High-temperature vibration testing device and testing method for fuel-to-oil temperature sensor

A technology of temperature sensor and vibration test, applied in vibration test, thermometer test/calibration, thermometer, etc., can solve the problems of unbearable, unable to simulate working environment, narrow temperature range, etc., to improve test ability, reliability and quality , the effect of reducing the test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

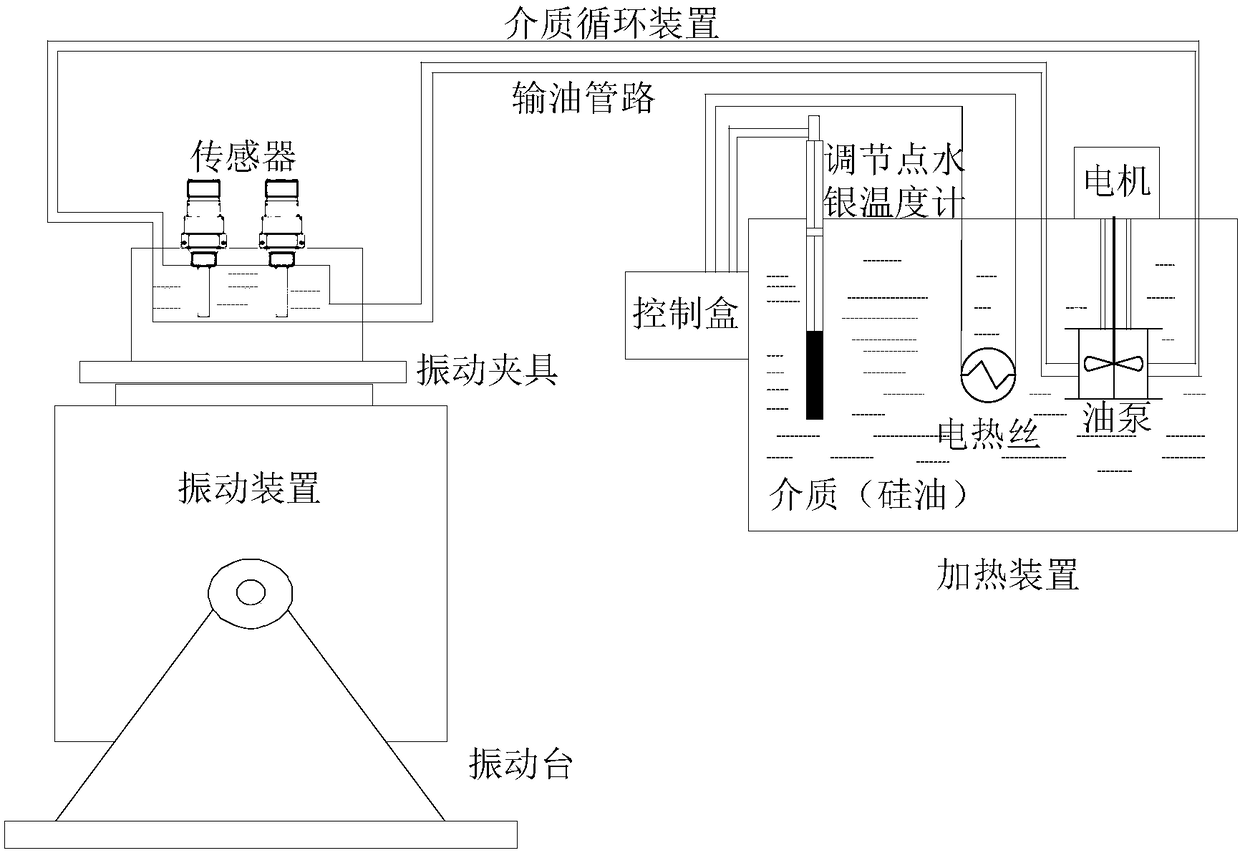

[0021] The high-temperature vibration test device of the fuel oil temperature sensor of the present invention is used to simulate the real working environment of the engine fuel oil temperature sensor, and specifically includes a heating device, a medium circulation device, and a vibration device; wherein the heating device includes a heating wire, an adjustment point mercury Thermometers, control boxes and constant temperature barrels; medium circulation devices include oil pumps and oil pipelines; vibration devices include vibrating fixtures and vibrating tables, such as figure 1 shown.

[0022] The working medium (silicone oil) is installed in the constant temperature barrel, which is heated by the electric heating wire, and the temperature of the working medium is adjusted by the control box and the mer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com