Patents

Literature

881 results about "Mixing zone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mixing Zone A mixing zone is an area of a lake or river where pollutants from a point source discharge are mixed, usually by natural means, with cleaner water.

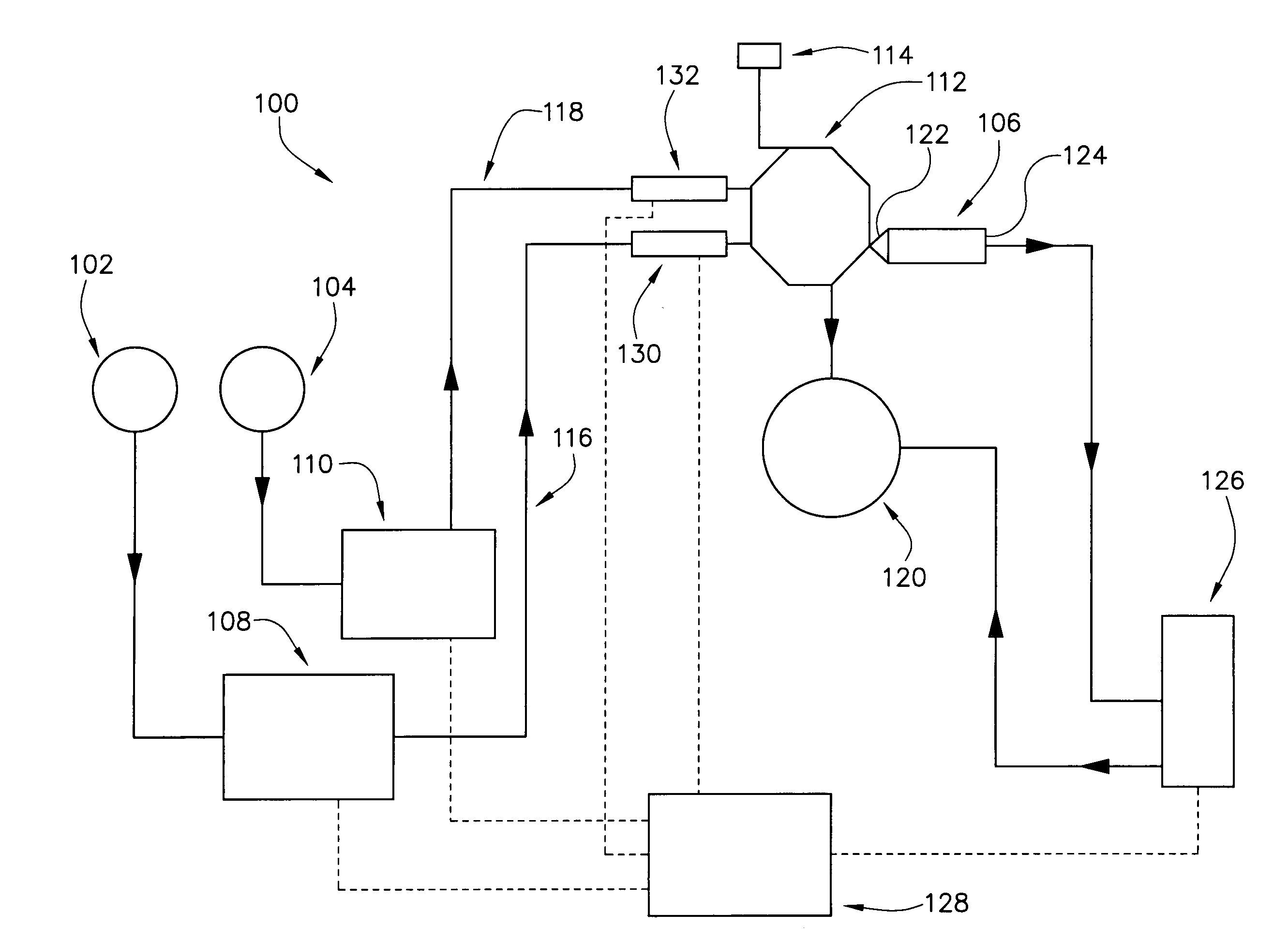

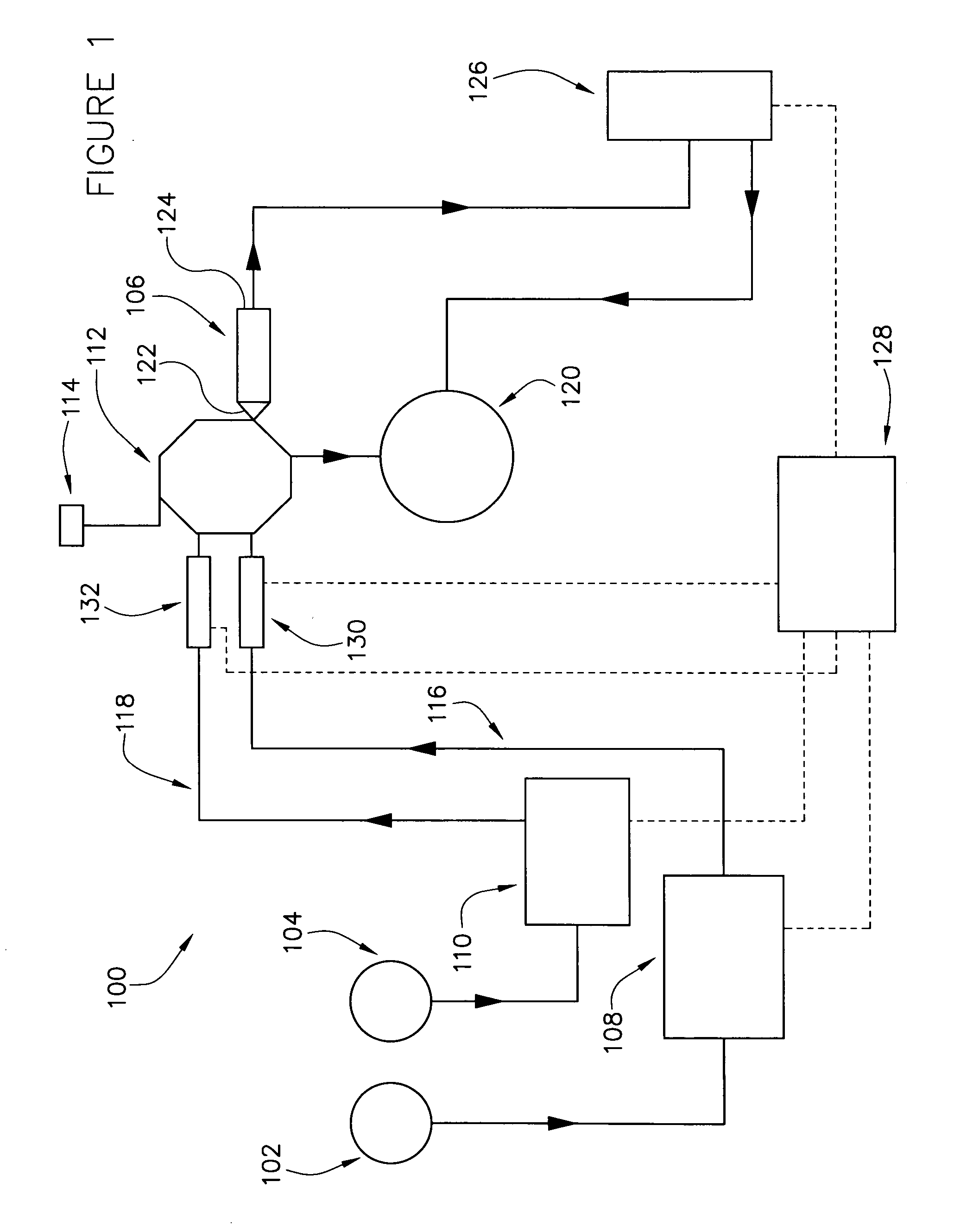

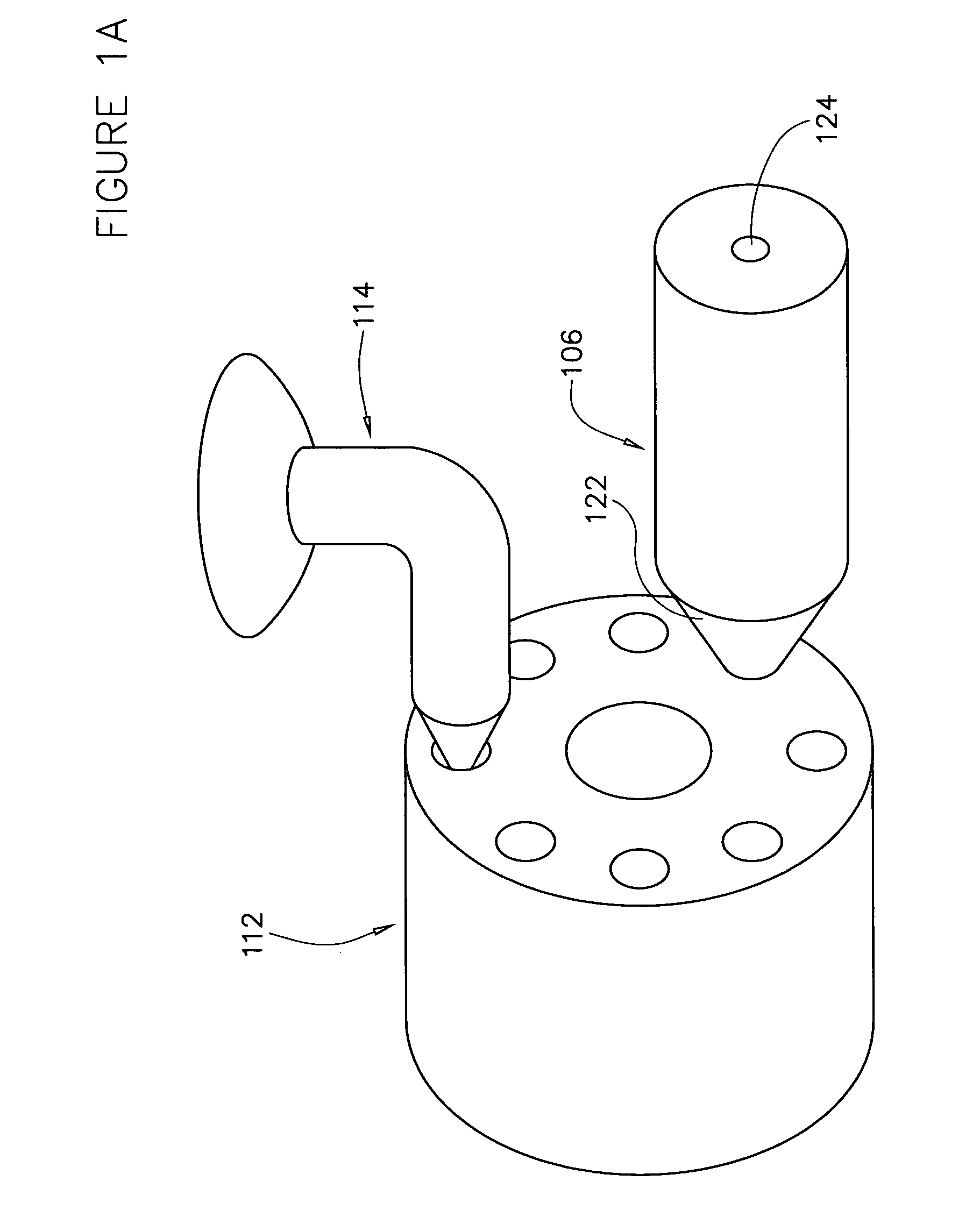

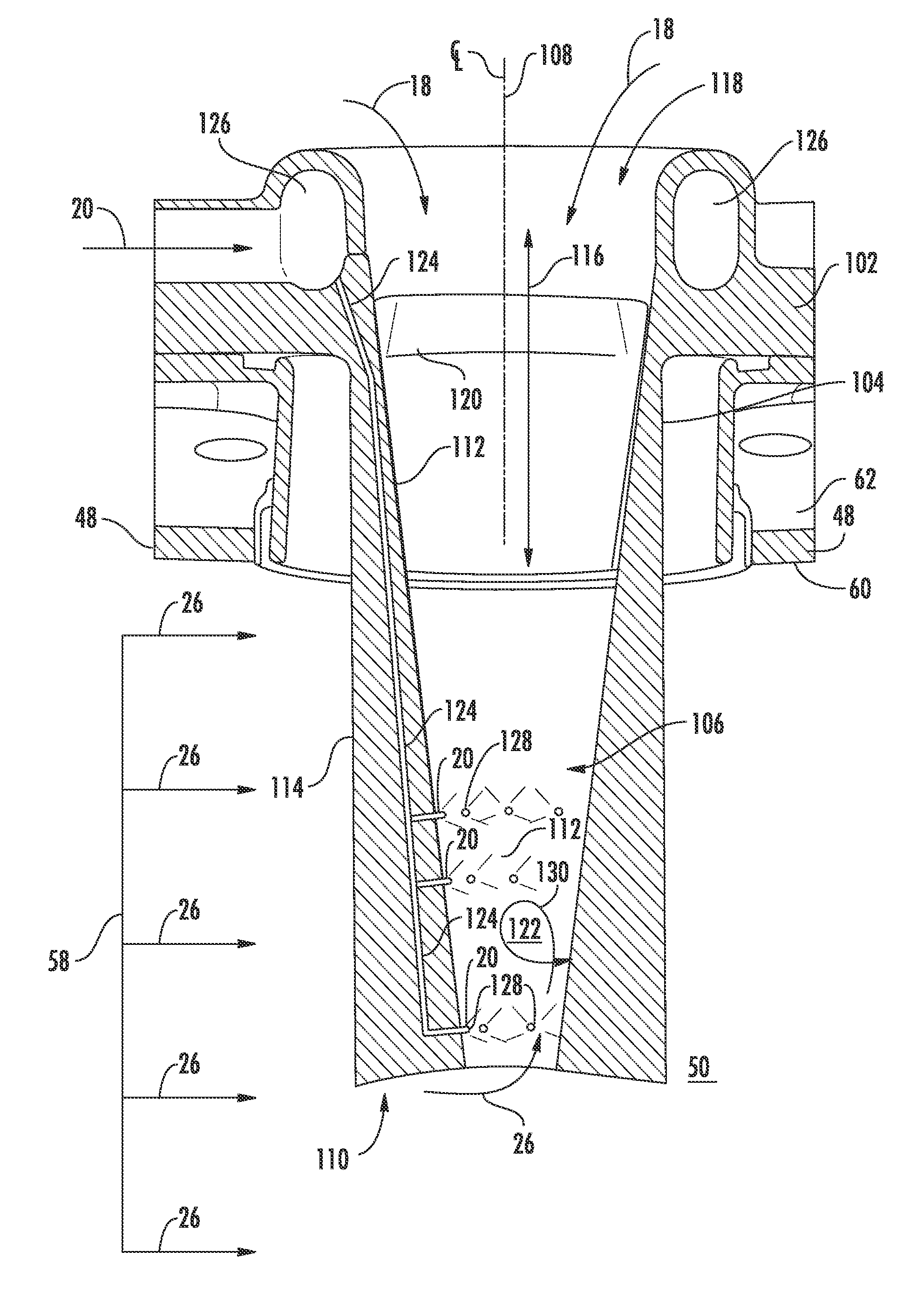

Pyrolytic reactor

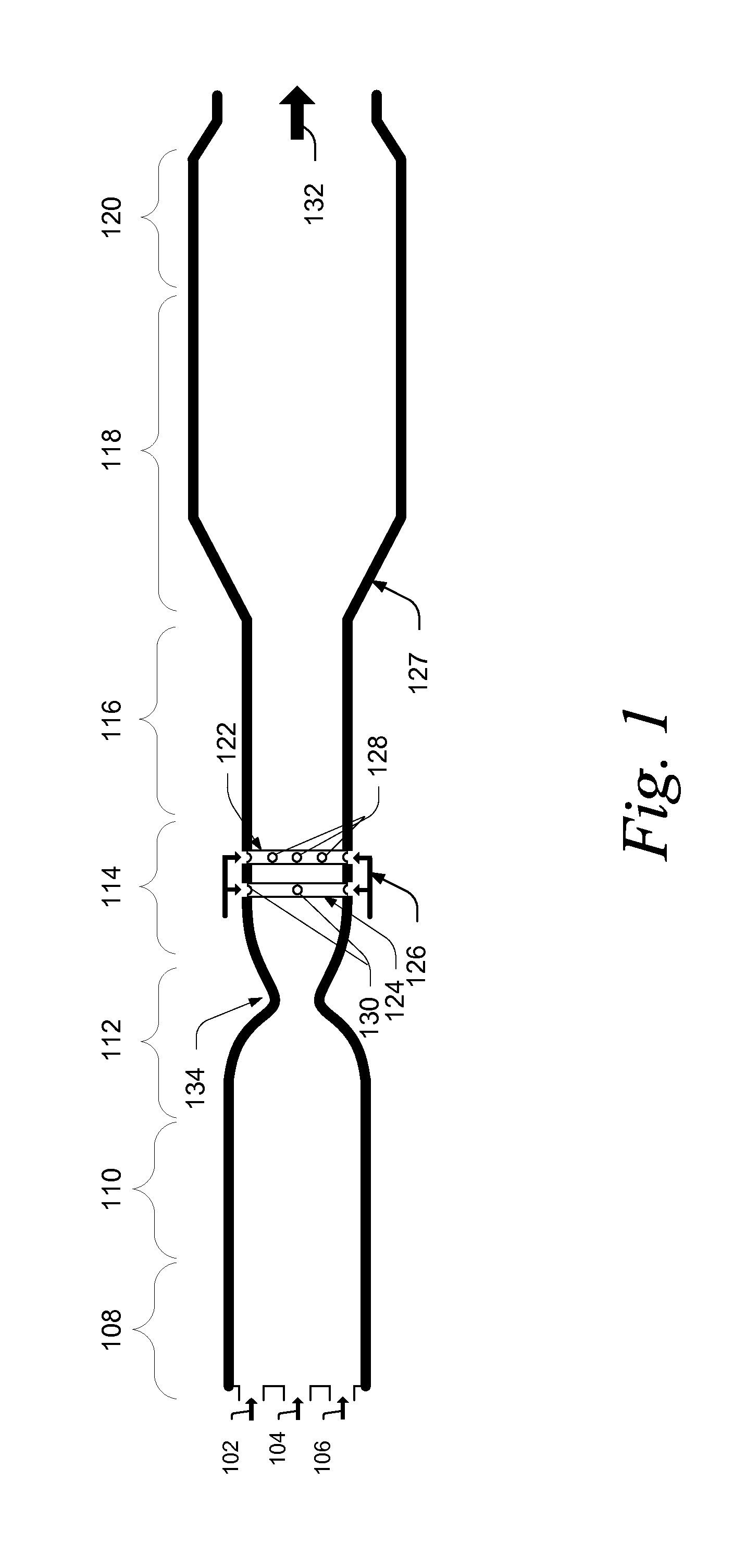

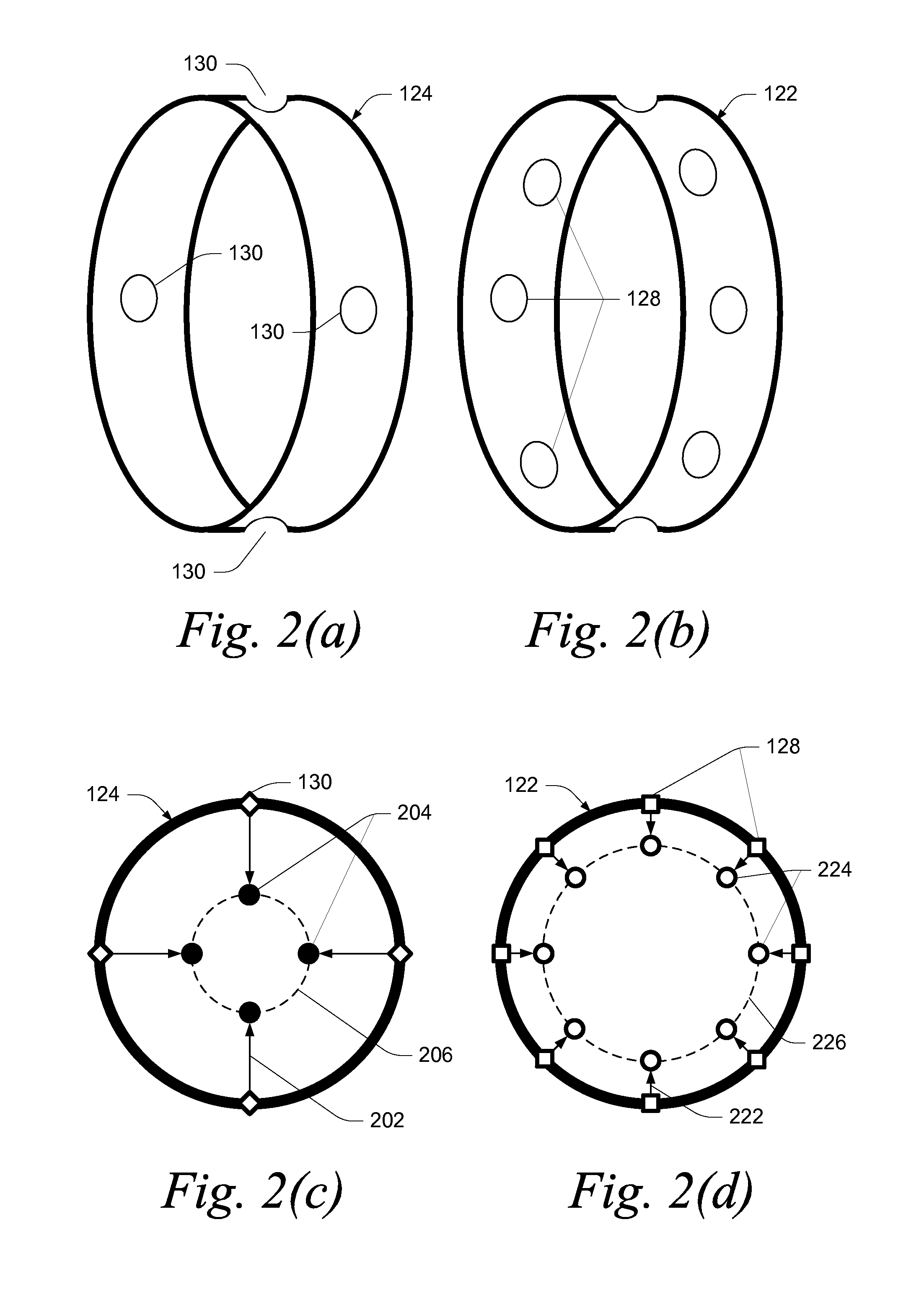

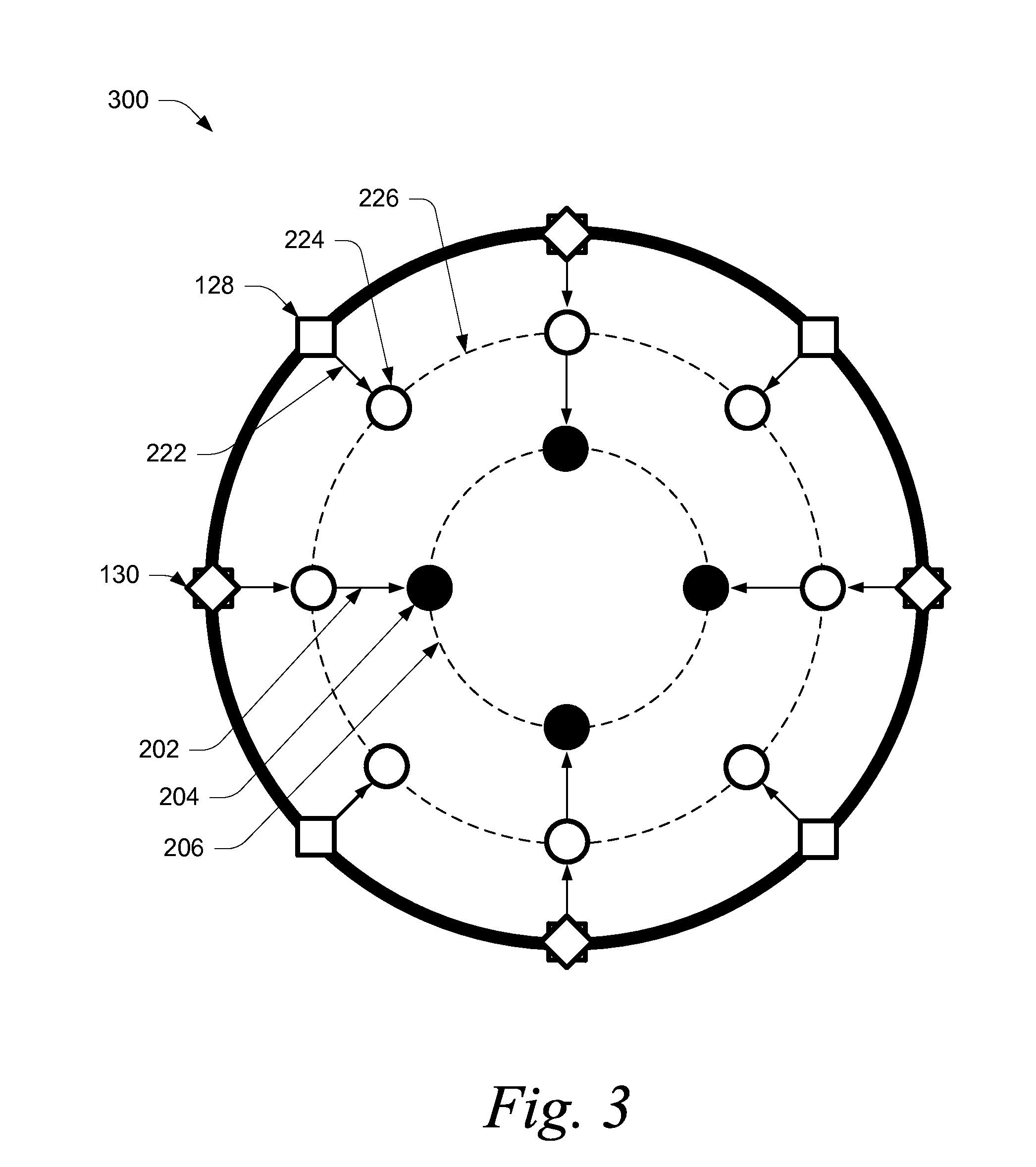

A pyrolytic reactor comprising a fuel injection zone, a combustion zone adjacent to the fuel injections zone, an expansion zone adjacent to the combustion zone, a feedstock injection zone comprising a plurality of injection nozzles and disposed adjacent to the expansion zone, a mixing zone configured to mix a carrier stream and feed material and disposed adjacent to the feedstock injection zone, and a reaction zone adjacent to the mixing zone. The plurality of injection nozzles are radially distributed in a first assembly defining a first plane transverse to the feedstock injection zone and in a second assembly transverse to the feedstock injection zone.

Owner:UOP LLC

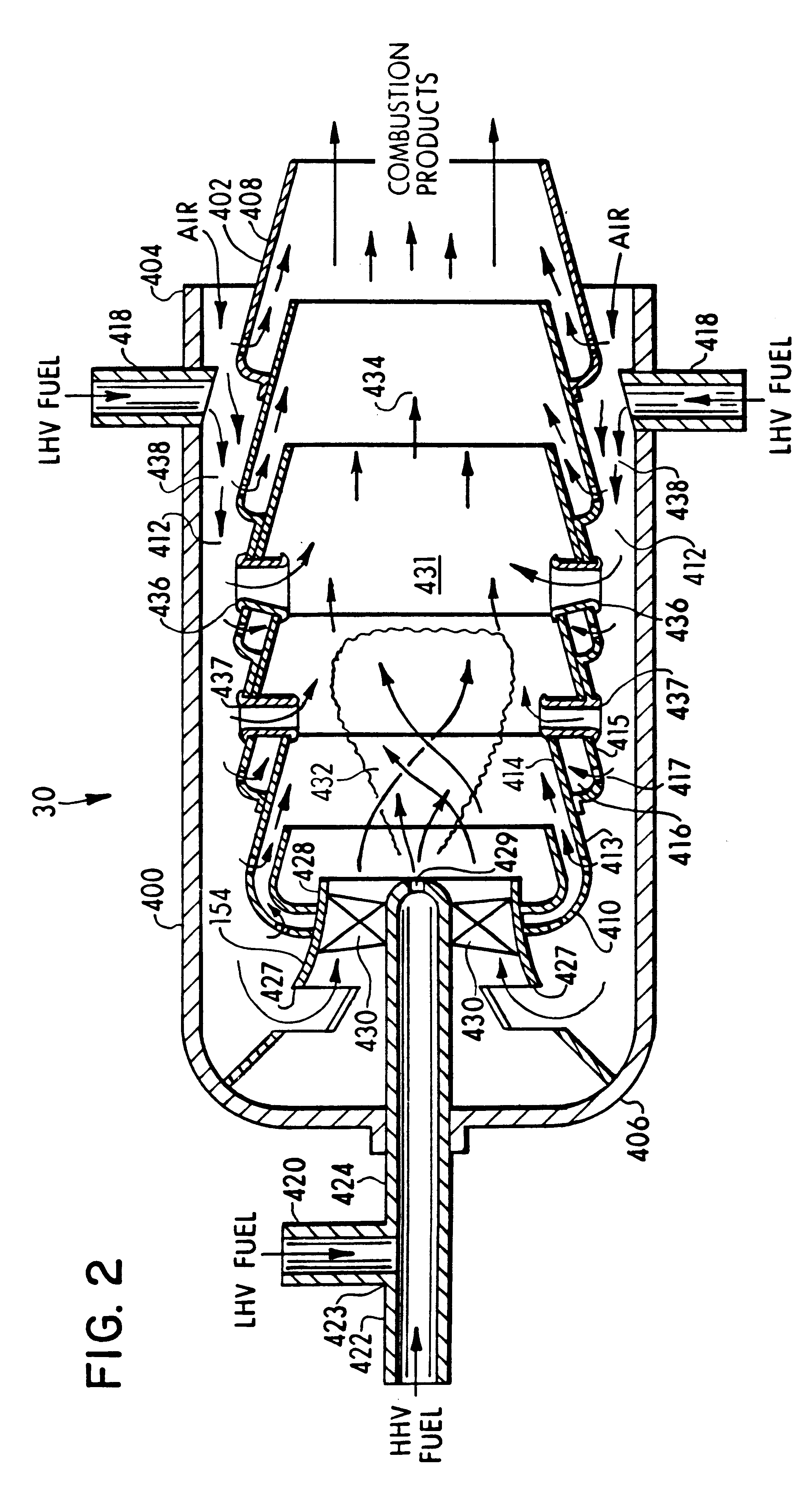

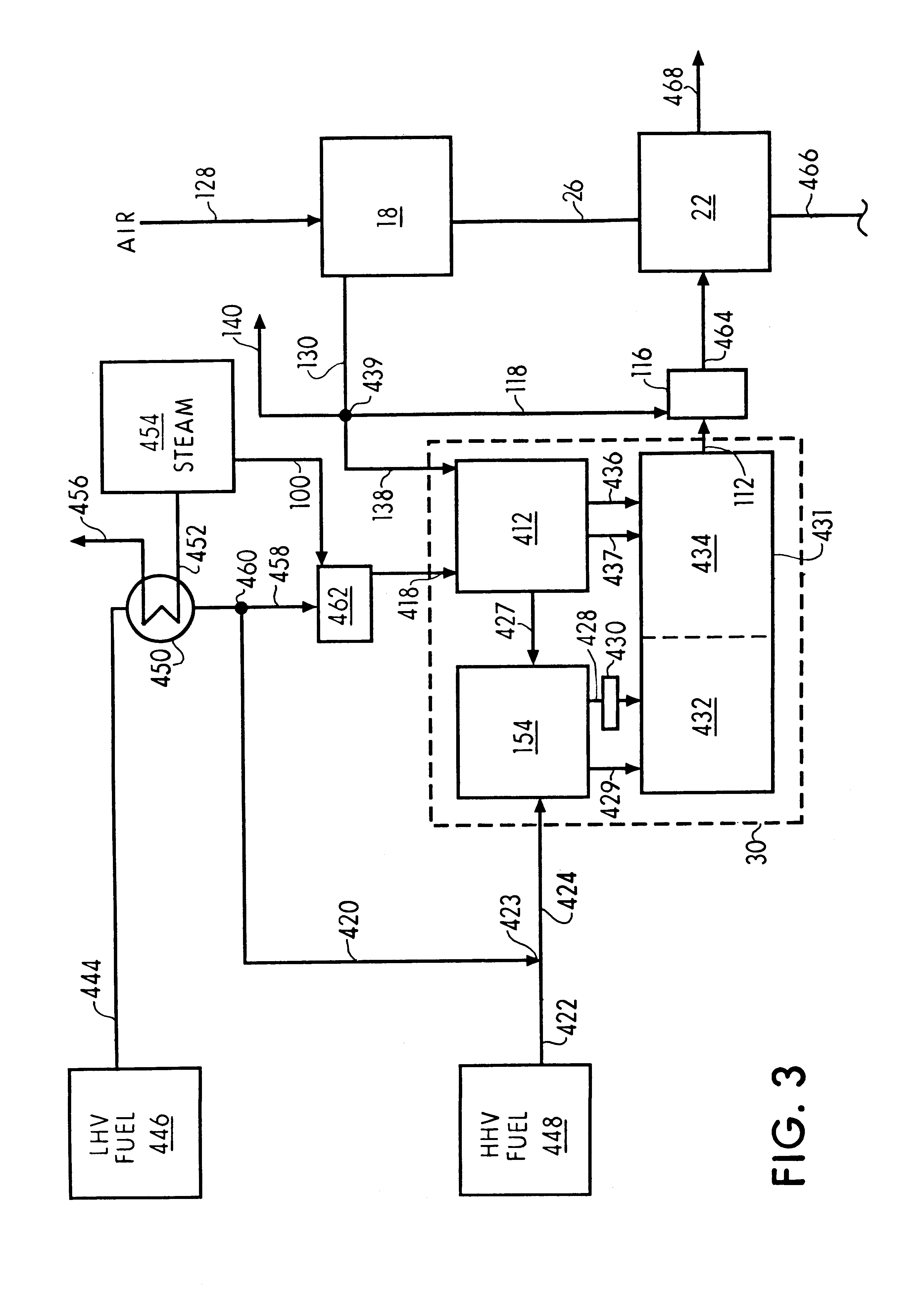

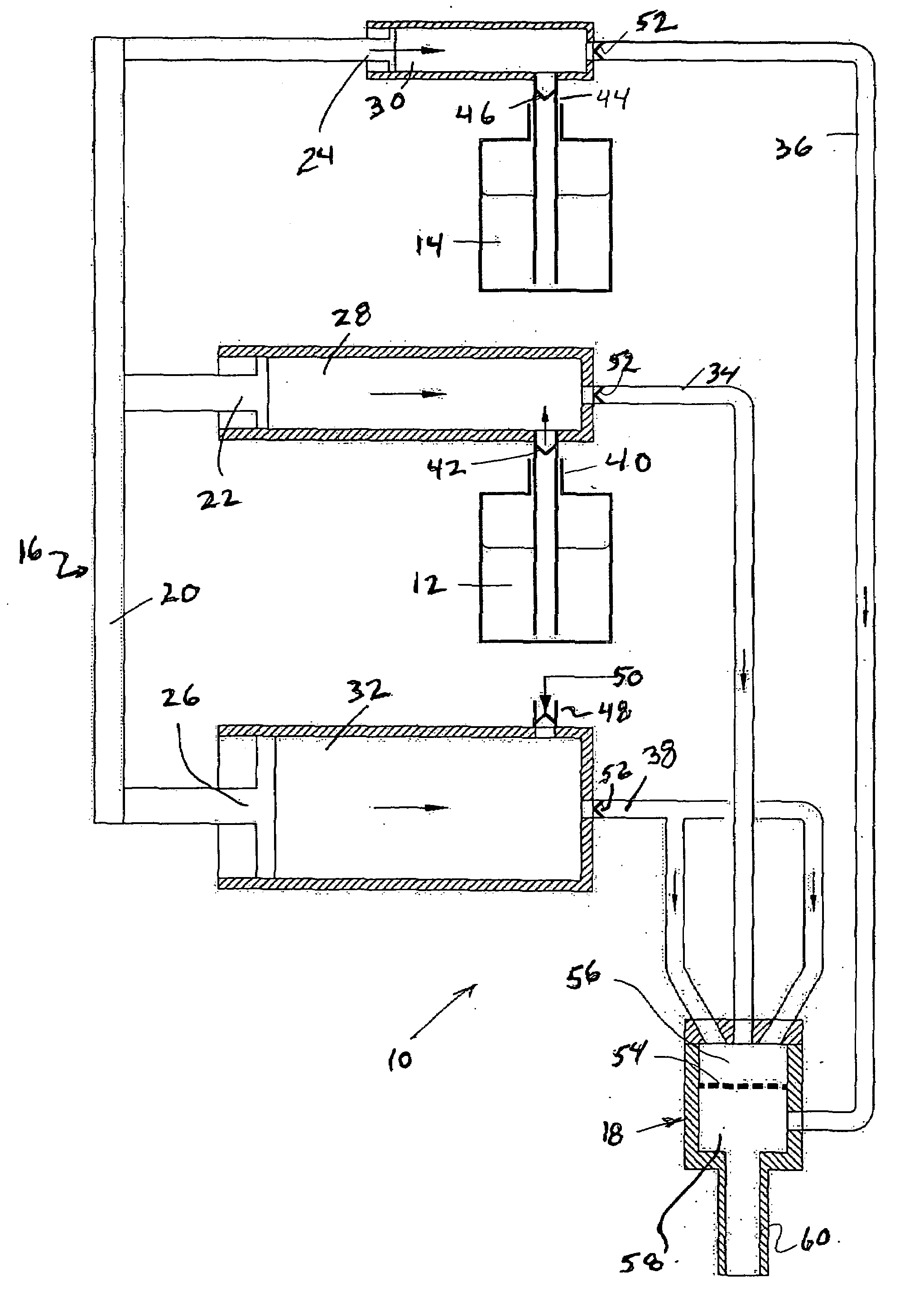

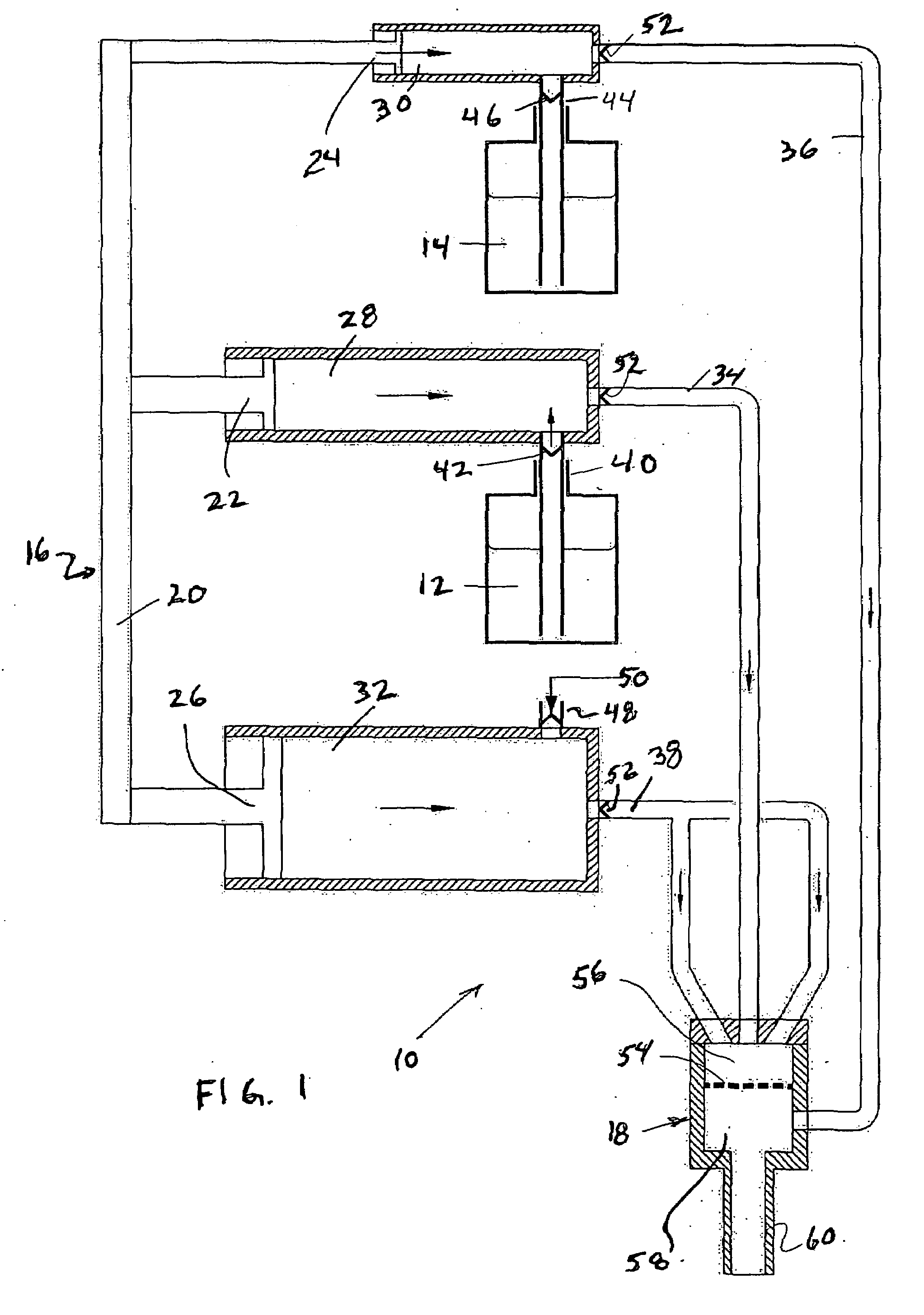

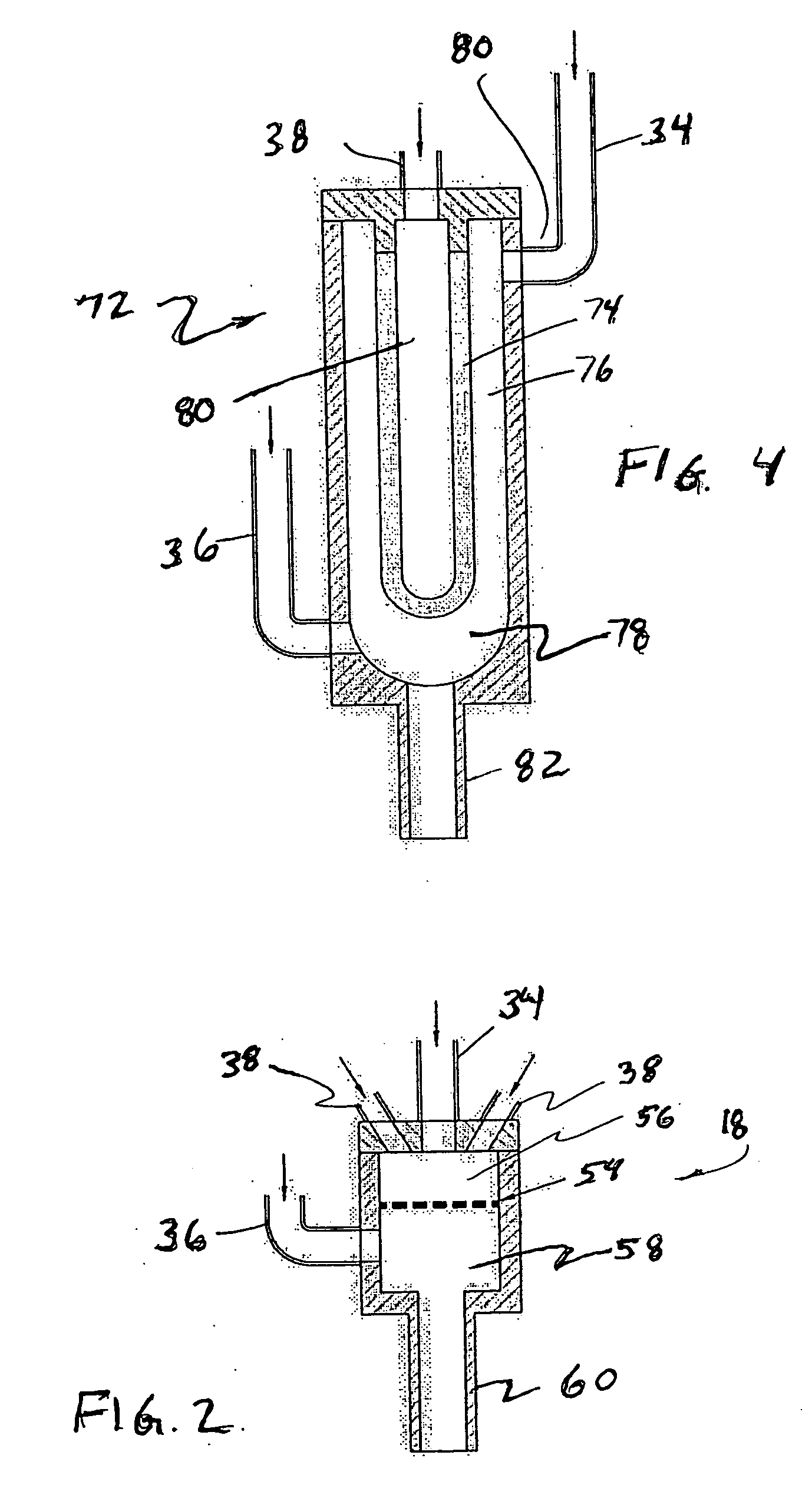

Staged combustion of a low heating value fuel gas for driving a gas turbine

A process is provided for combusting a low heating value fuel gas in a combustor to drive an associated gas turbine. A low heating value fuel gas feed is divided into a burner portion and a combustion chamber portion. The combustion chamber portion and a combustion air are conveyed into a mixing zone of the combustor to form an air / fuel mixture. The burner portion is conveyed into a flame zone of the combustor through a burner nozzle while a first portion of the air / fuel mixture is conveyed into the flame zone through a burner port adjacent to the burner nozzle. The burner portion and first portion of the air / fuel mixture are contacted in the flame zone to combust the portions and produce flame zone products. The flame zone products are conveyed into an oxidation zone of the combustor downstream of the flame zone while a second portion of the air / fuel mixture is also conveyed into the oxidation zone. The second portion is combusted in the oxidation zone in the presence of the flame zone products to produce combustion products. The combustion products are conveyed into the associated gas turbine and drive the gas turbine.

