Method for improving propone output during catalytic conversion process

A catalytic conversion, propylene technology, applied in the production of bulk chemicals, chemical recovery, organic chemistry, etc., can solve the problem of not involving low-carbon olefin process and other problems, and achieve the effect of reducing fixed investment, small changes, and reducing energy consumption of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

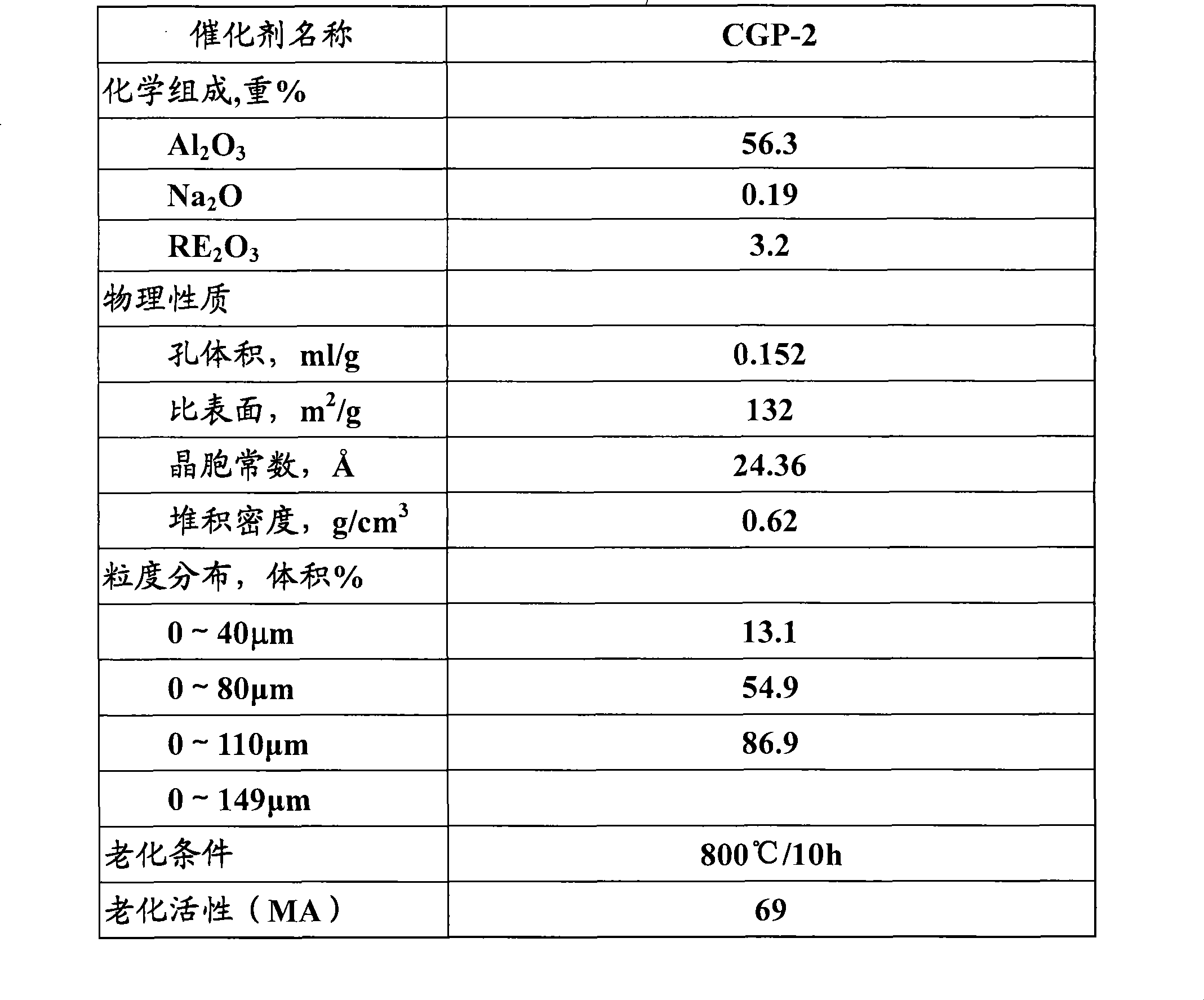

Embodiment 1

[0039] This example illustrates that the method provided by the invention can be implemented under different C4 feed ratios. Tests were carried out in a continuous riser reactor using CGP-2 catalyst with C4-rich gaseous hydrocarbons and FCC feedstocks, as shown in Table 1 for C4-rich gaseous hydrocarbons and FCC feedstocks as shown in Table 3 The oil enters the bottom and middle and lower parts of the riser reactor respectively. The outlet temperature of the first reactor is 510°C, the pressure at the top of the reactor is 200 kPa, the weight ratio of water to catalytic cracking feedstock is 0.1:1, and the catalyst to catalytic cracking feedstock oil is Contact with the catalyst under the condition of the weight ratio of 8:1 to carry out the catalytic reaction. The oil gas and catalyst are lifted to the separator together, and the oil gas enters the rear fractionation system from the top of the settler after settling and filtering. The oil and gas enter the fractionation towe...

Embodiment 2

[0042] This example illustrates that the method provided by the invention can be implemented under different C4 feed ratios and process conditions. Tests were carried out in a continuous riser reactor using CGP-2 catalyst with C4-rich gaseous hydrocarbons and FCC feedstocks, as shown in Table 1 for C4-rich gaseous hydrocarbons and FCC feedstocks as shown in Table 3 The oil enters the bottom and middle and lower parts of the riser reactor. The outlet temperature of the first reactor is 510°C, the pressure at the top of the reactor is 200 kPa, the weight ratio of water to catalytic cracking feedstock oil is 0.1:1, and the catalyst to catalytic cracking feedstock Contact with the catalyst under the condition of the weight ratio of 8:1 to carry out the catalytic reaction. The oil gas and catalyst are lifted to the separator together, and the oil gas enters the rear fractionation system from the top of the settler after settling and filtering. The oil and gas enter the fractionati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com