Patents

Literature

346results about How to "Reach the purpose of recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

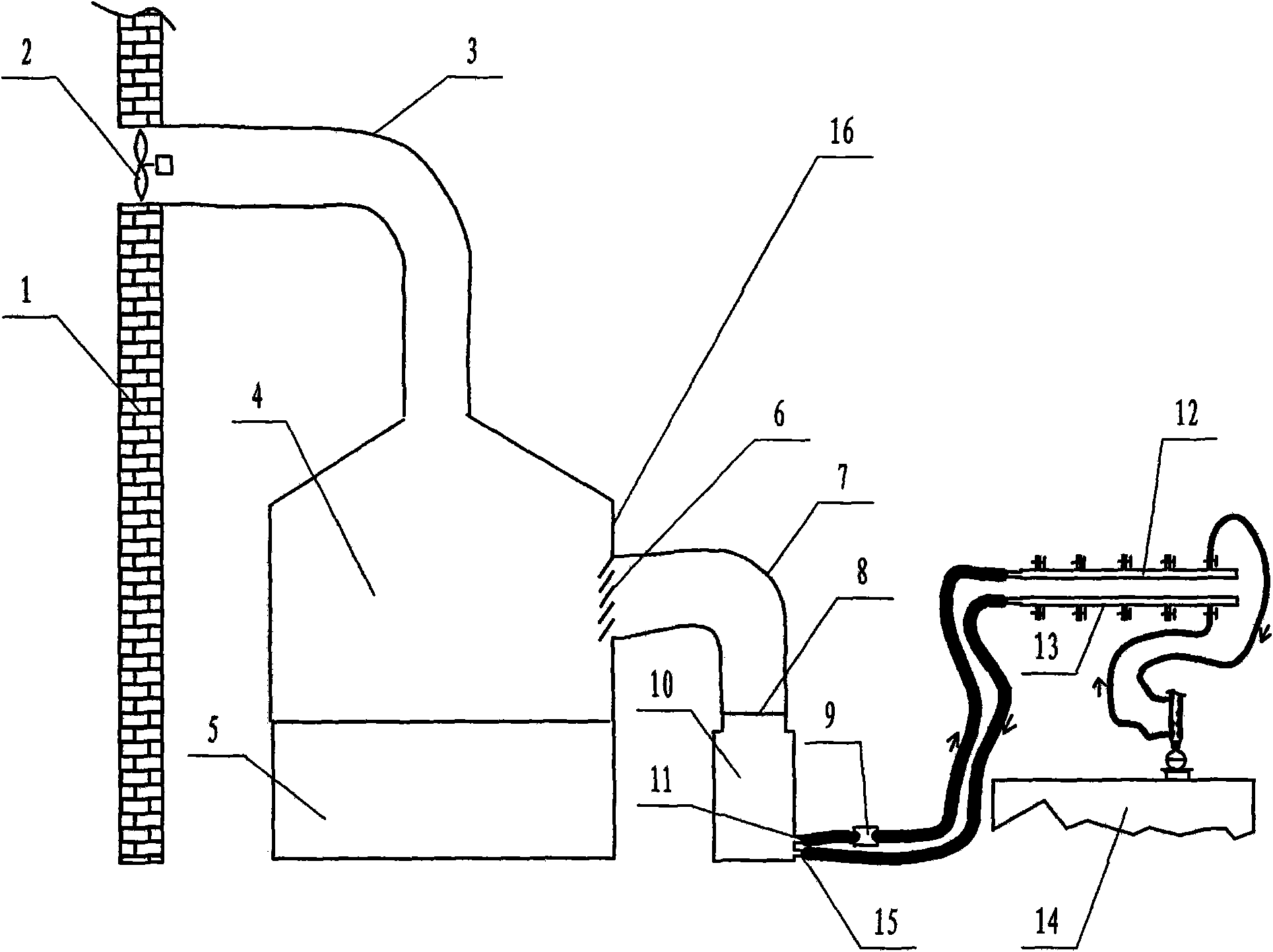

Device and process for recycling and treating hydrogen sulfide-containing chemical acid waste gas

InactiveCN103301732AReach the purpose of recyclingDispersed particle separationEnergy inputHigh heatSulfur dioxide

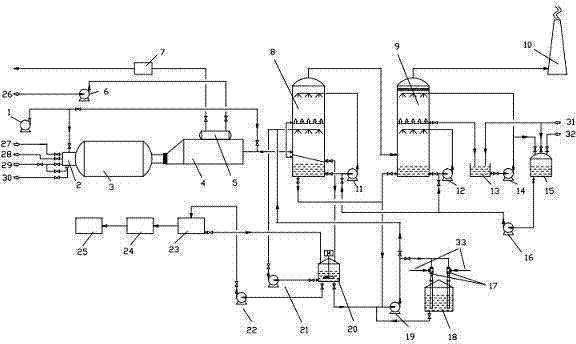

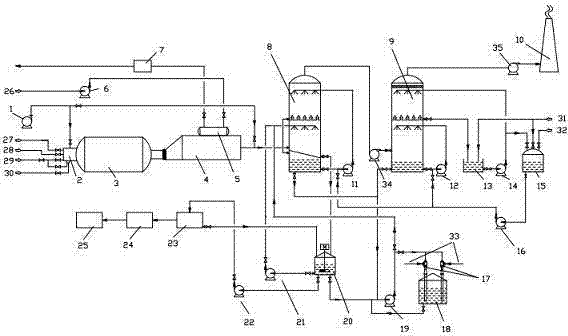

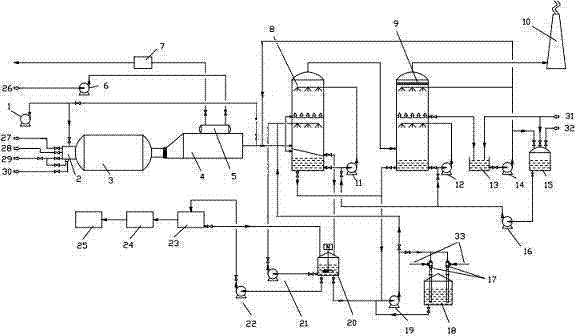

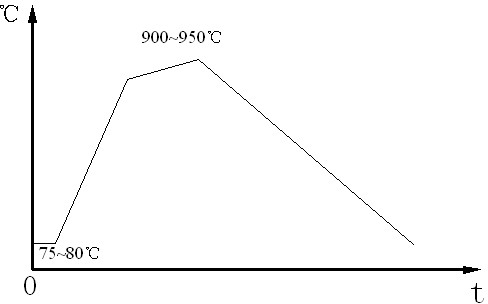

The invention belongs to the technical field of chemical waste gas treatment, and mainly relates to a device and a process for recycling and treating hydrogen sulfide-containing chemical acid waste gas. The process for recycling and treating hydrogen sulfide-containing chemical acid waste gas comprises the following steps of: igniting and completely burning the hydrogen sulfide-containing chemical acid waste gas into sulfur dioxide-rich high-temperature flue gas, recycling much heat and adjusting the temperature of the flue gas by cold air, and enabling the flue gas to enter an adsorption tower; completely absorbing the sulfur dioxide in the flue gas by utilizing an alkaline solution, removing less alkaline solution and sulfite contained in the flue gas absorbed by the alkaline solution, and exhausting the demisted pure flue gas to the atmosphere. The sulfite, which is generated by absorbing sulfur dioxide by the alkaline solution, is oxidized, concentrated, crystallized and dried to obtain side product sulfate.

Owner:义马煤业集团煤生化高科技工程有限公司 +1

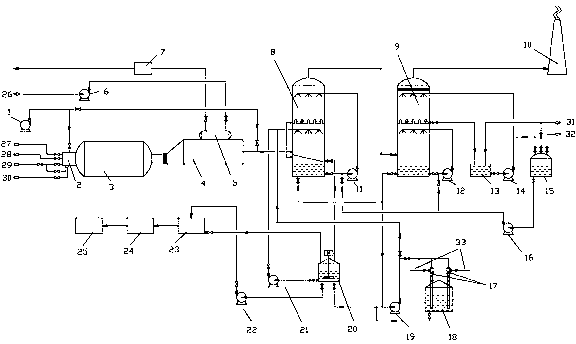

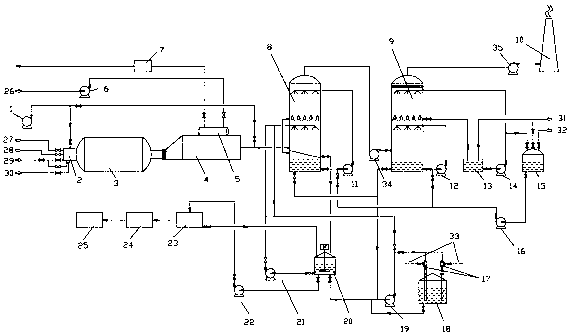

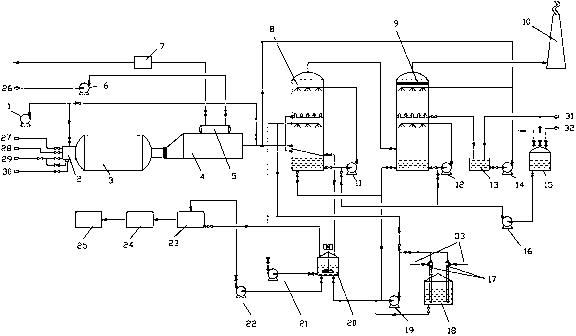

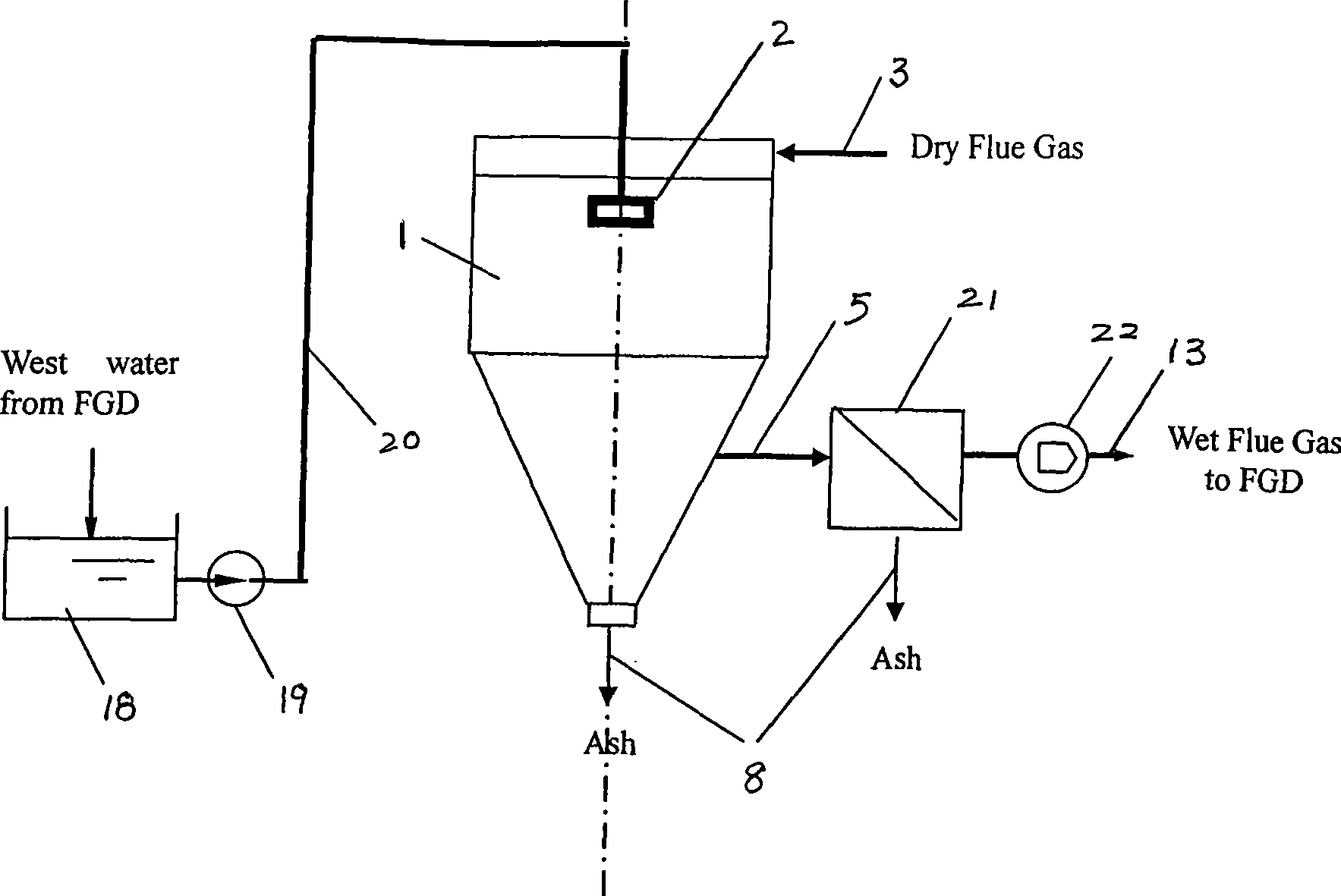

Technique method for processing desulphurization waste water

ActiveCN101417827ALow costReduce energy consumptionWater/sewage treatmentEnergy based wastewater treatmentSalt contentFlue gas

The invention discloses a technology method for treating desulfurization wastewater, which are applicable to treating the wastewater generated from limestone-plaster wet flue gas desulfurization and other wastewater with high salt content. The method uses the flue gas of heat-engine plants to carry out evaporation and solidification treatment to the desulfurization wastewater or other wastewater with high slat content which is hard to be recovered. The method is characterized by low cost, little area occupation and low energy consumption, which can provide help to the original limestone-plaster wet flue gas desulfurization treatment technology and realize zero discharge of the wastewater of the limestone-plaster wet flue gas desulfurization technology.

Owner:CHENGDU RAISE ENVIRONMENTAL PROTECTION TECH CO LTD

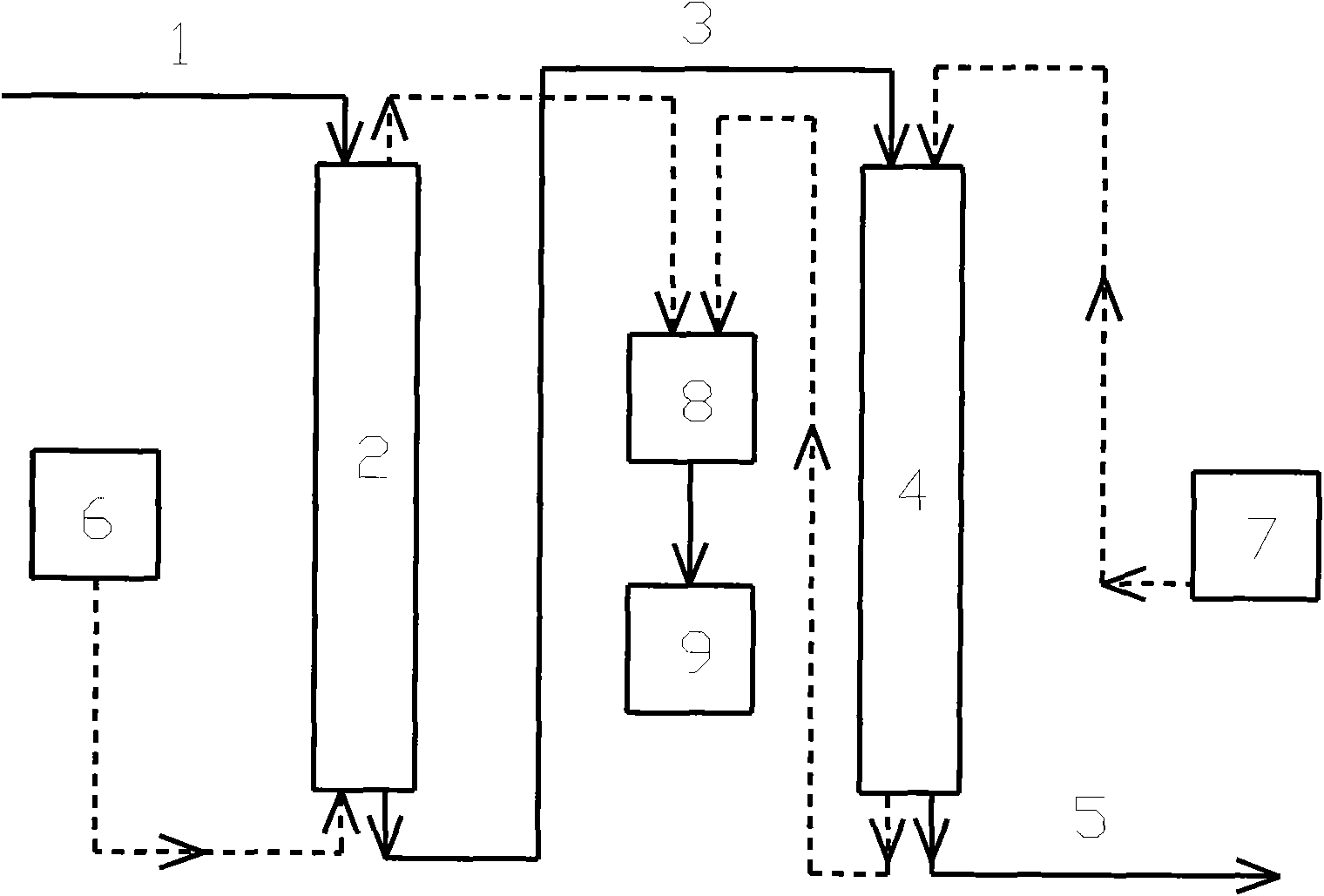

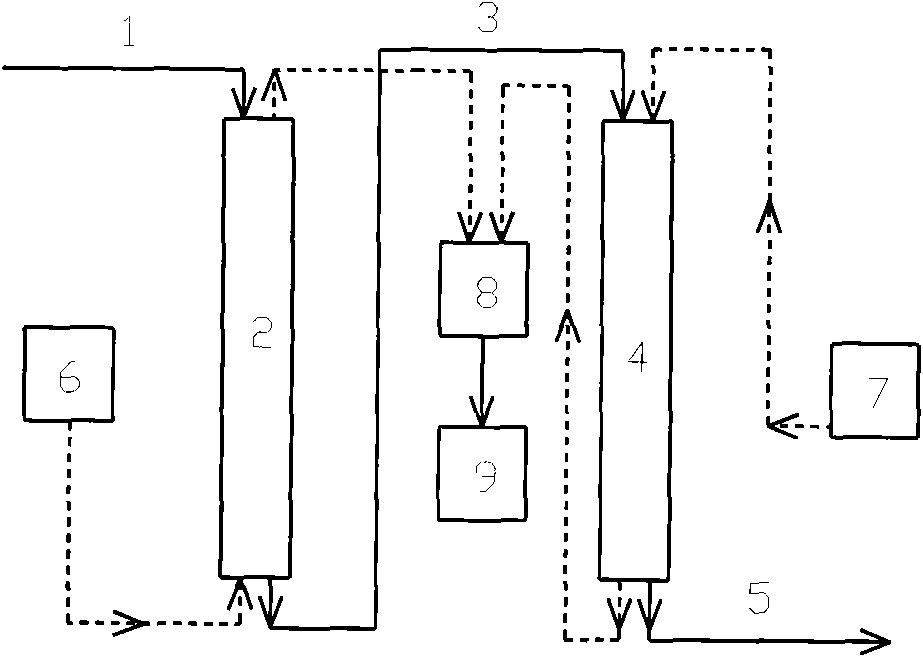

Process for treating nitrogen-containing wastewater by ion exchange and reclaiming ammonium nitrate

InactiveCN101891316AAchieve reuseFlexible operation and managementAmmonium nitratesWater/sewage treatment by ion-exchangeHigh concentrationStrong acids

The invention discloses a process for treating nitrogen-containing wastewater by ion exchange and reclaiming ammonium nitrate, and belongs to the technical field of environmental protection and wastewater treatment. The process is characterized in that: a strong acid cation exchanger and a weak alkali anion exchanger are connected in series to realize denitrification of the nitrogen-containing wastewater of a nitrogen fertilizer plant; the process is used for treating the high-concentration ammonia nitrogen and median-concentration nitrate nitrogen containing wastewater of the nitrogen fertilizer plant; strong acid cation exchange resin and weak alkali anion exchange resin are regenerated by adopting nitric acid and aqueous ammonia respectively; and the regenerated waste liquid ammonium nitrate is evaporated and concentrated to reclaim the ammonium nitrate. Compared with the traditional wastewater denitrification method, the process can remove ammonia nitrogen and nitrate nitrogen from the wastewater at the same time, reclaim the ammonium nitrate and recycle production water, does not produce secondary pollution, reclaims products from the pollutants, has obvious environmental benefit and economic benefit, and is a new path for treating the high-concentration ammonia nitrogen and median-concentration nitrate nitrogen containing wastewater of the nitrogen fertilizer plant.

