Patents

Literature

91results about How to "Increase mass transfer driving force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

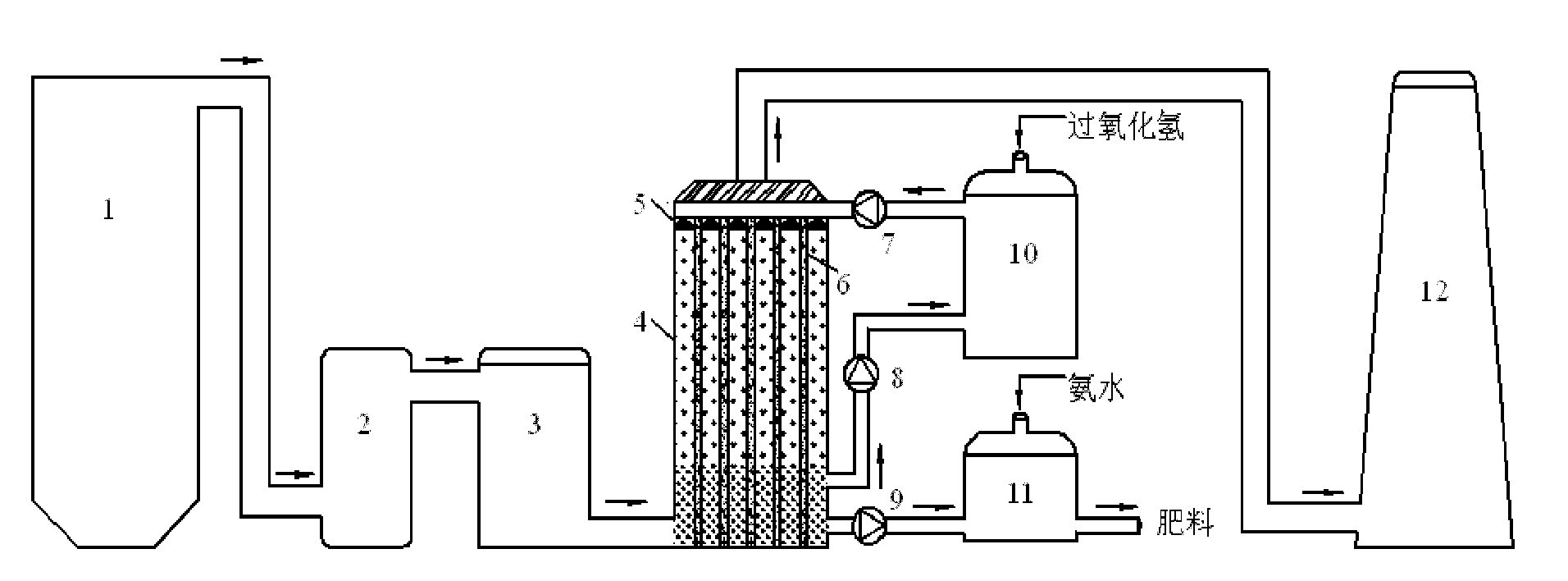

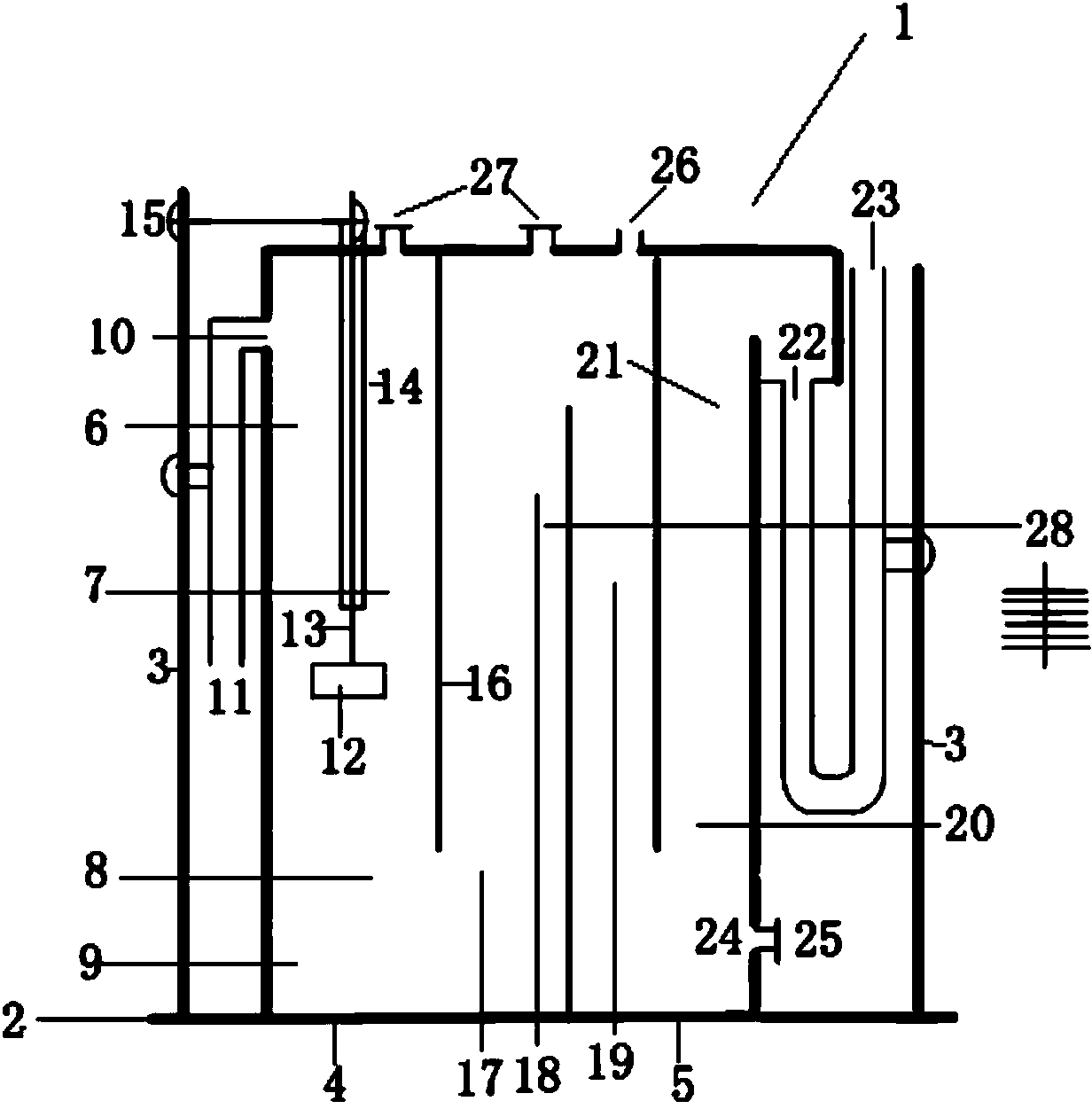

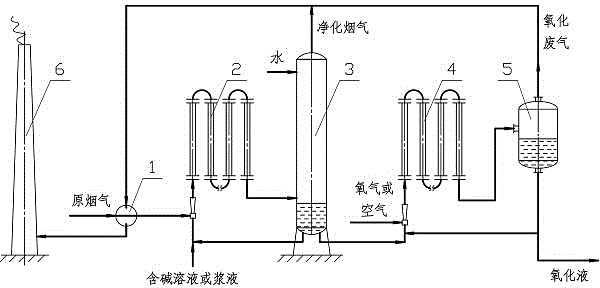

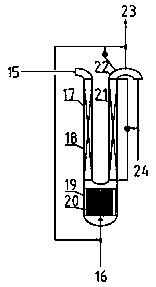

Photochemical advanced oxygenation-based simultaneous desulfuration and denitration system

InactiveCN101940871AThe process is simple and reliableSmall footprintDispersed particle separationAir quality improvementFertilizerAmmonium sulfate

The invention discloses a photochemical advanced oxygenation-based simultaneous desulfuration and denitration system. The system is provided with a burning and exhausting system consisting of a burner, an electrostatic dust collector, a heat exchanger, a spray tower, a liquid adding tower and a chimney, wherein fume generated by the burner enters the electrostatic dust collector, fume particles are removed from the fume by the electrostatic dust collector, the fume enters the heat exchanger and is cooled by the heat exchanger, and then the fume enters the spray tower; an UV light tube is arranged in the spray tower; hydrogen peroxide solution from the liquid adding tower is pumped by a circulating pump, sprayed into the spray tower through an atomizing nozzle and is activated by ultraviolet light to decompose hydrogen peroxide and then generate hydroxyl radicals (.OH) with strong oxidizing property; after being contacted with the fume in the spray tower, the hydroxyl radicals undergoes a gas-liquid absorption reaction with the fume to oxidize and remove NOx and SO2 in the fume; the fume, after being absorbed and washed, enters the chimney from the top of the spray tower and is exhausted; and sulfuric acid solution and salpeter solution generated in the spray tower are pumped into the separating column by the circulating pump and are reacted with added ammonia water to generate agricultural fertilizers including ammonium sulfate and ammonium nitrate.