Owner:MARATHON OIL CO +1

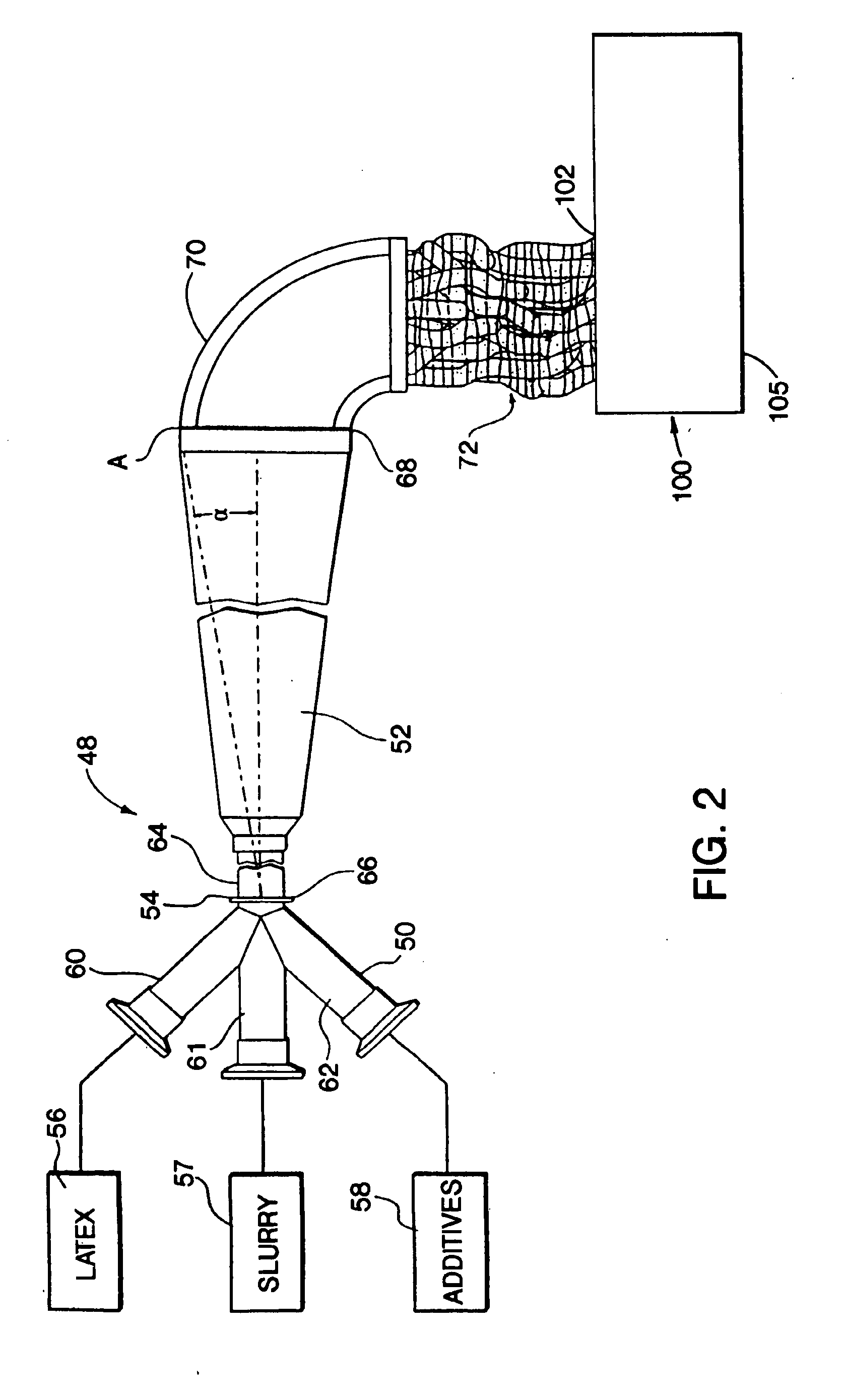

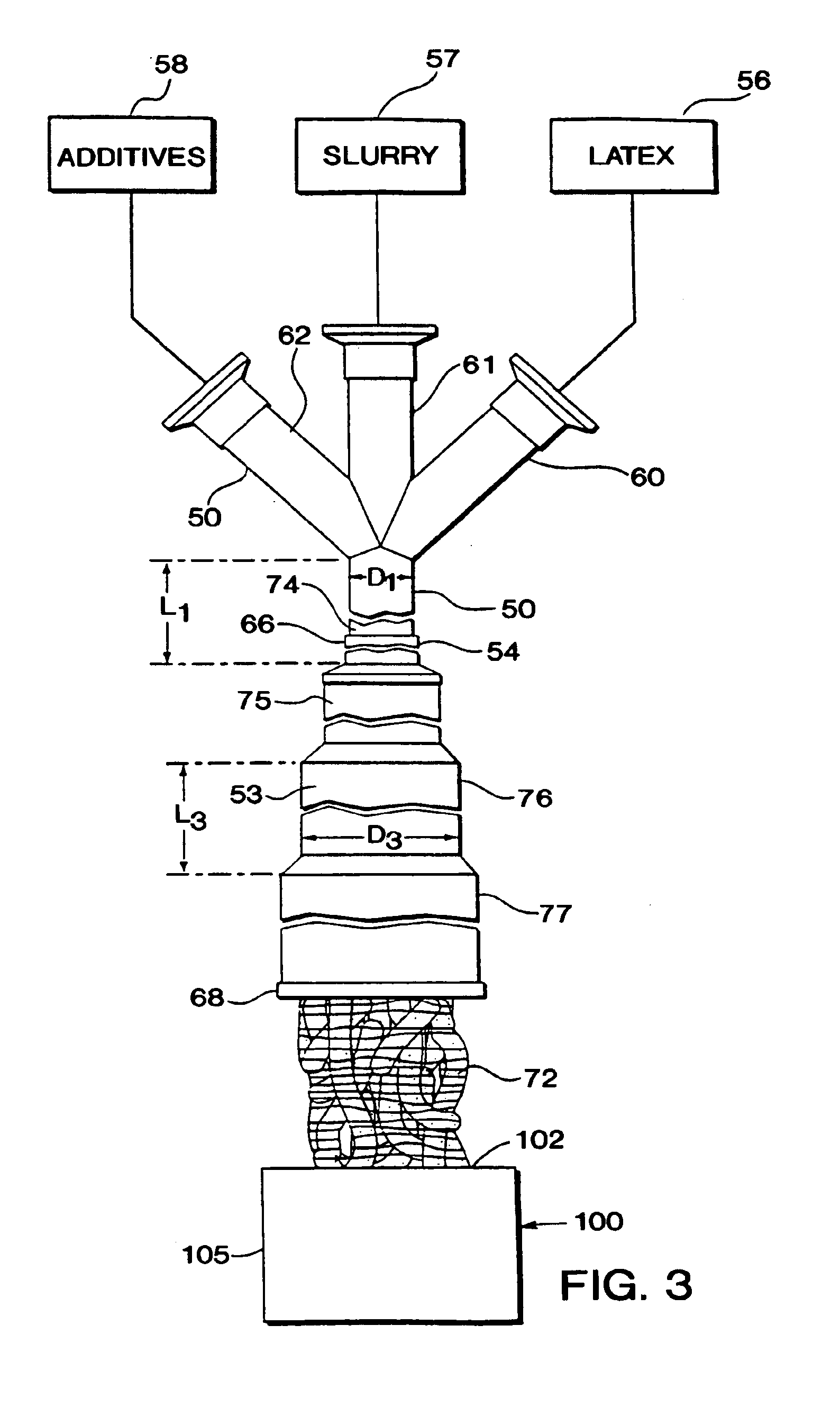

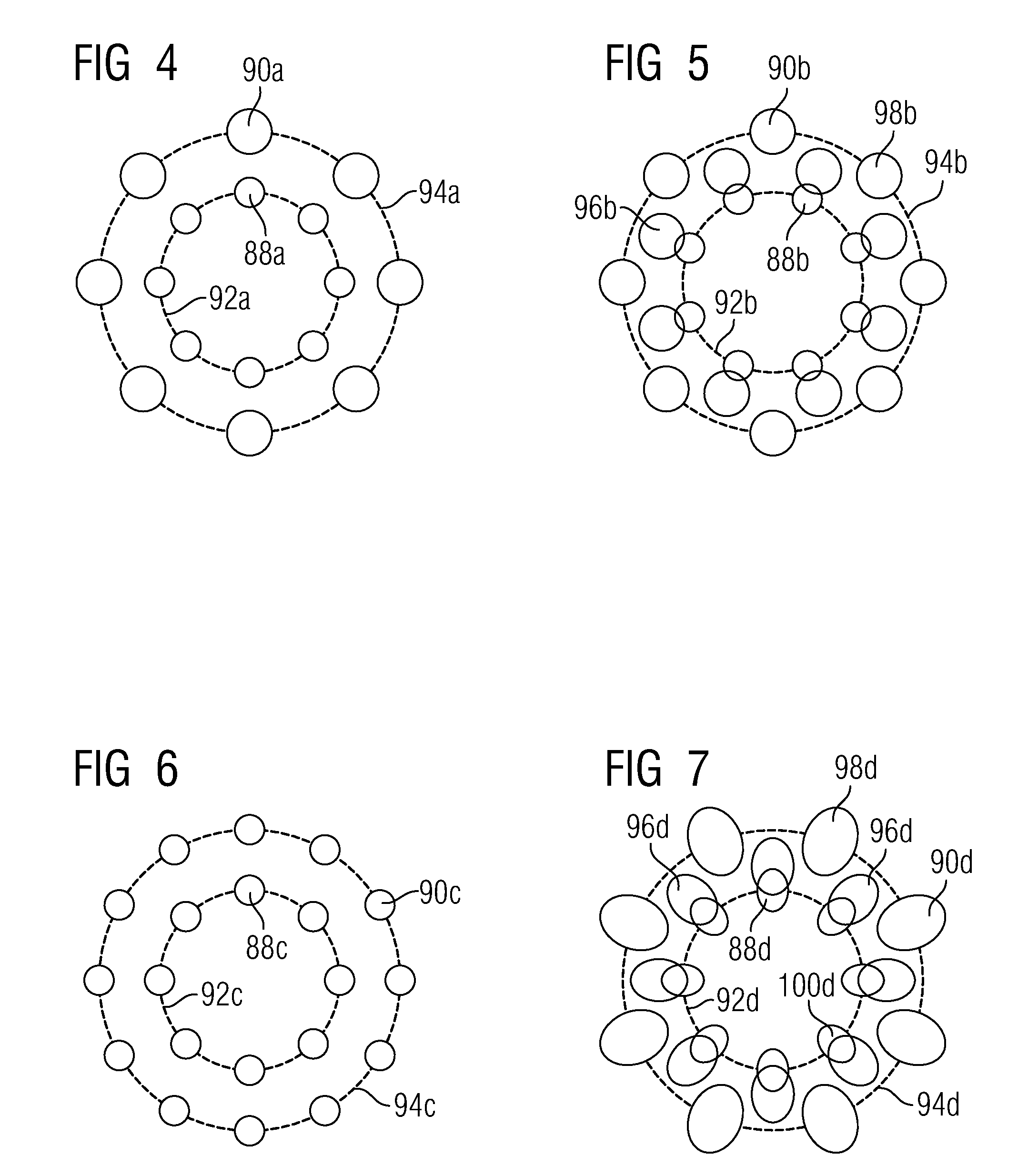

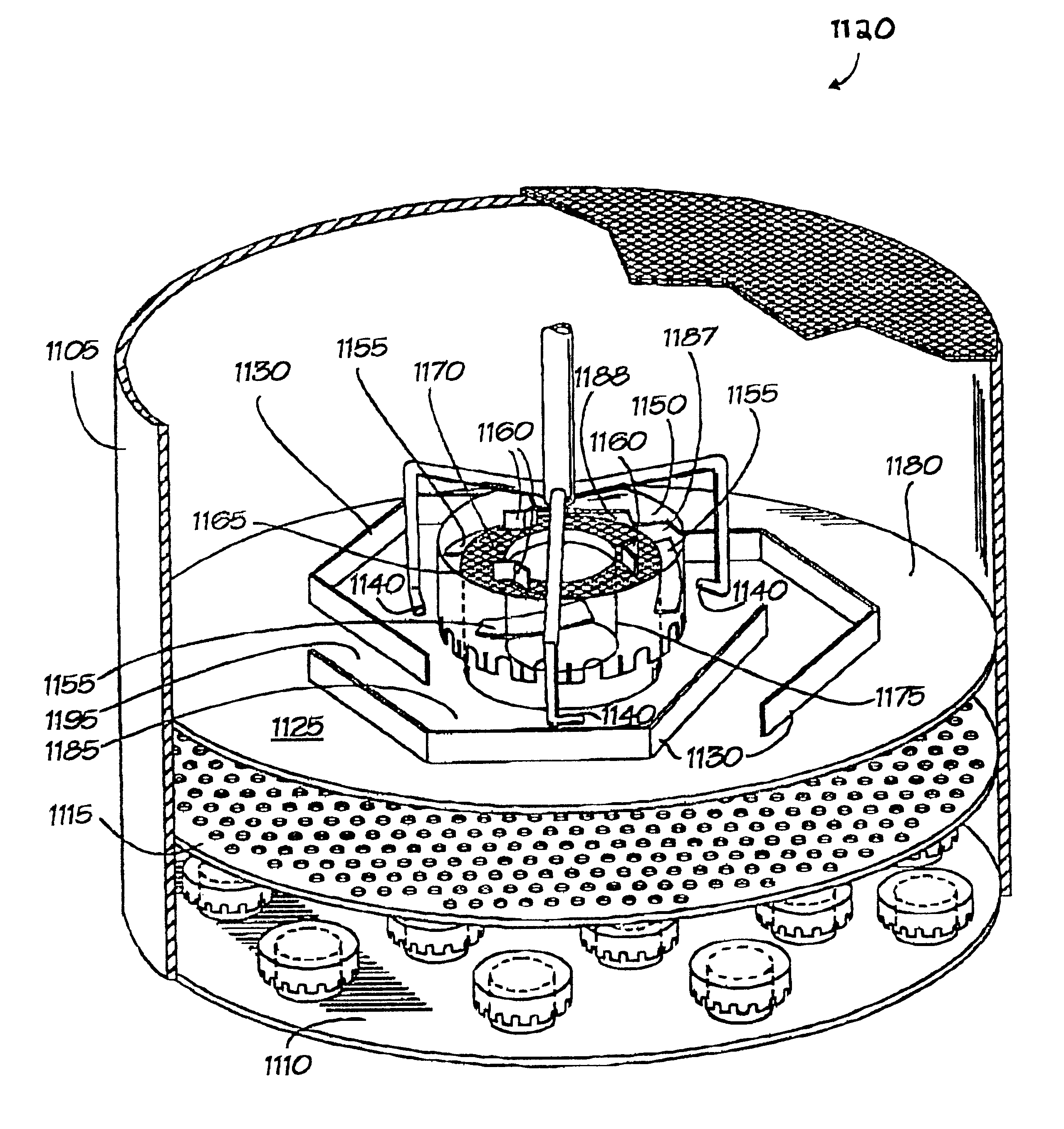

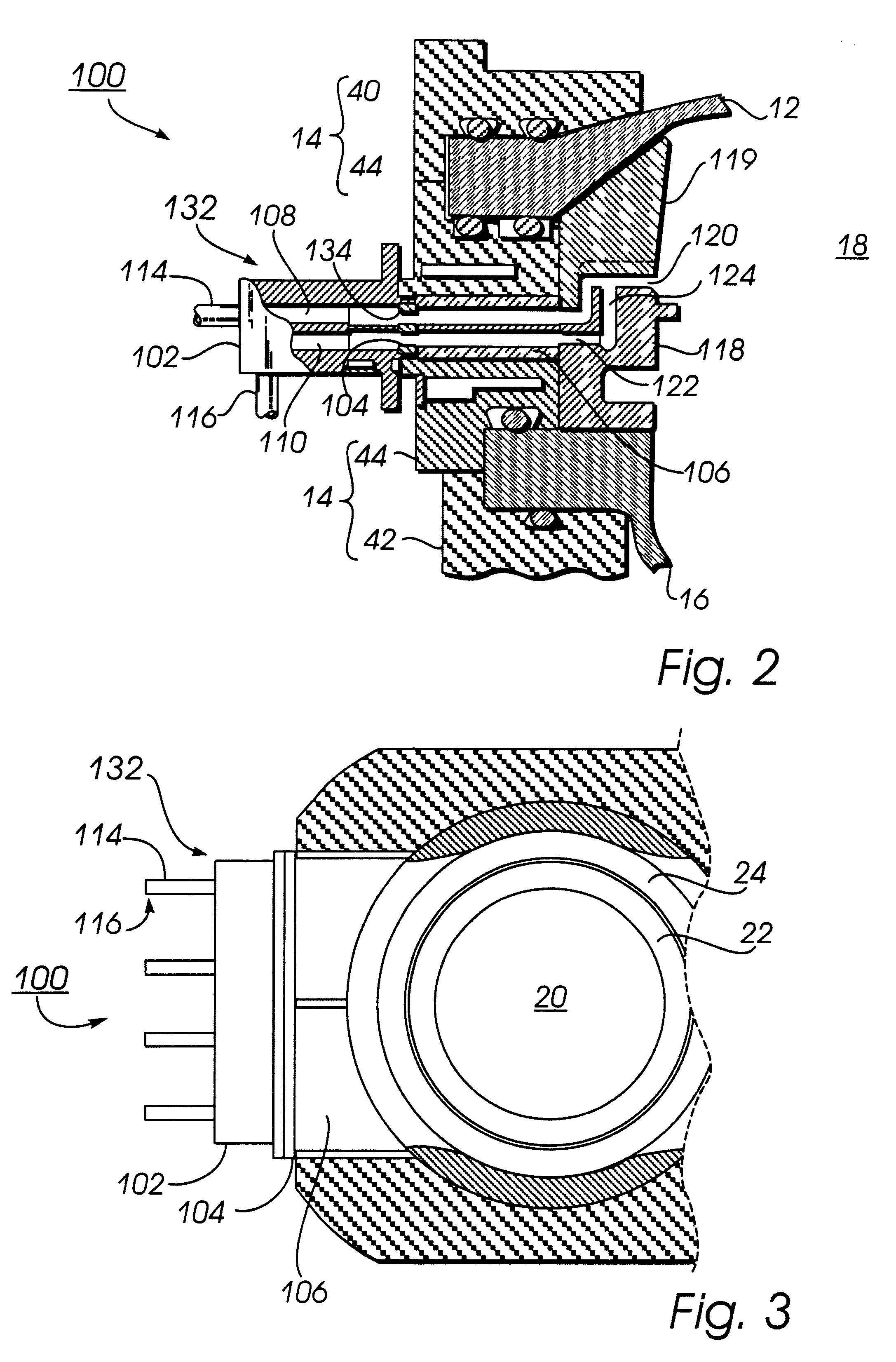

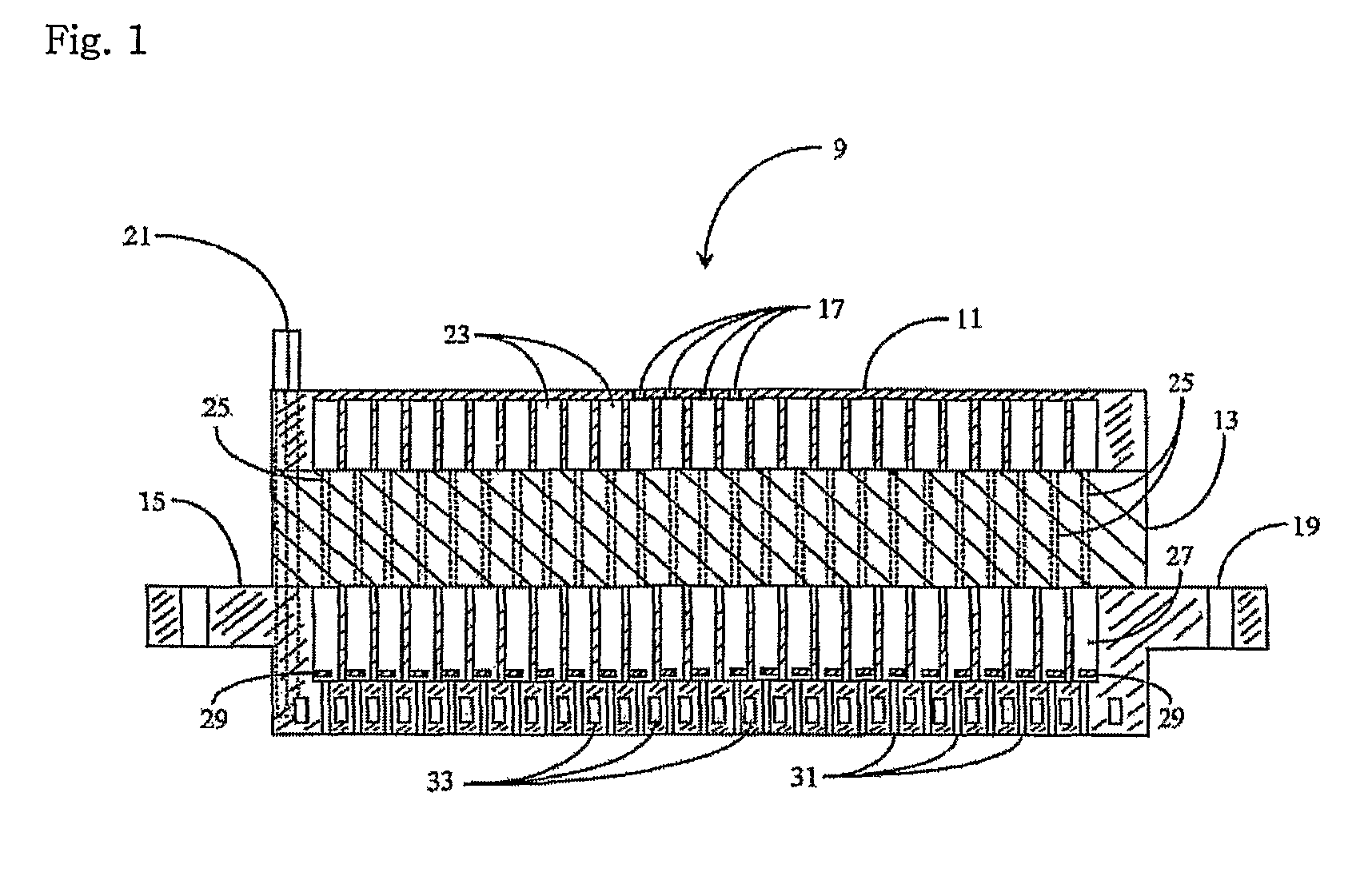

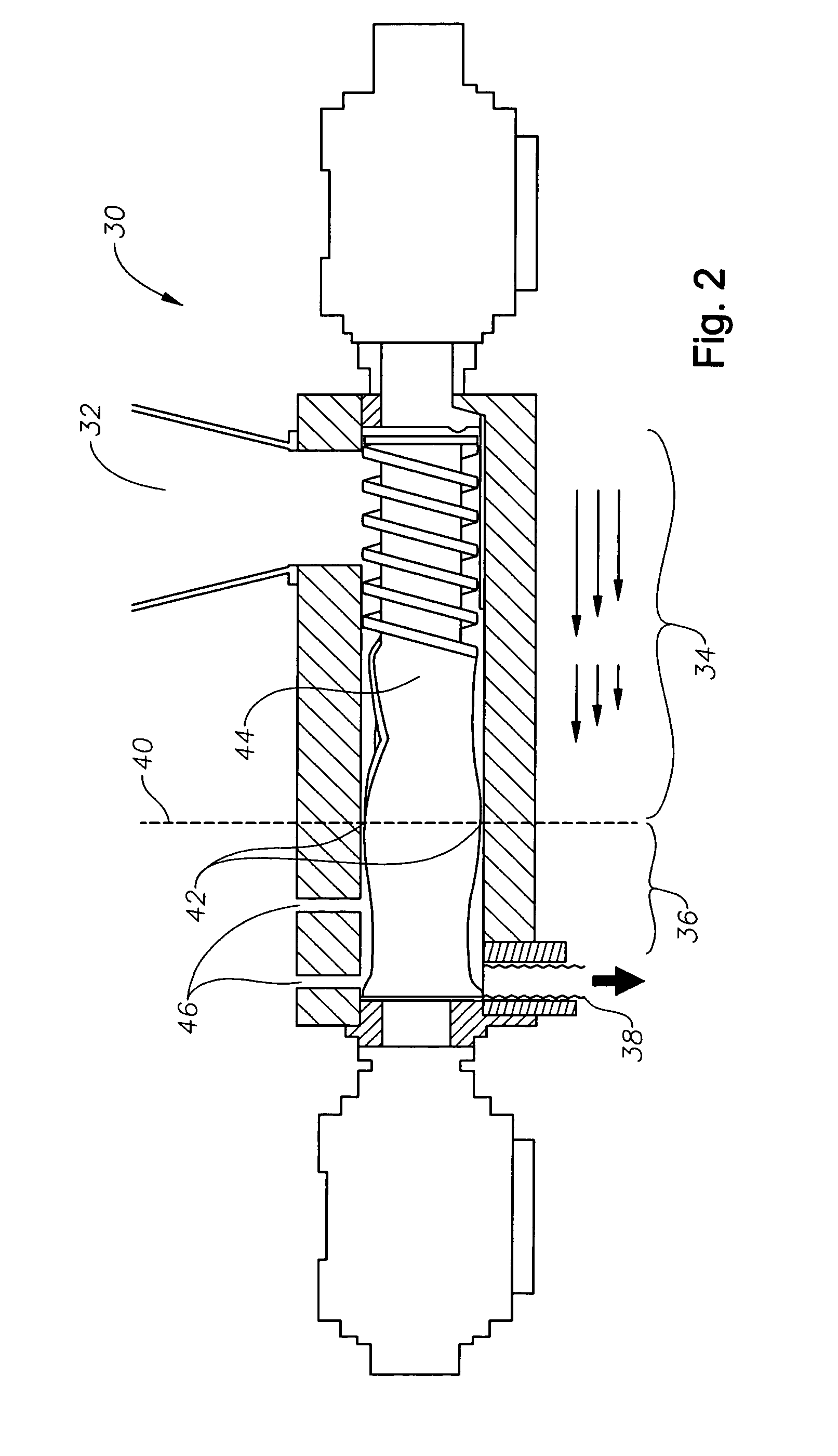

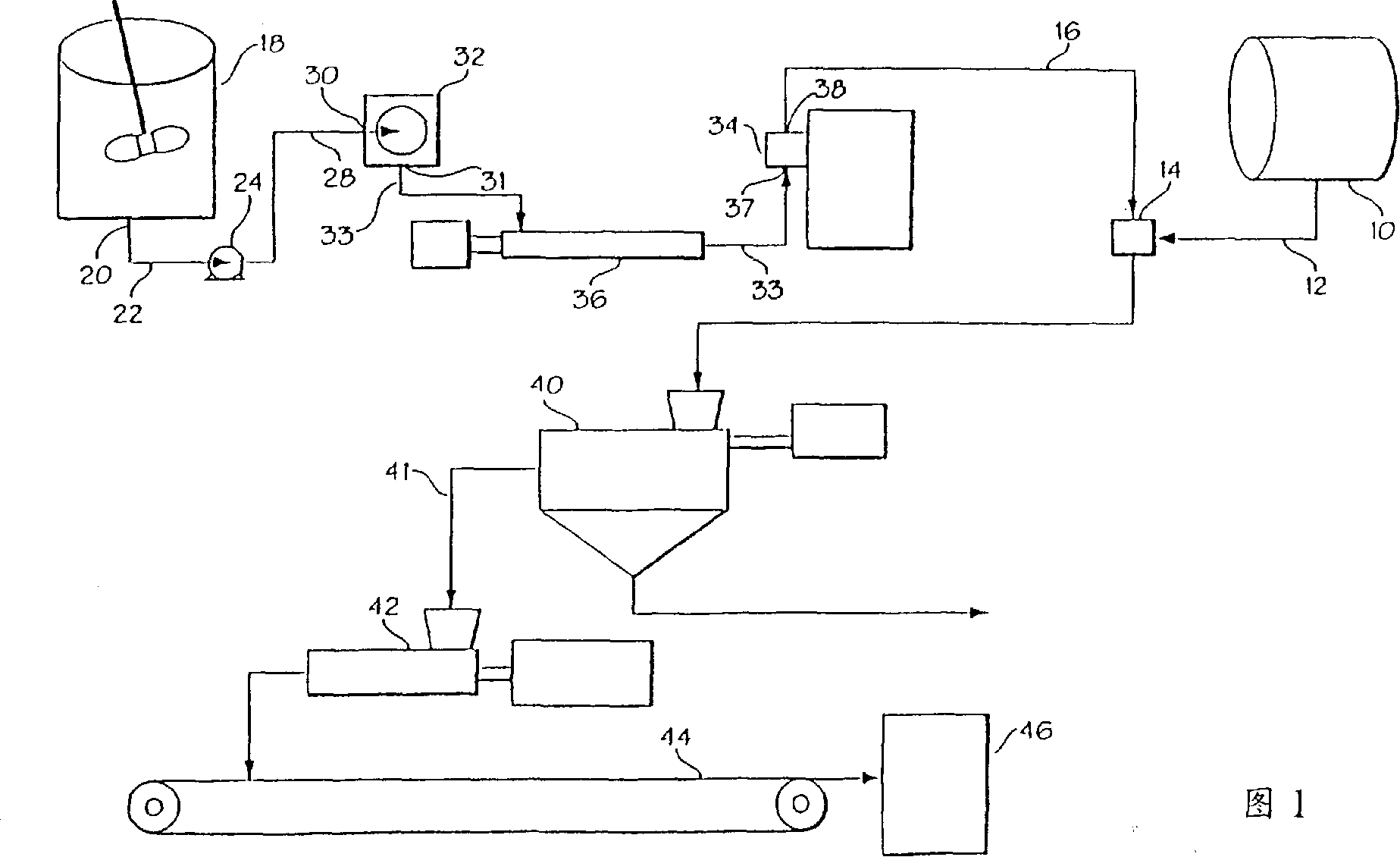

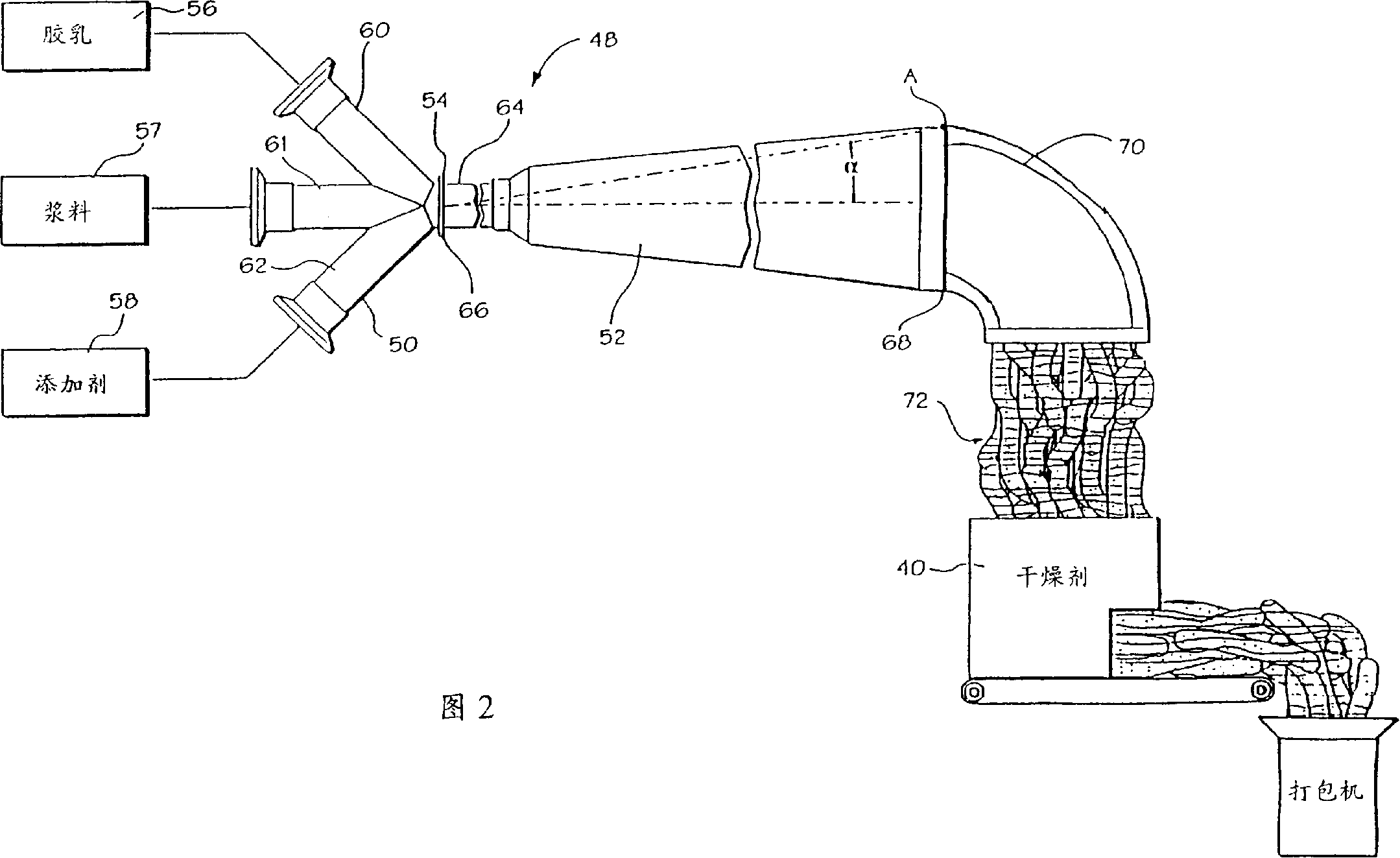

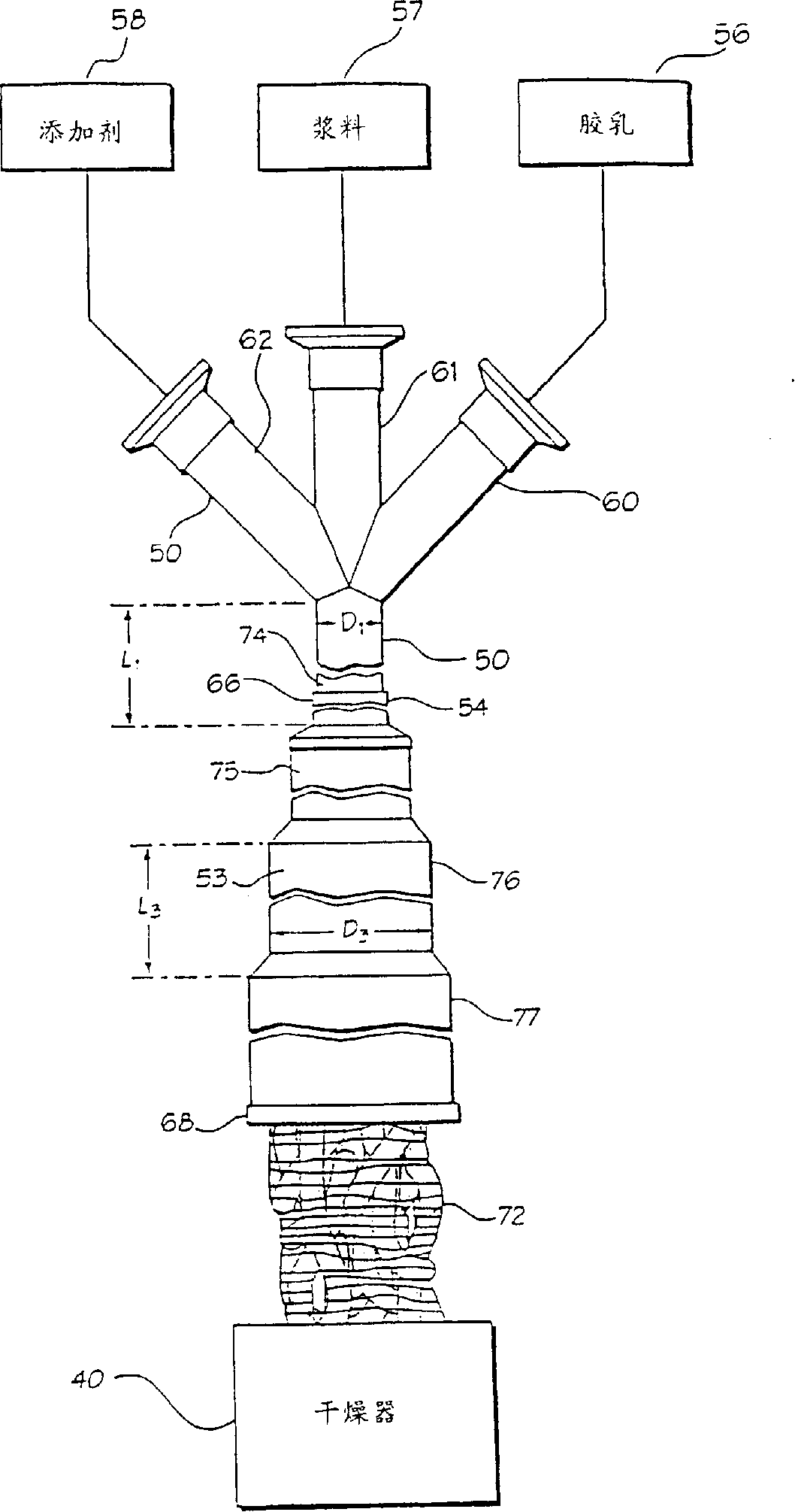

Method and apparatus for producing and treating novel elastomer composites

InactiveUS6929783B2Facilitate controlling and changing operating parameterImprove economyLiquid degasificationSpecial tyresParticulatesMasterbatch

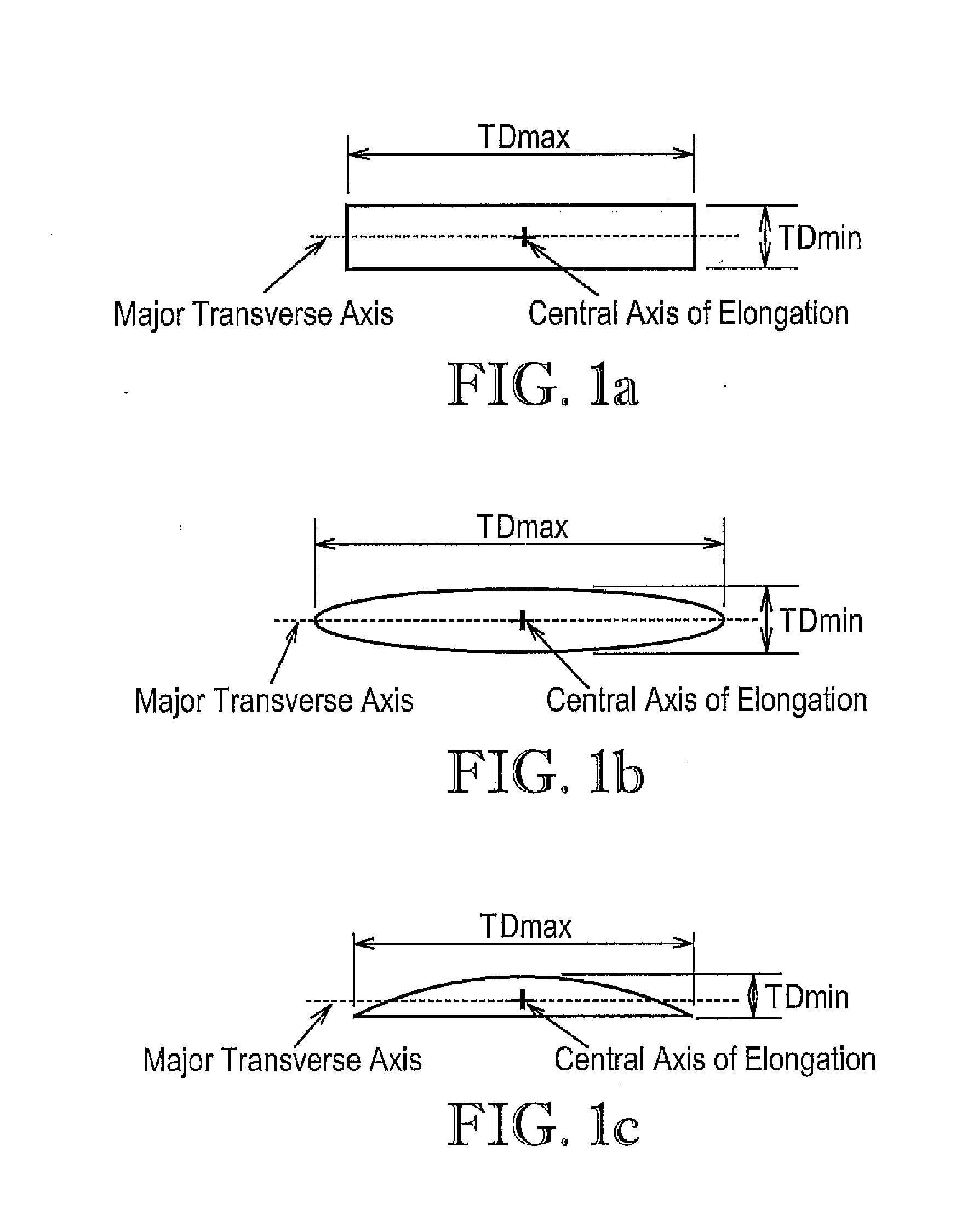

Elastomer masterbatch is processed in a continuous compounder having multiple parallel elongate rotors axially oriented in an elongate processing chamber. Optionally, additional materials are compounded into the masterbatch, e.g., additives, other elastomeric compositions, etc. Preferably, the masterbatch then is further processed in an open mill. Excellent control of Mooney Viscosity is achieved.In certain preferred embodiments, elastomer composites are produced by novel continuous flow methods and apparatus in which fluid streams of particulate filler and elastomer latex are fed to the mixing zone of a coagulum reactor to form a coagulated mixture in semi-confined flow continuously from the mixing zone through a coagulum zone to a discharge end of the reactor. The particulate filler fluid is fed under high pressure to the mixing zone, such as to form a jet stream to entrain elastomer latex fluid sufficiently energetically to substantially completely coagulate the elastomer with the particulate filler prior to the discharge end without need of adding acid or salt solution or other coagulation step. The coagulated elastomer and particulate filler composite is fed into the aforesaid continuous compounder for processing and control of its moisture level and Mooney Viscosity. Novel elastomer composites are produced. Such novel elastomer composites combine material properties and characteristics, such as choice of filler, elastomer, level of filler loading, moisture level, Mooney Viscosity, balance between molecular weight and amount of bound rubber, and macro-dispersion not previously achieved.