Owner:TAIYUAN UNIV OF TECH

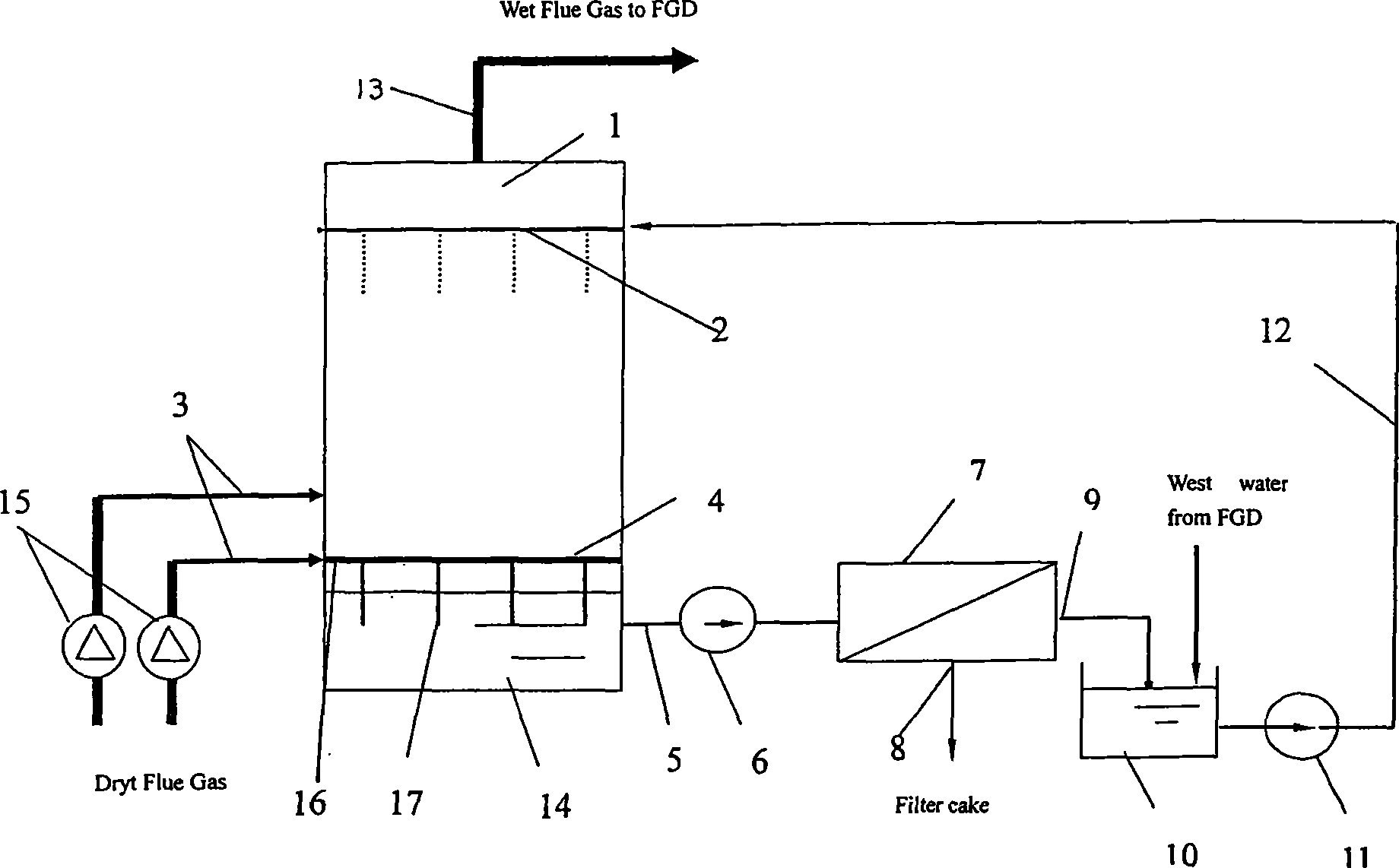

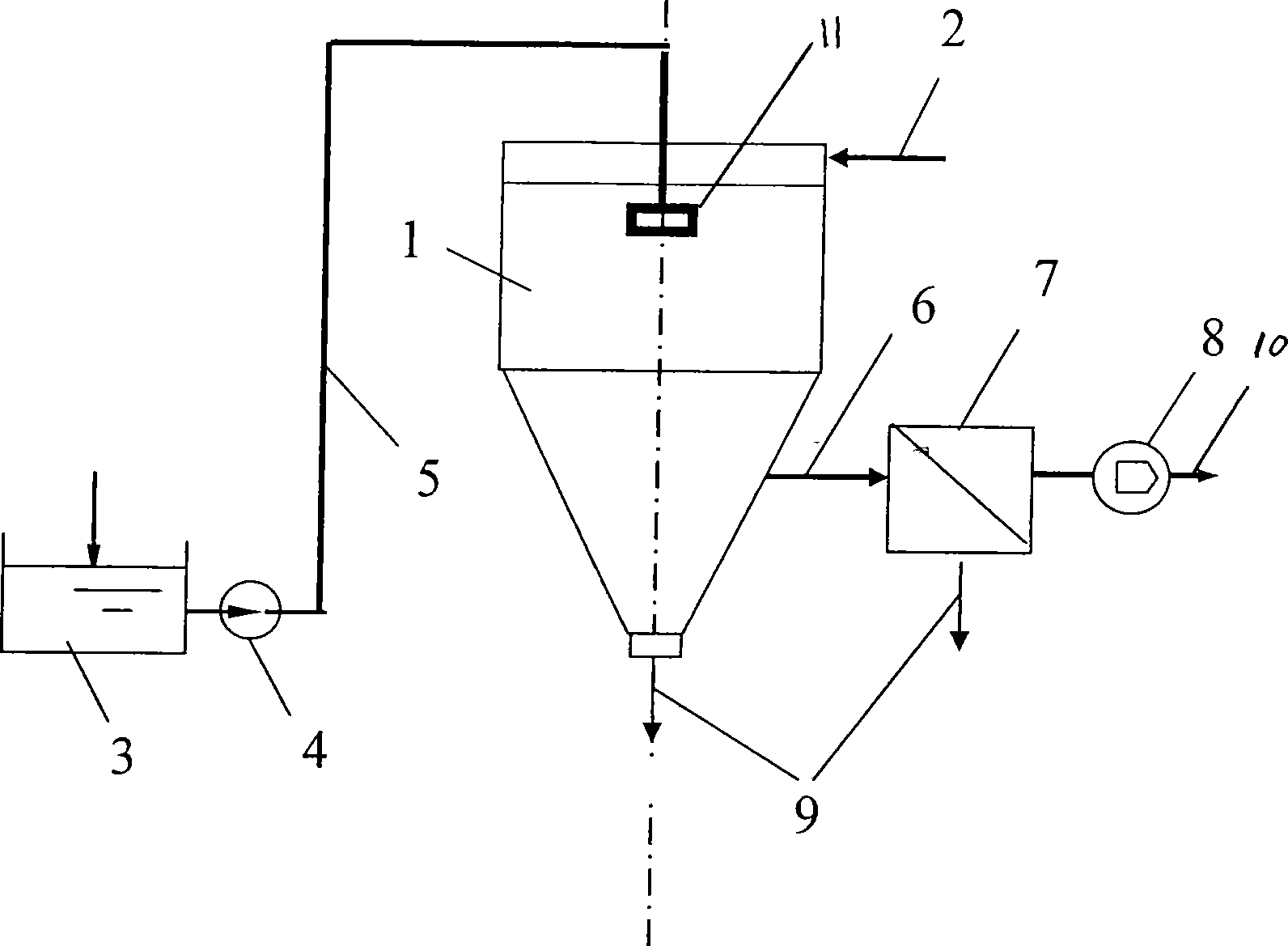

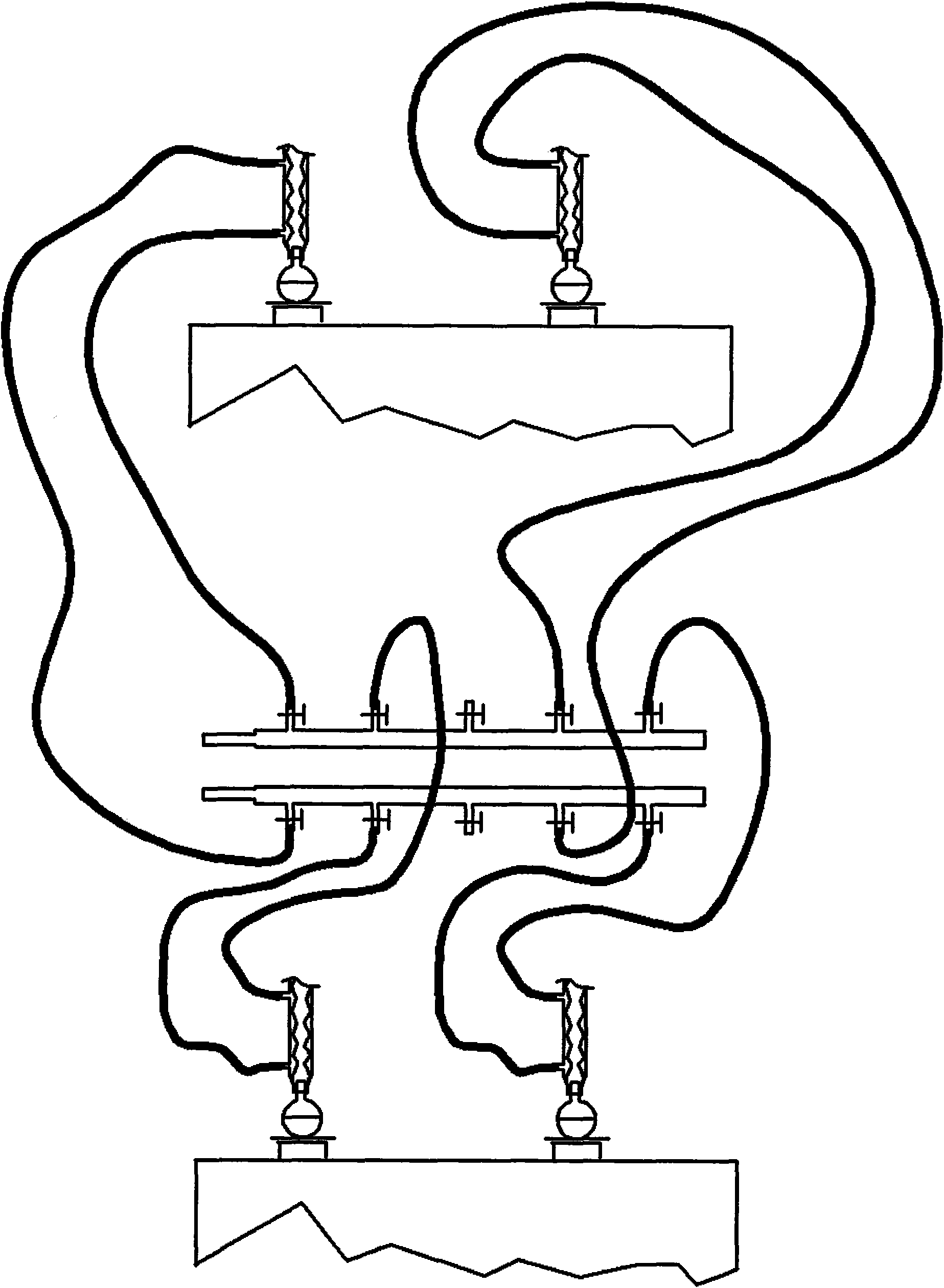

Method and system for processing desulphurization waste water

ActiveCN101417828AReduce water consumptionImprove desulfurization process efficiencyWater/sewage treatmentEnergy based wastewater treatmentSuspended particlesFlue gas

The invention discloses a method and a system for treating desulfurization wastewater, which are applicable to treating the wastewater generated from limestone-plaster wet flue gas desulfurization and other wastewater with high salt content. The system comprises a spray drier, a flue gas transport pipeline, a dust catcher, a smoke exhaust fan, a waste ash outlet and the like. The method comprises the steps: in the spray drier, hot flue gas and the desulfurization wastewater exchange heat through convection contact, so as to change the wastewater to particles and wet flue gas, discharge the settled particles and remove the wet flue gas and the suspended particles through the dust catcher. The method and the system have the advantages of low cost, little area occupation and low energy consumption, which can realize zero discharge of the wastewater of the limestone-plaster wet flue gas desulfurization technology and improve contribution.

Owner:CHENGDU RAISE ENVIRONMENTAL PROTECTION TECH CO LTD

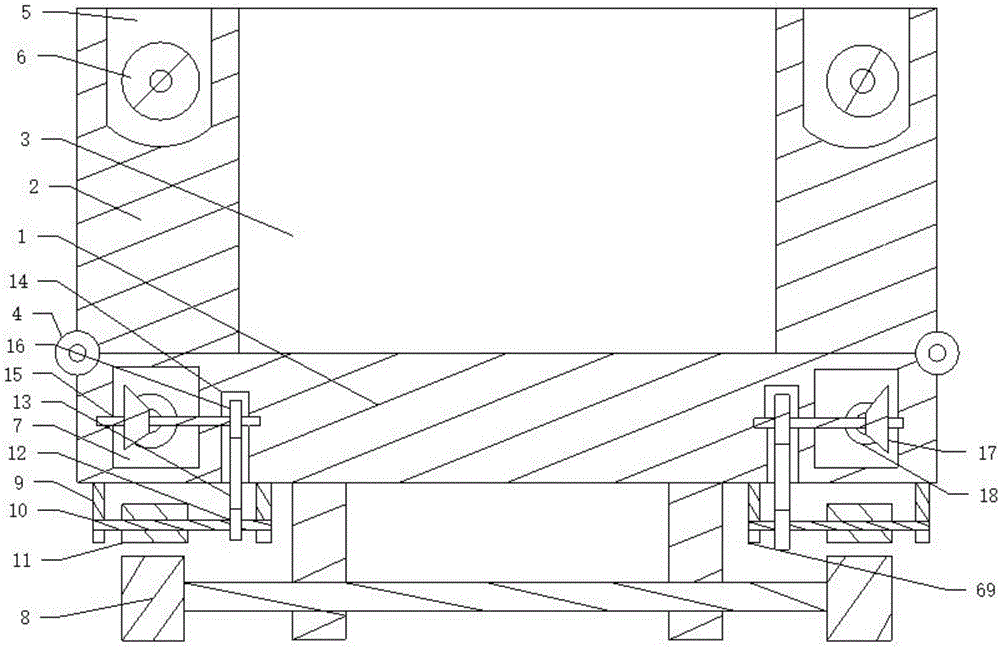

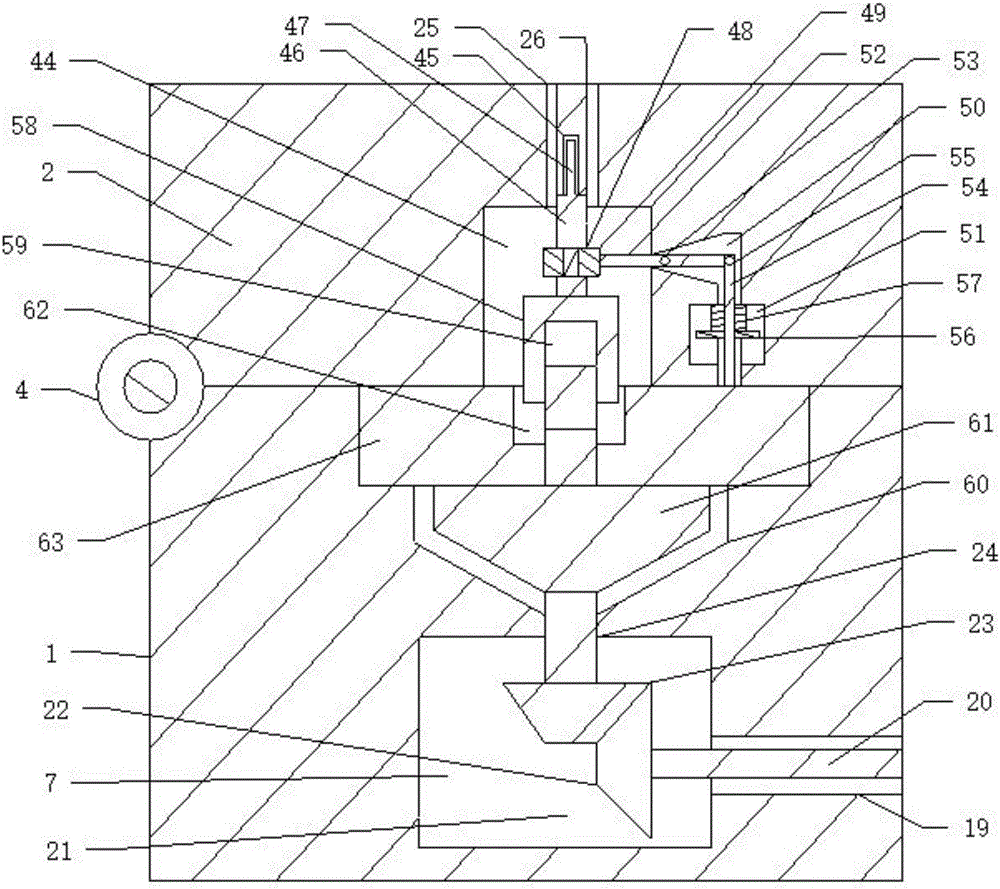

Environment-friendly abrasive cutting machine

ActiveCN102873624ASmooth cutting processImprove work efficiencyGrinding machinesGrinding/polishing safety devicesOperating tableGrinding wheel

The invention belongs to the technical field of machinery and provides an environment-friendly abrasive cutting machine which solves the problems of poor safety, serious resource waste and poor environment friendliness of existing abrasive cutting machines. The environment-friendly abrasive cutting machine comprises a base, a support, a motor, an abrasive wheel blade connected with a motor rotary shaft, and a frame with an operating table plate. The motor is fixedly arranged on the support which is hinged to the base, the base is fixedly arranged on the operating table plate which is provided with a cut allowing a blade to be embedded into, and the lower side of the operating table plate is provided with a collection mechanism which is communicated with the cut and capable of collecting cutting chips. An operating handle is fixedly connected onto the support, and a dust collection mechanism which is capable of at least covering the motor and the abrasive blade is arranged on the operating table plate and provided with an avoidance port allowing feeding and discharging. By means of the environment-friendly abrasive cutting machine, safety of operators is improved, and cutting chips and wastes are recovered, so that waste is reduced, and high environment friendliness is achieved.

