Integrated internal circulation type denitrification and decarburization bio-membrane reactor and operating method thereof

A biofilm reactor, internal circulation technology, applied in aerobic and anaerobic process treatment and other directions, can solve the problems of large power consumption, high operating cost, low denitrification rate, etc., achieve low operating cost, reduce operating cost, The effect of low engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

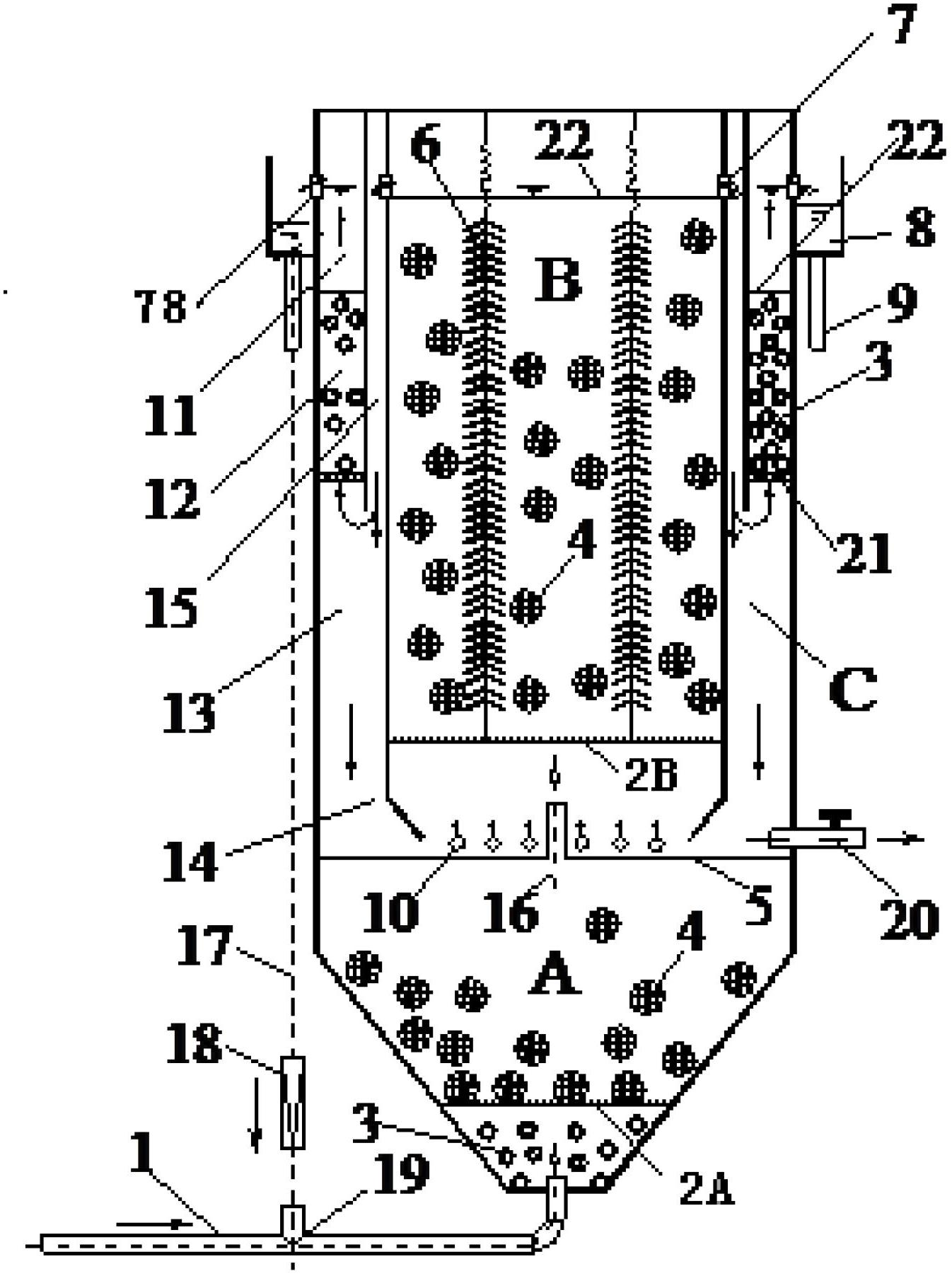

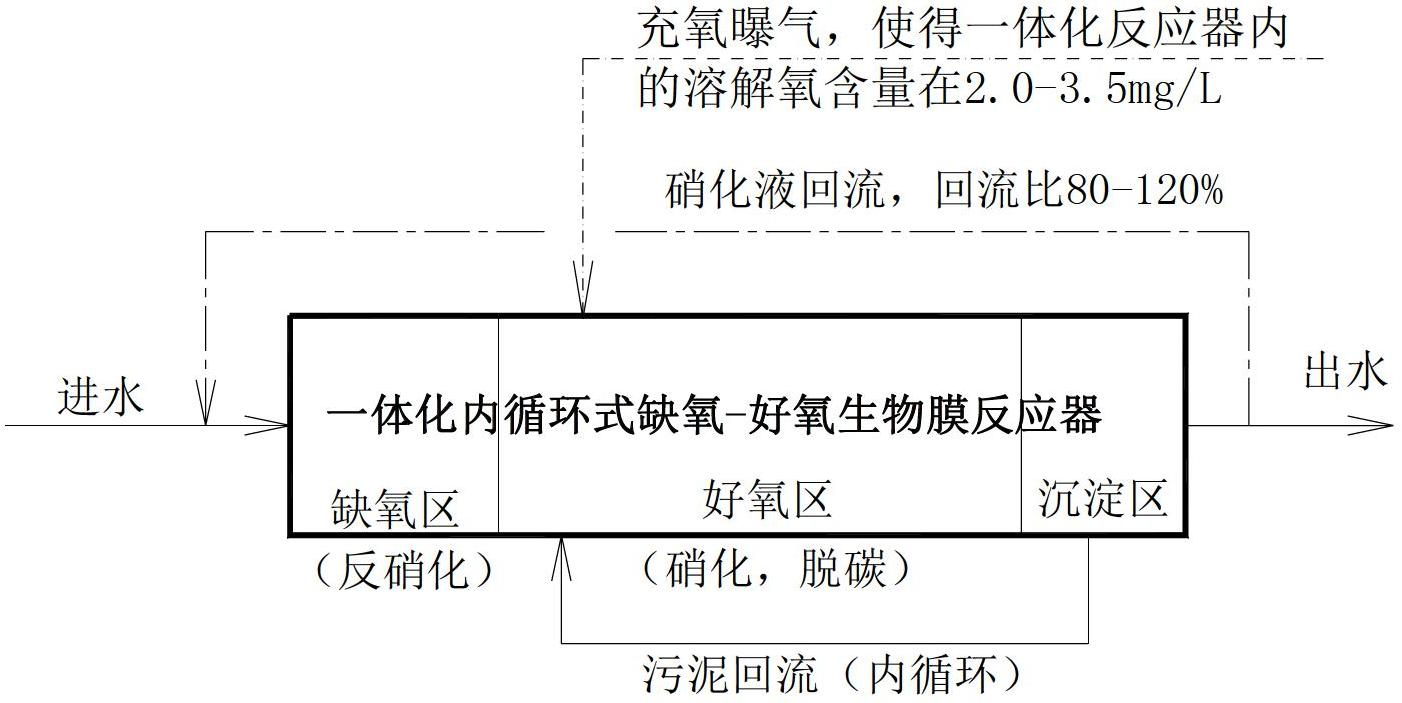

[0085] Industrial wastewater with a small amount of water to be treated, such as printing and dyeing wastewater after coagulation and sedimentation pretreatment, belongs to wastewater with poor biodegradability. The integrated reactor provided by the invention is used for processing. Methods as below:

[0086] First, the pretreated raw water is lifted into the anoxic zone A through the water inlet pipe 1 by a lift pump. In the lower part of the anoxic zone A, the incoming water will first contact the filler 3. Due to the disturbing effect of the incoming water, the filler 3 below the anoxic zone will continuously roll up and down, so that the sludge deposited at the bottom of the anoxic zone is in a suspended state without dead ends, which is conducive to the full contact of mud and water . Then the water flows through the orifice plate 2A, and after being dispersed and cut, it enters into the top of the orifice plate 2A in a multi-point water inlet manner. Here, the raw w...

