Patents

Literature

100results about How to "Increased depth of response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

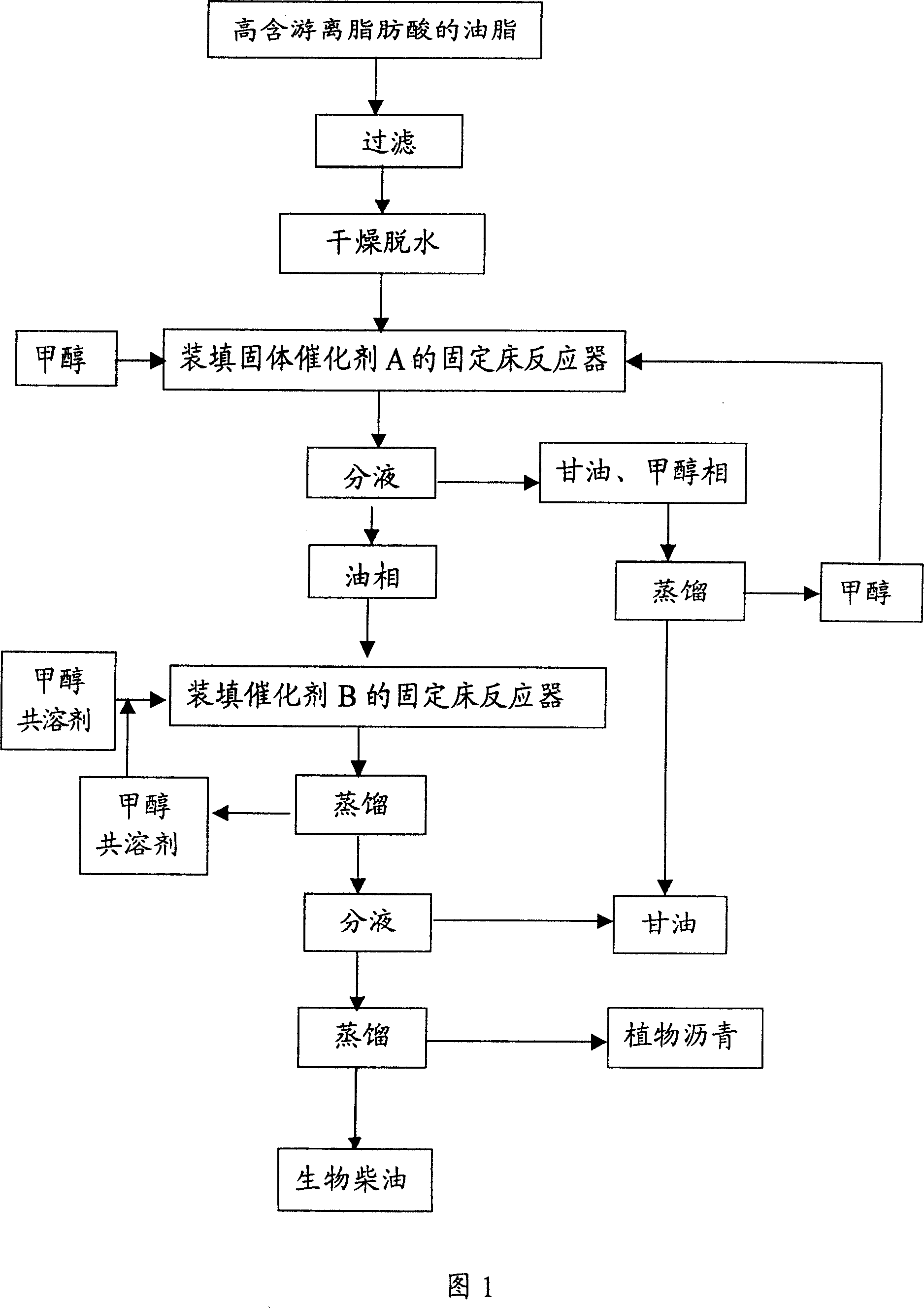

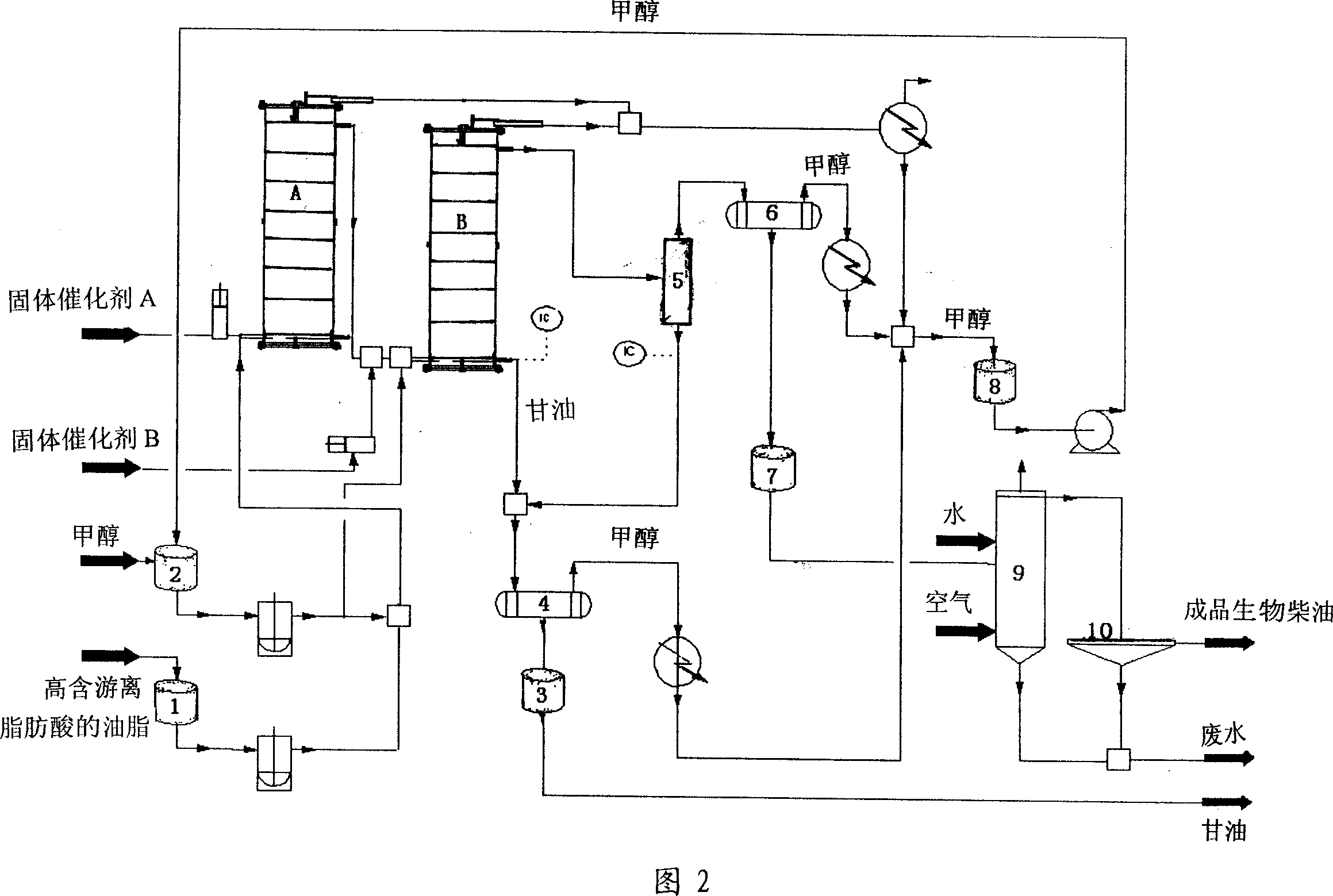

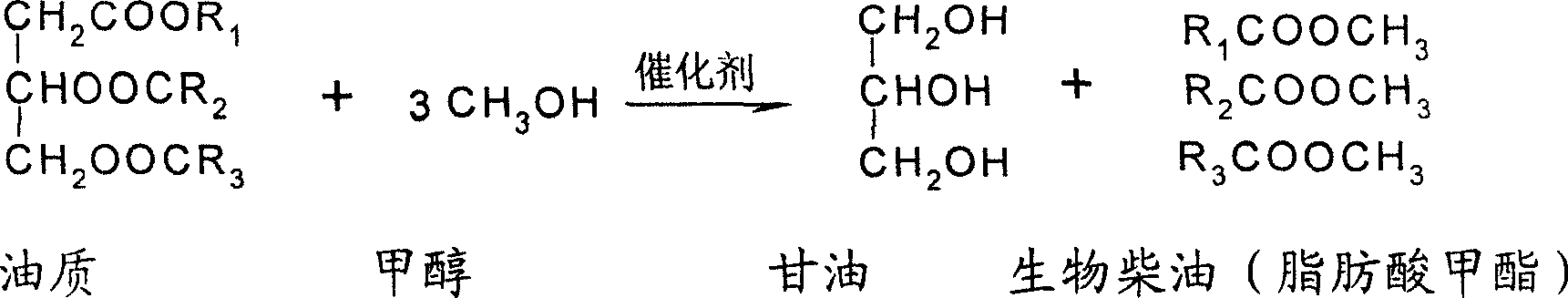

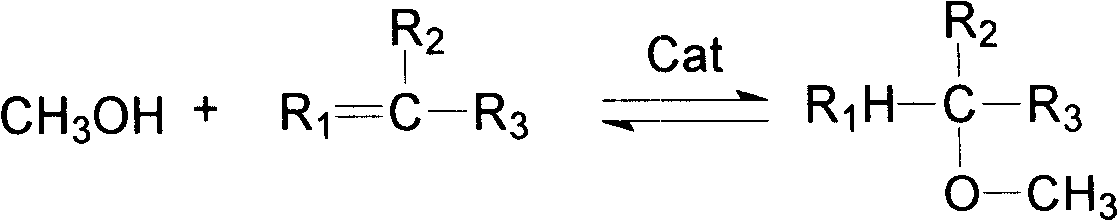

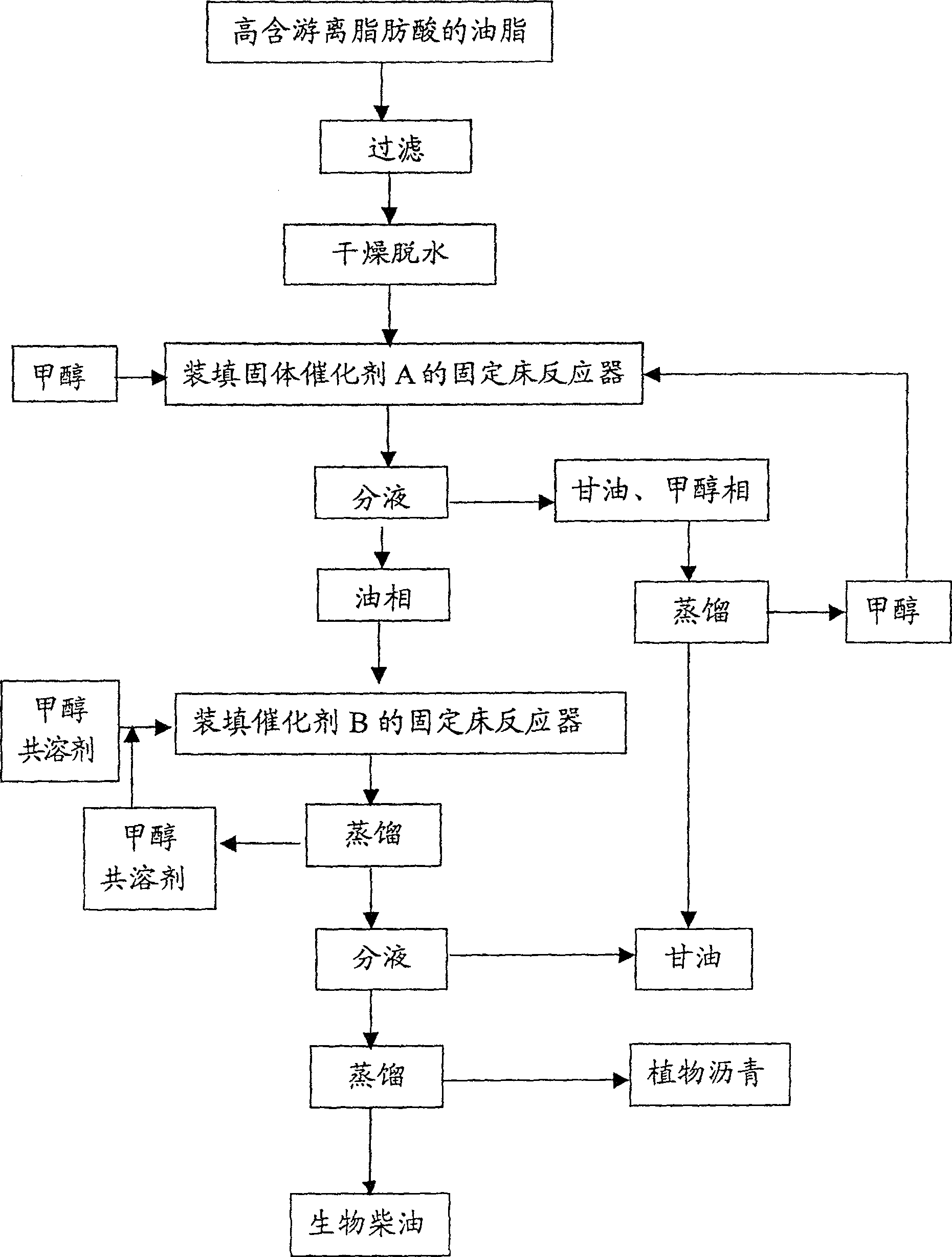

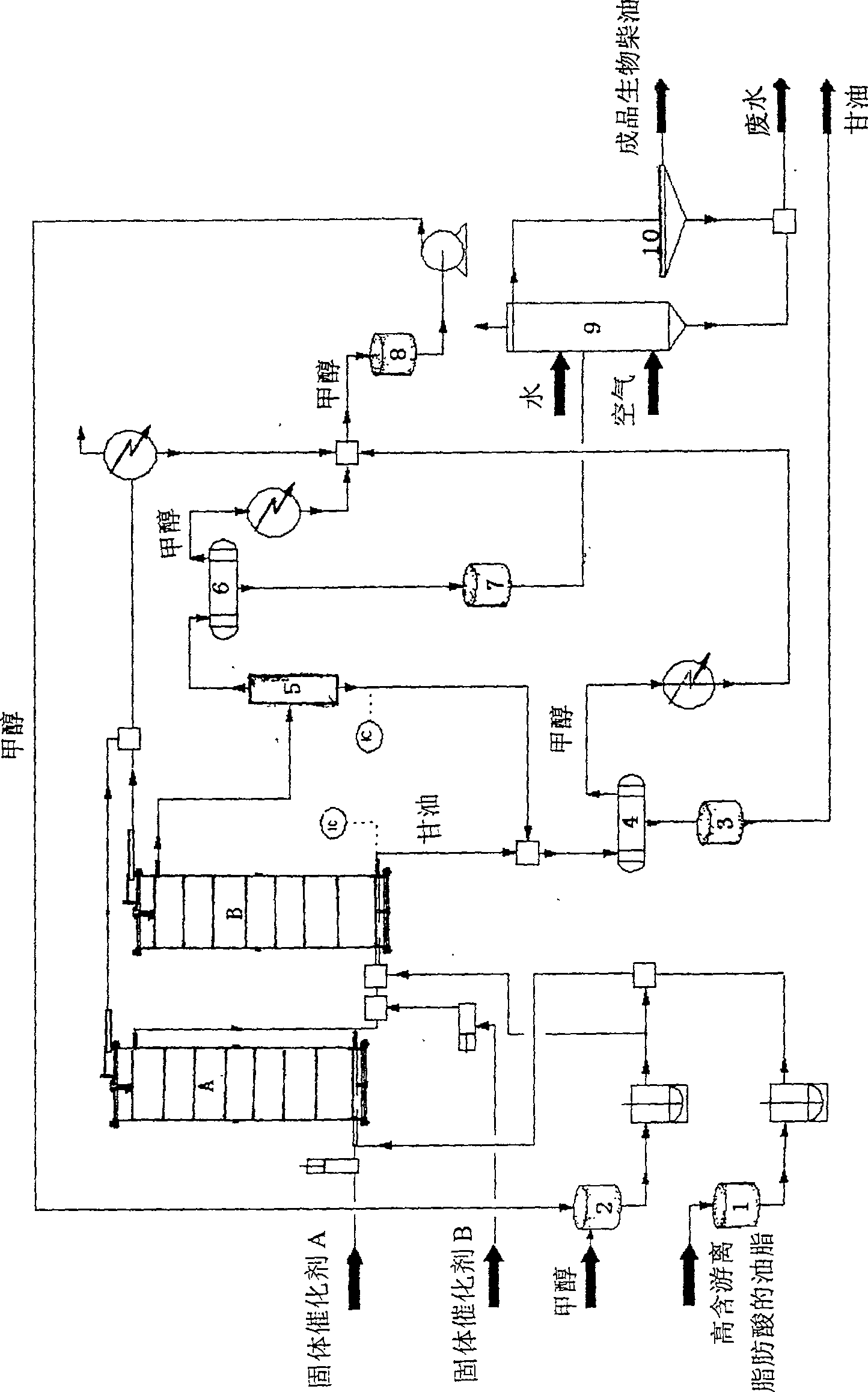

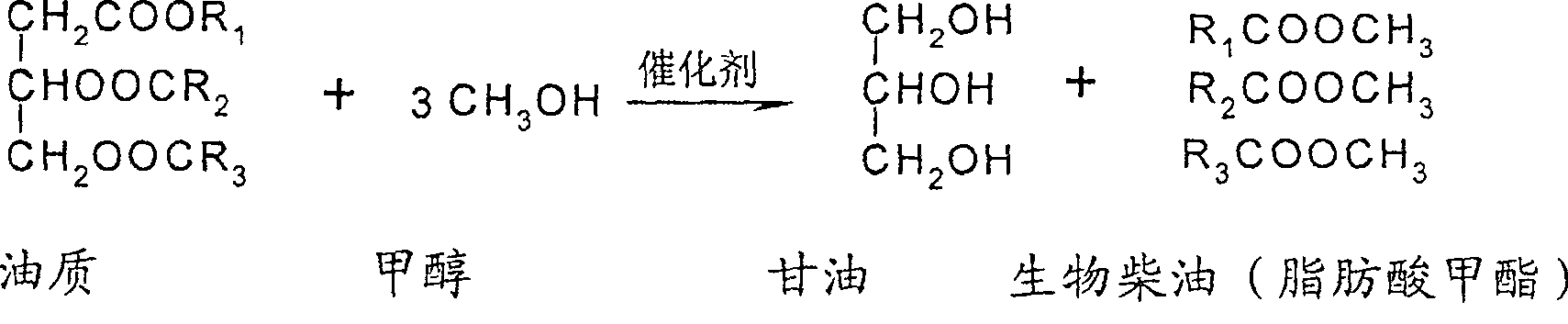

Preparation method of biological diesel oil

InactiveCN1928016AHigh catalytic activityLower activation energyBiofuelsLiquid hydrocarbon mixture productionSolventGlycerol

The present invention relates to biodiesel oil preparing process, and provides one biodiesel oil preparing process with solid acid and solid alkali as catalyst to lower the activating energy and raise the reaction speed. The biodiesel oil preparing process includes the following steps: reacting dried grease with high free fatty acid content, methanol or ethanol, and cosolvent in the molar ratio of 1 to 6-1 to 6.05 in the first fixed bed reactor with solid catalyst A at 60-65 deg.c for about 3 hr; separating the oil phase from others; reacting the oil phase in the second fixed bed reactor with solid catalyst B with methanol or ethanol and cosolvent at 60-65 deg.c for about 3 hr; distilling out methanol or ethanol and cosolvent; separating the biodiesel oil from glycerin phase; and distilling the biodiesel oil phase to obtain biodiesel oil product. The catalyst of the present invention has high catalytic activity and can lower the activating energy and raise the reaction speed.

