Method for treating and recycling high-concentration ammonia nitrogen and COD sewage

A high-concentration ammonia and ammonia nitrogen recovery technology, applied in neutralization water/sewage treatment, water/sewage treatment, degassed water/sewage treatment, etc., can solve the problems of high-concentration ammonia nitrogen and COD sewage treatment and reuse, and achieve Increased processing costs, high cost, and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Embodiment 1, the treatment reuse of highly concentrated ammonia nitrogen and COD sewage

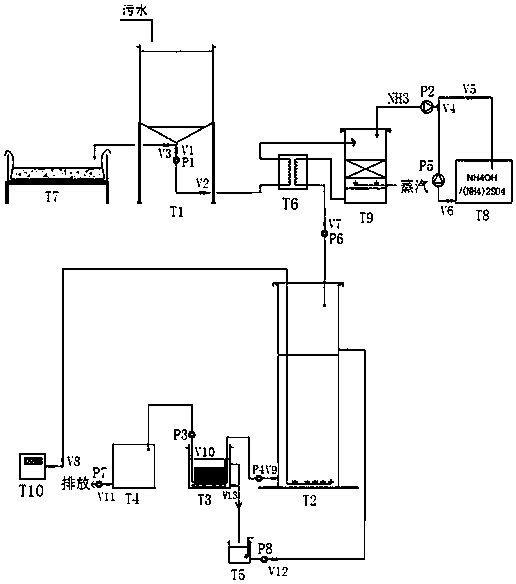

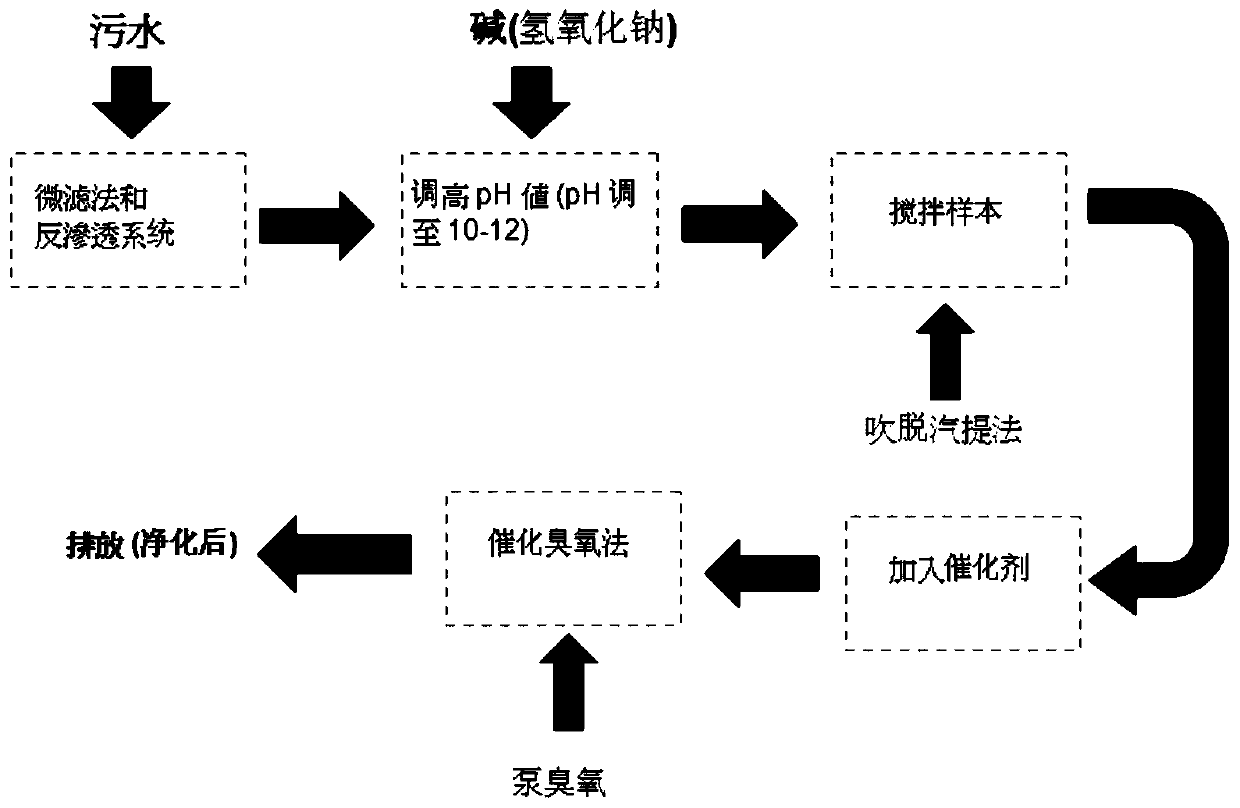

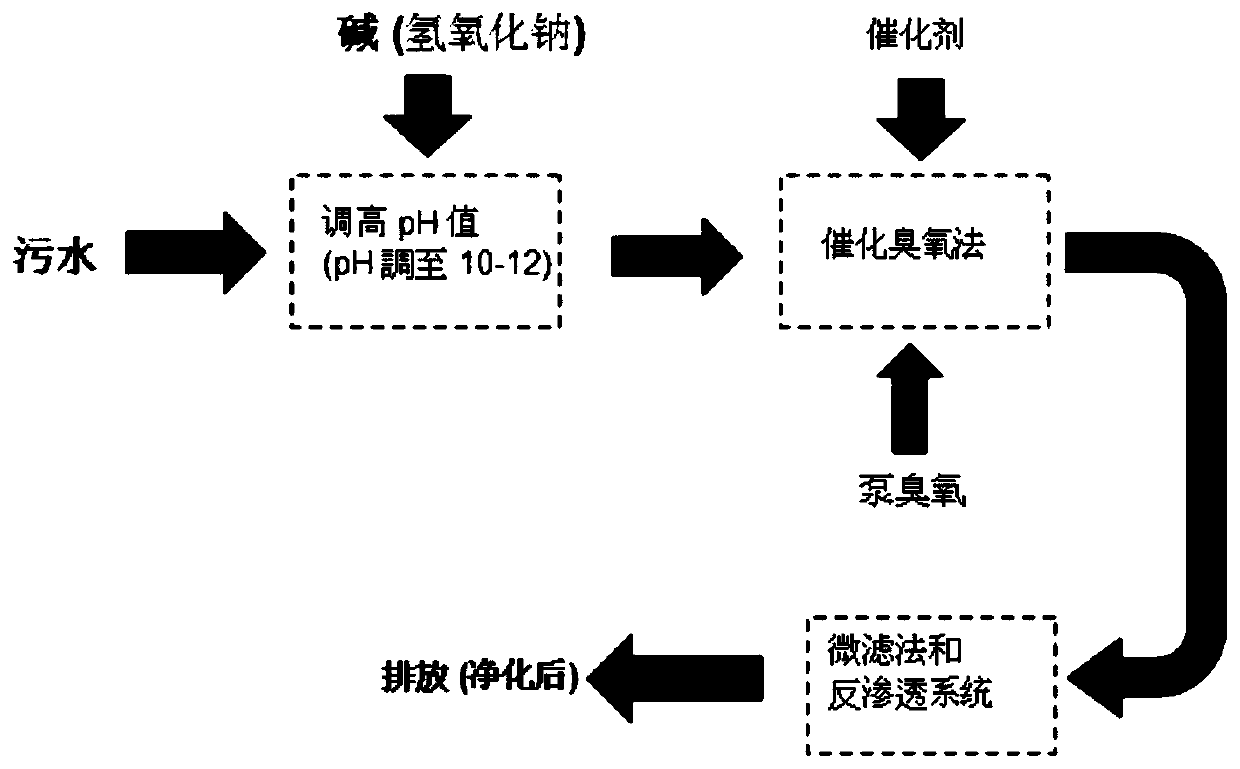

[0060] as attached figure 1 As shown, it is a treatment and reuse system for high-concentration ammonia nitrogen and COD sewage. The specific process of this treatment and reuse system for treating sewage containing high-concentration ammonia nitrogen and COD is divided into three parts. The first part is first in the dosing tank T1 In this process, the pH value of the sewage is increased, and then the metal ions in the sewage are removed, and then the sewage is discharged to the heating tank T9; the second part is to recover the ammonia nitrogen in the sewage in the ammonia nitrogen recovery tank T8; The ammonia nitrogen and COD in the ozone reaction tank T2 are subjected to the catalytic ozone method. After the powder catalyst is put into the ozone reaction tank T2, the sewage powder catalyst will enter the microfiltration ceramic membrane, and the microfiltration ceramic membr...

Embodiment 2

[0067] Embodiment 2, the influence of sewage pH on ammonia helium removal rate

[0068] Ammonia in sewage is converted to ammonium ions (NH 4 + ) and free ammonia (NH 3 ) to maintain balance, the balance relationship is shown in formula (1):

