Patents

Literature

160results about How to "Completely processed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

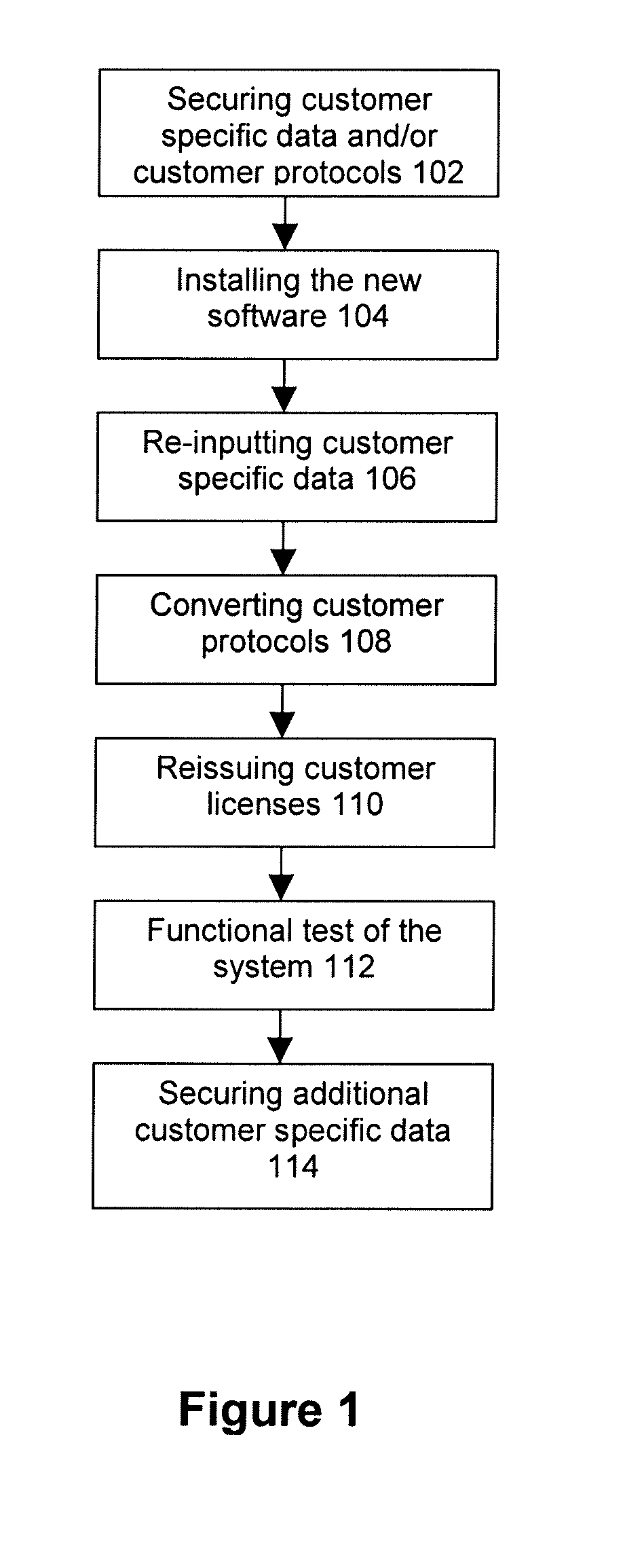

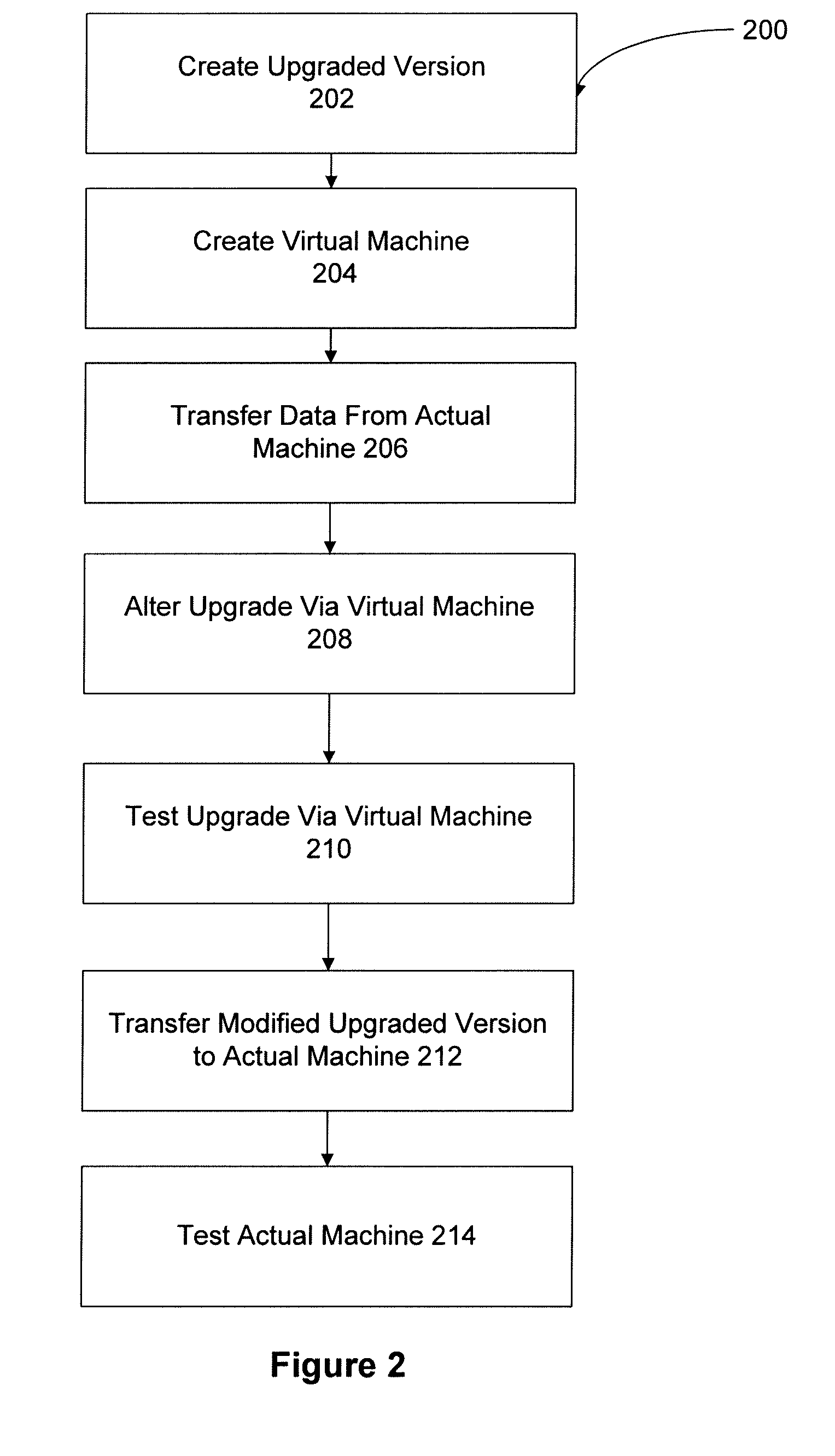

Offline Upgrades

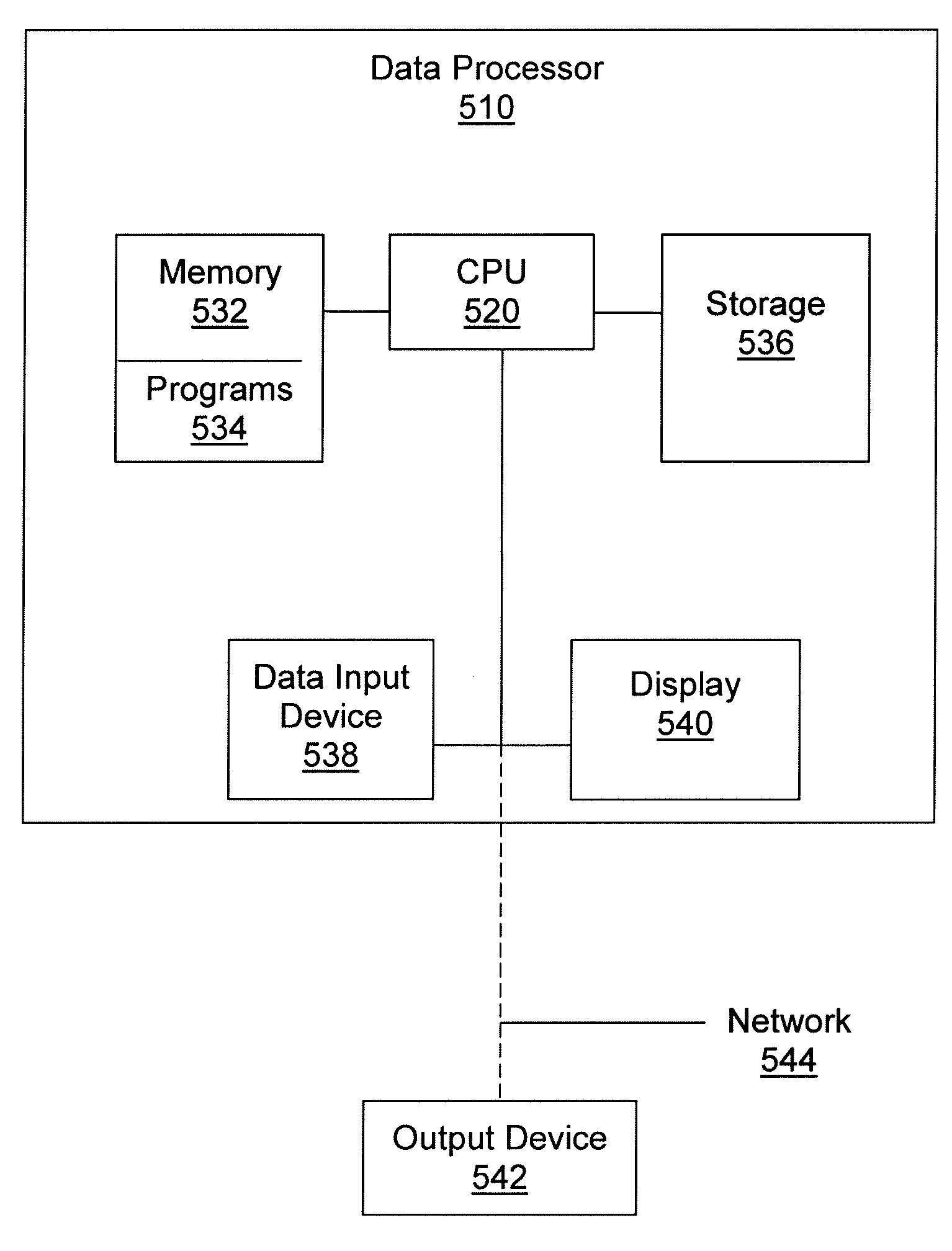

InactiveUS20090113413A1Minimize downtimeCompletely processedLocal control/monitoringSoftware engineeringDowntimeSoftware engineering

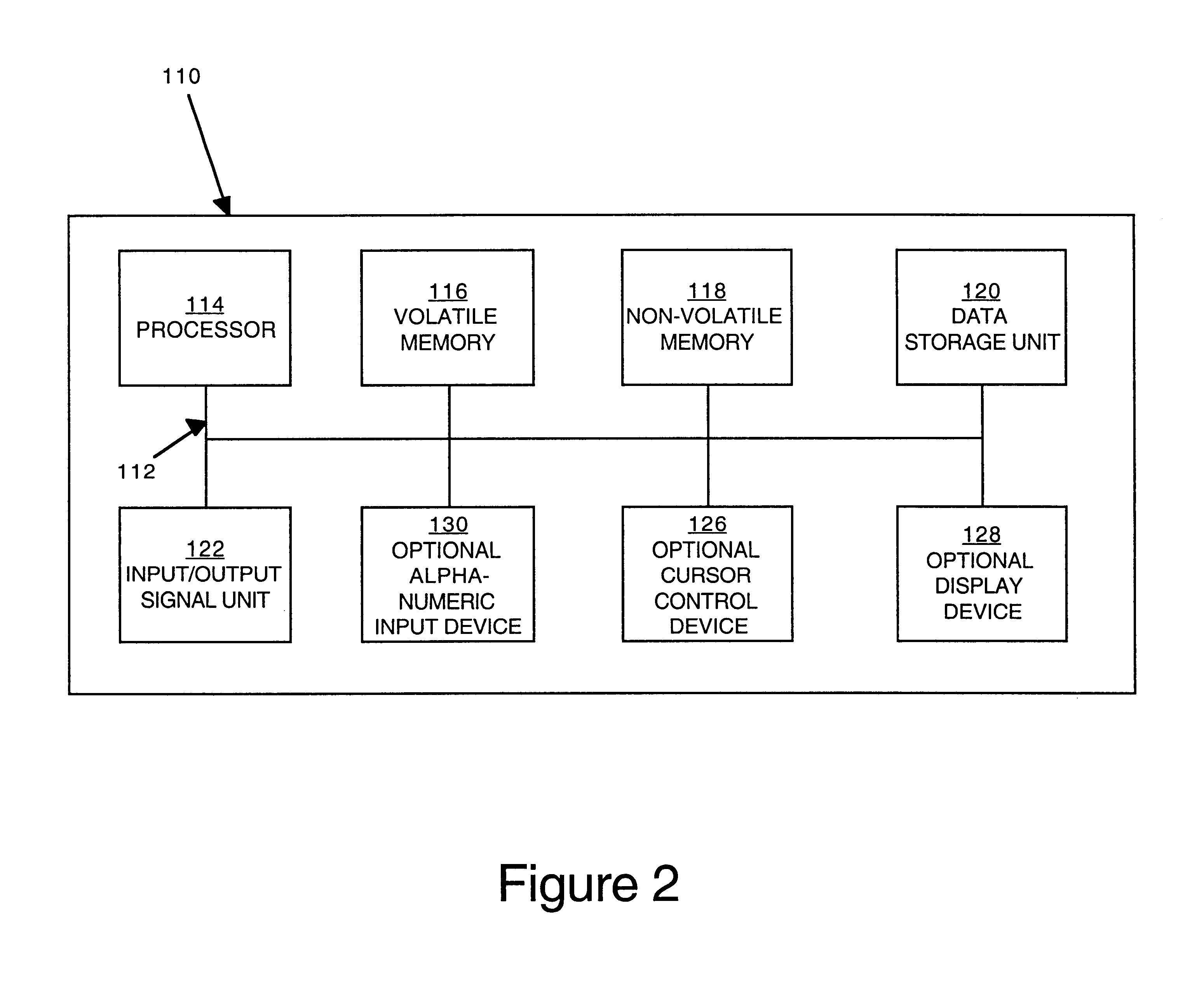

A system and method upgrade software applications offline using a virtual machine. Software applications used by actual customer machines may rely upon customer specific data and protocols. An upgraded version of a software application may become available. The upgrade may be loaded onto a virtual machine. Customer specific data or protocols associated with a previous version of the application may be copied to the virtual machine. The upgraded version may be modified on the virtual machine using the data associated with the previous version. The upgrade process using the virtual machine may detect and eliminate problems with the upgrade associated with the customer machine and / or settings. Once modified, the upgraded version may be transferred from the virtual machine to the customer machine. The upgrade process may be performed primarily on the virtual machine. Therefore, the downtime of the customer machine required to complete the upgrade process may be substantially reduced.

Owner:SIEMENS HEALTHCARE GMBH

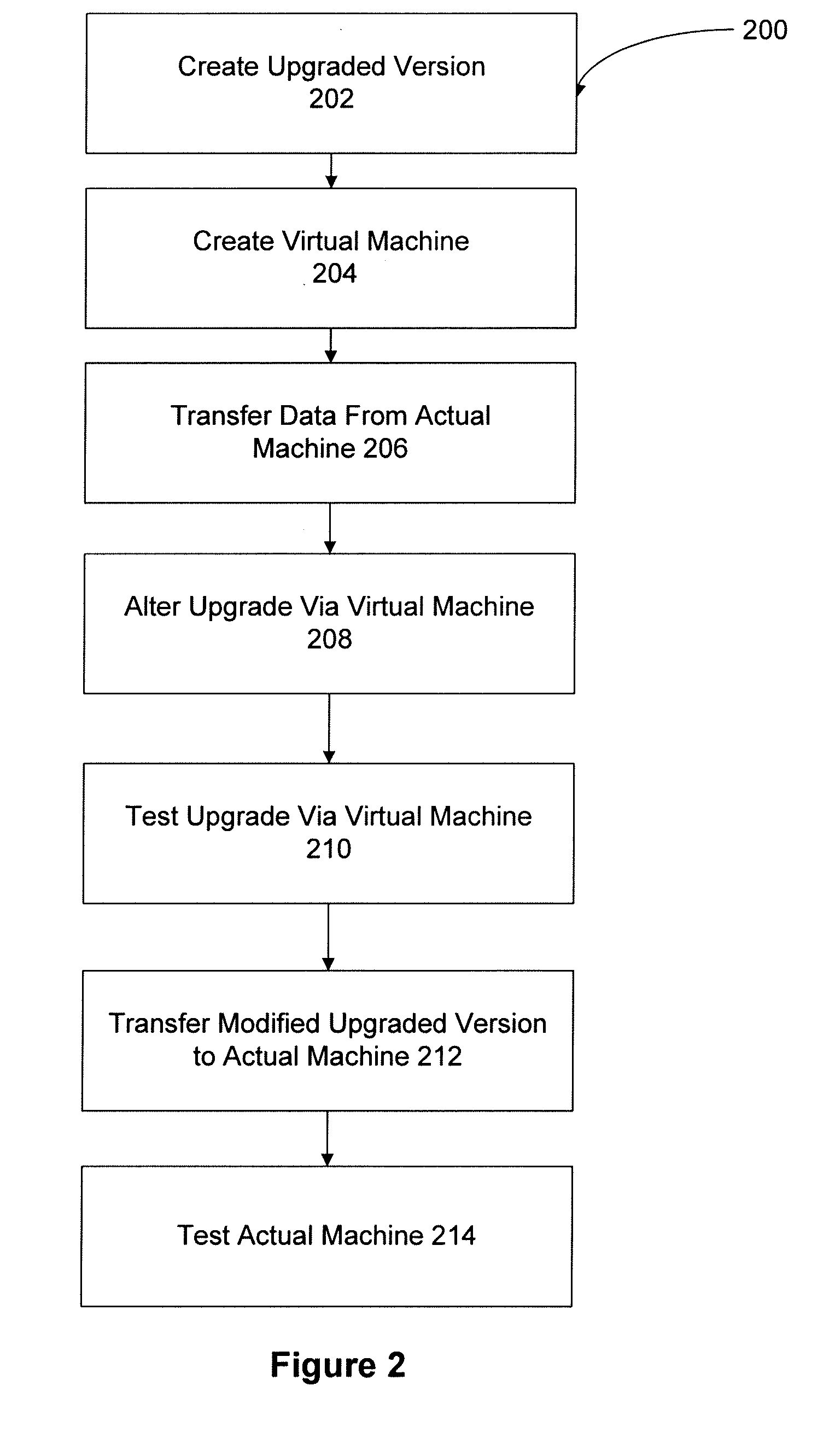

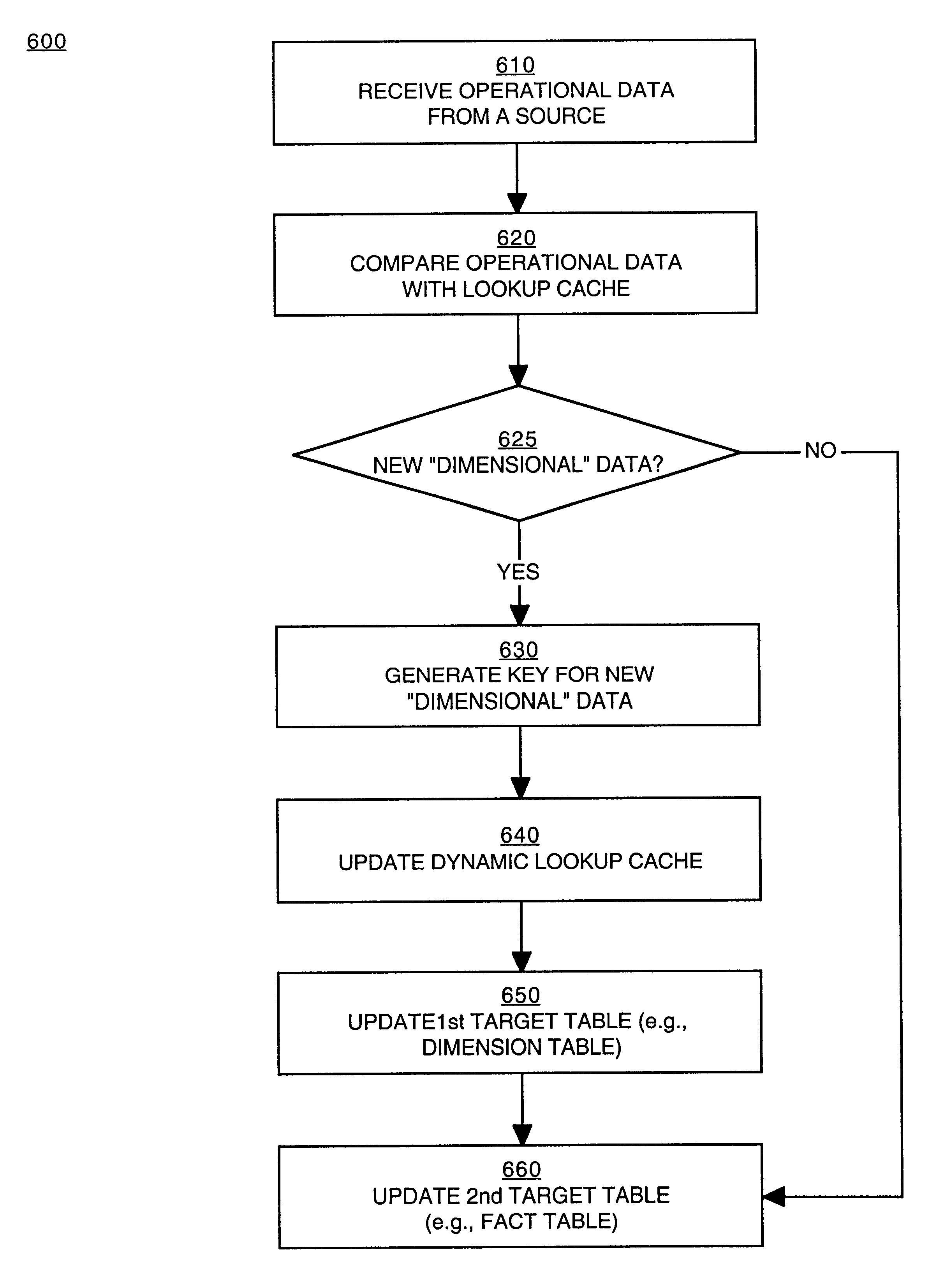

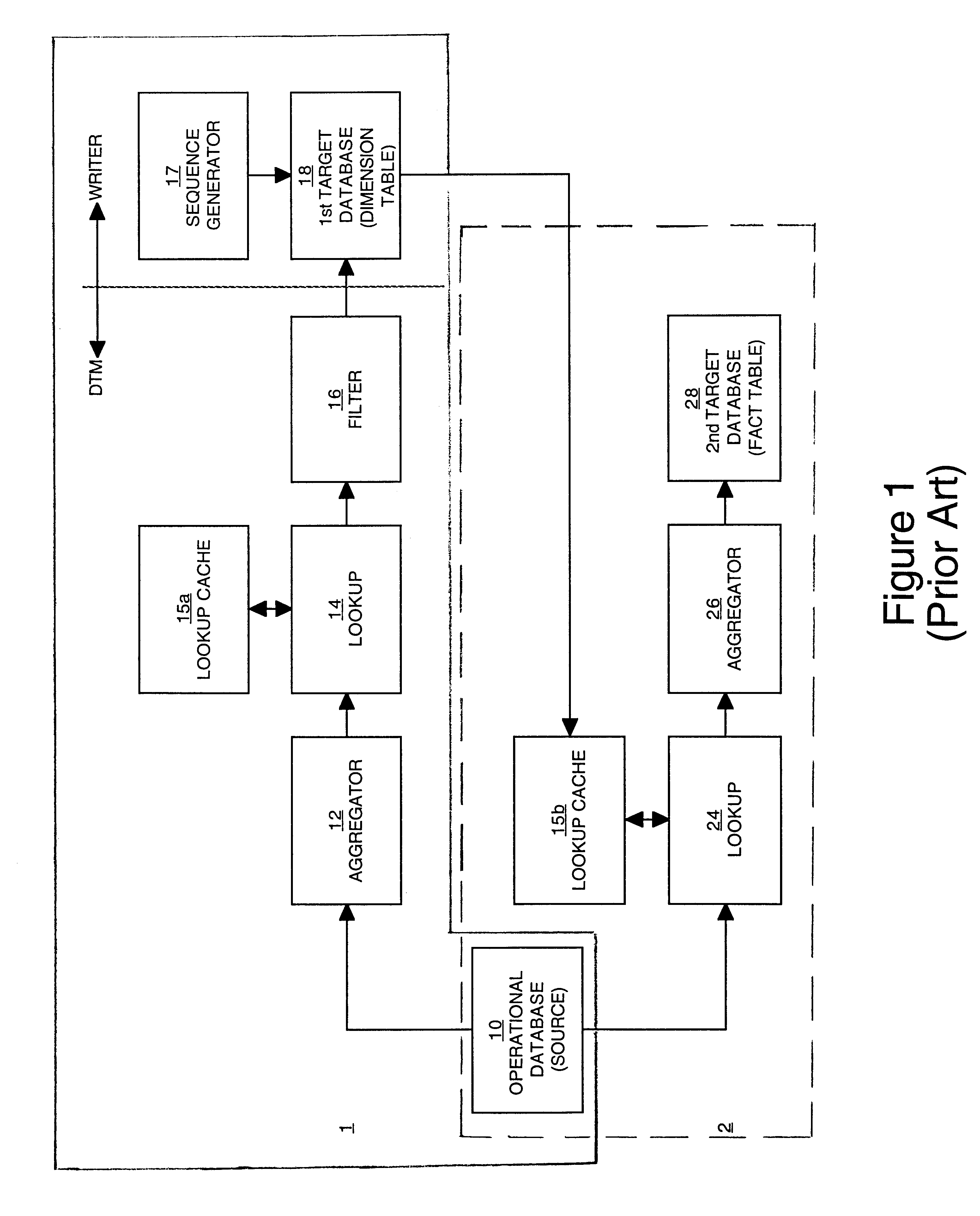

Method and apparatus for synchronizing cache with target tables in a data warehousing system

InactiveUS6895471B1Increase speedReduce loadDatabase updatingData processing applicationsData warehouseData set

A method and apparatus for processing (transporting) data, such as in a data warehouse system. In one embodiment, the data are received from a source and compared to data in a lookup cache comprising a subset of data from a first data set (e.g., a dimension table). Instances of the data not present in a lookup cache (that is, new data) are identified. Information corresponding to these instances are generated (e.g., a unique identifier is associated with each of these instances), and the first data set is updated accordingly. The lookup cache is then updated with the new data and the unique identifiers. Accordingly, the information (data) in the lookup cache and in the first data set are in synchronization. The lookup cache does not need to be rebuilt (e.g., to update a second data set such as a fact table).

