Patents

Literature

260results about "Fractional condensation purification/separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

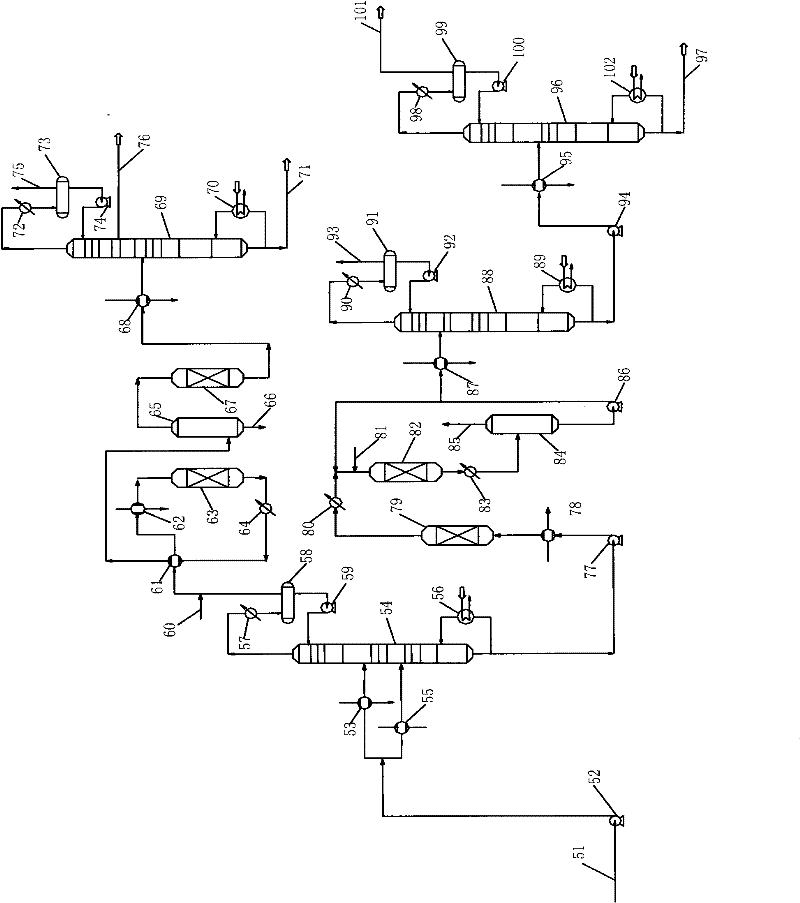

Non-copious cooling lower carbon number hydrocarbons separation method containing light gas

ActiveCN101353286AHigh ethylene contentHigh recovery rateFractional condensation purification/separationHydrocarbonsCarbon numberProduct gas

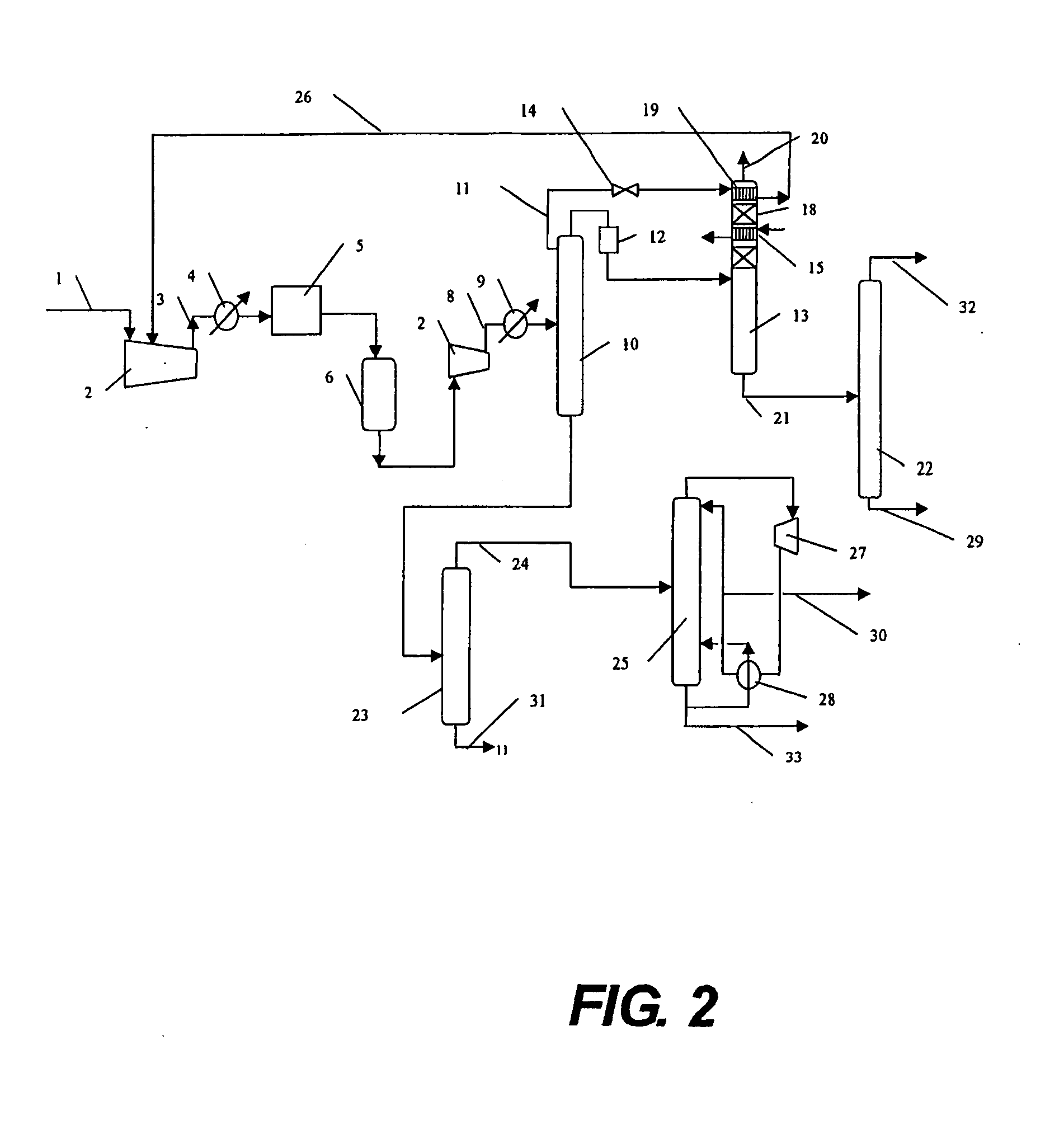

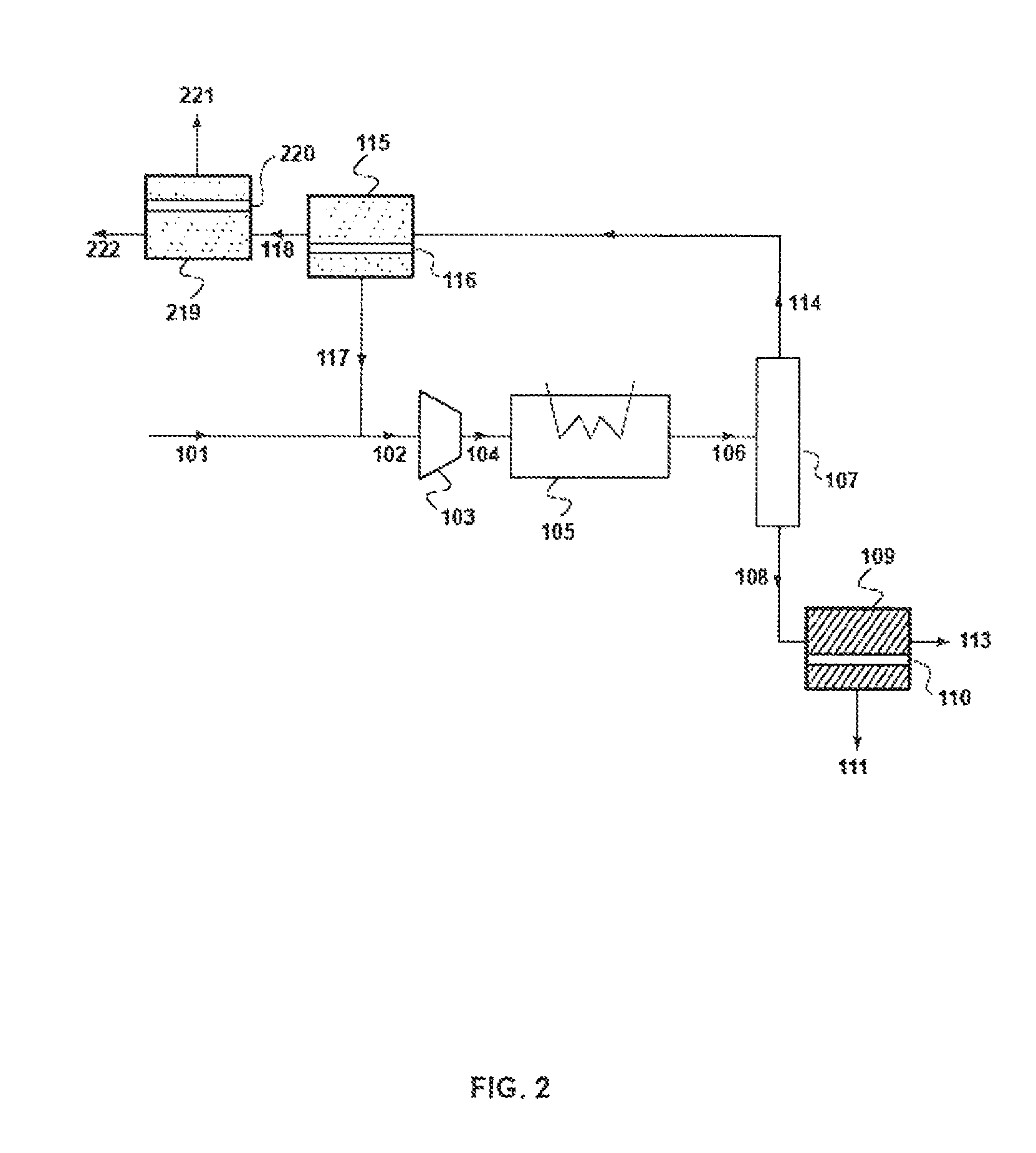

The invention relates to a separation method for non-cryogenic low-carbon hydrocarbon containing light gases. The method comprise the steps as follows: (1) pre-treated gas at the outlet of a reactor is cooled to the temperature of 10-37 DEG C and sent to a pre-cutting tower; (2) a product at the top of the pre-cutting tower is cooled and sent to an absorption tower, and C2 hydrocarbons in the product at the top of the pre-cutting tower are absorbed by an absorbent consisting of C3, C4, C5 or the mixture of hydrocarbons thereof; and (3) tower kettle products of the pre-cutting tower are sent to a deethanizing column for clearly cutting the C2 and the C3 to obtain C2 distillate at the top of the tower; the tower kettle products are C3 and heavier components. Compared with the prior art, the method has the advantages of lower investment, lower energy consumption, higher recycling rate of materials, simpler operation, less maintenance workload, reliable operation, etc.

Owner:WISON ENG

Method for producing ethylbenzene

InactiveUS6252126B1Chemical industryFractional condensation purification/separationBenzeneVapor phase

An ethylbenzene production system comprises a reactor vessel, a vapor phase ethylene feed stream, a benzene feed stream entering the reactor vessel, and a product stream containing ethylbenzene exiting the reactor vessel. The reactor vessel has an ethylation section and a benzene stripping section, whereby fluid communication via integrated vapor and liquid traffic is maintained between the ethylation section and stripping section. The vapor phase ethylene feed stream contains 3 to 50 mol % ethylene and at least 20 mol % methane entering the reactor vessel.

Owner:NETZER DAVID

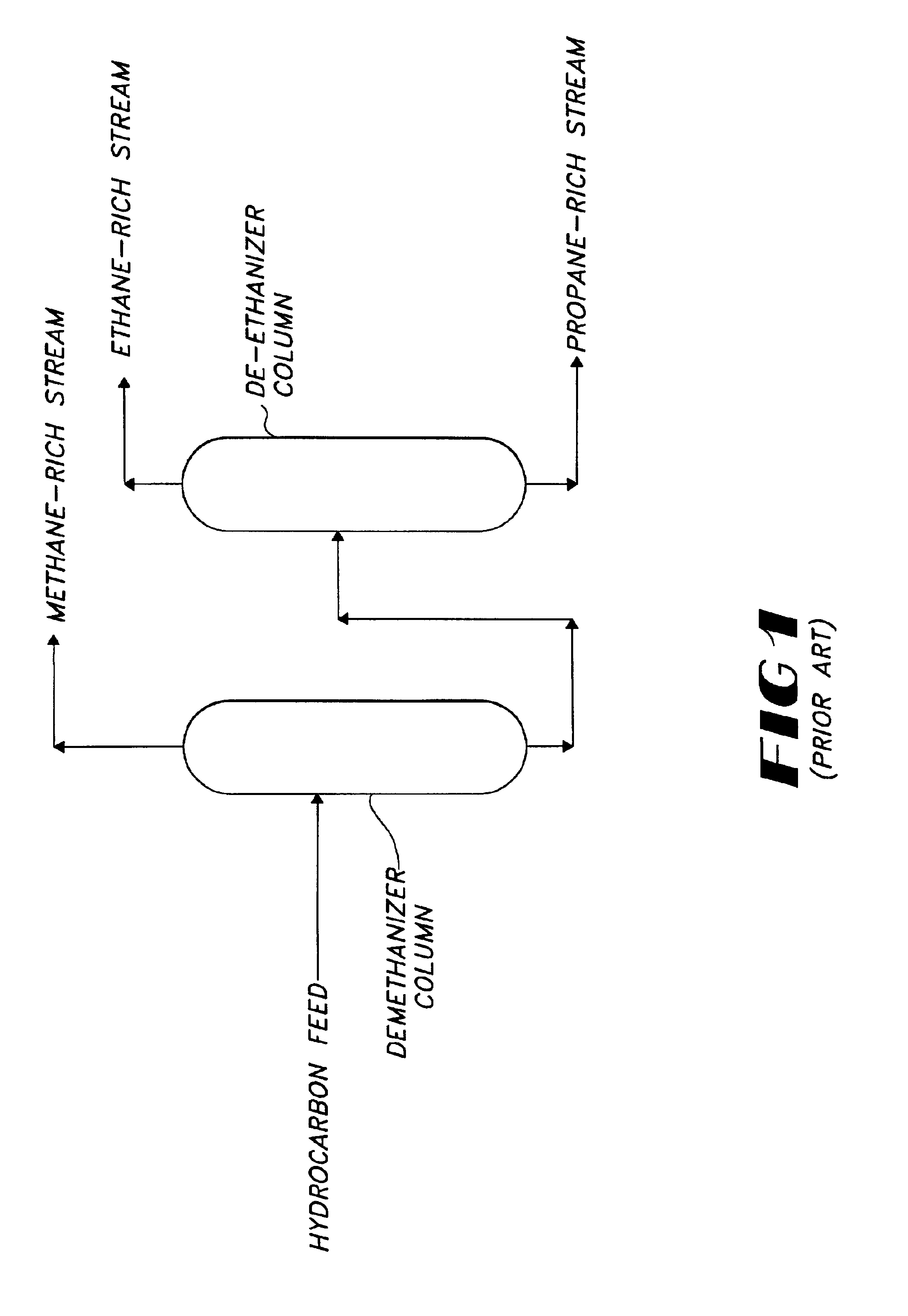

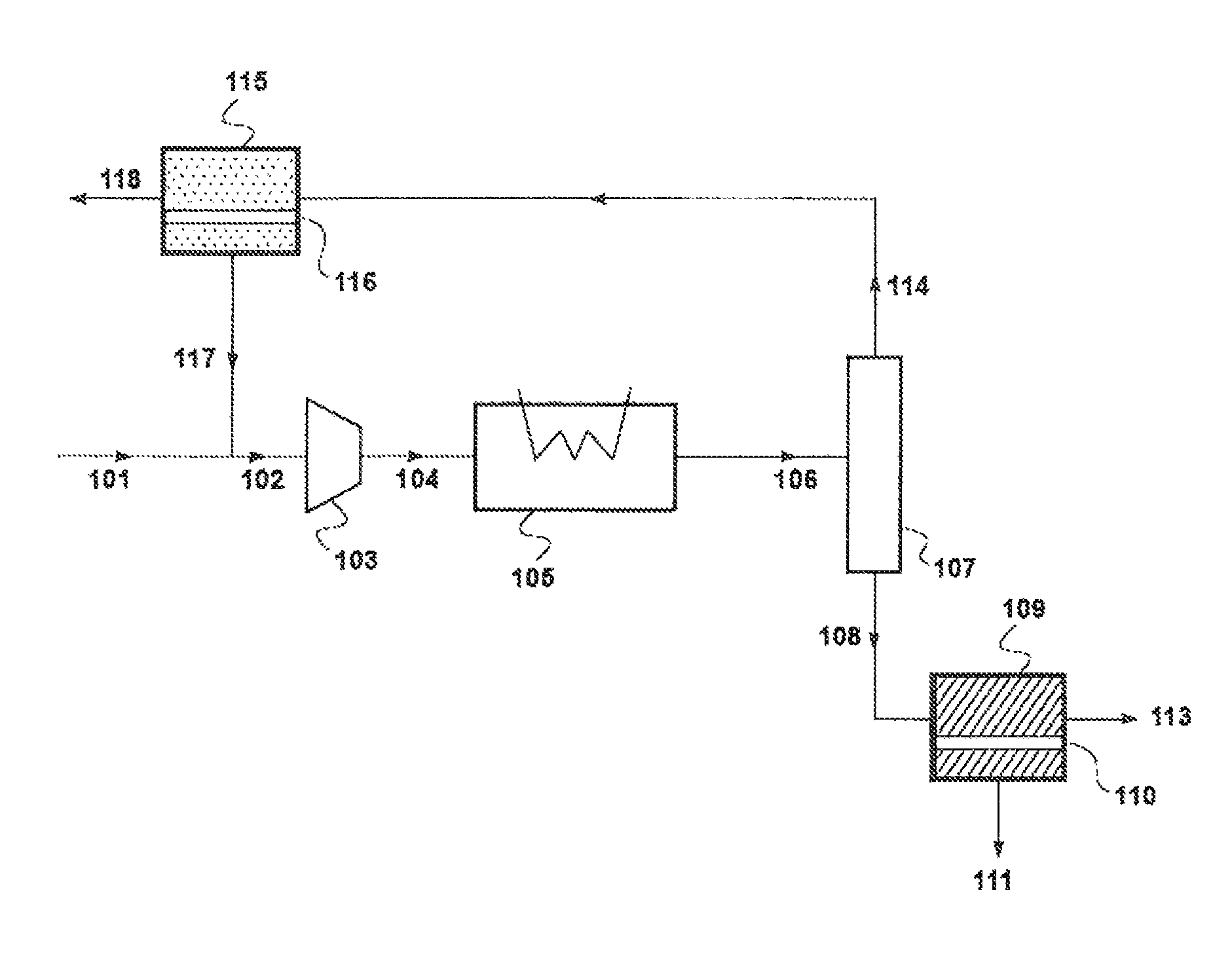

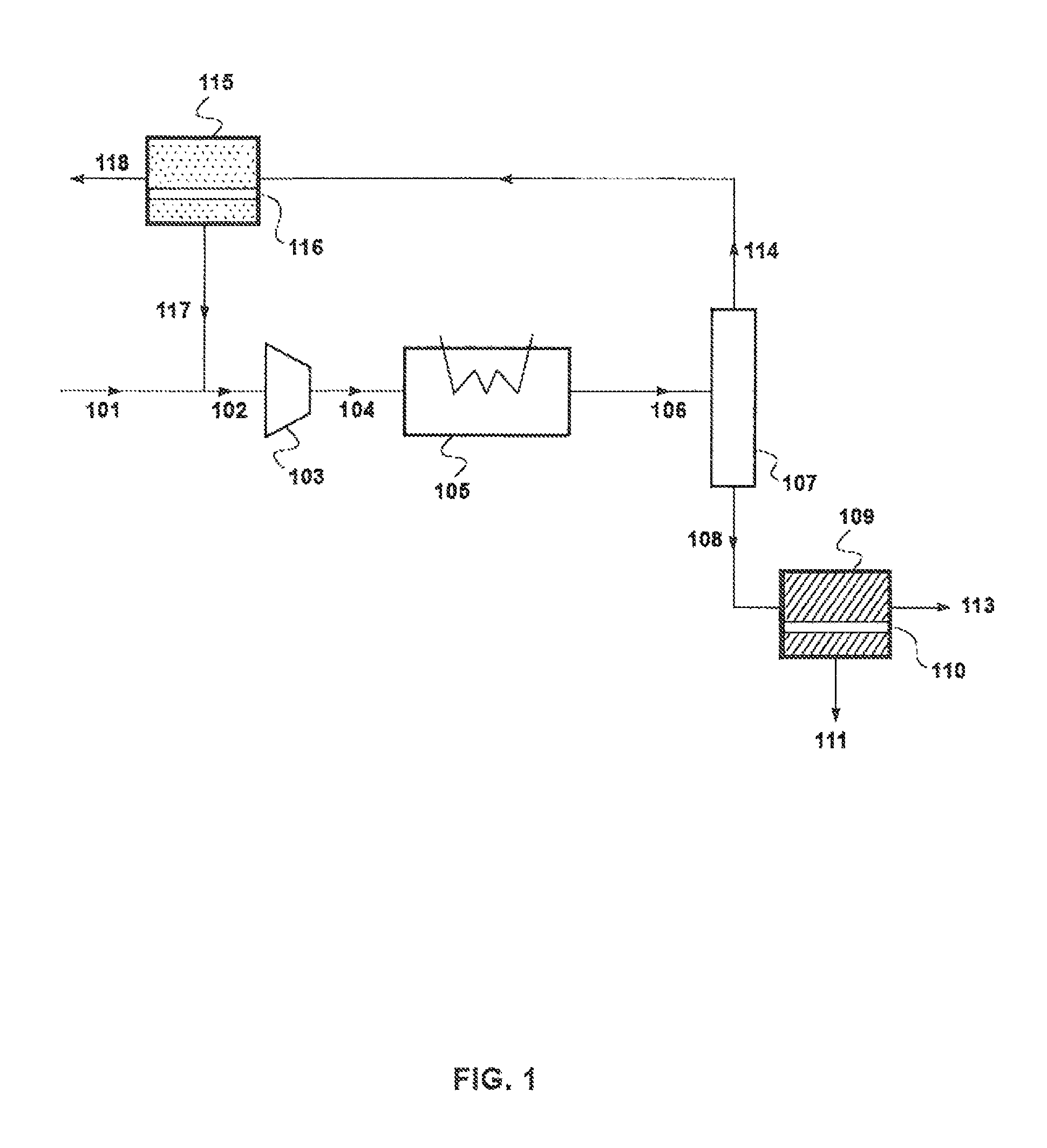

Ethane extraction process for a hydrocarbon gas stream

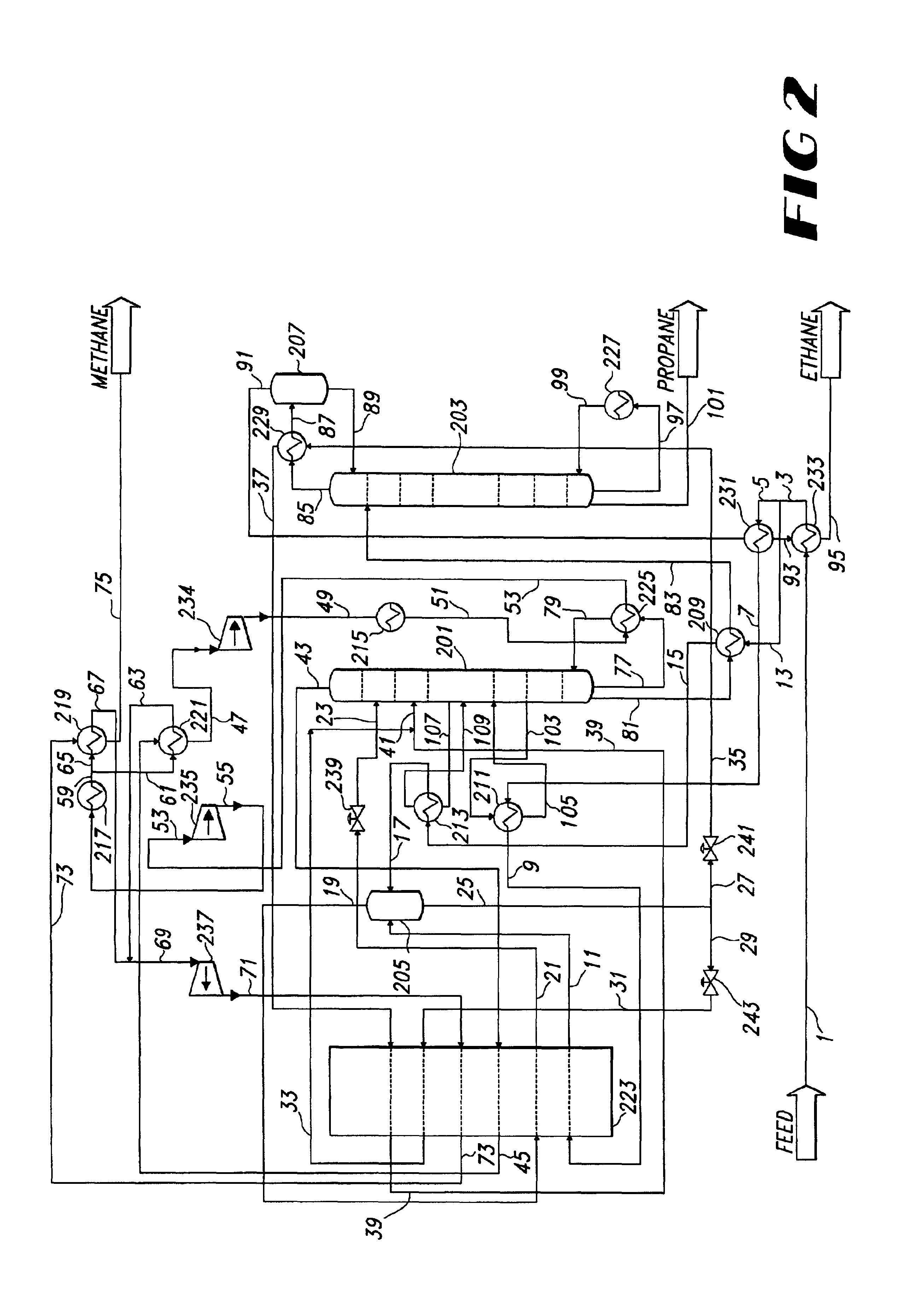

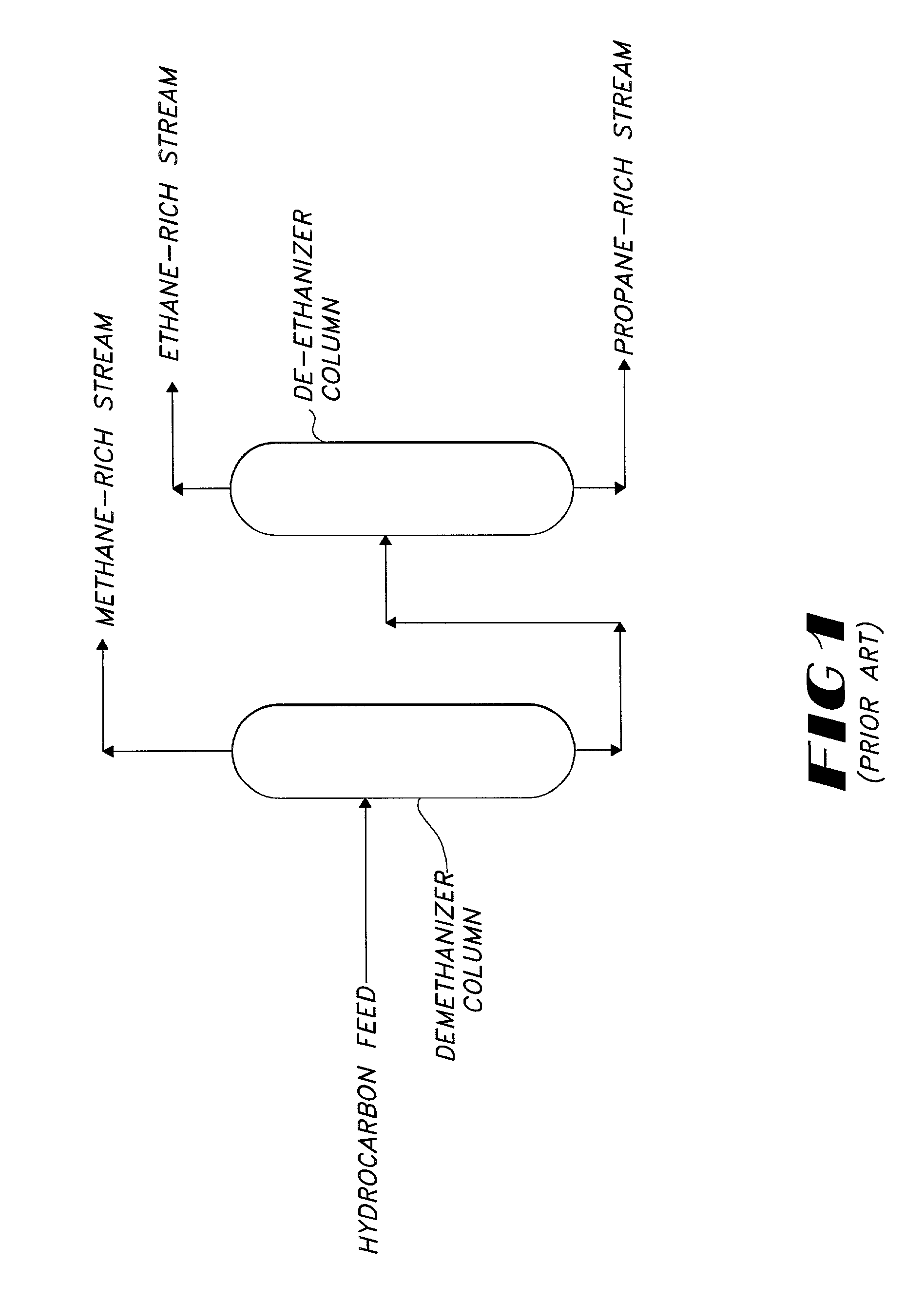

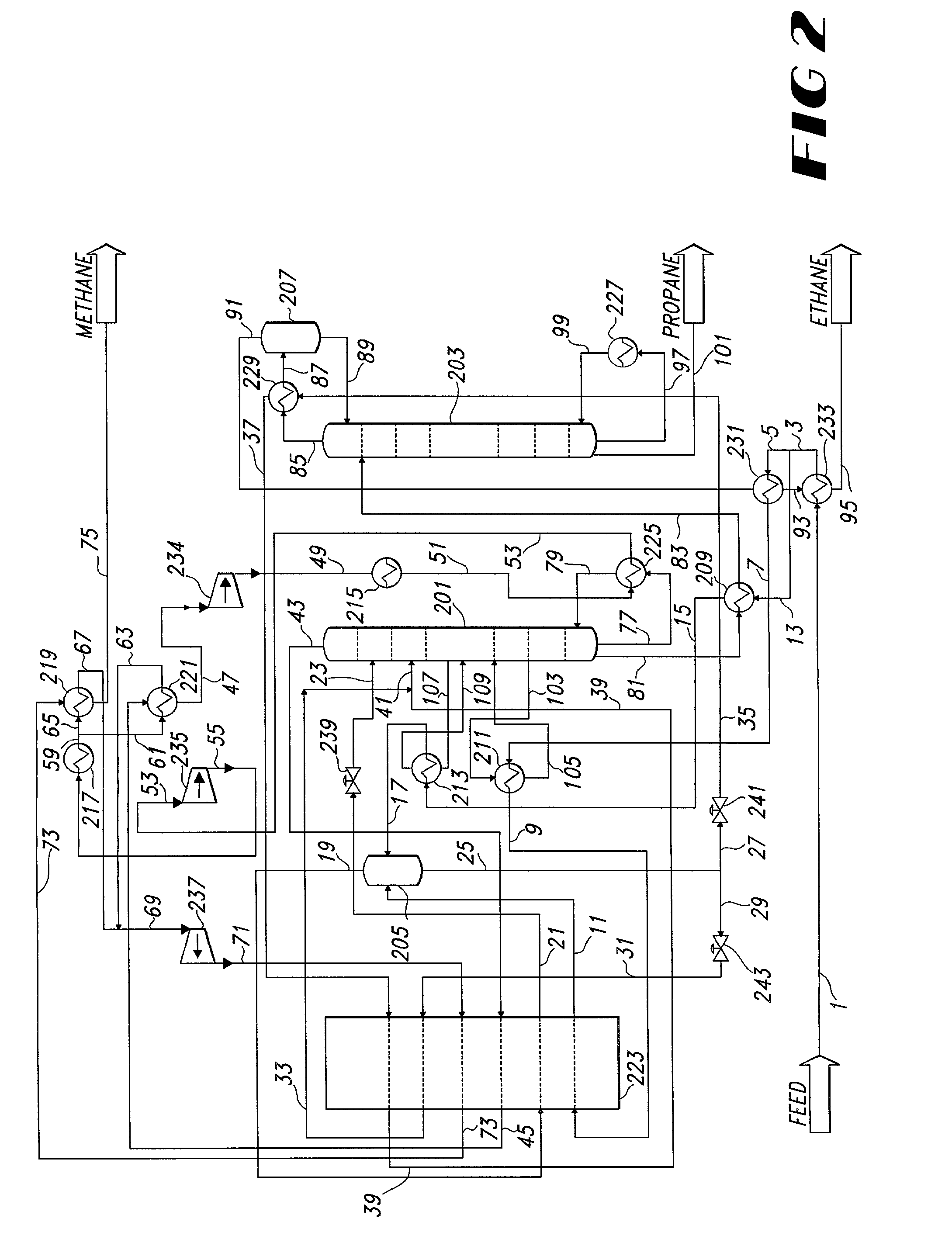

A process for ethane extraction from a gas stream based on turboexpansion and fractionation with no mechanical refrigeration is provided. The feed gas is sweetened and dehydrated by a conventional amine process and by a molecular sieve unit, to remove carbon dioxide and water. After this pretreatment, the feed gas undergoes to a series of cooling steps through a cryogenic brazed aluminum heat exchanger and fed to a demethanizer column. A stream rich in methane is recovered from the top of this column and fed to a centrifugal compressor and subsequently routed to a booster / turboexpander. The temperature of the methane gas is greatly reduced by the expansion allowing the cooled methane stream to be a cooling source for cryogenic heat exchanger. Feed for a de-ethanizer column comes from the bottom liquids of the de-methanizer column. Ethane is recovered overhead at the de-ethanizer column.