Owner:CABOT CORP

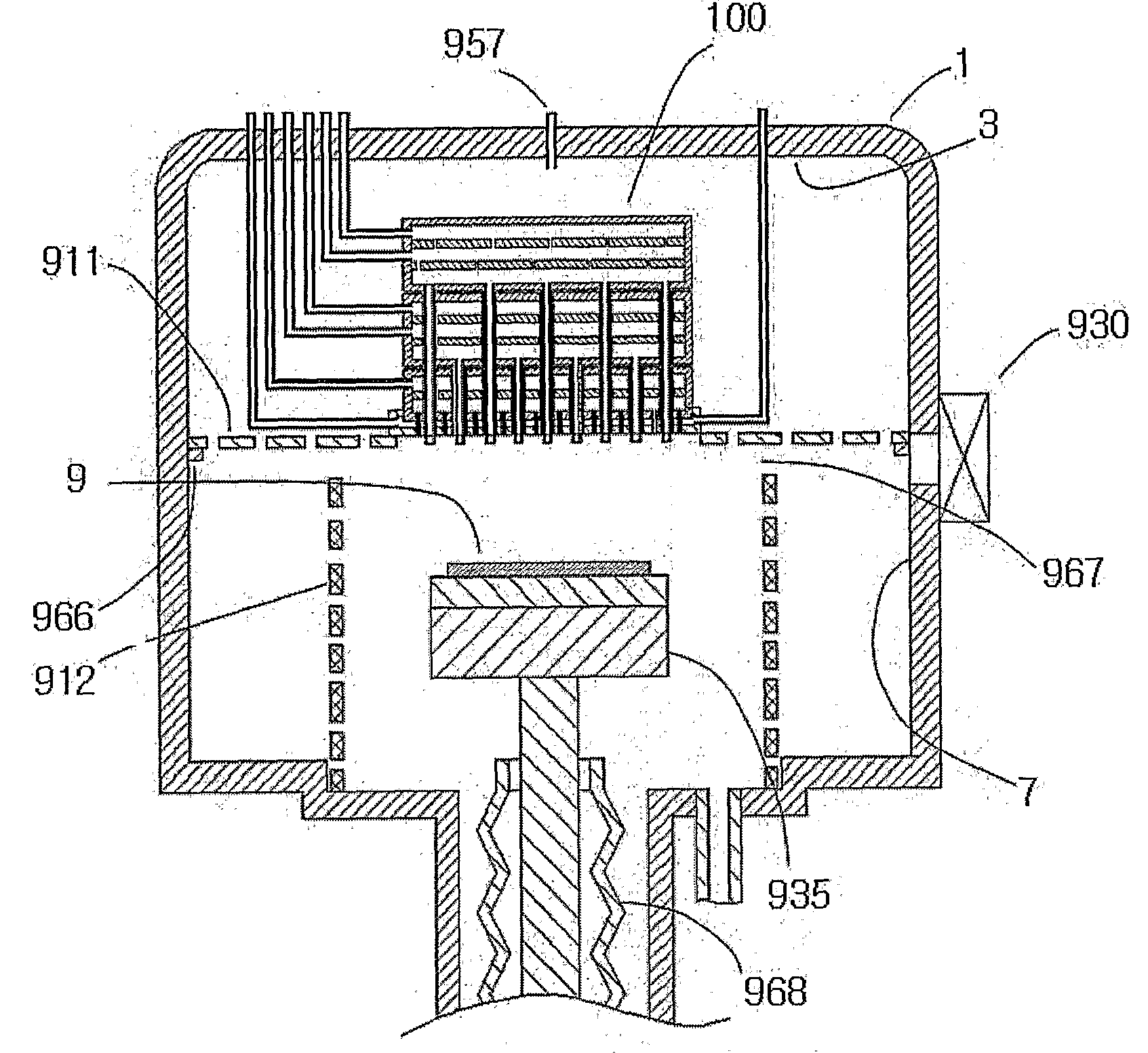

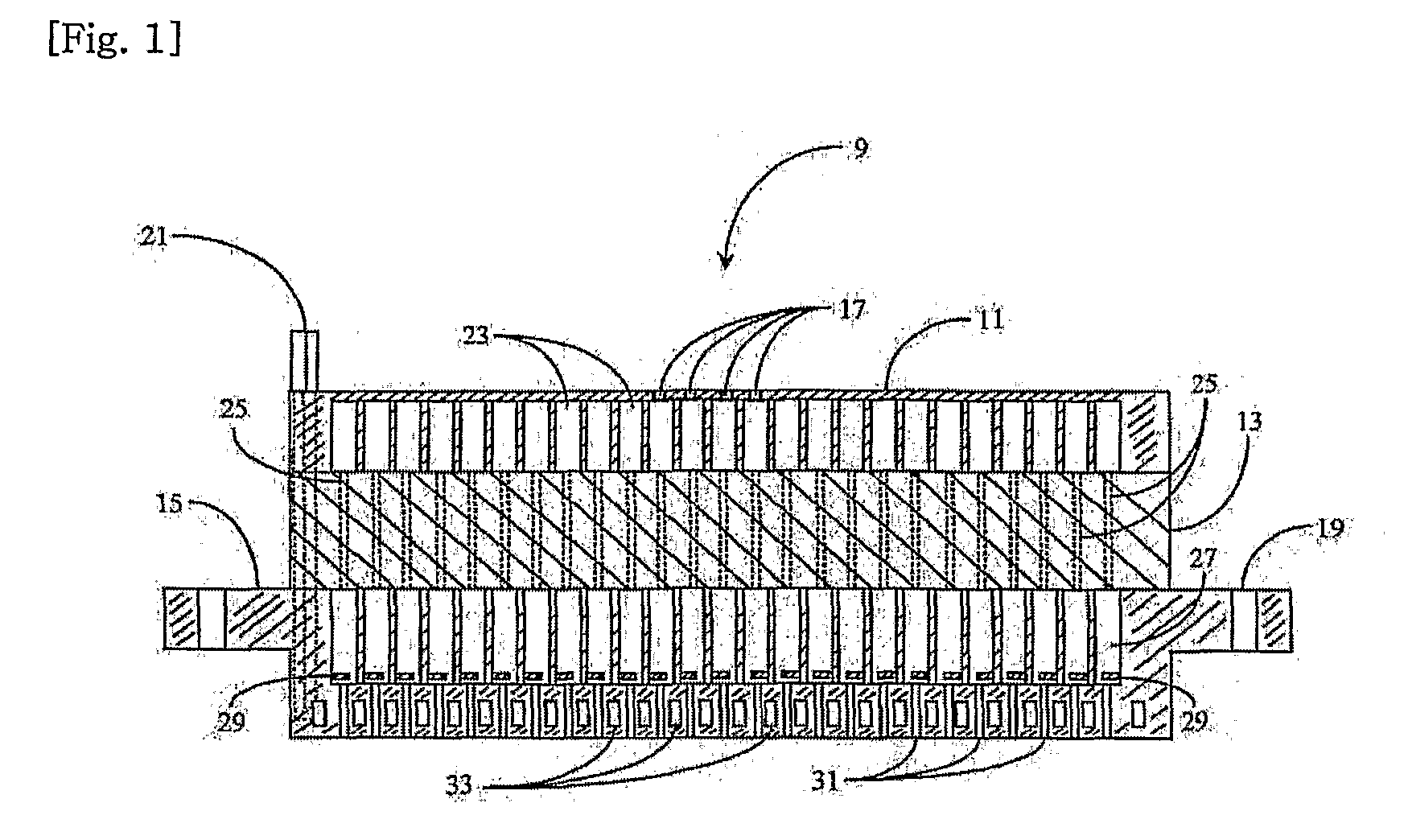

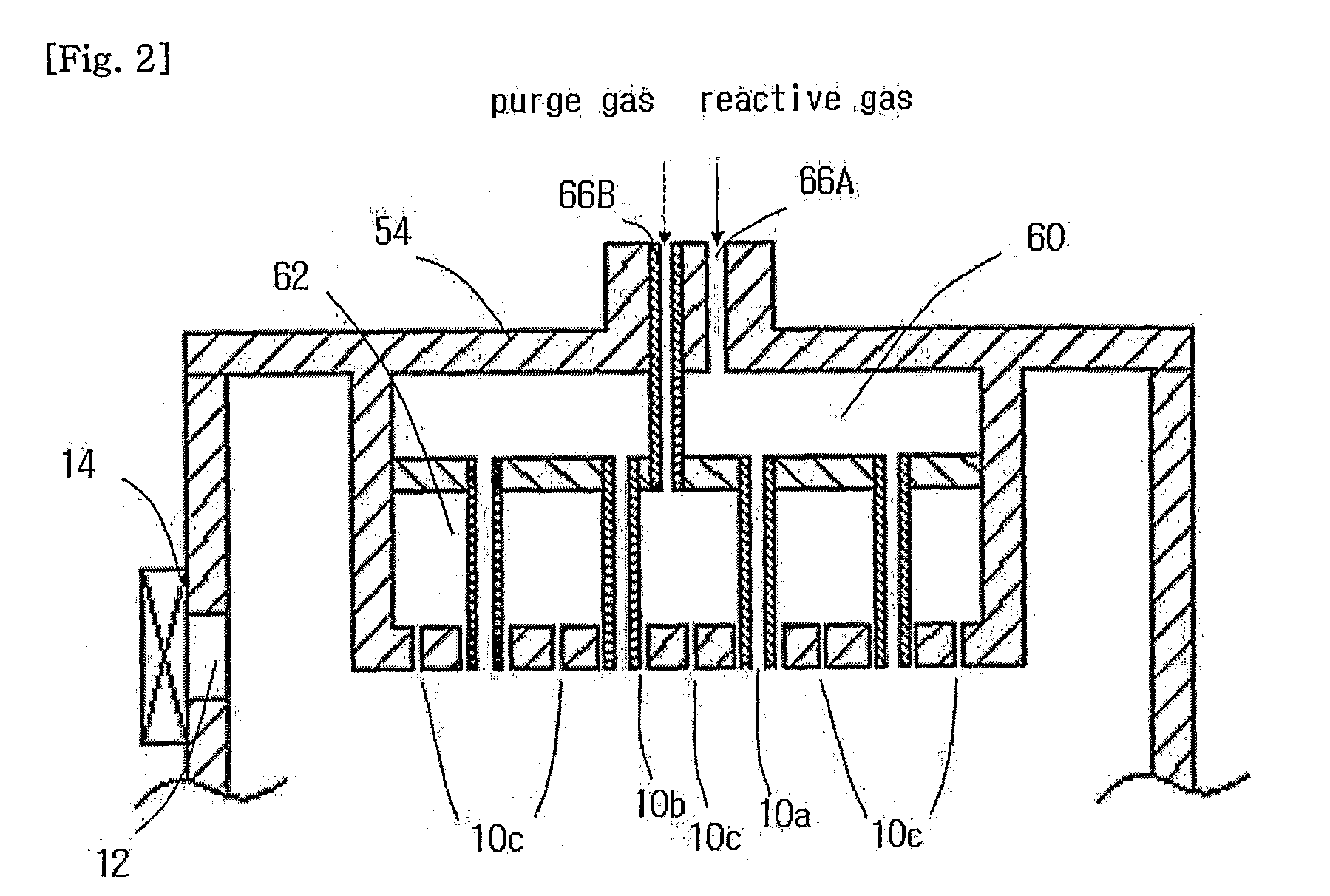

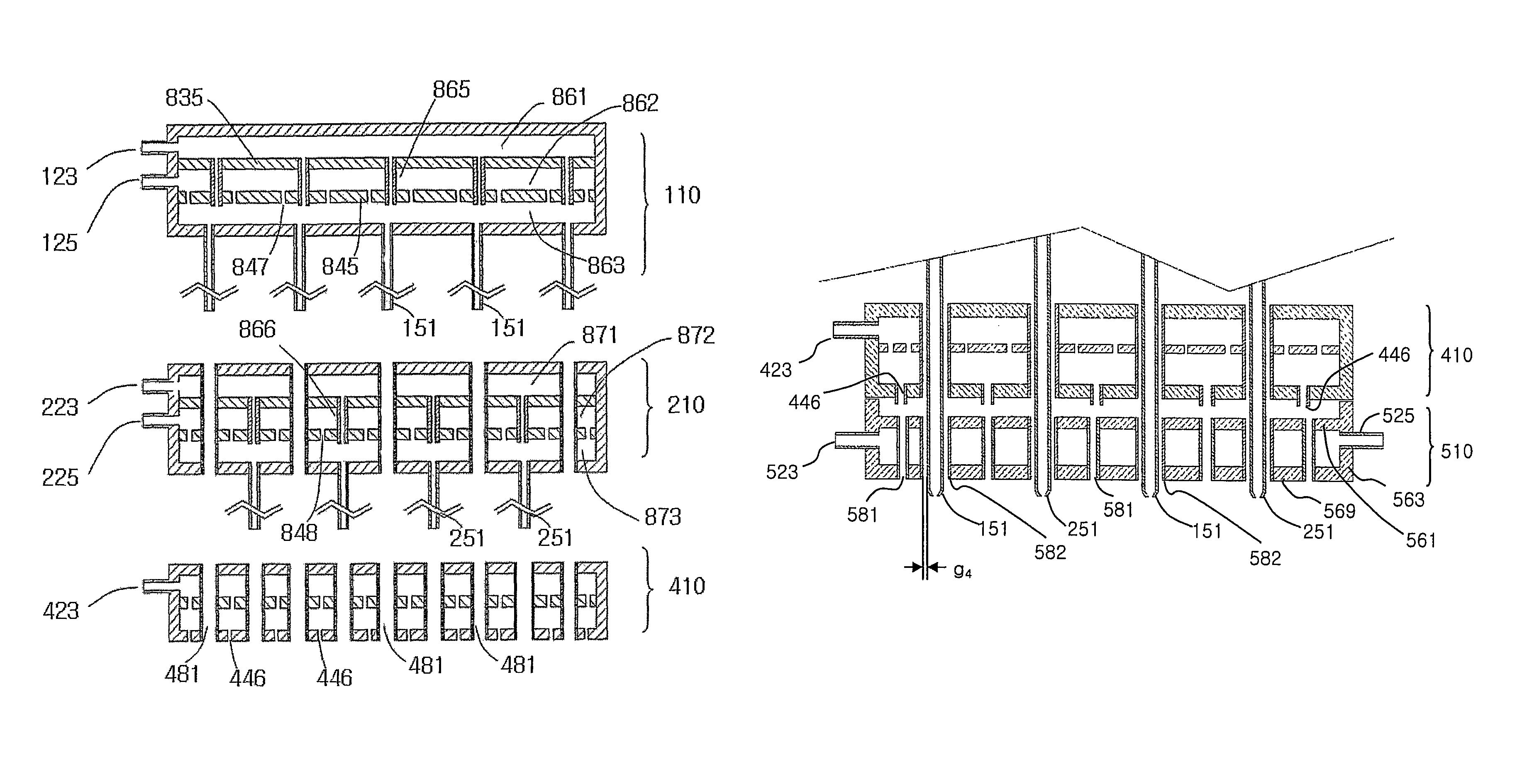

Apparatus of chemical vapor deposition with a showerhead regulating injection velocity of reactive gases postively and method thereof

ActiveUS20090169744A1Suppress DiffuseAvoid pollutionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingReactive gasGas phase

The present invention is related to an apparatus and a method for chemical vapor deposition (CVD) using a showerhead through which a reactive gas of at least one kind and a purge gas is injected over a substrate on which a film is growing. A plural number of reactive gas showerhead modules are laid on a purge gas showerhead module. Each reactive gas is injected from a bottom of the showerhead after flowing through the showerhead as separated, thereby preventing the reactive gases from causing homogeneous gas phase reactions and from generating unwanted particles at the inside of the showerhead. And purge gas is injected from the bottom surface of the showerhead by forming a protective curtain, thereby suppressing diffusion of the reactive gas injected backwardly. Each reactive gas is mixed with an injection support gas which is a kind of inert gas in a mixing zone at inside of the showerhead, where the injection velocity of each reactive gas is regulated positively by the amount of the injection support gas mixed. The present invention further includes an apparatus and a method, wherein the showerhead is cooled by a cooling jacket which keeps the temperature of the showerhead at proper levels to prevent both the condensation and the thermal decomposition of the reactive gas used.

Owner:KOREA INST OF IND TECH +1

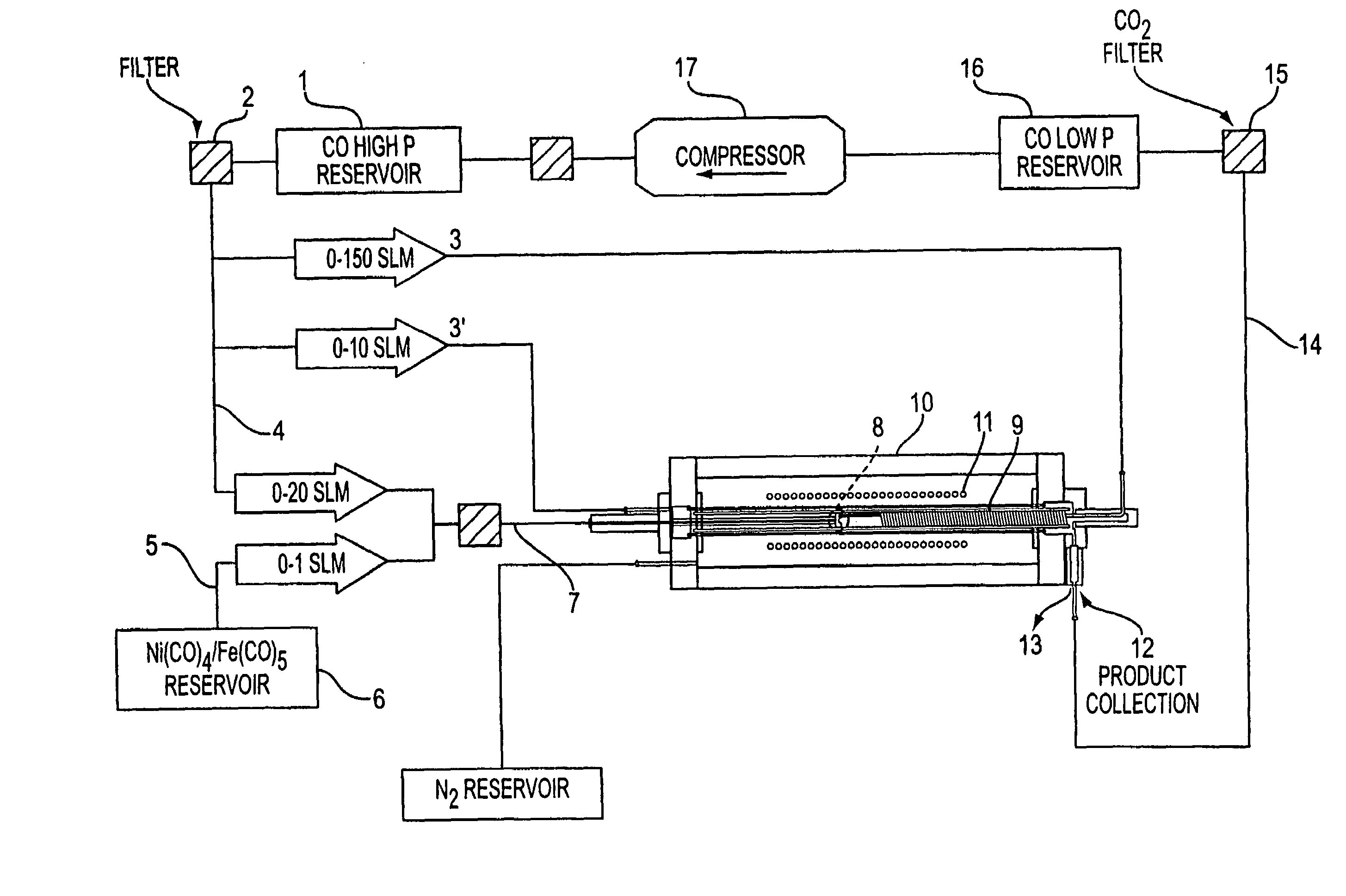

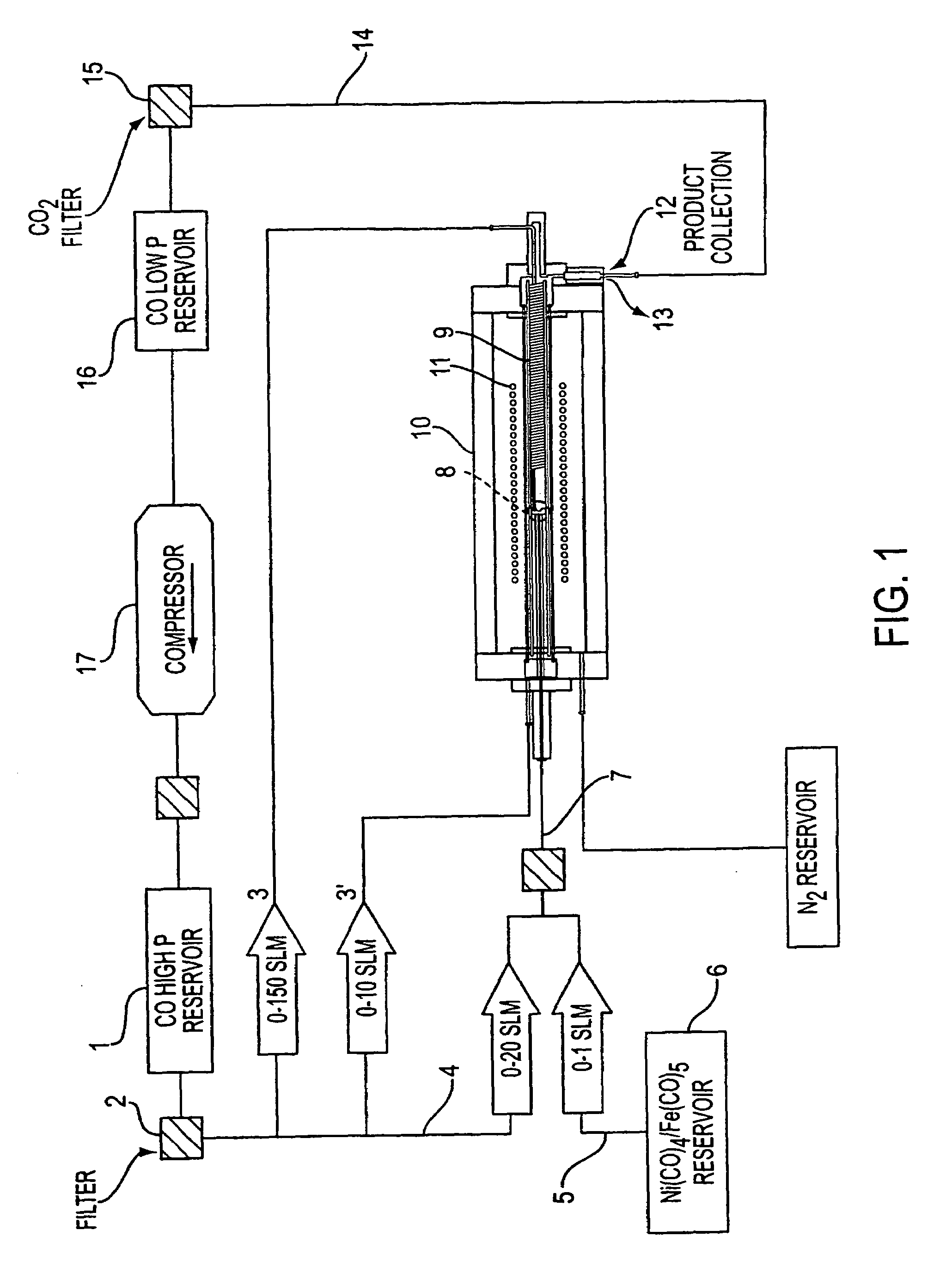

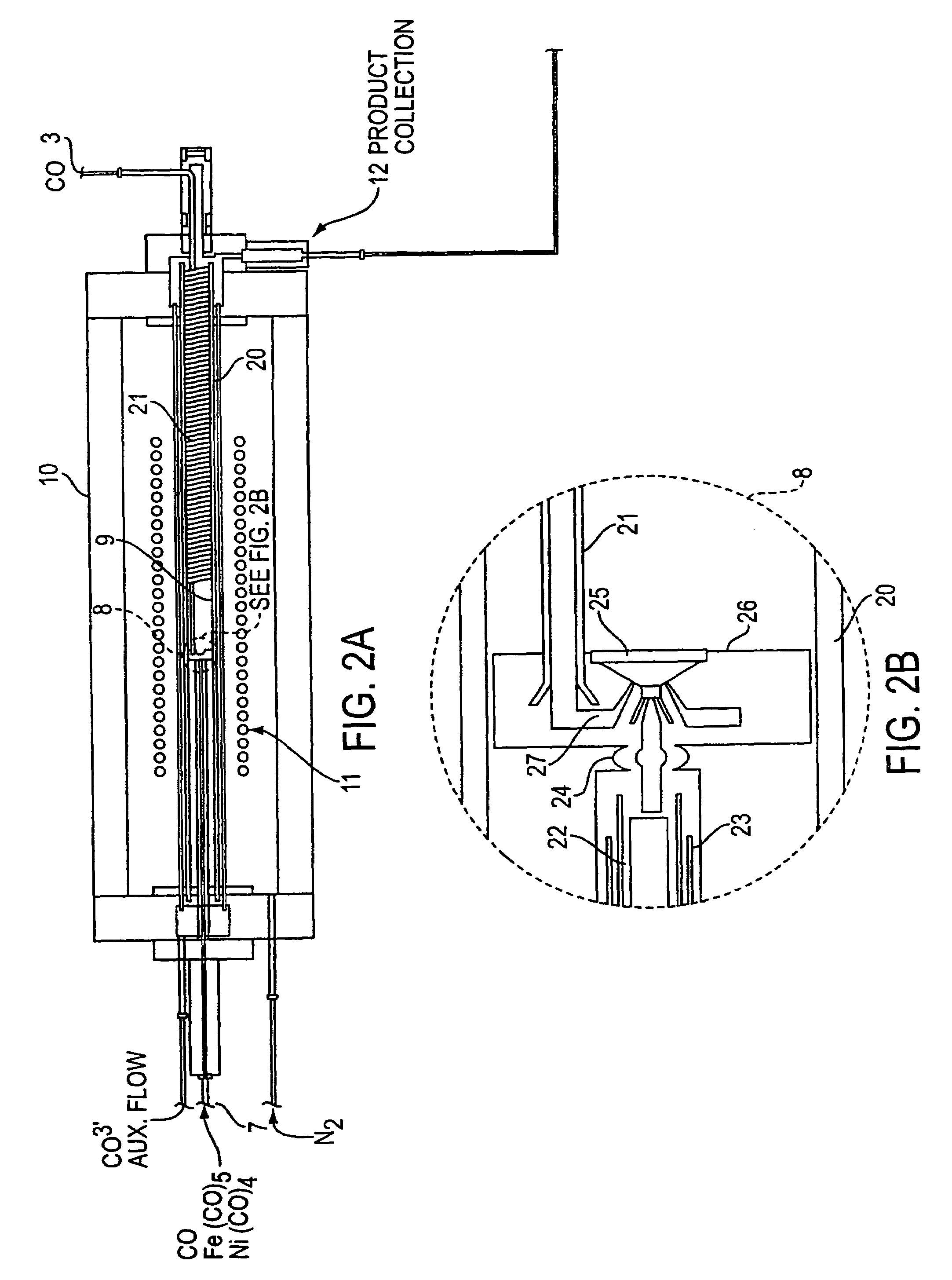

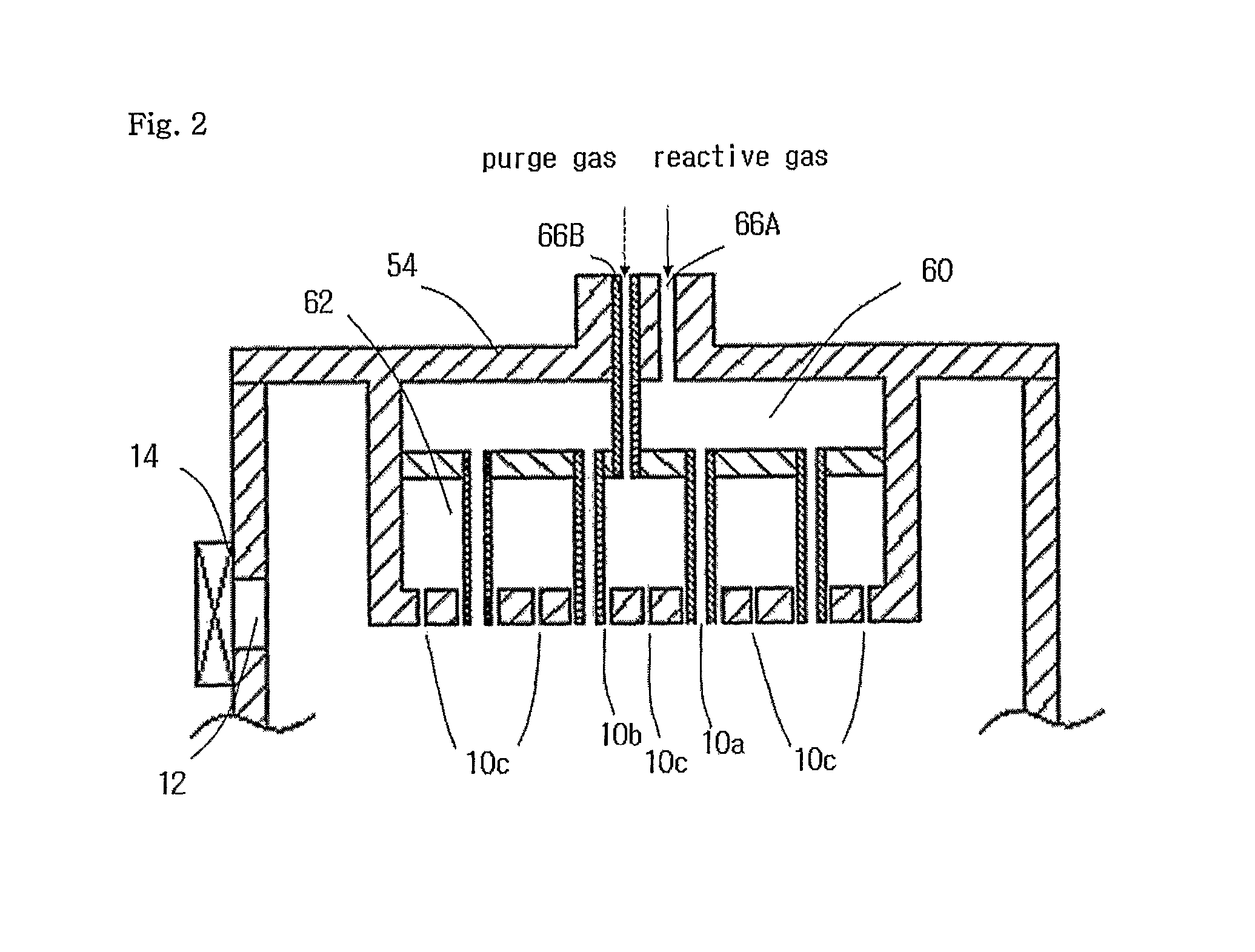

Single-wall carbon nanotubes from high pressure CO

InactiveUS7204970B2Promote rapid formationIncrease pressureMaterial nanotechnologyNanostructure manufactureDecompositionCarbon nanotube

The present invention discloses the process of supplying high pressure (e.g., 30 atmospheres) CO that has been preheated (e.g., to about 1000° C.) and a catalyst precursor gas (e.g., Fe(CO)5) in CO that is kept below the catalyst precursor decomposition temperature to a mixing zone. In this mixing zone, the catalyst precursor is rapidly heated to a temperature that results in (1) precursor decomposition, (2) formation of active catalyst metal atom clusters of the appropriate size, and (3) favorable growth of SWNTs on the catalyst clusters. Preferably a catalyst cluster nucleation agency is employed to enable rapid reaction of the catalyst precursor gas to form many small, active catalyst particles instead of a few large, inactive ones. Such nucleation agencies can include auxiliary metal precursors that cluster more rapidly than the primary catalyst, or through provision of additional energy inputs (e.g., from a pulsed or CW laser) directed precisely at the region where cluster formation is desired. Under these conditions SWNTs nucleate and grow according to the Boudouard reaction. The SWNTs thus formed may be recovered directly or passed through a growth and annealing zone maintained at an elevated temperature (e.g., 1000° C.) in which tubes may continue to grow and coalesce into ropes.

