Patents

Literature

99results about How to "Complete workmanship" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Unitary or polybasic aerogel thermal insulation material and preparation method thereof

ActiveCN102584162AGood application effectApplicability is differentThermal insulationSingle component

The invention discloses a unitary or polybasic aerogel thermal insulation material and a preparation method of the material. The method comprises the steps of preparing sol, solidifying sol to form gel, aging and drying, or comprises the steps of preparing sol, preparing a prefabricated body, infiltrating, coagulating sol, aging and drying. The aerogel component in the thermal insulation materialdisclosed by the invention is formed in a unitary or polybasic way, and can be formed by flexibly adjusting a single component, so that the characteristic of aerogel can be given a full play to the greatest extent, the material can be used in different temperature resisting fields, and aerogel formed by different components can be used aiming at the different temperature resisting fields, so thatthe heat insulation effect of the aerogel thermal insulation material can be more high-efficiency. The production and forming method of the unitary or polybasic aerogel thermal insulation material, disclosed by the invention, is a set of technology which is complete, continuous, and low in cost, and can be used in industrial method production, the produced aerogel thermal insulation material withhigh performance is wide in application field, is wide in using temperature, can meet different using requirements of war industry fields, civil fields, heat-protection fields with special requirements, and the like.

Owner:GUANGDONG ALISON HI TECH

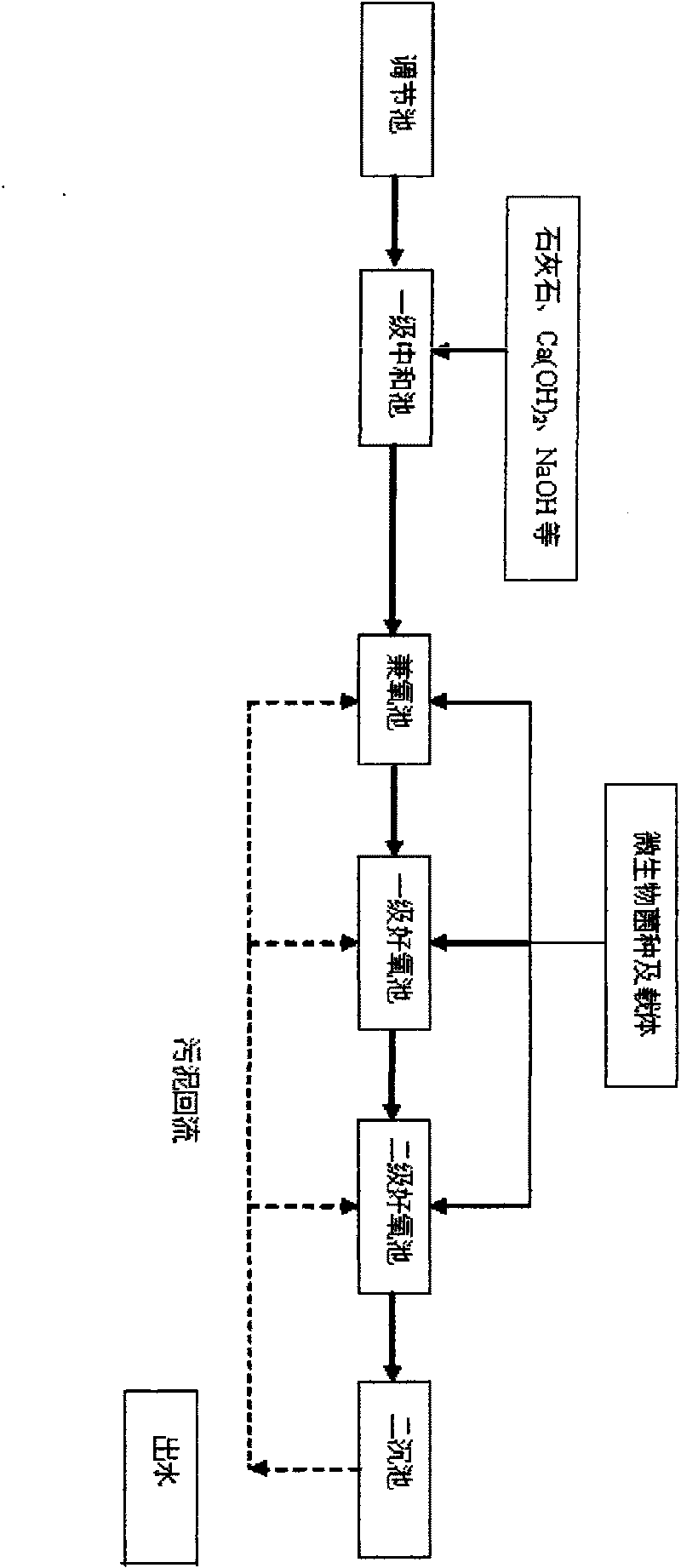

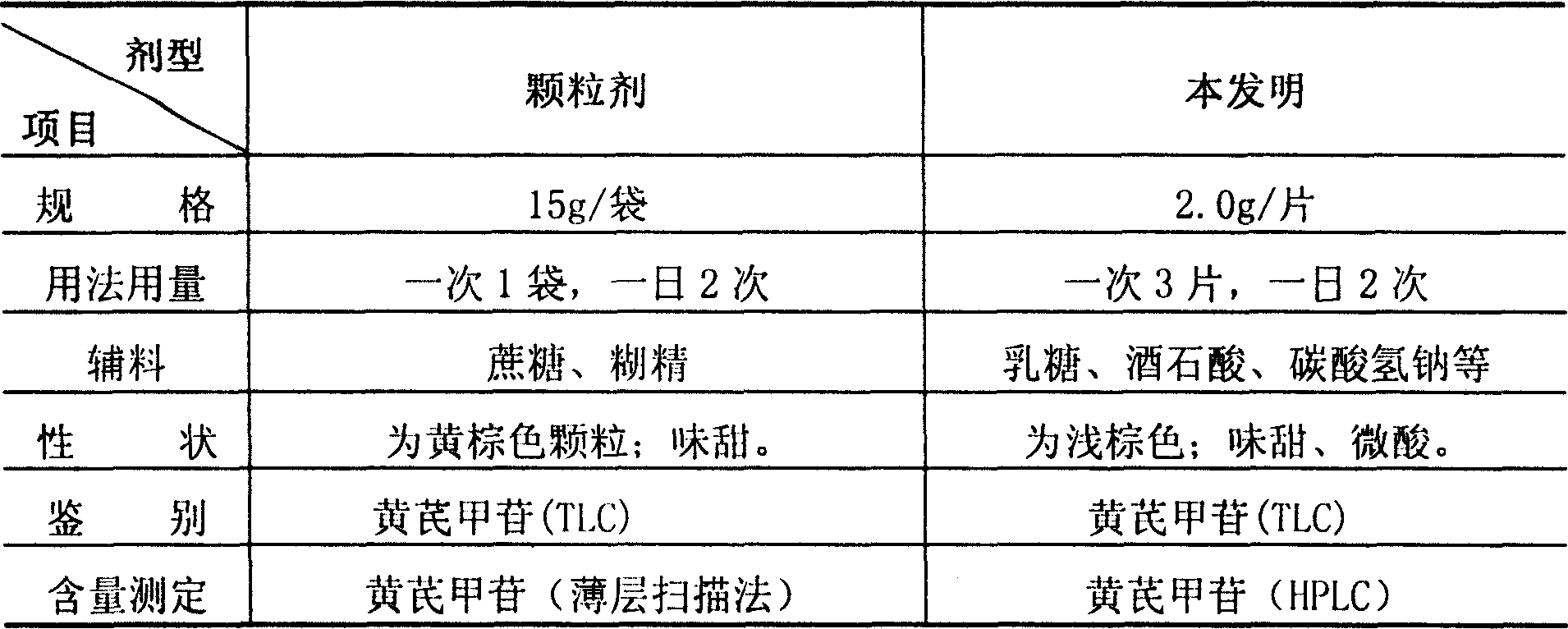

Method for processing organosilicon waste water

ActiveCN101759329AImprove biodegradabilityReduce processing costsWater contaminantsTreatment with aerobic and anaerobic processesElectrolysisWater volume

The invention relates to a method for processing organosilicon waste water. The method optimizes and combines a preprocessing unit and a biochemistry unit, aiming at the properties of high salt and difficult degradation of the organosilicon waste water. The method can process the organosilicon waste water to the second grade standard of integrated wastewater discharge standard (GB8978-1996). The organosilicon waste water is strongly acidic. A preneutralization pool is arranged at the front end of technological process and neutralizes the PH of the waste water to about 1 to 2. The waste water enters a micro-electrolysis reactor which is filled with micro-electrolysis stuffing. The effluent enters a secondary neutralization pool, and water volume and PH value are adjusted further. The waste water enters a biochemistry processing establishment and at last enters a secondary sedimentation tank. The biochemistry processing system of the waste water comprises a primary oxygen compatibility pool, a primary aerobic pool and a secondary aerobic pool. Microbial flora and relative carriers are added to the pools. The invention has the advantages that the processed organic waste water is guaranteed to meet the specified standard and the processing cost is reduced greatly. The win-win solution of economy and environment is realized.