Owner:INELECTRA

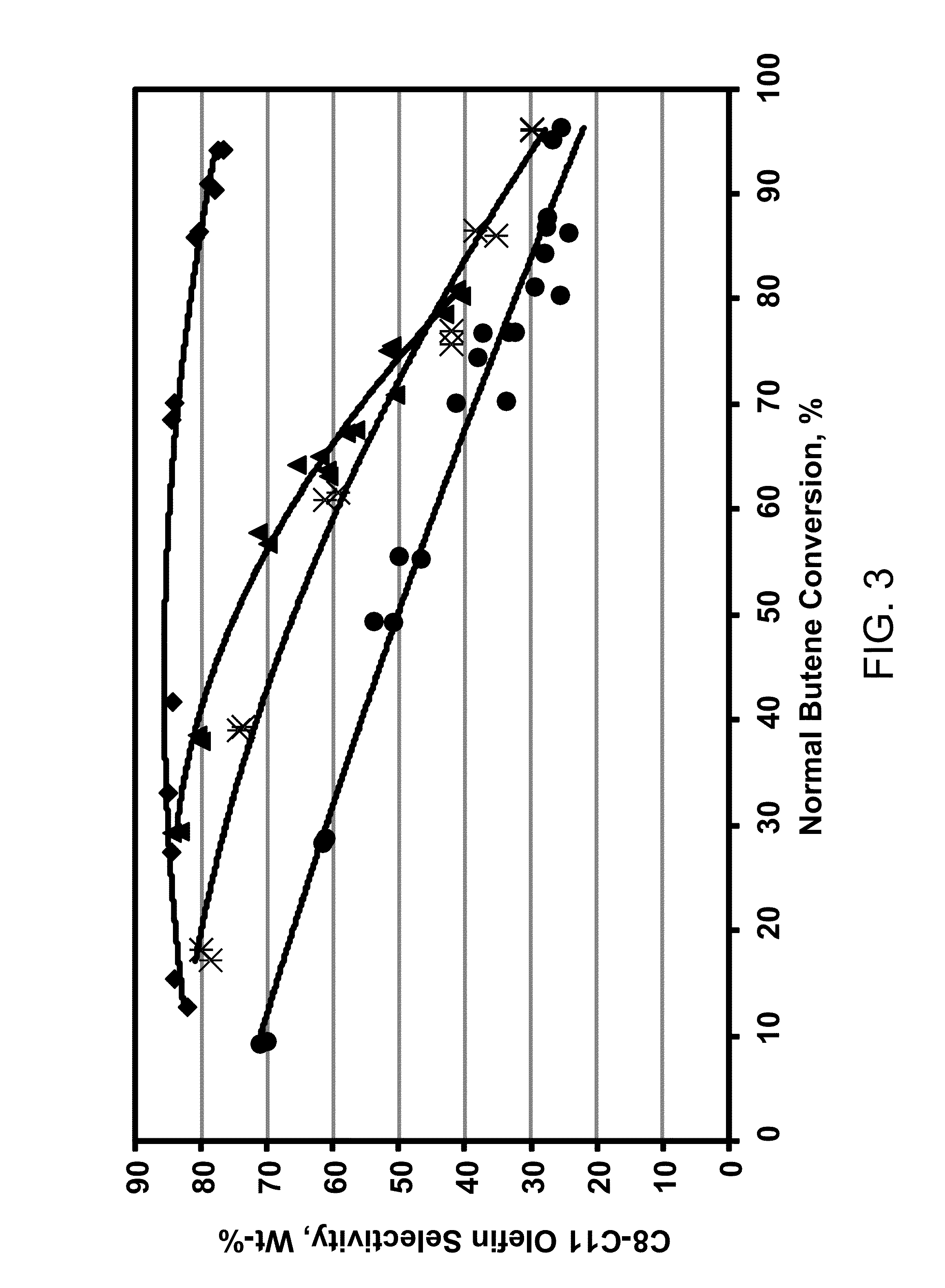

Process for making diesel by oligomerization of gasoline

InactiveUS20140135554A1Molecular sieve catalystLiquid hydrocarbon mixtures productionOligomerGasoline

Owner:UOP LLC

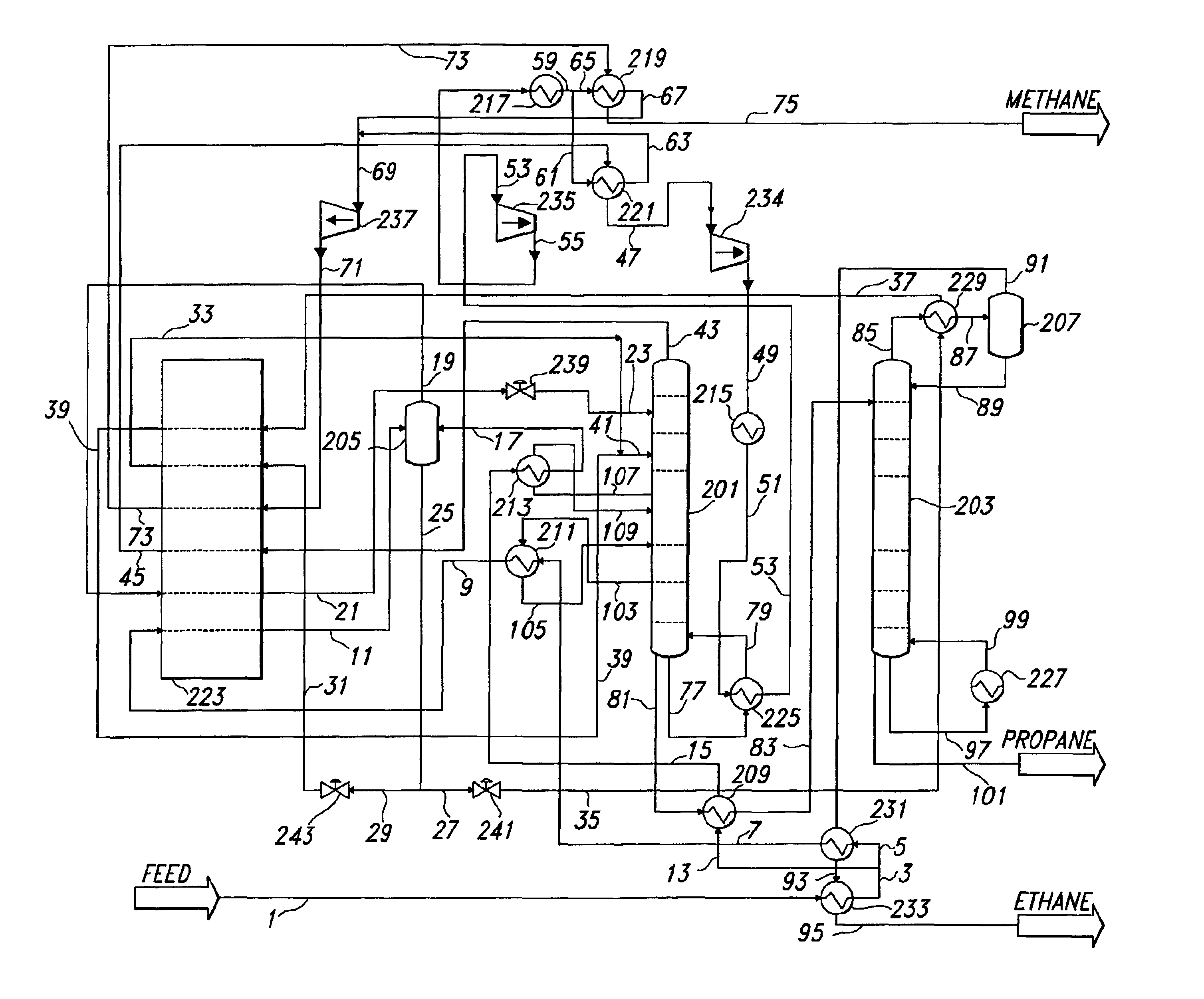

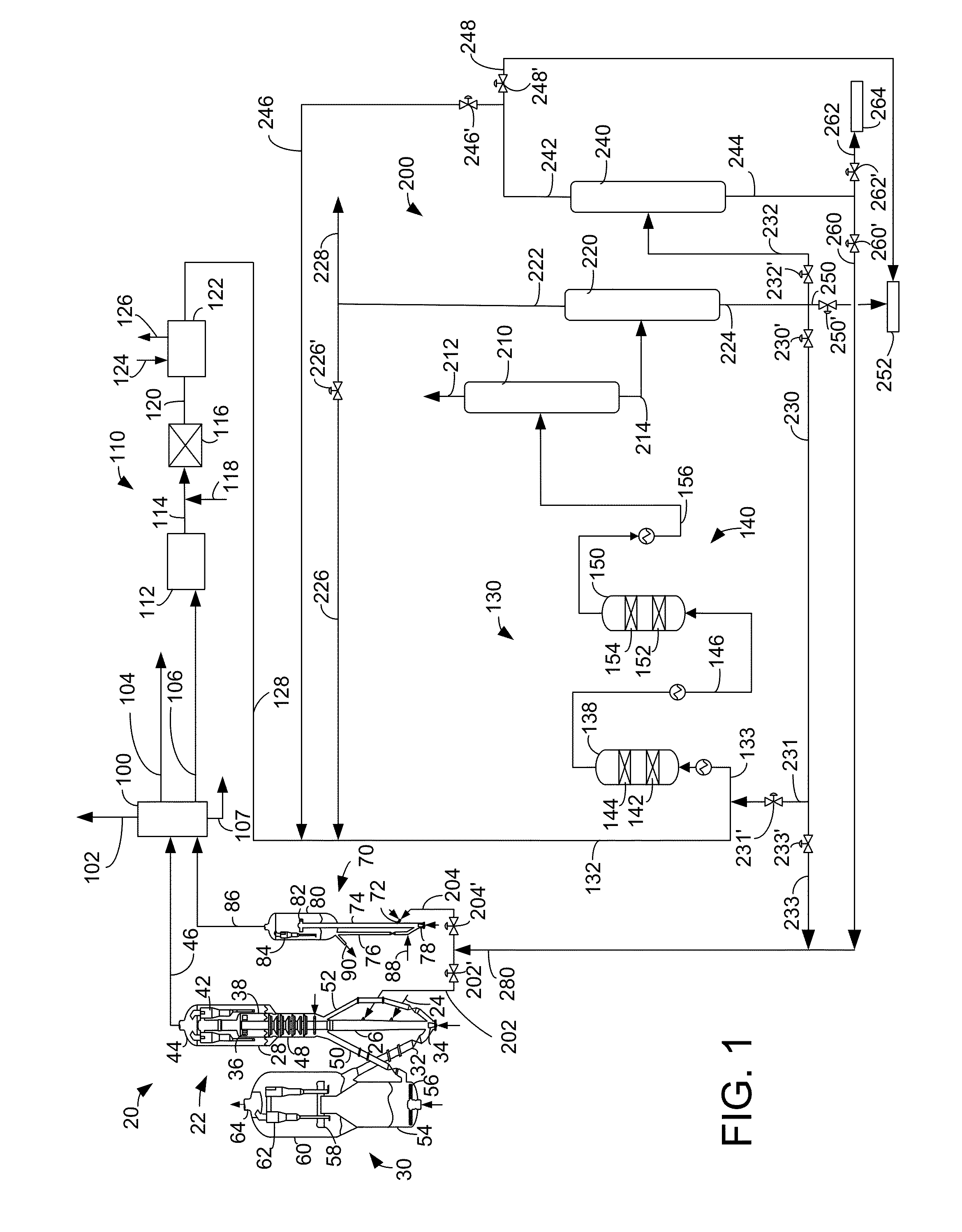

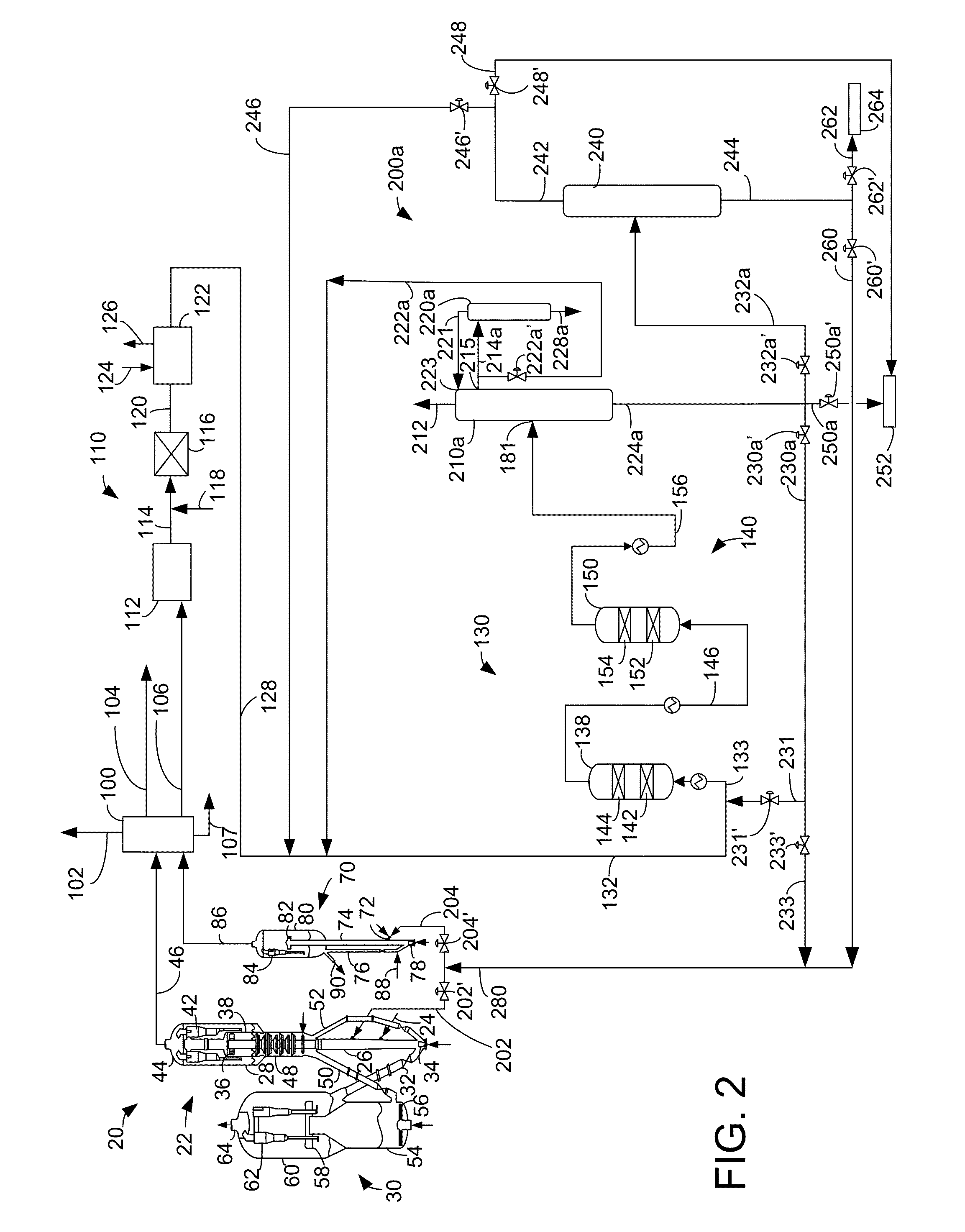

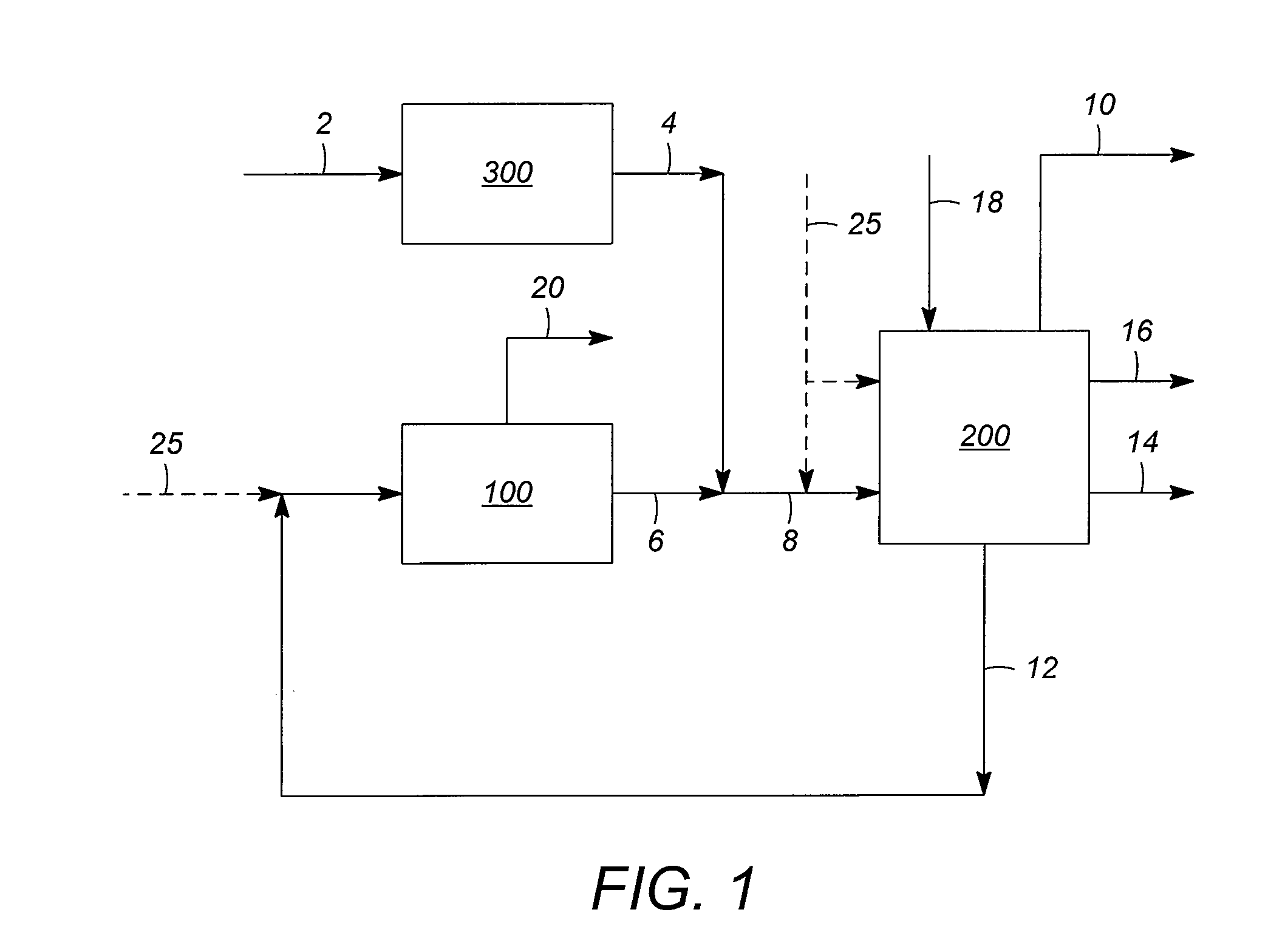

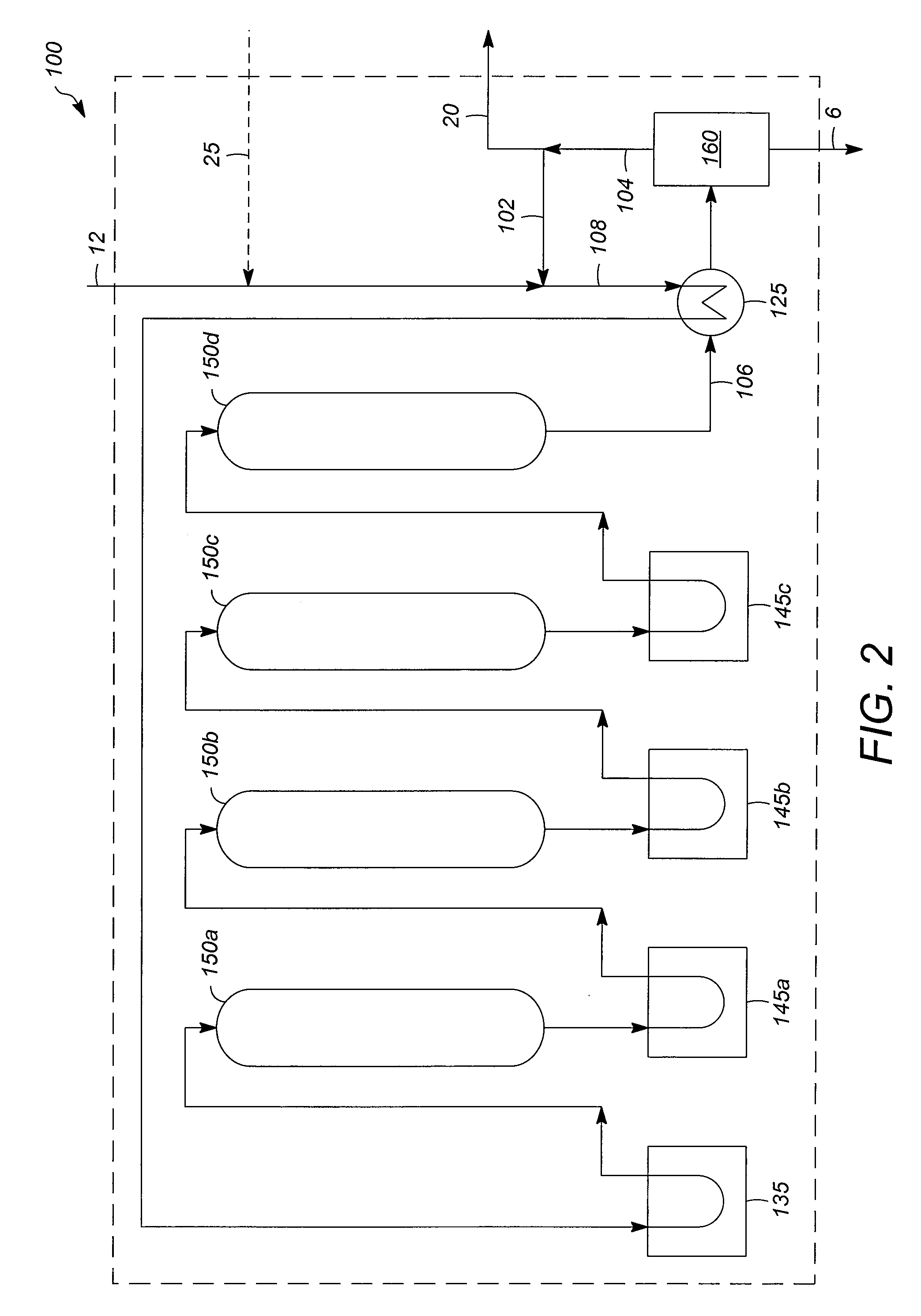

Integrated processes for propylene production and recovery

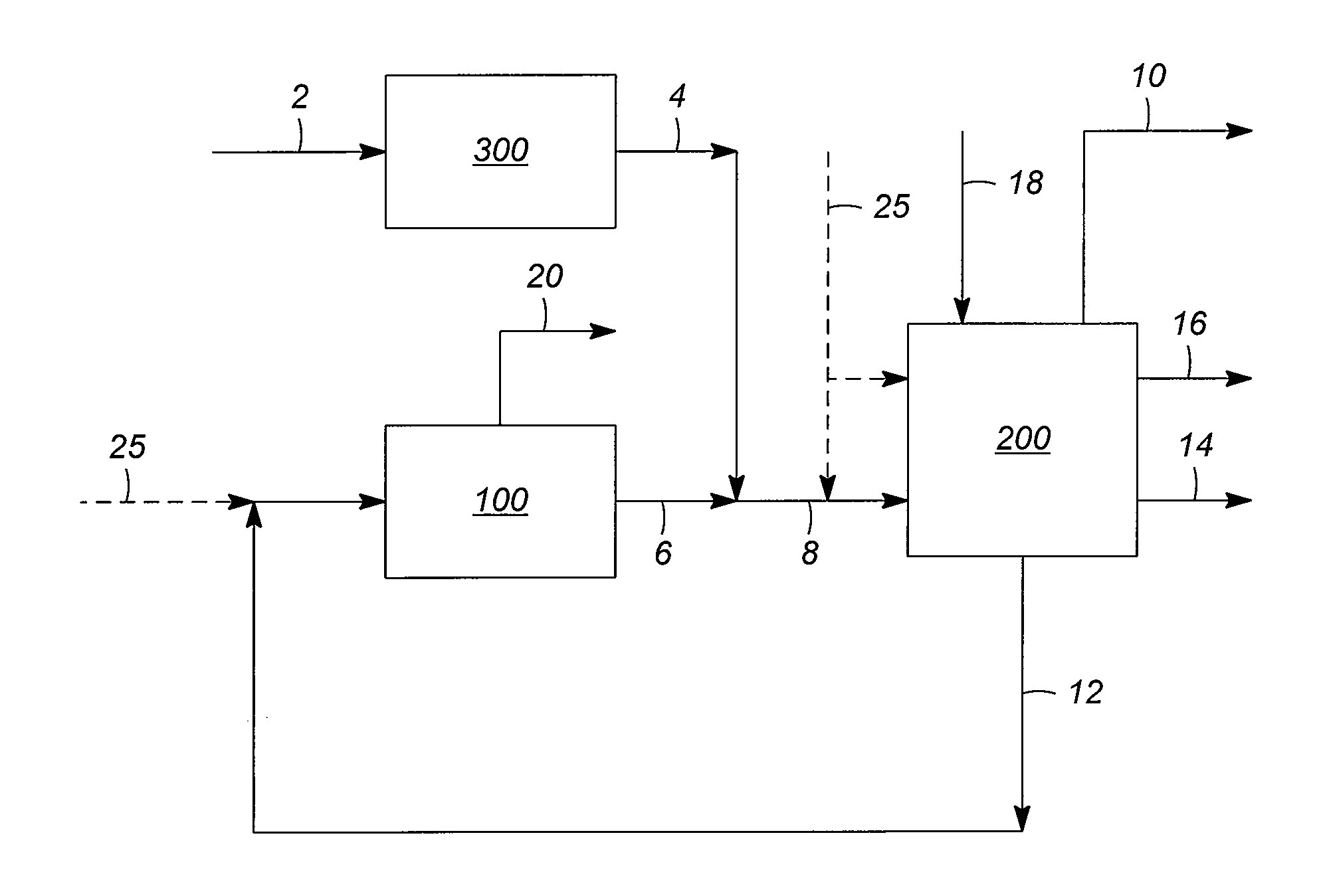

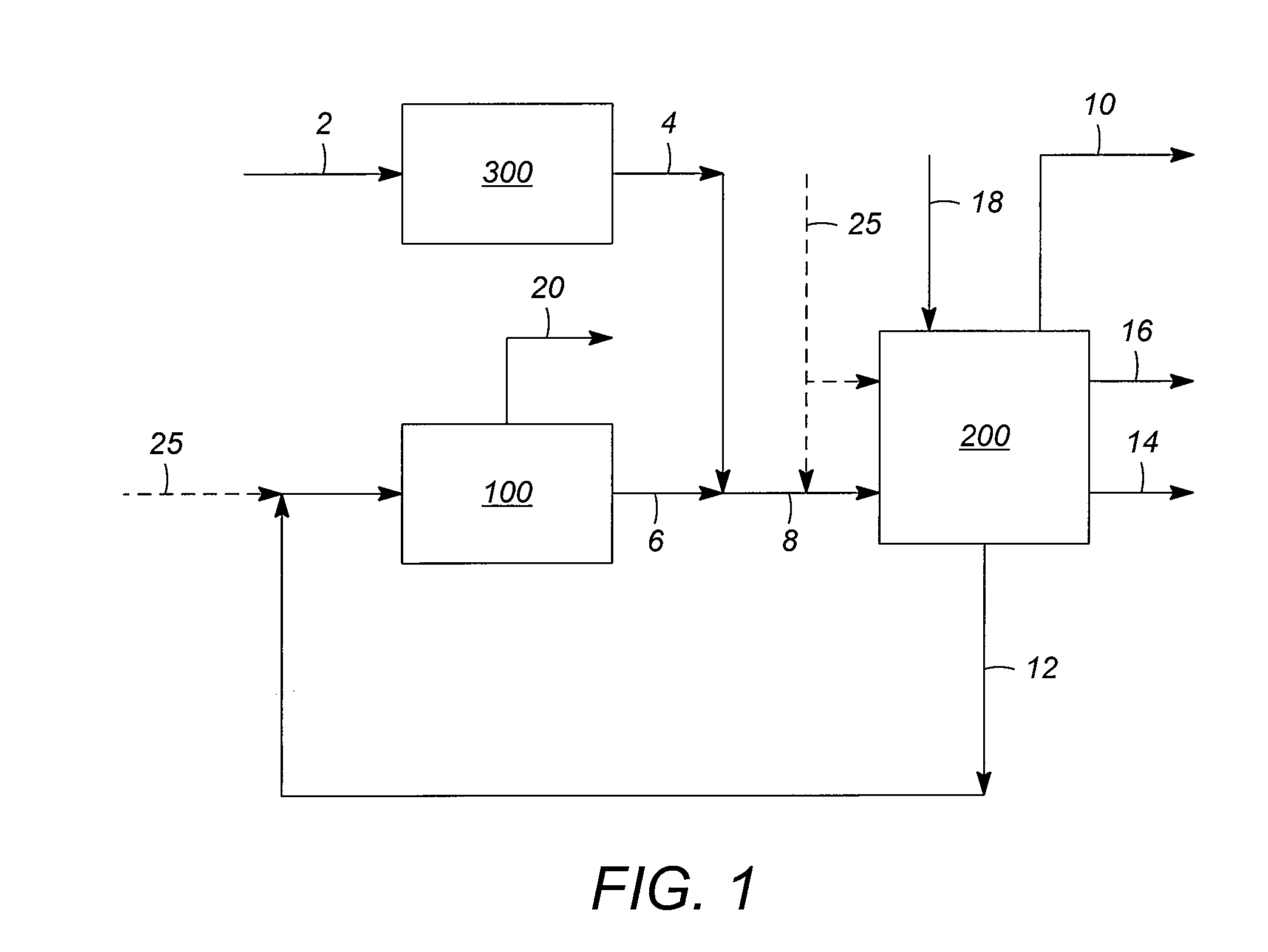

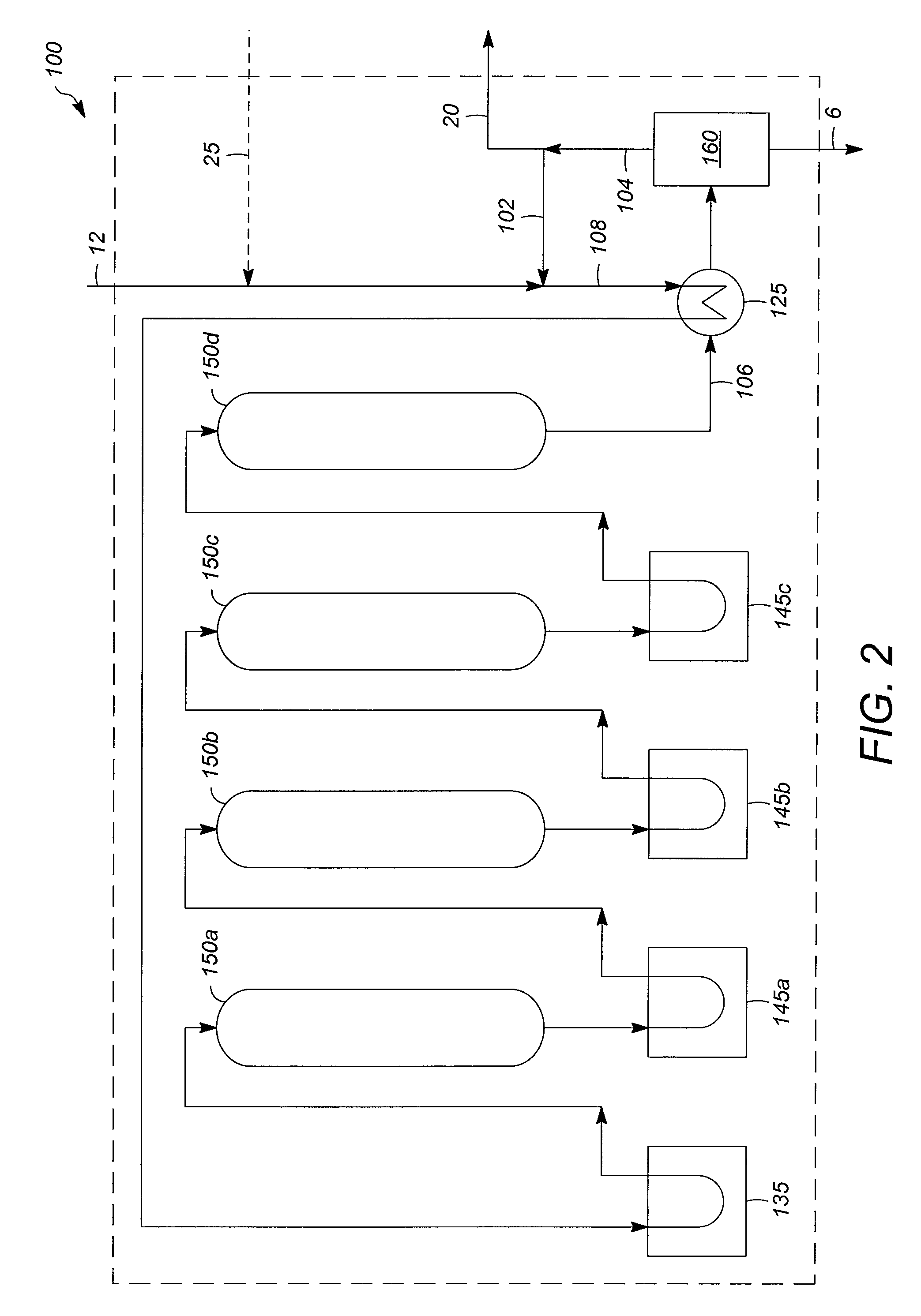

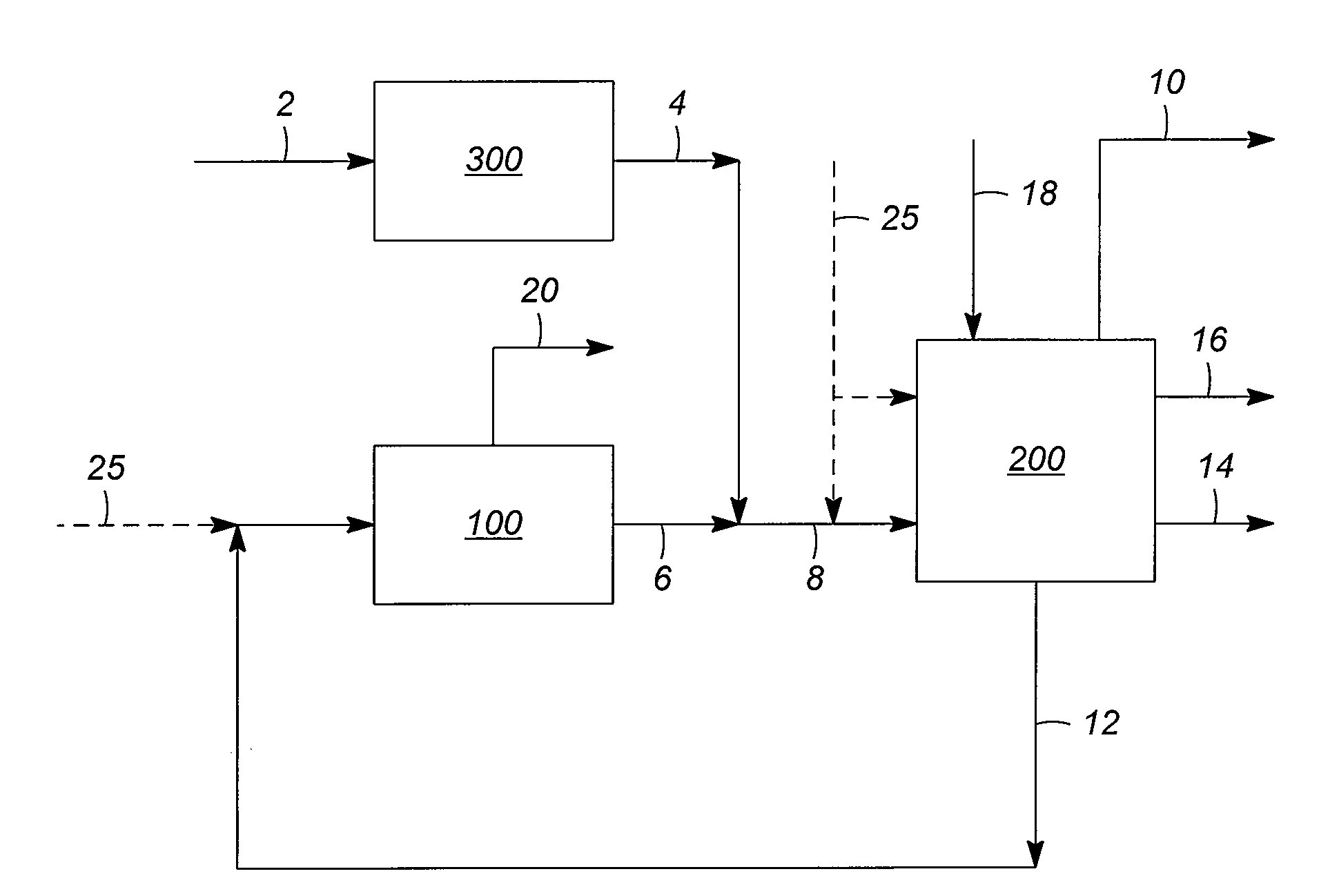

ActiveUS8563793B2Guaranteed maximum utilizationSolve large capacityCatalytic crackingHydrocarbon by hydrogenationDehydrogenationConventional fractionation