Owner:INFORMATICA CORP

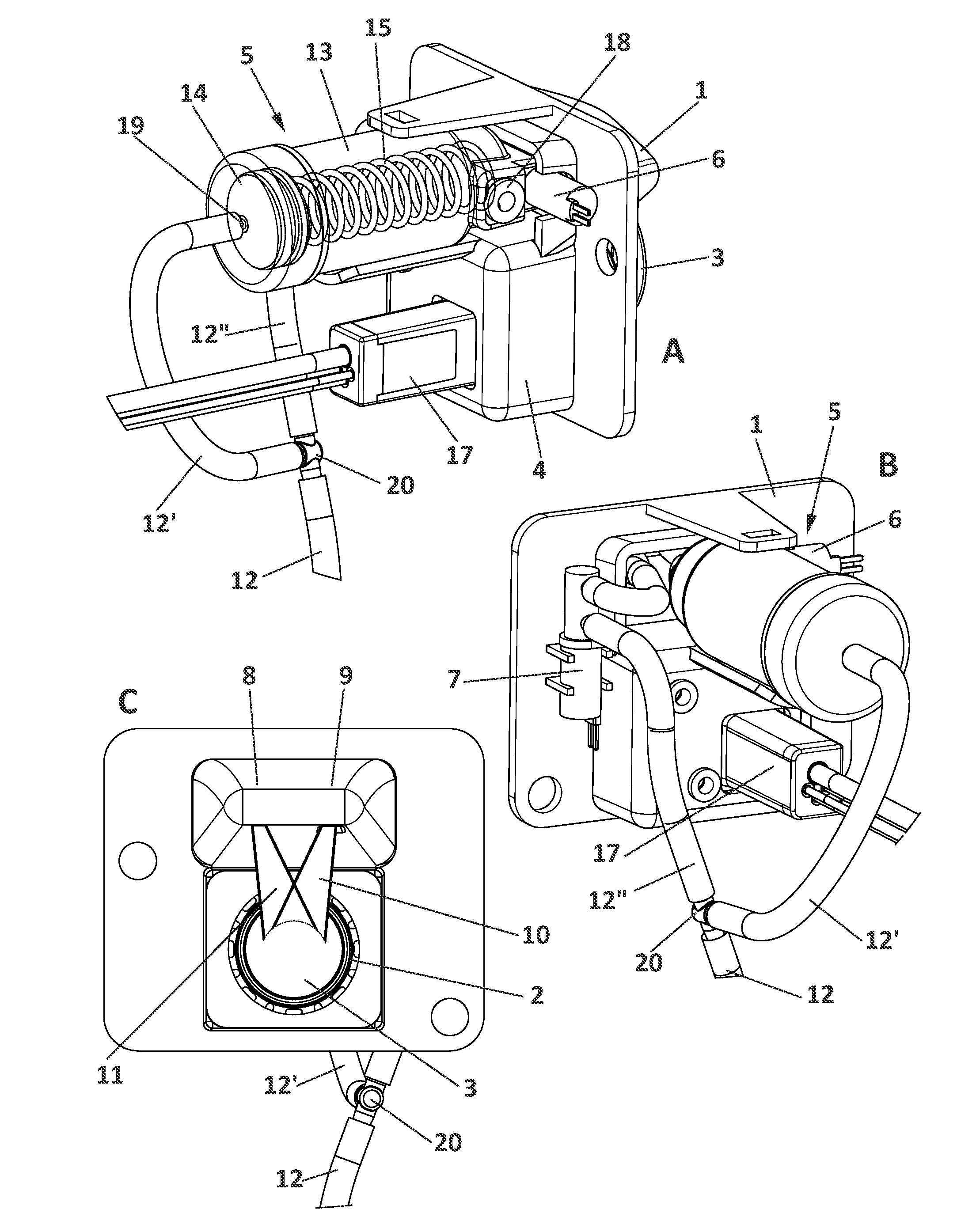

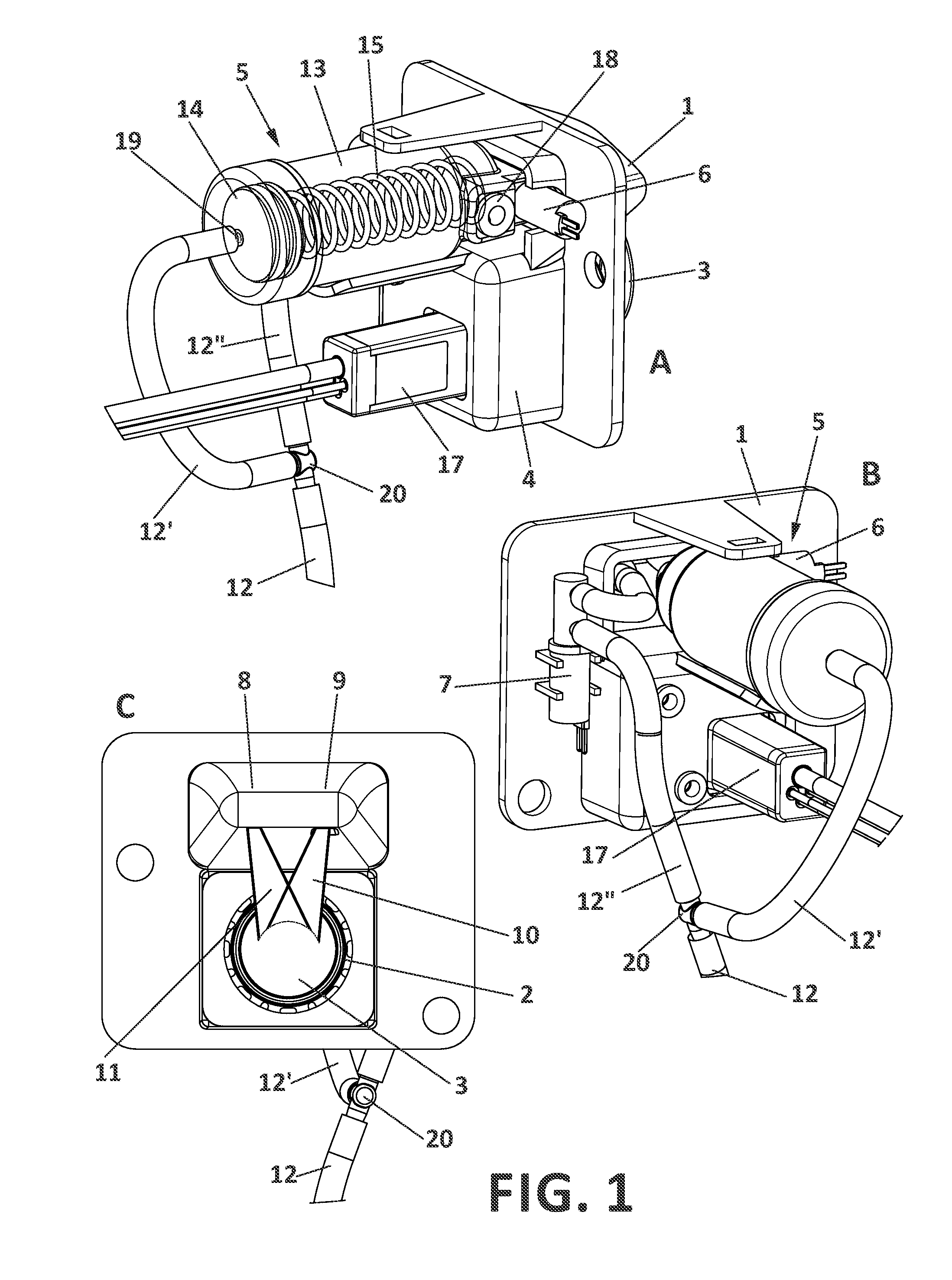

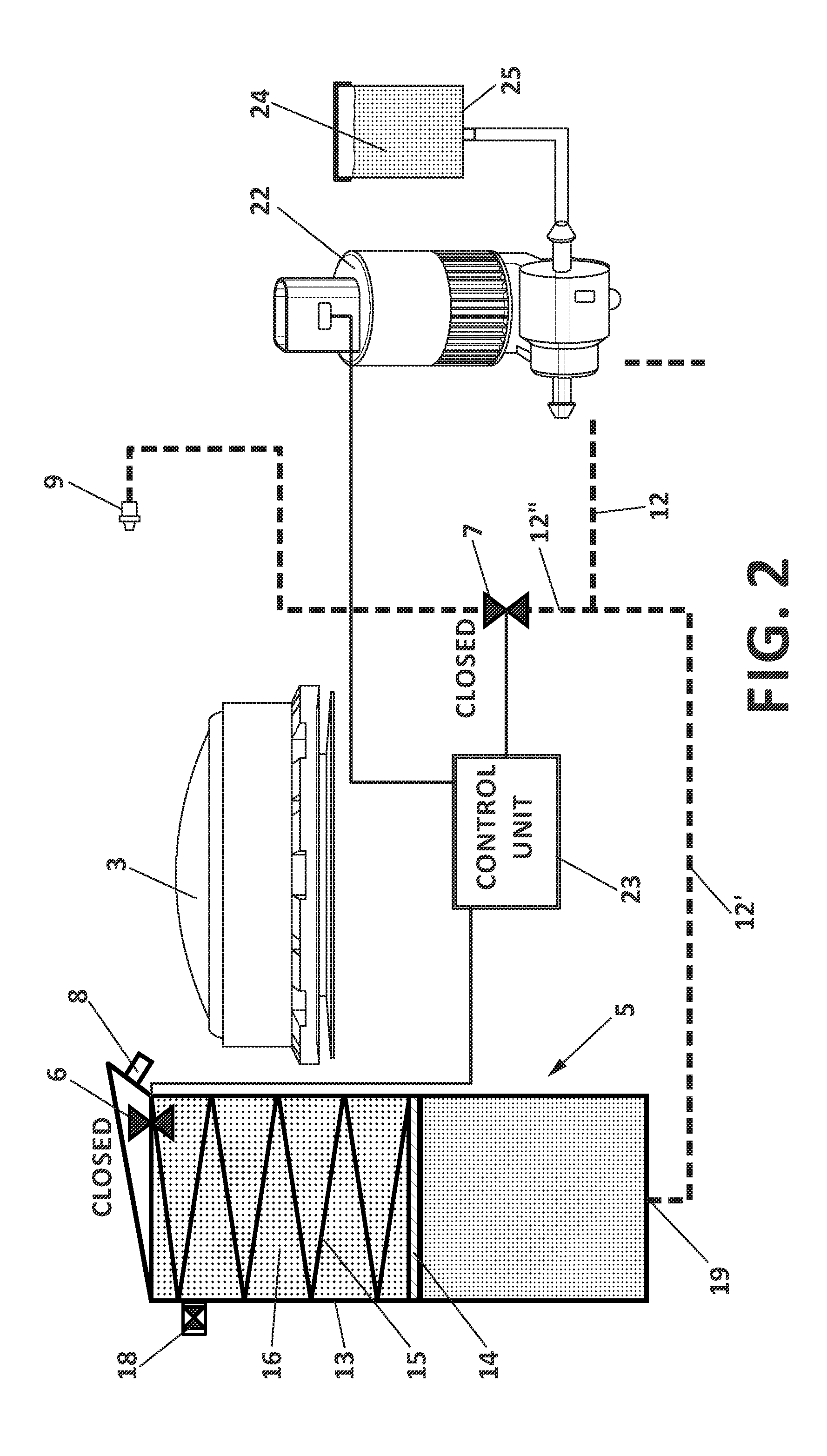

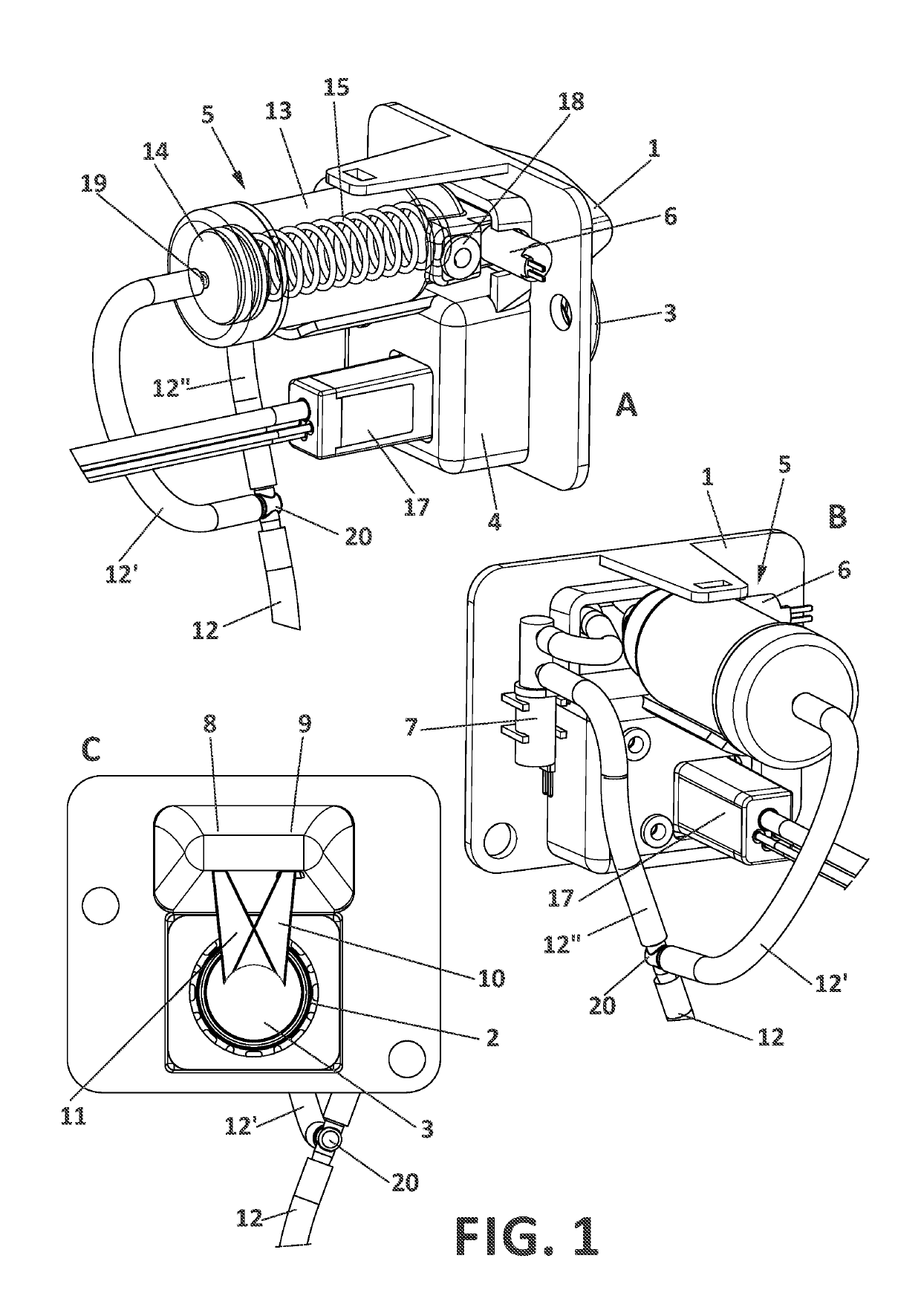

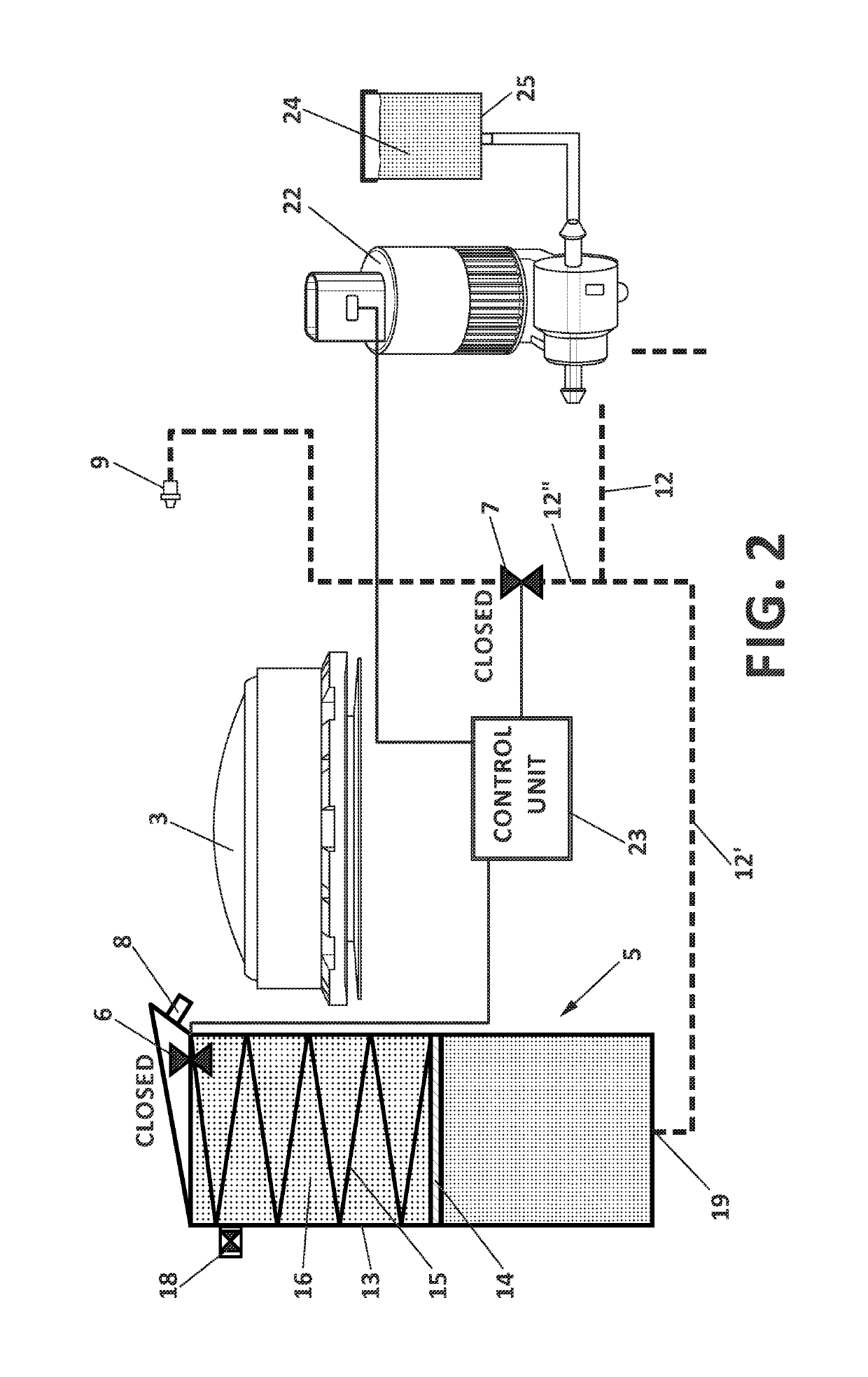

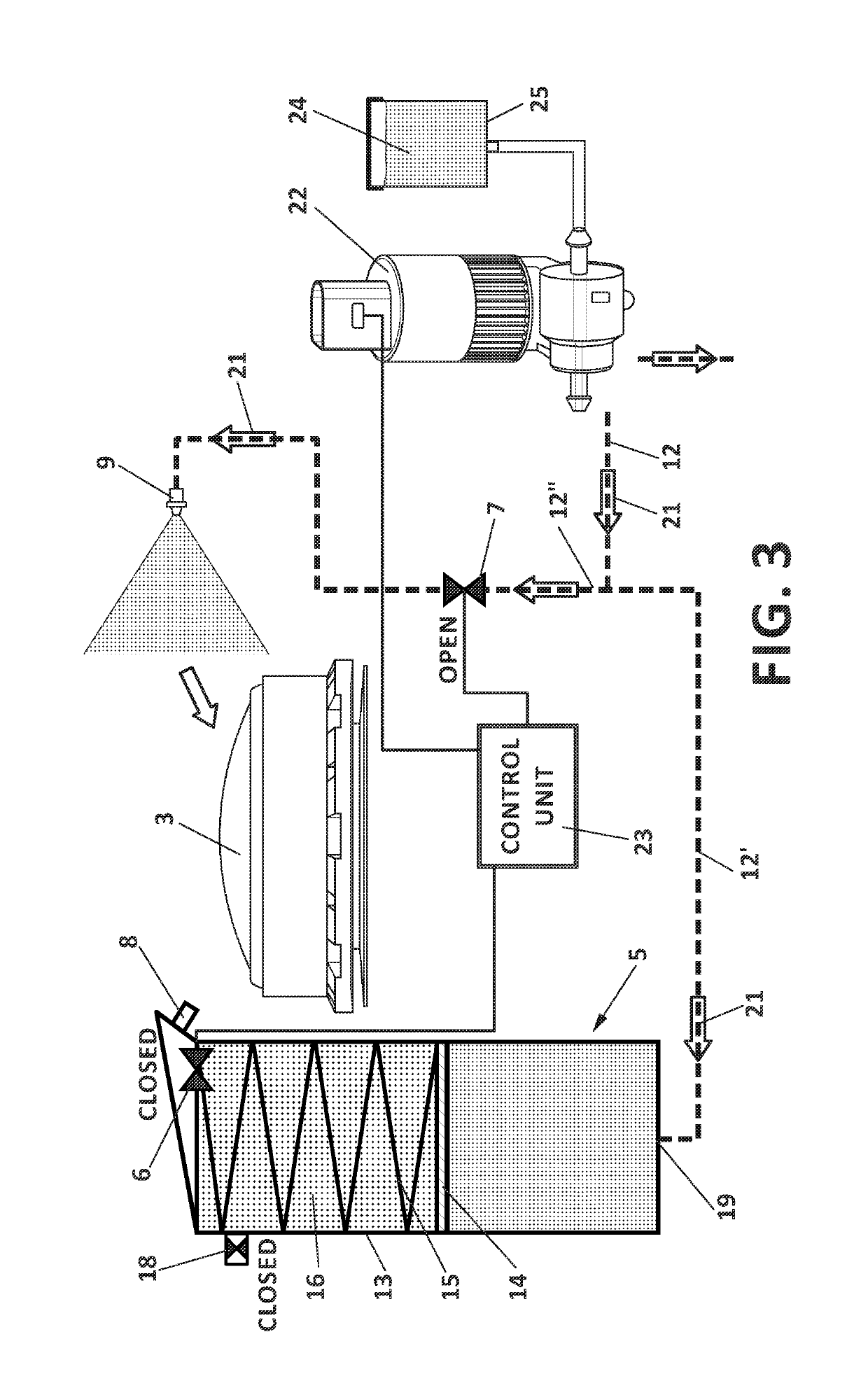

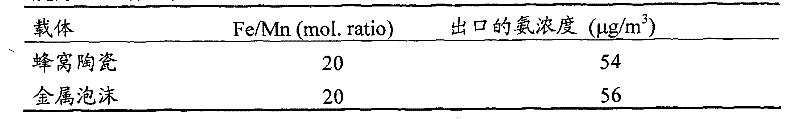

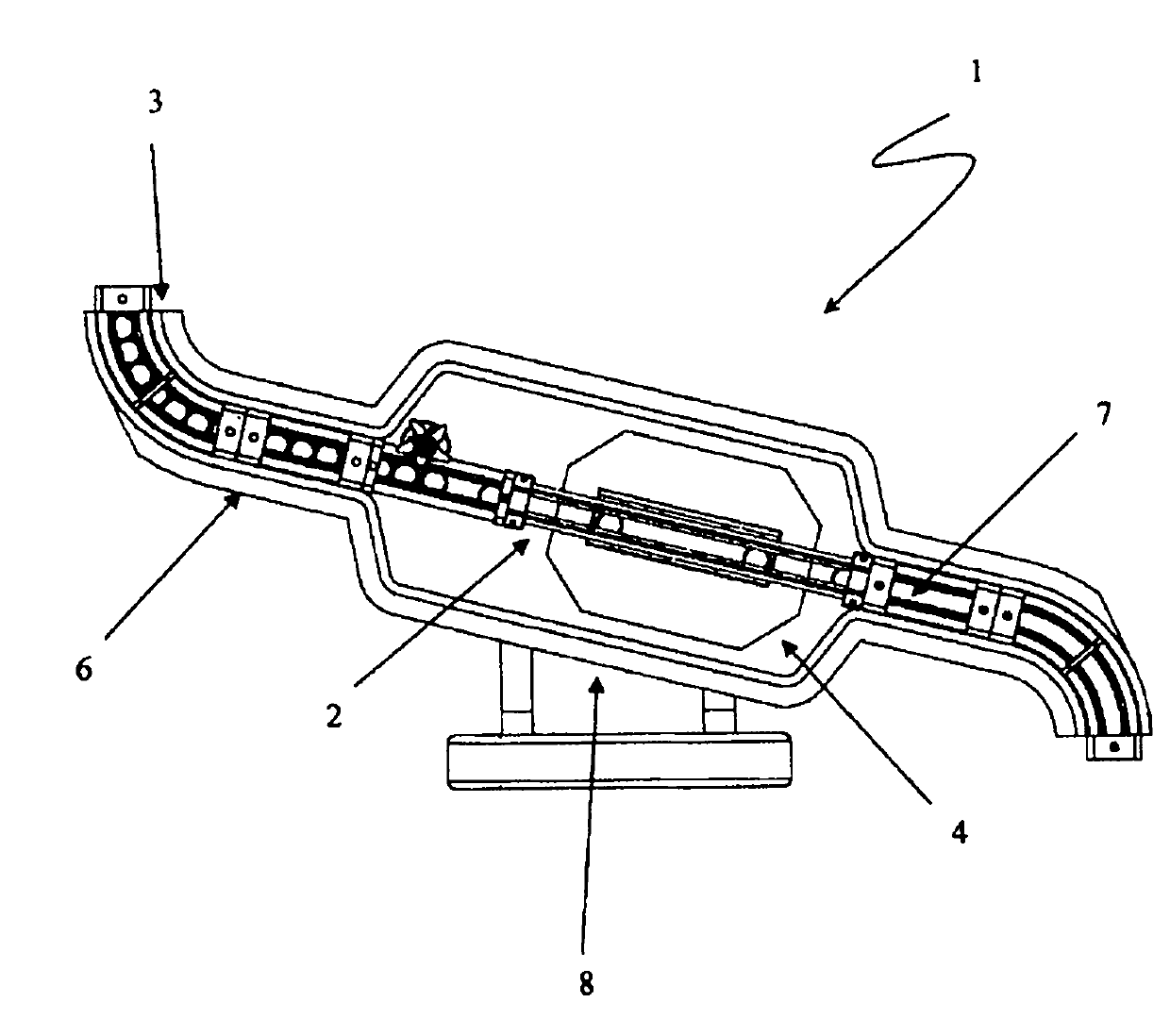

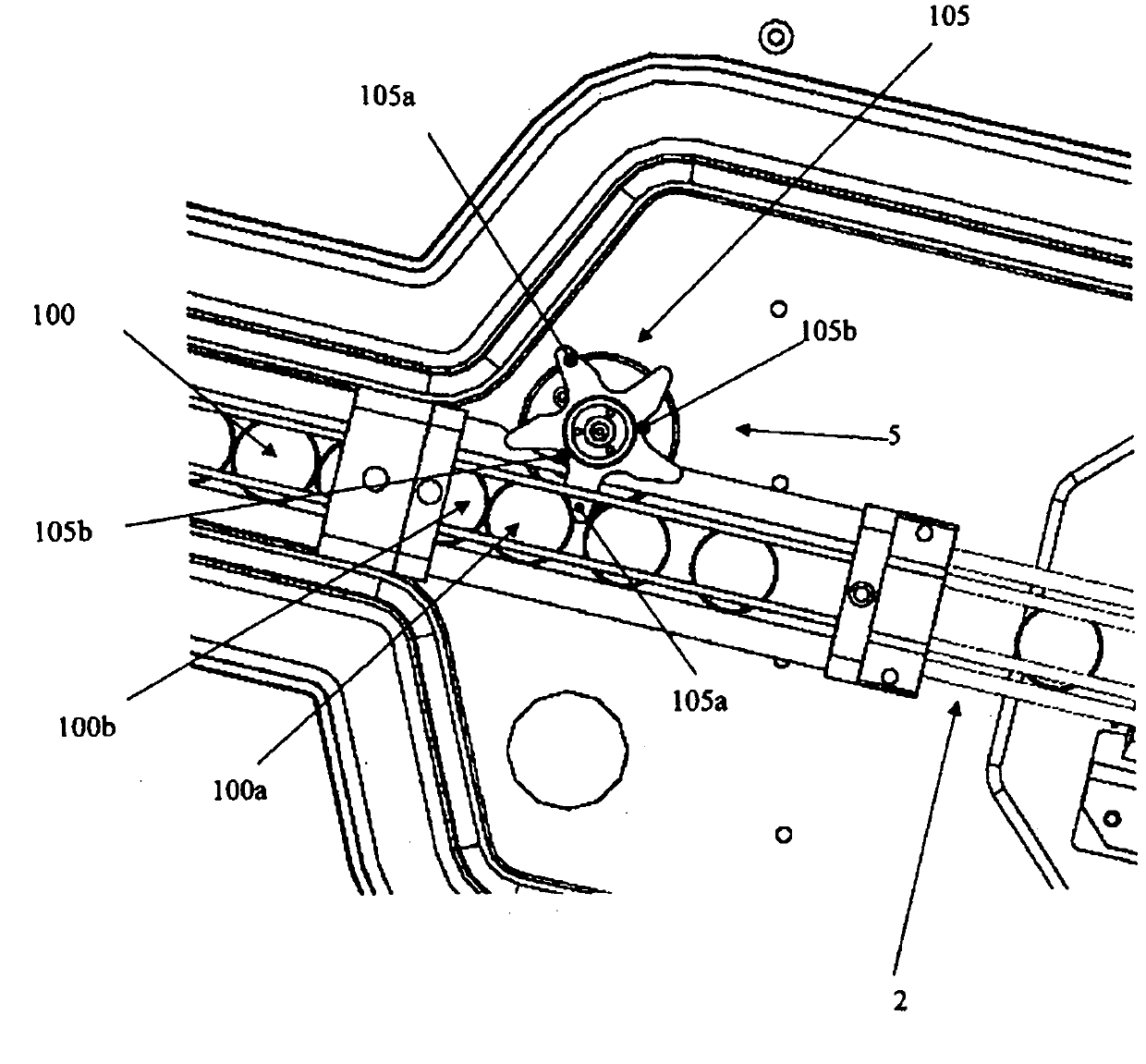

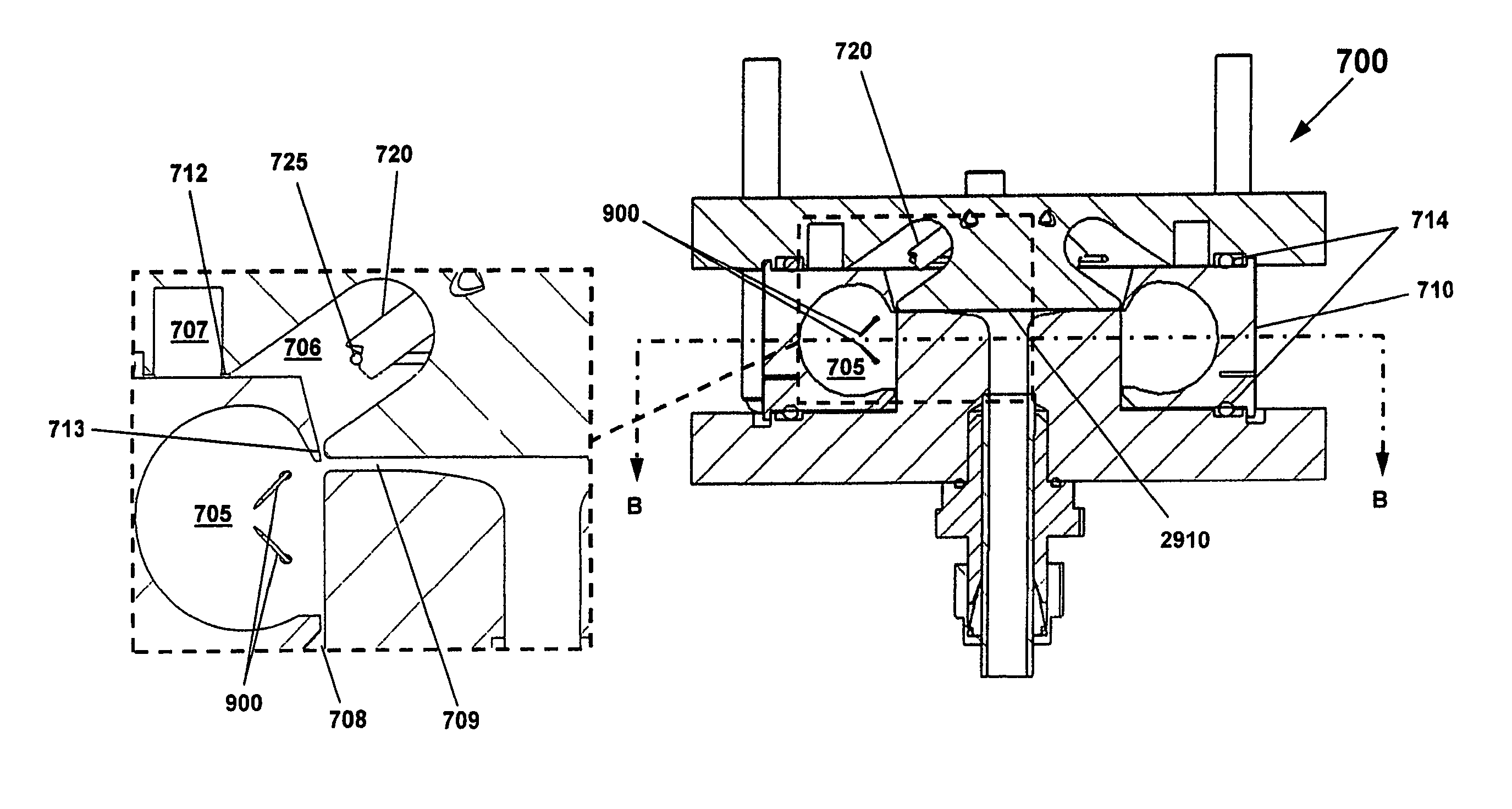

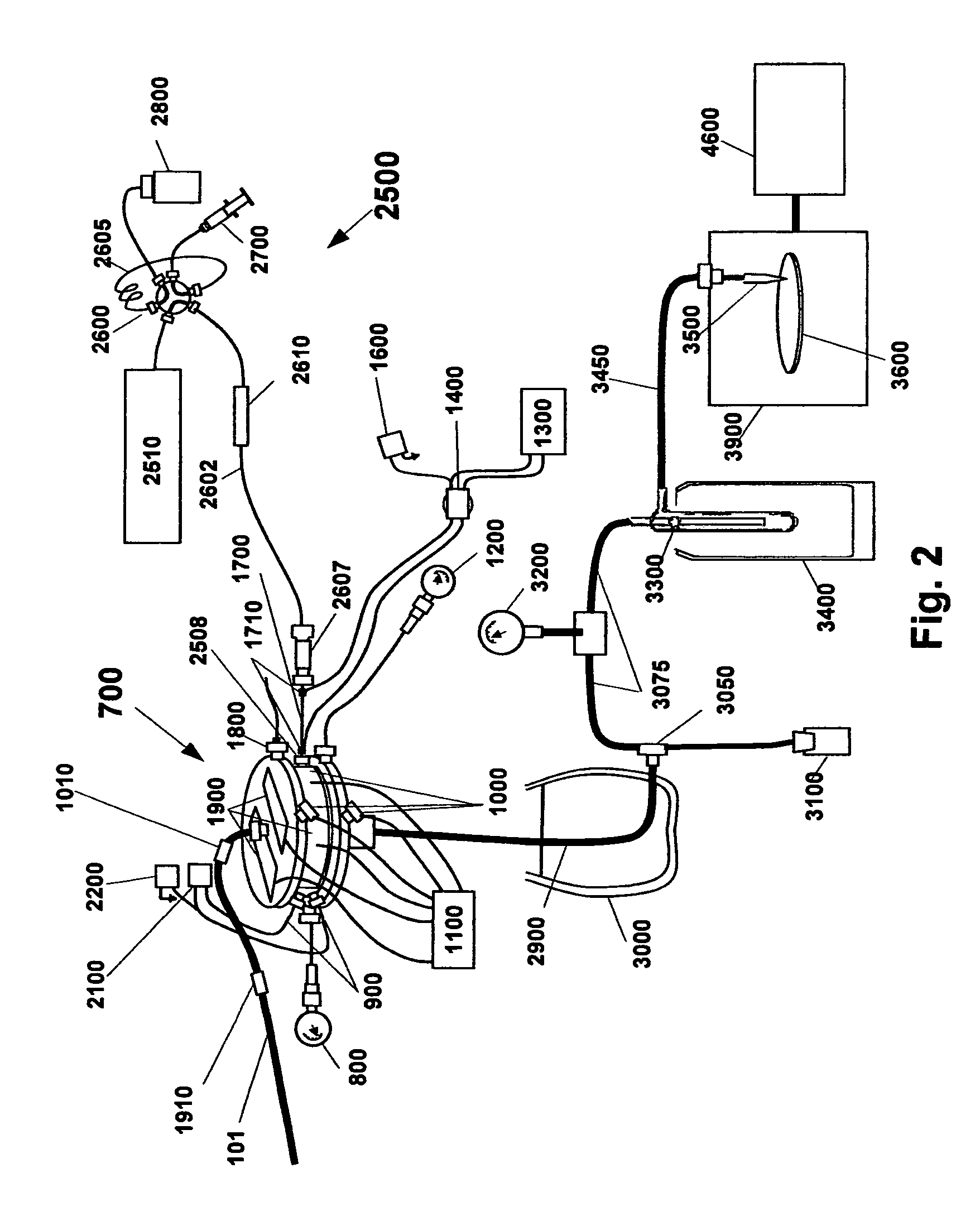

System and method for cleaning a vehicle-mounted optic lens

ActiveUS20150343999A1Reduce in quantityCompletely processedVehicle cleaningCleaning using liquidsCamera lensOptic lens

The present invention refers a system and a method for automatically cleaning an optic lens mounted on a vehicle, by spraying a washing liquid to remove any type of dirt from the lens such as a clear image or optic signal can be captured anytime, where an air pump is provided including a variable volume compression chamber to pressurize a volume of air, and a washing liquid conduit is communicated with a liquid nozzle and with the air pump, such as the air pump can be operated by the flow of pressurized washing liquid, such as the same flow of pressurized washing liquid is used to clean the optic surface, and to operate the air pump and generate a blast of air to blow off any liquid drop from the optic lens.