Owner:RICE UNIV

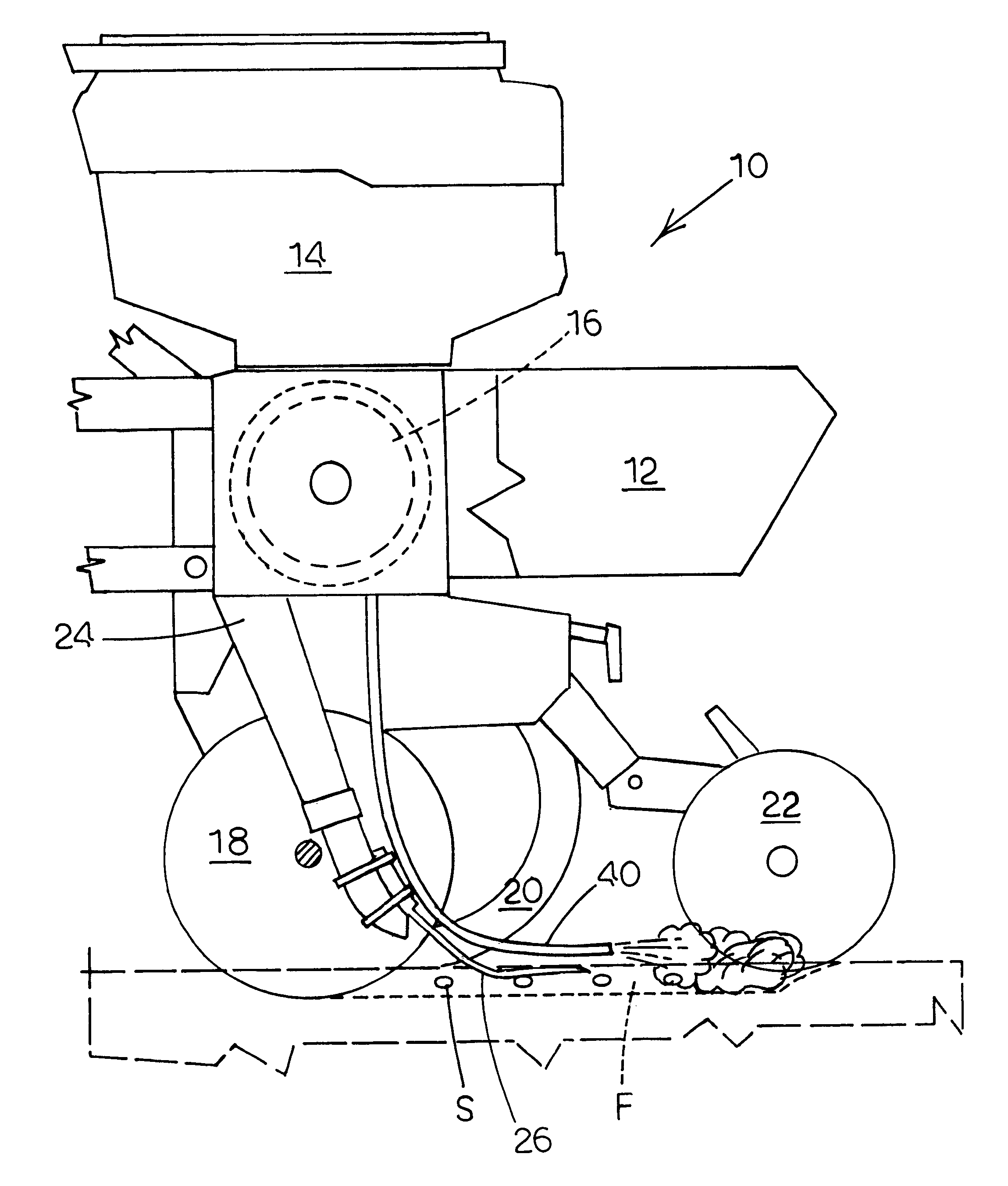

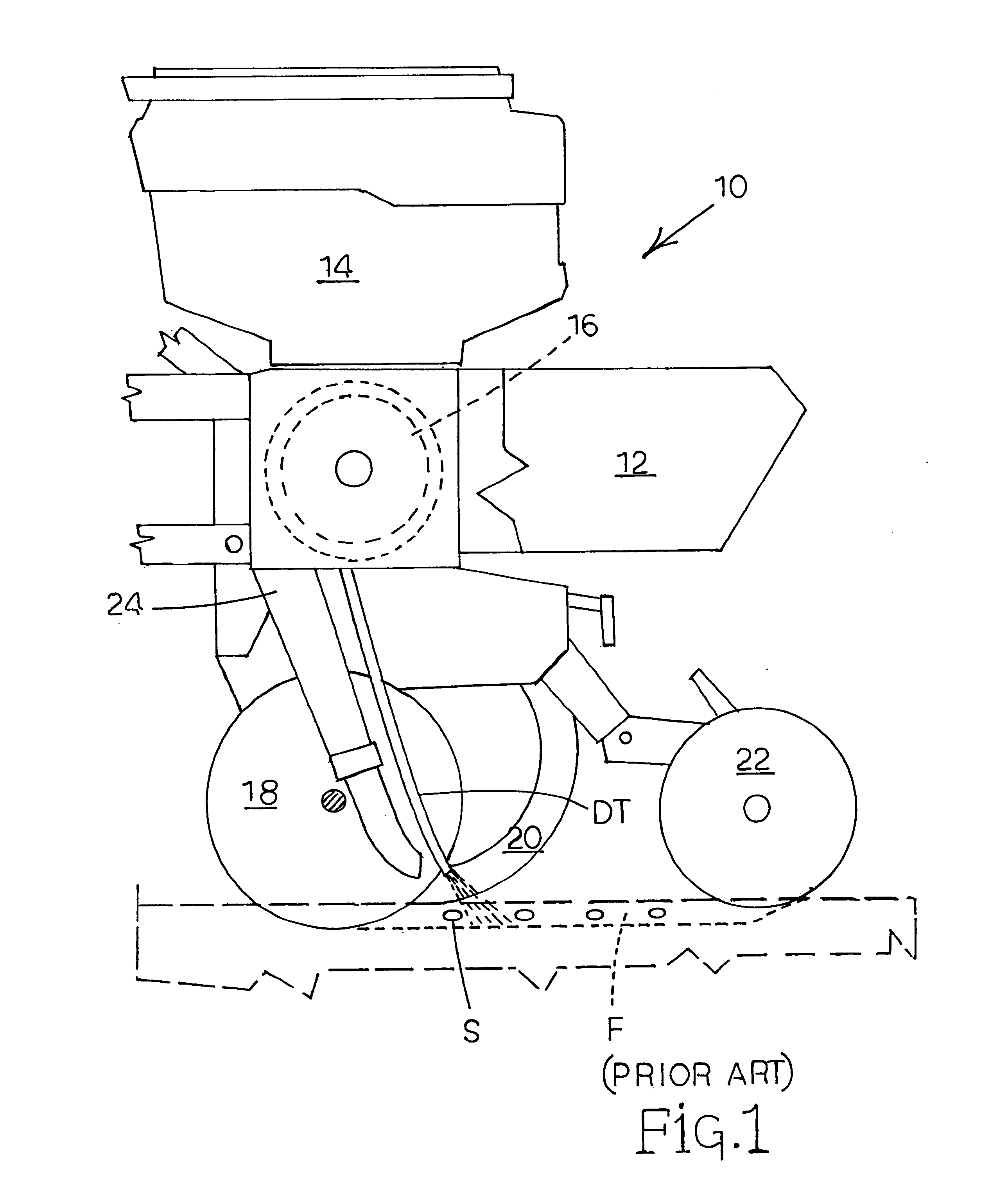

Planting apparatus with improved liquid pesticide delivery device and related method for delivering liquid pesticide

A planting machine for delivering liquid pesticides to the soil mixing zone preceding the furrow closing mechanism to effectively distribute liquid pesticide throughout soil covering seed in a furrow. The planting machine has a furrow opening mechanism, seed dispensing means, and furrow closing mechanism and includes a seed positioning means mounted on the seed dispensing means for effectively locating seeds in the furrow. Also, the planting machine includes means for liquid pesticide spray delivery mounted thereon so as to direct a spray towards the furrow closing mechanism and into the soil mixing zone being created by the furrow closing mechanism. The means for spray delivery can be mounted on the conventional seed positioning means as well as independently mounted on the planting machine.

Owner:MERIAL LTD +1

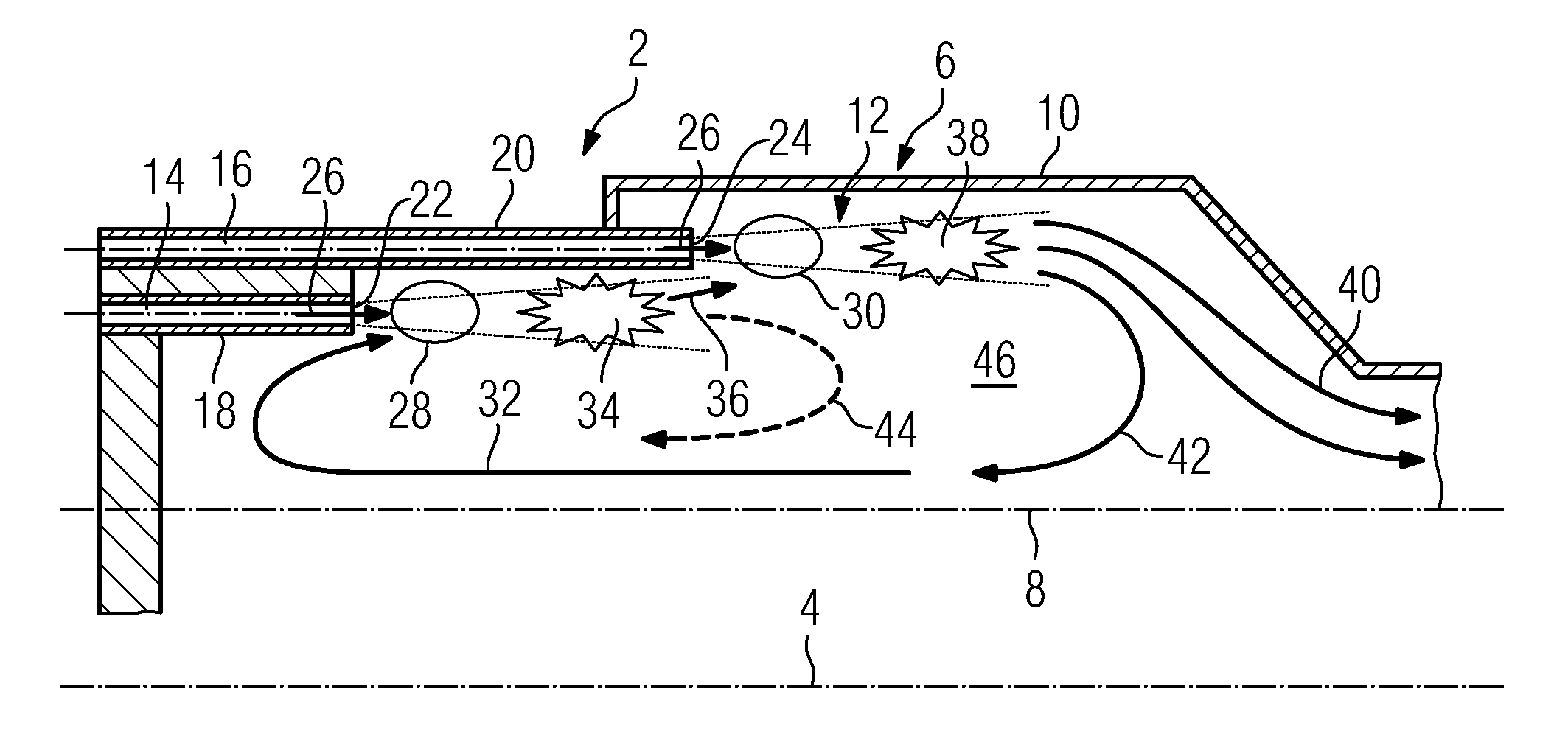

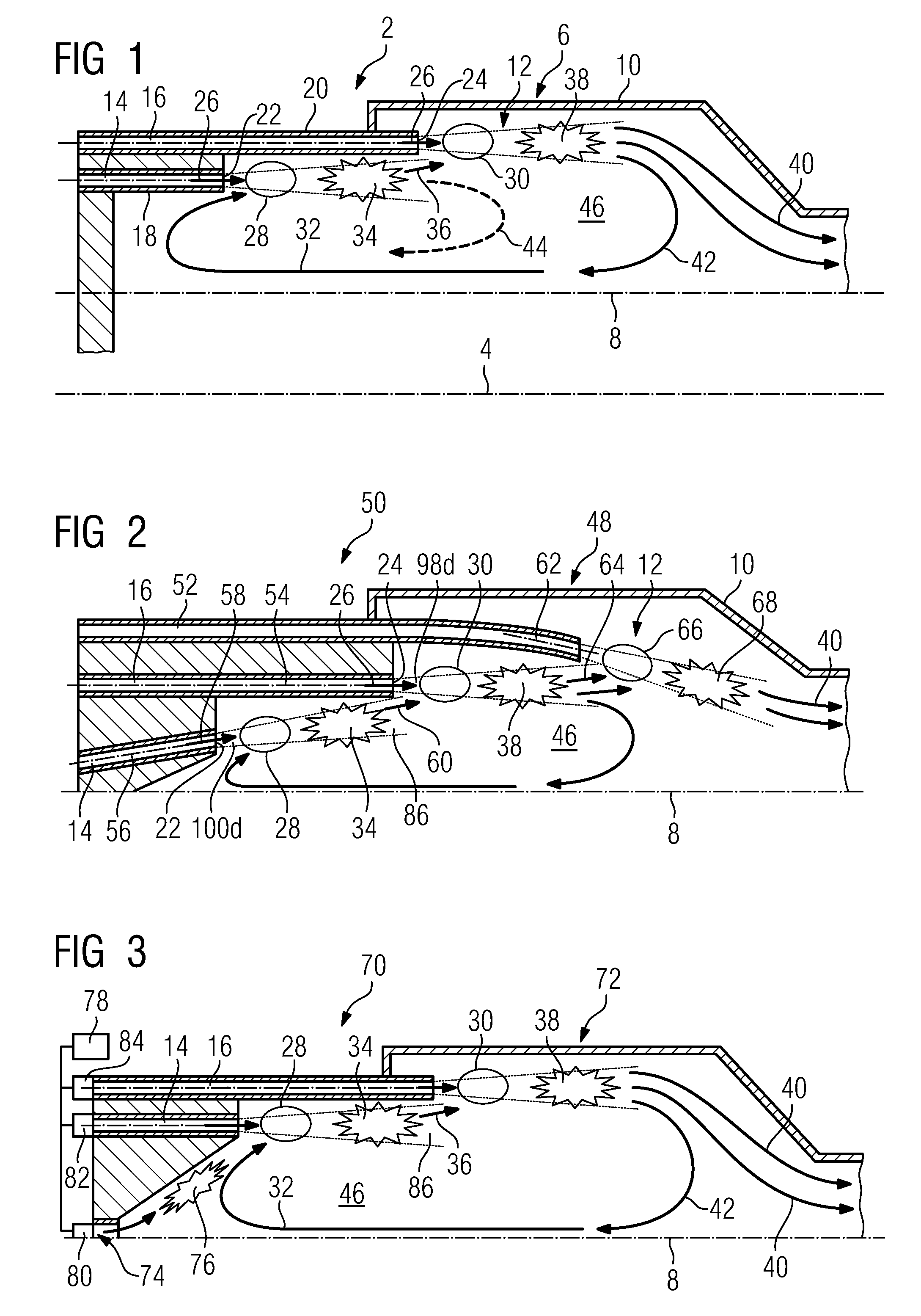

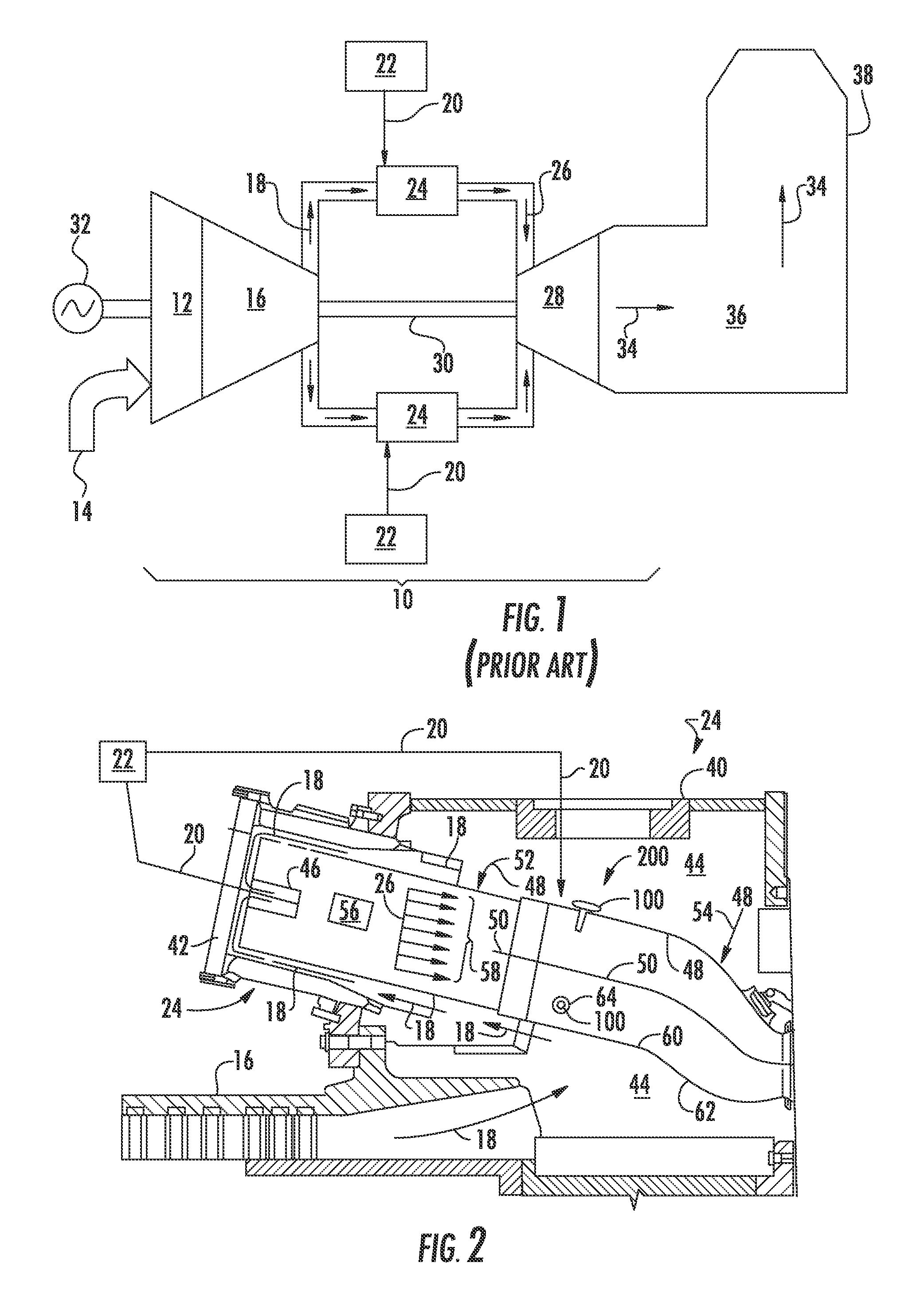

Combustion chamber for a gas turbine

ActiveUS20100058732A1Compact designBroaden applicationContinuous combustion chamberGas turbine plantsCombustion chamberGas turbines

A combustion chamber for a gas turbine is provided. The combustion chamber comprises at least one first and one second jet carrier, of which at least one is provided for injecting an operating gas in the combustion chamber such that waste gas fanned in the flame zone thereof is circulated to a mixing zone of the first jet carrier. In order to achieve a compact combustion chamber, the jet carriers are positioned in relation to each other such that waste gas from the flame zone of the first jet carrier flows directly to the mixing zone of the second jet carrier.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

System and method for rapid chromatography with fluid temperature and mobile phase composition control

InactiveUS20060054543A1Easy to separateMinimizing temperature variationIon-exchange process apparatusComponent separationChromatographic separationFraction Collector

The invention relates to liquid chromatography techniques for rapidly characterizing samples, such as polymer solutions, emulsions and dispersions, and to devices for implementing such techniques. The system includes a design that provides the ability to perform chromatographic separations by using mobile phase composition gradients and temperature gradients during separations. The invention accomplishes this by providing mixing zones for a plurality of fluids as well as heated and chilled feeds feeding the fluids to the mixing zones. Additionally, the system provides the ability to analyze separated components with a detector and / or collect separated fractions into vessels of a fraction collector for further separation and / or analysis.

Owner:UNCHAINED LABS

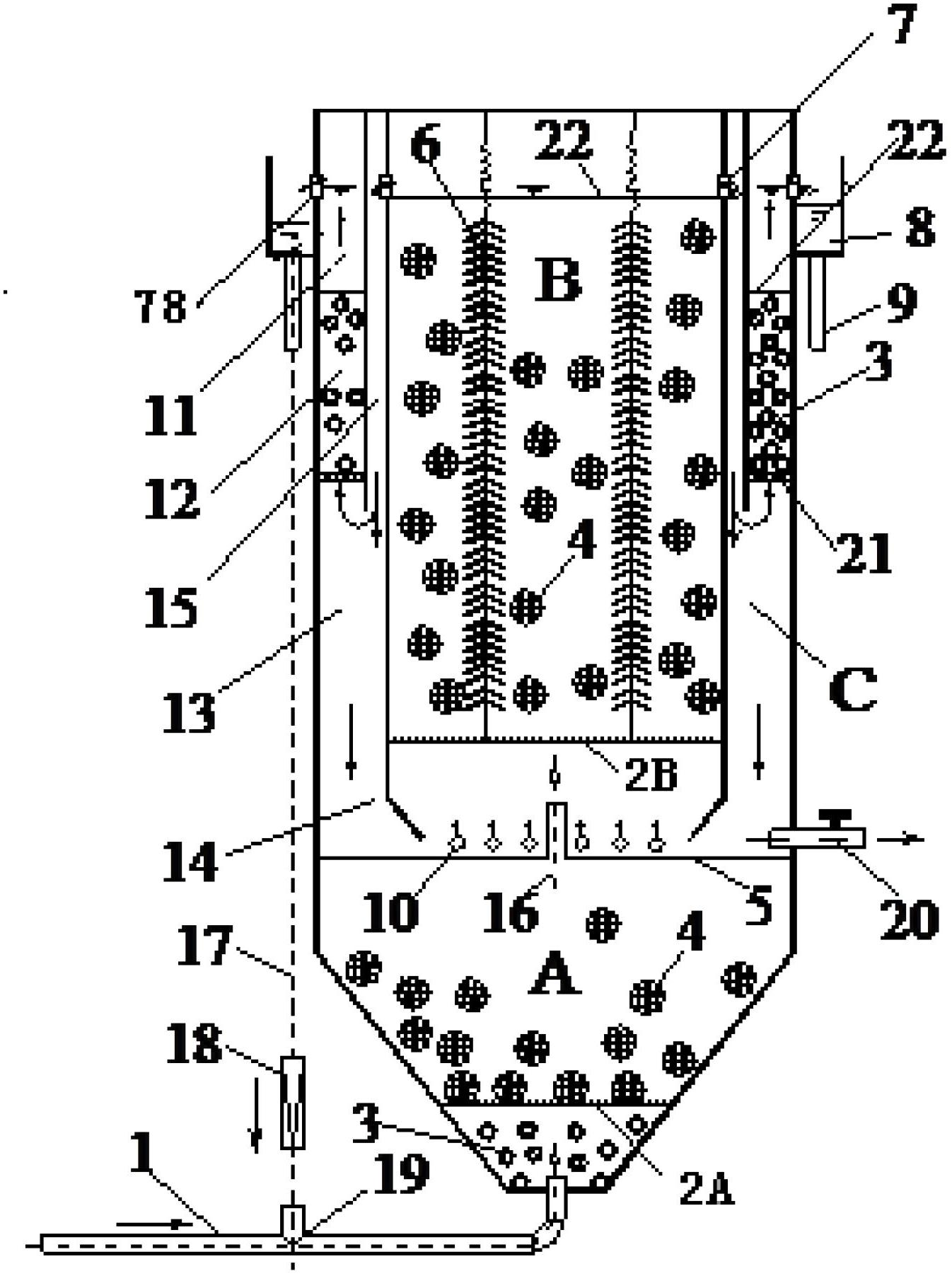

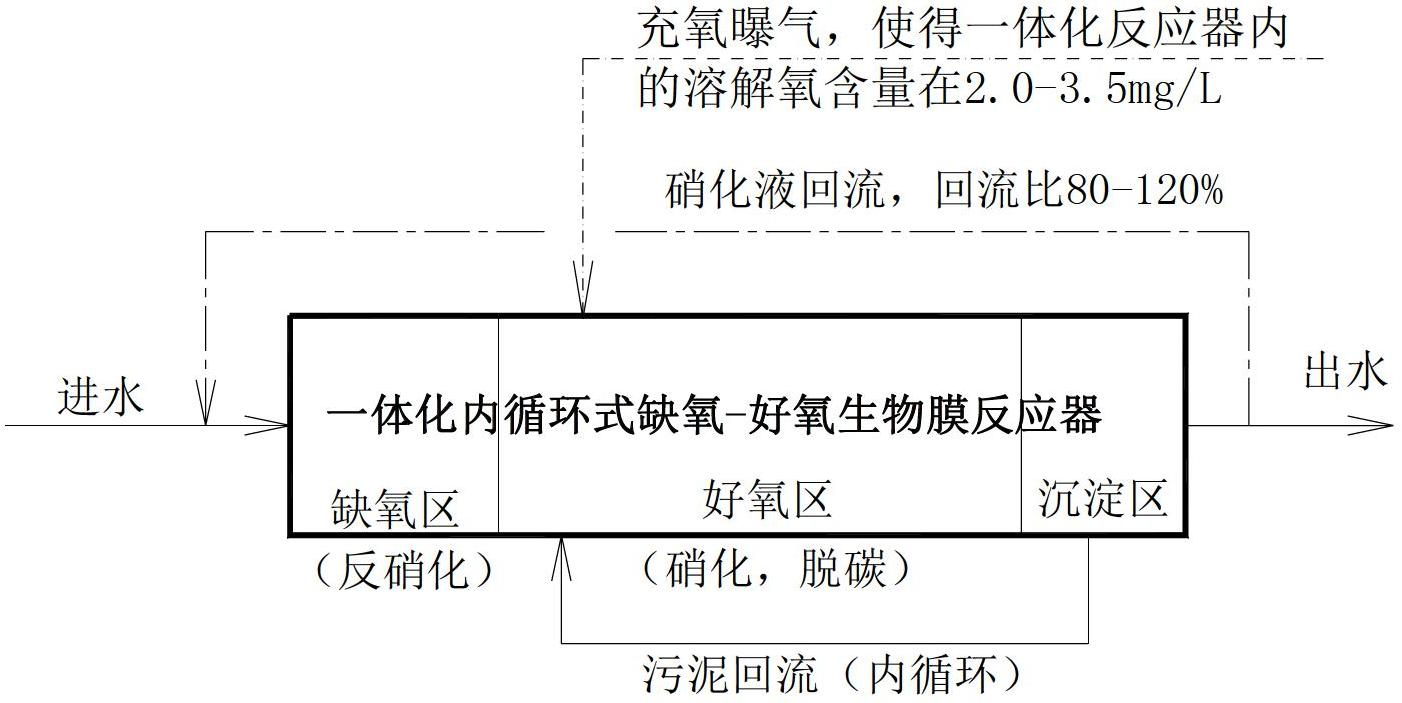

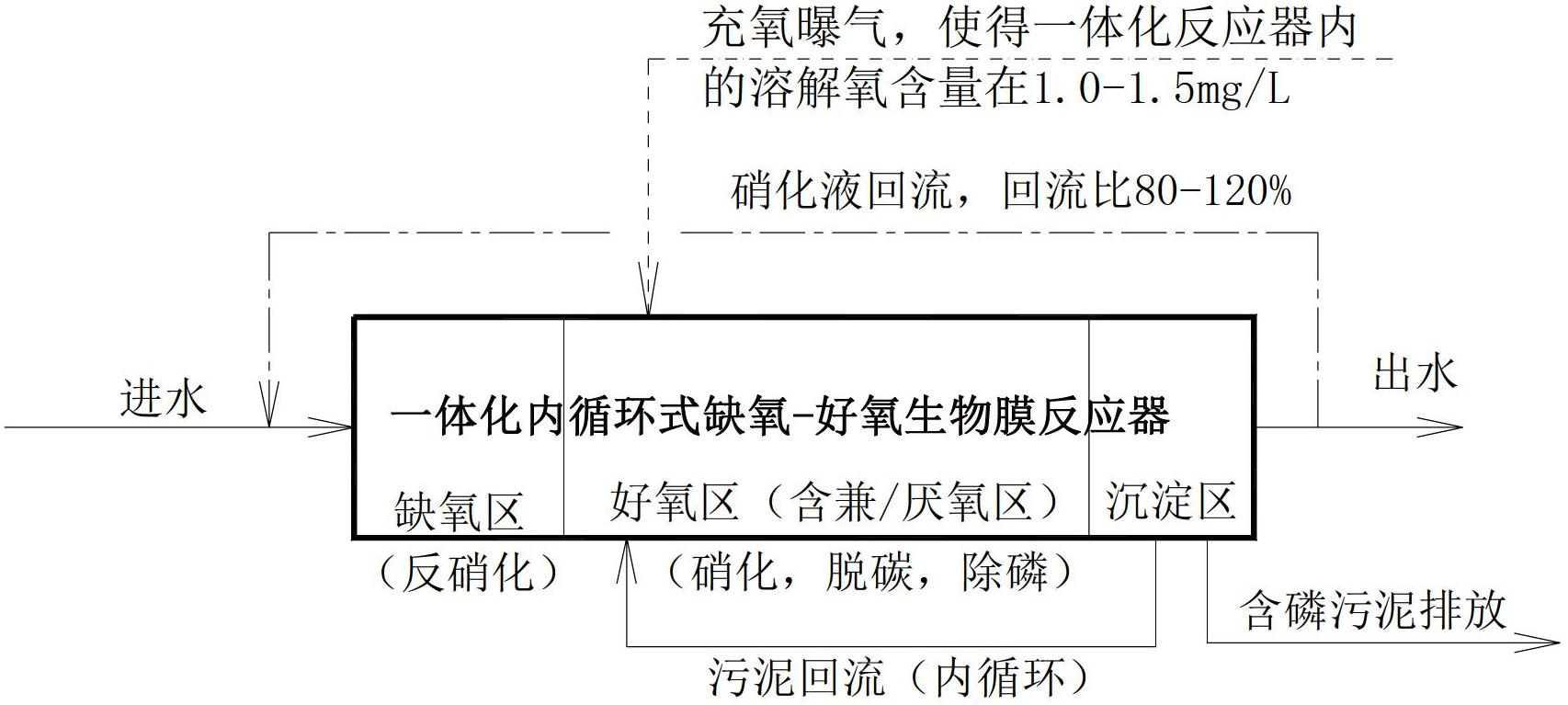

Integrated internal circulation type denitrification and decarburization bio-membrane reactor and operating method thereof

InactiveCN102659244AEfficient removalEfficient nitrogen and carbon removalTreatment with aerobic and anaerobic processesSludgeMembrane reactor

The invention provides an integrated internal circulation type denitrification and decarburization bio-membrane reactor and an operating method thereof. The main body of the reactor consists of an anoxic zone on the lower part, an aerobic zone on the upper part and a settling zone on the periphery of the aerobic zone; a composite filler is filled in the anoxic zone, and a water inlet pipe is communicated with the bottom of the anoxic zone; the aerobic zone is partitioned into a filler zone for adding a carrier on the upper part and a mud-water mixing zone on the lower part by adopting an orifice plate, the anoxic zone and the aerobic zone are partitioned through an impermeable partition plate, and a plurality of aeration pipes are arranged at the bottom of the aerobic zone and provided with air inlet pores; and the settling zone consists of three parts, namely a clean water zone, a contact settling zone and a sludge returning zone which are sequentially arranged from top to bottom, wherein the bottom of the sludge returning zone is provided with a sludge returning seam and communicated with the bottom of the aerobic zone. The reactor realizes zero power consumption in sludge returning, and is compact in structure; and a back flushing system is not required in the contact settling zone, and additional agents and carbon sources are not required, so that the reactor is low in running cost.

Owner:SUZHOU UNIV OF SCI & TECH

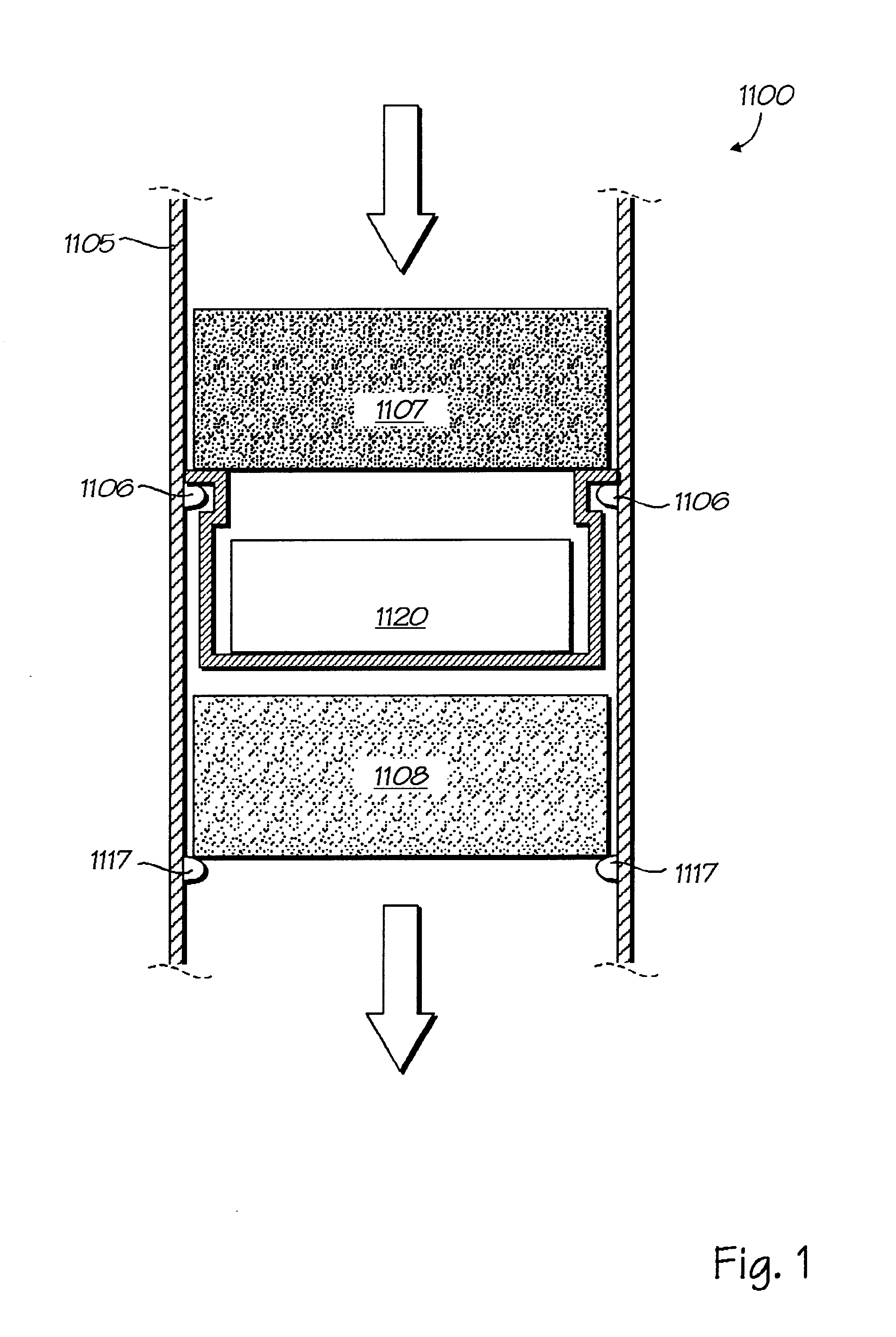

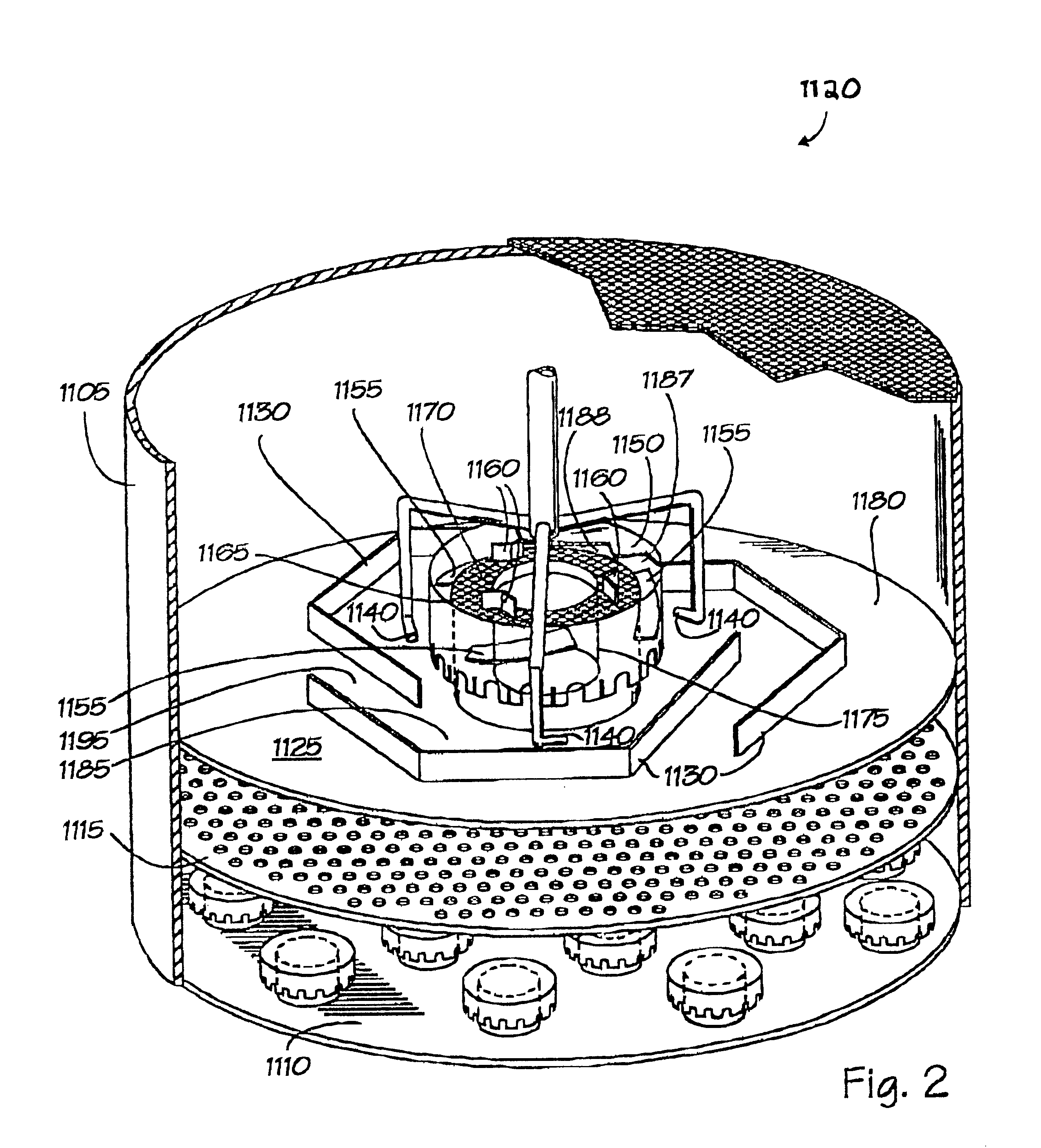

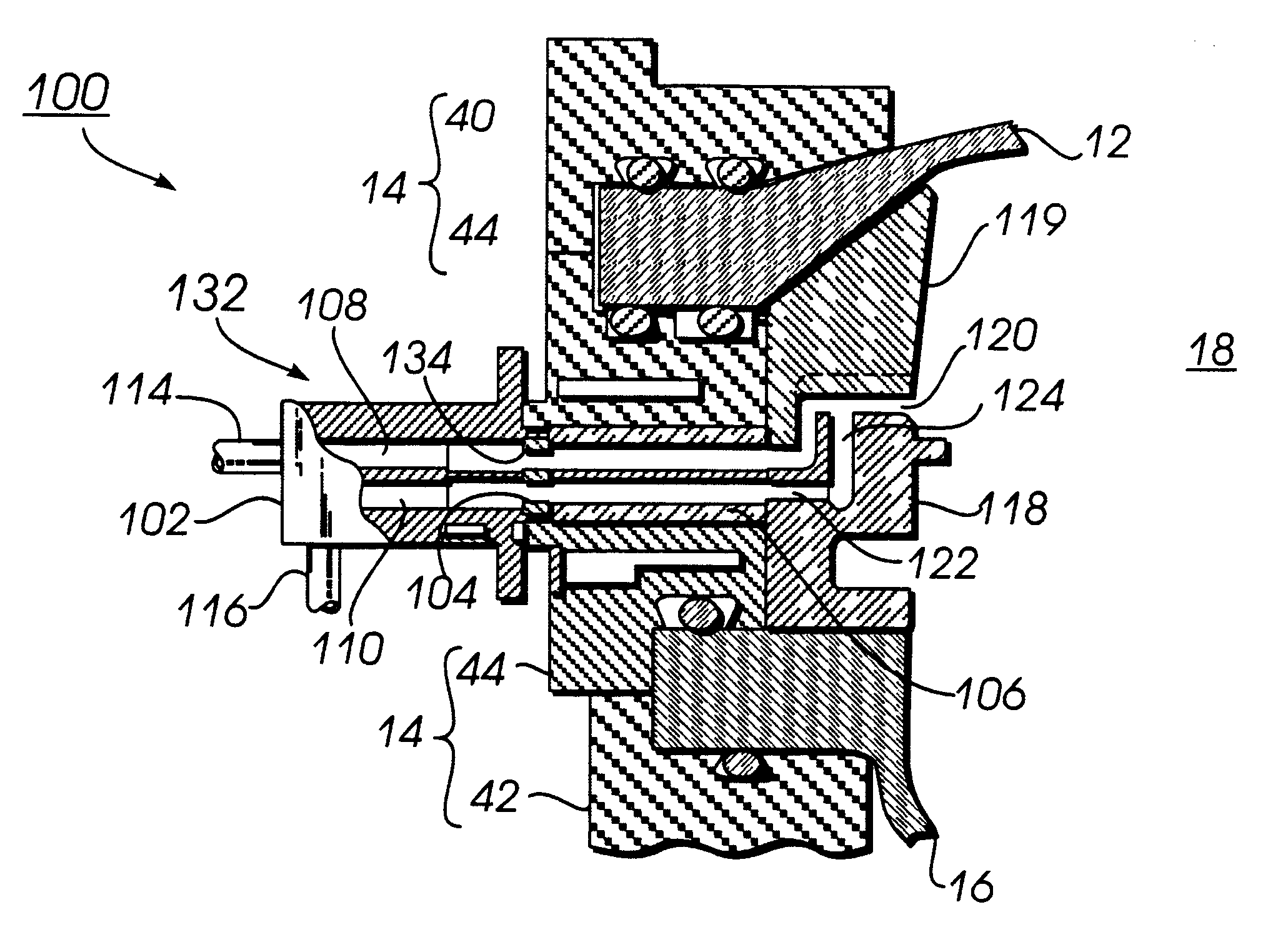

Fluid distributor assembly for a multi-bed, downflow catalytic reactor

InactiveUS6183702B1Low liquid holdupWell mixedPhysical/chemical process catalystsFuel re-atomisation/homogenisationProduct gasEngineering

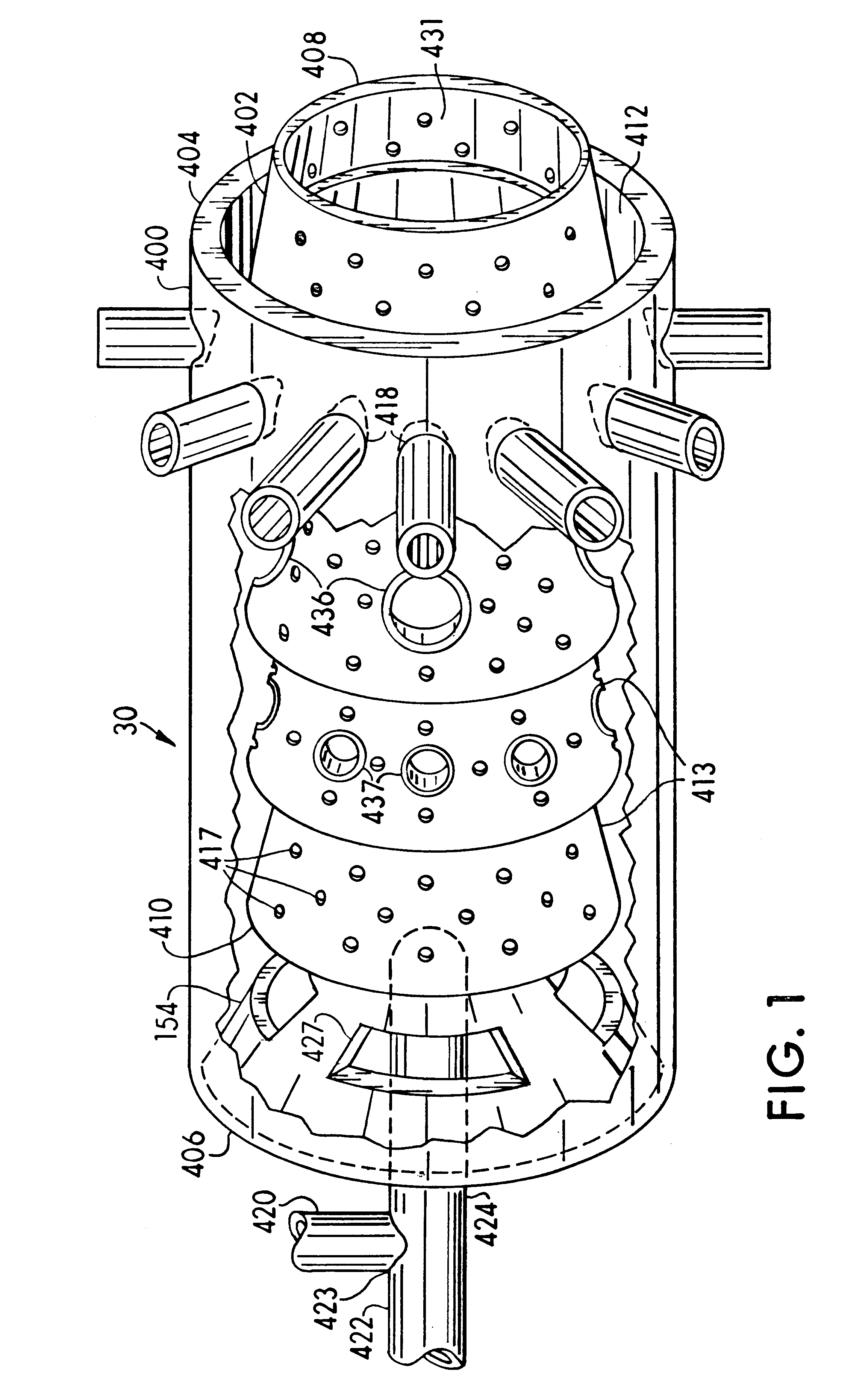

A distributor assembly for a multi-bed, downflow catalytic reactor is disclosed. The distributor assembly is configured for disposal and fixable attachment between the inner surfaces of the walls of a multi-bed downflow cylindrical reactor wall and for disposal between vertically stacked catalyst beds within the reactor. The assembly includes:(a) a collection plate configured for substantially horizontal disposal between the walls of a cylindrical reactor;(b) a plurality of generally arc-shaped elongated baffles disposed in a staggered, substantially symmetrical pattern about the collection plate;(c) a first mixing zone configured to be bounded on the bottom by the collection plate, on one side by a wall of a cylindrical reactor, and on the opposite side by the outer surface of the elongated baffles;(d) a cylindrical weir fixably attached to the collection plate about the outlet;(e) a second mixing zone bounded on the bottom by the collection plate, on one side by the outer surface of the cap and the first cylindrical weir, and on the opposite side by the inner surface of the elongated baffles;(f) a cap disposed over and about the first cylindrical weir, thereby forming a third mixing zone, plurality of semi-spiral-shaped baffles disposed in the third mixing zone, the semi-spiral-shape;(g) baffles having an elongated shape, having one lateral edge fixed to an inner surface of the cap or an opposite lateral edge fixed to an outer surface of the first cylindrical weir;(h) a substantially doughnut-shaped screen member disposed over a top portion of the cylindrical weir;(i) a plurality of fourth-mixing-zone baffles fixably attached to a top surface of the doughnut-shaped screen member; and(j) a plurality of quench gas ports disposed in the second mixing zone.