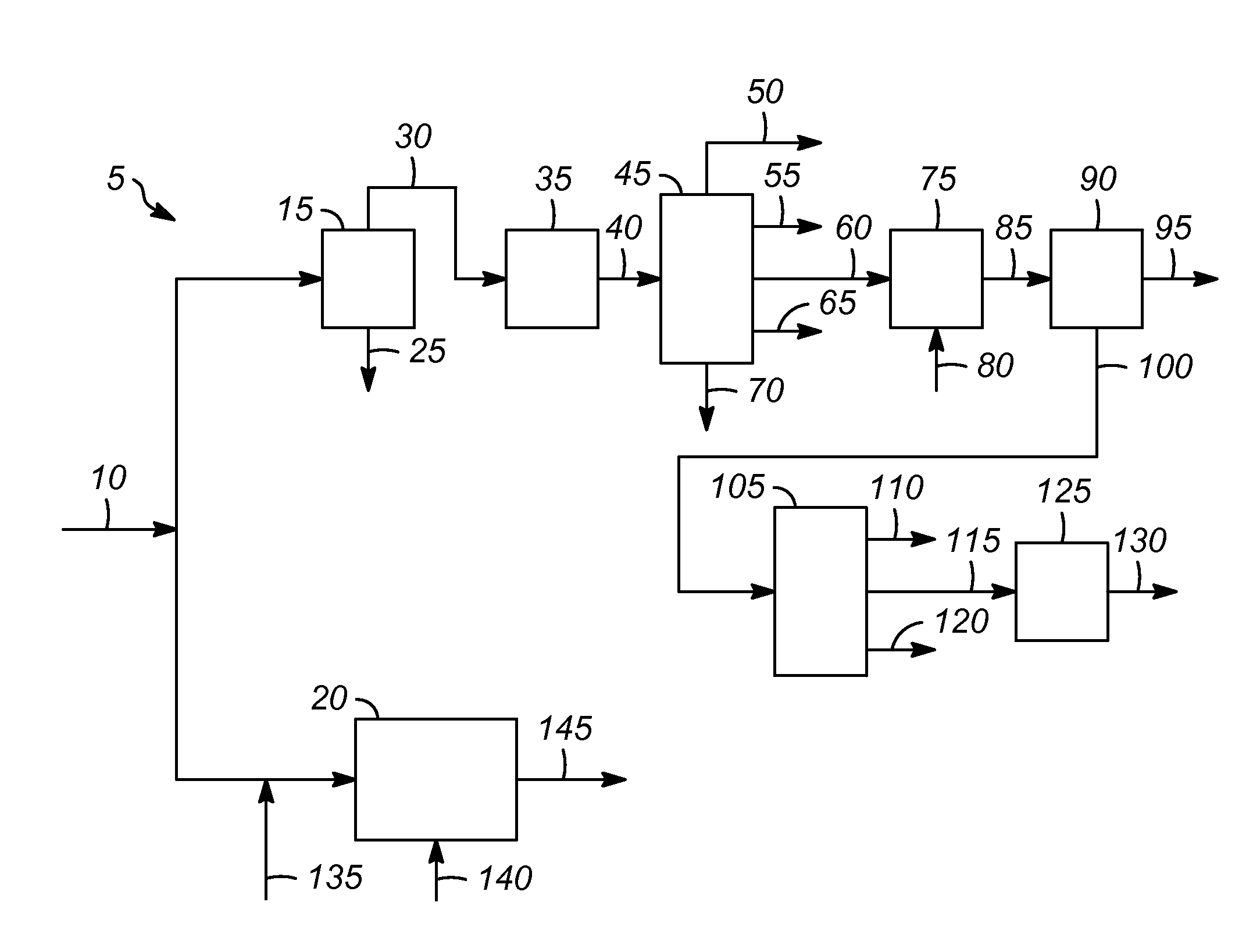

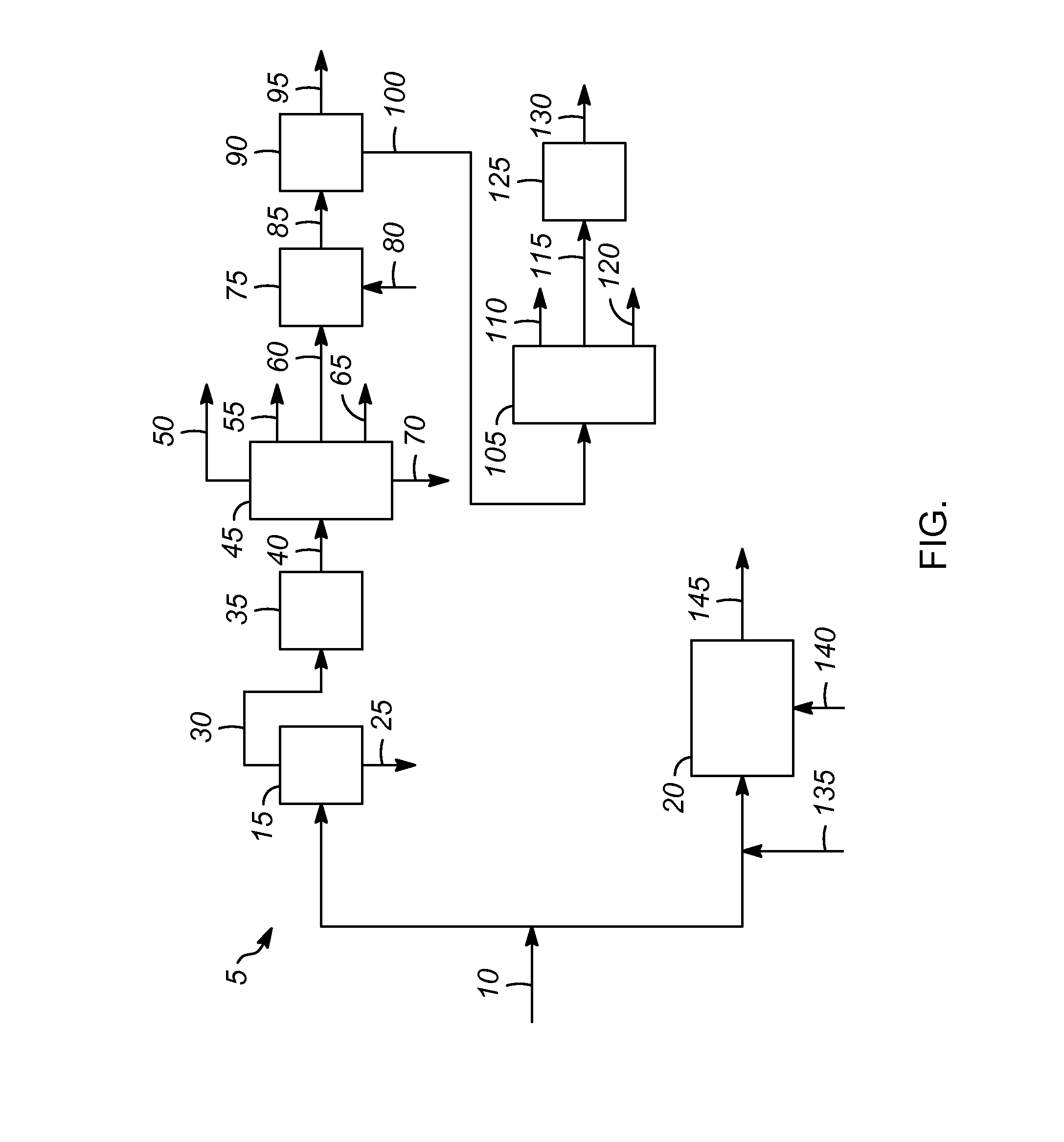

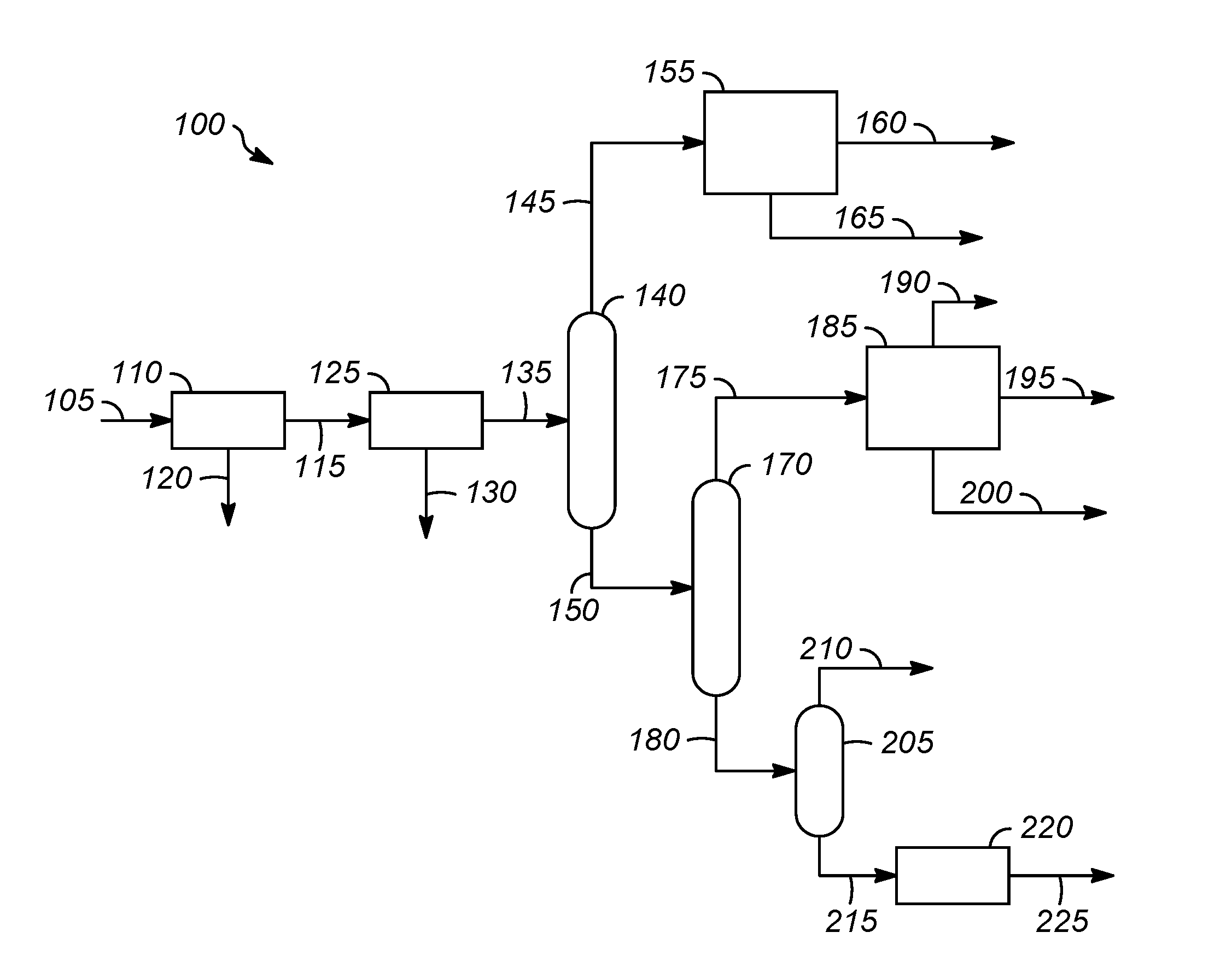

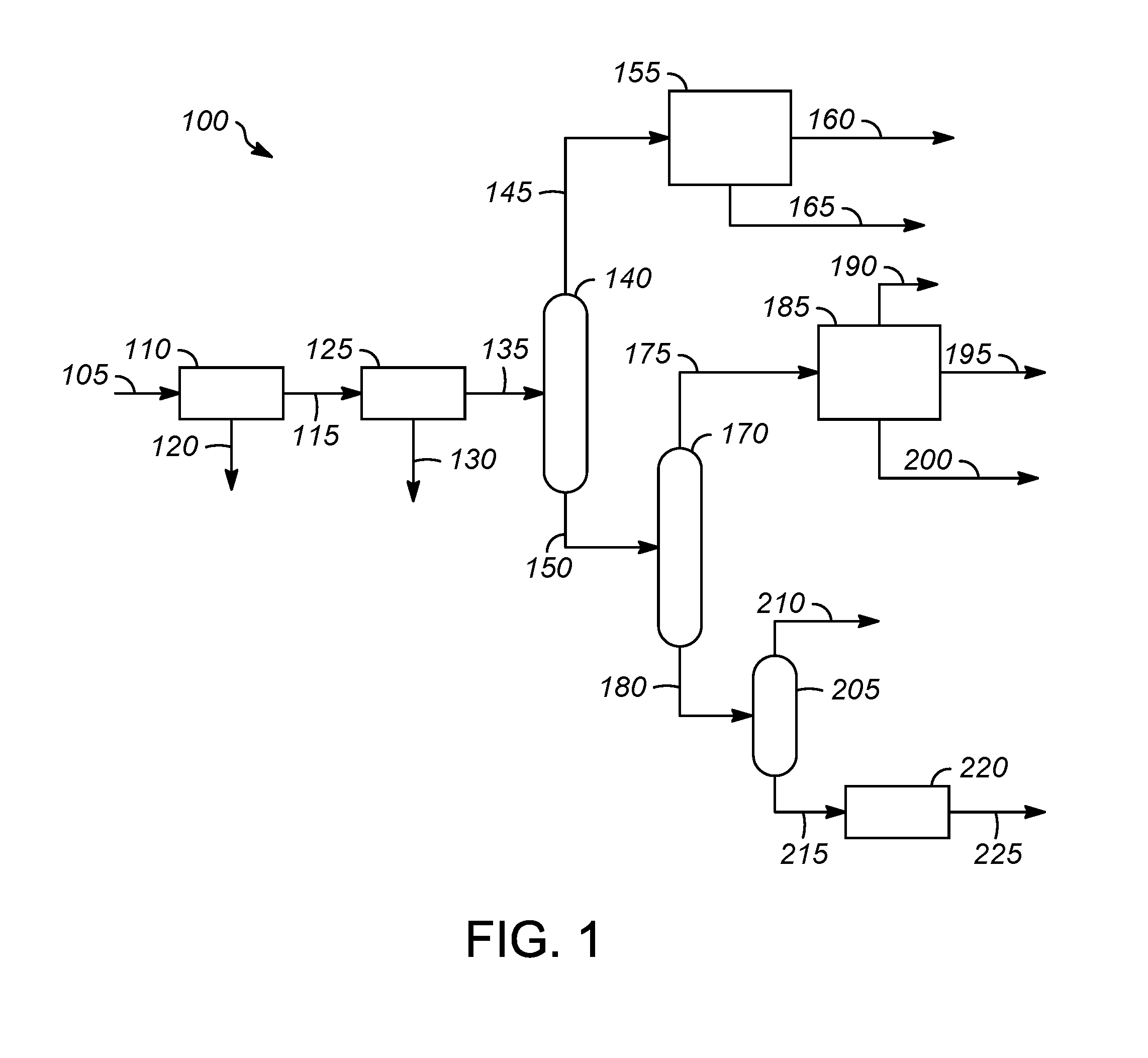

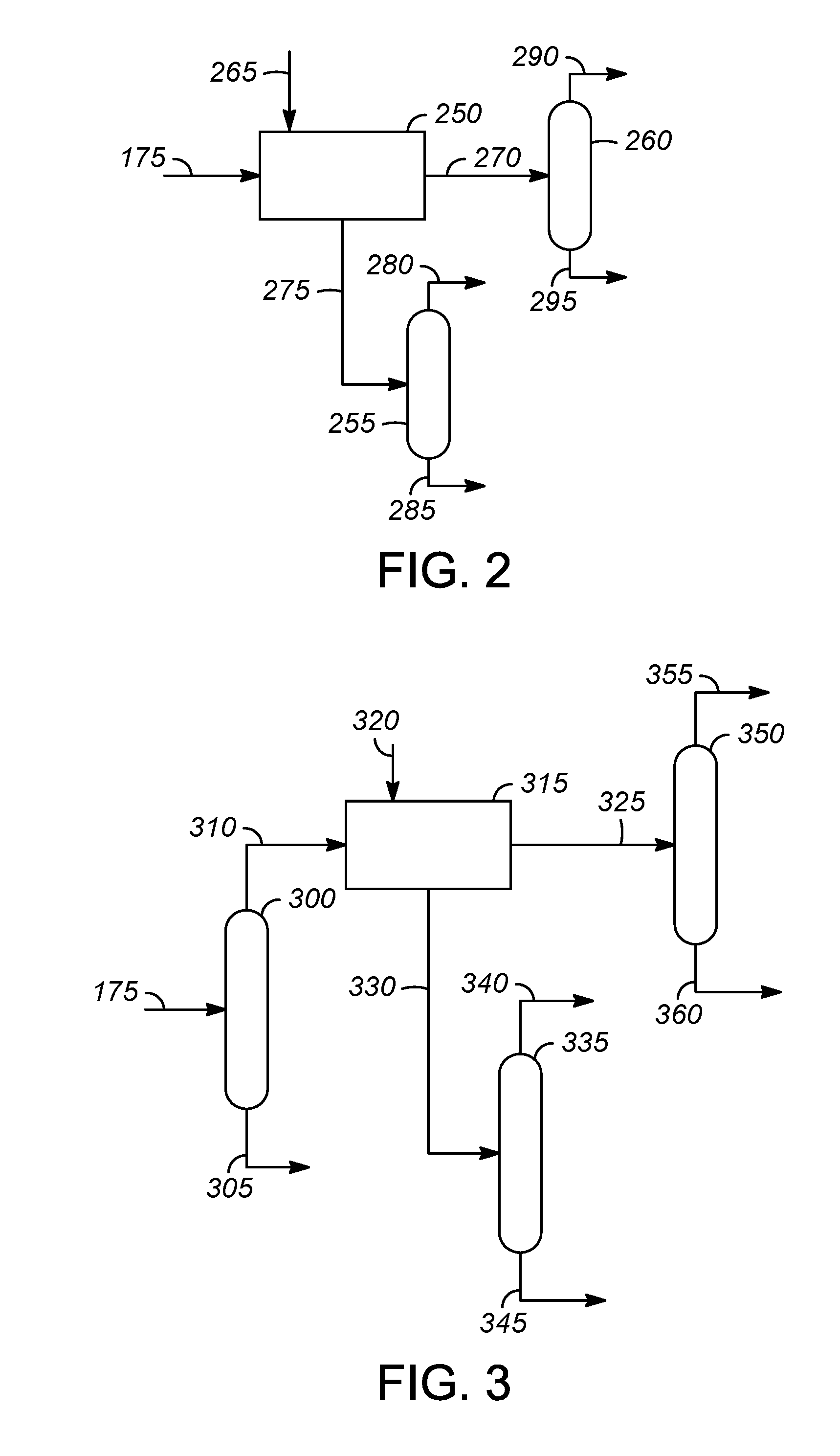

Processes utilizing the integration of (i) processes and the associated equipment used to purify and recover propylene from propane- and / or C4+-containing refinery hydrocarbon streams, with (ii) catalytic dehydrogenation are disclosed. This integration allows for elimination of some or all of the conventional fractionation section of the dehydrogenation process, normally used to purify propylene from unconverted propane in the reactor effluent. Significant capital and utility savings are therefore attained.

Owner:UOP LLC

Integrated processes for propylene production and recovery

ActiveUS20100331589A1Solve large capacityEconomy of scaleCatalytic crackingHydrocarbon by hydrogenationDehydrogenationProcess engineering

Processes utilizing the integration of (i) processes and the associated equipment used to purify and recover propylene from propane- and / or C4+-containing refinery hydrocarbon streams, with (ii) catalytic dehydrogenation are disclosed. This integration allows for elimination of some or all of the conventional fractionation section of the dehydrogenation process, normally used to purify propylene from unconverted propane in the reactor effluent. Significant capital and utility savings are therefore attained.

Owner:UOP LLC

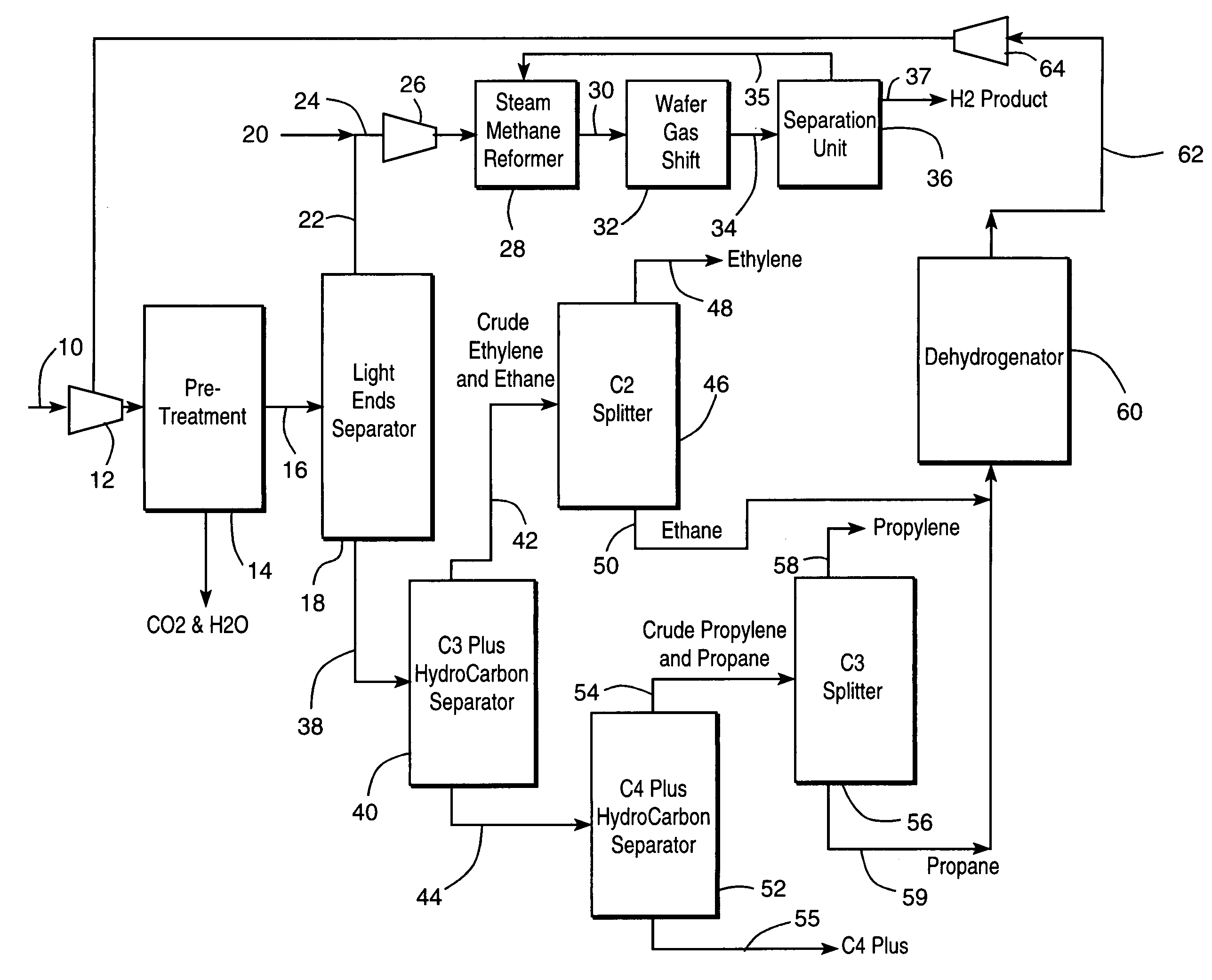

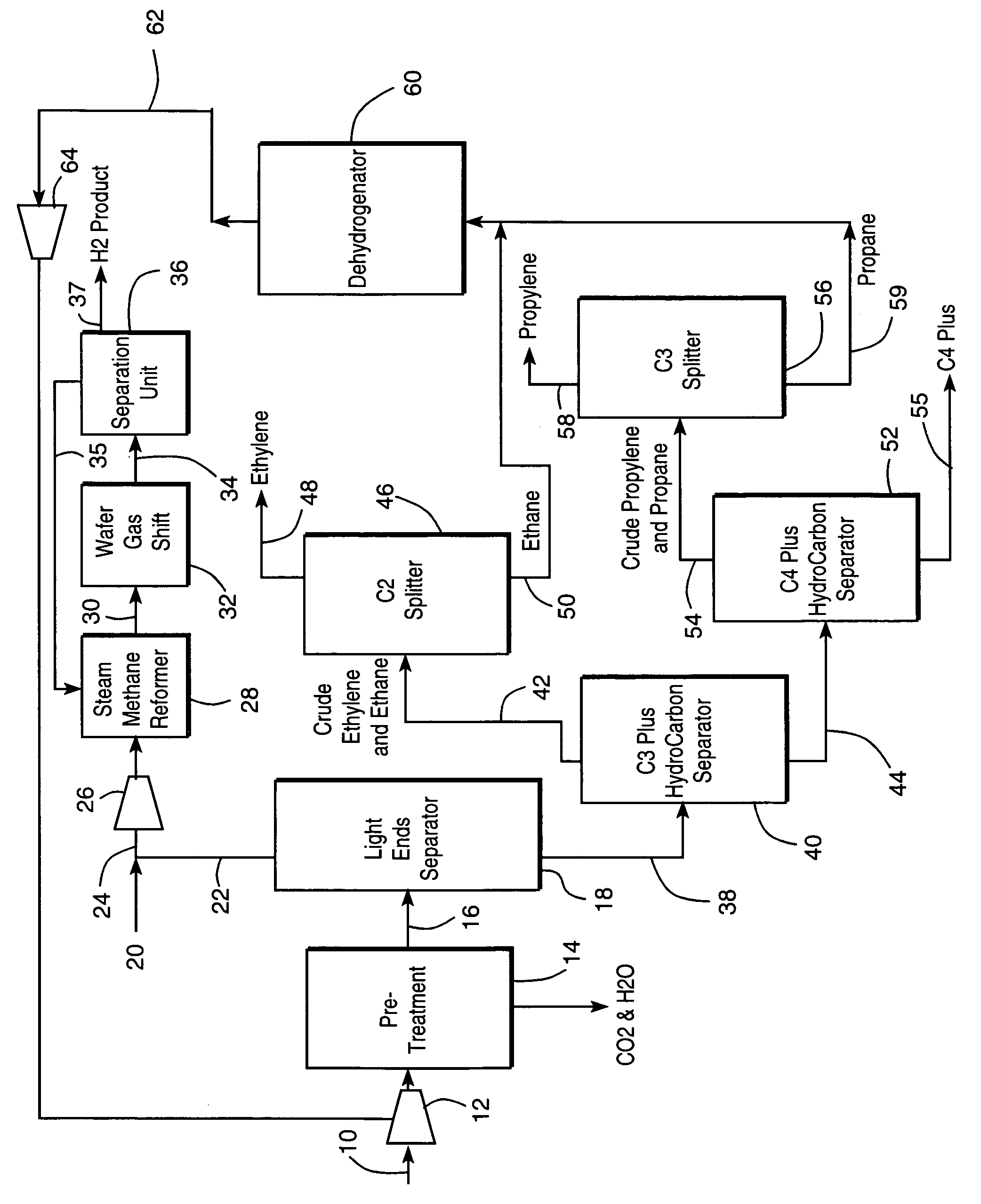

Integrated olefin recovery and hydrogen production from refinery off-gases

A method is disclosed a method for recovering olefins and for producing hydrogen from a refinery off-gas stream in which such stream is conventionally pretreated and separated to obtain a light ends stream that contains nitrogen, hydrogen and carbon monoxide and a heavy ends stream that contains the olefins. The light ends stream is subjected to reforming and a water gas shift reactions after addition of a natural gas stream. The addition of the natural gas increases the hydrogen recovery from the light ends and also stabilizes the hydrocarbon content in the stream to be subjected to the reforming and water gas shift reactions. The heavy ends can be further treated to recover olefins such as ethylene and propylene. The rate of natural gas addition is controlled so that the concentration of the nitrogen in a stream exiting the water gas shift reactor is less than about 5 percent by volume so that hydrogen separation from such stream becomes practical.

Owner:PRAXAIR TECH INC

Ethane extraction process for a hydrocarbon gas stream

A process for ethane extraction from a gas stream based on turboexpansion and fractionation with no mechanical refrigeration is provided. The feed gas is sweetened and dehydrated by a conventional amine process and by a molecular sieve unit, to remove carbon dioxide and water. After this pretreatment, the feed gas undergoes to a series of cooling steps through a cryogenic brazed aluminum heat exchanger and fed to a demethanizer column. A stream rich in methane is recovered from the top of this column and fed to a centrifugal compressor and subsequently routed to a booster / turboexpander. The temperature of the methane gas is greatly reduced by the expansion allowing the cooled methane stream to be a cooling source for cryogenic heat exchanger. Feed for a de-ethanizer column comes from the bottom liquids of the de-methanizer column. Ethane is recovered overhead at the de-ethanizer column.

Owner:INELECTRA

Fluid separation assembly to remove condensable contaminants and methane conversion process using a supersonic flow reactor

InactiveUS20140058095A1Fractional condensation purification/separationMechanical vibrations separationThroatTrace Amounts

Methods and systems are provided for converting methane in a feed stream to acetylene. The hydrocarbon stream is introduced into a supersonic reactor and pyrolyzed to convert at least a portion of the methane to acetylene. The reactor effluent stream may be treated to convert acetylene to another hydrocarbon process. The method according to certain aspects includes controlling the level of water, carbon dioxide and other condensable contaminants in the hydrocarbon stream by use of a fluid separation assembly such as a supersonic inertia separator. In addition, one or more adsorbent beds may be used to remove remaining trace amounts of condensable contaminants. The fluid separation assembly has a cyclonic fluid separator with a tubular throat portion arranged between a converging fluid inlet section and a diverging fluid outlet section and a swirl creating device.