Owner:FICO TRANSPAR

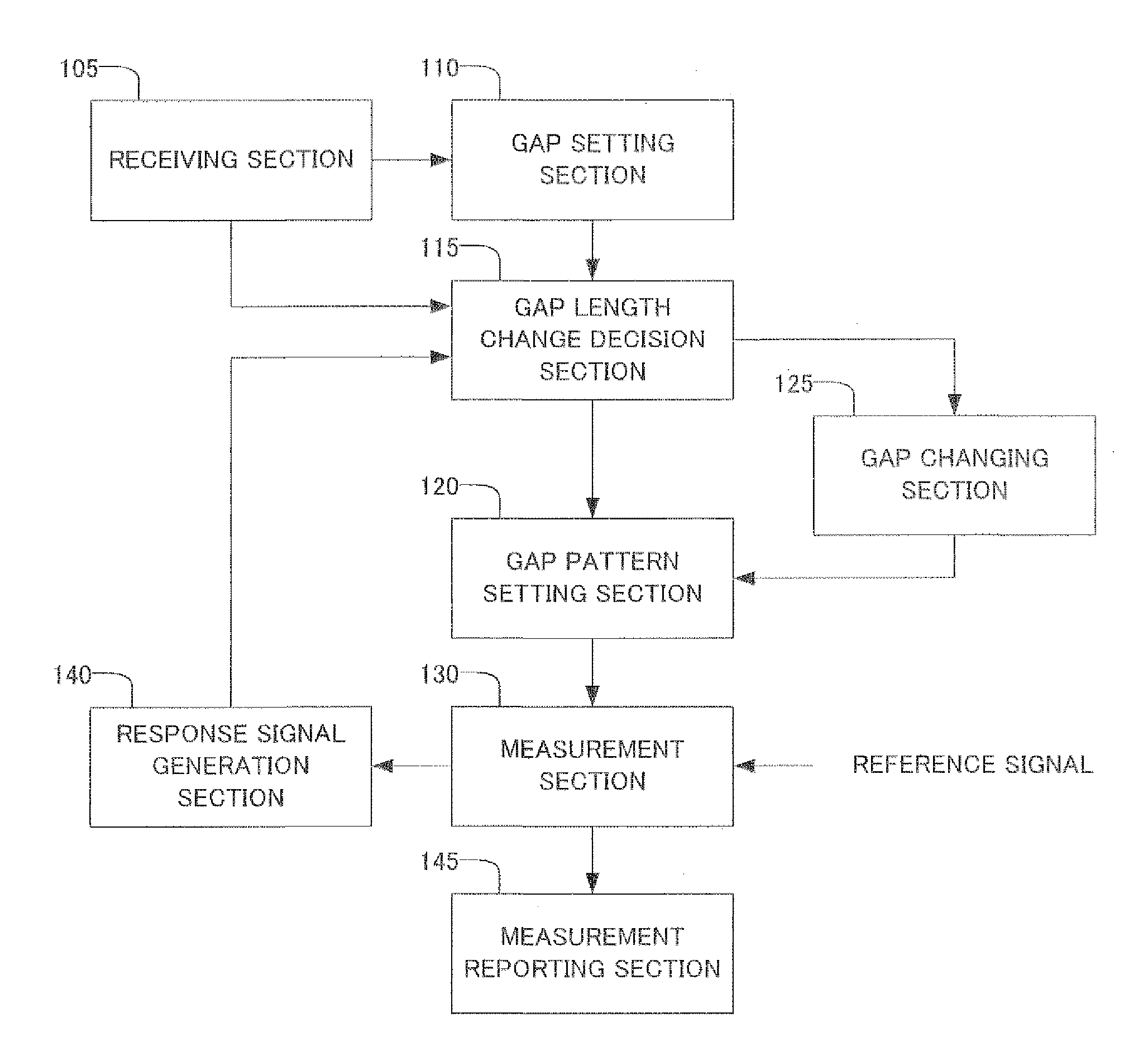

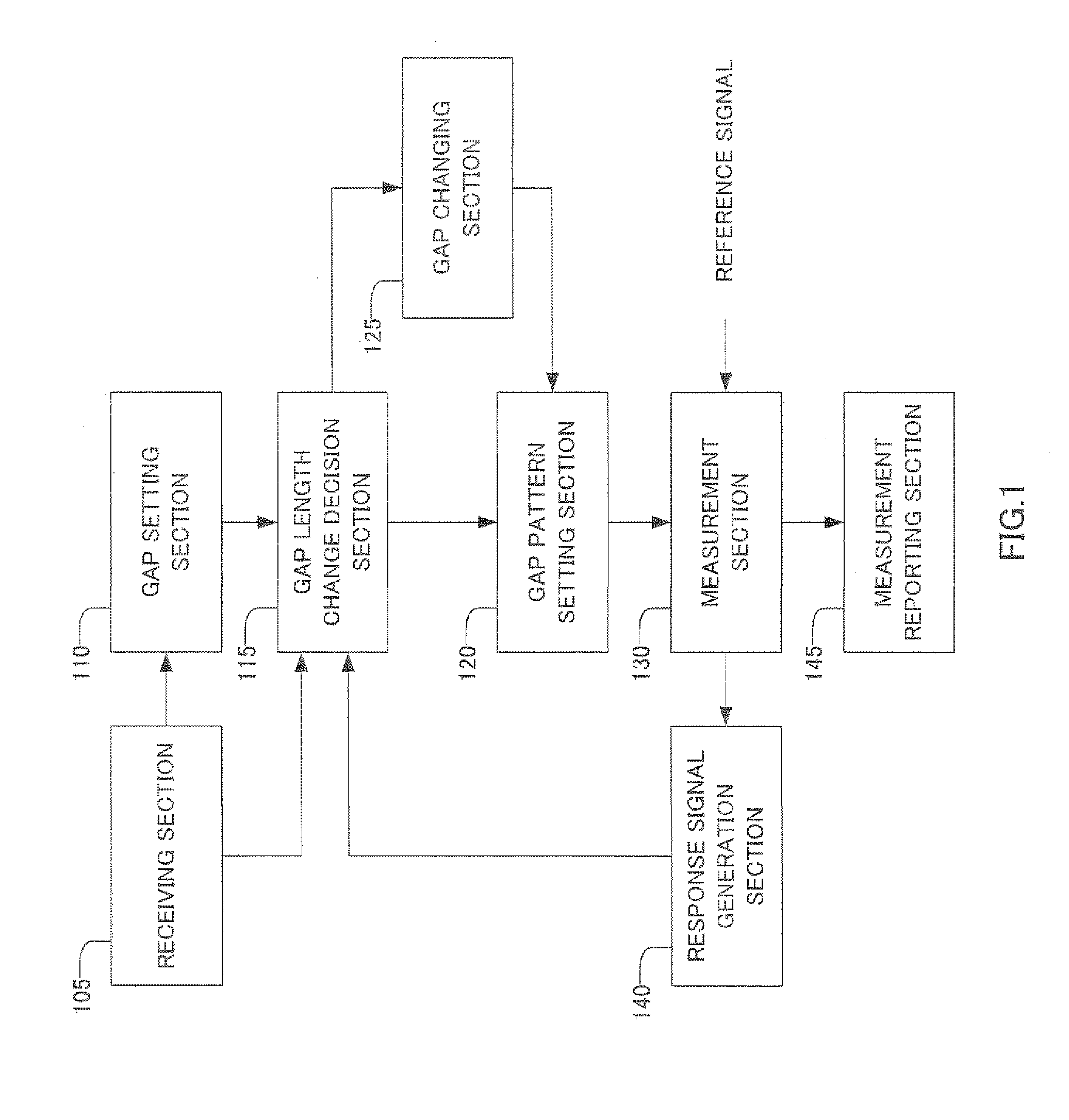

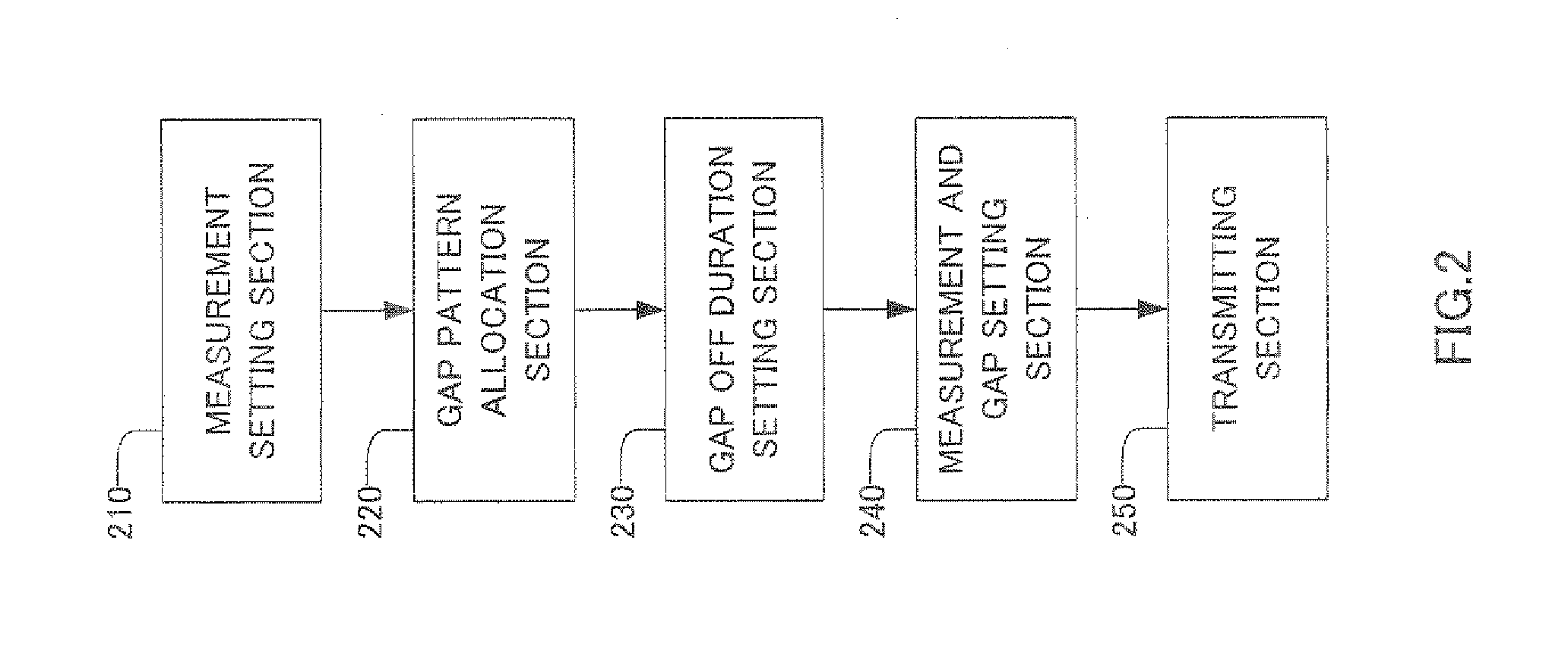

Radio communication terminal device and gap allotting method

InactiveUS20100309803A1Reduce in quantityComplete measurement processingTransmission systemsFrequency-division multiplex detailsPhysical layerTerminal equipment

The invention provides a wireless communication terminal device and a gap allotting method capable of completing a measuring process at high speed and reducing the number of retransmissions. Upon determining that the average number of retransmissions exceeds the parameter for the average number of retransmissions in gap length change judging unit (115), a gap changing unit (125) changes the currently set gap length using a gap off duration “G_Off_Duration”. A gap pattern setting unit (120) sets a gap pattern based on a gap parameter or the changed gap length, and a measuring unit (130) creates a gap by using the set gap pattern and measures the reference signal in a physical layer input during the gap.