Owner:陈美青

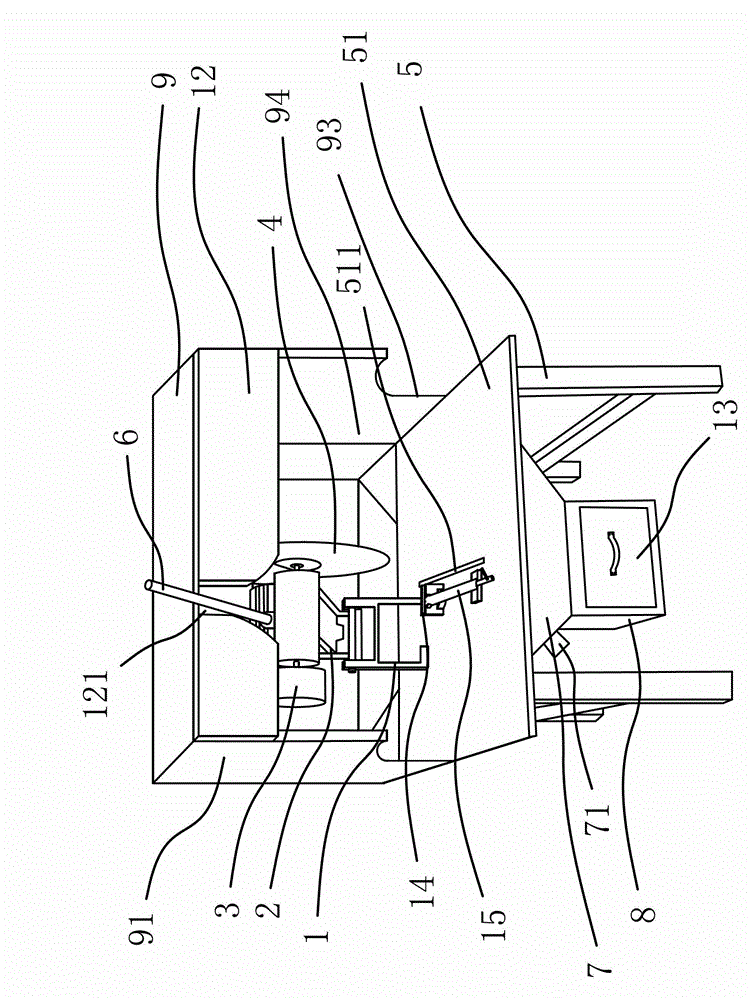

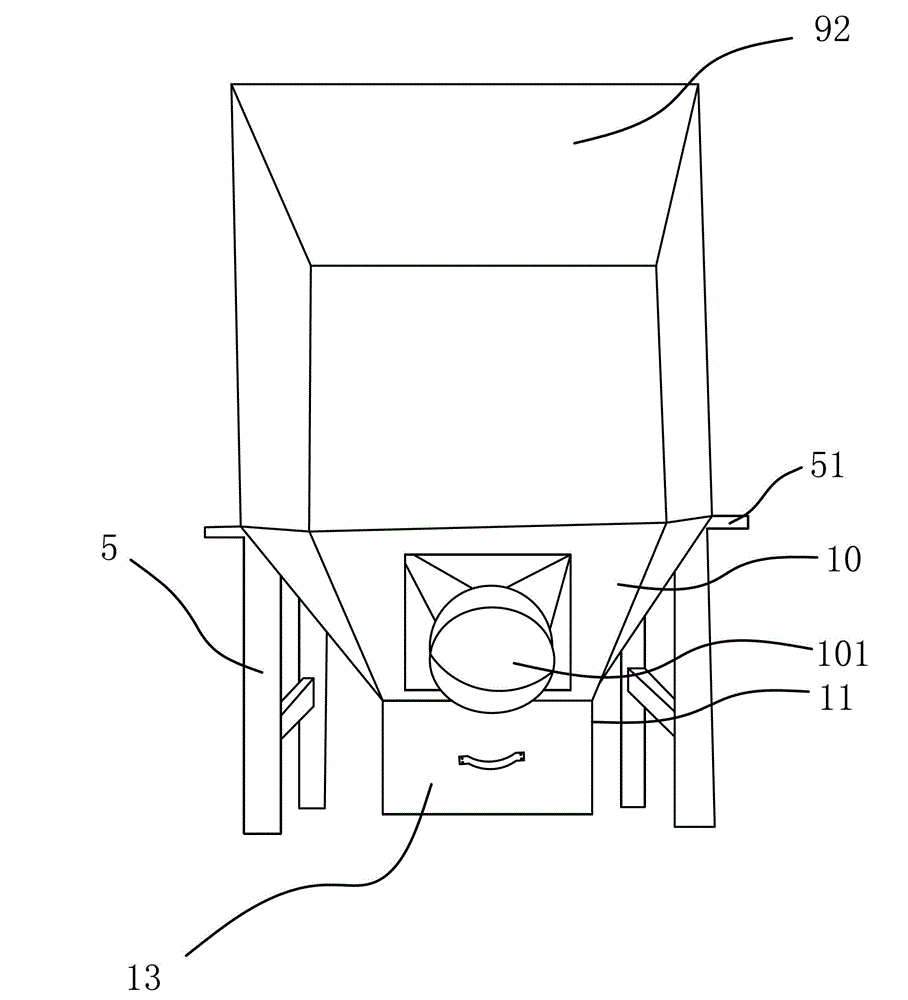

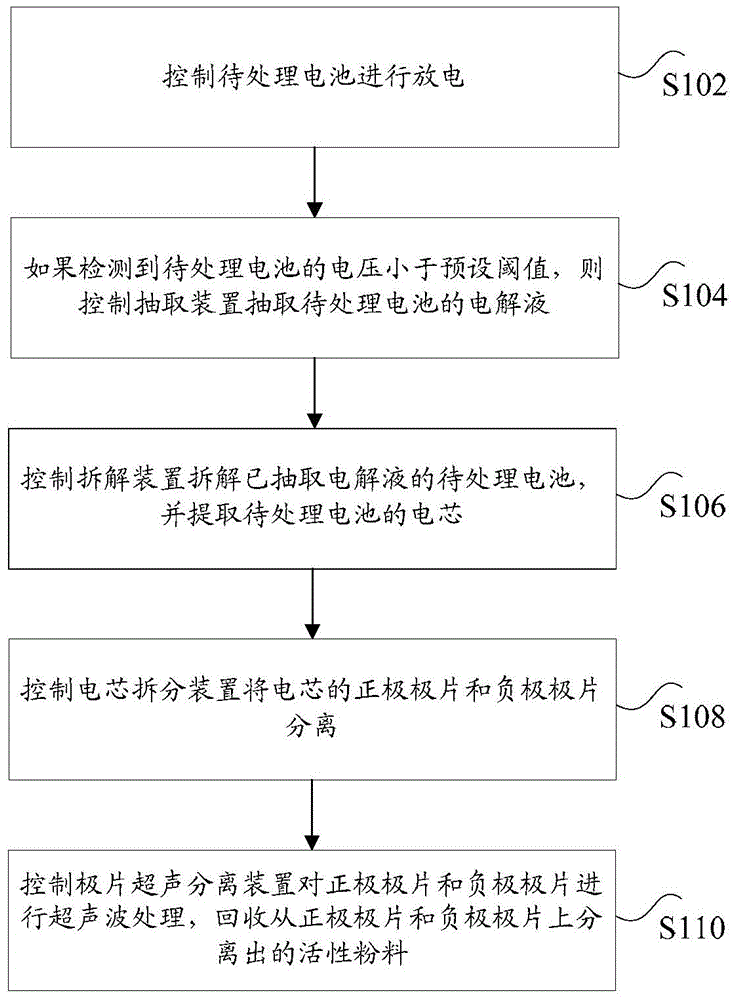

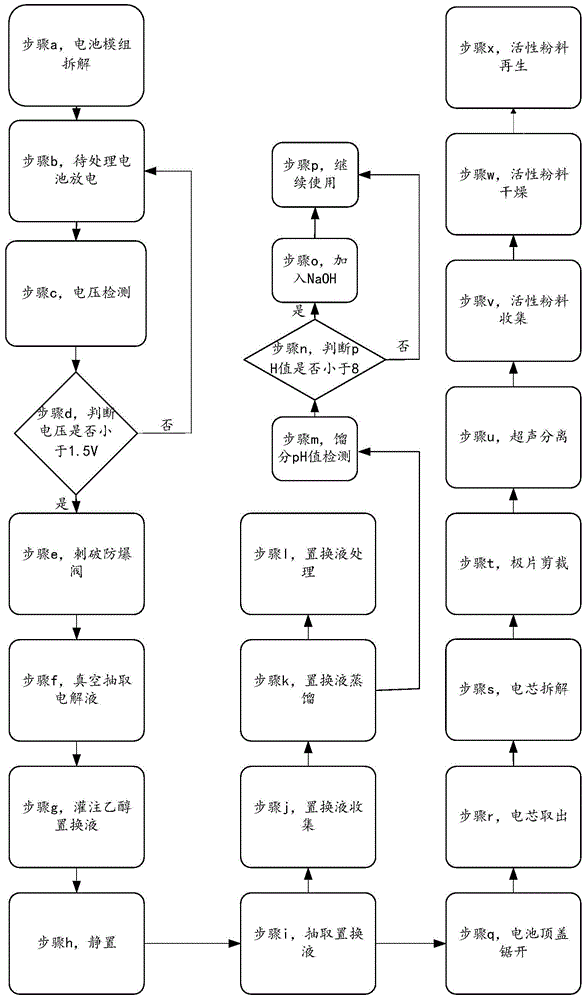

Battery recycling and disposal method and device

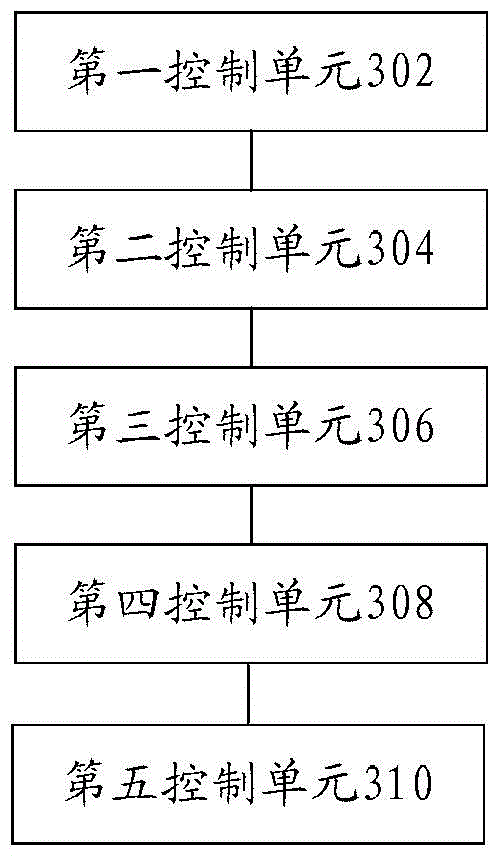

InactiveCN105098284AReach the purpose of recyclingImprove protectionWaste accumulators reclaimingBattery recyclingEngineeringPole piece

The invention discloses a battery recycling and disposal method and device. The method comprises: controlling a to-be-disposed battery to discharge; if detecting that the voltage of the to-be-disposed battery is less than a preset threshold value, controlling an extraction apparatus to extract the electrolyte of the to-be-disposed battery; controlling a disassembling apparatus to disassemble the to-be-disposed battery after extracting the electrolyte, and extracting the core of the to-be-disposed battery; controlling a core separating apparatus to separate the positive electrode pole piece from the negative electrode pole piece of the core; and controlling a pole piece ultrasonic separating device to perform ultrasonic treatment on the positive electrode pole piece and the negative electrode pole piece, and recycling active powder material separated from the positive electrode pole piece and the negative electrode pole piece. The technical problem of over-high resource consumption caused by impossibility in recycling waste lithium ion batteries is solved by the battery recycling and disposal method.

Owner:STATE GRID BEIJING ELECTRIC POWER +1

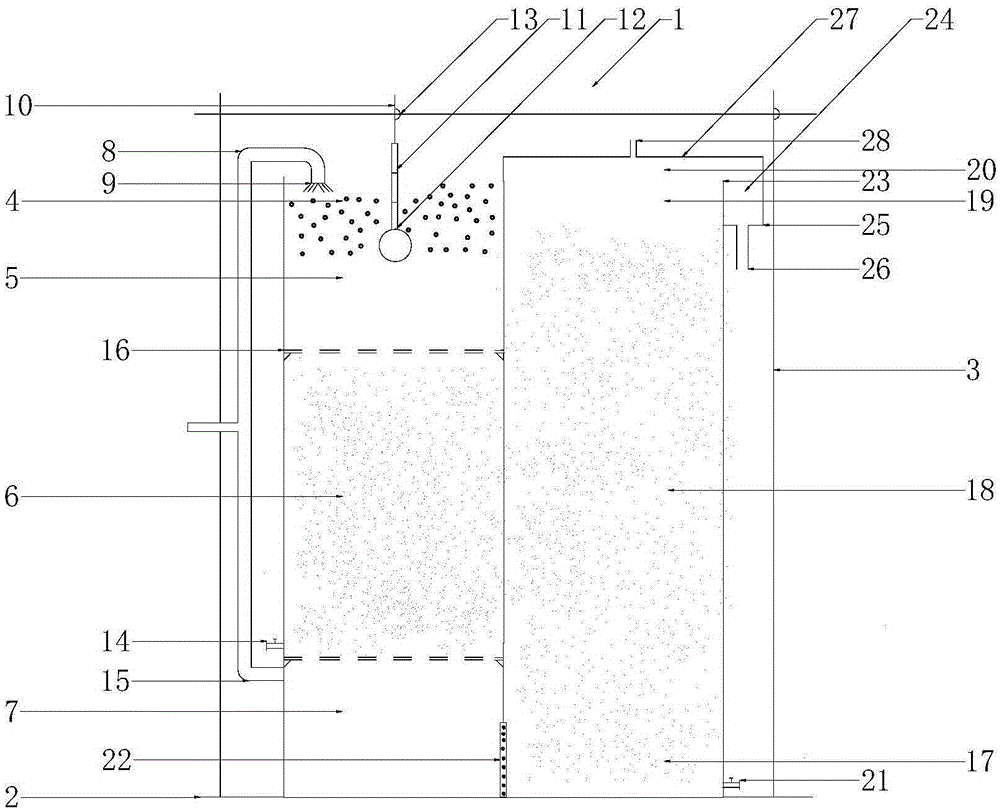

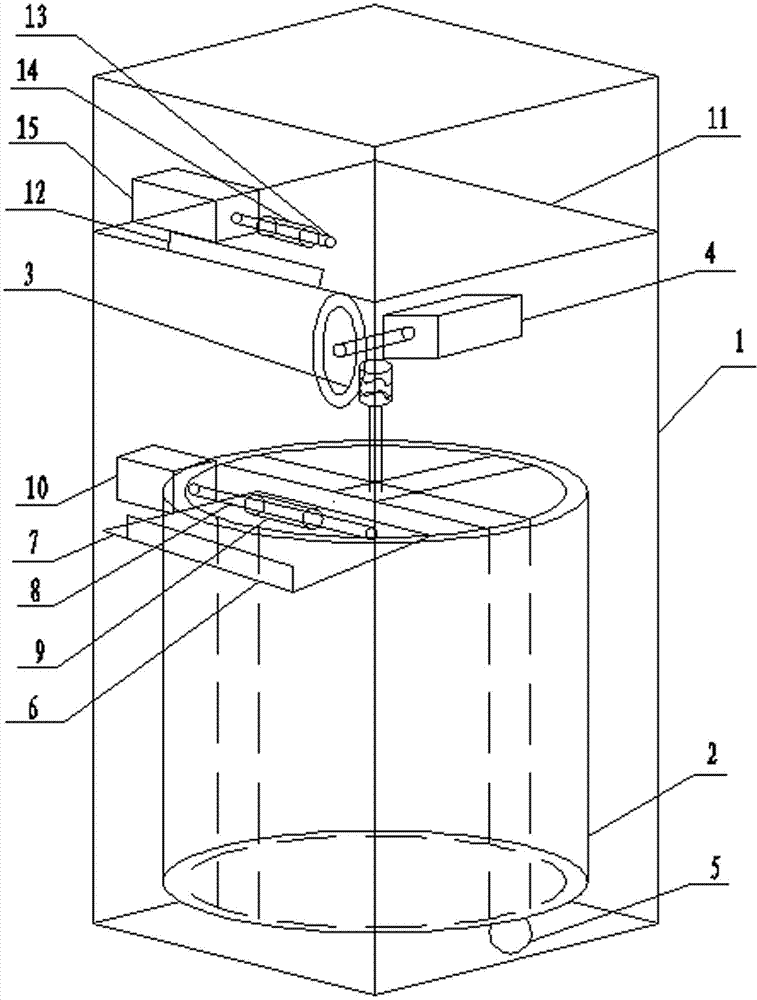

Integration automatic flow type biological nitrogen and sulfur removal reactor

ActiveCN105330023ARealize denitrification and desulfurizationReach the purpose of recyclingWater contaminantsTreatment with aerobic and anaerobic processesCarbon sourceWaste recovery

The invention discloses an integration automatic flow type biological nitrogen and sulfur removal reactor. The reactor comprises a reactor body, a base, a support arranged on the base, a water inlet pipeline and a water outlet pipeline. The reactor body is installed on the base. The water inlet pipeline and the water outlet pipeline are installed on the support. The reactor body is communicated with an outside water source through the water inlet pipeline. An inner cavity of the reactor body is divided into a first cavity body and a second cavity body through a vertical partition plate. The first cavity body is sequentially divided into a primary water inlet area, a short-cut nitrification unit, an anaerobic ammonia oxidation unit and a secondary water inlet mixing area from top to bottom. The second cavity body is sequentially divided into a sulfur elementary substance recovery area, an anaerobic ammonia oxidation coupling sulfur autotrophic denitrification unit, a water outlet area and a gas collecting area from bottom to top. The integration automatic flow type biological nitrogen and sulfur removal reactor has the advantages that nitrogen and sulfur can be removed at the same time, and the occupied area is small; the purpose of waste recovery is achieved while one hundred percent conversion is realized, and the method is efficient and thorough; no extra carbon source is needed; meanwhile, water flow basically depends on gravity, so that power consumption is reduced, and the method is economical and reasonable.

