Patents

Literature

192results about How to "Less fixed investment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for promoting sludge to be reduced by ozone

InactiveCN101708937ASmall particle sizeLow mineralization rateSludge treatment by oxidationWaste based fuelBrickBiological filter

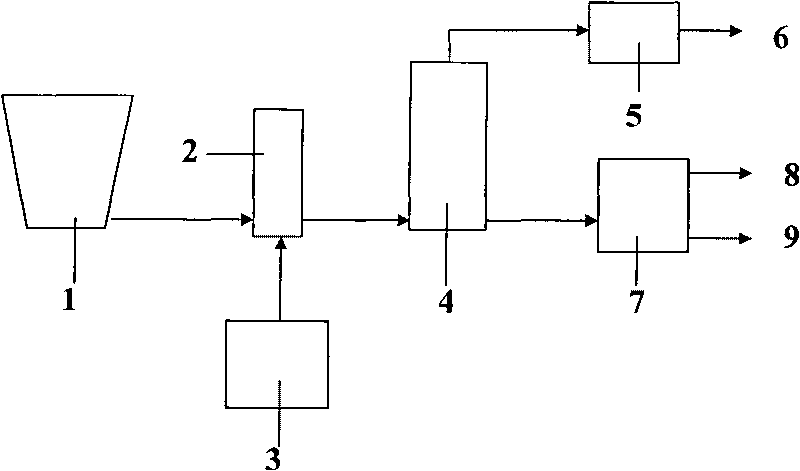

The invention relates to a method for promoting sludge to be reduced by ozone, in particular to a technology used for pretreating the sludge and accelerating anaerobic sludge digestion speed by utilizing ozone oxidation technique, which is widely applied to the sludge treatment technique of a sewage plant. The method comprises: the residual sludge of the sewage plant is concentrated and then treated by a sludge pretreatment reactor; due to the strong oxidizing property of ozone, the cell wall and the cell membrane of microorganism inside the sludge are broken, and a great deal of organic matter is released out of cells; after being treated by the ozone, the sludge enters into an anaerobic digestion reactor, and anaerobic digestion can be carried out in a closed anaerobic state; gas generated by digestion is treated by a gas purifying device, and methane can be obtained; after anaerobic digestion, the sludge is treated by flocculation and dehydration, and dewatering sludge can be obtained; then, final treatment can be carried out, for example, the sludge can be used for manufacturing agricultural fertilizer, bricks, porcelain granules or auxiliary fuel of fire coal; and anaerobic supernate is treated by biological filtering bed technique, so that the organic matter, ammonia and nitrogen in the solution can be removed.

Owner:NANJING UNIV OF TECH

Bioorganic fertilizer and its production process

A bioorganic fertilizer is produced with cake dregs, farm animal excrement and stalk and straw as raw materials and through fermentation with the solid bacteria strain cultured by using lichen bacillus and subtilis bacillus, drying in air or stoving after being throughly decomposed, and crushing. During fermentation, the C / N ratio is controlled at 15-26, organic material water content is controlled at 38-52 % and microbe fermentation temperature is 50-70 deg.C. The present invention has wide material source, low cost and simple production process, and applying the fertilizer can raise the yield and quality of crops, improve physical and chemical characteristics of soil, reduce environmental pollution and shorten the growth period of crops.

Owner:YUEYANG HUAWEI COTTON PROD DEV

Novel supercritical carbon dioxide coal-fired boiler

ActiveCN104728823AShorten the lengthIncrease temperatureCombustion processIndirect carbon-dioxide mitigationAir preheaterGas cooler

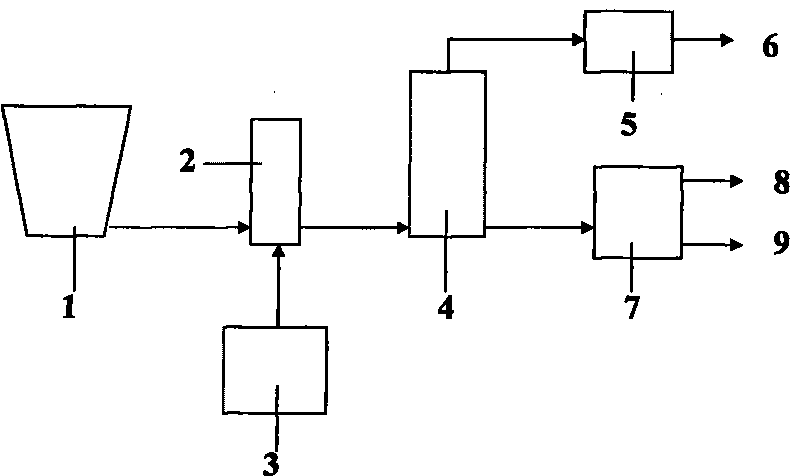

The invention discloses a novel supercritical carbon dioxide coal-fired boiler. The novel supercritical carbon dioxide coal-fired boiler comprises a horizontally arranged hearth, a wall-attached radiation cooling heating surface system, a superheater and reheater system, smoke gas coolers and air preheaters, wherein the wall-attached radiation cooling heating surface system is arranged in the hearth in a graded and segmented mode, the superheater and reheater system is arranged in a horizontal flue in a graded mode, and the smoke gas coolers and the air preheaters are arranged in a tail flue in a graded and flow-dividing mode. The wall-attached radiation cooling heating surface system greatly reduces the length of a high-temperature working medium pipeline, and reduces the number of needed high-temperature convection heating surfaces and high-temperature alloy pipelines, thereby reducing fixed investment of equipment. The superheater and reheater system combines with turbines which are arranged in a multi-stage and multi-axis mode, so the air inlet temperature and the turbine efficiency of the turbine of each grade can be improved. The tail flue comprises an upper-grade smoke gas coal economizer and a lower-grade smoke gas coal economizer which are used for heating a new working medium to meet requirements of an inlet of a primary wall-attached radiation cooling heating surface of the boiler, and the upper-grade air preheater and the lower-grade air preheater are used for heating combustion air, so that the special requirements for hearth combustion and heat transfer of the supercritical working medium circulation are met.

Owner:XIAN THERMAL POWER RES INST CO LTD

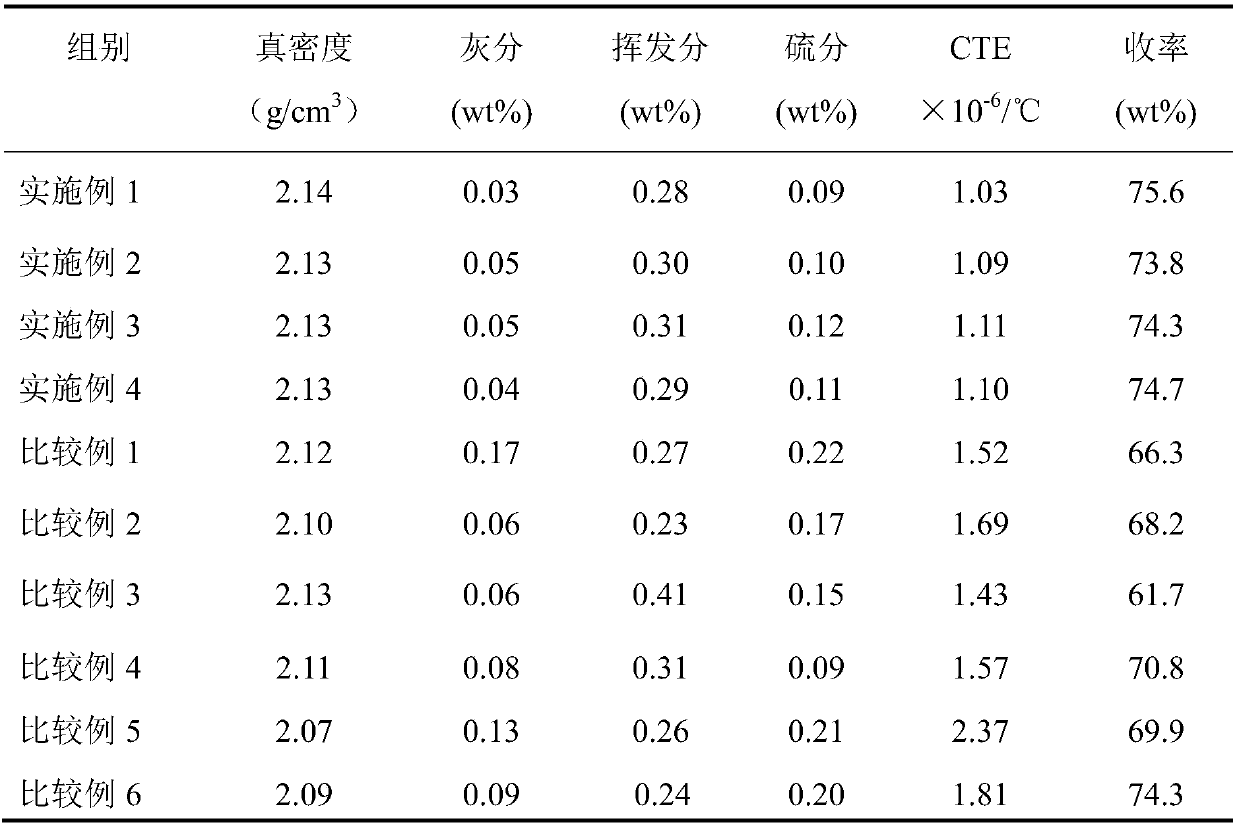

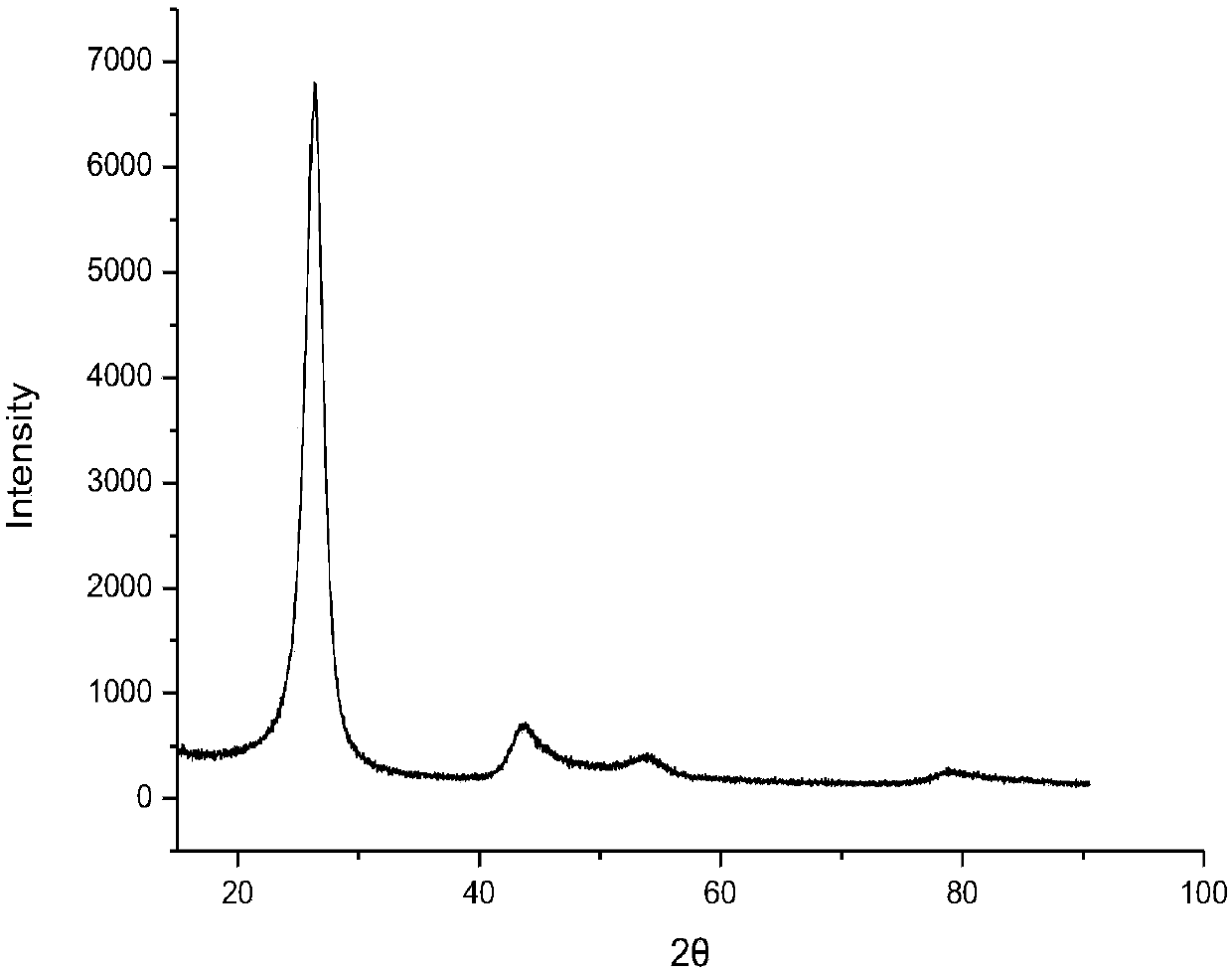

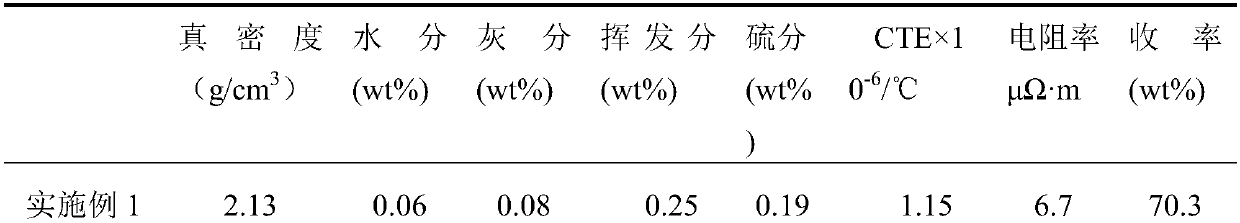

Technology for producing coal-series needle coke by taking middle-temperature and low-temperature coal tar asphalt as raw material

ActiveCN107694552AGood qualityHigh yieldWorking-up pitch/asphalt/bitumen by selective extractionPhysical/chemical process catalystsPre treatmentWide area

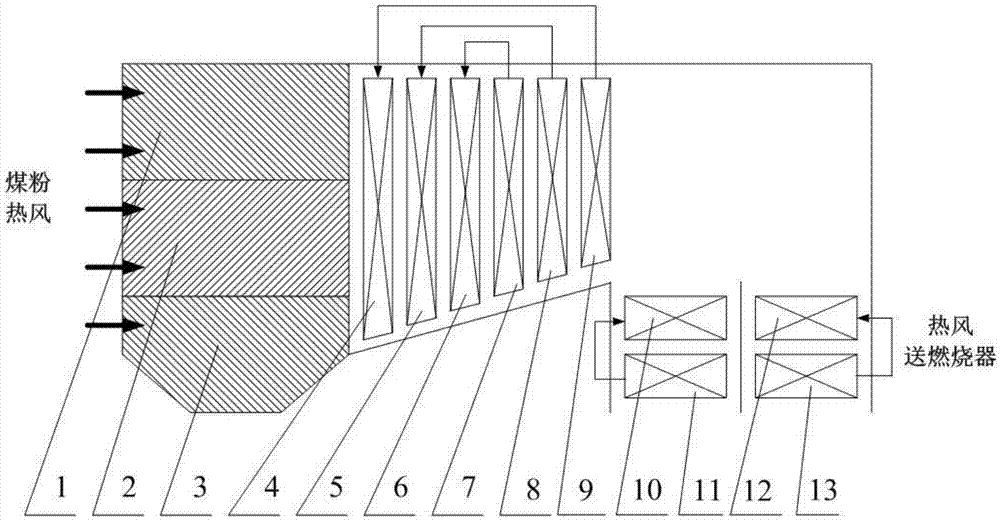

The invention relates to a technology for producing coal-series needle coke by taking middle-temperature and low-temperature coal tar asphalt as a raw material. The technology mainly comprises the following steps: carrying out decompression and distillation, and extraction and removal on middle-temperature and low-temperature coal tar; combining hydrogenation treatment, thermal polymerization andcalcining technologies under the action of a non-metal homogeneous mild-hydrogenation catalyst to prepare the coal-series needle coke with good performance and relatively high yield. The non-metal homogeneous mild-hydrogenation catalyst is mainly prepared from the following raw materials in percentage by mass: 55 weight percent to 79 weight percent of semi-coke, 20 weight percent to 40 weight percent of coke and 1 weight percent to 5 weight percent of graphene. According to the technology provided by the invention, after the raw material is subjected to combined pre-treatment, a refined asphalt raw material is reasonable in constitution and has a few of impurities; the catalyst has excellent modification performance and does not need to be separated subsequently; the graphene component also can be used for promoting a middle phase in a thermal polymerization process to form a wide-area and ordered fibrous structure and a high-performance needle coke product is easy to form.