Owner:PANASONIC CORP

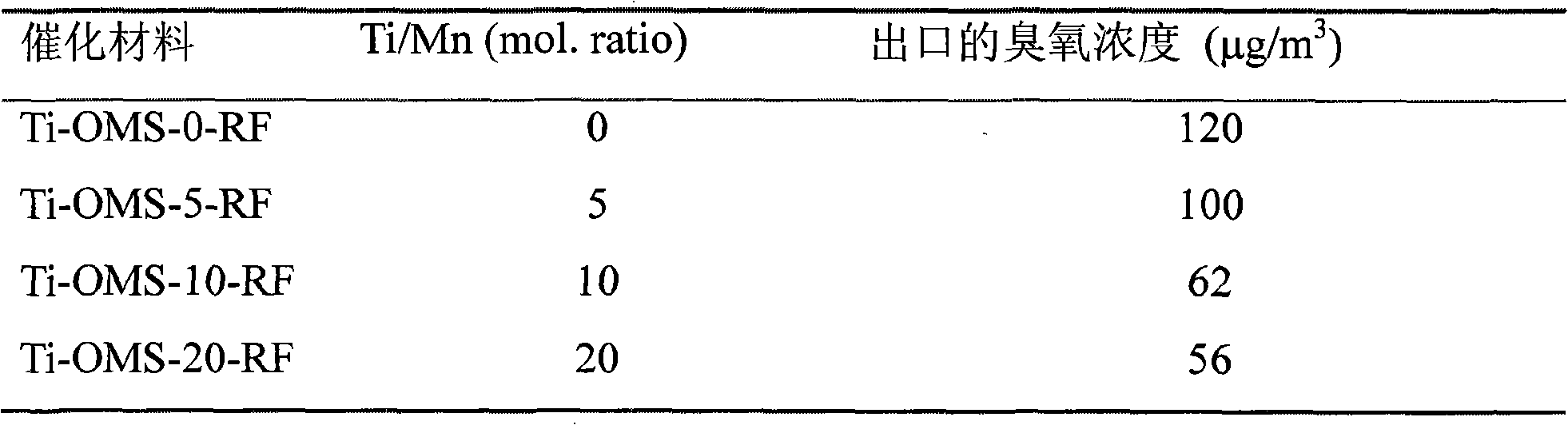

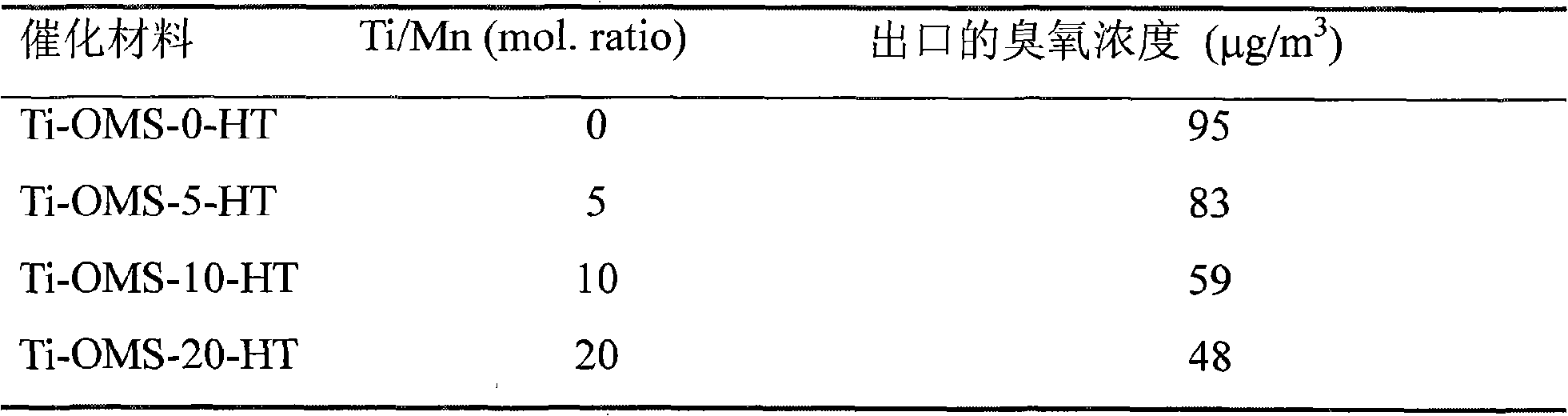

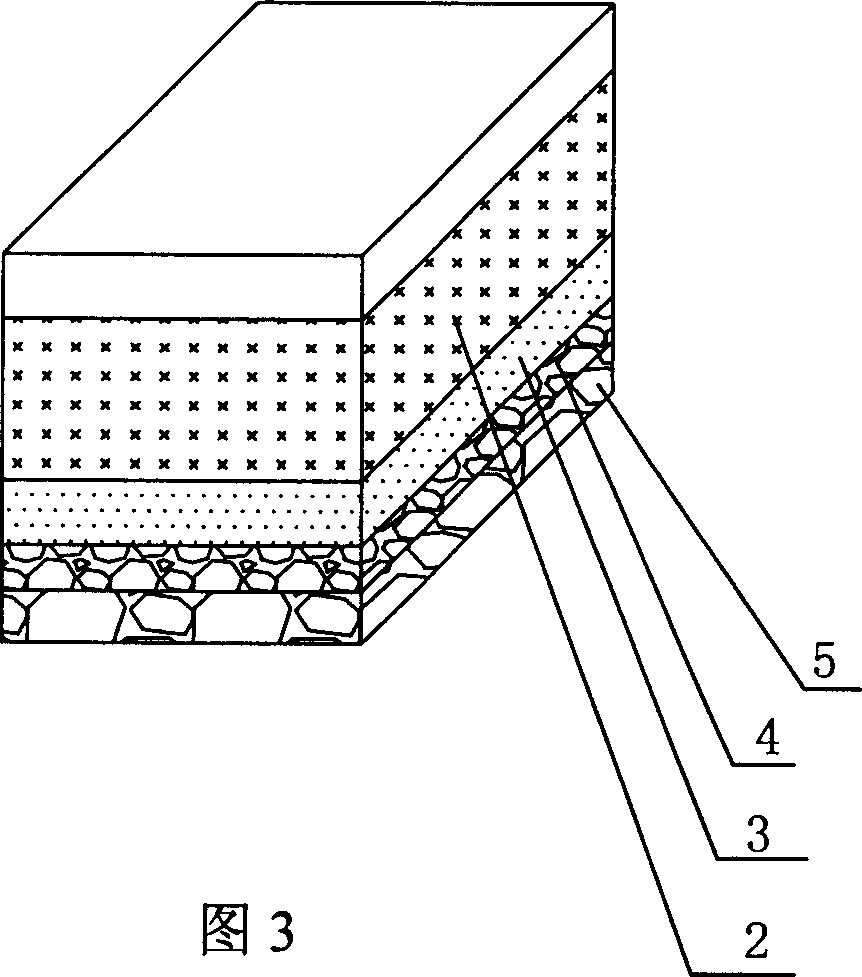

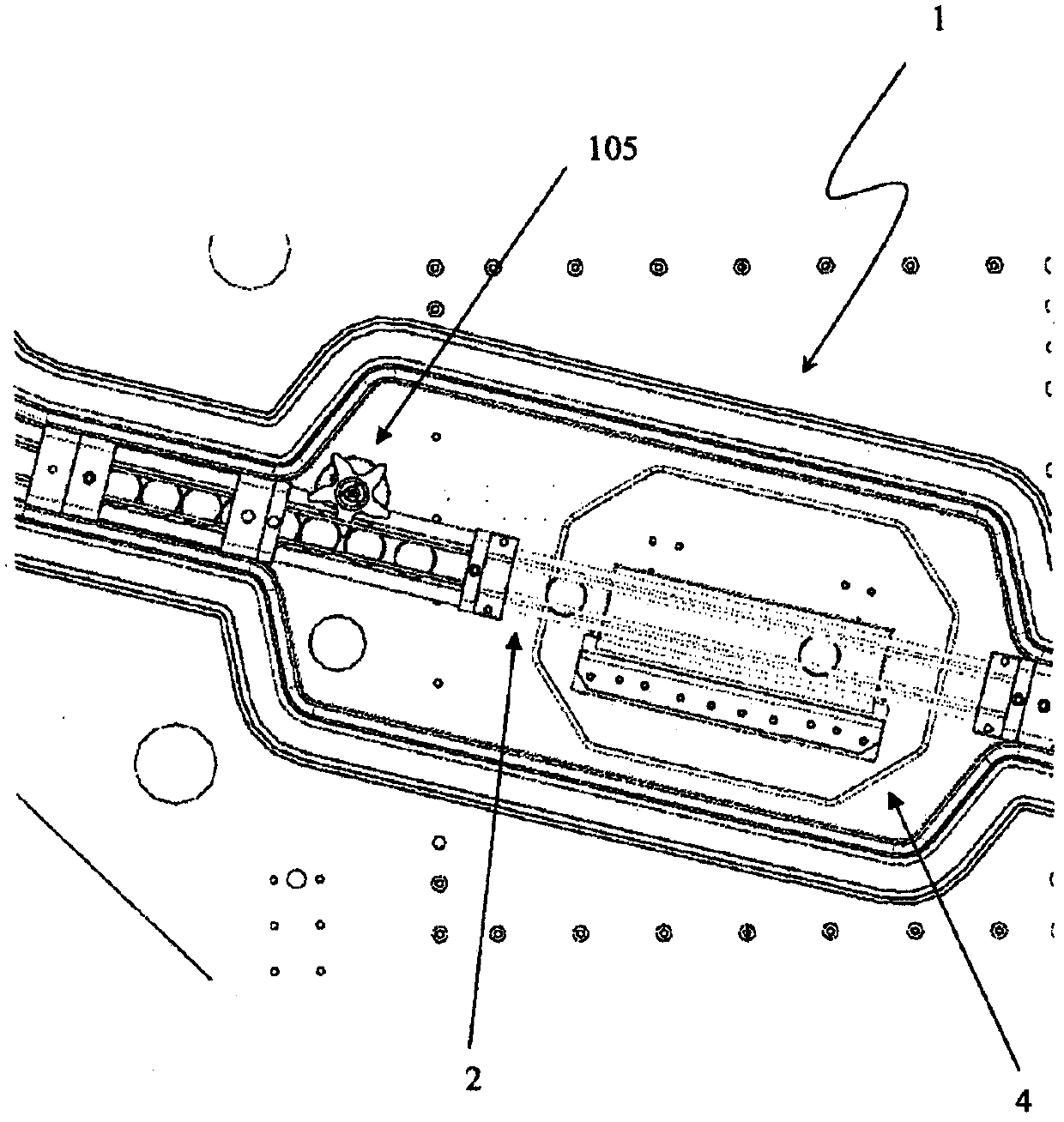

Room-temperature decomposition ozone catalysis material and preparation method thereof

InactiveCN101357331AImprove moisture resistanceImprove processing efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAir volumeDecomposition

The invention discloses a manganese oxide molecular sieve-doped monolithic catalyst for decomposing ozone (O3) at room temperature and a preparation method thereof, which relates to the fields of catalysis and environmental protection. The preparation method is characterized in that a ceramic honeycomb monolithic type or porous foam metal carrier is adopted, and the manganese oxide molecular sieve doped with cobalt or titanium is taken as an active component. The manganese oxide molecular sieve doped with the cobalt or titanium is characterized in that: 1) the manganese oxide molecular sieve has Hollandite-typed manganese oxide octahedral molecular sieves (OMS-2) structure, the pore size is about 0.46nm multiplied by 0.46nm; 2) cobalt or titanium ions are introduced on a framework of the Hollandite-typed manganese oxide octahedral molecular sieves to form the manganese oxide molecular sieve doped with cobalt or titanium. An ozone decomposition catalyst is prepared by an oxidation reduction-refluxing method or an oxidation reduction-hydrothermal synthesis method, namely, the solution with manganese salt and cobalt salt or titanium salt is added with a strong oxidizer to synthesize the ozone decomposition catalyst by refluxing at the temperature of 90-200 DEG or hydrothermal process for more than 12 hours. The monolithic catalyst is characterized in that the input of additional energy sources such as light, heat, electricity, and the like, is unnecessary, and the ozone can be stably decomposed into oxygen under the conditions of normal temperature, normal humidity and large air volume.

Owner:李永刚

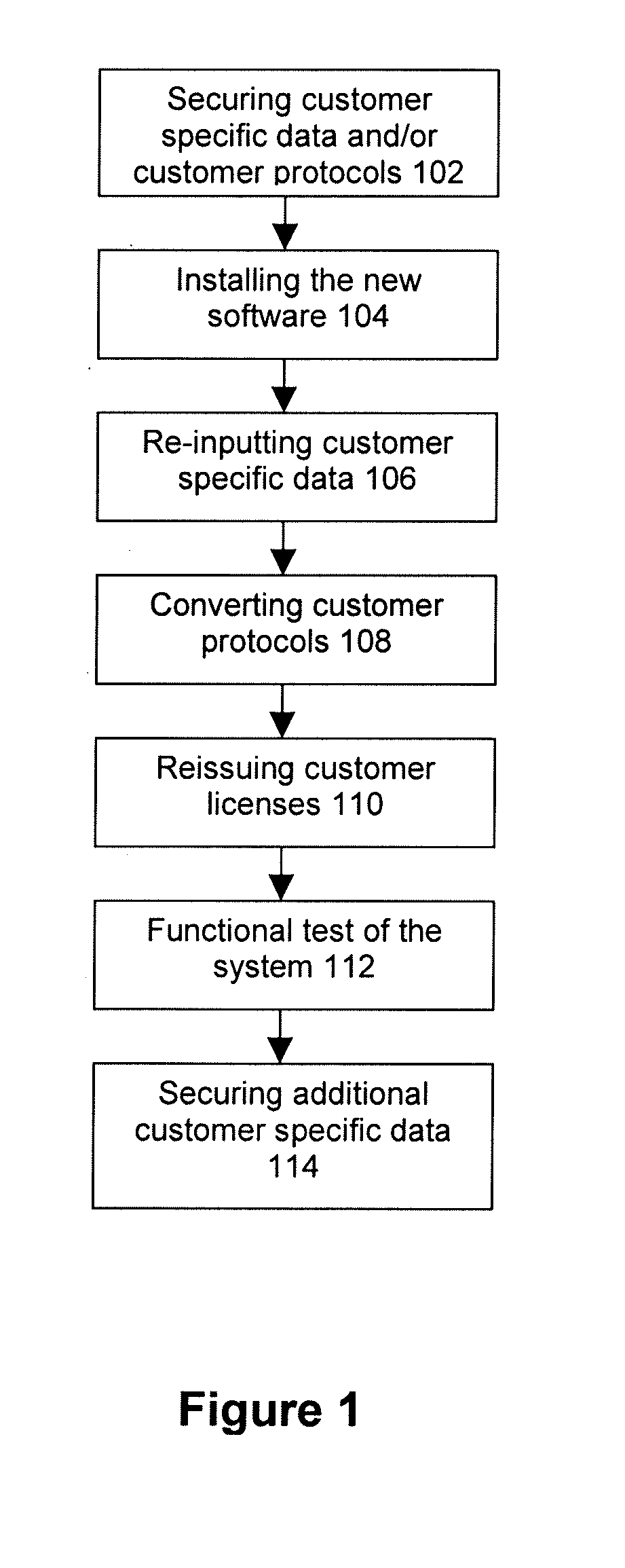

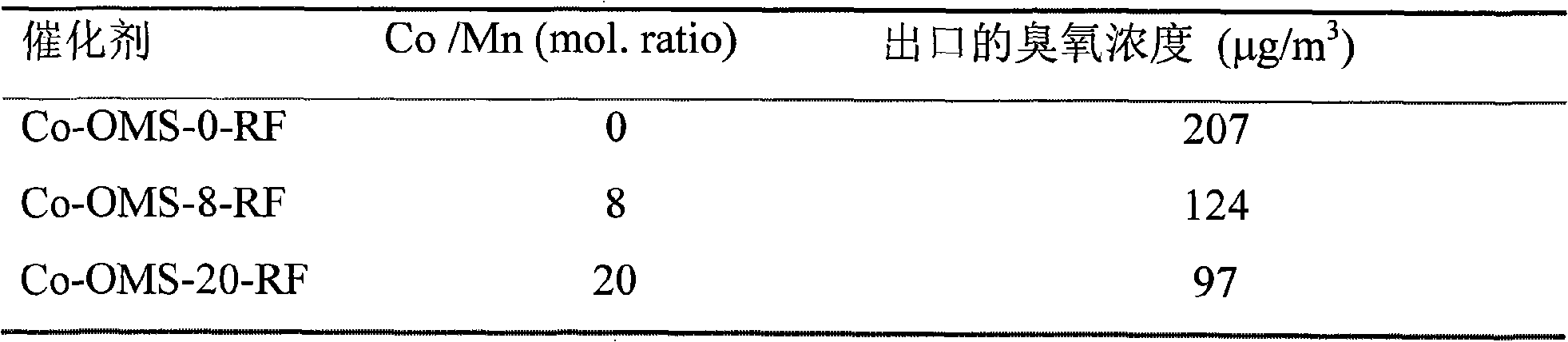

Upgrading software applications offline using a virtual machine

InactiveUS8392902B2Completely processedMinimize downtimeLocal control/monitoringSoftware engineeringDowntimeApplication software

A system and method upgrade software applications offline using a virtual machine. Software applications used by actual customer machines may rely upon customer specific data and protocols. An upgraded version of a software application may become available. The upgrade may be loaded onto a virtual machine. Customer specific data or protocols associated with a previous version of the application may be copied to the virtual machine. The upgraded version may be modified on the virtual machine using the data associated with the previous version. The upgrade process using the virtual machine may detect and eliminate problems with the upgrade associated with the customer machine and / or settings. Once modified, the upgraded version may be transferred from the virtual machine to the customer machine. The upgrade process may be performed primarily on the virtual machine. Therefore, the downtime of the customer machine required to complete the upgrade process may be substantially reduced.

Owner:SIEMENS HEALTHCARE GMBH

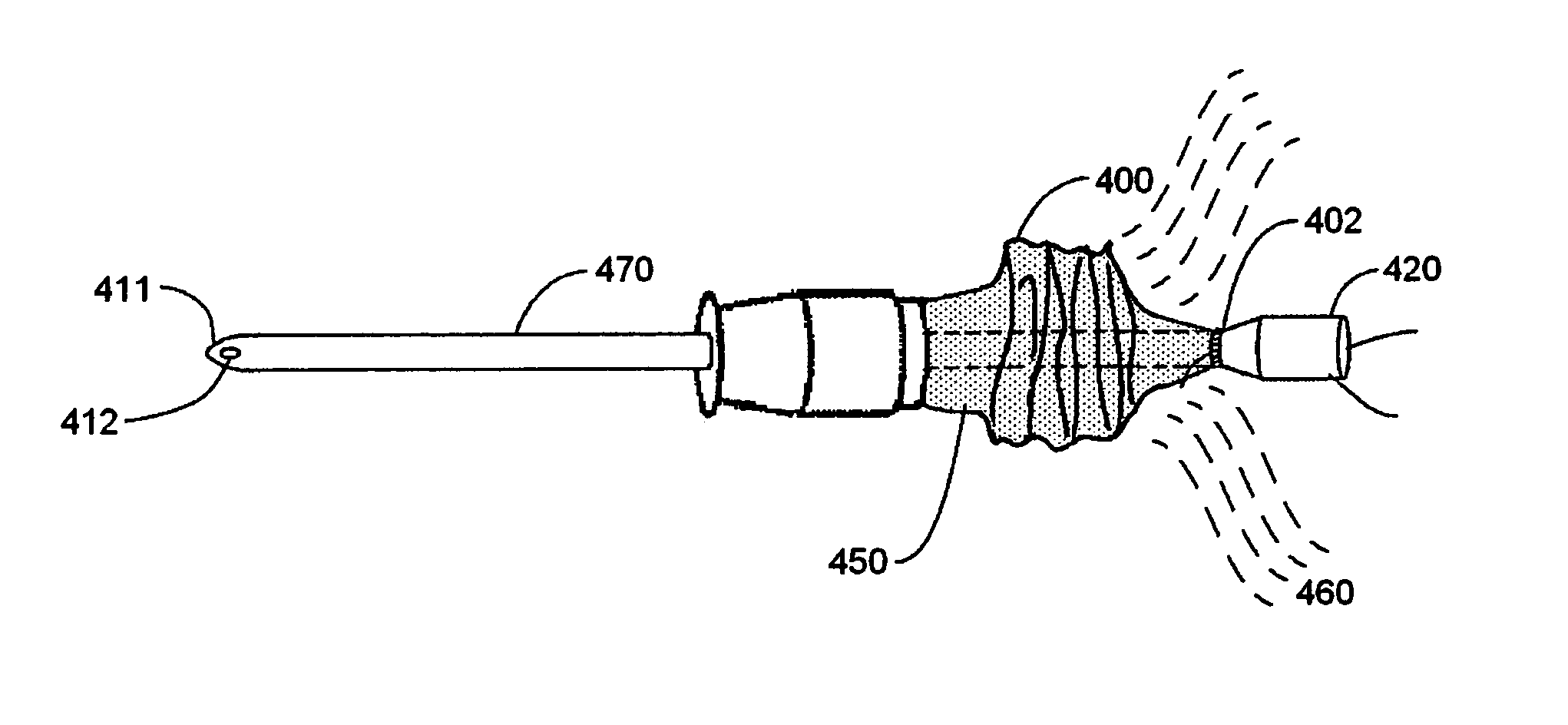

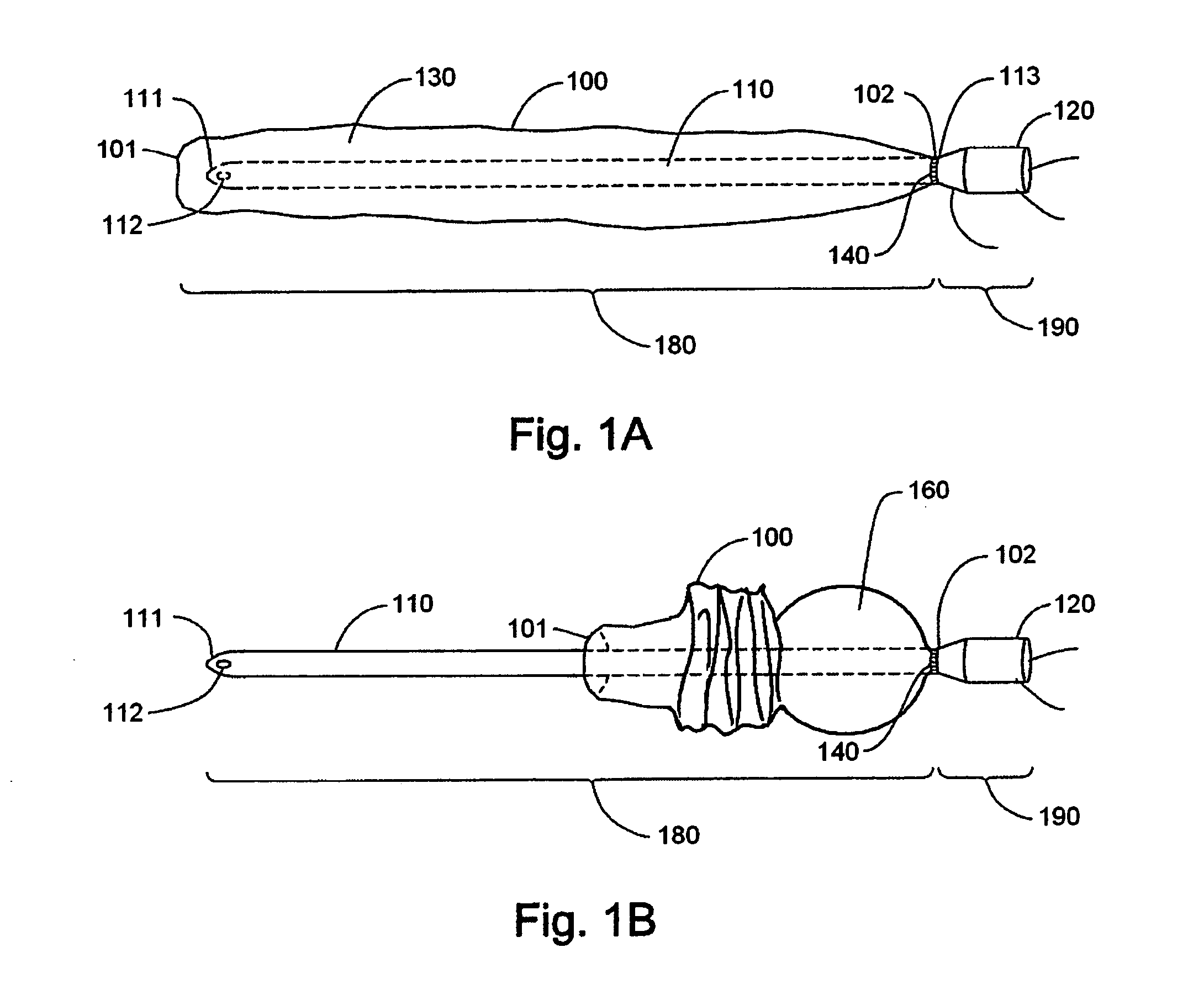

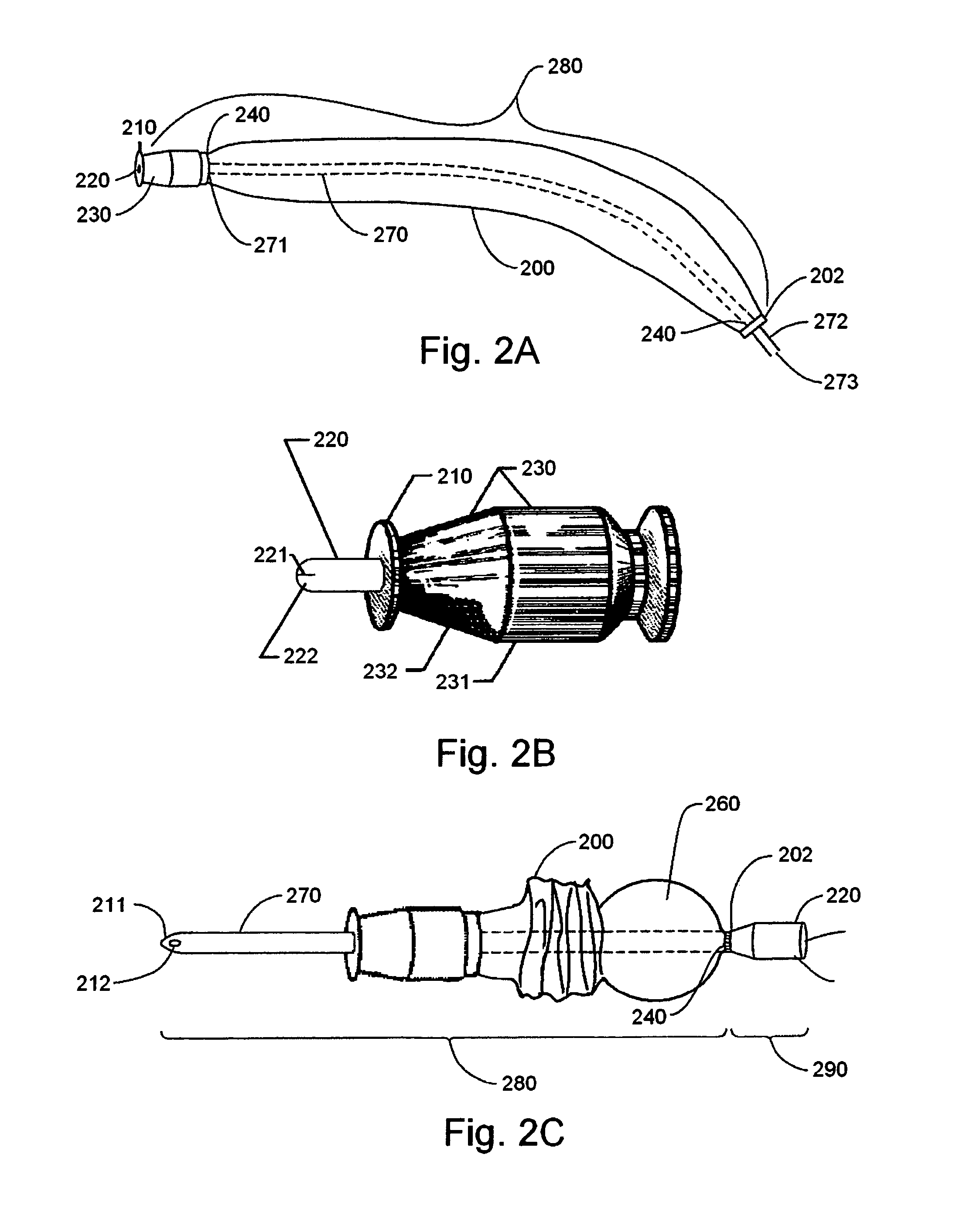

Catheter assembly having protective sheath

InactiveUS7918831B2Relieving build-upCompletely processedCatheterInfusion needlesLimited Manual DexterityGuide tube

Devices and methods are disclosed for a catheterization process, particularly useful for self-performed catheterizations. A catheter is enclosed in a sheath made from a gas-permeable material. This sheath maximizes gas permeability to prevent air build-up at the distal end of the sheath, resulting in easy self-catheterization for even those with limited manual dexterity.