Owner:CHEVROU USA INC

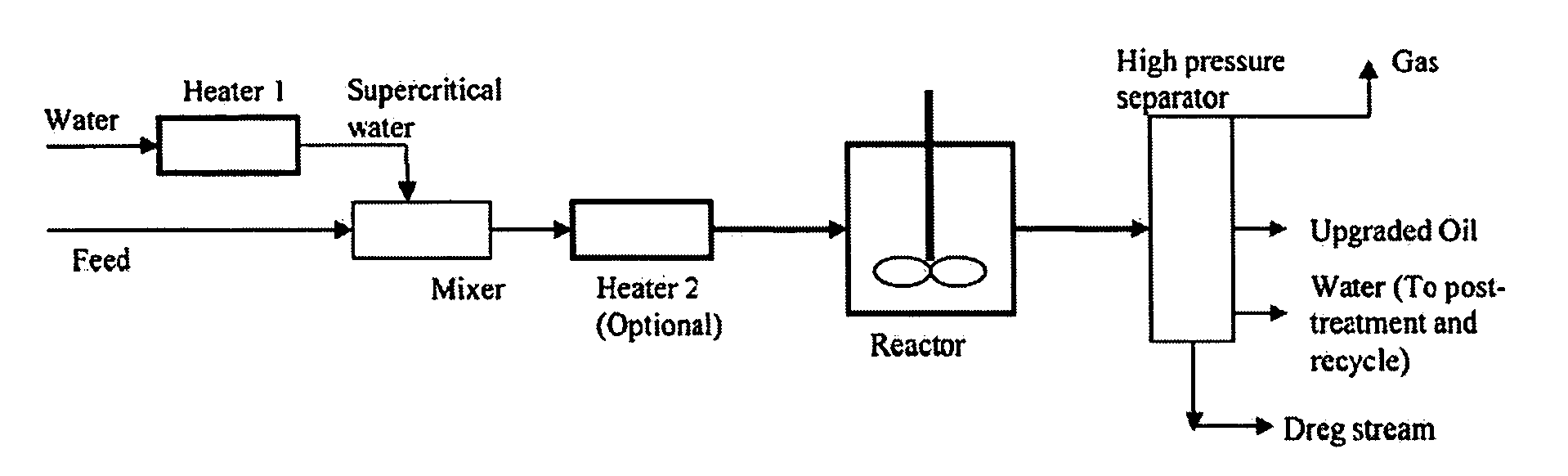

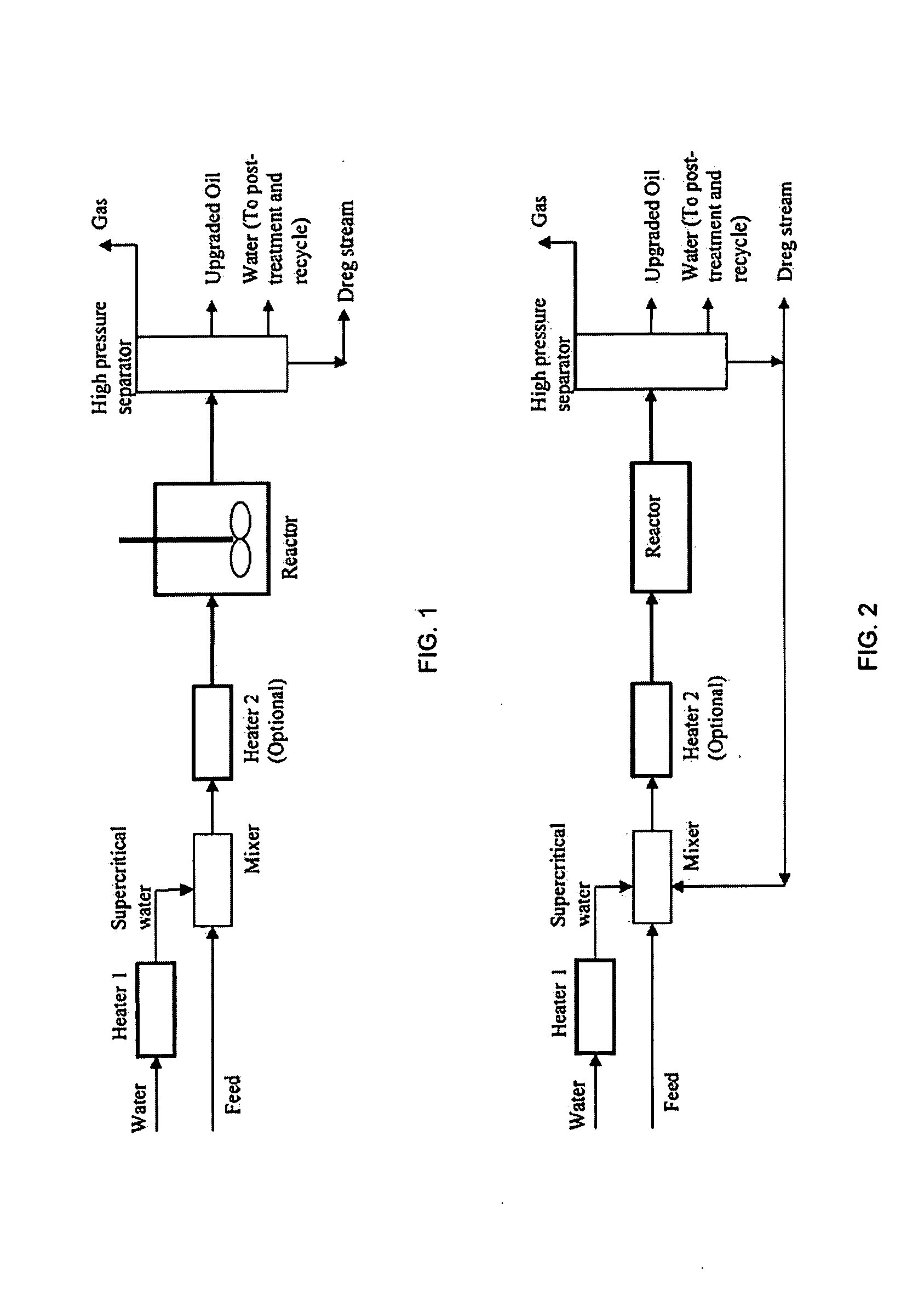

Simultaneous metal, sulfur and nitrogen removal using supercritical water

InactiveUS20090166262A1Reduce concentrationRefining by water treatmentLiquid carbonaceous fuelsNitrogen removalHydrogen

A process for removing metals, sulfur and nitrogen in the upgrading of hydrocarbons comprising: mixing hydrocarbons containing metals, sulfur and nitrogen with a fluid comprising water that has been heated to a temperature higher than its critical temperature in a mixing zone to form a mixture; passing the mixture to a reaction zone; reacting the mixture in the reaction zone under supercritical water conditions in the absence of externally added hydrogen for a residence time sufficient to allow upgrading reactions to occur while maintaining an effective amount of metals, derived from the hydrocarbon undergoing upgrading, in the reaction zone to catalyze the upgrading reactions; and recovering upgraded hydrocarbons having a lower concentration of metals, sulfur and nitrogen than the hydrocarbons before reaction is disclosed.

Owner:CHEVROU USA INC

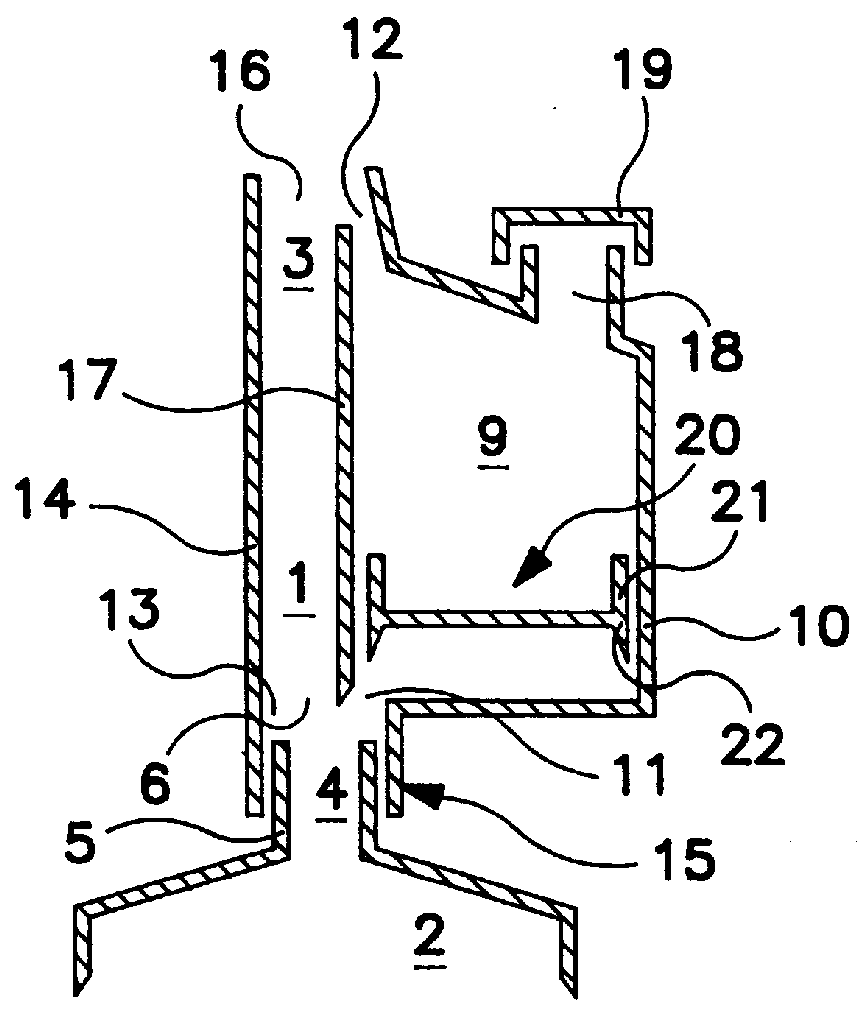

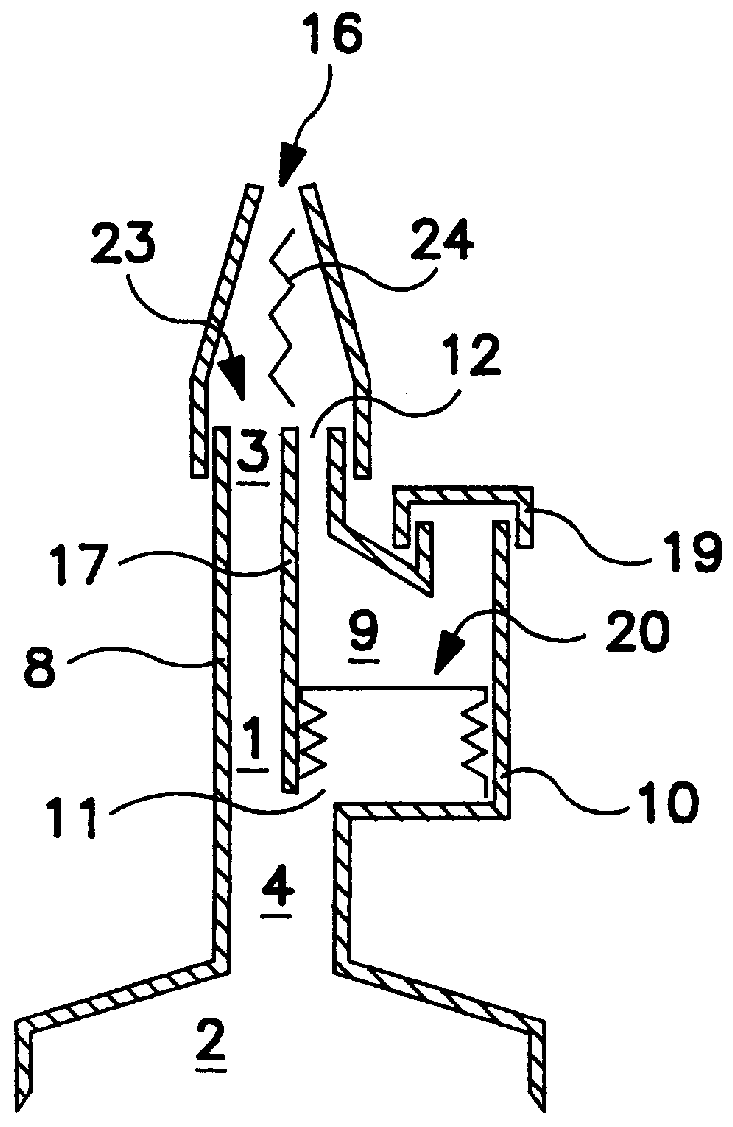

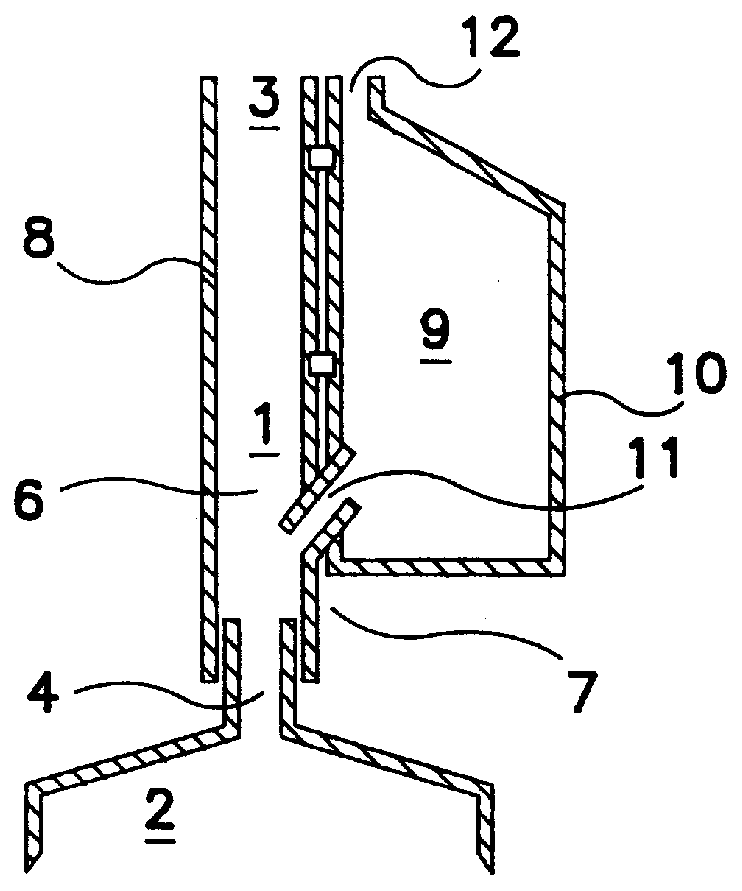

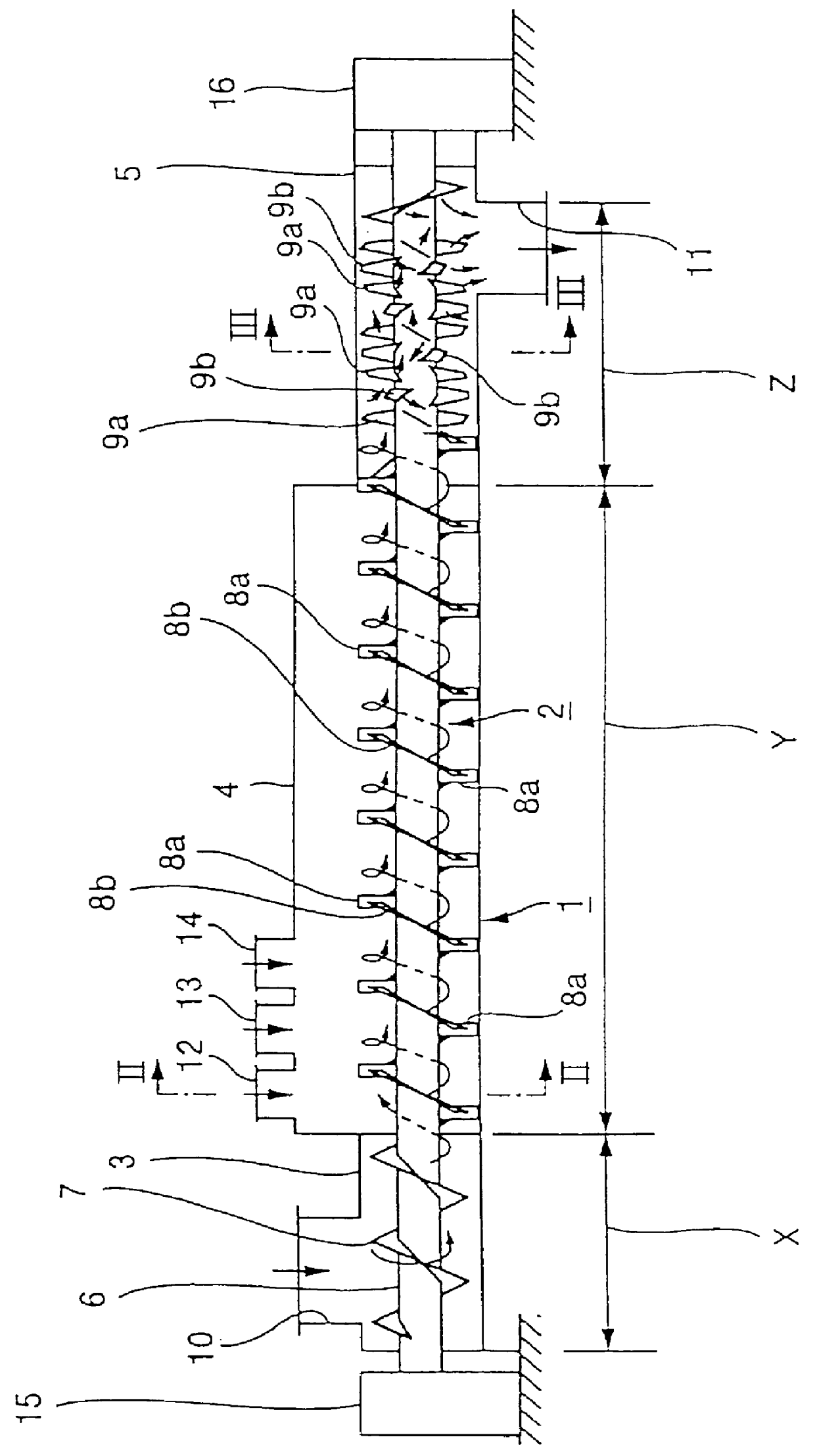

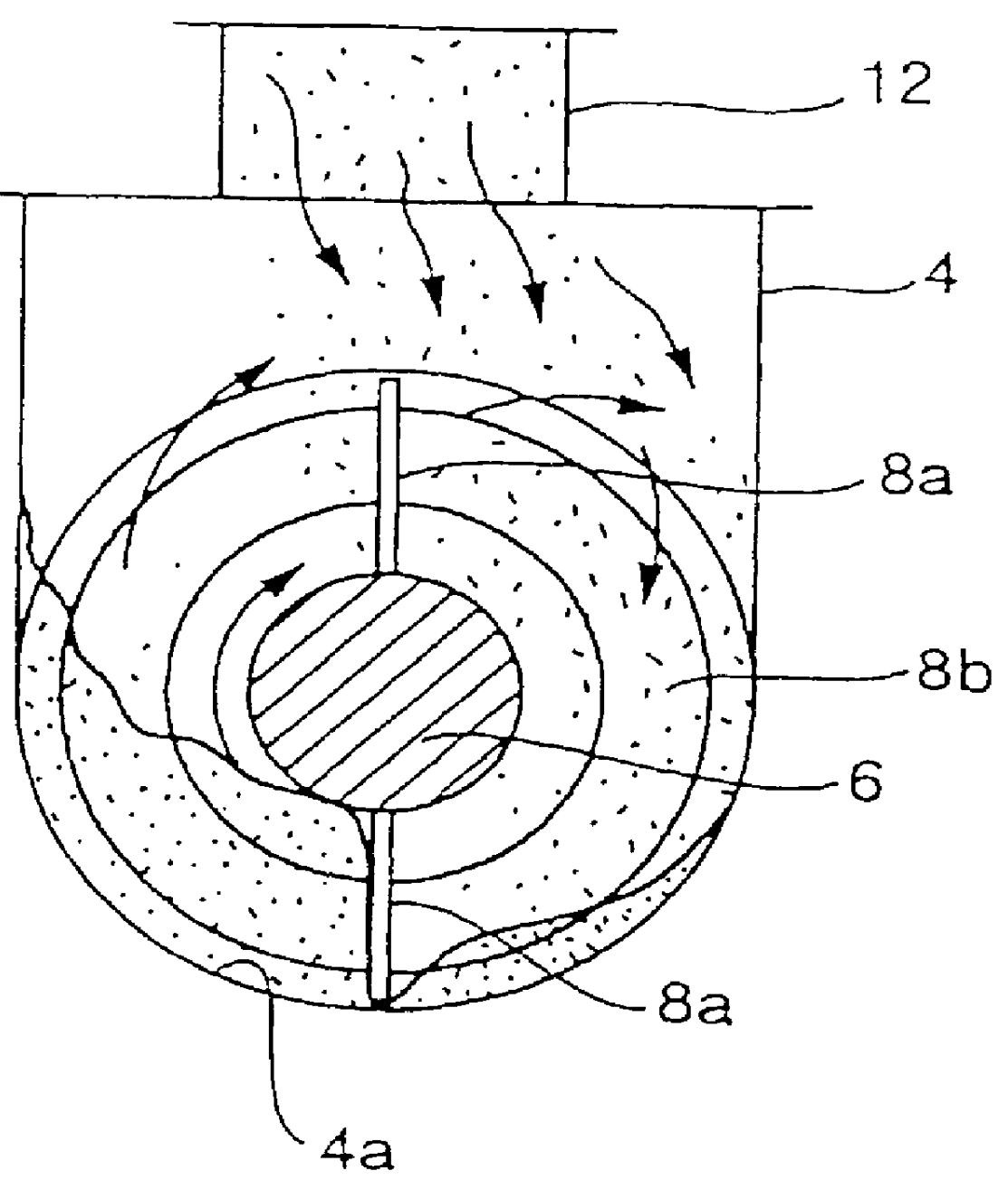

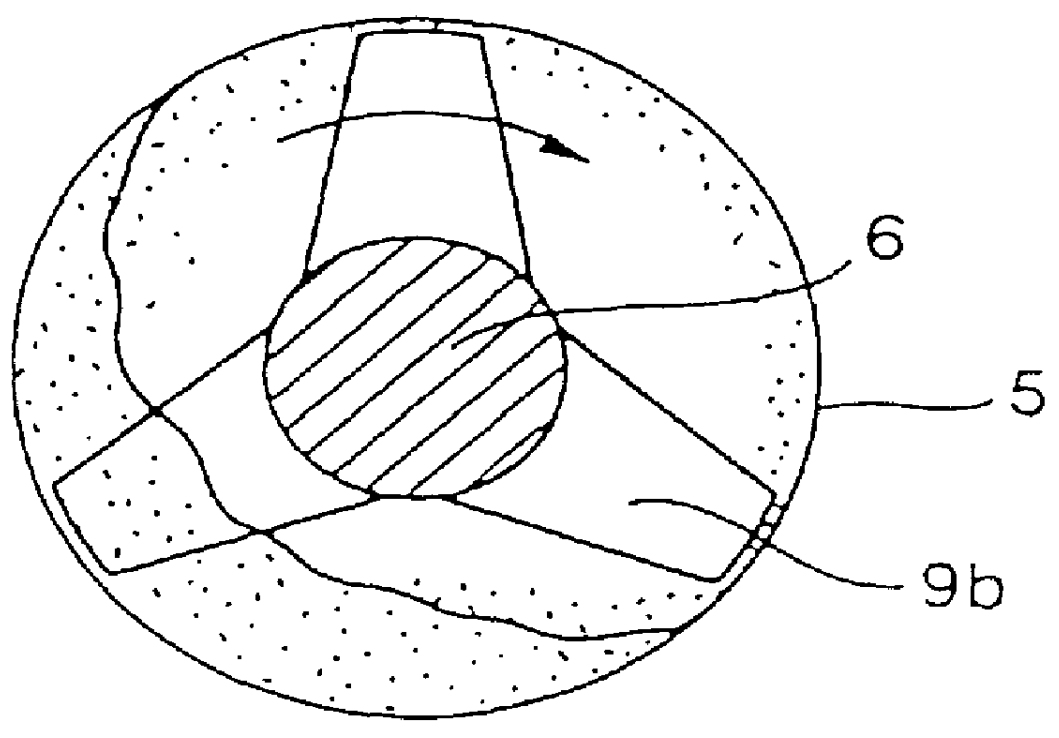

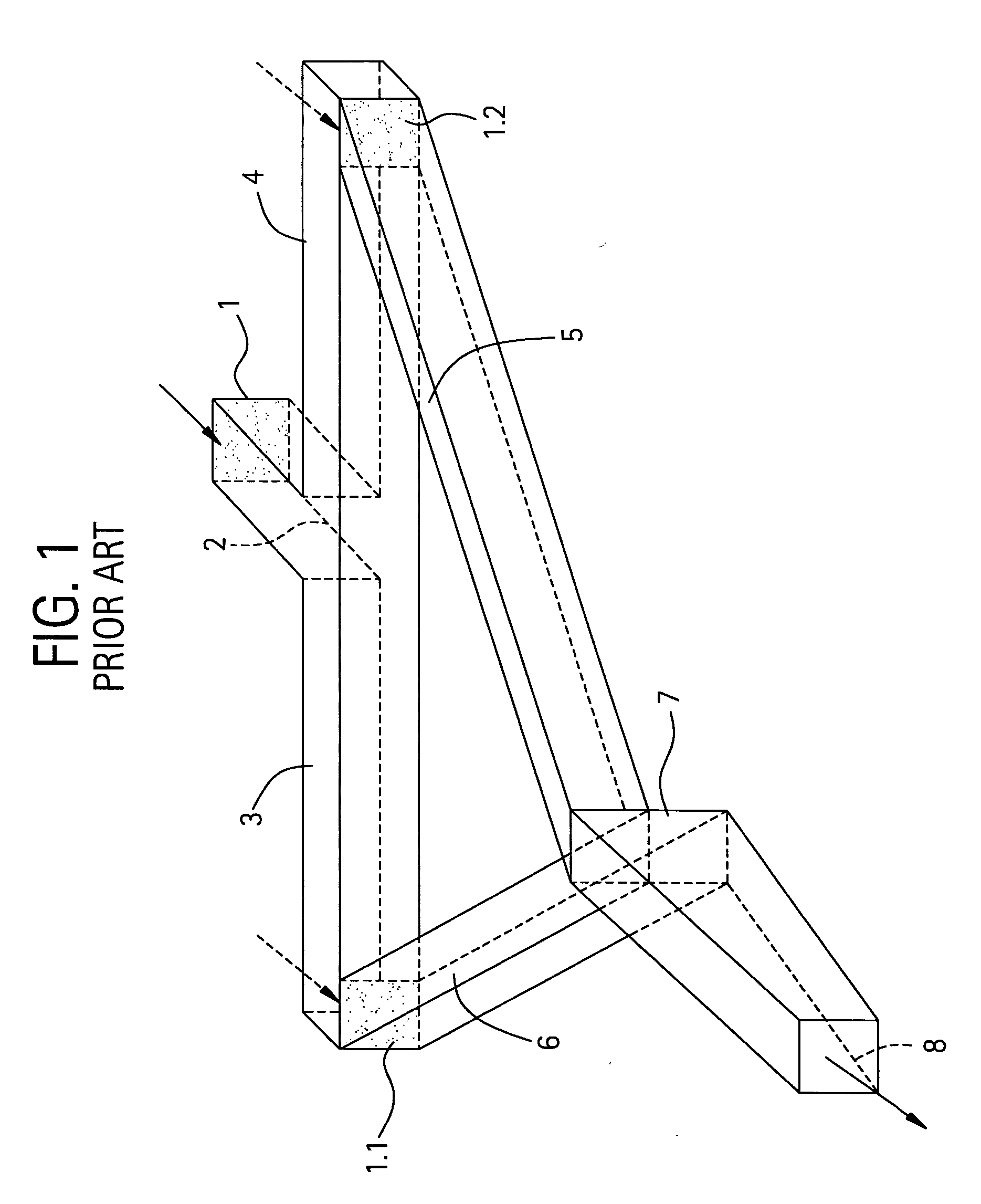

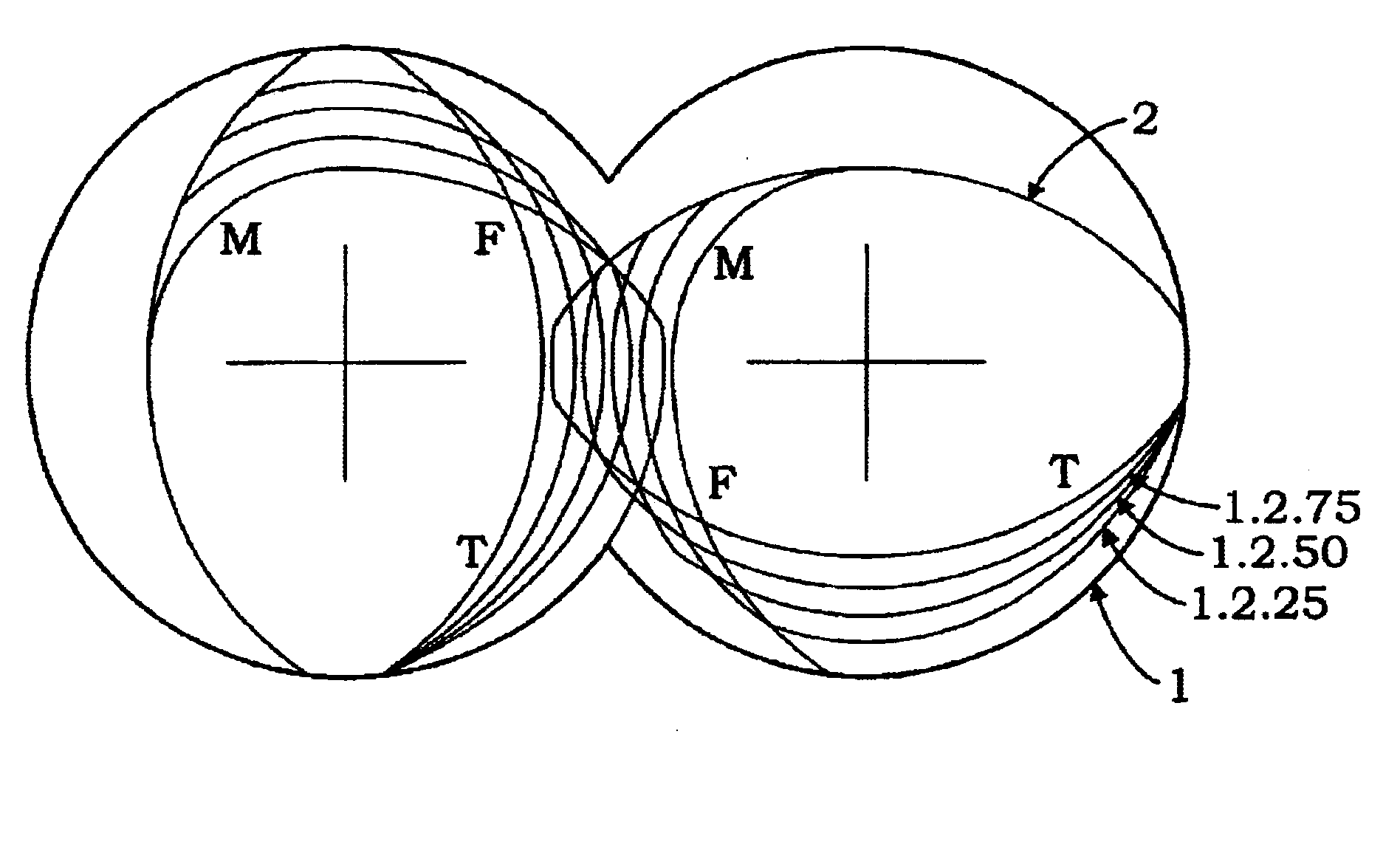

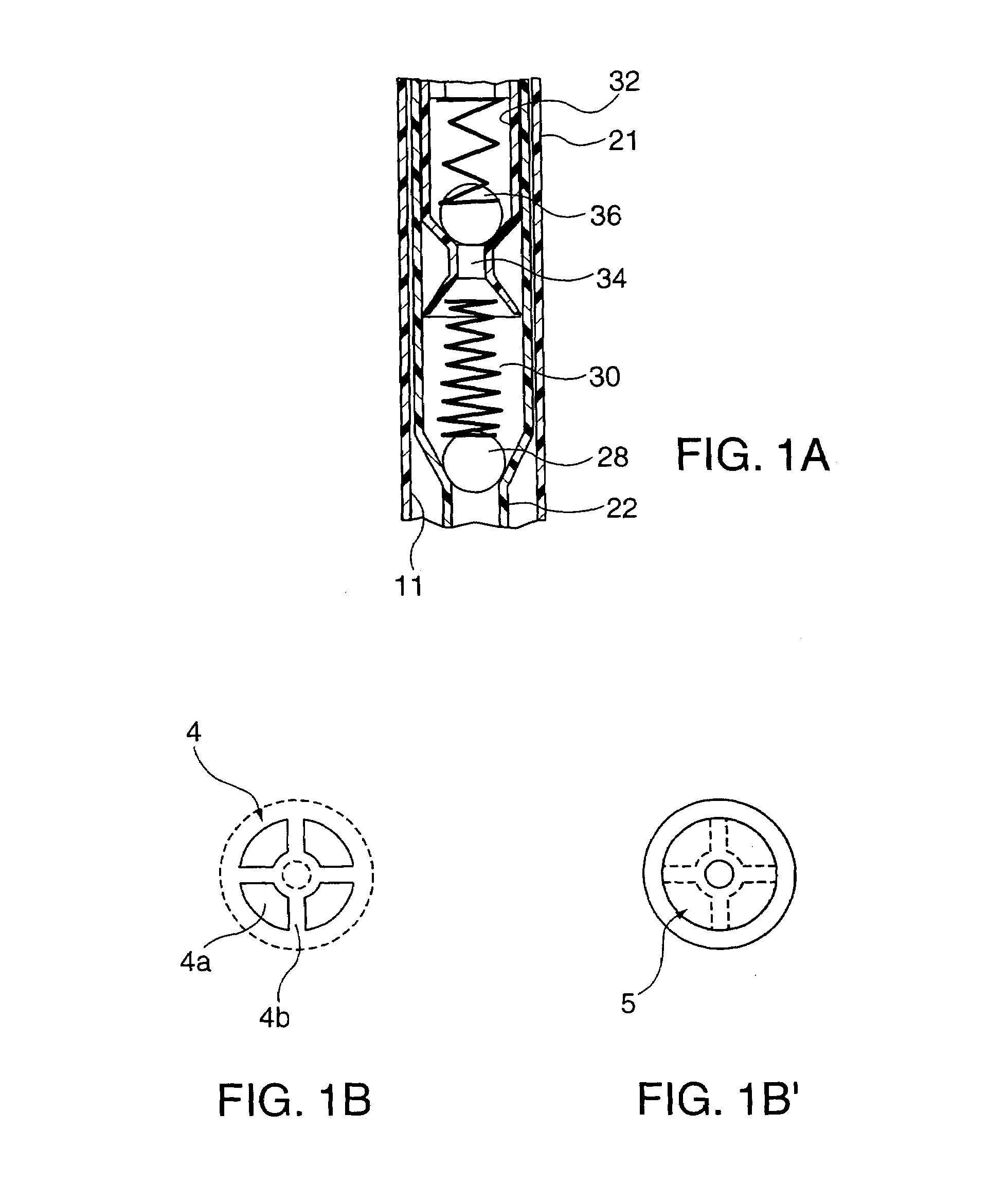

Method and device for combining at least two fluid media

PCT No. PCT / DE95 / 00462 Sec. 371 Date Dec. 5, 1996 Sec. 102(e) Date Dec. 5, 1996 PCT Filed Apr. 7, 1995 PCT Pub. No. WO95 / 27558 PCT Pub. Date Oct. 19, 1995The invention is a device and a method for combining at least two fluid media. The device comprises a flow region (1) which is attached to and / or formed with an opening of a first chamber (2) and which is designed to accommodate the fluid medium coming from the first chamber and to transport it to the outlet (3) of the flow region (1) which is preferably followed by a mixing zone. A second chamber (9) designed to be filled with a second fluid medium is connected to the flow region and / or to the first chamber through at least one first opening element (inlet opening) (11) for diverting part of the first fluid medium from the first into the second chamber. The second chamber is provided with at least one second opening element (second opening) (12) opening into or adjoining the flow region (1) for discharging the second fluid medium displaced into it by the first fluid medium. Several first chambers (2) or second chambers (9) may be provided.

