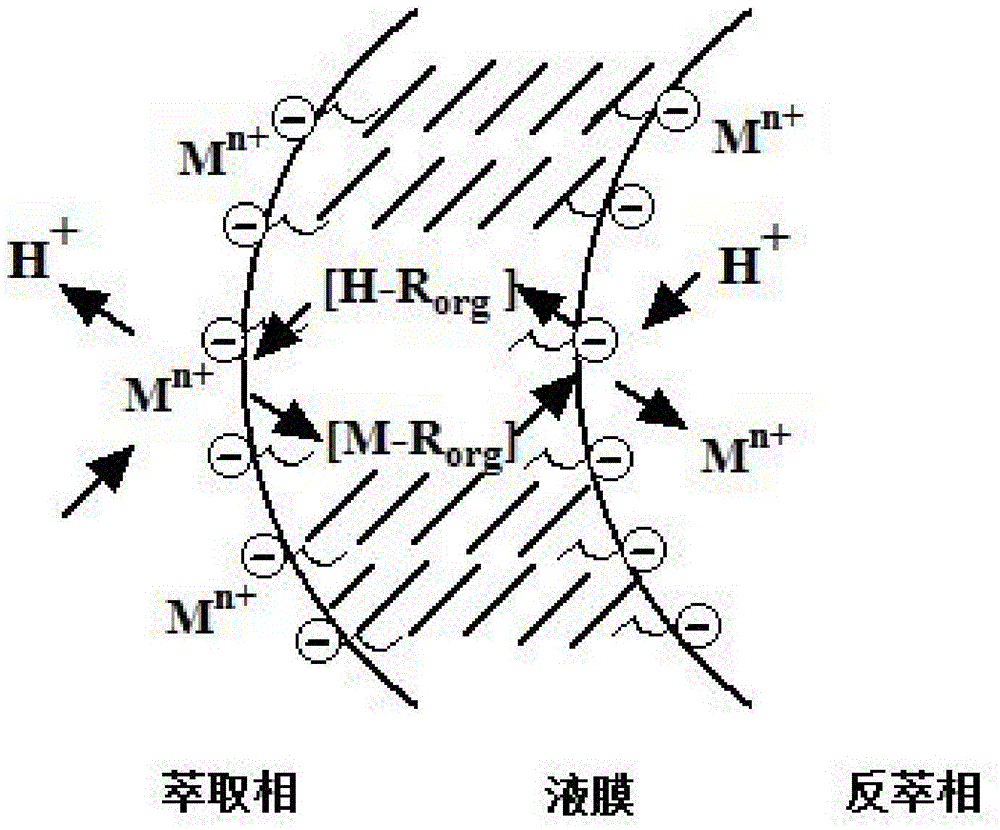

Liquid film extraction method for recovering copper and nickel in wastewater by using ionic liquid reinforced mass transfer

An ionic liquid and wastewater technology, applied in the direction of improving process efficiency, to achieve the effect of speeding up the transmission rate and improving the extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This implementation example adopts emulsion liquid membrane extraction technology to separate and reclaim the copper-nickel ion in the waste water, when the copper extraction agent P507 is 5% (v / v), the inner aqueous phase H 2 SO 4 Concentration 3.0mol / L, surfactant Span805.0% (v / v), [C 4 mim]Cl is 0.03% (v / v), liquid paraffin is 1% (v / v), and when the oil-to-inner ratio is 1:1, the extraction efficiency of the emulsion liquid film to copper ions is 98.73%, and the nickel extraction rate is only 3%, the separation effect on copper and nickel is better.

Embodiment 2

[0025] This implementation example adopts emulsion liquid membrane extraction technology to separate and recover the remaining nickel ions in the waste water, when the nickel extractant TBP is 4% (v / v), the inner aqueous phase NaOH concentration is 0.5mol / L, and the surfactant Span805.0% (v / v), liquid paraffin 1% (v / v), [C 4 mim][PF 6 ] was 0.03% (v / v), and when the oil-to-inner ratio was 1:1, the extraction rate of the emulsion liquid film to nickel ions was 99.03%.

Embodiment 3

[0027] This implementation example adopts emulsion liquid membrane extraction technology to separate and reclaim the copper-nickel ion in the waste water, when the copper extraction agent P507 is 5% (v / v), the inner aqueous phase H 2 SO 4 The concentration is 3.0mol / L; the nickel extractant TBP is 4% (v / v), the inner aqueous phase NaOH concentration is 0.5mol / L, the surfactant Span80 is 5.0% (v / v), and the liquid paraffin is 1% (v / v ), the oil-to-oil ratio is 1:1, the milking speed is 3500r / min, the milking time is 10min, the ratio is 1:3, the extraction speed is 300r / min, and the extraction time is 10min. When no ionic liquid is added, copper extraction The rate is 93.2%, and the nickel extraction rate is 92.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com