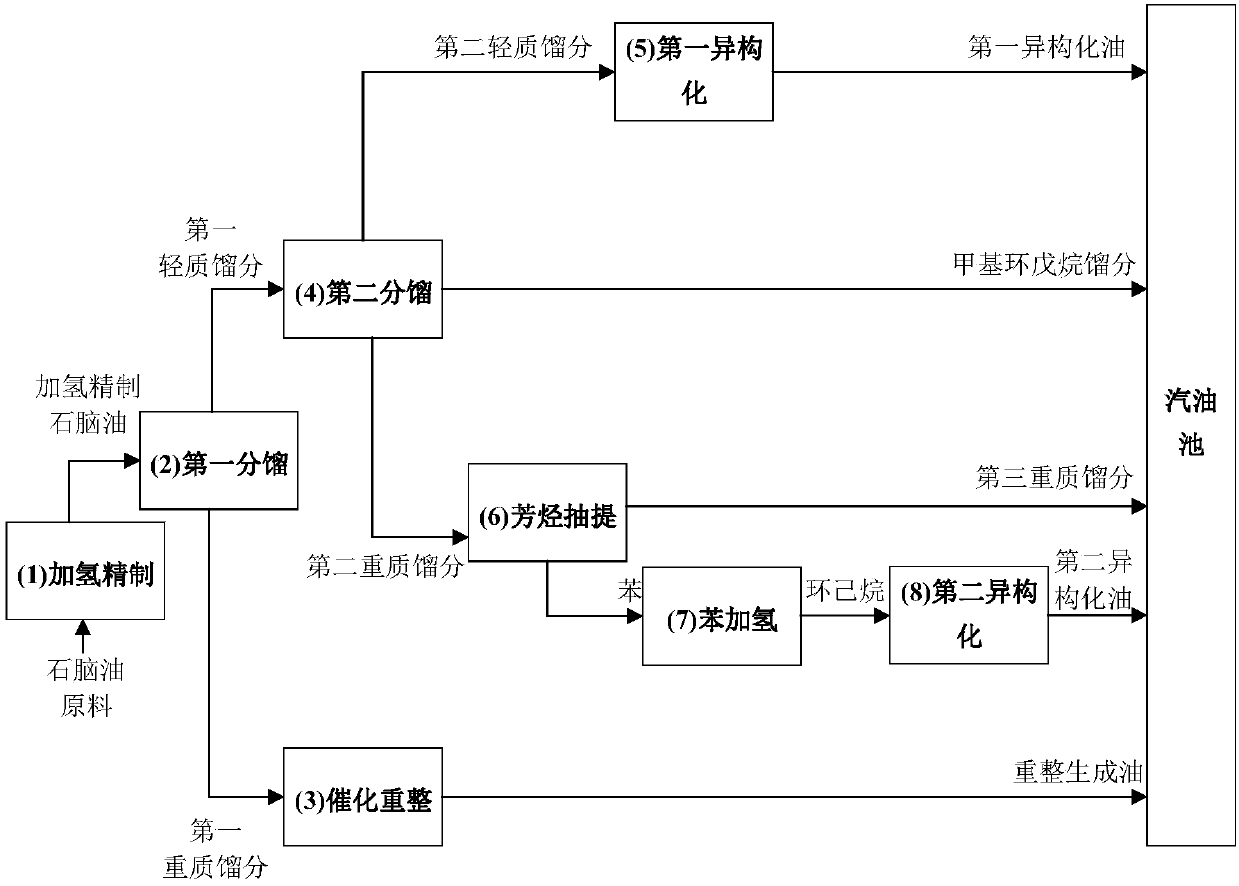

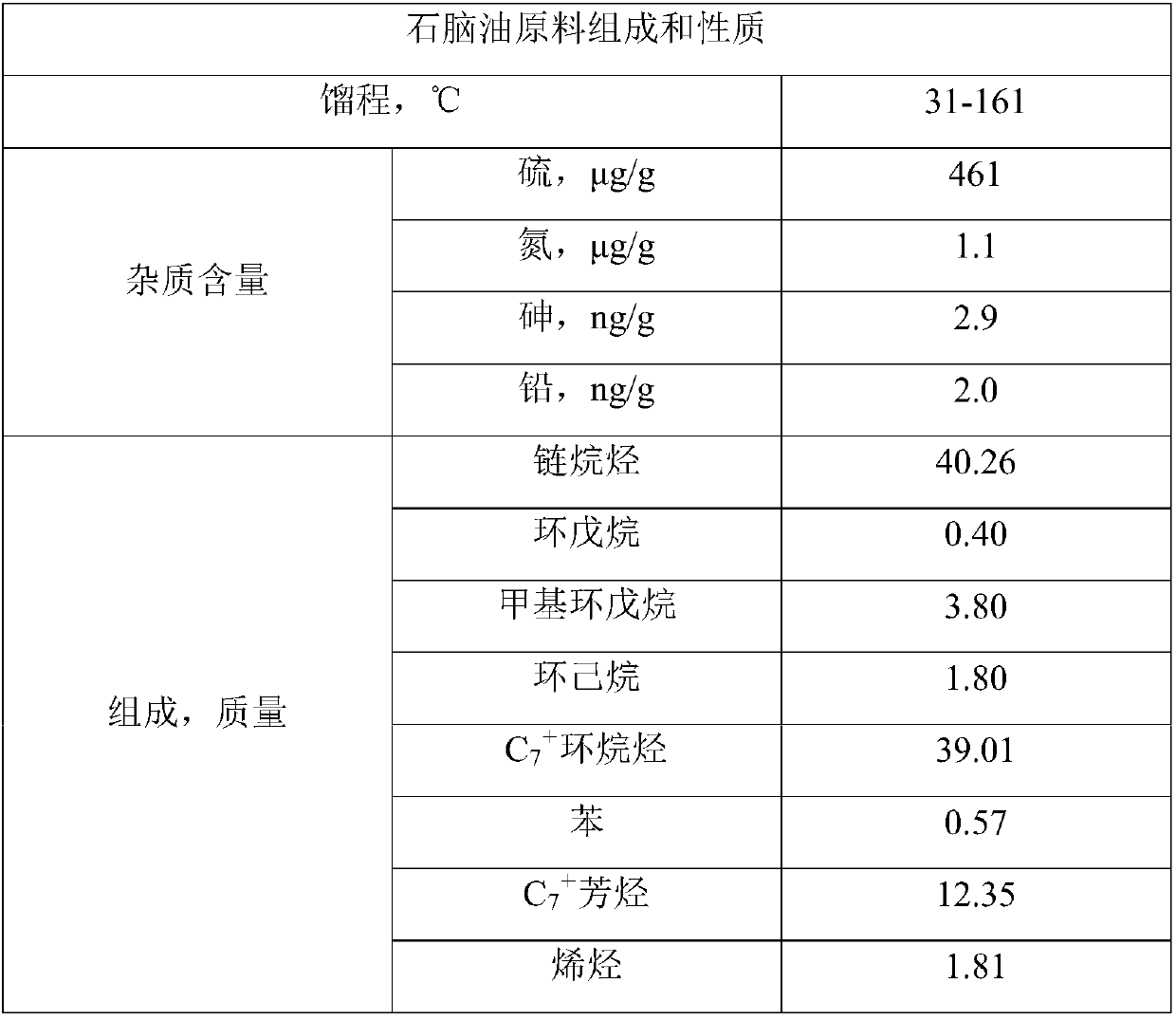

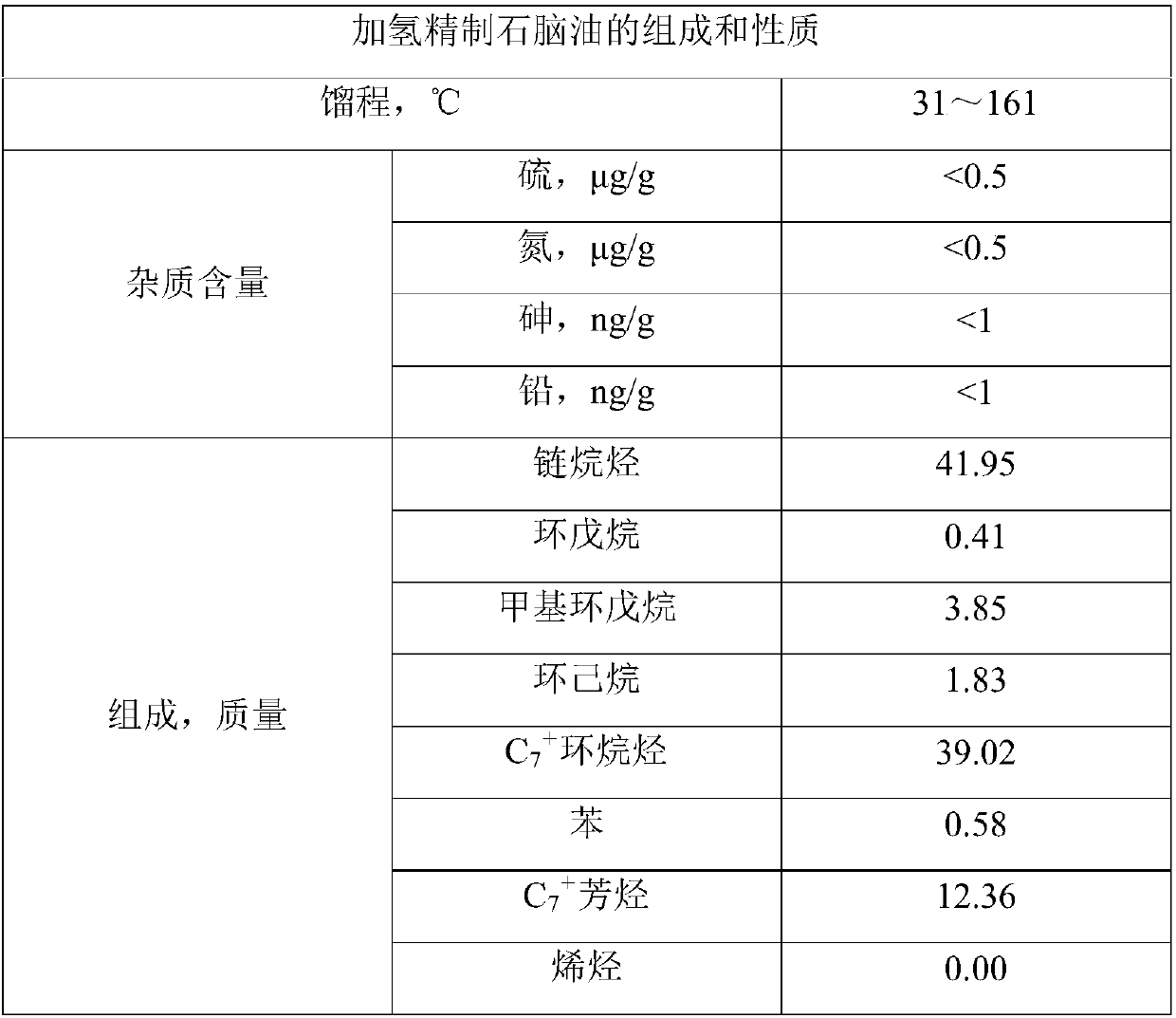

Method for producing high-octane gasoline through naphtha

ActiveCN109679691AHigh gasoline yieldSimple compositionTreatment with hydrotreatment processesHydrocarbon oils treatment productsCatalytic reformingAlkane

The invention relates to a method for producing high-octane gasoline through naphtha. The method comprises the steps: a naphtha raw material is subjected to hydrorefining, primary fractionation and secondary fractionation; methylcyclopentane, cyclohexane and multibranched paraffin are directly separated from the naphtha to serve as gasoline components; and then first heavy ends obtained through primary fractionation are subjected to catalytic reforming, second light ends obtained through secondary fractionation are subjected to an isomerization reaction to obtain a gasoline component, and benzene in the naphtha can further be hydrogenated to form the cyclohexane to be isomerized. According to the method, the gasoline yield can be increased, gasoline composition is optimized, the content ofisoparaffin and cycloparaffin in the gasoline is increased, and the content of arene and n-paraffin is decreased.

