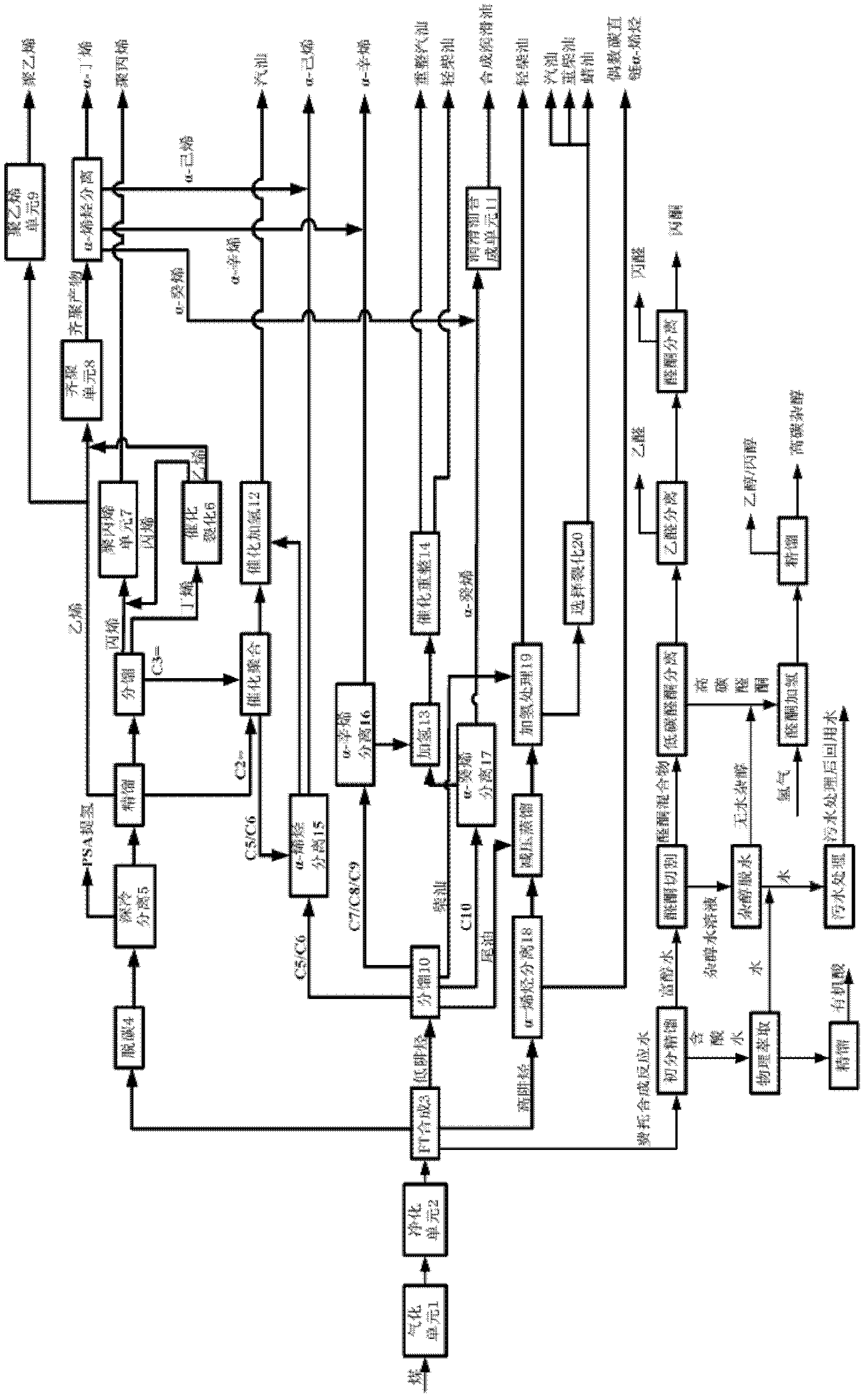

High and low-temperature Fischer-Tropsch synthesis co-production technology

A Fischer-Tropsch synthesis, high and low temperature technology, which is used in the petroleum industry, the preparation of liquid hydrocarbon mixtures, and the production of hydrocarbons by addition of unsaturated hydrocarbons. It can solve problems such as increased production costs and achieve the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

