Integration automatic flow type biological nitrogen and sulfur removal reactor

A biological denitrification and reactor technology, applied in chemical instruments and methods, water pollutants, water/sludge/sewage treatment, etc., can solve the problems of large area, large energy consumption, high cost, etc. Small area, economical and reasonable, and the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

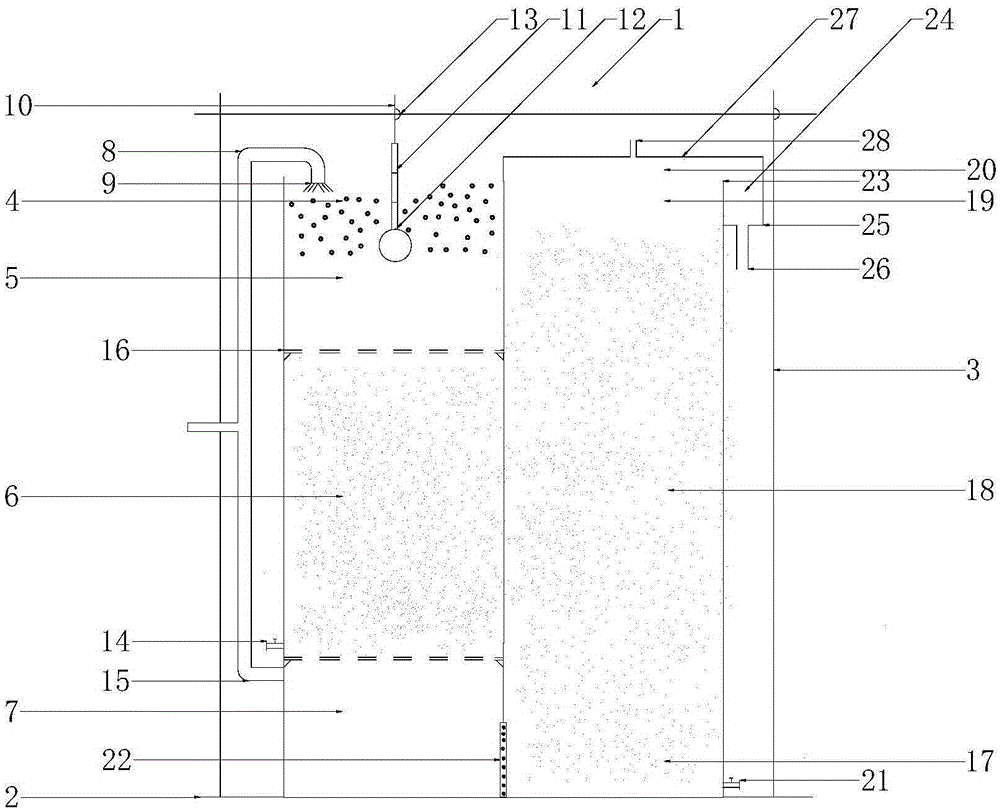

[0020] Example 1 An integrated self-flowing biological denitrification and sulfur removal reactor according to the present invention includes a reactor body 1, a base 2, a bracket 3 mounted on the base, a water inlet pipeline and a water outlet pipeline. The reactor body 1 is installed on the base 2, the water inlet pipeline and the water outlet pipeline are respectively installed on the bracket 3, and the reactor body 1 communicates with the outside world through the water inlet pipeline. The water source is connected, and the inner chamber of the reactor body 1 is divided into a first chamber and a second chamber by a vertical partition, and the first chamber is sequentially divided into a water inlet area 4 from top to bottom for filling light organisms The short-range nitrification unit 5 of the carrier, the anaerobic ammonium oxidation unit 6 used to fill the suspended filler, and the secondary water inflow mixing zone 7, above the primary water inflow zone 4, there is a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com