Owner:CHINA PETROLEUM & CHEM CORP +1

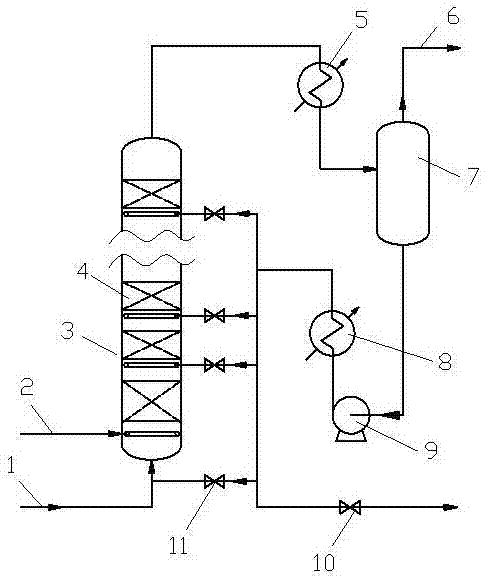

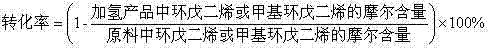

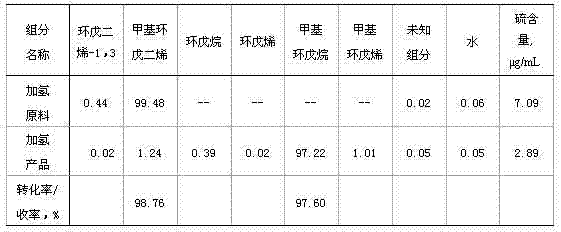

Method for preparing cyclopentane by hydrogenation of cyclopentadiene or preparing methyl cyclopentane by hydrogenation of methyl cyclopentadiene

A method for preparing cyclopentane by hydrogenation of cyclopentadiene or preparing methyl cyclopentane by hydrogenation of methyl cyclopentadiene is performed in a lower-feeding type adiabatic bubbling fixed bed reactor, the lower-feeding type adiabatic bubbling fixed bed reactor provided with 2 ~ 10 bed layers, and each bed layer is filled with a catalyst; the method is performed in the following continuous feed mode: raw materials of the cyclopentadiene or the methyl cyclopentadiene and hydrogen are introduced into respectively from a lower bed layer; a hydrogenated material coming out from the reactor top is cooled by a first heat exchanger and then enters into a gas-liquid separation tank, a liquid phase material in the gas-liquid separation tank is collected by a bottom reflux pump; the collected material is further cooled through a second heat exchanger, one stream of the cooled material is used as a product and is collected by a product collecting control valve, the rest streams of the cooled material are used as cyclopentadiene or methyl cyclopentadiene diluents, and are returned back to the lower part of each bed layer by respective flow control valves, and according to the returning amount of each stream, a corresponding bed layer is controlled to be heated. According to the method, cyclopentane or methyl cyclopentane is high in yield, low in sulfur content, and less in by-products, technological operation is flexible, and the operation cycle of the catalyst is long.

Owner:广东新华粤石化集团股份公司

Solvent composition, aerosol composition, cleaning agent, and article cleaning method

PendingCN113444492AReduce the burden onOrganic detergent compounding agentsOther chemical processesCleansing AgentsAerosol composition

