Subsonic-transonic flow field ejection operating method for transient type subsonic-transonic-supersonic wind tunnel

A temporary flushing and sub-span technology, applied in the field of wind tunnel testing, can solve the problems of high front chamber pressure, excessive load, and difficulty in establishing complex model flow fields, and achieve the goals of reducing usage, expanding test capabilities, and reducing loads Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

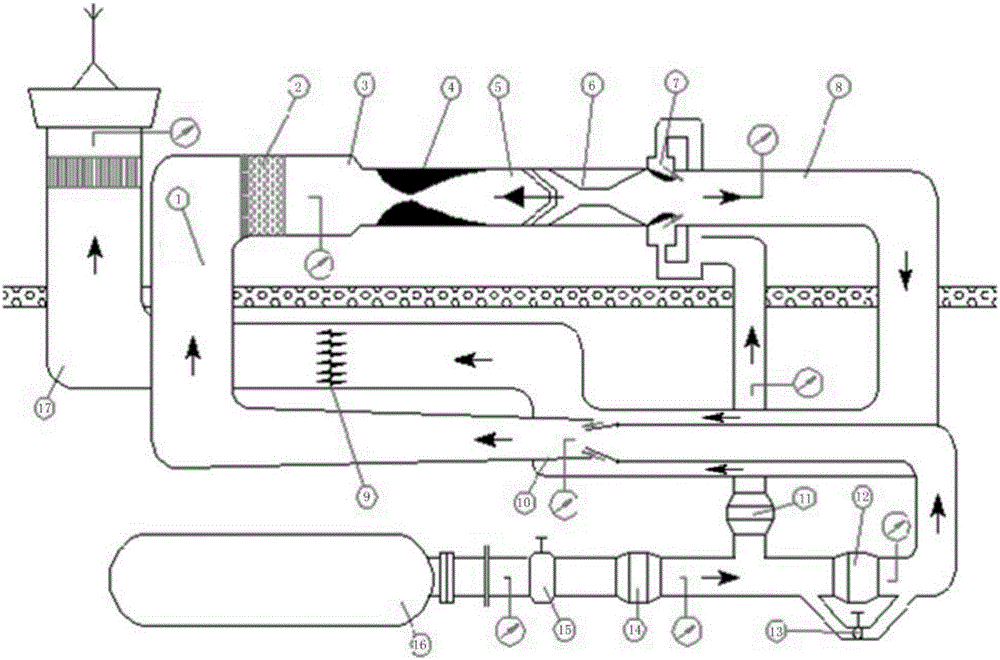

[0022] The present invention is based on the structural characteristics of the temporary sub-span super wind tunnel. During the sub-span blowing test, especially when blowing at a high Mach number of 0.8 to 1.2, it encounters an aircraft model with a large lifting surface, in order to reduce the load and ensure the smooth completion of the experiment. , Inspired by the supersonic ram ejection driving method, a method of subsonic flow field ejection driving was created.

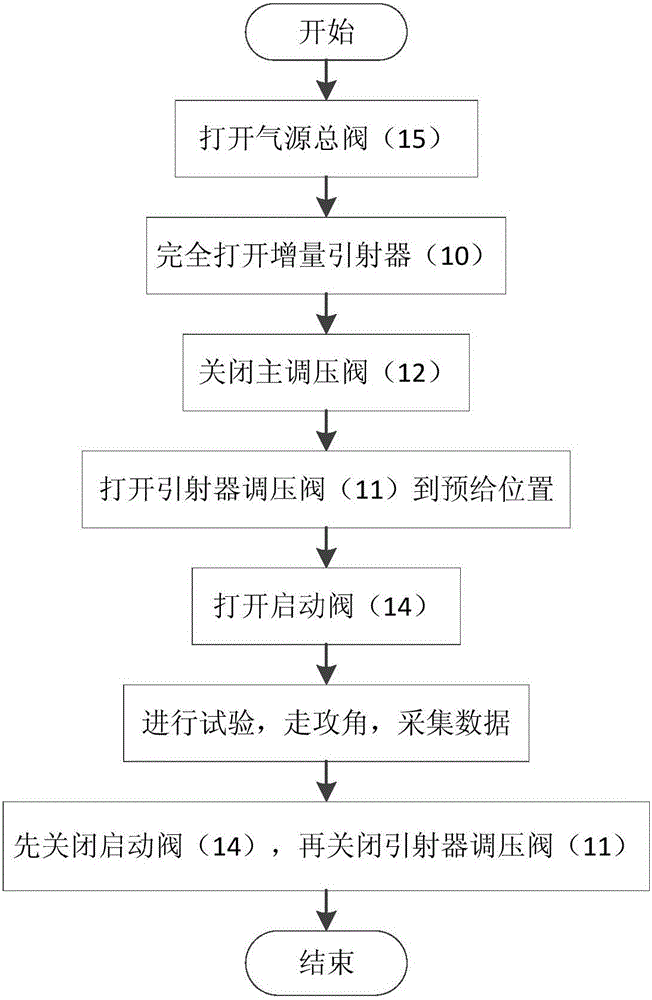

[0023] In view of the characteristics of the AT-1 wind tunnel, in the traditional sub-span wind tunnel test stamping drive mode, the main pressure regulating valve (12) opens slowly, while the start valve (14) can be opened quickly. When performing a blowing test, generally the main air source valve (15) is opened first, the main pressure regulating valve (12) is opened to a suitable preset position according to empirical values, and then the starting valve (14) is opened to quickly establish a flow field. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com