Patents

Literature

58 results about "Emulsion liquid membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

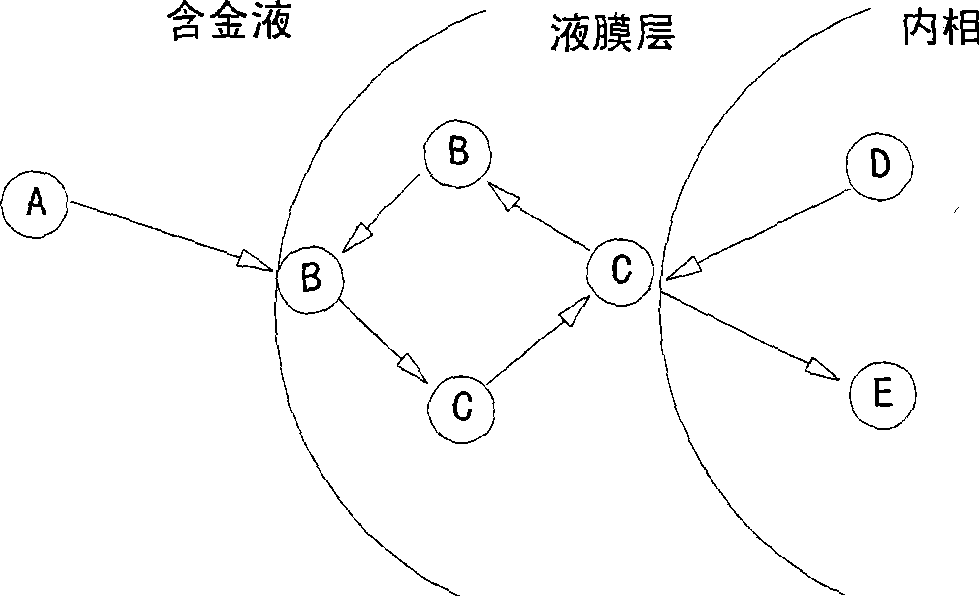

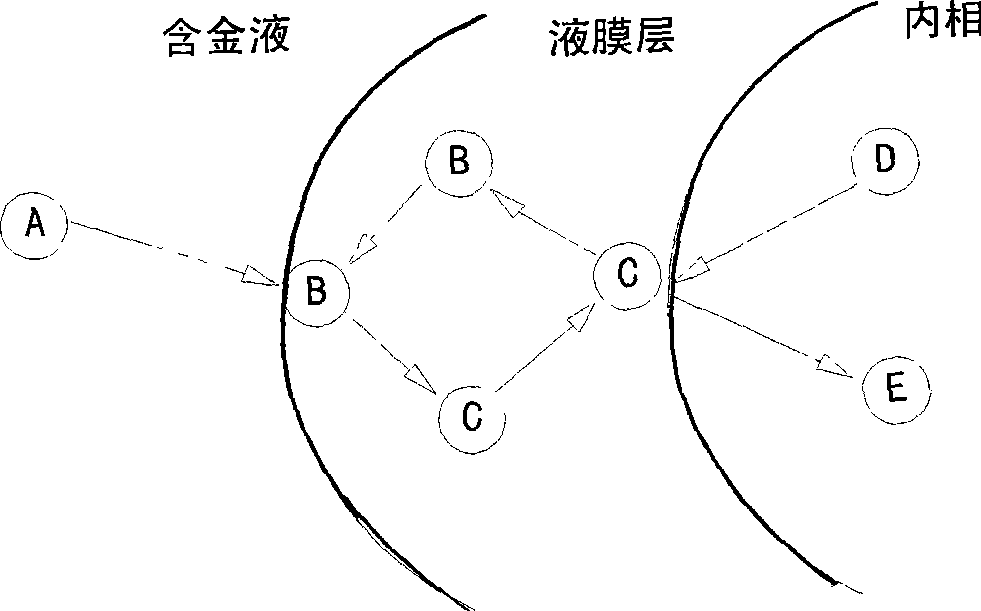

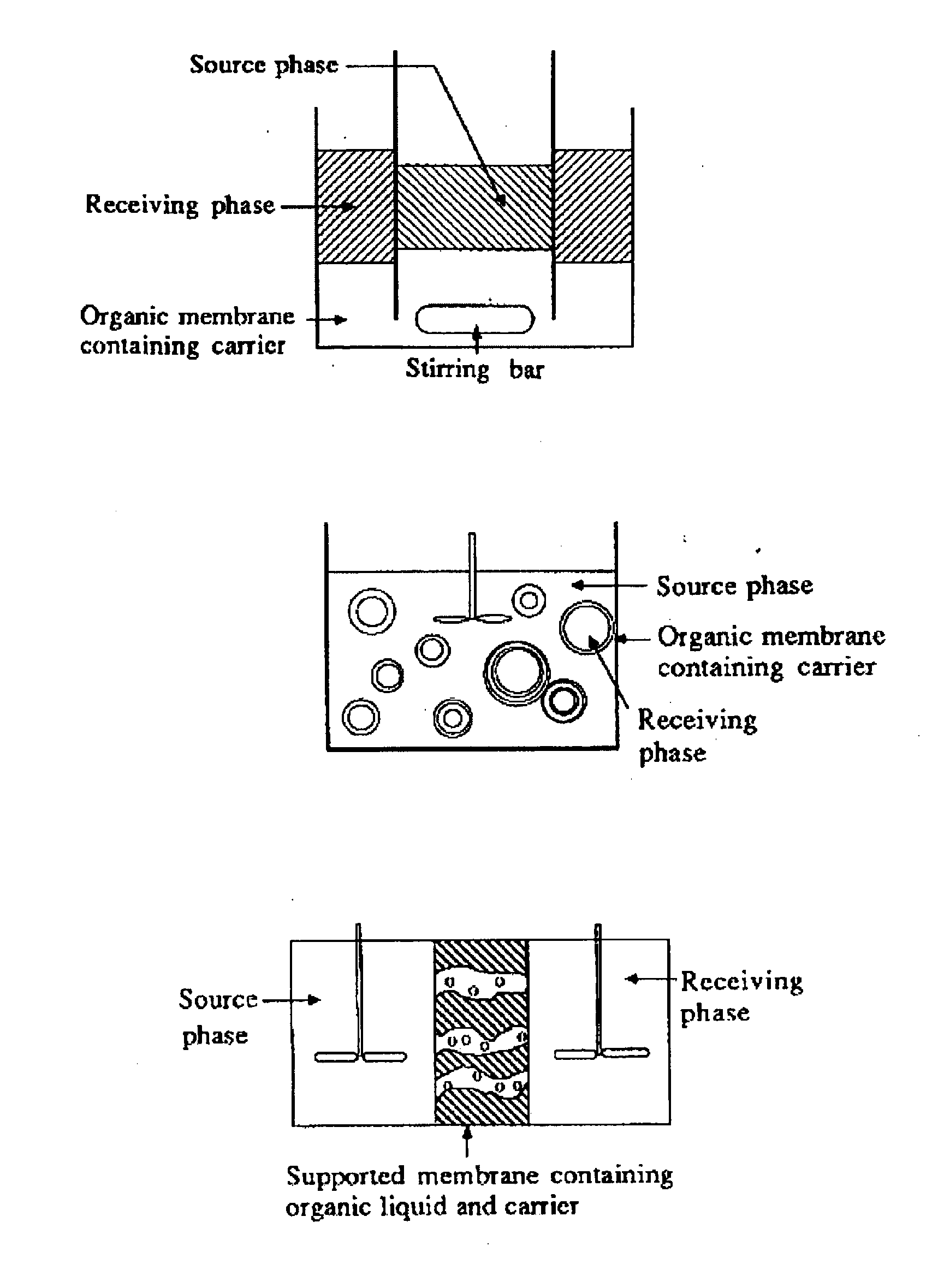

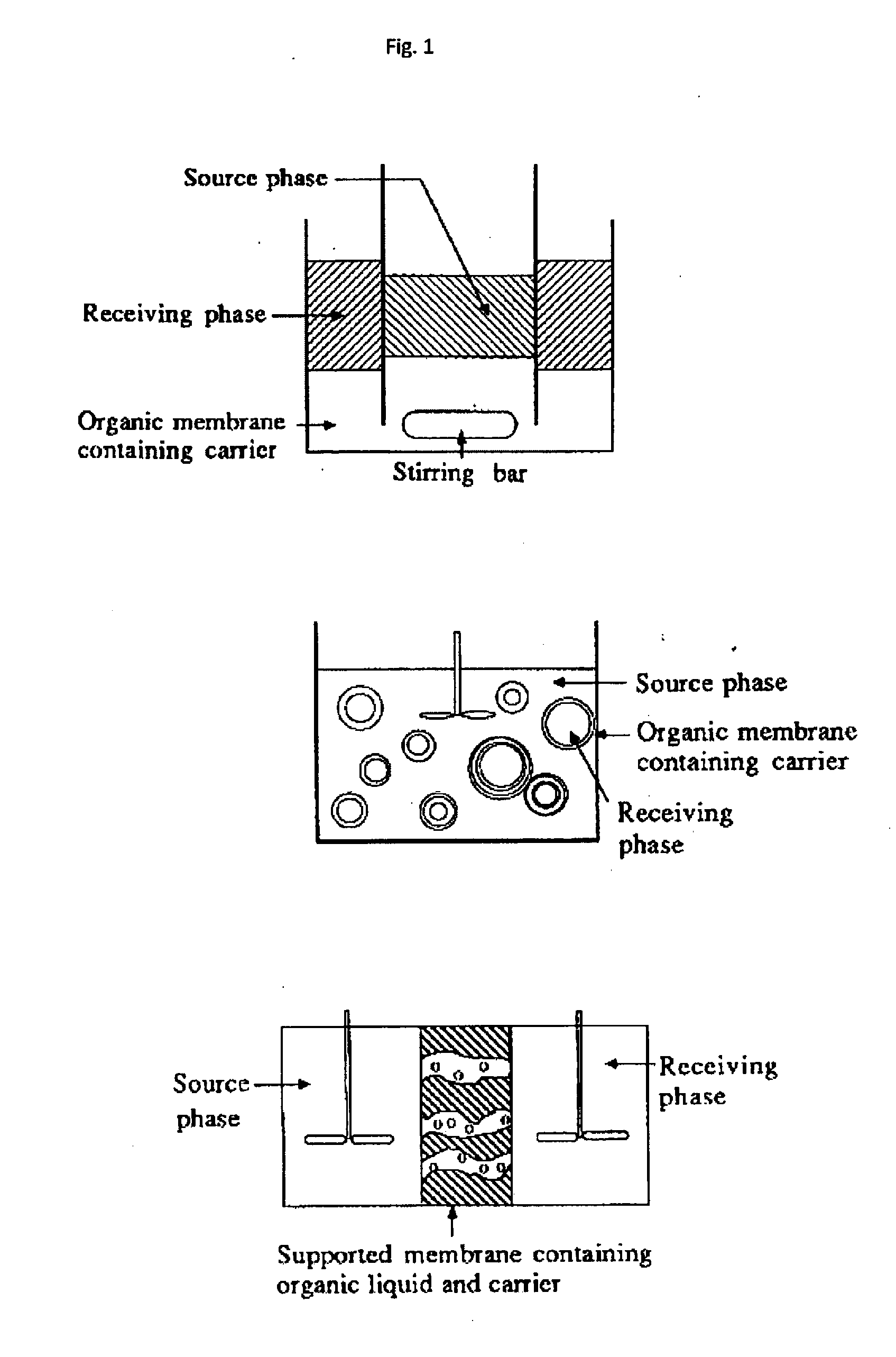

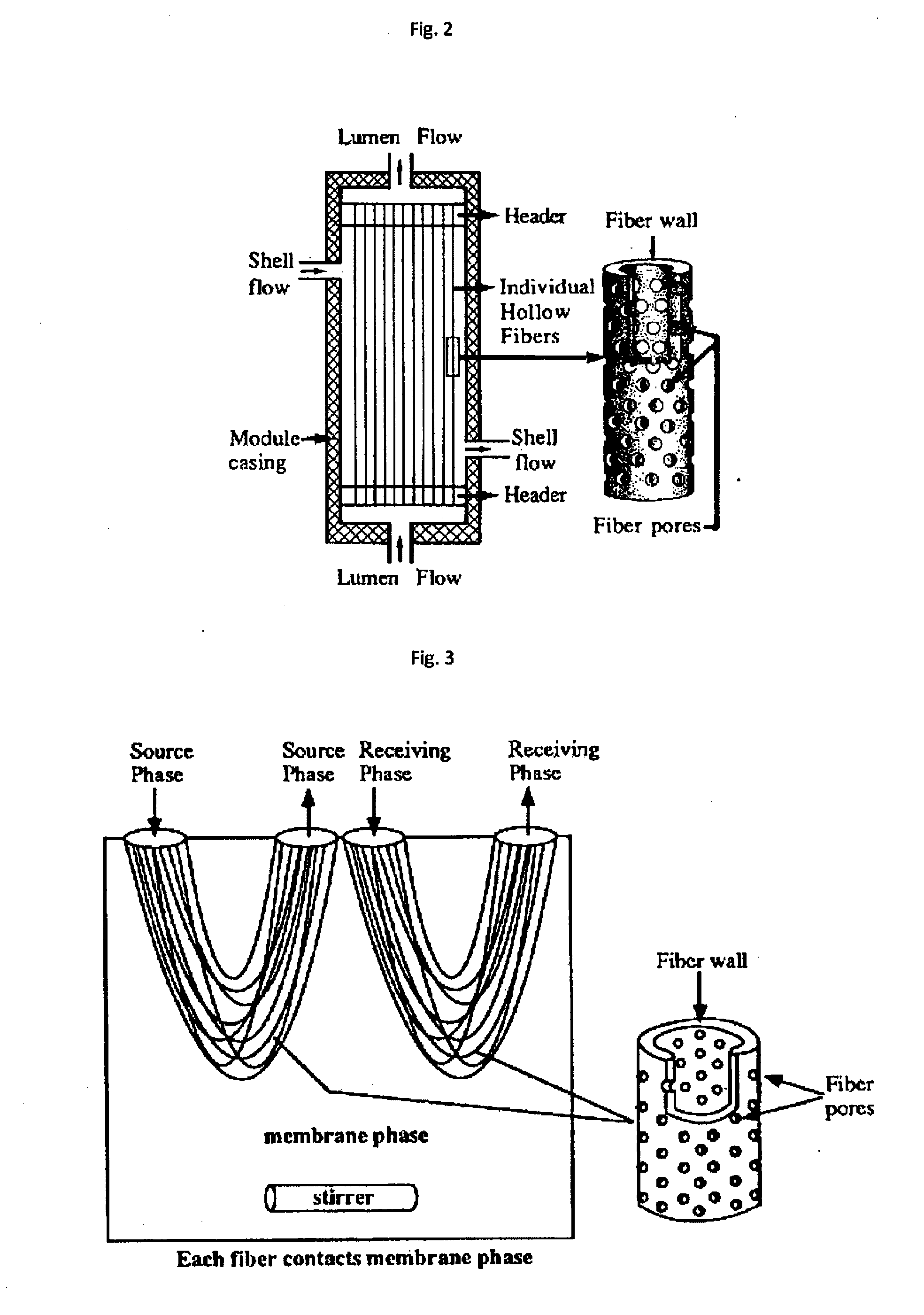

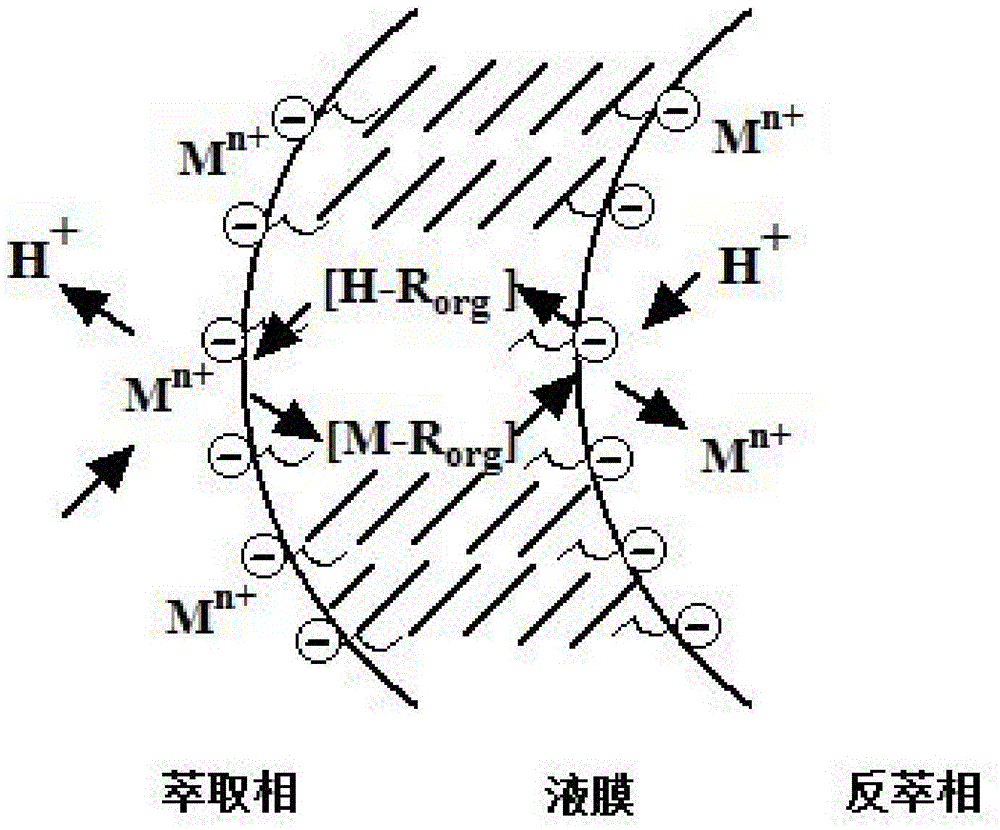

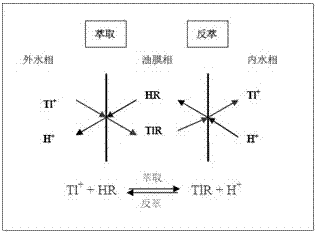

Emulsion liquid membrane is a promising method for industrial waste water recovery including heavy metals. The successful application is not only depend on the selection of suitable emulsification method but also the emulsion formulation in accordance with the solute which is to be recovered.

Method for separating chromiumin leather-making waste water by milked liquid and membrane separating method

A process for separating Cr from the tanning sewage by emulsion membrane method includes such steps as proportionally mixing Span 80, flowing carrier TOA and kerosene, adding the mixture to NaOH solution, high-speed stirring to obtain emulsion, proportionally mixing it with K2Cr2O7 solution to be treated, low-speed stirring, laying aside for layering, discharging the lower layer of colorless water phase, and high-voltage electrostatic or microwave demulsifying to obtain Cr salt in the form of water phase.

Owner:SHAANXI UNIV OF SCI & TECH

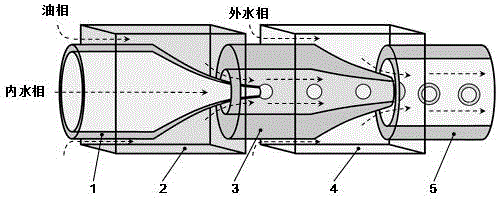

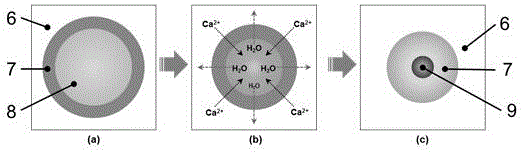

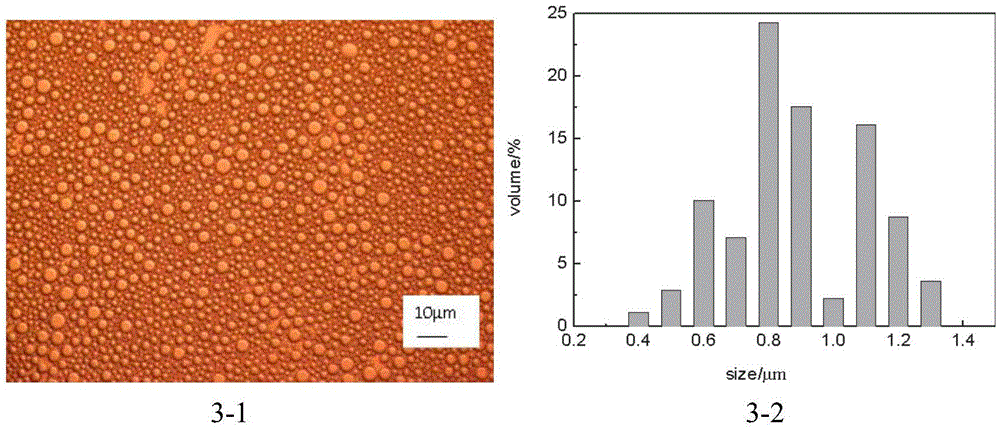

Method for preparing mono-dispersity calcium alginate microspheres based on emulsion liquid membrane mass transfer

ActiveCN106040117ASmall sizeGood size controllabilitySurgeryPharmaceutical non-active ingredientsDispersityCross-link

The invention relates to a method for preparing mono-dispersity calcium alginate microspheres based on emulsion liquid membrane mass transfer. The method includes the steps of firstly, preparing inner water phase, middle oil phase, outer water phase and collecting water phase fluid; secondly, respectively injecting inner water phase, middle oil phase and outer water phase fluid into the injection tube, the transition tube and the collecting tube of a microfluid device to form mono-dispersity water / oil / water emulsion, guiding the water / oil / water emulsion into the collecting water phase fluid, standing for at least 2 hours, allowing Ca<2+> in collecting water phase to enter inner water phase through the oil membrane mass transfer of water / oil / water double emulsion so as to have cross-linking reaction with sodium alginate to generate the calcium alginate gel microspheres, and allowing water in inner water phase to enter collecting water phase through oil membrane mass transfer; thirdly, using filter paper to filter collecting water phase solution containing the calcium alginate microspheres, and washing with deionized water to obtain the mono-dispersity calcium alginate microspheres.