Owner:HANGZHOU NORMAL UNIVERSITY

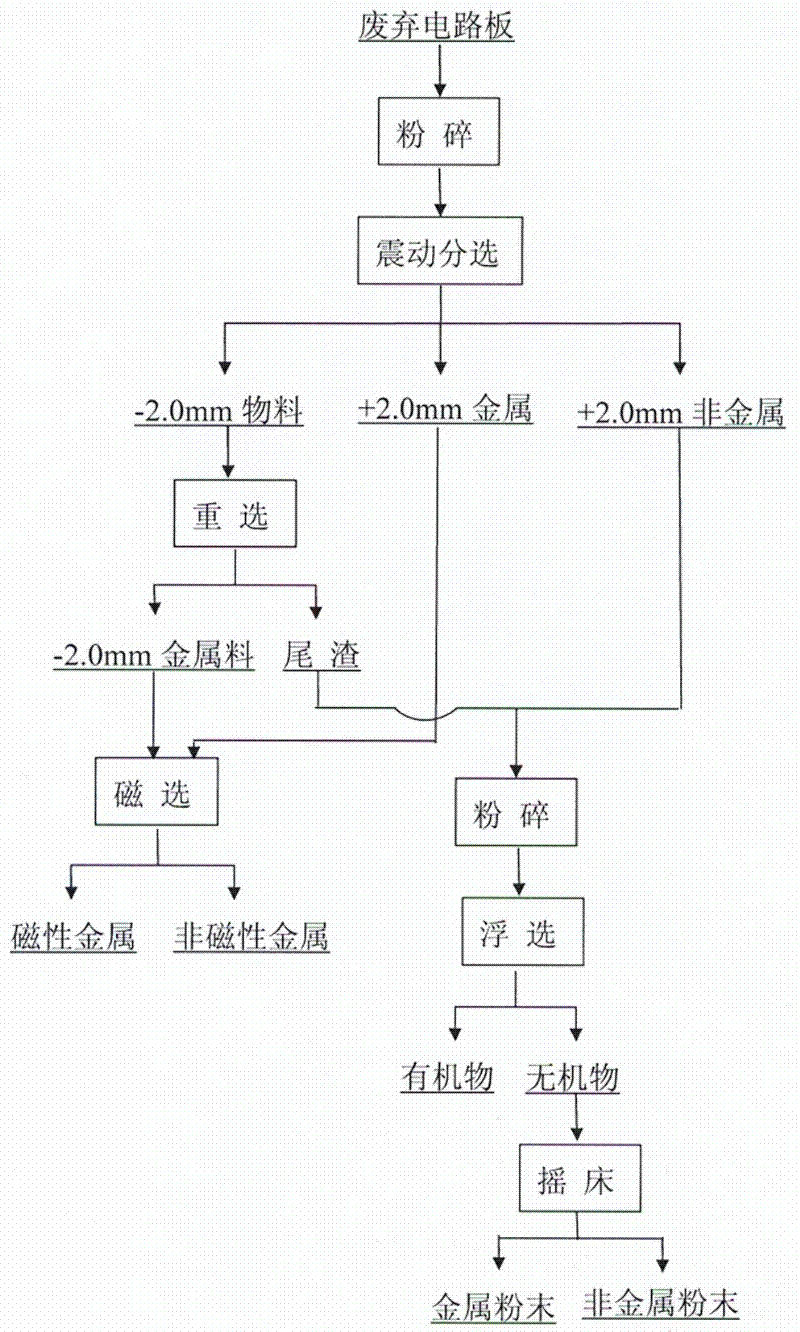

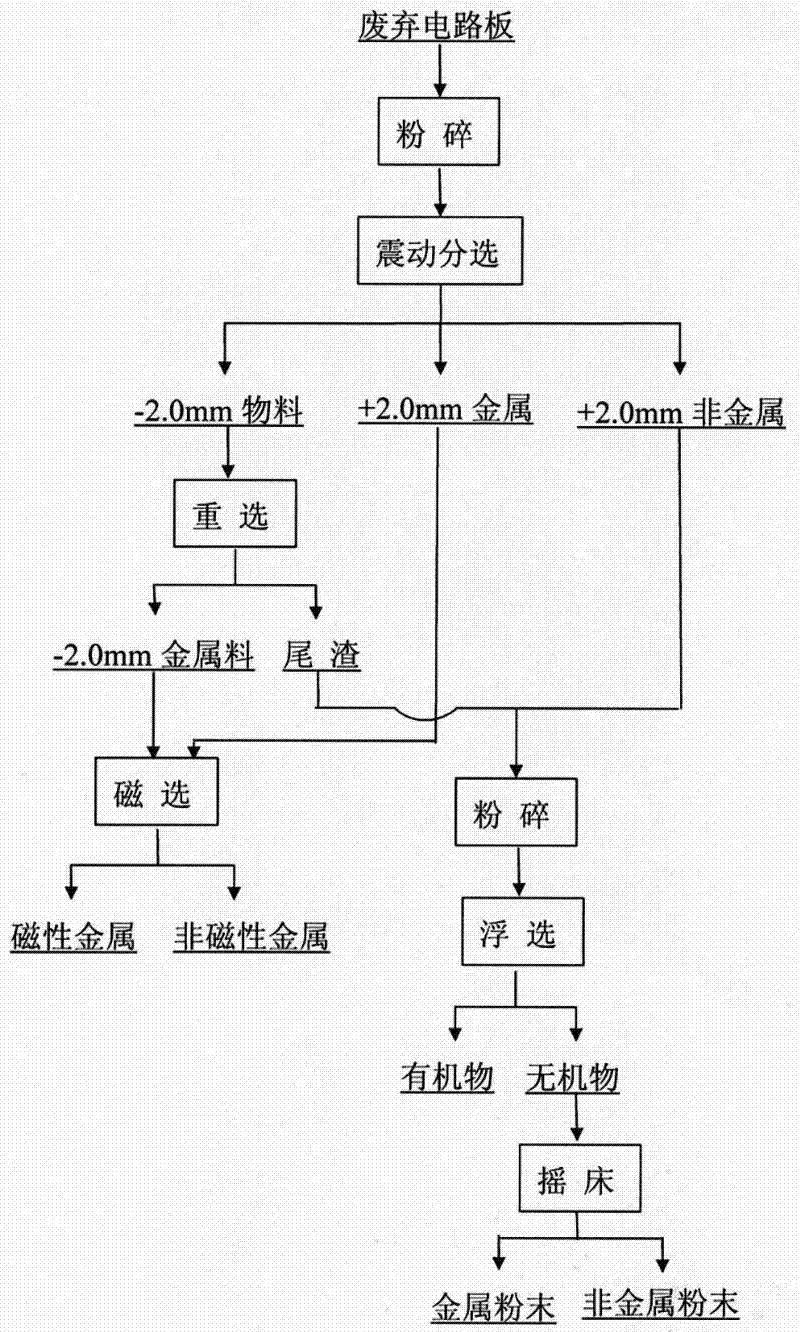

Discarded circuit board full-value recycling method

InactiveCN102172597AReach the purpose of recyclingAchieving Full Value Clean RecyclingSolid waste disposalElectronic waste recyclingRecovery methodOrganic matter

The invention relates to a discarded circuit board full-value recycling method. The method is characterized by comprising the following steps of: smashing a discarded circuit board, vibrating and sorting to obtain a material of minus 2.0mm, metal of plus 2.0mm and nonmetal of plus 2.0mm; sorting the material of minus 2.0mm by virtue of a table concentrator so as to obtain a metal material of minus 2.0mm and tailings; mixing the metal of plus 2.0mm and the metal material, and separating magnetic metal from nonmagnetic metal by wet magnetic separation; smashing the mixed nonmetal of plus 2.0mm and tailings until the particle size is less than 0.1mm, and under the condition of a neutral medium, carrying out flotation to separate organic matters and inorganic matters by adopting an octadecylamine collector; and sorting the inorganic matters by virtue of the table concentrator to obtain metal powder and nonmetal powder. The method provided by the invention is a high-efficiency, economic and clean discarded circuit board full-value recycling method and is applicable to recycling of electronic circuit boards of various electronic parts and components.

Owner:广东省资源综合利用研究所

Device and process for recycling and treating hydrogen sulfide-containing chemical acid waste gas

InactiveCN103301732BReach the purpose of recyclingDispersed particle separationEnergy inputCold airFlue gas

The invention belongs to the technical field of chemical waste gas treatment, and mainly relates to a device and a process for recycling and treating hydrogen sulfide-containing chemical acid waste gas. The process for recycling and treating hydrogen sulfide-containing chemical acid waste gas comprises the following steps of: igniting and completely burning the hydrogen sulfide-containing chemical acid waste gas into sulfur dioxide-rich high-temperature flue gas, recycling much heat and adjusting the temperature of the flue gas by cold air, and enabling the flue gas to enter an adsorption tower; completely absorbing the sulfur dioxide in the flue gas by utilizing an alkaline solution, removing less alkaline solution and sulfite contained in the flue gas absorbed by the alkaline solution, and exhausting the demisted pure flue gas to the atmosphere. The sulfite, which is generated by absorbing sulfur dioxide by the alkaline solution, is oxidized, concentrated, crystallized and dried to obtain side product sulfate.

Owner:义马煤业集团煤生化高科技工程有限公司 +1

Coal ash biological filter material and preparation method of coal ash biological filter material

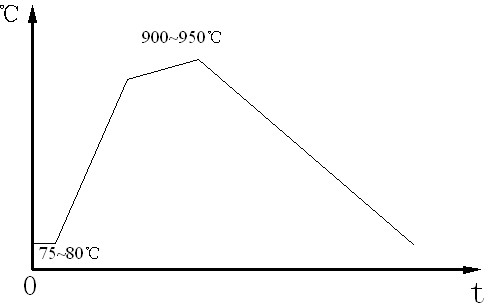

ActiveCN102603359AHigh activityHigh strengthSolid waste disposalCeramicwareBiological filterProcess engineering

The invention discloses a coal ash biological filter material and a preparation method of the coal ash biological filter material. The coal ash biological filter material comprises the following ingredients in percentage by mass: 86 percent to 95 percent of coal ash, 3 percent to 10 percent of lutaceous coal gangue, 0.5 percent to 10 percent of bonding agents and 1 percent to 3 percent of expanding agents. The preparation method of the coal ash biological filter material disclosed by the invention comprises the following steps that: 1) the coal ash is crushed and finely ground, and then, the coal ash, the lutaceous coal gangue, the bonding agents and the expanding agents are proportionally metered and mixed; 2) water is added into the mixture and stirring is carried out until the mixture is uniform, cores and balls are formed, and raw material balls are formed; 3) the raw material balls are fed into sintering equipment to be sintered, and the coal ash biological filter material is prepared. The bonding agents and the expanding agents are added, the coal ash activity is ffulfilled and enhanced, the filter material intensity is enhanced, the specific surface area of the filter material is high, the porosity is high, in addition, the raw materials are all solid wastes, the goal of waste recovery and utilization is reached, and the preparation cost of the filter material is low.

Owner:范峪铭

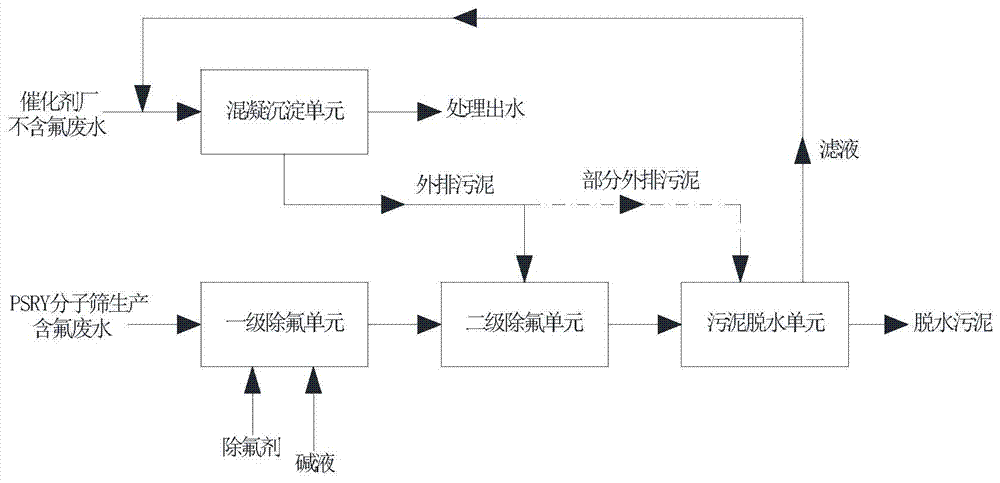

A treating method of fluorine-containing waste water

InactiveCN104512973AReduce dosageAvoid the impact of the defluoridation processWater contaminantsMultistage water/sewage treatmentWater solubleFluorine containing

A treating method of fluorine-containing waste water is disclosed. The fluorine-containing waste water comprises F-, SO4<2-> and Al<3+>. The method includes: bringing the fluorine-containing waste water and a water-soluble aluminum-source fluorine removing agent into contact and adjusting the pH value of the fluorine-containing waste water to be not lower than 5 to perform neutralization and sedimentation reactions; bringing the fluorine-containing waste water after the neutralization and sedimentation reactions and discharged sludge from a coagulating sedimentation treating unit of waste water free of fluorine into contact; and subjecting the obtained mixture to sludge dehydration to obtain dehydrated sludge and filtrate. The method can perform effective fluorine removal treatment for the fluorine-containing waste water having high contents of the F-, the SO4<2-> and the Al<3+>.

Owner:CHINA PETROLEUM & CHEM CORP +1

Concrete product prepared from stone sludge waste residues and preparation method thereof

The invention discloses a concrete product prepared from stone sludge waste residues and a preparation method thereof. The concrete product is prepared from the following raw materials in percentage by mass: 50 to 62.5 percent of fine aggregate sludge with moisture content of 5 to 20 percent, 8 to 28 percent of cement, 0.1 to 0.3 percent of fibers for constructional engineering, 13 to 20 percent of stone waste residues with grain diameter of less than 1 centimeter, 0.3 to 0.7 percent of masonry mortar plasticizer, 0.5 to 2 percent of intensifier, 3 to 5 percent of accelerating agent and 5 to 7 percent of sand or 0.5 to 1.5 percent of modifier. By the method, the concrete product with the economic benefit can be prepared from the stone sludge waste residues, the problem of pollution discharging in industry of stone sludge and residues is solved effectively, the aim of recycling wastes is fulfilled, precious occupied earth resources for stacking the stone sludge and the residues are reduced and even eliminated and resources and funds are saved.

Owner:YUNFU ASIA STONE MACHINERY

Porous inorganic ceramic membrane-graphene-TiO2 photocatalyst composite material and its preparation method

ActiveCN102728339AReach the purpose of recyclingLarge specific surface areaWater/sewage treatment by irradiationWater contaminantsSlagCoal

The invention discloses a porous inorganic ceramic membrane-graphene-TiO2 photocatalyst composite material and its preparation method, which belongs to the photocatalysis material filed. According to the present invention, coal slag in thermal power plants is taken as a raw material to a prepare the porous inorganic ceramic membrane carrier for raw materials preparation of porous inorganic ceramic membrane carrier, a grapheme and TiO2 complex is loaded on the surface of the carrier to obtain the porous inorganic ceramic membrane-aphene-TiO2 photocatalyst composite. In the composite material, the mass percentage of carrier to the graphene-TiO2 composite is 50% to 80% and 20% to 50%; in graphene-TiO2 composite, the mass percentage of grapheme to TiO2 is3% to 5% and 95% to 97% respectively; a porous structure expressed by the carrier can promote the surface mass transfer process and accelerate the adsorption reaction of the surface, its great specific surface area is capable of increasing the conversion rate of the organic substrate; graphene has a high specific surface area, high mechanical strength and unique electronic transport properties, and can improve material catalytic performance; the active component of the composite material is stable, and the synergistic catalytic properties of multi-components can be possessed.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

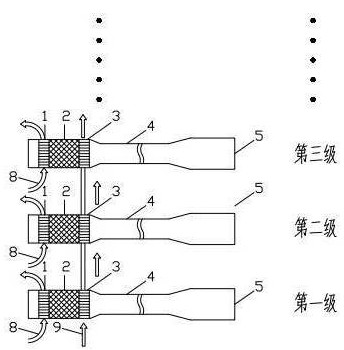

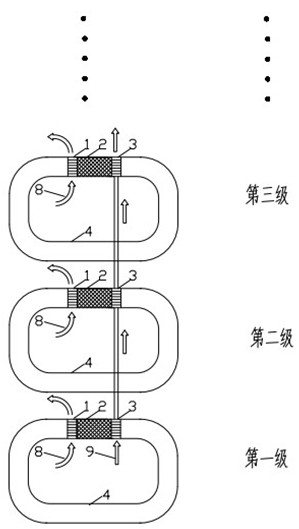

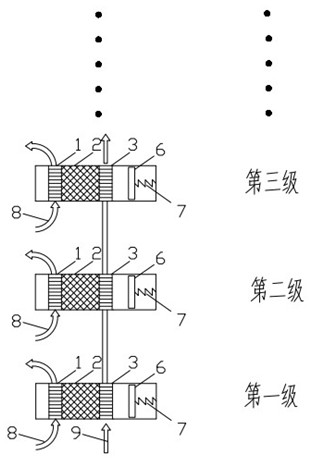

Thermoacoustic system capable of gradually recovering LNG (liquefied natural gas) cold energy

InactiveCN102536711AIncrease profitLow costMachines/enginesMechanical power devicesThermal energyMechanical energy

The invention discloses a thermoacoustic system capable of gradually recovering the LNG (liquefied natural gas) cold energy, which comprises a plurality of thermoacoustic engines, a low-grade heat energy supply system and an LNG cold energy supply system. The thermoacoustic engines are standing wave thermoacoustic engines, pure travelling wave thermoacoustic engines or piston phase-modulation thermoacoustic engines. The LNG cold energy supply system is connected with cold end heat exchangers of the thermoacoustic engines sequentially through pipelines, and the low-grade heat energy supply system is connected with hot end heat exchangers of the thermoacoustic engines through pipelines respectively. The temperature grade is built in a heat regenerator, the thermoacoustic effect is utilized to generate pressure fluctuation, the cold energy is transferred to the mechanical energy for outputting, and the high efficiency recovering of the cold energy is realized. Compared with the conventional LNG cold energy recovering manner, the multi-grade thermoacoustic system provided by the invention has a simple structure, eliminates mechanical moving parts, is low in cost and reliable in running, and adopts the multi-grade arrangement for recovering the LNG cold energy with a high cold energy recovering and utilizing rate.