Owner:蓝星环境工程有限公司

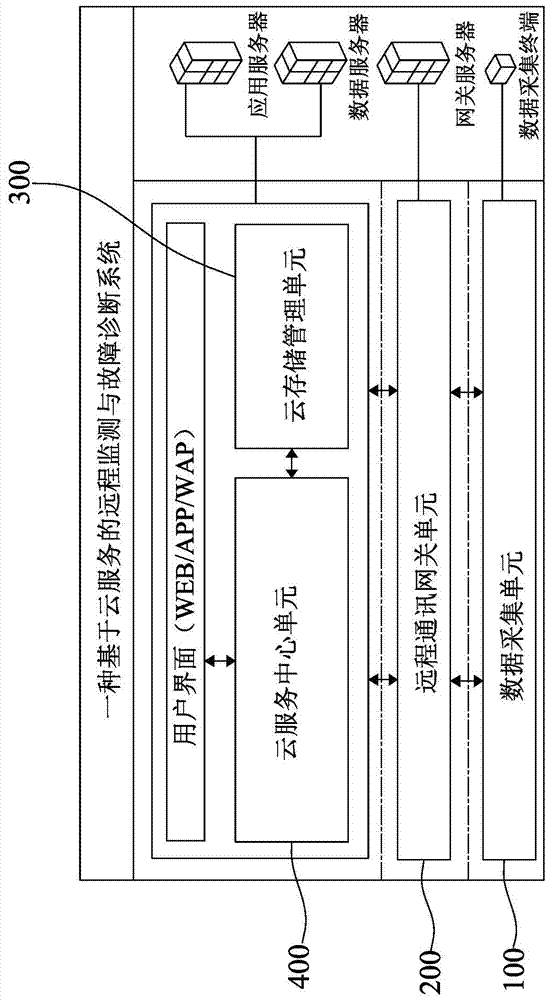

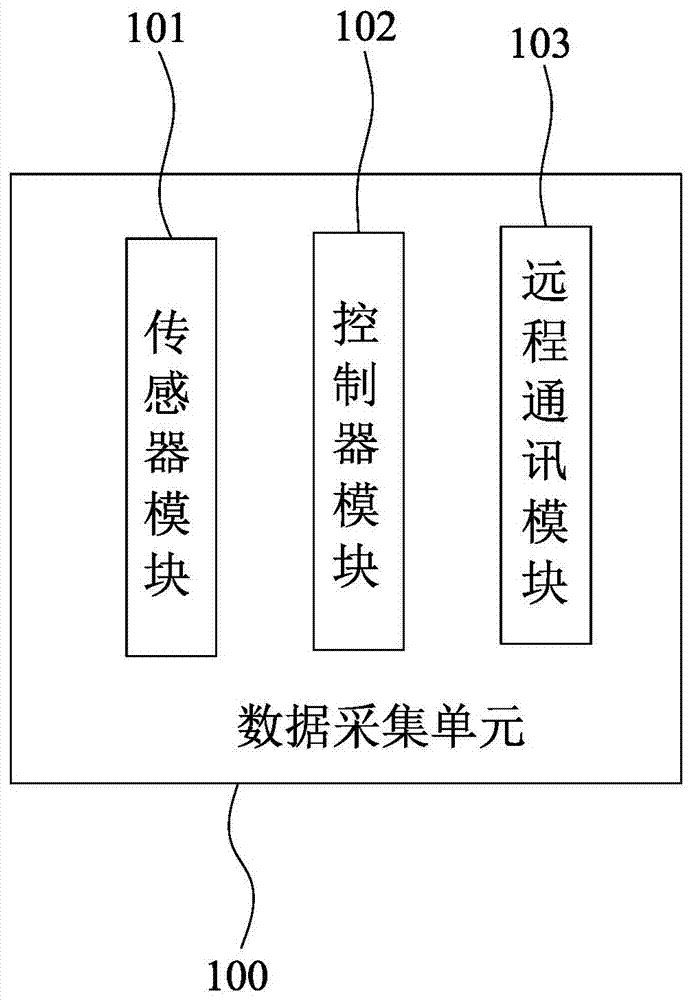

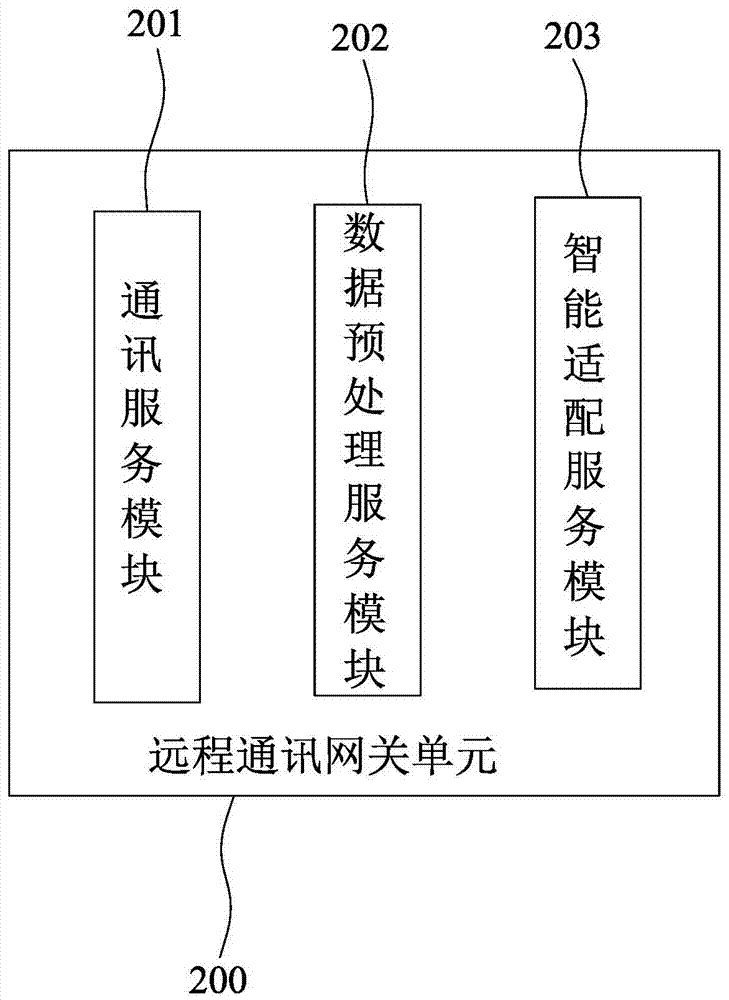

Remote monitoring and fault diagnosis system based on cloud service and fault diagnosis method

ActiveCN107276816AImprove reusabilityEfficient integrationData switching networksApplication serverManagement unit

The invention discloses a remote monitoring and fault diagnosis system based on a cloud service and a fault diagnosis method, and relates to the field of intelligent manufacturing and cloud diagnosis. The remote monitoring and fault diagnosis system comprises a data acquisition unit, a remote communication gateway unit, a cloud storage management unit and a cloud service center unit. The data acquisition unit is deployed on a data acquisition terminal; the remote communication gateway unit is deployed on a cloud front gateway server; the cloud storage management unit is deployed on a cloud data server and the cloud service center unit is deployed on a cloud application server. According to the invention, a BP neural network fault diagnosis method based on genetic algorithm optimization is creatively applied to the remote monitoring and fault diagnosis system, and a remote monitoring and fault diagnosis service suitable for a cross-region environment can be conveniently and rapidly provided; and mechanical equipment remote online working condition monitoring can be provided for technical personnel of equipment manufacturers, and rapid, accurate and efficient diagnosis on a complex fault can be provided for mechanical equipment used by production enterprises.