Owner:NORTHWEST UNIV +1

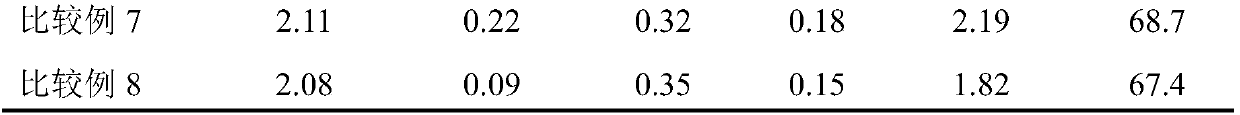

Method for producing coal gas by staged gasification of pulverized coal

InactiveCN102277200AAchieve desulfurizationAdaptableGranular/pulverulent flues gasificationCycloneSuperheated steam

The invention relates to a method for producing coal gas by staged gasification of pulverized coal. The steps are as follows: the pulverized coal fed into the furnace is mixed with rapidly fluidized high-temperature particles and gasification gas in a fluidized bed, and the pulverized coal of small and medium particles flows upwards. Pyrolysis at a high temperature of 900-1000°C, enter the cyclone separator through the gas-solid mixing pipeline for separation, the medium particles return to the lower part of the main body of the circulating fluidized bed through the first-stage feeder, and the gas carries small particles out of the upper port of the cyclone separator, and passes through the high temperature The gas pipeline enters the superheated steam heat exchanger for heat exchange and separation, and then enters the circulation separator, and the gas is discharged from the gas outlet for users. The invention has the characteristics of integrated circulating fluidized bed and entrained flow bed, high gasification intensity, flexible adjustment of production load, stable and reliable operation, high operation rate, reduced gas production cost, and no phenolic water pollution.

Owner:舒克孝

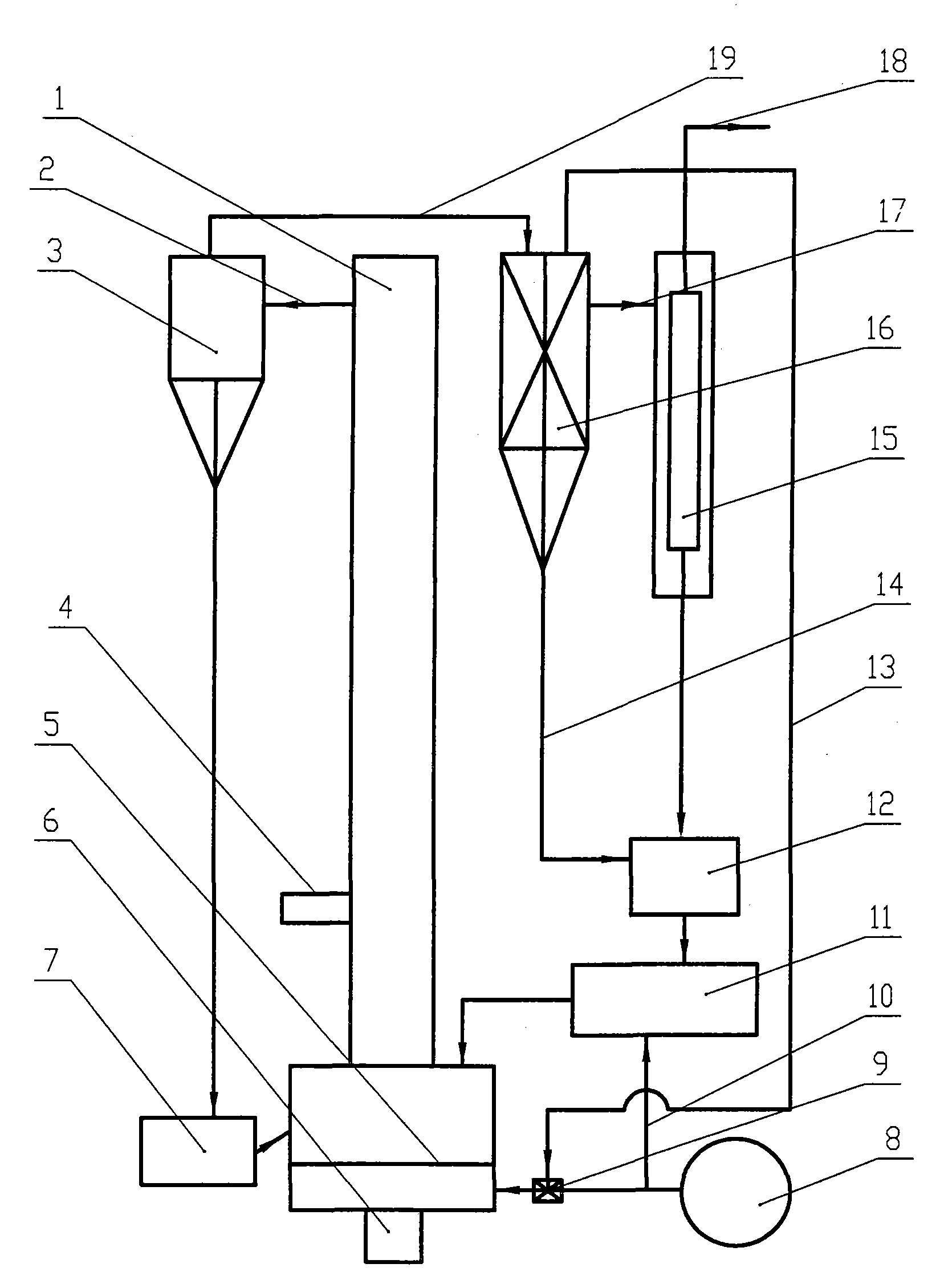

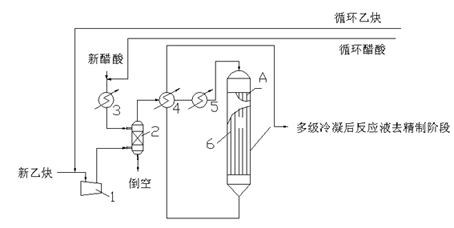

Novel method for synthetizing vinyl acetate by calcium carbide acetylene method

InactiveCN101928217AReduce generationGuaranteed circulation volumeOrganic compound preparationCarboxylic acid esters preparationFixed bedCarvacryl acetate

The invention relates to a novel method for synthetizing vinyl acetate by a calcium carbide acetylene method, which is characterized in that synthetic reaction is carried out on acetylene gas produced by adopting calcium carbide and acetic acid in a tube array type fixed bed reactor. The novel method is realized by utilizing a fixed bed technology in a process for synthetizing the vinyl acetate by the calcium carbide acetylene method, and especially, acetic acid simultaneously enters a gas-liquid mixed evaporator under the action of the acetylene gas after being preheated by changing an acetic acid feed mode into a gas-liquid mixed feed mode, and then enters the reactor through a second preheater and a third preheater, and the gas mixture passes through an inert heat transfer filler and then passes though a corresponding catalyst to be synthetized into the vinyl acetate. By adopting the mode, the novel method can reduce reaction byproducts and has the advantages of easy separation, raw material use ration improvement, production cost reduction, conversion rate improvement, small investment, high product purity, high quality and low impurity content.

Owner:国能英力特能源化工集团股份有限公司

Process for producing needle coke from compounded and blended components such as washing oil, anthracene oil and asphalt in medium and low temperature coal tar as raw materials

InactiveCN107868671AEasy to handleStrong targetingCoking carbonaceous materialsTar working-up by solvent extractionCarbolineumCalcination

The invention provides a process for producing needle coke from compounded and blended components such as washing oil, anthracene oil and asphalt in medium and low temperature coal tar as raw materials. The process comprises the steps as follows: raw material pretreatment of the medium and low temperature coal tar, fraction cutting of the components such as the washing oil, the anthracene oil andthe asphalt in the medium and low temperature coal tar, blending of the compounding raw materials, and preparation of the needle coke with thermal polymerization and calcination processes. The ideal raw materials for the needle coke are prepared from fractions of the coal tar by compounding and blending, formation of a wide-area ordered fibrous structure from an intermediate phase can be greatly promoted in a thermal polymerization process by means of reasonable raw material components, and a needle coke product with excellent performance is obtained after calcination.

Owner:SHAANXI YULIN ENERGY GRP CO LTD +1

Liquid-liquid phase-change absorbent for capturing carbon dioxide and application of such absorbent

InactiveCN110052117AAchieve enrichmentReduce total fluid volumeDispersed particle separationAir quality improvementFluid phaseEnvironmental engineering

The invention provides a liquid-liquid phase-change absorbent for capturing carbon dioxide and application of such absorbent. The liquid-liquid phase-change absorbent for capturing the carbon dioxidecomprises, by mass, 20%-60% of synergist, 10%-50% of organic amine, 0%-5% of auxiliary agent and the balance water. The liquid-liquid phase-change absorbent for capturing the carbon dioxide has the advantages that the liquid-liquid phase-change absorbent can be automatically layered into liquid-liquid phases when loading a certain amount of CO2 in the absence of energy consumption, wherein CO2 gathers in a rich phase layer, and a lean phase layer hardly loads CO2, so that CO2 can be effectively concentrated in the rich phase, the total amount of liquid entering a regenerating column is decreased through desorption of the CO2 rich phase, and energy consumption for regeneration and capture cost are reduced.

Owner:HUANENG POWER INT INC +1

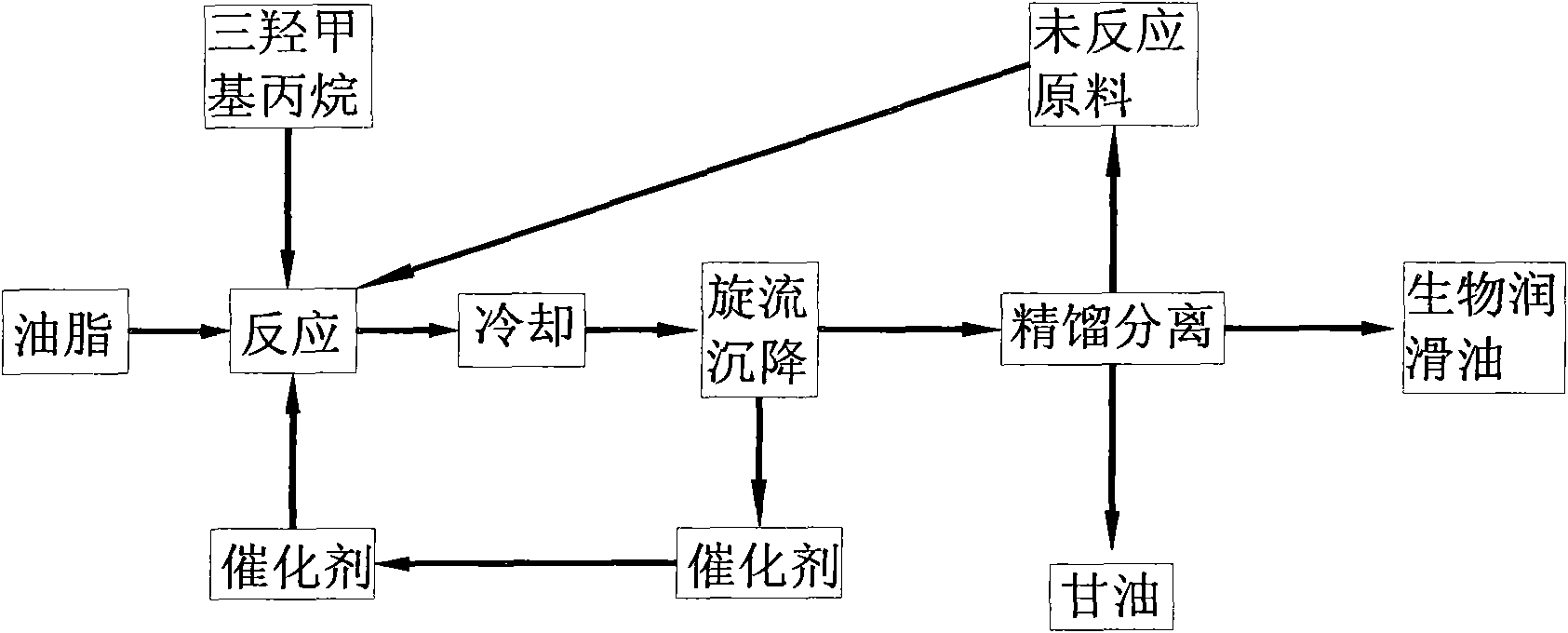

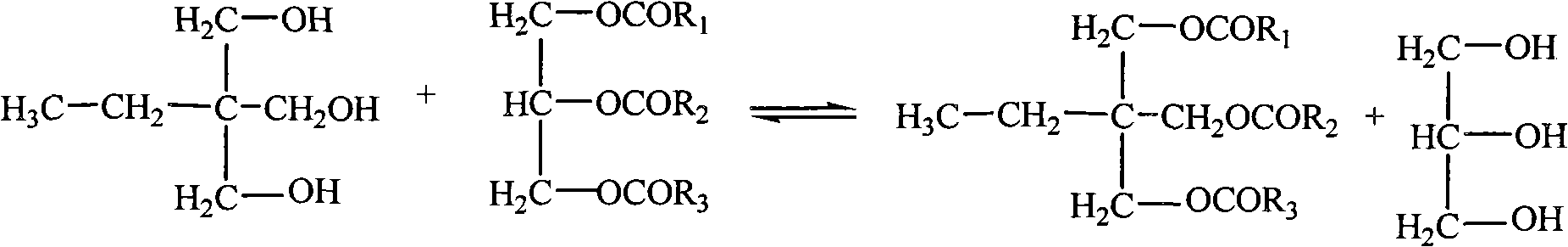

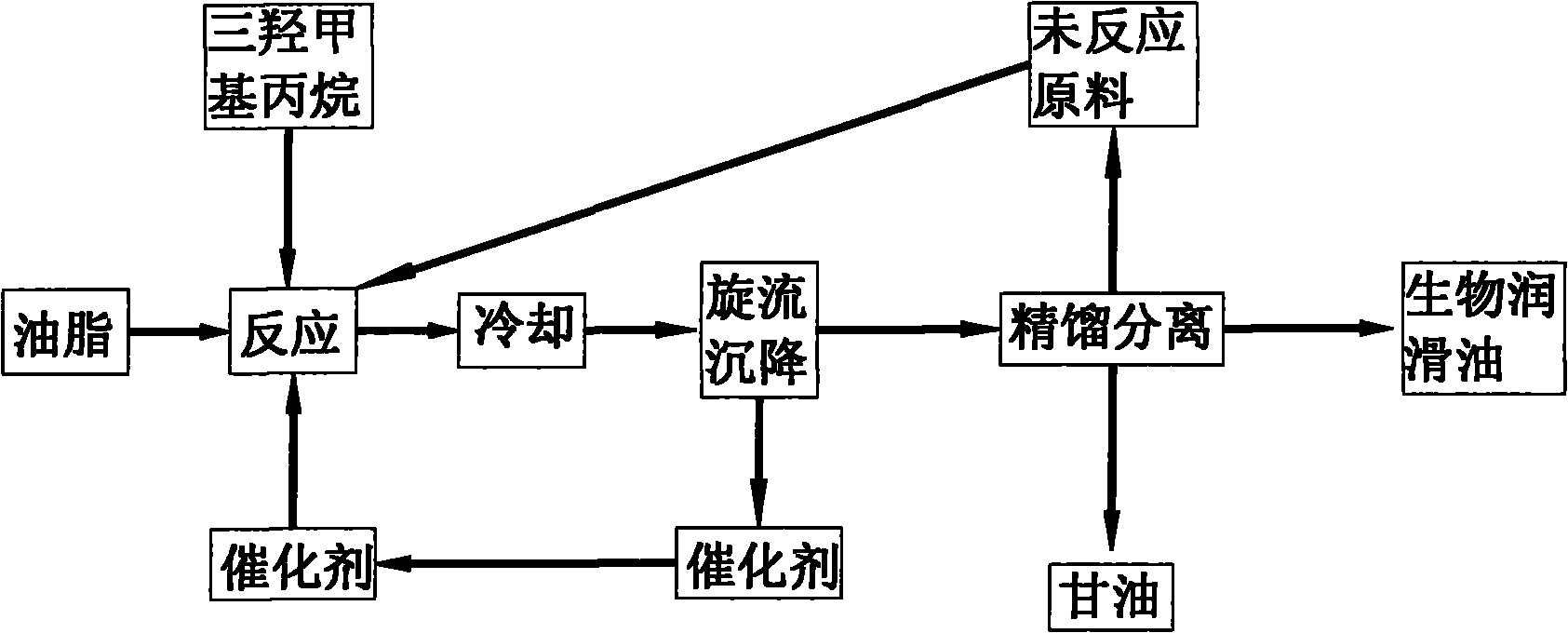

Biological lubricant prepared with ionic liquid as catalyst and preparation method

InactiveCN101955849AStable supplyWide variety of sourcesFatty acid esterificationBase-materialsOil and greaseVegetable oil

The invention discloses a biological lubricant prepared with ionic liquid as a catalyst and a preparation method. The preparation method specifically comprises the following steps: (1) mixing vegetable oil and trimethylolpropane in a weight ratio of 1-3:1 and then adding the B acid ionic liquid accounting for 0.5-1.5% of the above two raw materials by weight as the catalyst; (2) heating the above materials to 120-180 DEG C and stirring the materials to react for 4-8h; (3) rapidly cooling the materials after reaction to 30-50 DEG C, carrying out hydrocyclone settlement, cooling the B acid ionic liquid to solid, the solid settling at the bottom of a hydrocyclone tank after hydrocyclone settlement and the product and the materials which do not fully react being still liquid; and (4) distilling the product and the materials which do not fully react in a rectifying column, thus obtaining the biological lubricant at the bottom of the rectifying column. The biological lubricant has good biodegradability, good quality, low toxicity, good oxidation resistance and heat stability and lower cost as the intermediate products can be recycled.