Owner:HENKEL KGAA

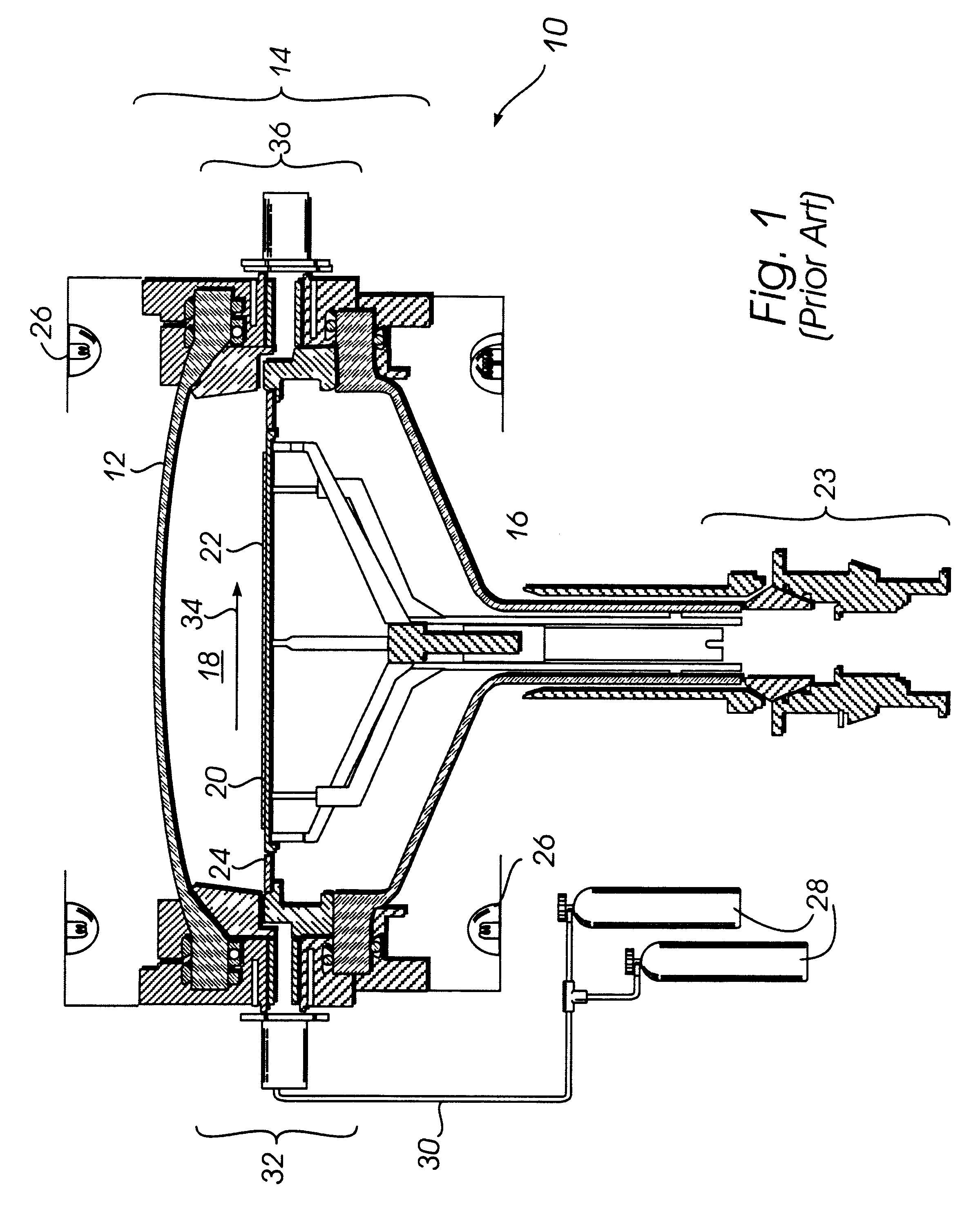

Gas inlets for wafer processing chamber

InactiveUS6500734B2Avoid mixingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorProduct gas

A system for supplying processing fluid to a substrate processing apparatus having walls, the inner surfaces of which define a processing chamber in which a substrate supporting susceptor is located. The system consists of a number of fluid storages, each which stores a separate processing fluid, at least two fluid conduits along which processing fluid flows from the fluid storages to the processing apparatus and a fluid inlet which connects the fluid conduits to the processing chamber. The inlet has a separate fluid passage, corresponding to each of the fluid conduits, formed along it. Each fluid passage opens at or near an inner surface of a wall to define a fluid mixing zone, so that fluid moving along one fluid passage is prevented from mixing with fluid moving along any other passage until reaching the mixing zone.

Owner:APPLIED MATERIALS INC

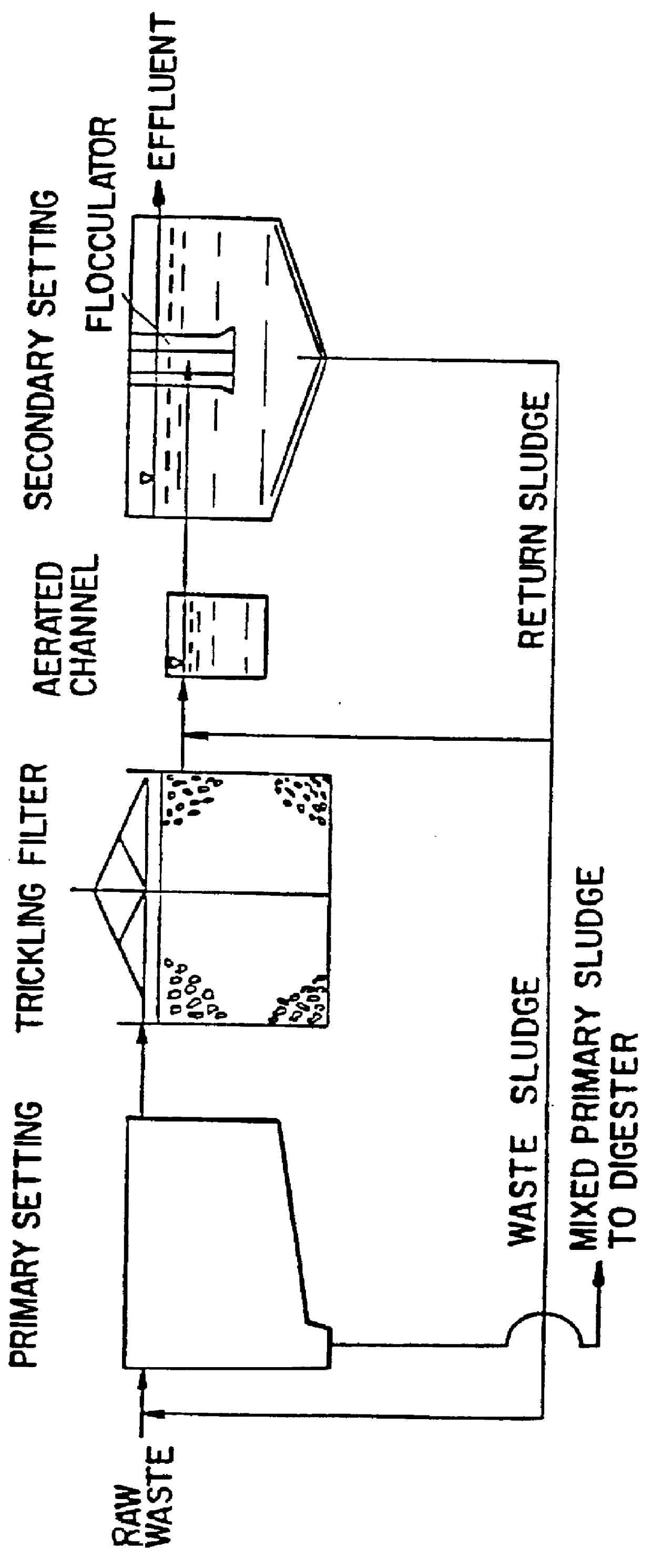

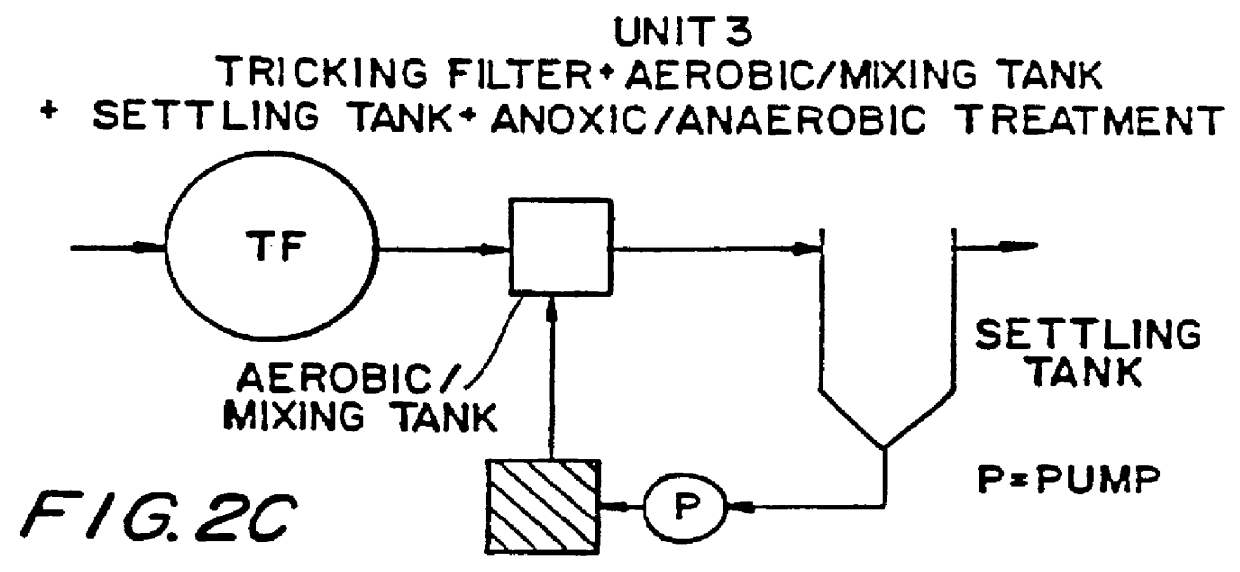

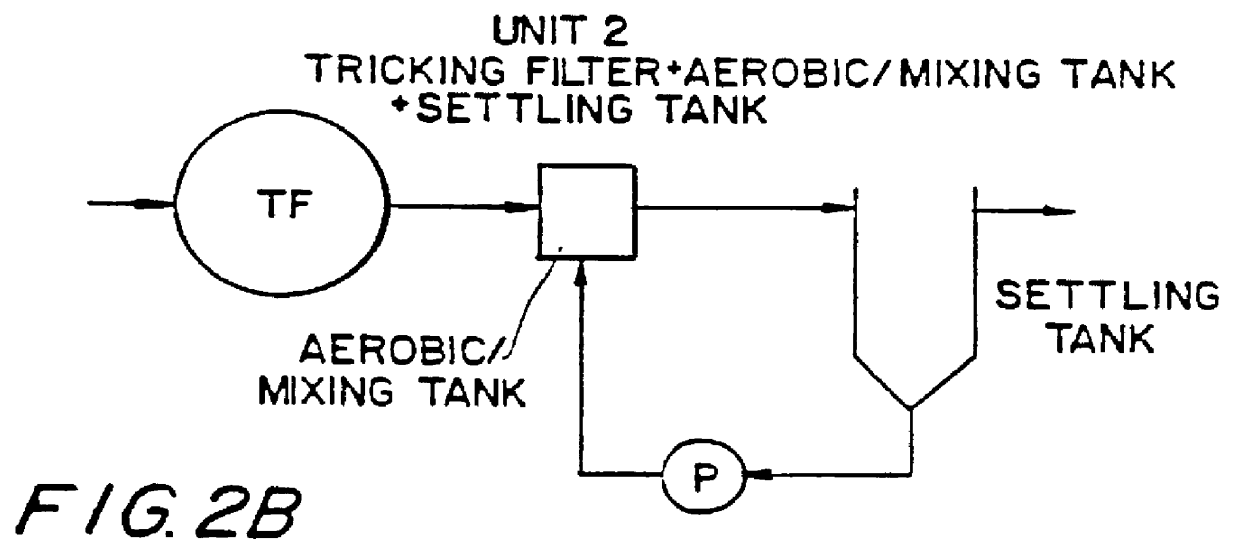

Wastewater treatment process

InactiveUS6113788AImprove efficiencyFacilitated releaseTreatment using aerobic processesSeparation devicesSludgePhosphate

A wastewater treatment process having improved solids separation characteristics and reduced biochemical oxygen demand (BOD) in the purified wastewater comprising the steps of: passing wastewater through a main aerobic biological oxidation zone and therein oxidizing a portion of the BOD a portion of the ammonia nitrogen content (NH3-N); passing the effluent from said aerobic biological oxidation zone to an aerobic / mixing zone and therein mixing said effluent with effluent from the anoxic / anaerobic zone; passing the effluent from said aerobic / mixing zone to a settling zone and therein separating purified wastewater having reduced BOD and suspended solids, and sludge containing suspended solids; passing a portion of the sludge formed in the settling zone and volatile acids to an anoxic / anaerobic zone and therein increasing the extracellular polymer content of said sludge, the release of phosphorus into solution and the reduction of nitrate nitrogen to molecular nitrogen gas; and recycling an effective amount of the effluent from said anoxic / anaerobic zone to said aerobic / mixing zone. In an alternative embodiment, a volatile acid is added to a zone to which no additional oxygen has been added that is in the flow path from the main aerobic biological oxidation zone or, alternatively, it may be added to the anoxic / anaerobic zone and the thus-treated effluent is passed to the aerobic / mixing zone wherein phosphate is removed from the effluent.

Owner:POLYTECHNIC INST OF NEW YORK

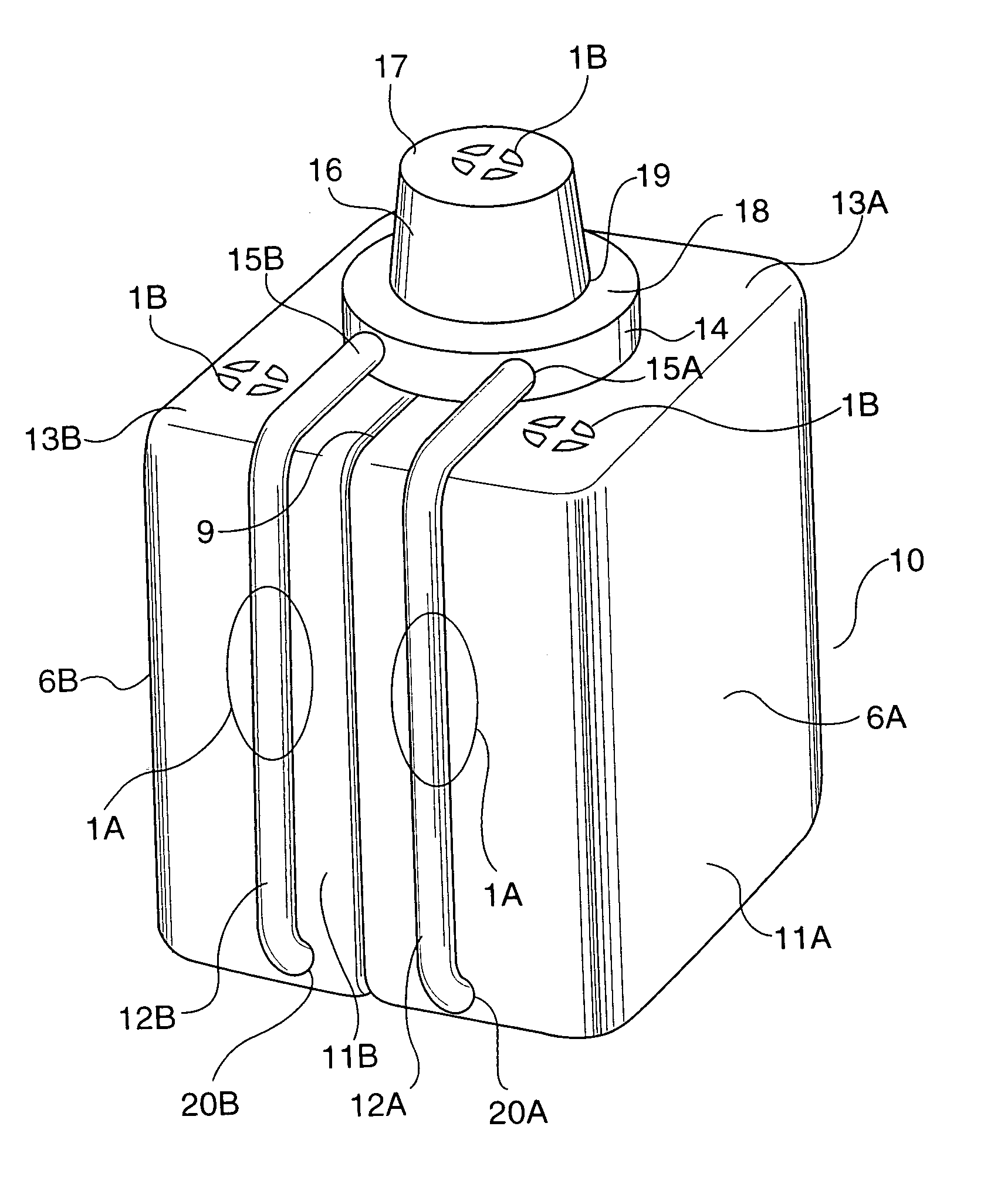

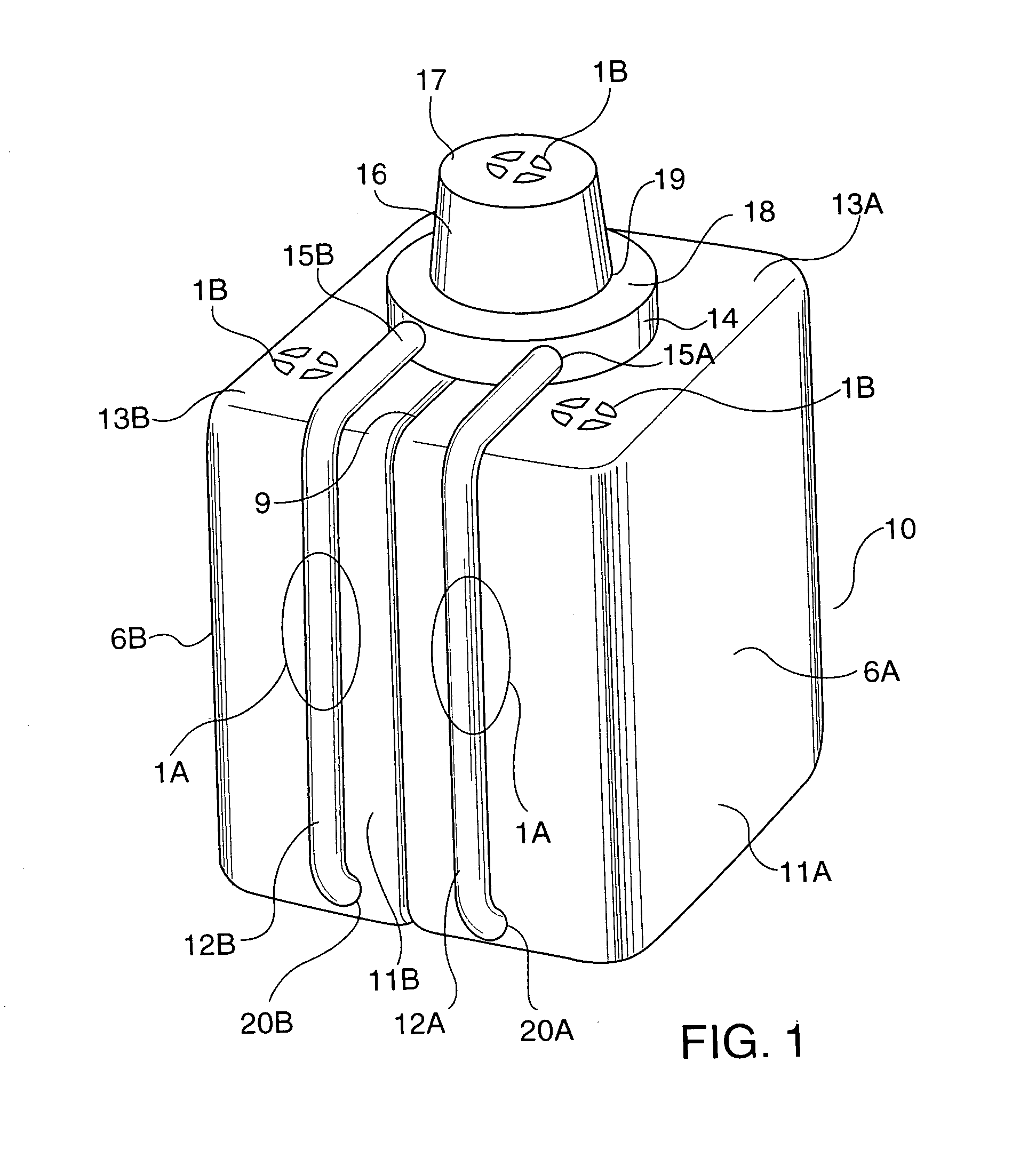

Continuous mixing feeder

The invention is for mixing at least one kind of an additive with a powdery or granular main material homogeneously so as to continuously supply the same quantitatively. A barrel comprises a front side cylindrical part, a trough part, and a rear side cylindrical part from the upstream side. A quantitative extruding zone comprises the front side cylindrical part and a quantitative extruding part having a full flight provided on the peripheral surface of the axis part of a screw, for quantitatively transporting a main material to the downstream side. A mixing zone comprises the trough part and a mixing part having an agitating blade formed zigzag on the axis part of the screw and a ribbon screw having a distance with respect to the peripheral surface of the axis part, for homogeneously dispersing additives added from additive supply openings in the main material. The scraping out zone comprises the rear side cylindrical part and a scraping out part having forward paddles and backward paddles formed alternately on the peripheral surface of the axis part of the screw, for discharging the mixture from a discharge opening.

Owner:JAPAN STEEL WORKS LTD

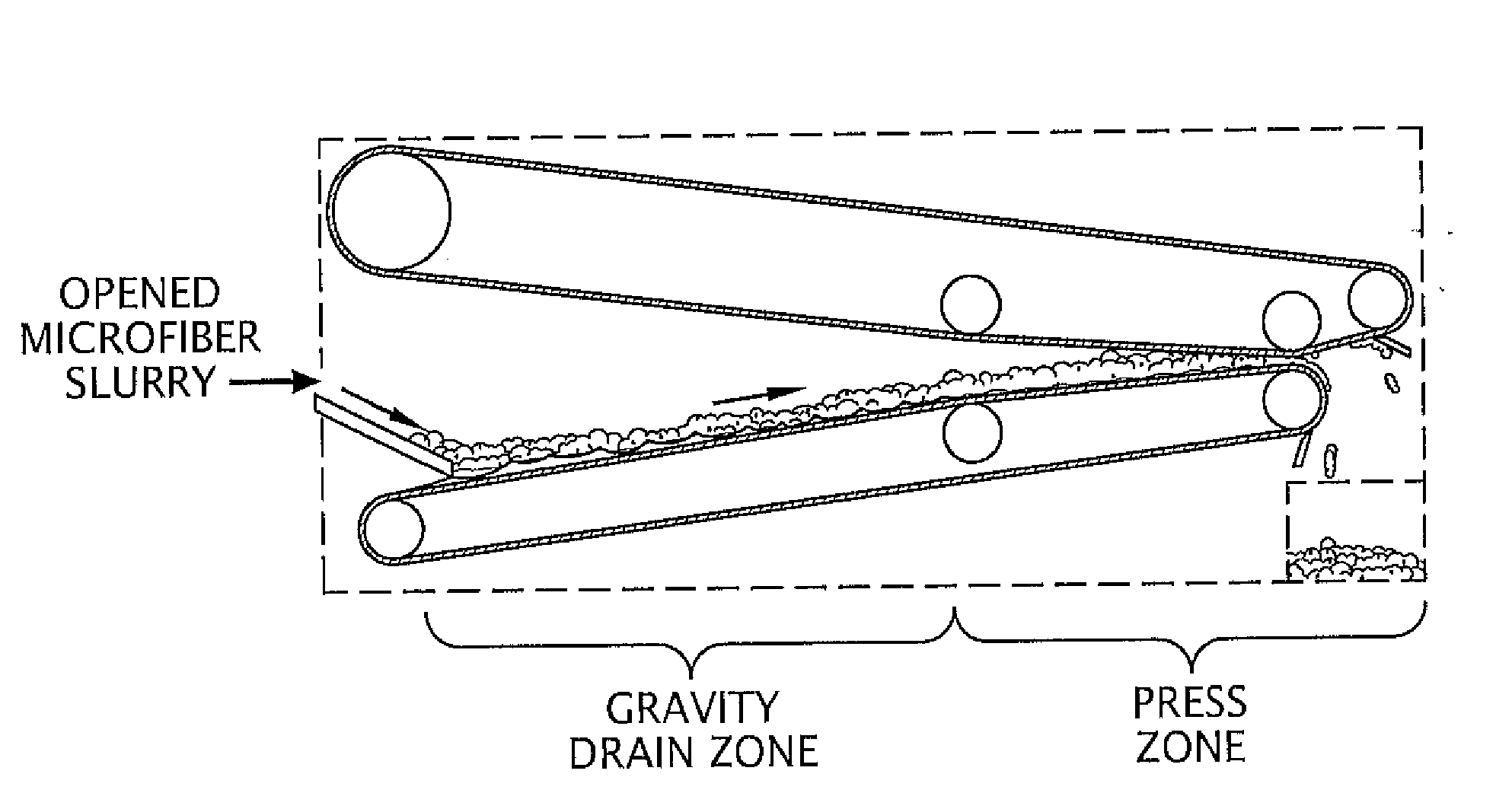

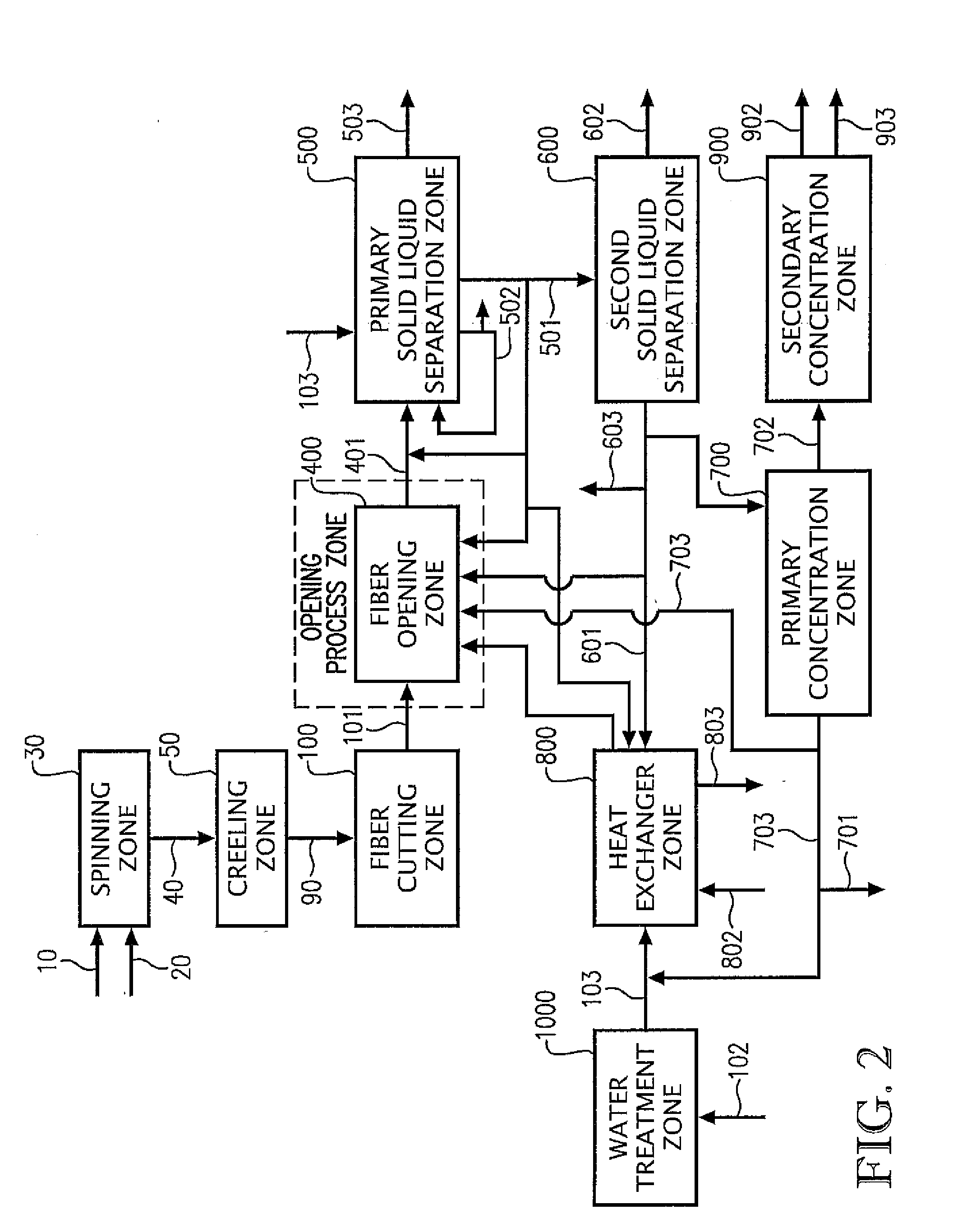

Processes to produce short cut microfibers

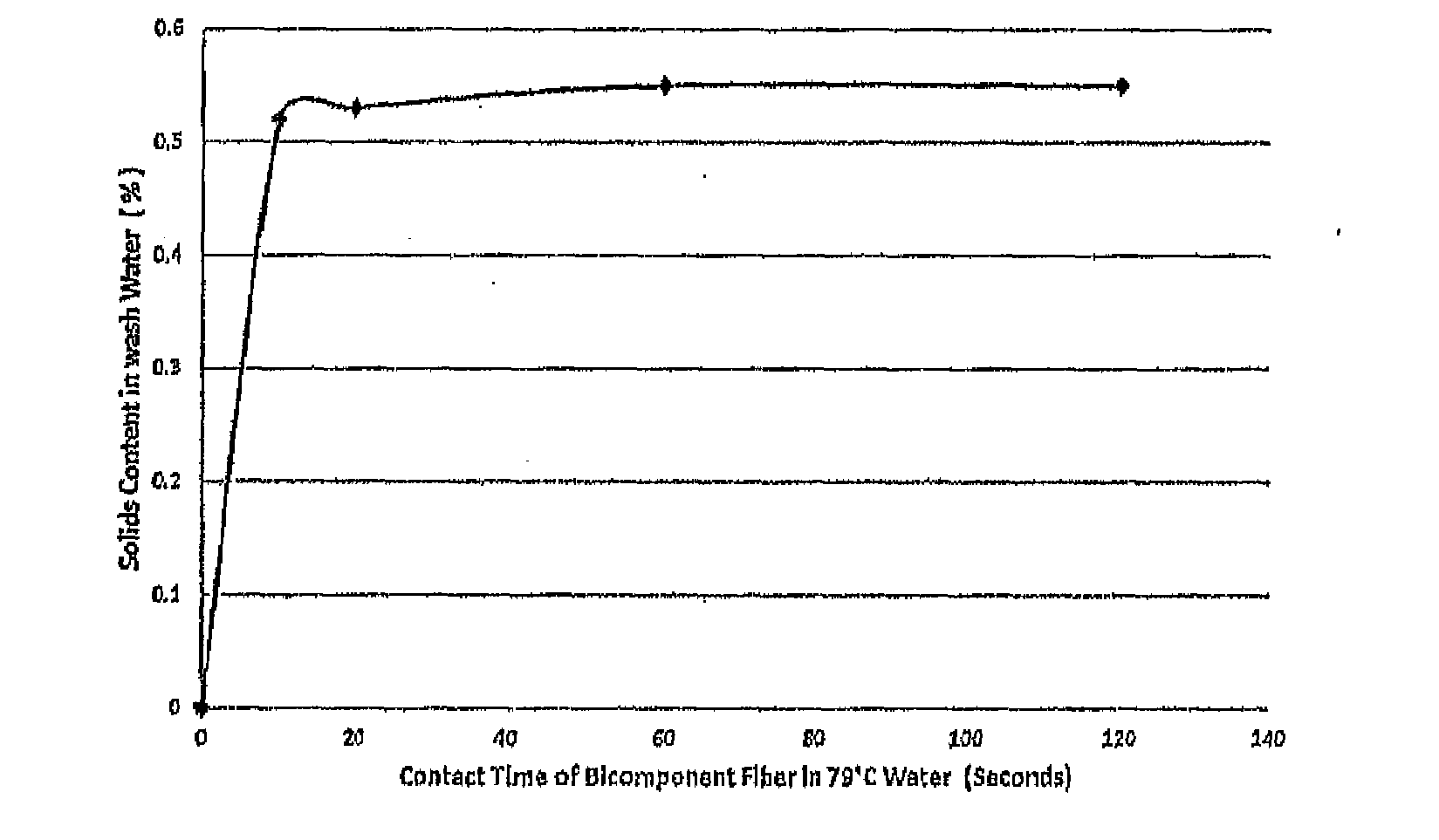

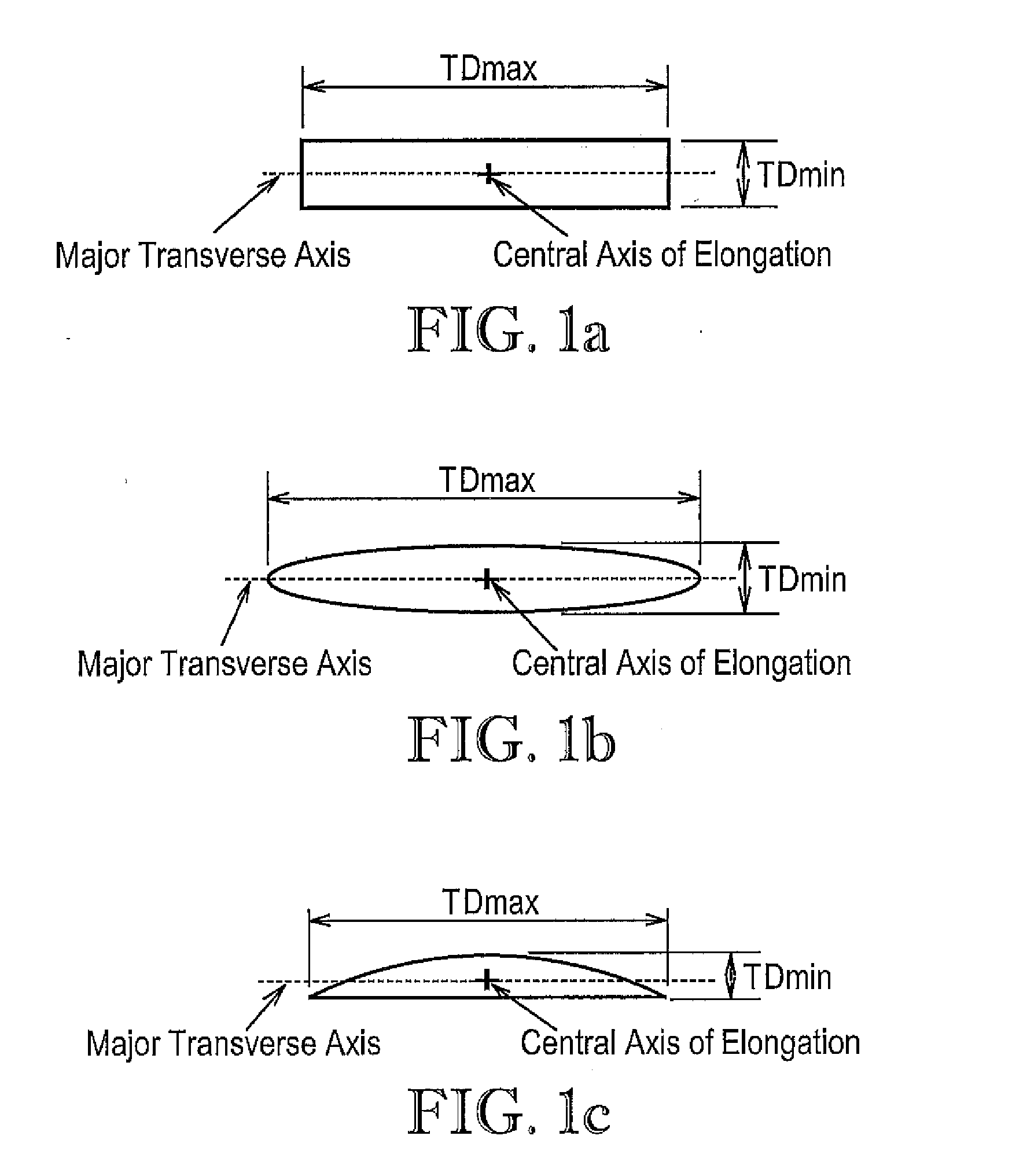

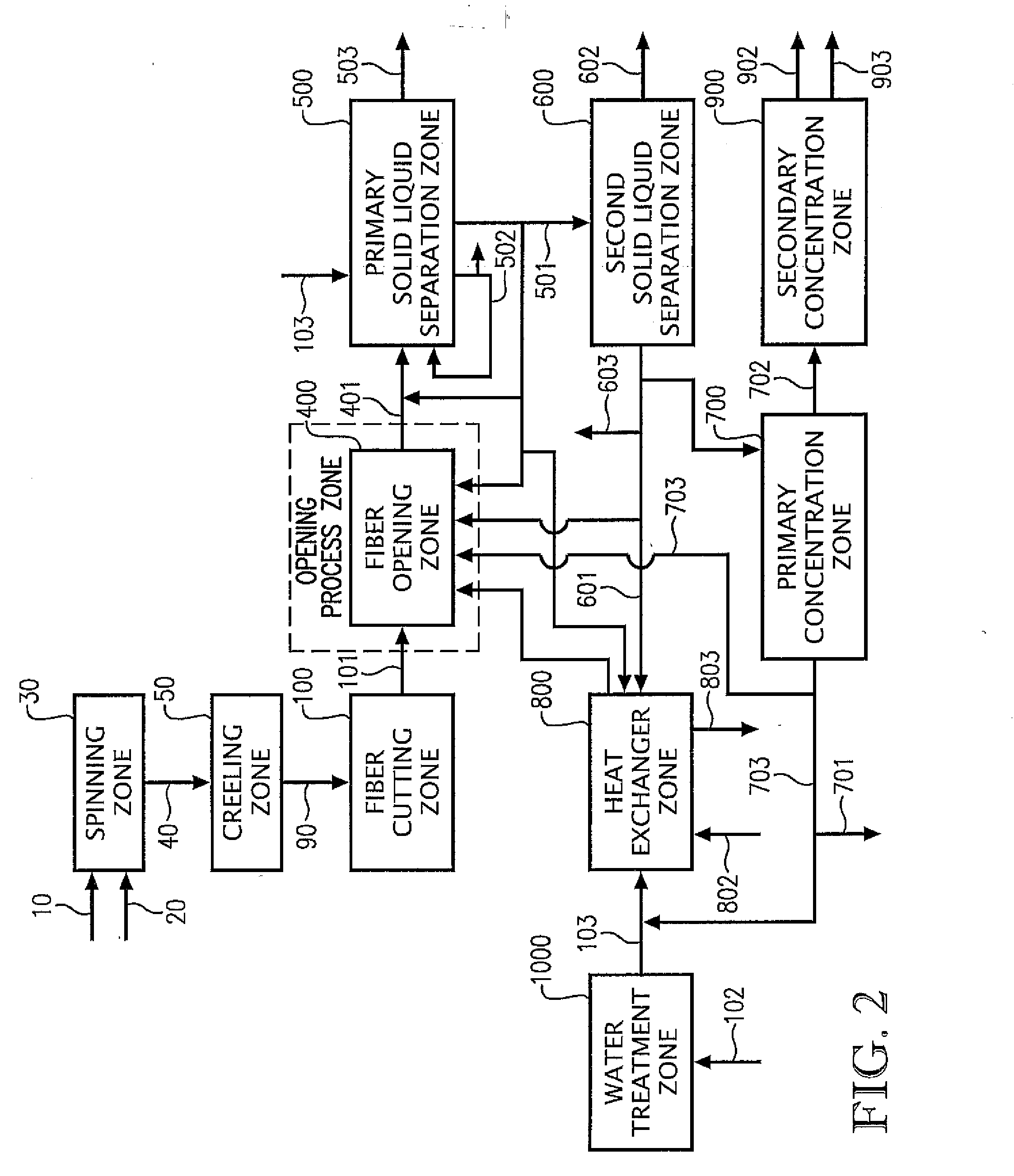

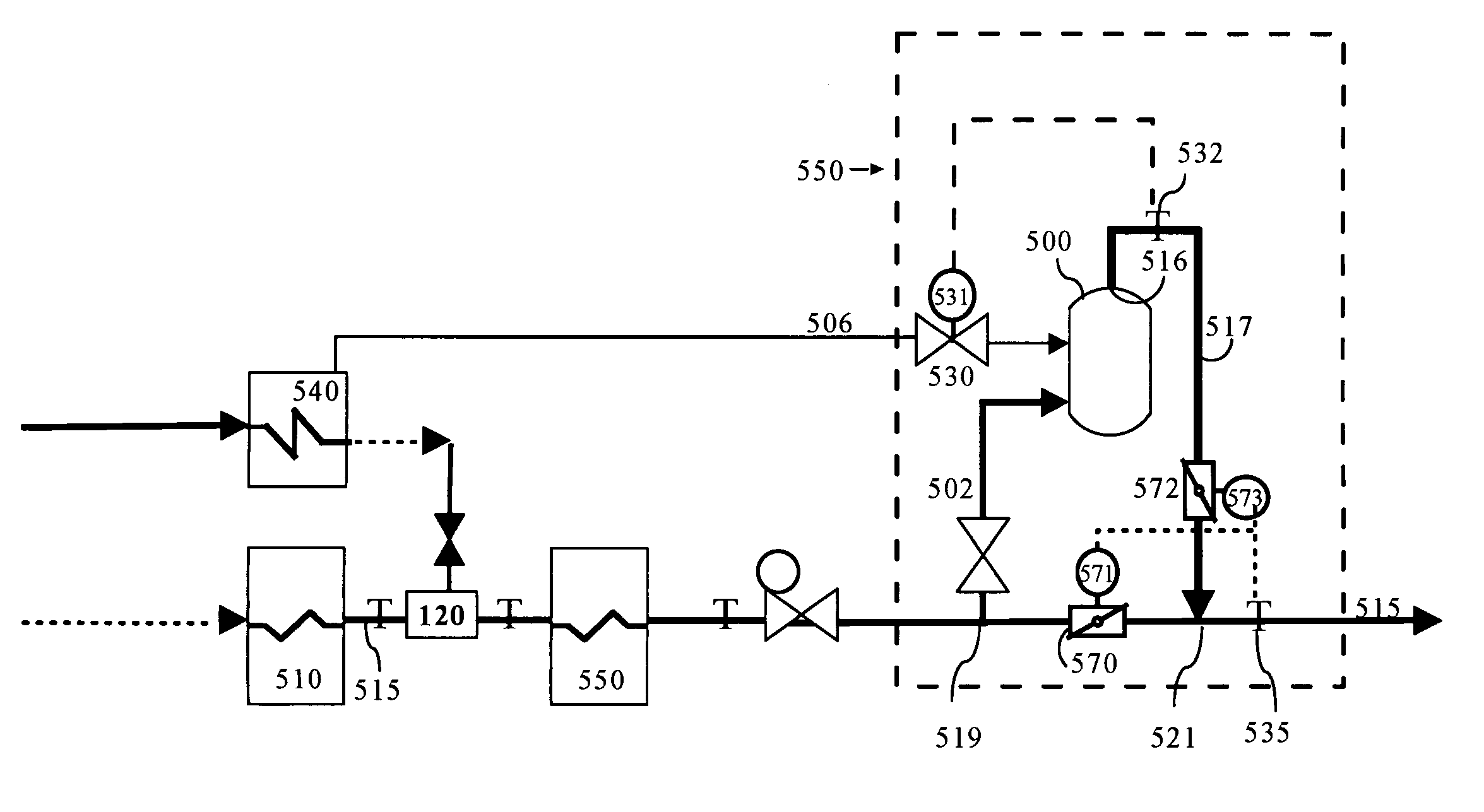

ActiveUS20130192779A1Reduce blockingReduce fusionNatural cellulose pulp/paperSpecial paperWater dispersibleSlurry

A process for producing a microfiber product stream, the process comprising:(A) contacting short cut multicomponent fibers having a length of less than 25 millimeters with a heated aqueous stream in a mix zone to produce a short cut multicomponent fiber slurry;(B) routing the short cut multicomponent fiber slurry and optionally, a heated aqueous stream, to a fiber opening zone to remove a portion of the water dispersible sulfopolyester to produce an opened microfiber slurry; and(C) routing the opened microfiber slurry to a primary solid liquid separation zone to produce the microfiber product stream and a first mother liquor stream.