Owner:张海军

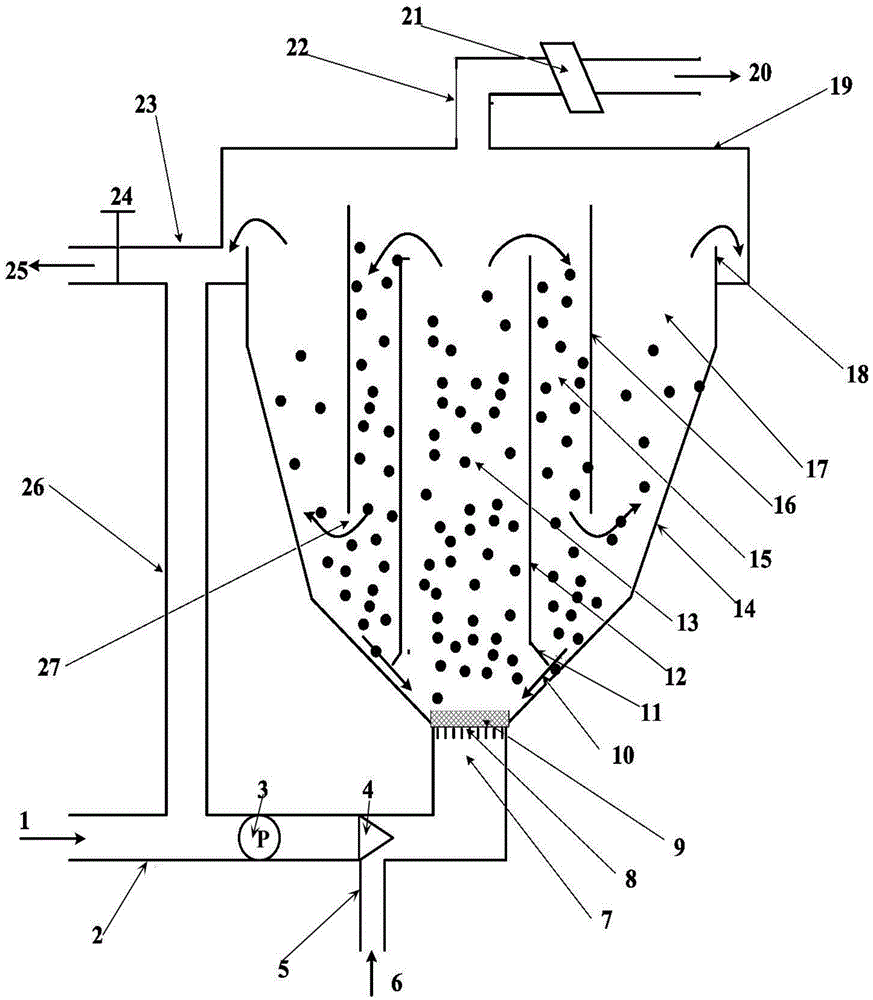

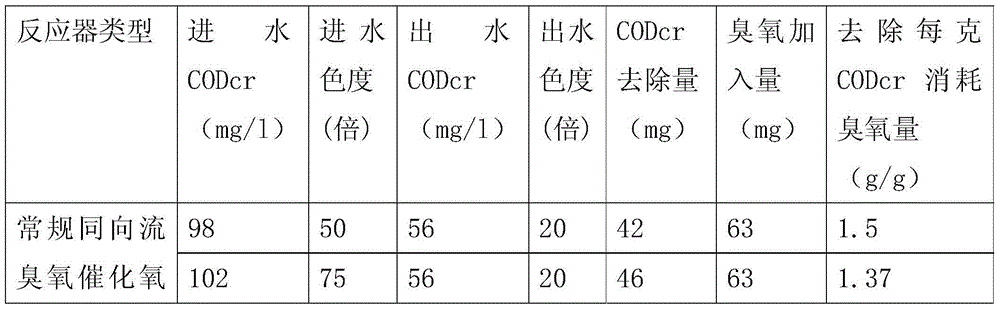

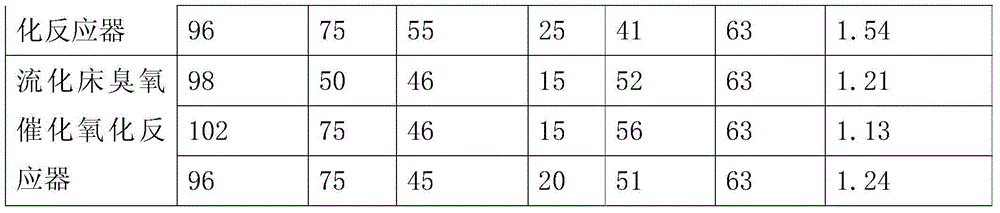

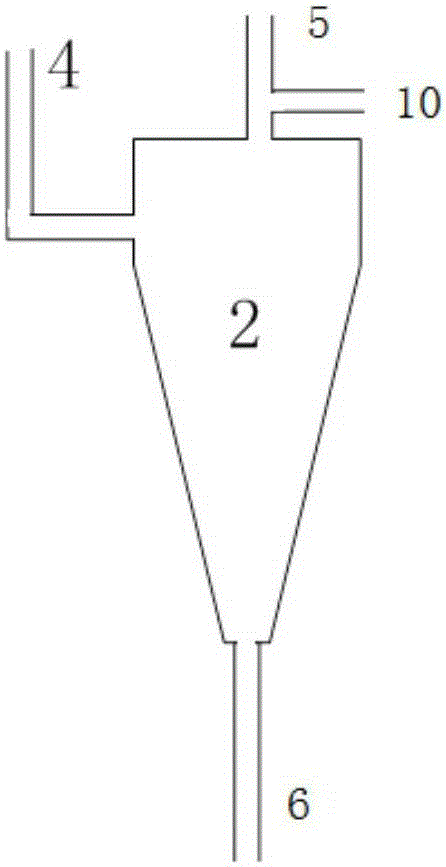

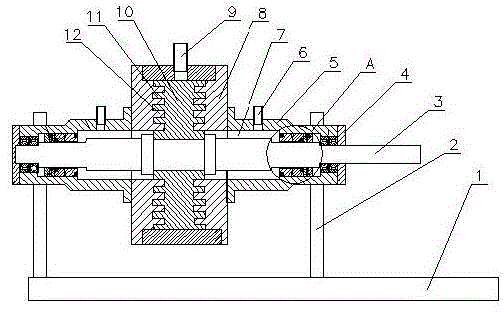

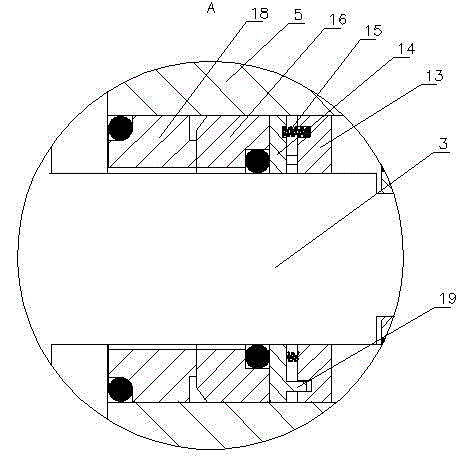

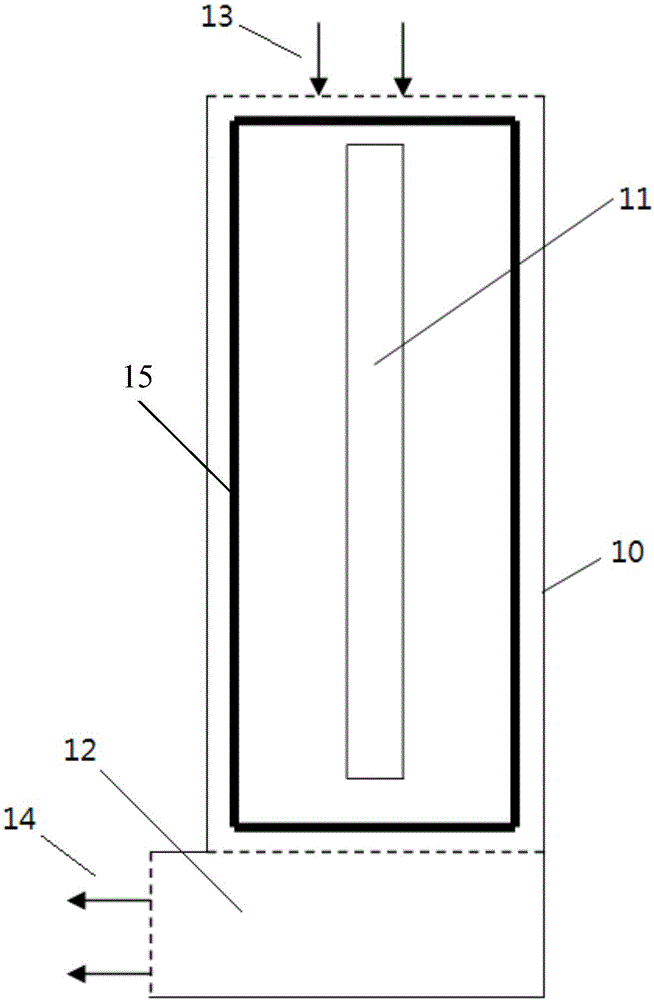

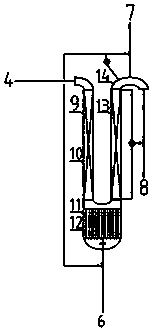

Wastewater treatment catalytic ozonation reactor for fluidized bed and wastewater treatment method of wastewater treatment catalytic ozonation reactor

InactiveCN104556347AImprove processing depthPrevent channelingWater/sewage treatment apparatusWater treatment fluid flow conditionsFluidized bedEngineering

The invention discloses a wastewater treatment catalytic ozonation reactor for a fluidized bed. The wastewater treatment catalytic ozonation reactor for the fluidized bed comprises a reactor housing, wherein an external cylinder is arranged in the housing, an internal cylinder is arranged in the external cylinder, the top part of the internal cylinder is lower than that of the external cylinder, the bottom of the internal cylinder is lower than that of the external cylinder; a baffling channel is formed between the bottom of the external cylinder and the inner wall of the housing, a refluxing channel is formed between the bottom of the internal cylinder and the inner wall of the external cylinder. According to the wastewater treatment catalytic ozonation reactor for the fluidized bed disclosed by the invention, a catalytic reaction region, a diversion region and a precipitation region can be arranged in the same reactor so as to realize integration without needing additional catalyst separation and back conveying equipment. The invention also discloses a wastewater treatment method with application of the wastewater treatment catalytic ozonation reactor. According to the wastewater treatment method disclosed by the invention, by virtue of wastewater refluxing, residual soluble ozone in wastewater is fully utilized, and the ozone utilization ratio and the wastewater treatment depth are greatly increased.