Owner:厦门嵘拓物联科技有限公司

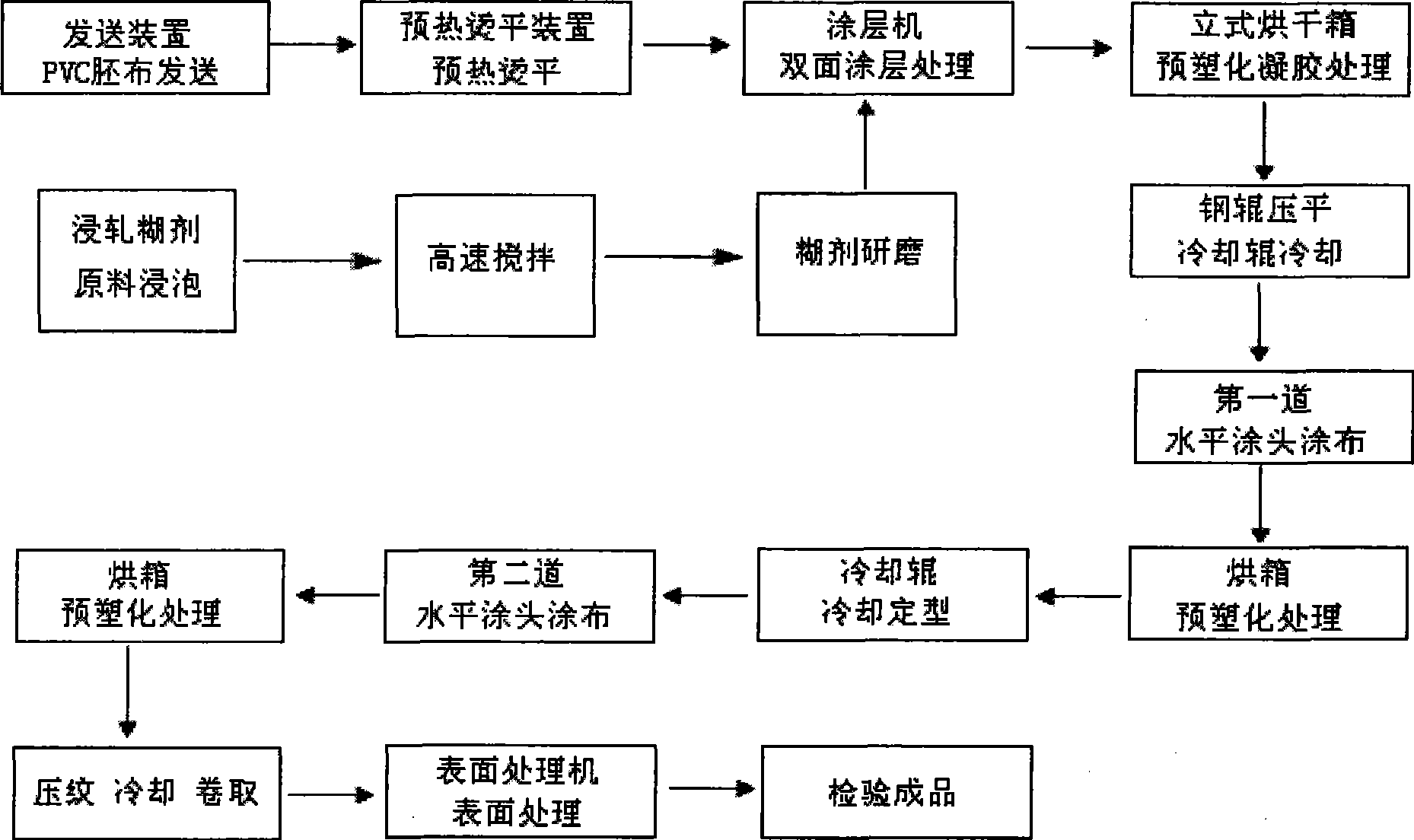

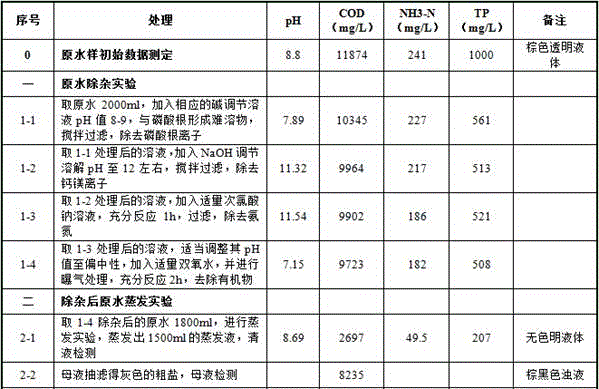

Preparation process for superaqueous surrounding-separating coating material of PVC

InactiveCN101509201AGuarantee processing qualityStay hydratedLiquid surface applicatorsWater cleaningSurface layerEconomic benefits

The invention provides a process for preparing a PVC overwater enclosure coating material, which comprises delivery of PVC grey cloth, preheating and ironing, double-face coating treatment, pre-plasticizing and gelling, planishing and cooling, primary coating of a horizontal coating head, plasticizing treatment, cooling and shaping, secondary coating of the horizontal coating head, plasticizing treatment, embossing, cooling, winding, surface treatment and preparation. The process combines net sandwich cloth coating and surface treatment process, is complete relatively to common coating processing, can process a vertical coating, a surface layer and a bottom layer, reduces the intrusion of ultraviolet rays on the coating by adopting the surface treatment process on the one hand, can prevent plasticizing agent from being transferred to the surface of a product on the other hand so as to achieve the antifouling effect and achieve the aim of self-cleaning by means of rainwater; and the product has good air tightness and superior abrasion-resisting property, is suitable for outdoor application, and has long service life and remarkable economic benefit.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