Owner:SOUTHEAST UNIV

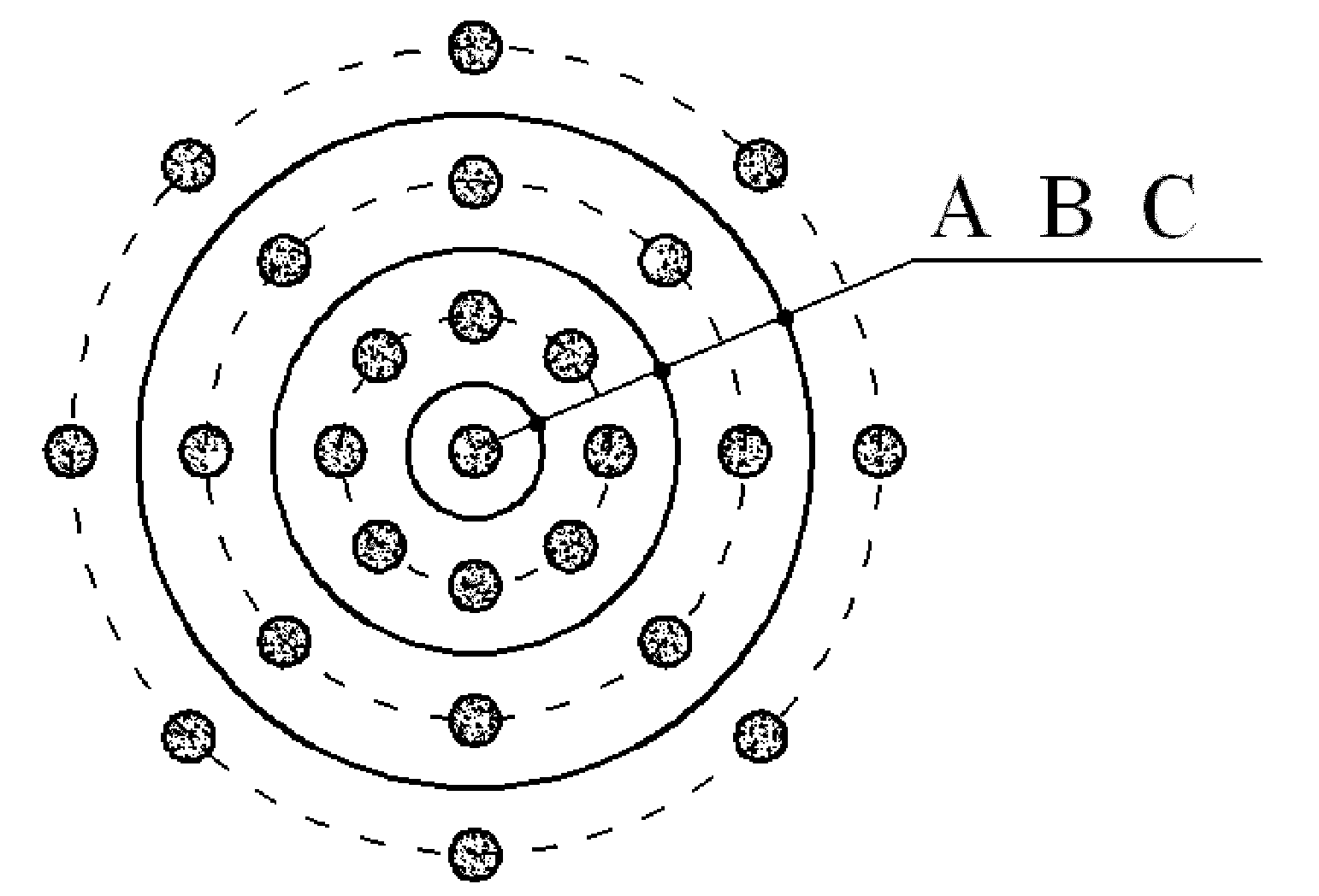

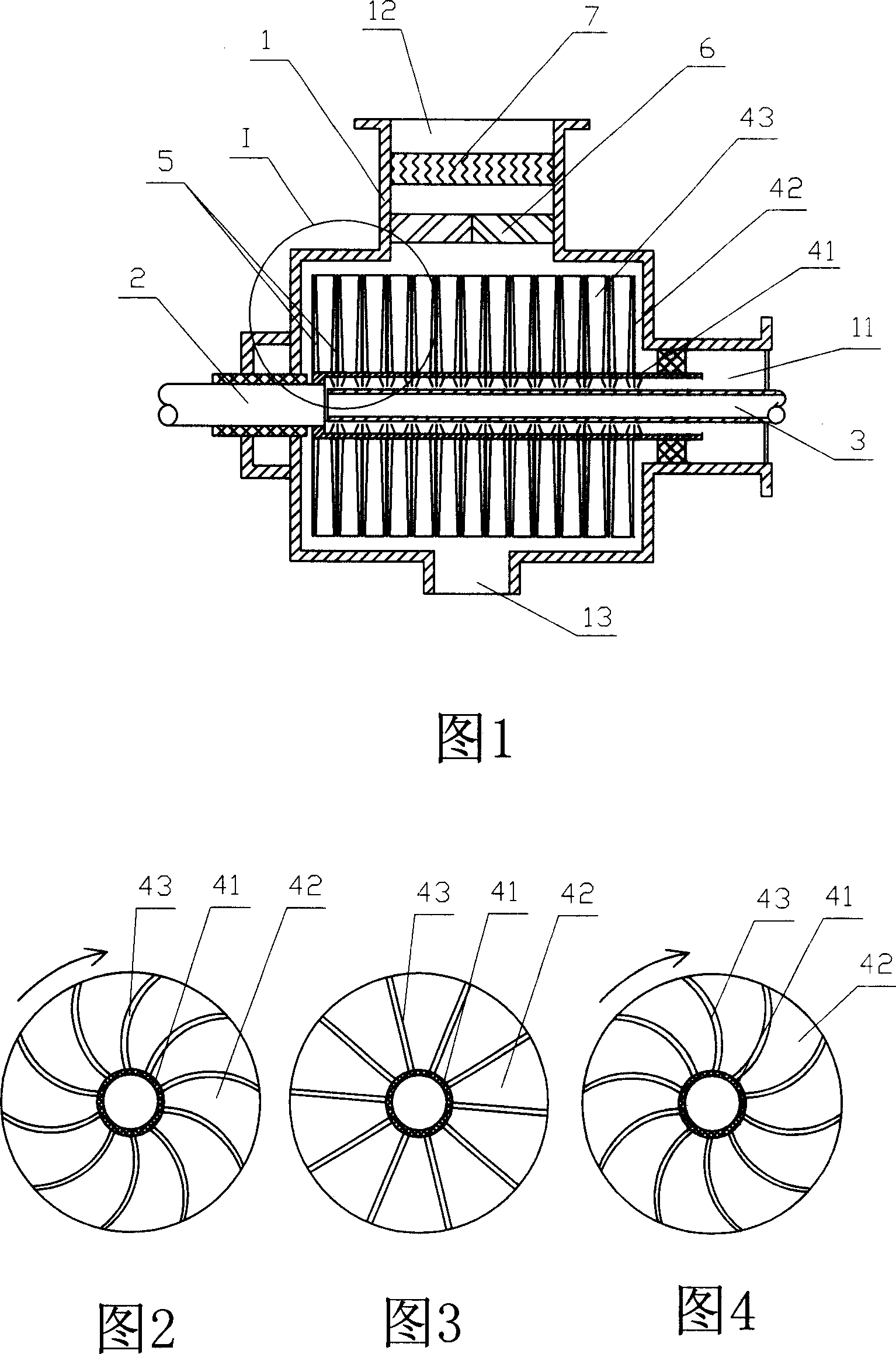

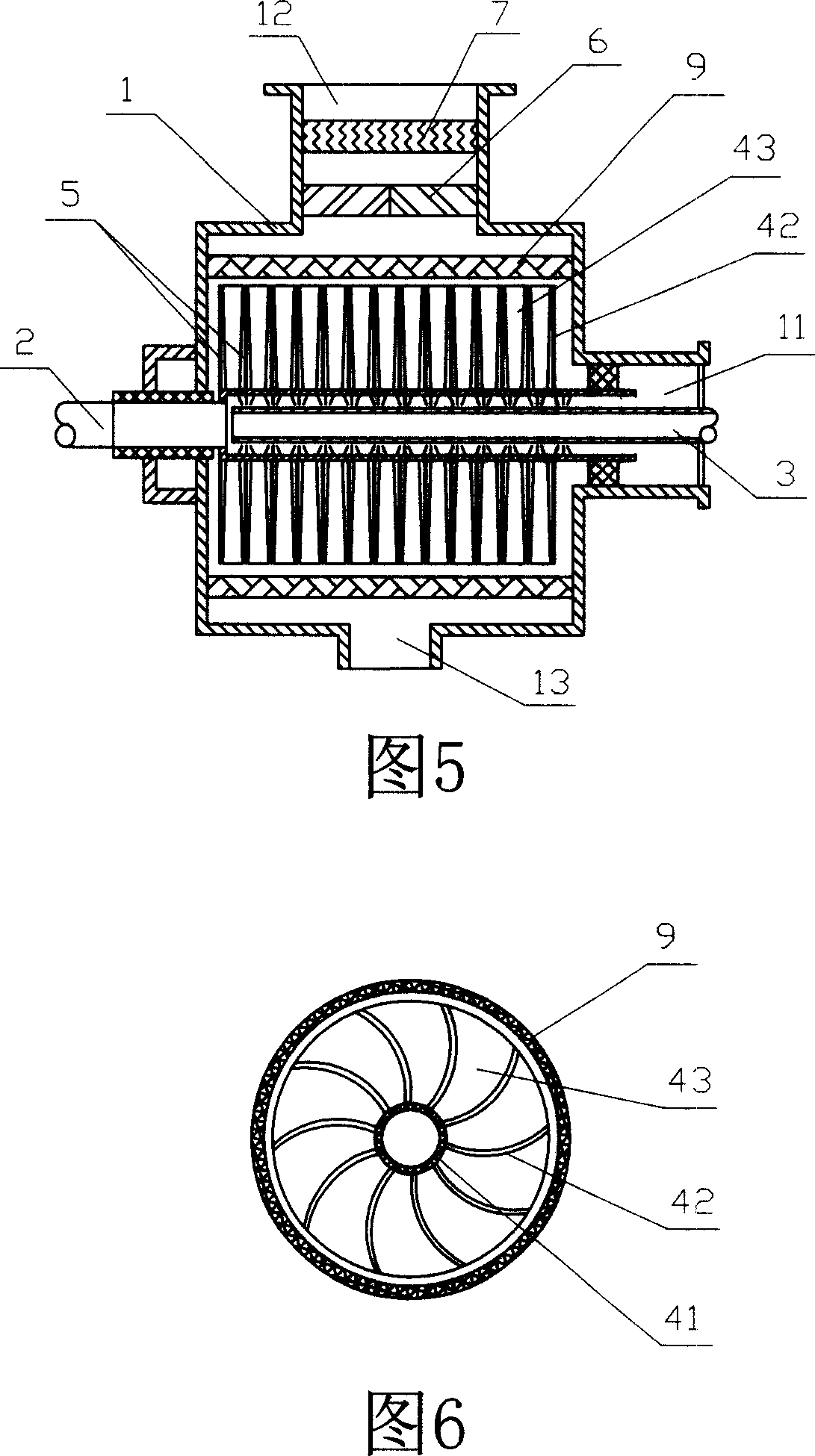

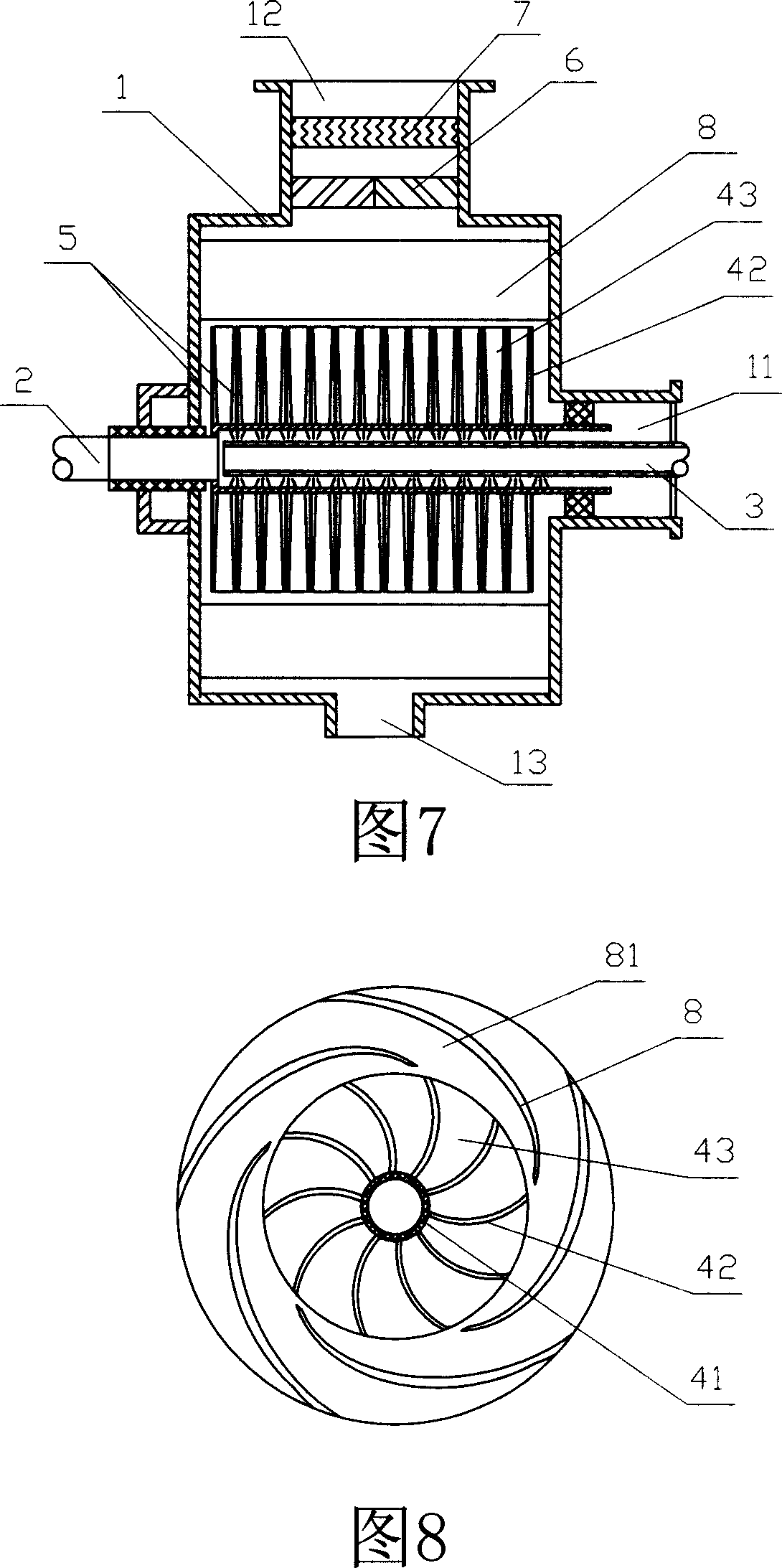

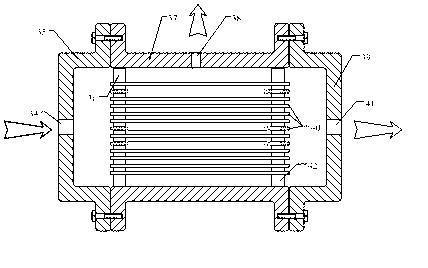

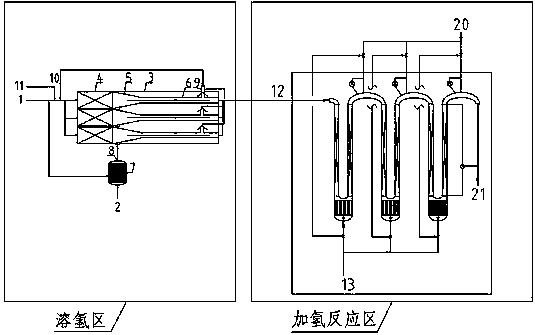

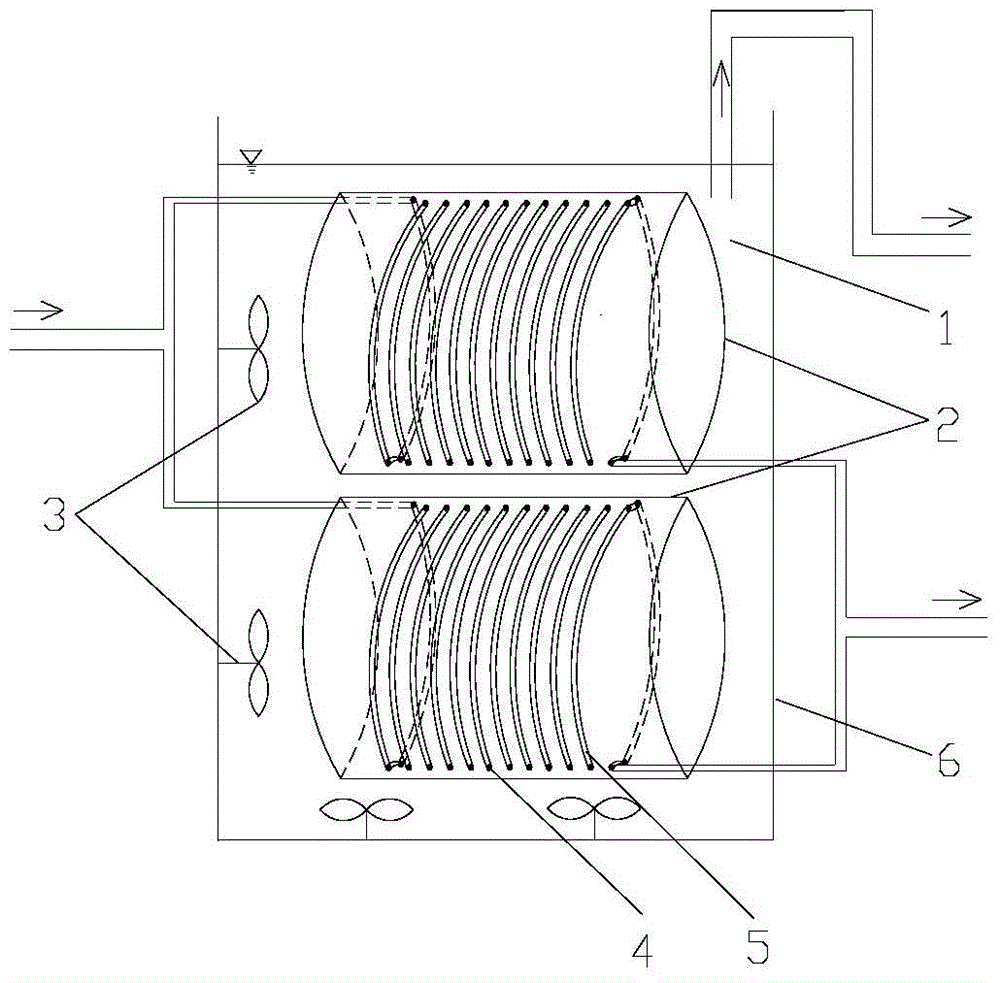

Hypergravity mass transfer apparatus

InactiveCN101013003AIncrease contact areaEnhanced mass transferDirect contact heat exchangersFiber layerMass transfer

The invention discloses a hypergravity transfer unit, comprising a frame, a rotary axle and a liquid inlet tube. The frame is arranged with an air inlet, an air outlet and a liquid outlet. The rotary axle is arranged with a rotor which comprises a cylinder central axle, several coaxial plates parallel arranged on the outer wall of cylinder central axle, and several blades arranged on the cylinder central axles between the plates. The blades and the plates have spaces reducing radial from inner to outer. The liquid inlet tube is through the frame to reach the center of cylinder central axle. The air inlet is communicated with the inlet of cylinder central axle. The rotator is arranged arc plates and cylinder woven fiber layer. The invention can dry, cool, or heat air as well as pressurize the air. And the gas-liquid direction is clockwise, to reduce the resistance and reduce energy consumption.

Owner:ZHEJIANG SCI-TECH UNIV

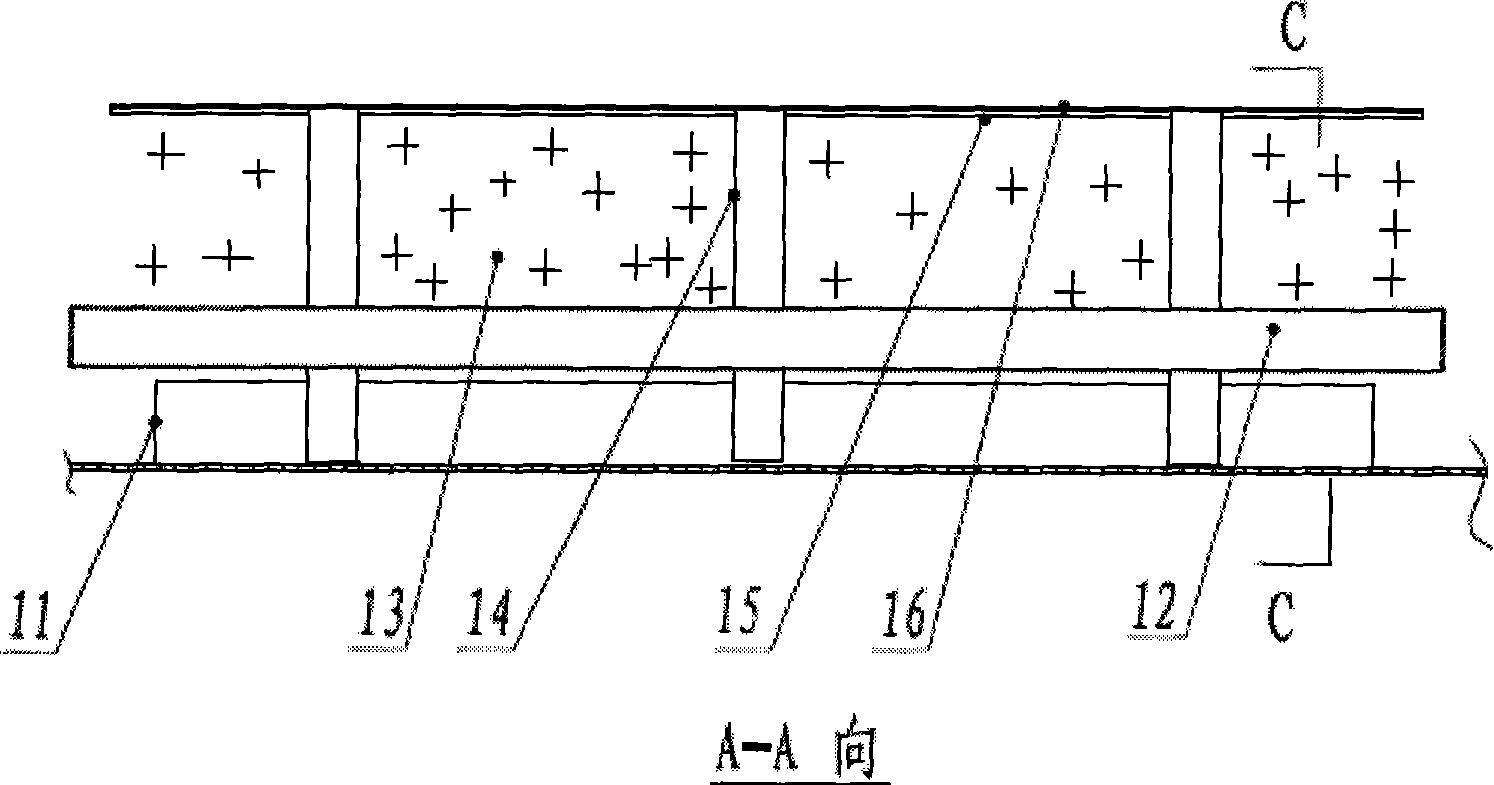

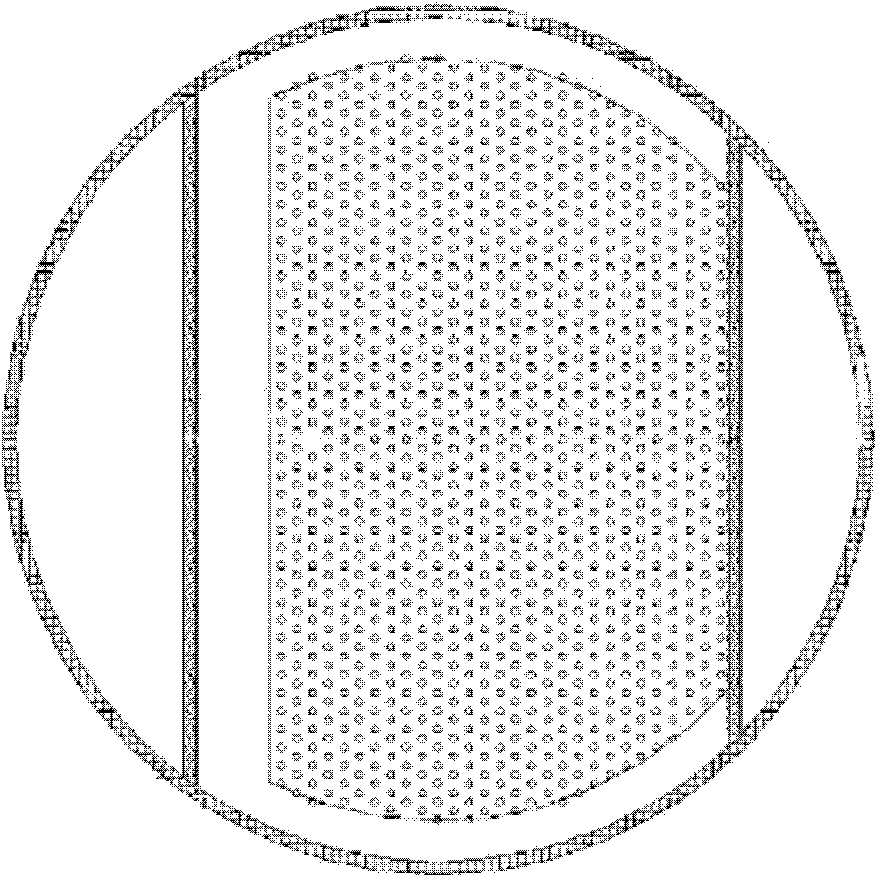

Film spray no-back mixing column plate

ActiveCN101507883AAvoid backmixingIncrease mass transfer driving forceDispersed particle separationFractional distillationEngineeringPlating efficiency

The invention relates to a film spray non-back-mixing column plate, which comprises two spray covers, a column tray ring and a down-flow plate. A column plate is provided with a raise steam hole, and a down-flow pipe is formed between the down-flow plate and the column plate, wherein a position opposite to the raise steam hole of the column plate is fixedly provided with a top cover through a supporting plate. The bottoms of the spray covers and the column plate are reserved with a gap which forms a channel for liquid to enter the spray cover, and both side walls of the spray covers are provided with spray holes. The film spray non-back-mixing column plate is characterized in that the raise steam hole on the column plate is rectangular, and the part of the raise steam hole is welded with a rectangular raise steam pipe, wherein the upper end of the raise steam pipe is provided with a nozzle; the top cover, the raise steam pipe and the supporting plate form the spray covers; and the space between the two spray covers and the outside of the edges of the spray covers are provided with a liquid guide groove, wherein three surfaces of the liquid guide groove are provided with walls, and one surface of the liquid guide groove is provided with an opening which extends into the down-flow pipe. The film spray non-back-mixing column plate can prevent the liquid from back mixing, and greatly improve mass transfer driving force and the column plate efficiency.