Owner:ZHEJIANG CATHAYRIPE ENVIRONMENTAL ENG

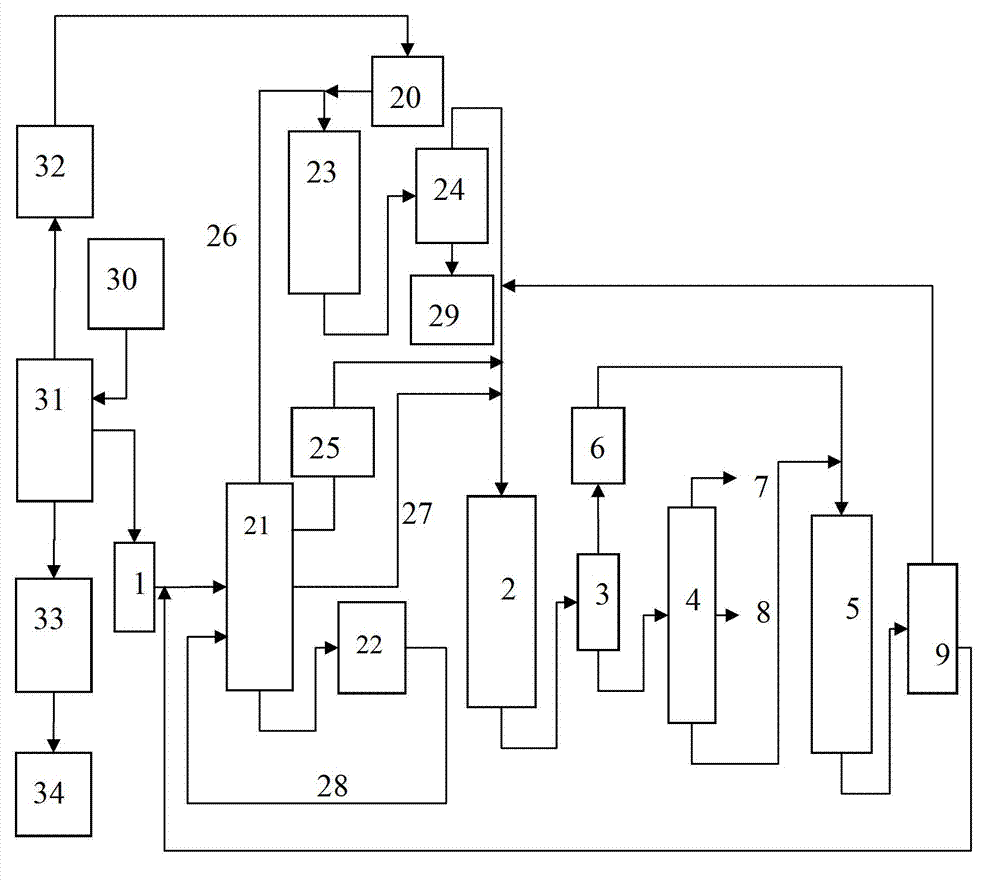

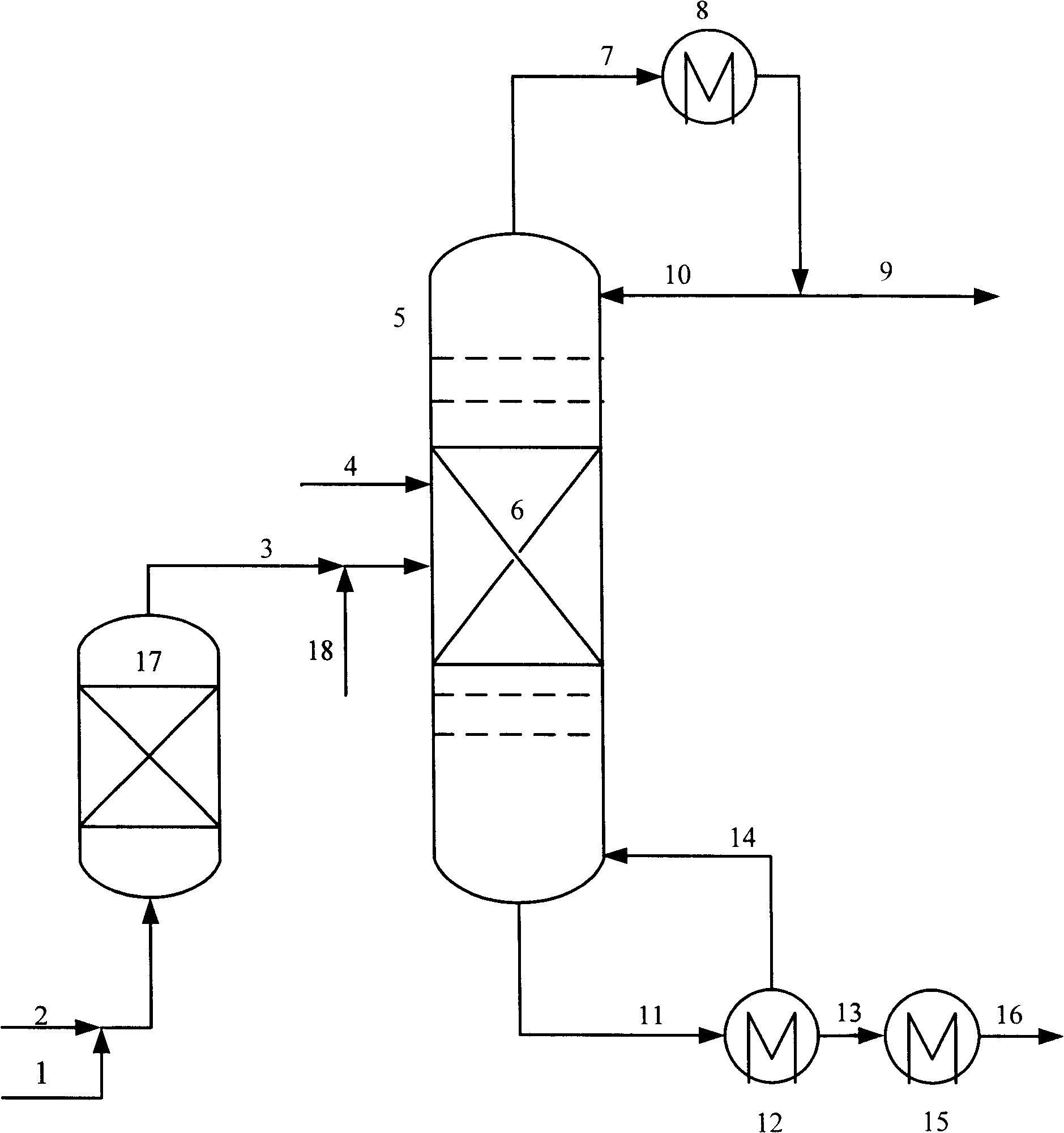

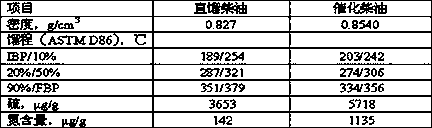

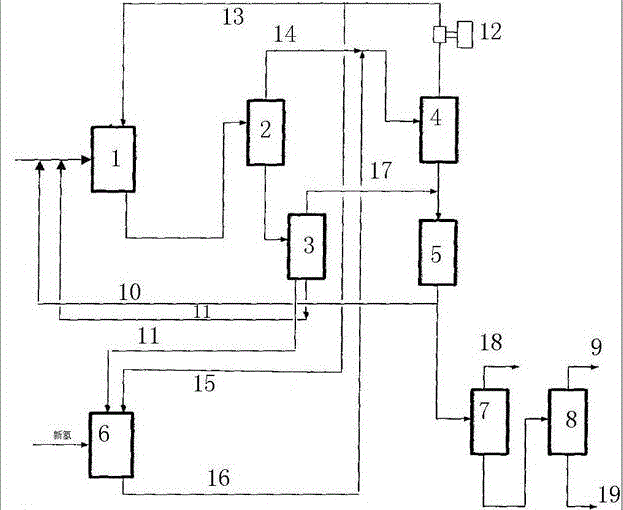

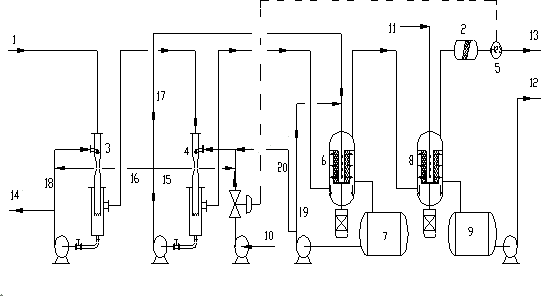

Hydrotreatment and catalytic cracking combined method of heavy hydrocarbon raw material

ActiveCN102876377AReduce the amount of mixed hydrogenStable temperatureTreatment with hydrotreatment processesFluid phaseHydrogenation reaction

The invention discloses a hydrotreatment and catalytic cracking combined method of a heavy hydrocarbon raw material. According to the invention, an upflow reactor is at least connected in series with a downflow fixed bed reactor. The heavy hydrocarbon raw material passes through UFR and is mixed with a catalytic cracking heavy fraction, and the mixture enters the downflow fixed bed reactor. A hydrogenation reaction effluent is separated so as to obtain a liquid phase, and the liquid phase is subjected to catalytic cracking. The obtained catalytic cracking heavy fraction returns to an inlet of the downflow fixed bed reactor. According to the method, the catalytic cracking heavy distillate oil, which is introduced into the inlet of the fixed bed reactor, is beneficial to hydrogenation reaction and can significantly improve temperature rising of the bed when used as cutback oil and can minimize the amount of hydrogen injected through the inlet when used as a hydrogen donor, thus further raising cooperative effect of combined flow equipment and prolonging the running period as well.

Owner:CHINA PETROLEUM & CHEM CORP +1

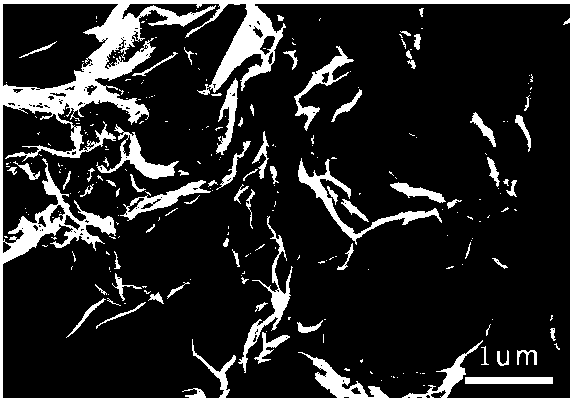

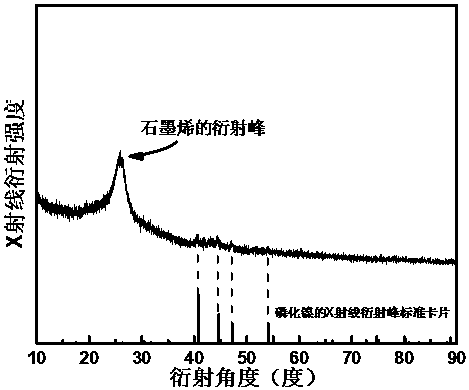

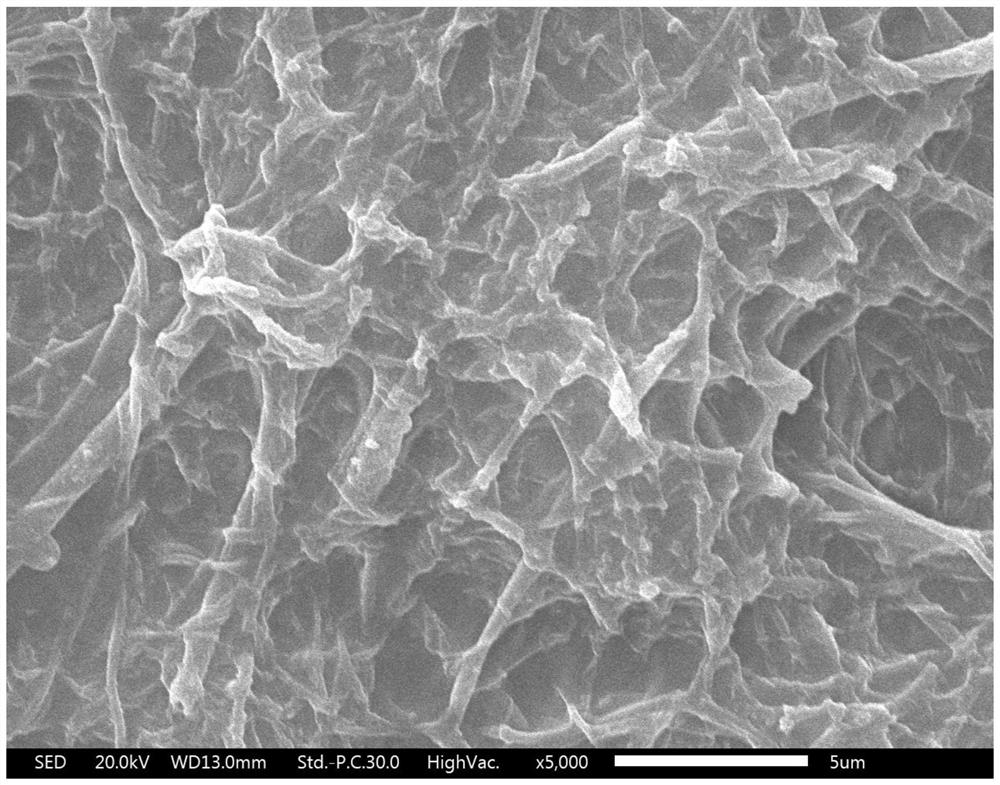

Preparation method of lithium-sulfur battery cathode material based on phosphorus-doped graphene supported nickel phosphide material

ActiveCN107665984AInhibition of volume expansionImprove the electrochemical reactivity of the interfaceCell electrodesLi-accumulatorsDoped grapheneFreeze-drying

The invention discloses a preparation method of a lithium-sulfur battery cathode material based on a phosphorus-doped graphene supported nickel phosphide material. The method comprises the following steps: (1) adding a surface active agent into graphene oxide to obtain graphene oxide dispersion liquid; (2) adding a nickel source and alkali liquor into distilled water to obtain a saline solution; (3) adding the saline solution into the graphene oxide dispersion liquid, carrying out a hydrothermal reaction, then washing, and carrying out freeze drying to obtain a graphene composite material loaded with a nickel precursor; (4) enabling the graphene composite material loaded with the nickel precursor to be subjected to a phosphating reaction so as to obtain the phosphorus-doped graphene supported nickel phosphide material; (5) compounding the phosphorus-doped graphene supported nickel phosphide material with sublimed sulfur to obtain the lithium-sulfur battery cathode material based on thephosphorus-doped graphene supported nickel phosphide material. The phosphorus-doped graphene supported nickel phosphide material prepared by the method has a three-dimensional space structure, thus having an obvious domain limiting effect on sulfur and remarkably inhibiting the shuttle effect of lithium polysulfide.

Owner:HARBIN INST OF TECH

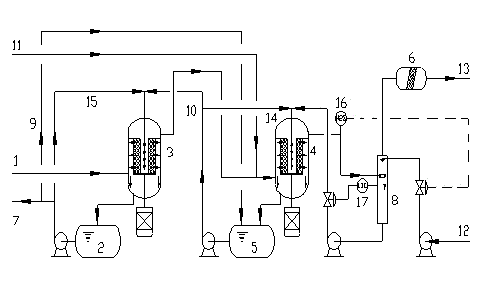

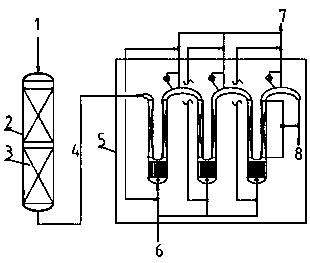

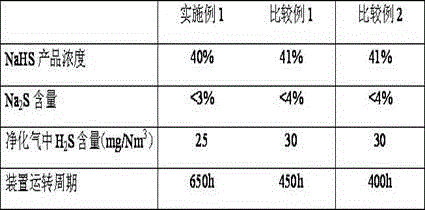

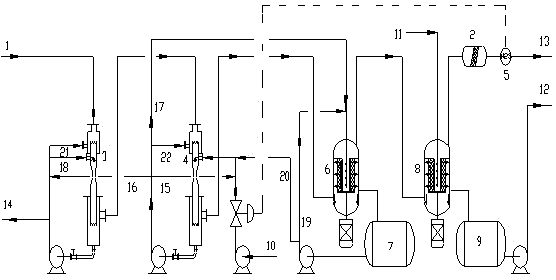

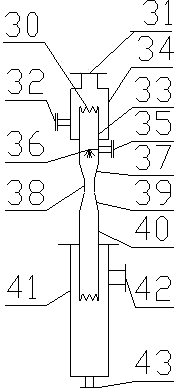

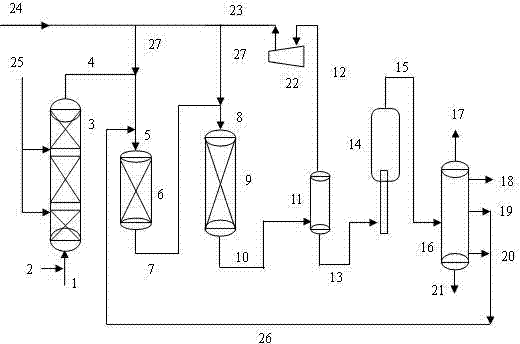

Process and apparatus for producing sodium hydrosulfide from acidic gas

ActiveCN104826463AIncreased depth of responseGuaranteed long-term operationSulfur compoundsDispersed particle separationPollutantGas pipeline

The invention discloses a process and apparatus for producing sodium hydrosulfide from acidic gas. The acidic gas treating process employs a two-stage gas-liquid two-phase countercurrent absorption reaction and uses a NaOH solution as an absorption liquid to treat acidic gas so as to produce NaHS. According to the process, a primary liquid reaction product and a secondary liquid reaction product are cyclically used, and the primary liquid reaction product is circulated to a secondary intermediate tank and used as a diluent; and a supplementary carrier gas pipeline is arranged between two-stage rotating packed bed reactors to introduce supplementary carrier gas, so the concentration of CO2 in the acidic gases is reduced and most CO2 is taken out of the apparatus together with the carrier gas, and thus, the contents of Na2CO3 and NaHCO3 are controlled, obstruction of the pipeline due to crystallization caused by production of a great amount of Na2CO3 is prevented, and long cycle operation of the apparatus is guaranteed. The rotating packed bed reactors are used as gas-liquid reactors which have high mass transfer and reaction efficiency. The acidic gas treating process provided by the invention is simple and can achieve the dual objectives of purification of acidic gas and reclamation of pollutants; and an acidic gas treating system has the advantages of small scale, low energy consumption and low proneness to obstruction.

Owner:CHINA PETROLEUM & CHEM CORP +1

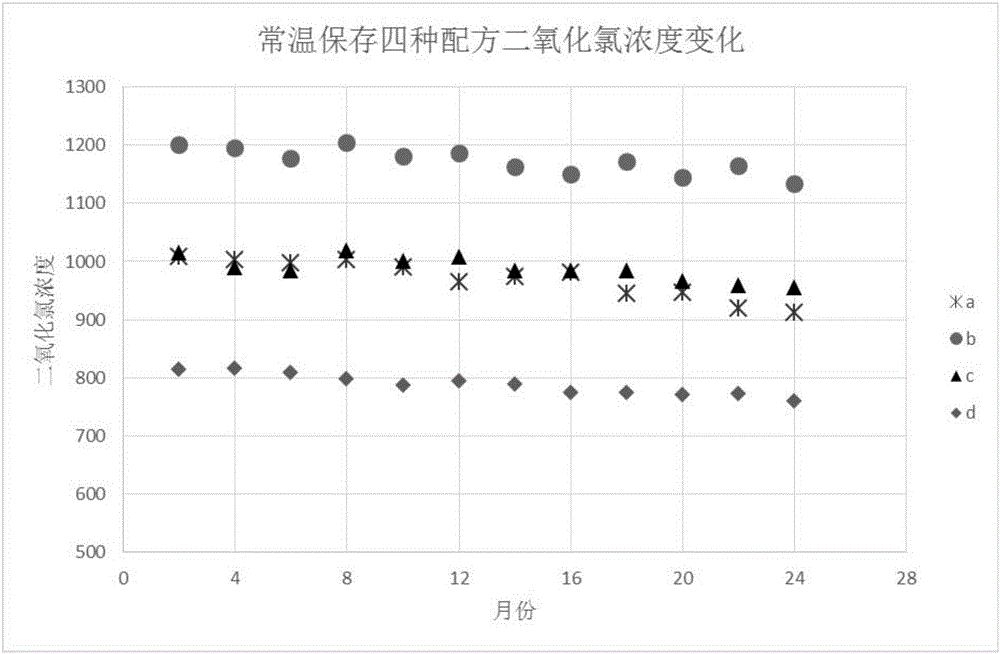

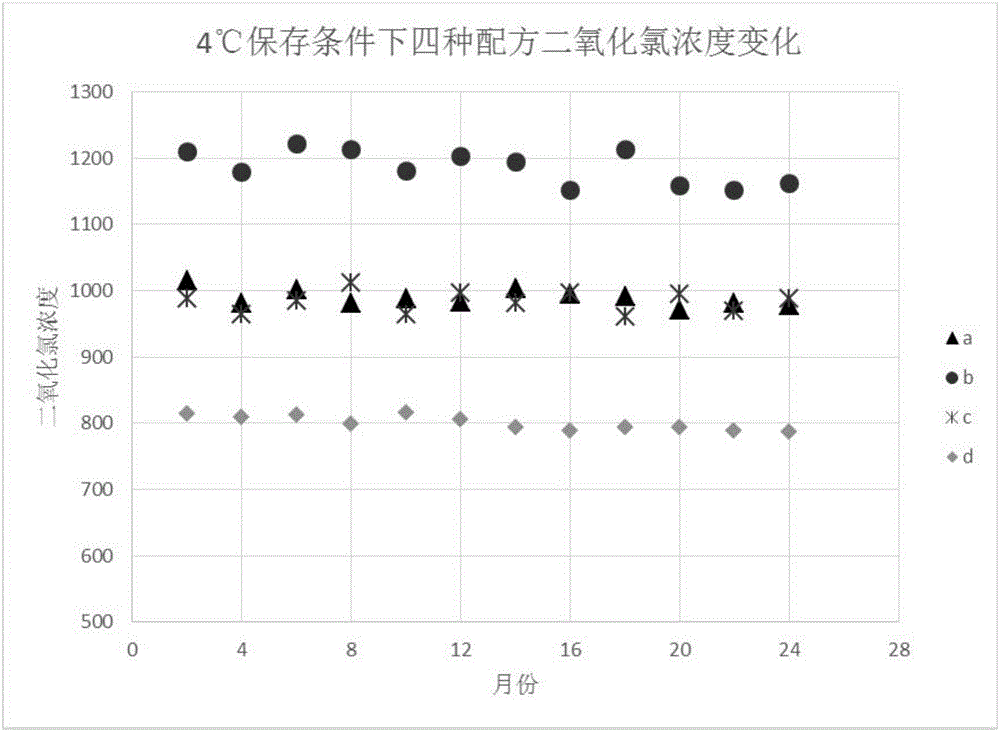

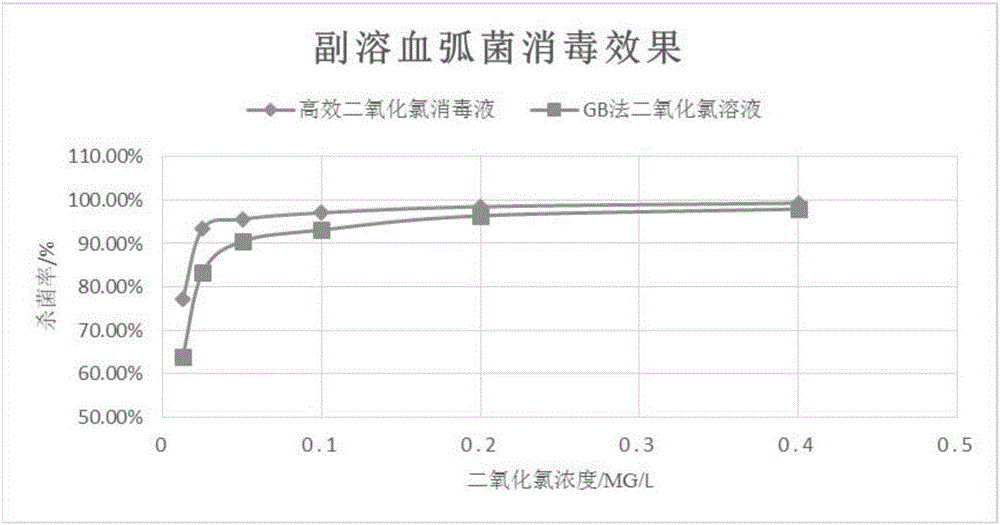

High-efficiency chlorine dioxide solution without activation as well as preparation method and application thereof