Owner:SOUTHWEST PETROLEUM UNIV

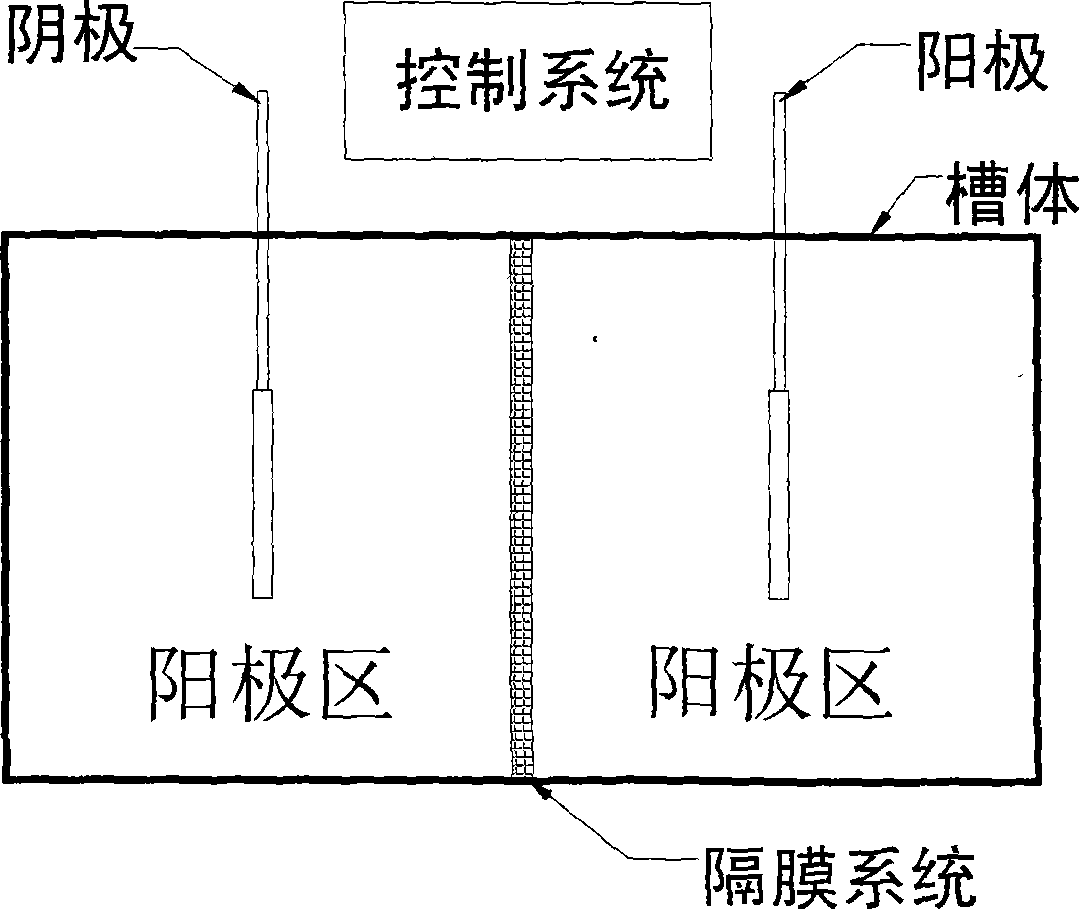

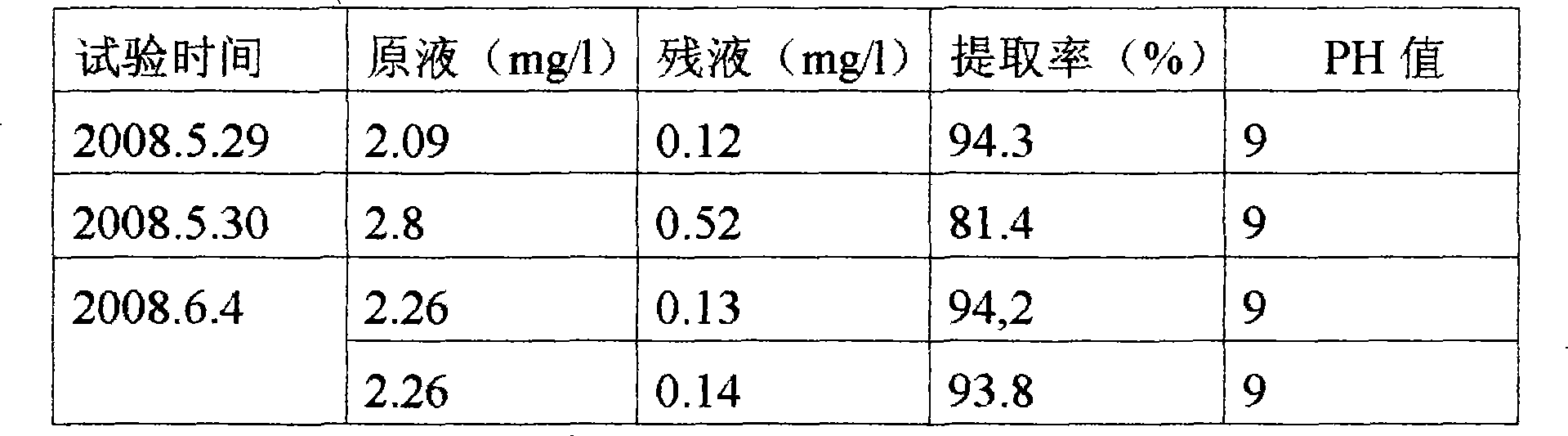

Liquid membrane extraction of gold-diaphragm electrolysis extraction of gold process

InactiveCN101418375AReduce consumptionEfficient use ofPhotography auxillary processesProcess efficiency improvementChemical industryElectrolysis

The invention relates to a liquid membrane gold extraction-diaphragm electrolysis gold extraction process, which belongs to the metallurgy and chemical industry. The process comprises two parts, namely emulsion liquid membrane gold extraction and gold-contained enrichment diaphragm electrolysis gold extraction, wherein the emulsion liquid membrane gold extraction comprises the preparation of an emulsion liquid membrane, the extraction process of the emulsion liquid membrane, and the emulsion breaking process of a gold-contained emulsion liquid membrane. The process has the advantages that the process has a large driving force of mass transfer, few separation stages needed, and little agent consumption; the process improves the production efficiency and greatly simplifies the gold extraction technical flow; useful materials are reclaimed so as to produce no secondary pollution and achieve the more effective energy utilization; and the process is taken as unit operation, and has flexible use, convenient operation and easy realization of automatic control.

Owner:CHANGCHUN GOLD RES INST +1

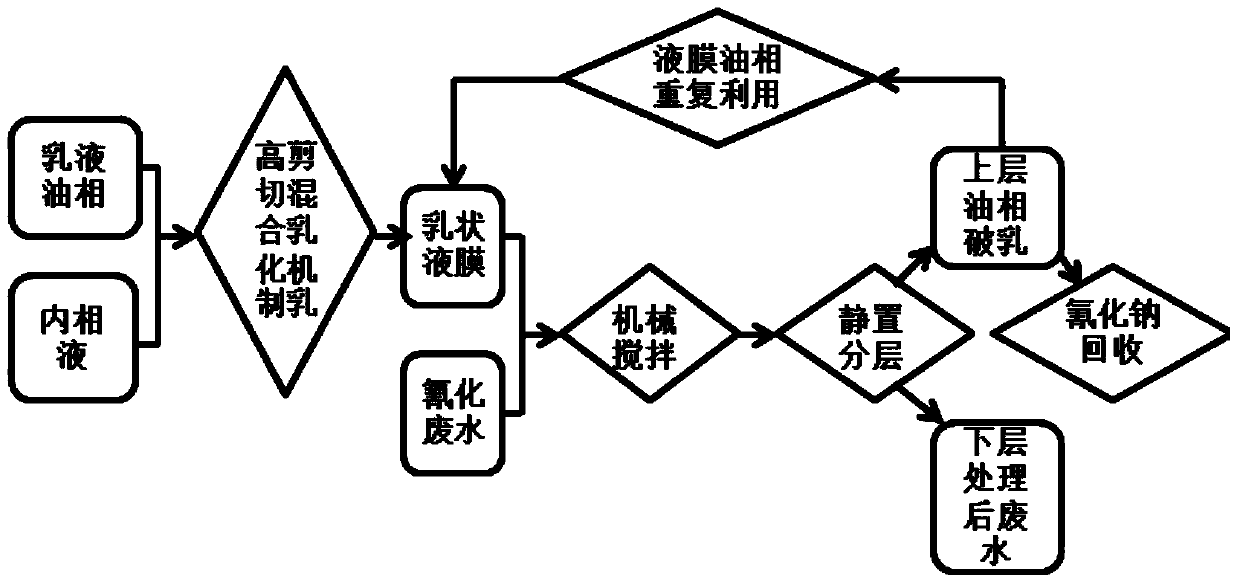

Method for removing cyanides in cyaniding wastewater by use of emulsion liquid membrane technology

InactiveCN103626254ALarge specific surface areaHigh enrichment factorWater/sewage treatment bu osmosis/dialysisWater/sewage treatment by extractionCyanideEmulsion liquid membrane

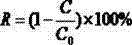

The invention discloses a method for removing cyanides in cyaniding wastewater by use of an emulsion liquid membrane technology, which comprises the steps of dissolving a surfactant into a membrane solvent, and adding a carrier, a membrane auxiliary and sodium hydroxide internal-phase liquid; mixing, and preparing a white water-in-oil type emulsion liquid membrane by an emulsion maker; performing a mixing reaction between the emulsion liquid membrane and the cyaniding wastewater; then demulsifying, and enriching and recycling the cyanides. By imitating the characteristic of active transmission of a biological membrane, the method disclosed by the invention has the characteristics of good selectivity, high separation efficiency, great enrichment multiple, low energy consumption, simplicity in operation and short treatment period; the cyanides can be recycled, and engineering application is easy to implement; moreover, due to the advantage of repeated utilization of the membrane, the removal rate can exceed 95%, and efficient treatment and resource recycling of cyanides can be realized.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method for extracting rare earth from phosphate rock by utilizing liquid membrane

InactiveCN102304628AImprove extraction efficiencyEfficient recyclingProcess efficiency improvementEmulsion liquid membraneKerosene

The invention belongs to the field of rare earth metallurgy, relates to an extraction of rare earth and provides a method for extracting rare earth from phosphate rock by utilizing a liquid membrane. The method comprises the following steps: mixing a neutral extracting agent with a surface active agent by the volume ratio of 5:1-1:5, mixing mixed liquid with kerosene by the volume ratio of 5:95-50:50 to prepare a mixed organic phase and mixing the mixed organic phase with a HNO3 solution by the volume ratio of 5:1-1:5 to finish the membrane preparation process; firstly adding phosphate decomposition liquid and an emulsion liquid membrane by the volume ratio of 500:15-200 into an extractor, then adding into a clarificator for demulsification after completion, and finally preparing rare earth oxide after precipitation and calcination by oxalic acid and oxalate. The purity of the rare earth oxide is more than 95 percent; and the total recovery rate of the rare earth oxide is more than 90 percent.