Owner:TIANJIN CHUANGJU TECHNOLGOY +1

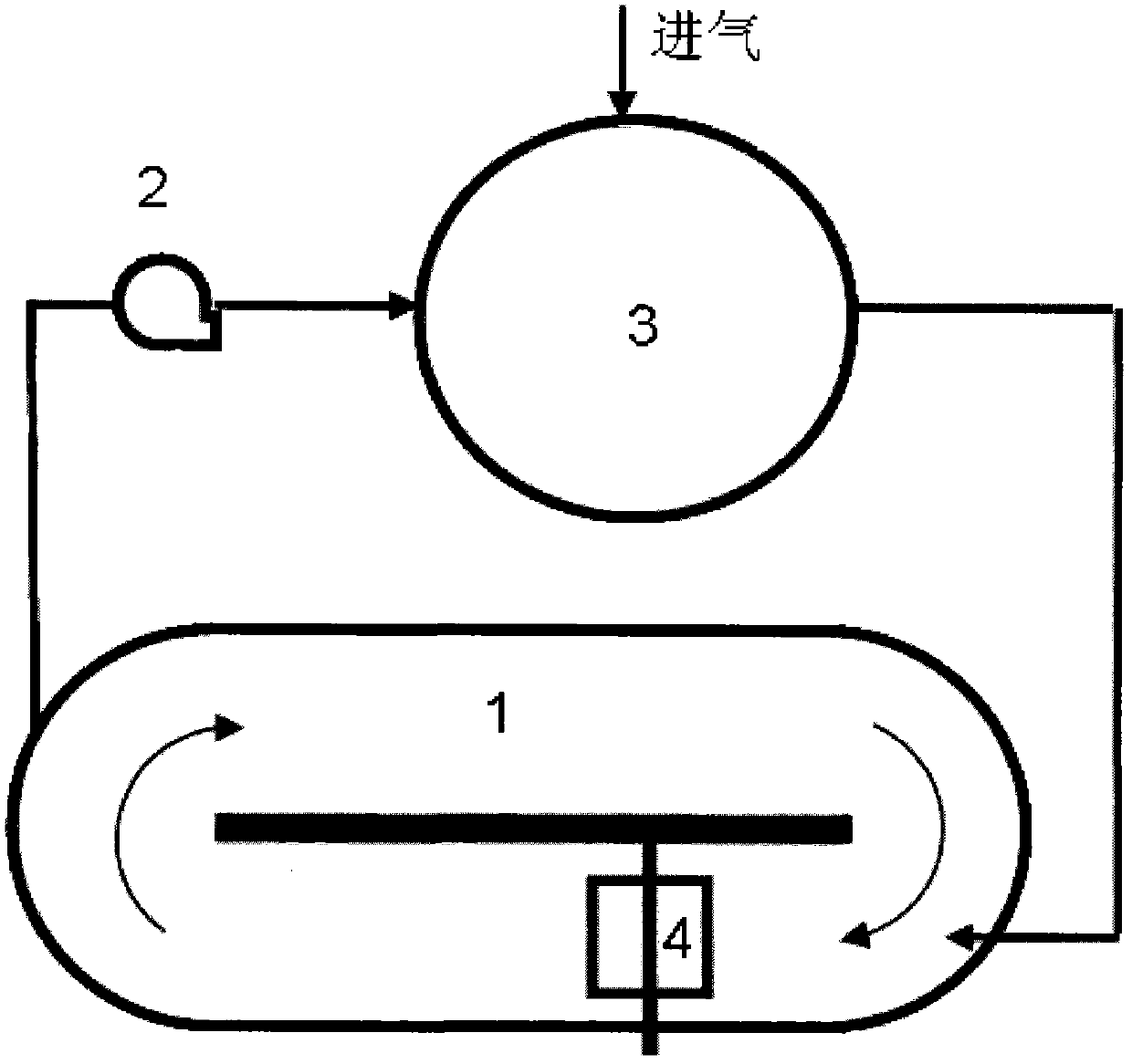

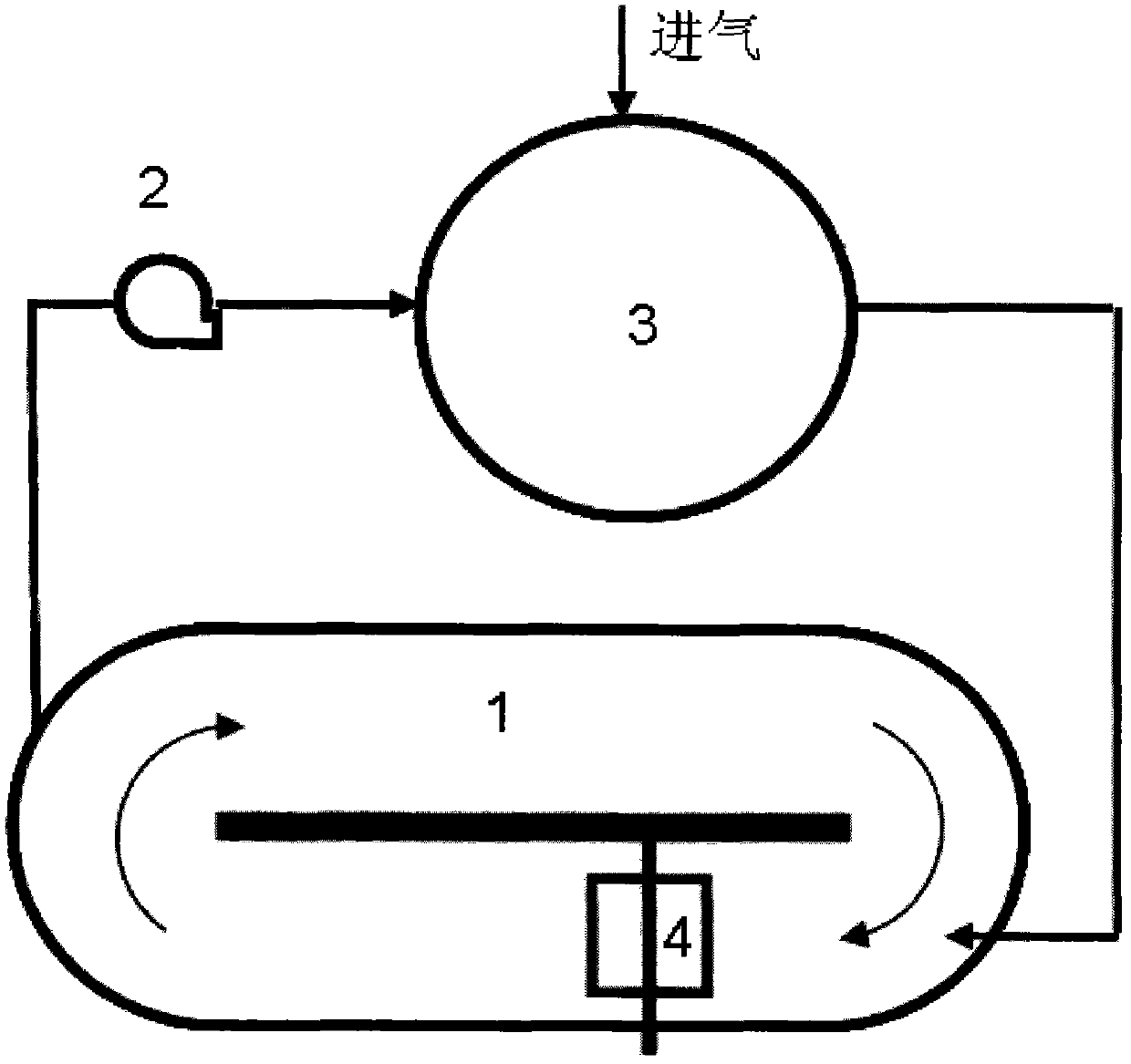

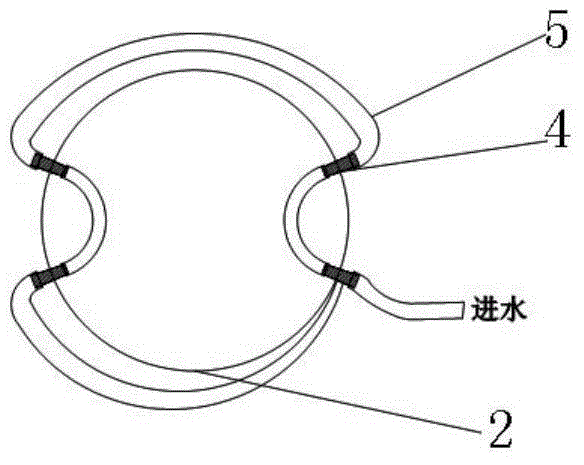

Microalgae culturing device and microalgae culturing method

InactiveCN102382755AIncreased driving force for gas-liquid mass transferImprove carbon replenishment efficiency and CO2 utilizationBioreactor/fermenter combinationsBiological substance pretreatmentsCulture fluidEngineering

The invention discloses a microalgae culturing device, which comprises an open runway pool, wherein the open runway pool is provided with a liquid outlet; the liquid outlet is connected with a liquid circulating pump, and is connected with a liquid inlet of a culturing liquid storage tank through the liquid circulating pump; the top of the culturing liquid storage tank is provided with a liquid outlet pipeline, so that a culture fluid can flow back into the open runway pool through the pipeline; and the bottom of the culturing liquid storage tank is provided with a gas distributor for introducing various CO2-containing gases for replenishing carbon for a microalgae culture fluid. By controlling the volume ratio and the circulating speeds of the culture fluid in the open runway pool and the culture fluid in the culturing liquid storage tank, the detention time of microalgae cells in the bright runway pool and the dark culturing liquid storage tank is adjusted, and bright and dark forced circulation of the microalgae cells is realized. By adopting the device and the method, the problems of poor bright and dark mixing of cells, low light energy utilization ratio and difficulties in charging gas and replenishing carbon in the culturing process of the conventional open runway pool are solved, the culturing efficiency, the growing rate and the area yield of microalgae are increased remarkably, and the investment and running costs of a mass microalgae culturing system are reduced.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI +1

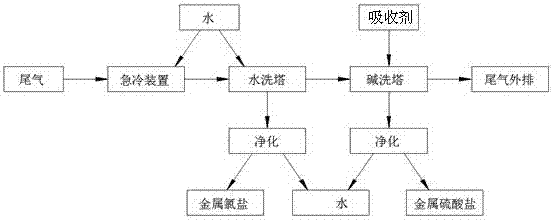

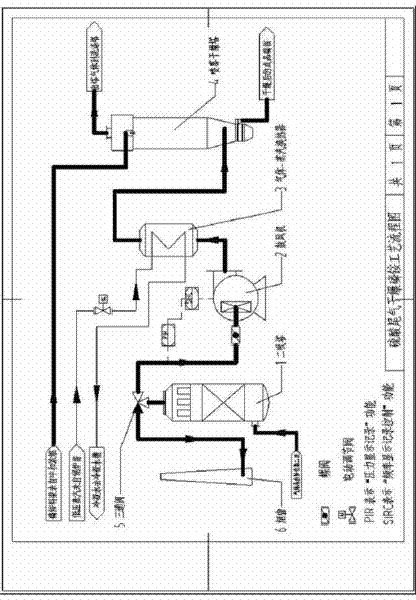

Plasma flying ash melting tail gas wet-purification process

InactiveCN107008127AImprove heat transfer efficiencyImprove mass transfer efficiencyDispersed particle separationLiquid wasteQuenching

The invention relates to a plasma flying ash melting tail gas wet-purification process. The process includes: after plasma flying ash melting tail gas is cooled to 100 DEG C or below by a quenching device, sequentially feeding into a water washing tower and an alkaline washing tower to realize deacidification, discharging smoke to the atmosphere from the alkaline washing tower, respectively purifying waste liquid discharged from the water washing tower and the alkaline washing tower, and recycling obtained metal chlorine salts and metal sulfuric acid salts. The purification process has advantages of completeness and effectiveness in removal of acid gases and the metal chlorine salts, heavy metal salt enrichment is avoided, HCl and SO2 in the tail gas are separated from the source of the tail gas purification process, and the two metal salts are recycled through a water treatment device, so that pollutants in the tail gas are effectively recycled.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

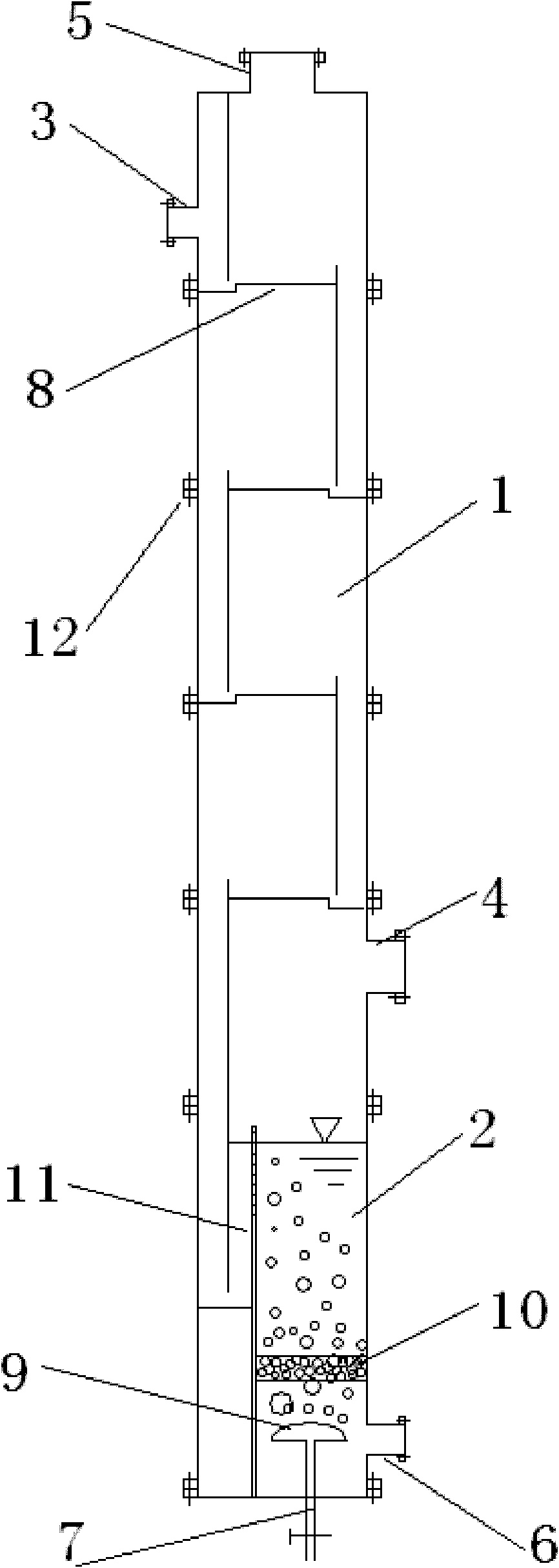

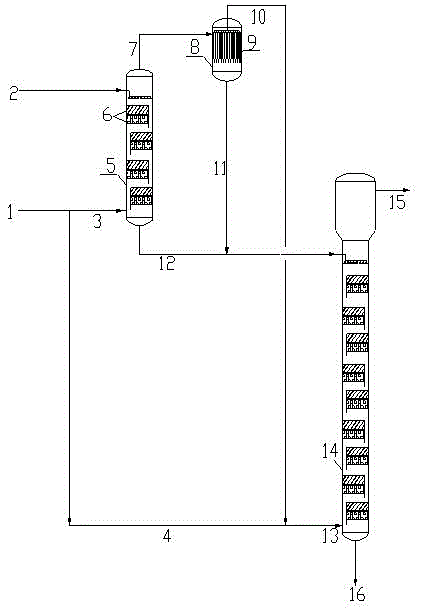

Novel blowoff and oxidation combined tower for polluted groundwater

InactiveCN102241444AGuaranteed treatment effectGuarantee water qualityMultistage water/sewage treatmentWater/sewage treatment by degassingHigh pressurePollution

The invention relates to a novel blowoff and oxidation combined tower for polluted groundwater. The combined tower has blowoff action on volatile organic matters and oxidation action on involatile organic matters in groundwater, and is approximately divided into a blowoff section and an oxidation section from top to bottom according to the reaction types, and the blowoff section and the oxidation section are connected by a flange structure. The combined tower has the advantages that: the device design is novel, and the functions of a blowoff tower and an oxidation tower are integrated, thus saving investment; after the blowoff section and the oxidation section are integrated, the high pressure of the blowoff section contributes to the sufficient dissolving of ozone in the oxidation section in water, and the escaping ozone can further contact with water; the combined tower has a wide range of treatment objects, is suitable for the treatment of the groundwater polluted by volatile and / or involatile organic matters, and has the advantages of high efficiency, energy conservation and no secondary pollution; and at the same time, aiming at the groundwater with different pollution site types and pollution degrees, the remediation technology requirements of the groundwater with different pollution site types can be realized by flexibly adjusting the tower plate number and process control switch, and the combined tower has a broad application prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

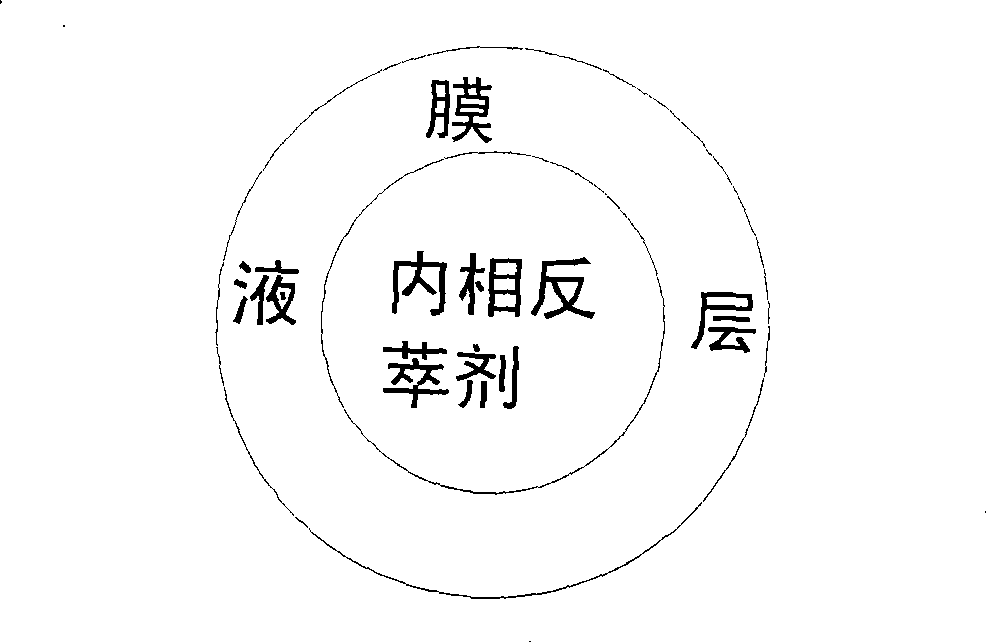

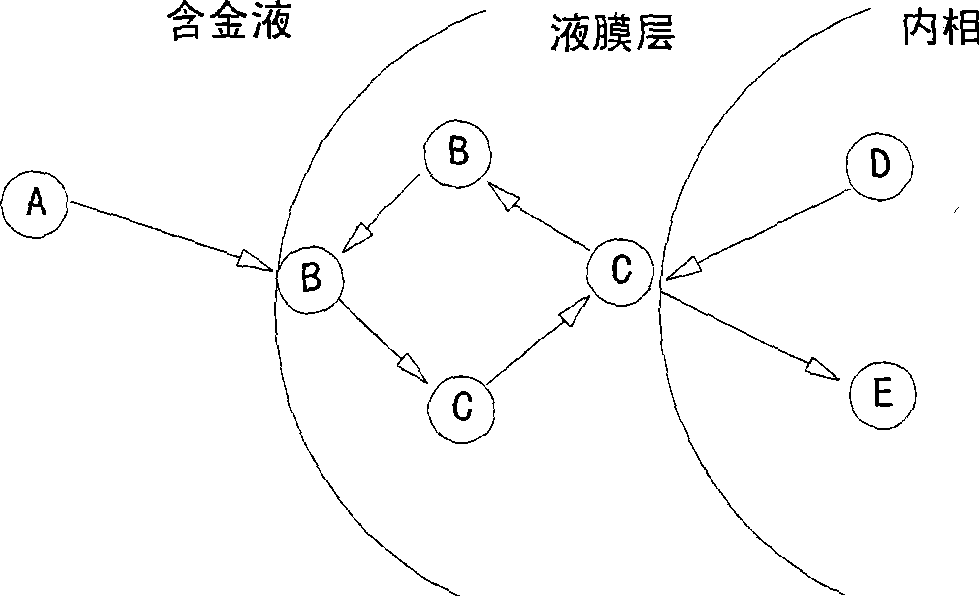

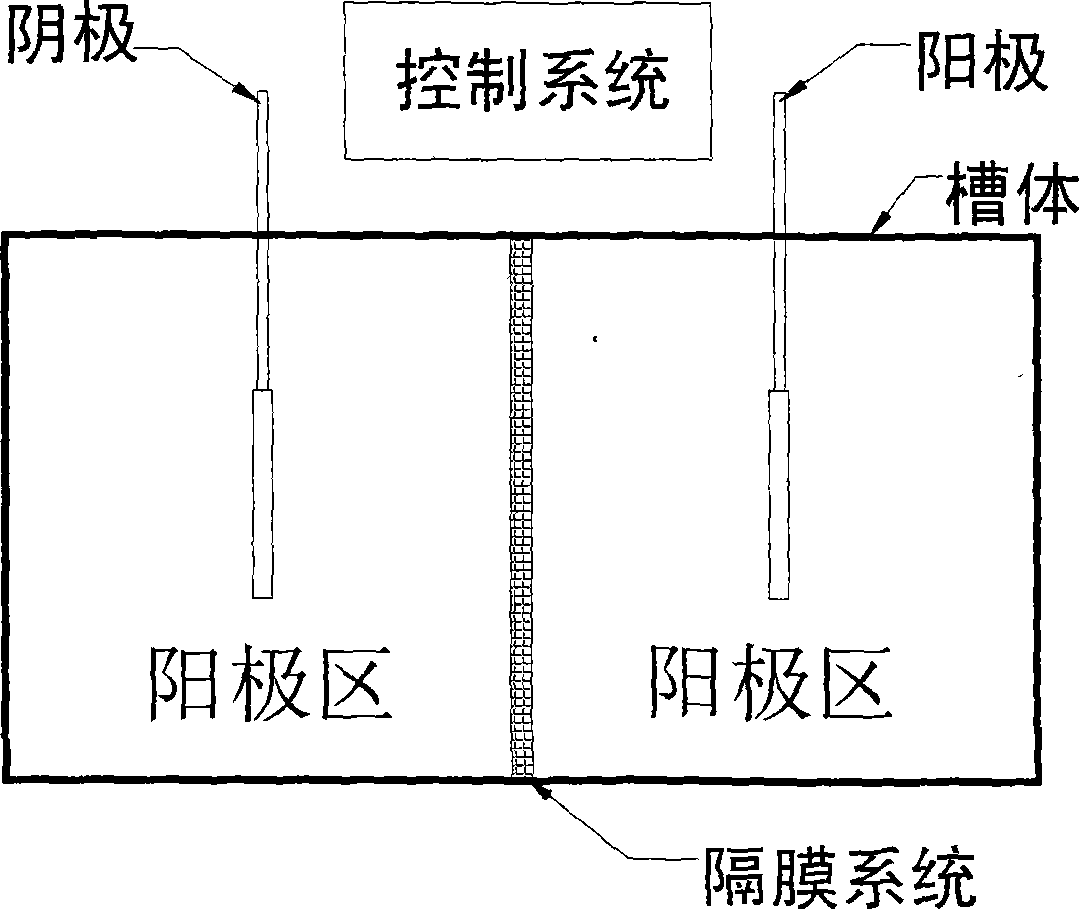

Liquid membrane extraction of gold-diaphragm electrolysis extraction of gold process

InactiveCN101418375AReduce consumptionEfficient use ofPhotography auxillary processesProcess efficiency improvementChemical industryElectrolysis

The invention relates to a liquid membrane gold extraction-diaphragm electrolysis gold extraction process, which belongs to the metallurgy and chemical industry. The process comprises two parts, namely emulsion liquid membrane gold extraction and gold-contained enrichment diaphragm electrolysis gold extraction, wherein the emulsion liquid membrane gold extraction comprises the preparation of an emulsion liquid membrane, the extraction process of the emulsion liquid membrane, and the emulsion breaking process of a gold-contained emulsion liquid membrane. The process has the advantages that the process has a large driving force of mass transfer, few separation stages needed, and little agent consumption; the process improves the production efficiency and greatly simplifies the gold extraction technical flow; useful materials are reclaimed so as to produce no secondary pollution and achieve the more effective energy utilization; and the process is taken as unit operation, and has flexible use, convenient operation and easy realization of automatic control.