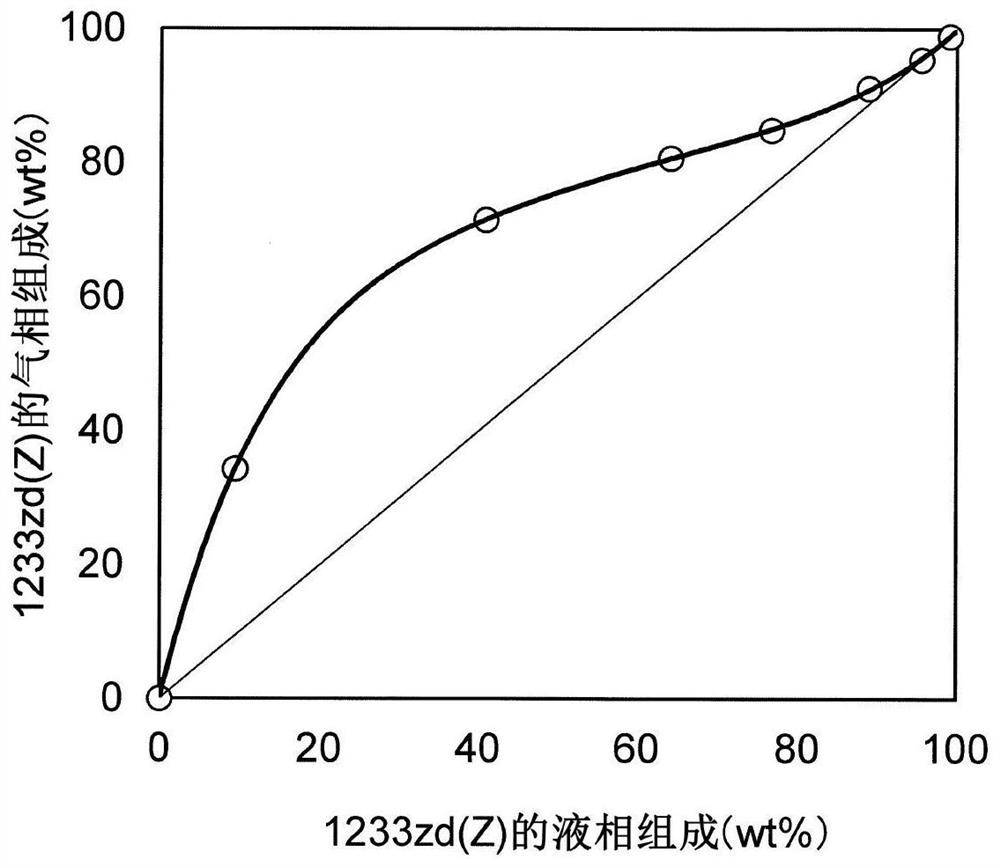

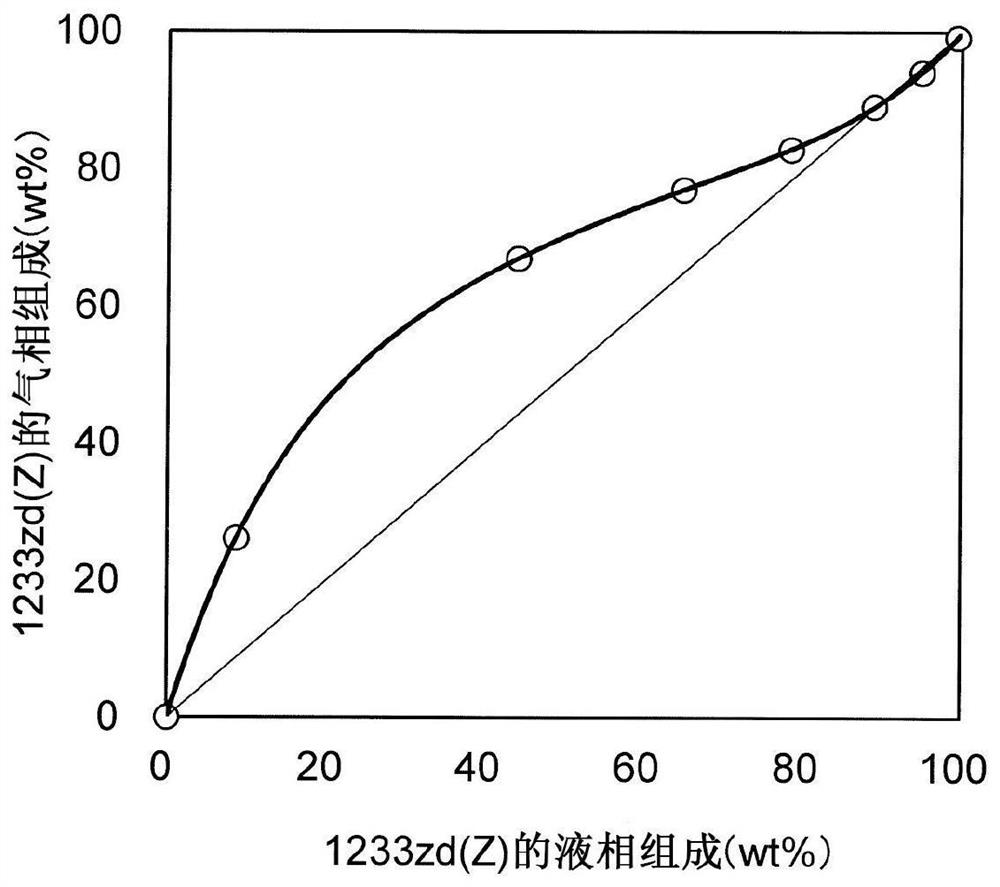

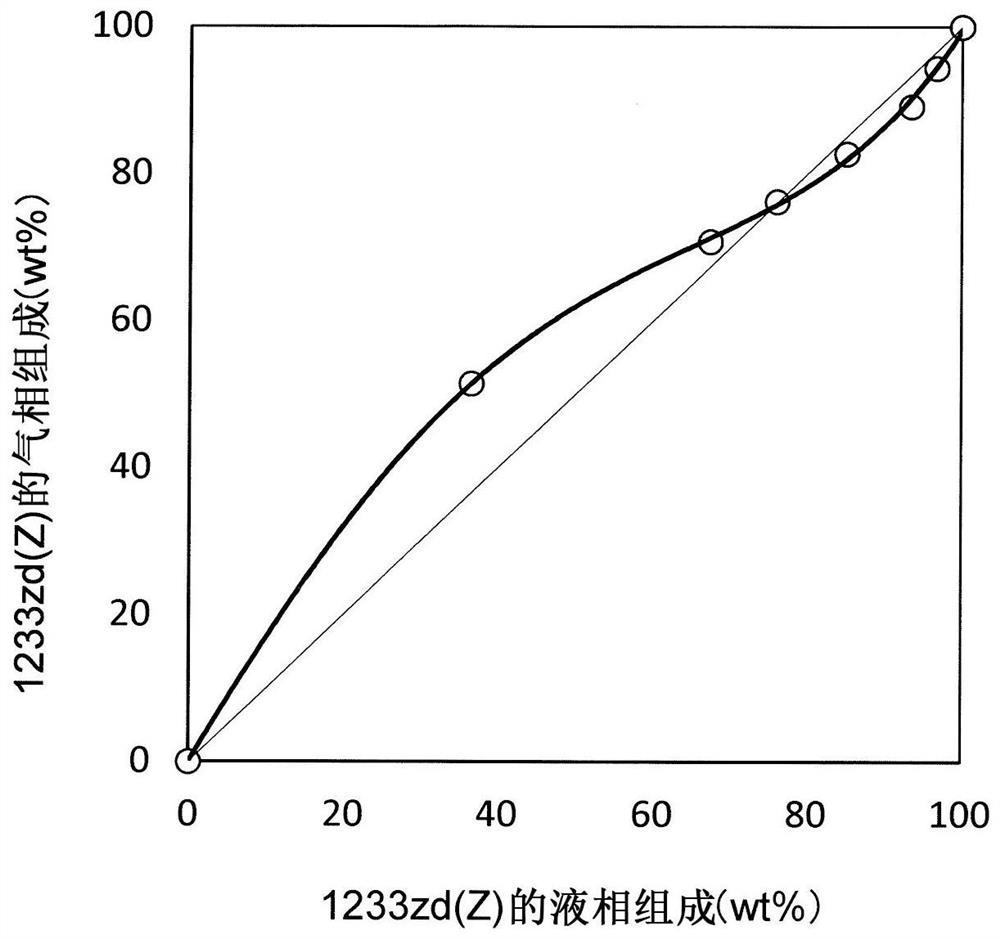

The present invention provides a solvent composition containing a novel (class) azeotropic composition containing Z-1-chloro-3, 3, 3-trifluoropropene (HCFO-1233zd (Z)), which is mild to the environment, and a hexane isomer, the composition of which does not change even if volatilized. Also provided are an aerosol composition containing the solvent composition, a cleaning agent, and a method for cleaning an article using the cleaning agent. An azeotrope-like composition according to one embodiment of the present invention contains Z-1-chloro-3, 3, 3-trifluoropropene and at least one substance selected from the group consisting of 3-methylpentane, 2, 3-dimethylbutane, 2, 2-dimethylbutane, and methylcyclopentane.