InactiveCN106818862ASlow degradationIncreased depth of responseBiocideDead animal preservationHalogenChlorine dioxide

The invention relates to a chlorine dioxide solution and in particular relates to a high-efficiency chlorine dioxide solution without activation as well as a preparation method and application thereof. The chlorine dioxide solution is mainly prepared from the following components in parts by weight: 30-40 parts of chlorite, 20-40 parts of an activating agent, and 10-20 parts of a halogen oxidant, wherein the content of chlorine dioxide gas in the solution is 600ppm or higher. According to the high-efficiency chlorine dioxide solution provided by the invention, a principle component of the solution is the chlorine dioxide gas, activation is not needed during use, and the solution can be directly used or used after dilution, and is safe and convenient; the solution can be preserved for 6 months or longer at a normal temperature, can be preserved for 18 months or longer at a temperature of 4 DEG C and is long in preservation period; the halogen oxidant in the solution can achieve a synergistic effect with the chlorine dioxide gas, so that the disinfection and sterilization effects of the chlorine dioxide can be improved, and the disinfection and sterilization effects are lasting and obvious. Therefore, the high-efficiency chlorine dioxide solution disclosed by the invention is safe, convenient, long in preservation period, and lasting and obvious in disinfection and sterilization effects.

Owner:清远海贝生物技术有限公司

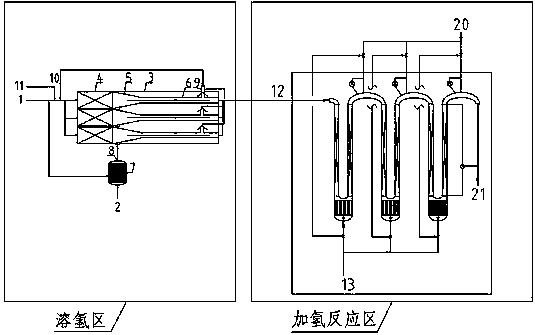

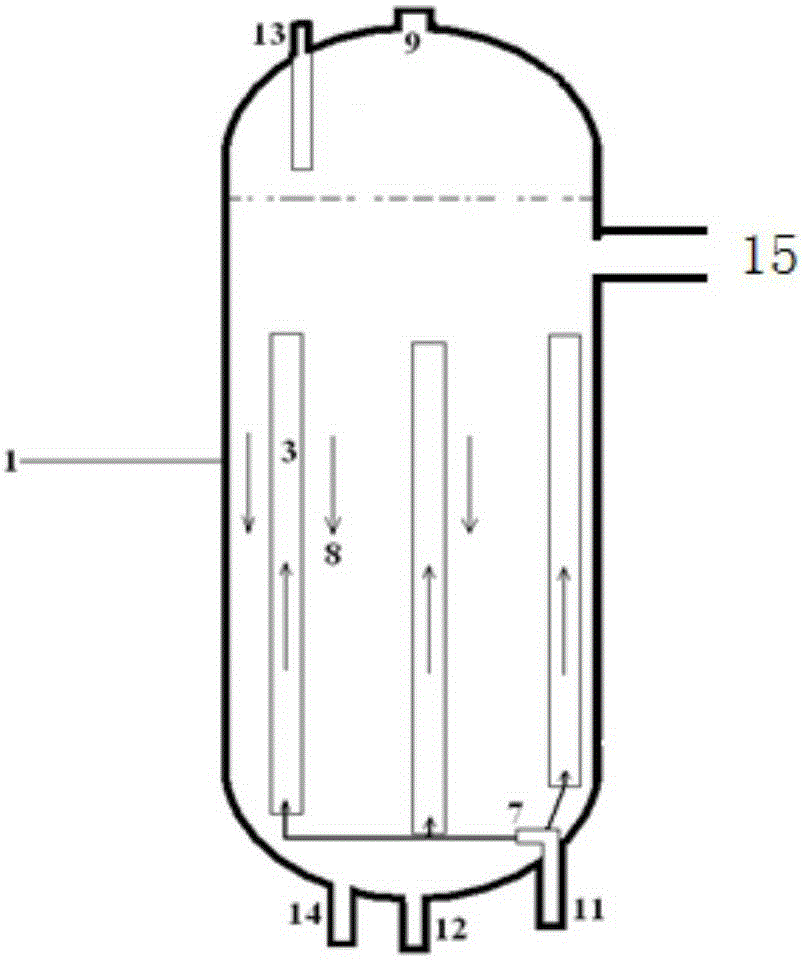

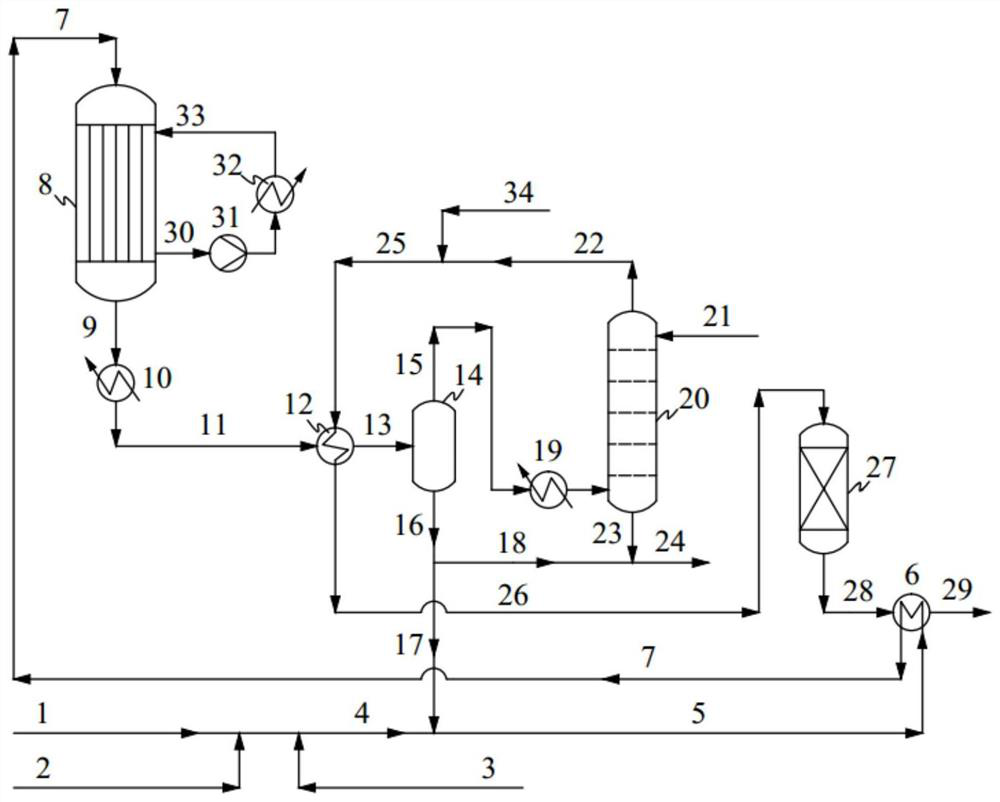

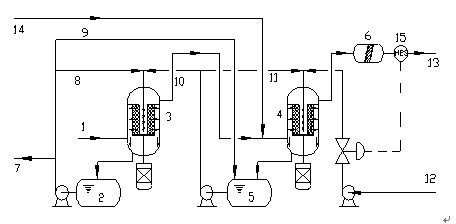

Liquid phase hydrogenation system and liquid phase hydrogenation method

ActiveCN111068589AExtended service lifeReduce hydrogen consumptionTreatment with hydrotreatment processesChemical/physical processesFluid phaseHydrogenation reaction

The invention discloses a liquid phase hydrogenation system and a liquid phase hydrogenation method. The system comprises a hydrogen dissolving zone and an efficient hydrogenation reaction zone, wherein the hydrogen dissolving zone is internally provided with a plurality of hydrogen dissolving devices, each hydrogen dissolving device comprises a hydrogen dissolving device shell, the hydrogen dissolving device shell internally comprises a plurality of hydrogen dissolving assemblies connected in parallel, the efficient hydrogenation reaction zone comprises a plurality of tubular reactors connected in series, and the tubular reactor is in a U shape and comprises straight pipe sections on the two sides and a horizontal section with the bottom communicated with the straight pipe sections on thetwo sides. According to the method disclosed by the invention, a gas-in-oil type gas-liquid mixed fluid formed in the hydrogen dissolving zone used as the feed of a liquid-phase hydrogenation reaction enters the U-shaped tubular reactor in the efficient hydrogenation reaction zone and is subjected to a deep hydrogenation reaction, so that the supplementary hydrogen-oil ratio during the hydrogenation reaction process can be substantially reduced, the hydrogen utilization rate can be improved, the hydrogen consumption and the energy consumption can be reduced, H2S, NH3 and other gases producedduring the reaction process can be continuously removed from the reaction system, the high hydrogenation reaction rate and the high reaction efficiency can be improved and maintained, and the deep hydrogenation reaction can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

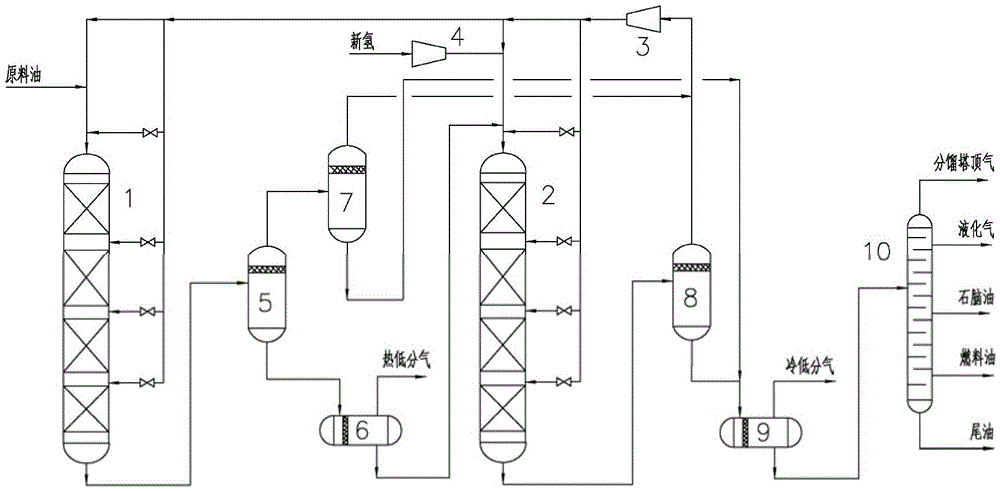

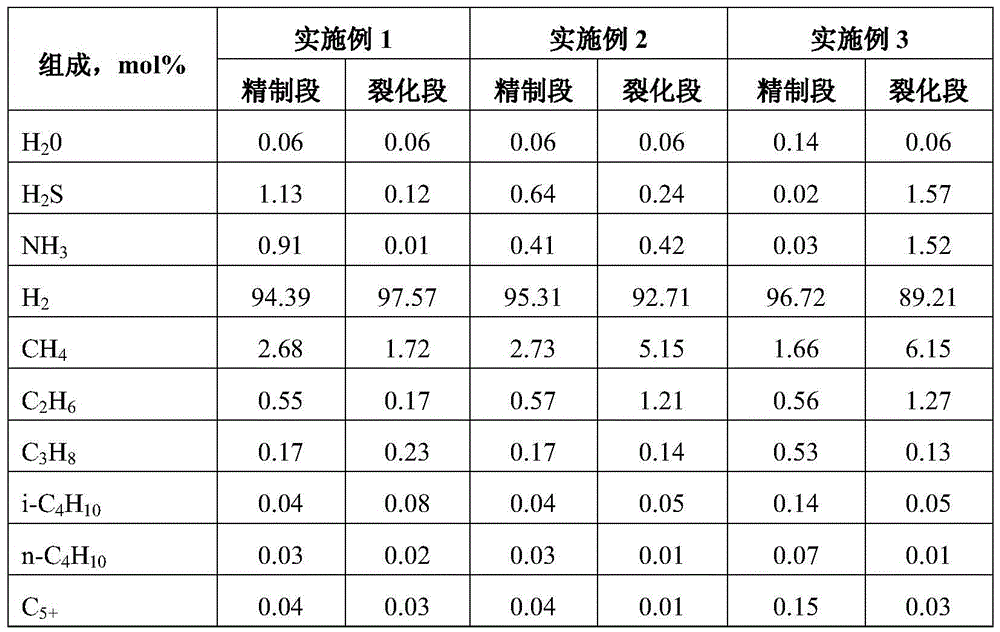

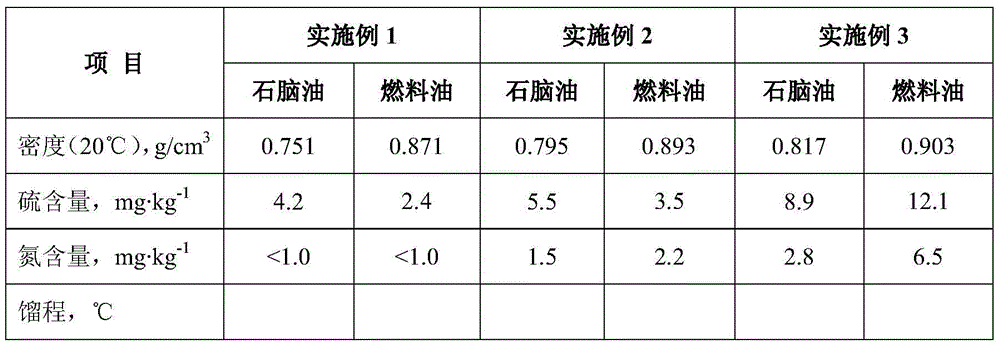

Anthracene oil hydrogenation method

ActiveCN105462610AAdd depthIncrease liquid collectionTreatment with hydrotreatment processesAnthraceneHydrogen purity

The invention discloses an anthracene oil hydrogenation method. According to the method, anthracene oil is diluted with hot low-pressure segregator oil, and then the diluted oil and inlet hydrogen are mixed to undergo hydrofining so as to obtain a hydrofining product; the hydrofining product is separated to obtain refined hot low-pressure segregator oil; part of the refined hot low-pressure segregator oil and inlet hydrogen are mixed, and new hydrogen is supplemented to carry out hydrocracking so as to obtain a hydrocracking product; the hydrocracking product is separated to obtain cracked cold high-pressure segregator oil; the cracked cold high-pressure segregator oil and refined cold high-pressure segregator oil are mixed and separation is then carried out to obtain cold low-pressure segregator oil; and the cold low-pressure segregator oil undergoes fractionation so as to obtain a product. by the method of introducing inlet hydrogen in the hydrofining stage and supplementing new hydrogen in the hydrocracking stage, the hydrogen circulatory system and new hydrogen joint point are adjusted, hydrogen purity and hydrogen partial pressure in the hydrogen circulatory system are guaranteed, hydrofining and hydrocracking depth is enhanced, liquid yield of the product is raised, and tail oil quantity is reduced. The method has advantages of simple technological flow, high conversion rate and stable plant operation.

