Technique method for processing desulphurization waste water

A technology of desulfurization wastewater and process methods, applied in the direction of energy wastewater treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of large consumption of electric energy or other thermal energy, limited weather conditions, and difficult operation control, etc., to achieve Avoid corrosion and scaling problems, improve wastewater reuse rate, and mature equipment and products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

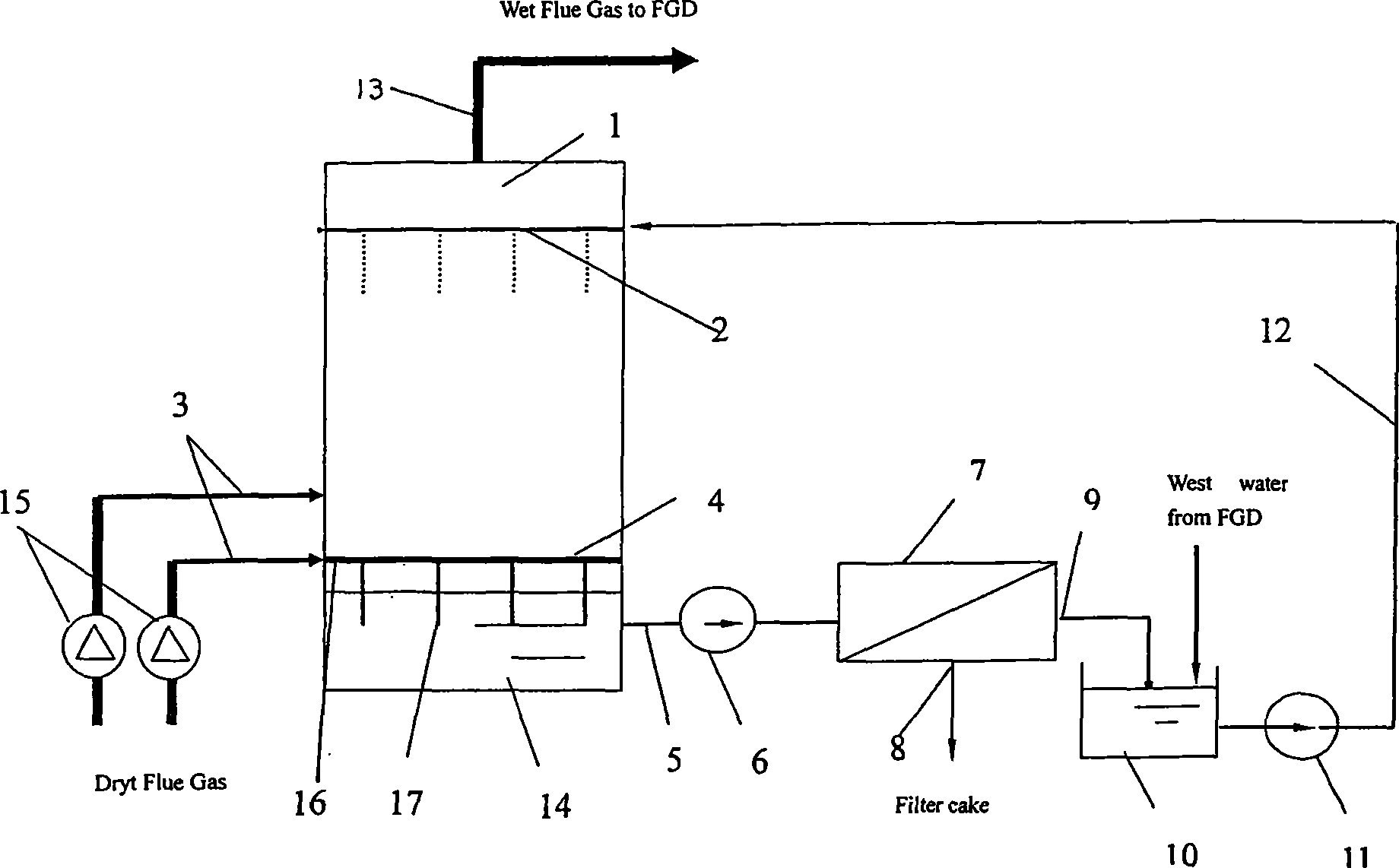

[0041] A process for treating desulfurization wastewater, such as figure 1 shown, including:

[0042] Drying tower 1, nozzle 2, smoke pipeline 3, concentrated waste box 14, output pipeline 5, filter press separation device 7, circulation pool 10, circulation pipeline 12;

[0043] Wherein, the upper part of the drying tower 1 is connected to the flue gas outlet pipe 13, and the flue gas outlet pipe 13 may be the inlet part of the flue gas input pipe to be desulfurized in the limestone-gypsum wet flue gas desulfurization technology system;

[0044]The waste water spraying device 2 is fixedly installed inside the drying tower 1. The nozzle 2 can be a long pipe with many small holes, or a nozzle with many small holes, or it can be a common technology. Various mature spraying devices, the desulfurization wastewater is sprayed into fine mist droplets through the nozzle 2;

[0045] The flue gas pipeline 3 is connected to the bottom of the drying tower 1, so that the hot flue gas of...