Owner:UOP LLC

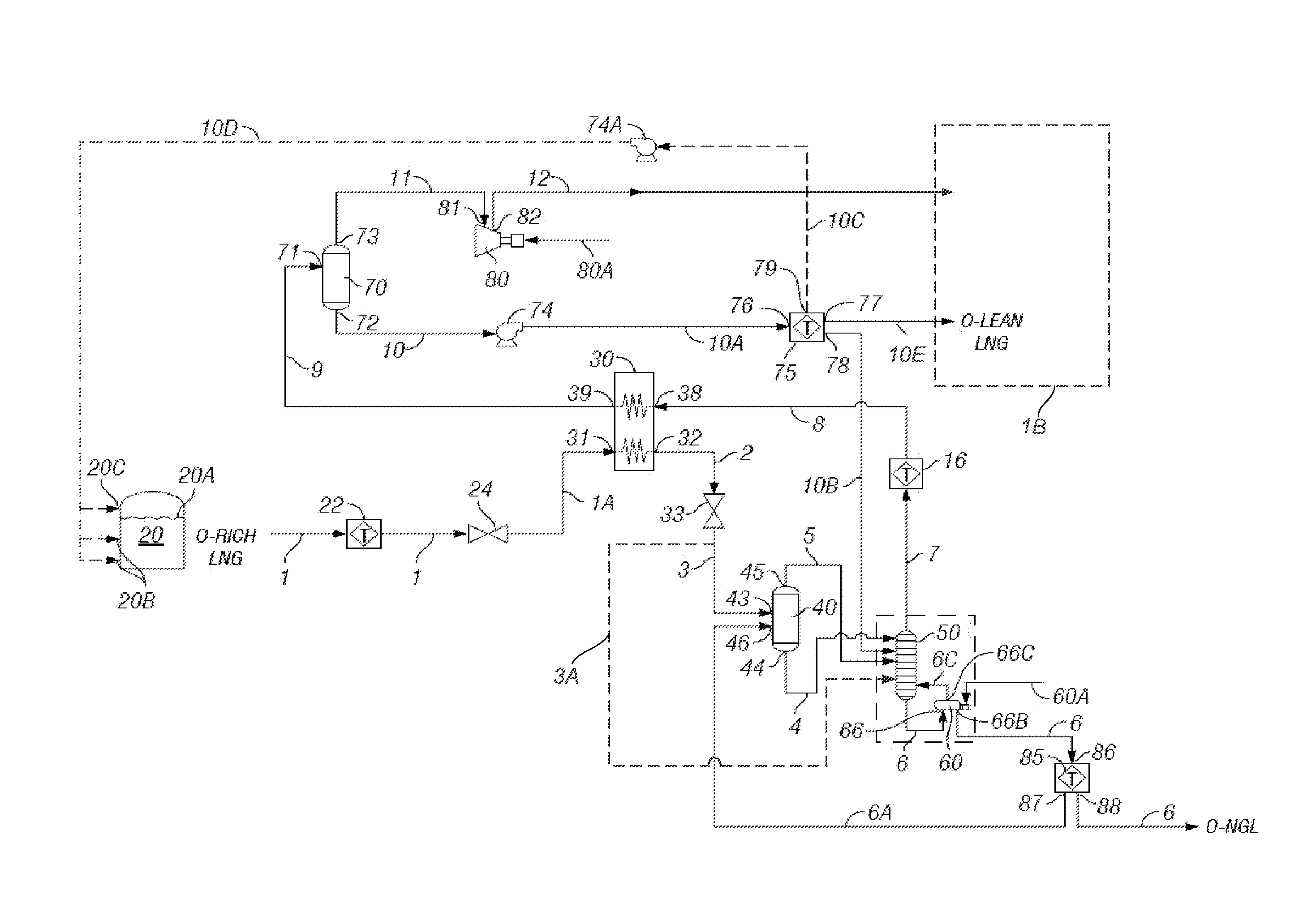

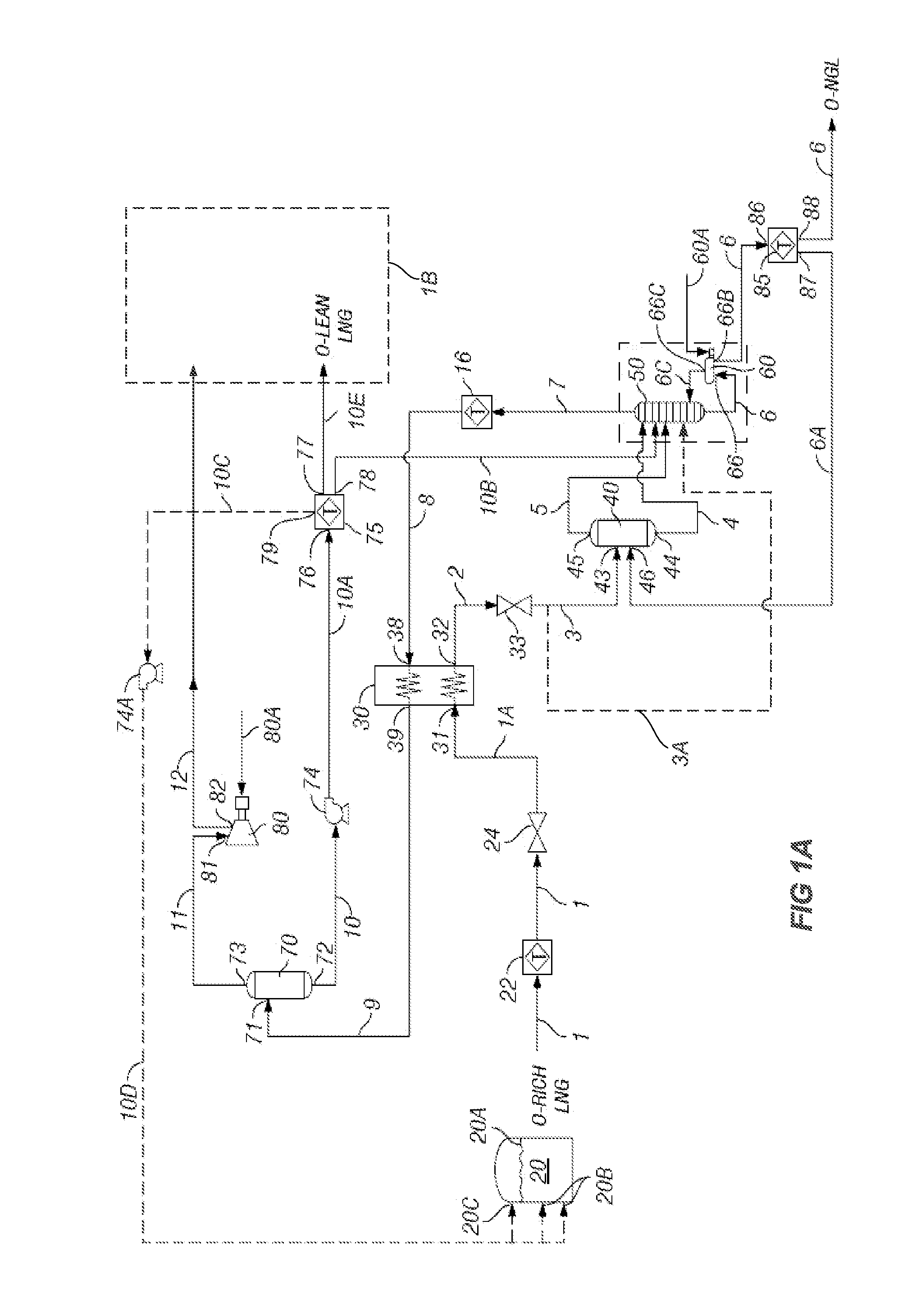

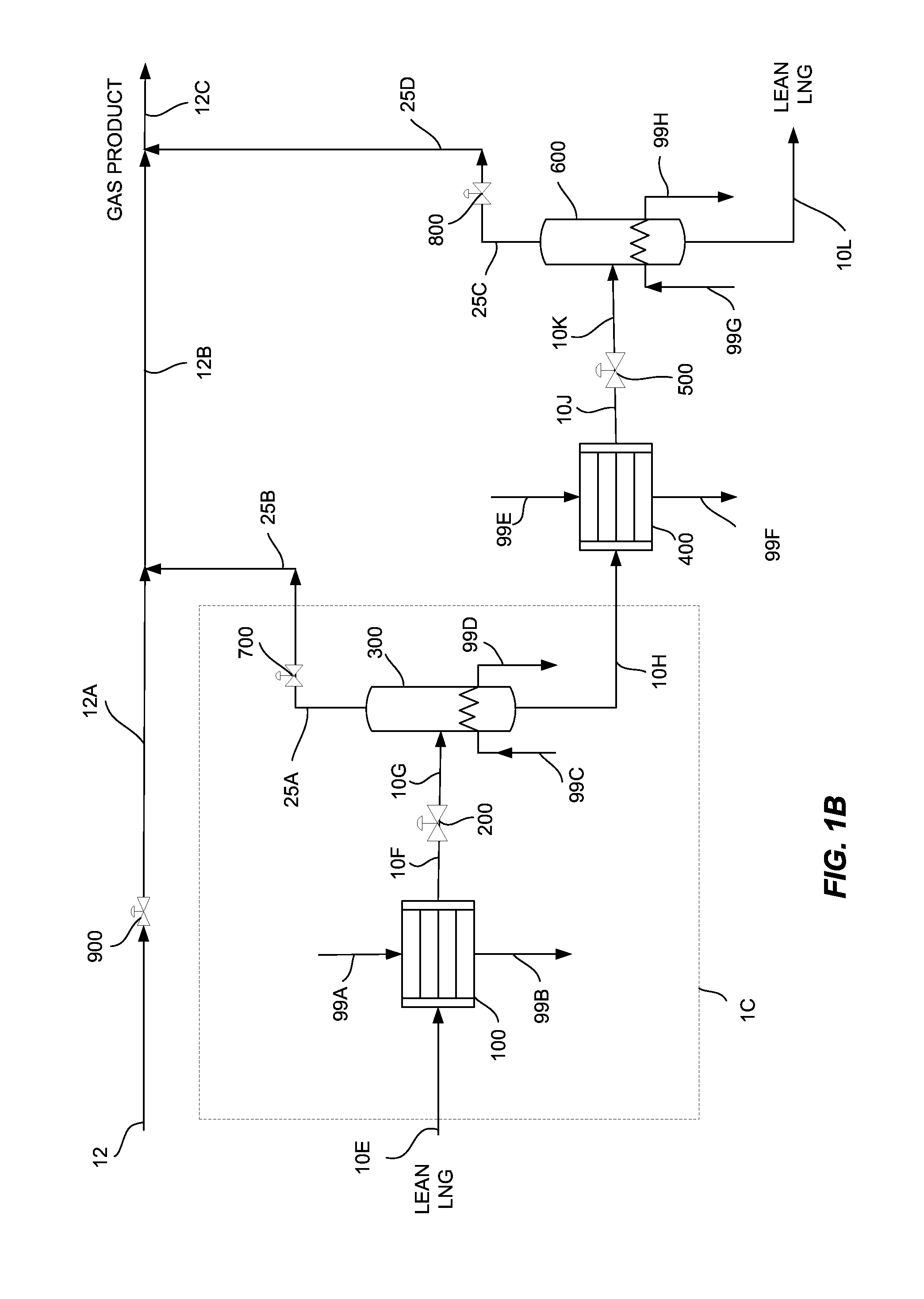

Process for separating and recovering ethane and heavier hydrocarbons from LNG

A process for extracting heavier components, e.g., NGL from liquid / fluid streams such as Rich LNG (RLNG) stream(s) with the streamlined economy. The process involves heating the RLNG stream in heat exchanger(s) (LNGX) against column overhead vapour stream; not requiring separation of Feed streams into feed and reflux by splitting either pre- or post- of heat LNGX. The source liquid RLNG is processed producing liquid NGL and at same time returning purified Lean LNG (LLNG) product in its Liquid LNG form. The process operates essentially without the need for compression equipment. The process further provides without compressors vaporized natural gas at pipeline pressure and specifications. This is a system that can flexibly change product compositions and specifications of product NGL / Lean LNG / Pipeline Gas and operate in both Pipeline Specification deep 99% Ethane (C2) Extraction and Ethane (C2) Rejection NGL recovery modes with economy of equipment and energy requirements.

Owner:PATEL KIRTIKUMAR NATUBHAI +1

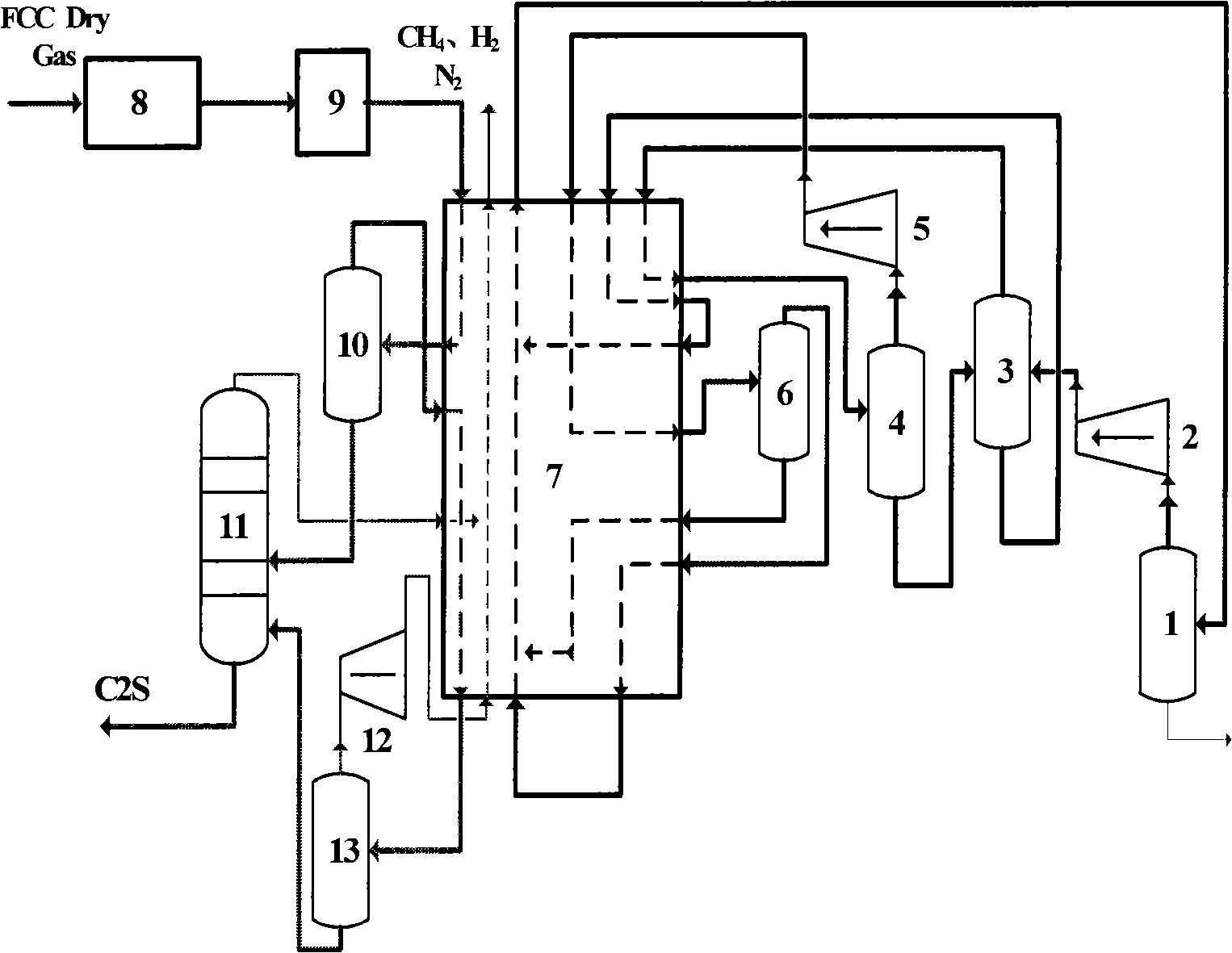

Method for reclaiming ethylene in catalytic dry gas

The invention discloses a method for reclaiming ethylene in catalytic dry gas, belongs to an ethylene separation method, and provides the method for separating the ethylene from the catalytic dry gas by using mixed gas as refrigerant in order to solve the problems that the prior process for reclaiming the ethylene from the dry gas of a refinery has high energy consumption, large equipment scale, high investment and the like. The method adopts an expander and an ice chest to reclaim cold energy through three-stage compression and refrigeration, and then obtains material flow rich in the ethylene from a tower bottom by removing methane and hydrogen in a methane removing tower so as to greatly improve the reclamation rate of the ethylene and reduce the energy consumption. The method of the invention has the advantages of less equipment, simple flow, simple refrigeration cycle and less investment.

Owner:CHINA PETROLEUM & CHEM CORP +1

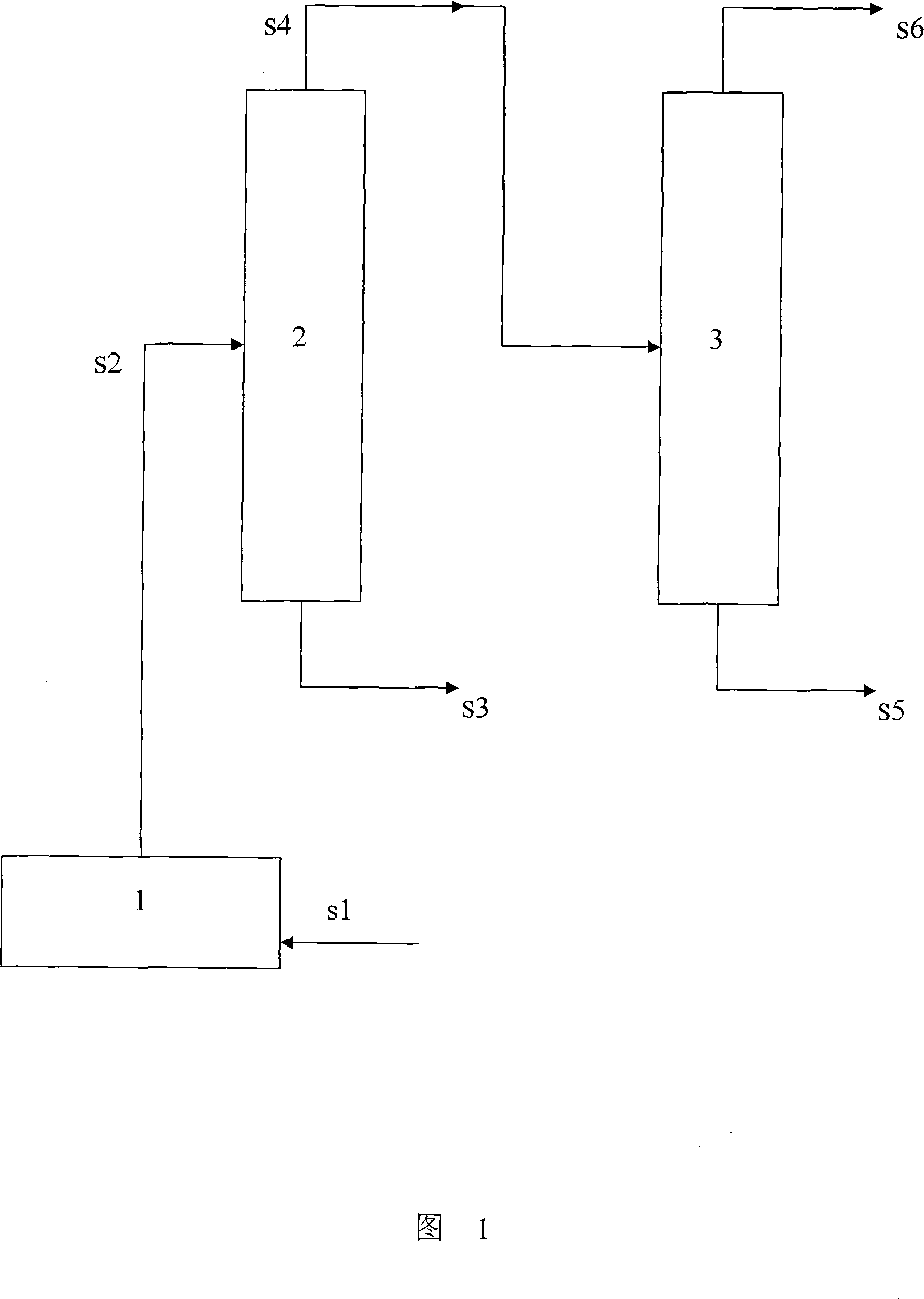

Process of separating cyclopentadiene and methyl cydopentadiene from ethylene side C9 product

ActiveCN101066902AExpand sourceEasy to separateFractional condensation purification/separationHydrocarbon by depolymerisationMethylcyclopentadieneEthylene

The present invention is process of separating cyclopentadiene and methyl cyclopentadiene from mixture containing dicyclopentadiene and dimethyl cyclopentadiene, and is especially suitable for separating and purifying cyclopentadiene and methyl cyclopentadiene from ethylene side C9 product or coarse cyclopentadiene product. The material, ethylene side C9 product or coarse cyclopentadiene product, is introduced into a high temperature cracking reactor, the high temperature cracked gas mixture is led to the first fractionating tower to separate out the fraction containing cyclopentadiene and methyl cyclopentadiene in the tower top, and the tower top fraction of the first fractionating tower is fed to the second fractionating tower to separate out cyclopentadiene in the tower top and methyl cyclopentadiene in the tower bottom.

Owner:天津天大天海化工新技术有限公司 +1

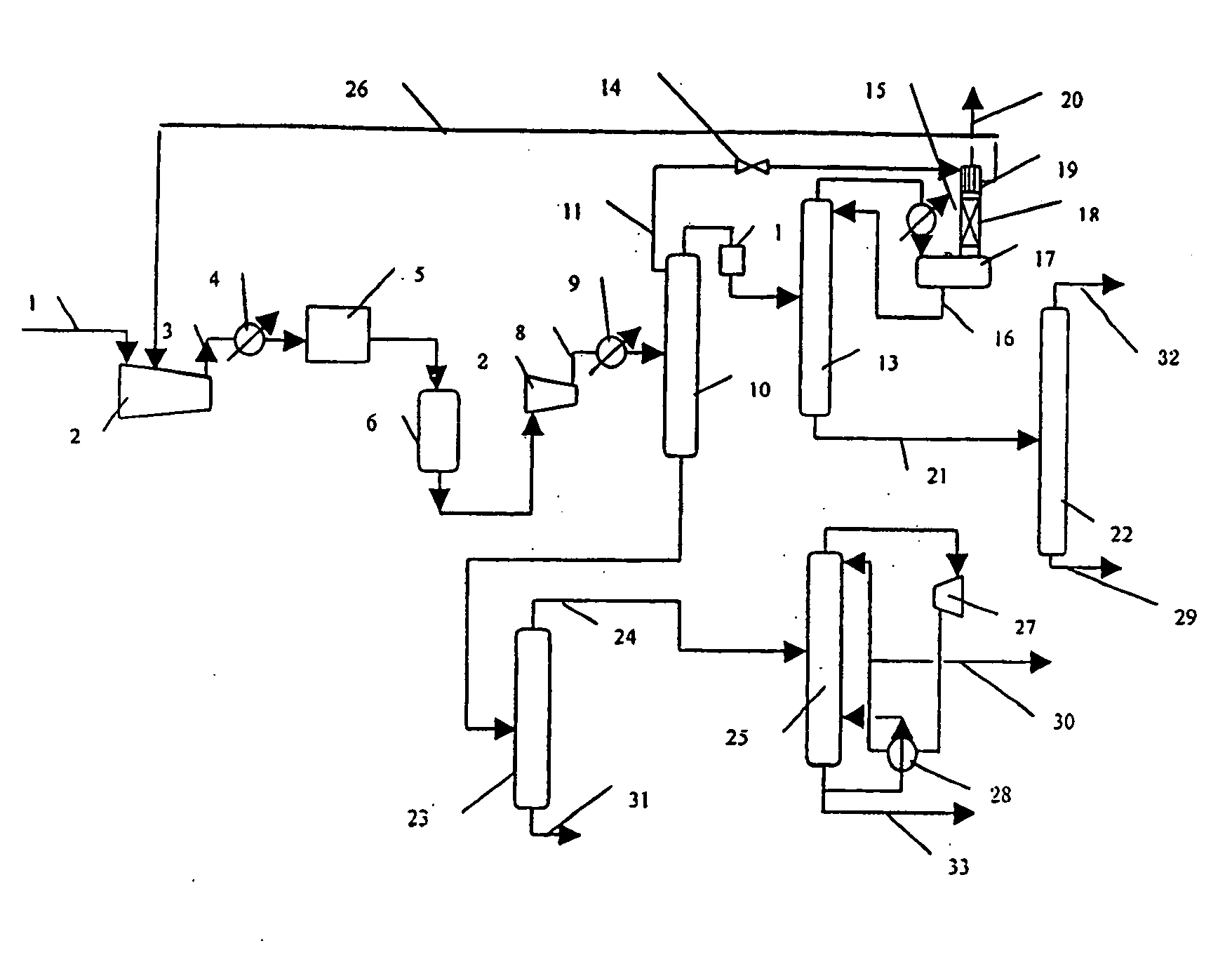

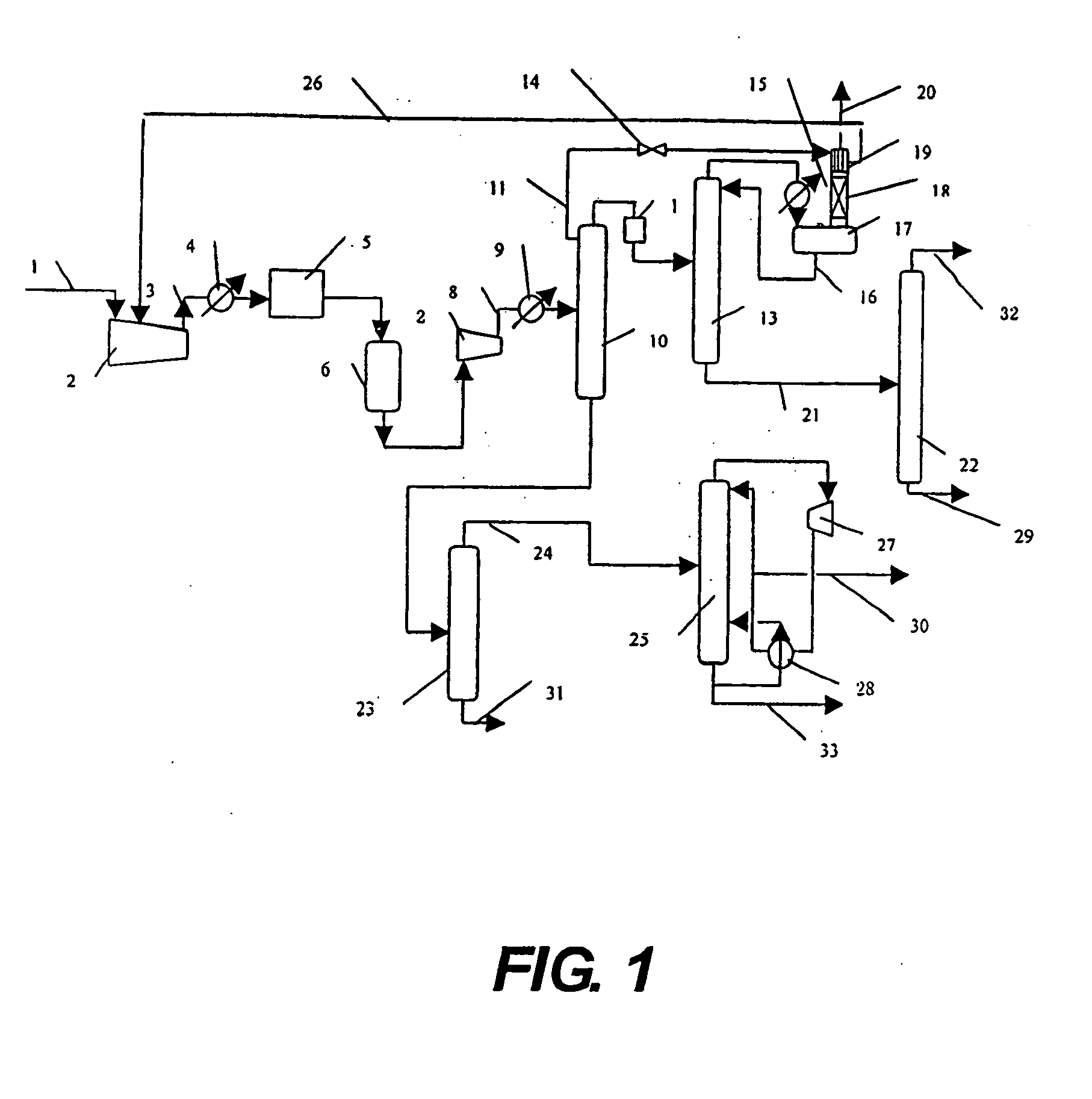

Process for recovery of cracker feed from dry gas

ActiveUS10052581B1Avoid temperatureHydrocarbon by hydrogenationDistillation purification/separationImpurityMethane

A process for recovering a steam cracking feed from FCC absorber off-gas comprising ethylene, ethane and heavier hydrocarbons and light gases involves removing hydrogen, nitrogen, sulfur species, carbon monoxide / dioxide, methane and other impurities from the off-gas. An absorption zone is upstream of an acetylene selective hydrotreating reactor to remove sufficient hydrogen sulfide that can poison the selective hydrotreating catalyst but leave sufficient sulfur in the feed stream to prevent temperature runaway.

Owner:UOP LLC

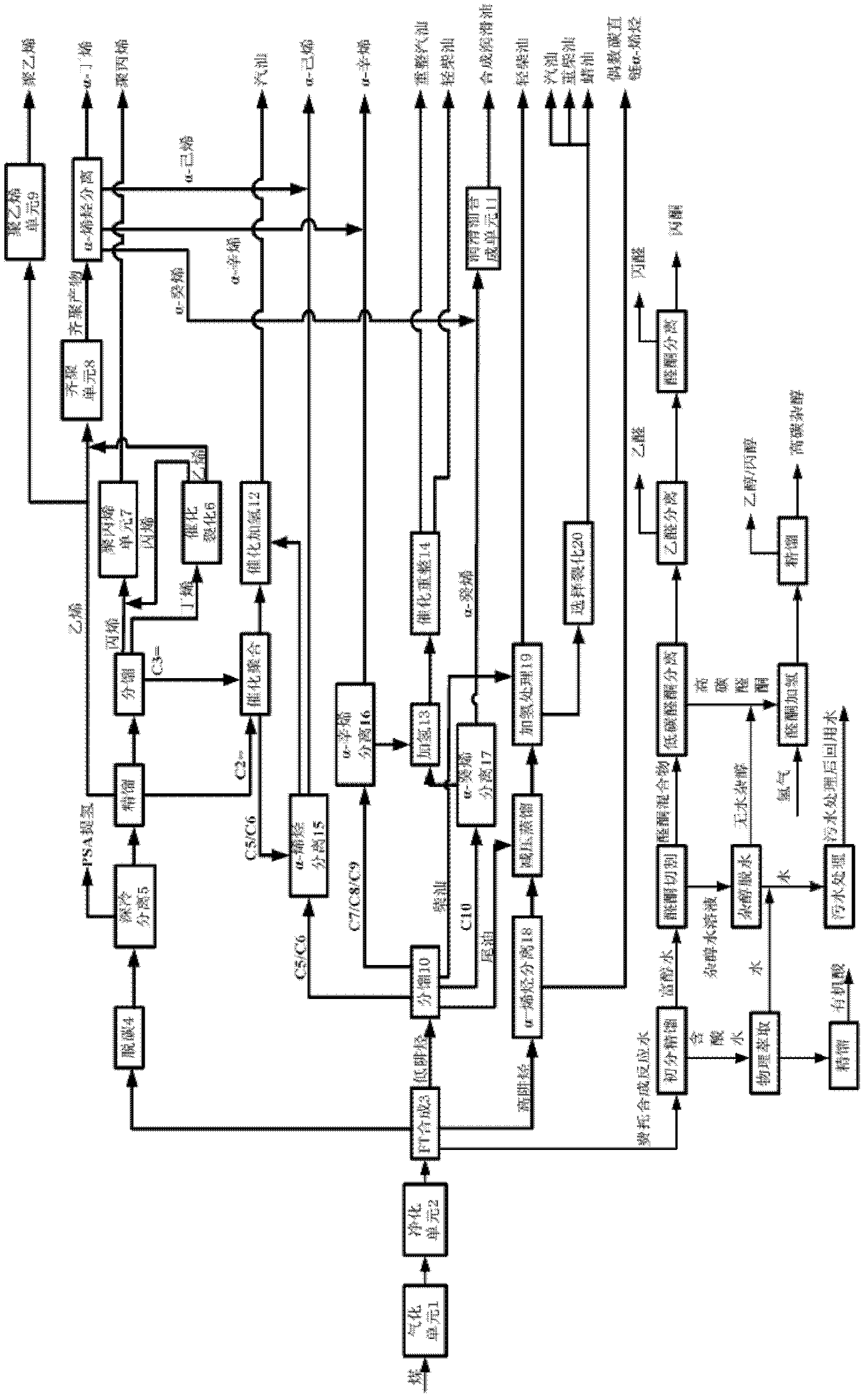

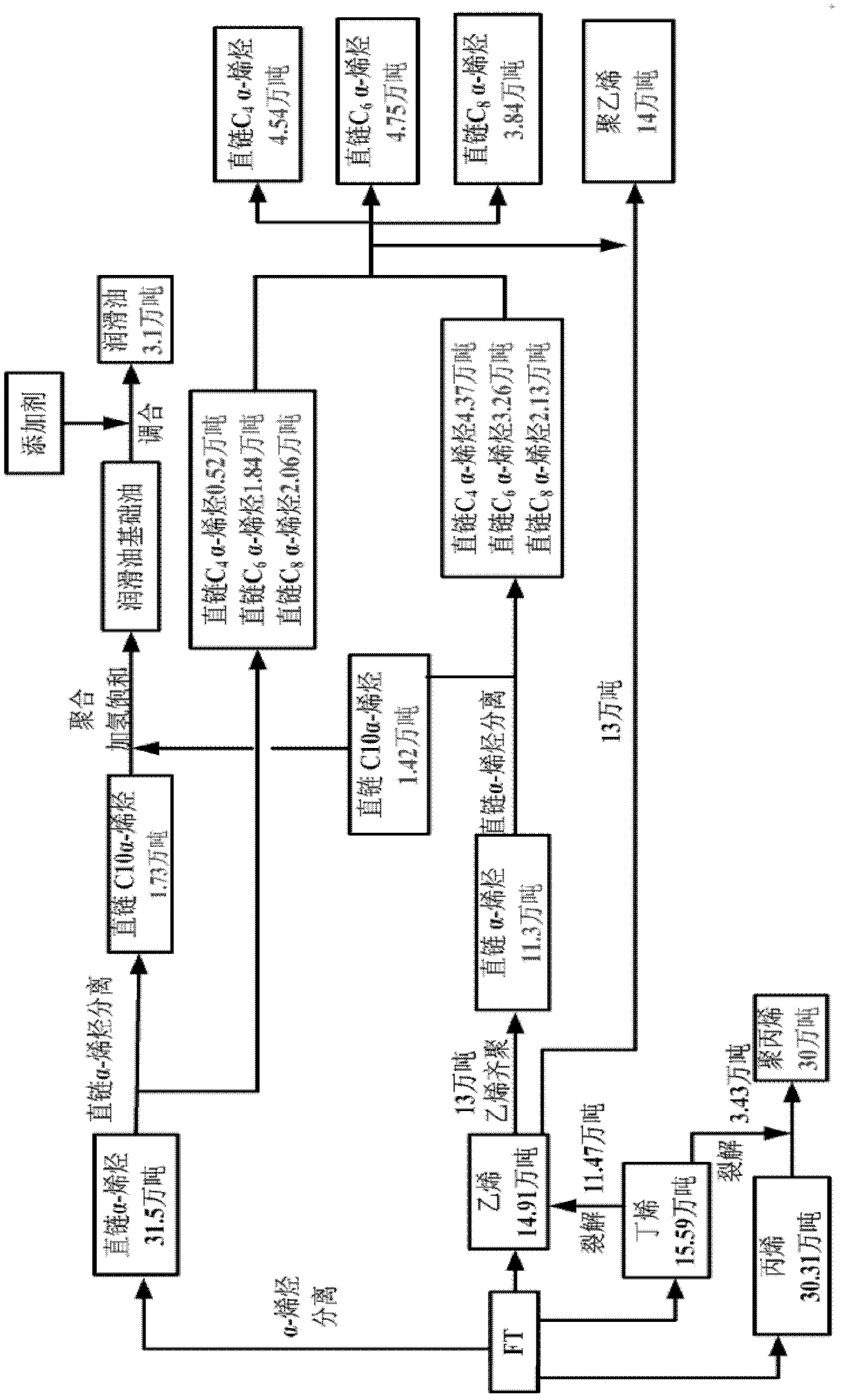

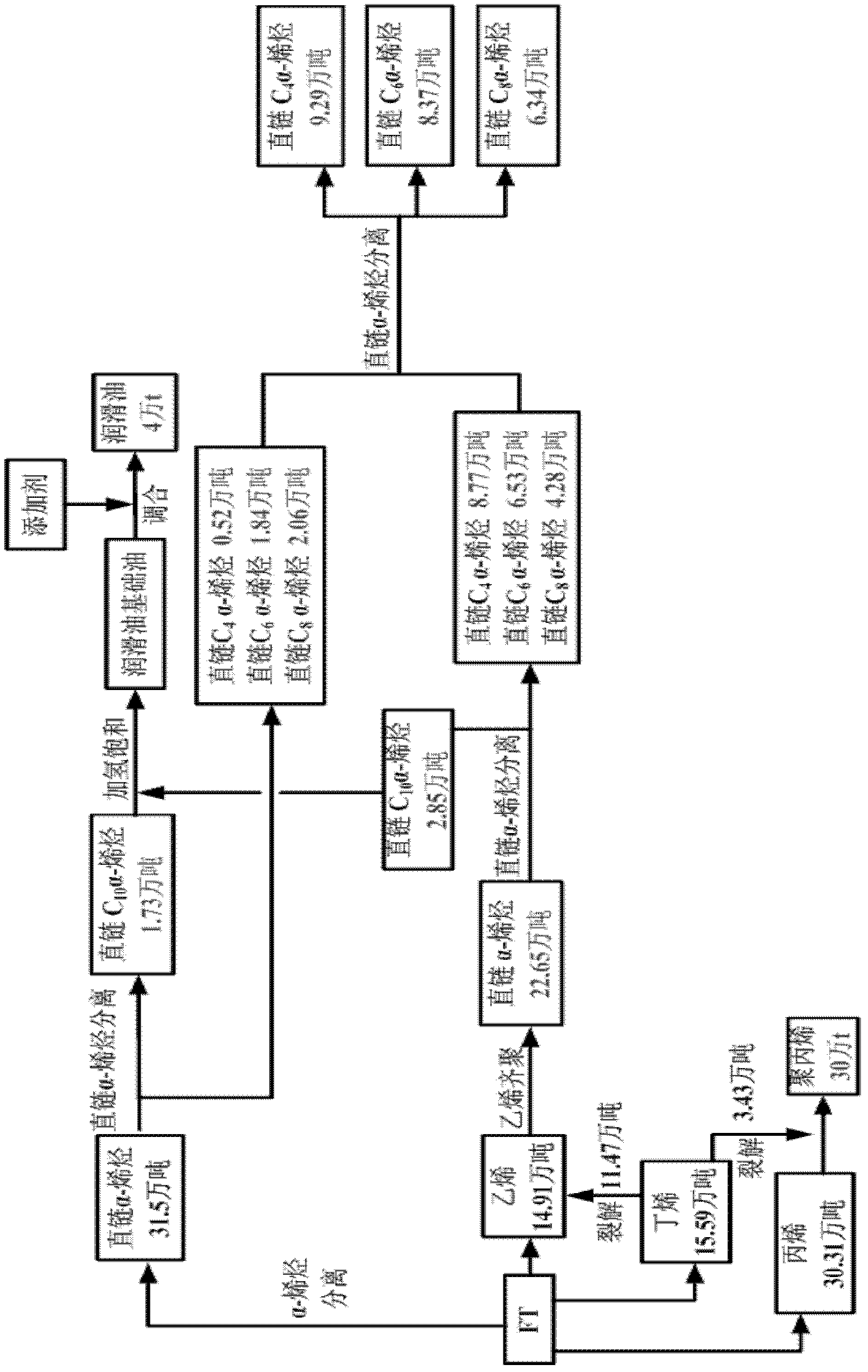

High and low-temperature Fischer-Tropsch synthesis co-production technology

ActiveCN102604677AImprove balanceIncrease added valueHydrocarbon from carbon oxidesHydrocarbons from unsaturated hydrocarbon additionDownstream processingChemical products

The invention relates to a high and low-temperature Fischer-Tropsch synthesis co-production technology which is characterized in that the high-temperature Fischer-Tropsch synthesis technology and the low-temperature Fischer-Tropsch synthesis technology are coupled; a coal gasifying and purifying unit is adopted to produce synthetic gases; the purified synthetic gases (CO+H2) enter a high-temperature Fischer-Tropsch synthesis unit and a low-temperature Fischer-Tropsch synthesis unit at different ratios of CO to H2 respectively; and the crude products obtained by the high-temperature Fischer-Tropsch synthesis unit and the low-temperature Fischer-Tropsch synthesis unit form a mixture flow which enters the subsequent oils deep-processing unit and hydrocarbon gas downstream processing unit according to the characteristics of different crude products to produce gasoline, diesel oil, synthetic lubricating oil, polypropylene, polyethylene and high value-added alpha-olefin. The technology provided by the invention avoids the uncertainty of the oils market under the fluctuation of the international crude oil market, realizes balance of the oils income by use of the income of chemical products, and finally achieves the aim of enhancing the competitiveness of the Fischer-Tropsch synthesis oils.