Owner:HUADIAN HEAVY IND CO LTD

Pretreatment method of hydrocarbon oil in petroleum hydrocarbon catalytic cracking process

InactiveCN1534081AReduce pollutionIncreased depth of responseCatalytic crackingRefining by water treatmentWater in oilMetal pollution

A process for pre-treating the raw hydrocarbon oill in the catalytic cracking procedure of petroleum hydrocarbon includes mixing the raw oil with emulsifier, passivator and water, and emulsifying at 60-100 deg.c to become emulsified water-in-oil material. It can improve atonizing effect, lower metal pollution and benefit to prepare low-olefin gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

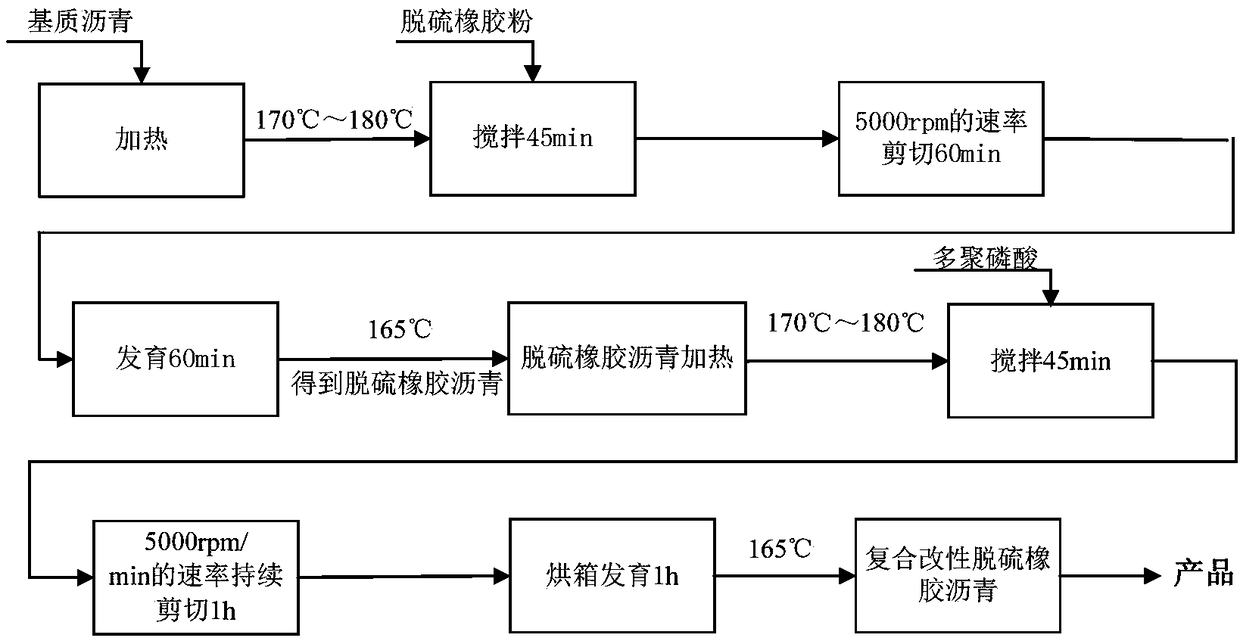

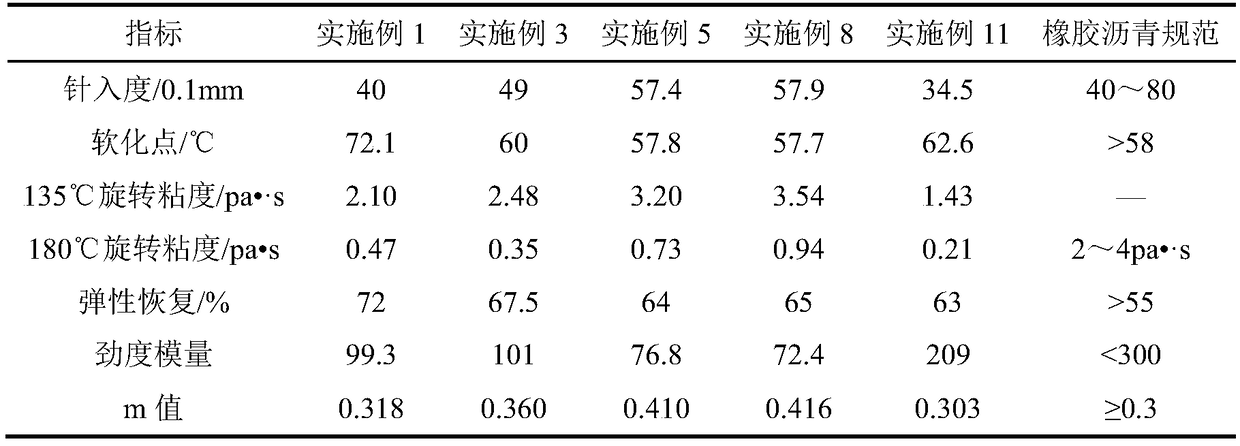

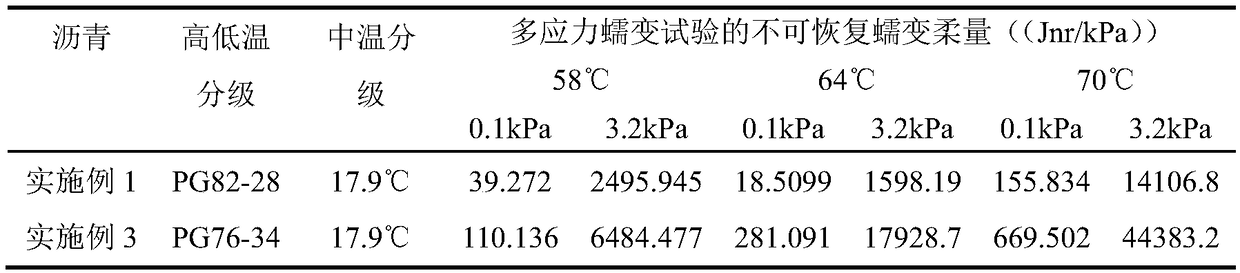

Composite modified desulfurized rubber asphalt and preparation method thereof

InactiveCN108727843AEnvironmental protection is goodGood environmental protection performance, good high and low temperature performanceBuilding insulationsPolymer scienceViscosity

The invention discloses composite modified desulfurized rubber asphalt and a preparation method thereof. After desulfurized rubber powder is added into matrix asphalt, the desulfurized rubber powder is evenly dispersed in the matrix asphalt, then the evenly-dispersed mixture is subjected to shearing, and the desulfurized rubber powder is finer through shearing under high-speed rotation, so that more reaction opportunities of the desulfurized rubber powder and the light component are created, then through a development technology, the desulfurized rubber powder swells in the matrix asphalt to form desulfurized rubber asphalt with good performance, after the desulfurized rubber asphalt is prepared, a composite modifying agent is added, a shearing technology is conducted, polyphosphoric aciddisperses more evenly in the desulfurized rubber asphalt, the reaction depth is improved, and through development, the polyphosphoric acid better swells in the desulfurized rubber asphalt to form thecomposite modified desulfurized rubber asphalt with good performance. The obtained composite modified desulfurized rubber asphalt is good in environment-friendly performance and high-and-low temperature performance, low in applicable viscosity and good in storage stability.

Owner:CHANGAN UNIV

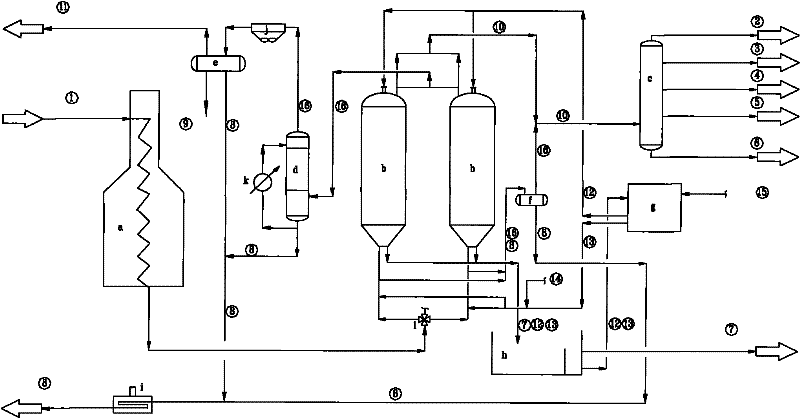

Deep processing method of non-caking coal or feebly caking coal

The invention discloses a deep processing method of non-caking coal or feebly caking coal, which comprises the following steps: performing medium-and-low-temperature carbonization reaction on non-caking coal or feebly caking coal to generate coal gas, semicoke and coal tar; treating the coal tar as follows: inputting the coal tar material, oil gas obtained through delayed coking reaction and a hydrocracking liquid-phase product into a distillation tower, and distilling out naphtha fractions, carbolic-oil-containing fractions, wax oil fractions and tower bottom oil; mixing the naphtha fractions with hydrogen, and inputting into a naphtha hydrofining reaction section; dephenolizing the carbolic-oil-containing fractions to obtain dephenolized oil, mixing with the wax oil fractions, and inputting into a hydrotreating reaction section; fractionating the hydrotreating reaction liquid phase into light fractions and heavy fractions, and performing hydrocracking on the heavy fractions; and inputting the tower bottom oil obtained through distillation into a delayed coker. Compared with the prior art, the method disclosed by the invention performs sufficient deep processing on coal, improves the yield of light fuel oil produced from coal tar, and simultaneously prolongs the service life of a catalyst in a hydrogenation device.

Owner:中铝能源有限公司

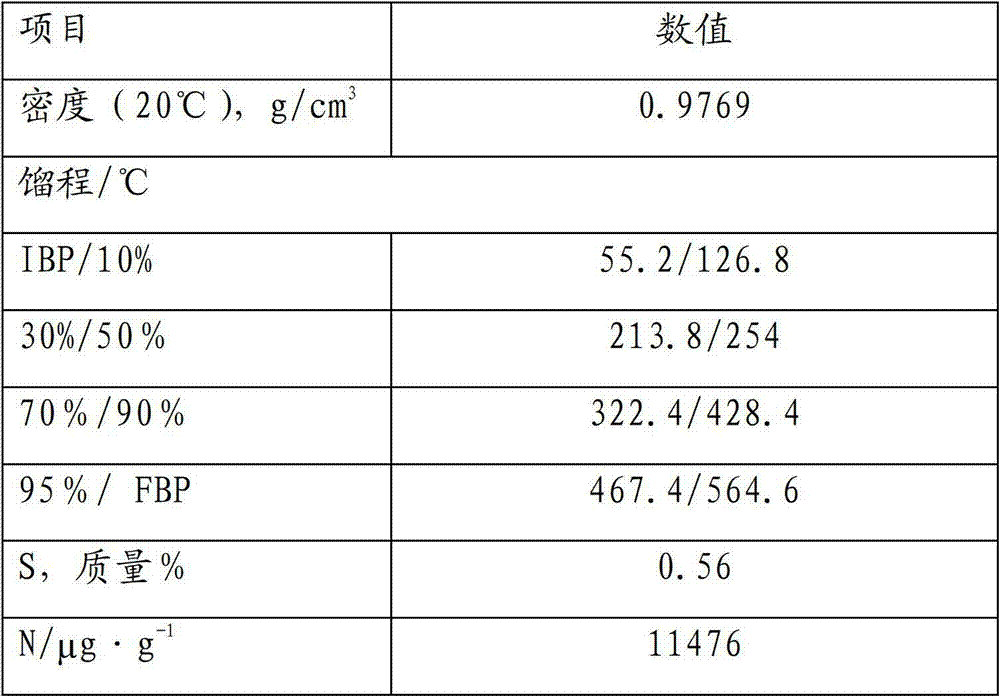

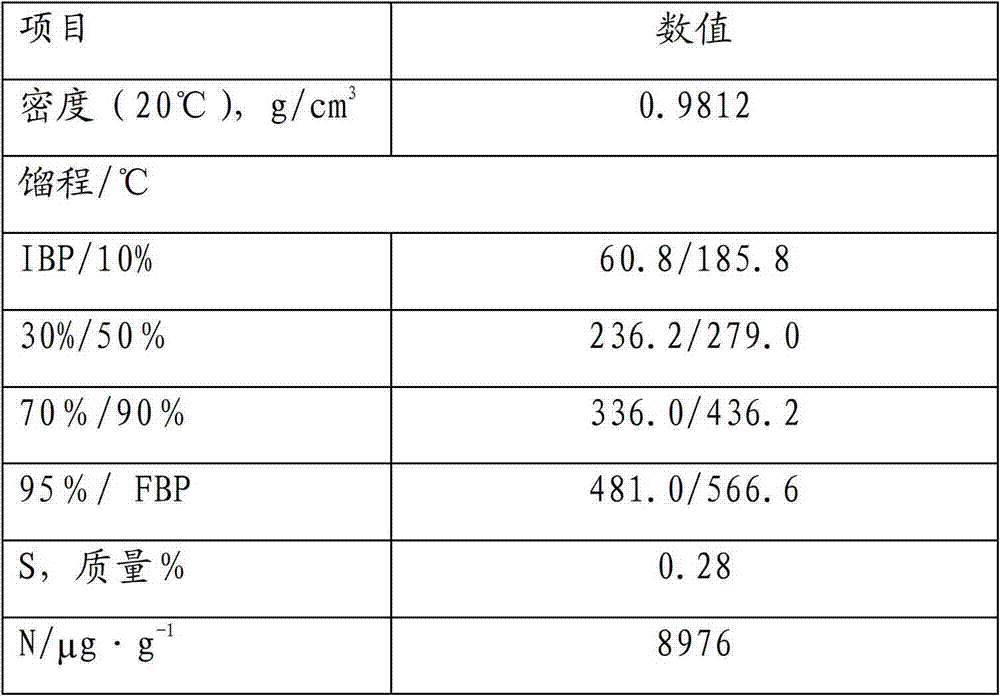

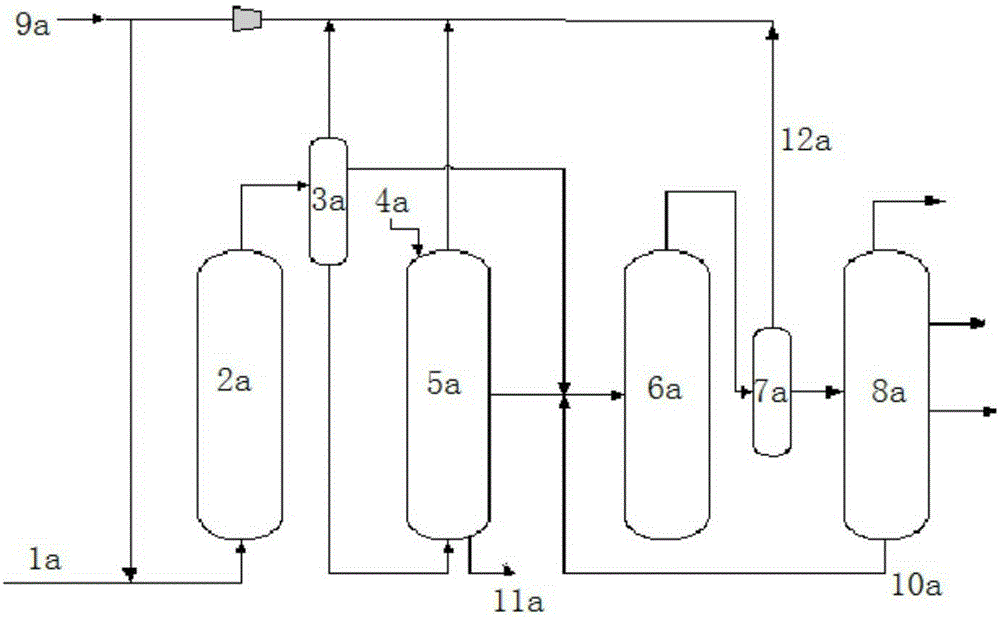

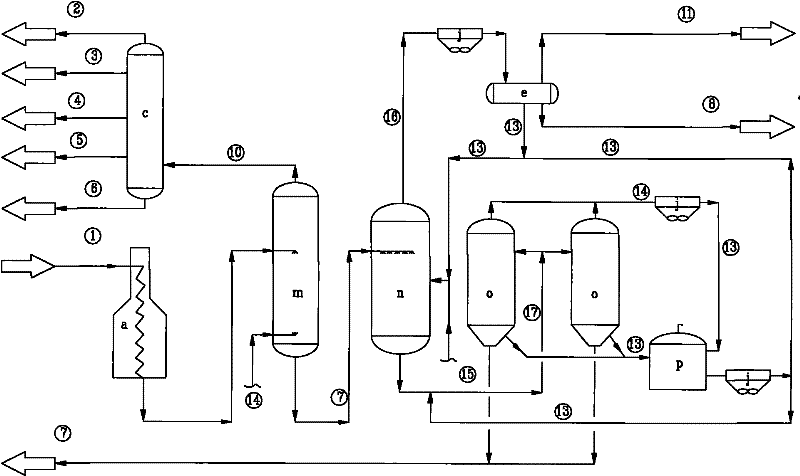

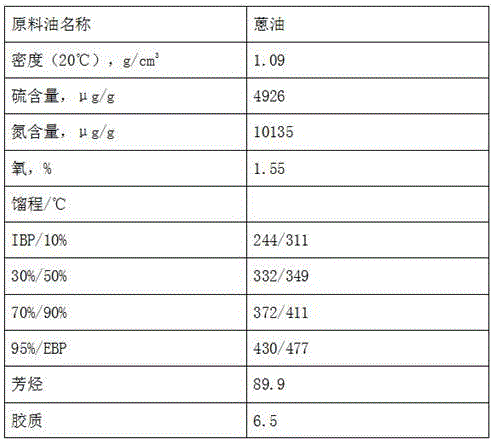

Method for processing full-range oil in coal tar

ActiveCN106635152AMaximize productionAvoid energy consumptionTreatment with hydrotreatment processesCycloneHigh concentration

