Method for pretreating catalytic conversion hydrocarbon oil crude material

A catalytic conversion and pretreatment technology, applied in catalytic cracking, water treatment, refining, cracking, etc., can solve the problems of reducing coke yield and achieve the effects of increasing reaction depth, reducing pollution, and reducing olefin and sulfur content in gasoline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

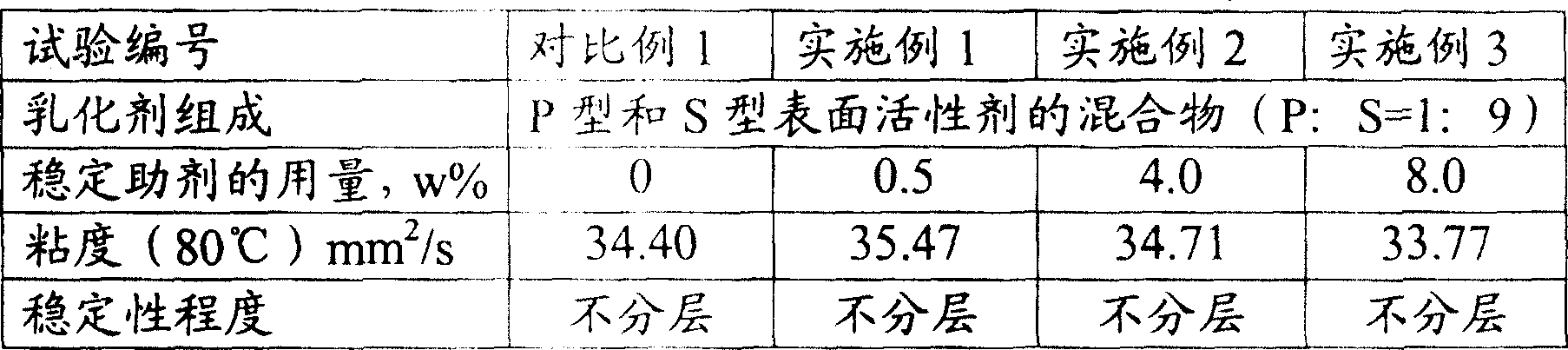

[0034] This embodiment illustrates: adopt the method provided by the invention to adopt the complex nonionic type surfactant system that alkylphenol polyoxyethylene emulsifier (P series) and sorbitan ester emulsifier (S series) form to stock oil Experimental results obtained after preprocessing.