Owner:ZHEJIANG UNIV

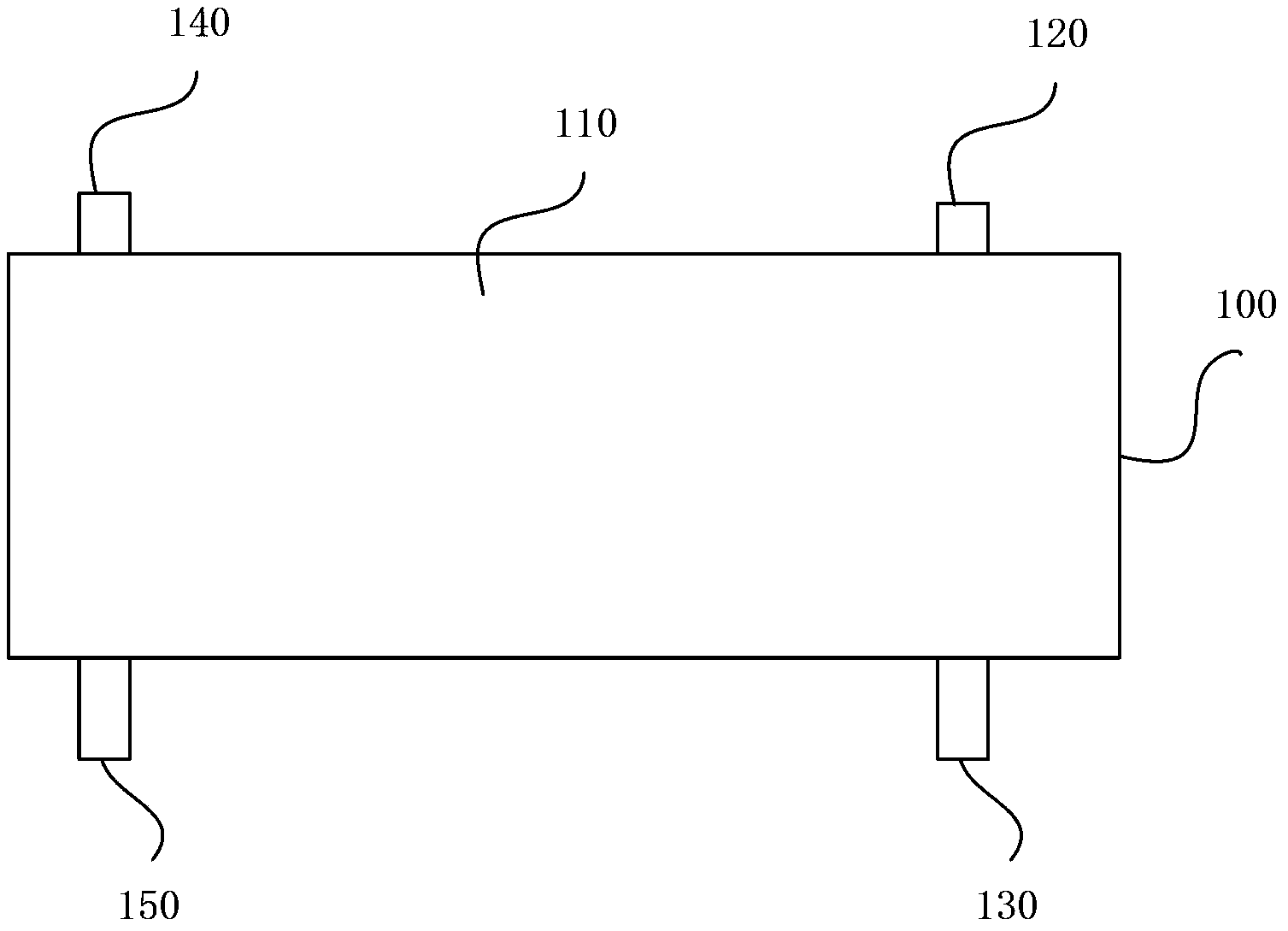

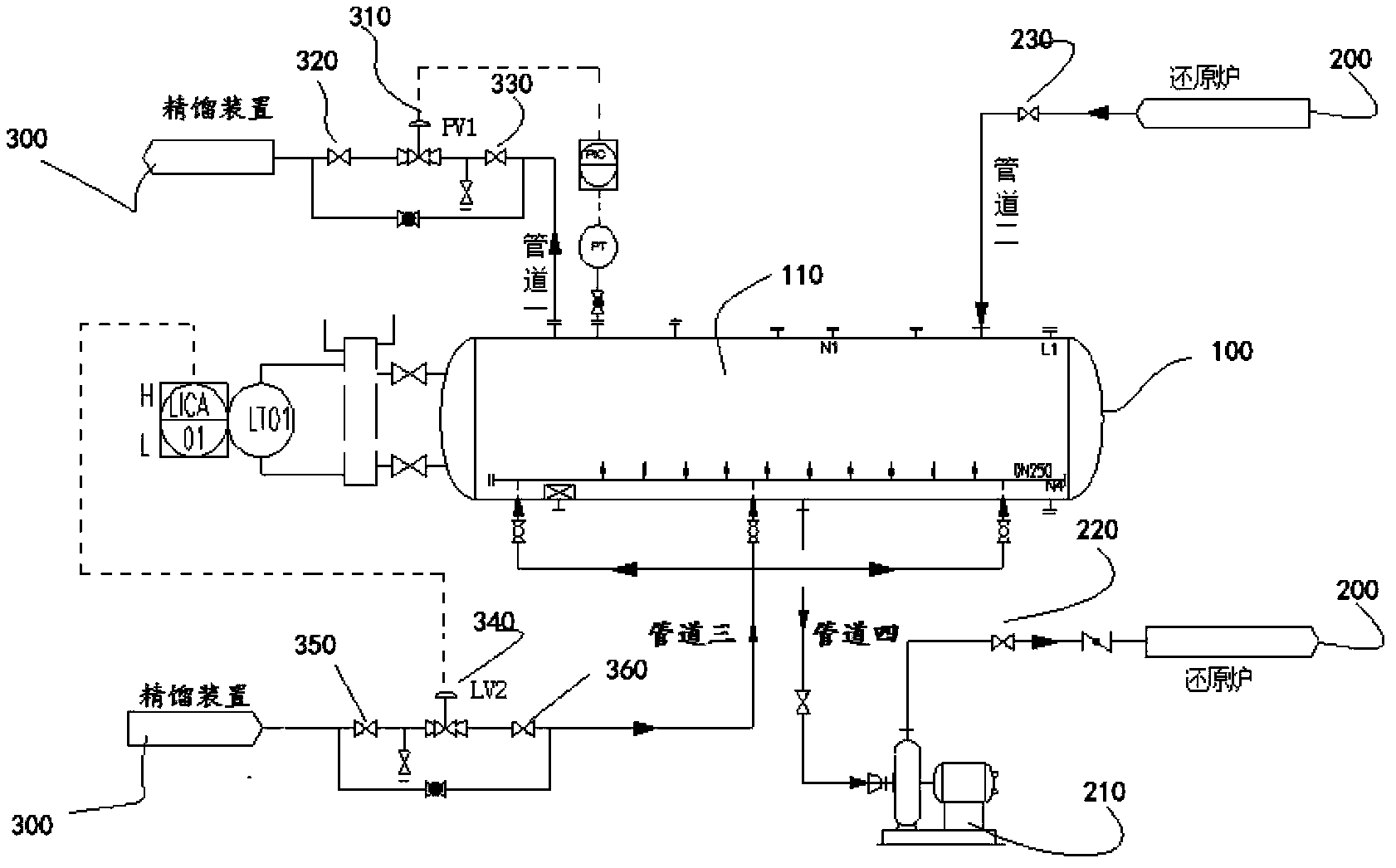

High-temperature water-circulation flash-evaporation integrated tank and system for producing polycrystalline silicon

ActiveCN103408017AAchieve flashReach the purpose of recyclingSilicon compoundsWater circulationPolycrystalline silicon

The invention provides a high-temperature water-circulation flash-evaporation integrated tank and a system for preparing polycrystalline silicon. The high-temperature water-circulation flash-evaporation integrated tank comprises a tank body, a high-temperature water inlet, a cooling water outlet, a flash-evaporation vapor outlet and a vapor condensed liquid inlet, wherein flash-evaporation space is limited in the tank body and used for carrying out flash-evaporation cooling on the high-temperature water in the flash-evaporation space; the high-temperature water inlet is formed in the tank body and suitable for being connected with a reduction furnace; the cooling water outlet is formed in the tank body and suitable for being connected with the reduction furnace; the flash-evaporation vapor outlet is formed in the tank body and is suitable for being connected with a rectification device; the vapor condensed liquid inlet is formed in the tank body and suitable for being connected with the rectification device. The high-temperature water-circulation and flash-evaporation integrated tank can be used for realizing the integrated treatment of high-temperature water circulation and flash evaporation.

Owner:云南冶金云芯硅材股份有限公司

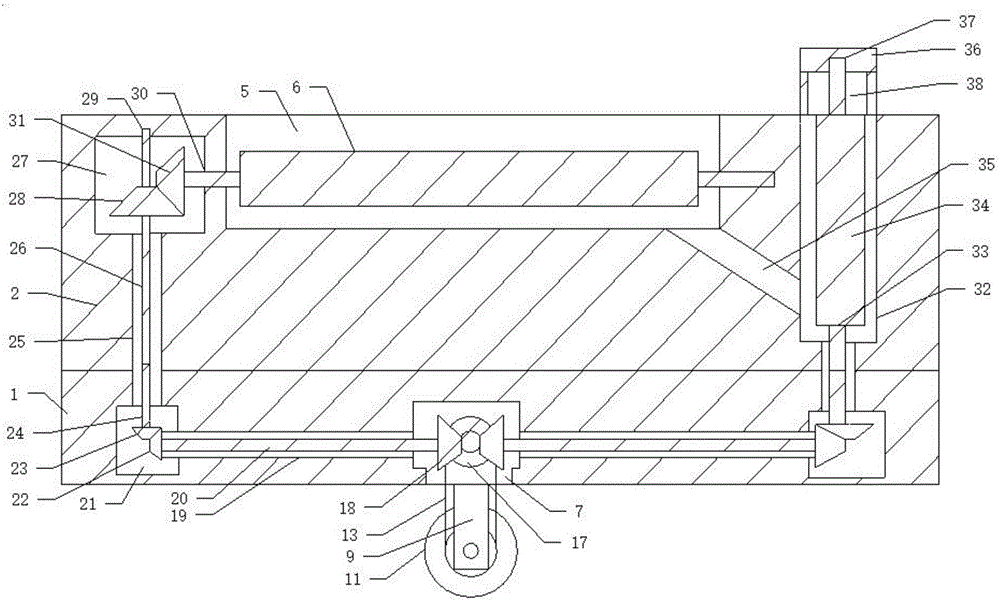

Pebble falling preventing compartment of building gravel carrier vehicle

ActiveCN106564414AAvoid harmGuarantee the safety of lifeLoading/unloading vehicle arrangmentItem transportation vehiclesBevel gear

The invention discloses a pebble falling preventing compartment of a building gravel carrier vehicle. The pebble falling preventing compartment of the building gravel carrier vehicle comprises a bottom plate; the two sides of the bottom plate are each provided with a rotational driving rotation wheel; the driving rotation wheels are correspondingly connected with tires on the two sides; compartment side plates on the two sides are each provided with a U-shaped compartment top groove; each compartment top groove is internally provided with a rotational first conveying disk; the end portions of sixth rotating shafts are each connected with a sixth bevel gear; the compartment side plates on the two sides are each provided with a conveying groove correspondingly communicated with the corresponding compartment top groove; a rotational second conveying disk is arranged in each conveying groove, and the rotational second conveying disks can be correspondingly connected with the tires by means of the driving rotation wheels in the rotating process of the tires, and therefore the first conveying disks can be further driven to rotate, gravel falling into the compartment top grooves can be further conveyed, and can be further conveyed into the conveying grooves, and it is further prevented that the gravel falls onto the driving vehicle, and consequently threats on the life safety of a driver are caused.

Owner:FUJIAN YONGTAI CONSTR ENG CO

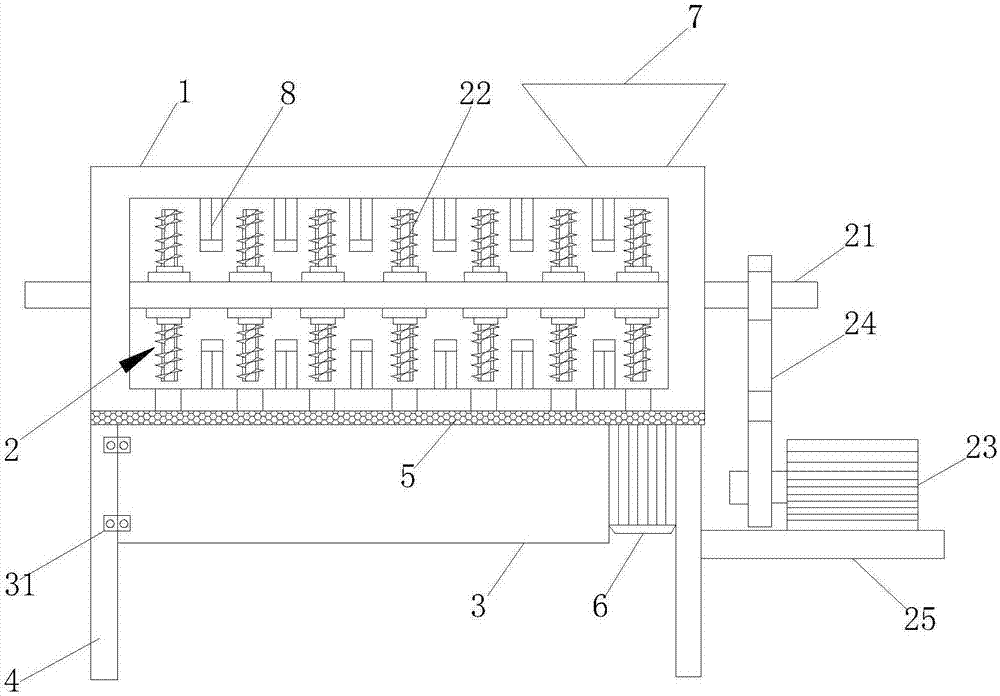

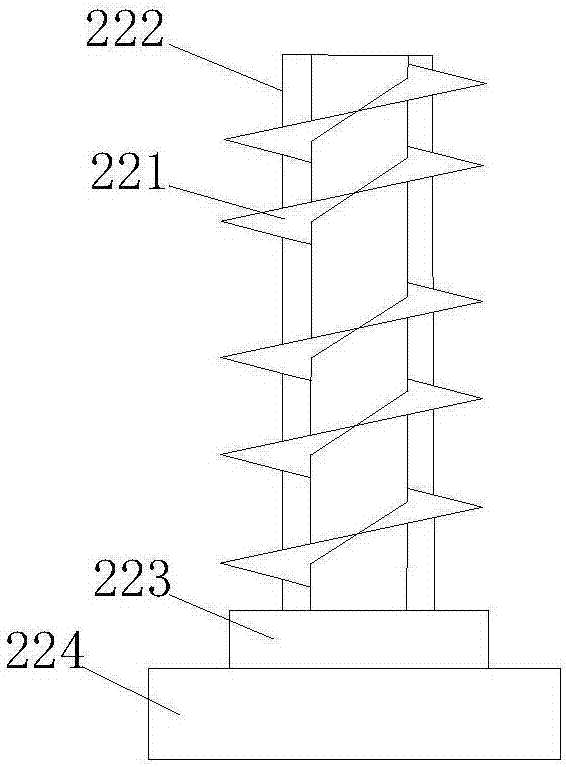

Smashing recycling technology and device for rock wool waste

ActiveCN106862248ASolve pollutionReach the purpose of recyclingSievingScreeningAdhesiveEnvironmental engineering

The invention discloses a smashing recycling technology and device for rock wool waste. The device comprises a stirring bucket shell of an integrated structure, a machining assembly for synchronous drive of two dimensions, and a feed-back bucket for collecting smashed rock wool waste. Ball-shaped rock wool waste is collected in a concentrated mode, and chopped through the machining assembly inside the recycling device in a stirring way of two dimensions, powdery rock wool waste is screened through a vibration screen, fine grains of extraneous residual powder comprising coke powder and dried biomass rock wool are matched through a certain proportion and cured by adding a sodium silicate adhesive, accordingly, rock wool waste is recycled, the environmental pollution problem caused by direct rock wool waste backfilling is avoided, meanwhile, the purpose of resource recycling is further achieved, and energy is saved.

Owner:马鞍山市北益环保科技有限责任公司

Technology for recovering lead, zinc, carbon, silver and iron from zinc smelting leaching residues

InactiveCN108531740AAchieve recyclingReach the purpose of recyclingProcess efficiency improvementHydrometallurgyZinc smelting

The invention discloses a technology for recovering lead, zinc, carbon, silver and iron from zinc smelting leaching residues, and belongs to the technical field of hydrometallurgy and mineral processing. The technology comprises the following steps of recovering the lead and the zinc; carrying out water quenching on kiln slags; carrying out carbon concentration on the kiln slags; carrying out silver concentration on the kiln slags; and carrying out iron concentration on the kiln slags. According to the technology, the valuable elements in the leaching residues can be comprehensively recoveredto the maximum extent, hazardous waste can be converted into general waste, a high-temperature reduction (volatilization) roasting metallurgical process and a flotation and magnetic separation beneficiation process are mainly adopted, a rotary kiln is applied to carry out the high-temperature reduction (volatilization) roasting metallurgical process, so that the components of the lead and the zinccan be recovered from the leaching residues, the kiln slags of the rotary kiln is ground to a certain fineness, then the flotation and magnetic separation beneficiation process is adopted, so that coke, silver-contained minerals and iron minerals in the slags can be recovered, and tailings with the valuable components recovered mainly contain nonmetallic minerals such as silicate and can serve asingredient for cement production for sale, so that harmless treatment of the tailings can be realized.

