Circulating water cooling tower

A circulating water cooling and cooling pool technology, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve problems such as streamline turbulence, reduced air flow, and large fan energy consumption. Achieve the effects of reducing turbulence, increasing air flow, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

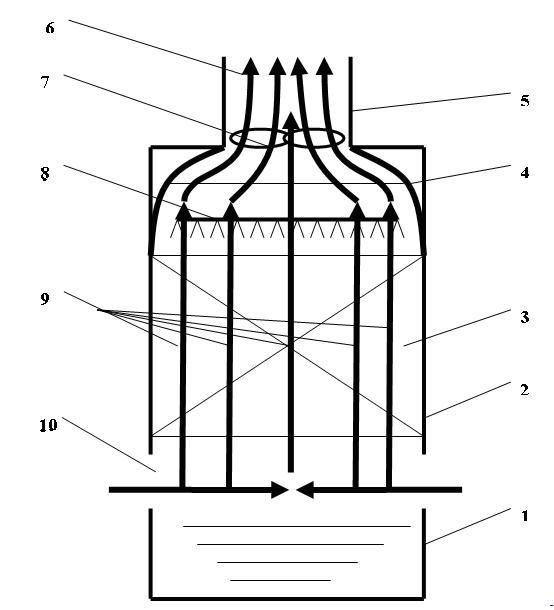

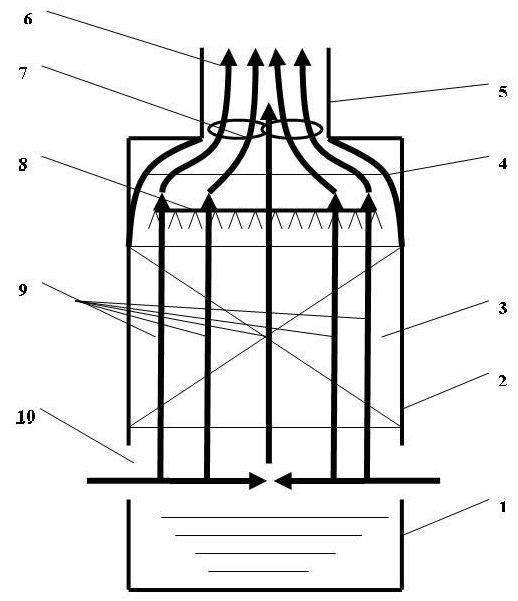

[0015] figure 1 It is a structural schematic diagram of an embodiment of the present invention.

[0016] Such as figure 1 As shown: a circulating water cooling tower, including a tower body 2, an air duct 5 and a cooling water pool 1, wherein the tower body 2 is filled with fillers to form a filler layer 3, and a cooling water distributor 8 is arranged on the upper part of the filler layer 3, and the wind The barrel 5 is set on the upper part of the tower body 2, the air blower 7 is set at its inlet, and the air outlet 10 is set at its outlet. In addition, the lower end of the tower body 2 is an air inlet 6, and the above-mentioned cooling water pool 1 is set on the tower body 2, between the packing layer 3 and the air fan 7, an air guiding device 4 is also arranged, and the horizontal cross-section of the upper end of the air guiding device 4 is consistent with the horizontal cross-sectional shape of the blower 5, and the upper end is consistent with the shape of the blower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com