Liquid phase hydrogenation system and liquid phase hydrogenation method

A technology of liquid-phase hydrogenation and hydrogenation reaction, applied in the fields of hydrogenation treatment process, chemical instruments and methods, petroleum industry, etc., can solve the problems of high cost, difficult operation, hydrogen waste, etc., and reduce hydrogen consumption and energy consumption , prolong the service life and improve the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

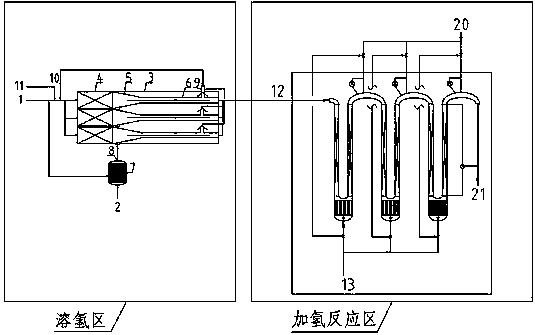

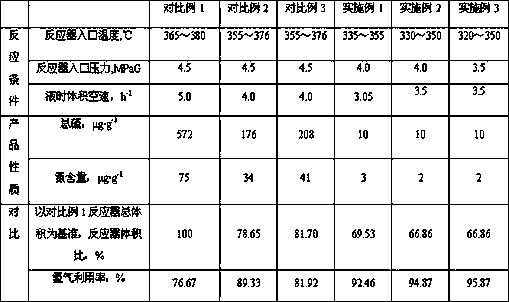

[0065] The hydrogen dissolving equipment in the hydrogen dissolving zone and the tubular reactor in the high-efficiency hydrogenation reaction zone are adopted in the present invention, wherein the hydrogen dissolving equipment is the same as in comparative example 3, and the tubular reactor in the high-efficiency hydrogenation zone is the same as in comparative example 2.

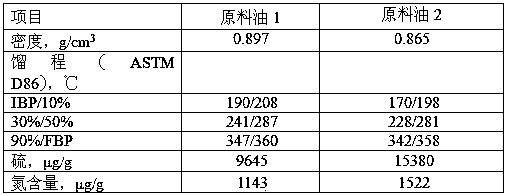

[0066] The feed oil 1 (straight-run diesel) and feed oil 2 (catalyzed diesel) in Table 1 were respectively used as raw materials, and the reaction products were obtained after hydrogenation reaction. The reaction conditions and product properties are shown in Table 2.

Embodiment 2

[0068] Using the hydrogen dissolving equipment in the hydrogen dissolving zone of the present invention and the tubular reactor in the high-efficiency hydrogenation zone, first, the raw material oil and hydrogen are formed into a stable "gas-in-oil" mixed fluid by using the hydrogen dissolving equipment in the present invention, and the The fluid is introduced into the tubular reactor in the high-efficiency hydrogenation zone for liquid-phase hydrogenation reaction.

[0069] The preliminary hydrogen dissolving section in the hydrogen dissolving equipment in the hydrogen dissolving area adopts a cylindrical internal filling spiral plate spoiler assembly, the residence time is 5.0 minutes, and the low-pressure escaped hydrogen is recycled, and the flow rate is 0.015% of the raw material mass; the accelerated dissolving The contraction angle of the hydrogen section is 20°, and the length ratio of the accelerated hydrogen dissolution section to the hydrogen release section is 1:15;...

Embodiment 3

[0073] Using the hydrogen dissolving equipment in the hydrogen dissolving zone of the present invention and the tubular reactor in the high-efficiency hydrogenation zone, first, the raw material oil and hydrogen are formed into a stable "gas-in-oil" mixed fluid by using the hydrogen dissolving equipment in the present invention, and the The fluid is introduced into a conventional fixed-bed liquid-phase hydrogenation reactor for liquid-phase hydrogenation reaction.

[0074] The preliminary hydrogen dissolving section of the hydrogen dissolving equipment in the hydrogen dissolving area adopts a cylindrical interior filled with rotating vane spoiler components, and the residence time is 4.5 minutes. The contraction angle of the section is 20°, and the length ratio of the accelerated hydrogen dissolution section to the hydrogen release section is 1:8; the operating conditions of the introduction position of the hydrogen-rich gas-liquid mixture in the accelerated hydrogen dissolutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com