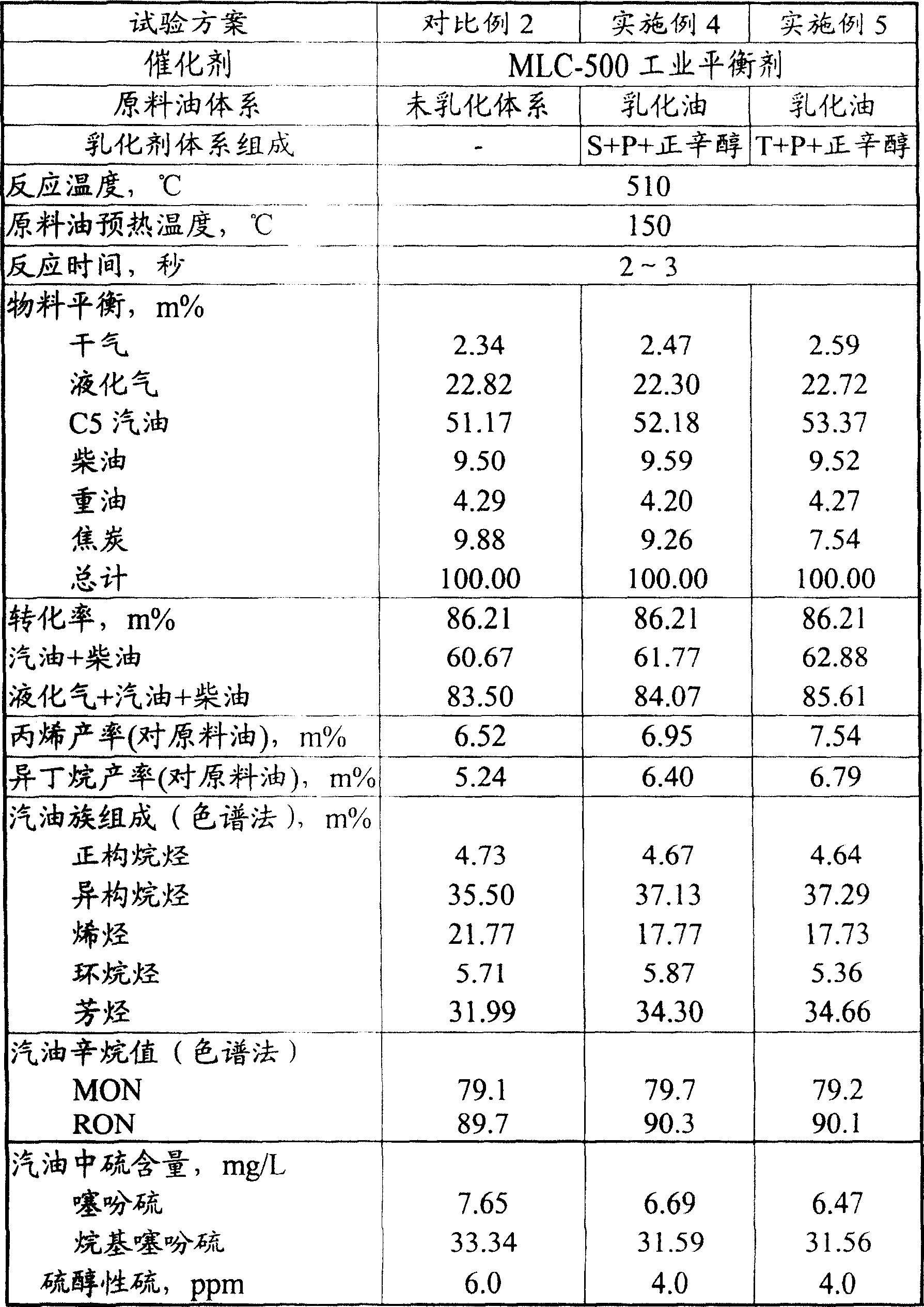

[0035] According to the method provided by the present invention, the raw oil is pretreated as described in the above-mentioned Example 2 to form emulsified oil, wherein the emulsifier system is S+P+n-octanol (wherein the ratio of P and S is 1:9, n-octanol The consumption of the emulsifier is 0.8% by weight of the total amount of the emulsifier), and the amount of the emulsifier is 2% by weight of the total weight of the passivator. The emulsified oil was contacted and reacted with the catalyst under the same catalytic cracking reaction conditions as in Comparative Example 2. The test conditions and main test results are shown in Table 4.

Embodiment 5

[0037] This embodiment illustrates: adopt the method provided by the invention to adopt the composite nonionic type surfactant system that alkylphenol polyoxyethylene emulsifier (P series) and sorbitan polyoxyethylene ether ester (T series) form The test results obtained after the raw oil was pretreated.

[0038] According to the method provided by the present invention, the raw material oil is pretreated to form emulsified oil as described in the above-mentioned Example 4, wherein the difference is that the emulsifier system is changed to T+P+n-octanol system. The emulsified oil was contacted and reacted with the catalyst under the same catalytic cracking reaction conditions as Comparative Example 4. The test conditions and main test results are shown in Table 4.

[0039] As can be seen from the test results in Table 4, compared with Comparative Example 2, gasoline, light oil yield (gasoline+diesel oil) and total liquid yield (liquefied gas) were obtained in Example 4 and Exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com