Embodiment 2

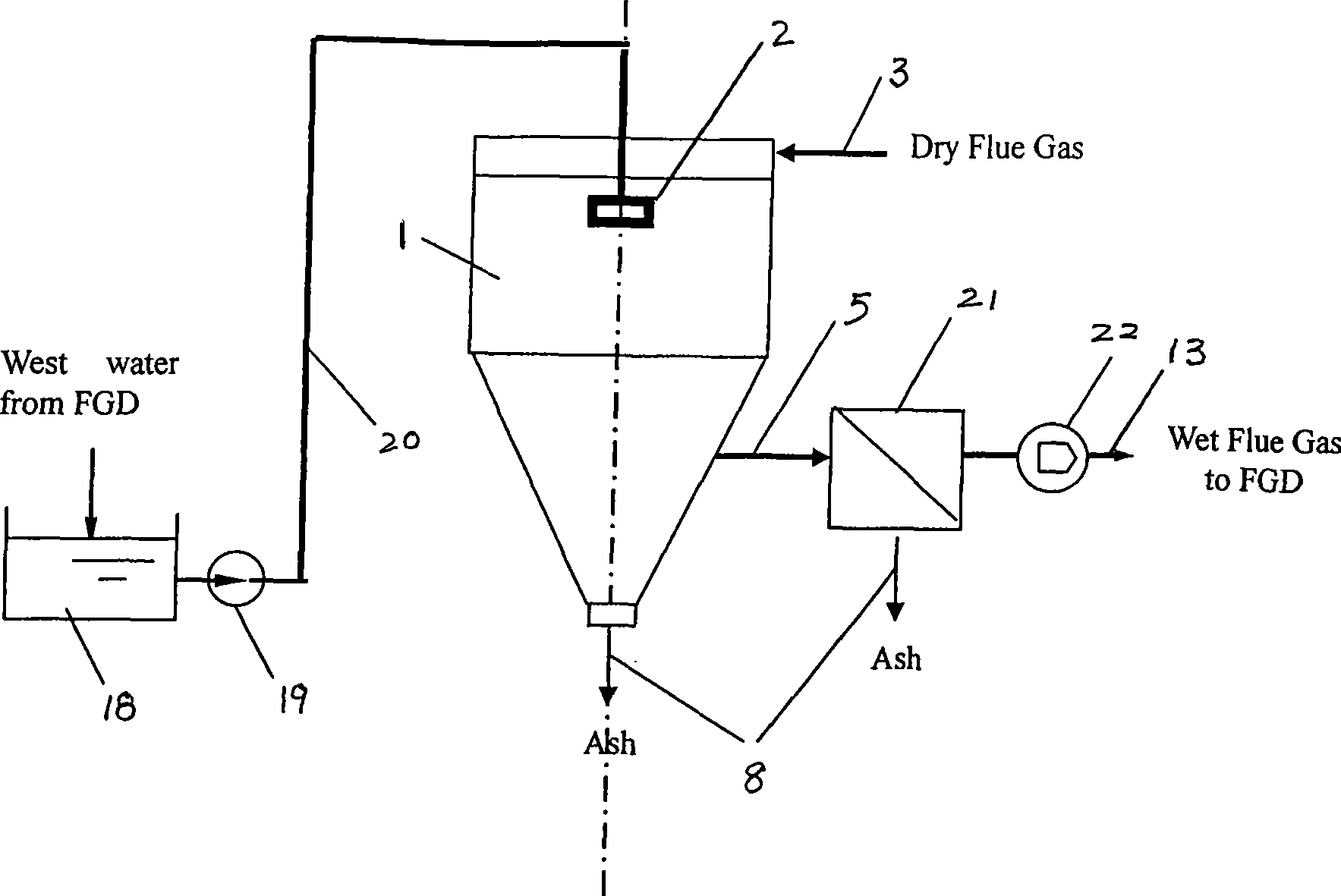

[0062] A process for treating desulfurization wastewater, as shown in Figure 2, includes:

[0063] Drying tower 1, smoke pipe 3, waste water pipe 20, output pipe 5, dust collector 21, exhaust fan 22, flue gas outlet pipe 13, solid outlet 8;

[0064] The drying tower 1 is a spray dryer 1, and the spray dryer 1 is a general technical product available on the market. The spray dryer 1 is equipped with a hot air inlet, a raw material liquid inlet, a material outlet, and a waste gas outlet;

[0065] Among them, the nozzles on the spray dryer 1 that are in contact with the desulfurization wastewater should be made of anti-corrosion materials.

[0066] The dust remover 21 is also a general technical product available on the market, and the dust remover 21 is provided with an inlet, an ash discharge port and an exhaust port;

[0067] Smoke exhaust fan 22 is also a general-purpose technical product available on the market. One end is the fan inlet, and the other end is the fan outlet....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com