Owner:JIANGXI UNIV OF SCI & TECH

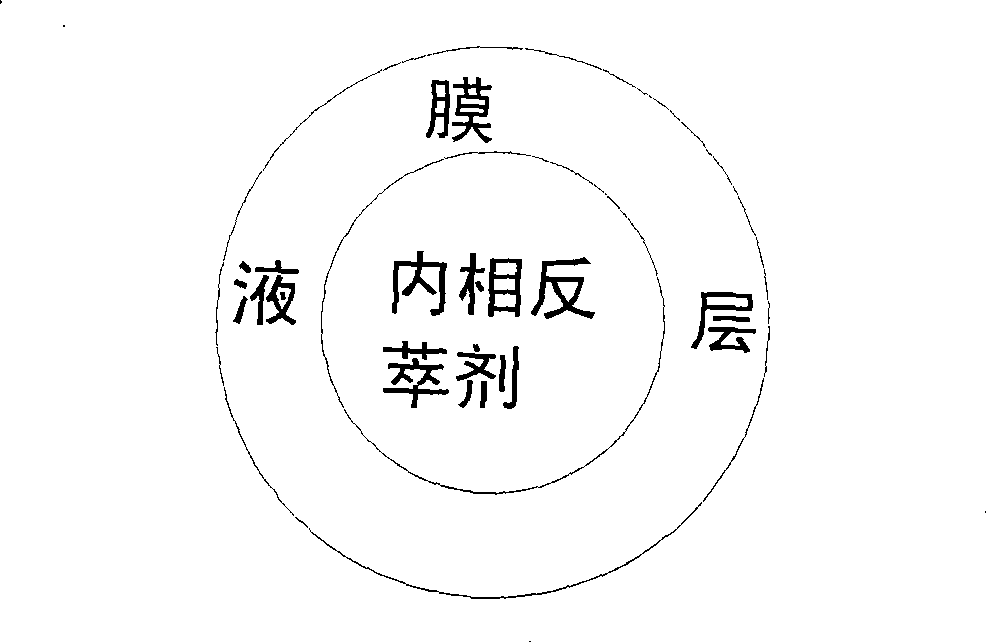

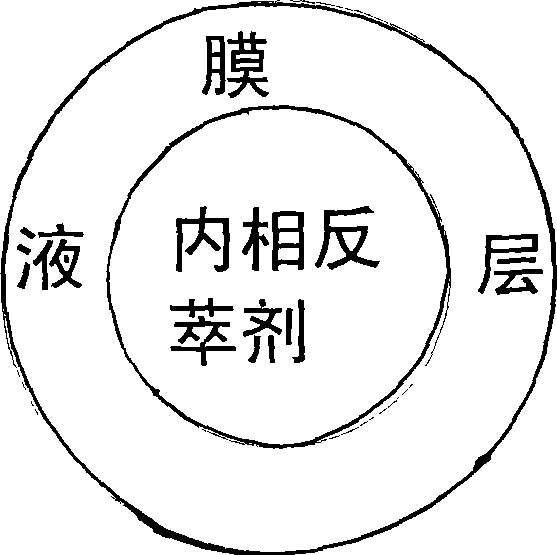

Emulsion liquid membrane for gold extraction

The invention relates to an emulsion liquid membrane for extracting gold, which belongs to the chemical industry class. The emulsion liquid membrane consists of a liquid membrane layer and an inner phase stripping agent, wherein the liquid membrane layer consists of a membrane diluting agent, a flowing carrier, surfactant, a membrane intensifier and a modifier, and the liquid membrane layer is mixed with the inner phase stripping agent to form the emulsion liquid membrane for extracting gold under the condition of high-speed stirring. The emulsion liquid membrane for extracting gold has the advantages of extracting the gold under the alkaline condition with good selectivity of the gold, and contributing to gold extraction and further application of the emulsion liquid membrane in the gold industry with strong practicability.

Owner:CHANGCHUN GOLD RES INST +1

Extraction of nicotine from waste tabacco leaf and offal by lactescence membrane method

InactiveCN101045726ALow priceIncrease concentrationOrganic chemistryHigh concentrationEmulsion liquid membrane

This invention relates to a emulsion membrane process of extracting nicotine from waste tobacco and cabo. (1) dissolve out nicotine from waste tobacco and cabo.(2) produce Water in oil ( W / O) type emulsion membrane; (3) filtration and enrichment; (4) emulsion breaking, use high tension electricity scintilla emulsion breaker to emulsion break the oil layer obtained from step third, the High Voltage of emulsion breaker at least reach 2500v. After emulsion breaking, return oil phase to step two for realizing cyclic utilization, and use sodium carbonate to neutralize obtained water phase as far as vitriol without surplus, then obtain tobacco juice solution of certain concentration. The characteristic of this invention consist in: (1) remedy and reagent adopted has low price, profit space is large; (2) nicotinic extraction yield high, and concentration of nicotine sulfate solution after emulsion breaking is large, could be used as raw material of further purification high concentration nicotin, and also could be directly used as pesticide after simple manipulation;(3) used solution has smallness erosion to equipment;(4) pollute fewness, even pollution-free.

Owner:SHENYANG NORMAL UNIV

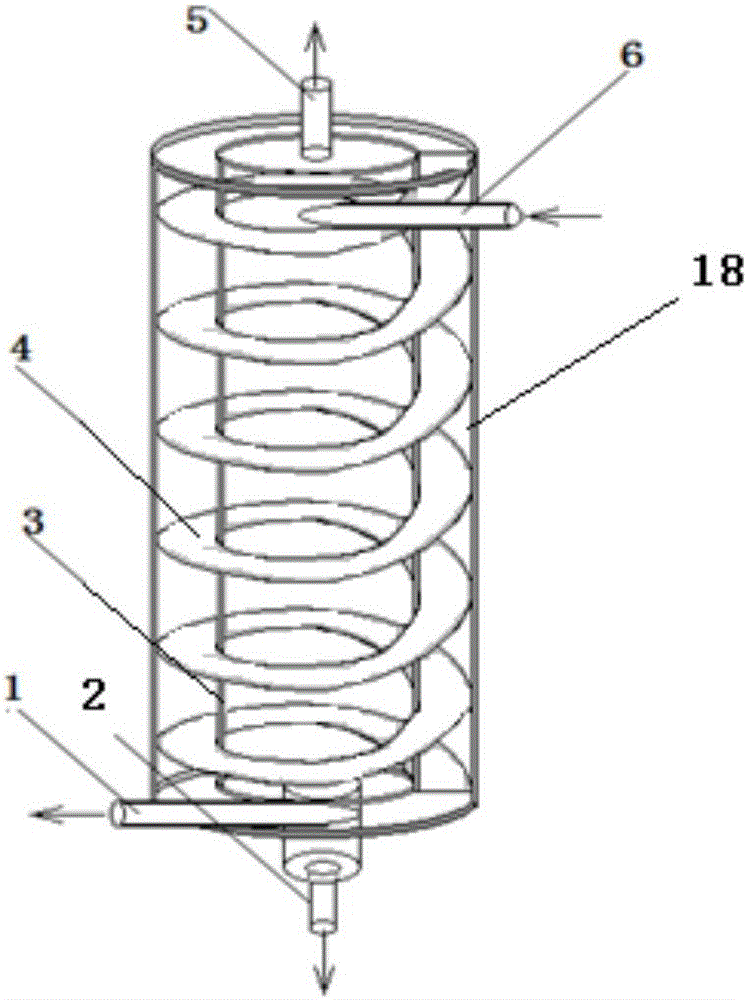

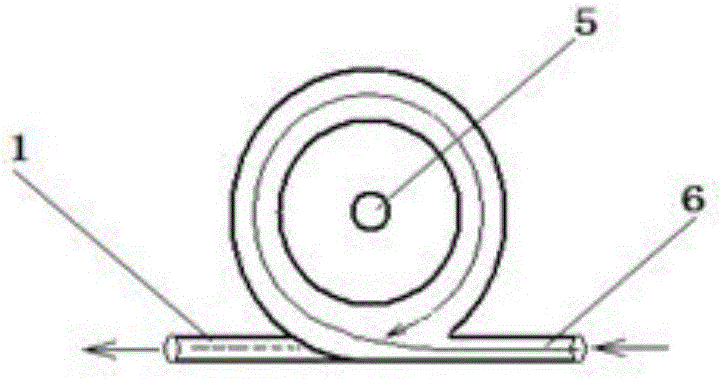

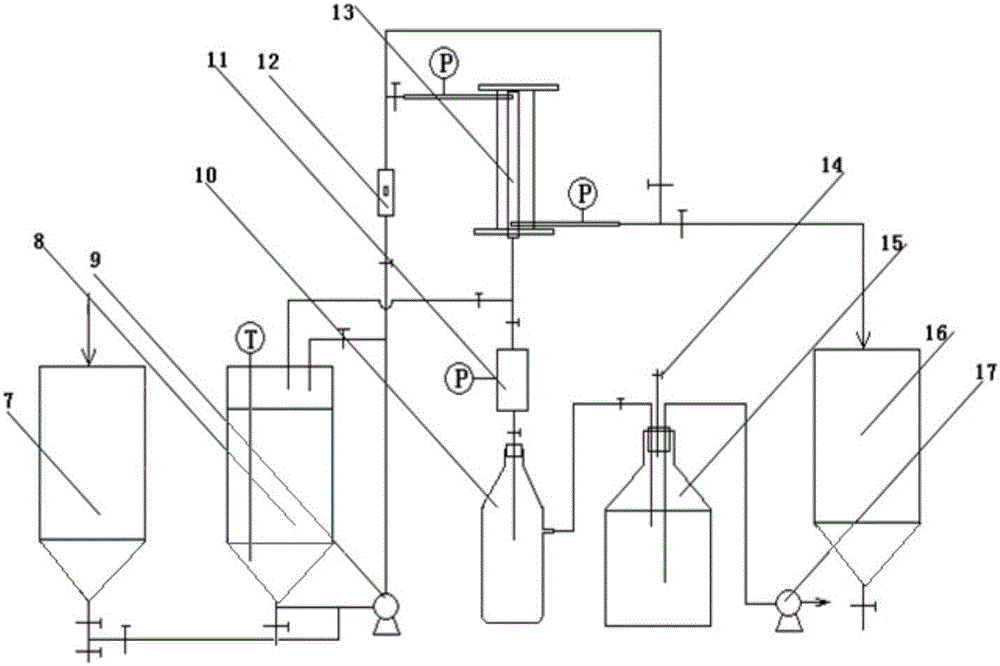

Outer rotational flow limited flow channel membrane separator and method for demulsifying emulsion membrane through same

InactiveCN105833569AGood self-cleaning functionImprove permeabilitySemi-permeable membranesNon-miscible liquid separationEmulsion liquid membraneRunning time

The invention discloses an outer rotational flow limited flow channel membrane separator and a method for demulsifying an emulsion membrane through the same, and belongs to the technical field of chemical technology and chemical equipment .The outer rotational flow limited flow channel membrane separator comprises a round pipe shell, an emulsion outlet, an internal water phase material liquid outlet, a membrane separation pipe, a limited flow channel rotational flow plate, a pressure measuring opening and a material inlet .A round pipe is a cylindrical hollow pipe .The emulsion outlet is horizontally arranged on the lower portion of the round pipe .The internal water phase material liquid outlet is arranged in the center of the bottom of the round pipe .The membrane separation pipe is arranged inside the round pipe and is concentric with the cross section circle of the round pipe .The limited flow channel rotational flow plate is spirally arranged on the outer side of the membrane separation pipe and the inner side of the round pipe along the outer side of the membrane separation pipe .The material inlet is horizontally arranged on the upper portion of the round pipe and is parallel to the emulsion outlet .Emulsion can be forced to do constant screw-pitch rotational motion, namely approximately constant-speed rotational motion between spiral plates, the emulsion runs in the state of initially entering the membrane separator, the running time is long, the demulsifying rate is high, and the outer rotational flow limited flow channel membrane separator can be developed to be applied in demulsifying practical production .

Owner:CHANGCHUN UNIV OF TECH

Method for treating waste water produced in production of EDTA (ethylene diamine tetraacetic acid)

ActiveCN104058541AImprove evaporation effectReduce manufacturing costMultistage water/sewage treatmentEmulsion liquid membraneKerosene

The invention belongs to the technical field of waste water treatment and in particular relates to a method for treating waste water produced in production of EDTA (ethylene diamine tetraacetic acid). The method for treating the waste water produced in production of EDTA comprises the following steps: (1) preparing an water-in-oil emulsion membrane, wherein the membrane phase of the water-in-oil emulsion membrane is composed of 1-5wt% of surface active agent, 1-5wt% of flowing carrier and 90-98wt% of diluent, the internal phase of the emulsion membrane is composed of 0.2-30wt% of caustic soda solution, the mass ratio of the membrane phase to the internal phase is (1.5-5):1, the surface active agent is tween-80 or span-80, the flowing carrier is trioctylamine, and the dilutent is kerosene; (2) regulating pH value of the waste water, then adding the emulsion membrane obtained in the step (1) into the waste water to carry out extraction, and carrying out evaporative crystallization treatment on the waste water after extraction is carried out; (3) demulsifying the extracted emulsion membrane to make a new emulsion membrane. The method for treating the waste water produced in production of EDTA has the advantages that organic matters in the waste water are extracted out, evaporation effect is greatly improved, and production cost is low.