Owner:CHANGCHUN GOLD RES INST +1

Double-flow-mode fuel oil ground pre-washing method and device thereof

InactiveCN102755870AIncrease mass transfer driving forceShorten washing timeInert gas productionProcess engineeringGas generator

The invention discloses a double-flow-mode fuel oil ground pre-washing method and device thereof. The double-flow-mode fuel oil ground pre-washing method comprises the following steps of: performing inertia treatment on fuel oil in an oil tank of a fuelling vehicle by using nitrogen-rich gas generated by a nitrogen-rich gas generating device, wherein the nitrogen-rich gas generating device comprises more than two nitrogen-rich gas generators, and the nitrogen-rich gas outlets of the nitrogen-rich gas generators are connected in series or in parallel or in series and parallel by switching bypass control valves respectively; and during inertia treatment on fuel oil, switching corresponding bypass control valves to make the flow and the purity of nitrogen-rich gas output by the nitrogen-rich gas generating device meet the practical requirements of inertia treatment, and arranging a suction pump at the nitrogen-rich gas outlet of each nitrogen-rich gas generator respectively. Due to the adoption of the method and the device, the contradictory relation between the flow and purity of nitrogen-rich gas generated by the nitrogen-rich gas generators in a decompressed washing process is coordinated, the separating effect of a separating film is optimized, the requirement of lower oxygen content in fuel oil at the end of washing is met, and washing time is reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

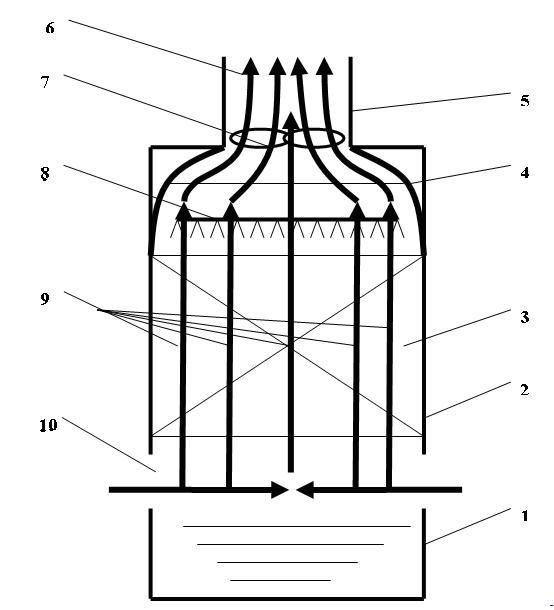

Circulating water cooling tower

The invention discloses a circulating water cooling tower, comprising a tower body, a chimney and a cooling water tank; wherein the interior of the tower body is filled with filler, so as to form a filler layer, the upper part of the filler layer is also provided with a cooling water distributor, the chimney is arranged at the upper part of the tower body, an air fan is arranged at the inlet thereof, and the outlet thereof is an air outlet, besides, the lower end of the tower body is an air inlet, the cooling water tank is arranged at the lower part of the tower body, and an air deflector is arranged between the filler layer and the air fan. The invention guides air by mounting an air deflector, air flow line is specified, turbulence degree thereof is reduced, air flow of circulating water cooling tower is increased, power consumption of air fan is reduced, contact of gas and liquid phases in the circulating water cooling tower is optimized, and heat transfer and mass transfer thrusts of air and cooling water in the circulating water cooling tower are improved, thus improving working efficiency of circulating water cooling tower.

Owner:江苏钟腾化工有限公司

Integrated baffle-type autotrophic biological denitrification reactor

ActiveCN103523910ASmall footprintSimple structureTreatment with anaerobic digestion processesSludgeCoupling

The invention discloses an integrated baffle-type autotrophic biological denitrification reactor which comprises a reactor body, wherein the reactor body is provided with a first baffle plate; the first baffle plate divides the reactor body into a partial nitrification unit and an anaerobic ammoxidation unit; the upper end of the first baffle plate is connected with the top of the reactor body, and a gap is reserved between the lower end and the bottom of the reactor body; the anaerobic ammoxidation unit is divided into a biofilm area I, a biofilm area II, a particle sludge area, a second precipitation area and a second water outlet area from left to right; a second baffle plate is arranged between the biofilm area II and the particle sludge area; and a third baffle plate is arranged between the particle sludge area and the second precipitation area. According to the reactor disclosed by the invention, the coupling of a partial nitrification process and an anaerobic ammoxidation process is realized in a single reactor; and with the multi-level baffle plates, the flow path of the wastewater is prolonged, the effective reaction time is increased, and the biological withholding ability is enhanced.

Owner:HANGZHOU NORMAL UNIVERSITY

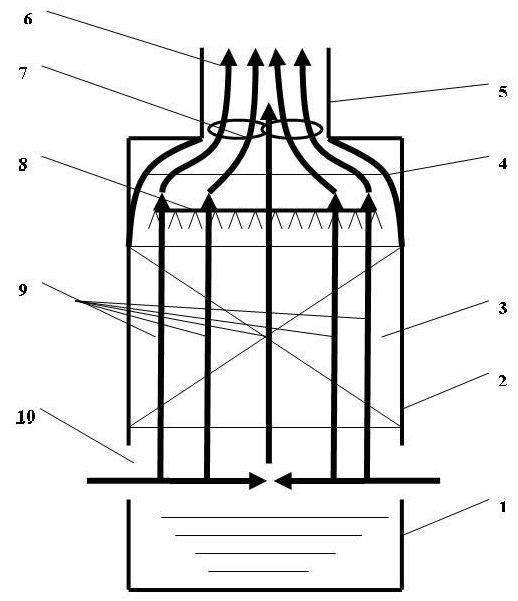

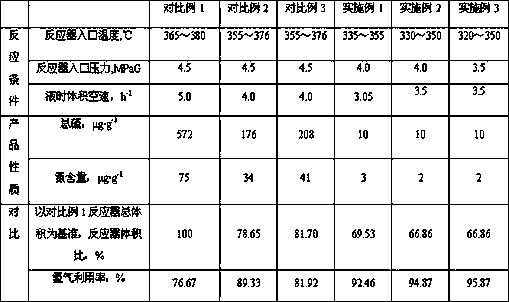

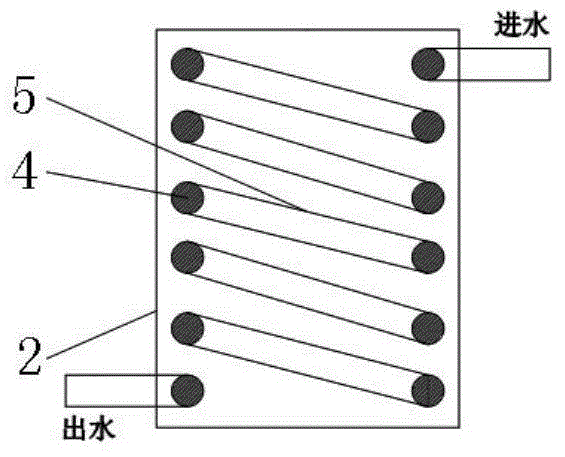

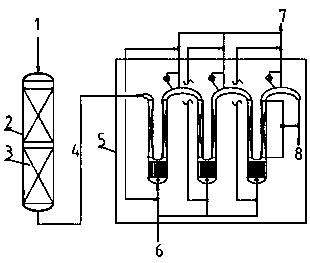

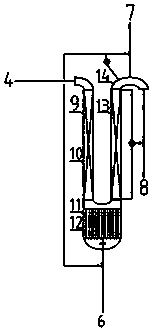

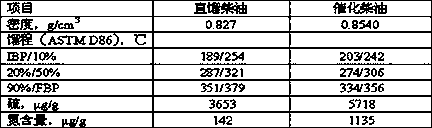

Liquid phase hydrogenation system and liquid phase hydrogenation method

ActiveCN111068589AExtended service lifeReduce hydrogen consumptionTreatment with hydrotreatment processesChemical/physical processesFluid phaseHydrogenation reaction

The invention discloses a liquid phase hydrogenation system and a liquid phase hydrogenation method. The system comprises a hydrogen dissolving zone and an efficient hydrogenation reaction zone, wherein the hydrogen dissolving zone is internally provided with a plurality of hydrogen dissolving devices, each hydrogen dissolving device comprises a hydrogen dissolving device shell, the hydrogen dissolving device shell internally comprises a plurality of hydrogen dissolving assemblies connected in parallel, the efficient hydrogenation reaction zone comprises a plurality of tubular reactors connected in series, and the tubular reactor is in a U shape and comprises straight pipe sections on the two sides and a horizontal section with the bottom communicated with the straight pipe sections on thetwo sides. According to the method disclosed by the invention, a gas-in-oil type gas-liquid mixed fluid formed in the hydrogen dissolving zone used as the feed of a liquid-phase hydrogenation reaction enters the U-shaped tubular reactor in the efficient hydrogenation reaction zone and is subjected to a deep hydrogenation reaction, so that the supplementary hydrogen-oil ratio during the hydrogenation reaction process can be substantially reduced, the hydrogen utilization rate can be improved, the hydrogen consumption and the energy consumption can be reduced, H2S, NH3 and other gases producedduring the reaction process can be continuously removed from the reaction system, the high hydrogenation reaction rate and the high reaction efficiency can be improved and maintained, and the deep hydrogenation reaction can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cellulose fiber fabric cationic modification and salt-free alkali-free dyeing method

The invention relates to a cellulose fiber fabric cationic modification and salt-free alkali-free dyeing method. The method comprises following steps: adding soft water into a gas-liquid dyeing machine, adding cellulose fiber fabrics and a cationic modifier into the dyeing machine, starting the dyeing machine; adding sodium hydroxide into the dyeing machine from a material dissolving cylinder, adjusting the water level, running the dyeing machine, raising the temperature, discharging the modification liquid, washing the fabrics by a water solution of glacial acetic acid at a room temperature,taking out the fabrics, dehydrating the fabrics to obtain cation modified fabrics; adding soft water, adding cation modified cellulose fiber fabrics, dissolving active dyes, injecting the dyes into the dyeing machine, raising the temperature to the dyeing temperature, maintaining the temperature, discharging dyeing liquid, taking out the fabrics, and dehydrating and drying the fabrics. In the gas-liquid dyeing machine, cellulose fiber fabrics are modified under conditions: medium-low temperatures and a small bath ratio; the using amount of modifier is little; the surface and interior of fabrics are uniformly modified; the modified fabrics can be dyed without salt or alkali, furthermore, the dyeing time is short, the dyeing process is simple and controllable, the color is uniform and bright, and the color fastness meets the standards.

Owner:SOUTH CHINA UNIV OF TECH +1

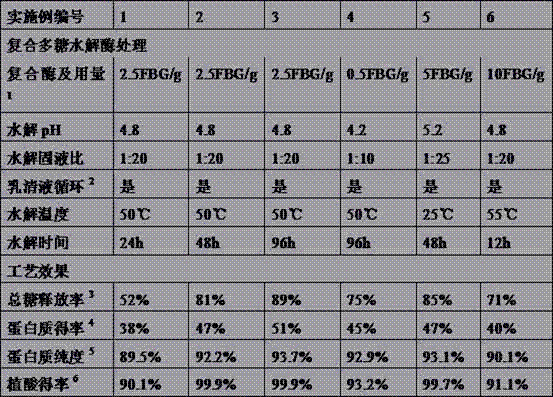

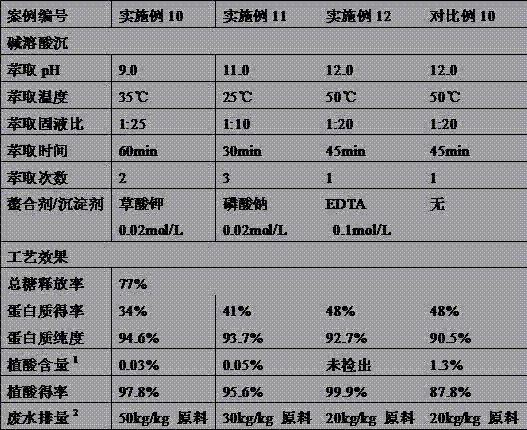

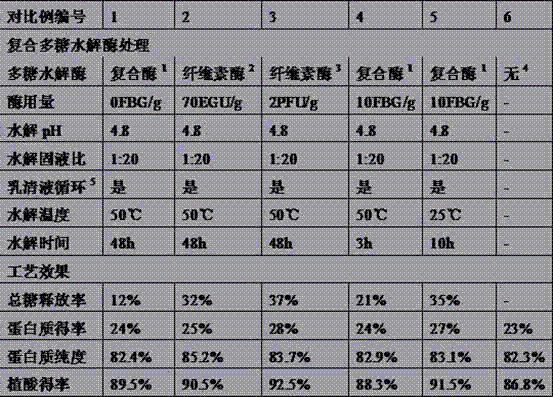

Method for extracting protein and phytic acid from rapeseed meal

InactiveCN102296099AResidue reductionEliminate residueGroup 5/15 element organic compoundsPeptide preparation methodsHydrolysatePolysaccharide Hydrolase

The method for extracting protein and phytic acid from rapeseed cake includes: using a compound of two or more polysaccharide hydrolytic enzymes to hydrolyze the rapeseed cake so that the ratio of the total sugar of the rapeseed cake released into the hydrolyzate liquid phase is greater than 50% ; Adjust the obtained hydrolyzate to pH 3-6 to extract phytic acid, and then separate solid-liquid to obtain phytic acid extract and hydrolyzed cake; use alkaline solution to extract protein in hydrolyzed cake at pH 9-12; use acid precipitation method Or membrane separation method to separate protein from alkaline extract. Improve the extraction efficiency of rapeseed protein and phytic acid, and improve the purity and quality of rapeseed protein products (reduce phytic acid residue).