[0069] NH 4 + +OH - ←→NH 3 +H 2 O (1)

[0070] It can be seen from formula (1) that the pH of sewage is one of the main factors affecting the solubility of free ammonia in water. As the pH of sewage increases, the solubility of ammonia in the liquid phase decreases, the equilibrium shifts to the right, and the removal rate of ammonia nitrogen increases. Generally, NaOH and Ca(OH) are used to adjust the pH of the sewage. Because of Ca(OH), it is easy to foul the tower equipment. In most cases, NaOH is used as a regulator. Utilize the countercurrent stripping tower to process and prepare the sewage with ammonia mass concentration of 3000mg / L for blowing off, the ammonia nitrogen removal rate increases with the increase of sewage p...

Embodiment 3

[0071] Embodiment 3, the influence of stripping temperature on ammonia nitrogen removal rate

[0072] When the temperature is higher, the volatilization rate of ammonia is greater than the dissolution rate, and the equilibrium of formula (1) shifts to the right. Therefore, in the stripping process, choosing an appropriate stripping temperature can improve the stripping efficiency. The high-concentration ammonia nitrogen sewage (1716.2mg / L) is treated by stripping to remove ammonia nitrogen. Under the conditions of air volume 1.0m / h, sewage pH 11, stripping time 60min, the effect of stripping temperature 70-80℃ on ammonia nitrogen removal rate was investigated. The experimental results show that when the final pH of the sewage is 10.0-12.0 and the influent temperature is 70-80°C, the removal rate of ammonia nitrogen can be stabilized above 90%. During the treatment of ammonia nitrogen sewage, it was found that the higher the stripping temperature, the higher the ammonia nitro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com