The invention relates to the field of coal chemical industry and discloses a method for processing full-range oil in coal tar; the method comprises: introducing full-range oil of coal tar, hydrogen and hydrogenation catalyst I into a primary slurry-bed reactor for hydrocracking reaction; separating cracked mixture; introducing hydrogen, hydrogenation catalyst II and the obtained heavy oil into a secondary slurry-bed reactor with external cyclone hydraulic separator to carry out mild hydro-conversion reaction, introducing the reacted material obtained through the mild hydro-conversion reaction into the cyclone hydraulic separator for separating; circulating the obtained high-concentration phase back to the secondary slurry-bed reactor, and introducing light oil and low-density phase into a fixed-bed hydrogenation apparatus for hydrogenation reaction. By processing the full-range oil of coal tar through the method of the invention, it is possible to maximally produce clean fuels. The method of the invention may also prevent the problems of the prior art, such as high energy consumption, short operation cycle, and unreasonable diesel-gasoline ratio.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hot water boiler and water heating method

InactiveCN104534674AReduce manufacturing costNo pollutionFluid heatersChemical industryEngineeringWater processing

Owner:威海都尔电子有限公司

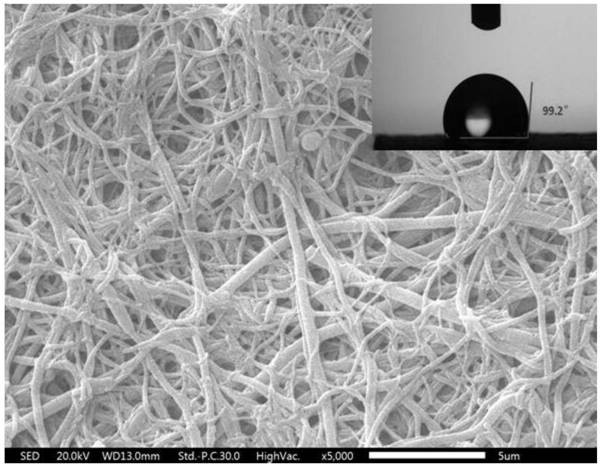

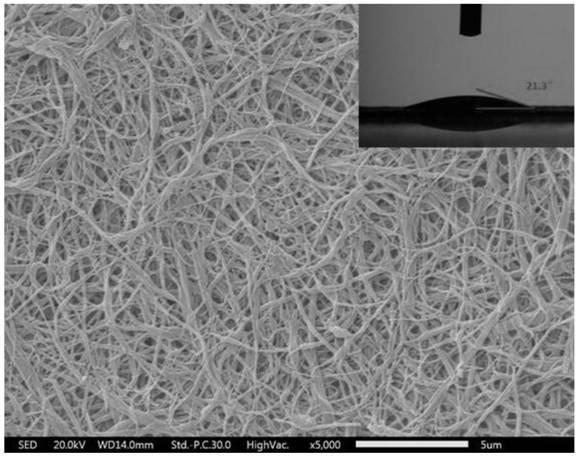

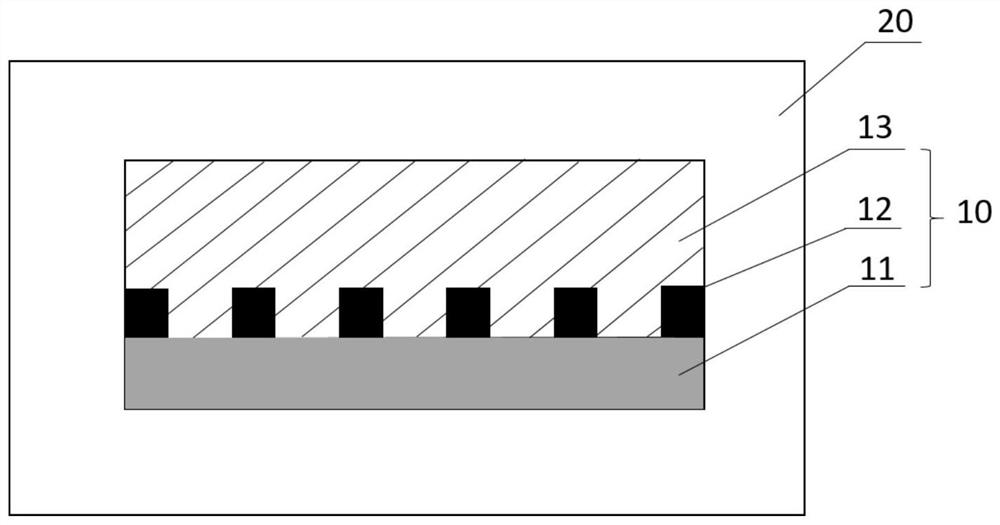

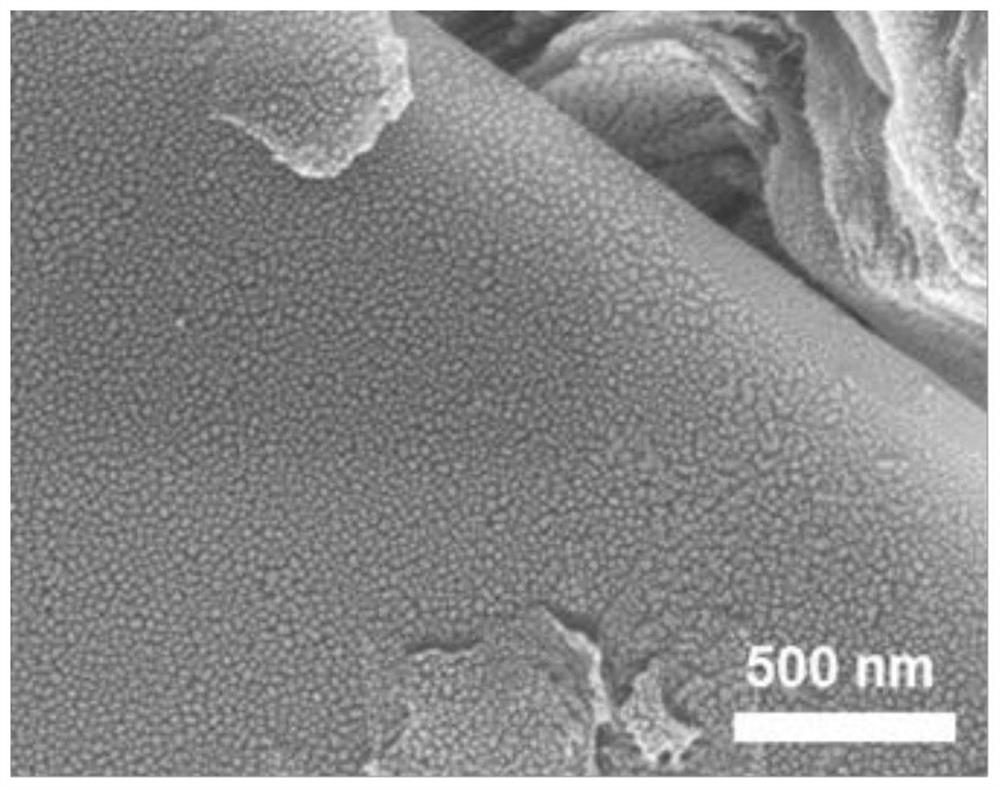

High-hydrophilicity nanofiber coating-based nanofiltration membrane and preparation method thereof

ActiveCN111644080AImprove hydrophilicityCompact structureMembranesSemi-permeable membranesPolymer scienceNanofiber

The invention provides a high-hydrophilicity nanofiber coating-based nanofiltration membrane and a preparation method thereof. The high-hydrophilicity nanofiber coating-based nanofiltration membrane is formed by compounding a high-hydrophilicity nanofiber coating base membrane and a nanofiltration separation layer loaded on the surface of the high-hydrophilicity nanofiber coating base membrane. The preparation method comprises the following steps: firstly, carrying out wet coating on an ethylene-vinyl alcohol copolymer nanofiber dispersion liquid on a non-woven fabric base layer to prepare a nanofiber coating base film; then carrying out alkali treatment and plasma treatment, and carrying out functional modification on the base membrane to obtain the high-hydrophilicity coating base membrane; and finally, carrying out interfacial polymerization to obtain the high-hydrophilicity nanofiber coating-based nanofiltration membrane. The composite nanofiltration membrane prepared by the invention is compact in structure, has high hydrophilicity, can realize synergistic improvement of flux and retention rate, and also has an excellent filtering effect. The preparation method provided by theinvention can optimize the interfacial polymerization process, and the preparation process is simple and controllable, green and pollution-free, and low in cost, and has a great industrial application prospect.

Owner:WUHAN TEXTILE UNIV

Combined processing method of heavy oil raw material

ActiveCN102643670AReduce the amount addedLow viscosityTreatment with plural serial stages onlyLiquid productFuel oil

A combined processing method of heavy oil raw materials. According to the invention, a proper amount of radical terminators are added into heavy oil raw materials, and the mixture is introduced into a thermal conversion reactor for mild thermal conversion; the material flow after thermal conversion enters a contact cracking reactor for a contact cracking reaction to obtain a oil gas product. After mild thermal conversion, the heavy raw oil with the added radical terminator has a decreased molecule size and reduced viscosity, and thus when the heavy oil enters the contact cracking reactor, better contact with contact agents is realized, and product distribution is improved. In addition, the addition of the radical terminator into the heavy oil raw materials increases the yield of liquid products of the mild thermal conversion, and reduces the coke yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

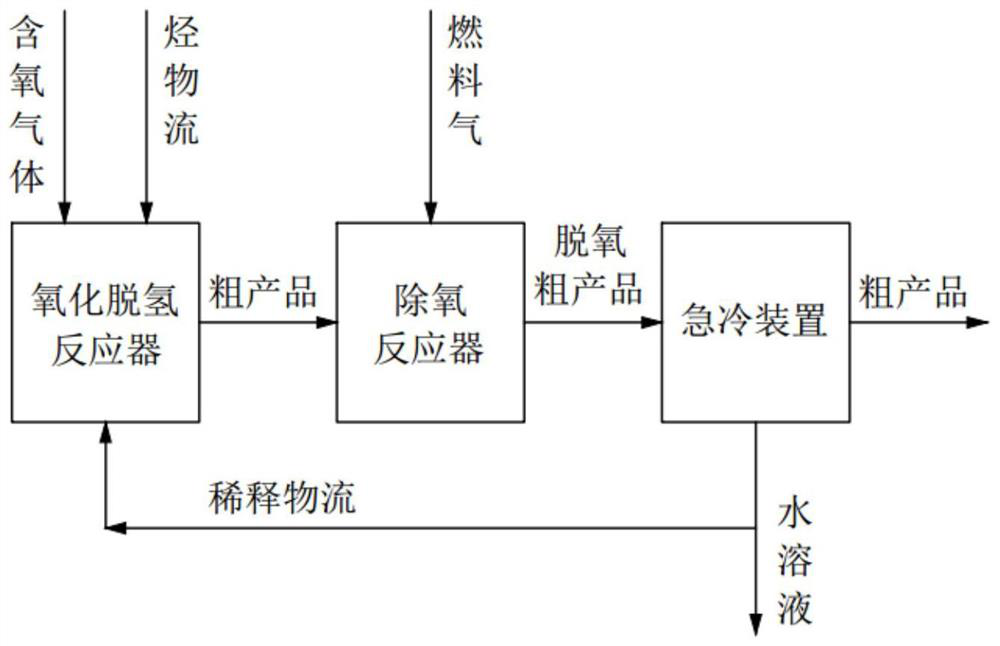

Method for removing residual oxygen in product flow of ethylene preparation by ethane catalytic oxidative dehydrogenation

PendingCN112142547AReduce processingSmall sizeChemical industryHydrocarbonsCatalytic oxidationDehydrogenation

The invention relates to a method for removing residual oxygen in a product flow of ethylene preparation by ethane catalytic oxidative dehydrogenation, wherein the method comprises the following steps: (1) feeding mixed raw material gas into an oxidative dehydrogenation reactor for reaction, carrying out waste heat recovery and cooling on the obtained crude product gas, and then feeding the crudeproduct gas into a gas-liquid separation tank for gas-liquid separation; (2) cooling a gas phase at the top in the gas-liquid separation tank, feeding the cooled gas phase into an absorption tower, and obtaining deacidified gas from the top of the absorption tower under the action of a tower top absorbent; and (3) feeding the obtained deacidified gas into a deaerator, and deoxidizing to obtain a deoxidized crude product. Compared with the prior art, the treatment capacity of the deaerator can be effectively reduced, the equipment investment is reduced, and meanwhile, the improvement of the deaeration reaction depth is facilitated. Besides, part of process condensate is injected into the mixed feed gas flow, and the reaction waste heat is gasified and recycled, so that the reaction temperature rise can be effectively controlled, and more reaction waste heat can be recycled.

Owner:WISON ENG +1

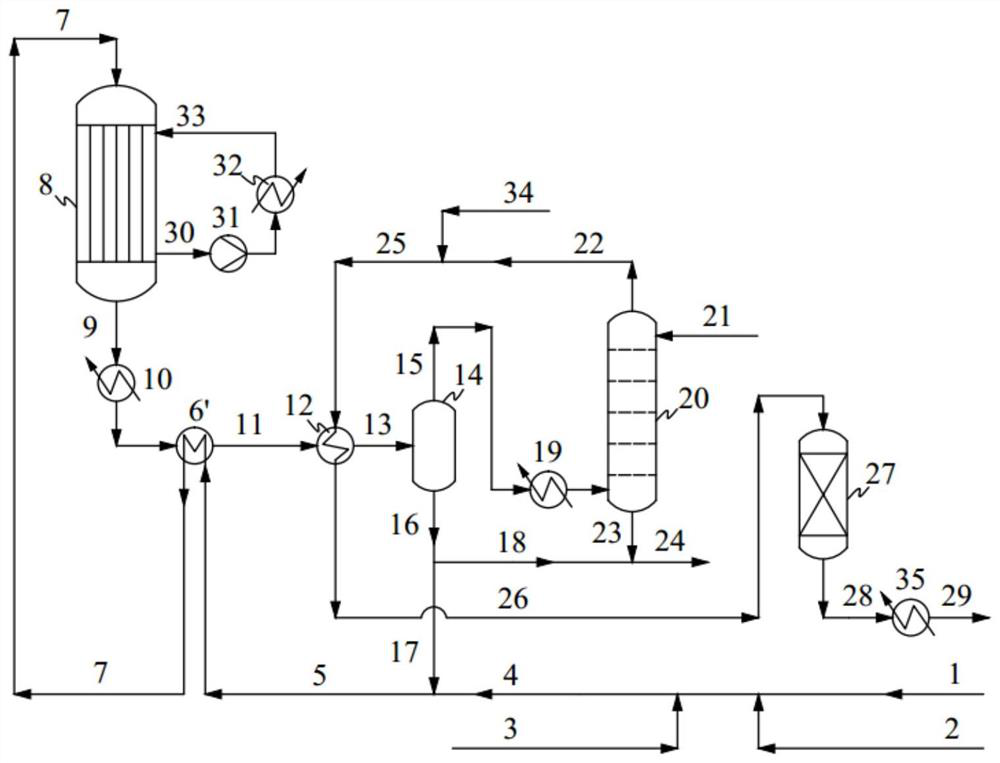

Etherification method combined with catalytic cracking absorption stable system

ActiveCN101245259AEffective combinationSave energy costHydrocarbon oils treatmentFractionationFatty alcohol

The invention provides a hydrocarbon etherification method which is combined with a catalytic cracking absorbing stabilizing system; after being mixed with the chosen fatty alcohol, the hydrocarbon etherification raw materials are sent into a pre-etherification reactor, and reacts with a pre-etherification catalyst in a contact way; without separation, the reaction products are directly put into catalytic cracking stabilizer after being mixed with the chosen fatty alcohol; during the reaction period in the catalytic cracking stabilizer, the reaction products react in contact with the etherification catalyst for fractionation, separated liquefied gas can be obtained from the top of the stabilizer, while stabilized gasoline containing ether compound is obtained from the bottom of the stabilizer. The method fully makes use of the mass transfer and heat transfer conditions of the catalytic cracking stabilizing system, which does not only reduce the energy and material consumption, but also obtains the stabilized gasoline with low content of olefin, high octane value and qualified vapor pressure; the method has great suitability towards the characteristic that domestic catalytic gasoline has high content of olefin, which can provide more operating flexibility for refineries to produce gasoline of high index.