Owner:TAIYUAN UNIV OF TECH

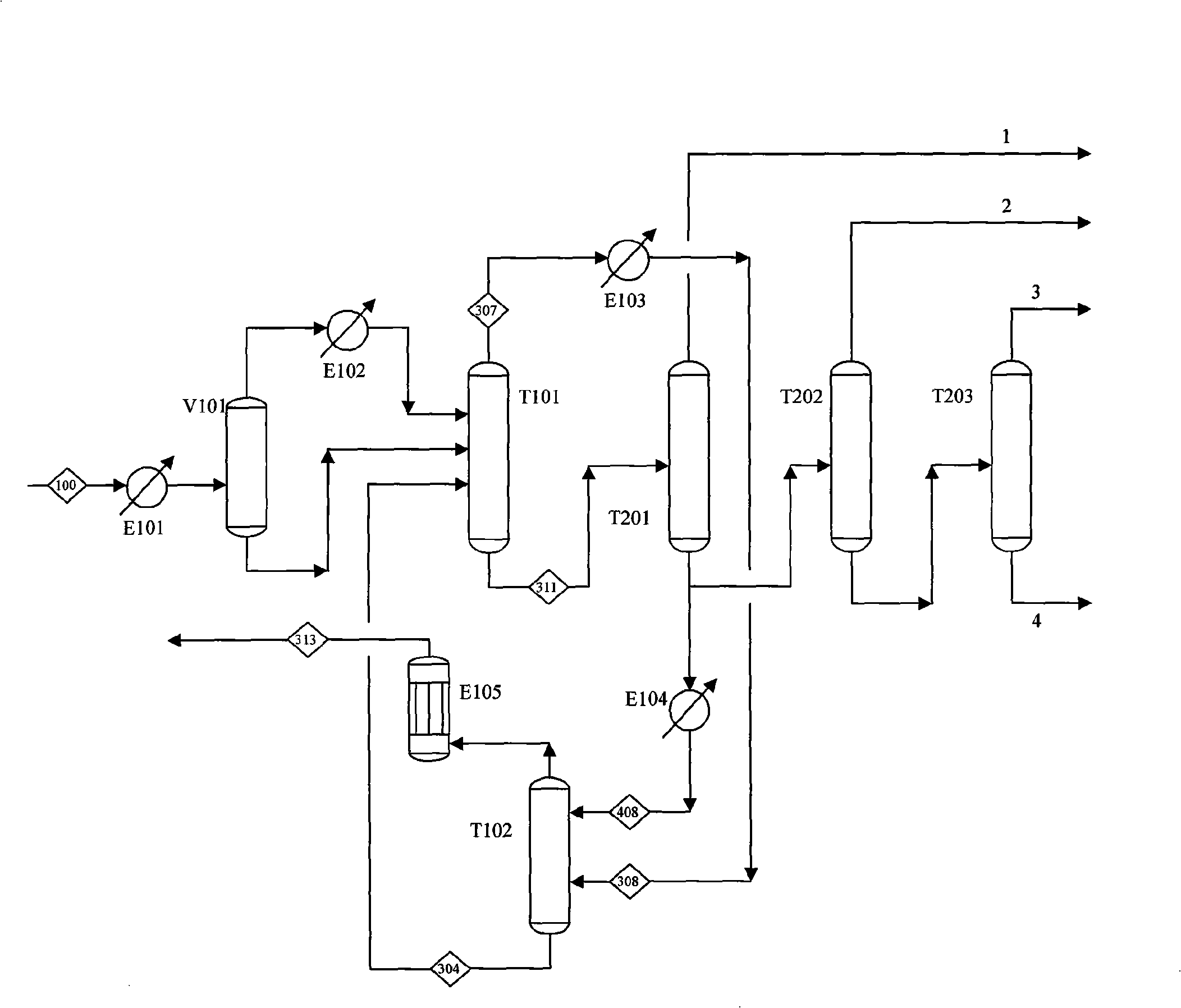

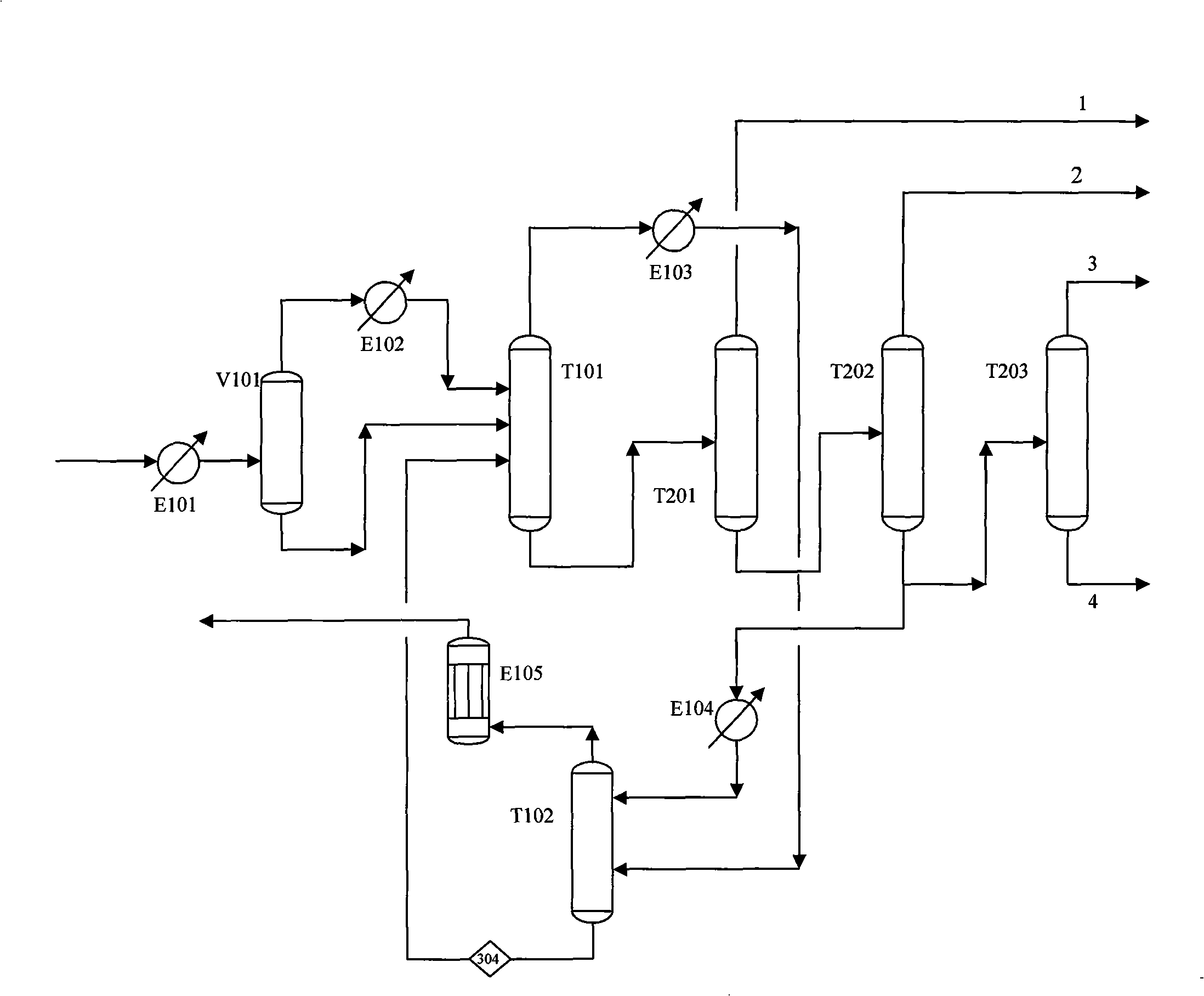

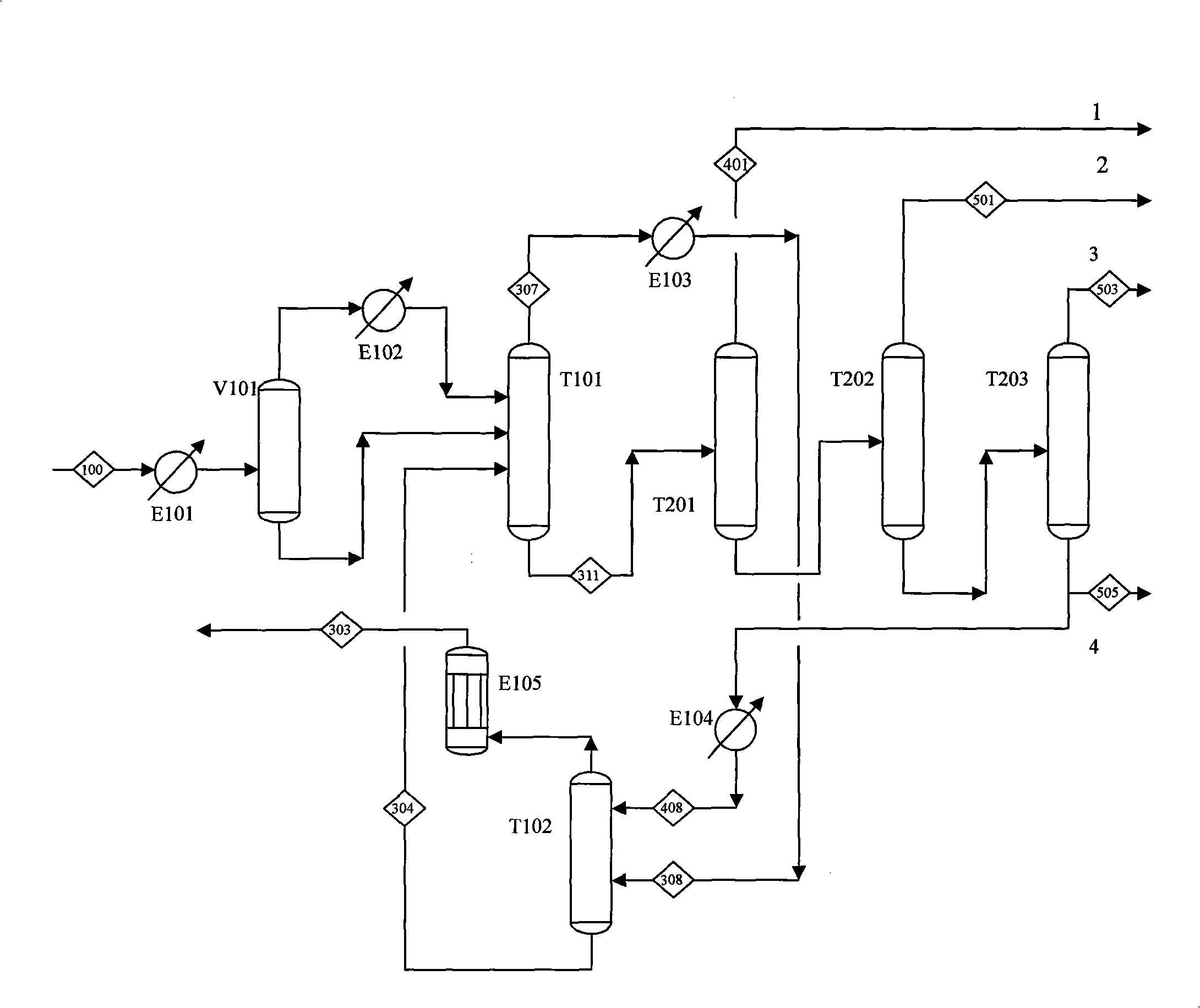

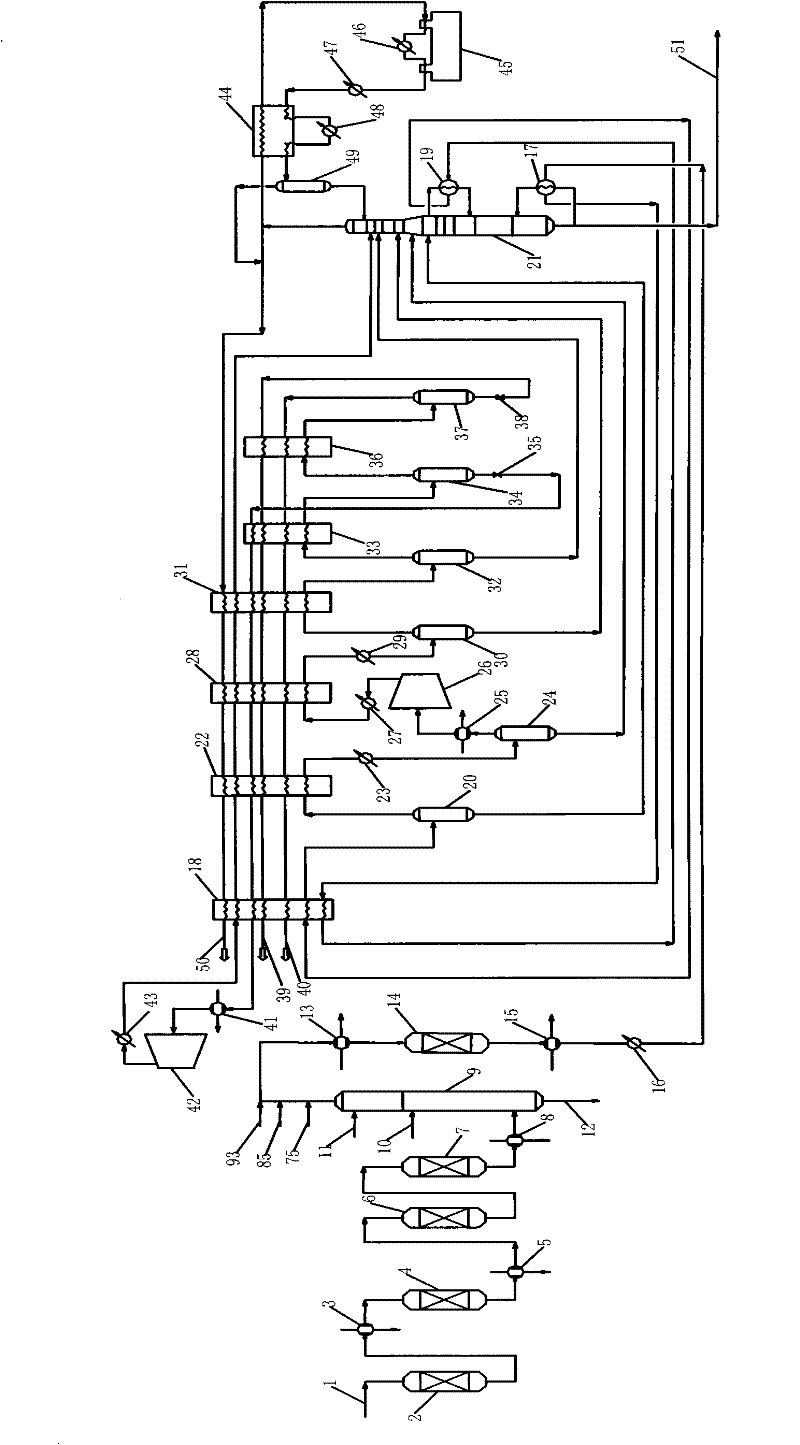

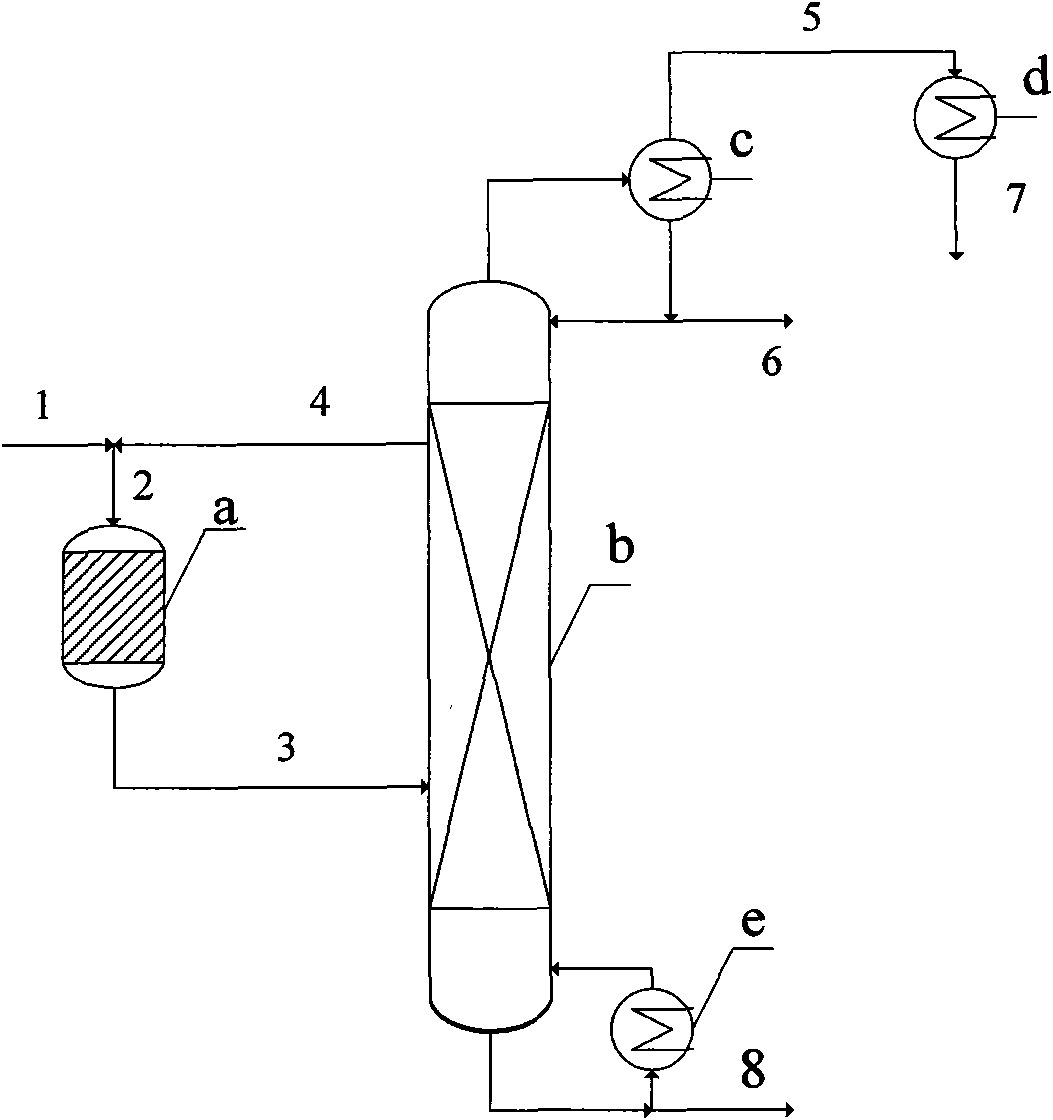

Separation process for preparing low-carbon alkene gases through conversion of methanol

The invention discloses a separation process for preparing low-carbon alkene gases through conversion of methanol and aims to solve the problems that high-purity products such as hydrogen, methane, ethane and propane cannot be obtained and oxygen and carbon monoxide in dimethyl ether and gas impurities cannot be effectively eliminated in the prior art. According to the alkene gas streams through conversion of methanol, eliminating steps of oxygen and carbon monoxide are added, the alkene gas streams through conversion of methanol after elimination of oxygen and carbon monoxide sequentially passes six knockout drums and then enters a low-pressure demethanizer, a deethenizer, an acetylene hydrogenation reactor, an ethylene rectification tower, an allylene hydrogenation reactor and a propylene rectification tower for separation, the liquid from the bottoms of the first four knockout drums sequentially enter the middle-upper portion of the demethanizer, and the liquid from the bottom of the fifth knockout drum enters the upper portion of the demethanizer or returns to a section of a compressor. The separation process for preparing the low-carbon alkene gases through conversion of methanol can obtain products such as polymer grade ethylene, propylene, and the high-purity products such as hydrogen, methane, ethane and propane.

Owner:CHINA PETROLEUM & CHEM CORP +1

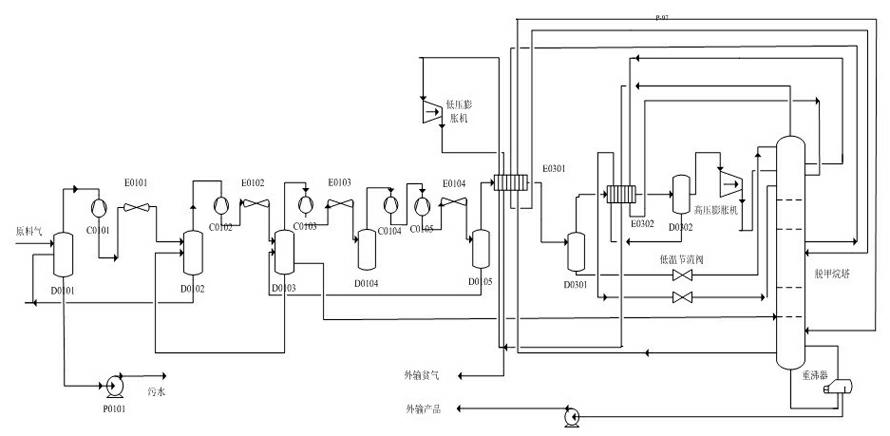

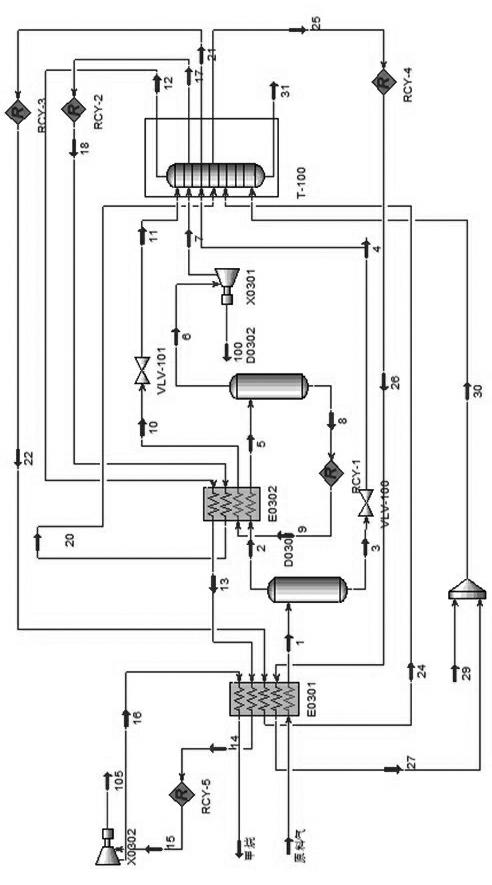

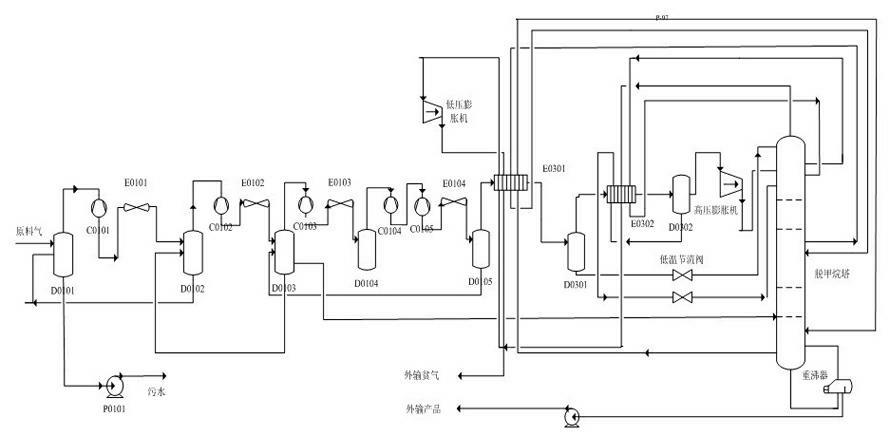

Oil field associated gas ethane recovery system

ActiveCN102351625AHigh recovery rateFit closelyFractional condensation purification/separationOil fieldComputational model

The invention relates to an oil field associated gas ethane recovery technology, or relates to an oil field associated gas ethane recovery system. The system is characterized by comprising a feed gas supercharging unit, a feed gas dehydration unit and a low-temperature fractionation unit, wherein the temperature of a bottom product of the low-temperature fractionation unit is 29.38 DEG C, and the pressure of the bottom product is 1.75 MPa; the bottom product is conveyed to a storage tank region; required cold in an ethane recovery process of the low-temperature fractionation unit is completely provided by turbo-expanders X0301 and X0302; two flows of liquid are extracted out of a tower by the low-temperature fractionation unit to perform intermediate reboiling; and compressors C0104 and C0105 are driven by the turbo-expanders X0301 and X0302 respectively. A computation model which is subjected to cryogenic separation has design reference values of adjusting parameters in real time, optimizing parameters, improving yield, reducing energy consumption and the like for established or to-be-established cryogenic device.

Owner:XIAN CHANGQING TECH ENG

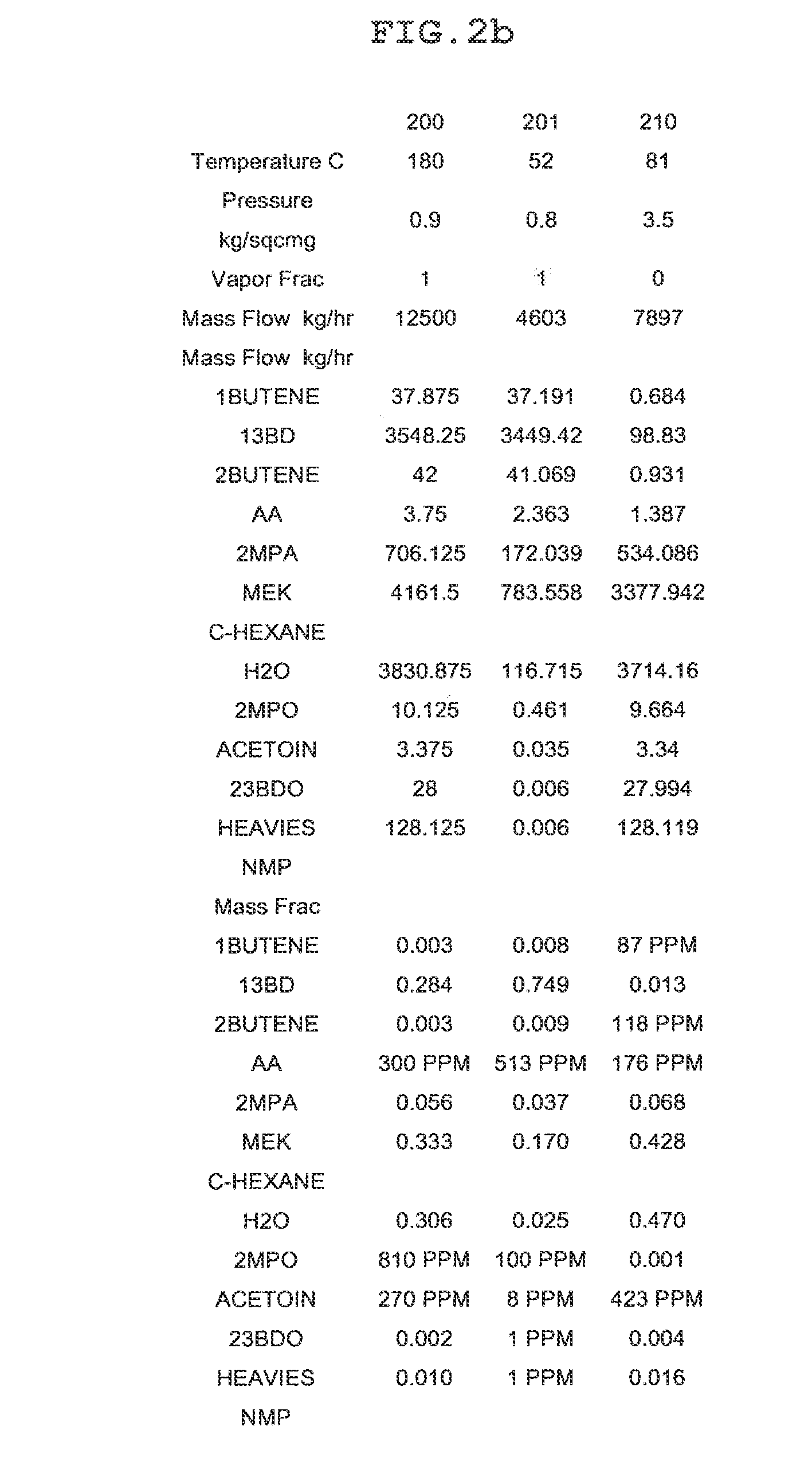

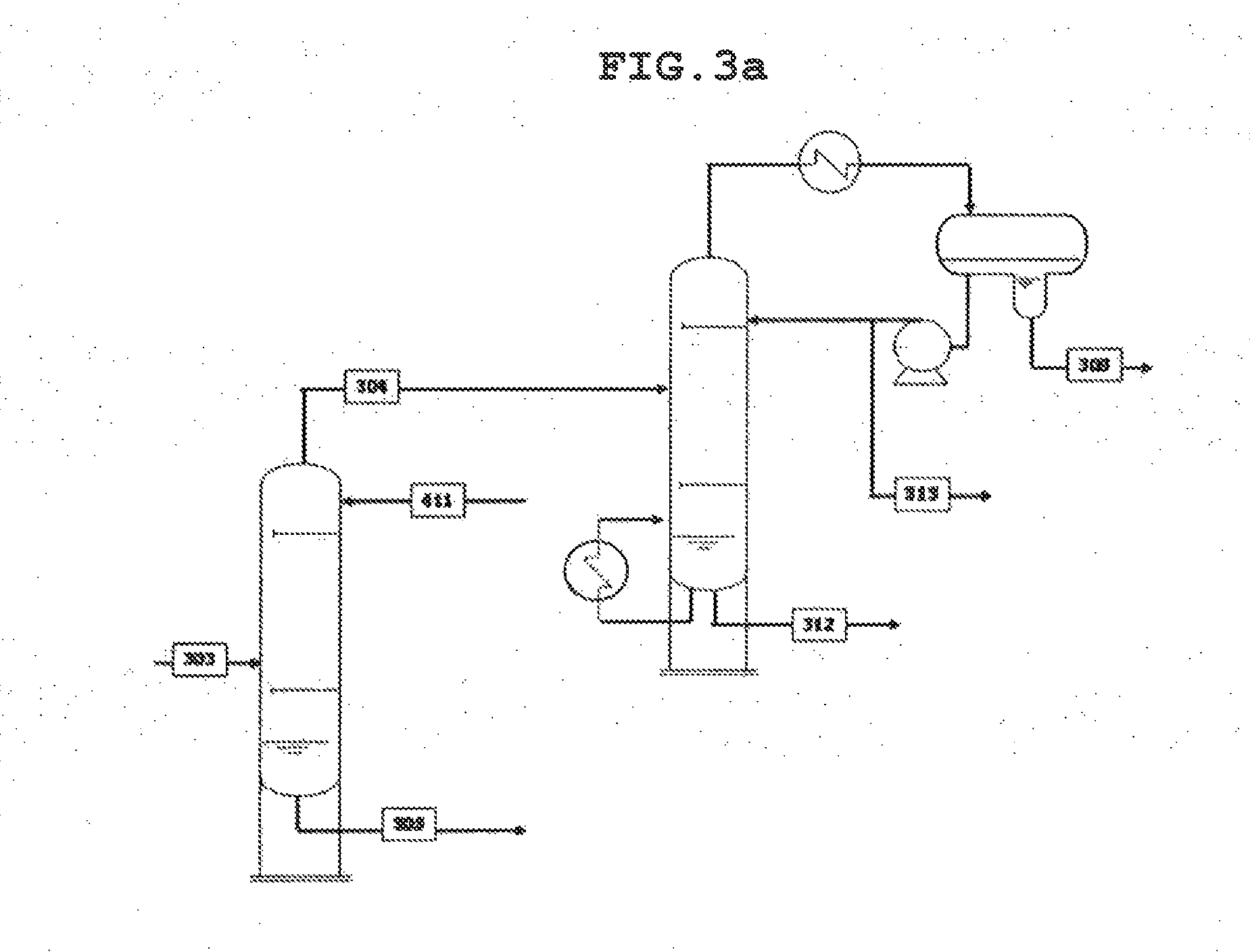

Method of recovering 1,3-butadiene and methylethylketone from dehydration products of 2,3-butanediol

ActiveUS20160251281A1Efficiently recovering highly pureOvercome limitationsFermented solutions distillation/rectificationGas treatment2,3-ButanediolButanediol

Disclosed is a method of efficiently separating 1,3-butadiene and methylethylketone, which are compounds of interest, from byproducts or impurities in the dehydration products of 2,3-butanediol so as to recover the compounds of interest at high purity.