Owner:EASTMAN CHEM CO

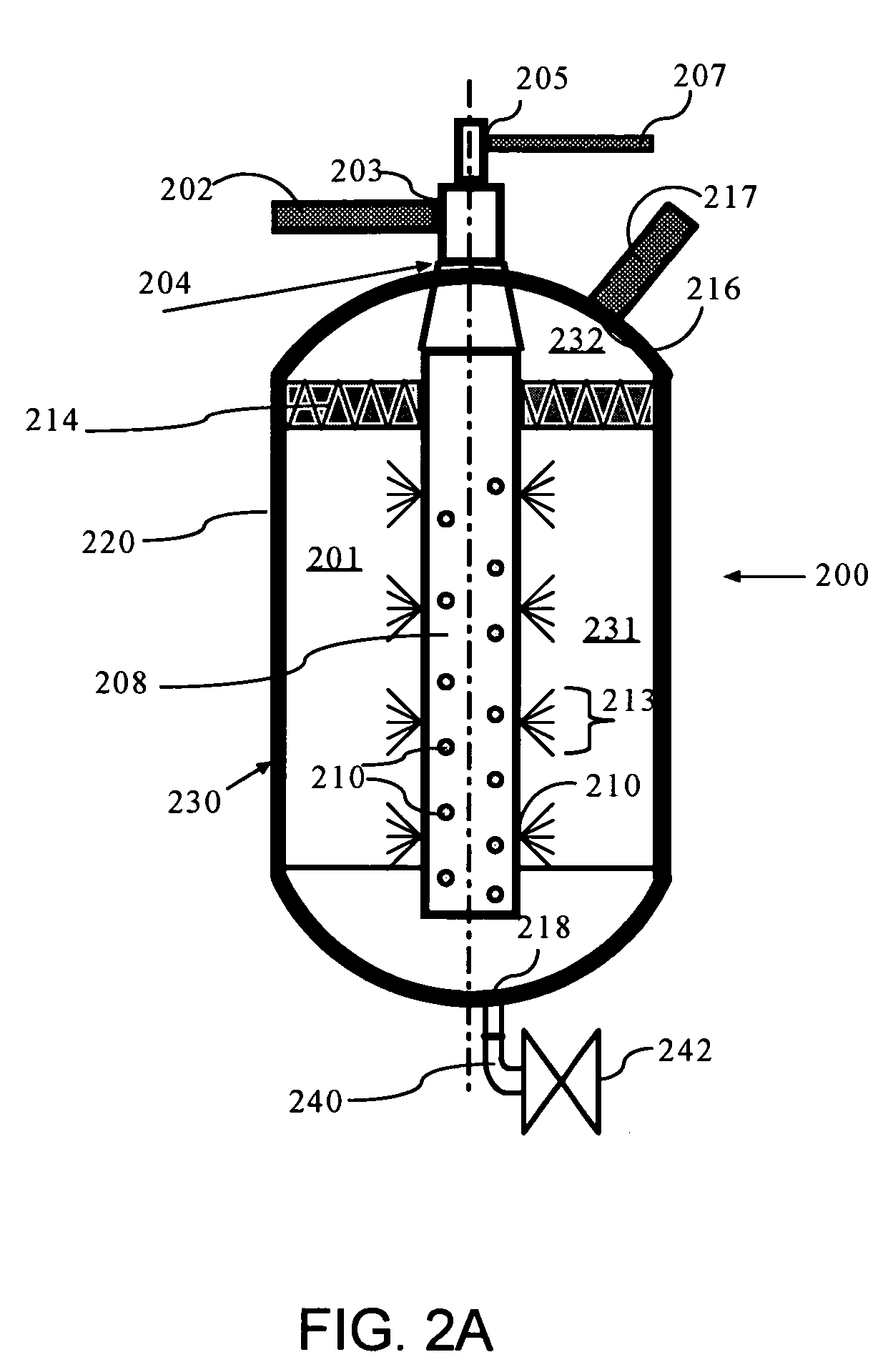

Hot to cold steam transformer for turbine systems

A steam transformer (200) receives steam through a steam inlet (203), and the steam is mixed in a mixing zone (231) with water entering through a water inlet (205). Steam cooled by contact with the water exits the steam transformer through a cold steam outlet (216). Between the mixing zone (231) and the cold steam outlet (216) is positioned a demister (214) that restricts the passage of water droplets.The steam transformer (200) is used to condition the steam temperature in steam turbine and combined cycle turbine facilities when adjustment of steam temperature is required, such as for cold starts of turbines. The steam transformer (200) may be installed into a bypass circuit or directly inline. A number of differing configurations and designs are disclosed.

Owner:SIEMENS ENERGY INC

Foam dispenser and method of making foam from more than one liquid

InactiveUS20070278247A1Liquid transferring devicesLiquid spraying apparatusProduct gasProcess engineering

A foam dispenser for dispensing foam from a first and a second liquid includes a first and a second liquid container for first and second liquids respectively. The dispenser includes a pumping mechanism for pumping the first liquid, second liquid and gas. The dispenser also includes a first foaming mechanism for forming a first foam. It is in flow communication with the first liquid container and a gas inlet and it includes a first mixing zone. A second mixing zone is in flow communication with the second liquid container and the first foaming mechanism wherein the first foam is mixed with the second liquid to form a final foam.

Owner:BANKS STEWART +1

Apparatus of chemical vapor deposition with a showerhead regulating injection velocity of reactive gases positively and method thereof

ActiveUS8882913B2Suppress DiffuseAvoid pollutionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseReactive gas

The present invention is related to an apparatus and a method for chemical vapor deposition (CVD) using a showerhead through which a reactive gas of at least one kind and a purge gas is injected over a substrate on which a film is growing. A plural number of reactive gas showerhead modules are laid on a purge gas showerhead module. Each reactive gas is injected from a bottom of the showerhead after flowing through the showerhead as separated, thereby preventing the reactive gases from causing homogeneous gas phase reactions and from generating unwanted particles at the inside of the showerhead. And a purge gas is injected from the bottom surface of the showerhead by forming a protective curtain, thereby suppressing diffusion of the reactive gas injected backwardly. Each reactive gas is mixed with an injection support gas which is a kind of inert gas in a mixing zone at inside of the showerhead, where the injection velocity of each reactive gas is regulated positively by the amount of the injection support gas mixed. The present invention further includes an apparatus and a method, wherein the showerhead is cooled by a cooling jacket which keeps the temperature of the showerhead at proper levels to prevent both the condensation and the thermal decomposition of the reactive gas used.

Owner:KOREA INST OF IND TECH +1

Processes to produce short cut microfibers

ActiveUS20130192780A1Reduce blockingReduce fusionNatural cellulose pulp/paperSpecial paperWater dispersibleSlurry

A process for producing a microfiber product stream, the process comprising:(A) contacting cut multicomponent fibers having a length of less than 25 millimeters with a treated aqueous stream in a fiber slurry zone to produce a cut multicomponent fiber slurry;(B) contacting the cut multicomponent fiber slurry with a heated aqueous stream in a mix zone to produce a heated multicomponent fiber slurry;(C) routing the heated multicomponent fiber slurry to a fiber opening zone to remove a portion of the water dispersible sulfopolyester to produce an opened microfiber slurry; and(D) routing the opened microfiber slurry to a primary solid liquid separation zone to produce the microfiber product stream and a first mother liquor stream.

Owner:EASTMAN CHEM CO

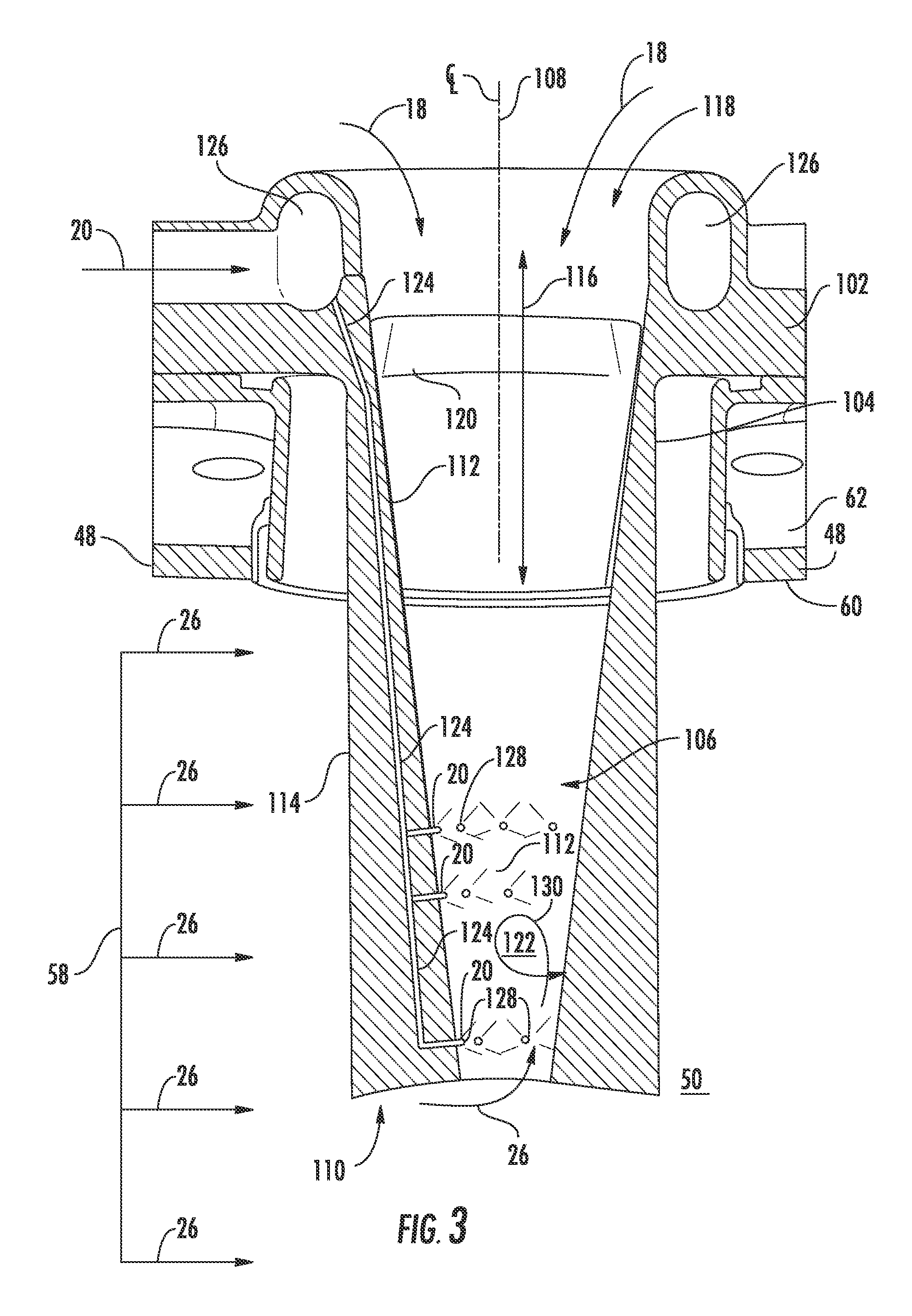

Trapped vortex fuel injector and method for manufacture

ActiveUS20150285504A1Additive manufacturing apparatusContinuous combustion chamberCombustionEngineering

A trapped vortex fuel injector includes a main body having an annular portion and a semi-annular portion coaxially aligned with the annular portion. The semi-annular portion extends downstream from the annular portion. An inner wall and an opposing outer wall of the main body extend between the annular and semi-annular portions. The annular portion at least partially defines a combustion air flow passage through the trapped vortex fuel injector. The semi-annular portion defines a trapped vortex pre-mix zone downstream from the combustion air flow passage. The main body further defines a fuel circuit that is fully circumscribed within the main body and that extends between the annular portion and the semi-annular portion. A plurality of fuel injection ports provide for fluid communication between the fuel circuit and the trapped vortex pre-mix zone. The main body may be fabricated using an additive manufacturing process.

Owner:GENERAL ELECTRIC CO

Oxygen tailoring of polyethylene resins

InactiveUS20050012235A1Improve stabilityImprove uniformityWood working apparatusFlat articlesMolten stateEthylene Homopolymers

A process is provided for extruding a bimodal polyethylene resin. The process includes providing a polyethylene homopolymer or copolymer resin having a bimodal molecular weight distribution; conveying the resin through an extruder having a feed zone in which the resin is not melted, a melt-mixing zone in which at least a portion of the resin is melted, and a melt zone in which the resin is in a molten state, each zone being partially filled with the resin; and contacting the molten resin in the melt zone with a gas mixture of 8 to 40% by volume O2. The resin can be further pelletized. The oxygen-tailored resin can be used to make polyethylene films having improved bubble stability.

Owner:EXXONMOBIL CHEM PAT INC +1

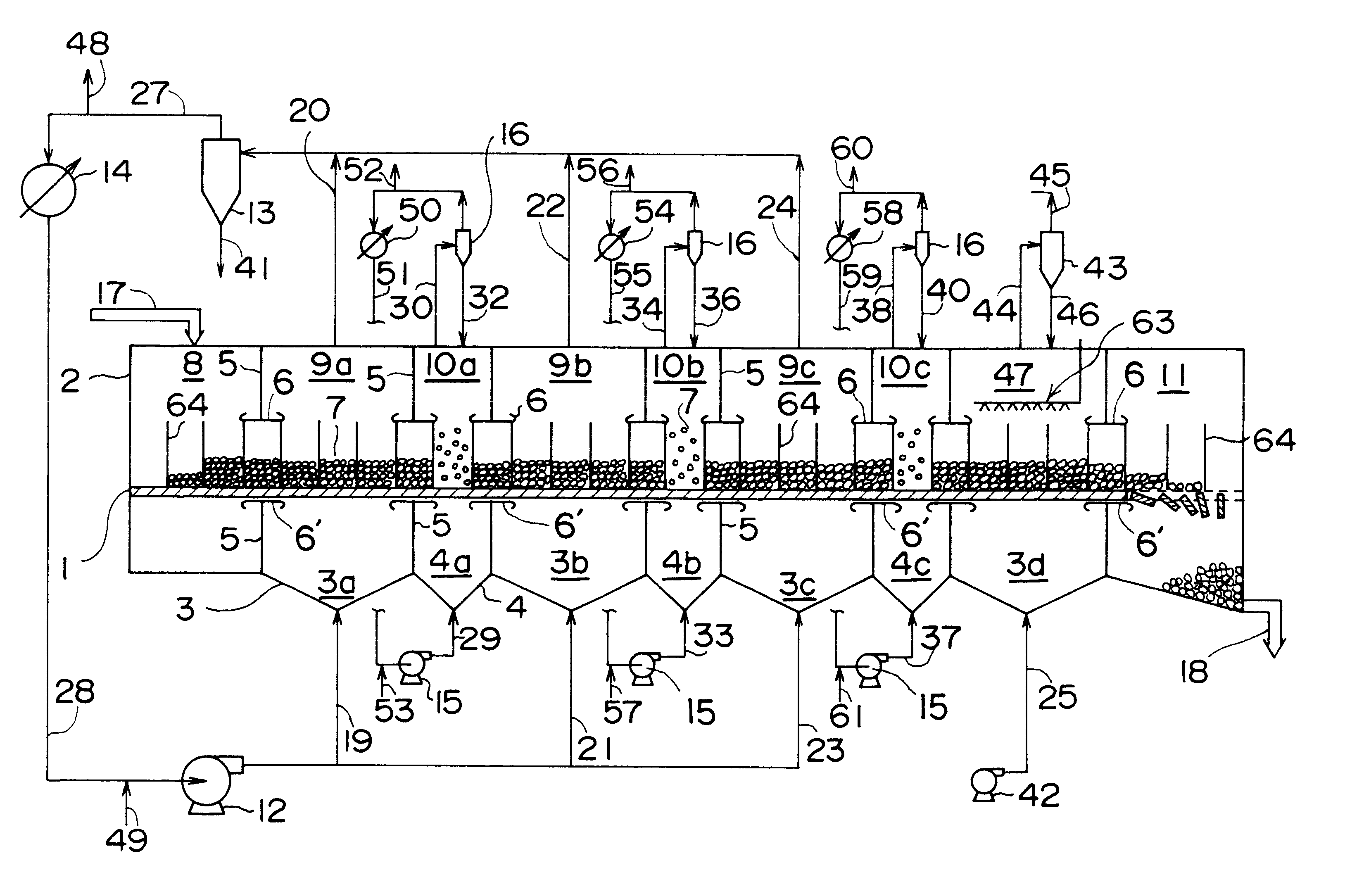

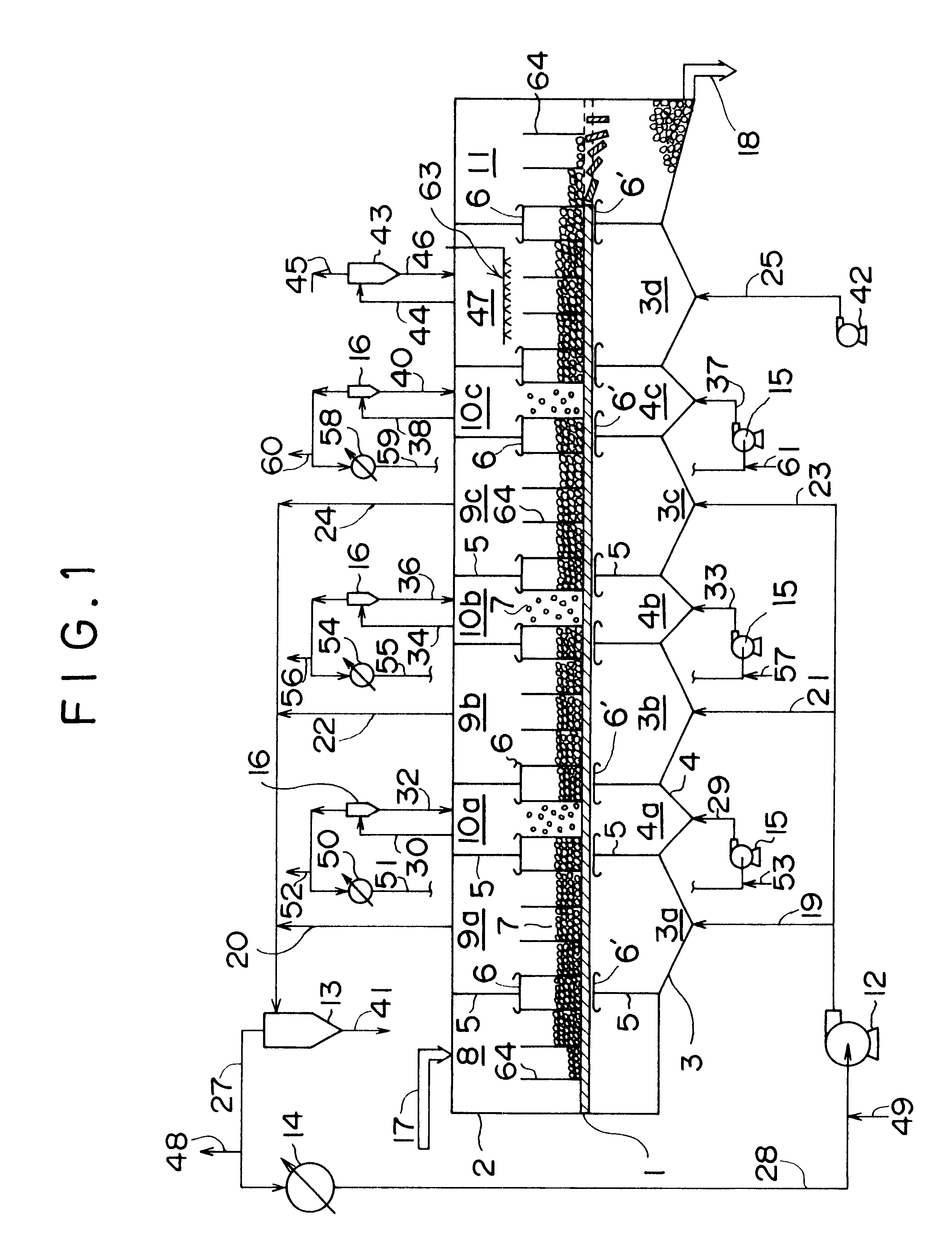

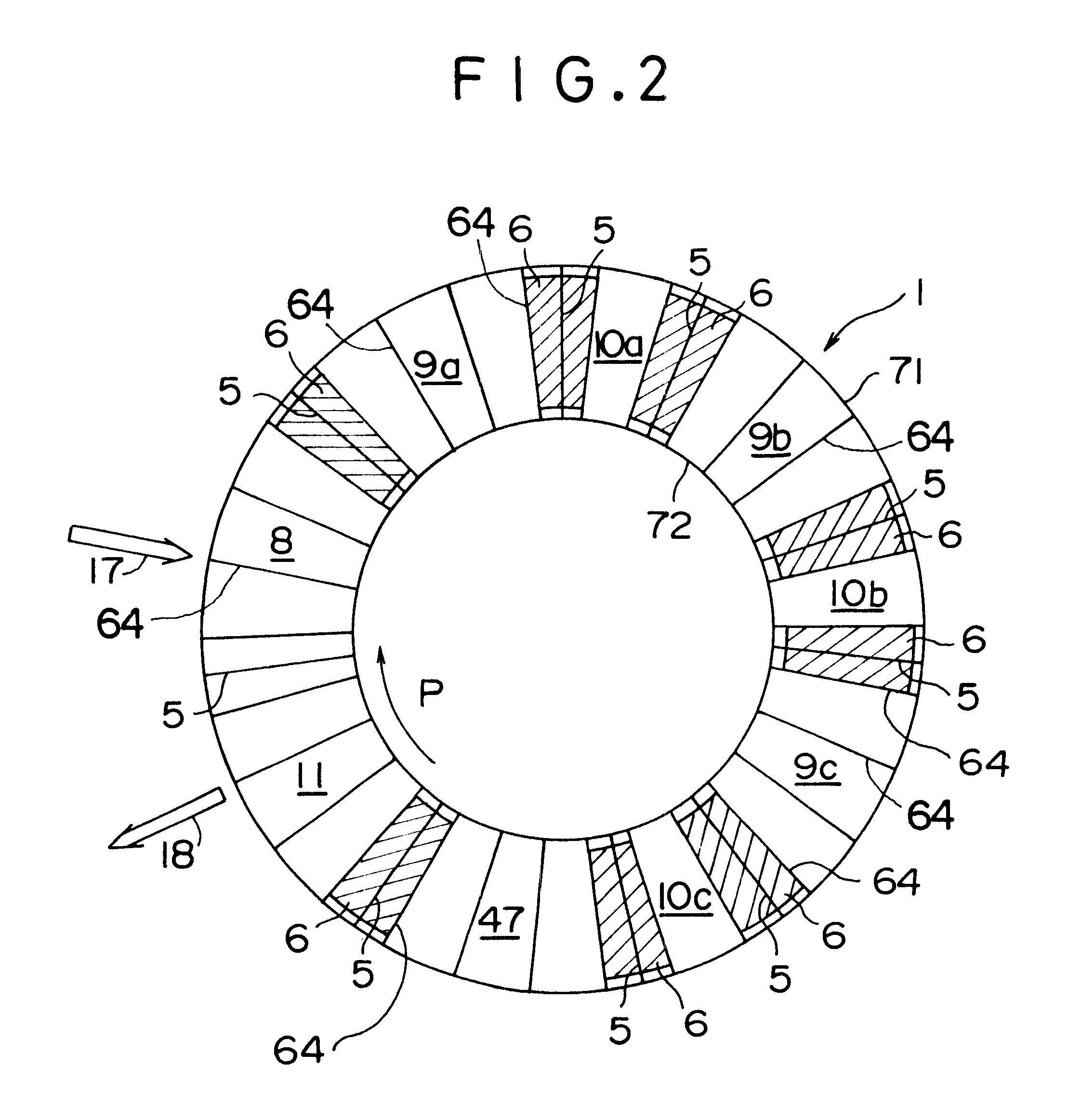

Coal reforming process and apparatus therefor

As one of the coal reforming treatment steps constituting a coal reforming process, an oxidation treatment step is carried out on a circular grate. For this purpose, there is used a coal reforming apparatus comprising a circular grate, the circular grate being separated into a plurality of zones which include fixed bed zones and mixing zones for fluidizing the coal properly between adjacent fixed bed zones.

Owner:MITSUBISHI HEAVY IND LTD

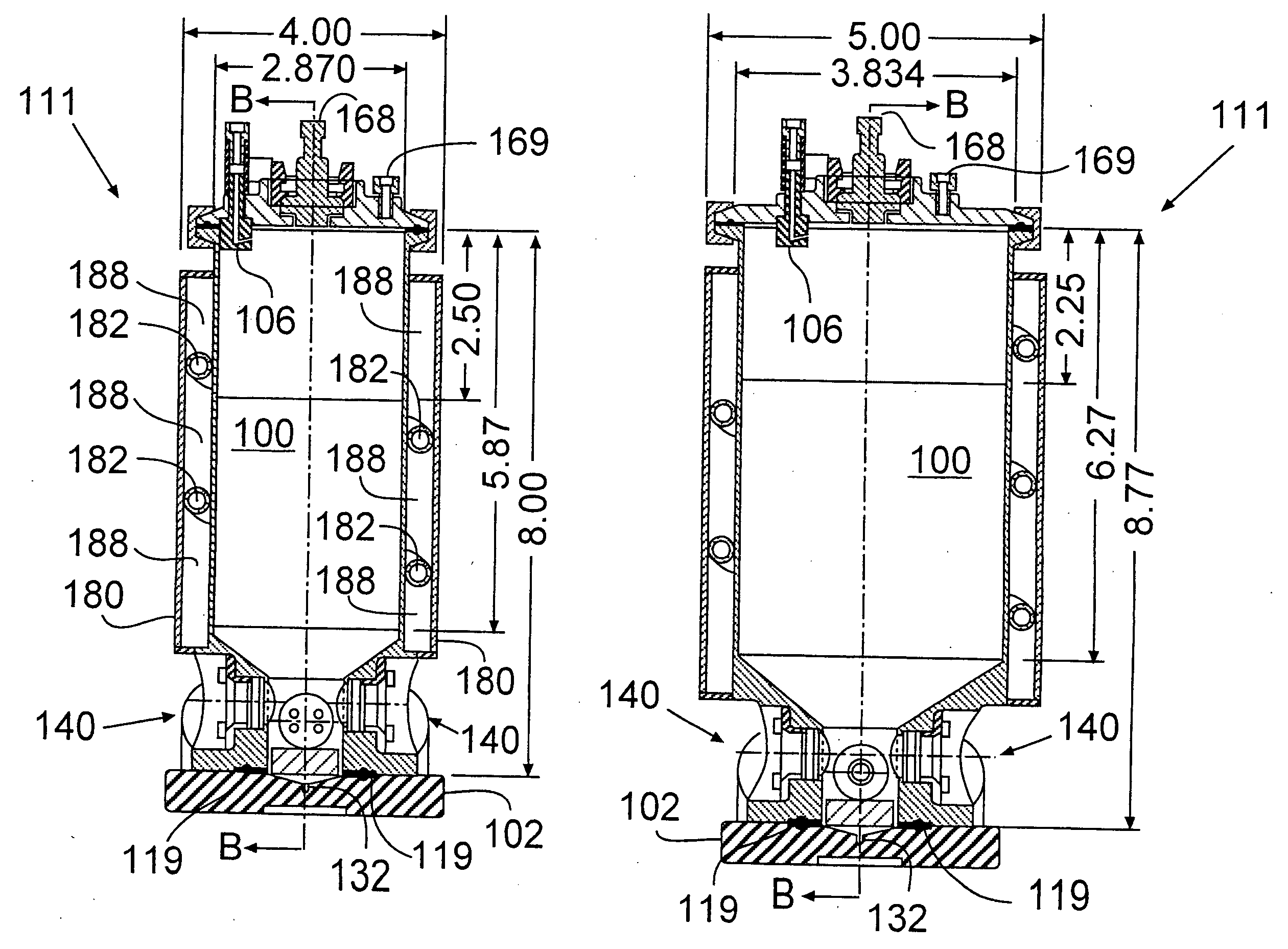

Automated low-volume tangential flow filtration process development device

InactiveUS20050023194A1Economical and fastEasy to disassembleIon-exchanger regenerationUltrafiltrationProcess developmentLaboratory scale

An automated process development device providing flexibility and accuracy for the investigative development of tangential flow filtration processes. The development device is used for evaluating the process parameters of a laboratory scale tangential flow filtration process with an eye towards developing a larger, commercial scale process. The process development device—operable to an unprecedented minimum reliable recirculation volume of less than approximately 20 milliliters—includes: (a) a reservoir having a distinct mixing zone; (b) a tangential flow filtration module; (c) conduits defining, together with the distinct mixing zone and the tangential flow filtration module, a fluid process stream through which a liquid sample is recirculated; (d) pumps for driving the flow of the liquid sample through the fluid process stream; (e) valves for regulating the flow of the liquid sample through the fluid process stream; (f) sensors for acquiring data about the liquid sample as it flows through the fluid process stream; and (g) an electronic data processing network capable of receiving, transmitting, processing, and recording data associated with the operation of the pumps, valves, and sensors, the recorded data being sufficiently comprehensive to determine the conduct of the tangential flow filtration process at a substantially larger scale.

Owner:MILLIPORE CORP

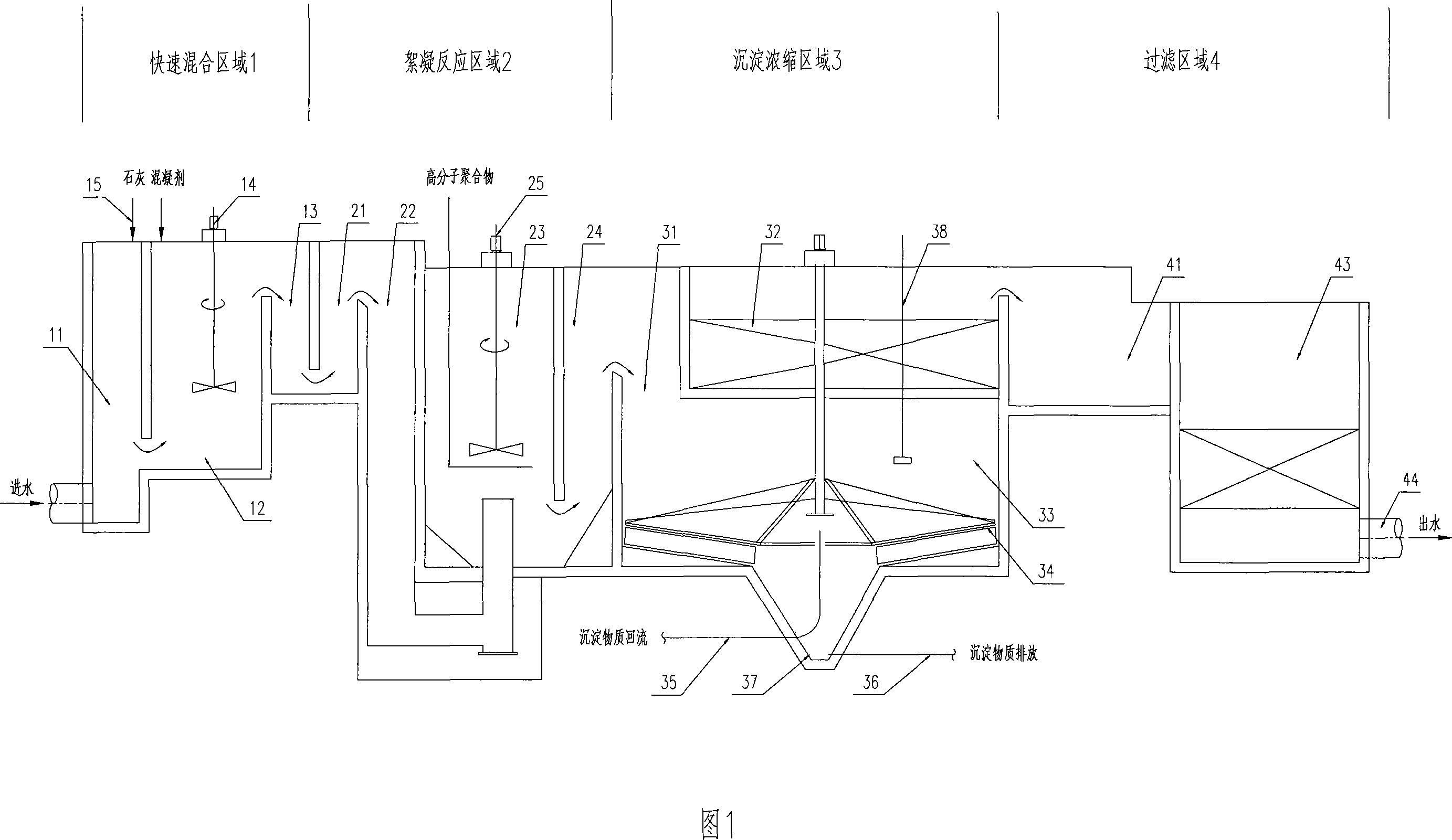

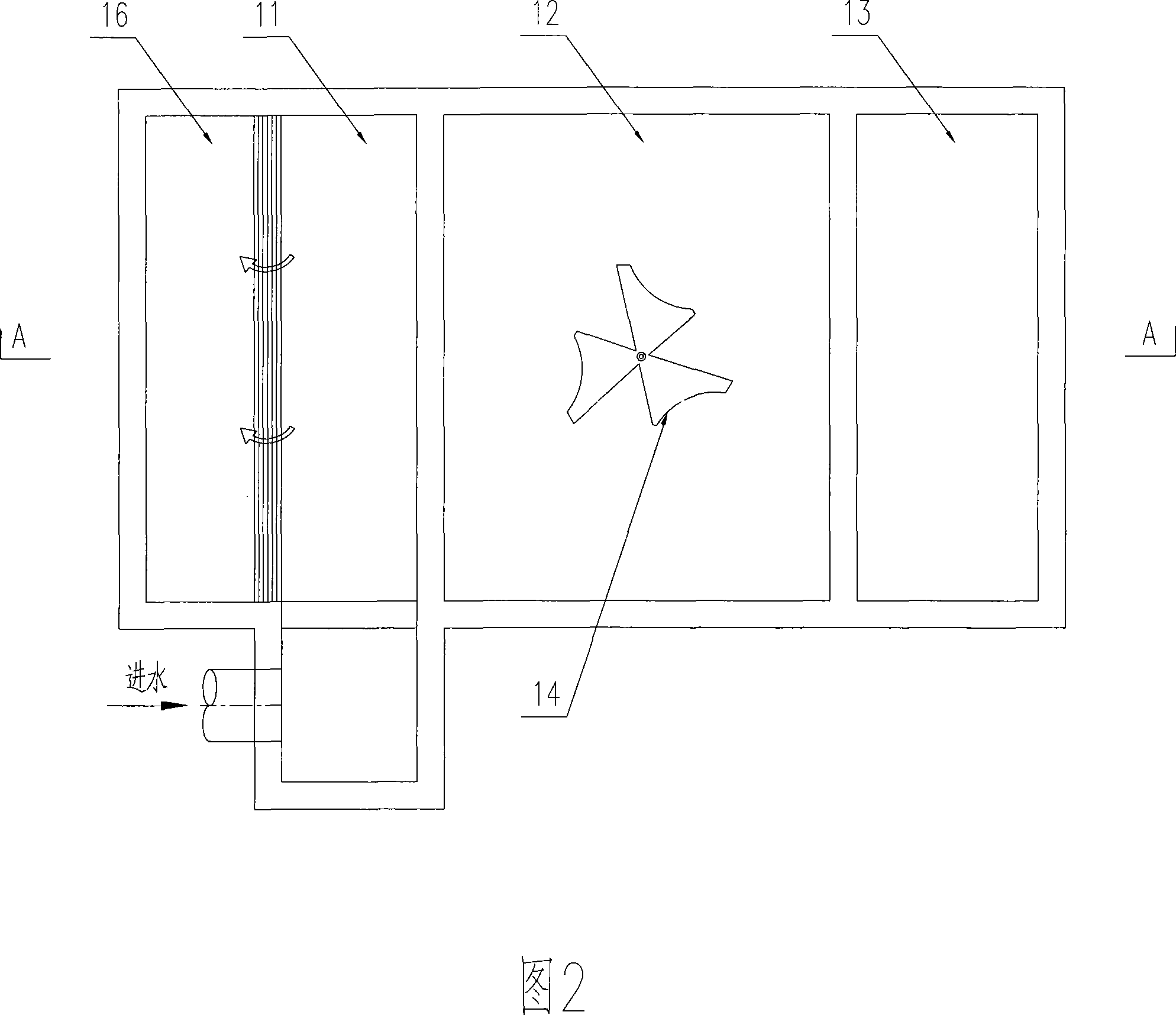

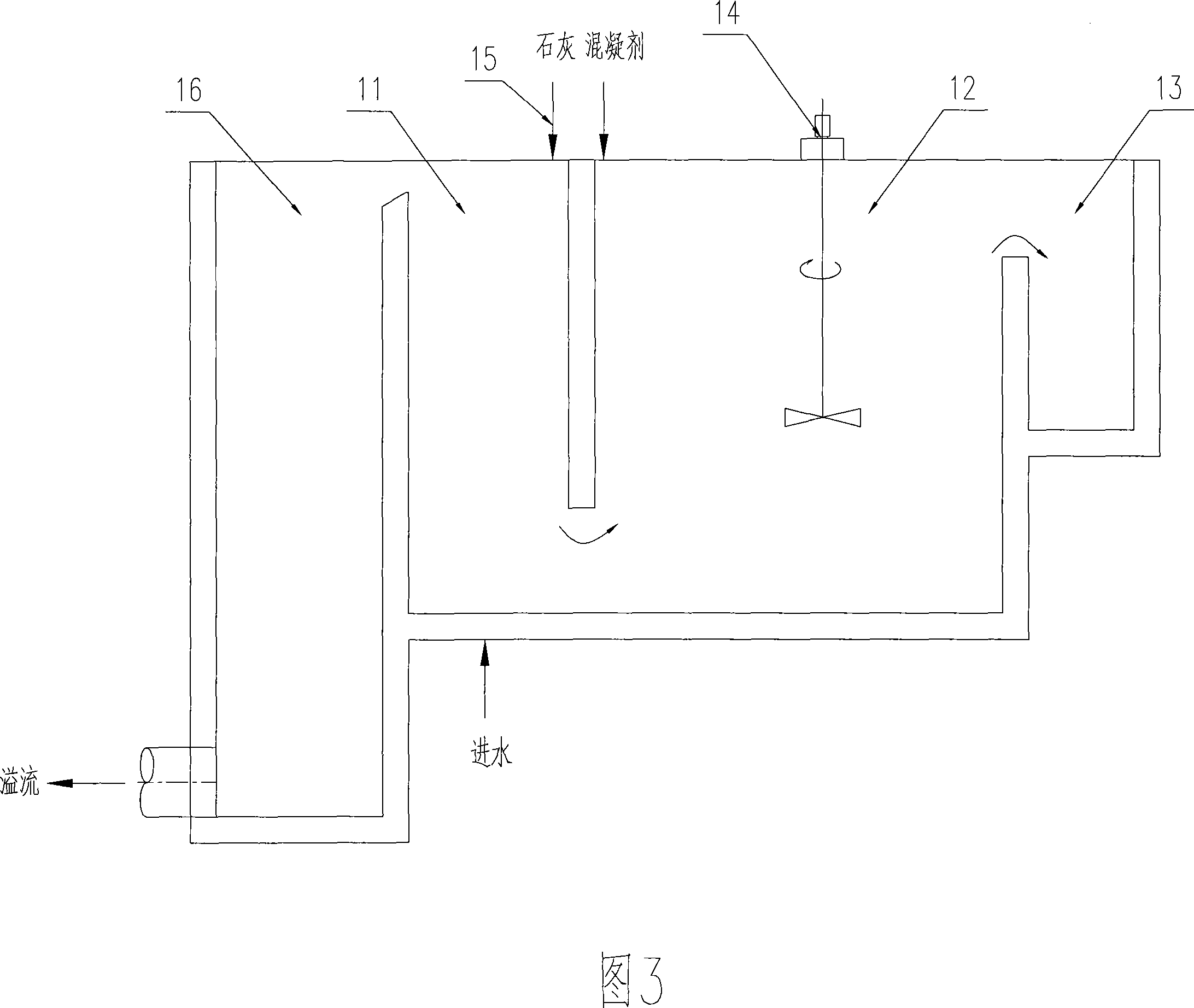

Method and equipment for purifying recirculated cooling water or town B-grade sewage

ActiveCN101117250APromote productionEasy to quantifyWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationPurification methodsWater quality

The invention relates to a purification method and equipment for cool circulating water or town secondary sewage water, and is characterized in that the invention has the following steps: a quick mixing zone 1 for mixing a ready treated liquid and a mixing medicament, a flocculating reaction zone 2 for mixing and flocculating a mixed liquid with a backflow deposit substance to get a compact alum at an outlet of the zone, a depositing and concentrating zone 3 for separating a supernatant liquor and a suspension solid and for returning and draining a deposit substance, and a filtering facility zone 4 for purifying the supernatant liquor; the equipment of the invention mainly comprises the quick mixing zone, a high efficient clarification tank and a filtering zone; the invention designs the purification method and equipment for liquid and water; the water quality from the invention is stable, the cost is lower, which changes the prior purification method for liquid and water.

