Thermoacoustic system capable of gradually recovering LNG (liquefied natural gas) cold energy

A technology of liquefied natural gas and thermoacoustic system, which is applied in the field of thermoacoustic system capable of recovering the cold energy of liquefied natural gas in cascades. Utilization, reliable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

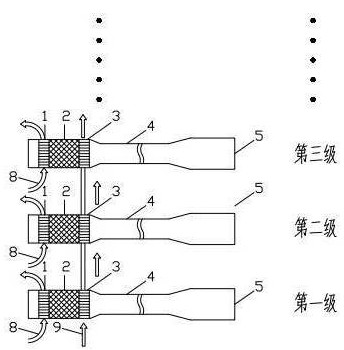

[0018] Such as figure 1 As shown, the standing wave thermoacoustic system capable of recovering the cold energy of liquefied natural gas in stages includes several standing wave thermoacoustic engines, low-grade heat energy supply system (8) and liquefied natural gas supply system (9), and the standing wave thermoacoustic engine includes sequentially Connected hot end heat exchanger (1), regenerator (2), cold end heat exchanger (3), resonance tube (4) and gas storage (5). The low-grade heat energy supply system (8) uses air, water or other low-grade heat energy as a heat source, and is connected to the hot-end heat exchangers (1) of thermoacoustic engines at all levels through pipelines. The liquefied natural gas supply system (9) is connected to the cold-end heat exchanger (3) of the first-stage thermoacoustic engine through pipelines. When there is a sufficient temperature difference between the two ends of the regenerator (2), the working medium gas in the engine is Period...

Embodiment 2

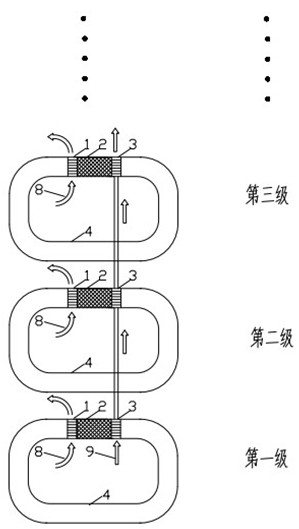

[0020] Such as figure 2 As shown, the pure traveling wave thermoacoustic system capable of recovering the cold energy of liquefied natural gas in stages includes several pure traveling wave thermoacoustic engines, a low-grade heat energy supply system (8) and a liquefied natural gas supply system (9). The thermoacoustic engine includes a hot end heat exchanger (1), a regenerator (2), a cold end heat exchanger (3) and a resonance tube (4); a hot end heat exchanger (1), a regenerator (2) 1. The cold end heat exchanger (3) is connected in sequence, the hot end of the resonant tube (4) is connected with the hot end heat exchanger (1), and the cold end of the resonant tube (4) is connected with the cold end heat exchanger (3). The low-grade heat energy supply system (8) uses air, water or other low-grade heat energy as a heat source, and is connected to the hot-end heat exchangers (1) of the thermoacoustic engines at all levels through pipelines. The liquefied natural gas supply ...

Embodiment 3

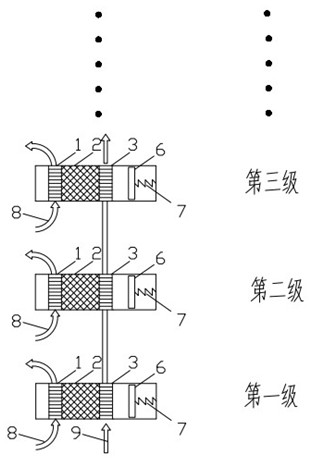

[0022] Such as image 3 As shown, the piston phasing thermoacoustic system capable of recovering the cold energy of liquefied natural gas in stages includes several piston phasing thermoacoustic engines, a low-grade heat energy supply system (8) and a liquefied natural gas supply system (9). The phase-tuned thermoacoustic engine includes sequentially connected hot-end heat exchangers (1, regenerators (2, cold-end heat exchangers (3), vibrators (6) and springs (7). The low-grade heat energy supply system ( 8) Use air, water or other low-grade heat energy as the heat source, and connect with the hot-end heat exchangers (1) of the thermoacoustic engines at all levels through pipelines. The liquefied natural gas supply system (9) is connected with the first-stage heat exchanger through pipelines. The cold-end heat exchanger (3) of the acoustic engine is connected. When there is a sufficient temperature difference between the two ends of the regenerator (2), the working medium gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com