Owner:SK INNOVATION CO LTD +1

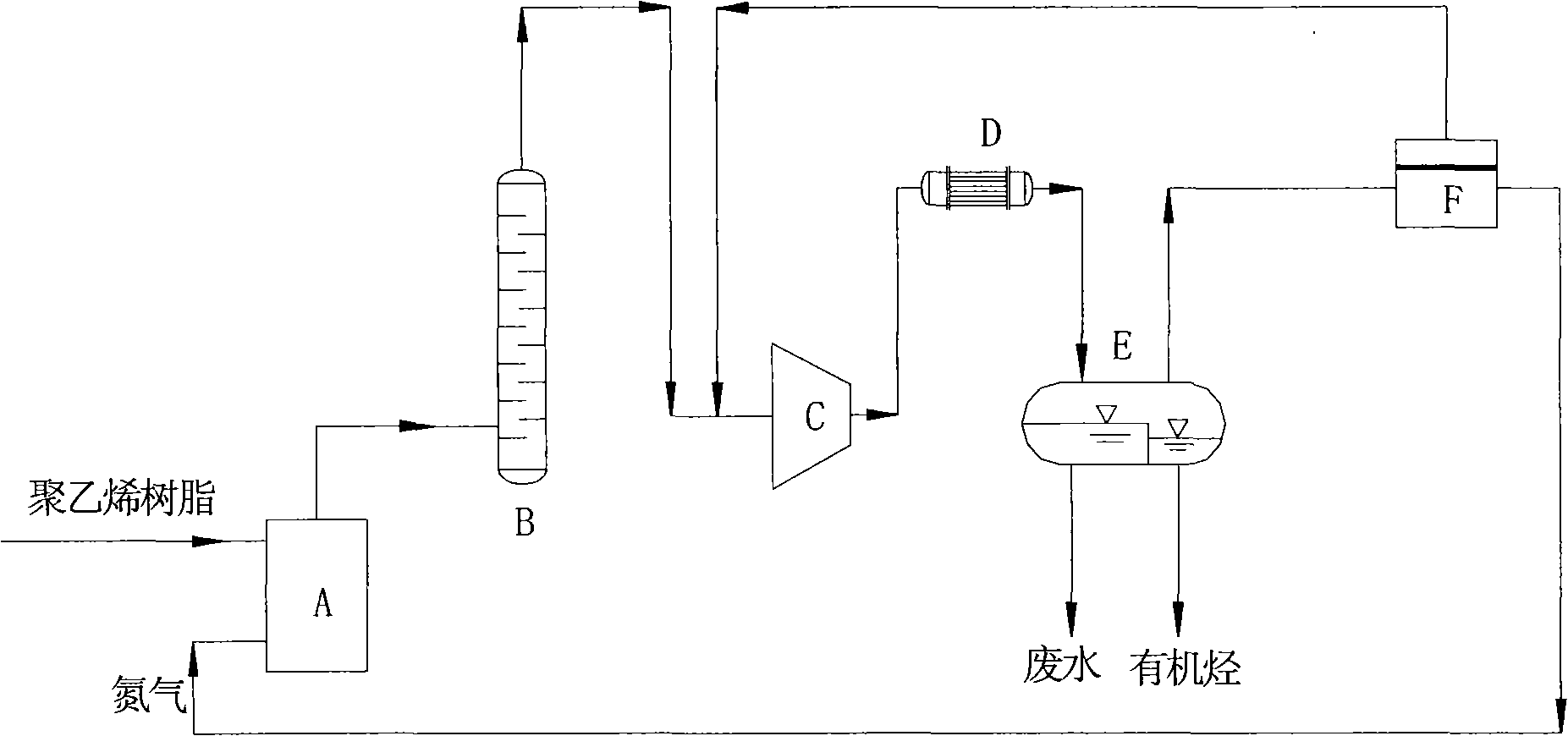

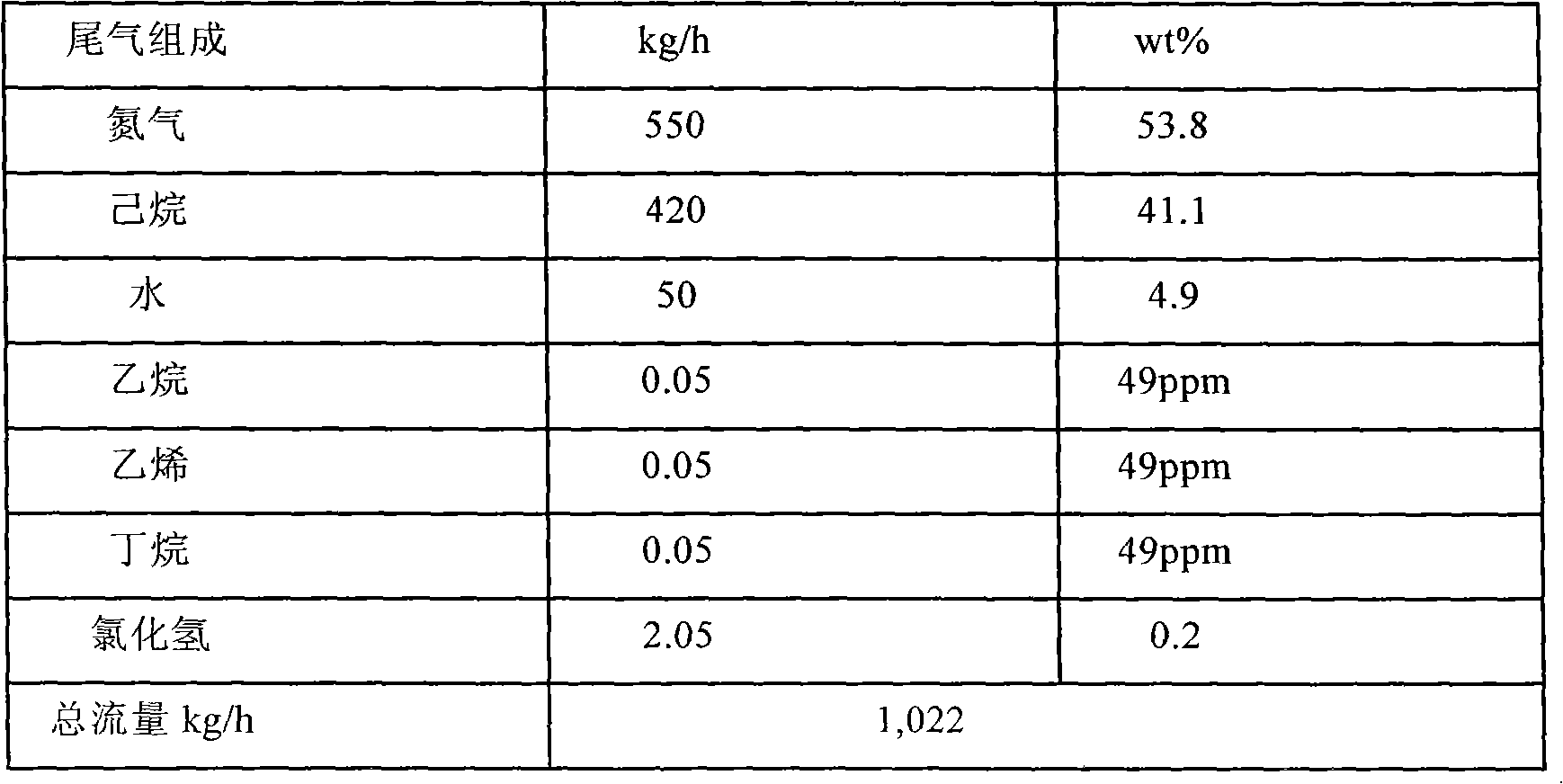

Technique for reclaiming organic hydrocarbon and nitrogen gas from polyethylene device tail gas

InactiveCN101265153AHigh recovery rateSimple processNitrogen purification/separationFractional condensation purification/separationNitrogenNitrogen gas

The invention discloses a membrane separation process for recovering organic hydrocarbons and nitrogen from the tail gas of a polyethylene device. The recovery technology caustic-washes, compresses and cools the tail gas; the tail gas after being cooled is put in a segregator, and the organic hydrocarbons is separated and recovered; gas exhausted from the segregator is put in an organic steam membrane; the gas which enters into a membrane separator is divided into a permeating airflow rich in the organic hydrocarbons and a retentate airflow rich in N2. The technology can lead the recovery rate of the organic hydrocarbons to reach more than 99 percent, lead the recovery rate of the nitrogen to reach more than 99 percent, and lead the purity to be 99 percent. The membrane separation process is applied to the recovery and treatment of the tail gas of the polyethylene device.

Owner:SHANGHAI DONGHUA ENVIRONMENT ENG

Recovering device for oxidization low pressure end gas in process of preparing terephthalic acid

ActiveCN1923788ASolve entrained liquid problemsImprove recycling ratesOrganic compound preparationCarboxylic acid esters preparationMethyl acetateOil–water separator

The invention discloses a recycling device of p-xylene and methyl acetate, which comprises the following parts: high-effective condenser, which quenches gas p-xylene and methyl acetate into liquid; oil-water separator, which separates p-xylene and methyl acetate from water automatically. The invention solves the problem of tail gas with liquid as well as the problem of separation and recycling.

Owner:SINOPEC YIZHENG CHEM FIBER

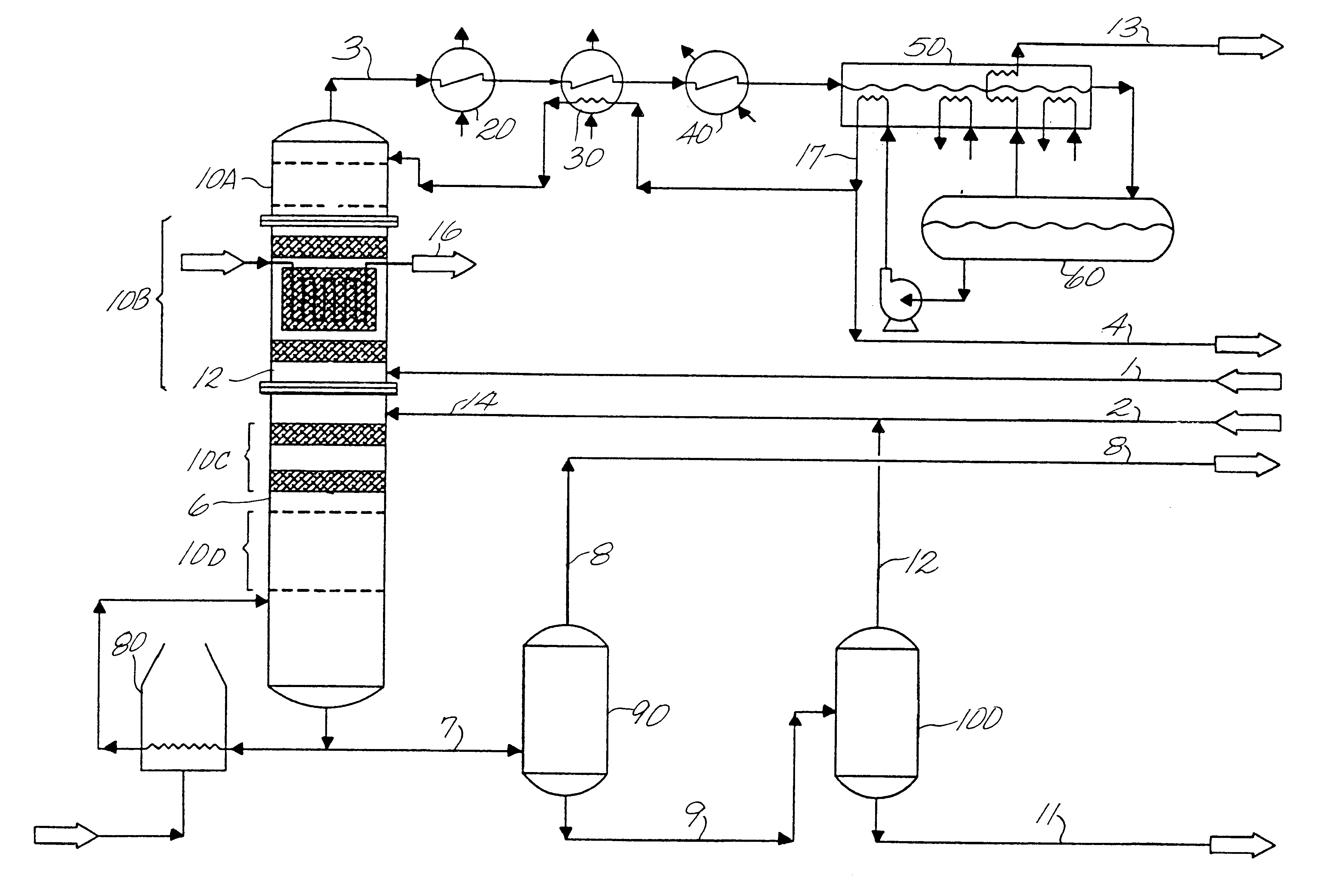

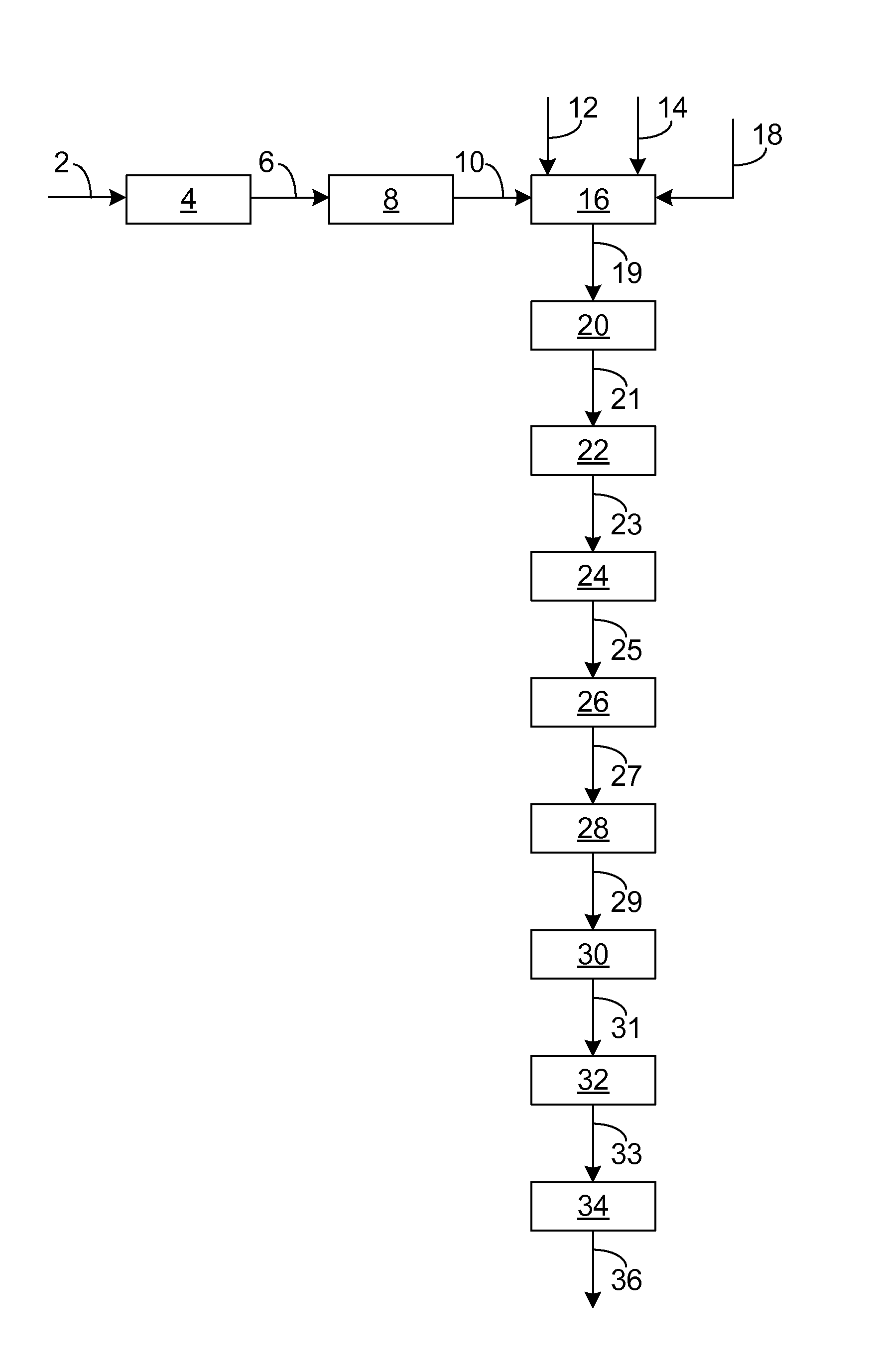

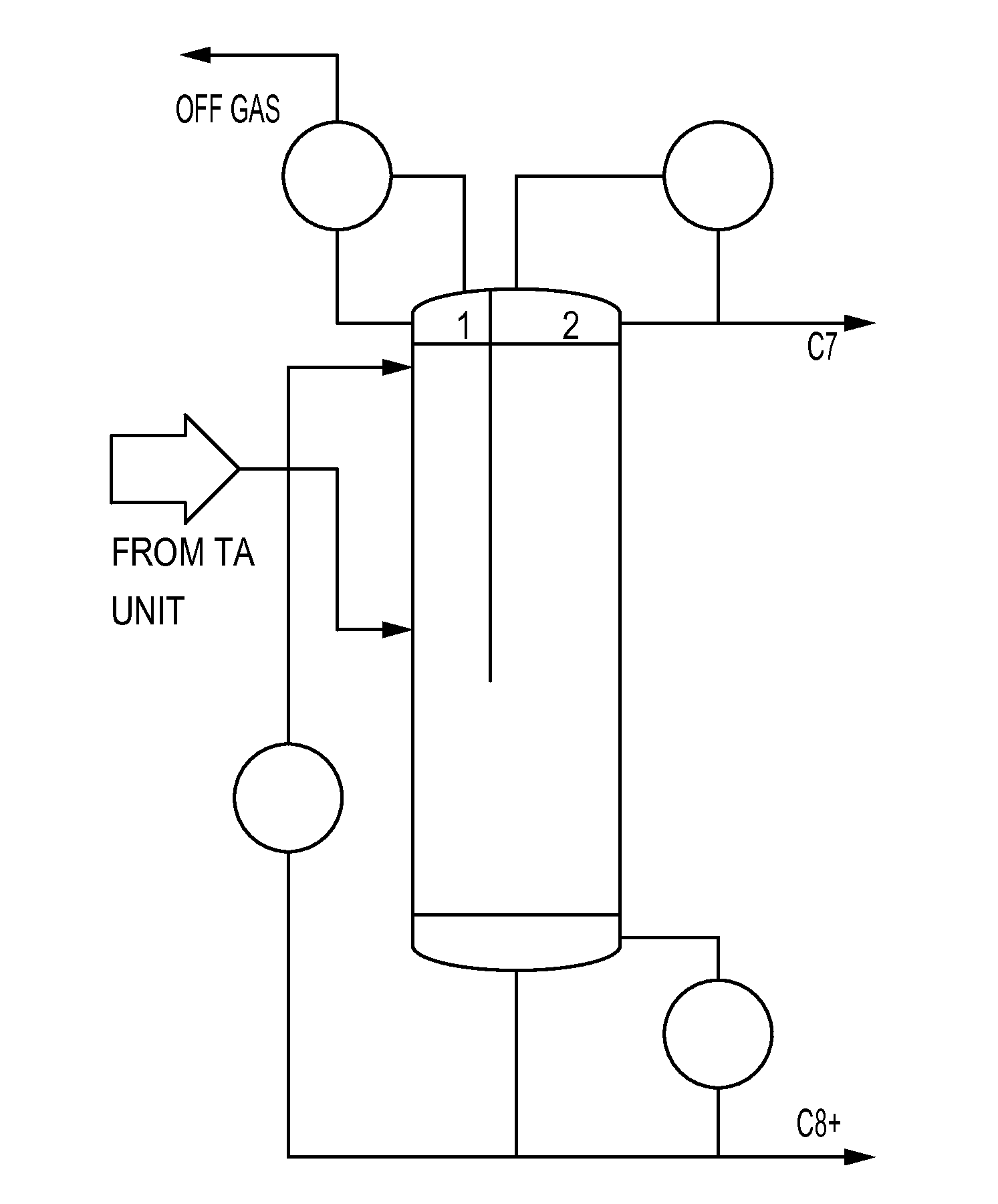

Method of carrying out absorption/distillation in a single column design

Embodiments of the invention are directed to a process wherein two different unit operations (absorption and distillation) take place on either side of a top dividing wall column. One side of the dividing wall column uses absorption to separate non-condensable components from the feed; the other side of the dividing wall uses distillation to separate heavier liquid components.

Owner:SULZER MANAGEMENT AG

Process for recovering olefins in polyolefin plants

A process for recovering unreacted olefin in a polyolefin manufacturing process comprising the treatment of a purge bin vent gas. The process involves cooling and condensing the vent gas (purge stream), which contains at least an olefin, a paraffin, and nitrogen, to produce a liquid condensate and an uncondensed (residual) gas stream. Both streams are then passed through membrane separation steps. The membrane separation of the uncondensed gas stream results in a residue stream containing mostly nitrogen and / or paraffin and a permeate stream enriched in either C2+ hydrocarbons or olefin, depending on the type of separation. The permeate from this step is recirculated within the process prior to the condensation step. The membrane separation of the condensate results in a residue stream containing paraffin and a permeate stream enriched in olefin, which may be recycled to the polymerization reactor.