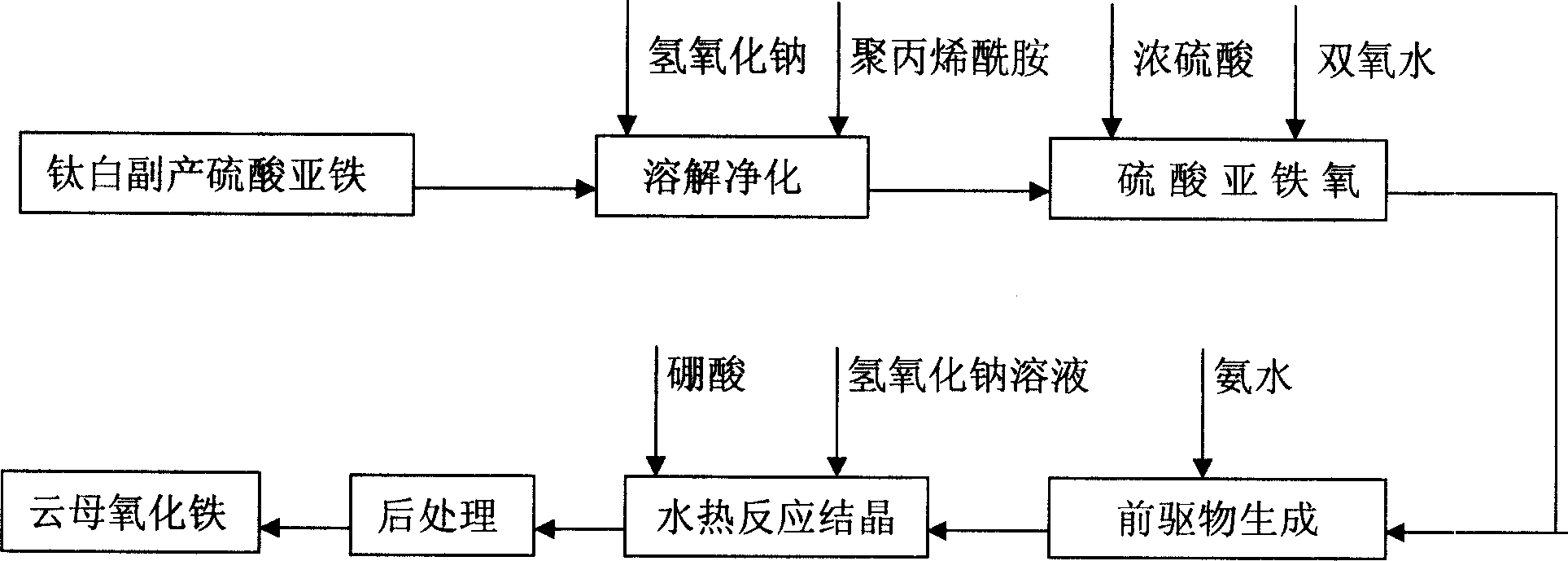

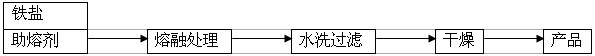

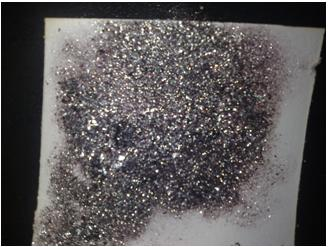

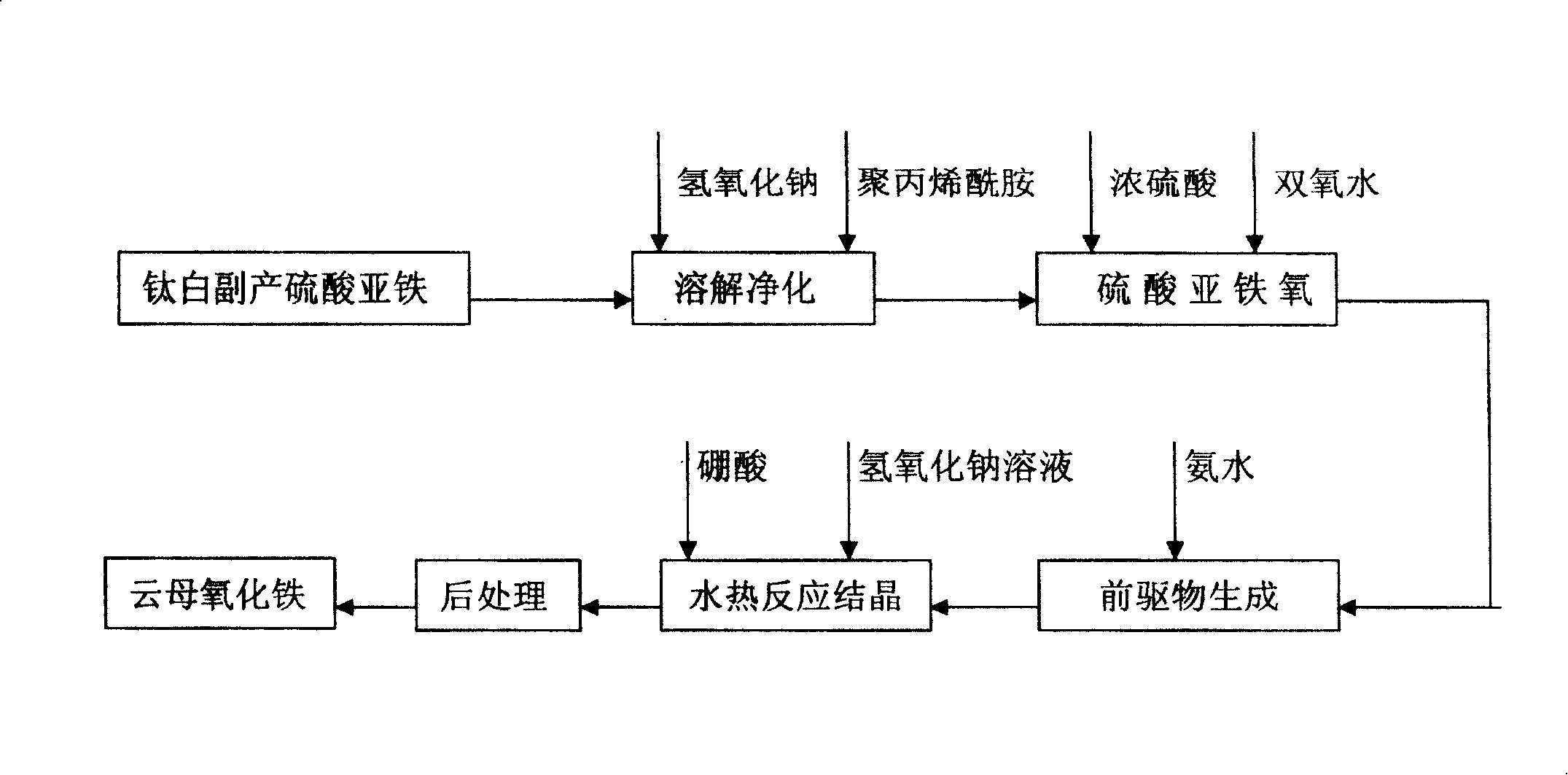

Method for preparing mica iron oxide by hydrothermal reaction and crystallizing

InactiveCN1944274AThe method is simple and reliableComplete workmanshipPigmenting treatmentFerric oxidesSide productBrown iron oxide

The present invention provides preparation process of mica iron oxide with controllable particle size and color. Ferrous sulfate as the side product of titanium white powder production is used as the material, and through dissolving and purifying, oxidation, creating precursor, hydrothermal reaction and crystallization in controlled conditions, and post-treatment, mica iron oxide with controllable particle size and color is prepared. The mica iron oxide product is in regular hexagonal sheet shape and has particle size of 40-180 micron and color regulated through altering the crystal growth promoter adding amount, medium concentration, temperature and time in the hydrothermal reaction and crystallization stage.