Owner:潍坊滨海石油化工有限公司

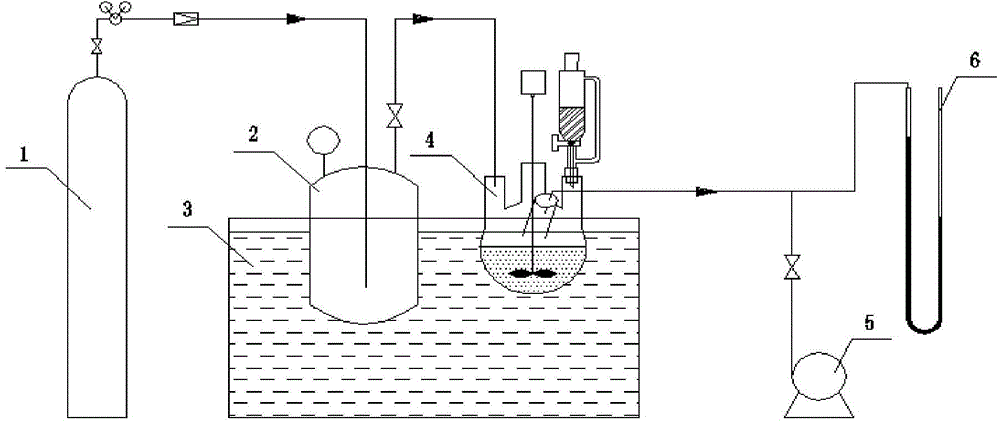

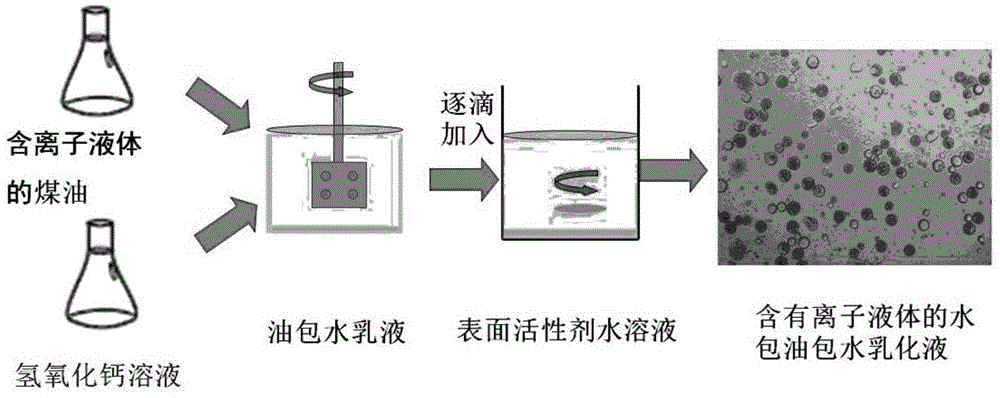

Method for strengthening carbon dioxide absorption with ionic liquid-containing emulsion liquid membrane in coupling micro-fine calcium carbonate synthesis

InactiveCN103551024ASolid load implementationRealize separation and captureDispersed particle separationAir quality improvementSolubilityEmulsion liquid membrane

The invention provides a method for strengthening carbon dioxide absorption with an ionic liquid-containing emulsion liquid membrane in coupling micro-fine calcium carbonate synthesis. A water-in-oil-in-water emulsion liquid membrane dispersion system containing the ionic liquid is prepared; the absorption rate of the carbon dioxide by an absorbent is strengthened by dispersing oil droplets; meanwhile, the mass transfer of the carbon dioxide in the liquid membrane is quickened and promoted by using the ionic liquid with high solubility to the carbon dioxide in the oil membrane, so that the carbon dioxide enters an internal water phase containing calcium hydroxide, further the carbon dioxide and the calcium hydroxide react to produce calcium carbonate; the fine calcium carbonate particles are prepared under the condition that the internal water phase space is used as a soft template under the limitation of the size of the internal water phase droplets. According to the method, the gas-liquid interfacial turbulence is strengthened by using the turbulence of the dispersed droplets in the gas-liquid interface, and the surface renewal is quickened, so that the mass transfer speed is improved.

Owner:SHENYANG POLYTECHNIC UNIV

Biomimetic membranes and uses thereof

InactiveUS20130277307A1General water supply conservationSeawater treatmentEmulsion liquid membraneDesalination

A liquid membrane system is disclosed in the form of a biochannel containing bulk liquid membrane (BLM), biochannel containing emulsion liquid membrane (ELM), and biochannel containing supported (immobilised) liquid membrane (SLM), or a combination thereof, wherein said liquid membrane system is based on vesicles formed from amphiphilic compounds such as lipids forming a bilayer wherein biochannels have been incorporated and wherein said vesicles further contain a stabilising oil phase. The uses of the membrane system include water extraction from liquid aqueous media by forward osmosis, e.g. for desalination of salt water.

Owner:AQUAPORIN AS

Method of separating and extracting natural base from coptis chinensis with latex membrane

InactiveCN101108214AQuick extractionEfficient extractionPlant ingredientsLow speedEmulsion liquid membrane

The invention discloses a method for extracting alkaloid in Chinese goldthread coptis through separating emulsion liquid membrane. The emulsion is prepared by taking cooking oil as the membrane solvent, the Span 80 or the mixture of the Span 80 and the cosurfactant as the surface active agent and the phosphate ester as the carrier. Adding the Chinese goldthread coptis hydrochloric acid extraction liquid or vitriol extraction liquid with the pH value equals to 4 and the emulsion with the volume ratio between water and the emulsion as (50:5 to 50:20); stiring with low speed of 200 times per mins to 300 times per mins for extracting for 5 to 15 min; separating out the oil layer after breaking the emulsion through heating in water and the water obtained is just the solution of the total alkaloid in the Chinese goldthread coptis. The invention, by taking the cooking oil as the membrane solvent, resolves the difficulty that the organic solvent used for the existing emulsion membrane is venomous and is unsuitable being used for human and animal after extracted the Chinese medicinal herb, has the advantages of speedy extraction, high efficiency and simple operation, which is applied for producing, developing and inspecting the Chinese goldthread coptis medicine and veterinary medicine.

Owner:HUNAN NORMAL UNIVERSITY

Liquid film extraction method for recovering copper and nickel in wastewater by using ionic liquid reinforced mass transfer

InactiveCN105603194AImprove extraction efficiencyBroaden the formation processProcess efficiency improvementEmulsion liquid membraneSolvent

The invention provides a liquid film extraction method for recovering copper and nickel in wastewater by using ionic liquid reinforced mass transfer. P507 and TBP are respectively used as copper and nickel ion extractants, sulfuric acid and sodium hydroxide are used as stripping agents, proper amounts of film aid and film solvent are added, a proper ionic liquid is used as a reinforced mass transfer medium, and a proportionally prepared raw material solution is stirred at high speed to obtain an emulsion film extractant. By utilizing the salting-out effect and hydration characteristic of the ionic liquid, the ionic liquid is matched with the organic extractant, and neutral compounding, anion / cation-exchange and other modes are utilized to increase the formation and transmission rates of the metal ion complex, thereby enhancing the extraction efficiency. The corresponding extractant and ionic liquid can be selected according to different substances in need of extraction separation so as to carry out extraction treatment on wastewater containing other metal ions, textile and dye printing wastewater, and other types of biological nondegradable organic wastewater.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Emulsion film method for removing dust in gas fume