Owner:MEMBRANE TECH & RES

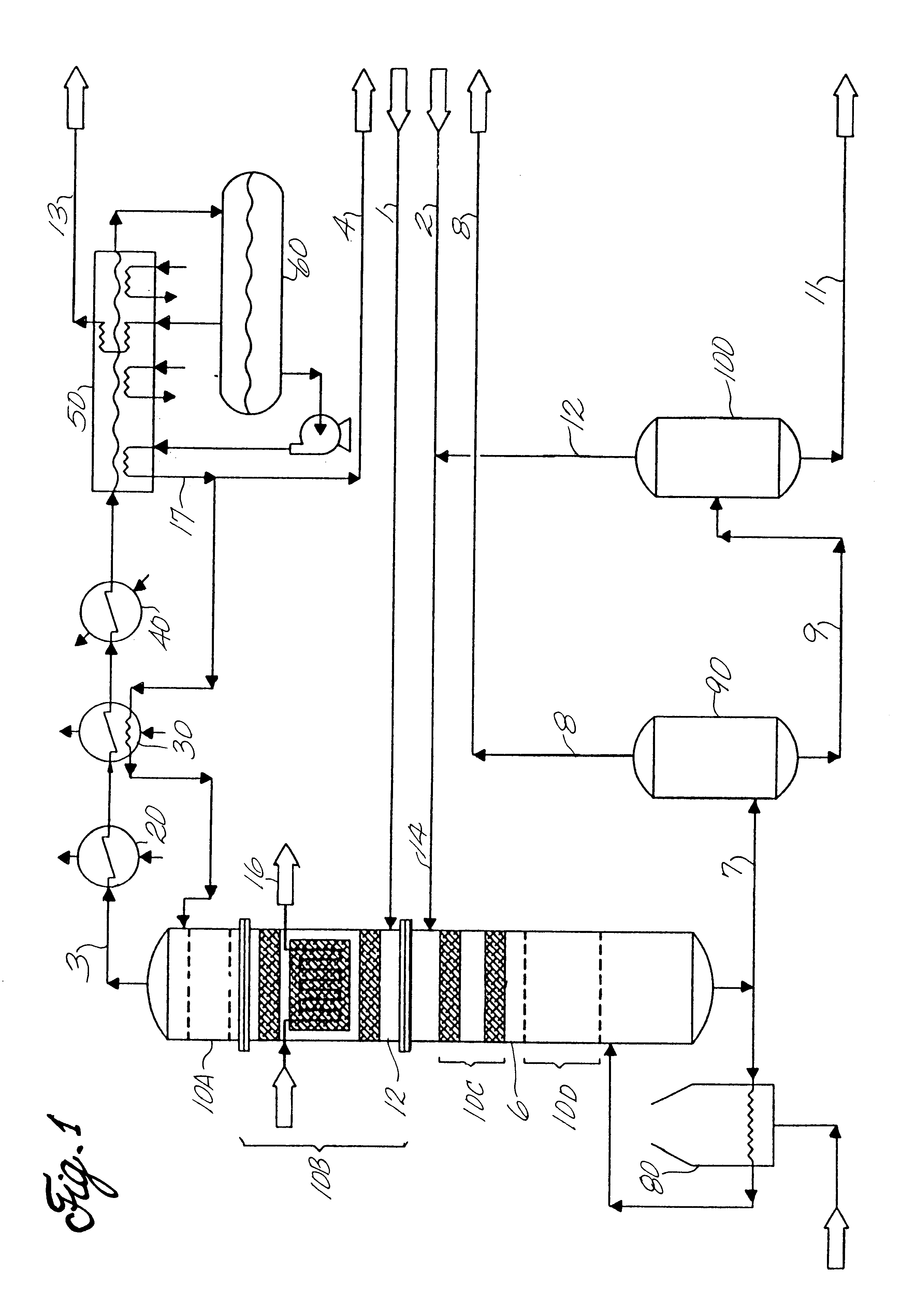

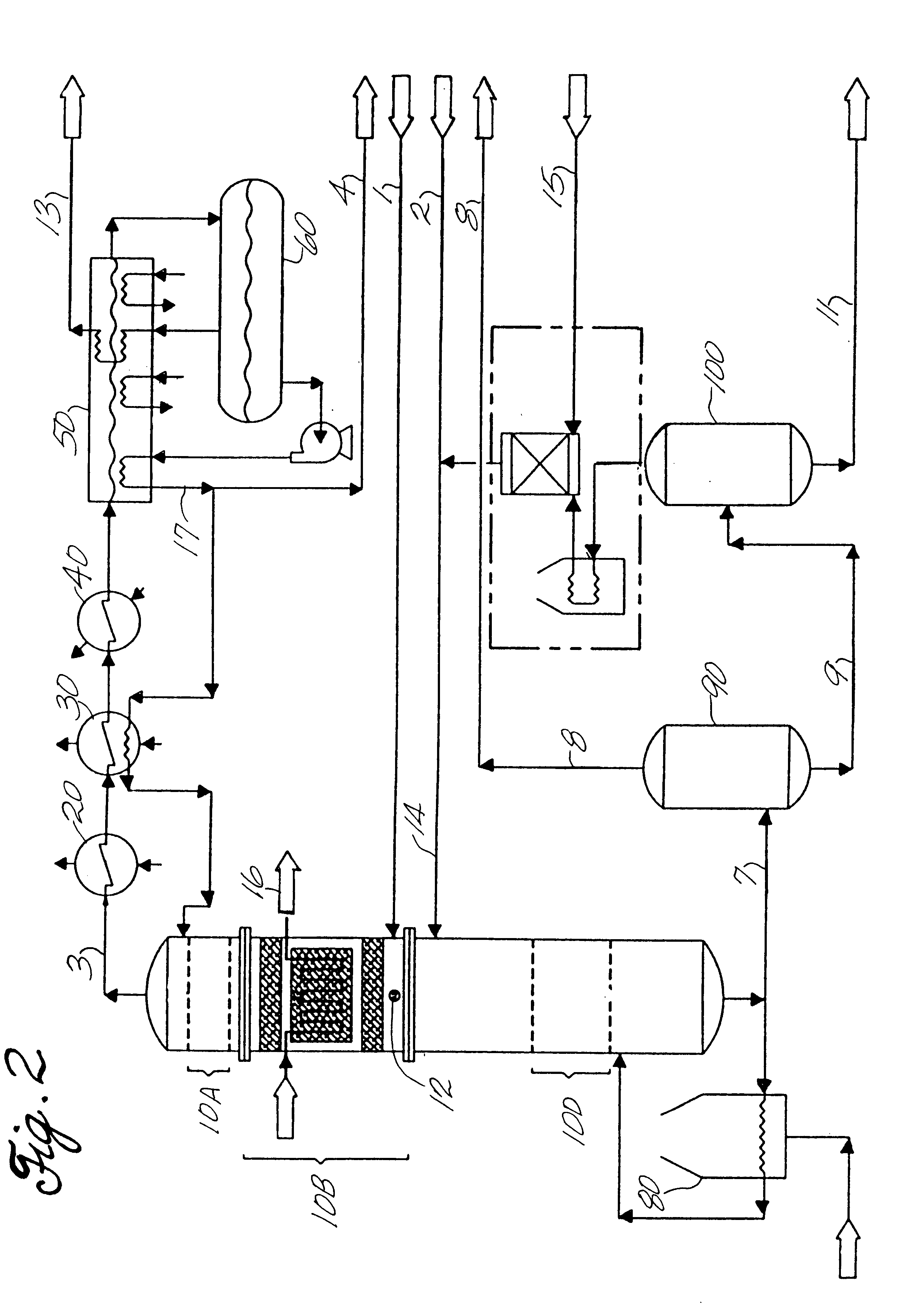

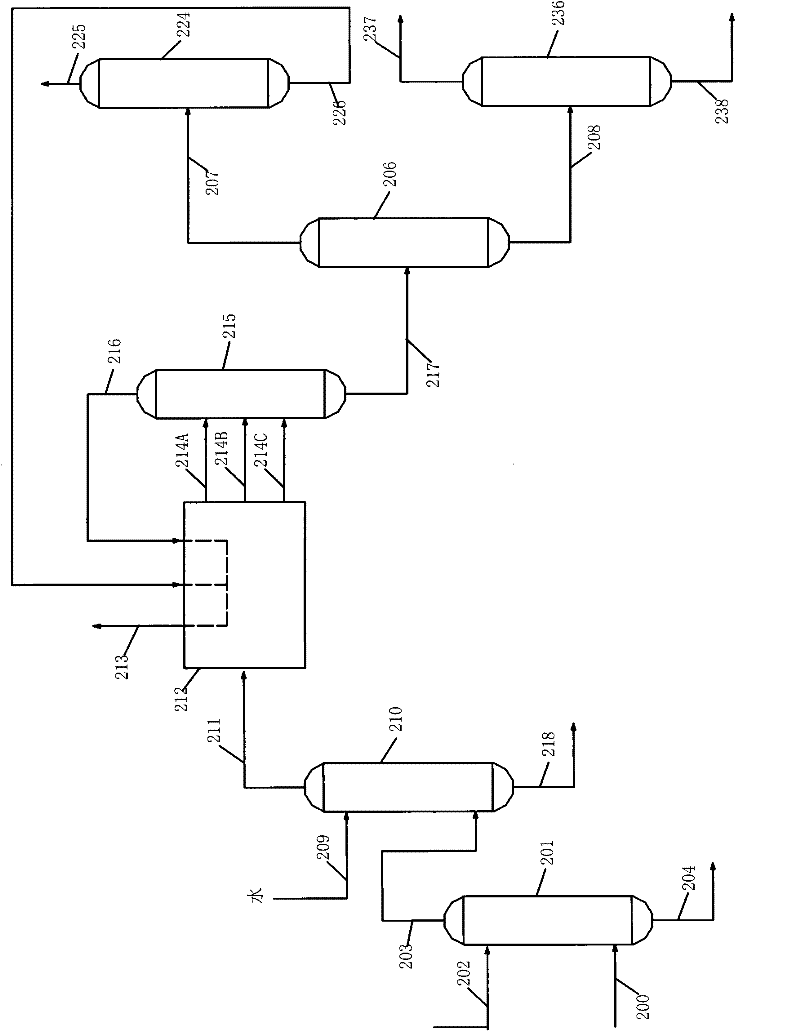

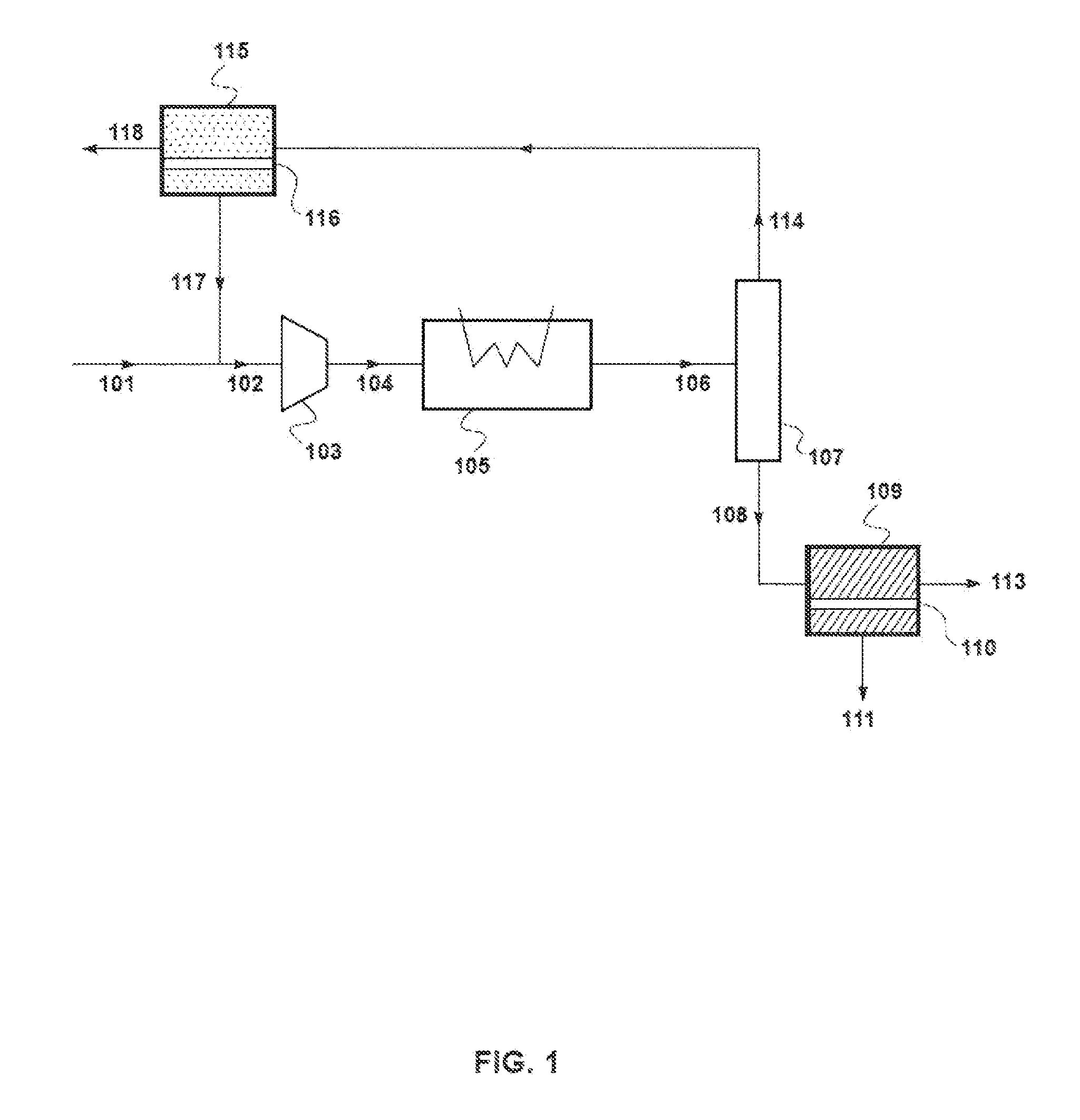

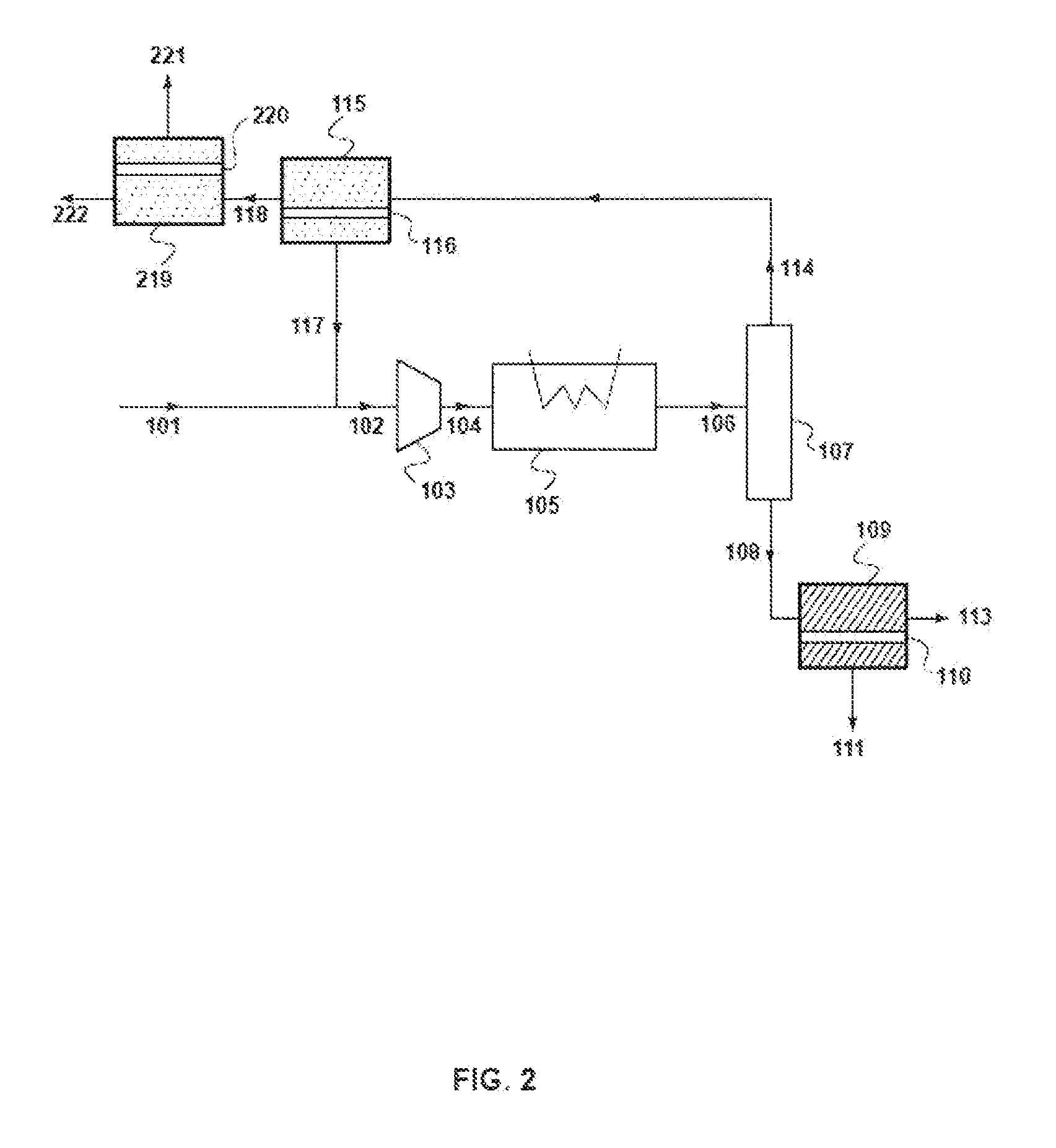

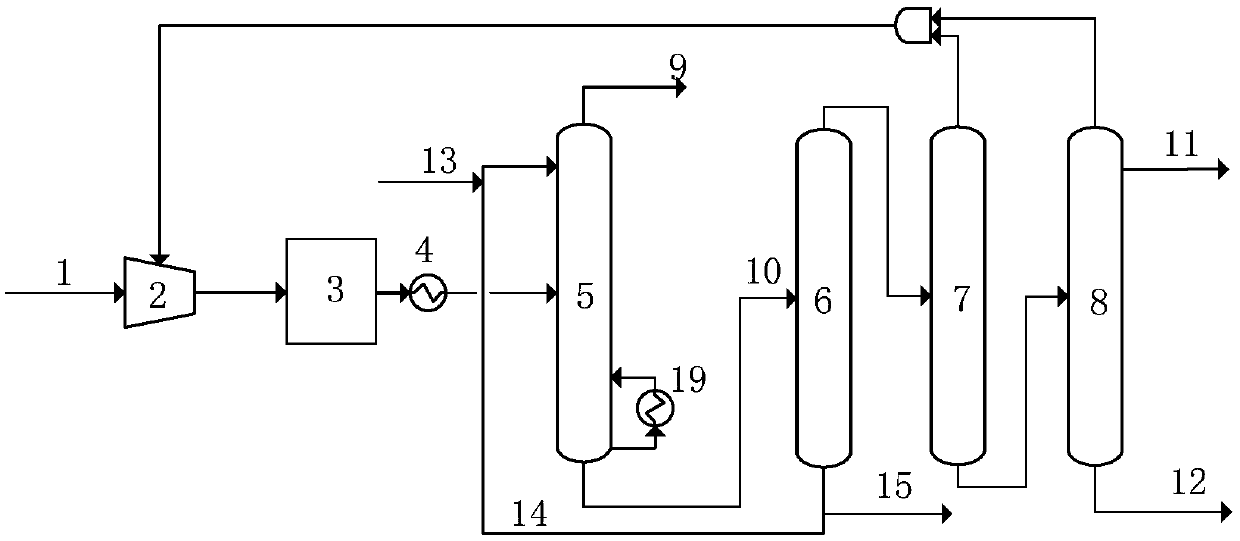

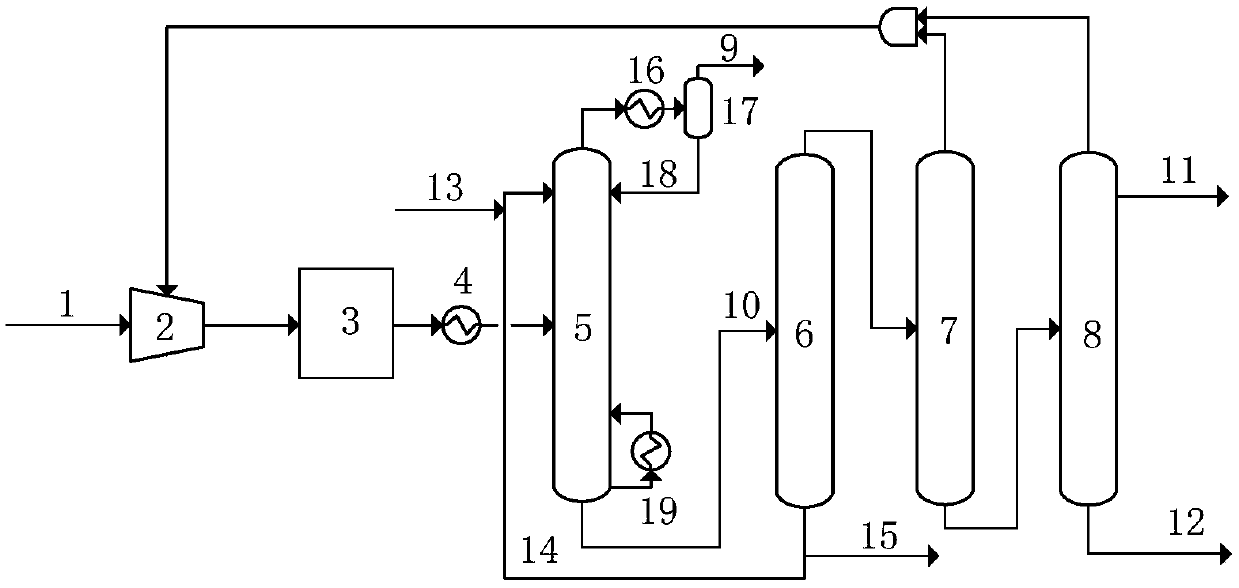

Process for recovering lower carbon olefins from product gas for production of olefins

The present invention concerns a process for recovering lower carbon olefins from MTO or DTO product gas. Said process primarily comprises the product gas compressing, pre-deethanizing, demethanizing and ethylene recovering apparatus, depropanizing column, ethylene rectification column, propylene rectification column and the like. In addition, the process of the present invention needs no independent ethylene cooling system, and the ethylene recovery rate may achieve 99.5%.

Owner:CHINA PETROCHEMICAL CORP +1

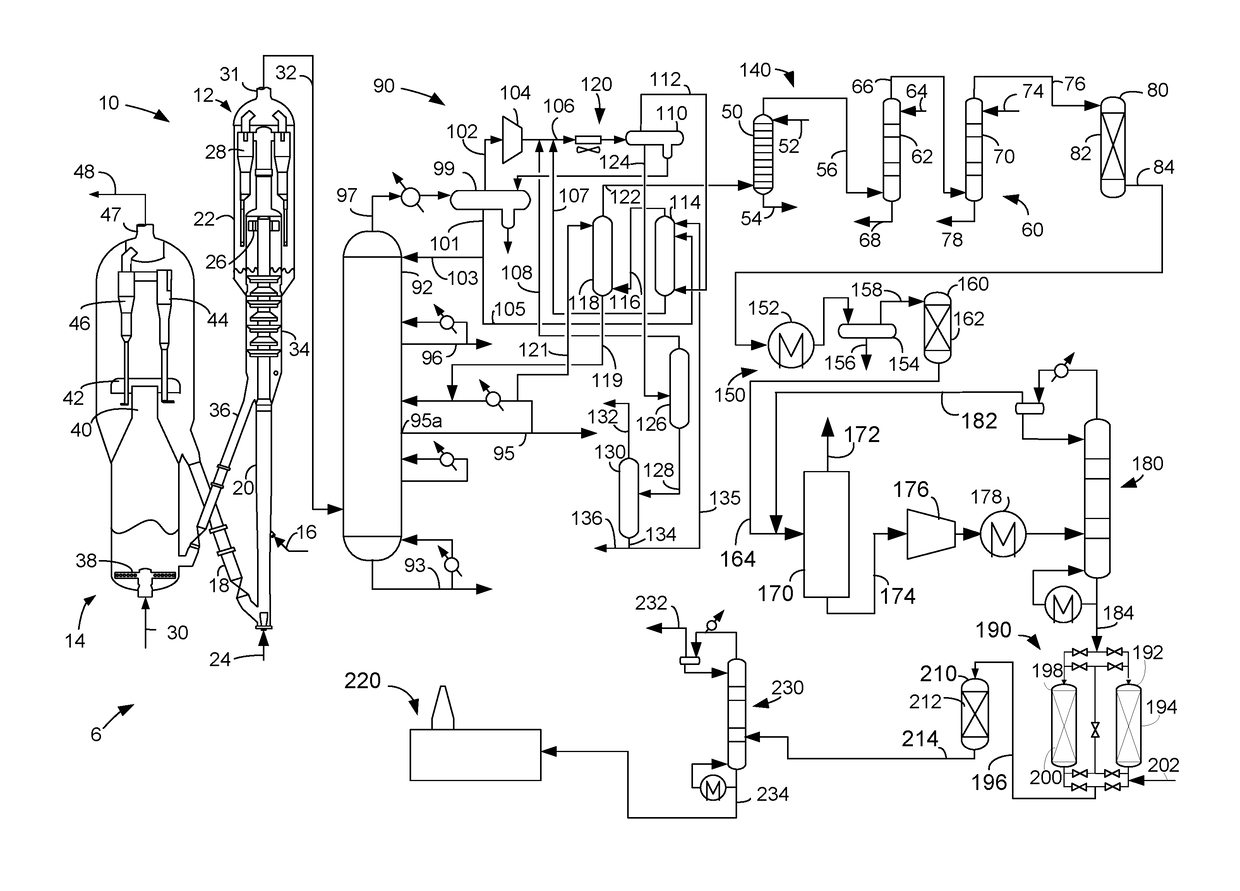

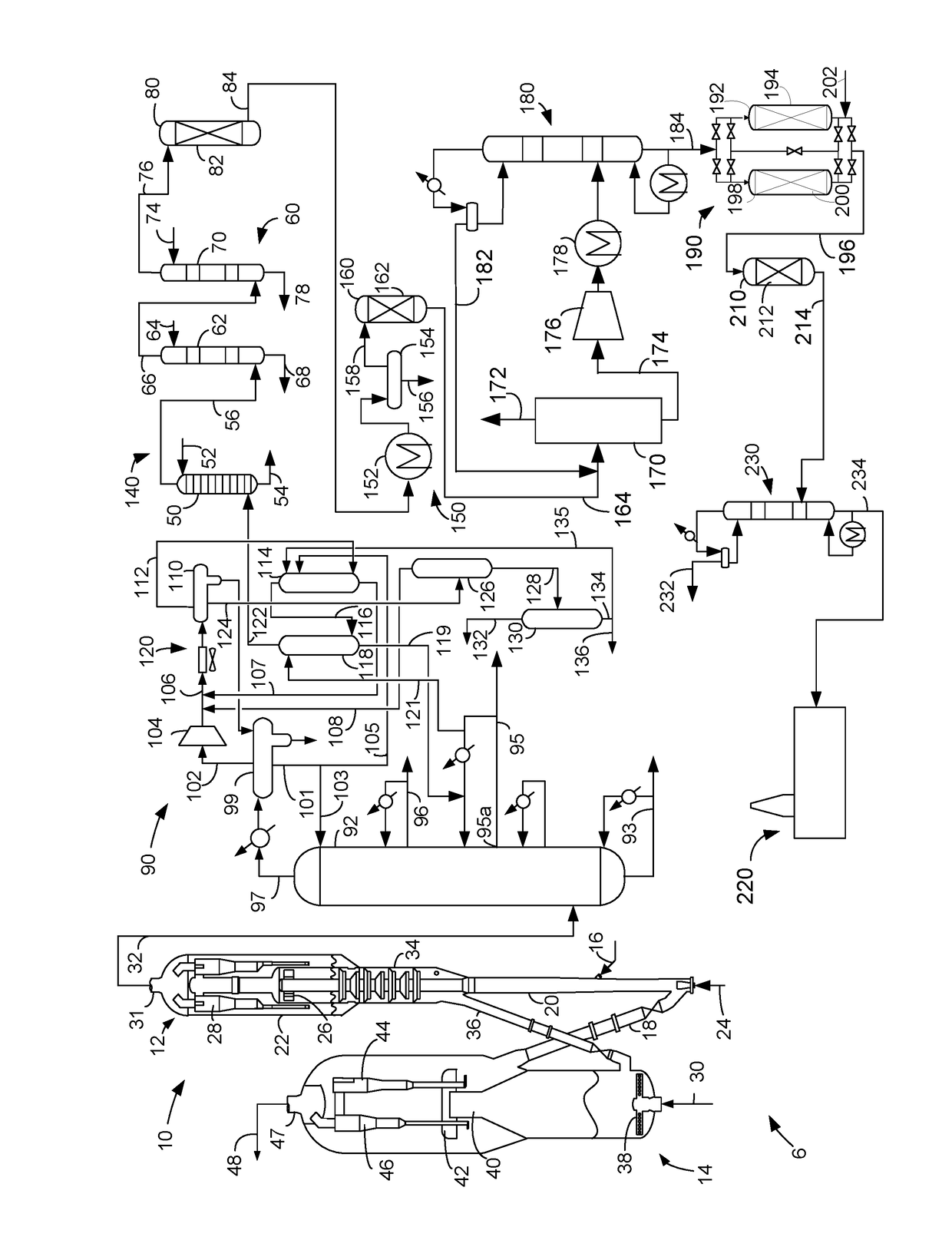

Process for producing olefins from a coal feed

InactiveUS20150141726A1Reduce concentrationCatalytic crackingDistillation purification/separationSulfurBoiling point

A process for producing olefins from a coal feed includes providing a coal tar stream and fractionating the coal tar stream to provide a hydrocarbon stream that includes hydrocarbons having an initial boiling point of about 250° C. or greater. The hydrocarbon stream is hydrotreated to reduce a concentration of one or more of nitrogen, sulfur, and oxygen in the hydrocarbon stream, and the hydrotreated hydrocarbon stream is cracked in a fluidized catalytic cracking zone to produce an olefin stream.

Owner:UOP LLC

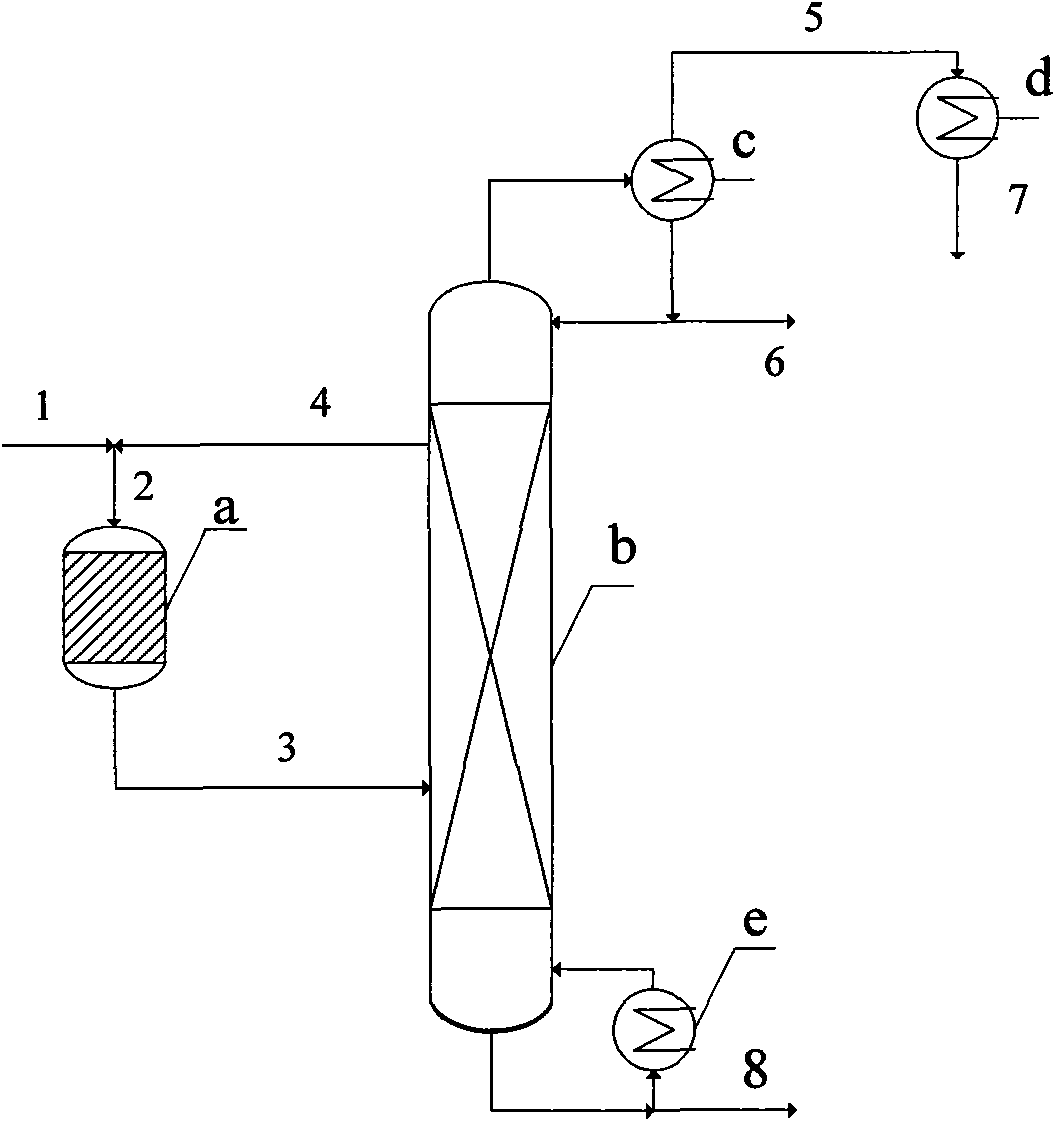

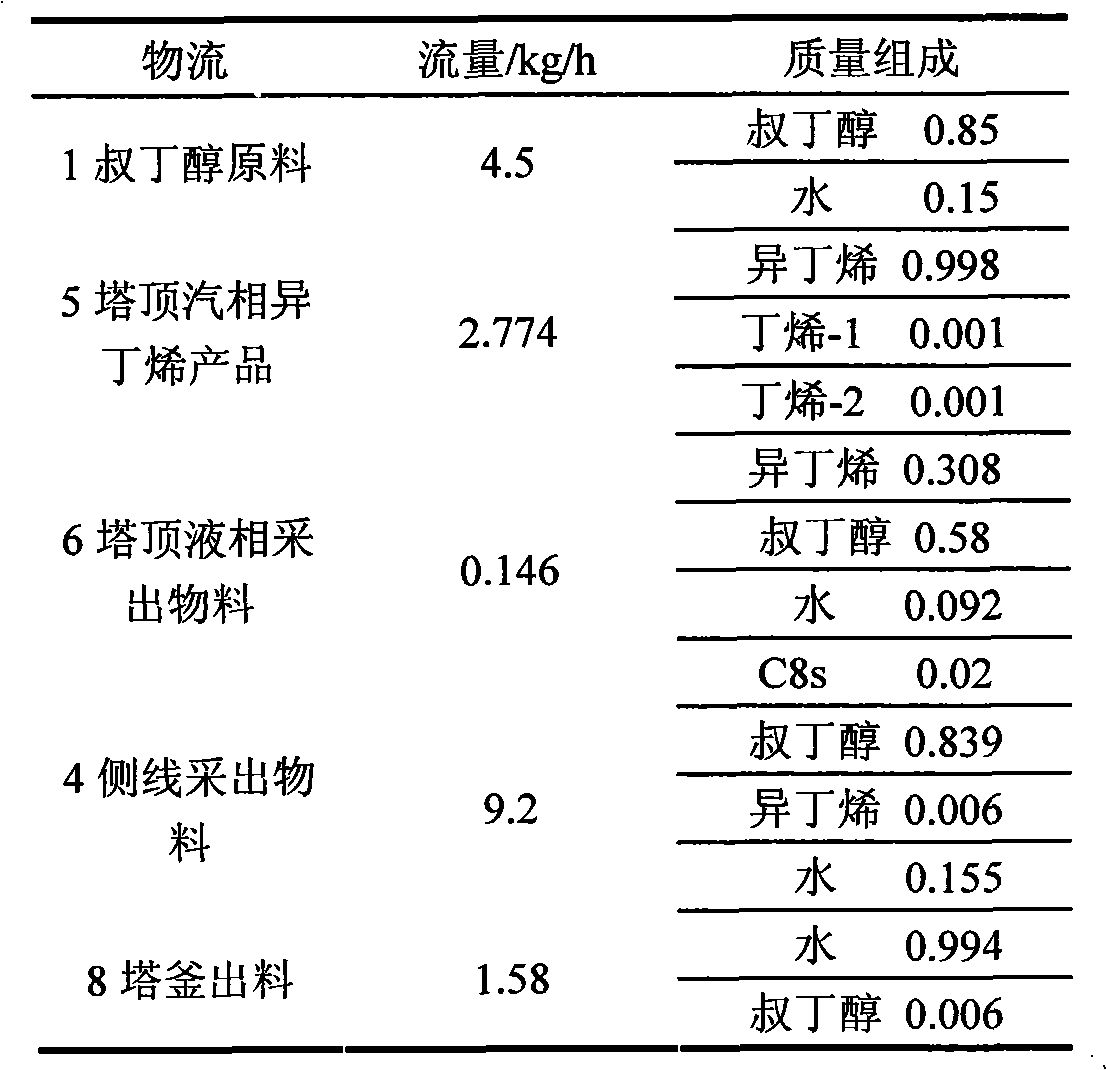

Preparing method of isobutene using tert-butyl alcohol

ActiveCN102020526AReduce contentEasy to fillDistillation purification/separationFractional condensation purification/separationFixed bedTower

A preparing method of isobutene using tert-butyl alcohol is characterized in that a fixed bed is applied as a rector for the dehydration of tert-butyl alcohol, reaction products are separated in a rectifying tower, the condenser in the tower top is a partial condenser, liquid phase is almost in infinite reflux state, only a few is collected to prevent enrichment of 8 carbon byproduct in the tower, steam phase isobutene is collected and transformed into liquid phase isobutene product after being deeply cooled in the condenser, another product water is collected from the tower bottom, and the mixture of tert-butyl alcohol and water close to azeotropic composition is collected from the lateral line to return to the fixed bed reactor. The reactor and the rectifying tower in the invention combine as a system, wherein complete reaction of tert-butyl alcohol and separation of products can be achieved through adjusting operations of rectifying tower. Water is collected from column bottom, andhigh purity isobutene is collected from tower top. The method is characterized by low investment of equipment, convenient filling of catalyst and easy operation.

Owner:PETROCHINA CO LTD

Process for recovering olefins in polyolefin plants

A process for recovering unreacted olefin in a polyolefin manufacturing process comprising the treatment of a purge bin vent gas. The process involves cooling and condensing the vent gas (purge stream), which contains at least an olefin, a paraffin, and hydrogen, to produce a liquid condensate and an uncondensed (residual) gas stream. Both streams are then passed through membrane separation steps. The membrane separation of the uncondensed gas stream results in a residue stream containing mostly nitrogen and / or paraffin and a permeate stream enriched in either C2+ hydrocarbons or olefin, depending on the type of separation. The permeate from this step is recirculated within the process prior to the condensation step. The membrane separation of the condensate results in a residue stream containing paraffin and a permeate stream enriched in olefin, which may be recycled to the polymerization reactor.

Owner:MEMBRANE TECH & RES

Processes for producing polymer grade light olefins from mixed alcohols

Processes for providing a high purity olefin product are described. The processes involve dehydrating a feedstream comprising a mixture of alcohols having 3 to 8 carbon atoms and forming a mixed olefin stream and a water stream, the mixed olefin stream comprising a mixture of olefins having 3 to 8 carbon atoms. The mixed olefin stream is separated into at least a C3 olefin stream comprising olefins having 3 carbon atoms and a C4-8 olefin stream comprising olefins having 4 to 8 carbon atoms. The C4-8 olefin stream is separated into a C4 olefin stream comprising olefins having 4 carbon atoms and a C5-8 olefin stream comprising olefins having 5 to 8 carbon atoms. At least one of the C3 olefin stream and the C4 olefin stream is purified.