Owner:SOUTH CHINA UNIV OF TECH

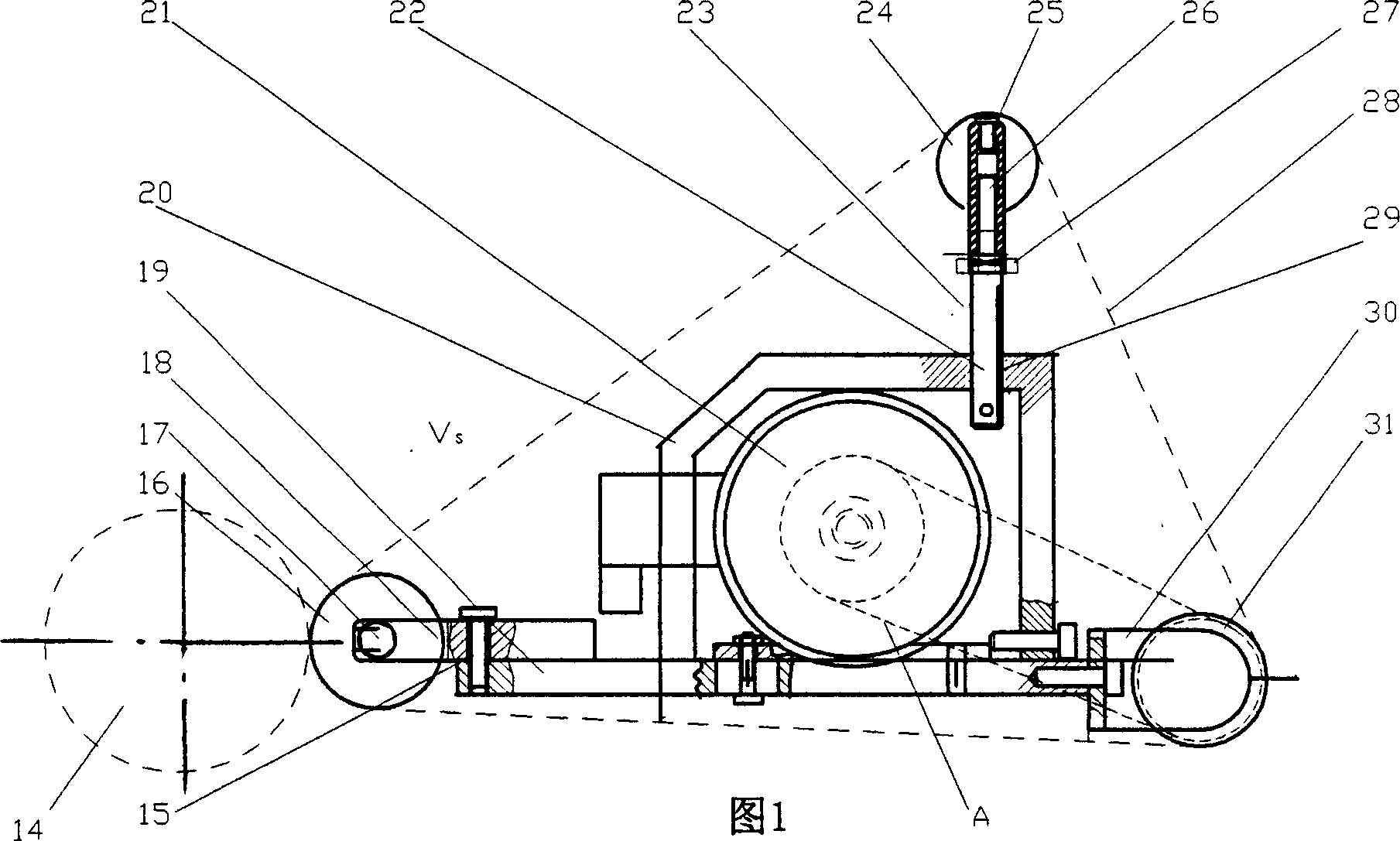

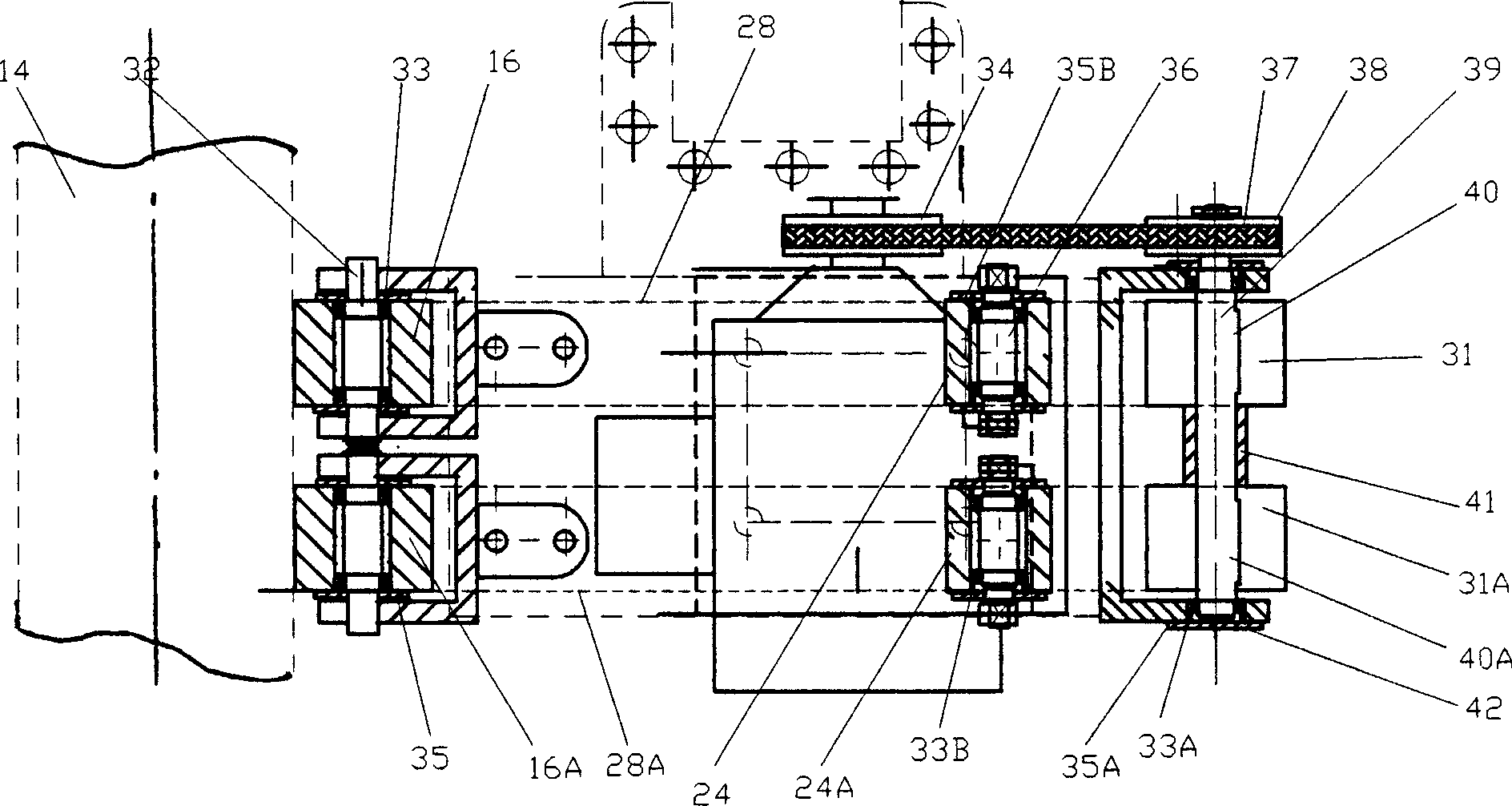

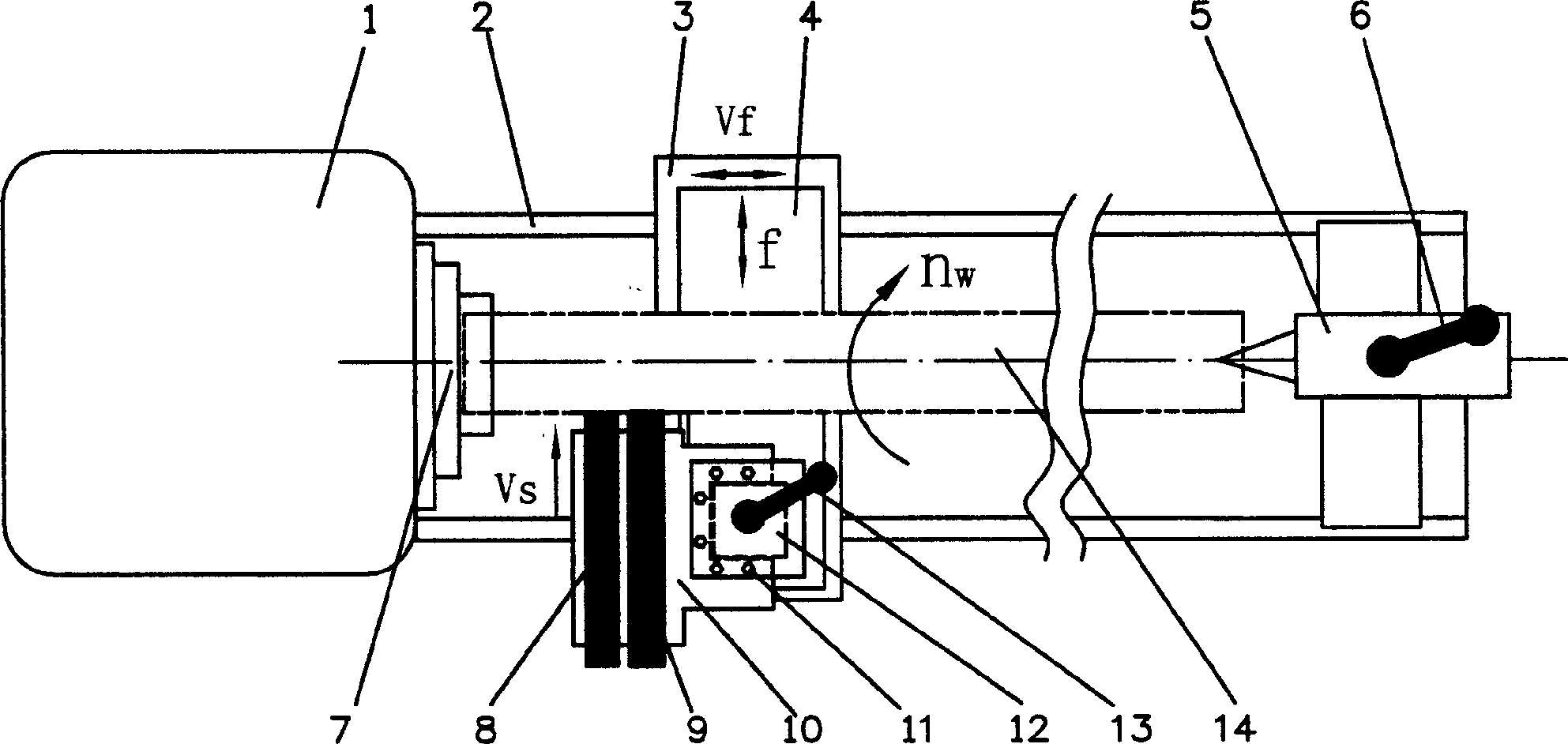

High performance mirror polish equipment with double grinding heads and technique method of mirror polish

InactiveCN1562565ALess fixed investmentEasy to replace and adjustBelt grinding machinesEngineeringCutting fluid