Owner:刘晔

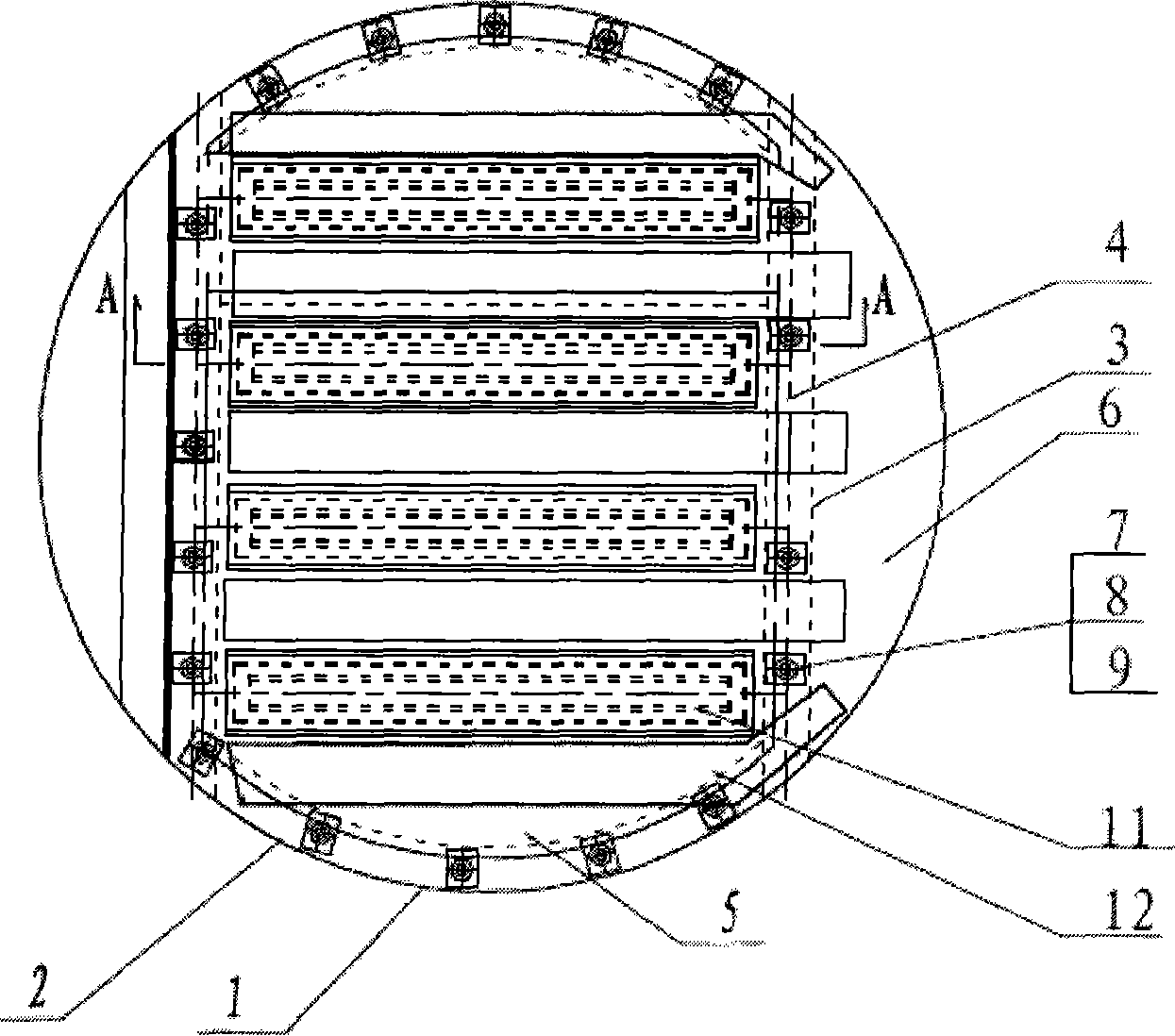

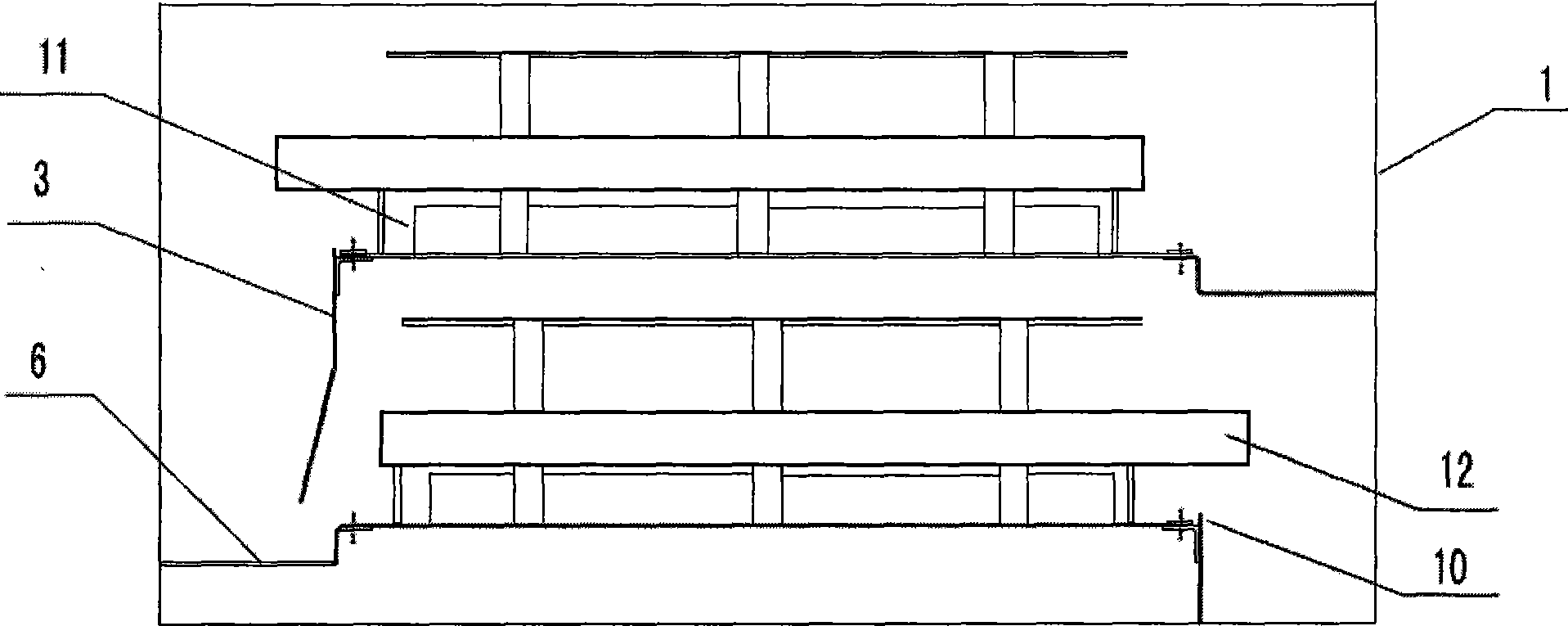

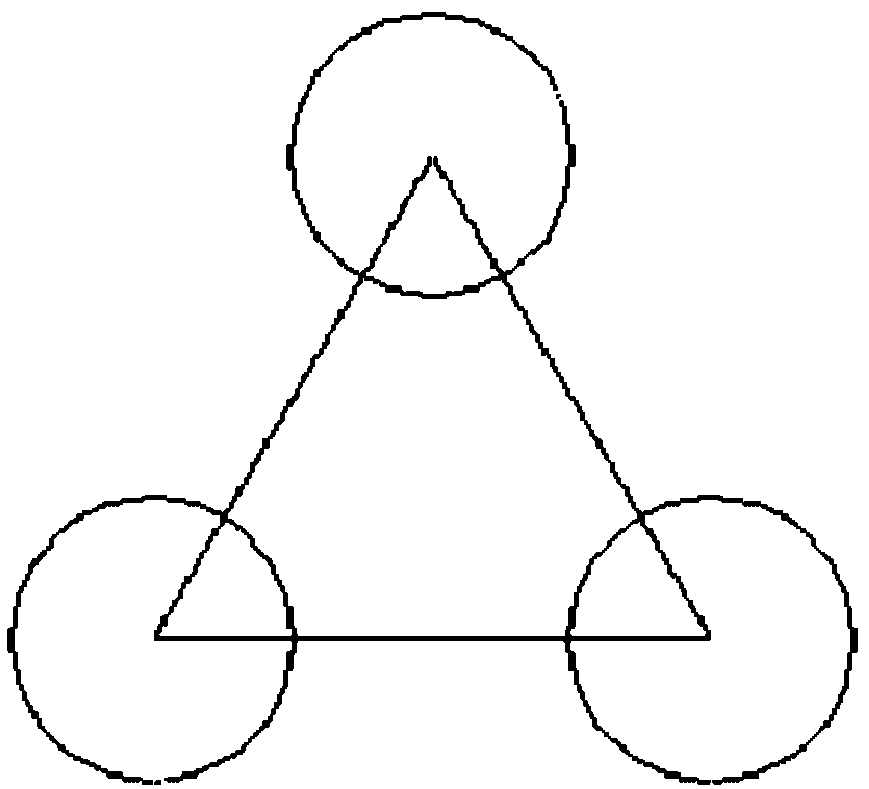

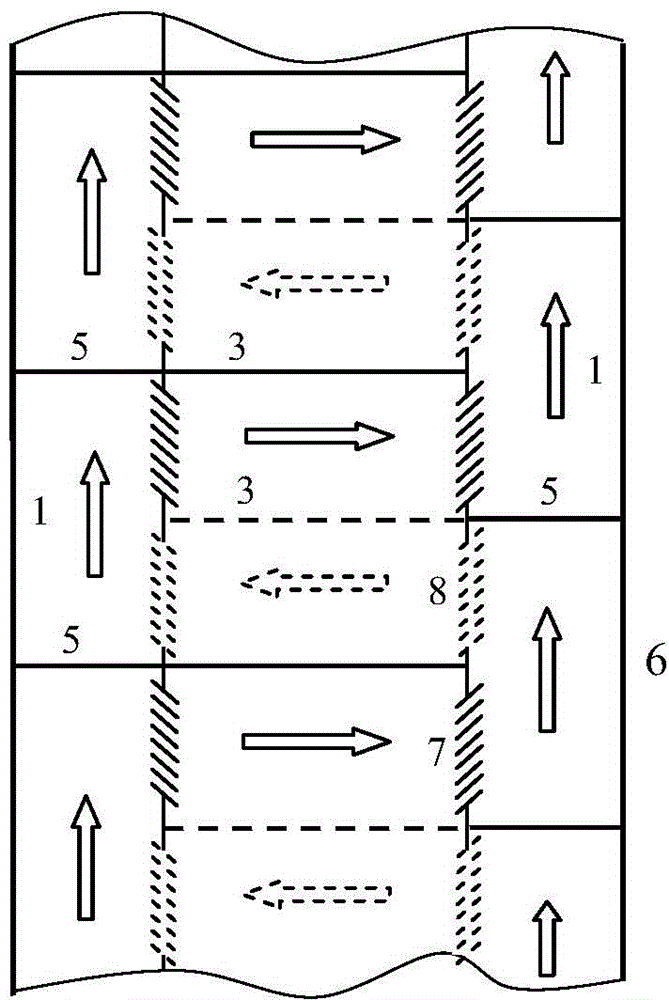

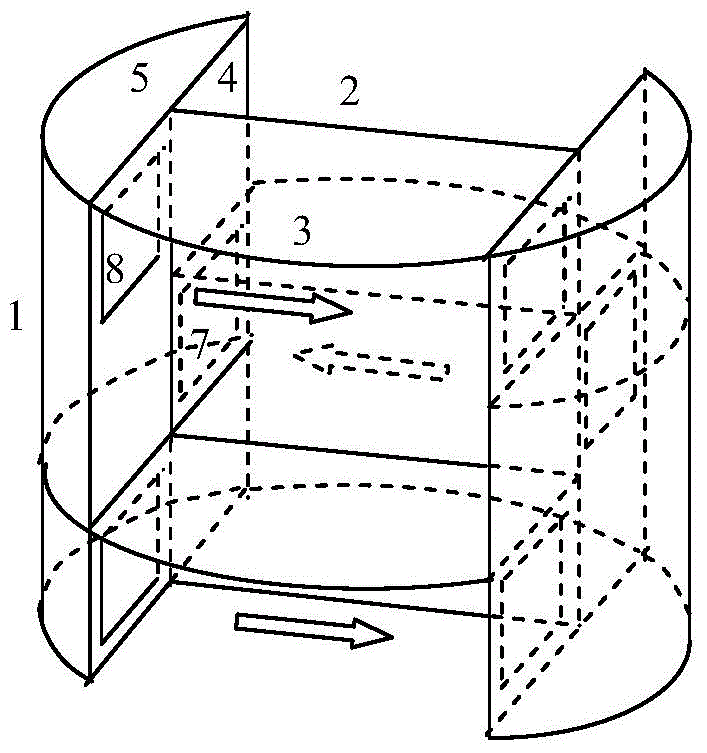

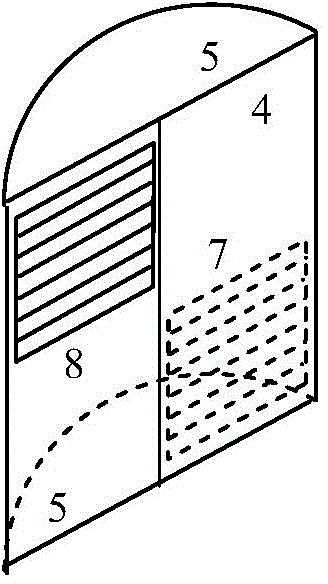

Separator-plates alternative extraction tower and extraction method

The invention discloses a separator-plates alternative extraction tower and an extraction method. The round extraction tower is equally divided from the center through a vertical separator plate into two parts, and semicircular tower plates are alternately equally spaced at two sides of the separator plate. A continuous-phase material flows among the semicircular tower plates at one side and flows along a downcomer (or a riser tube) at the edge among two tower plates at the other side of the separator plate after mass exchange with a dispersed-phase material which passes through the tower plates; and the dispersed-phase material passes through the tower plates and flows between tower plates of the next stage at the same side after gathered on (or below) the tower plates. Through the above arrangement of the tower plate structure, the continuous phase flows step by step at two side of the separator plate, but the dispersed phase only flows step by step at the same side of the separator plate. By the arranging method of the tower plates, the continuous-phase material at the same side of the separator plate flows in the same direction on (or below) the two adjacent tower plates, thus raising average mass transfer force of a single tower plate. The extraction tower is especially suitable for a liquid-liquid extraction process of two large phases with the lower-flow one being a continuous phase.

Owner:ZHEJIANG UNIV

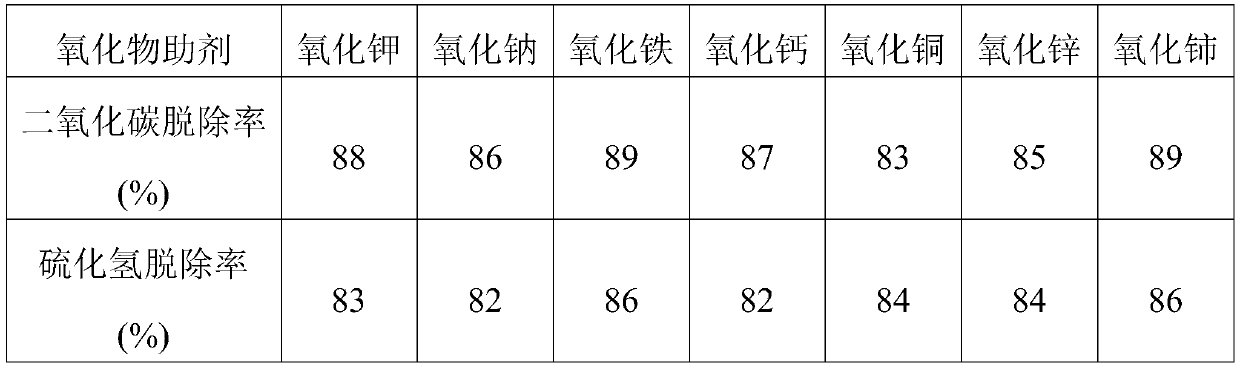

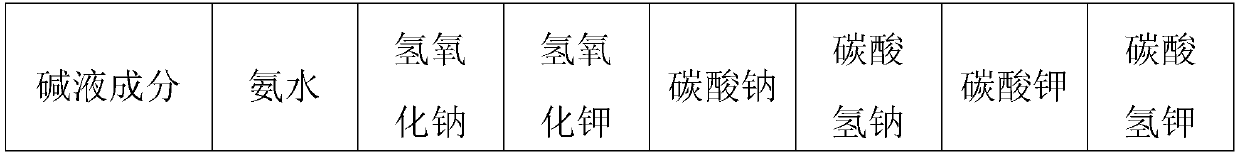

Composite adsorbent for biogas desulfurization and decarburization as well as preparation method and application of the composite adsorbent

InactiveCN111569821AHigh removal rateIncrease concentrationOther chemical processesGaseous fuelsSorbentPhysical chemistry

The invention discloses a composite adsorbent for biogas desulfurization and decarburization as well as a preparation method and application of the composite adsorbent, and belongs to the technical field of biogas impurity removal and purification. A metal oxide additive is loaded in the multi-layered pore structure of an alkaline oxide solid waste carrier subjected to negative pressure degassing,and metal oxide and alkaline oxide solid waste can synergistically play the roles of desulfurization and decarburization, so that the removal rate of CO2 and H2S can be effectively improved, and theconcentration of a prepared biomass natural gas product is improved. With the composite adsorbent as well as the preparation method and the application of the composite adsorbent adopted, the utilization rate of the basic oxide solid waste can be improved; the activity and capacity of the composite desulfurization and decarburization adsorbent can be improved; the service life of the composite desulfurization and decarburization adsorbent can be prolonged; the reaction rate can be accelerated; carbon dioxide and hydrogen sulfide in biogas can be simultaneously removed; and an efficient and low-cost biogas purification technology is provided.

Owner:CHINA HUANENG GRP CO LTD +1

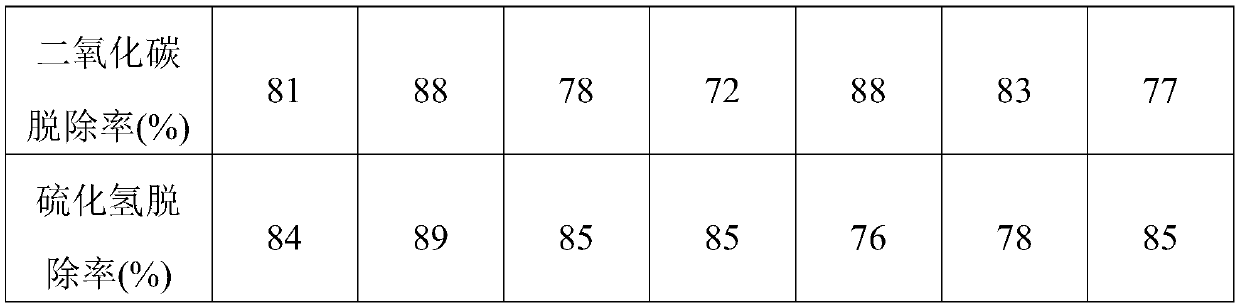

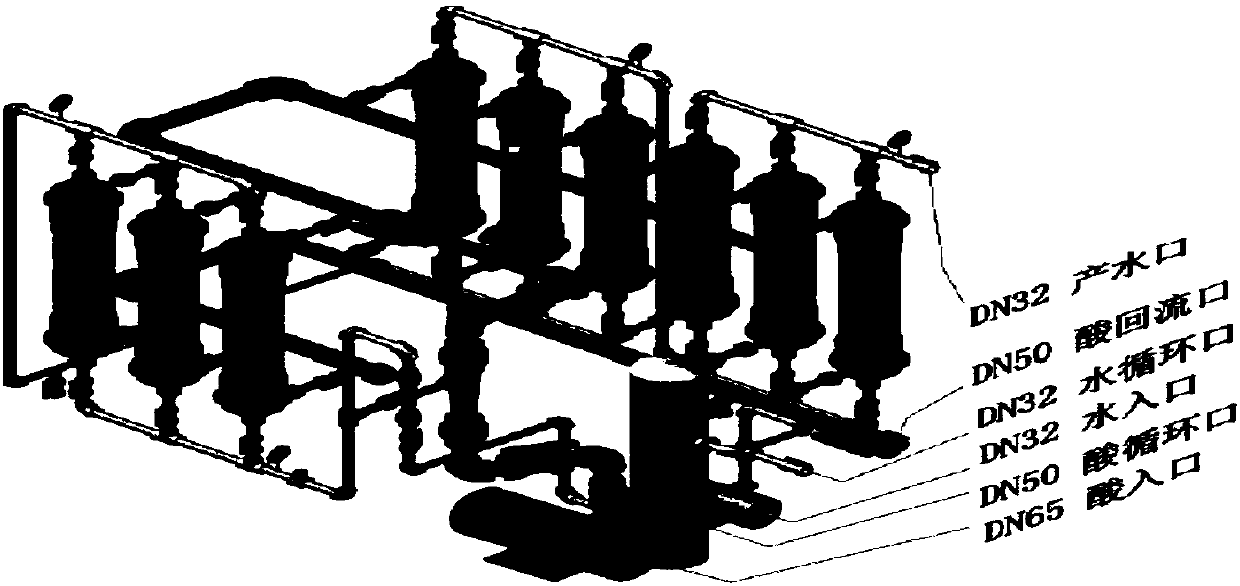

High ammonia-nitrogen wastewater treatment method

InactiveCN107902793AMeet the subsequent process requirementsSmall footprintSpecific water treatment objectivesWater contaminantsFiberSalt content

The invention discloses a high ammonia-nitrogen wastewater treatment method. Wastewater is subjected to pretreatment through an air floatation device, a sand filtration device, a microfiltration device and an ultrafiltration membrane, and then the treated wastewater enters an RANS membrane system. The high ammonia-nitrogen wastewater flows in a membrane fiber shell side, and a dilute acid serves as an absorption liquid and flows in the membrane fiber tube side in a cross-flow mode. Under an alkaline condition (the pH value is equal to 10.5-12), free ammonia molecules in the wastewater penetrate through membrane holes of a strongly hydrophobic membrane in the RANS membrane system, enter the membrane fiber tube side, and rapidly react with the acid in the tube side. After the wastewater is subjected to ammonia nitrogen removal treatment, the ammonia nitrogen value of outgoing water is reduced to 40 mg / L, and the salt content of the ammonium salt solution is 10-30%.

Owner:绍兴齐英膜科技有限公司

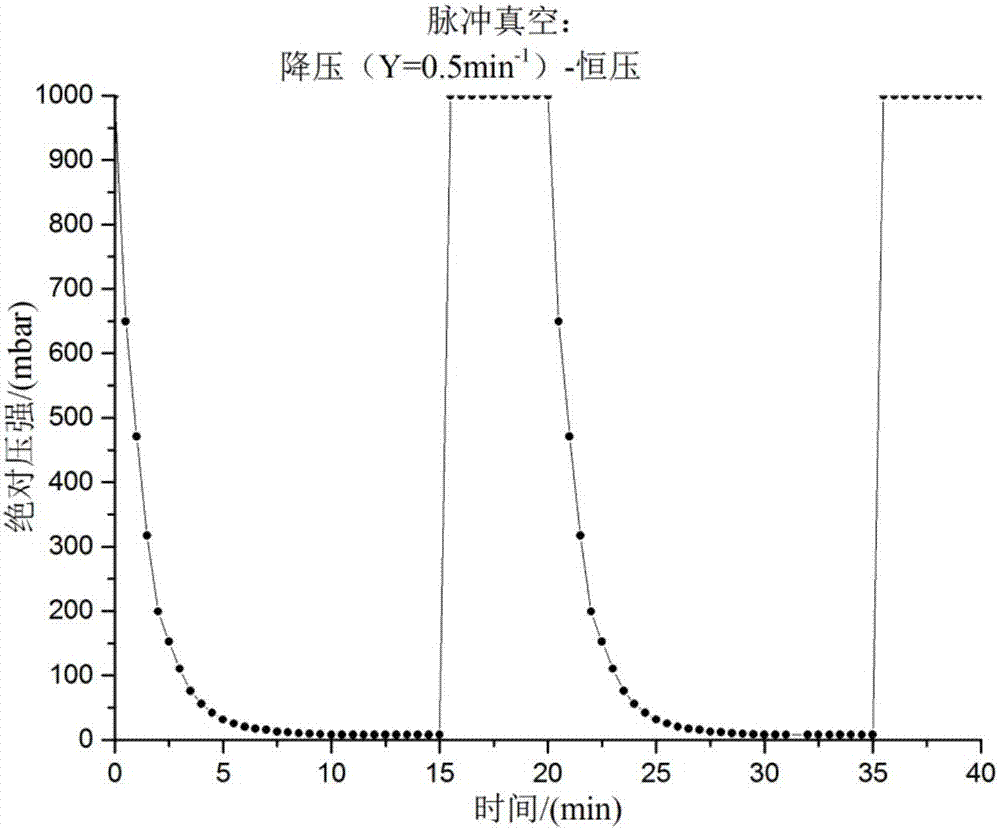

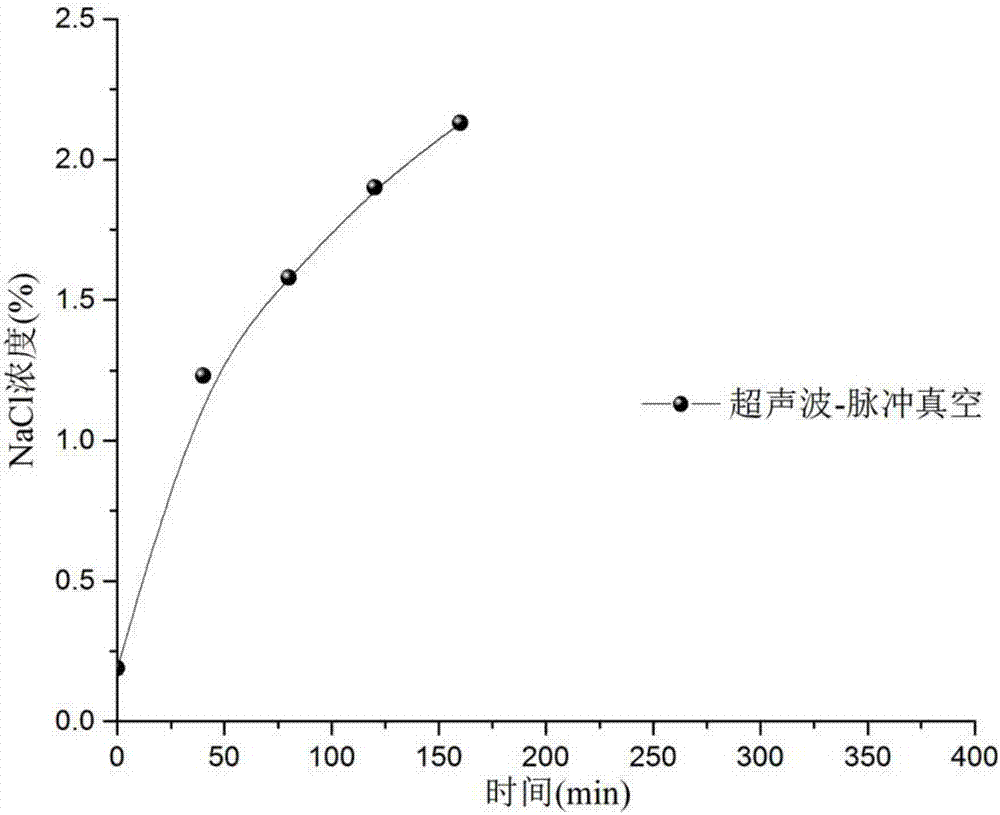

Ultrasonic wave-pulse vacuum synergistic fish meat salting method

ActiveCN106962826APrevent spoilageImprove mass transfer coefficientClimate change adaptationFood ultrasonic treatmentFisherySaline solutions

The invention relates to an ultrasonic wave-pulse vacuum synergistic fish meat salting method. The ultrasonic wave-pulse vacuum synergistic fish meat salting method includes the steps of S1, slaughtering live fish to remove scales and viscera, and cutting the slaughtered fish into fish blocks with a uniform thickness prior to cold storage; S2, putting the fish blocks subjected to cold storage into a low-temperature saline solution to make the temperatures of the fish blocks and the saline solution within 4+ / -1 DEG C, and subjecting the fish blocks and the saline solution to synchronous ultrasonic treatment and pulse vacuum treatment until salting is completed. Compared with the prior art, the ultrasonic wave-pulse vacuum synergistic fish meat salting method has the advantages that the ultrasonic wave-pulse vacuum synergistic fish meat salting method is higher in mass transfer coefficient and salting efficiency through ultrasonic wave-pulse vacuum synergistic assistance in salting.