Owner:XIANGTAN UNIV

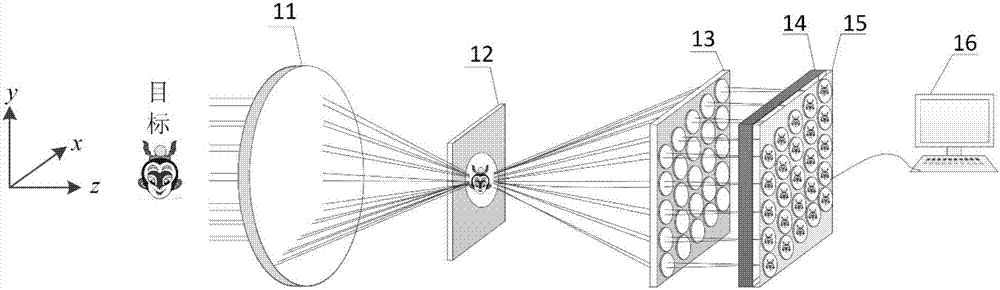

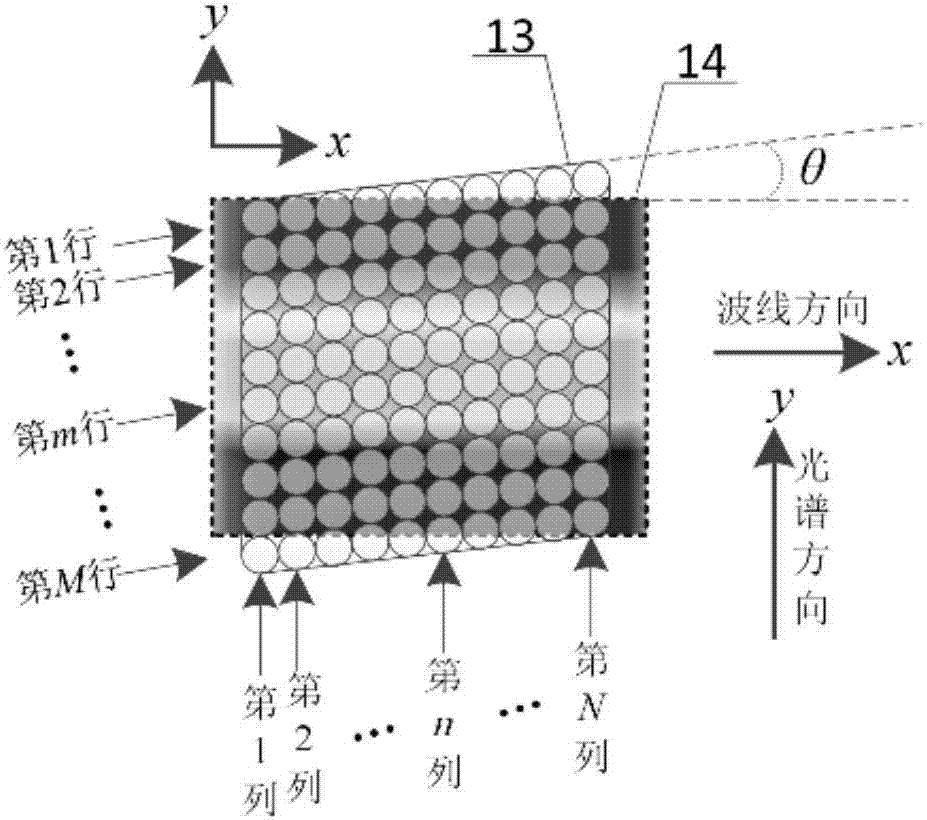

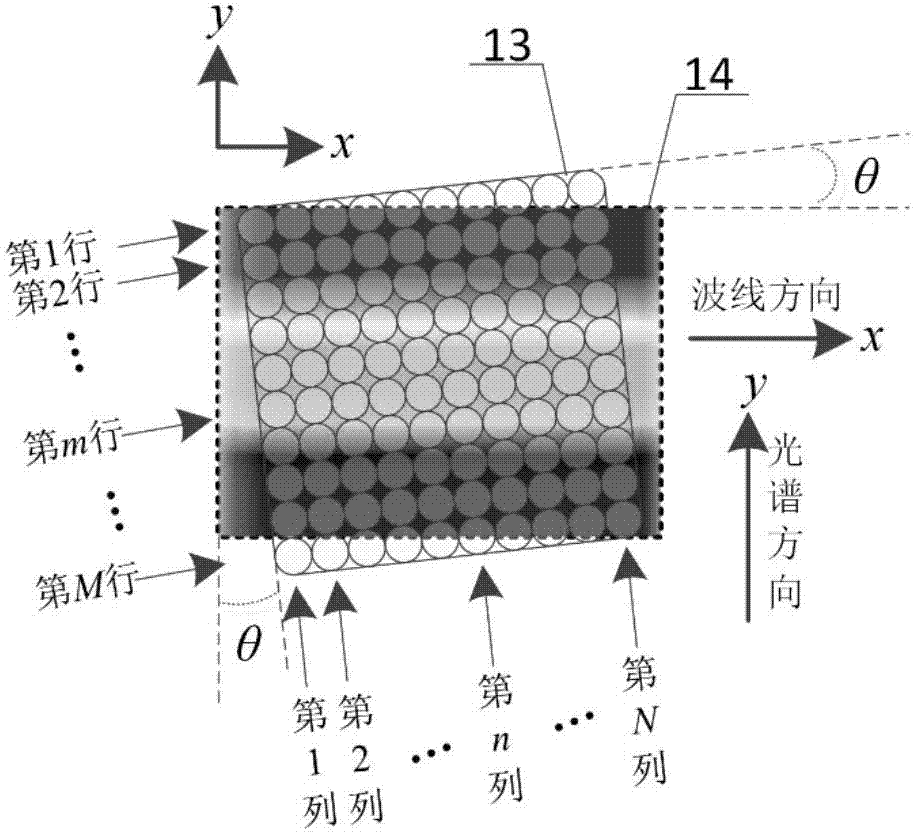

Compact miniature snapshot spectral imaging detection device and detection method

ActiveCN107271039AEffective associationImprove time resolutionSpectrum investigationJitter noiseData acquisition

The invention discloses a compact miniature snapshot spectral imaging detection device and detection method. The device comprises a spectral image replication module and a data acquisition, processing and display system. The spectral image replication module comprises a micro-lens array, linear gradient filters and an area array detector which are arranged along the incident light direction in turn. The linear gradient filters are closely clung to the light sensing surface of the area array detector. The light sensing surface of the area array detector is arranged on the image surface of the micro-lens array and connected with the data acquisition, processing and display system. The arrangement direction of each row of lenses of the micro-lens array and the filtering wave line direction of the same wavelength in the linear gradient filters have an inclined angle. The device is suitable for detecting the spectral image information of a dynamic or fast change target so that the adverse influence caused by target change, jitter noise or environmental change and other factors can be effectively avoided, and the device has potential application value in the field of astronomical observation, space detection, earth remote sensing, machine vision and biomedical diagnosis.