Owner:GUANGDONG IND TECHN COLLEGE

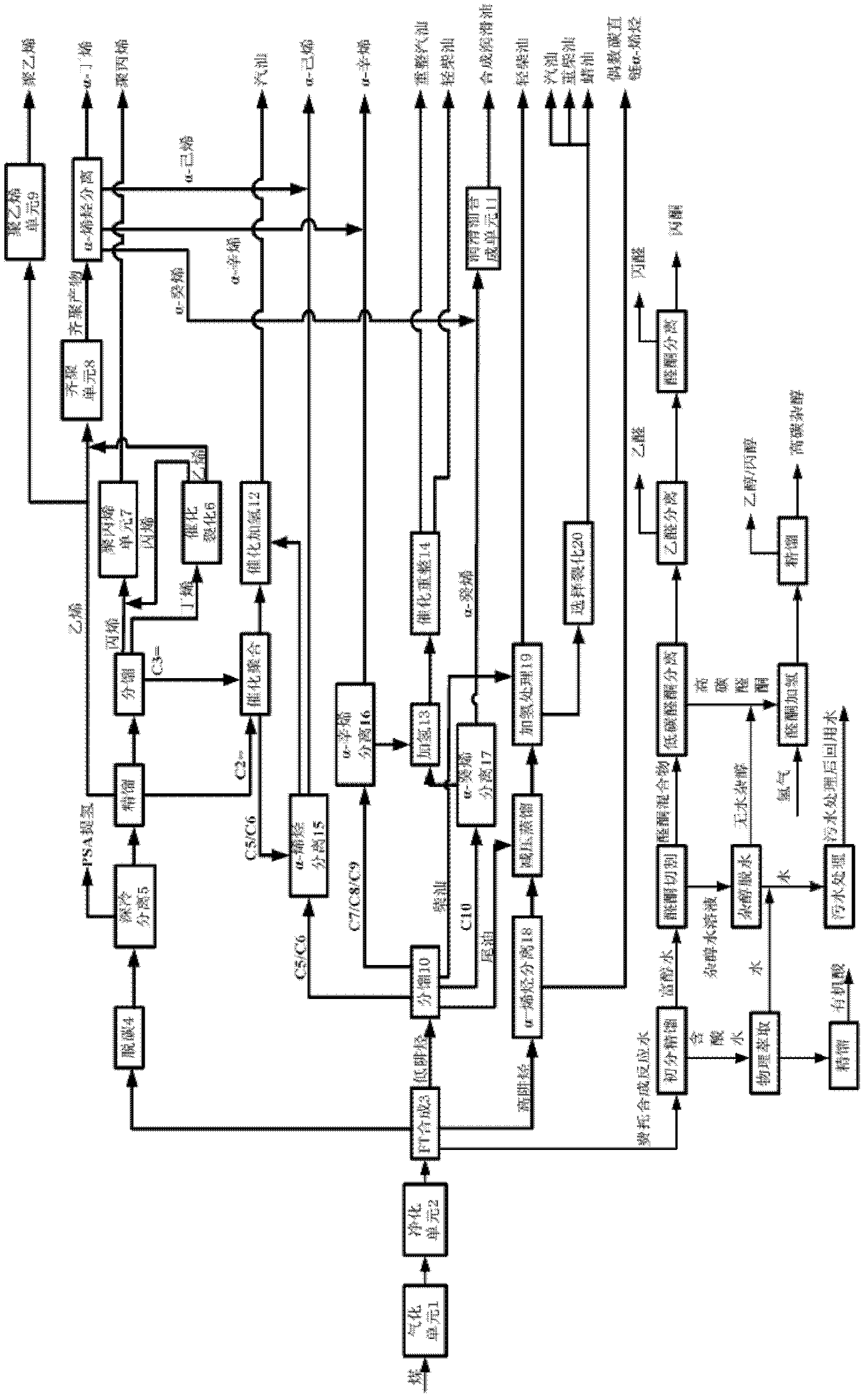

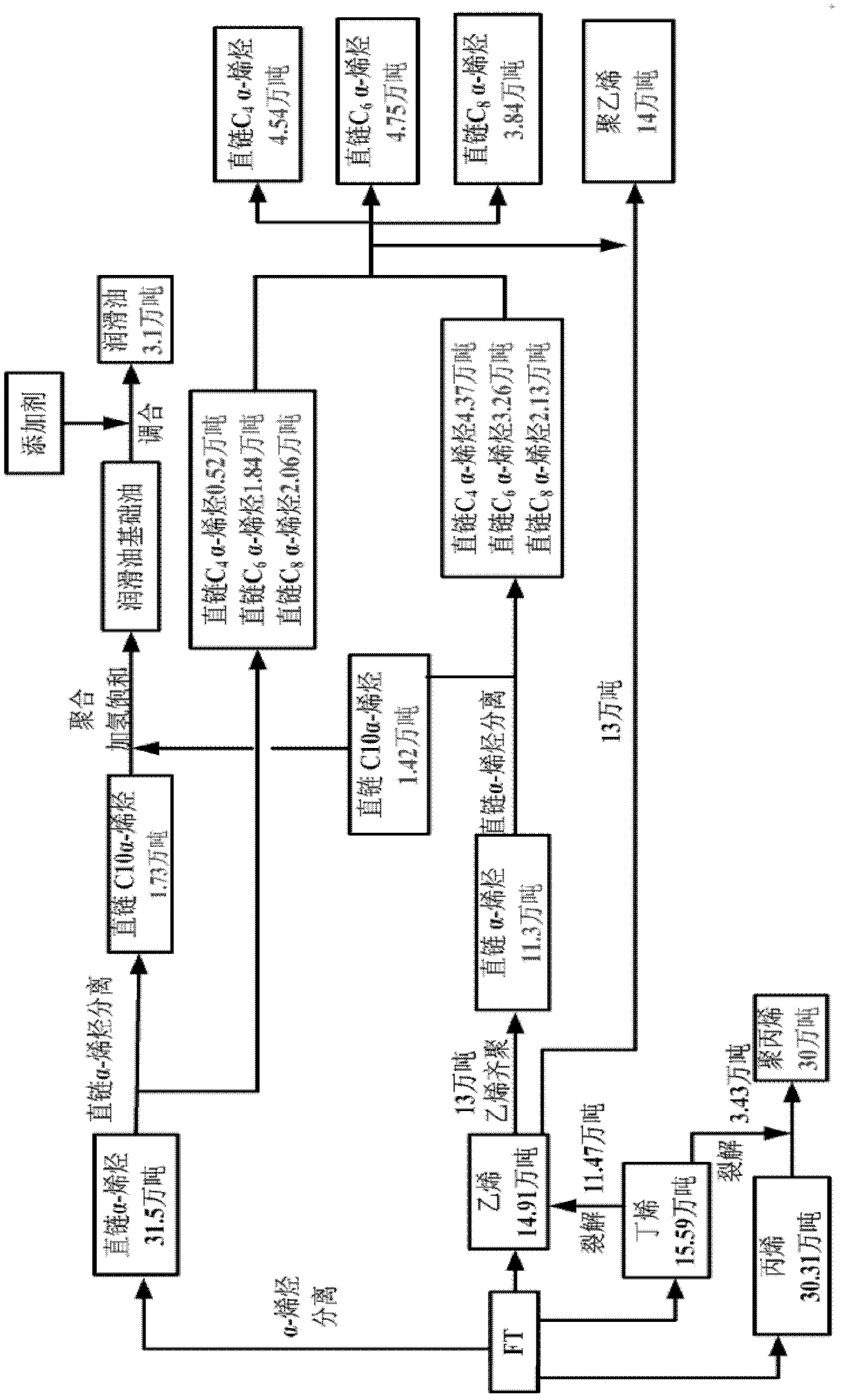

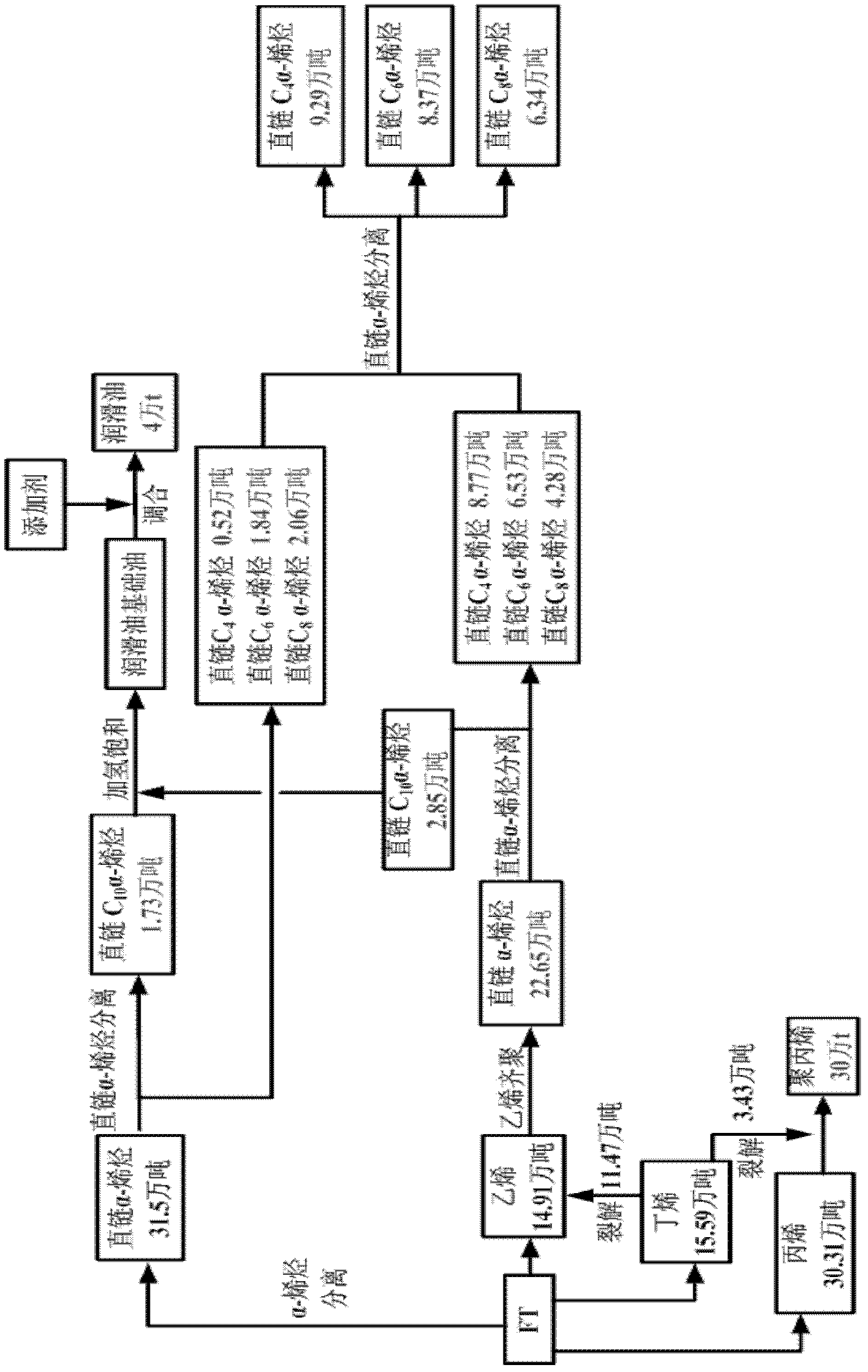

High and low-temperature Fischer-Tropsch synthesis co-production technology

ActiveCN102604677AImprove balanceIncrease added valueHydrocarbon from carbon oxidesHydrocarbons from unsaturated hydrocarbon additionDownstream processingChemical products

The invention relates to a high and low-temperature Fischer-Tropsch synthesis co-production technology which is characterized in that the high-temperature Fischer-Tropsch synthesis technology and the low-temperature Fischer-Tropsch synthesis technology are coupled; a coal gasifying and purifying unit is adopted to produce synthetic gases; the purified synthetic gases (CO+H2) enter a high-temperature Fischer-Tropsch synthesis unit and a low-temperature Fischer-Tropsch synthesis unit at different ratios of CO to H2 respectively; and the crude products obtained by the high-temperature Fischer-Tropsch synthesis unit and the low-temperature Fischer-Tropsch synthesis unit form a mixture flow which enters the subsequent oils deep-processing unit and hydrocarbon gas downstream processing unit according to the characteristics of different crude products to produce gasoline, diesel oil, synthetic lubricating oil, polypropylene, polyethylene and high value-added alpha-olefin. The technology provided by the invention avoids the uncertainty of the oils market under the fluctuation of the international crude oil market, realizes balance of the oils income by use of the income of chemical products, and finally achieves the aim of enhancing the competitiveness of the Fischer-Tropsch synthesis oils.

Owner:TAIYUAN UNIV OF TECH

Clean production method of natural gas

InactiveCN105316053AEliminate potential safety hazardsLess fixed investmentGaseous fuelsNatural gasSewage

The invention discloses a clean production method of natural gas, which is composed of the following steps: (1) addition of an ice inhibitor: adding an ice inhibitor liquid or the ice inhibitor into natural gas or / and a natural gas flow channel so that the ice inhibitor liquid or the ice inhibitor is contacted or mixed with the natural gas or / and gas-phase water, liquid-phase water, ice or / and natural gas hydrates in the natural gas flow channel to form sewage containing the ice inhibitor; and (2) ventilation for water removal: evaporating the water in the ice inhibitor sewage in a ventilating manner and recycling the ice inhibitor liquid or the ice inhibitor from the ice inhibitor sewage. The method solves the problem of influence on natural gas exploitation and production due to natural hydrates or ice, can solve the problem of environment pollution and energy consumption during the natural gas exploitation and production, can eliminate safety risk in the natural gas exploitation and production, can reduce fixed investment, cost and energy consumption in the natural gas exploitation and production, is easy to carry out, is safe and reliable, is wide in application and is easy to popularize, and has significant economic benefit, environment protective benefit and safety benefit.

Owner:BEIJING UNITY BENEFICIAL TECH CO LTD

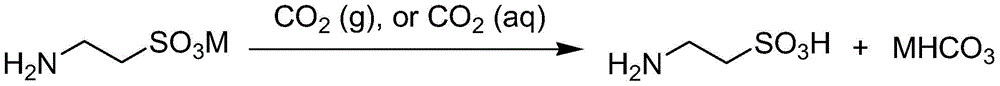

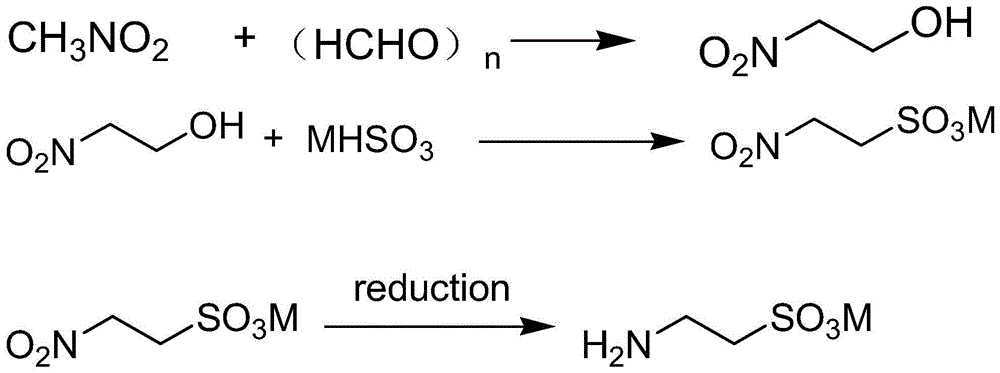

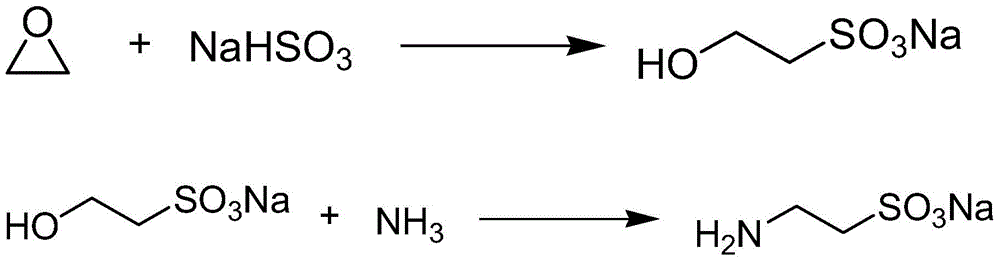

Method for preparing taurine and co-producing bicarbonate

ActiveCN105693559ASolve the dangerSolve the problems that need to be dealt withChemical industryAmmonium carbonates/bicarbonatesTaurineAlkali metal

The invention discloses a method for preparing taurine and co-producing bicarbonate. The method comprises the step of leading carbon dioxide gas or adding a carbon dioxide water solution to an amino ethyl sulfonate water solution of alkali metal or ammonium to regulate a pH value so as to obtain the taurine and the bicarbonate. The method can replace an existing taurine preparation method of using sulfuric acid or sulfur dioxide to regulate the pH value, meanwhile can treat boiler exhaust gas, turns the carbon dioxide in the exhaust gas into wealth, co-produces the bicarbonate and is a safe, environmentally-friendly and energy-saving method for producing the taurine and co-producing the bicarbonate.

Owner:HUBEI GRAND LIFE SCI & TECH CO LTD

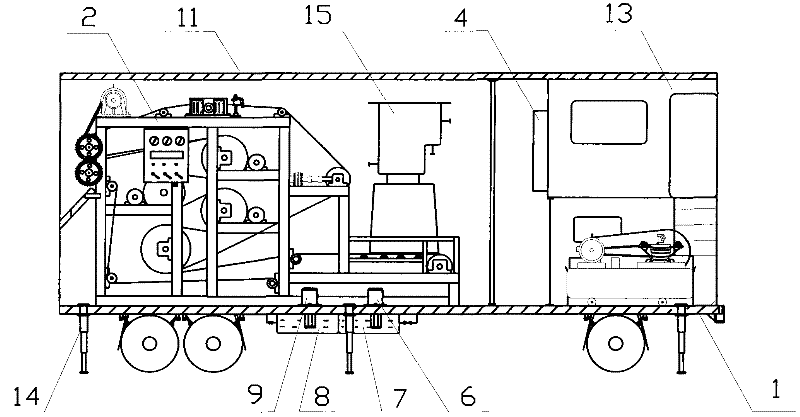

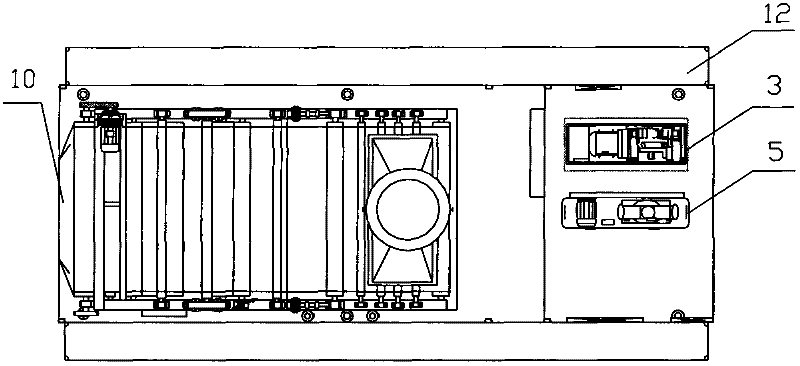

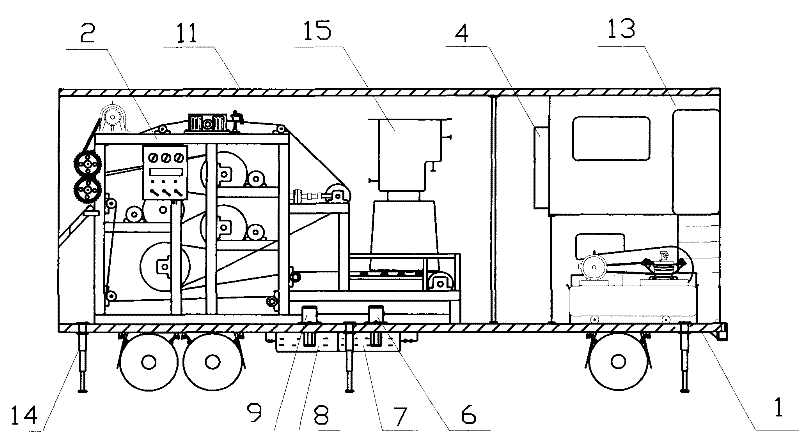

Vehicular integrated dewatering system

InactiveCN102602320AFully equippedMeet job requirementsItem transportation vehiclesFiltration circuitsReduction treatmentResource utilization

The invention relates to a vehicular integrated dewatering system, which comprises a bearing vehicle, dewatering equipment and auxiliary corollary equipment. The dewatering equipment and the auxiliary corollary equipment are mounted on the bearing vehicle and flexibly move along with the same. The dewatering equipment is used for material filter-pressing and dewatering operations on the bearing vehicle. The vehicular integrated dewatering system has the advantages that the integrated system is complete in function, wide in application and capable of flexibly moving to realize onsite dewatering quantity reduction treatment of scattered industrial and agriculture waste residue, waste residue transport cost is multiply reduced, the equipment can be used for waste residue treatment and collection of various waste residue discharge sources simultaneously, and vehicular integrated dewatering system can be used for dewatering waste residue in a fluid, semifluid and solid state without depending on external environment conditions and can be operated normally in various operational environments. Various scattered resources can be fully collected to create conditions for subsequent industrial, massive and recycling utilization, and social environmental protection can be promoted while resource utilization rate can be increased.