Owner:SHAOGUAN COLLEGE

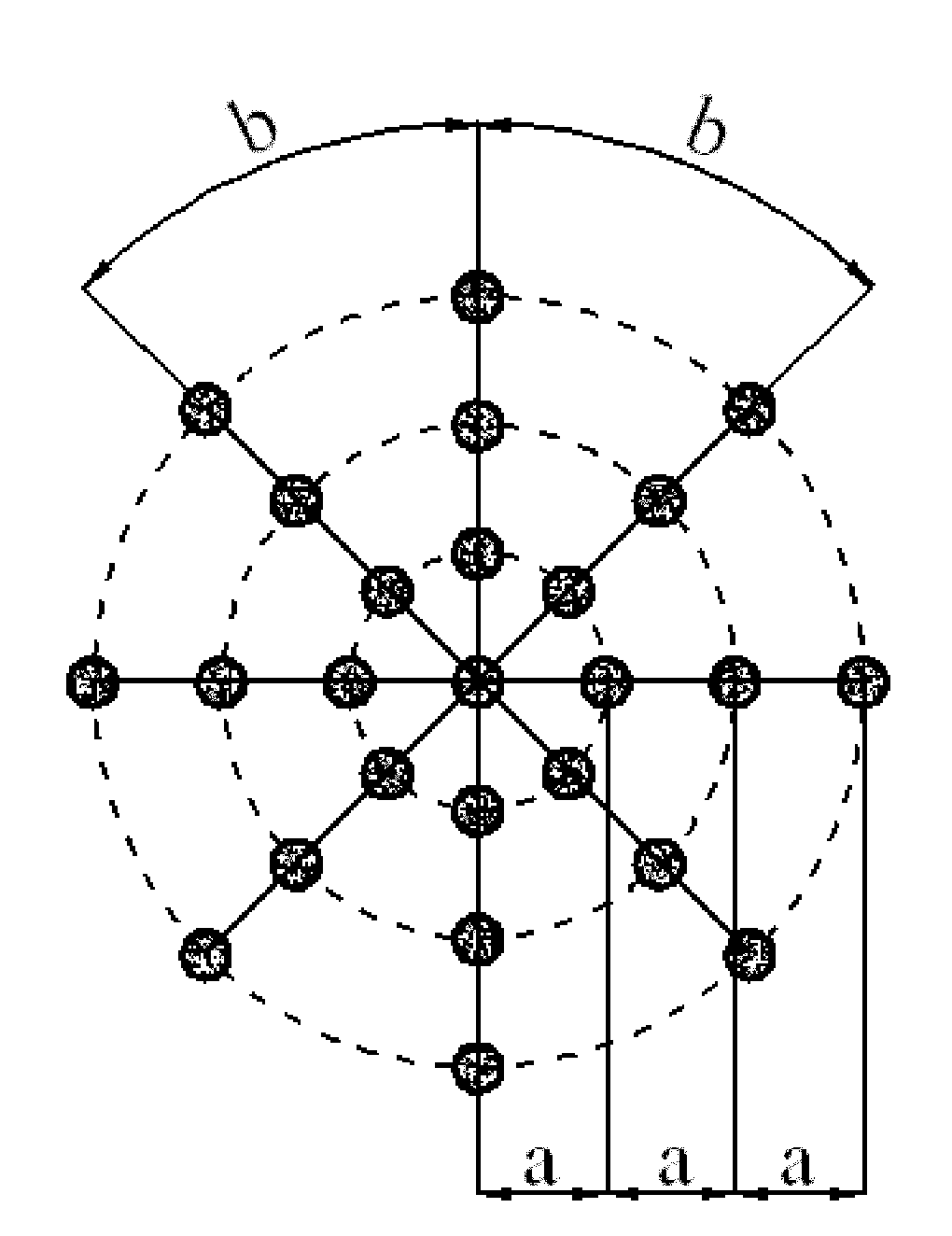

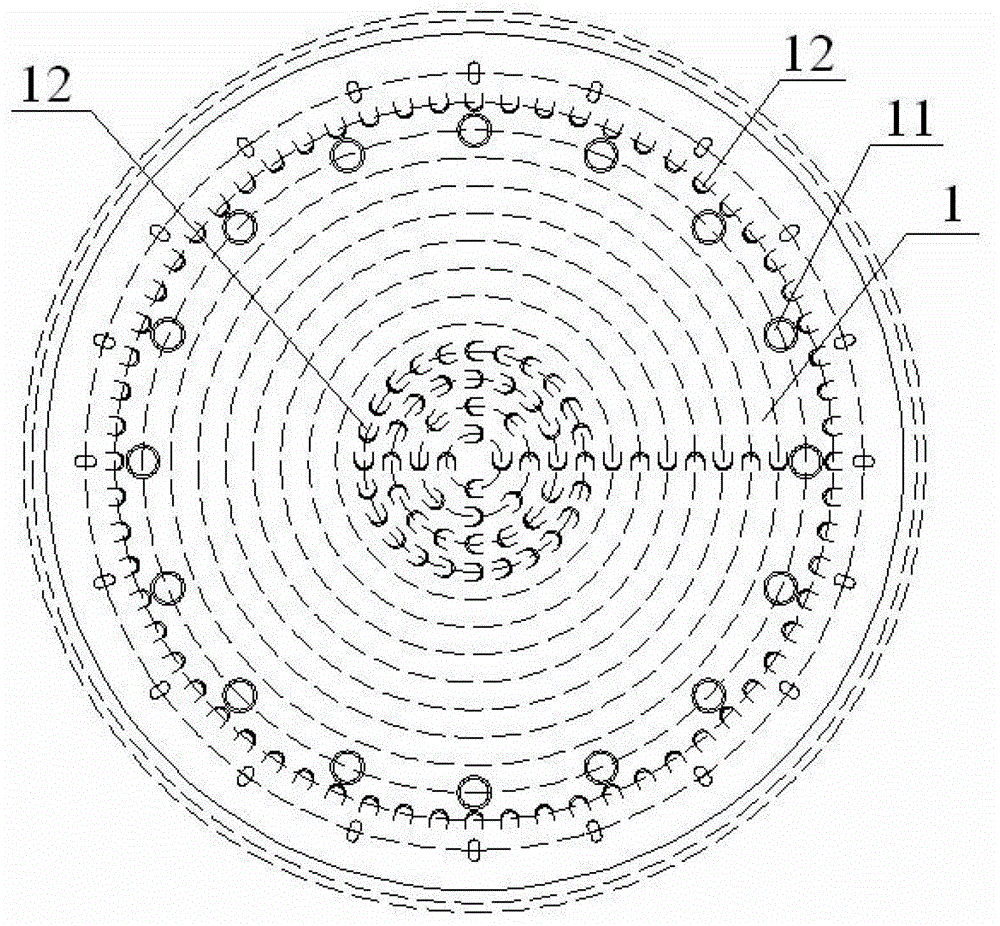

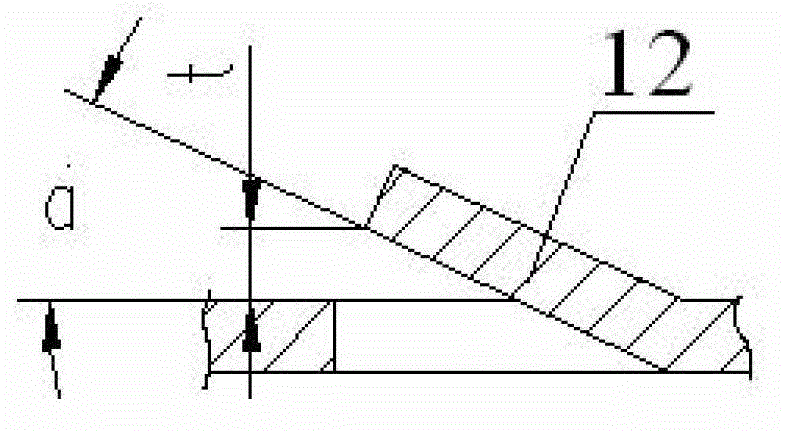

Rotary shear flow tray

InactiveCN103143186AGuaranteed multiple countercurrent contactsAvoid short circuitDispersed particle separationChemical/physical/physico-chemical processesContact timeEngineering

The invention provides a rotary shear flow tray which includes a tray. A plurality of downcomers and a plurality of spraying inclined holes are arranged on the tray, one end of each downcomer is fixed on a periphery of the tray, and the other end extends towards the centre of the tray until being communicated with a central liquid-collecting tube below the tray. A liquid outlet of the central liquid-collecting tube is communicated with a liquid-receiving groove arranged below the central liquid-collecting tube. The spraying inclined holes which regard the center of the tray as the center of a circle form multiple circles of concentric spraying inclined hole rings in a circumferential arrangement. Spraying holes of each spraying inclined hole ring which is arranged inside a circle of a downcomer tube ring are arranged at intervals in a clockwise or counterclockwise mode. The rotary shear flow tray has the advantages of 1) increasing a contact area of gas and liquid, accelerating the updating of two-phase surfaces of the gas and the liquid, and decreasing the resistance of a gas membrane and a liquid membrane; 2) strengthening eddy diffusion transmission; 3) prolonging the contact time of the gas and the liquid; 4) ensuring that the gas and the liquid are in a countercurrent contact for multiple times, preventing short-circuit, entrainment, and backmixing of the air and the liquid, and enhancing mass transfer driving force.

Owner:沈宏

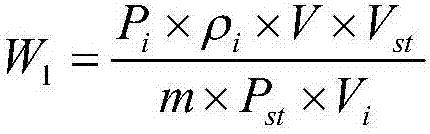

High-efficiency extraction process in hydrogen peroxide production process

ActiveCN105621364AImprove extraction efficiencyReduce the number of platesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHigh concentrationTower

The invention discloses a high-efficiency extraction process in a hydrogen peroxide production process. According to the invention, in an extraction process of an anthraquinone method for producing hydrogen peroxide; an extraction tower I and an extraction tower II are arranged; an oxidation liquid is divided into two parts which are an oxidation liquid I and an oxidation liquid II; pure water is introduced from the top of the extraction tower I, and the oxidation liquid I is introduced from the bottom of the extraction tower I; the two phases are subjected to countercurrent extraction in the extraction tower I; raffinate is discharged from the top of the extraction tower I, and is subjected to separation in a liquid / liquid separator, such that a heavy phase and a light phase are obtained; the heavy phase is mixed with extract liquid from the bottom of the extraction tower I, and the mixture of the heavy phase and the extract liquid from the bottom of the extraction tower I is introduced from the top of the extraction tower II; the light phase is mixed with the oxidation liquid II, and the mixture of the light phase and the oxidation liquid II is introduced from the bottom of the extraction tower II; the two phases are subjected to countercurrent extraction in the extraction tower II; a tower top raffinate phase is introduced into a post-treatment process; and the tower bottom extraction liquid is the high-concentration hydrogen peroxide product. The high-efficiency extraction process provided by the invention is provided aiming at the defects of prior arts. The process has the advantages of high mass transfer rate, high Murphree efficiency, high product concentration, low raffinate content, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

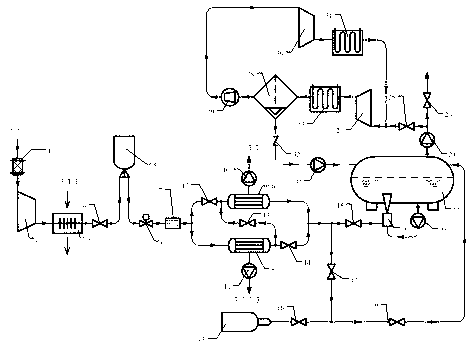

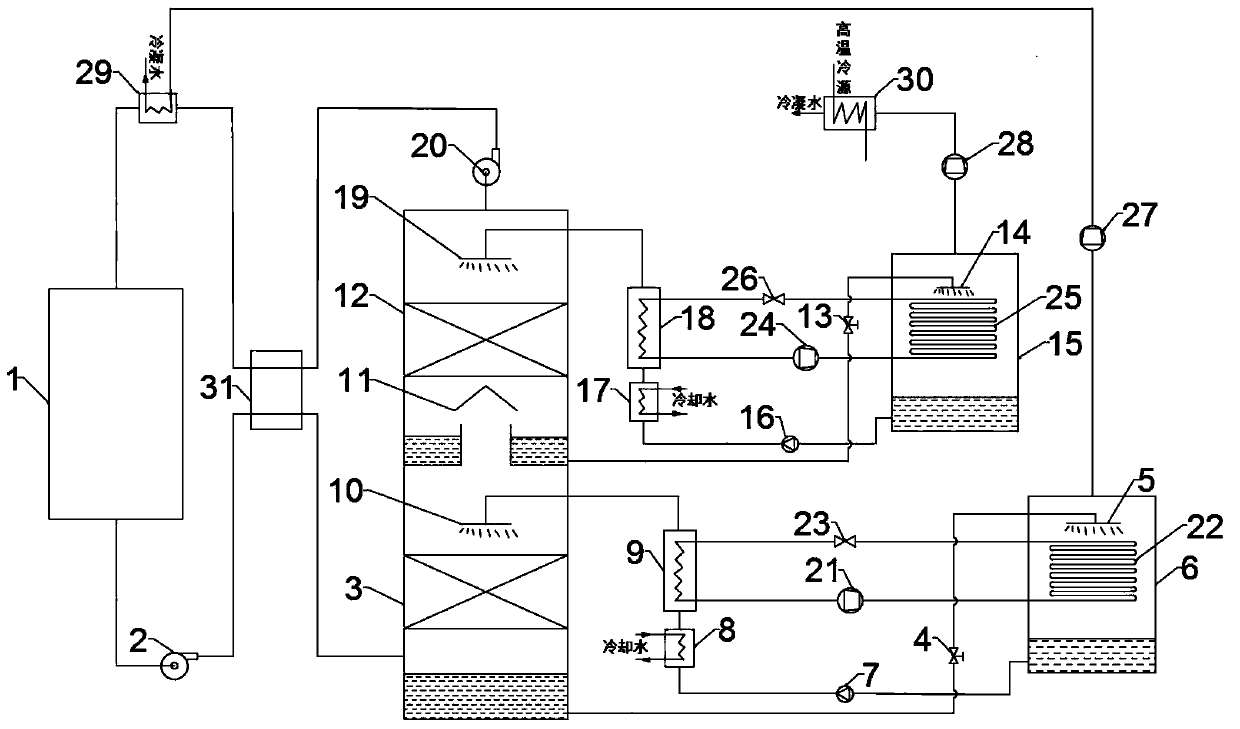

Closed-loop circulation drying system based on two-stage solution dehumidification

ActiveCN110986486AIncrease mass transfer driving forceImprove dehumidification efficiencyDrying solid materials with heatDrying gas arrangementsProcess engineeringMechanical engineering

The invention discloses a closed-loop circulation drying system based on two-stage solution dehumidification. The system comprises a drying medium circulation subsystem, a first-stage solution dehumidification-regeneration circulation subsystem, a second-stage solution dehumidification-regeneration circulation subsystem, a first heat pump circulation subsystem and a second heat pump circulation subsystem. The two-stage solution dehumidification technology is adopted to dehumidify a drying medium, so the problems that in the traditional cooling dehumidification process, a heat exchanger is prone to freezing, and energy consumption is large are solved; the hygroscopic solution is regenerated by adopting the vacuum technology, so the solution regeneration energy consumption is reduced, and the generated secondary steam is recycled by utilizing the compression technology, so the problem that the latent heat of water vapor is not utilized in the traditional cooling and dehumidifying processis solved; the mechanical heat pump technology is adopted for adjusting the solution dehumidification and regeneration temperature, so the energy utilization rate of the system is increased.