Owner:COLORADO CATHETER

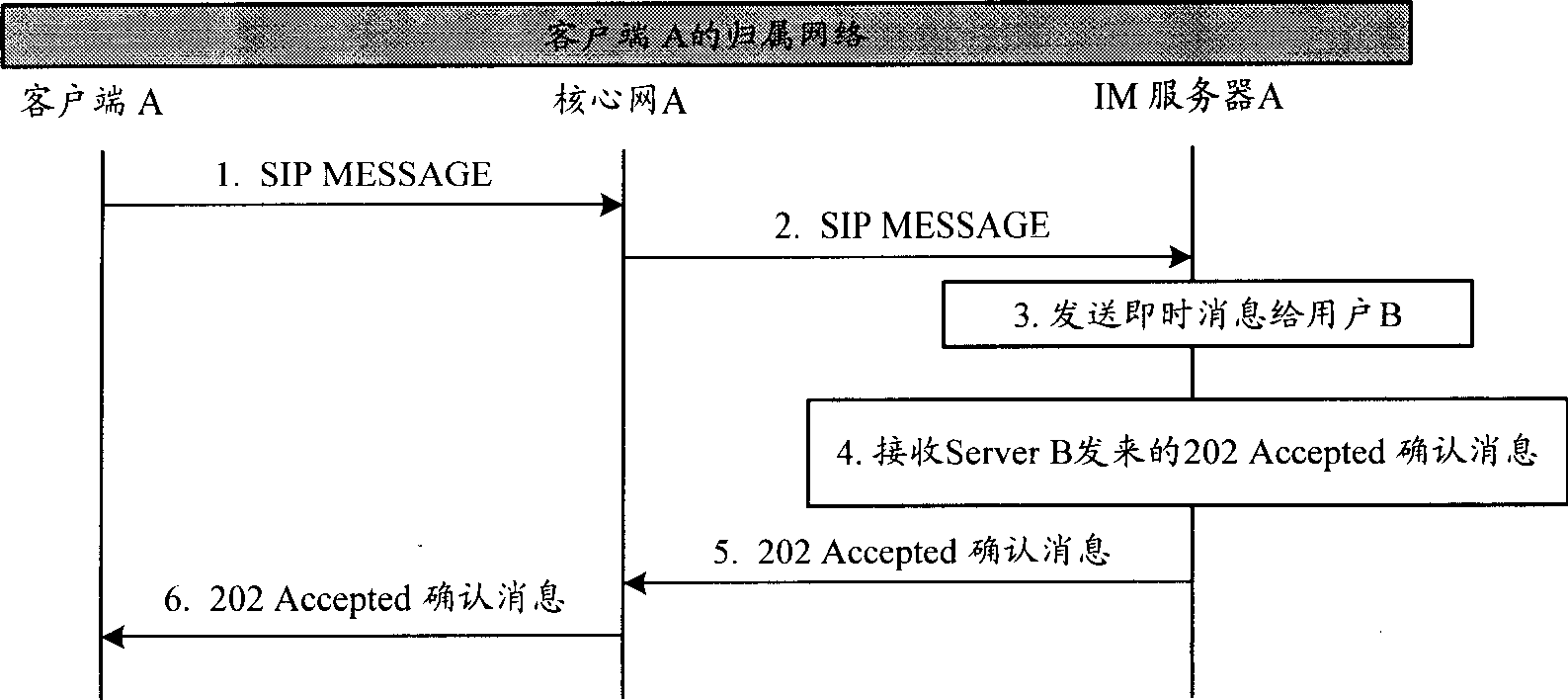

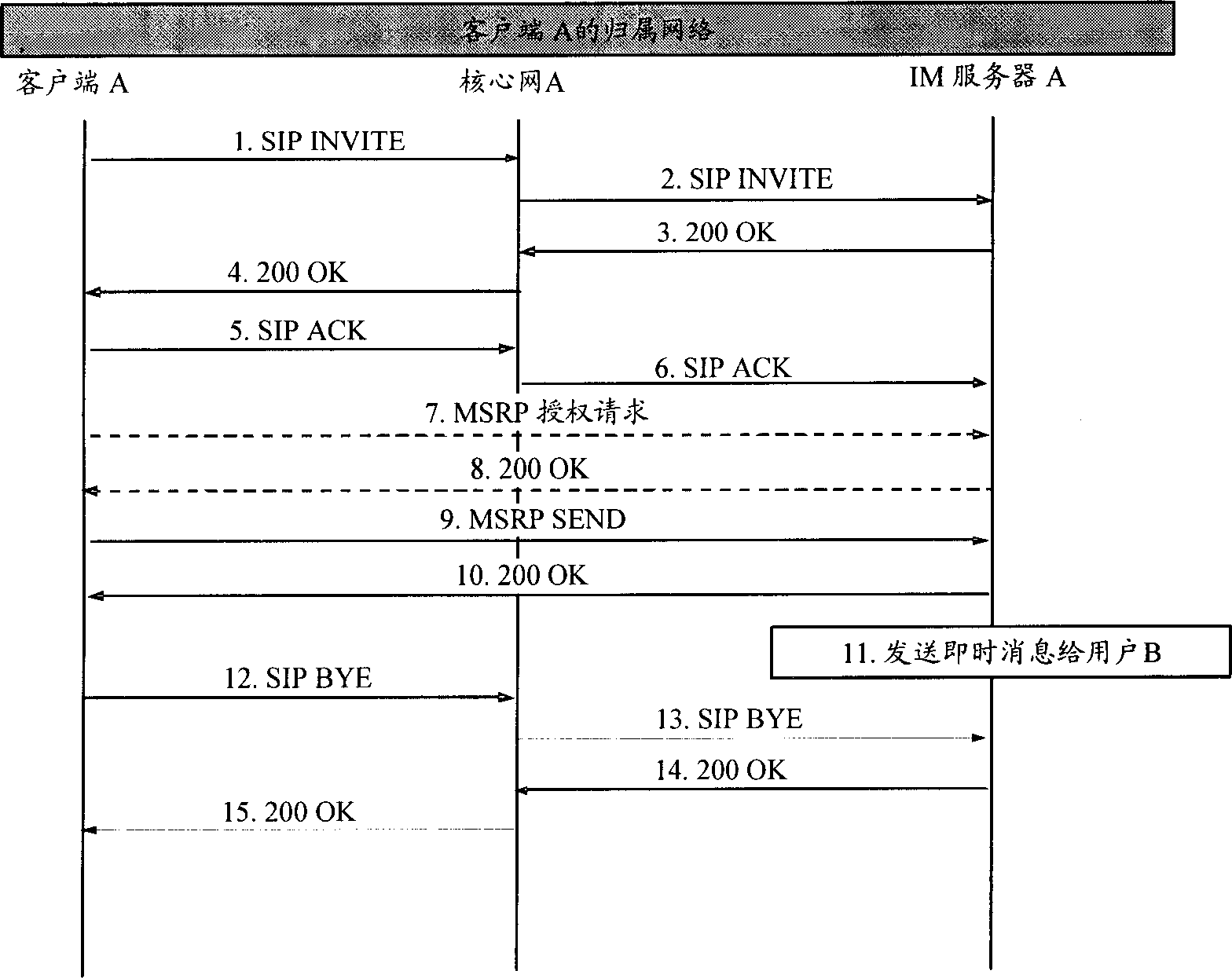

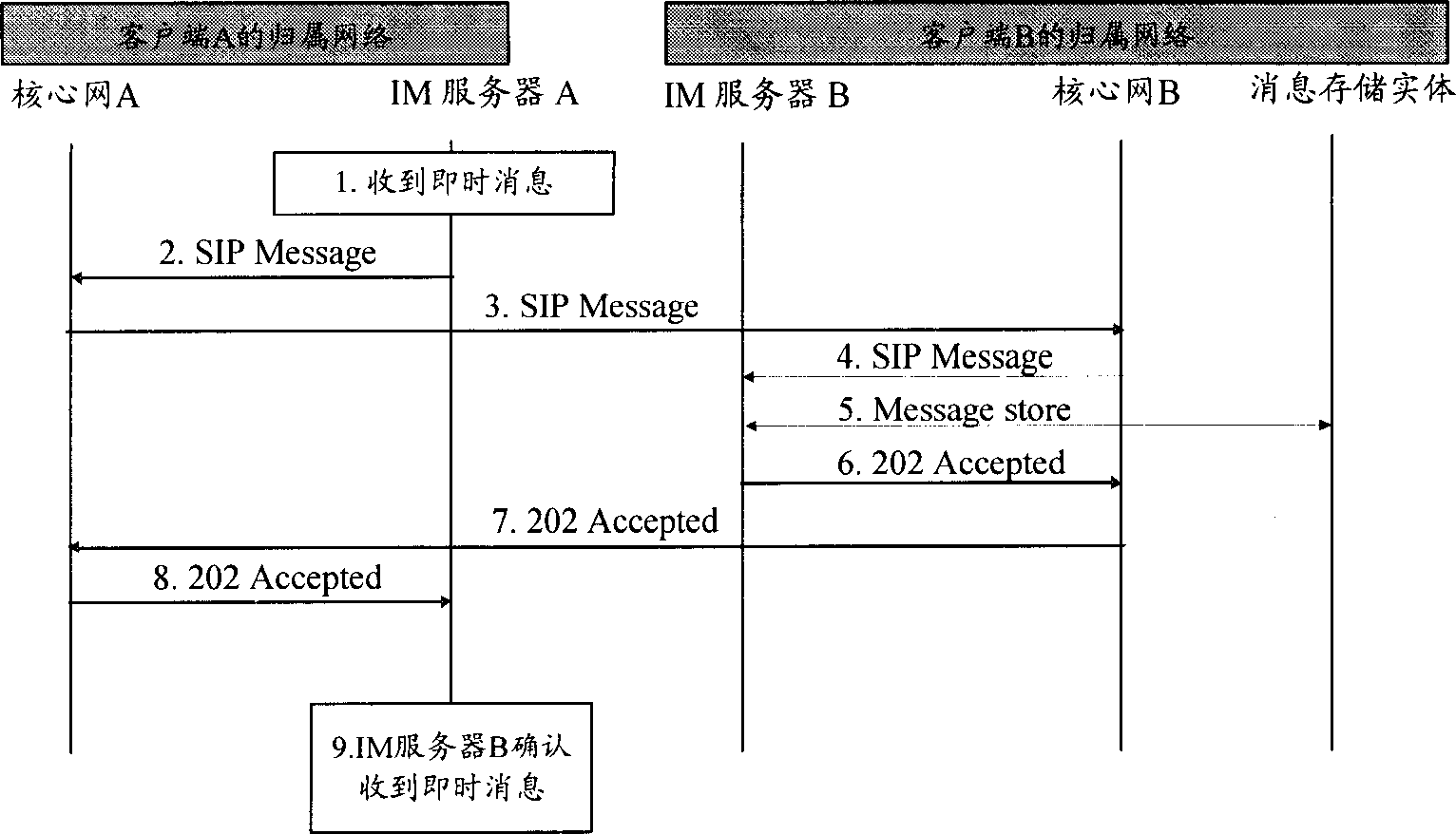

Method for obtaining off line message

The present invention discloses off line message obtaining method, used in adopting SIP / SIMPLE protocol instant message system. It contains when client-side registers to system and receives instant message (IM) server transmitted off line message notifying, executing the following steps: client-side originating obtaining off line message content request to said IM server; said IM server obtaining said client-side off line message content and down issuing to the client-side. The present invention combines current technologic off line message transmission and storage process to make off line message process into a complete solution scheme.

Owner:HUAWEI TECH CO LTD

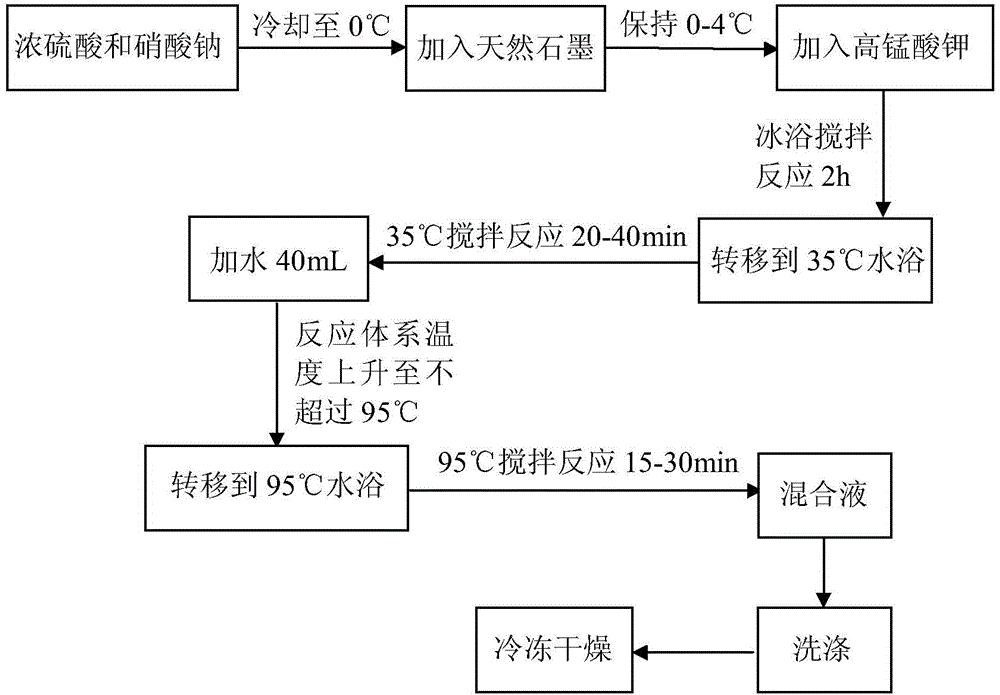

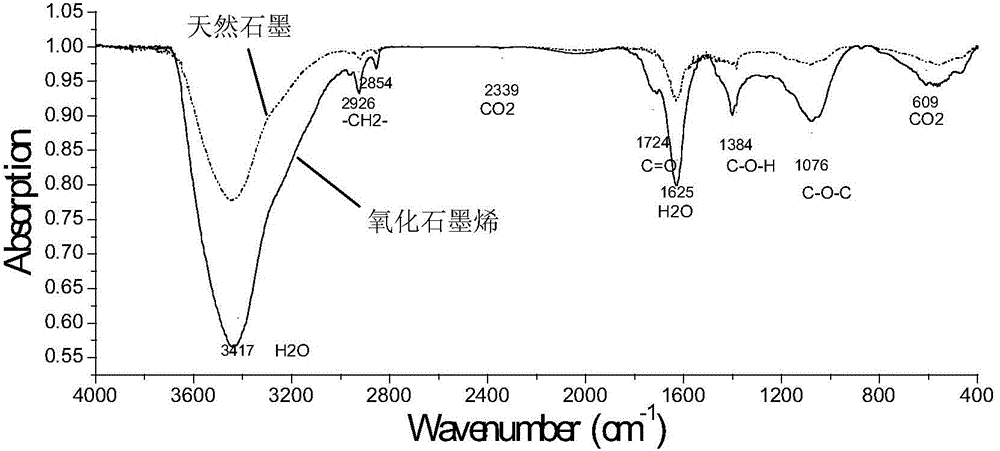

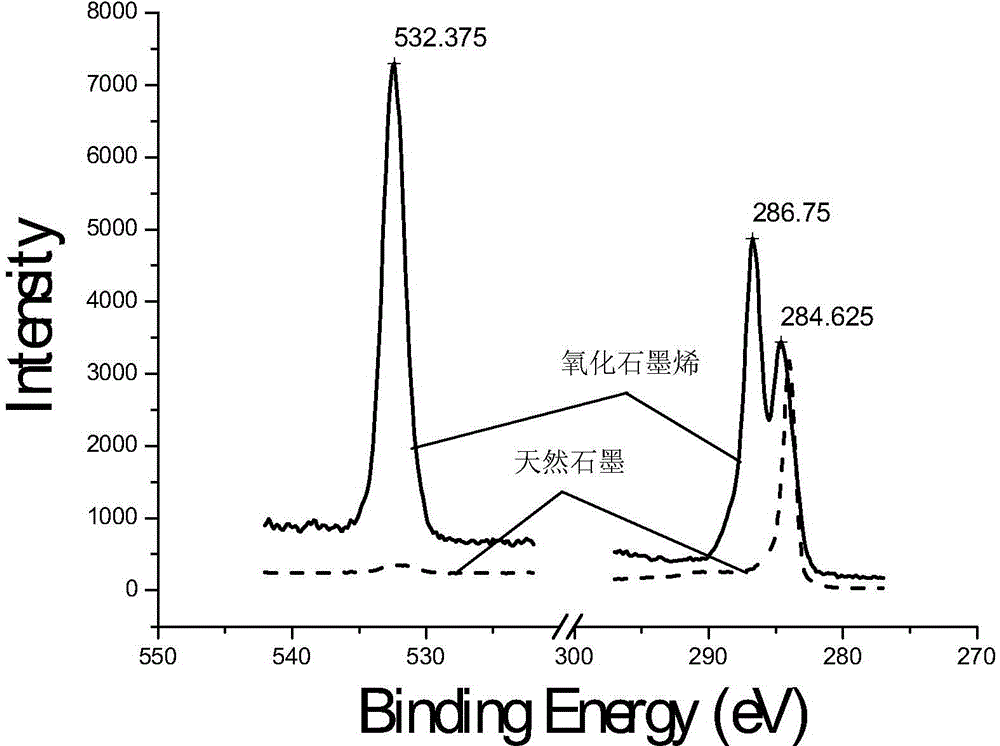

Graphene oxide, preparation method and application thereof

The invention provides graphene oxide, a preparation method and application thereof. The preparation method of the graphene oxide comprises the following steps: under a stirring condition, adding natural graphite, sodium nitrate and potassium permanganate into concentrated sulfuric acid, continuing to stir at 0-4 DEG C and taking a reaction for 2 hours; raising the temperature to 35+ / -5 DEG C, continuing to stir, and taking a thermal insulation reaction for 20-40 minutes; raising the temperature to 90-95 DEG C, continuing to stir and performing the thermal insulation reaction for 15-30 minutes; then adding hydrogen peroxide, centrifuging the solution, washing the supernatant with diluted hydrochloric acid, centrifuging the washed supernatant until sulfate ions cannot be detected out from the supernatant, washing the solution with pure water and centrifuging until the supernatant is neutral; after freeze drying, obtaining the graphene oxide. The invention further provides the application of the graphene oxide in removal of pollutants from water. The graphene oxide provided by the invention can be used for quickly and efficiently adsorbing pollutants such as BPA and heavy metal ions in water, so that the treated water quality can reach the drinking water standard.

Owner:NANJING UNIV

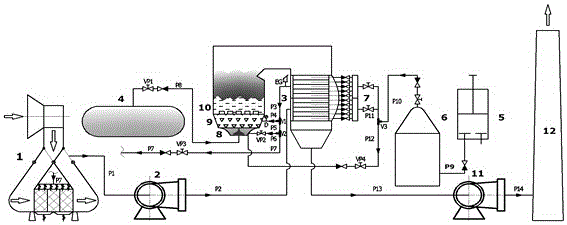

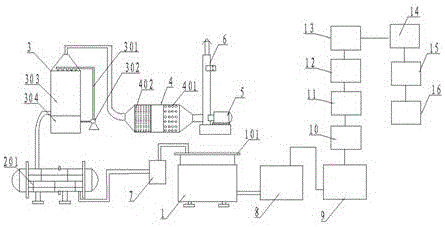

Treatment method and system for sprayed VOCs (Volatile Organic Chemicals) mixed gas

InactiveCN105964141AReduce complexityImprove processing efficiencyGas treatmentDispersed particle separationHydrogenFlue gas

The invention provides a treatment method and system for sprayed VOCs (Volatile Organic Chemicals) mixed gas. The method comprises the following steps: firstly, removing paint mist in mixed gas; then raising the temperature of the gas without the paint mist to 320 DEG C to 350 DEG C; and carrying out a catalytic oxidization reaction under a catalytic condition of a catalyst to thermally decompose the mixed gas into high-temperature flue gas containing a carbon-oxygen compound and a hydrogen-oxygen compound, and then discharging out the high-temperature flue gas. The system comprises a paint mist removing device for removing the paint mist in the sprayed VOCs mixed gas, a heating unit for heating the sprayed VOCs mixed gas, a catalytic oxidization reaction chamber and a centralized emission device, wherein the paint mist removing device is provided with a gas inlet of the sprayed VOCs mixed gas and a gas outlet of the sprayed VOCs mixed gas; the gas outlet of the paint mist removing device is connected with the gas inlet of the heating unit; the gas outlet of the heating unit is connected with the gas inlet of the catalytic oxidization reaction chamber; and the gas outlet of the catalytic oxidization reaction chamber is communicated with the centralized emission device, and the catalytic oxidization reaction chamber is internally filled with a catalyst and a heat accumulation body.

Owner:CHONGQING UNIV

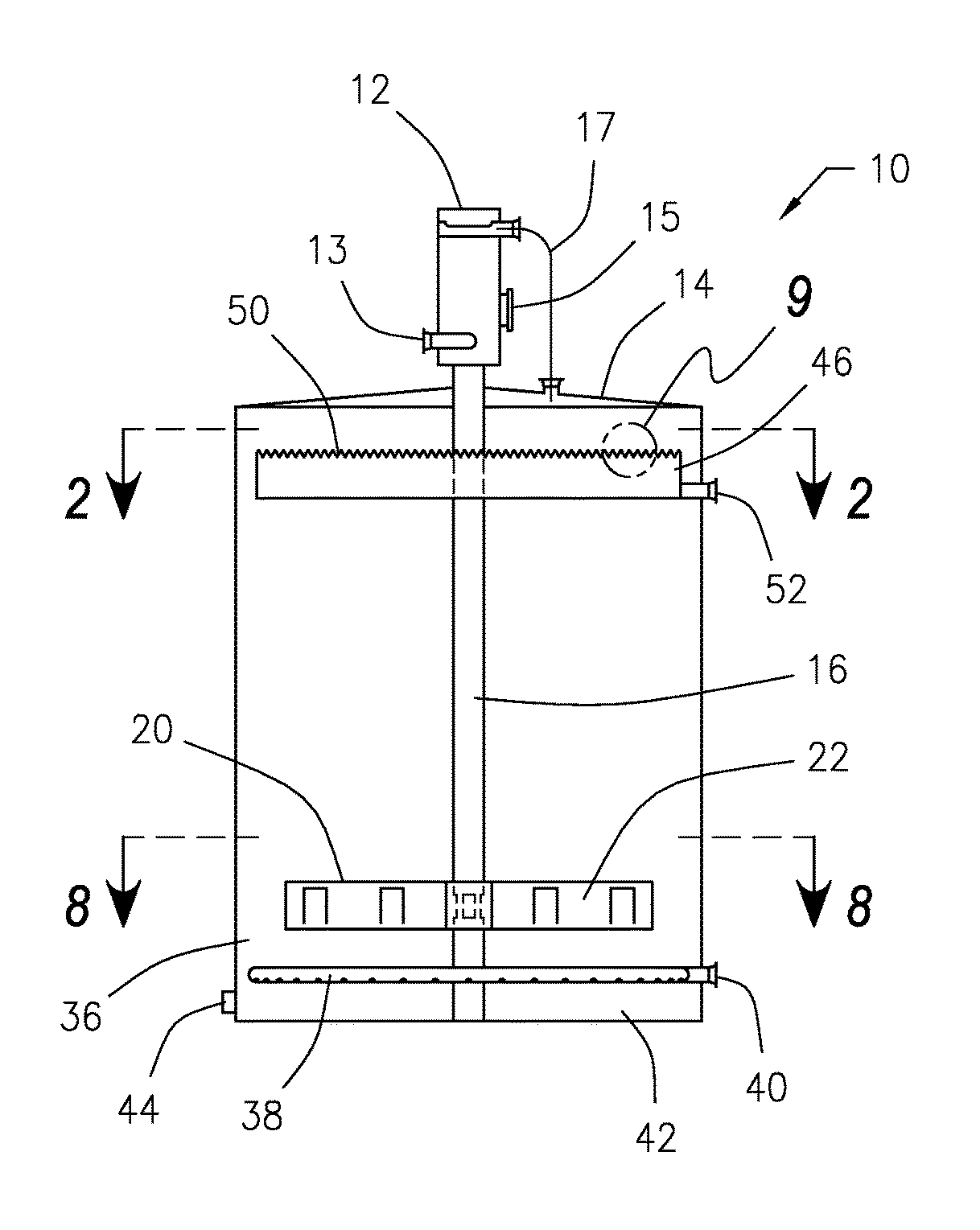

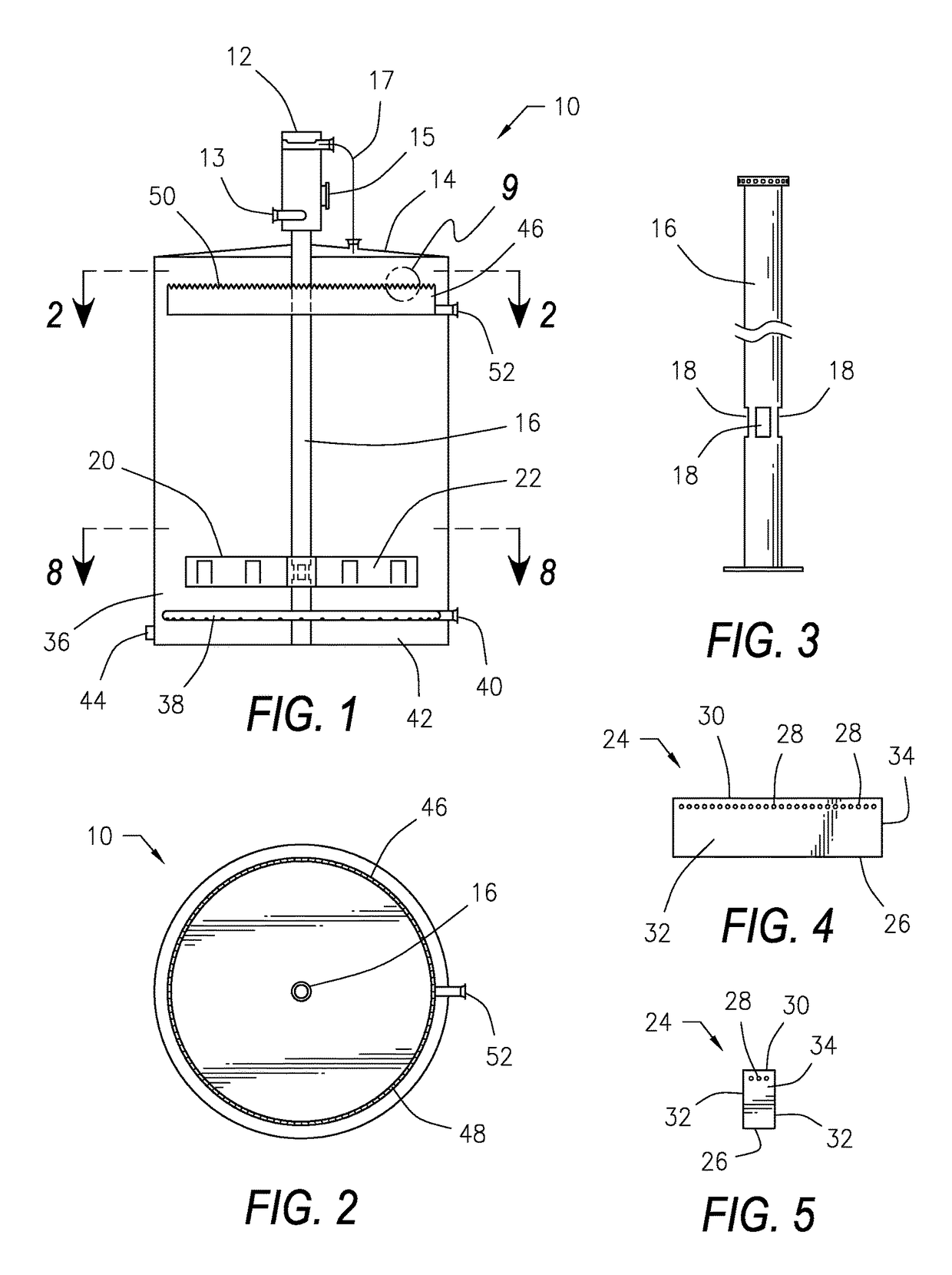

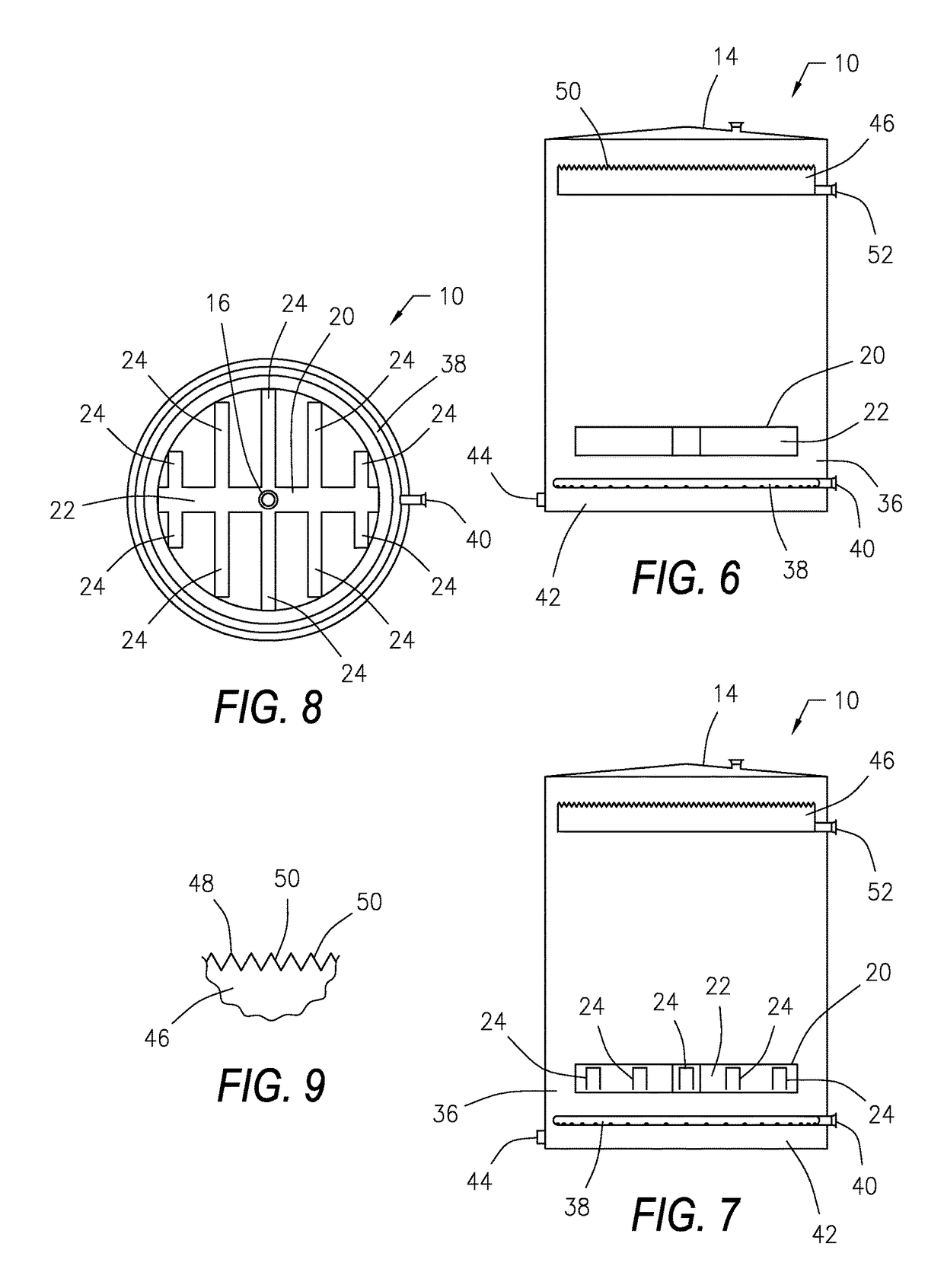

System and method for cleaning a vehicle-mounted optic lens

ActiveUS10286877B2Reduce in quantityCompletely processedVehicle cleaningCleaning using liquidsCamera lensAir pump

The present invention refers a system and a method for automatically cleaning an optic lens mounted on a vehicle, by spraying a washing liquid to remove any type of dirt from the lens such as a clear image or optic signal can be captured anytime, where an air pump is provided including a variable volume compression chamber to pressurize a volume of air, and a washing liquid conduit is communicated with a liquid nozzle and with the air pump, such as the air pump can be operated by the flow of pressurized washing liquid, such as the same flow of pressurized washing liquid is used to clean the optic surface, and to operate the air pump and generate a blast of air to blow off any liquid drop from the optic lens.