Owner:GUANGXI LIYUANBAO SCI & TECH

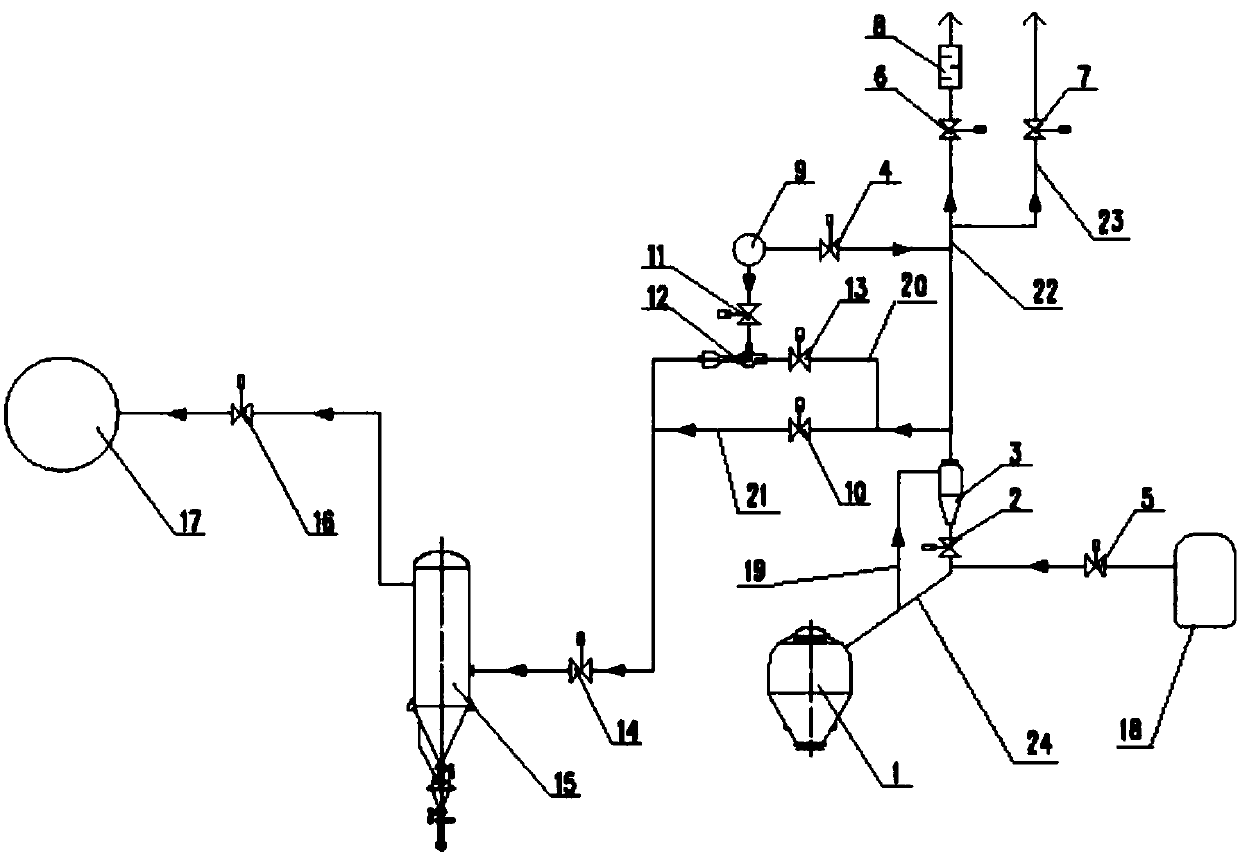

Complete recovery system and method for iso-pressure blow-off gas at blast furnace top

The invention discloses a complete recovery system for iso-pressure blow-off gas at blast furnace top. The complete recovery system comprises a furnace top charging bucket of a blast furnace, a cyclone dust collector, an ejector and a bag-type dust collector, wherein the furnace top charging bucket is communicated with the cyclone dust collector through a first pipe; an outlet of the first pipe iscommunicated with an inlet of a three-way joint; a first outlet of the three-way joint is communicated with a second pipe; the ejector and a forced recovery valve are arranged on the second pipe; anoutlet of the ejector is communicated with an inlet of the bag-type dust collector; an outlet of the bag-type dust collector is communicated with a purified gas pipe network; a natural recovery valveis arranged on a third pipe, and an outlet of the third pipe is communicated with an inlet valve of the bag-type dust collector; a second outlet of the three-way joint is communicated with a fourth pipe. The invention further discloses a complete recovery method for the iso-pressure blow-off gas at the blast furnace top. The complete recovery system and method for the iso-pressure blow-off gas atthe blast furnace top have the following beneficial effects: two recovery measures are taken correspondingly according to the change of pressure in the furnace top charging bucket, environmental pollution and resource waste caused by direct blow-off of iso-pressure gas into the atmosphere are avoided, and the requirements for energy saving, emission reduction and environmental production are met.

Owner:WISDRI ENG & RES INC LTD

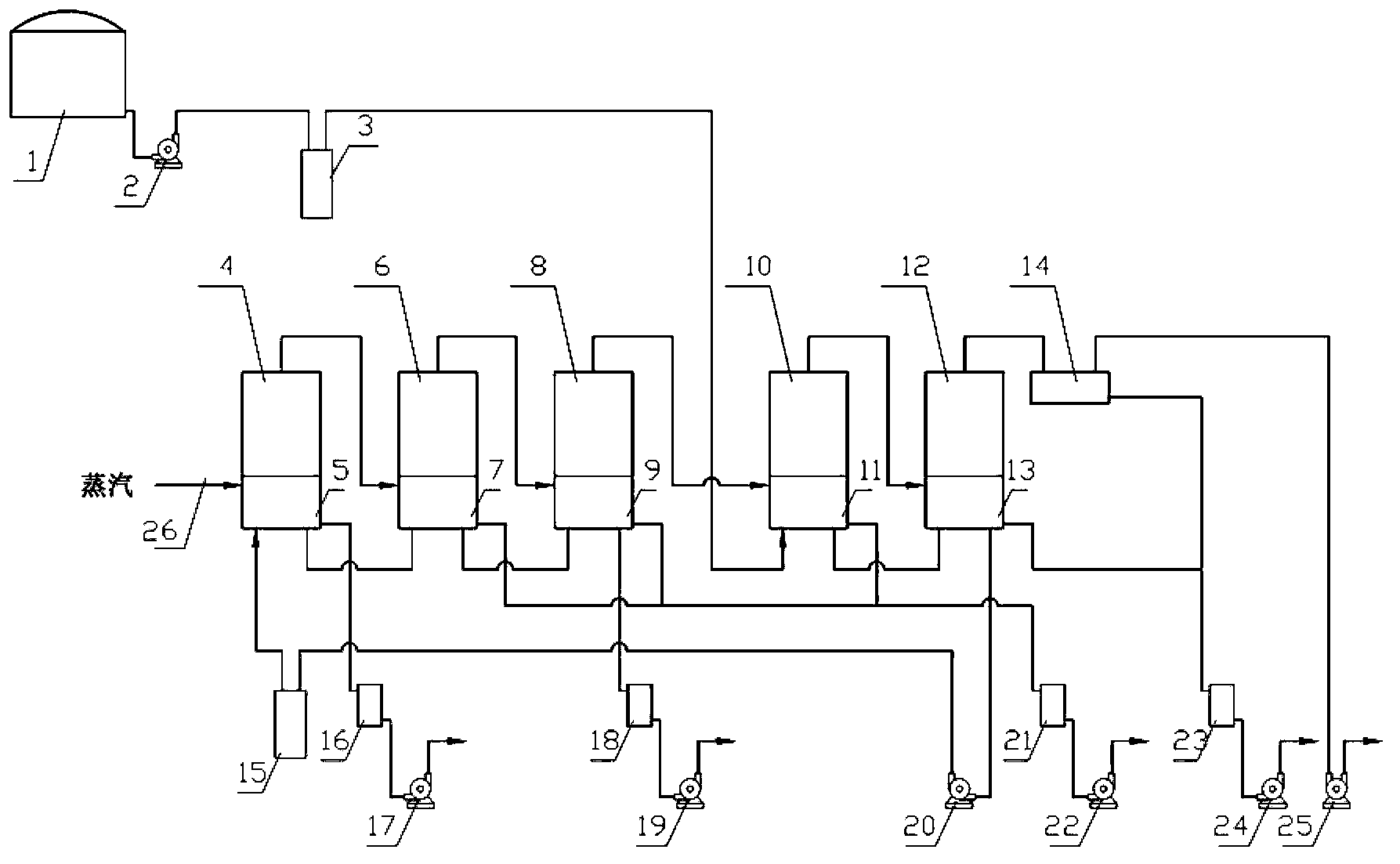

Molasses alcohol fermented mature mash multi-effect evaporation concentration integrated equipment and process

InactiveCN103394205ADifficult to solveLess fixed investmentMultiple-effect evaporationLiquid wasteAqueous alcohol

The invention discloses molasses alcohol fermented mature mash multi-effect evaporation concentration integrated equipment and process. The equipment comprises five effect evaporating pots, a separation chamber of the previous effect evaporating pot is communicated with a heating chamber of the next effect evaporating pot, and a mature mash pot is communicated with a heating chamber of the fourth effect evaporating pot; a heating chamber of the first effect evaporating pot is communicated with a condensing water collection pot, heating chambers of the second, third and fourth effect evaporating pots are communicated with a pure water collection pot, and a heating chamber of the fifth effect evaporating pot is communicated with an alcohol collection pot; a heating chamber of the third effect evaporating pot is communicated with a concentrated waste liquid collection pot. The molasses alcohol fermented mature mash multi-effect evaporation concentration integrated equipment has the advantages that a multi-effect differential pressure evaporation concentration system is used for replacing the alcohol separation extraction function of a mash tower, and can be used for concentrating residual waste liquid which can be used as boiler fuel after the residual waste liquid reaches a certain concentration, so that the fixed investment on equipment can be saved, energy consumption can be reduced, the production operation cost can be effectively reduced, and the problem of high difficulty in waste liquid treatment in molasses alcohol production process can be effectively solved.

Owner:NANNING KECHAO ALCOHOL TECH DEV

Method for treating heavy metal wastewater through electric flocculation-chemical precipitation

InactiveCN105060580ASimple equipmentLess fixed investmentMultistage water/sewage treatmentIonHeavy metals

The invention provides a method for treating heavy metal wastewater through electric flocculation-chemical precipitation. The method comprises the following steps: regulating the pH value of wastewater, performing electric flocculation treatment in an electric flocculation reactor for 30-60 min, adding a settling agent for sedimentation for 10-30 min and then discharging water. According to the method for treating heavy metal wastewater through electric flocculation-chemical precipitation, provided by the invention, heavy metal wastewater containing trace heavy metal ions is firstly subjected to electric flocculation, ions produced by electrolysis are hydrolyzed to produce a great deal of polyhydroxy compounds, the polyhydroxy compounds are subjected to reaction, absorption and chelation with trace heavy metal ions, therefore a large proportion of heavy metal ions can be gathered, and besides, the settling agent is added for further gathering the heavy metal ions, the settling agent has a synergistic effect with the electrochemical floccules, and at the same time the obtained flocculating constituents start to precipitate, finally, the obtained effluent can be enabled to meet the emission standard.

Owner:BEIJING JINGRUN NEW TECH DEV

Process and device for treating copper-lead smelting mixed slag through bottom-blowing bath smelting technology

InactiveCN103643051AWide applicabilityLess fixed investmentProcess efficiency improvementAutomatic controlLead smelting

The invention belongs to the technical field of smelting of copper-lead mixed smelting slag in the non-ferrous metal metallurgy industry, and in particular relates to a process and a device for producing two main products, namely crude copper and crude lead, in the treatment period of copper-lead mixed slag through a bottom-blowing bath smelting technology by using a single piece of equipment. The lead-copper mixed slag is treated through a one-step smelting furnace to produce the crude lead, the crude copper, waste slag and the like. The crude copper and the crude lead are produced as final system products. Iron-silicon-calcium slag is produced in the smelting process, and furnace slag which meets requirements of the waste slag can be comprehensively utilized as raw materials of a building material factory. The process is single in equipment, short in process route, high in heat utilization rate, friendly to smelting environment, easy to operate and high in labor productivity; the automatic process control is easily realized. The process and the device conform to a concept of circular economy and meet the development trend of the energy conservation and emission reduction industry.

Owner:HENAN YUGUANG GOLD & LEAD

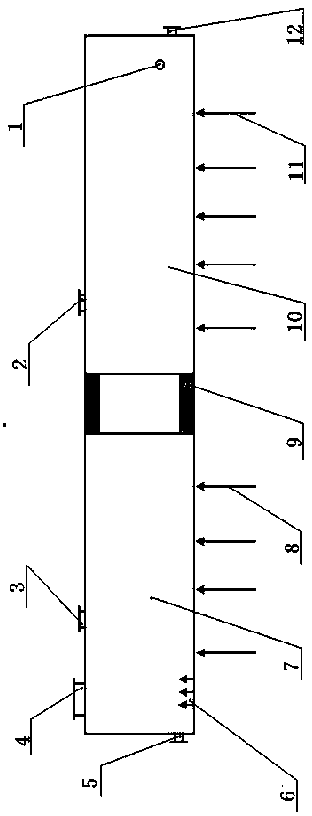

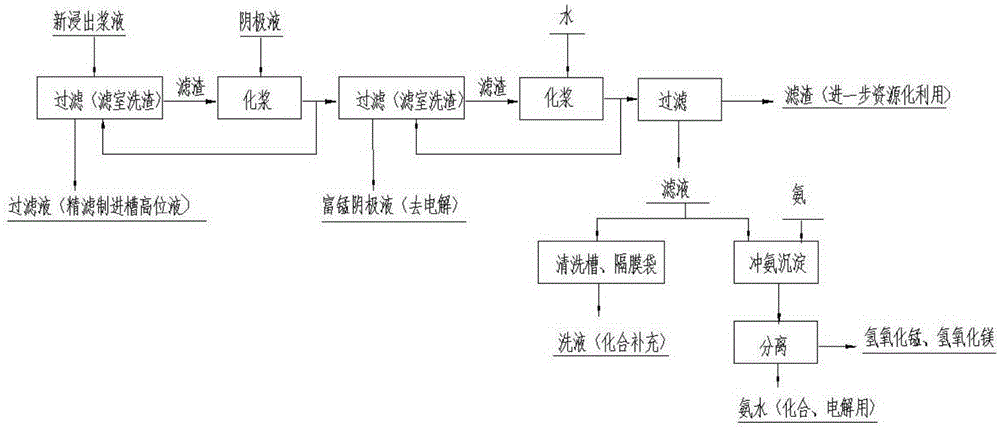

Method for comprehensively using water and manganese slag in electrolytic manganese production

ActiveCN105274580ALess fixed investmentLow running costElectrolysis componentsProcess efficiency improvementEnvironmental resistanceElectrolysis

The invention discloses a method for comprehensively using water and manganese slag in electrolytic manganese production. The method includes the steps that the manganese slag is subjected to slurry washing through catholytes and the water, and the manganese slag and filter liquor are respectively obtained and recycled; manganese of the manganese slag is firstly recycled, then ammonium salt and magnesium salt are recycled, and finally all the manganese slag can be used for building cement materials; and the water is firstly used for washing the manganese slag, then used for cleaning a bath and washing a membrane bag, and finally used as liquid making supplementary water and ammonia washing water, and full resource efficient use is achieved. According to the method, fixed input is low, recycling cost is low, quite high economic benefits and quite high environment-protection benefits are achieved, and the important effect is achieved on achieving high-standard clean production of the electrolytic manganese industry.