Owner:ZHEJIANG UNIV OF TECH +1

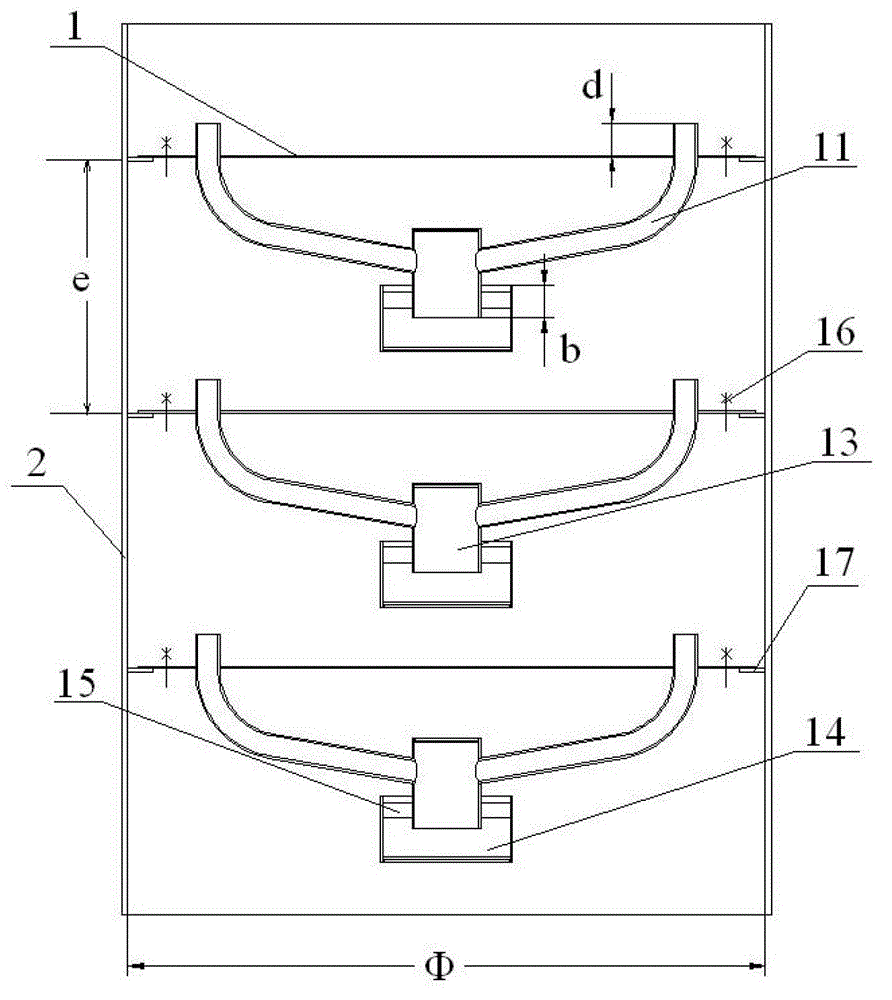

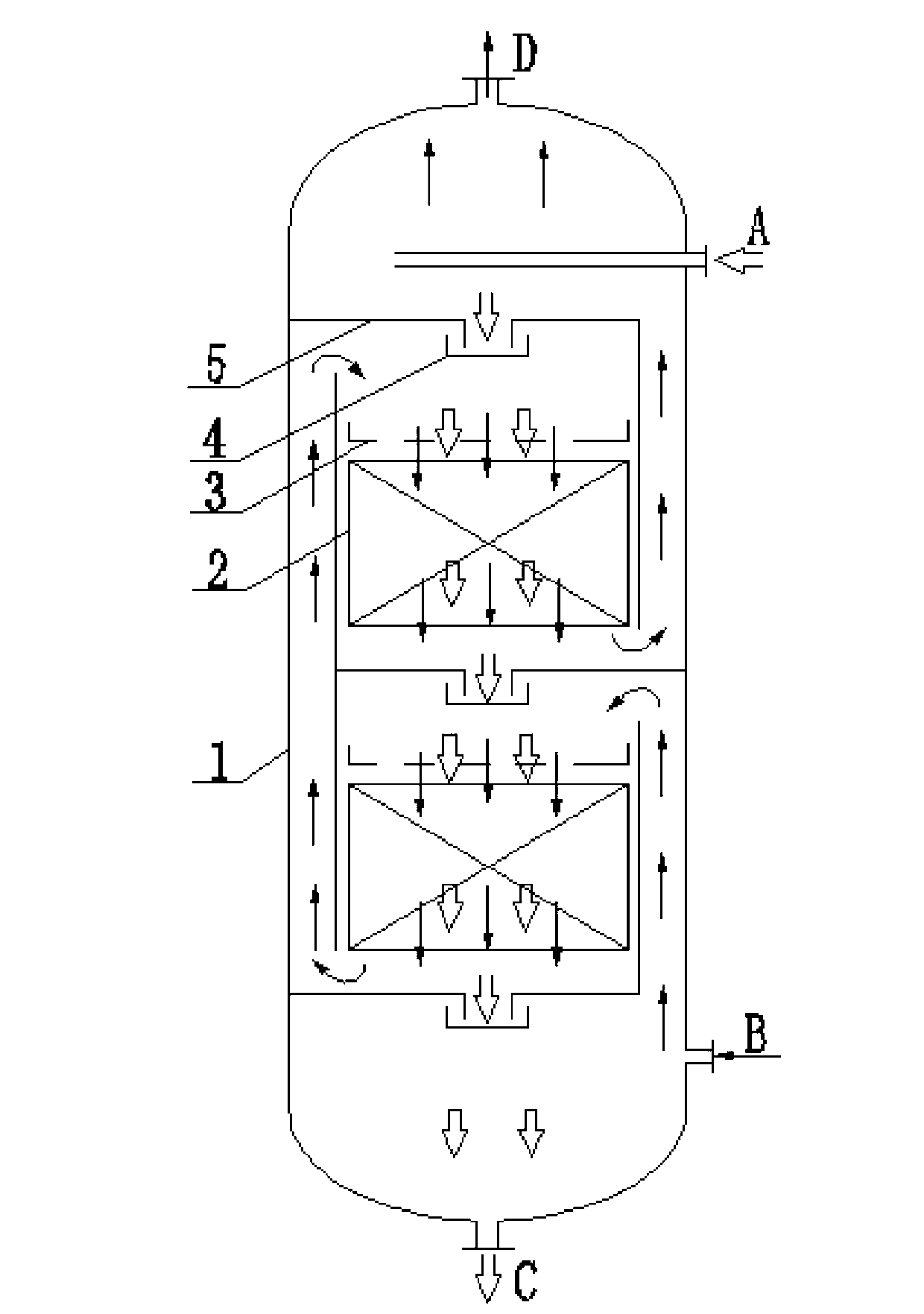

Gas-liquid mass transfer device

InactiveCN103100291AContact is sufficiently stableReduce entrainmentDispersed particle separationDistillation separationCounter flowGas phase

Belonging to the field of gas-liquid mass transfer devices, the invention discloses a gas-liquid mass transfer device. The device comprises: a tower body, two or more mass transfer unit groups, an independent liquid collector and an independent liquid receiving disc. The top of the tower body is provided with a gas outlet and a liquid inlet, and the bottom is provided with a liquid outlet and a gas inlet. The independent liquid collector and the independent liquid receiving disc are positioned at the bottom of the tower body. Each mass transfer unit group consists of a liquid collector, a liquid receiving disc, a liquid distributor and a mass transfer area from top to bottom, and the mass transfer unit groups are in up-down arrangement inside the tower body. The bottom of each liquid receiving disc is provided with small holes. When the device operates, the gas-liquid two-phase flow direction shows overall counter-flow and local co-current flow, that is to say, a gas flows into the tower body from the bottom and flows out from the top, while a liquid flows into the tower body from the top and flows out from the bottom. And in each mass transfer area, the gas and the liquid are in top-down co-current contact for mass transfer. The special flow state combines respective advantages of counter-flow and co-current flow, a large mass transfer driving force and complete and stable gas-liquid contact can be realized simultaneously, the mass transfer rate can be improved, and the mass transfer effect can be ensured.

Owner:中船(天津)环境工程技术有限公司

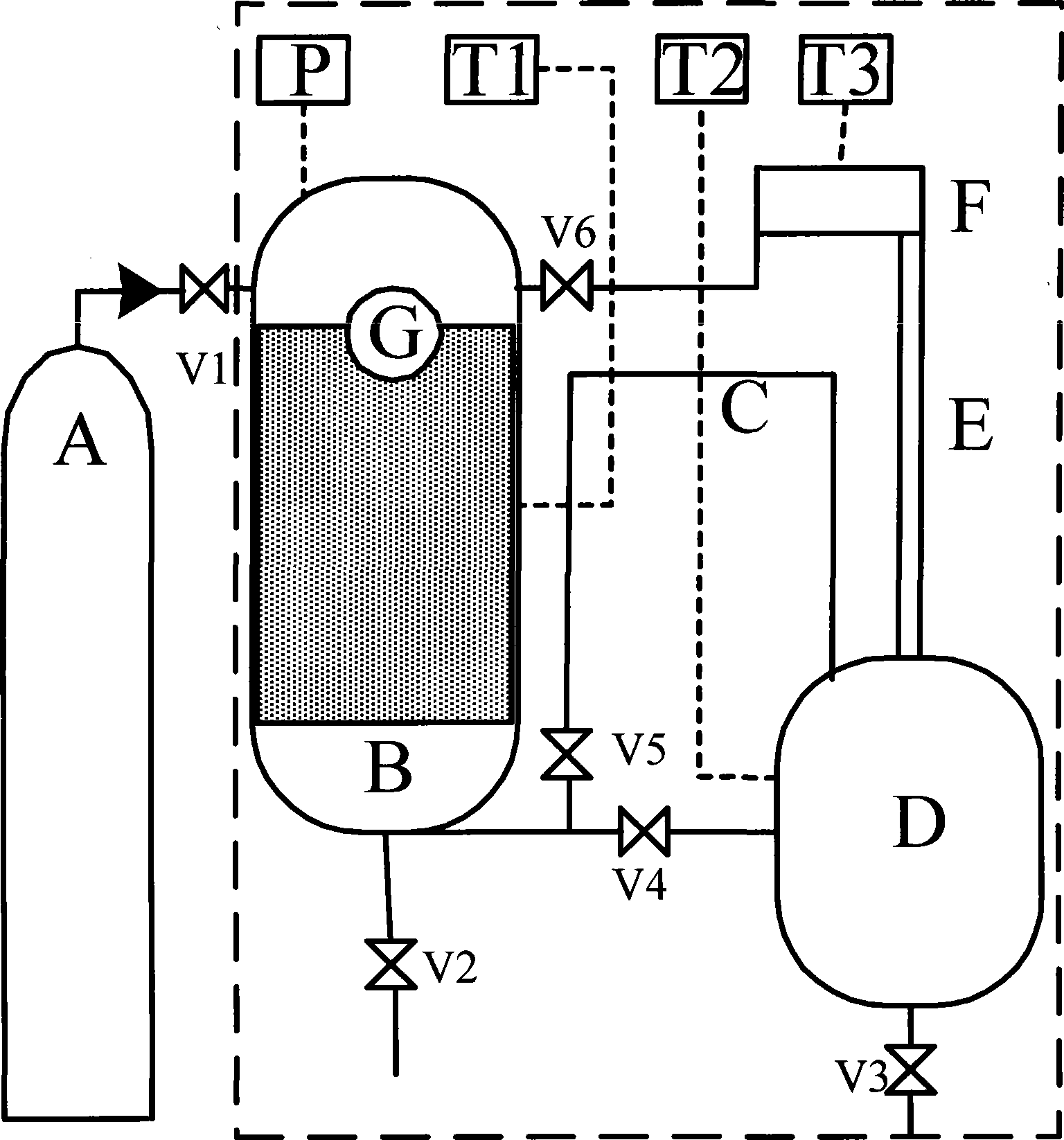

Self-circulation dry cleaning machine

InactiveCN101429722AImprove performanceRealize closed loop refluxSolvent-treatmentDry-cleaning apparatusSiphonSewage outfall

The invention discloses a self-circulating dry washer, and relates to a dry washer, in particular to a device for self-circulating dry washing by subcritical or combined supercritical fluid. A pumplessly driven self-circulating dry washer for the self-circulating dry washing by the subcritical or the combined supercritical fluid is provided, and is provided with a washing kettle, a siphon tube, a dirt kettle, a lift tube and a condenser, wherein the washing kettle is provided with an inlet of a pressure fluid source, the siphon tube is arranged between the washing kettle and the dirt kettle, the dirt kettle is provided with a heating device and a sewage outfall, the lift tube is arranged between the dirt kettle and the condenser, and a water return tube is arranged between an outlet of the condenser and the washing kettle.

Owner:XIAMEN UNIV

A kind of method utilizing sulfuric acid tail gas to dry ammonium phosphate

InactiveCN102261830AIncrease speedIncrease mass transfer driving forceDrying gas arrangementsEnvironmental engineeringSpray dried

A method for drying ammonium phosphate by using sulfuric acid tail gas. The tail gas temperature of the sulfuric acid plant is about 80°C, and the moisture content is less than 0.1g / m3. It can be regarded as a dry gas without moisture. After the sulfuric acid tail gas is heated to 140-160°C by steam, it is sent to the spray drying tower as dry phosphorus ammonium medium. The implementation of this method will not affect the existing production systems of sulfuric acid and ammonium phosphate, and its advantage is that it can not only recycle the sensible heat of sulfuric acid tail gas, but also increase the drying rate of ammonium phosphate.

Owner:刘宏

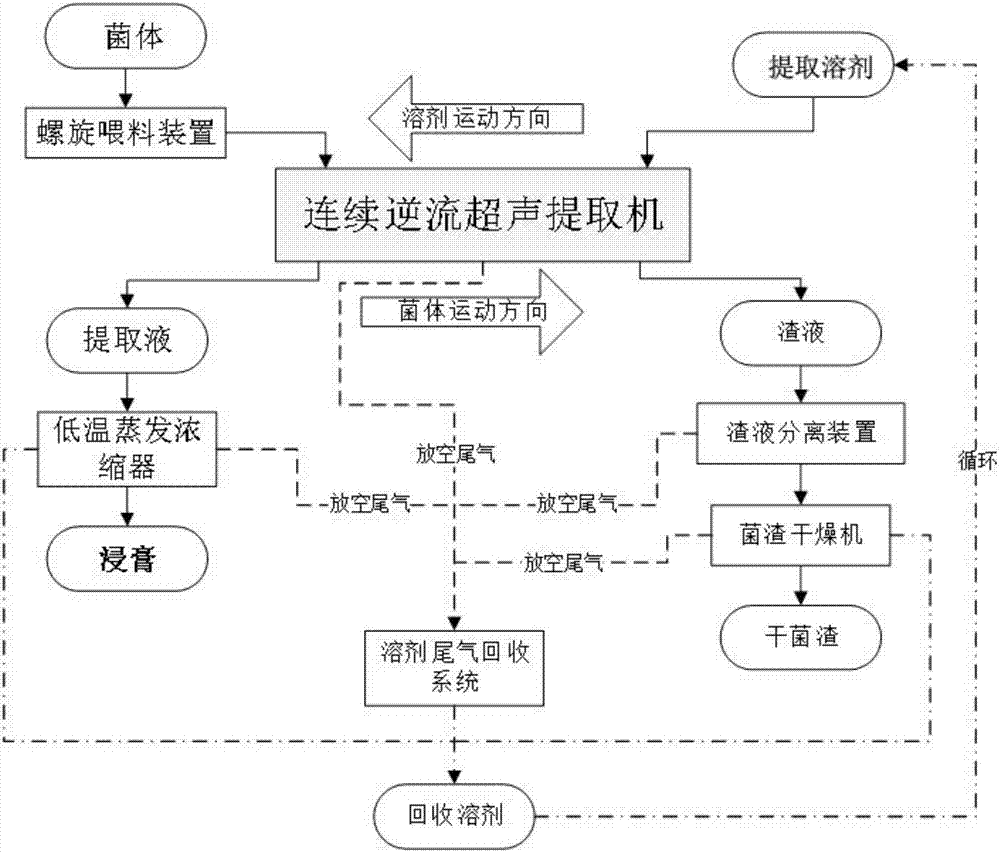

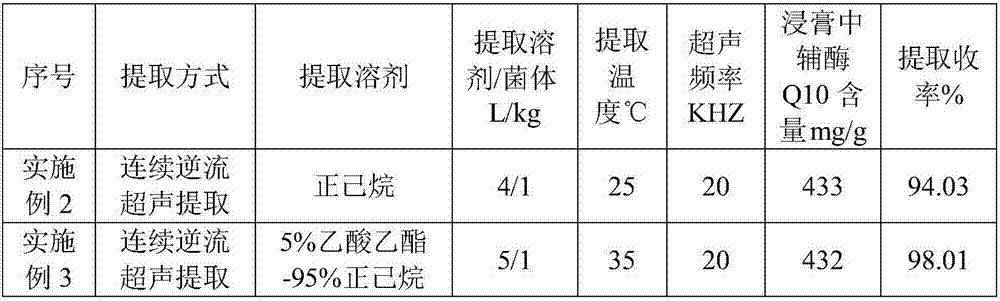

Method for continuous countercurrent ultrasonic extracting of coenzyme Q10

InactiveCN107445815AImprove leaching effectIncrease concentrationQuinone separation/purificationDigestionContinuous dynamic

The invention discloses a method for continuous countercurrent ultrasonic extracting of coenzyme Q10. The method comprises the following steps: respectively feeding thalli and an extraction solvent into a digestion cabin from the feeding ports at the two ends of a continuous countercurrent ultrasonic extracting machine, making the thalli and extraction solvent flow reversely and meanwhile starting an ultrasonic oscillator for assisting in extraction; evaporating and concentrating the extracting solution; purifying, thereby acquiring coenzyme Q10; recovering the solvent; performing residue and liquid separation on the extracted thalli, mixing the extracting solution with the extracting solution acquired in the last step and concentrating, drying and desolventizing the wet thalli residue, thereby acquiring dry thalli residue and recovering the solvent; recovering the gas generated in the processing process through a solvent tail gas recovering system and condensing, thereby acquiring the recovered solvent; and re-pouring all the recovered solvent into a solvent storage tank for recycling. According to the extracting method disclosed by the invention, the continuous dynamic countercurrent ultrasonic extraction is realized within a shorter extracting pipe, the gradient ratio is guaranteed, the yield is increased, the solvent dosage is reduced, the output of later filtering, separation and concentration is relieved, the energy is saved, the consumption is reduced and the production cost is lowered.

Owner:INNER MONGOLIA KINGDOMWAY PHARMA LTD +1

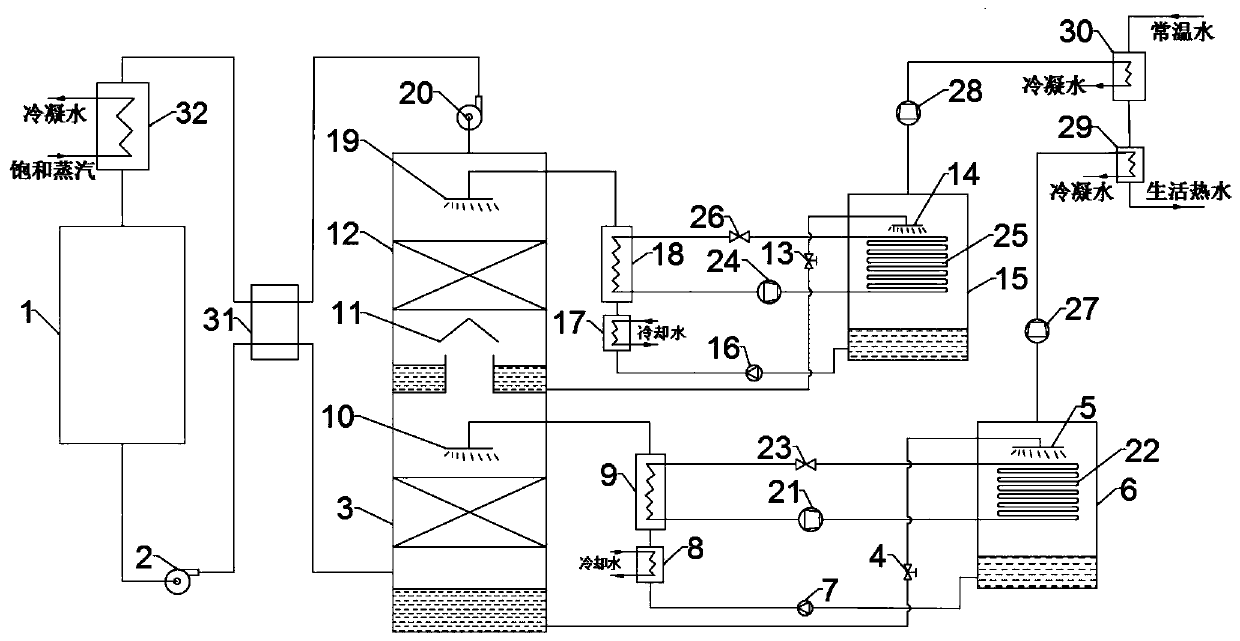

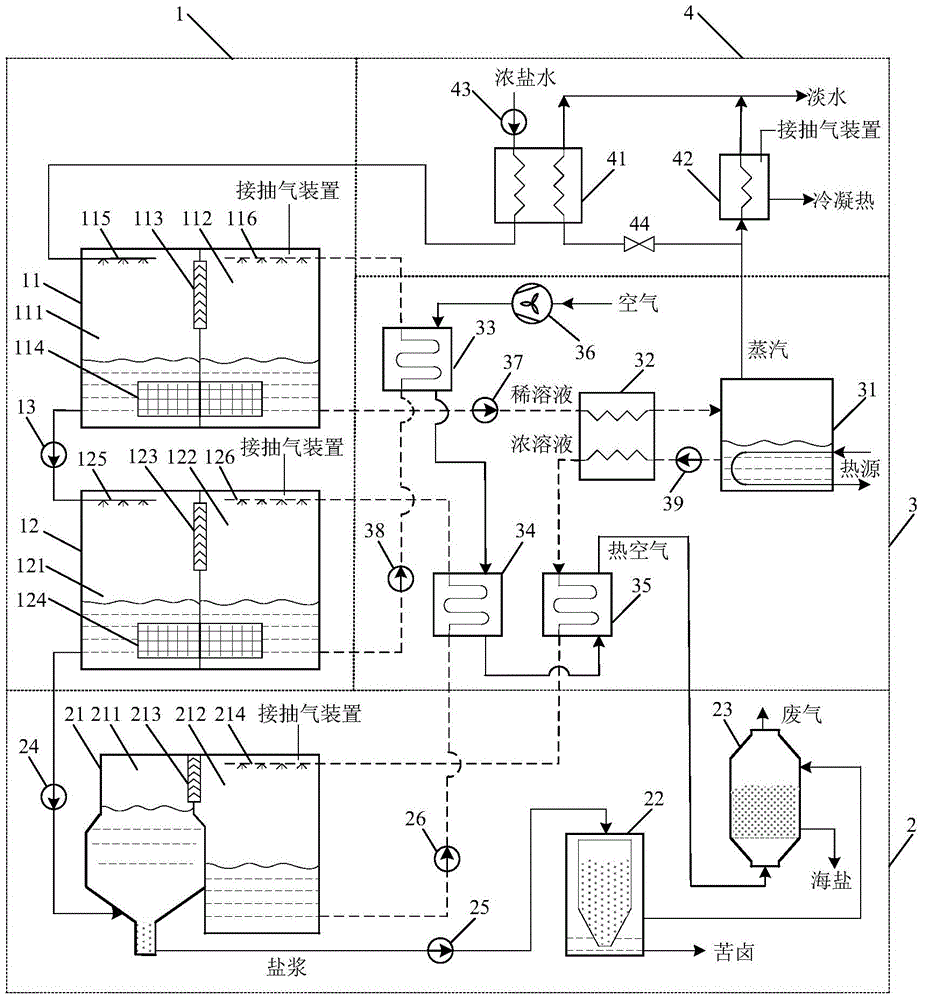

Trigeneration system of fresh water, sea salt and heat energy based on deep concentration of sea water desalination strong brine

InactiveCN104528850AImprove economyLow costGeneral water supply conservationSeawater treatmentWater desalinationSaline water

The invention discloses a trigeneration system of fresh water, sea salt and heat energy based on deep concentration of sea water desalination strong brine and relates to strong brine treatment. The invention provides the trigeneration system of fresh water, sea salt and heat energy based on deep concentration of sea water desalination strong brine, which is efficient, energy-saving, compact in structure and good in economical benefit. The system is provided with a deep concentration sub system, a salt manufacturing sub system, a solution regeneration sub system and a condensation sub system, wherein the deep concentration sub system is provided with at least one evaporation-absorber which is provided with an evaporation chamber, an absorption chamber, a liquid baffle plate, a heat tube exchanger, a strong brine spray tube and an evaporation-absorber lithium bromide solution spray tube; the solution regeneration sub system is provided with a generator, a solution heat exchanger and an air cooler; the condensation sub system is provided with a brine preheater and a condenser.