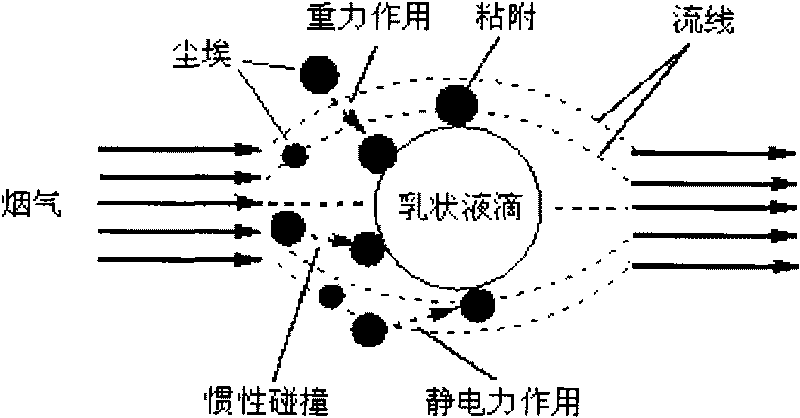

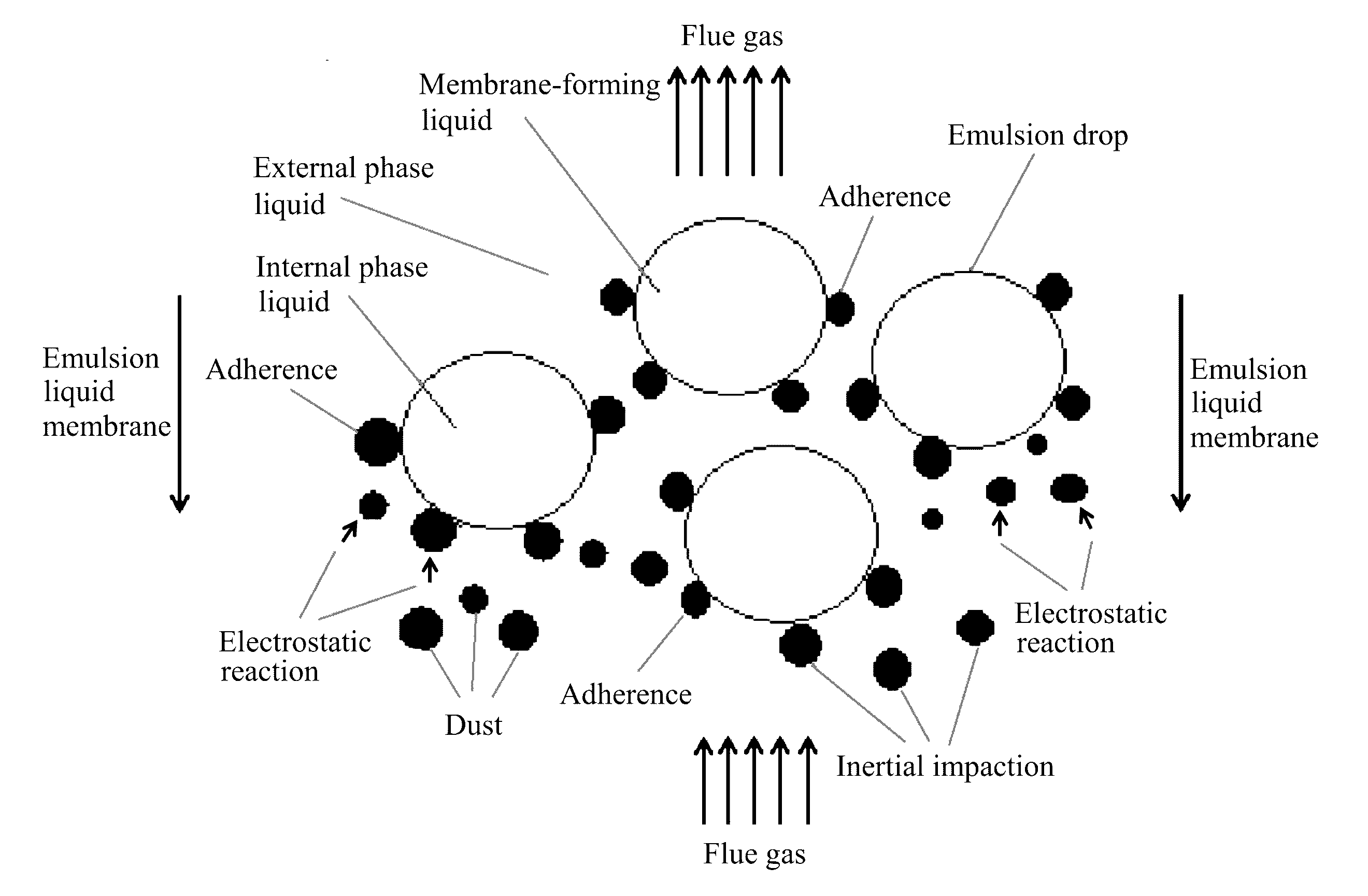

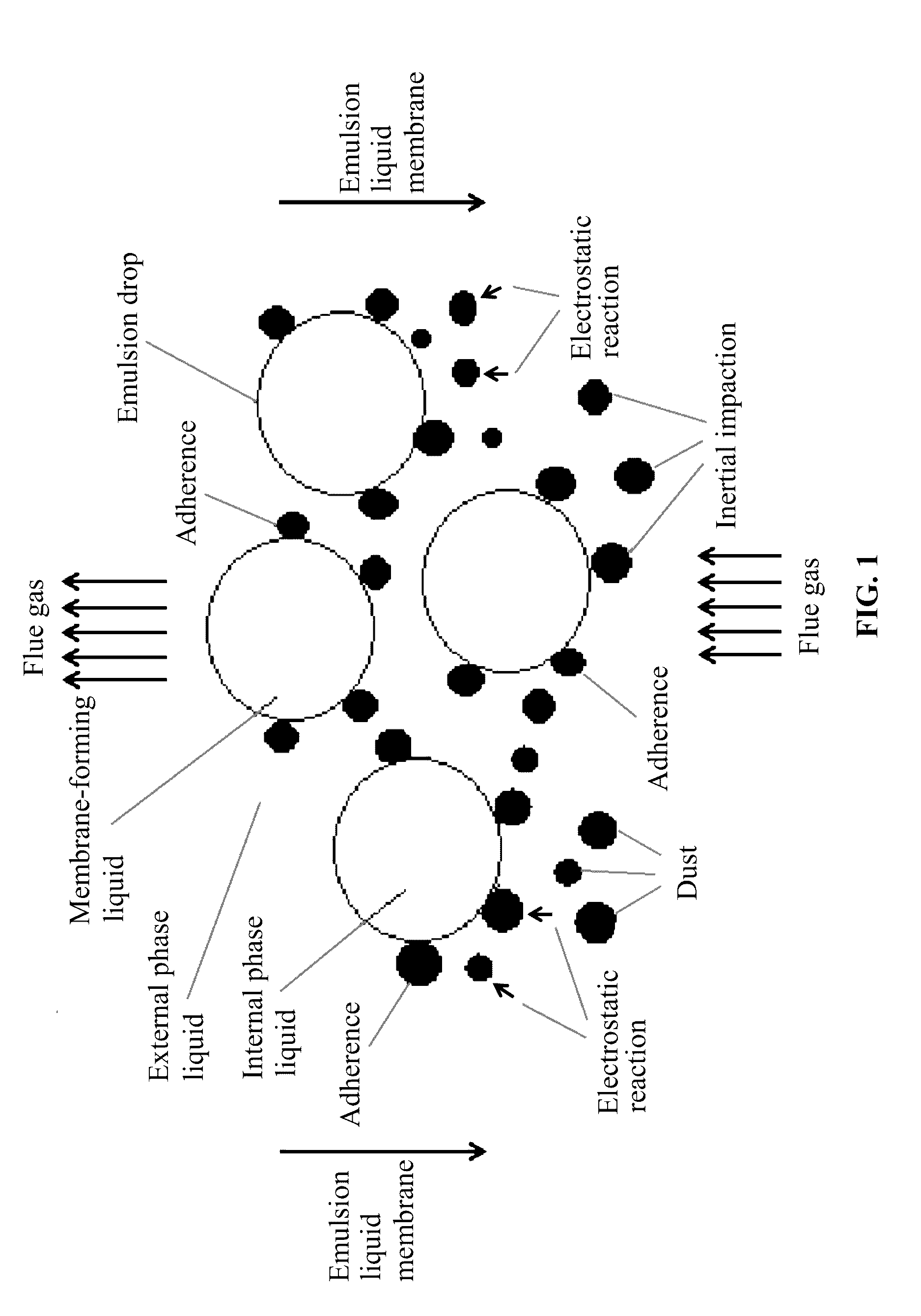

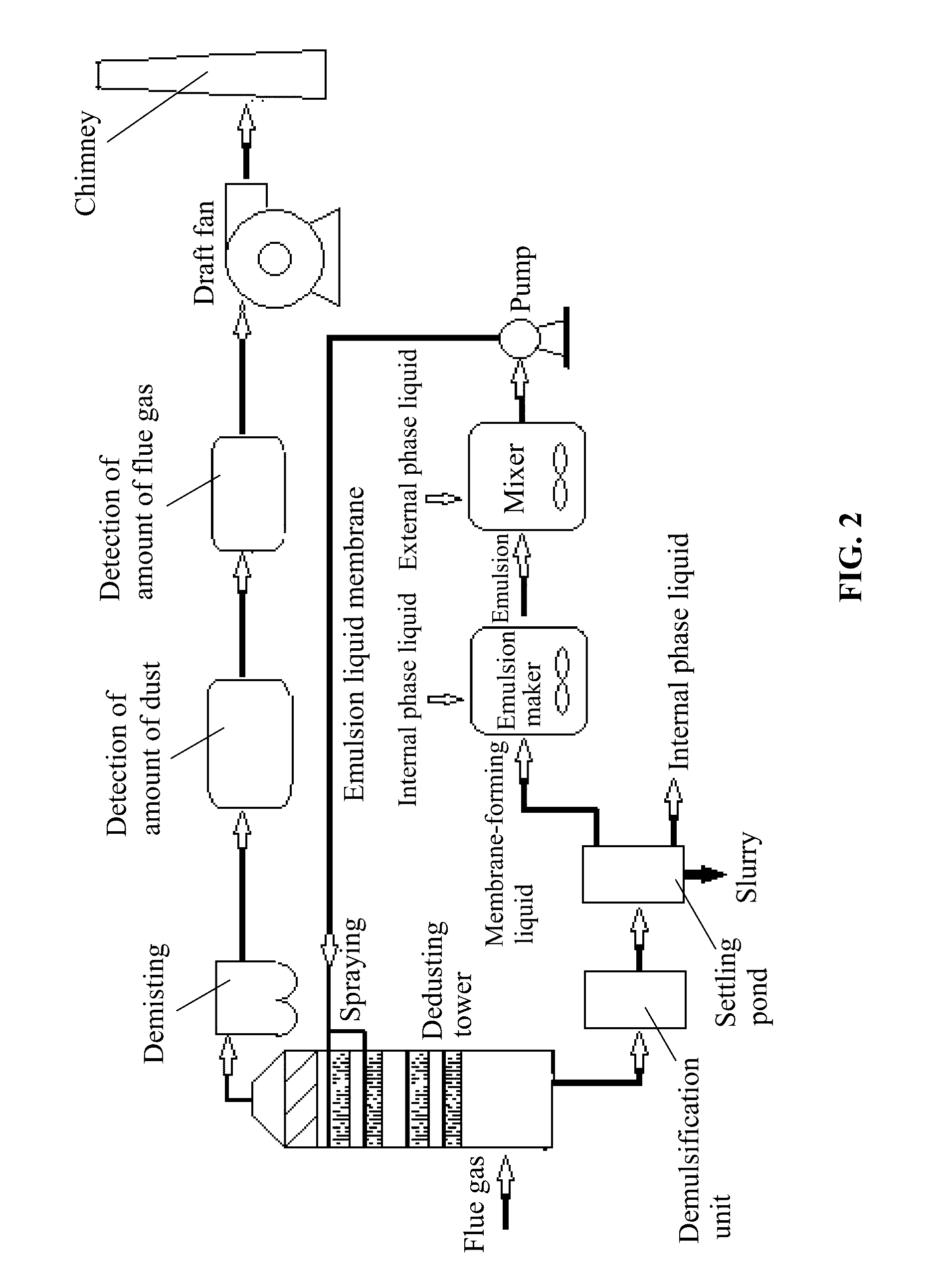

InactiveCN101711938ALarge specific surface areaFully contactedSemi-permeable membranesUsing liquid separation agentEmulsion liquid membraneBoiling point

The invention aims to provide a method for removing dust in gas fume by adopting an emulsion film technology. The method comprises the following steps that: (1) a surface active agent is dissolved in a film solvent, and water is added and used as internal phase liquid to prepare a water-in-oil type emulsion; (2) the prepared emulsion is dispersed into the water so as to ensure that the emulsion is in contact with gas fume by a spraying mode or a reaction pool (pot) mode; (3) dust adsorbed by a liquid film can automatically subside, and the dust is discharged from the bottom of a dust removal pool (pot) or a dust removal tower in the form of slurry; and (4) due to the gravity action of the dust, partial emulsion can automatically demulsify, and the film phase liquid floating on the surface of the water can be used for renewedly preparing an emulsion. The method has the advantages that the specific surface area of emulsion drops of the emulsus liquid film is large, and the adhesion of an oily film phase and the dust is strong, thus the dust removal effect is improved; the film phase liquid has higher boiling point and effectively reduces water quantity taken away by the gas fume; and the film phase liquid is not mixed and dissolved with water and can be repeatedly used.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for removing dust from flue gas using emulsion liquid membrane

InactiveUS20170050143A1Easy dischargeImprove dust removal effectSemi-permeable membranesLiquid separation by electricityEmulsion liquid membraneFlue gas

A method for removing dust from flue gas using an emulsion liquid membrane, including: a) dissolving a surfactant into a membrane solvent to yield a membrane-forming liquid; stirring and injecting an internal phase liquid into the membrane-forming liquid to yield an emulsion; b) stirring and adding the emulsion to an external phase liquid to disperse the emulsion into the external phase liquid to yield an emulsion liquid membrane; c) allowing the emulsion liquid membrane to contact with a flue gas for removing dust; d) separating a dust-loaded emulsion, and demulsifying the dust-loaded emulsion under an electrostatic field to release the dust from the membrane-forming liquid; recycling the membrane-forming liquid to a); and e) allowing the dust released from the demulsification to precipitate in the form of a slurry and discharging the slurry.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method of liquid membrane separation for extracting alkaloid of Macleaya cordata

InactiveCN101091748AQuick extractionEfficient extractionPlant ingredientsWater bathsEmulsion liquid membrane

The present invention discloses a method for extracting total alkaloid of macleaya cordata by using liquid-membrane separation process. The preparation of its emulsion is characterized by that it includes the following steps: using edible oil as membrane solvent, using mixture of Span 80 and assistant of surfactant or Span 80 as surfactant, using organic phosphate as carrier, making macleaya cordata hydrochloric acid extrat or sulfuric acid extract whose pH is 4 and the emulsion be added into an extractor according to the emulsion-water volume ratio of 50:5-50:20, making extraction for 5-15 min under the condition of low-stirring speed of 200 rpm-300 rpm, heating by means of water bath and emulsion-breaking, then separating out oil layer so as to obtain water phase, said water phase is solution of total alkaloid of macleaya cordata.

Owner:HUNAN NORMAL UNIVERSITY

Pressure acid leaching-emulsion liquid membrane method for extracting nickel from laterite

InactiveCN104232891AAchieve reusePromote cleaner productionProcess efficiency improvementEmulsion liquid membraneCentrifugation

The invention relates to a pressure acid leaching-emulsion liquid membrane method for extracting nickel from laterite. The method adopts a heating-centrifugation combined demulsification method, and reaches an emulsion breaking rate of 98%; the oil phase can be reused; after repeated use, the liquid membrane can realize an extraction efficiency up to 80%. The invention promotes clean production technology of pressure acid leaching of nickel laterite, and is innovative.