Owner:永州市鑫城锰业有限公司

Natural gas production method

ActiveCN102444396ARealize no heatingSimple production processFluid removalThermal insulationProcess engineering

The invention discloses a natural gas production method, which comprises following steps (1) a thermal insulation oil pipe is arranged in a gas well shaft sleeve or an oil pipe, and (2) natural gas is enabled to rise to a well opening through the thermal insulation oil pipe. When the natural production method is applied to natural gas production, natural energy can by fully used to produce natural gas, temperature of the well opening of the natural gas well can be remarkably improved, the problem that hydrate can affect production of natural gas is effectively resolved, production processes that natural gas is not heated and pressurized is achieved, heating of a heating furnace and pressurization concentration transportation of a compressor can be eliminated, and production cost and energy consumption of production of natural gas can be greatly reduced. The natural gas production method has the advantages of being easy to operate, safe, reliable and the like.

Owner:BEIJING UNITY BENEFICIAL TECH CO LTD

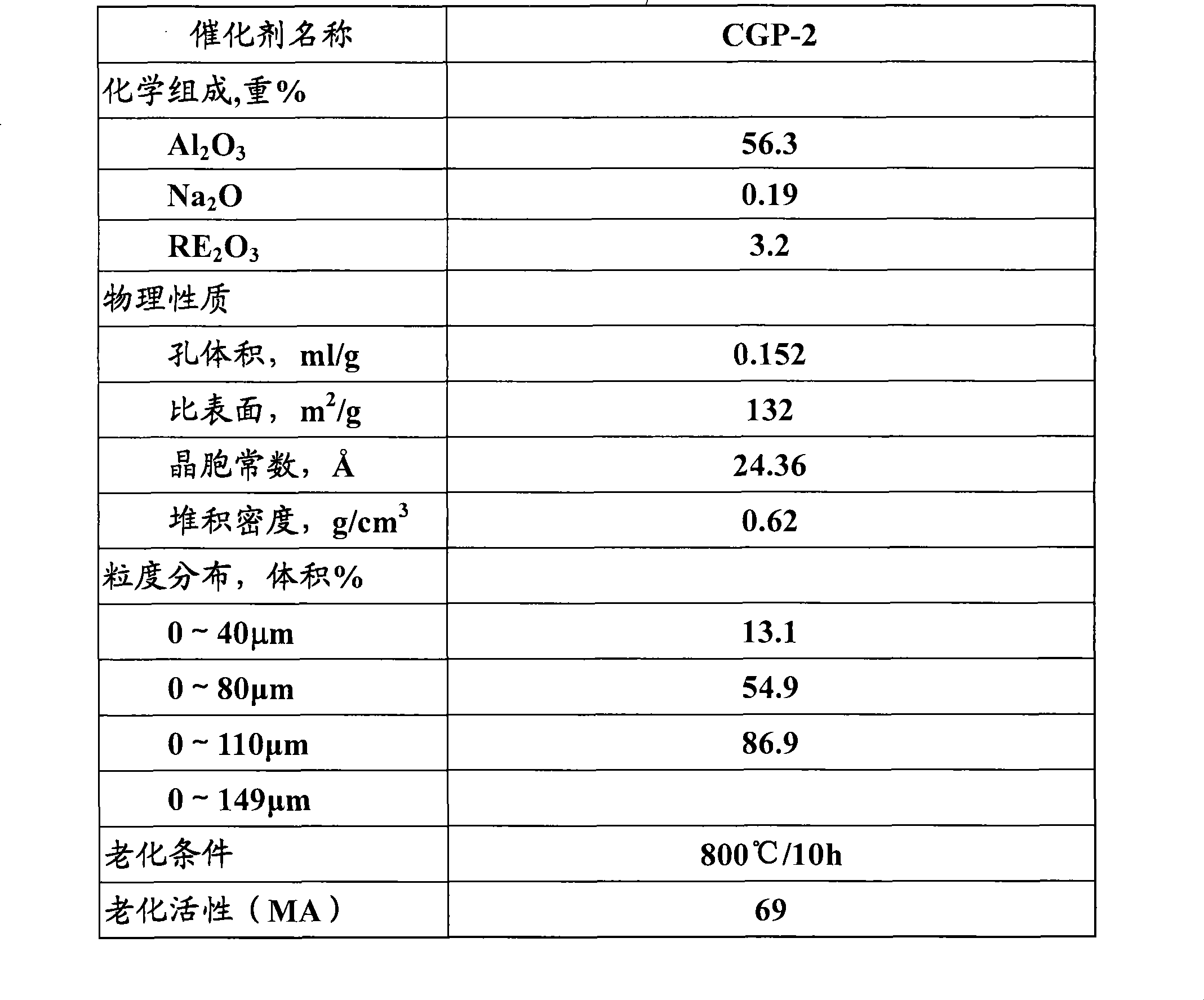

Method for improving propone output during catalytic conversion process

InactiveCN101456782AImpurity content no special requirementsMinor changesChemical recyclingBulk chemical productionLiquid productWater vapor

The invention relates to a method for improving the yield of propylene during catalytic conversion, which comprises: preheated raw oil enters a reactor which comprises two reaction zones; gaseous hydrocarbon which is rich in C4 fractions is injected into the bottom of a first reaction zone or / and the bottom of a second reaction zone, and contacts a hot cracking catalyst and reacts with the hot cracking catalyst in the presence of water vapor; reaction products and a spent catalyst are separated; the reaction products are further separated by a fractionating system into gaseous products which are rich in the propylene and the C4 fractions and liquid products such as gasoline, diesel fuel and so on; and the spent catalyst is subjected to steam stripping, enters a regenerator, and is burnt and recycled. The method can treat hydrocarbon fractions which are rich in the C4 and processed and produced by different technical skills, and produce miacromolecular olefin and particularly the propylene on the premise of not influencing the prior product distribution of catalytic conversion technology.

Owner:CHINA PETROLEUM & CHEM CORP +1

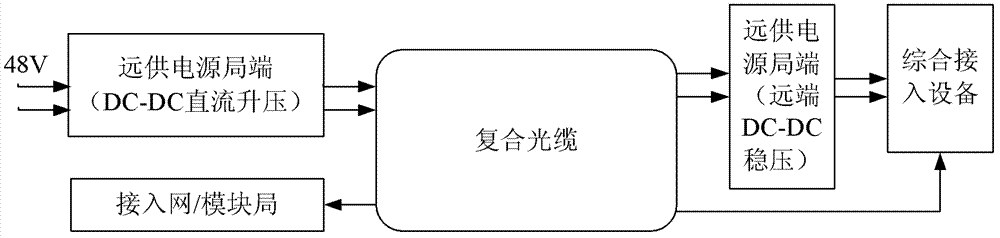

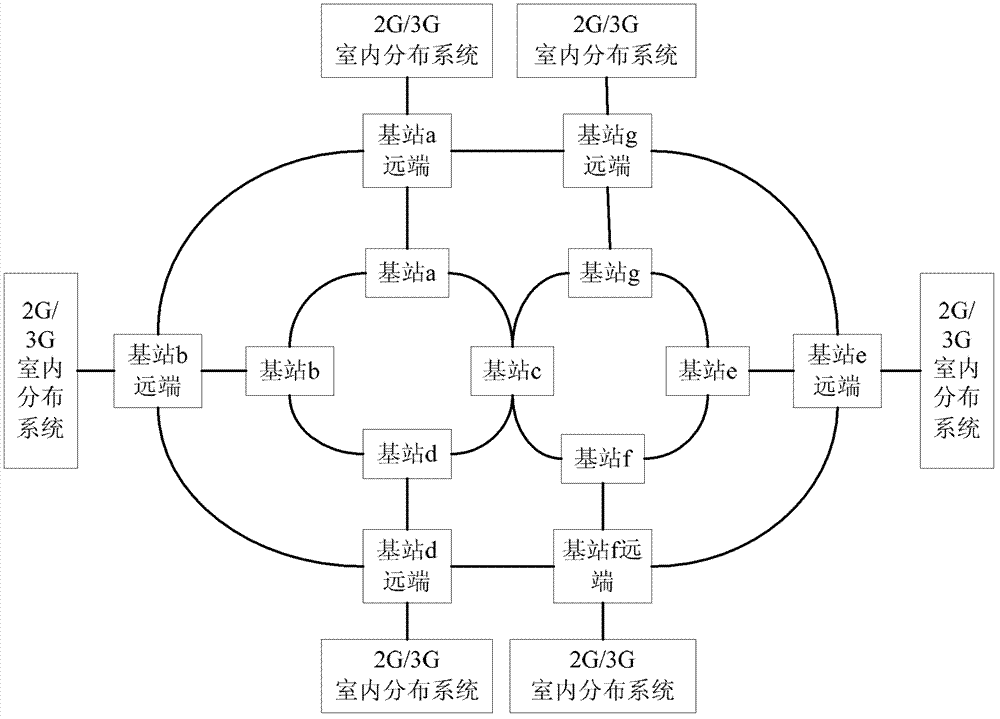

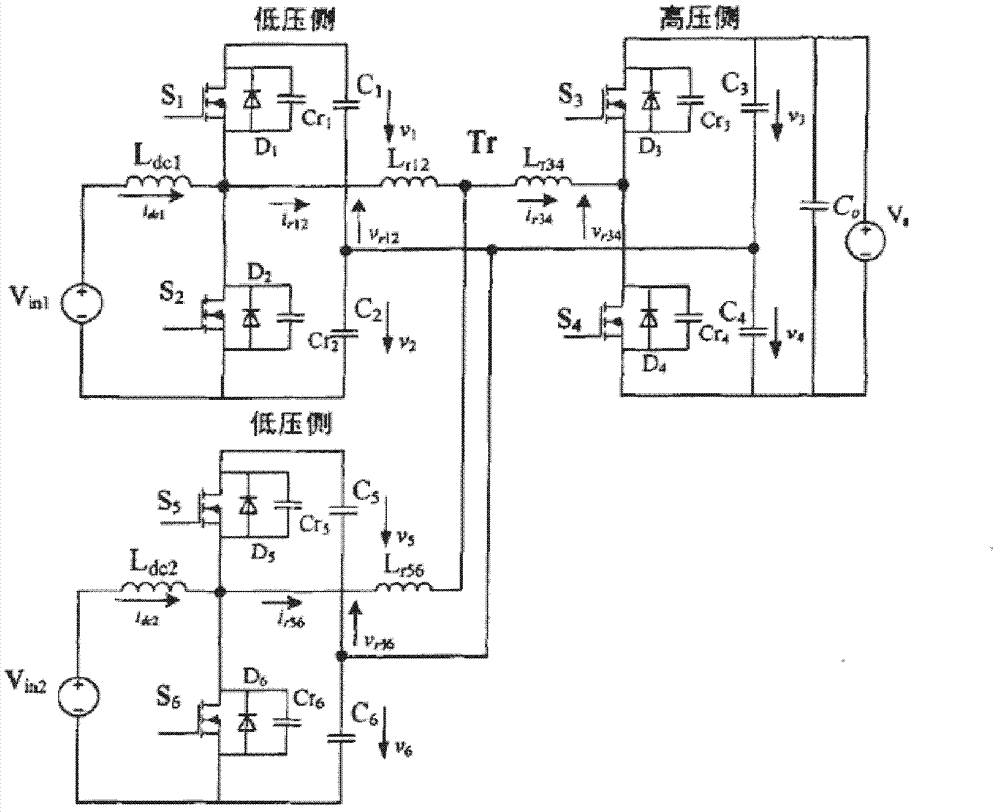

Base station power supply network system and base station emergency power supply method

ActiveCN103248038ALess fixed investmentEliminate power failuresDc network circuit arrangementsDc-dc conversionEnergy balancingDc dc converter

A base station power supply network system comprises a core power supply network which is formed by sequentially connecting a plurality of base stations to form an annular loop. Each base station comprises an AC / DC (Alternative Current / Direct Current) two-way DC-DC converter, a detection module and an energy balance module, wherein the AC / DC two-way DC-DC converter is used for sending a DC high voltage current to adjacent base stations or receiving the DC high voltage current; the detection module is used for controlling the AC / DC two-way DC-DC converter to send a detection current to the adjacent base stations, and confirming an optimal voltage value and a current value for sending the current through comparing the sent current with the received current; and the energy balance module is used for controlling the local AC / DC two-way DC-DC converter to supply power for a base station with abnormal power fluctuation. The invention further provides a base station emergency power supply method. According to the base station power supply network system and the base station emergency power supply method, base station power supply systems which are mutually independent originally are connected to form an annular power supply network, and each base station in the network can obtain power supply support from all other base stations.

Owner:中国移动通信集团甘肃有限公司 +2

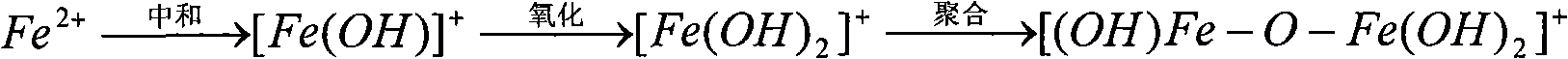

Method for preparing ferric oxide yellow pigment by waste iron hydrochloric acid lotion

InactiveCN101649130ALow costReduce energy costsPigment physical treatmentPigment treatment with non-polymer organic compoundsFerric oxide yellowIron oxide

The invention discloses a method for preparing ferric oxide yellow pigment by waste iron hydrochloric acid lotion, which adopts a wet oxidation method. The method comprises the following steps: processing the waste iron hydrochloric acid lotion; preparing a crystal seed; fading red; carrying out two-step oxidation; pressing and filtering; and drying. The method can rapidly and simply process the waste iron hydrochloric acid lotion with lower ferrous concentration, more impurity iron content and higher acidity, which is discharged by industries, such as metallurgy, steel, machinery, chemistry,pharmacy, and the like, the waste iron hydrochloric acid lotion can reach the Chinese allowed discharge standard, and the ferric oxide yellow pigment which can be used for industries, such as construction, paint, and the like is prepared.

Owner:ZHEJIANG UNIV

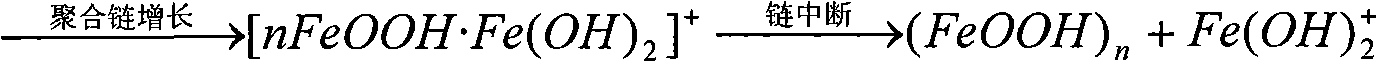

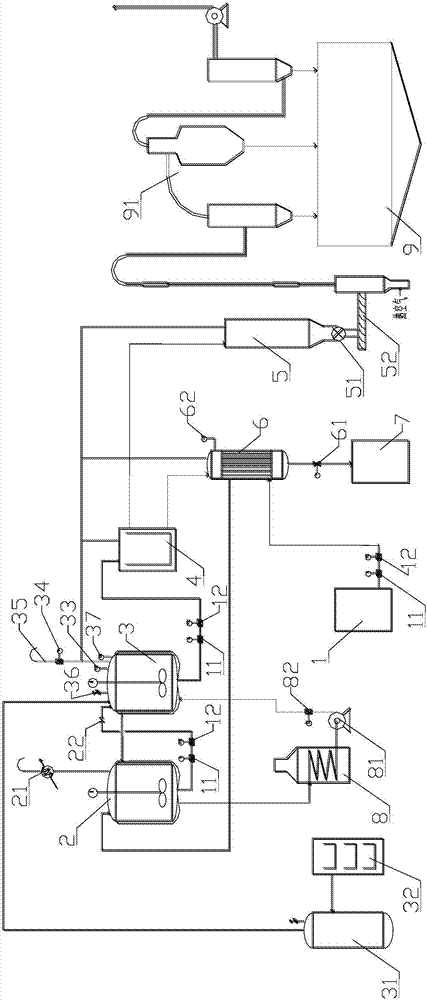

Process for preparing manganese sulfate by high-temperature crystallization method and automatic continuous production device

ActiveCN107055622AReduce consumptionAdvanced production technologyManganese sulfatesSulfateEnergy consumption

The invention discloses a process for preparing manganese sulfate by a high-temperature crystallization method and an automatic continuous production device. The process comprises the following steps: adding manganese sulfate solution which is impurity-removed and purified to a preheating kettle, and heating the added manganese sulfate solution to 90-100 DEG C by the preheating kettle; adding the heated manganese sulfate solution into a high-temperature crystallization kettle, and heating the added manganese sulfate solution to 160-180 DEG C in the high-temperature crystallization kettle for high-temperature crystallization; then adding the manganese sulfate solution of high-temperature crystallization into an automatic discharge centrifuge, putting a centrifuged water manganese sulfate crystal into a silo, and then obtaining a water manganese sulfate crystal through the drying of an air flow dryer unit. The process for preparing the manganese sulfate by the high-temperature crystallization method and the automatic continuous production device have the advantages that the production process is advanced; the design is scientific and reasonable; the safe, automatic and continuous production can be realized; the fixed investment is less; the labor intensity is reduced; the energy consumption is greatly reduced; the water consumption and production cost are saved, especially the water consumption and production cost of high-purity manganese sulfate production are saved; because soluble impurities are dissolved and saved in the mother liquor, several-time recrystallization is not required.

