Flue gas desulfurization process for small-sized heating or short-running-cycle boiler

A technology of boiler flue gas and desulfurization process, which is applied in the field of desulfurization and can solve problems such as desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

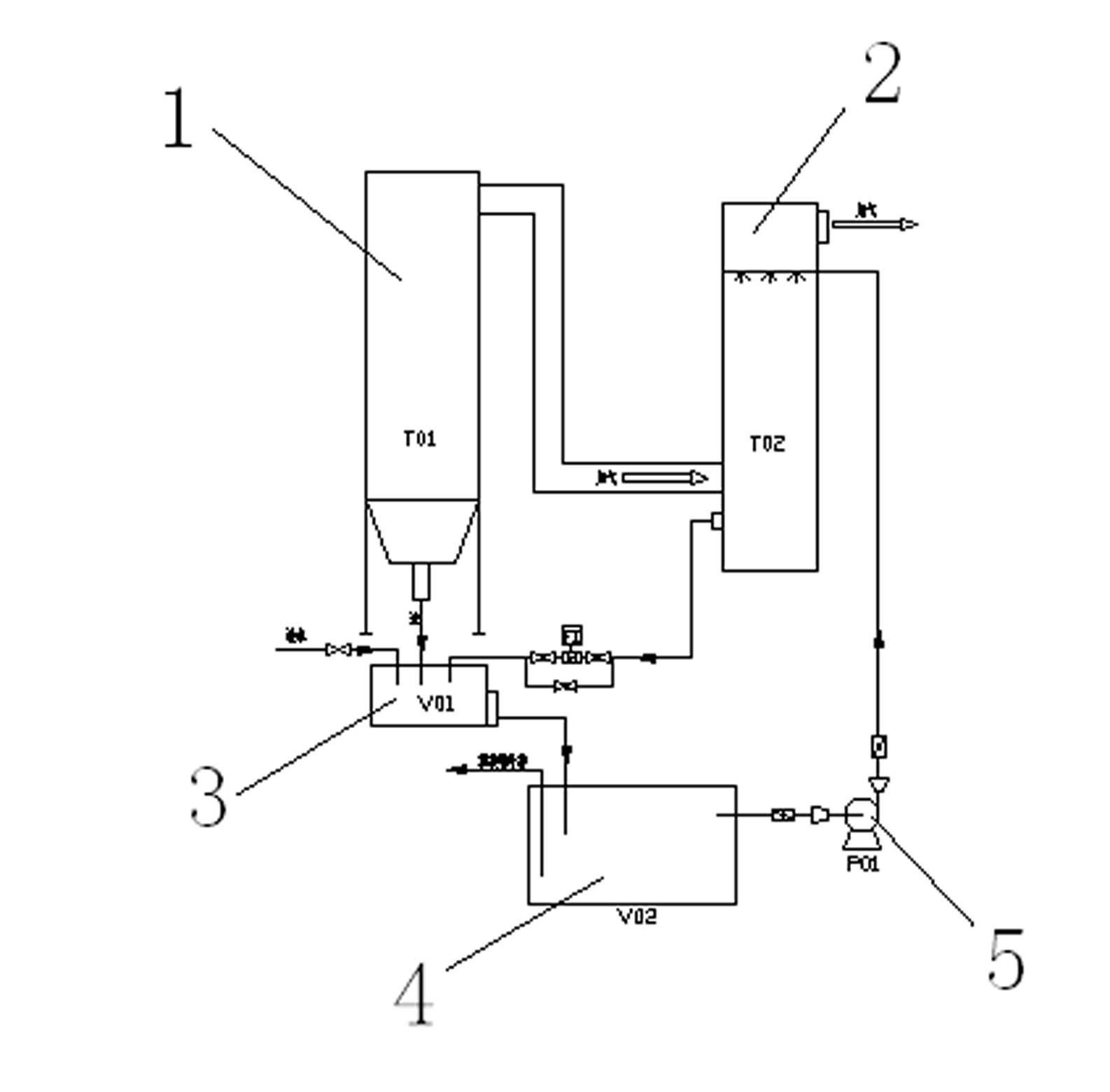

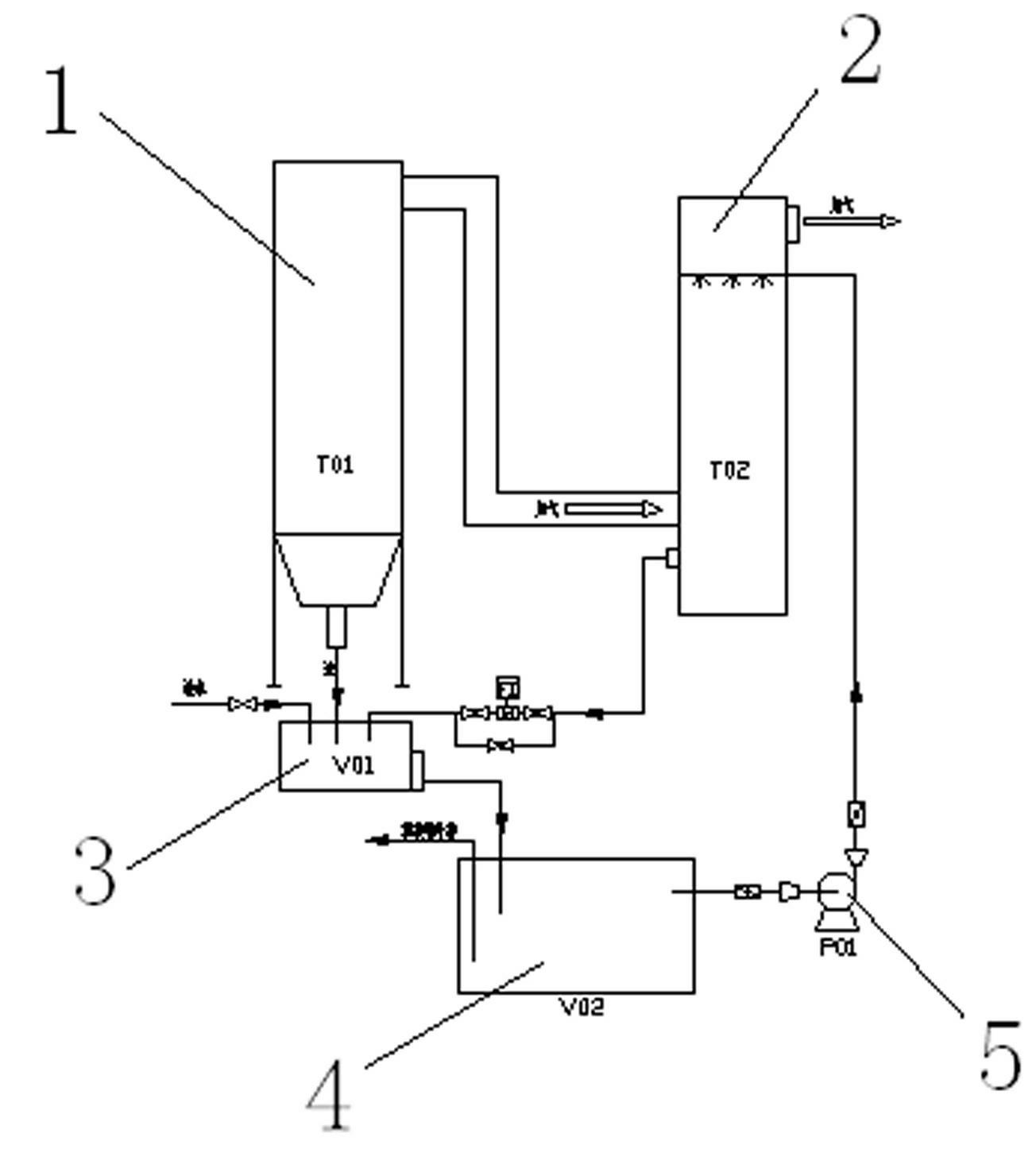

[0023] like figure 1 As shown, taking a 10T boiler as an example, according to the coal consumption of the boiler and the sulfur content in the coal, limestone powder is mixed into the coal and added to the boiler furnace 1 together, and the ratio of calcium to sulfur is 1.3. In furnace 1, sulfur dioxide produced by coal combustion reacts with limestone powder to complete about 80% desulfurization process. The solids generated by the reaction are washed together with the slag into the desulfurization sedimentation tank 4; the remaining 20% sulfur dioxide enters the desulfurization tower 2 along with the flue gas. In the desulfurization sedimentation tank 4, the precipitated slag and the solids produced by the reaction are regularly cleaned out manually or mechanically, and the slurry containing lime in the upper part is pumped into the desulfurization tower 2 through the desulfurization circulating pump 5, and contacts with the flue gas flowing upstream from the lower part ...

Embodiment 2

[0027] Taking a 20T boiler as an example, according to the coal consumption of the boiler and the sulfur content in the coal, limestone powder is mixed into the coal and added to the furnace 1 of the boiler together, and the ratio of calcium to sulfur is 1.4. All the other process operations are the same as embodiment 1, and its detection effect is as follows:

[0028] When directly discharged, the sulfur content at the chimney inlet flue is 2350mg / Nm 2 , after desulfurization:

[0029] Detection position

[0030] The desulfurization efficiency reaches 91%.

Embodiment 3

[0032] Taking a 20T boiler as an example, according to the coal consumption of the boiler and the sulfur content in the coal, limestone powder is mixed into the coal and added to the furnace 1 of the boiler together, and the ratio of calcium to sulfur is 1.4. All the other process operations are the same as embodiment 1, and its detection effect is as follows:

[0033] When directly discharged, the sulfur content at the chimney inlet flue is 2410mg / Nm 2 , after desulfurization:

[0034] Detection position

[0035] The desulfurization rate is 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com