Owner:无锡市森信精密机械厂

Method of refining wood vinegar based on emulsion liquid membrane

PendingCN106422785AReduce investmentReduce consumptionSemi-permeable membranesBiofuelsParaffin waxEmulsion liquid membrane

The invention discloses a method of refining the wood vinegar based on an emulsion liquid membrane. The method specifically comprises the following steps: (1) preparing an emulsion liquid membrane through adopting the following components in concentration: 5% of liquid paraffin, 2-10% of surfactant T154, 0-3.5% of tri-n-butyl phosphate as a carrier and 0.2-1 mol / L of internal-phase NaOH, wherein the volume ratio of the oil phase of the membrane to the aqueous NaOH solution is 5:2 - 5:8; subjecting above materials to ultrasonic treatment for 5-10 minutes, and then subjecting the materials to emulsification treatment for 5-30 minutes at 4500 r / min, wherein the concentration of each of the above materials is respectively the volume percentage of the material to the total volume of the oil phase of the membrane and the oil phase solvent of the membrane is composed of kerosene; (2) dephenolizing the emulsion liquid membrane with the volume ratio of the emulsion liquid membrane to the to-be-processed wood vinegar to be 1:2 - 1:10, wherein the mass transfer time is 5 -40 minutes, and the stirring speed is 150 - 500 r / min. the method is simplified in technical process, simple in unit operation, small in personnel and equipment investment and low in energy consumption. Meanwhile, the repeated recycle and reuse is enabled.

Owner:TIANJIN UNIV OF COMMERCE

Method for recovering nickel in solution

InactiveCN102703729ALow priceLow costMultistage water/sewage treatmentProcess efficiency improvementEmulsion liquid membraneActive agent

A method for recovering nickel in solution includes steps of adding 4-6% of surfactant Span85, 3-5% of flowing carrier TBP (tributyl phosphate), and 1% of liquid paraffin into an emulsifying device to dissolve in membrane solvent kerosene, mixing at the speed of 500r / min for five minutes, dropwise adding 1-2mol / L NH3*H2O solution into the emulsifying device at the speed of 10-20mL / min according to an oil-inner ratio of 1:1, stirring at the speed of 4000-6000r / min for 15-20 minutes to obtain milk white emulsion, and allowing the emulsion to stand in a set time for standby; transferring a certain amount of 100-500mg / L into a mixing cup, stirring at the speed of 200-400r / min, adding product of stirring into another mixing cup according to an emulsion-water ratio of 1:3 to 1:5, stirring for 10-15 minutes, performing extraction and separation, allowing solution to stand and layer, and separating out emulsion for standby after 30 minutes; and subjecting the emulsion to combined heating-centrifugal demulsification to separate oil phase and water phase, and performing cyclic emulsification to recover rich nickel in the water phase. Emulsion liquid membranes obtained by the method are highly stable, nickel ion selectivity is high, and the method is simple.

Owner:SHENYANG LIGONG UNIV

Prepn process of nanometer alumium hydroxide

InactiveCN1887715ASmall particle sizeEvenly distributedNanostructure manufactureAluminium oxides/hydroxidesAluminium sulfateEmulsion liquid membrane

The present invention relates to preparation of nanometer aluminum hydroxide, and is especially chemical emulsion film process of preparing nanometer aluminum hydroxide. The preparation process includes the following steps: 1. preparing water solution of aluminum sulfate of 0.5-1.5 mol / L concentration; 2. preparing water solution of sodium hydroxide of 0.5-1.0 mol / L concentration; and 3. mixing kerosene, emulsifier and tributyl phosphate in the ratio of 45 to 2 to 3 with sodium hydroxide solution in the same volume through stirring to form emulsion, mixing the emulsion with aluminum sulfate aqua in the ratio of 3 to 7 through stirring, stopping stirring for layering, taking out emulsion, stilling to demulsify and stoving to obtain nanometer aluminum hydroxide powder. The preparation process has full utilization of the material, and is simple and low in production cost. The obtained nanometer aluminum hydroxide powder has size in 20-80 nm.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method for comprehensively extracting changium smyrnioide polysaccharides and amino acid

InactiveCN101955547AMild conditionsLess polysaccharide lossOrganic compound preparationChemical industryHigh concentrationEmulsion liquid membrane

The invention relates to a method for comprehensively extracting changium smyrnioide polysaccharides and changium smyrnioide amino acid. The method comprises the following steps of: extracting with hot water and acid water, filtering, putting the extract on a cation exchange resin column, collecting effluent liquid which is not adsorbed by resin, adding high-concentration ethanol into the effluent liquid, leaching precipitates, washing with acetone and performing freeze drying so as to obtain the changium smyrnioide polysaccharides; and eluting the resin with ammonia water, adjusting pH, separating an emulsion liquid membrane, concentrating an organic nanofiltration membrane and drying so as to obtain the changium smyrnioide amino acid. The method has the advantages of mild reaction condition, a small amount of polysaccharide loss, high amino acid activity, short process path, energy saving and suitability for mass production.

Owner:NANJING ZELANG MEDICAL TECH

Method for recycling copper and cyanide in cyanide-containing wastewater by using emulsion liquid membrane

InactiveCN104609495AImprove permeabilityLarge specific surface areaPhotography auxillary processesWater/sewage treatment bu osmosis/dialysisHigh concentrationEmulsion liquid membrane

The invention discloses a method for recycling copper and cyanide in cyanide-containing wastewater by using an emulsion liquid membrane, and belongs to the technical field of sewage treatment. The method mainly comprises the following steps: dissolving a Span80 surfactant, a Lix7950 guanidine extraction agent, a n-dodecyl alcohol modifier and a paraffin additive in a certain ratio in a membrane solvent with kerosene, stirring to obtain oil phase, and adding an alkaline solution into the oil phase to prepare a water-in-oil type emulsion liquid membrane; dispersing the water-in-oil type emulsion liquid membrane into cyanide-containing wastewater in a certain ratio, stirring, and leaving to stand and separate, thereby obtaining emulsion membrane phase with enriched high-concentration copper-cyanide complex and wastewater of which the copper-cyanide complex is desorbed; further performing demulsification, thereby effectively recycling copper and cyanide. The method has the advantages of being high in permeability, large in specific surface area, relatively high in enrichment rate, selectivity and applicability, relatively low in cost and the like.

Owner:NORTHEASTERN UNIV

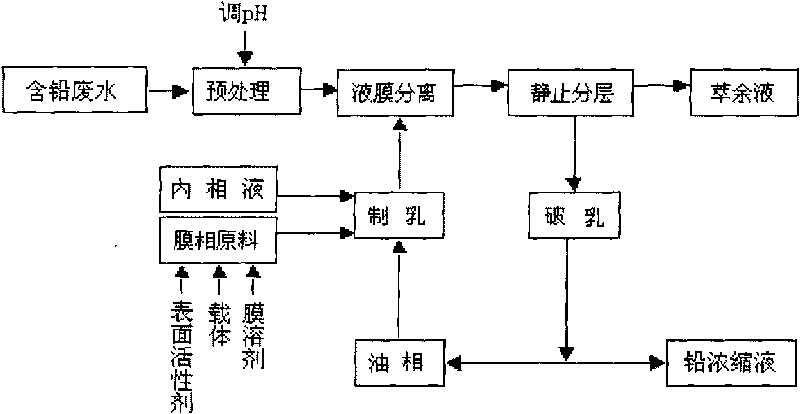

Method for reclaiming lead from waste water

InactiveCN101712486AImprove separation efficiencyGood choiceWater contaminantsWater/sewage treatment by extractionEmulsion liquid membraneKerosene

The invention aims to provide a method for reclaiming lead from waste water by using an emulsion membrane, and belongs to the field of environmental chemical engineering. The method comprises the following steps: (1) preparing an emulsion by stirring L113A serving as surfactant, N7301 serving as a carrier for conveying the lead, industrial kerosene serving as a membrane solvent and acid solution serving as an internal water phase at a high speed; (2) dispersing the emulsion to the lead-containing waste water, separating the lead-containing waste water at a low rotating speed, conveying the lead from the waste water phase to the internal water phase through a liquid membrane, enriching the lead, standing the waste water, and then separating the lead-loaded emulsion and the waste water; and (3) breaking the lead-loaded emulsion under high-voltage static electricity, and separating the oil phase and the aqueous phase, wherein the oil phase is used for cyclically preparing the emulsion, and the aqueous phase is the concentrated lead-containing solution. The method provided by the invention has the characteristics that: (1) the emulsion has good stability; (2) the adopted carrier has the advantages of good selectivity for lead ions, high separation efficiency, low price, easy synthesis and the like; and (3) the reclaimed lead can be reused so as not to cause secondary pollution.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

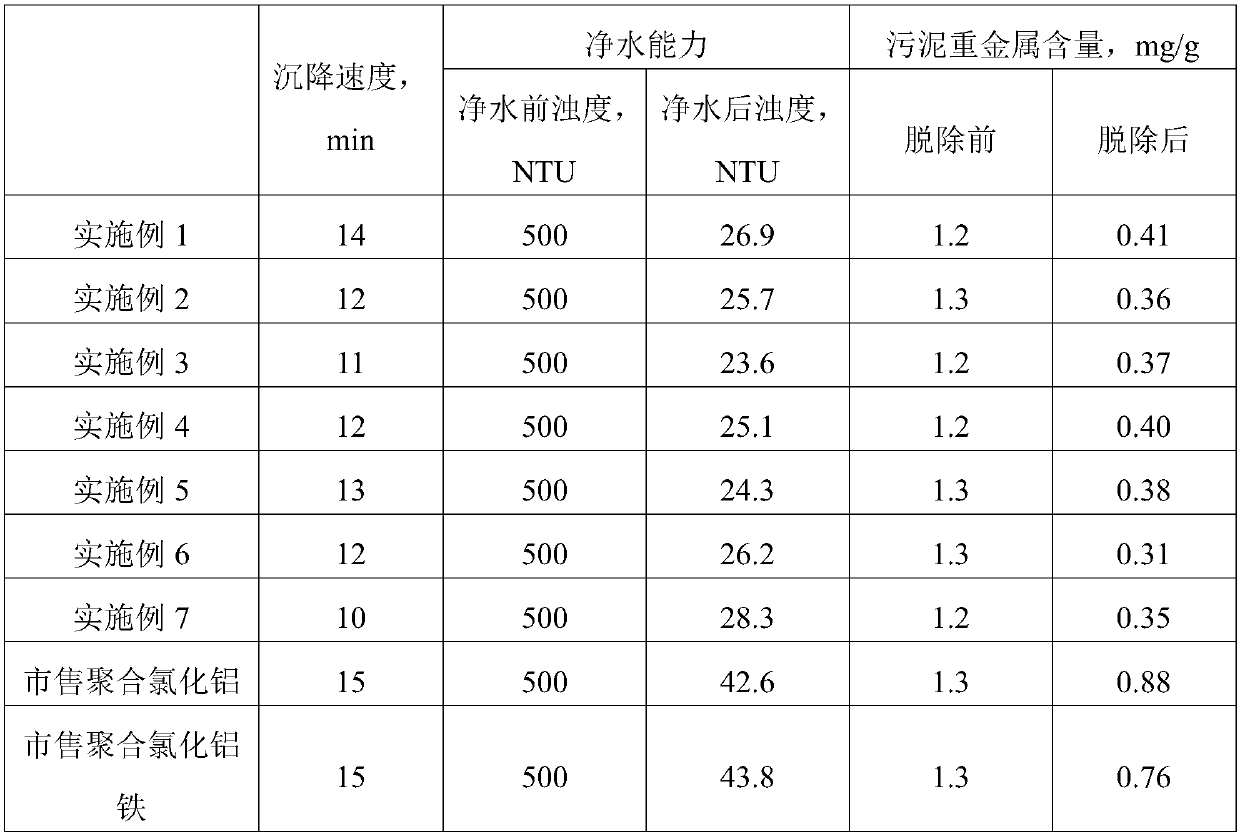

Recyclable environment-friendly water purifying agent and method for preparing same

ActiveCN109574168APromote enrichmentReach the purpose of recyclingWater treatment compoundsWater/sewage treatment by magnetic/electric fieldsEnvironmental resistanceEmulsion liquid membrane

The invention discloses a recyclable environment-friendly water purifying agent. The recyclable environment-friendly water purifying agent is of a core-shell structure. Core layers of the core-shell structure are nanometer magnetic particles, shell layers of the core-shell structure are emulsion liquid membranes, and inorganic polymer coagulants are deposited outside the emulsion liquid membranes.The recyclable environment-friendly water purifying agent has the advantages that the release amount of inorganic polymer coagulant water purifying agents can be reduced, dense alum floc can be formed, the recyclable environment-friendly water purifying agent is high in sedimentation velocity, and good purification effects can be realized by the recyclable environment-friendly water purifying agent; the nanometer magnetic particles of the core layers of the recyclable environment-friendly water purifying agent are easy to enrich and recycle. The invention further discloses a method for preparing the recyclable environment-friendly water purifying agent.

