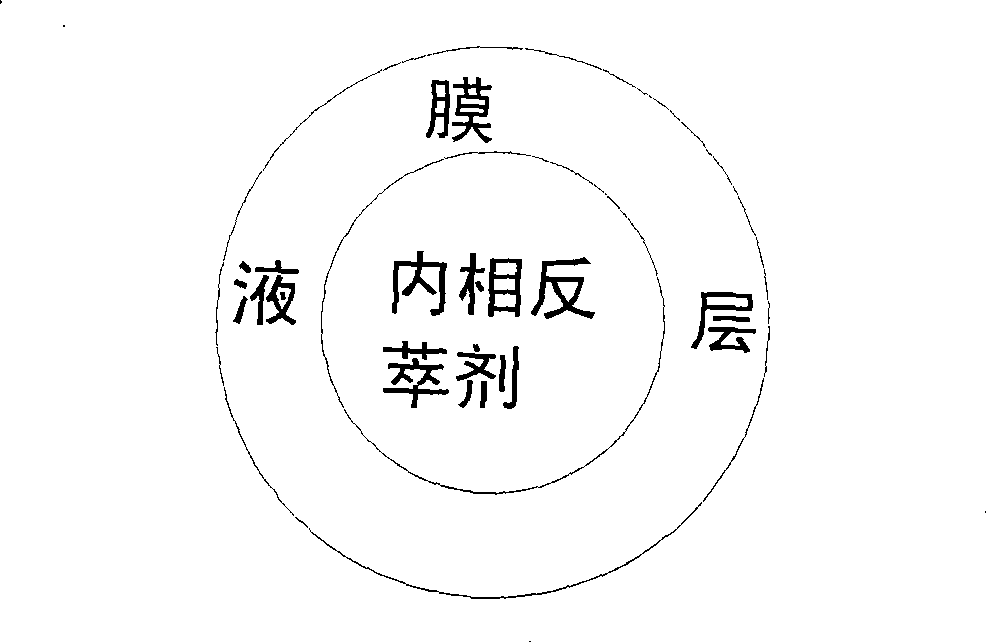

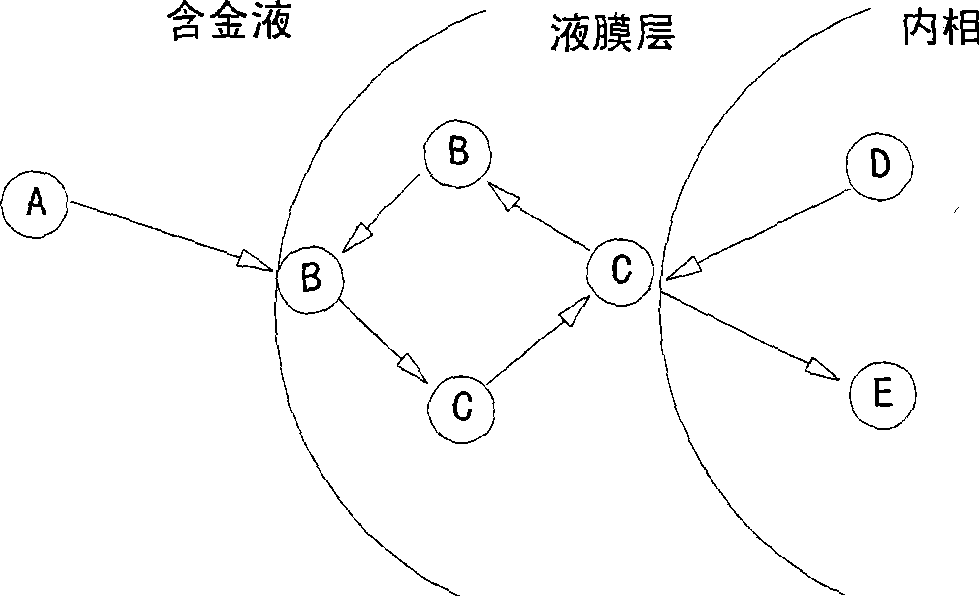

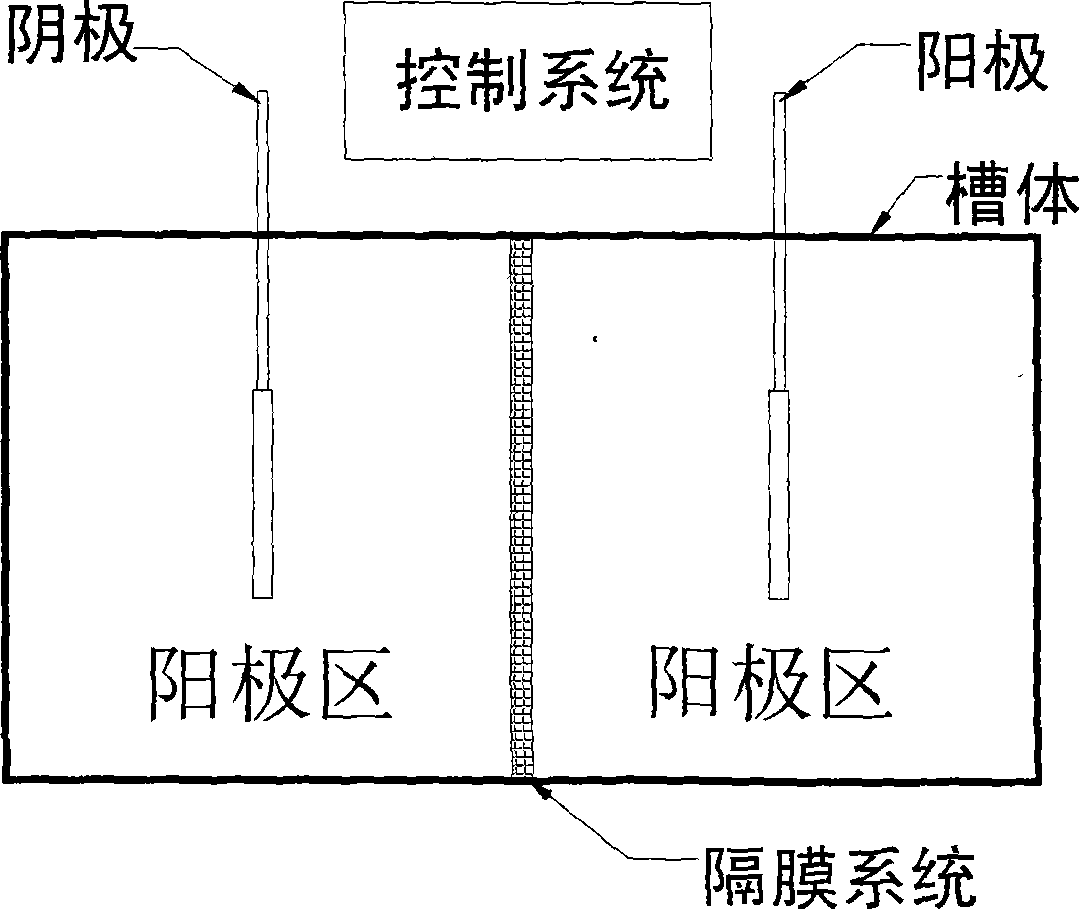

Liquid membrane extraction of gold-diaphragm electrolysis extraction of gold process

A diaphragm electrolysis and liquid membrane technology, which is applied in the field of metallurgy and chemical industry, can solve the problems of low comprehensive recovery rate, high production cost, lengthy process, etc., and achieve the effect of fewer separation stages, convenient operation and flexible application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The cyanide leaching gold-containing precious liquid produced in the actual production process of Baiyun Gold Mine in Liaoning carries out liquid film extraction and diaphragm electrolysis test according to the process steps of the present invention, and the test results are shown in Table 1 and Table 2:

[0043] Table 1 Results of liquid membrane gold extraction test

[0044]

[0045] Table 2 Electrolysis test results of gold-containing inner phase separator

[0046] Electrolysis voltage

[0047] It can be seen from the above test results that using the emulsified liquid film gold extraction-diaphragm electrolysis process of the present invention can effectively extract gold in the actual gold-containing solution of a gold mine under high pH conditions.

Embodiment 2

[0049] The embodiment of the present invention adopts the cyanidation leaching gold-containing precious liquid produced in the actual production process of Liaoning Tianli Mining Company to carry out the emulsified liquid membrane extraction and diaphragm electrolysis test under different pH conditions according to the process steps of the present invention. The test results are shown in Table 3. Table 4:

[0050] Table 3 Results of liquid membrane gold extraction test

[0051]

[0052] Table 4 Electrolysis test results of gold-containing inner phase separator

[0053] Electrolysis voltage

[0054] Can find out by above-mentioned test result, use emulsified liquid film of the present invention to extract gold-diaphragm electrolysis process can carry out effective extraction to the gold in the actual gold-containing solution of gold mine under the condition of high pH value, simultaneously the gold in the gold-containing inner phase Gold also electrodeposits well ...

Embodiment 3

[0056] Embodiment 3 of the present invention adopts the cyanidation leaching gold-containing precious liquid produced in the actual production process of the heap leaching field of Liaoning Jinfeng Gold Mine to carry out liquid film gold extraction and diaphragm electrolysis tests under the situation of pH=8 according to the process steps of the present invention, and For Au and CN in the electrolyte - The changes were tracked and analyzed, and the results are shown in Table 5 and Table 6:

[0057] Table 5 Results of liquid film gold extraction test

[0058] stock solution raffinate Extraction rate pH 2.05 0.12 94.1 8 1.94 0.18 90.7 8 2.12 0.21 90.1 8 2.16 0.15 96.1 8 1.97 0.14 92.9 8 1.83 0.15 91.8 8 2.08 0.18 91.3 8 2.11 0.23 89.1 8 2.21 0.22 90.0 8

[0059] Table 6 Electrolysis test results of gold-containing inner phase separator

[0060]

[0061] As can be seen from the above test resu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com