Owner:CHINA PETROLEUM & CHEM CORP

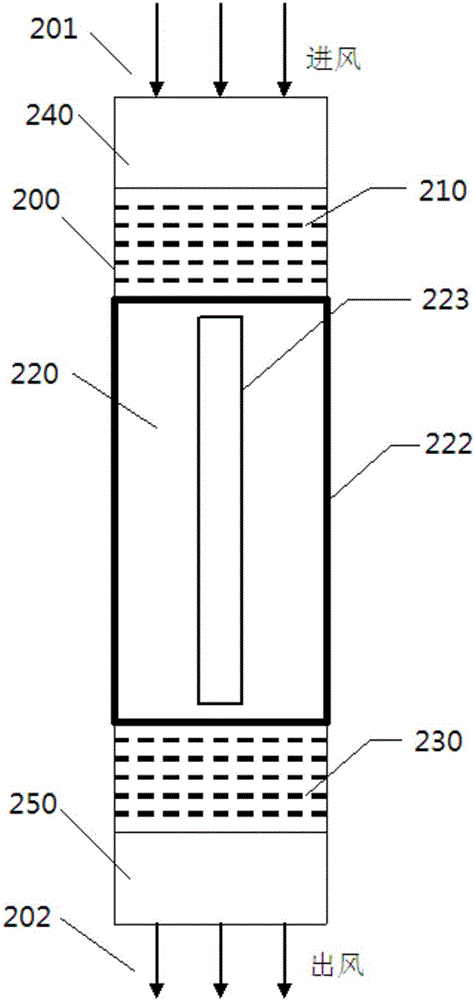

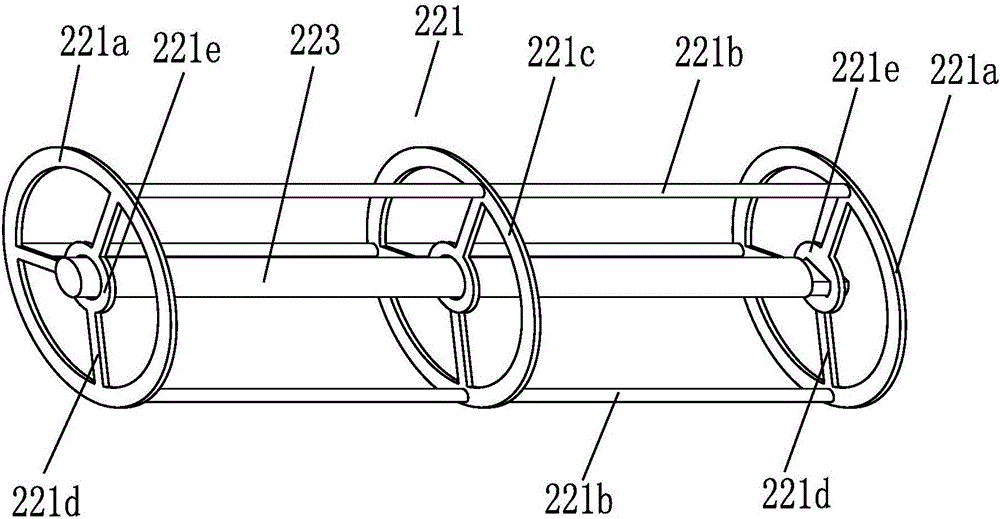

Air purification device for removing low concentration formaldehyde and benzene series

InactiveCN106466553AQuick clearEfficient removalGas treatmentDispersed particle separationBenzenePhysical chemistry

The invention provides an air purification device for removing low concentration formaldehyde and benzene series. The device comprises a casing provided with an air inlet and an air outlet communicating with a space to be purified, a pretreatment bin arranged in the casing and located behind the air inlet, Wherein a physical adsorption layer for adsorbing formaldehyde in air and benzene series molecular particles in air is arranged in the pretreatment bin, a photocatalyst reaction bin arranged in the casing and behind the pretreatment bin, and an exhaust gas recovery bin which is arranged in the casing, behind the photocatalyst reaction bin and in front of the air outlet and is used for recovering and trapping trace amounts of formaldehyde and benzene molecular particles undecomposed catalytically by the photocatalyst reaction bin. The air purification device utilizes a pretreatment bin-photocatalyst reaction bin-exhaust gas recovery bin three-grade composite bin structure to solve the technical problem that the existing photocatalyst technology can not clear the low concentration of formaldehyde and benzene series particles in the air.

Owner:湖北尼帕莱尔环保科技有限公司

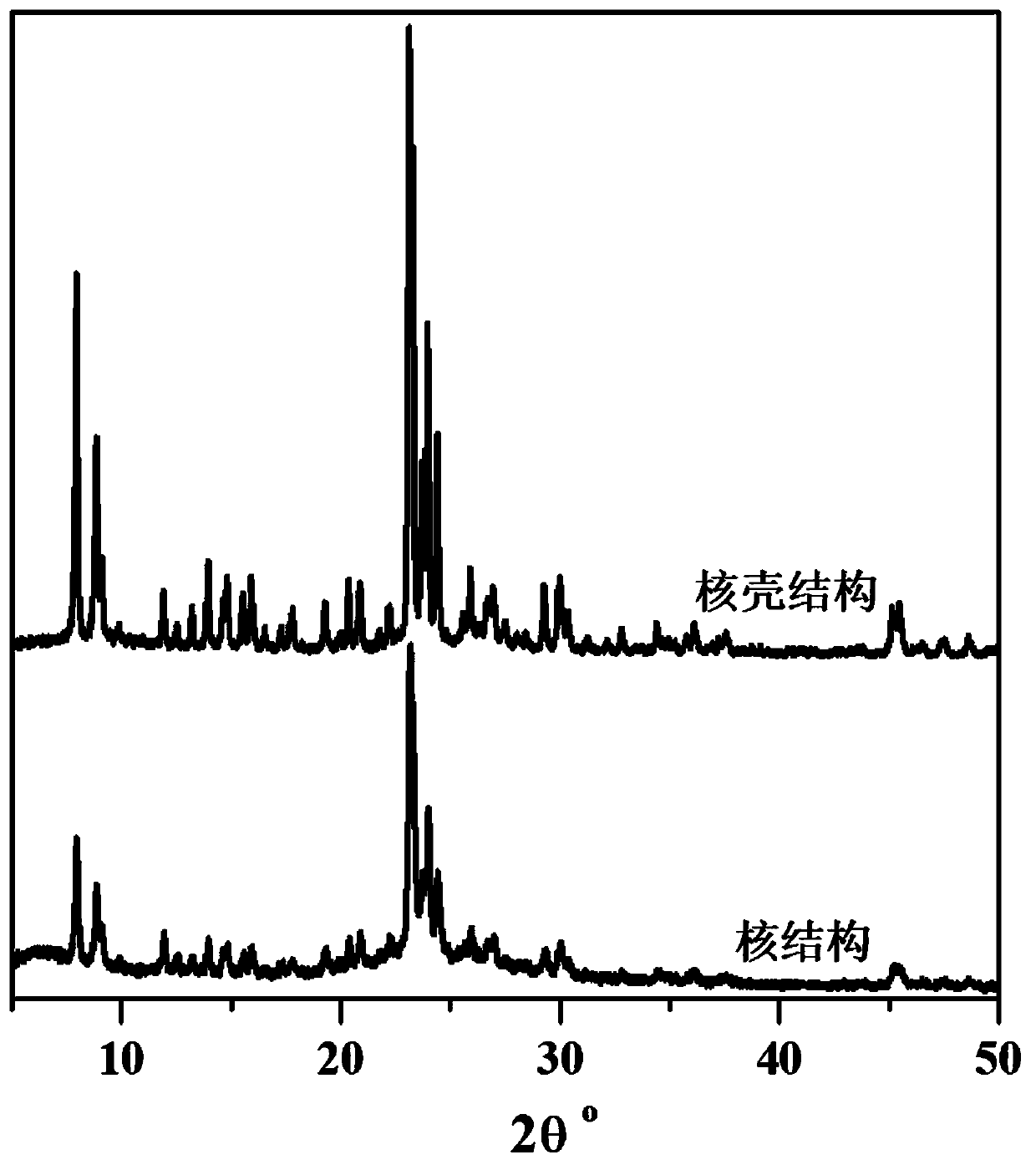

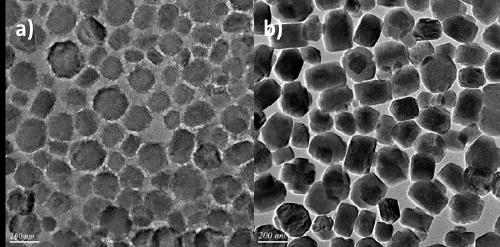

HZSM-5 molecular sieve with core-shell structure for methanol-to-aromatic hydrocarbon reaction and preparation method thereof

ActiveCN111054430AImplement a step-by-step conversion processEasy to controlMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sievePtru catalyst

The invention relates to an HZSM-5 molecular sieve with a core-shell structure for a methanol-to-aromatic hydrocarbon reaction and a preparation method thereof. The shell layer of the catalyst is a ZSM-5 molecular sieve with a high silica-alumina ratio for catalyzing the reaction of preparing low-carbon olefin from methanol, and the core part of the catalyst is low silica-alumina ratio MZSM-5 loaded with a metal species M, so that the reaction process of further aromatizing the low-carbon olefin generated from the shell layer into aromatic hydrocarbon is realized. By adopting the ZSM-5 catalyst with the core-shell structure disclosed by the invention, coupling of two reaction processes of preparing low-carbon olefin from methanol and preparing aromatic hydrocarbon from low-carbon olefin can be realized on one catalyst, and the aromatic hydrocarbon is obtained with high selectivity.

Owner:TAIYUAN UNIV OF TECH

Preparation method of lithium-ion battery

InactiveCN109786855AIncrease in sizeSizeElectrode manufacturing processesFinal product manufactureFlocculationTetrafluoroethylene

The invention discloses a preparation method of a lithium-ion battery. The method comprises a preparation process of positive paste and negative paste, wherein the positive paste and the negative paste are prepared through the process of mixing, soaking, dispersion and flocculation of a positive raw material and a negative raw material; the positive paste contains, by weight, 80-90 parts of a nickel-cobalt-manganese ternary material, 1-5 parts of a binder and 5-20 parts of a conductive agent; and the negative paste contains polytetrafluoroethylene which is added according to the proportion of60% of negative raw material paste, wherein the 60% of polytetrafluoroethylene contains 2 parts of carboxymethylcellulose. According to the method, the nickel-cobalt-manganese ternary material is adopted as the positive raw material of the lithium-ion battery first, the positive raw material is made into appropriate paste through pretreatment of the positive material and the paste making process of mixing, soaking and flocculation, and the positive paste is spread on an aluminum thin film to form the intact lithium-ion battery in cooperation with the functions of the negative material, an electrolytic solution and a membrane. The battery has the advantages that discharge voltage is high, safety is good, and repeated discharge can be performed multiple times cyclically.

Owner:泰顺永庆电力技术有限公司

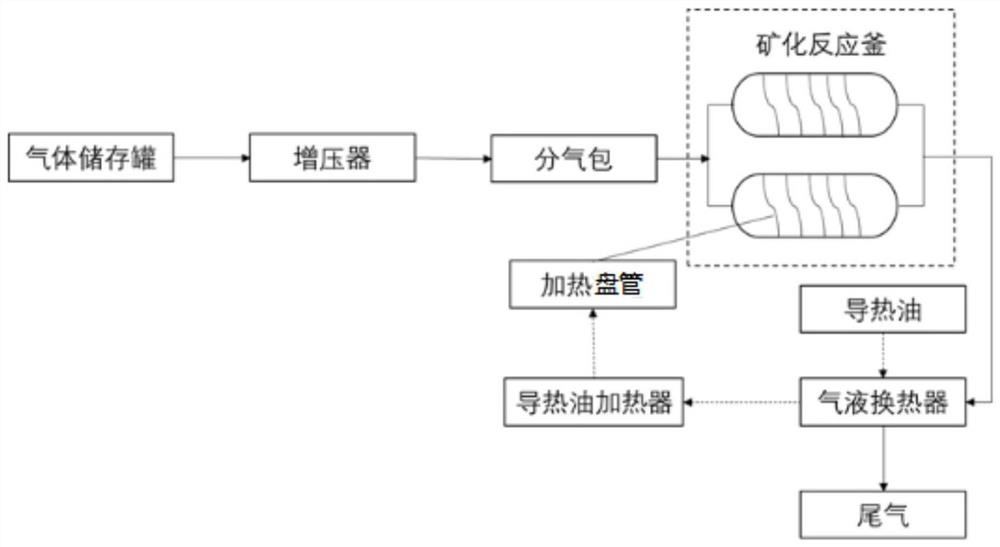

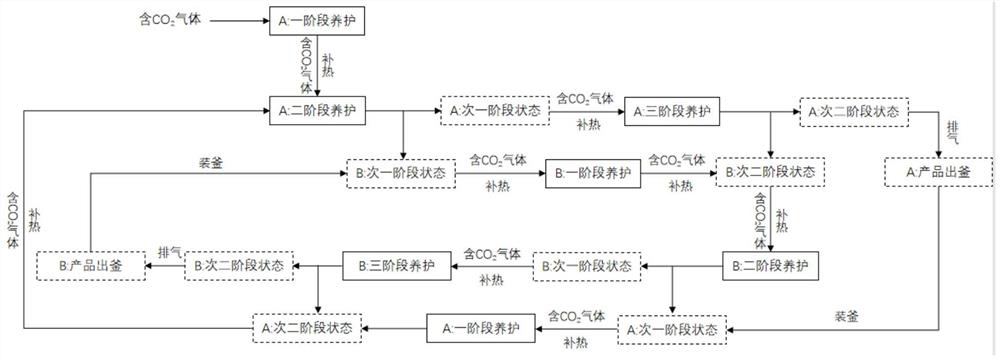

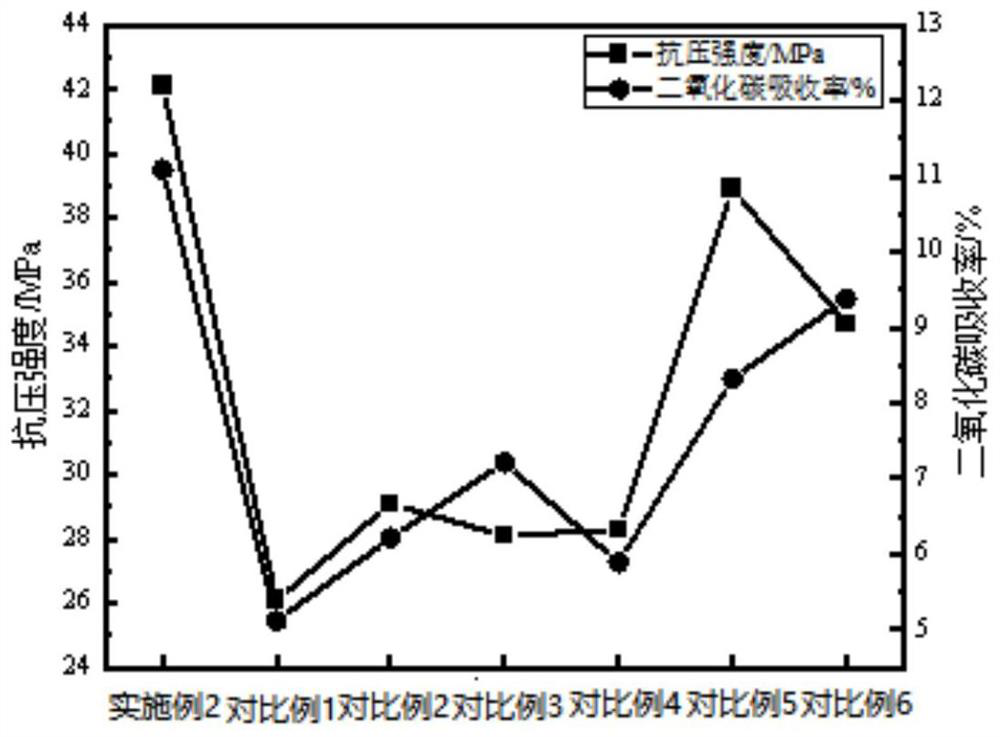

Device and method for mineralizing low-concentration carbon dioxide by solid waste

ActiveCN114210694ACut costsSave energyTransportation and packagingSolid waste disposalWaste treatmentHolding tank

The invention relates to the field of waste treatment and carbon dioxide mineralization utilization, in particular to a method for rapidly fixing carbon dioxide by using bulk solid waste and application of the method. The device for mineralizing the low-concentration carbon dioxide in the solid waste comprises a gas storage tank, a supercharger, a gas distributing bag and a plurality of groups of mineralization reaction kettles with heating coils which are connected in sequence, and an outlet of the gas storage tank, an inlet of the supercharger, an outlet of the supercharger, an inlet of the gas distributing bag, an outlet of the gas distributing bag and inlets of the plurality of groups of mineralization reaction kettles are connected in sequence. The device and the method are low in cost, efficient resource utilization is achieved, mineralization of low-concentration carbon dioxide gas is achieved, and meanwhile internal defects of mineralized products are greatly reduced.

Owner:江苏集萃功能材料研究所有限公司

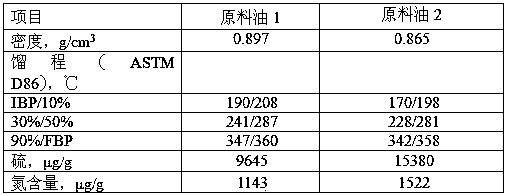

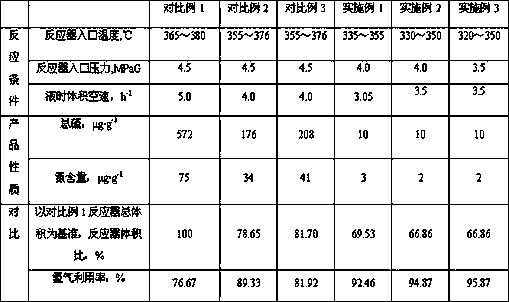

Diesel oil ultra-deep desulfurization device and diesel oil hydrogenation reaction system

ActiveCN111068588AAccelerate Dissolution and DispersionIncrease mass transfer driving forceChemical/physical processesHydrocarbon oils treatment productsThermodynamicsHydrodesulfurization

The invention discloses a diesel oil ultra-deep desulfurization device and a diesel oil hydrogenation reaction system. The ultra-deep desulfurization device comprises a plurality of U-shaped tubular reactors connected in series, wherein the adjacent tubular reactors are communicated through arc-shaped pipes, and the tubular reactor is in a U shape and comprises straight pipe sections on the two sides and a horizontal section at the bottom and communicated with the straight pipe sections on the two sides. The diesel oil hydrogenation reaction system comprises a fixed bed hydrogenation reactor and a plurality of U-shaped tubular reactors connected in series. According to the invention, H2S, NH3 and other gases generated in the reaction process can be continuously moved out of the reaction system, the hydrogenation reaction rate is improved, the continuous high efficiency of the hydrogenation reaction process is maintained, and deep hydrodesulfurization and ultra-deep desulfurization arerealized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Continuous delay coking device and method

ActiveCN102344825AReduce frequent switching timesReduce labor intensityTreatment with plural serial stages onlyLiquid productWater circulation

The invention provides a continuous delay coking device and a continuous delay coking method. The method comprises the following steps that: oil gas generated by a delay coking reactor is introduced into a fractionate tower from the top of the reactor, and the coke obtained by the reaction is stripped with steam and stays for 6-18 h in the reactor and then continuously flows out from the bottom of the reactor and introduced into a coke quench tower or is directly used for gasifying raw material; and the high temperature coke is introduced into the quench tower filled with water, the coke is cooled and introduced into a drain sump or a centrifuge with cooling water, the dehydrated coke is delivered to a feed bin through a belt, water vapour obtained by heat absorption and vaporization in the quench tower is subject to self-pressure heat exchange or condensing and cooling, and the condensed water is recycled. According to the invention, processing capability and liquid product yield of the device are improved, the adaptability to raw material of low quality is improved, the energy consumption and investment of the device are reduced, the occupied area is reduced, the pollution is reduced, the service life of the device and pipelines is prolonged, the potential safety hazard of coke tower shaking and the like caused by shot coke production by the traditional delay coking device is prevented, and strong adaptability to raw material is achieved.