Owner:UOP LLC

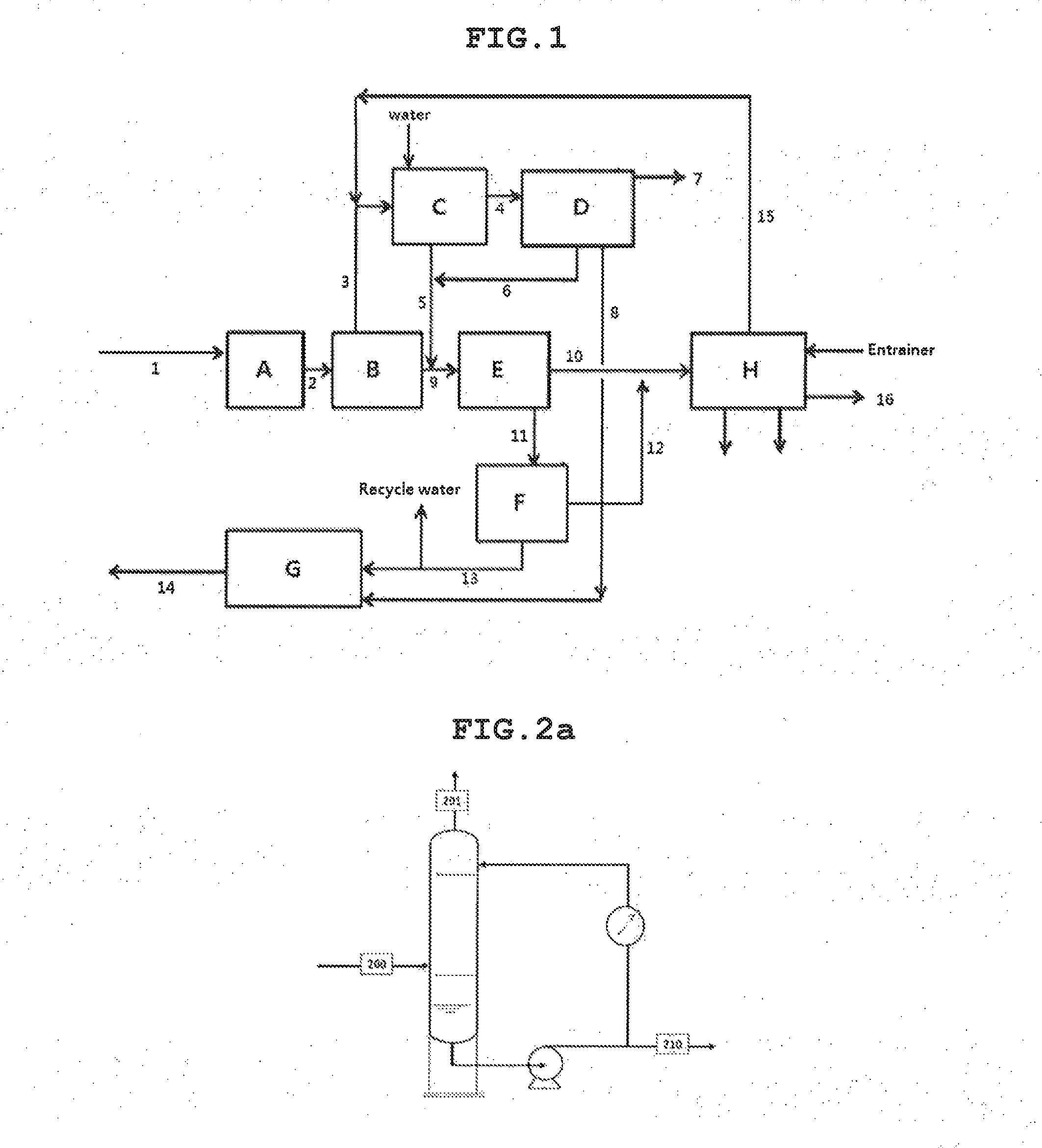

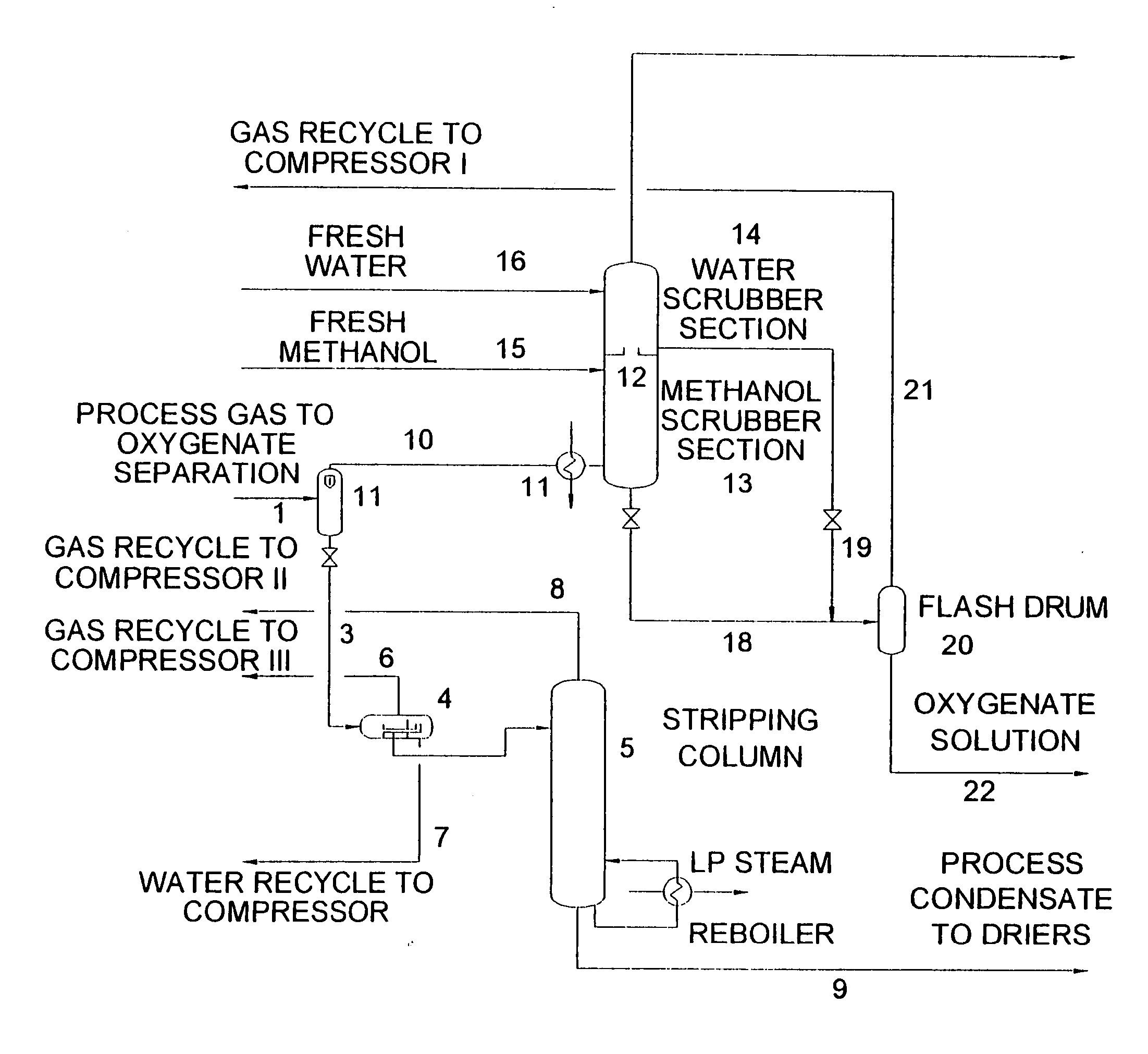

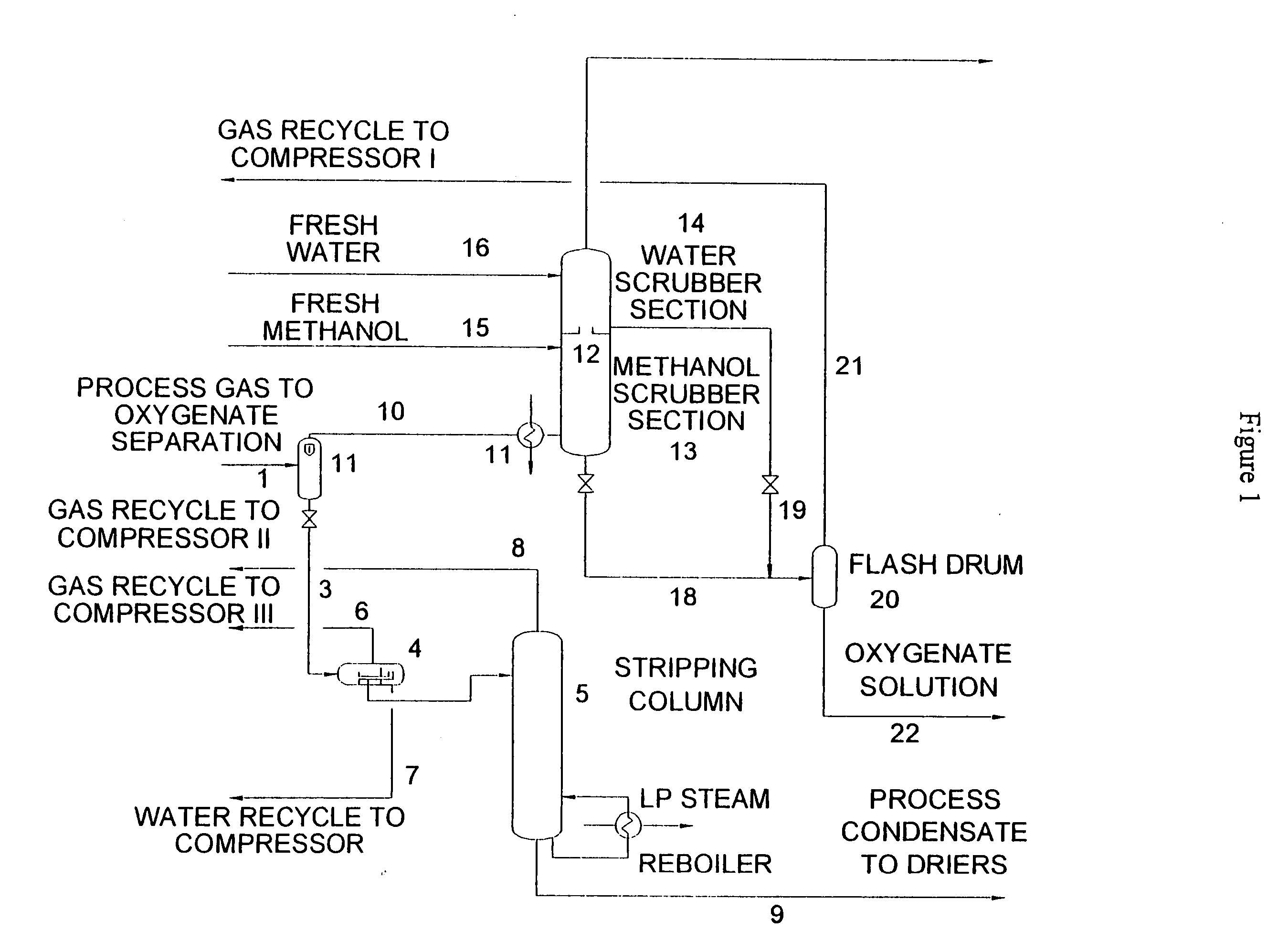

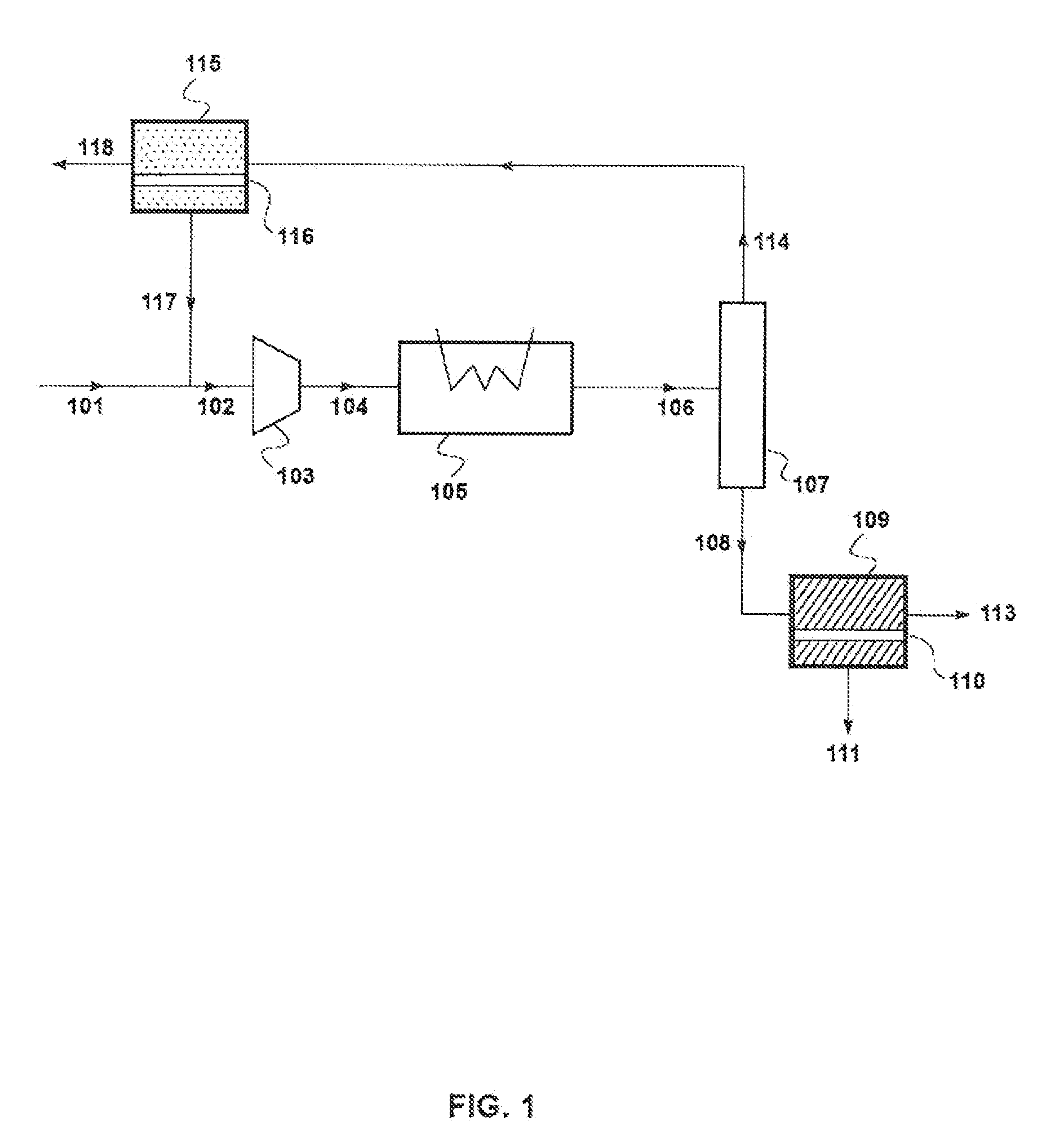

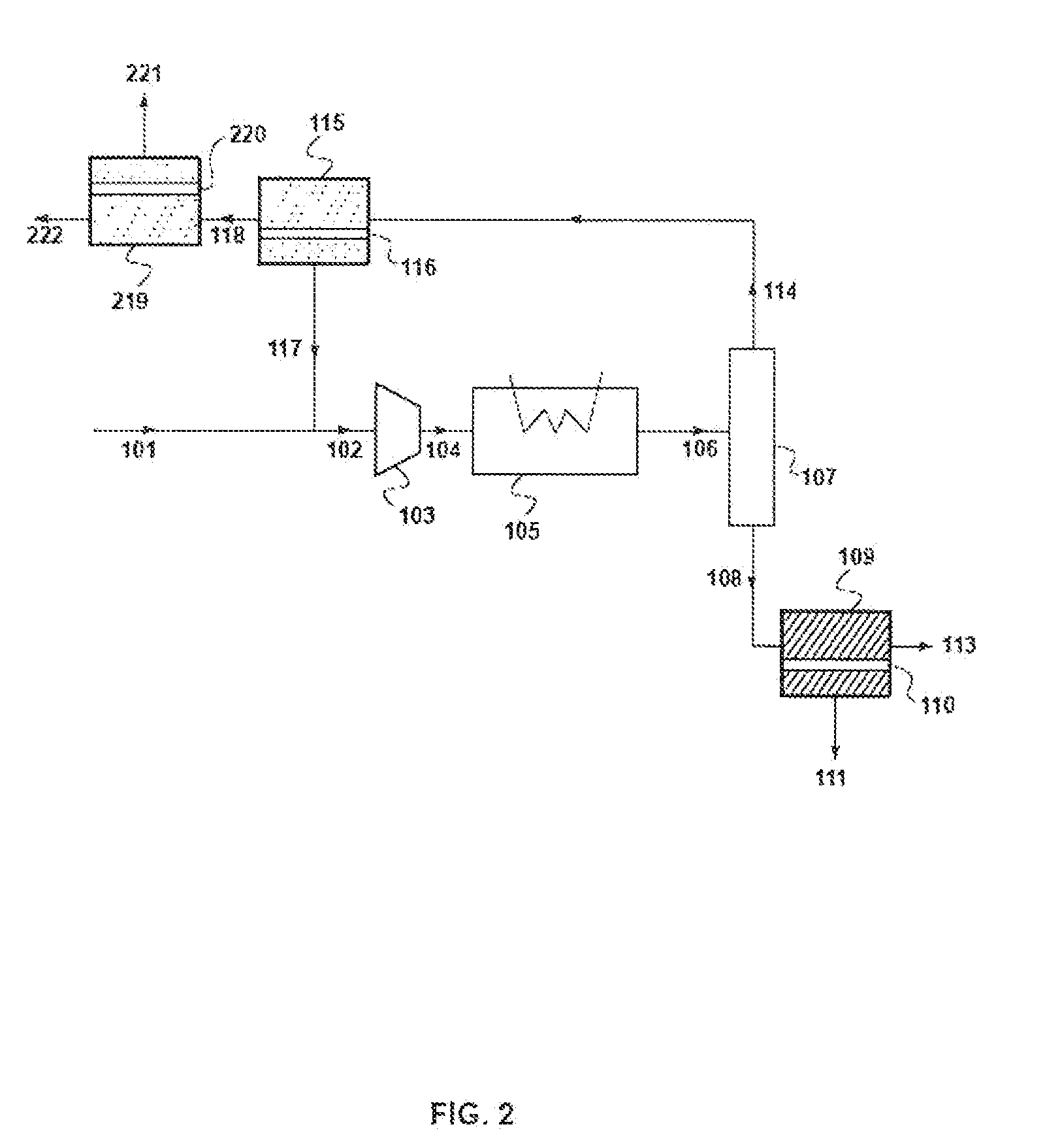

Method for processing an olefin-containing product stream

ActiveUS20050222478A1Easy to disassembleFractional condensation purification/separationEthylene productionFractionationOxygenate

A method is described for processing an olefin-containing product stream (1) that contains, besides ethylene and propylene, longer-chain olefins and compounds of hydrocarbons with oxygen (oxygenates). Such a product stream (I) can occur in particular in olefin synthesis from methanol. The product stream is dewatered in successive process steps, optionally compressed in several steps and dried. Then it is subjected to fractionation. For removal of the undesired oxygenates it is proposed that the oxygenates be washed out of the gaseous product stream after the compression steps and before the drying step in a column (12) with methanol.

Owner:EXXONMOBIL CHEM PAT INC

Process for Recovering Olefins from Manufacturing Operations

A process for treating an effluent gas stream arising from a manufacturing operation that produces an olefin or a non-polymeric olefin derivative. The process involves cooling and condensing the effluent gas stream, which comprises an olefin, a paraffin, and a third gas, to produce a liquid condensate and an uncondensed (residual) gas stream. Both streams are then passed through membrane separation steps. The membrane separation of the uncondensed gas stream results in an olefin-enriched stream and an olefin-depleted stream. The olefin-enriched stream is recirculated within the process prior to the condensation step. The membrane separation of the condensate also results in an olefin-enriched stream, which may be recycled for use within the manufacturing operation, and an olefin-depleted stream, which may be purged from the process.

Owner:MEMBRANE TECH & RES

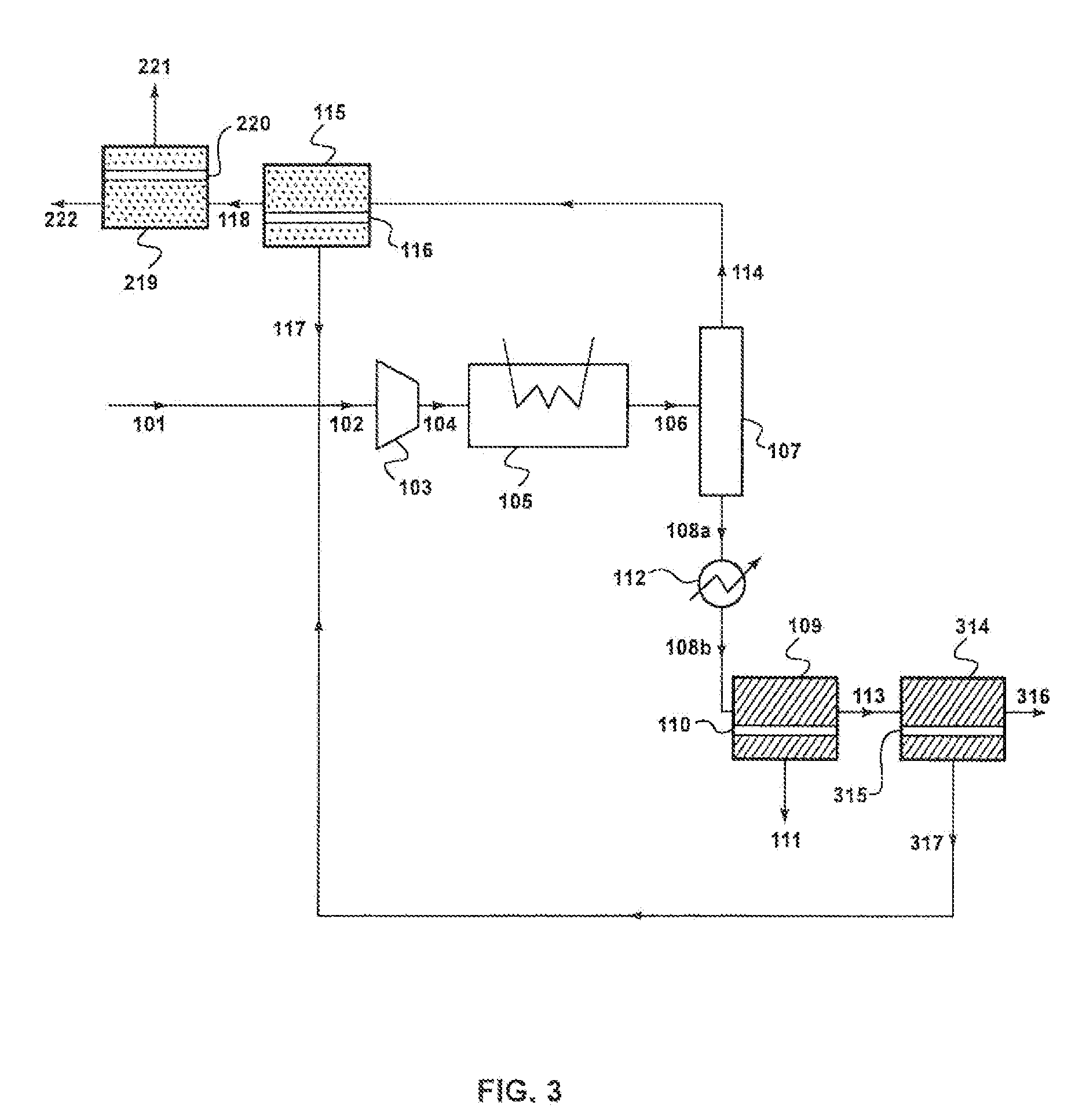

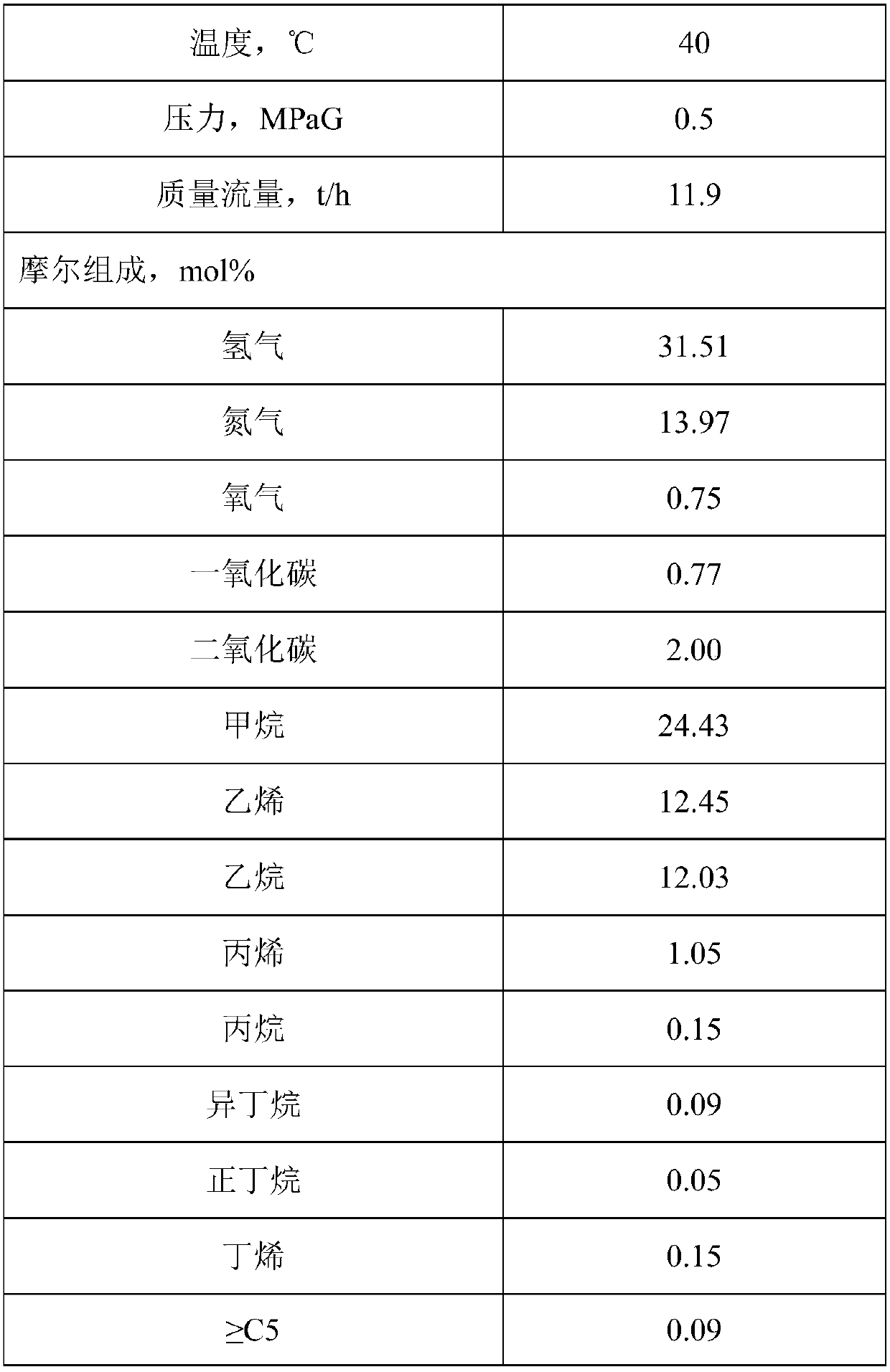

Method and device for separating ethylene from refinery plant dry gas

ActiveCN111320523AAvoid dependenceRaise the condensation temperatureDistillation purification/separationFractional condensation purification/separationProcess engineeringPropane

The invention belongs to the field of chemical engineering, and particularly discloses a method and a device for separating ethylene from refinery plant dry gas. The method comprises the steps of compression, purification, cooling, absorption, propane removal, methane removal, and ethylene refining. The method is based on a shallow cold oil absorption technology, directly produces a polymer-gradeethylene product from refinery plant dry gas on the premise that the refrigeration process is simplified, the cold consumption is reduced and the investment is saved, and has great industrial application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

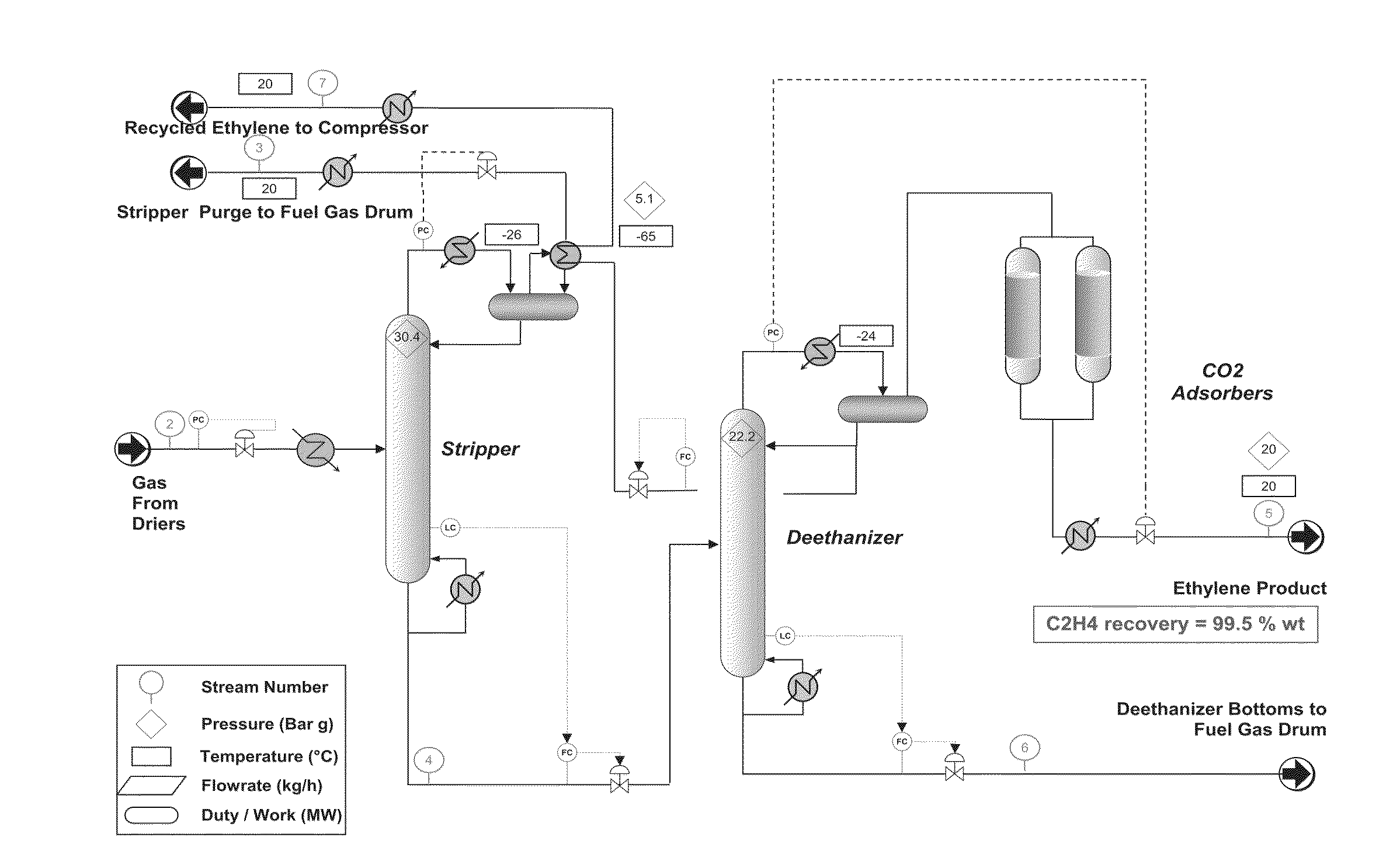

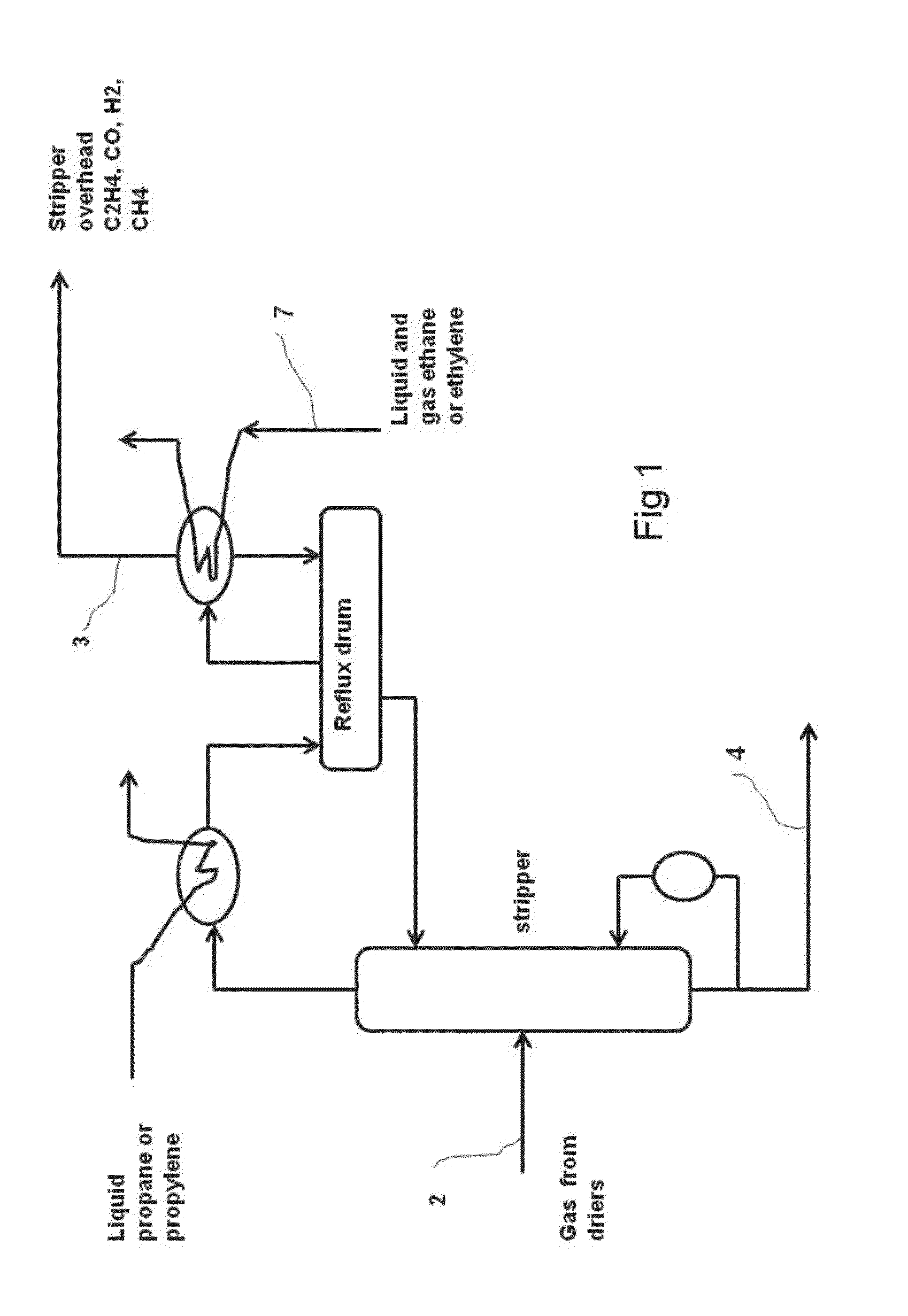

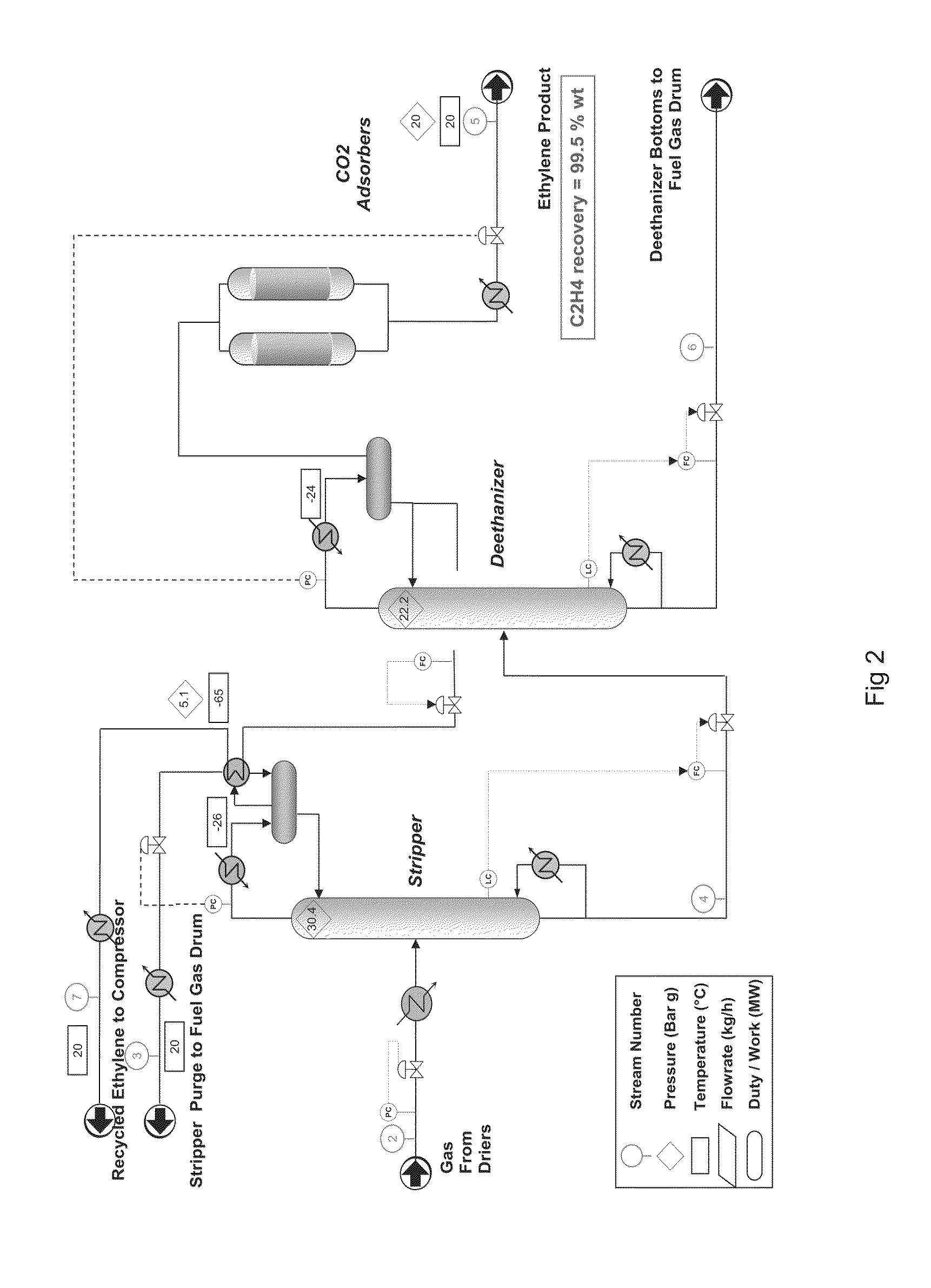

Process for removing light components from an ethylene stream

A process for removing light components from an ethylene stream may include providing a dried ethylene stream containing ethylene, ethane, CO, CO2, H2, CH4, and C3+ hydrocarbons. The process may include sending the dried ethylene stream to a stripper to produce an overhead stream containing ethylene, CO, H2 and CH4, and a bottom stream containing ethylene, ethane, CO2, and C3+ hydrocarbons. The gaseous phase on top of the stripper may be condensed in a heat exchanger cooled by a refrigerant stream to get a first gaseous phase and a first liquid phase. The first gaseous phase may be condensed in a heat exchanger cooled by liquid ethane or liquid ethylene to get a second gaseous phase containing ethylene CO, H2 and CH4 and a second liquid phase. The first and second liquid phases may be the reflux of the stripper.

Owner:TOTAL RES & TECH FELUY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com