Embodiment 2

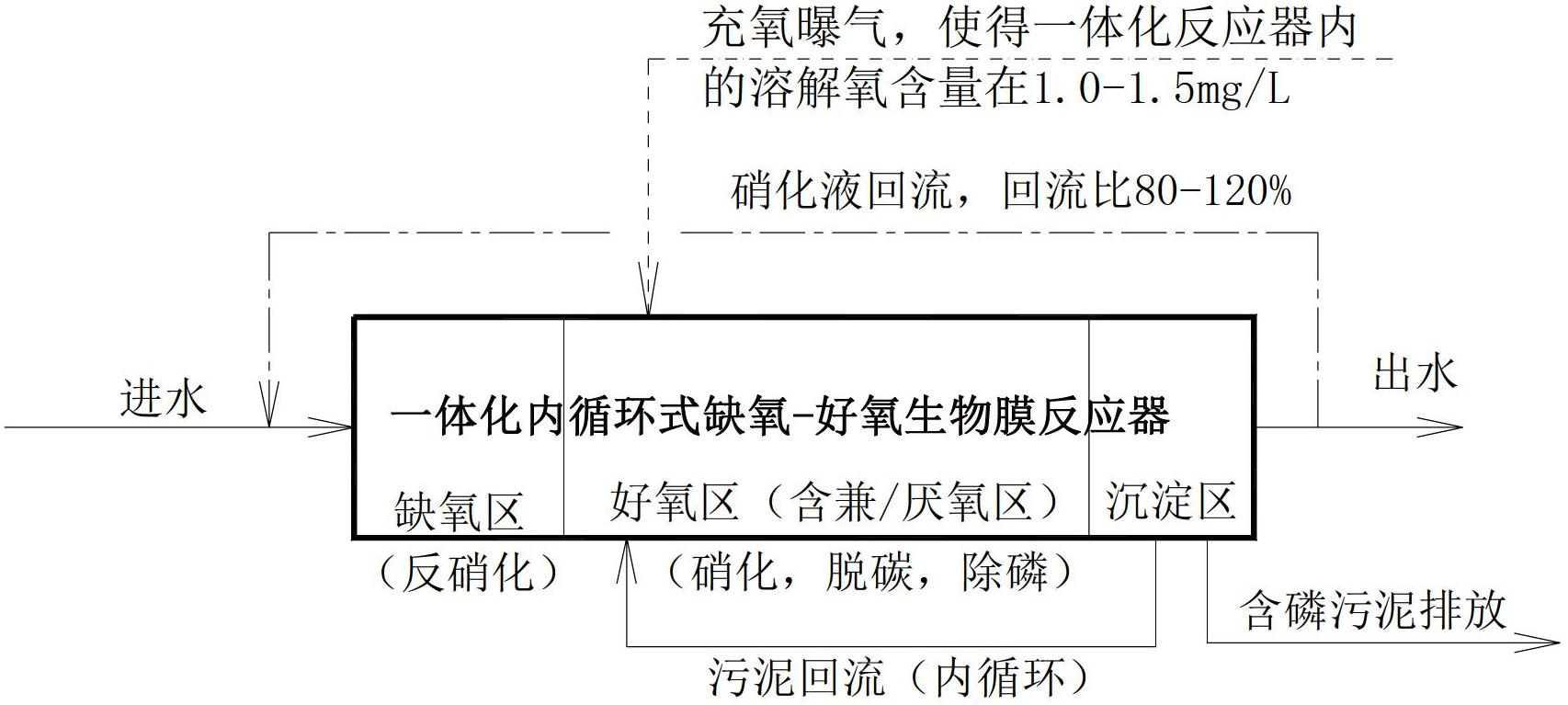

[0092] The urban domestic sewage with slightly larger water volume is treated, and the urban domestic sewage belongs to the nitrogenous sewage that needs to remove a small amount of phosphorus, and the integrated reactor provided by the invention is used for treatment. Methods as below:

[0093] First, determine the amount and efficiency of phosphorus and nitrogen removal required. Then use the lift pump to directly lift the pre-settled sewage into the anoxic zone A through the water inlet pipe 1 . Below the anoxic zone A, the domestic sewage first contacts the filler 3, and then enters the top of the orifice plate 2A. Here, the denitrifying bacteria degrade part of the organic matter as a carbon source during the denitrification process. The biodegradability of the sewage itself is very good, and the concentration of organic matter entering the anoxic zone is relatively high. Therefore, there is no need to add additional carbon sources in the anoxic zone. Moreover, the pH v...

Embodiment 3

[0098] Treatment of industrial wastewater, such as printing and dyeing wastewater pretreated by coagulation and sedimentation, should be treated with the integrated reactor provided by this patent. The steps are as in Example 1, and the final test enters the water quality of the printing and dyeing wastewater after the pretreatment of the integrated reactor, the organic matter COD cr The ammonia nitrogen is 225-322mg / L, the ammonia nitrogen is 24-28mg / L, the total nitrogen is 41-46mg / L, the color is 80-102 times, and the suspended matter SS is 84-115mg / L. In treated sewage, COD cr The ammonia nitrogen is 50-72mg / L, the ammonia nitrogen is 1.4-3.2mg / L, the total nitrogen is 7.0-13.1mg / L, the color is 22-33 times, and the suspended matter SS is 21-46mg / L. The denitrification efficiency reached 93.4%, COD cr The removal rate reached 72.7%, and the removal rates of chroma and suspended solids were 64.4% and 72.0%, respectively. It can be seen that the integrated anoxic-aerobic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com