Owner:JIANGXI UNIV OF SCI & TECH +1

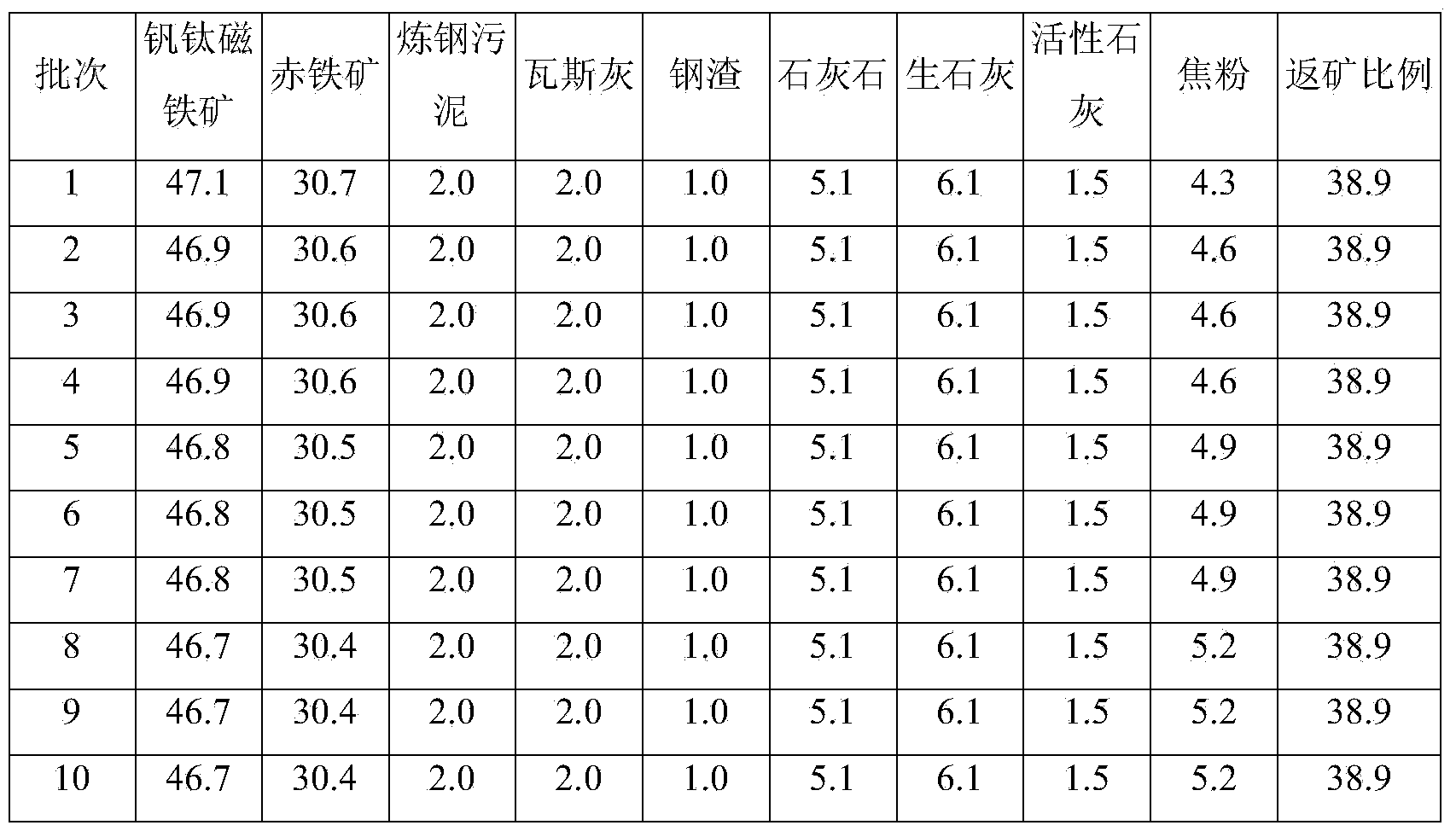

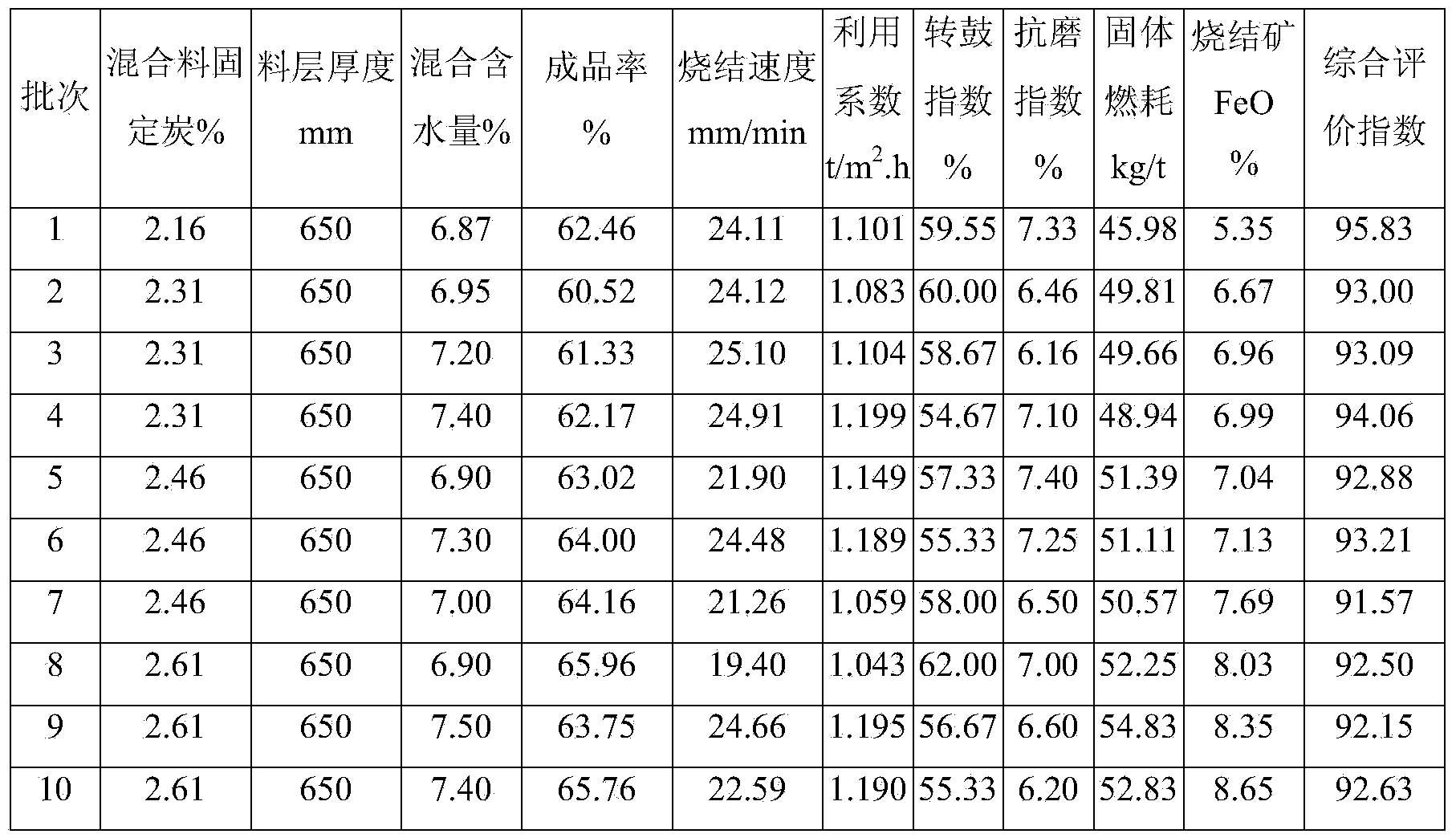

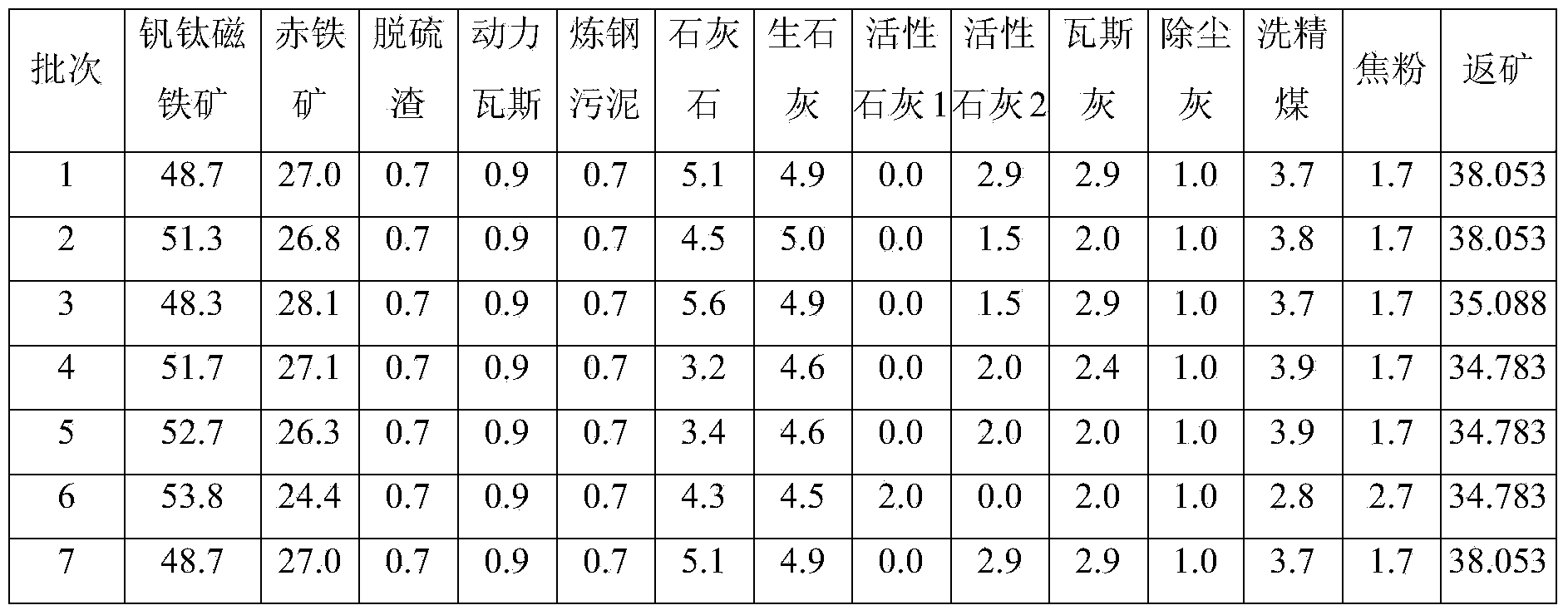

Iron ore low-carbon sintering method

ActiveCN104313308AIncrease incomeReduce the amount of carbonProcess efficiency improvementIronstoneMagnetite

The invention belongs to the field of steel smelting, and particularly relates to an iron ore low-carbon sintering method which is low in sintering energy consumption. According to the technical scheme, the iron ore low-carbon sintering method includes the steps that iron ore, fuel and a fluxing agent are distributed and mixed to form a mixture for sintering, wherein magnetite in the iron ore is not smaller than 50% by mass, non-magnetite m1 is greater than 0 but smaller than or equal to 40%, metallurgy waste m2 is greater than or equal to 0 but smaller than or equal to 10%, the non-magnetite is at least one of hematite, limonite and siderite, and the metallurgy waste is iron waste mainly composed of Fe and FeO. According to the method, raw material constitutes of the mixture and technical parameters are adjusted, so that non-carbon heat input is increased, carbon content is reduced, and sintering energy consumption is reduced.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

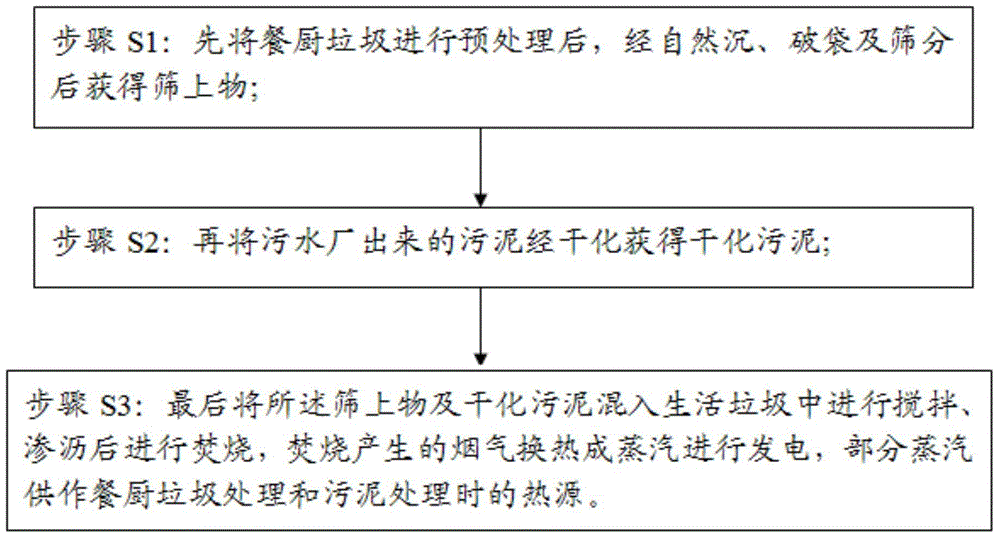

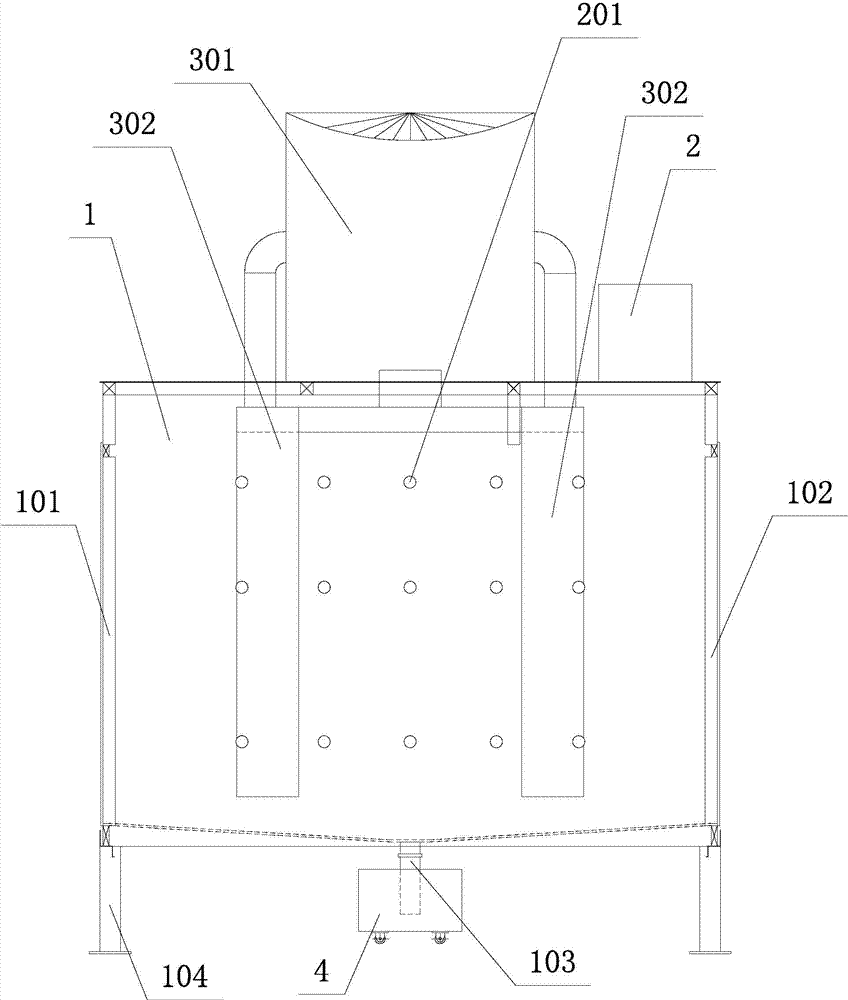

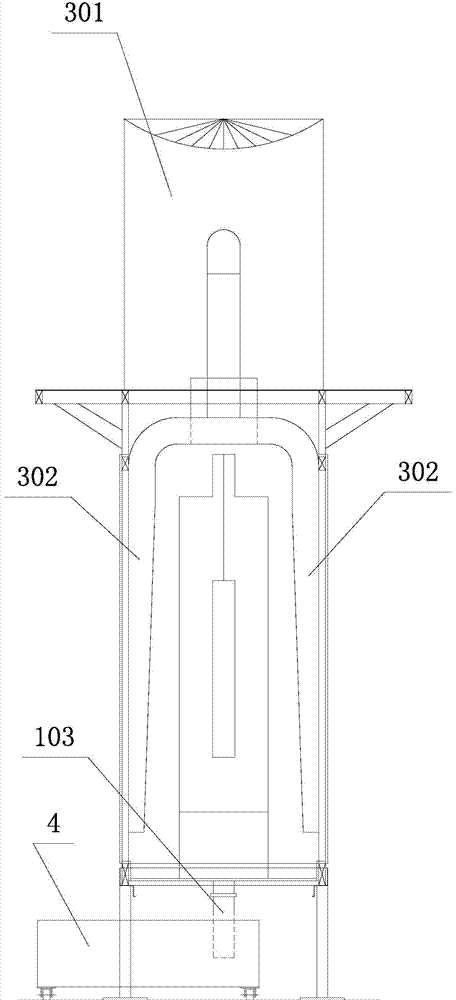

Method for co-processing municipal solid wastes

ActiveCN104668270AReach the purpose of recyclingAchieve recyclingSolid waste disposalCombustionSludge

The invention discloses a method for co-processing municipal solid wastes. The method comprises the following steps: pretreating kitchen wastes, performing natural bag settling and breaking, screening, thereby obtaining the oversize product; drying the sludge discharged from a sewage plant, thereby obtaining the dried sludge; and finally, mixing the oversize product and the dried sludge into household garbage for stirring, infiltrating and combusting, performing heat exchange on the flue gas generated by combustion so as to form steam for generating power, and taking one part of steam as a heat source in the process of treating the kitchen wastes and sludge. According to the method for co-processing municipal solid wastes provided by the invention, the oversize product of the kitchen wastes can be doped into the household garbage, the dried sludge is subjected to incineration disposal, the multiple municipal solid wastes are integrally co-processed, and the aim of recycling the resources is achieved due to reasonable flue gas utilization, so that the energy, materials and water resources are recycled in the process of treating the municipal solid wastes, and secondary pollution can be effectively avoided.

Owner:SHOUGANG ENVIRONMENTAL IND

Method for PEG abduction cloud point abstraction and organic compound inverse abstraction

InactiveCN101269275AOvercome separation difficultiesAchieve separationLiquid solutions solvent extractionWater in oilDistribution system

The invention discloses a method of PEG-induced cloud point extracting and back extracting organic compound in the chemical engineering technology field, which uses the property that polyethyleneglycol induces hydrophilic surfactant to form two-phase distribution system at room temperature to achieve the extraction of organic compound, and causes the organic compound to be concentrated in the concentrated surfactant phase of the cloud point system. Since the PEG is hydrophilic and is distributed in the superfluous water phase, Winsor 2 micro-emulsion is used to remove the small amount of PEG in the concentrated surfactant phase, the surfactant and the organic compound are obtained after the water-in-oil phase in Winsor 2 micro-emulsion is further vaporized. Winsor 1 micro-emulsion is used for separating the surfactant from the organic compound, then the surfactant in the concentrated surfactant phase in the cloud point system is separated from involatile organic compound, and the surfactant can be recovered.

Owner:SHANGHAI JIAO TONG UNIV

Electrostatic spray coating system

InactiveCN104759368AAvoid runningPrevent overflowLiquid spraying plantsLiquid surface applicatorsSpray nozzleSpray coating

The invention provides an electrostatic spray coating system. The electrostatic spray coating system comprises a working shed, a spray coating system, an electrostatic generator, a recovery system and a carrying device; a spray coating chamber is formed in the working shed, and a feeding hole and a discharge hole are formed in the two sides; the spray coating system comprises an atomizing box; the inlet end of the atomizing box is connected with a liquid inlet pipe, while the outlet end of the atomizing box is connected with a nozzle in the spray coating chamber; the electrostatic generator is located at the outlet end of the nozzle; the recovery system comprises a recovery box and an exhaust tube; an exhaust fan is arranged on the exhaust tube, and the outlet end of the exhaust tube is communicated with the recovery box; the carrying device is located in the spray coating cavity and grounded. The electrostatic spray coating system is capable of realizing quick and even coating, high in coating quality, high in raw material utilization rate, environmental friendly and pollution-free.

Owner:互美方向(江苏)环保科技有限公司

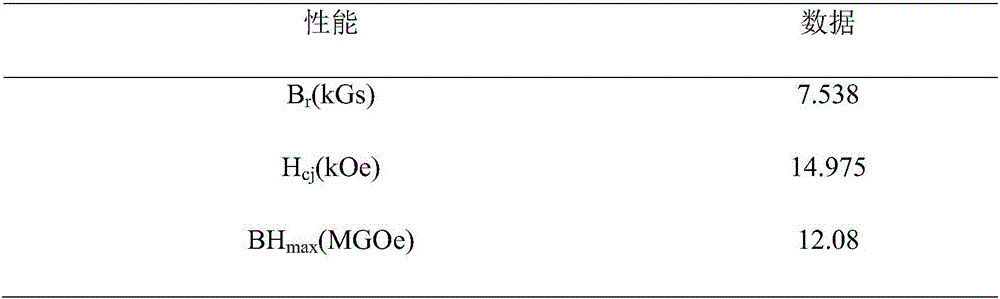

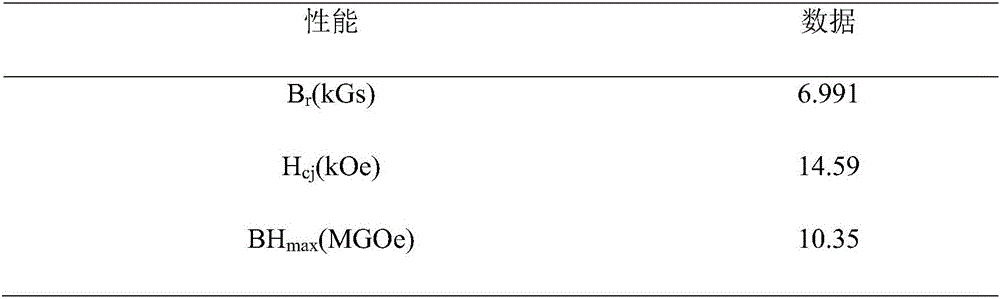

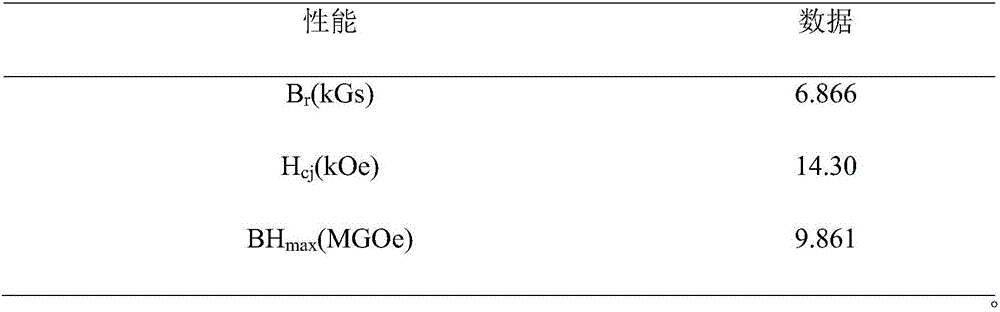

Recycling and reusing method for waste HDDR bonded neodymium iron boron permanent magnets

ActiveCN106001541ALow costReach the purpose of recyclingTransportation and packagingMetal-working apparatusWater bathsMaterials preparation

The invention provides a recycling and reusing method for waste HDDR bonded neodymium iron boron permanent magnets and belongs to the technical field of material preparation methods. The recycling and reusing method for the waste HDDR bonded neodymium iron boron permanent magnets is short in technological process, low in cost and capable of facilitating industrialization. According to the technical scheme, the similarity and intermiscibility theory, after the waste HDDR bonded neodymium iron boron permanent magnets are subjected to swelling in a mixed solvent for a period of time, swelled epoxy resin on the surfaces of HDDR magnetic powder is stripped off through water bath stirring and ultrasonic cleaning methods so as to recycle the magnetic powder; the recycled magnetic powder and magnetic powder sold on the market are mixed in proportion and used for preparing HDDR bonded neodymium iron boron permanent magnets. By means of the method, epoxy resin bonding agents on the surfaces of magnetic powder can be effectively removed without damaging the properties of magnetic powder, so that the properties of original magnetic powder and magnets are maintained for recycled magnetic powder and prepared magnets to the maximum extent.