Owner:CHINA PETROCHEMICAL CORP +1

Anthracene oil hydrogenation method

InactiveCN106221792ALow aromatic contentHigh purity hydrogenTreatment with hydrotreatment processesHydrocarbon oils treatment productsAnthraceneGasoline

The invention belongs to the technical field of coalification industry and particularly relates to an anthracene oil hydrogenation method. The anthracene oil hydrogenation method comprises the following steps that after anthracene oil hydrofining, separation is performed through a hot high-pressure separator, a liquid-phase product enters a hot low-pressure separator, and hot low-fraction oil is partially circulated to a hydrofining reactor; the residual hot low-fraction oil enters a hydrocracking reactor to obtain a hydrocracking product, the hydrocracking product and gas separated from the hot high-pressure separator enter a cold high-pressure separator, the liquid separated from the hot high-pressure separator and gas separated from the hot low-pressure separator enter a cold low-pressure separator for further gas-liquid separation, cold low-fraction oil separated from the cold low-pressure separator is partially circulated to the hydrofining reactor; fractionation is conducted on the residual cold low-fraction oil to obtain various products and tail oil. The method is small in temperature rise at a refining stage and stable in operation, can not only used for production of light gasoline and diesel products through anthracene oil hydrogenation, makes the devices safe and stable in operation and prolongs the operating cycle of the devices.

Owner:山东恒信科技发展有限公司

Acidic gas treating process and system

ActiveCN104826468AIncreased depth of responseFully contactedSulfur compoundsDispersed particle separationGas liquid reactionPhysical chemistry

The invention discloses an acidic gas treating process and system. The acidic gas treating process employs a two-stage gas-liquid two-phase countercurrent absorption reaction and uses a NaOH solution as an absorption liquid to treat acidic gas so as to produce NaHS. According to the process, a primary liquid reaction product and a secondary liquid reaction product are cyclically used, and the primary liquid reaction product is circulated to a secondary intermediate tank and used as a diluent. The acidic gas treating system adopts a rotating bed reactor as a gas-liquid reactor; CO2 in the acidic gas reacts with NaOH to produce nanometer Na2CO3 crystal, so obstruction of a pipeline by the Na2CO3 crystal during fluid conveying is prevented. The acidic gas treating process provided by the invention is simple and can achieve the dual objectives of purification of acidic gas and reclamation of pollutants; and the acidic gas treating system has the advantages of small scale, low energy consumption and low proneness to obstruction.

Owner:CHINA PETROLEUM & CHEM CORP +1

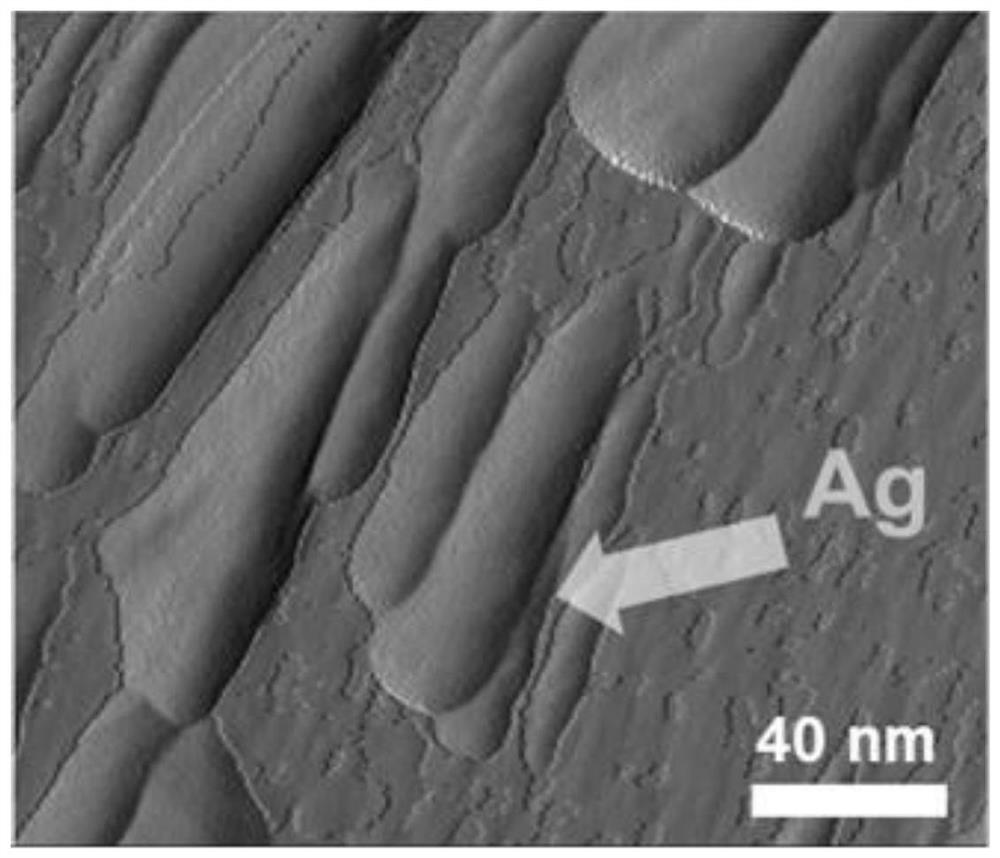

Pre-lithiated negative plate, preparation method thereof and lithium battery

PendingCN114335417AStabilize electron conductivityIncrease profitSecondary cellsNon-aqueous electrolyte accumulator electrodesPhysicsElectron transmission

The invention discloses a pre-lithiation negative electrode plate, a preparation method thereof and a lithium battery, and the pre-lithiation negative electrode plate comprises a negative electrode current collector, an active material layer covering the surface of the negative electrode current collector, a plurality of modification layers covering part of the surface of the active material layer, and lithium-containing layers covering the residual surface of the active material layer and the surfaces of the plurality of modification layers, the multiple modification layers are distributed on the surface of the active material layer at intervals, and the coverage rate is 30-75%. The modification layer / lithium-containing layer interface in the pre-lithiation negative electrode serves as an artificial electronic path and is responsible for stabilizing electron transmission between two phase interfaces in the pre-lithiation process, damage of interface stress fluctuation to the structure of the electronic path is avoided, the reaction depth of contact pre-lithiation is remarkably enhanced, the utilization rate of the lithium-containing layer is increased, and the service life of the lithium-containing layer is prolonged. The yield of inert lithium is reduced, and the capacity retention ratio and the cycling stability of the battery are improved.

Owner:TSINGHUA UNIV

Preparation method of biological diesel oil

InactiveCN100513521CHigh catalytic activityNo emissionsBiofuelsLiquid hydrocarbon mixture productionOil and greaseBiodiesel

Owner:张海军

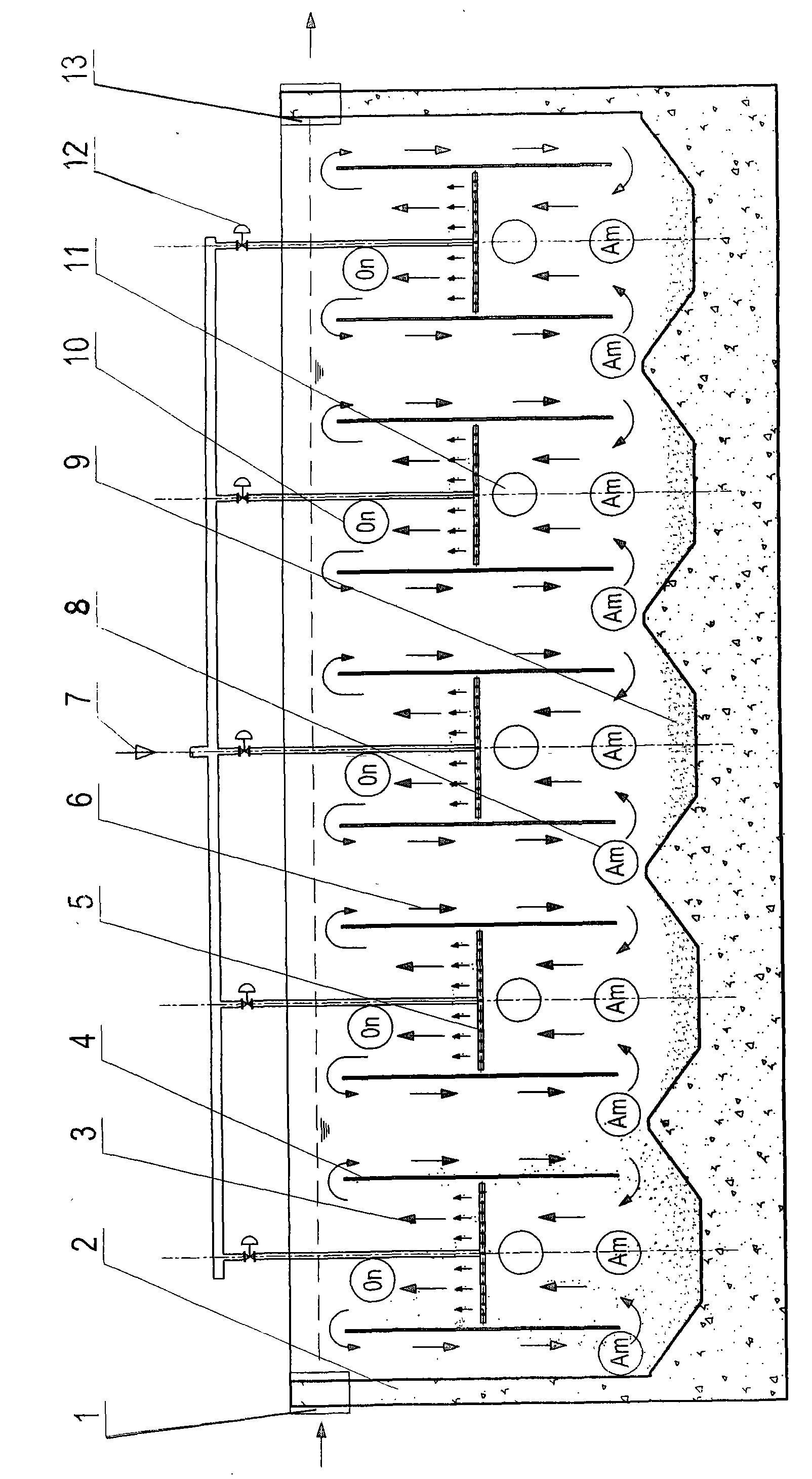

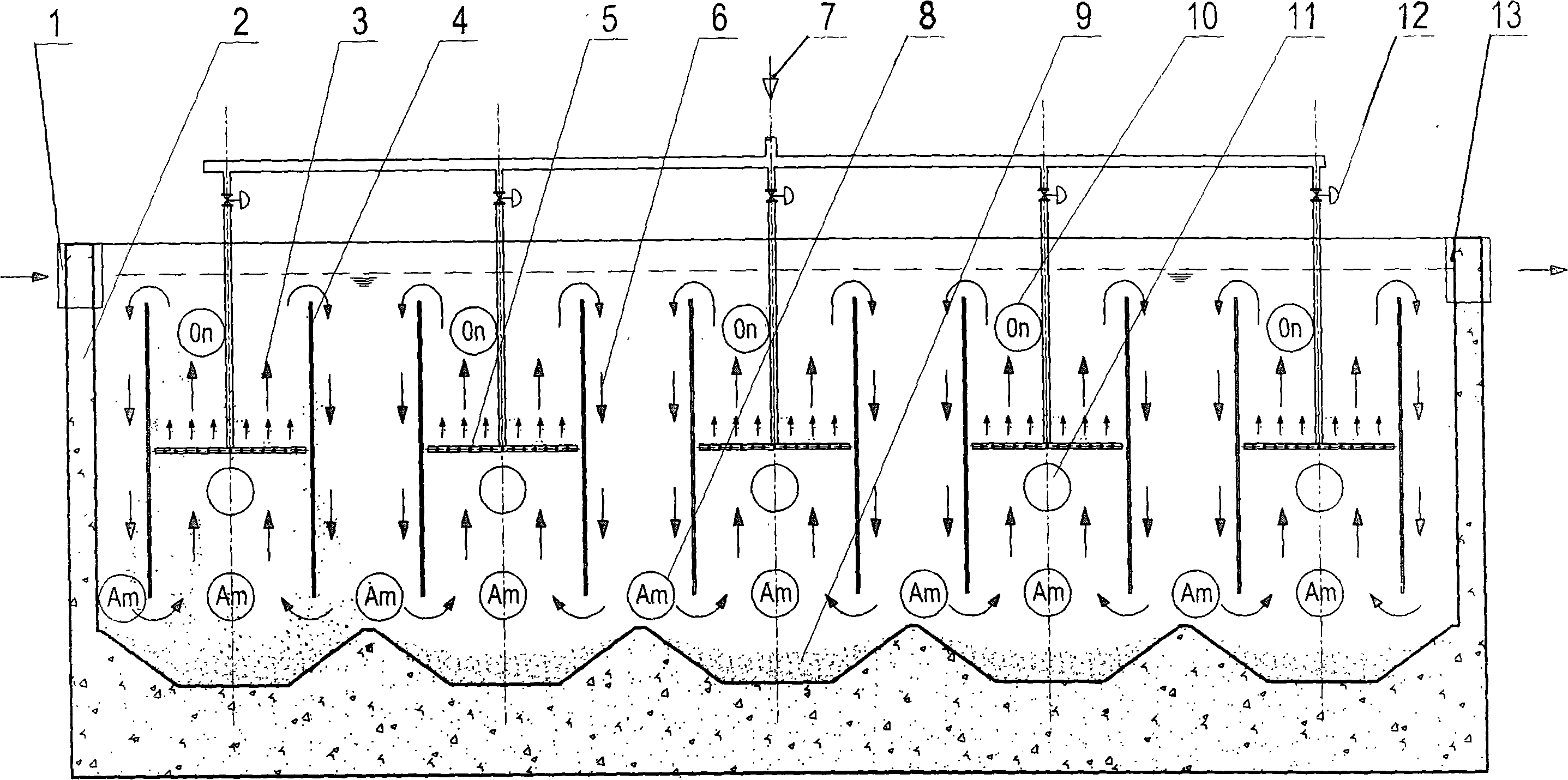

Aerobic sedimentation pond for sewage treatment

InactiveCN101857306AWell mixedControl dwell timeTreatment with aerobic and anaerobic processesCyclic processReflux

The invention relates to an aerobic sedimentation pond for sewage treatment, which is characterized in that one end of a pond body is provided with a water inlet weir gate, the other end of the pond body is provided with a water outlet weir gate, the bottom of the pond body is provided with a sludge hopper, at least two separation barrels are arranged in the pond body, and an aeration pipe is arranged in each separation barrel. The aerobic sedimentation pond is provided with a plurality of regional separation barrels, the aeration pipe arranged in each separation barrel forms ascending current of mud-water mixed liquid in the local region, and the ascending current flows through an anoxic region and an aerobic region, overflows from the upper edges of the regional separation barrels and refluxes to an anaerobic region on the bottom layer to perform denitrification reaction in a cyclic process. Due to the plurality of regional separation barrels, the reaction process is repeated so as to greatly improve the reaction depth and efficiency of nitration and denitrification.

Owner:上海达源环境科技工程有限公司

Novel acidic gas treating process and apparatus

ActiveCN104826464AIncreased depth of responseFully contactedDispersed particle separationPhysical chemistryPrecipitation

The invention provides a novel acidic gas treating process and apparatus. The acidic gas treating process employs a gas-liquid two-phase countercurrent absorption reaction and uses a NaOH solution as an absorption liquid to treat acidic gas so as to produce NaHS. According to the process, a primary liquid reaction product and a secondary liquid reaction product are cyclically used, the secondary liquid reaction product is used a tertiary reaction absorption liquid, and an MDEA solution is used as a fourth-stage reaction absorption liquid; thus, the purpose of replacement of CO2 with H2S is achieved, the generation amounts of Na2CO3 and NaHCO3 in a liquid phase product are reduced, precipitation of crystals is prevented, and long cycle operation of the apparatus is guaranteed. The acidic gas treating process provided by the invention is simple and can achieve the dual objectives of purification of acidic gas and reclamation of pollutants.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrotreatment and catalytic cracking combined method of heavy hydrocarbon raw material

ActiveCN102876377BReduce the amount of mixed hydrogenStable temperatureTreatment with hydrotreatment processesFluid phaseHydrogenation reaction

The invention discloses a hydrotreatment and catalytic cracking combined method of a heavy hydrocarbon raw material. According to the invention, an upflow reactor is at least connected in series with a downflow fixed bed reactor. The heavy hydrocarbon raw material passes through UFR and is mixed with a catalytic cracking heavy fraction, and the mixture enters the downflow fixed bed reactor. A hydrogenation reaction effluent is separated so as to obtain a liquid phase, and the liquid phase is subjected to catalytic cracking. The obtained catalytic cracking heavy fraction returns to an inlet of the downflow fixed bed reactor. According to the method, the catalytic cracking heavy distillate oil, which is introduced into the inlet of the fixed bed reactor, is beneficial to hydrogenation reaction and can significantly improve temperature rising of the bed when used as cutback oil and can minimize the amount of hydrogen injected through the inlet when used as a hydrogen donor, thus further raising cooperative effect of combined flow equipment and prolonging the running period as well.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com