Vacuumizing system and method for vacuum cabin of ramjet engine

A technology of ramjet and vacuum pumping system, which is applied in the direction of engine testing, machine/engine, jet engine testing, etc. It can solve the problems of limited ramjet test capability, inability to meet large flow conditions, and small vacuum working range, etc. Achieve the effect of saving test site, compact structure and maintaining stable vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to solve the problem that the vacuum system of the vacuum chamber of the ramjet engine cannot meet the conditions of large flow. The invention provides a vacuum pumping system and method for a vacuum chamber of a ramjet engine.

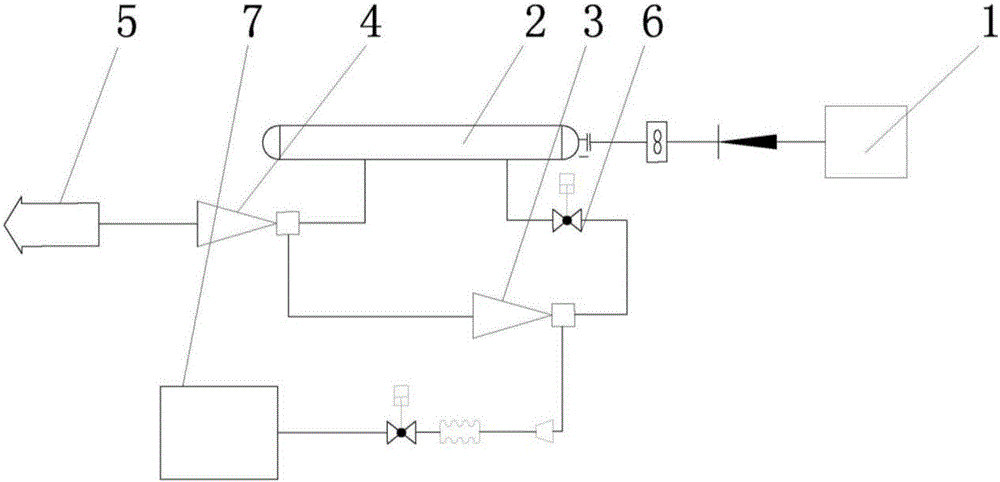

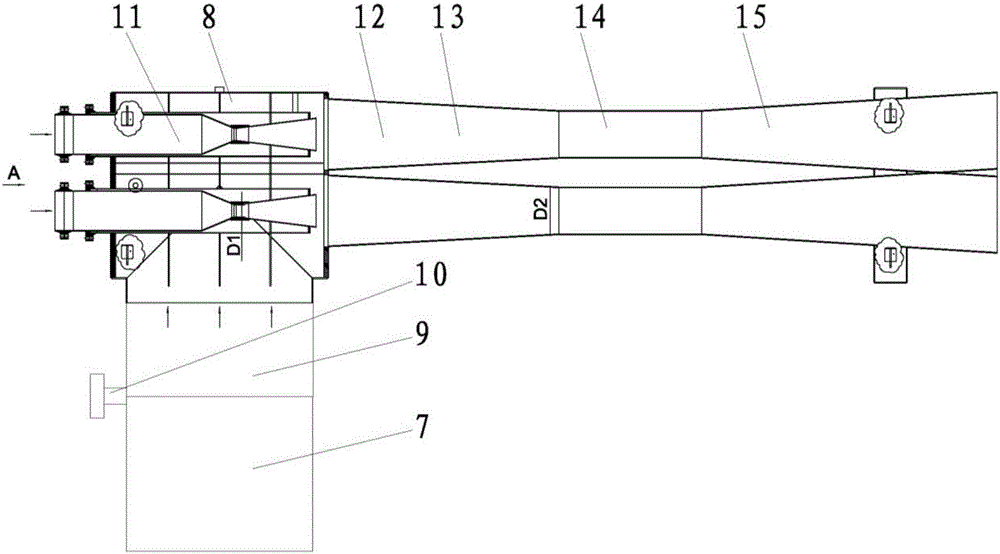

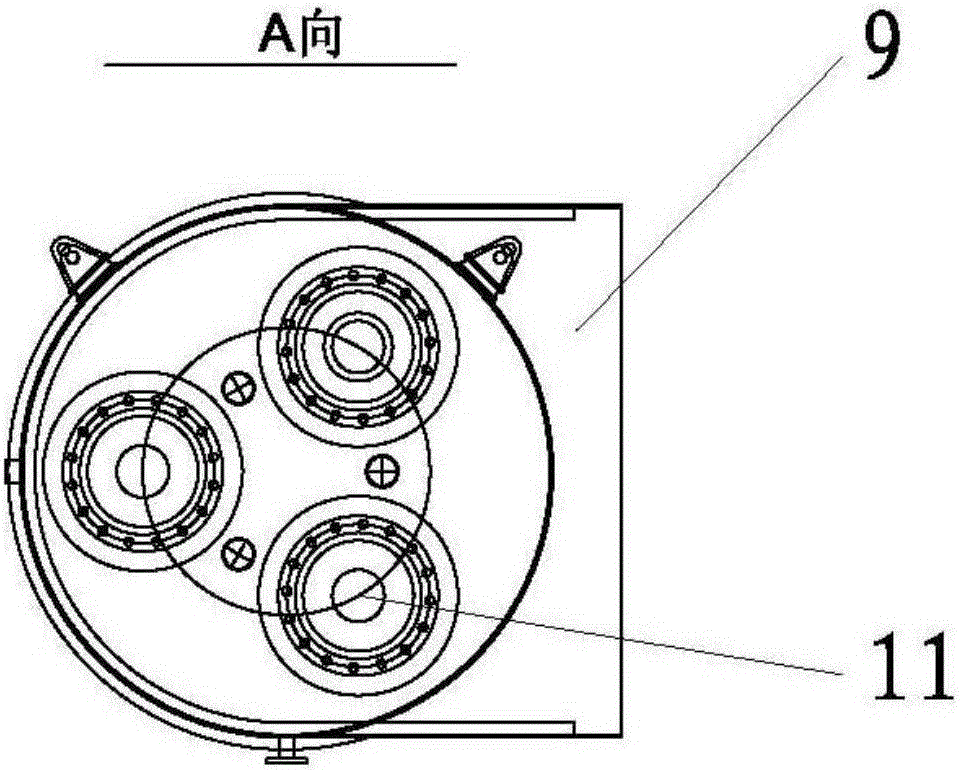

[0028] Such as figure 1 As shown, the system includes a steam source 1, a steam distributor 2, a primary injection device 3, a secondary injection device 4, a silencer tower 5 and a switching valve 6;

[0029] The primary injection device 3 and the secondary injection device 4 are connected in series, the steam inlet of the primary injection device 3 communicates with the steam distributor 2 through the switching valve 6; the steam inlet of the secondary injection device 4 is connected to the steam distributor 2 Communication; the steam outlet of the secondary ejection device 4 communicates with the external environment through the silencer tower 5; the vacuum inlet of the primary ejection device 3 communicates with the vacuum chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com