Owner:广州市三珍商贸有限公司

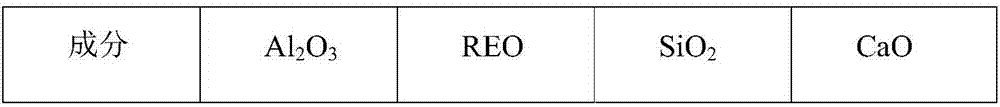

Comprehensive recovery method for rare earth, aluminum and silicon in aluminum-silicon waste

InactiveCN107022681AEmission reductionReduce alkali consumptionProcess efficiency improvementAluminum sulphatePhysical chemistry

The invention discloses a comprehensive recovery method for rare earth, aluminum and silicon in aluminum-silicon waste. The method comprises the following steps that 1, the aluminum-silicon waste is subjected to acid leaching to obtain acid leaching liquid containing rare earth and aluminum and silicon-rich slag; 2, a precipitant is added into the acid leaching liquid containing the rare earth and the aluminum, and rare earth compound salt precipitate and aluminum-containing filtrate are obtained; and 3, sodium metaaluminate or aluminum sulfate is prepared from the aluminum-containing filtrate. By means of the method, rare earth and aluminum are thoroughly separated, the yield and purity of the rare earth and the aluminum are greatly improved, meanwhile, valuable recovery of silicon is completed, and comprehensive recycling of main elements in the aluminum-silicon waste is truly achieved. The recovery technological process has the advantages of being low in alkali consumption, low in water consumption, low in waste water discharge amount and the like, and meanwhile has the characteristics that the fixed investment is low, the production cost is low, and industrialized production can be easily achieved.

Owner:GRIREM ADVANCED MATERIALS CO LTD

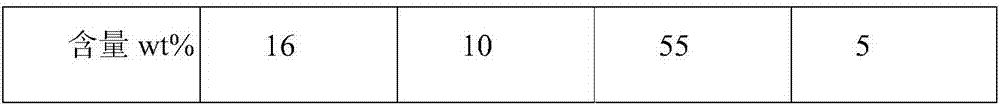

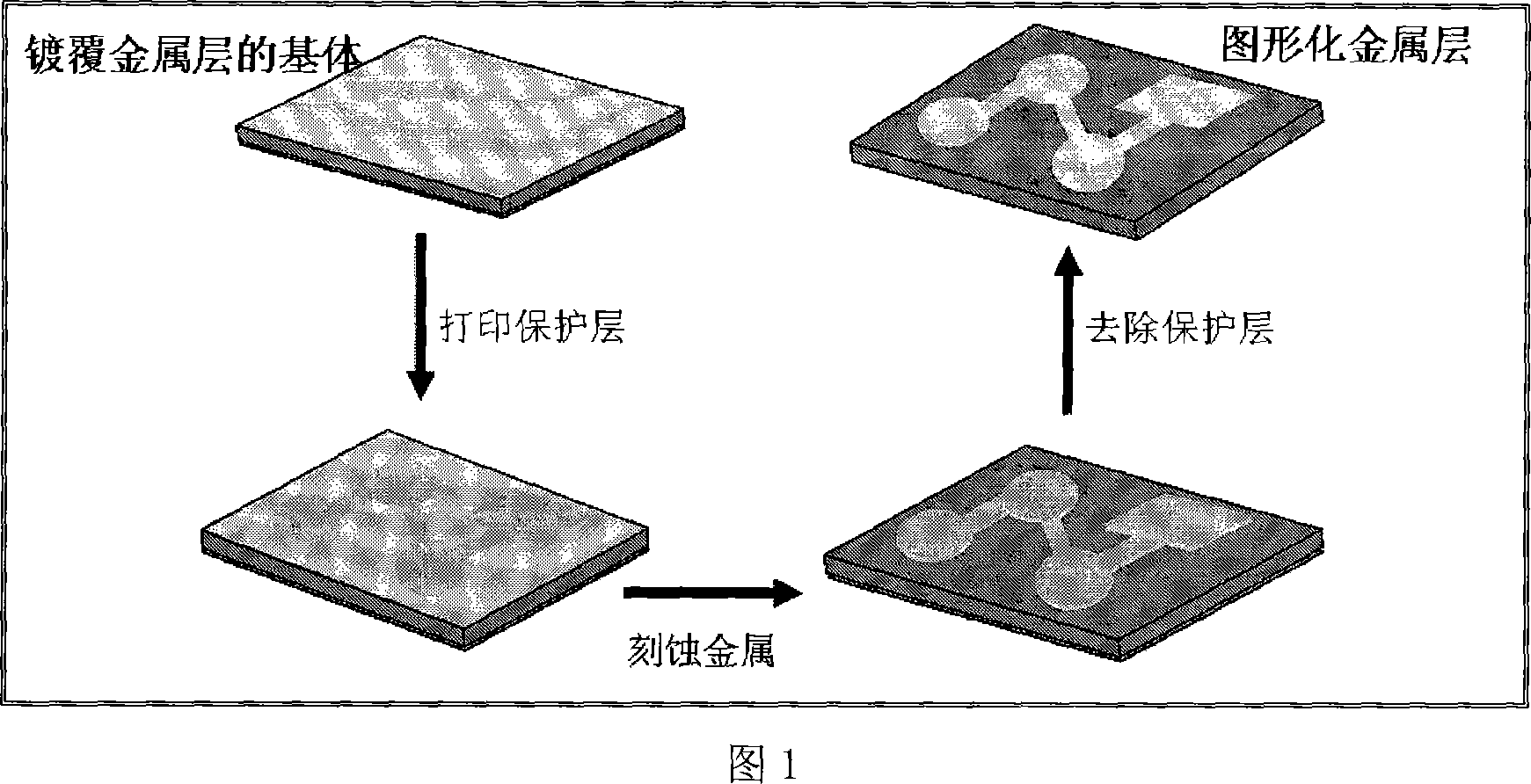

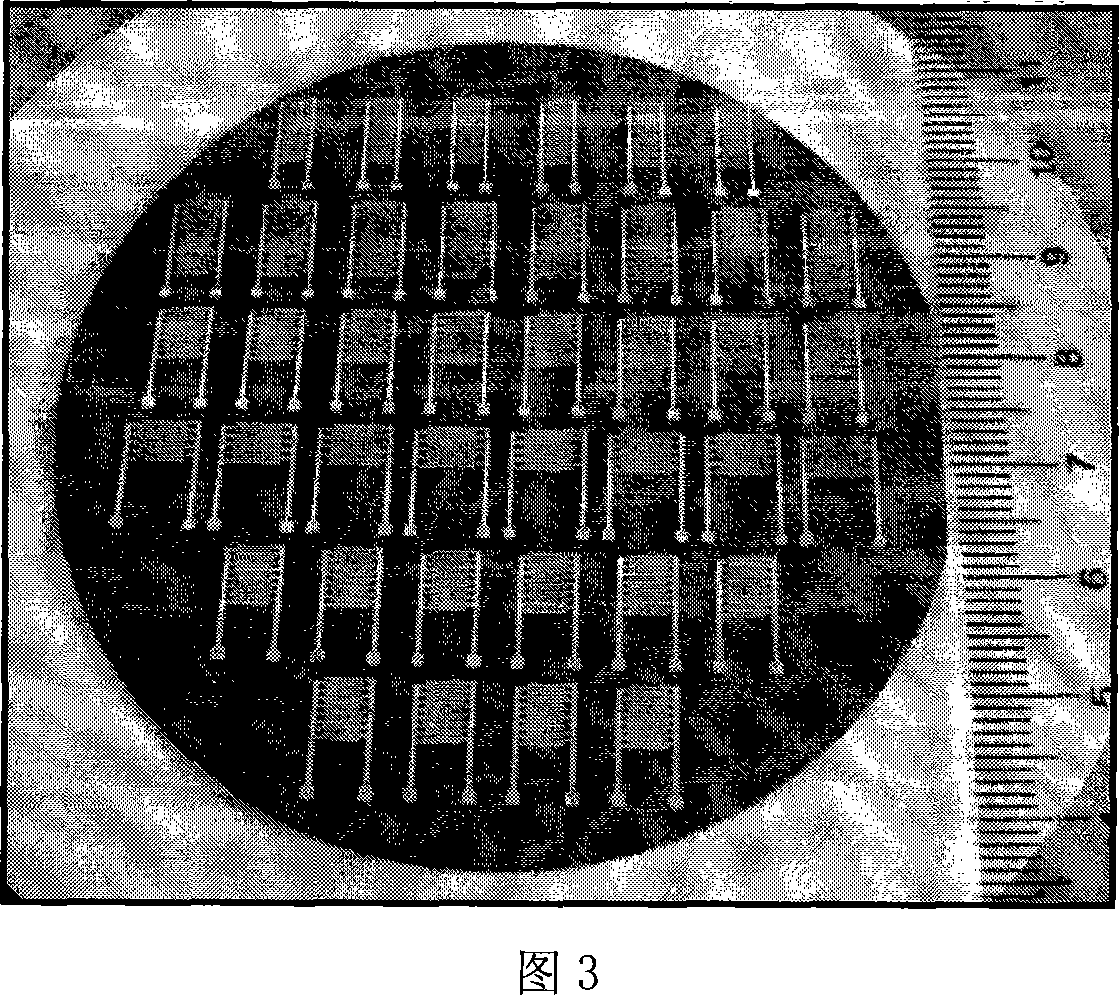

Metal wiring method based on mask print

InactiveCN101052278AImprove bindingHigh size resolutionConductive material chemical/electrolytical removalMetallic pattern materialsMetal formingImage resolution

The invention is a mask-print based metal wiring method. It comprises: using a board coated with or pressed with a metal layer as the basal body, and using an etching resistance protectant as the print materials; using a printer as the apparatus for positioning and distributing the print materials; constructing a patterned protection layer on the metal layer; using chemical etching approach to form the metal lines and pattern on the basal body.

Owner:FUDAN UNIV

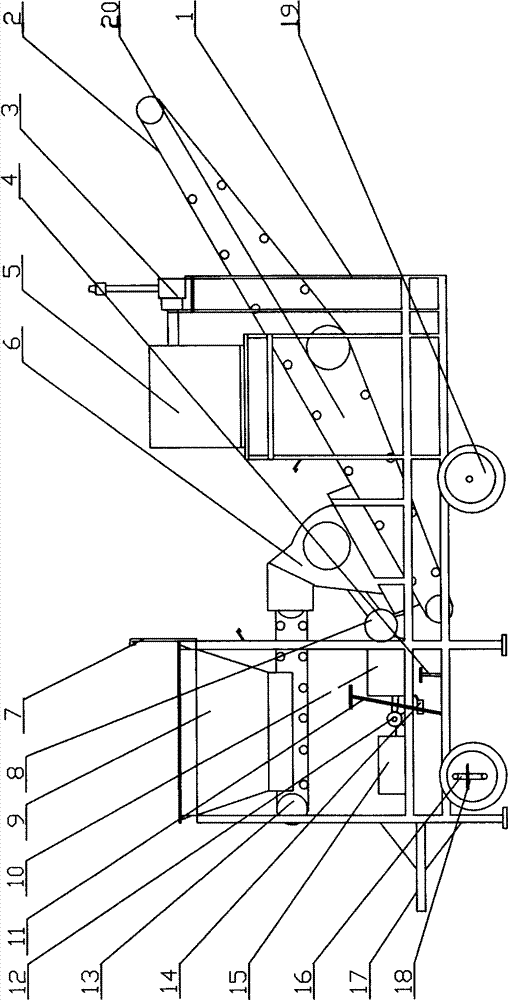

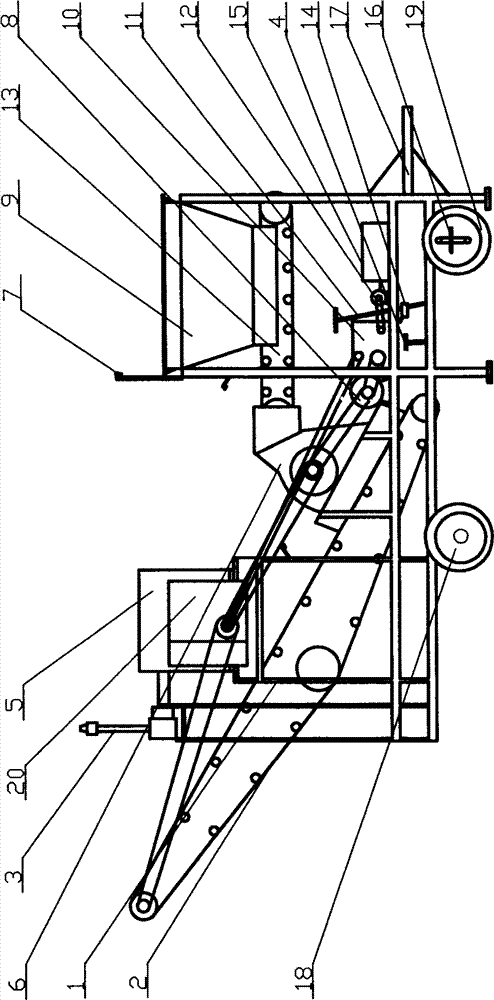

Combined crushing device

The invention provides a combined crushing device. Specifically, a crusher, a belt, a feeder, a power system, and a walking system are composed into the small combined crushing device. The power system can adopt electric power, and also can use of diesel and gasoline as power. The processes of charging, feeding, crushing, transporting, stacking are completed by one device. And the walking system is disposed to realize walking by making use of the power of the device. Or other power machinery can be utilized to perform transfer to a new crushing operation site conveniently. The device provided in the invention has the characteristics of compact structure, convenient use and high degree of automation, saves crushing operation site, reduces repeated fixed investment of equipment, and improves labor productivity.

Owner:张琪

Process and antistaling agent for ordinary-temp freshness-retaining producing raw wolfberry juice

InactiveCN1419860ANon-toxicNo side effectsFood preservationFood preparationFruit juiceLycium barbarum fruit

A process for antistaling the raw juice of wolfberry fruit at ordinary temp includes choosing fresh wolfberry fruits, washing, immersing in solution of potassium permanganate at pH=3-6.5 disinfecting in solution of peracetic acid, squeezing juice, and adding an invented antistaling agent. Its advantages are no toxicity and by-effect, natural wolfberry fruit juice, long storage period at ordinary temp (2 years) and low cost.