Owner:BEIJING UNIV OF TECH

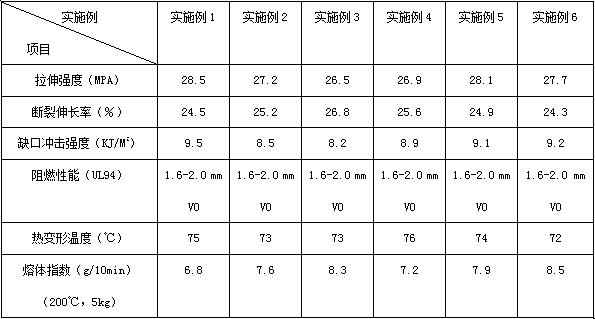

Halogen-free flame retardant HIPS (High Impact Polystyrene) plastic modified material and preparation method thereof

ActiveCN103242614AImprove flame retardant performanceImprove securityPlastic materialsUltimate tensile strength

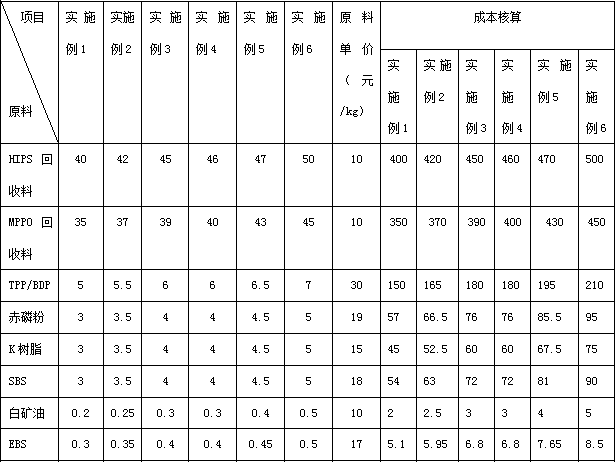

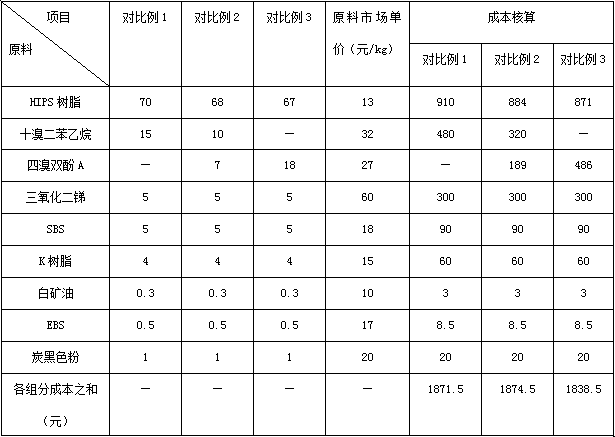

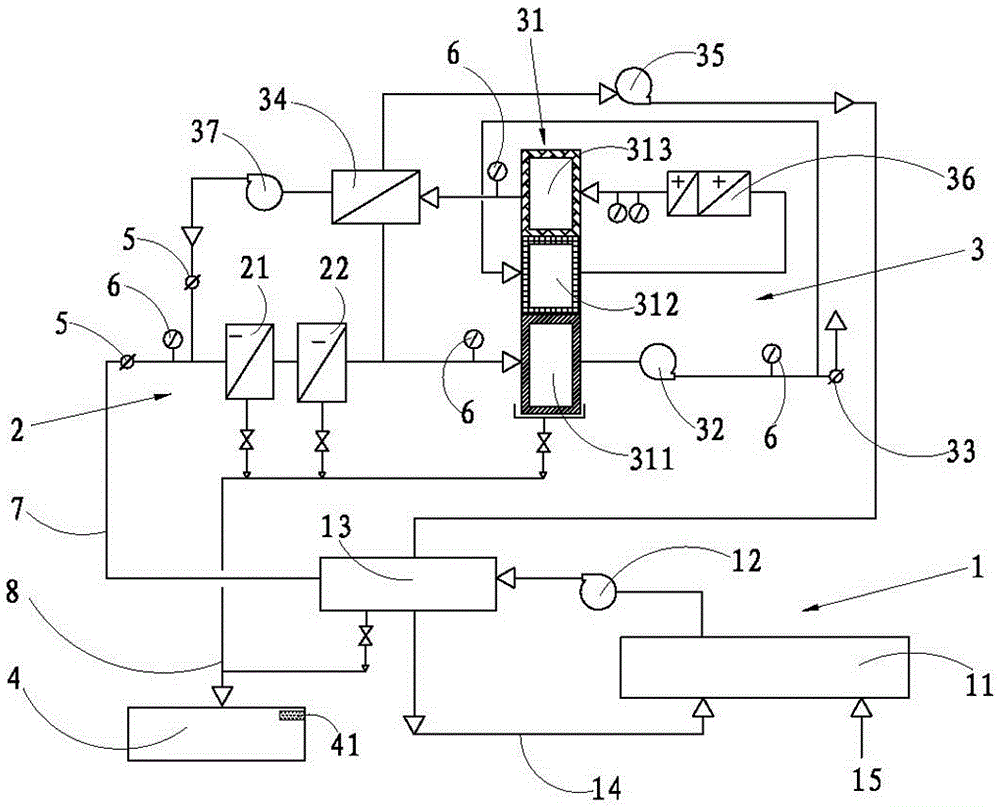

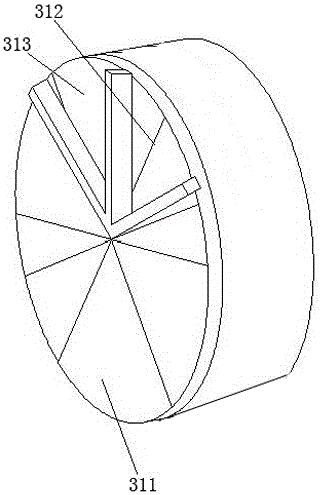

The invention relates to a halogen-free flame retardant HIPS (High Impact Polystyrene) plastic modified material and a preparation method thereof. The halogen-free flame retardant HIPS plastic modified material comprises the following materials in parts by weight: 40-45 parts of HIPS, 35-40 parts of MPPO (Modified Polyphenylene Oxide), 5-7 parts of halogen-free flame retardant, 3-5 parts of red phosphorus powder, 3-5 parts of K resin, 3-5 parts of SBS (Styrene Butadiene Styrene), 0.3-0.5 part of lubricating agent, 0.2-0.5 part of white mineral oil and 0.5-2 parts of carbon black powder. The halogen-free flame retardant HIPS plastic modified material not only has good flame retardation and strong safety, but also has good mechanical performances including tensile strength and the like; a television enclosure, which is manufactured by the halogen-free flame retardant HIPS plastic modified material, has stronger impact resistance and a long service life, and can be recycled. The processing materials MPPO and HIPS are mainly reclaimed materials, so that the cost of the modified HIPS plastic material is greatly lowered. The halogen-free flame retardant HIPS plastic modified material is free of halogen, environment-friendly and capable of generating great environment-friendly benefits. Besides, the preparation method of the halogen-free flame retardant HIPS plastic modified material is simple to operate, less in needed equipment and low in production cost.

Owner:东莞国立高分子材料有限公司

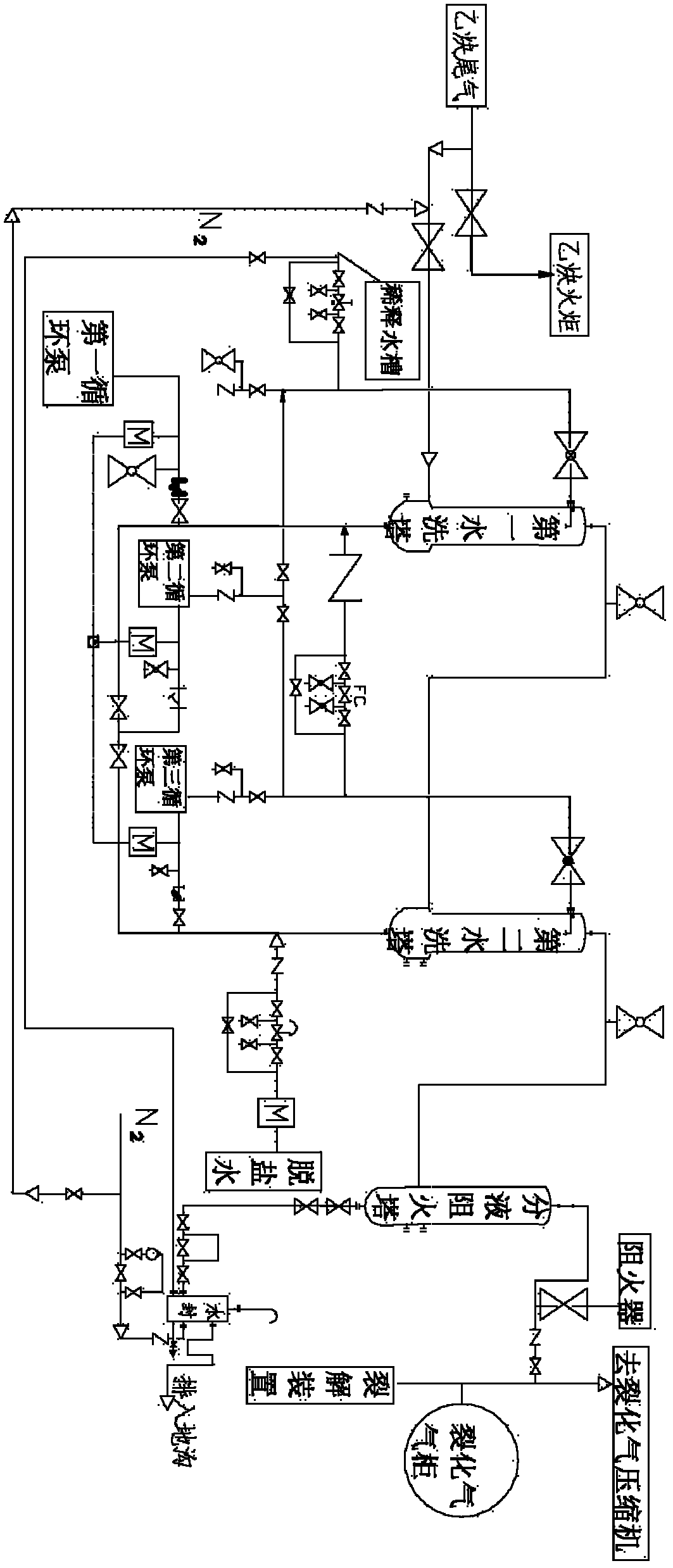

NMP gas recovery system and technology thereof

InactiveCN105797420AReduce reheatingImprove recycling ratesOrganic chemistryMultiple-effect/fractional condensationActivated carbonResource recovery

The invention belongs to the technical field of industrial production waste gas recovery, and particularly relates to a recovery system for N-methyl pyrrolidone in lithium battery industrial waste gas treatment and a technology of the recovery system. The recovery system comprises a precooling and exchanging unit, a condensing unit, an adsorption and regeneration unit and an NMP waste liquor recovery tank which are sequentially connected, and the precooling and exchanging unit and the condensing unit are both connected with the NMP waste liquor recovery tank. Compared with the prior art, according to the NMP gas recovery system, equipment is simple, the technological process is short, no activated carbon adsorbent is used, eluting tower waste liquor is not generated, and the primary recovery rate of NMP can reach 99% or above; the production environment is effectively improved, personnel body health is prevented from being harmed, the cost of enterprise consumables is reduced, and the resource recovery utilization rate is increased.

Owner:DONGGUAN TAFEL NEW ENERGY TECH CO LTD +1

Wastepaper recovering device

InactiveCN104709647AReach the purpose of recyclingTimely replacementPaper recyclingRefuse receptaclesControl systemElectric machinery

The invention discloses a wastepaper recovering device. The wastepaper recovering device comprises at least one wastepaper storage space, wherein the wastepaper storage spaces are connected with a worm gear; the worm gear is connected with a motor; a universal wheel is mounted under the wastepaper storage spaces; a weighing sensor is mounted at the bottom of each wastepaper storage space; the weighing sensors are connected with a PLC control system; a wastepaper feeding system and a partition plate are mounted above the wastepaper storage spaces; a paper output window is arranged on the partition plate; a paper twisting wheel covering a rotating shaft is mounted in the paper output window; the rotating shaft is connected with a stepping motor; the stepping motor is connected with the PLC control system. According to the wastepaper recovering device, wastepaper can be recovered and classified, and a piece of new paper can be output; and therefore, the recovering device has the positive meaning.

Owner:WUHAN UNIV OF TECH

Water-saving device in chemistry lab combining ventilation mechanism in lab

InactiveCN101637734ASolve wasteReach the purpose of recyclingLaboratory apparatusWater savingCooling tower

The invention relates to a water-saving device in a chemistry lab combining a ventilation mechanism in a lab, belonging to the field of water collection and distribution. The invention aims at solvingthe problem of waste of the water resource for cooling in the experiment process of basic teaching for the department of chemistry in colleges and universities. The water-saving device comprises a distributing pipe, a collecting pipe, a cross flow cooling tower, a water pump and a ventilation kitchen. A water outlet port of the cross flow cooling tower is communicated with a water inlet port of the water pump; the water outlet port of the water pump is communicated with the distributing pipe; the water inlet port of the cross flow cooling tower is communicated with the collecting pipe; both the collecting pipe and the distributing pipe are provided with a plurality of taps; and the side wall of the ventilation kitchen is provided with a branch air port which is communicated with an air vent of the cross flow cooling tower. The scheme breaks through the usual thought and behavior that the tap water is directly used as cooling water and is waste after flowing through the device in the experiment process of basic teaching for the department of chemistry in colleges and universities. The device is beneficial to solving the problem of water resource waste.

Owner:NINGBO UNIV

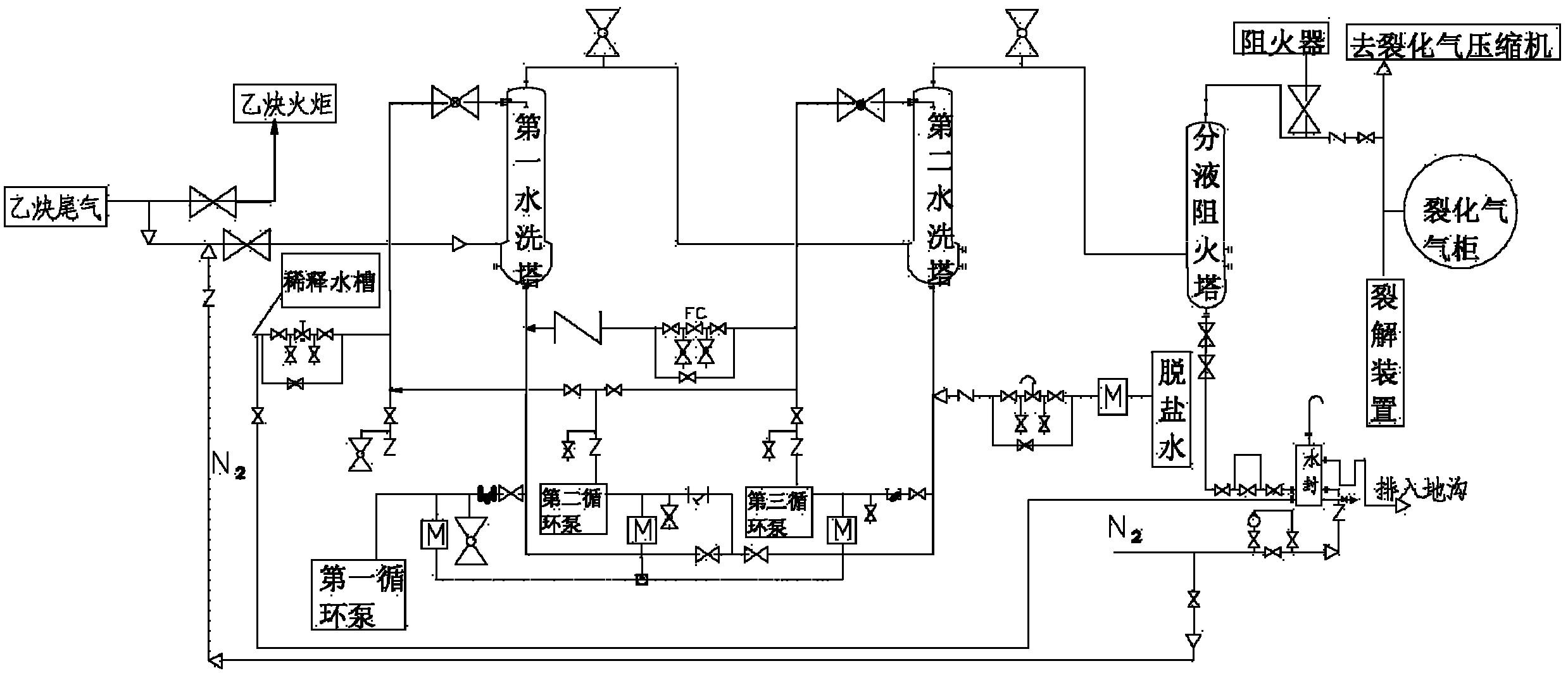

Acetylene tail gas recovery device

InactiveCN102357330AReach the purpose of recyclingDispersed particle separationAbsorption purification/separationProcess engineeringTower

The invention relates to an acetylene tail gas recovery device, which belongs to the field of energy conservation and pollution preservation and comprises a tee joint. Three ends of the tee joint are respectively connected with an acetylene tail gas discharge device, an acetylene torch and a first water washing tower. The first water washing tower is connected with a second water washing tower which is connected with a liquid separating fire retarding tower, the liquid separating fire retarding tower is connected with a cracked gas removal compressor inlet, and a cracked gas removal compressor outlet is connected with an extracting and concentrating device. Acetylene tail gas firstly enters the first water washing tower to be carried out preliminary washing, and then enters the second water washing tower to be carried out secondary washing. After two-stage washing of the tail gas, methanal in the tail gas is almost soluble in washing liquid completely, purified tail gas passes through the liquid separating fire retarding tower to be directly sent to an inlet of the cracked gas removal compressor inlet and mixed with pyrolysis gas, and then sent to the extracting and concentrating device after being pressurized by a cracked gas removal compressor, so that recovery and reusing purposes are achieved.