Owner:XI AN JIAOTONG UNIV

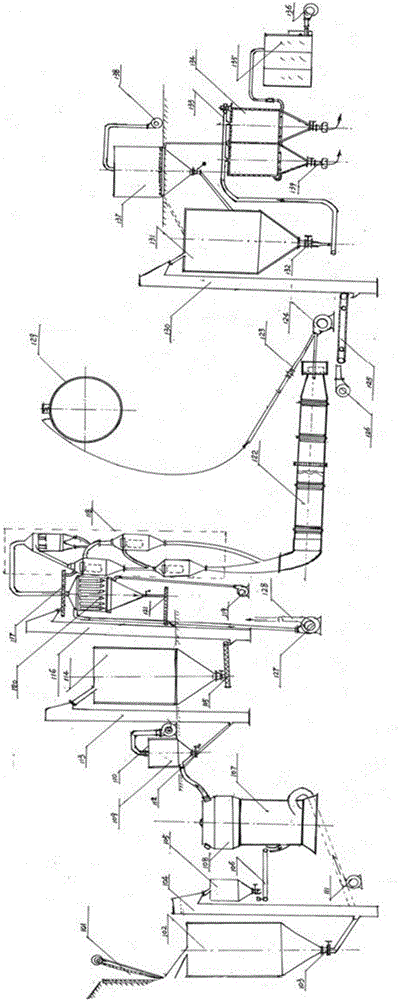

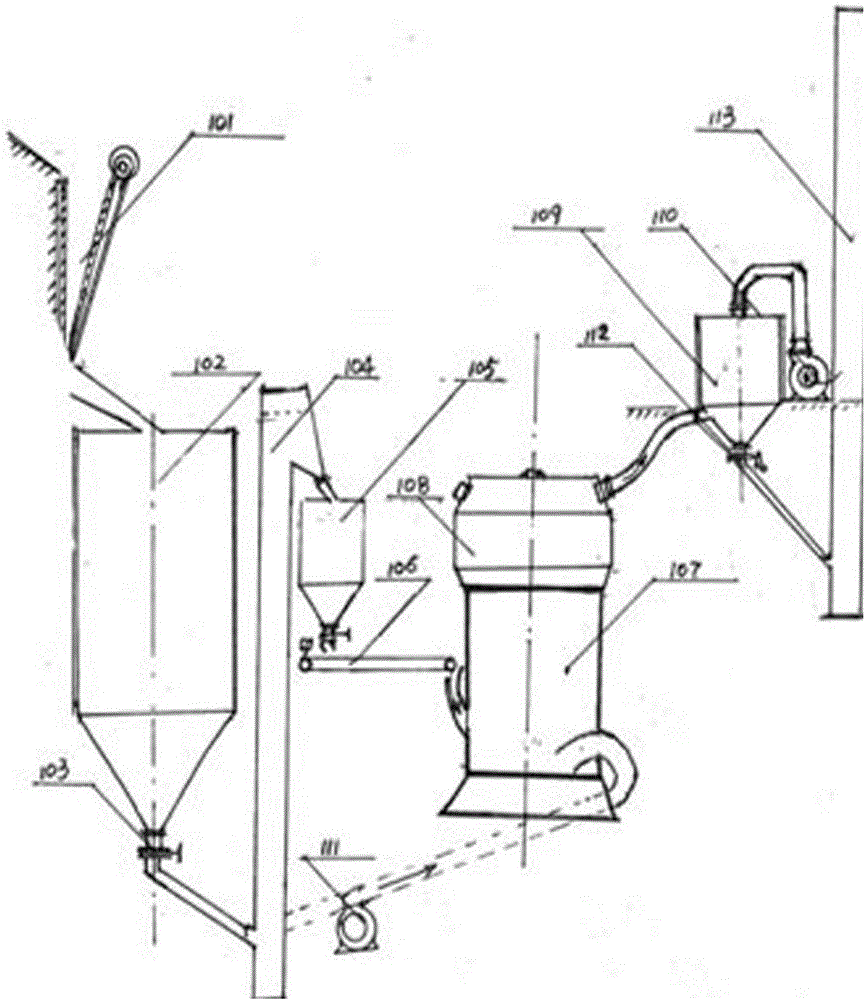

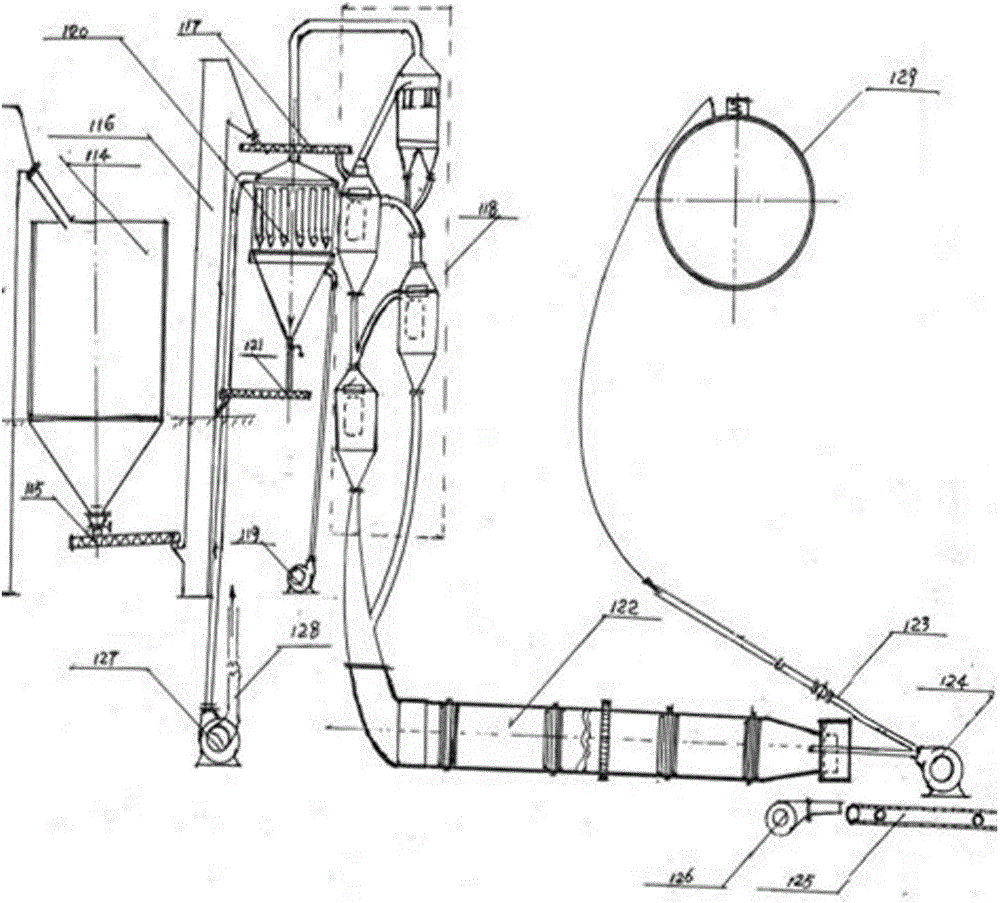

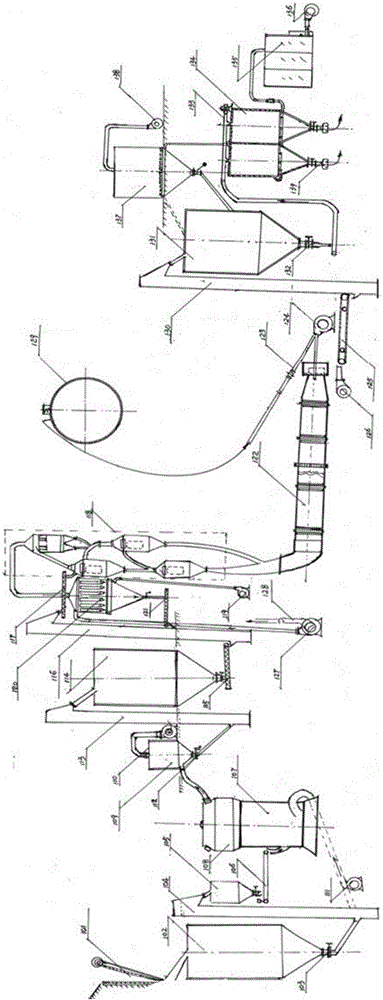

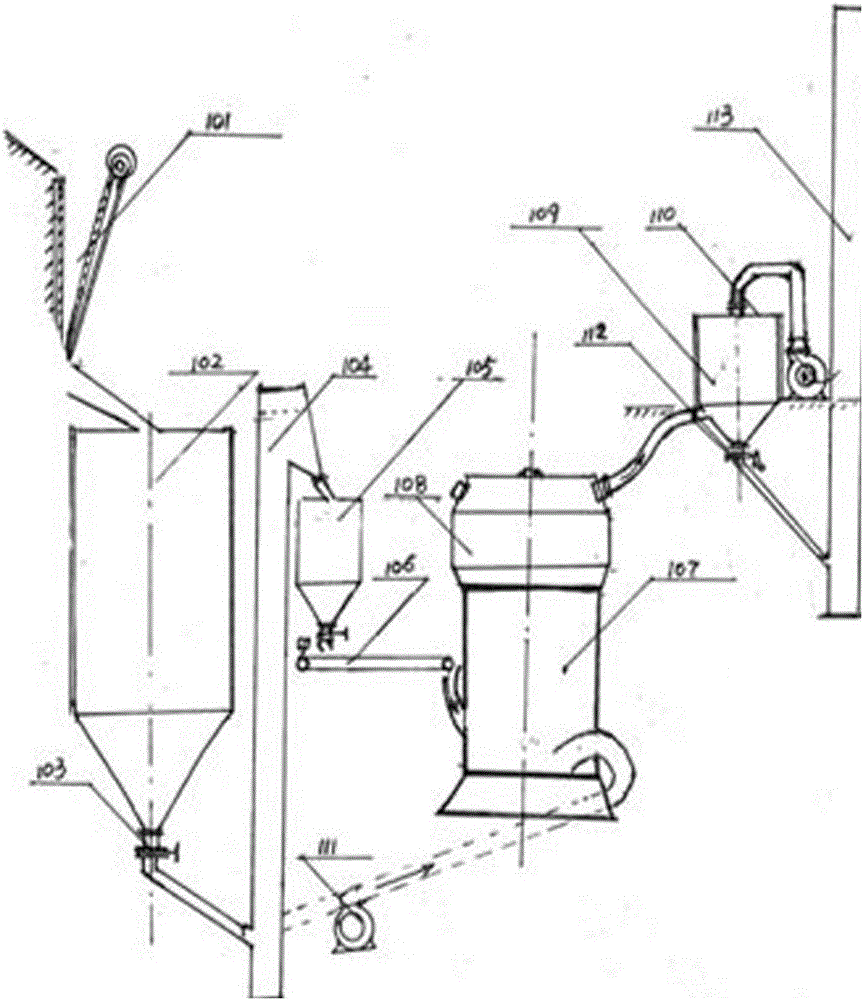

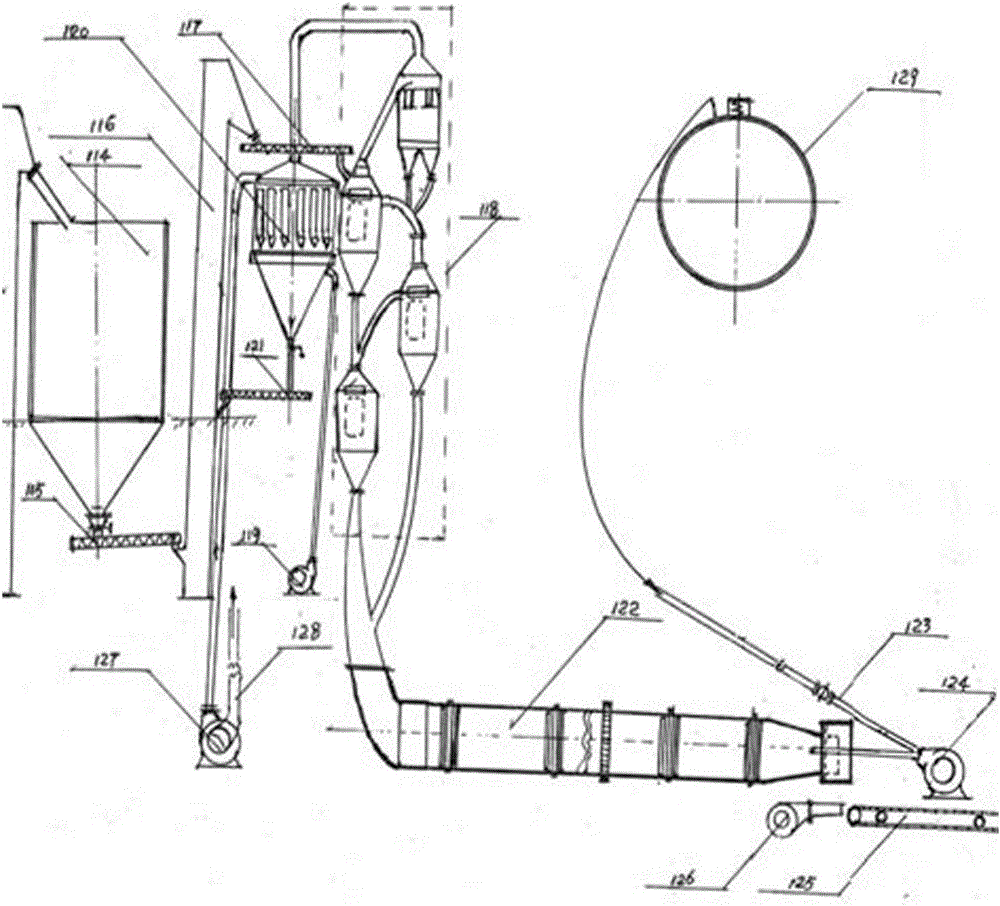

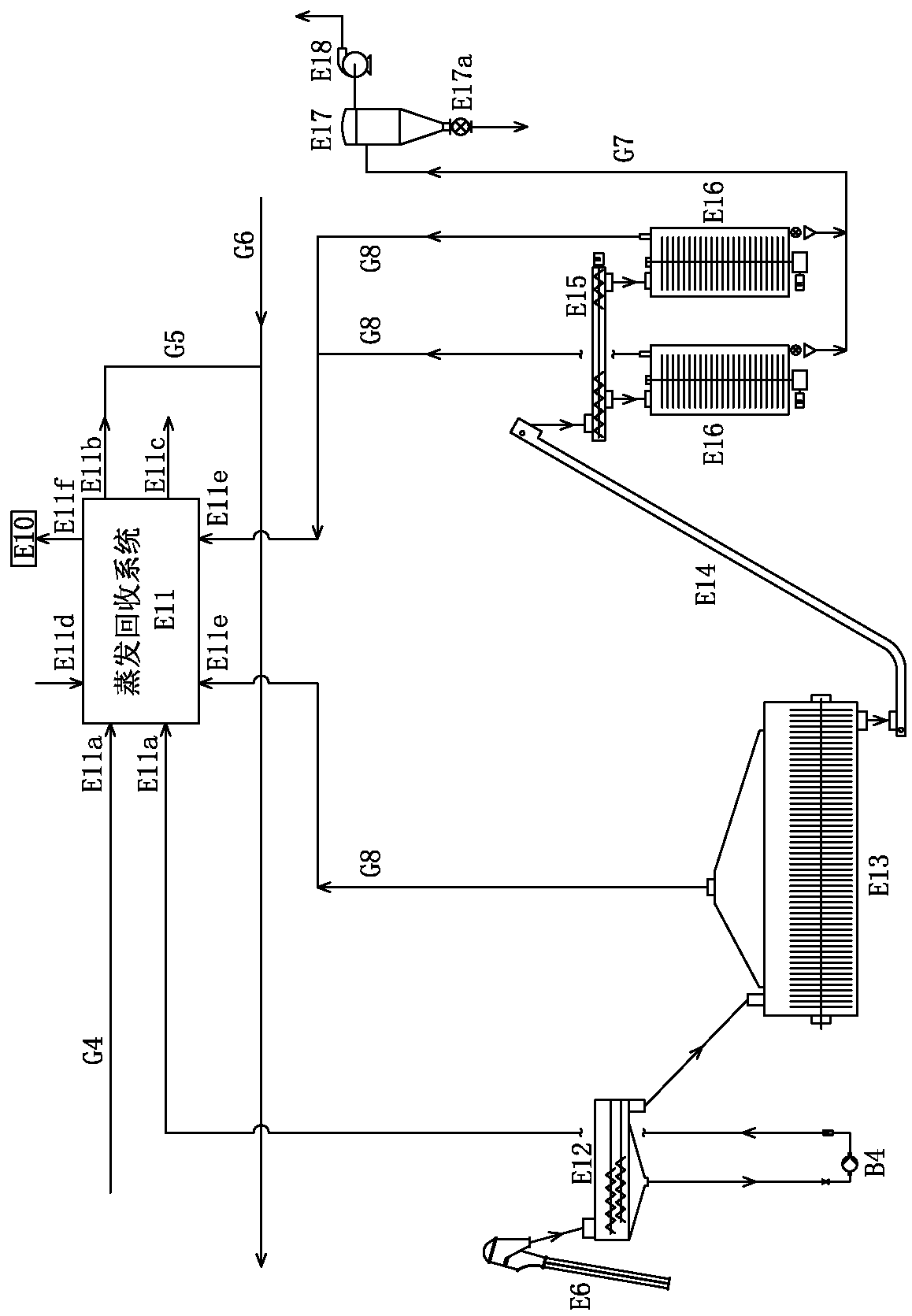

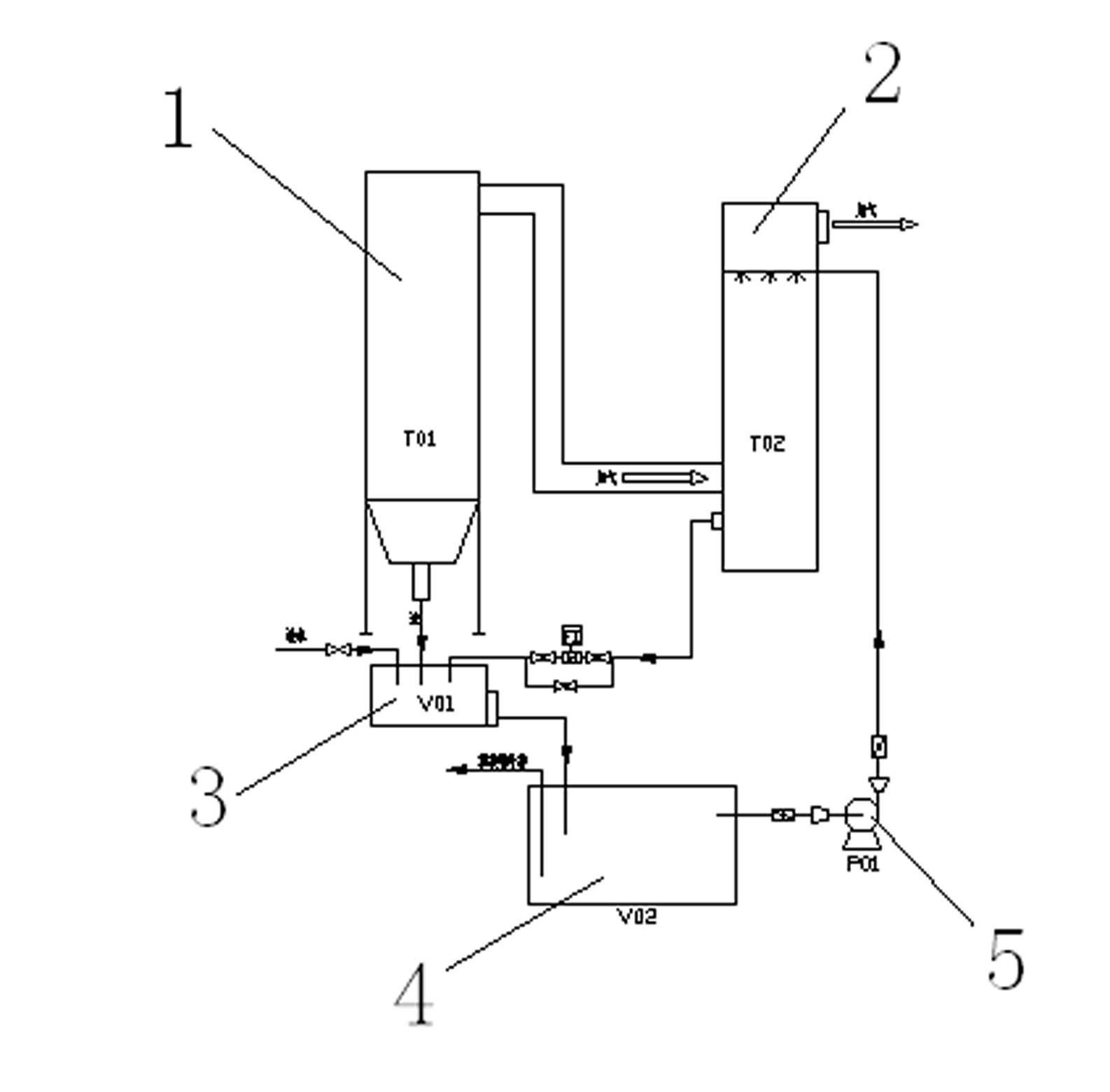

Molten carbon heating type induction furnace based vacuum magnesium production system and magnesium production method thereof

InactiveCN106011500AEfficient collectionContinuous productionProcess efficiency improvementGas emission reductionMelting tankThree stage

The invention discloses a molten carbon heating type induction furnace based vacuum magnesium production system. The system is characterized by comprising a pulverizing system, a preheating decomposing system, a roasting system, a secondary heating system, a vacuum reaction system and a condensing collecting system which are sequentially connected. The magnesium production method of the system comprises three