Owner:FICO TRANSPAR

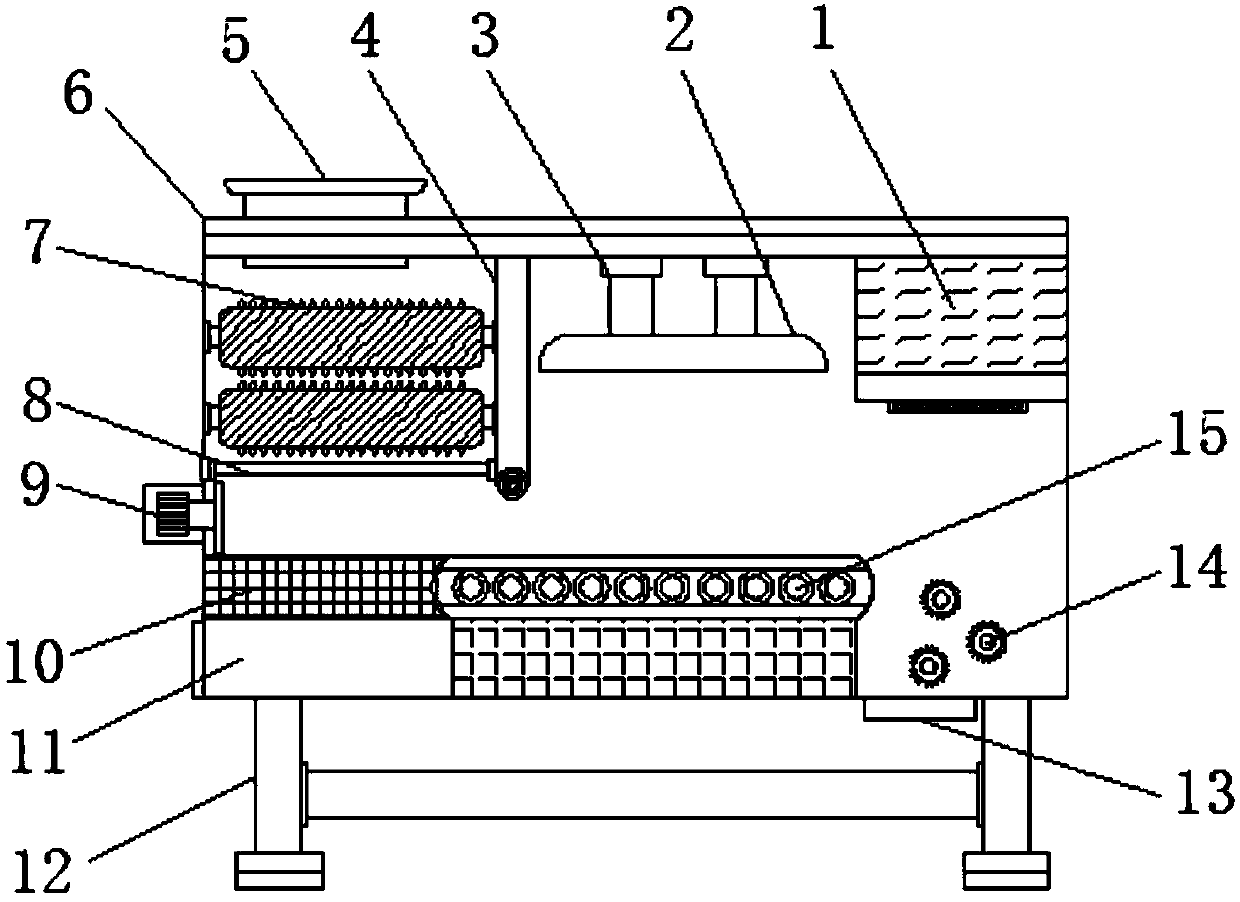

Building waste extruding device high in efficiency and high in practicability

InactiveCN107837870ACompletely processedThorough treatmentUsing liquid separation agentGrain treatmentsArchitectural engineeringConstruction waste

The invention discloses a construction waste extruding device with high efficiency and strong practicability. The bottom of the support plate is provided with an infrared sensor, and the bottom of the device body is welded with feet. In the present invention, the construction waste extruding device is mainly used to process the wood waste produced in the construction. First, a rolling roller, a briquetting block and a crushing gear are arranged inside it, which can respectively process the construction waste. Carry out crushing treatment, extrusion treatment and crushing treatment. Through these three different crushing methods, the construction waste can be crushed more completely and processed more thoroughly. Secondly, an electromagnetic rod is set under the crushing drum, so that after crushing The iron nails scattered out of the waste crushed by the roller will be adsorbed on the electromagnetic rod, and finally the electromagnetic rod is pulled out to take out the iron nails.

Owner:CHENGDU KECHUANGGU TECH CO LTD

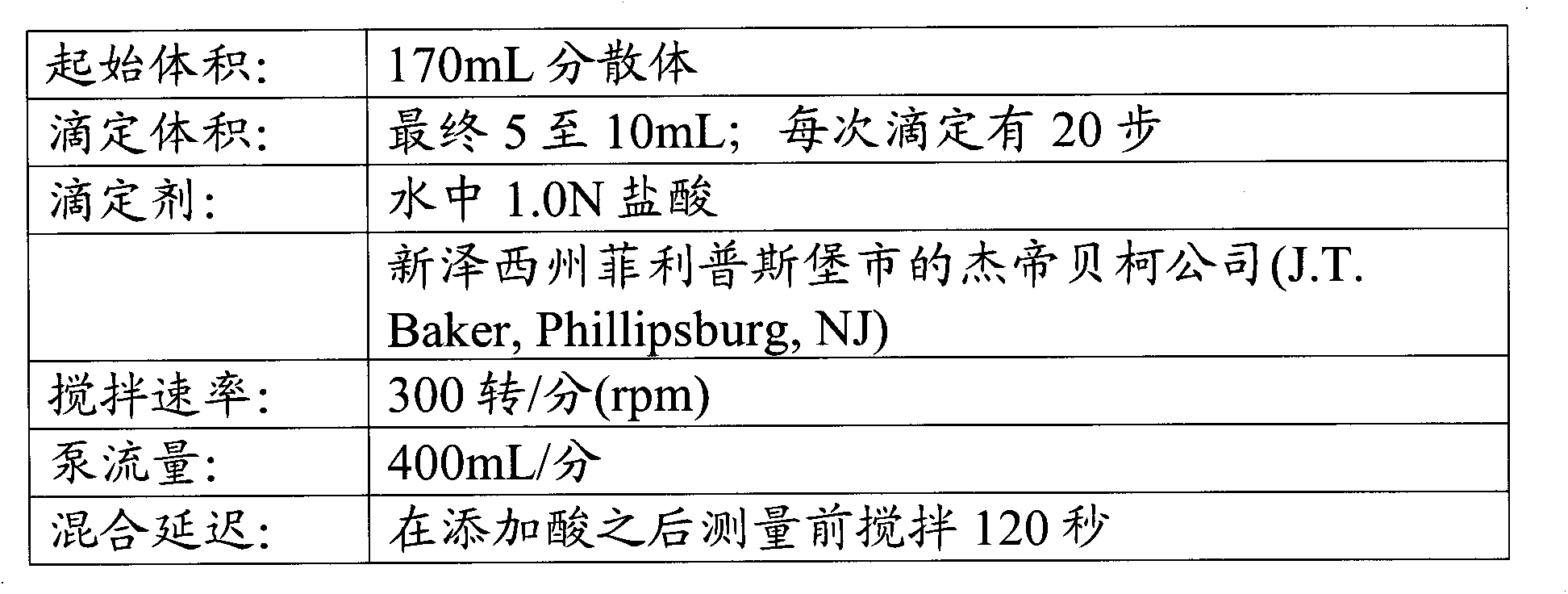

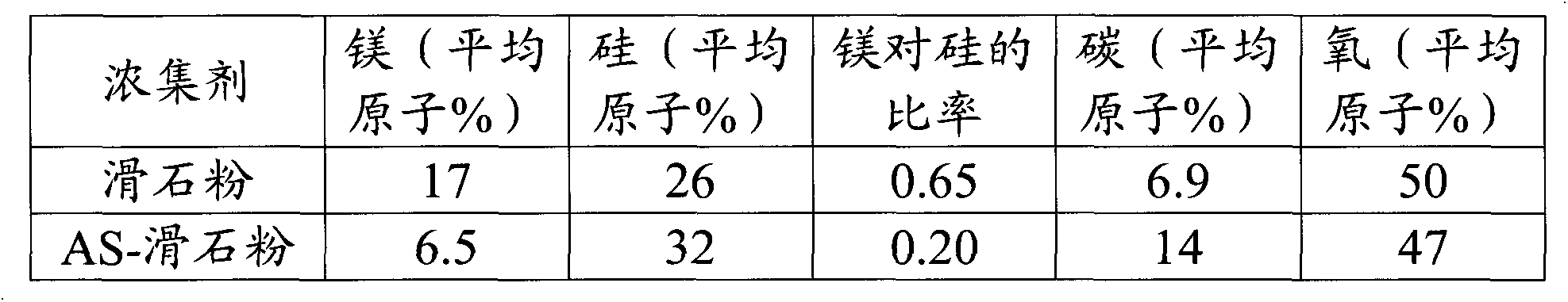

Microorganism concentration process and device

ActiveCN103221550AReduce contact timeLow costBioreactor/fermenter combinationsBiological substance pretreatmentsFiberMicroorganism

A process for capturing or concentrating microorganisms for detection or assay comprises (a) providing a concentration device comprising (1) a porous fibrous nonwoven matrix and (2) a plurality of particles of at least one concentration agent that comprises a metal silicate, the particles being enmeshed in the porous fibrous nonwoven matrix; (b) providing a sample comprising at least one target cellular analyte; (c) contacting the concentration device with the sample such that at least a portion of the at least one target cellular analyte is bound to or captured by the concentration device; and (d) detecting the presence of at least one bound target cellular analyte.

Owner:3M INNOVATIVE PROPERTIES CO

Event-triggered transaction processing for electronic data interchange

InactiveUS7340426B1Completely processedFinancePayment architectureBusiness ruleElectronic data interchange

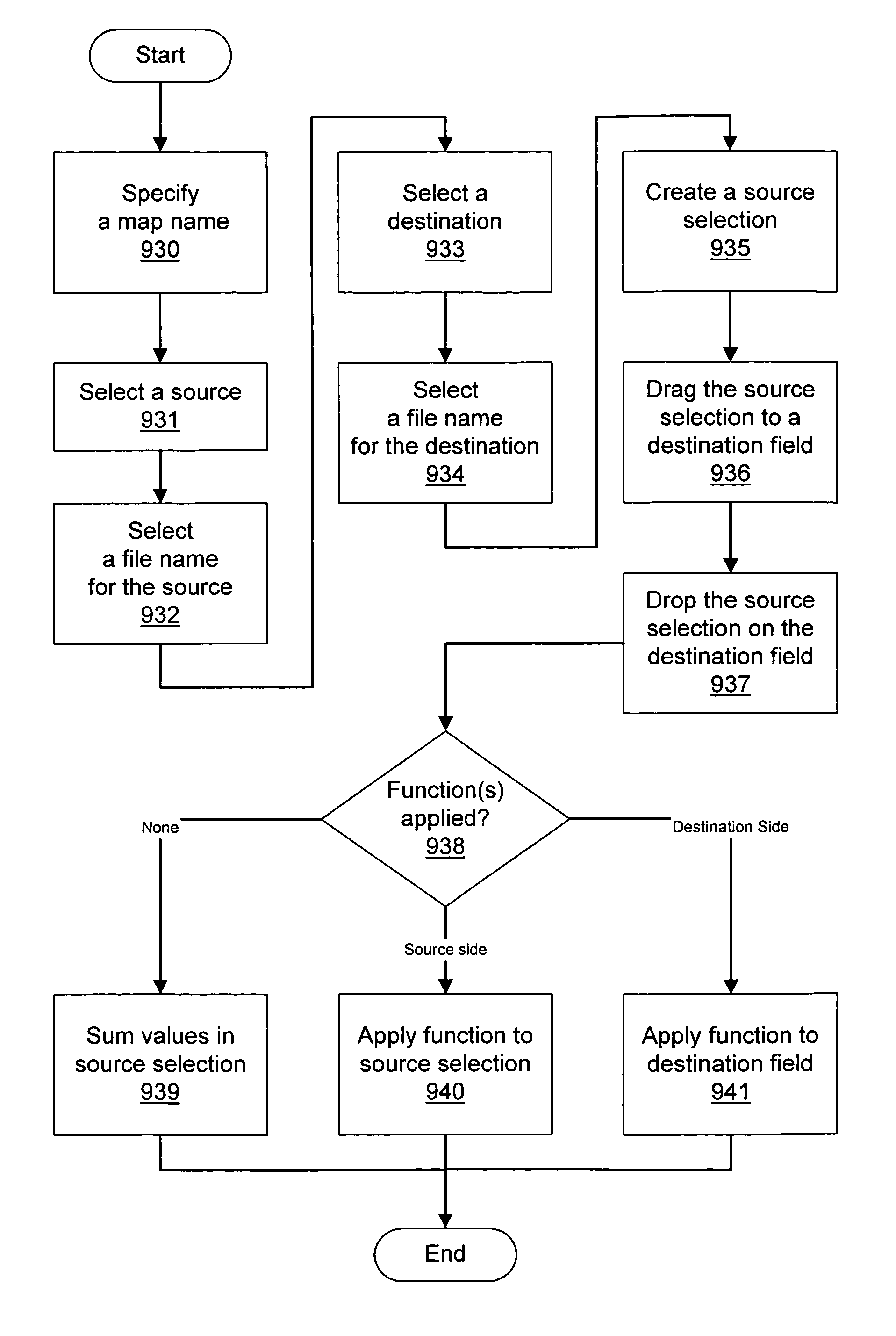

A method and system for automating data exchange processing by using event-triggered transaction processing. Transaction data may be exchanged electronically with industry clearinghouses or in-house administration systems. A trading relationship between trading partners is stored in a trading relationship database. At least one trading partner is a sending trading partner and at least one trading partner is a receiving trading partner with respect to a transaction between the sender and receiver. Maps and rules may be created and stored with respect to transactions and / or trading partners. An incoming transaction is received through an industry clearinghouse from the at least one sending partner as identified in the trading relationship. In response to receiving the incoming transaction, additional information is read from an administration system specified by a map in order to complete the processing of the transaction. The incoming transaction is a triggering event which prompts the obtaining of additional data. The additional data may be obtained according to user-specified business rules. In response to obtaining additional information, an outgoing transaction which may include the additional data is generated and sent to the receiving trading partner through the industry clearinghouse.

Owner:COMP SCI A OF NV

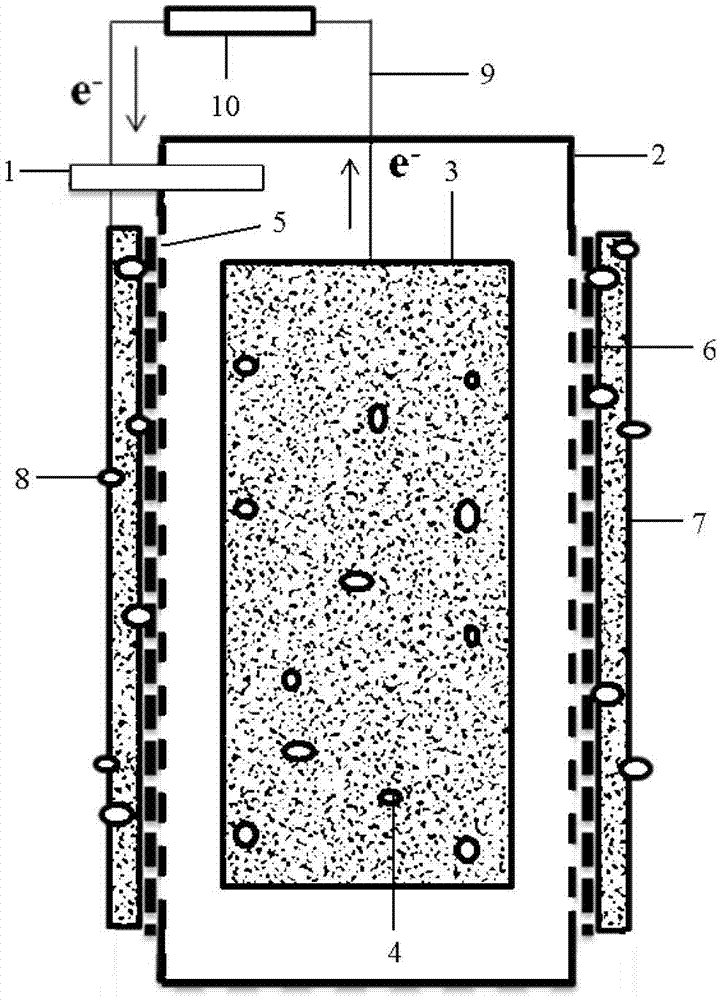

Electrochemical membrane bioreactor

ActiveCN103204590AAvoid energy-consuming behaviors such as artificial aeration and oxygenationReduce energy consumptionBiochemical fuel cellsTreatment with aerobic and anaerobic processesWater qualityMembrane bioreactor

The invention discloses an electrochemical membrane bioreactor. The electrochemical membrane bioreactor comprises an anode chamber, an anode, a filtering separation membrane and an air cathode, wherein a water inlet pipe is arranged on the anode chamber, an electro-microorganism is adhered to the anode, the anode and the air cathode are connected through a conducting wire, the anode chamber is of an enclosed structure, a through hole is formed in the wall of the anode chamber, a filtering separation membrane is sheathed on the outer side of the through hole, the air cathode is sheathed on the outer side of the filtering separation membrane, and a cathode microorganism is adhered to the air cathode. The electrochemical membrane bioreactor provided by the invention has the advantages that after waste water is sequentially treated through the anode, the filtering separation membrane and the cathode, high-quality effluent is obtained, and the air cathode is exposed in air, so that the energy consumption behaviors such as manual aeration and oxygenation are avoided, thus the energy consumption is reduced while wastewater is treated.

Owner:UNIV OF SCI & TECH OF CHINA

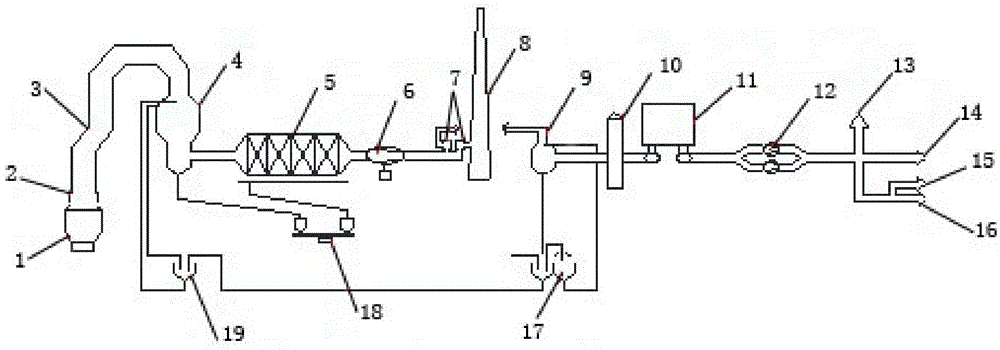

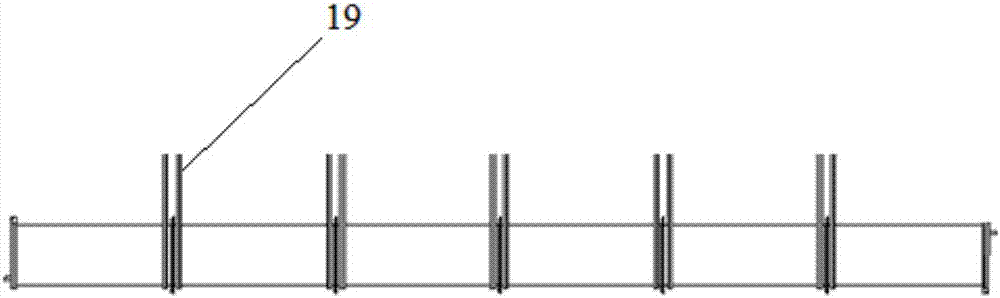

Process and equipment for pyrolyzing coking wastewater by utilizing dust-removed high temperature flue gas of converter

ActiveCN104016429ATo achieve the purpose of treating coking wastewaterCompletely processedCombination devicesWater/sewage treatment by heatingEvaporative coolerChiller

The invention discloses a process and equipment for pyrolyzing coking wastewater by utilizing dust-removed high temperature flue gas of a converter. The equipment comprises a waste heat boiler (3), an evaporation cooler (4), an electric dust remover (5), an ID air blower (6), and a coking wastewater spray system (19). The equipment is characterized in that the waste heat boiler (3), the evaporation cooler (4), the electric dust remover (5) and the ID air blower (6) are connected in sequence, wherein the coking wastewater spray system (19) is connected with the evaporation cooler (4); the evaporation cooler (4) is used for atomizing coking wastewater and carrying out pyrolytic reaction in the presence of the catalyst. The invention further relates to a process for pyrolyzing coking wastewater by utilizing the dust-removed high temperature flue gas of the converter. According to the equipment and method disclosed by the invention, coking wastewater can be directly treated without carrying out early-stage biochemical treatment, so that a process step of biochemical treatment in a coking plant is not required.

Owner:北京泰和元环保科技发展有限公司

Process for dyeing and finishing cuprammonuium fabric

InactiveCN102634988ACompletely processedFabric breaking/softeningBiochemical fibre treatmentProcess engineeringDyeing

The invention relates to a process for dyeing and finishing a fiber fabric, in particular to a process for dyeing and finishing a cuprammonuium fabric, which includes invert-sewing, prewashing, desizing, bleaching, enzymatic washing and polishing via an airflow dyeing machine, dyeing, setting and softening of rolling stock, AIRO finishing, tentering finishing and obtaining the finished product. According to the technical scheme, the process has the advantages that the traditional preprocessing technique is eliminated and replaced by the novel environment-friendly desizing, scouring and bleaching preprocessing technique using both sodium carbonate and hydrogen peroxide so that processing is complete while fabric functions are unspoiled, the fully slack dyeing and finishing process is adopted, and accordingly qualified fabric quality and internal indexes are guaranteed, and the best effect of the cuprammonuium fabric is achieved.