Owner:XINJIANG MARKORCHEM

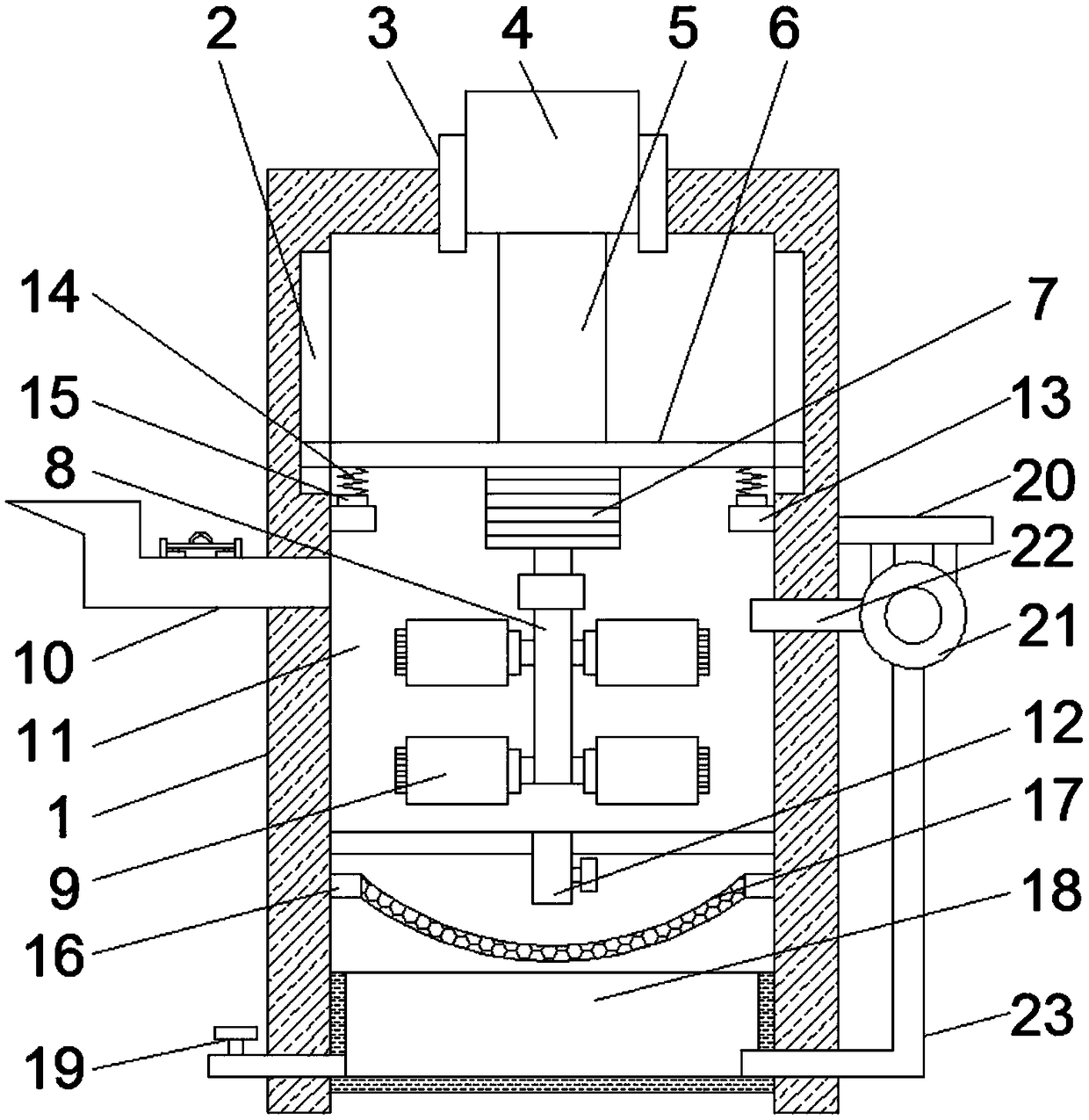

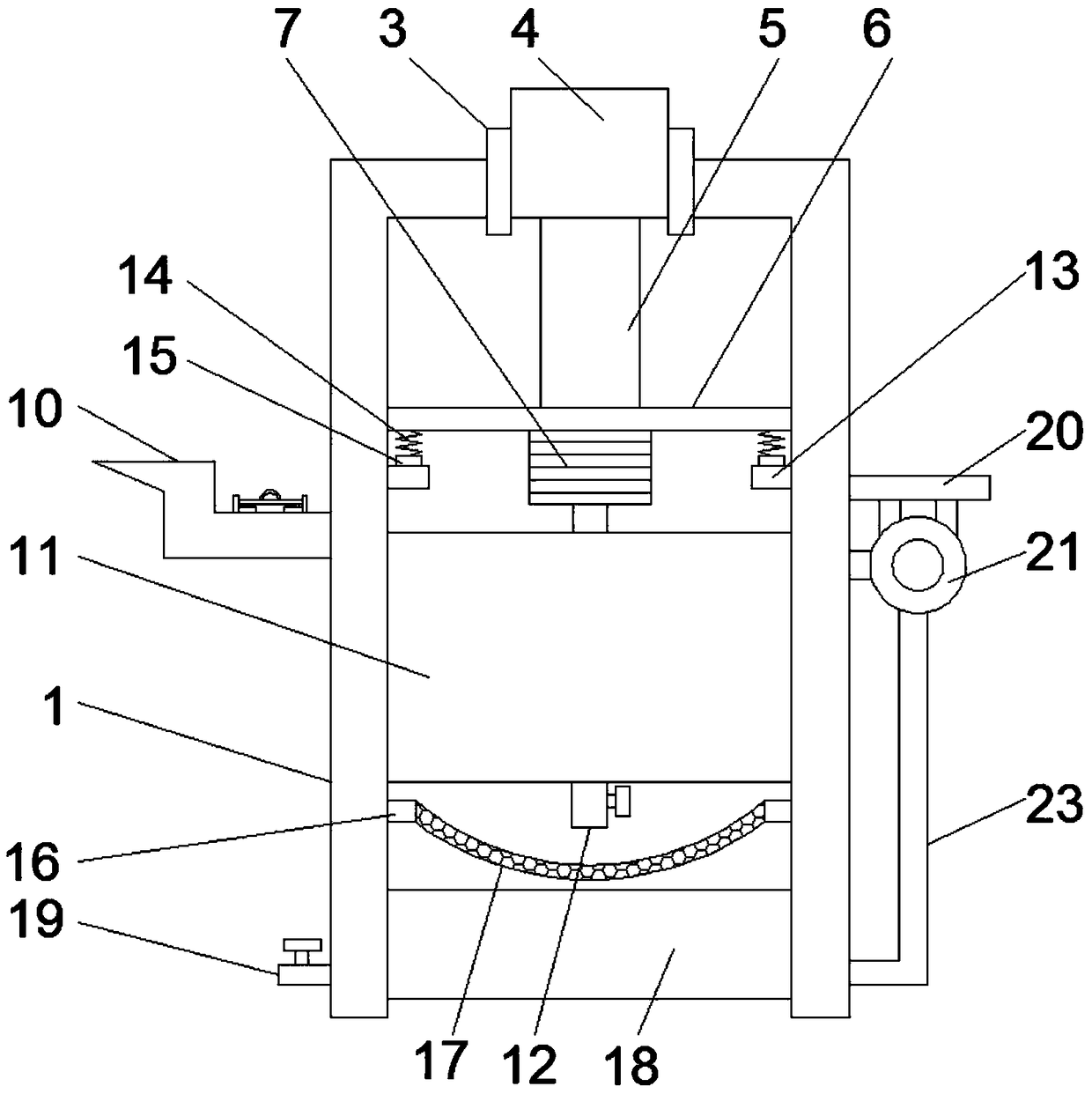

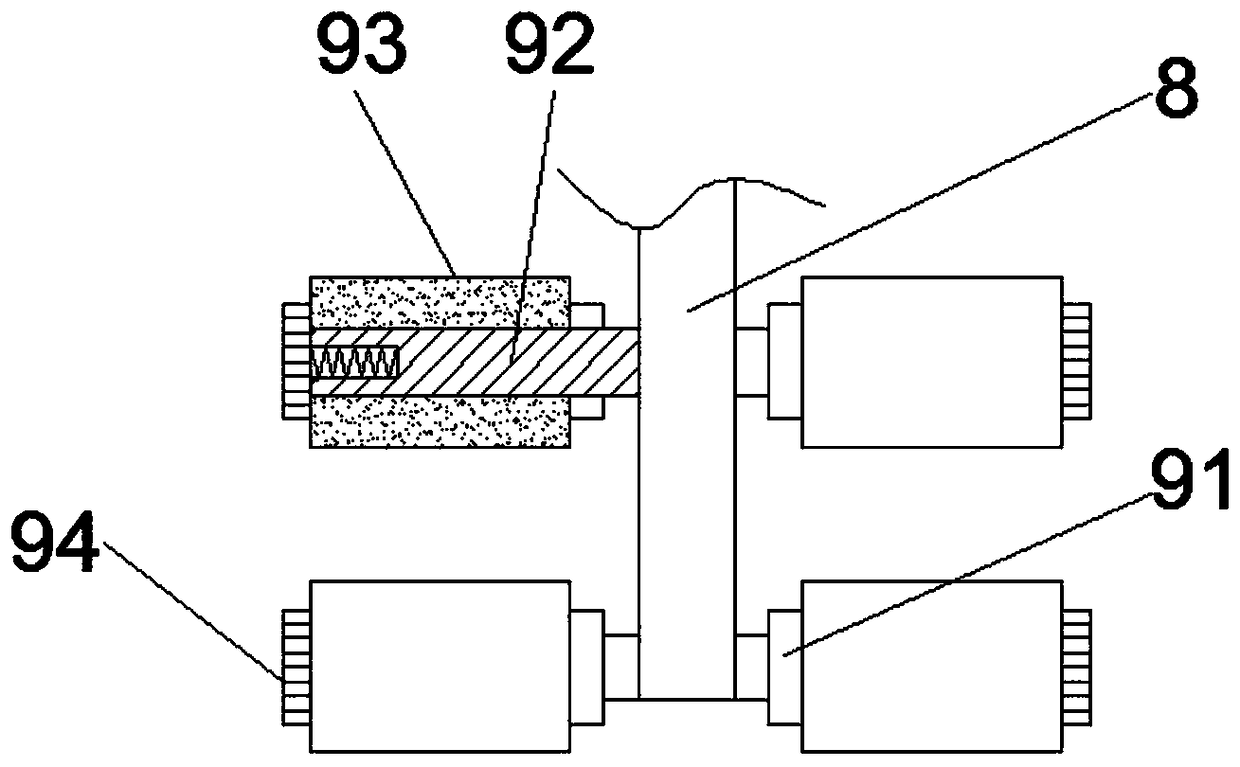

Iron scrap filtering and recycling device for sewage treatment

PendingCN108892307AEasy to collectEasy to useTreatment involving filtrationWater/sewage treatment by magnetic/electric fieldsScrapMagnet

The invention discloses an iron scrap filtering and recycling device for sewage treatment. The iron scrap filtering and recycling device comprises a frame and a stirring tank and is characterized in that the stirring tank is arranged in the middle of the frame, slide grooves are formed in the left and right sides of the inner side of the upper portion of the frame, fixing plates are arranged in the middle of the upper end of the frame in a left-right symmetry manner, a hydraulic device is arranged between the two fixing plates, and a telescopic rod is arranged at the lower end of the hydraulicdevice. The iron scrap filtering and recycling device has the advantages that magnetic components stir sewage to prevent the precipitation of iron scraps in the sewage, the iron scrap attracting effect of the magnetic components is benefited, the magnetic components adopting magnet sleeves are large in surface area, the contact area between the magnetic components and the sewage can be increased,and iron scrap attracting efficiency can be increased; the magnetic components can move upwards by the aid of the telescopic rod, the magnet sleeves can be taken down by removing fixing screws, the iron scraps on the magnet sleeves can be collected in a centralized manner, the iron scraps can be conveniently and fast collected, the magnet sleeves can be replaced conveniently, and attracting effect lowering caused by long-term use can be avoided at the same time.

Owner:陈碧霞

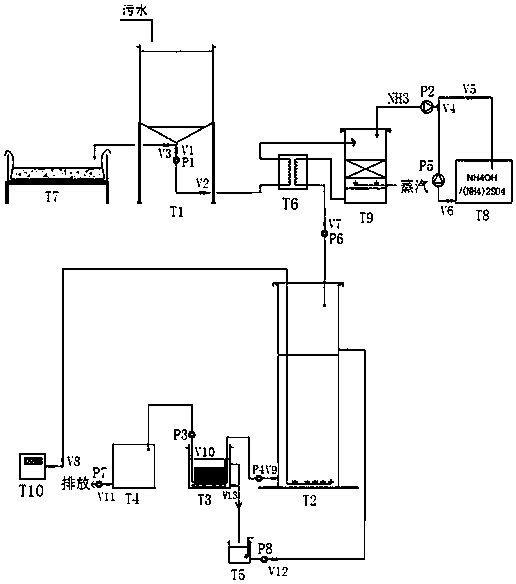

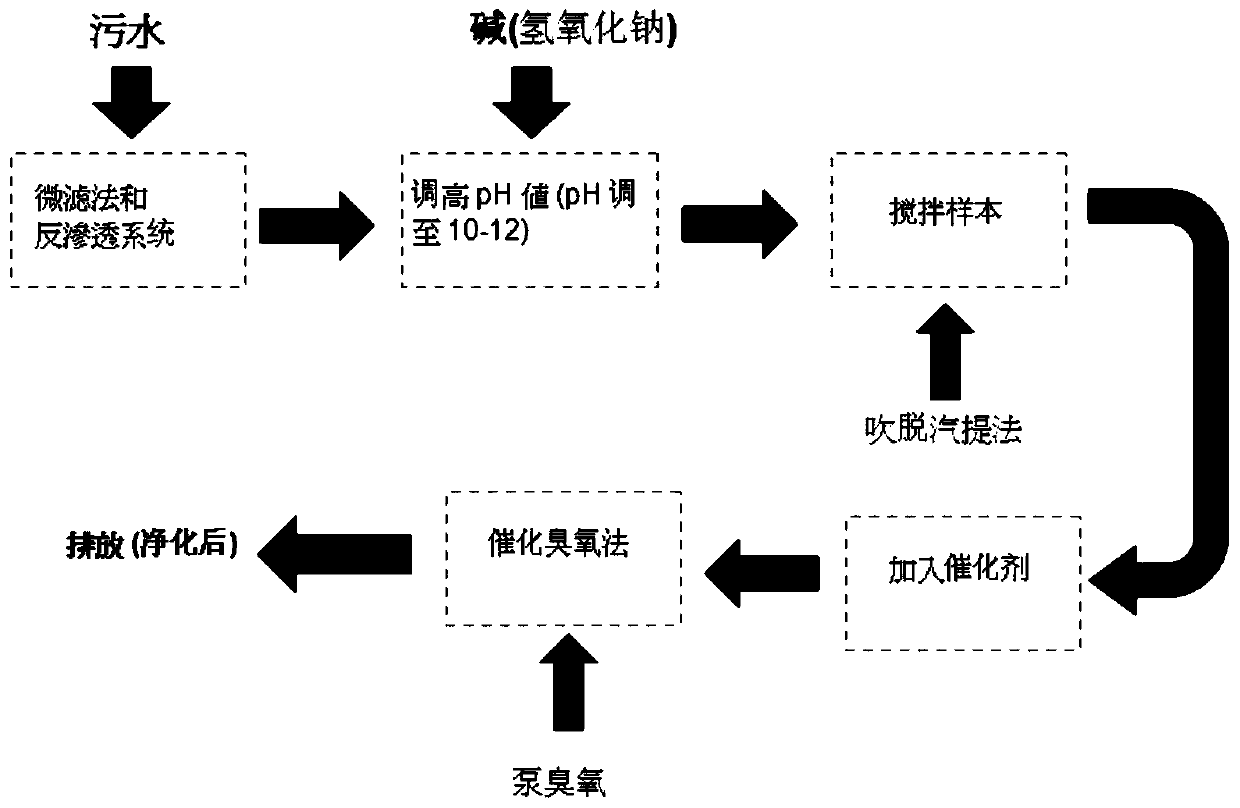

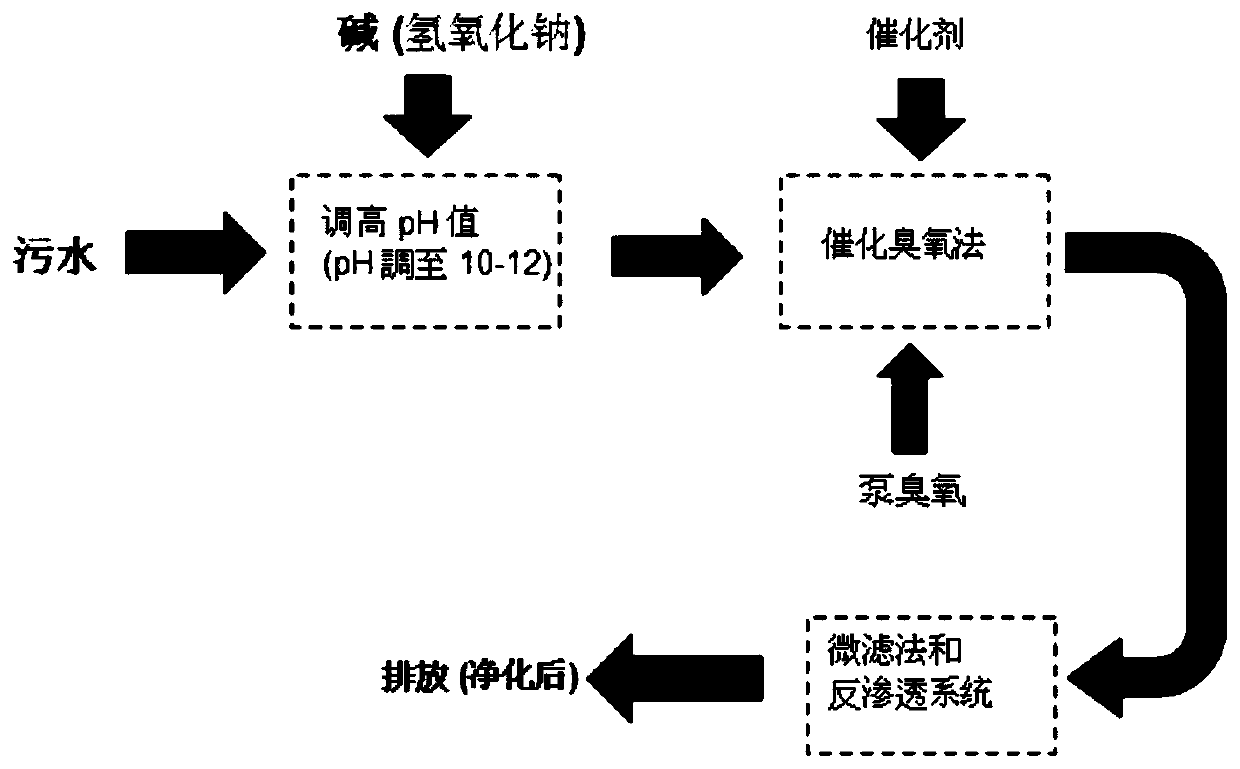

Method for treating and recycling high-concentration ammonia nitrogen and COD sewage

InactiveCN111392943AIncreased processing costsGood removal effectWater treatment parameter controlWater contaminantsAmmonium sulfateEnvironmental chemistry

The invention discloses a method for treating and recycling high-concentration ammonia nitrogen and COD (Chemical Oxygen Demand) sewage. The method comprises the following specific steps: pre-treatingthe sewage, removing ammonia nitrogen in the sewage by air stripping and steam stripping methods, removing ammonia nitrogen and COD in the sewage by a catalytic ozonation method, and performing filtering. The treatment process comprises the following steps: removing most of ammonia nitrogen in water by using air stripping and steam stripping methods, removing residual ammonia nitrogen by using acatalytic ozonation method, decomposing COD in the water into carbon dioxide and discharging the carbon dioxide, and finally, filtering a catalyst and residual COD in the water by using a two-stage ceramic membrane and a reverse osmosis system to enable the water to be dischargeable or recyclable. The method has the advantages of being good in removal effect, simple in technological process, easyto operate and the like, ammonia nitrogen obtained after air stripping can be recycled in the form of ammonia water or ammonium sulfate, and the purpose of resource recycling can be achieved.

Owner:北京耀智环保科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com