Owner:CENT GLASS CO LTD

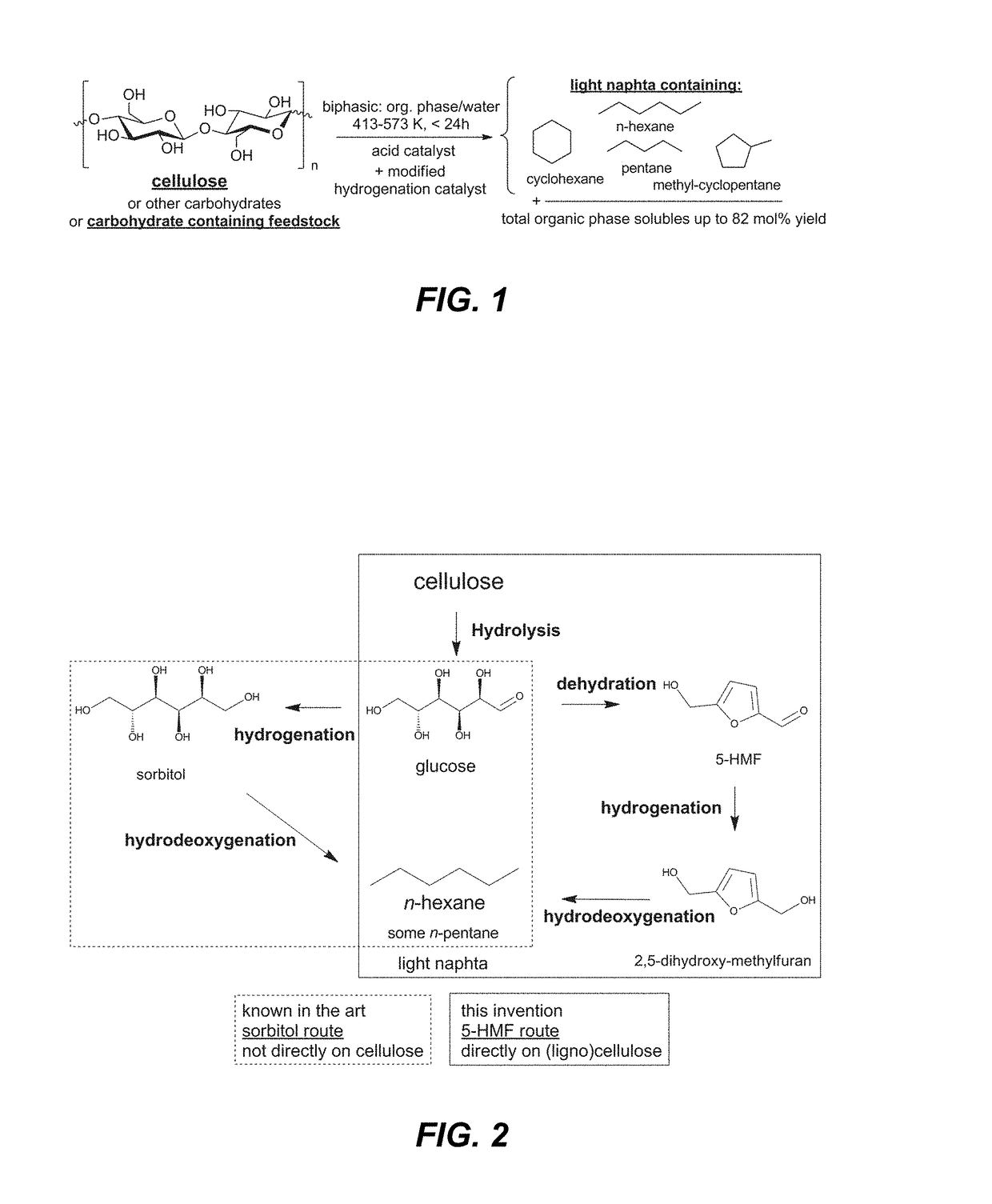

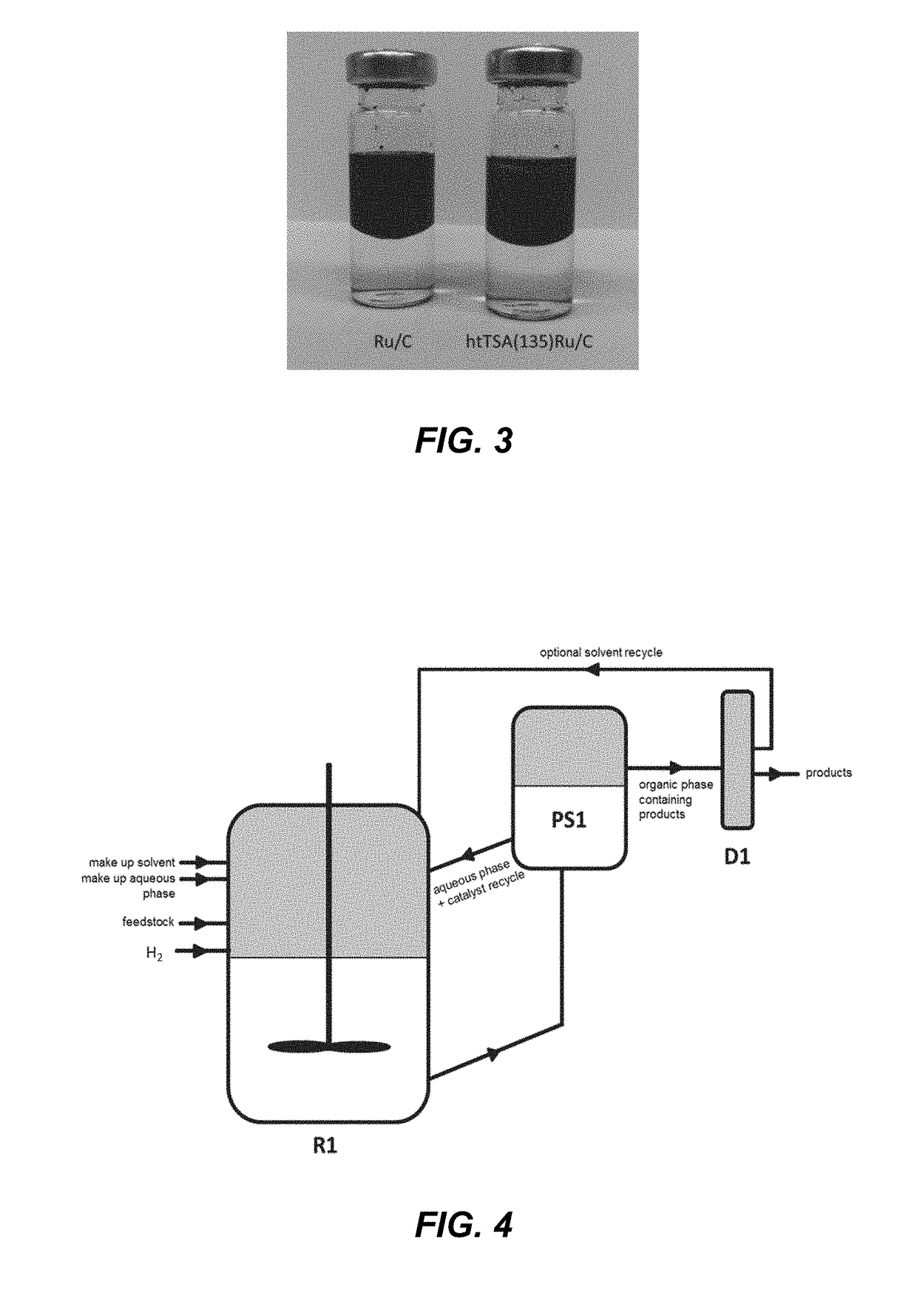

Biphasic solvent catalytic process for the direct production of light naphtha from carbohydrate-containing feedstock

ActiveUS20170190978A1Increase valueHigh yieldLiquid hydrocarbon mixture productionBio-feedstockCelluloseGasoline fuel

The disclosure describes a one-step liquid biphasic catalytic process for converting a carbohydrate-containing feedstock, preferably lignocellulose, to light naphtha (e.g., hexane, pentane, methyl cyclopentane, cyclohexane, etc.) in the presence of an acidic reactive aqueous phase and a redox catalyst in the organic extracting / reaction phase. The process provides a cost-effective route for producing light-naphtha components, in presence or not of deoxygenates. The light naphtha components are useful as feedstock for steam and catalytic cracking to produce value-added platform molecules like ethylene and propylene, as precursor for the synthesis of bioaromatics like benzene and as gasoline fuel feedstock, and as fuel additives (e.g., the concomitantly formed oxygenates) to improve the biological origin of carbon in the fuel.

Owner:KATHOLIEKE UNIV LEUVEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com