Owner:HUAFANG

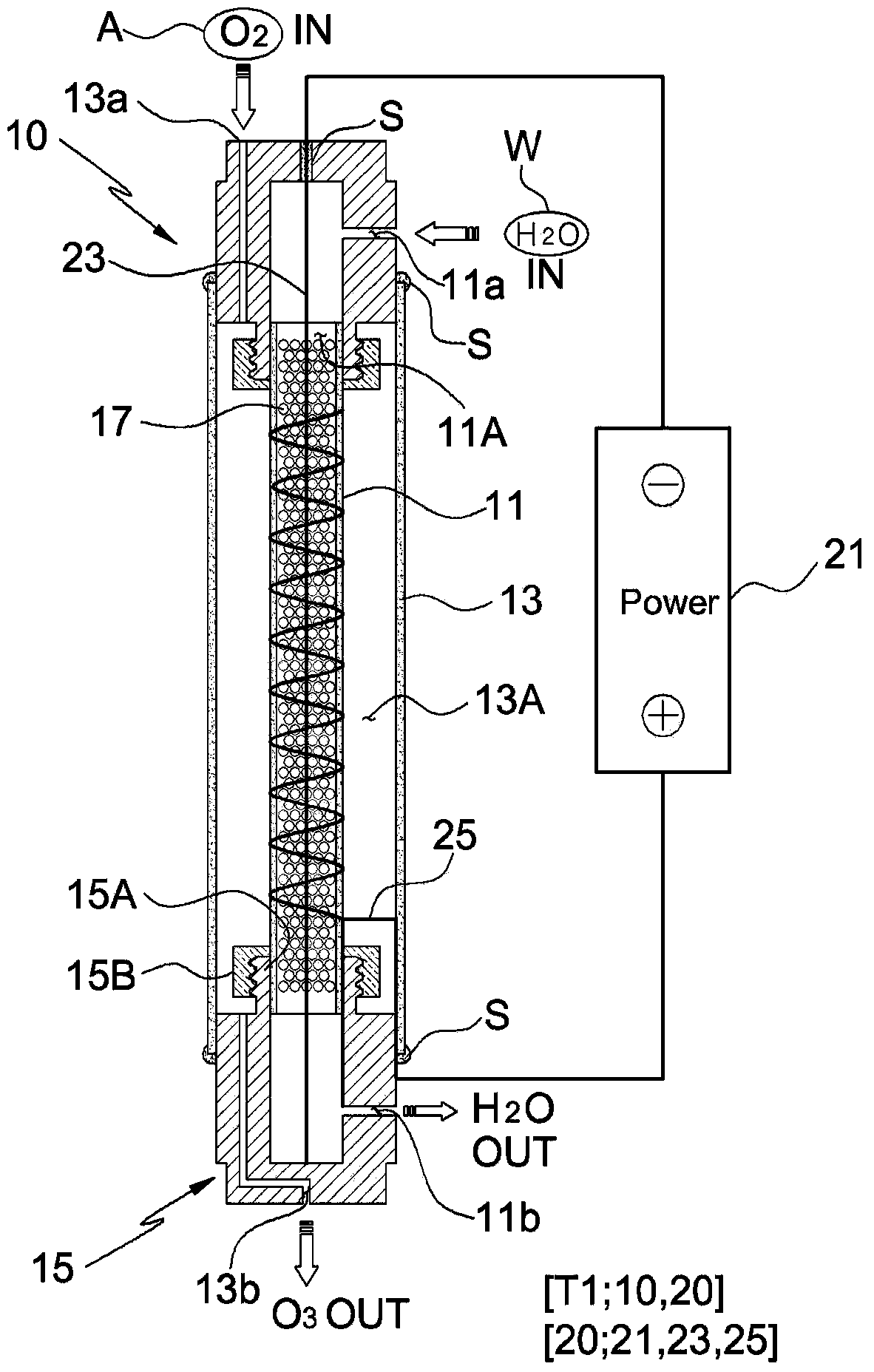

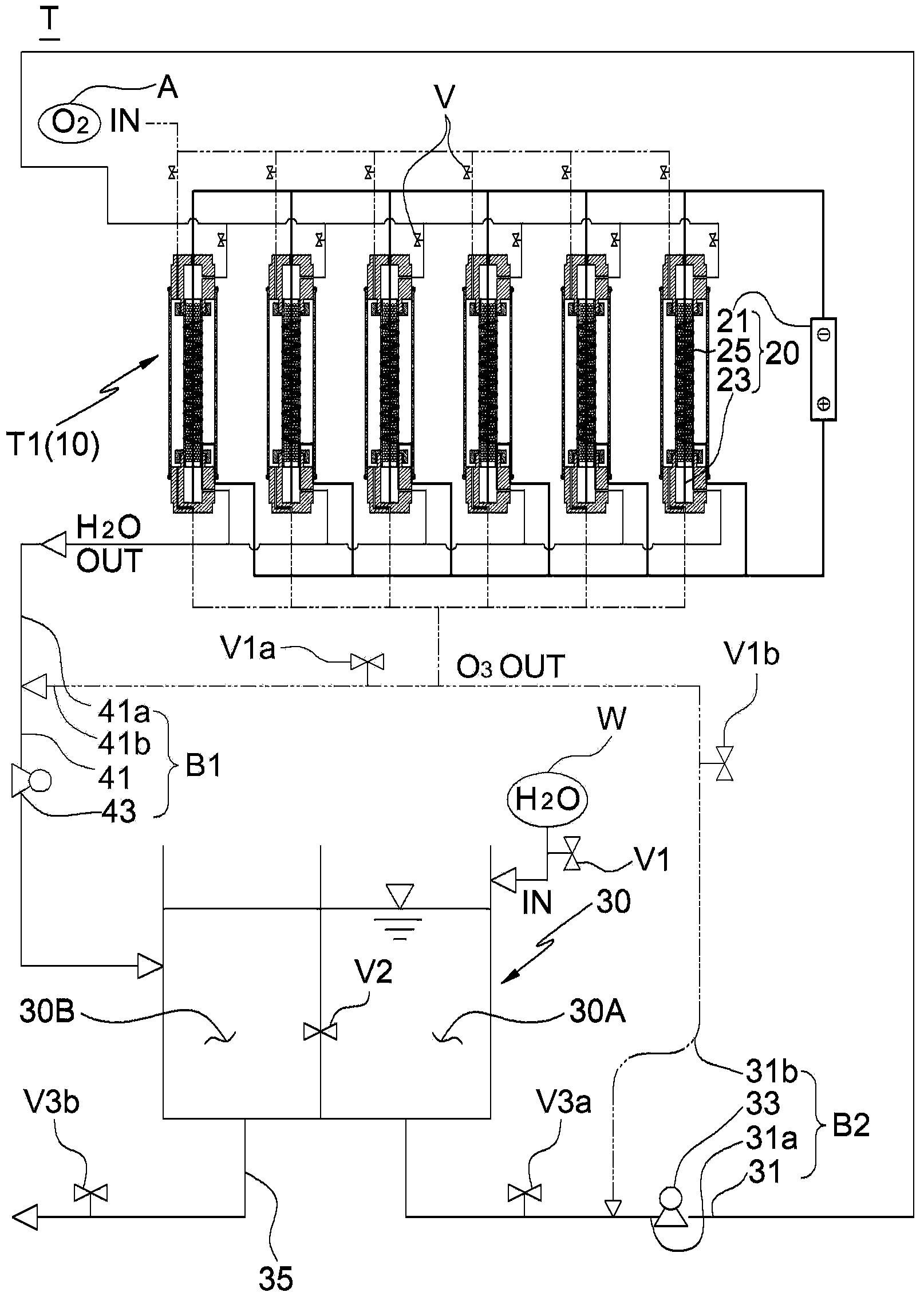

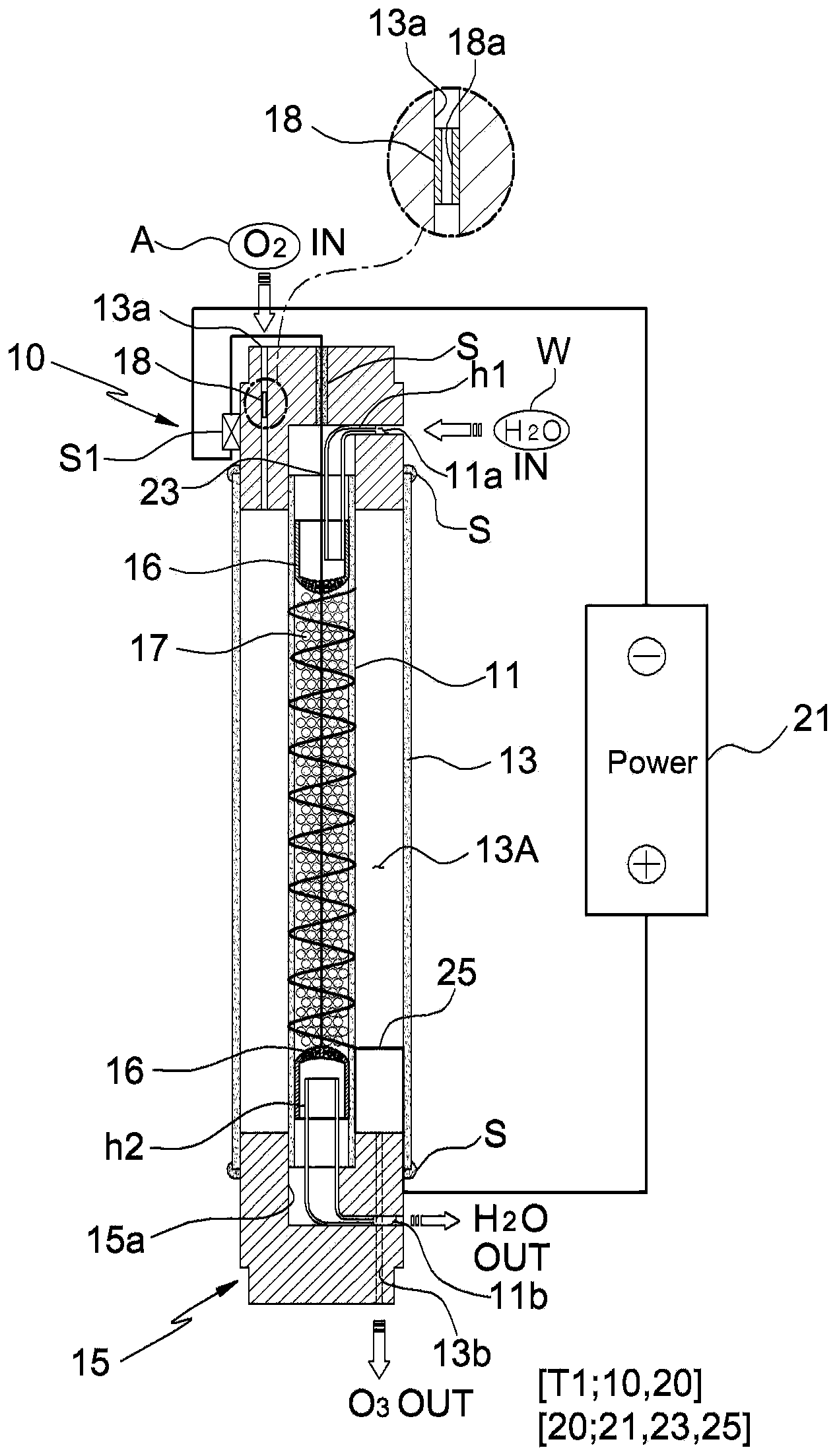

Plasma advanced water treatment apparatus

InactiveCN103429538AImprove work efficiencyReduce resistanceWater/sewage treatment by irradiationWater/sewage treatment by electrochemical methodsEngineeringFree-radical reaction

The present invention relates to a plasma advanced water treatment apparatus which removes coliform bacillus or various bacteria using plasma discharge and also removes various non-biodegradable organics through a radical generating source such as ozone. The plasma advanced water treatment apparatus includes: a double pipe having a first passage for water to be treated and a second passage for radical reaction gas, which are separated from each other; a plasma generation unit including electrodes arranged in each of the first and second passages of the double pipe and a power source part connected to the electrodes; and a water tank connected to the double pipe to provide a space in which the water to be treated and the radical generation source react with each other.

Owner:JARWON ELECTRONICS +1

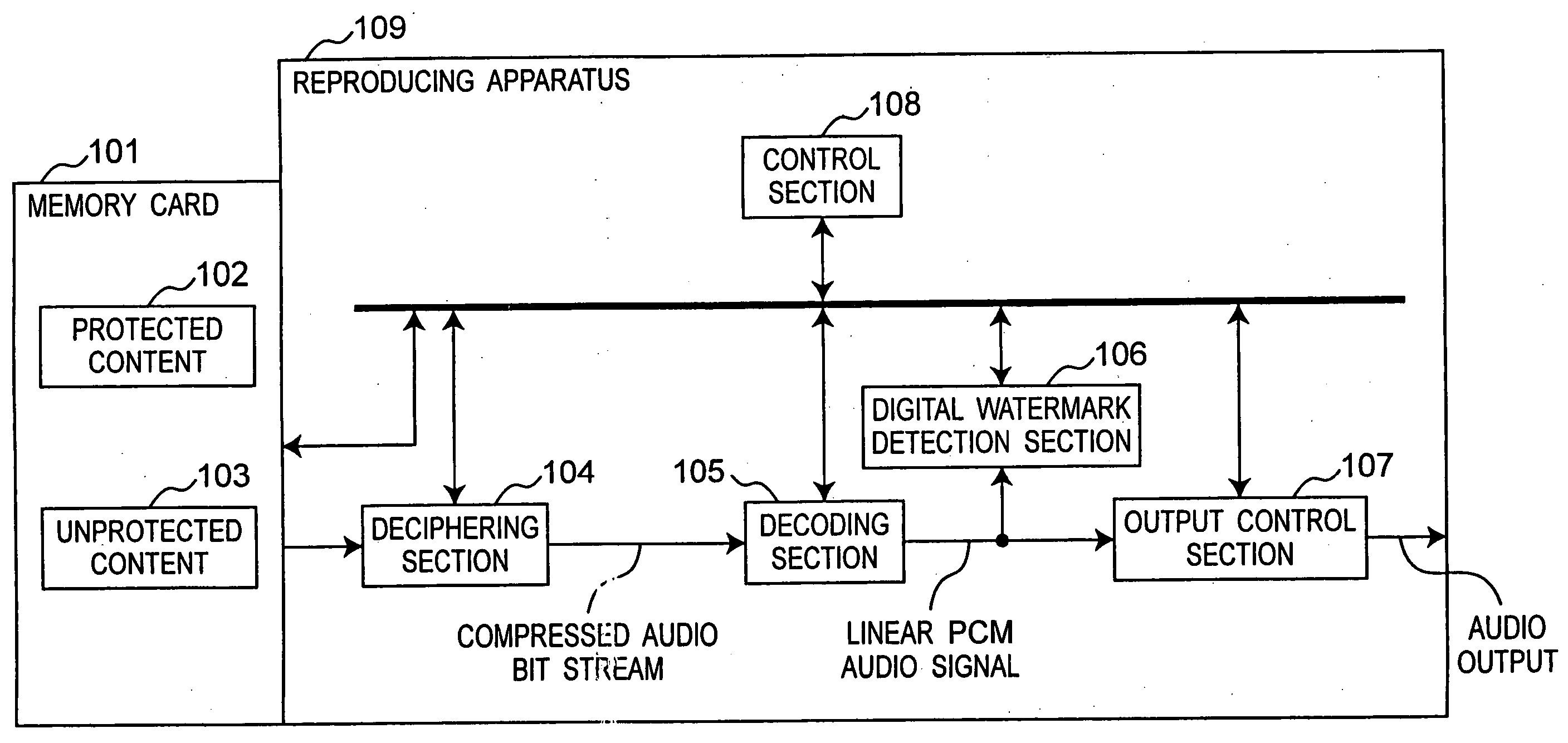

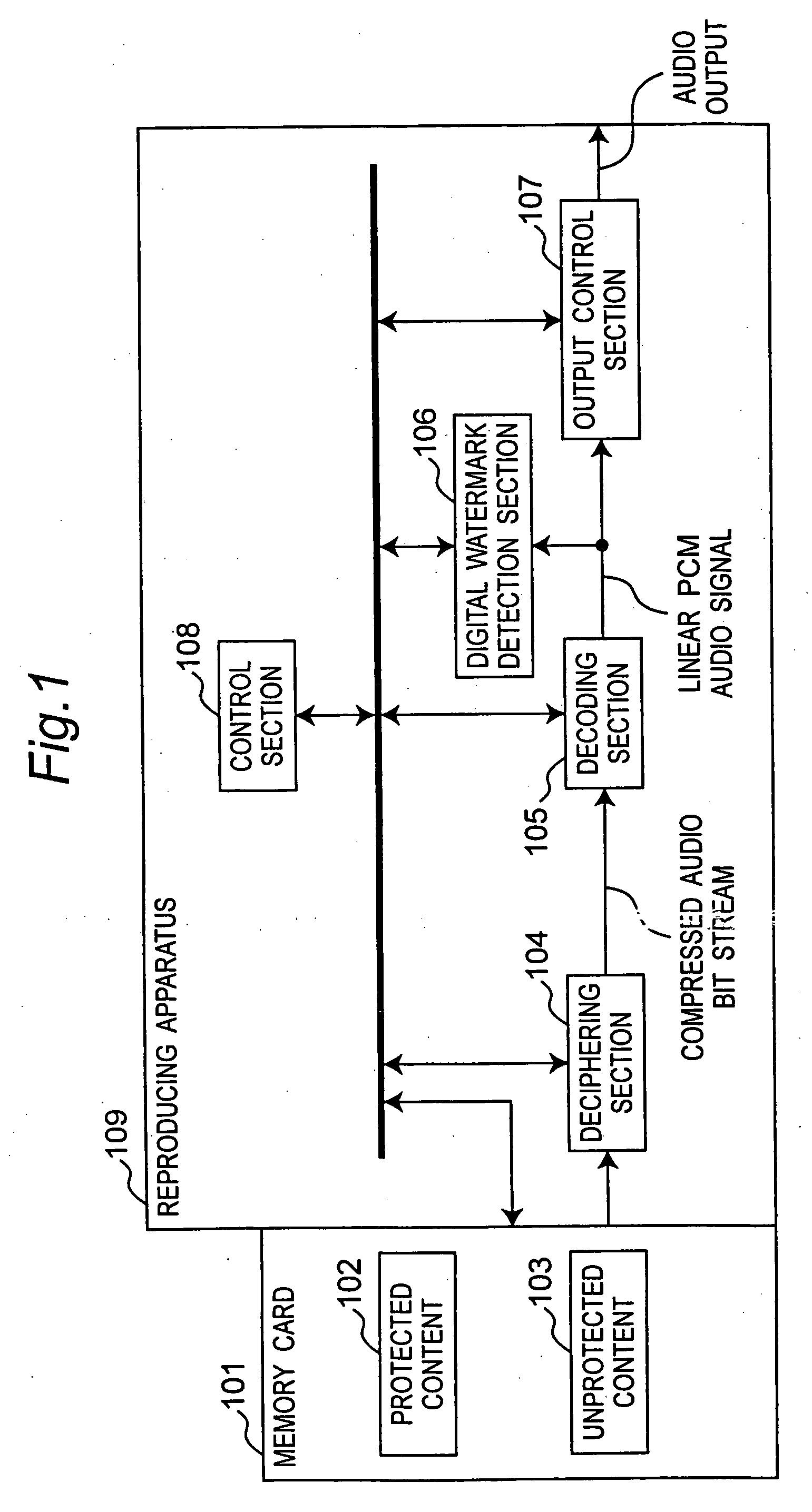

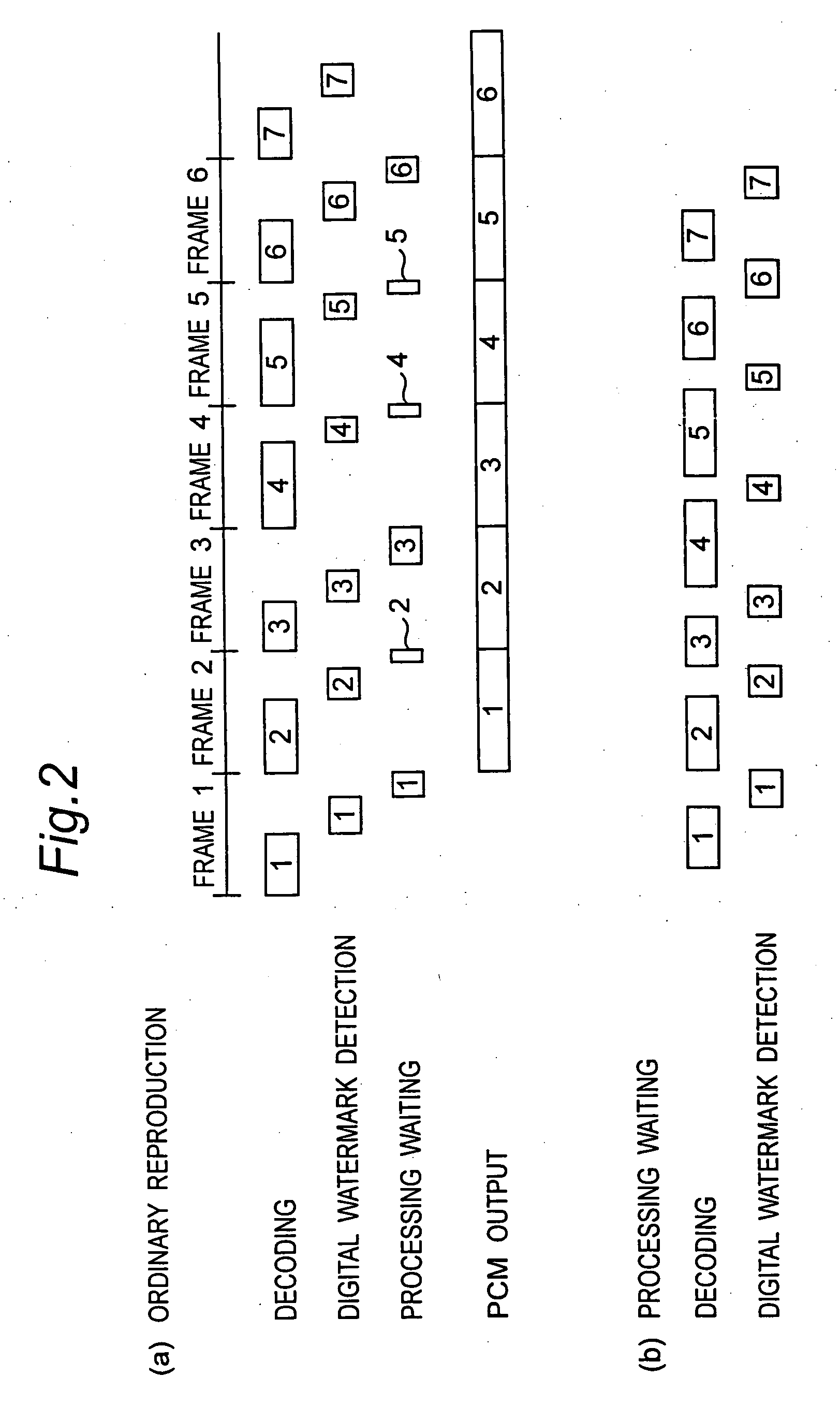

Reproducing method and reproducing apparatus

InactiveUS20070140078A1Improve efficiencyEasy to handleTelevision system detailsRecord information storageComputer hardwareComputer science

In an apparatus that carries out reproduction control on the basis of digital watermark information embedded in a content, for the purpose of providing a reproducing apparatus and a reproducing method in which reproduction stoppage in the middle of reproduction according to the detection result of the digital watermark information does not occur, the reproducing apparatus and the reproducing method are configured so that before reproduction the detection section thereof detects attached information embedded in a content that is recorded on a recording medium, so that the content and the attached information that is detected using the detection section are stored in the storage section thereof so as to be related to each other, and so that the reproduction of the content corresponding to the attached information stored in the storage section is controlled according to the attached information.

Owner:PANASONIC CORP

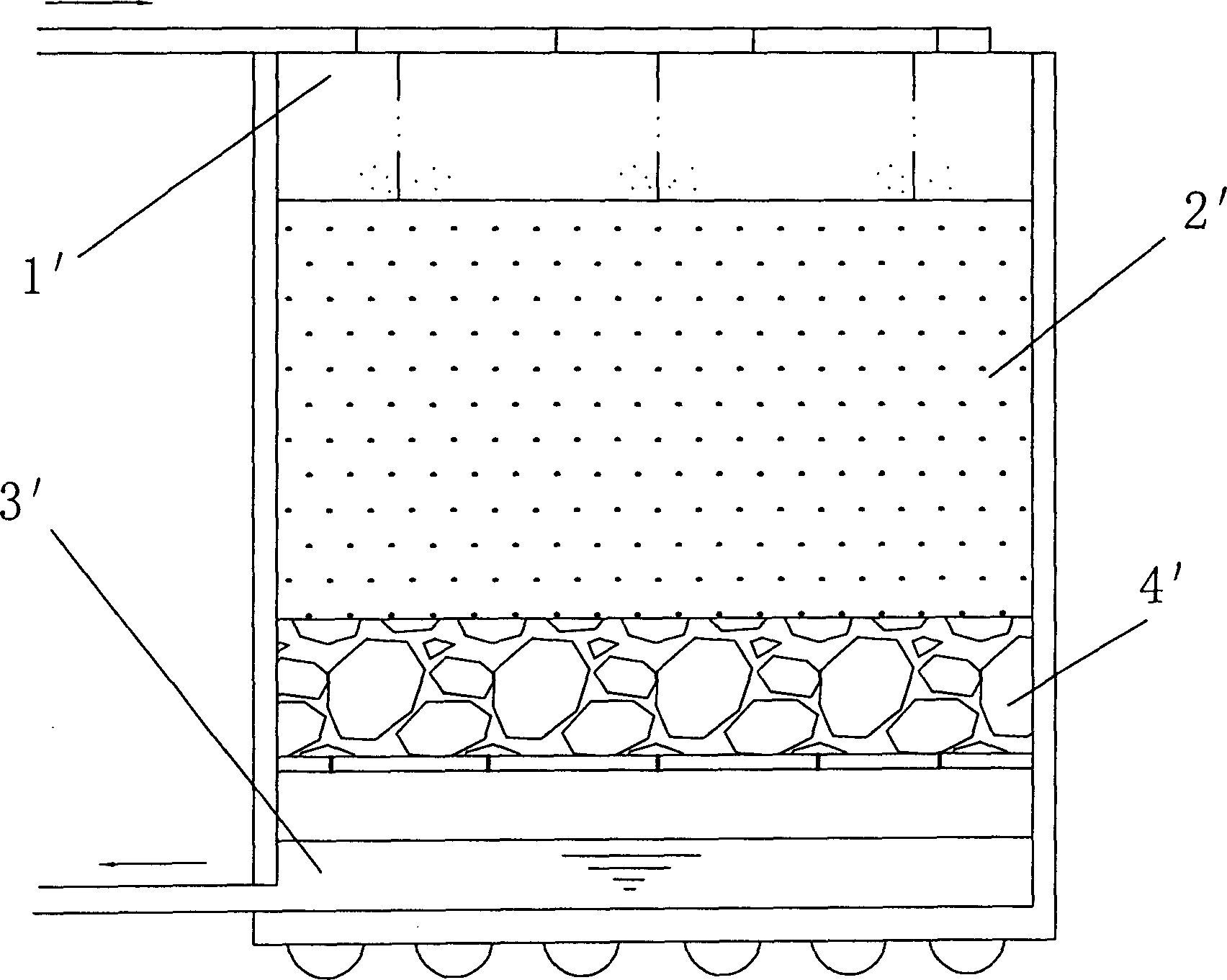

Method of carrying out sewerage treatment by using zoology filter cell and earthworm tower type zoology filter cell

InactiveCN1562812AEasy to handleHigh removal rateMultistage water/sewage treatmentBiological water/sewage treatmentSewageEngineering

The method of sewage processing has high nitrogen-phosphorus disloading ratio. It includes following process steps: pretreatment is to make sewage will be processed pass through grille to get rid of impurities; precipitating treatment is to do precipitating to the pretreated sewage in sedimention tank to get rid of grits; ecological filtering treatment is to send the sewage precipitation processed into worm lizard tower-type ecological filter to make the processed sewage reaching standard.