Owner:宁波顺帆净水剂有限公司

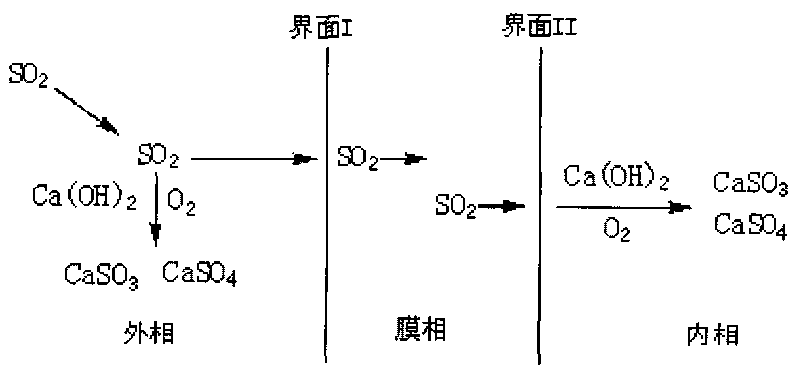

Emulsion film method for removing sulphur in flue gas

InactiveCN101716466ALarge specific surface areaReduce dosageSemi-permeable membranesDispersed particle separationEmulsion liquid membraneSulfur

The invention aims at providing a method for removing sulphur in flue gas by adopting emulsion film technology. The method includes the following steps: (1) surfactant is dissolved in film solvent, and alkaline internal phase liquid is added, so as to obtain water-in-oil type emulsion; (2) the emulsion is dispersed into alkaline desulphurization medium and then is contacted with flue gas for desulphurization in spraying or reaction tank (jug) manner; (3) settled desulphurized product is removed at the bottom of desulphurization tank (jug) or desulphurization tower; (4) part of demulsified emulsion is subject to standing, and film phase liquid floating on the surface is collected and used for preparing emulsion again. The invention has the following advantages: special area of emulsion drop is large, and emulsion drop can be fully contacted with flue gas by reciprocating collision, thus improving desulphurization efficiency; film phase liquid has higher boiling point, thus effectively reducing water amount taken away by flue gas; and film phase liquid and water are not blended or dissolved mutually, film phase liquid floats on the water phase and can be used for preparing emulsion again through collection.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Liquid film micro-extraction method for controlled substance in blood or urine

InactiveCN101907597AThe proportion of dosage is smallReduce the impactPreparing sample for investigationMaterial analysis by electric/magnetic meansEmulsion liquid membraneToxicant

The invention relates to a liquid film micro-extraction method for controlled substances in blood or urine, which belongs to the chemical field, is used for analyzing controlled substances in body fluid and overcomes the defects of complicated process, low enrichment rate, human body injuries and environmental pollution of a traditional method. A detection method of controlled substances in urine comprises the following steps of: mixing span 80, coal oil and dilute hydrochloric acid to prepare a stable emulsion liquid film, wherein the outer layer of the liquid film is an organic phase on the outer layer and the outer layer of the liquid film is a hydrochloric acid phase; adjusting a pH value of the urine to 8-9; and adding the liquid film to the urine for the liquid film micro-extraction and connecting with an AC to break the emulsion; and centrifugating and delaminating the broken emulsion liquid, wherein an aqueous solution of the inner phase in the lower layer is used for detecting the contents of the controlled substances in the urine. A detection method of amphetamine toxicants in blood comprises the following steps of: centrifugating blood in a centrifuge at a high speed; standing still to delaminate; taking out supernatant liquor on the upper layer to detect; and analyzing the rest by the same method with the analysis of the urine. The invention has the advantages of high enrichment recycle rate, little organic solvent consumption, normal temperature operation, less influence on operators and environment, repeated organic phase use and low detection cost.

Owner:吉林省公安厅物证鉴定中心

Method for extracting rare earth from emulsion liquid membrane

InactiveCN105219960ALow rare earth contentImprove extraction efficiencyProcess efficiency improvementEmulsion liquid membraneLow speed

The invention belongs to the field of rare earth metallurgy and provides a method for extracting rare earth from strong-acid leachate of phosphates containing rare earth. The method is characterized by comprising the following steps of stirring oil phases and an internal-phase resolving agent, namely an HCl solution with the concentration of 2-12mol / L, according to the volume ratio of 1:1 to prepare an emulsion at a high speed, wherein the oil phases include 4-14% (volume fraction, the same below) of a mobile carrier, namely phenylamine, 2-12% of a surfactant T154 and a film solvent, namely sulfonated kerosene; stirring at a low speed, and extracting rare earth in leachate, wherein the volume ratio of the emulsion to external-water-phase leachate is 1:10 to 1:100, and the highest extracting efficiency of the extracting system to rare earth in phosphate leachate can be up to more than 92%.

Owner:GUIZHOU UNIV

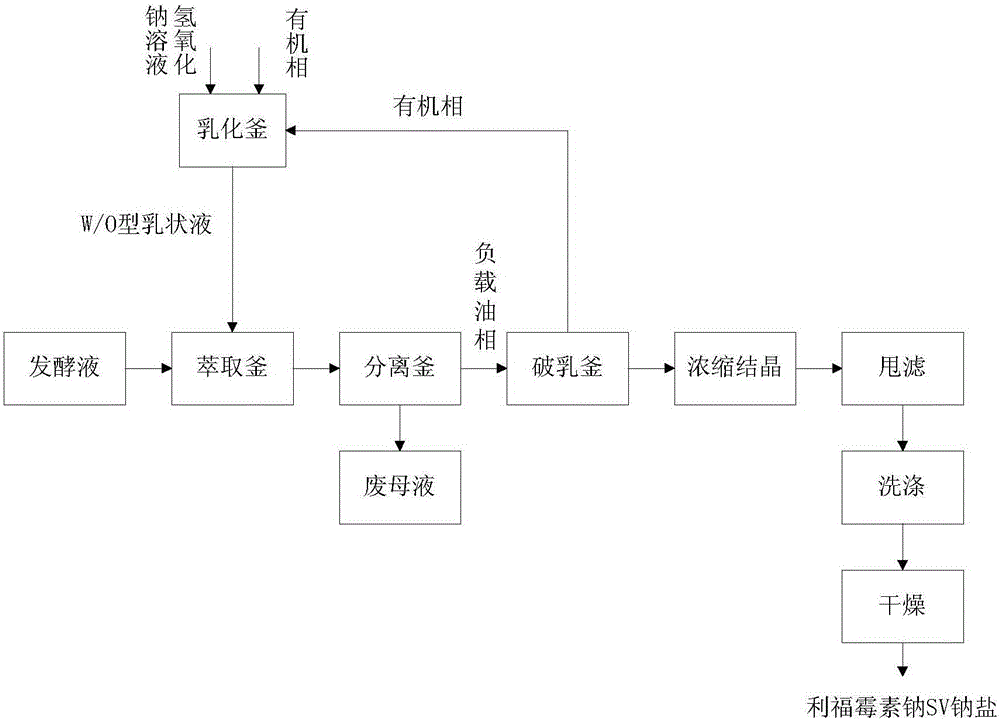

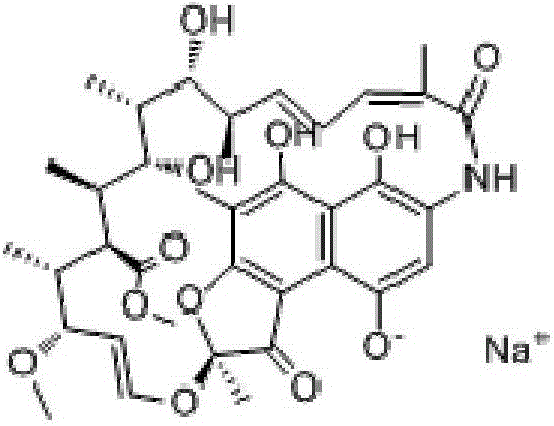

Novel rifamycin SV sodium salt production technology

ActiveCN105713010AQuality assuranceHigh yieldOrganic chemistryEmulsion liquid membraneRifamycin SV Sodium

The invention relates to a bulk pharmaceutical chemical production technology, in particular to a novel rifamycin SV sodium salt production technology.A W / O emulsion liquid membrane is extracted from fermentation broth, and rifamycin SV sodium is directly generated.The content of the product obtained by means of the production technology is 90-97%, and water content is 2.6-5%.The technological process is short, three-waste output is low, raw material consumption is low, the yield of rifamycin SV sodium is effectively increased, and the problems of existing technologies that the technological process is long, impurity content is high and yield is low are solved.The novel rifamycin SV sodium salt production technology has great significance in promoting industrial development and has broad industrialized application prospects.

Owner:SHENYANG RES INST OF CHEM IND +1

A method for extracting lignin from papermaking black liquor by magnetic emulsion liquid membrane separation

The invention provides a method for extracting lignin in papermaking black liquor by magnetic emulsion liquid-membrane separation. The method comprises the following steps: taking oleic acid cladded ferriferrous oxide (Fe3O4) nano solid particles as a stabilizer and mixing an organic solvent and a carrier to form an oil membrane; dispersing the particle stabilizer into the oil membrane to form anoil phase; then shearing and emulsifying the oil phase and a water phase to obtain needed stable water-in-oil type emulsion; adding the stable water-in-oil type emulsion into supernatant of the blackliquor and stirring to form water-in-oil-in-water composite emulsion; under the action of a pushing force of concentration difference, enriching the lignin into the water phase through the carrier; after finishing extraction, demulsifying to recycle an emulsifier and the oil membrane for recycling. The method provided by the invention is simple in steps, convenient to operate and strong in practicability.

Owner:QILU UNIV OF TECH

Method for separating and removing heavy-metal thallium from sintering flue gas desulfurization wastewater of ferrous metallurgy by emulsion liquid membrane

InactiveCN106946305ASimple processSimple equipmentWater contaminantsWaste water treatment from gaseous effluentsEmulsion liquid membraneSolvent

The invention discloses a method for separating and removing heavy-metal thallium from sintering flue gas desulfurization wastewater of ferrous metallurgy by an emulsion liquid membrane. The method comprises the steps of firstly, preparing the emulsion liquid membrane prepared from a solvent, a surfactant, a carrier, membrane auxiliaries, an internal-phase solution and the like, then, enabling the sintering flue gas desulfurization thallium-containing wastewater to be in contact with the emulsion liquid membrane for mass transfer, then, carrying out natural settlement separating, discharging obtained wastewater after reaching standards, subjecting an emulsion phase to demulsifying treatment, recycling an obtained oil phase to the preparation of the emulsion liquid membrane, subjecting an obtained aqueous phase to retreatment by methods such as chemical precipitation and salting-out, then, returning a small volume of wastewater to a sintering flue gas desulfurization system for cyclic utilization, and subjecting obtained solids to dangerous waste treatment and disposal. According to the method, heavy-metal pollutants in the sintering flue gas desulfurization wastewater of ferrous metallurgy are removed and treated by using an emulsion liquid membrane separation technology, the removal effect is good, and particularly the removal rate of thallium is close to 100%; and the method has the characteristics of simple process and equipment, convenience in operation, low cost and energy consumption, and the like and has a good industrial application value.

Owner:HUNAN VALIN ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com