Owner:华电水务(天津)有限公司

Elastomer composite blends and method for producing them

Elastomer composite blends are produced by novel wet / dry mixing methods and apparatus. In the wet mixing step or stage, fluid streams of particulate filler and elastomer latex are fed to the mixing zone of a coagulum reactor to form a mixture in semi-confined flow continuously from the mixing zone through a coagulum zone to a discharge end of the reactor. The particulate filler fluid is fed under high pressure to the mixing zone, such as to form a jet stream to entrain elastomer latex fluid sufficiently energetically to substantially completely coagulate the elastomer with the particulate filler prior to the discharge end. Highly efficient and effective elastomer coagulation is achieved without the need for a coagulation step involving exposure to acid or salt solution or the like. Elastomer composites are produced. Such elastomer composites may be cured or uncured, and combine material properties, such as choice of filler, elastomer, level of filler loading, and macro-dispersion, nor previously achieved. The coagulum produced by such wet mixing step, with or without intermediate processing steps, is then mixed with additional elastomer in a dry mixing step or stage to form elastomer composite blends. The additional elastomer to the coagulum may be the same as or different from the elastomer(s) used in the wet mixing step.

Owner:CABOT CORP

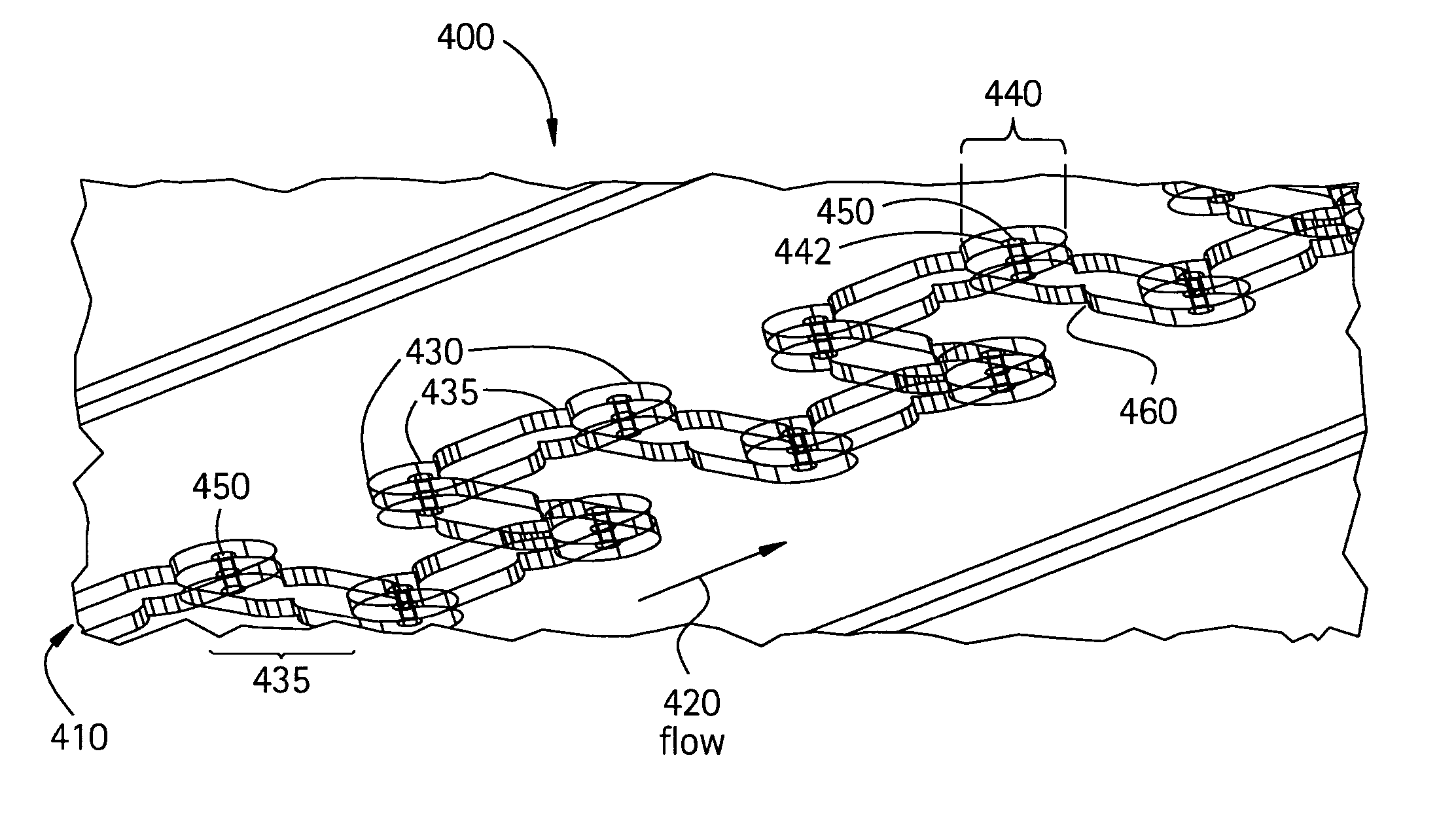

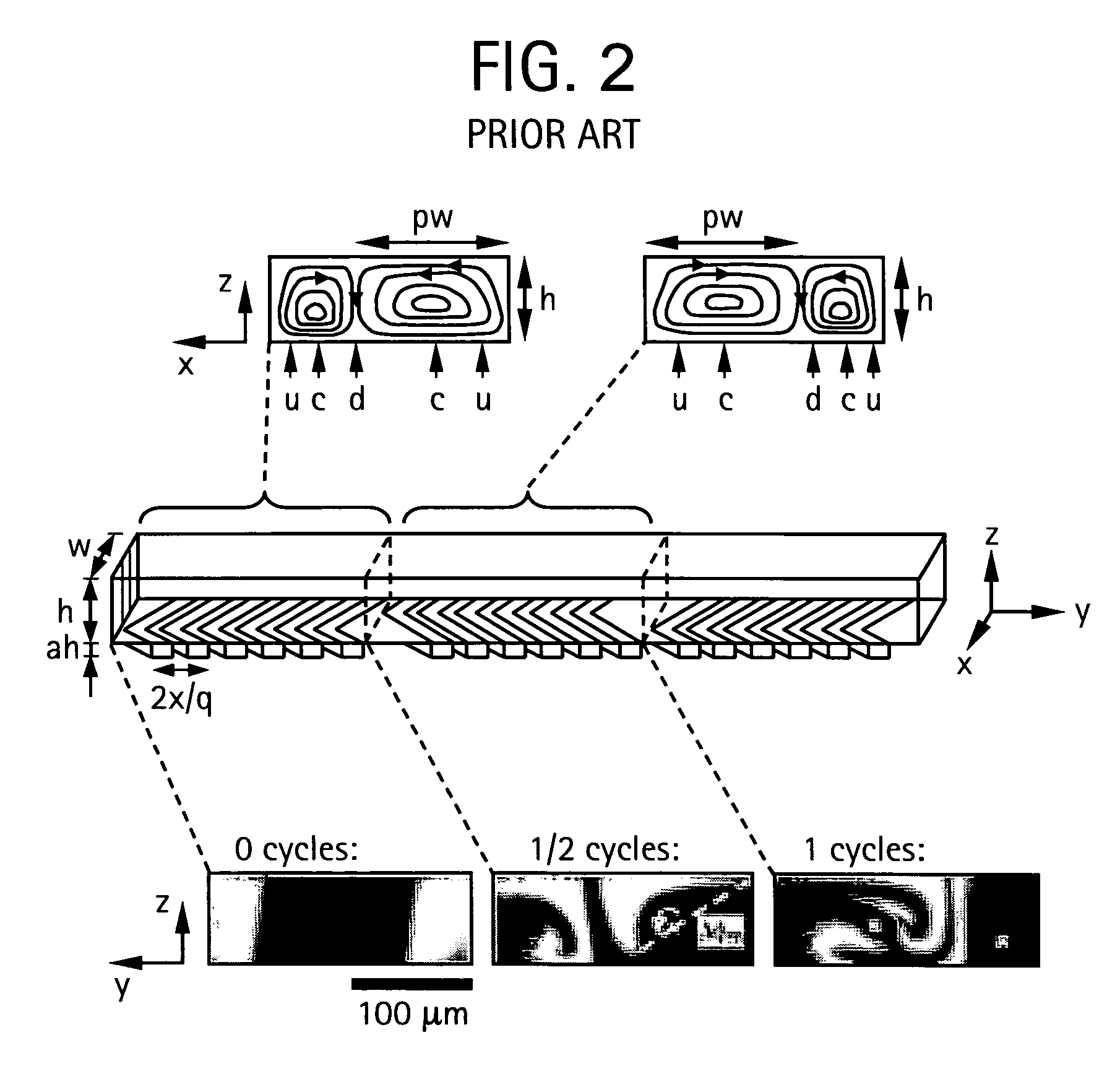

Microstructure designs for optimizing mixing and pressure drop

ActiveUS20050276160A1Efficient mixingImprove mixing efficiencyFlow mixersOther chemical processesContinuous flowEngineering

A class of designs is provided for a mixer in micro reactors where the design principle includes at least one injection zone in a continuous flow path where at least two fluids achieve initial upstream contact and an effective mixing zone (i.e. adequate flow of fluids and optimal pressure drop) containing a series of mixer elements in the path. Each mixer element is preferably designed with a chamber at each end in which an obstacle is placed (thereby reducing the typical inner dimension of the chamber) and with optional restrictions in the channel segments. The obstacles are preferably cylindrical pillars but can have any geometry within a range of dimensions and may be in series or parallel along the flow path to provide the desired flow-rate, mixing and pressure-drop. The injection zone may have two or more interfaces and may include one or more cores to control fluids before mixing.

Owner:CORNING INC

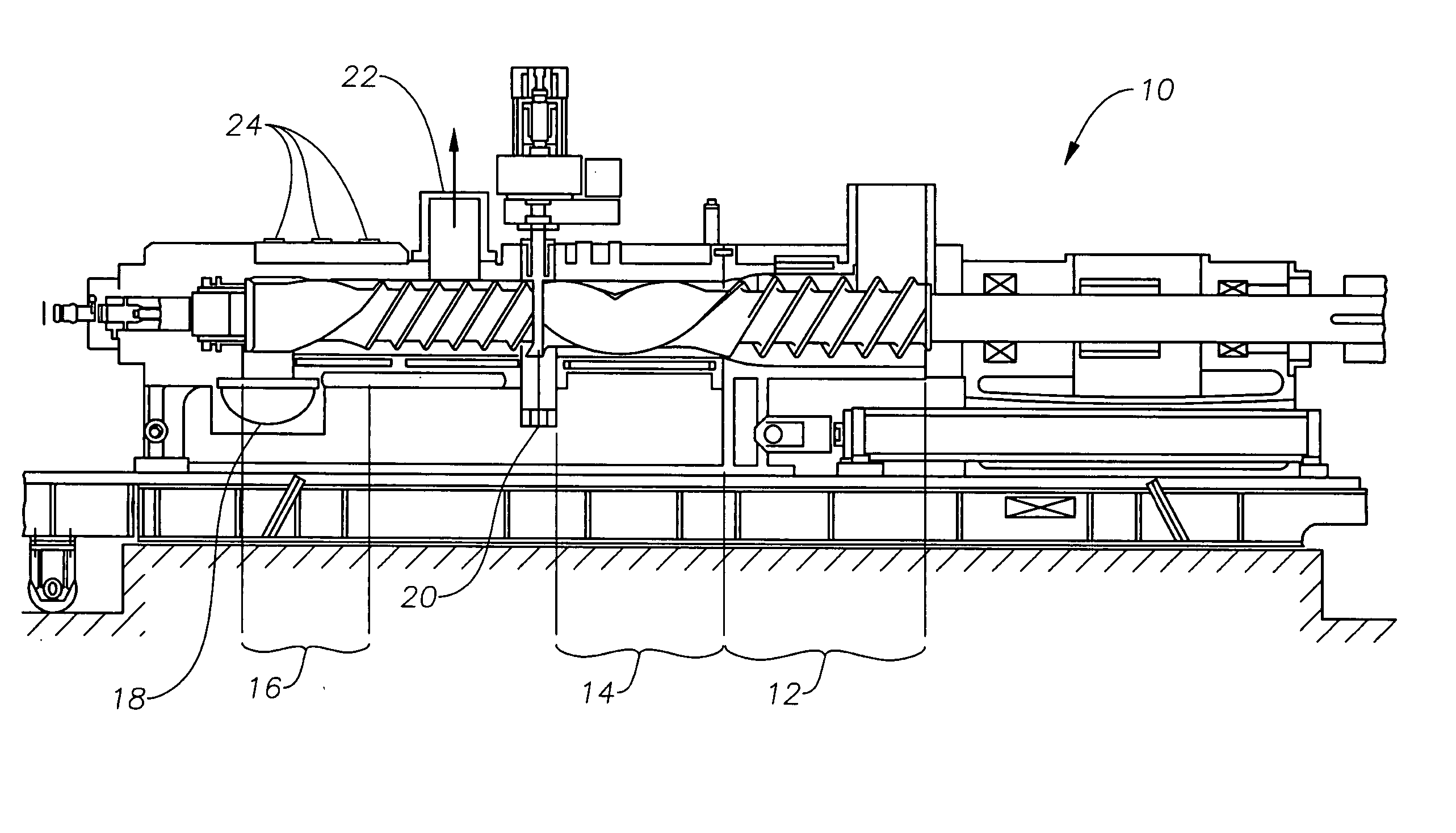

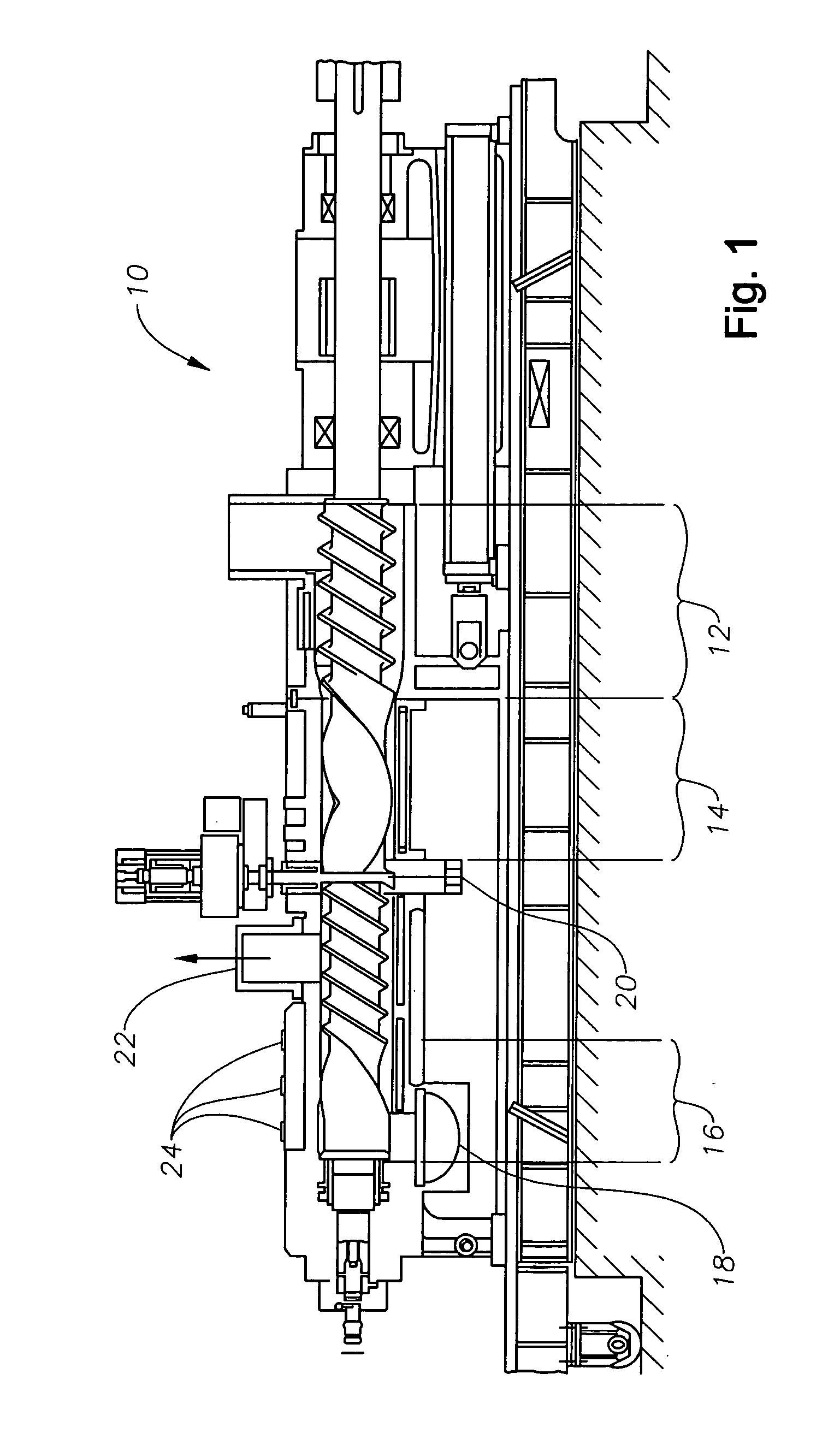

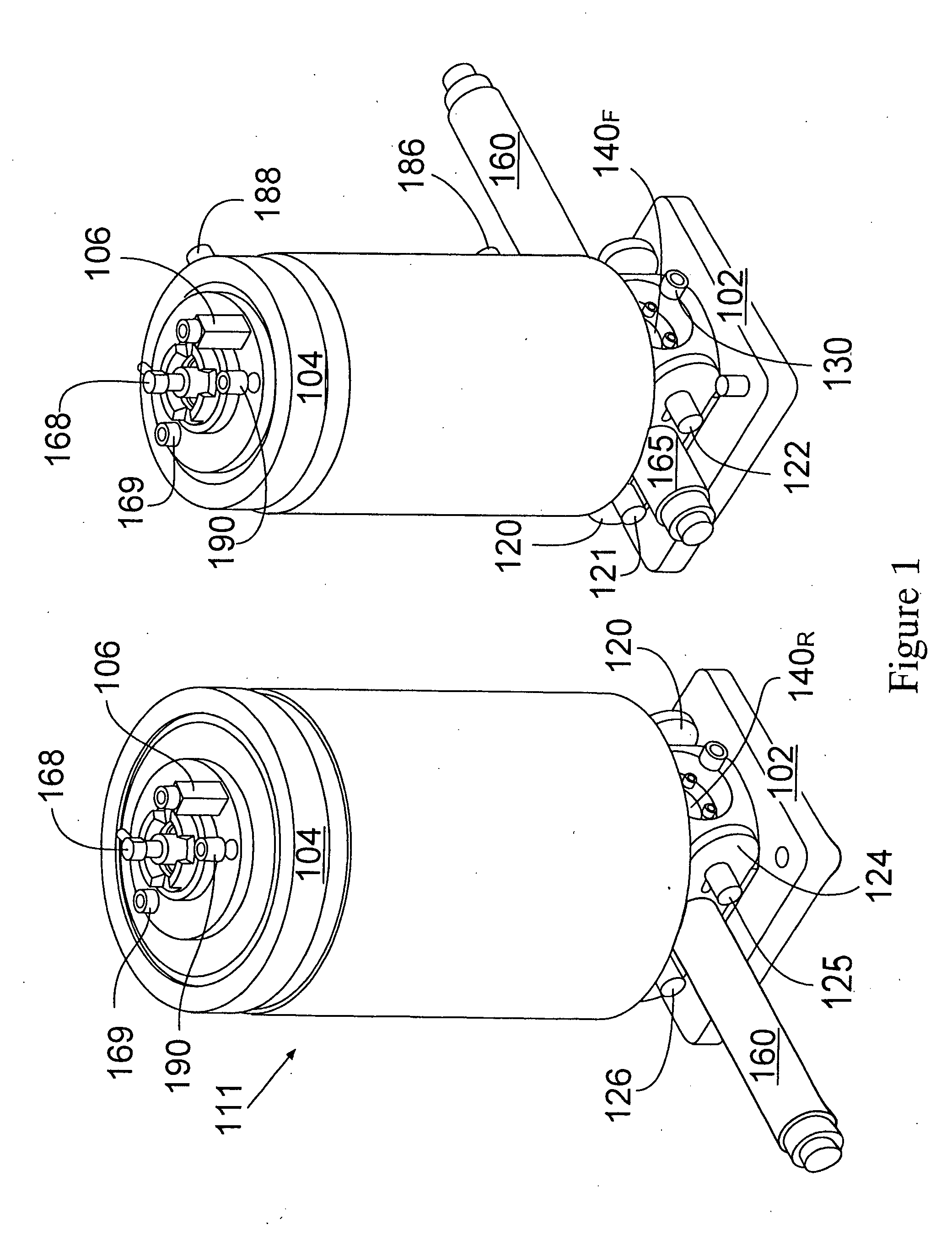

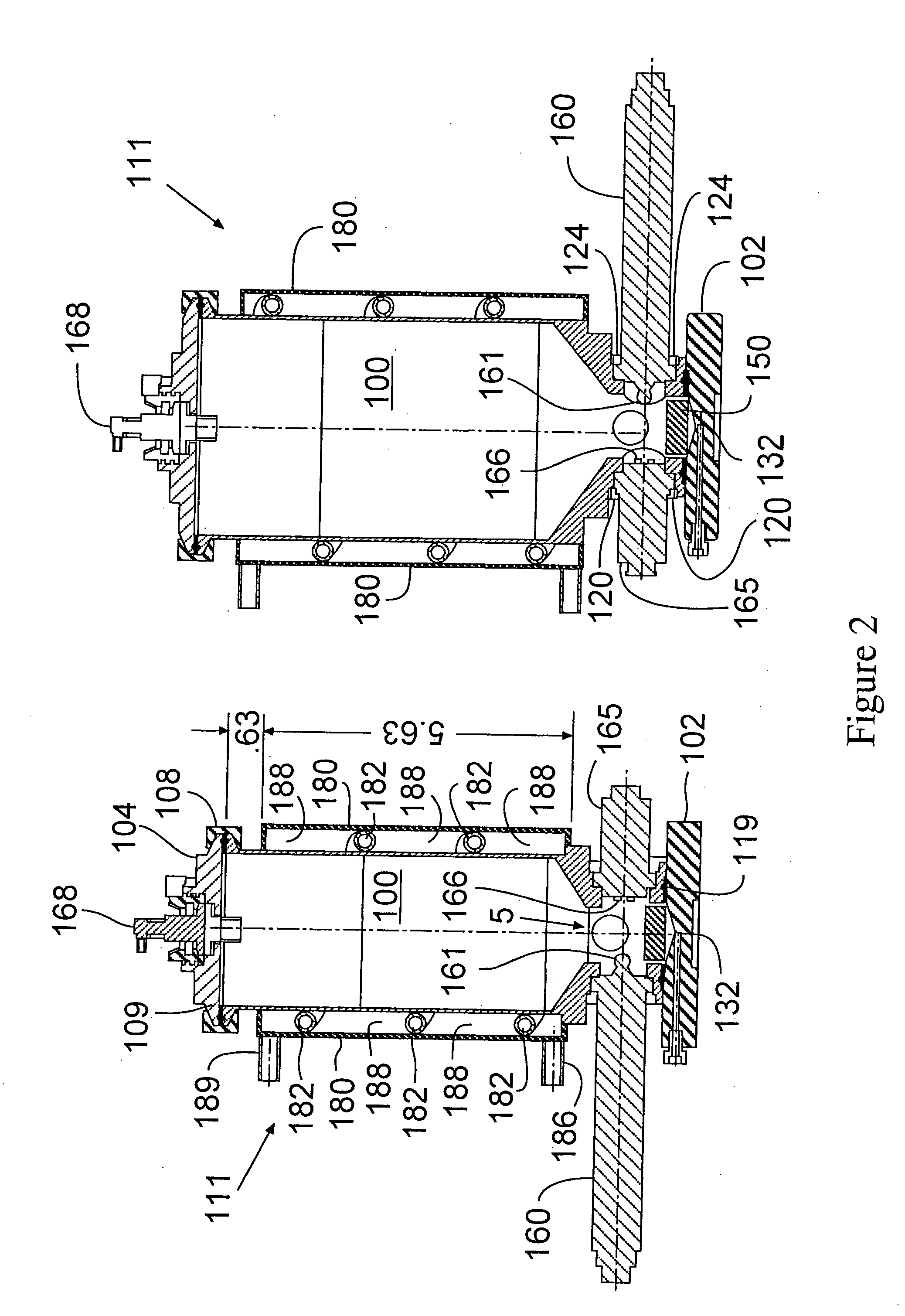

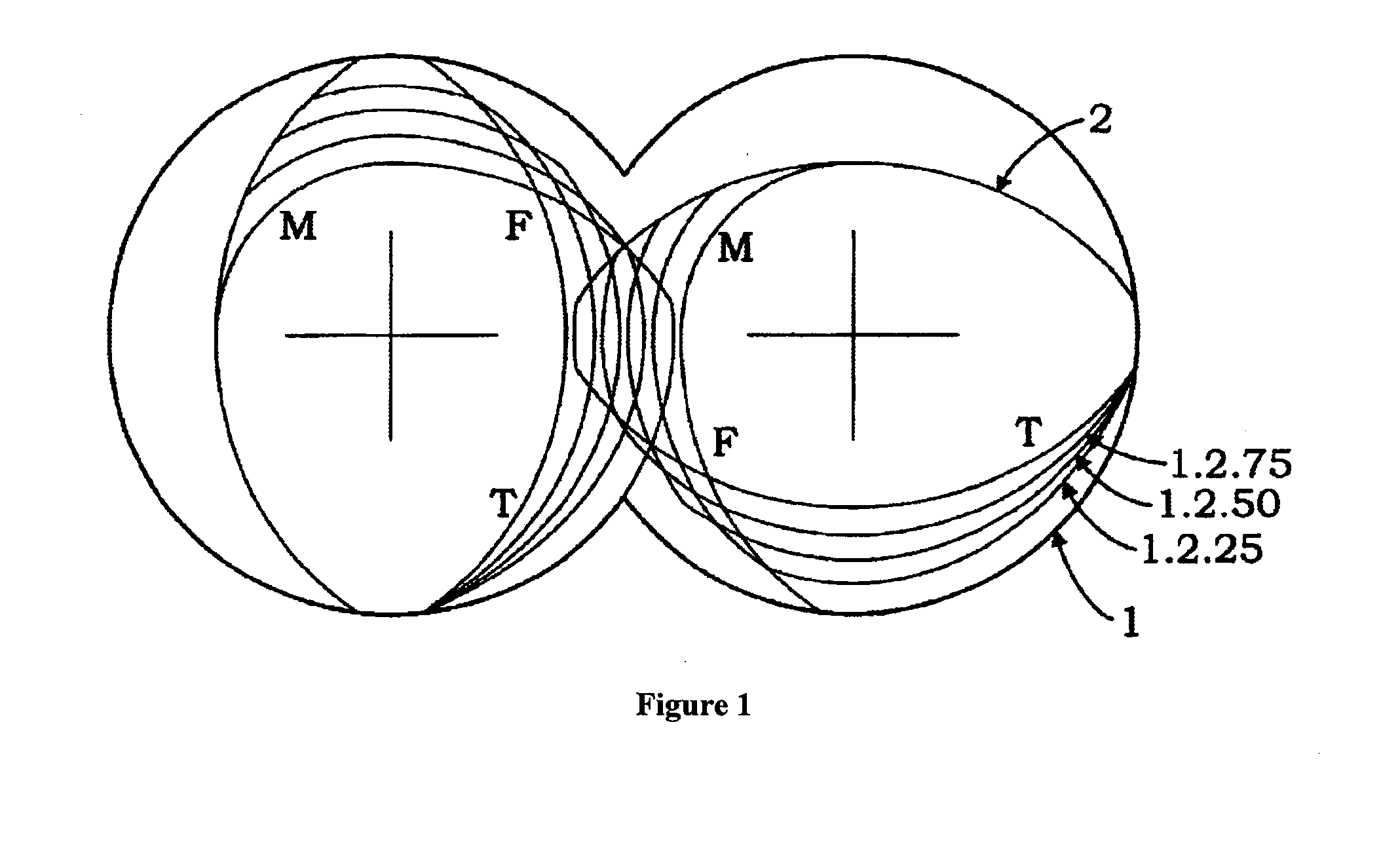

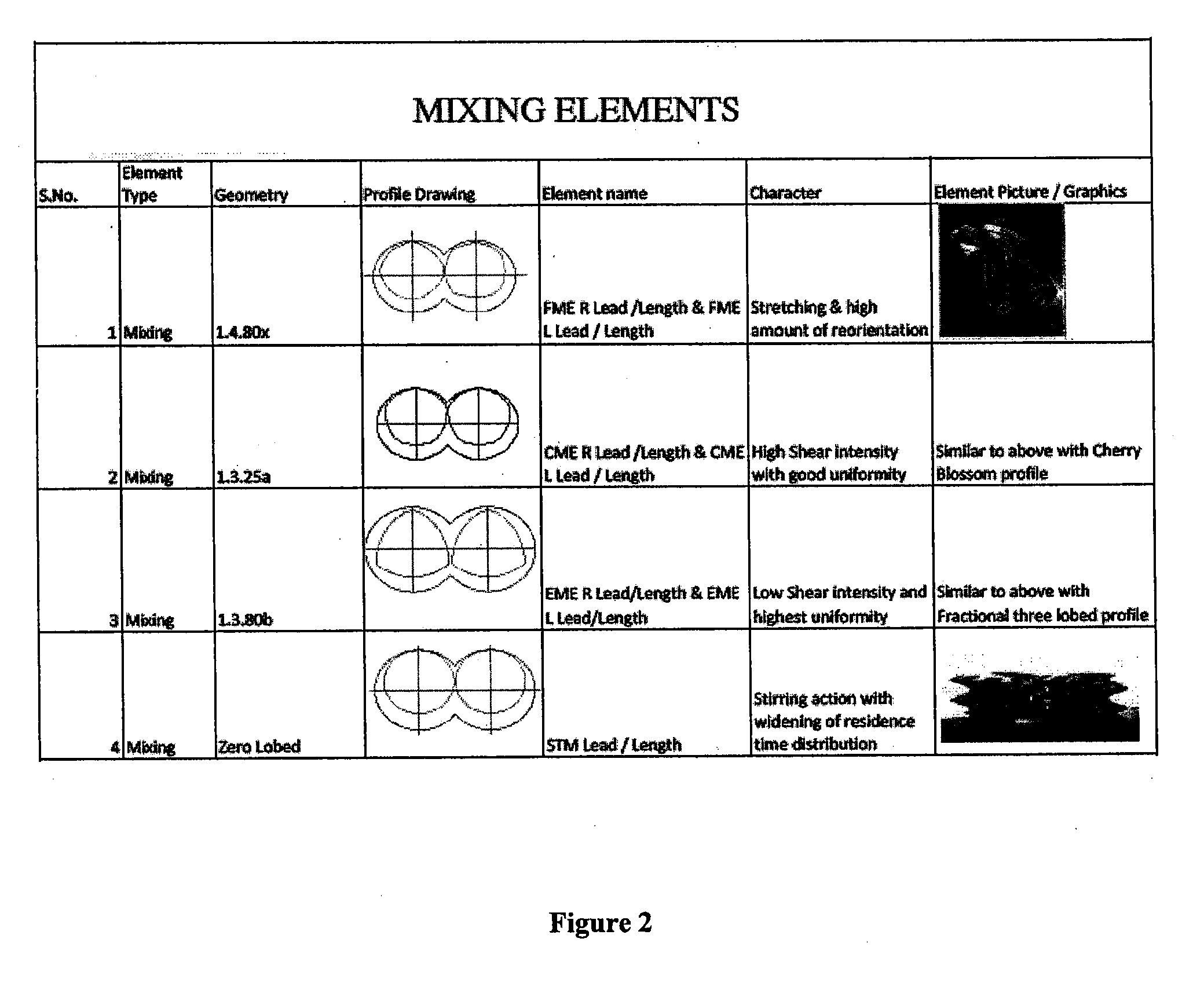

Method of extruder operation

InactiveUS20110063940A1Rotary stirring mixersMixing/kneading with horizontally-mounted toolsMechanical engineeringMixing zone

An extruder capable of improved mixing is disclosed. The extruder comprises of a housing having at least two cylindrical housing bores, each housing bore having an axis disposed parallel to the other axis. The extruder further comprises of at least a first screw shaft and a second screw shaft being disposed in the first and second housing bores. The first and second screw shaft being provided with extruder processing elements that defines a mixing zone. The first and second screw each having extruder D and a screw root diameter d. The first and second screw shaft each having a volumetric ratio of at least 1.4 wherein the volumetric ratio is defined by the extruder diameter D divided by the screw inner diameter d.

Owner:STEER ENG PRIVATE

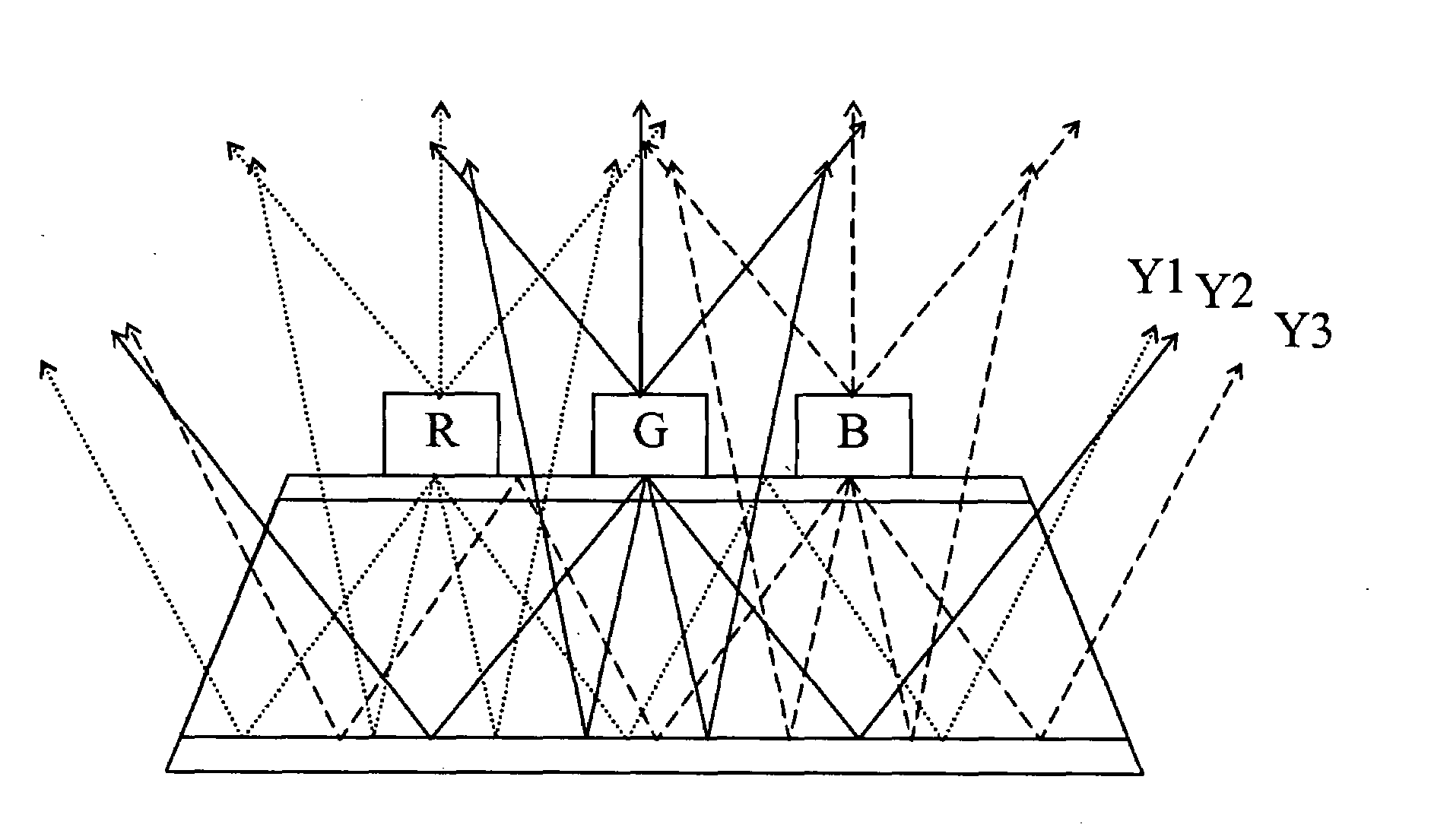

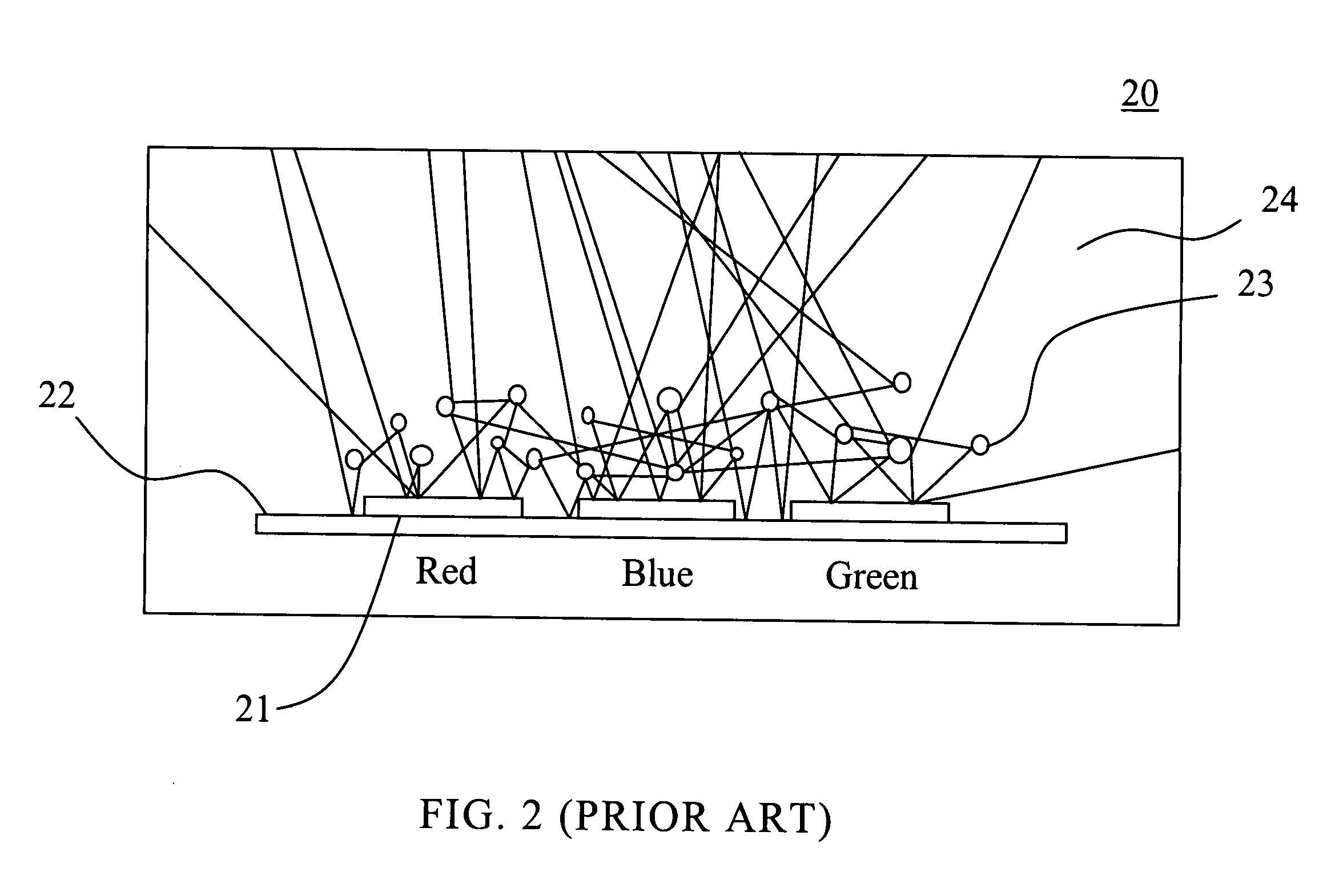

Light-mixing type light-emitting apparatus

ActiveUS20070263384A1Improve efficiencyShorten the mixing distanceSolid-state devicesSpectral modifiersHybrid typeLight beam

A light-mixing type light-emitting apparatus comprises a plurality of light-emitting diodes (LEDs) formed on a transparent carrier, wherein each of the LEDs with a transparent substrate emits light of a distinct color when driven, and the light beams generated from the LEDs are mixed to form a specific color. The transparent carrier setting forth in the present invention provides a mixing zone underlying the plurality of LEDs for the light beams to mix uniformly so as to improve the light-mixing efficiency of the light-emitting apparatus and shorten the mixing distance.

Owner:EPISTAR CORP

Multi-compartment storage and delivery containers and delivery system for microencapsulated fragrances

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com