Twin array Michelson optical fiber white light interference strain gage

A technology of white light interferometry and strain gauges, which is applied in the direction of instruments, scientific instruments, and optical devices, can solve the problems of small number of multiplexes, unfavorable deployment and use, and low signal-to-noise ratio of optical fiber interferometers, and achieve low cost and effective Facilitate promotion and reduce test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

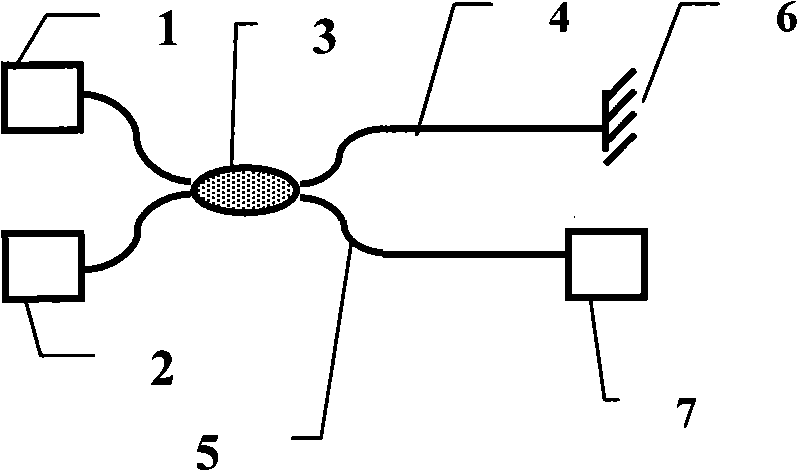

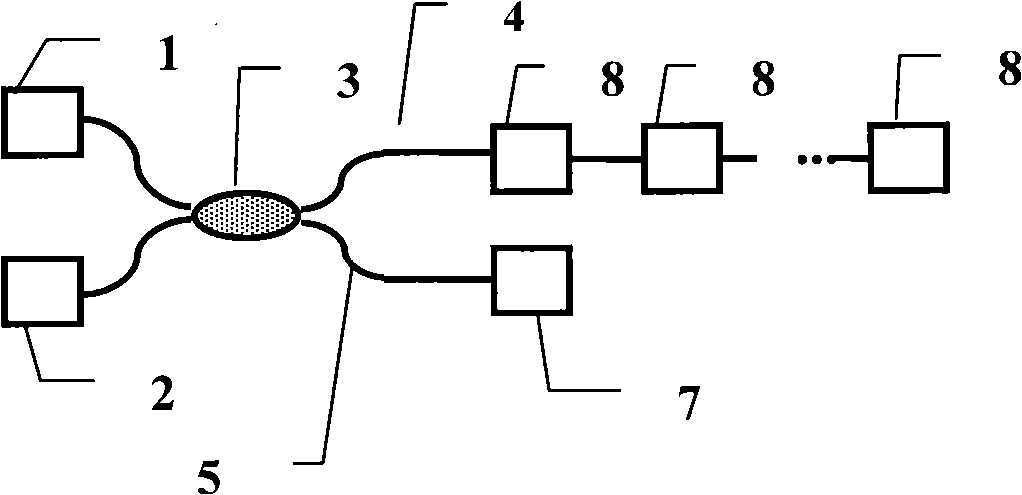

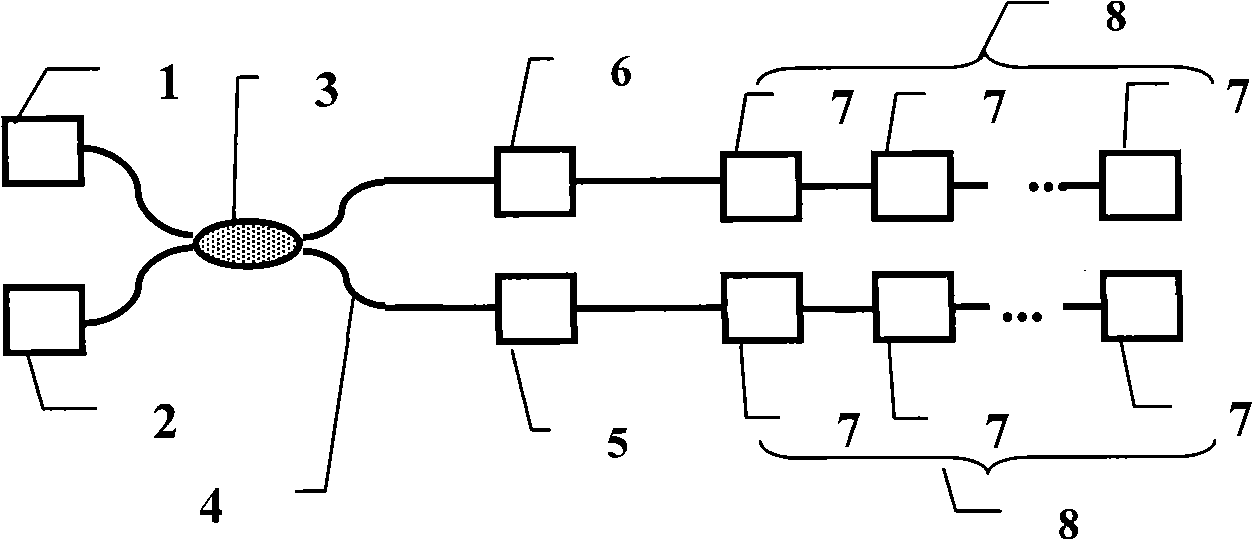

[0039] Embodiment: Utilize the scheme of the multiplexing fiber optic interferometer constructed by twin array fiber optic sensor devices, combined with image 3 , it can be seen from the figure that the multiplexed twin fiber interferometer consists of a broadband light source 1, a photodetector 2, a 3dB fiber 2×2 coupler 3, a single-mode connecting fiber 4, an optical attenuator 5, an optical delay line 6 and An array 8 of twin optical fiber sensors 7 is formed.

[0040] The optical fiber sensor 7 is composed of a section of optical fiber of any length with vertical reflective end faces with arbitrary reflectivity at both ends. The typical structure is as follows Figure 4 As shown, a section of single-mode optical fiber intercepted according to the actual measurement needs is equipped with ceramic ferrule 701 at both ends, and after the end face is polished, an optical fiber end face with a reflectivity perpendicular to the direction of transmitted light greater than 1% is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com