Owner:李振声

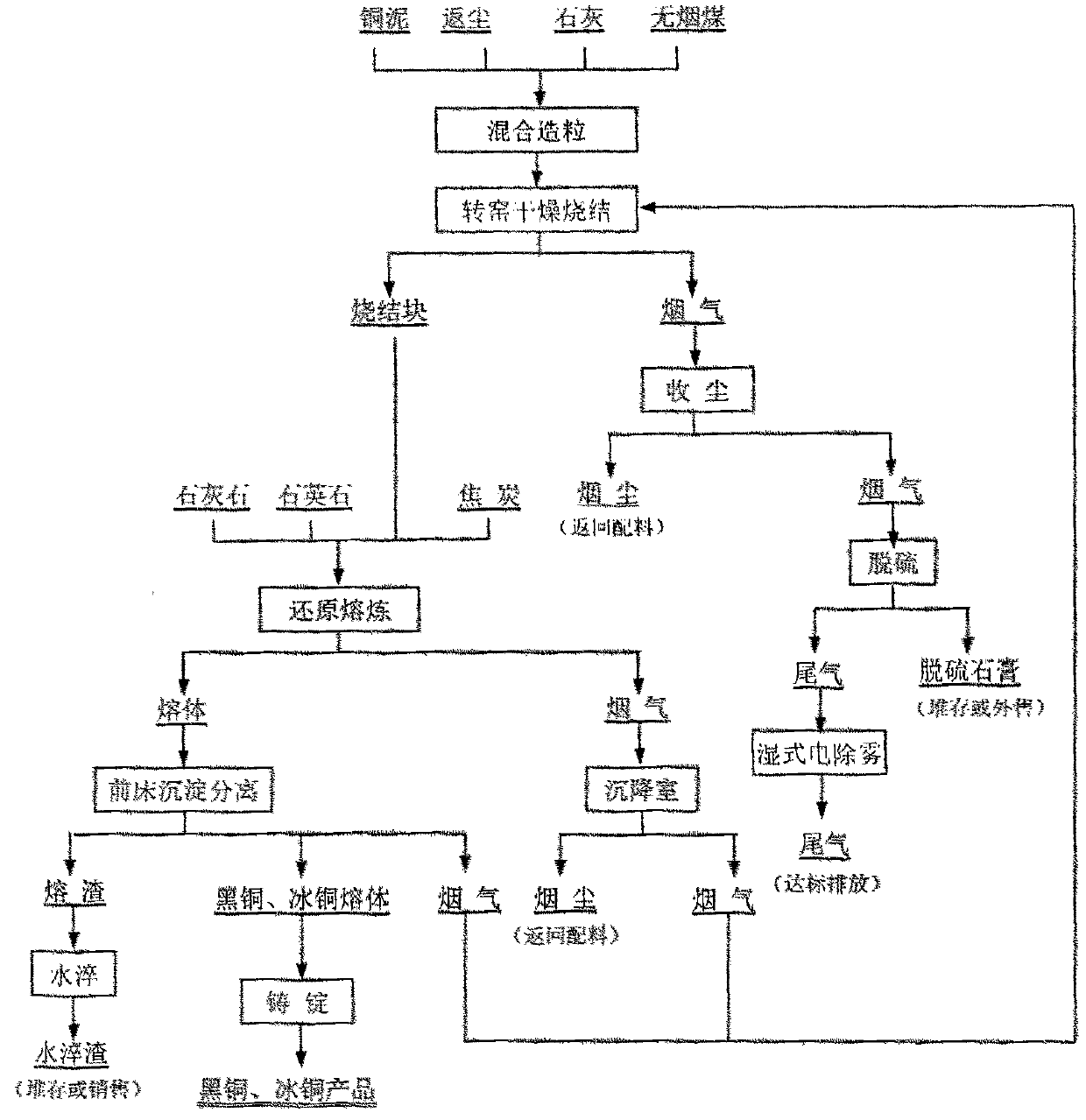

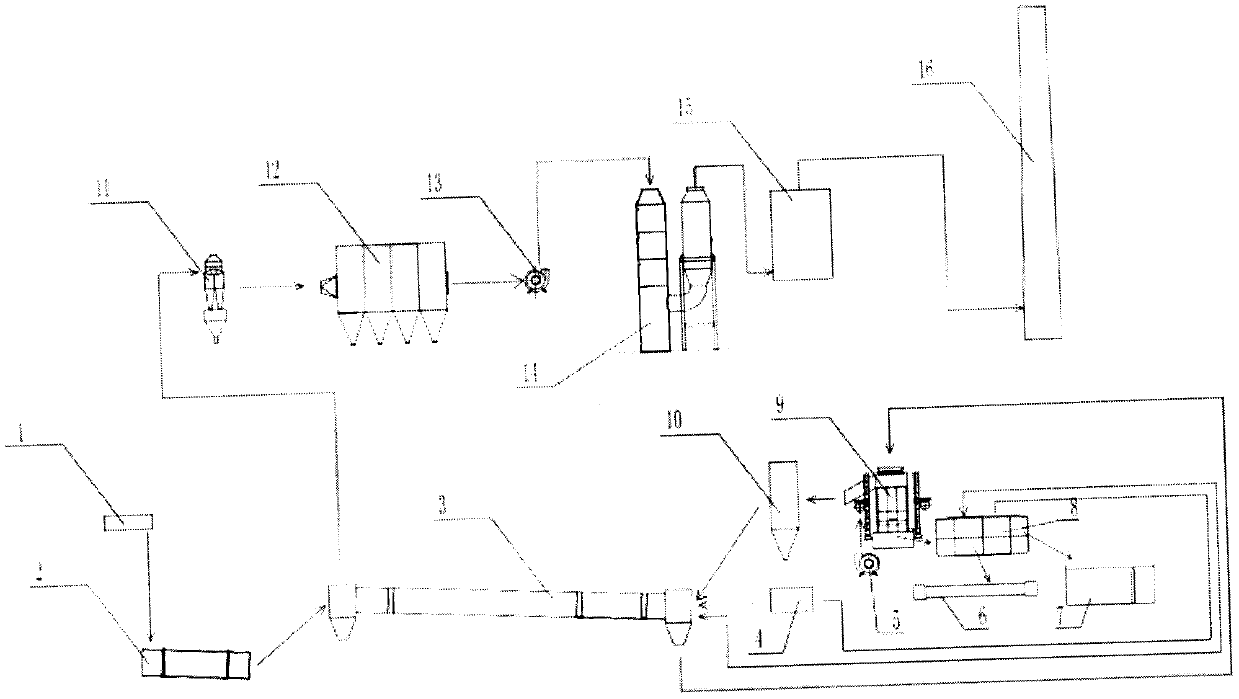

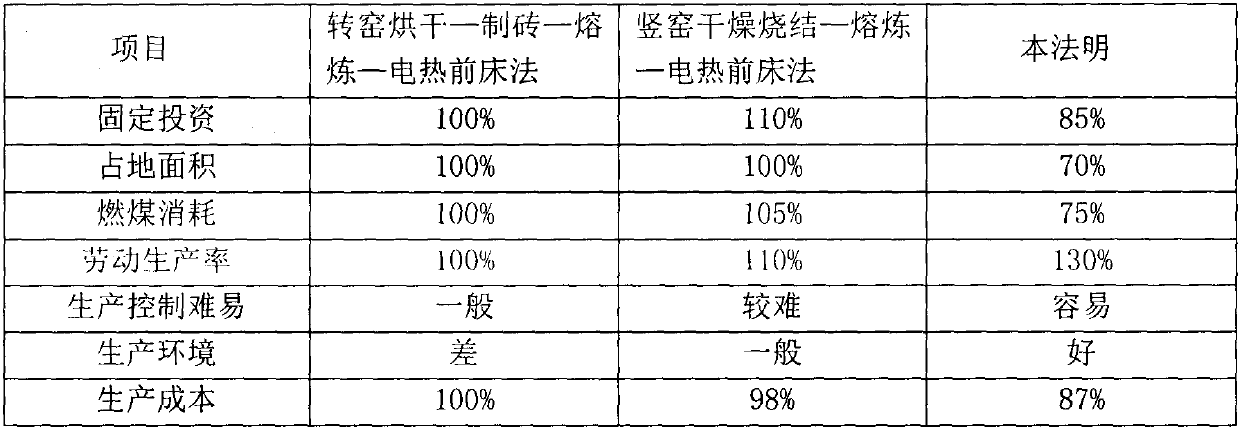

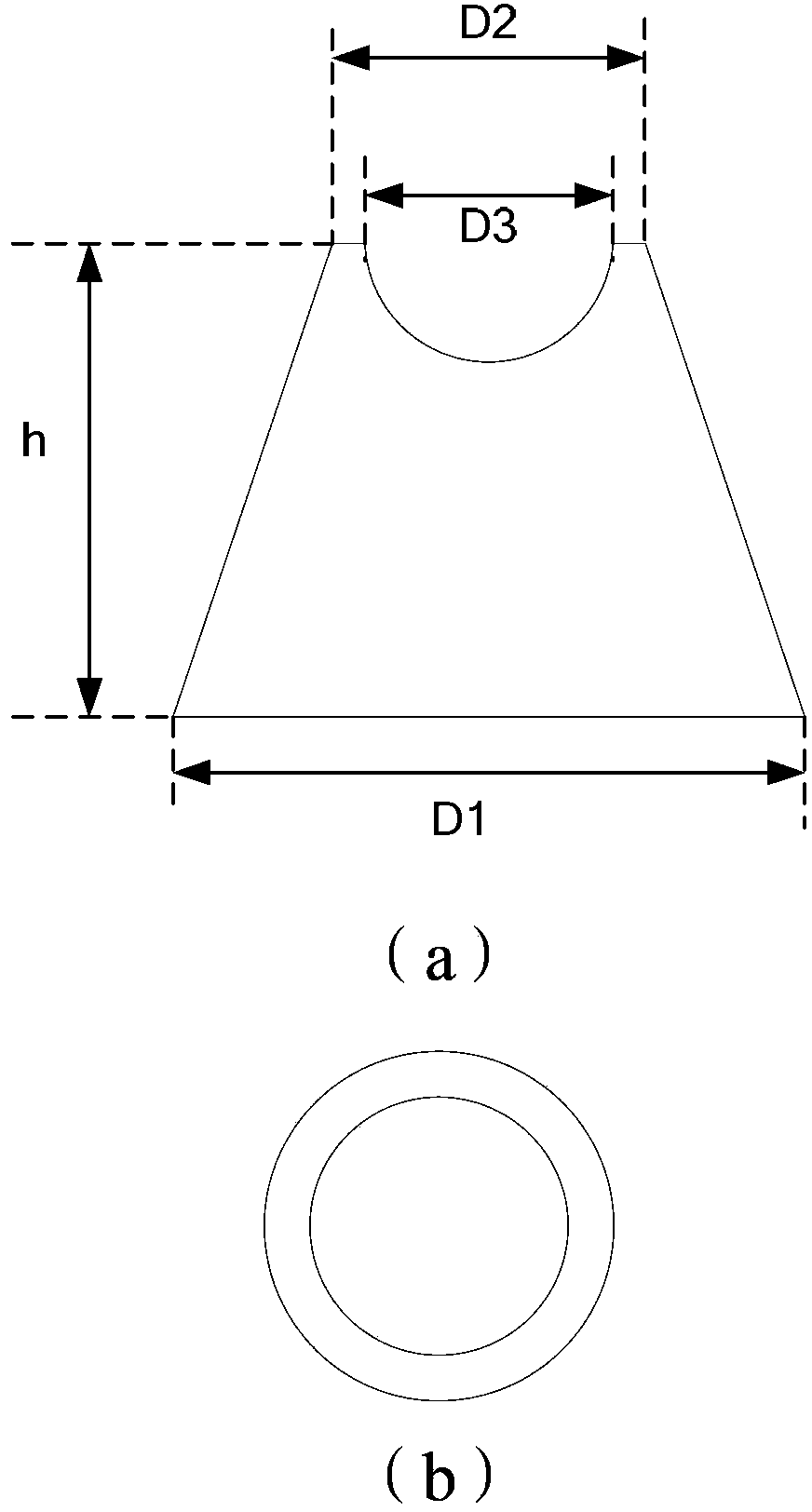

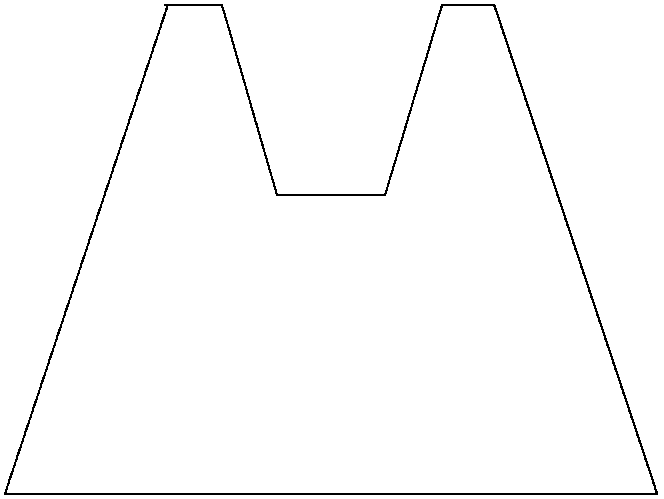

Energy-saving environment-friendly copper-containing sludge smelting method

The invention discloses an energy-saving environment-friendly copper-containing sludge smelting method, and belongs to the field of pyrometallurgy. The method is characterized in that copper-containing sludge, lime and powdered coal are proportionally and uniformly mixed, then, black copper and fused slag are obtained through pelletizing, rotary kiln drying sintering and smelting furnace smelting, the black copper and the fused slag are separated in a forehearth, the black copper is sold as a copper smelting raw material, the fused slag serves as a raw material for making cement or bricks after being subjected to water quenching, and smelting smoke is exhausted through a chimney after being processed through cyclone dust collection, cloth bag dust collection, dual-alkali desulfuration and demisting of an electric demister to reach the standard. Heat required by rotary kiln drying sintering is obtained from waste heat of forehearth smoke and smelting furnace smoke preferably, and when waste heat is insufficient, heat is supplemented by burning natural gas, coal gas or heavy oil; heat is supplied to the forehearth by burning the natural gas, the coal gas or the heavy oil, air is preheated and burned with assistance of high-temperature smoke exhausted from the forehearth so that the burning temperature of fuel can be increased. According to the smelting method, energy utilization is sufficient, the fixed investment is small, the occupied area is small, the production operation cost is low, and social, economic and environmental protection benefits are remarkable.

Owner:广西冶金研究院有限公司

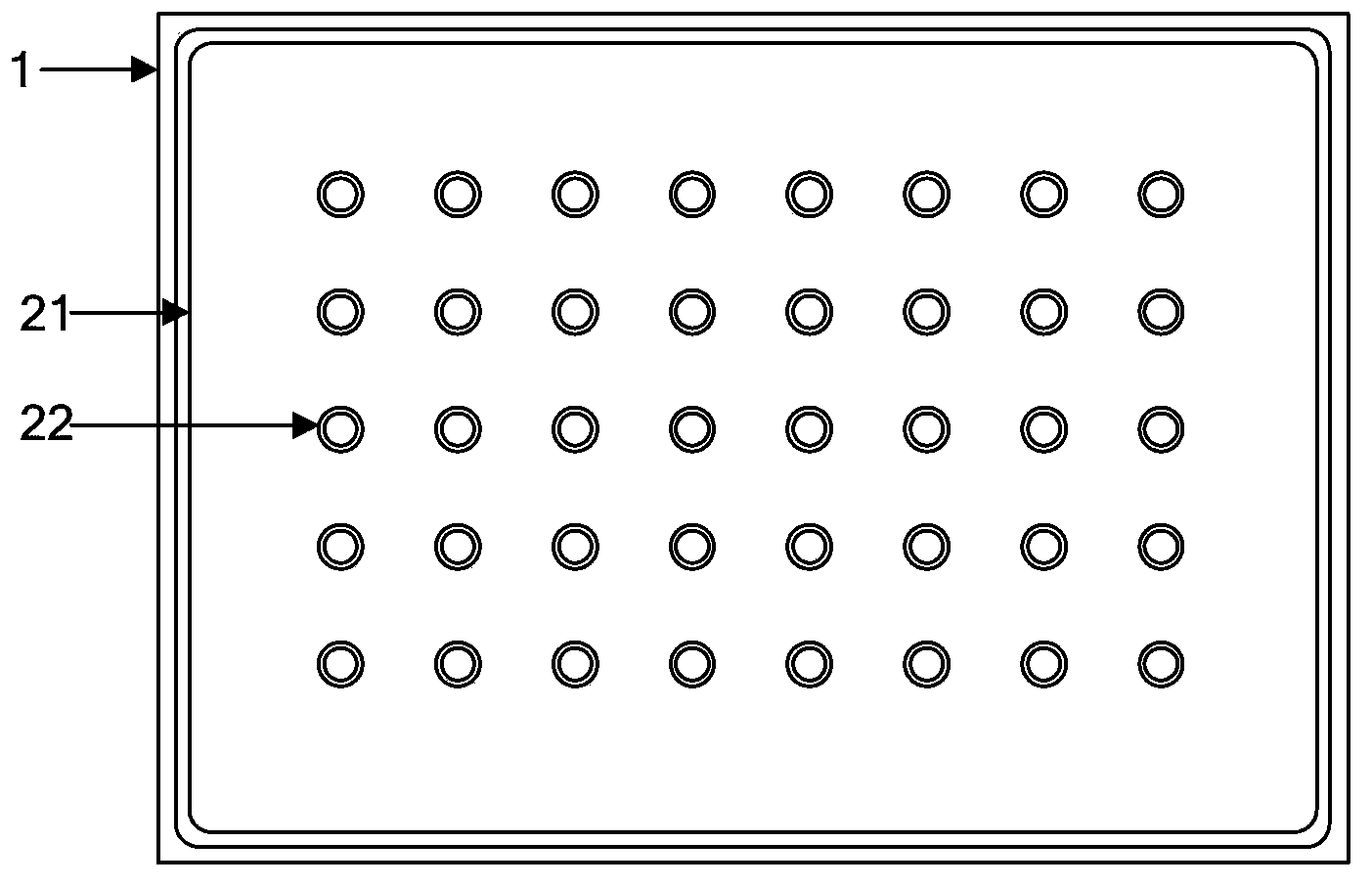

Display panel and manufacturing method thereof

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com