Sludge treatment process and system

A technology for sludge treatment and treatment process, which is used in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. problems, to achieve the effect of reduction and resource processing, low operating costs, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

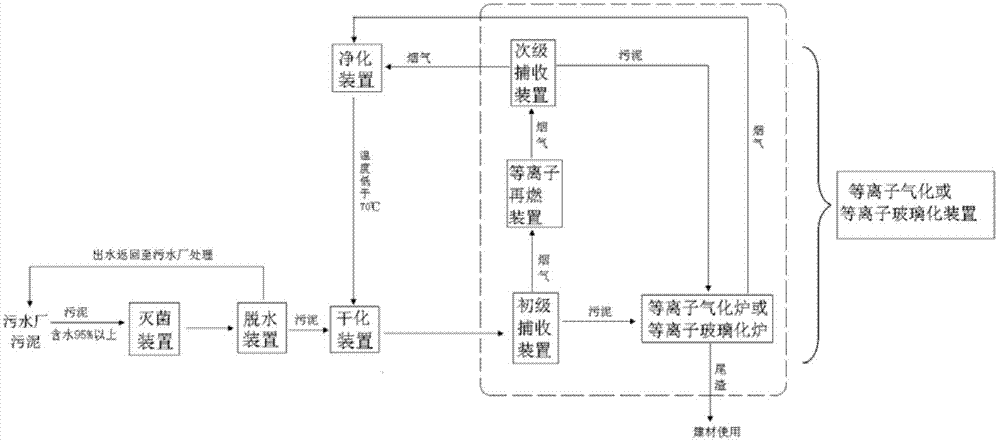

[0024] as attached figure 1 As shown, the sludge treatment system of the present invention includes a sterilizing device, a dehydrating device, a drying device, a plasma gasification or plasma vitrification device, and a purification device connected in sequence. The plasma gasification or plasma glass The sterilization device includes a primary collection device, a plasma reburning device, a secondary collection device, and a plasma gasification furnace or a plasma vitrification furnace, wherein the sterilization device can use an ultrasonic generator with a frequency not less than 40 kHz, and its water inlet is connected to the The sludge produced by the sewage treatment plant with a water content of more than 95% is connected, and its effluent enters the dehydration device; the dehydration device can use a mechanical dehydration device su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com