Owner:NANJING UNIV

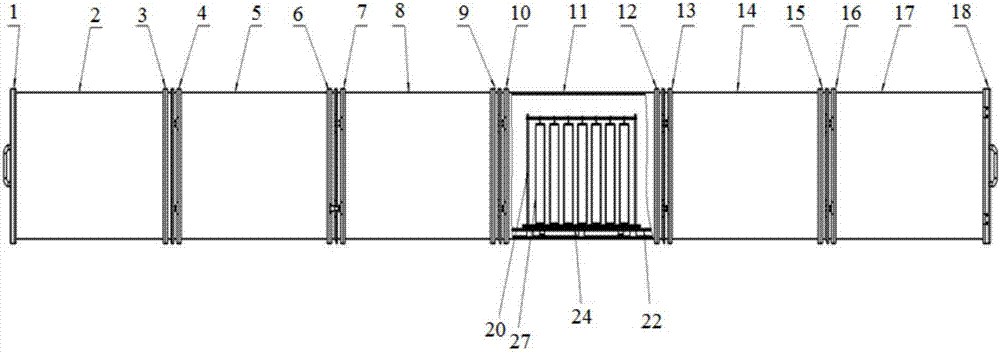

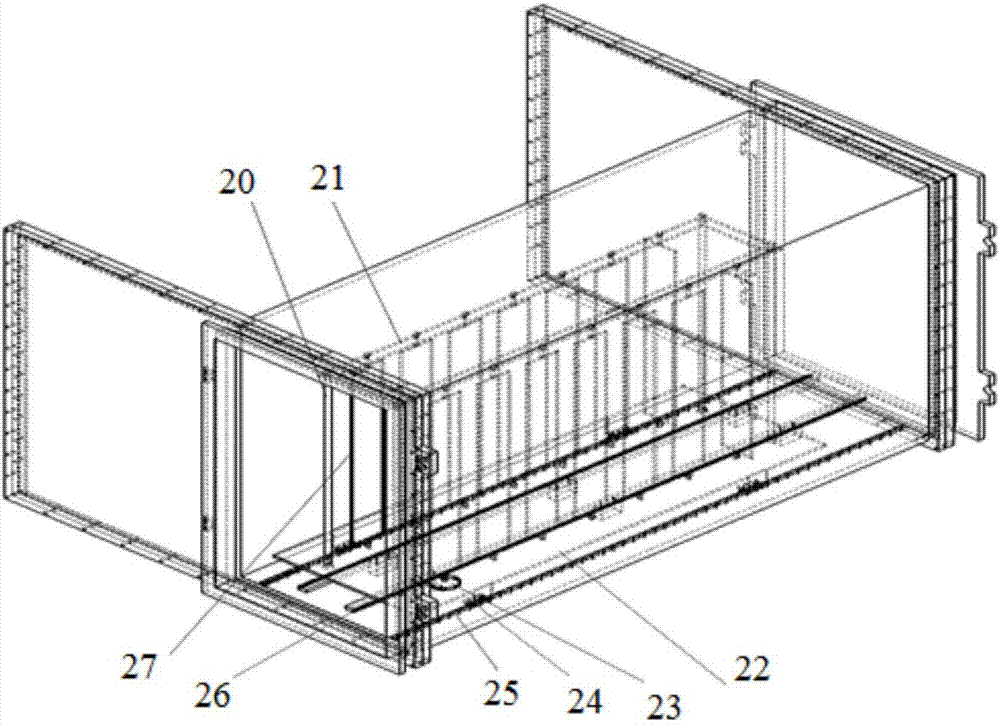

Fuel cell metal polar plate vacuum coating flow-line equipment and coating method thereof

ActiveCN107058970AReduce uplinkLess upliftVacuum evaporation coatingSputtering coatingFuel cellsConductive coating

The invention relates to fuel cell metal polar plate vacuum coating flow-line equipment and a coating method thereof. The flow-line equipment comprises a vacuum cavity set, a support, a transmission mechanism and a PLC control system, wherein the vacuum cavity set comprises a furnace-entering cavity, a front processing cavity, a first coating cavity, a second coating cavity, a back processing cavity and a furnace-outing cavity which are sequentially connected in a sealed mode and mutually independent, a heating device and an ion source device are arranged in the front processing cavity, the first coating cavity is used for depositing an element layer of a bottom layer for the fuel cell metal polar plate, the second coating cavity is used for depositing a corrosion resistant conductive coating for the fuel cell metal polar plate, and an independent vacuum pump is arranged in each cavity; the support is used for arranging the to-be-handled fuel cell metal polar plate; and the transmission mechanism comprises a flow-line guide rail which sequentially penetrates through the cavities in the vacuum cavity set and a power assembly driving the support to move along the flow-line guide rail. Compared with the prior art, the flow-line equipment is extractive and simple in structure, convenient to install, reliable in maintenance, high in production efficiency and the like.

Owner:SHANGHAI JIAO TONG UNIV

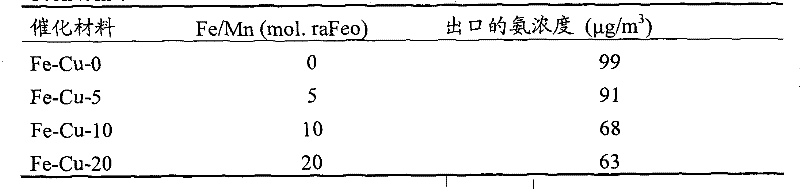

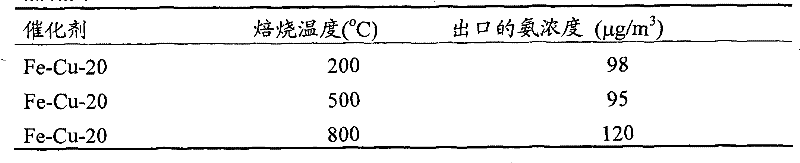

Absorption and Catalytic Decomposition for Ammonia Removal at Low Temperature

InactiveCN102284294AApplicable eliminationImprove moisture resistanceDispersed particle separationCatalyst activation/preparationCatalytic decompositionNitrogen gas

The invention relates to an iron-copper composite oxide catalyst for catalytically removing ammonia at a low temperature and a preparation method thereof, and relates to the fields of catalysis and environmental protection. It is characterized in that zinc oxide is used as carrier and iron-copper composite oxide is used as active component. The characteristics of the monolithic catalyst of the present invention are that it does not require additional energy input such as light, heat and electricity, and can stably reduce ammonia to nitrogen under the conditions of normal temperature, humidity and large air volume.

Owner:SHANGHAI NIUYI NEW ENERGY TECH

Silver-supported nano manganese dioxide catalyst and preparation method and application thereof

InactiveCN102198404BEasy to makeImprove processing efficiencyMolecular sieve catalystsCarbon compoundsMolecular sievePtru catalyst

The invention belongs to the technical field of chemical catalysts, and particularly relates to a silver-supported nano manganese dioxide catalyst and a preparation method and application thereof. The active ingredient of the catalyst is silver-supported doped manganese dioxide molecular sieve (OMS-2) formed by directionally doping metallic silver into nano manganese dioxide molecular sieve pores; and the supporting amount of the metallic silver is 1 to 25 percent. The catalyst can be used for catalyzing oxidation reaction of formaldehyde at a low temperature, and the formaldehyde can be fully oxidized into carbon dioxide and water under the low-temperature condition so as to remove the formaldehyde; the concentration of the formaldehyde is 1.5 to 2,000ppm; and the full catalytic oxidation temperature of the formaldehyde is 0 to 120 DEG C. The catalyst can be used for removing formaldehyde pollutants from closed systems such as vehicles and rooms.

Owner:FUDAN UNIV

Device for feeding container closures

InactiveCN102026905ACompletely processedAvoid formingClosing machinesCapsEngineeringMechanical engineering

Owner:GEA PROCOMAC

Method for removing surface and impurities of quartz ore

The invention provides a method for removing the surface and impurities of quartz ore. The method comprises the following steps: firstly, placing crushed stones into a plastic storage bin and closing the plastic storage bin; then adding an acid solution which is heated to 50-110 DEG C and has the concentration of more than 25% by mass percent into the storage bin through a pipeline; producing an acid gas through an atomizer; recovering the acid gas and the acid solution after the high-temperature acid gas and the acid solution react with the surface and impurities of quartz stone in the closed storage bin, and washing the crushed stones with water; obtaining clean quartz stone, neutralizing waste water generated by washing the crushed stones with alkali or lime, and performing cyclic utilization or standard emission. The method provided by the invention is simple in process, high in efficiency, low in cost, good in effect, free from environmental pollution and suitable for wide popularization and application.

Owner:王林

Method and apparatus for desolvating flowing liquid

ActiveUS8695813B2Quick releaseAvoid contactParticle separator tubesIon-exchanger regenerationTemperature controlTemporal resolution

Methods and apparatus for desolvating flowing liquid streams while retaining temporal resolution of dissolved substrates are disclosed. A novel small-scale self-regulating spray dryer preserves temporal resolution while desolvating a liquid chromatography eluent stream and depositing the solute onto an optical surface for infrared spectrographic analysis. The liquid eluent is pumped through a heated nebulizer to create a high-speed jet of solute containing liquid and solvent vapor. This jet is directed circumferentially inside a hot cylindrical cavity. Centrifugal force causes the larger liquid droplets to travel along the outer diameter of the cavity. The cavity surface is heated to cause the droplets to film boil. Film boiling reduces droplet contact with the cavity surface thereby retaining the solute in the droplets. The solute temperature is limited by controlling the pressure into which the solvent evaporates from the droplets. When the droplets are sufficiently small, Stokes drag from the exiting solvent vapor carries the droplets out through the center of the cylindrical cavity. After exiting, the superheated solvent vapor further dries the droplets. Solvent vapor is removed by condensation onto a cooled surface. A freezing point reducing agent may be added to improve removal of solvent condensate. Stokes drag from a non-condensable gas maintains the dried droplets in suspension. This suspension travels through an orifice that focuses the impaction of the dried droplets onto the optical surface for infrared analysis. The deposition surface is in an evacuated chamber and is temperature controlled to freeze liquid solutes yet allowing sublimation of residual solvent.

Owner:SPECTRA ANALYSIS INSTR

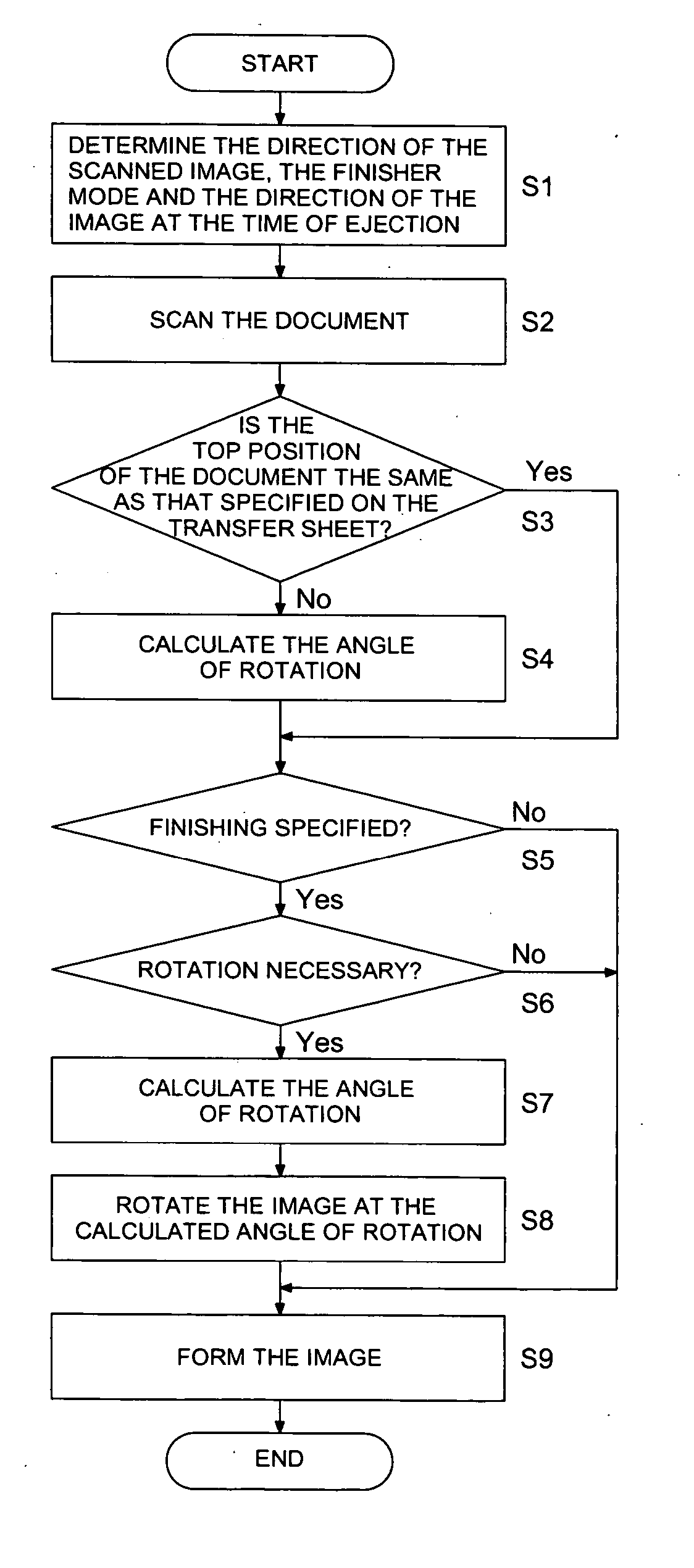

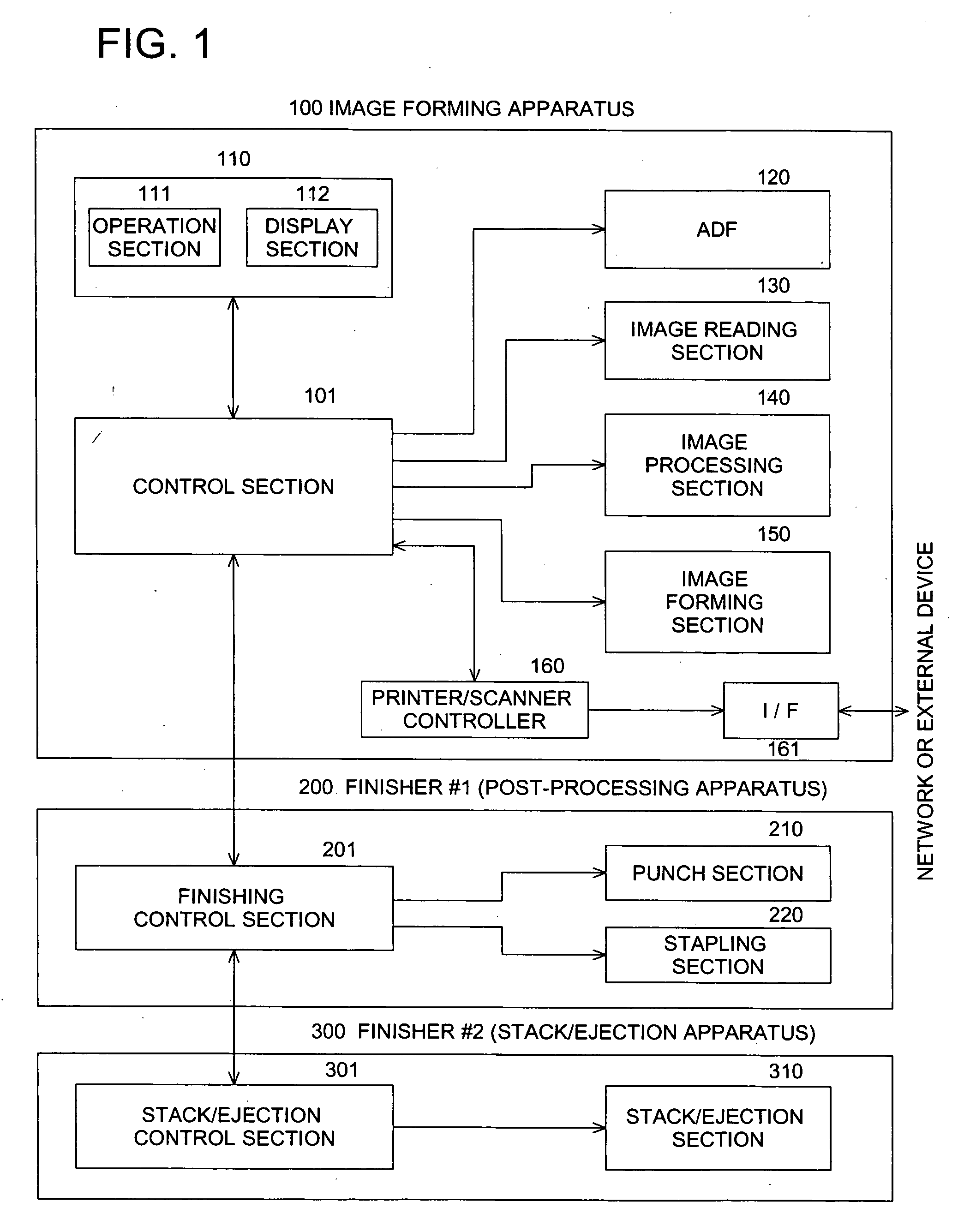

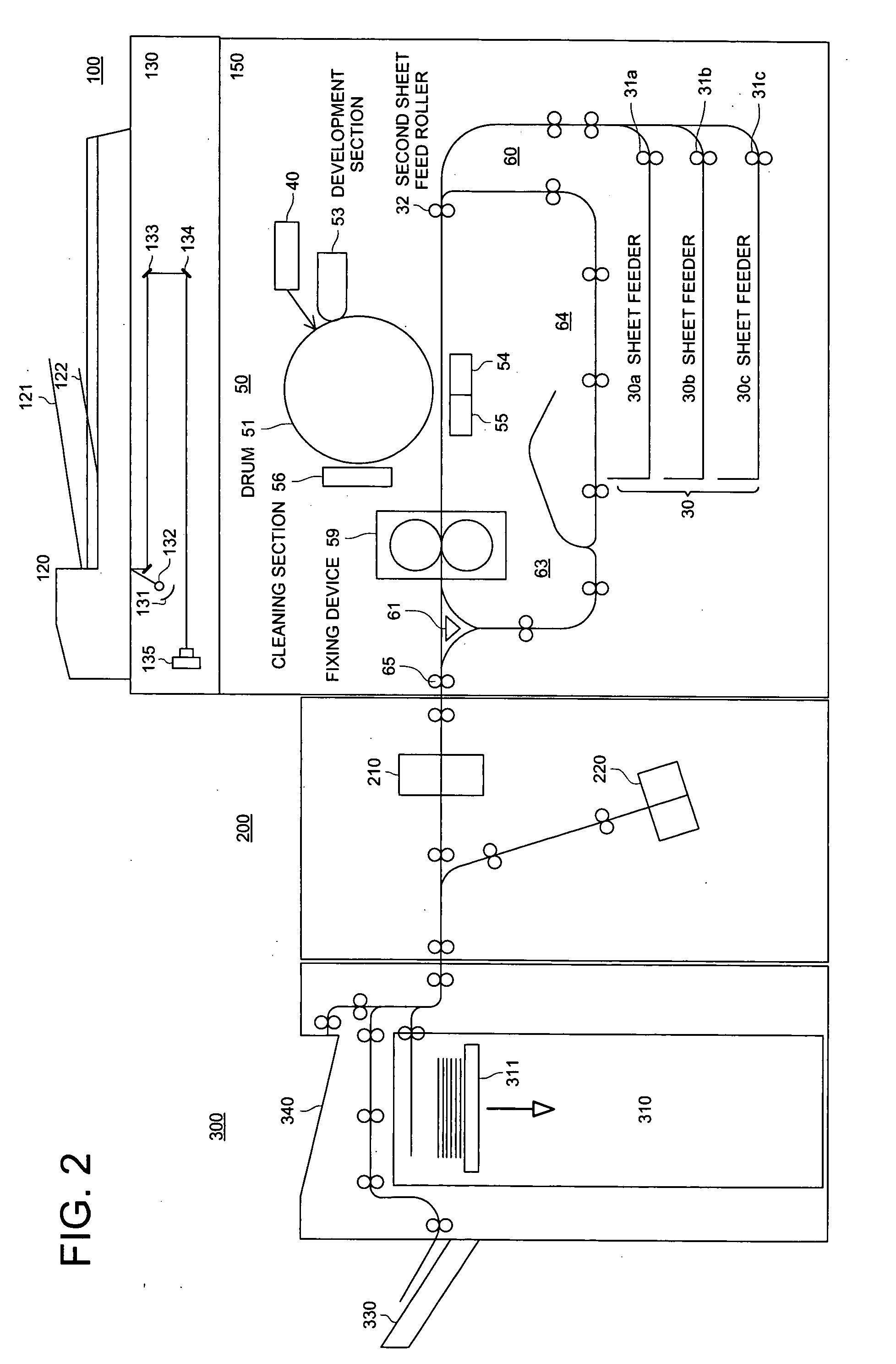

Image forming method and image forming apparatus

ActiveUS20050158068A1Easy to disassembleCompletely processedGeometric image transformationElectrographic process apparatusData controlImaging processing

There is described an image forming apparatus combined with a finisher for applying finish processing such as stapling. The image-forming apparatus includes: a reading section to read an original image so as to generate image data of the original image; a designating section to designate a first direction of the original image to be read by the reading section and a second direction of an output image to be ejected; an image-processing section to apply image-processing, which includes an image-rotation processing, to the image data so as to generate processed image data; a controlling section to control a rotation angle to be employed for rotating the image data by the image-rotation processing, referring to the first direction and the second direction, so that a direction of the output image coincides with the second direction; and an image-forming section to form the output image based on the processed image data.

Owner:KONICA MINOLTA BUSINESS TECH INC

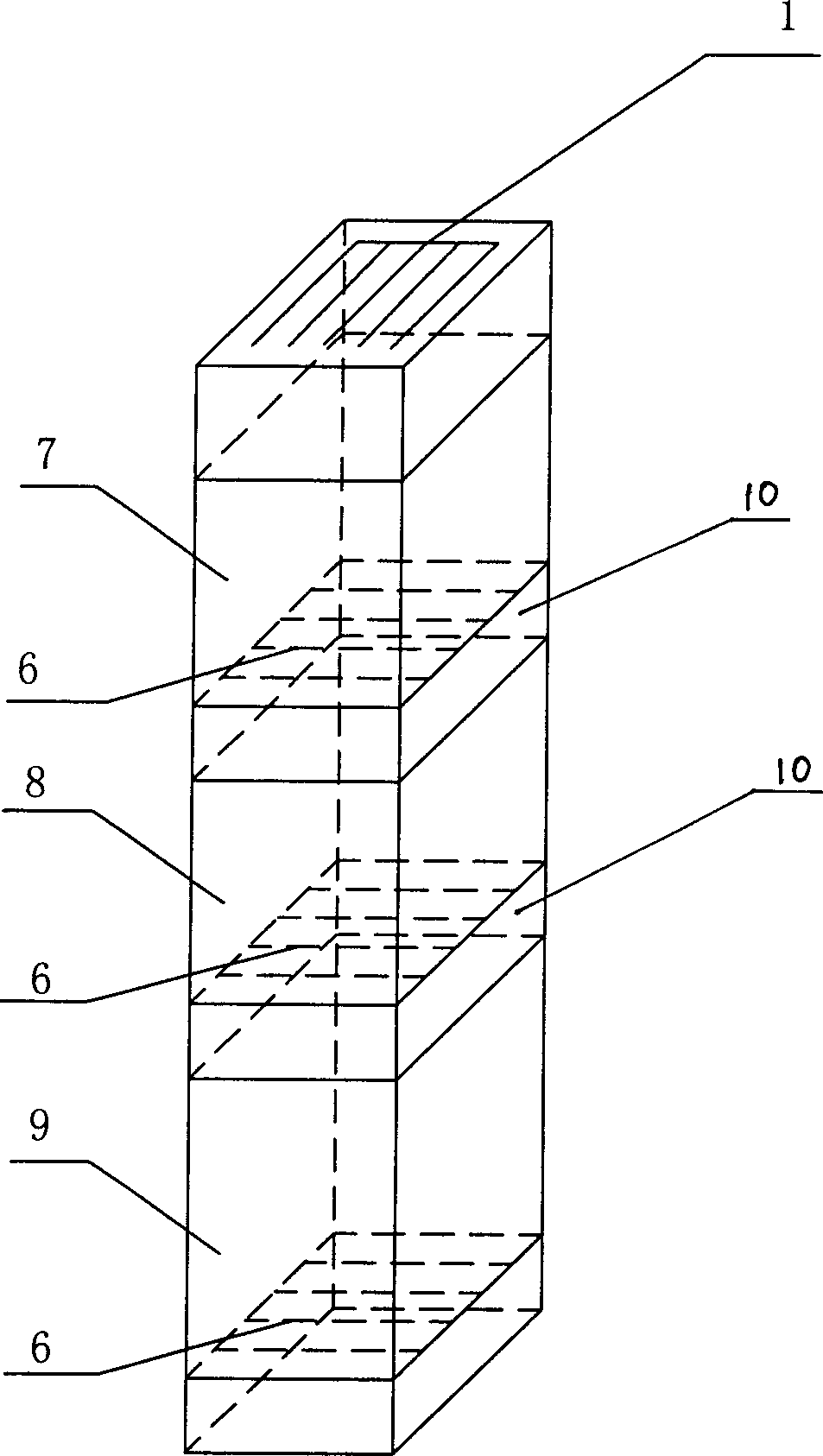

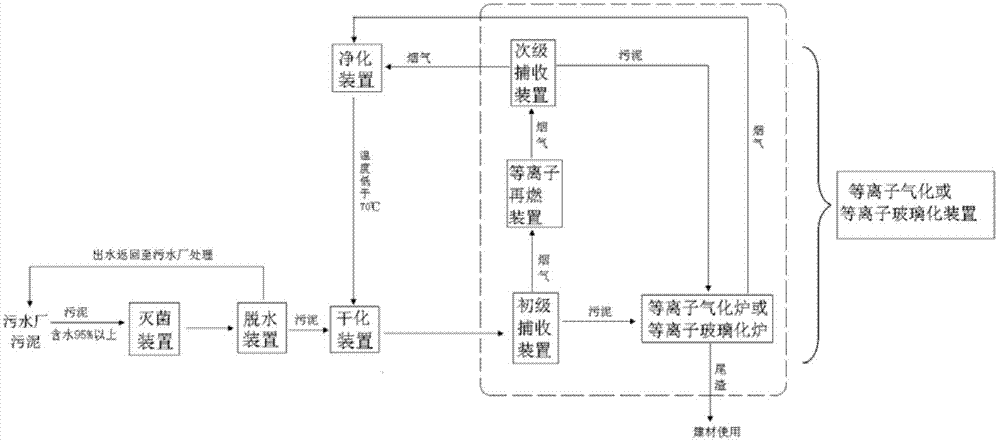

Sludge treatment process and system

ActiveCN104261645AComplete workmanshipReduction and RecyclingSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisWater contentChemistry

The invention discloses a sludge treatment process which comprises the following steps: (1) sterilizing sludge so as to kill microorganisms in the sludge; (2) dewatering and drying the sterilized sludge so as to reduce the water content of the sludge; (3) separating the dried sludge, carrying out high temperature plasma treatment on the separated sludge, and burning separated smoke; (4) carrying out sludge-smoke separation on smoke generated by reburning treatment, carrying out high temperature plasma treatment on the separated sludge again, and purifying and cooling the separated smoke. The invention further discloses a sludge treatment system capable of carrying out the sludge treatment process. The sludge treatment system comprises a sterilizing device, a dewatering device, a drying device, a plasma gasifying or plasma vitrifying device and a purifying device. The sludge treatment system can realize harmless, reducing and resourceful treatment for the sludge and does not generate secondary pollution, is safe and reliable, and can realize thorough treatment for the sludge.

Owner:山东博润环保科技有限公司

High efficiency fluid separation device

ActiveUS9630126B1Maximize retention timeEasy to separateLiquid degasificationNon-miscible liquid separationEngineeringDistributor

A gun barrel tank for treating raw crude oil mixtures. The fluid mixture enters through a degassing boot where gas is separated from the liquid. The liquid travels through a central column to a horizontal hydraulic distributor located in the lower area of the tank, first entering a central distributor trough, then passing into open bottom horizontal inverted lateral troughs and finally out through a plurality of metering orifices provided near the top edges of the lateral troughs to provide uniform distribution of the liquid in the tank. A circular oil collection trough provided at the top of the tank has a plurality of V-shaped notches on its top edge over which oil flows into an oil collection trough to provided uniform collection of the separated crude. A circular water collector in the bottom of the tank removes separated water, and solids are removed from the bottom of the tank.

Owner:KBK IND

Waste gas and wastewater treatment system for electroplating industry

ActiveCN105920964ACompletely processedEmission complianceCombination devicesGas treatmentWater treatment systemEmission standard

The invention discloses a waste gas and wastewater treatment system for electroplating industry. The waste gas and wastewater treatment system comprises a waste gas treatment part and a wastewater treatment part and is characterized in that an air suction hood of a hood structure is arranged at the upper end of an electroplating workshop, provided with an air outlet and connected with a waste gas pipeline through the air outlet, a valve structure is arranged at the lower end of the electroplating workshop, and the electroplating workshop is connected with a waste water discharge pipeline through a valve. By the waste gas and wastewater treatment system, the waste gas treatment of the electroplating industry is allowed to conform to national emission standards, the heavy metal ion emission of the electroplating industry conforms to national standards, and environment quality is improved.

Owner:太仓市顺邦防腐设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com