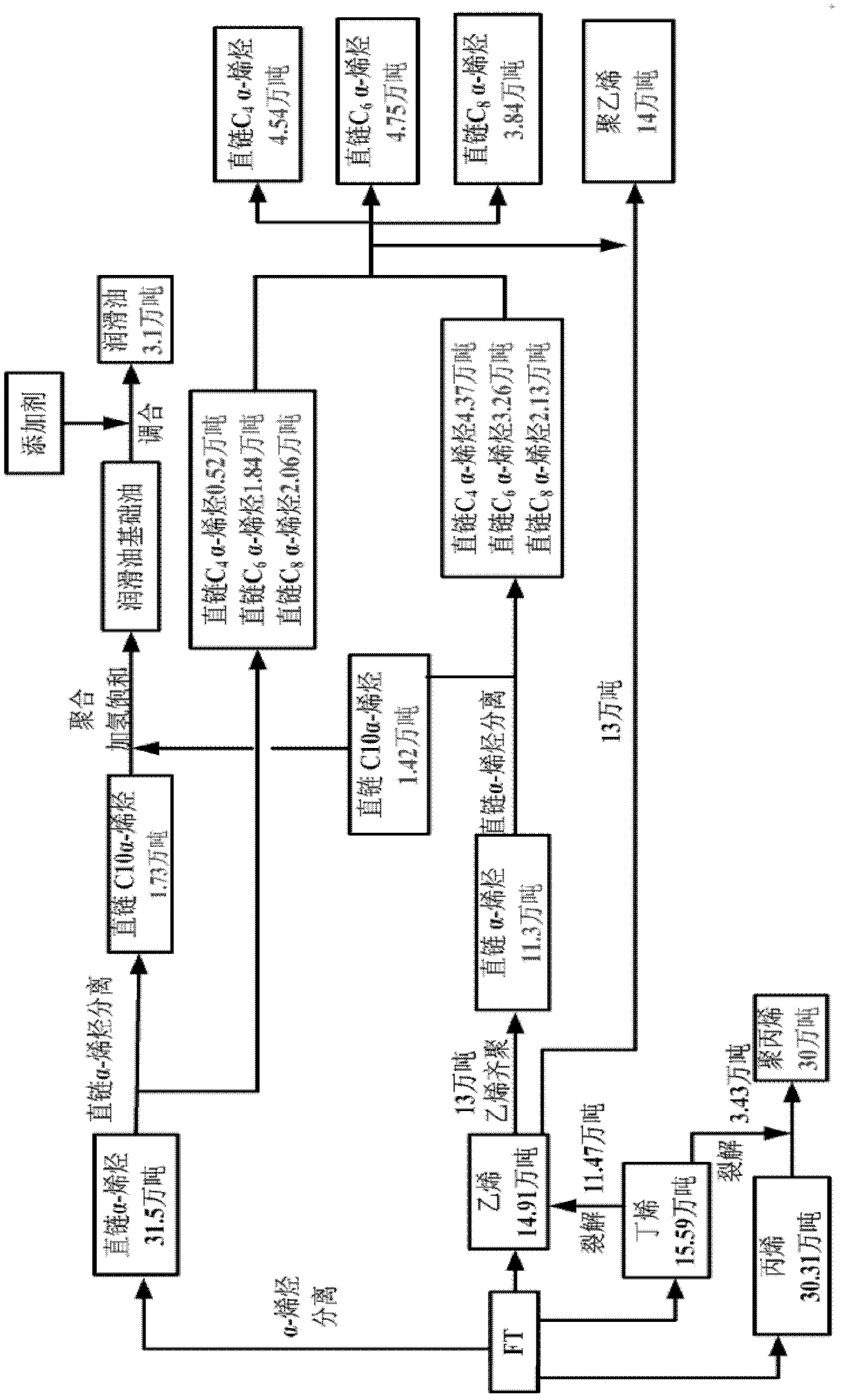

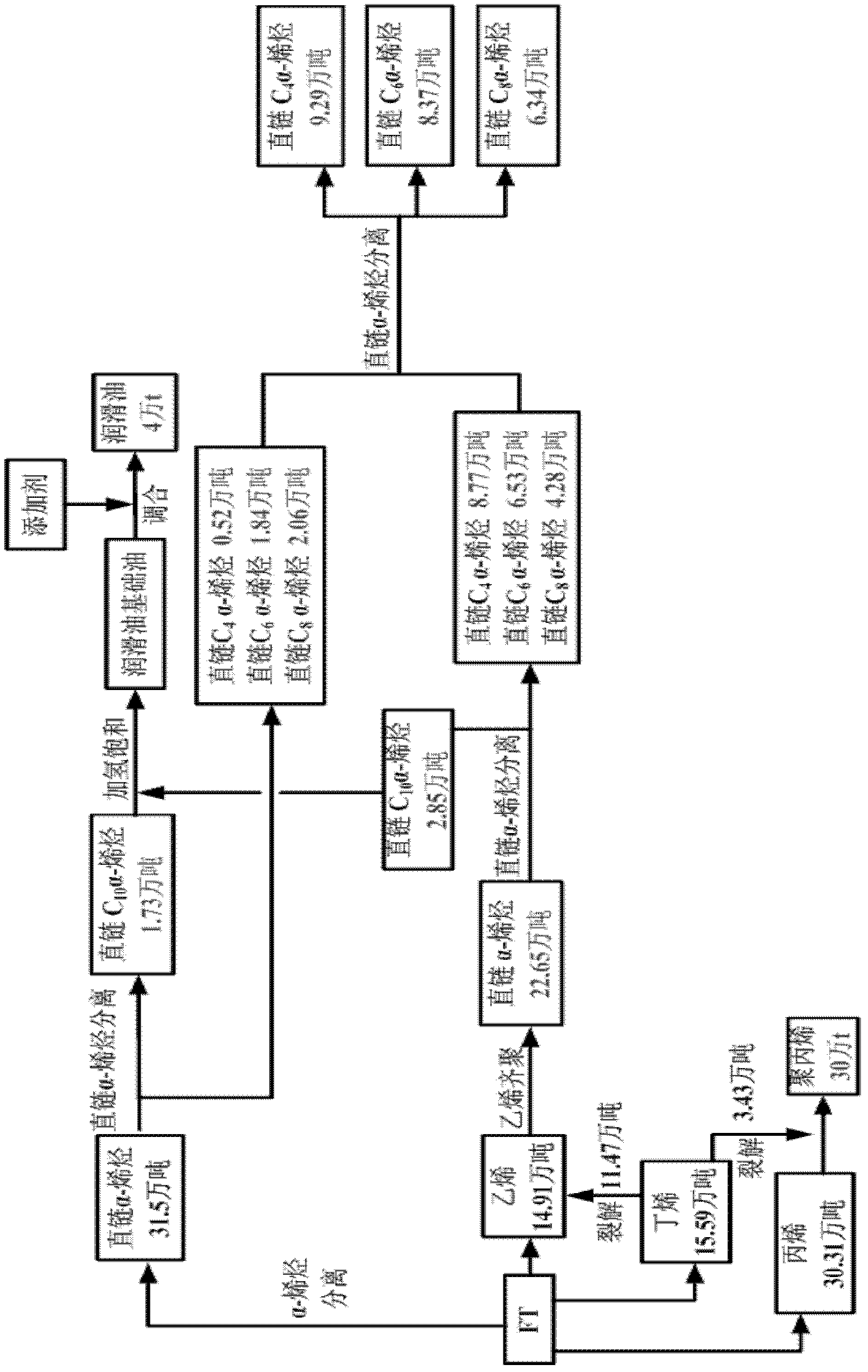

Embodiment 1

[0069] The following logistics analysis and economic analysis are based on the high and low temperature Fischer-Tropsch synthesis with an annual output of 5 million tons of oil products, and the combination of high and low temperature co-production in a 2:3 manner. The share of α-olefin in the total product is calculated as 40wt%. The proportions of ethylene, propylene and butene in the product are based on the data reported in the literature. The α-olefin separation efficiency in the process is 90%. The technical characterictic that does not mention in this embodiment adopts the technology routinely used in high-temperature Fischer-Tropsch synthesis and low-temperature Fischer-Tropsch synthesis, and conditions such as catalyst, temperature of reaction, pressure are conventional technology etc., and it changes within a certain range to the present invention There is no influence on the process effect, which is not described one by one in this embodiment.

[0070] For the spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com