Owner:JIMEI UNIV

Alkali-water desulphurization dust removal technology

InactiveCN105983307AFully contactedIncrease mass transfer driving forceUsing liquid separation agentSulfateSpray nozzle

The invention relates to an alkali-water desulphurization dust removal technology, and relates to a wet-method environment-friendly treatment technology for sulfur-containing smoke. The alkali-water desulphurization dust removal technology comprises the following steps: performing primary desulphurization dust removal by taking a sulfur-containing solution as a first desulphurization agent, performing the secondary desulphurization dust removal by adopting the water as a second desulphurization agent, performing the primary desulphurization dust removal in a tubular reaction device, and performing the secondary desulphurization dust removal in a tower-type device; and enabling the desulphurized dust-removed sulphite-containing mixed solution to enter an independent tubular oxidation reactor, and performing the oxidation reaction to obtain a sulfate mixed solution. By adopting the alkali-water desulphurization dust removal technology, the technical defects of the traditional wet-method desulphurization technology that a spray nozzle is blocked by scales formed on the inner wall and components in the desulphurization tower can be overcome, and the long-term operation of the device can be guaranteed; the equipment investment is low, the operation expense is low, the operation flexibility is high, the absorption, neutralization and oxidation are thoroughly carried out, and the desulphurization efficiency is high.

Owner:吴剑华

Device and method for recovering and concentrating ortho-toluidine in ortho-toluidine wastewater by membrane extraction

InactiveCN105013210AReduce concentrationImprove absorption efficiencyAmino compound purification/separationLiquid solutions solvent extractionWastewaterOrtho-Toluidine

The invention relates to a device and a method for recovering and concentrating ortho-toluidine in ortho-toluidine wastewater by membrane extraction. The method comprises: conveying wastewater containing ortho-toluidine to a silicon rubber extraction membrane tube, wherein the silicon rubber extraction membrane tube is put in an acidic extraction solution, ortho-toluidine in the wastewater can penetrate through the tube wall of the silicon rubber extraction membrane tube, enter into the extraction solution and react to generate ortho-toluidine ions, and the rest of the wastewater is discharged from the outlet of the silicon rubber extraction membrane tube with standard level or post-treatment; and taking out the extraction solution when the concentration of the ortho-toluidine ions in the extraction solution exceeds a predetermined value, and adding alkali liquor into the extraction solution to obtain recovered and concentrated ortho-toluidine. According to the device and method provided by the invention, the extraction solution is acidic and is reacted with alkalescent ortho-toluidine to generate the ortho-toluidine ions which cannot penetrate through the silicon rubber extraction membrane tube so as to prevent the ortho-toluidine from returning to the wastewater again. A lot of ortho-toluidine can be separated and concentrated, the mass transfer velocity is relatively rapid, industrial treatment and concentration and recovery of the ortho-toluidine are facilitated, and the use level of the extraction solution is extremely little.

Owner:SHAANXI UNIV OF SCI & TECH

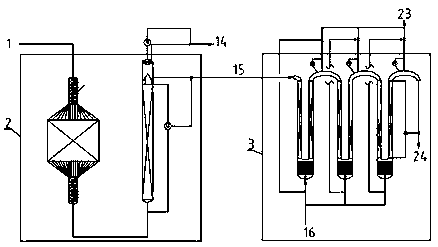

Liquid-phase hydrogenation reaction device and liquid-phase hydrogenation reaction method

ActiveCN111068587AShorten the flow pathReduced Diffusion EscapeTreatment with hydrotreatment processesChemical/physical processesFluid phaseHydrogenation reaction

The invention discloses a liquid-phase hydrogenation reaction device and a liquid-phase hydrogenation reaction method. The liquid-phase hydrogenation reaction device comprises an efficient hydrogenation reaction zone and an ultra-deep hydrogenation reaction zone, wherein the efficient hydrogenation reaction zone comprises a down-flow type fixed bed reactor and an up-flow type tubular reactor whichare connected in series, the fixed bed reactor is in an up-flow type or a down-flow type, the tubular reactor is in an up-flow type, the ultra-deep hydrogenation reaction zone comprises a plurality of U-shaped tubular reactors connected in series, and the adjacent tubular reactors are communicated through arc-shaped pipes. According to the invention, the liquid-phase hydrogenation reaction deviceis used for carrying out efficient hydrogenation reaction and deep hydrogenation reaction, so that the hydrogenation reaction rate and the reaction efficiency are effectively improved, the hydrogen utilization rate is increased, the hydrogen consumption and the energy consumption are reduced, the total volume of the reactor is reduced, H2S, NH3 and other gases generated in the reaction process are continuously moved out of the reaction system in the reaction process, the continuous high efficiency of the hydrogenation reaction process is maintained, and deep hydrogenation reaction and ultra-deep hydrogenation reaction are realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

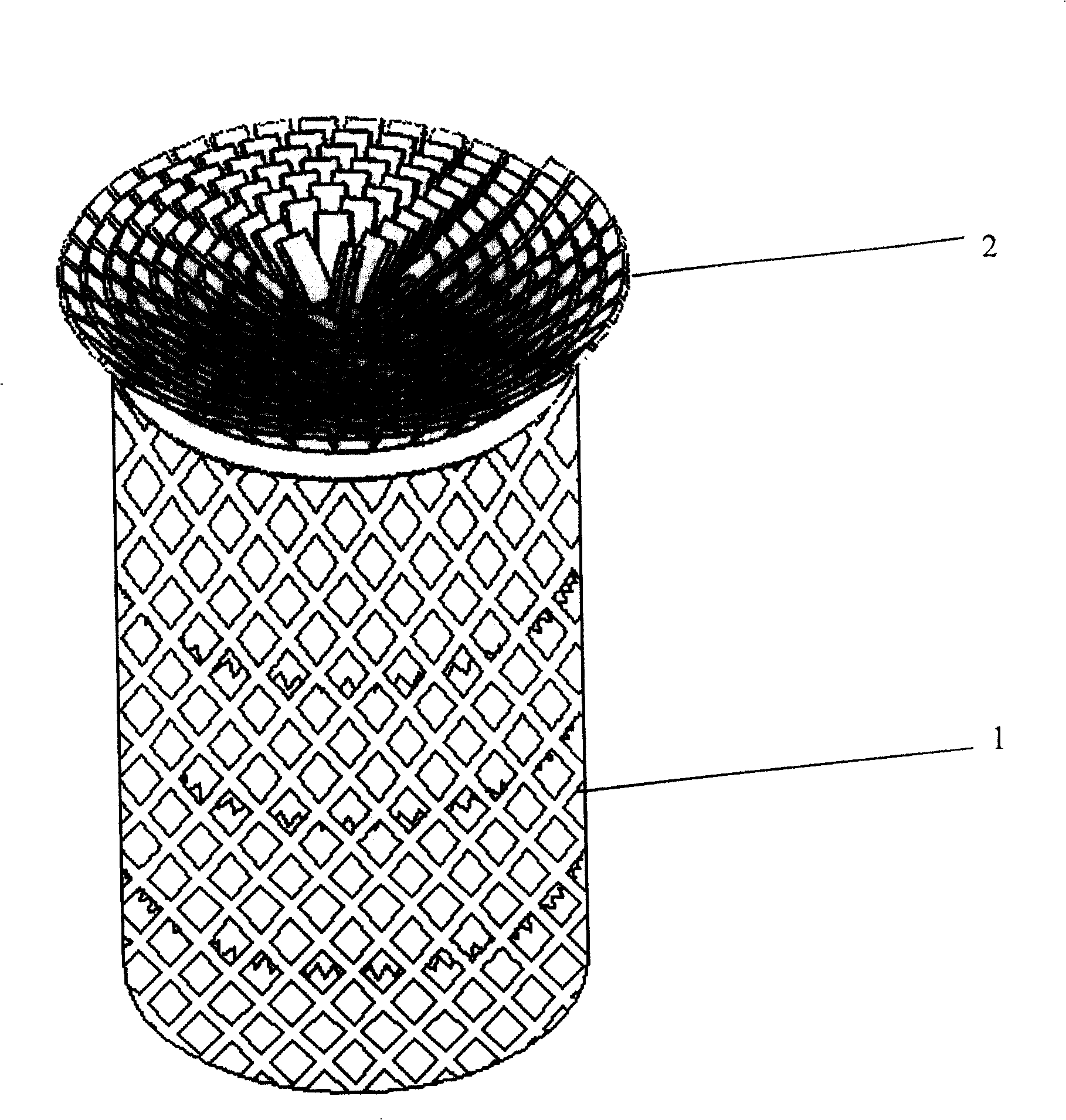

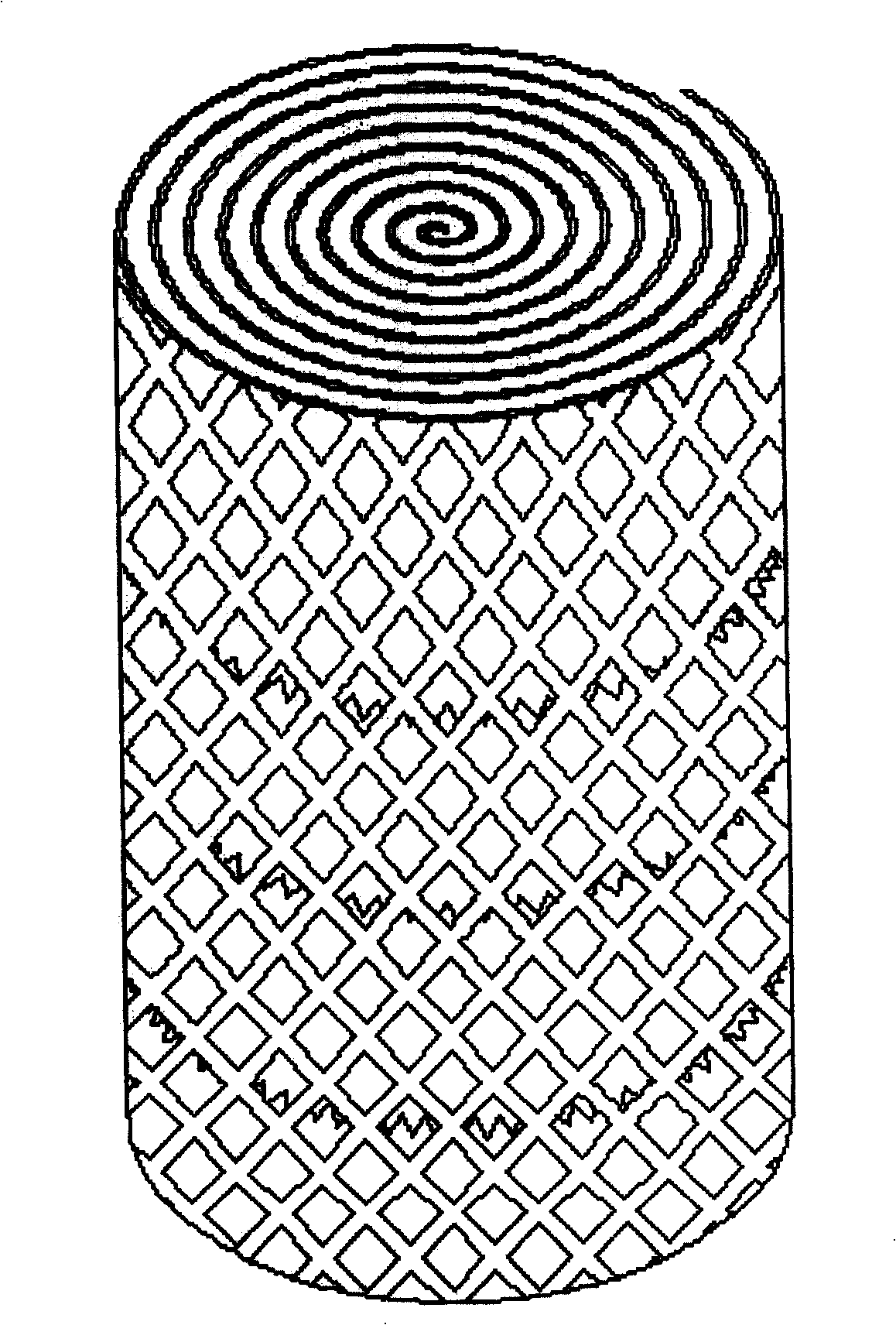

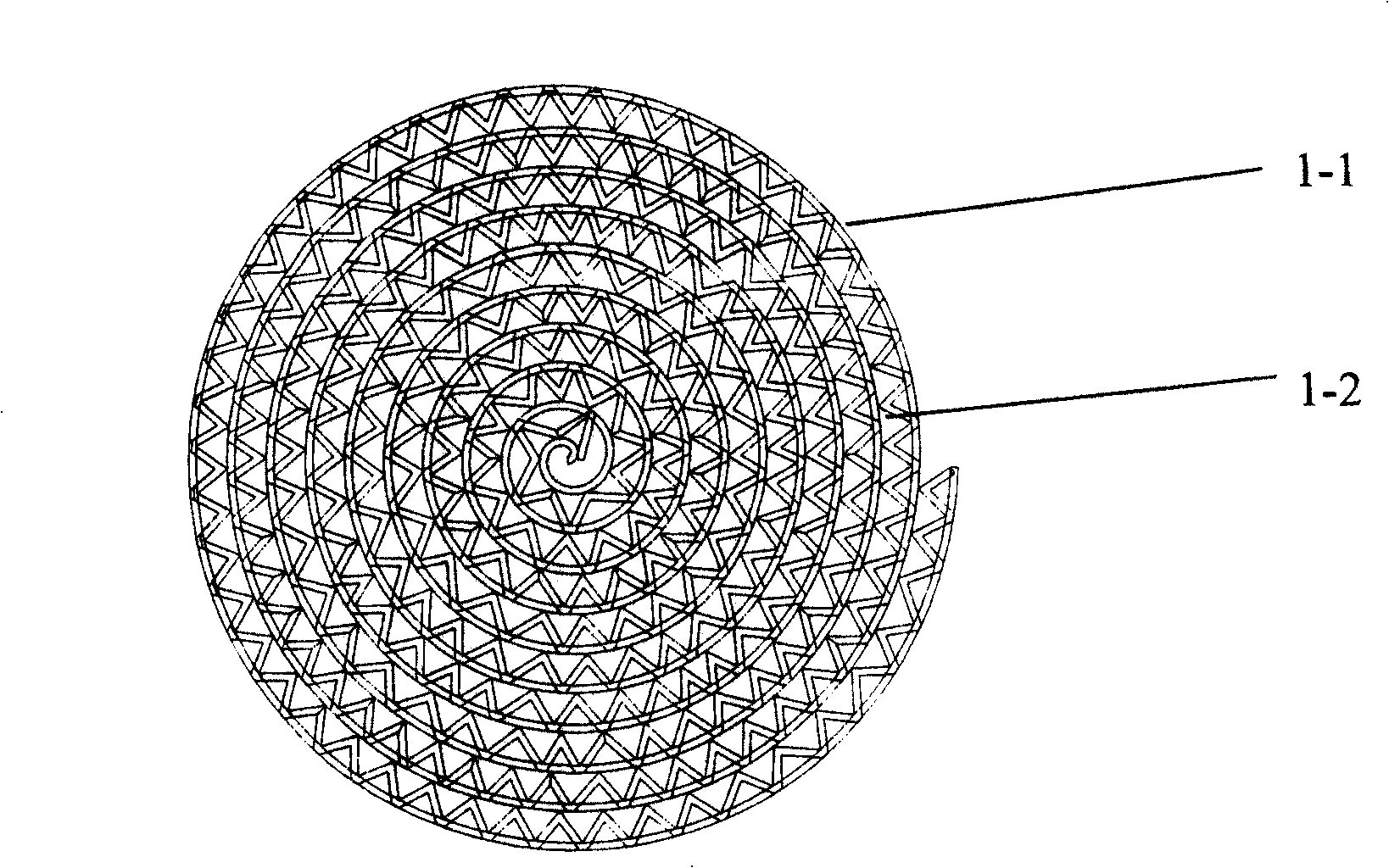

Regular packing of helical cylindrical net

ActiveCN100431687CIncreased turbulenceAvoid pressure dropChemical/physical/physico-chemical processesGas phaseMechanical engineering

The present invention discloses one kind of regular helical cylindrical net packing, and belongs to the field of gas-liquid mass transfer separator packing technology. The regular helical cylindrical net packing unit includes a cylindrical helical net and a conic disc on the upper end of the cylindrical helical net. The cylindrical helical net is one multilayer one made of plate net and springs and has several supporting spring rings between helical net layers. The conic disc includes a short helical plate cylinder in the same diameter, layer number and interval between layers and a helical cone disc connected to the short helical plate cylinder. The packing of the present invention is used in gas-liquid mass transfer process, and has the advantages of parallel gas and liquid channels, plunger type flow with low gas phase resistance and high mass transfer efficiency, easy processing of the packing and low cost.

Owner:TIANJIN UNIV

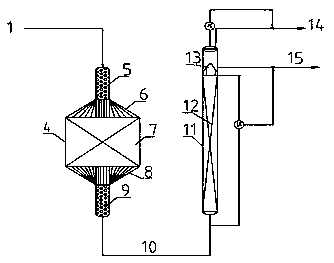

Diesel oil ultra-deep desulfurization device and diesel oil hydrogenation reaction system

ActiveCN111068588AAccelerate Dissolution and DispersionIncrease mass transfer driving forceChemical/physical processesHydrocarbon oils treatment productsThermodynamicsHydrodesulfurization

The invention discloses a diesel oil ultra-deep desulfurization device and a diesel oil hydrogenation reaction system. The ultra-deep desulfurization device comprises a plurality of U-shaped tubular reactors connected in series, wherein the adjacent tubular reactors are communicated through arc-shaped pipes, and the tubular reactor is in a U shape and comprises straight pipe sections on the two sides and a horizontal section at the bottom and communicated with the straight pipe sections on the two sides. The diesel oil hydrogenation reaction system comprises a fixed bed hydrogenation reactor and a plurality of U-shaped tubular reactors connected in series. According to the invention, H2S, NH3 and other gases generated in the reaction process can be continuously moved out of the reaction system, the hydrogenation reaction rate is improved, the continuous high efficiency of the hydrogenation reaction process is maintained, and deep hydrodesulfurization and ultra-deep desulfurization arerealized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com