stages, namely, the preparation stage, the induction furnace based vacuum magnesium production stage, and the starting and stopping stage after finishing. According to the system and the method, magnesium-contained powder which is pulverized, decomposed and heated is utilized; a melting tank in which iron is molten into liquid is subjected to vacuum treatment and then charged with argon; high-temperature carbon powder and the magnesium-contained powder are sprayed in the melting tank to reduce so as to produce magnesium steam; the magnesium steam is converted into molten magnesium after being collected and condensed, wherein the molten magnesium is coarse magnesium which is refined to obtain a magnesium ingot. The system and the method are reasonable and compact in production process, complete in equipment coordination and process, fast to react, short in reacting time, and high in production efficiency, and can reduce more than 1 / 3 of the production cost.

Owner:狄保法

Method for preparing micaceous iron oxide by molten salt growth method

InactiveCN101792186ALarge flakesGood optical performanceFerric oxidesFerrous ammonium sulfatePhysical chemistry

The invention provides a method for preparing micaceous iron oxide, which has the advantages of controllable grain size and color change, high purity, complete and reliable production process, easy operation and high resource utilization rate, by a molten salt growth method. In the method, ammonium ferrous sulfate or ferrous sulfate or a mixture of ammonium ferrous sulfate and ferrous sulfate serving as an iron source and sulfates or chlorides or a mixture of sulfates and chlorides serving as a fluxing agent are mixed and melted to form the micaceous iron oxide, wherein the main component of the micaceous iron oxide is a-Fe2O3. The method has the advantages of low cost, easy operation, complete process, no toxicity, high chemical stability, high purity, high crystallinity, high heat resistance, easy realization of industrialization and the like.

Owner:FUJIAN KUNCAI MATERIAL TECH

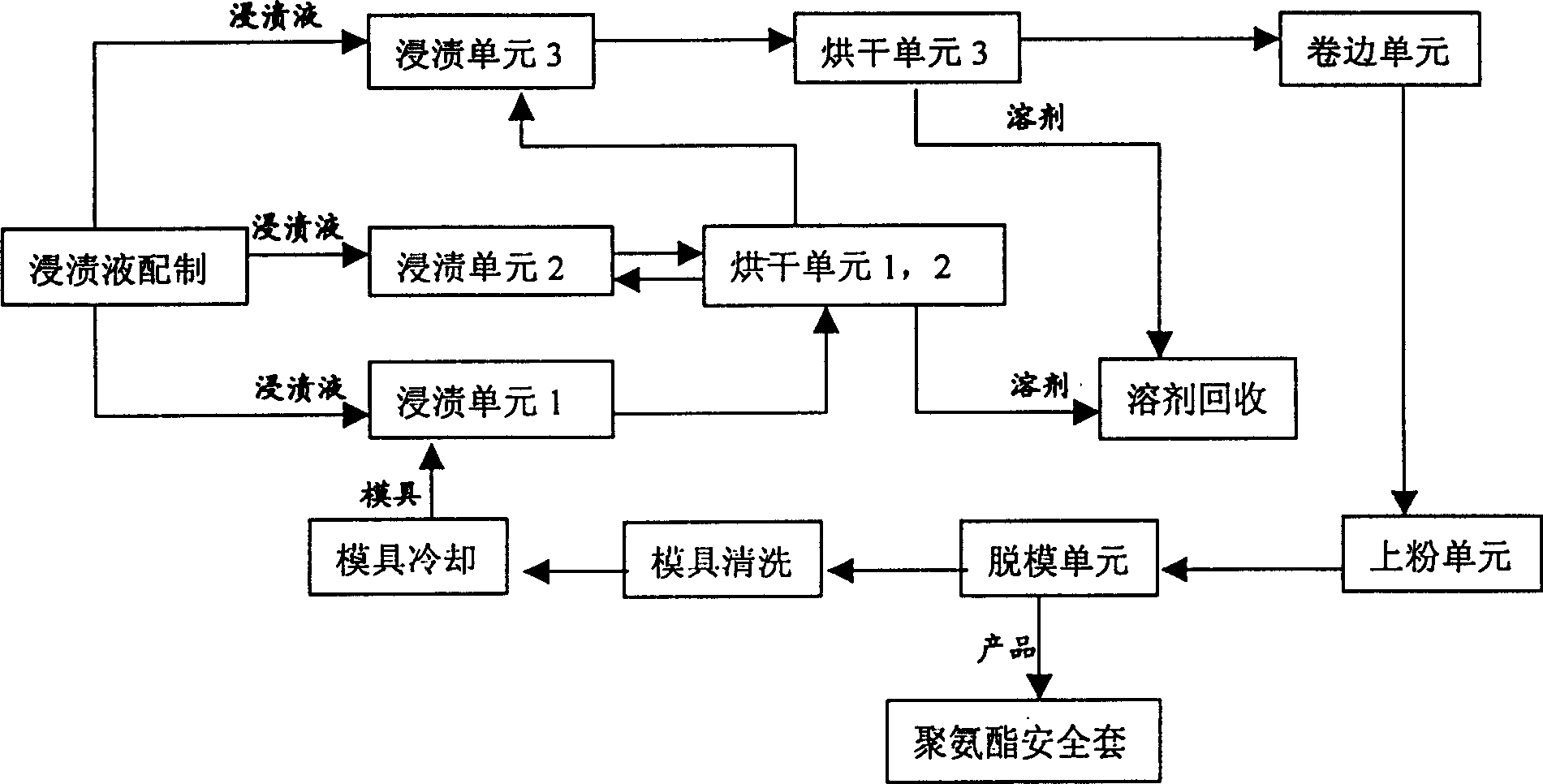

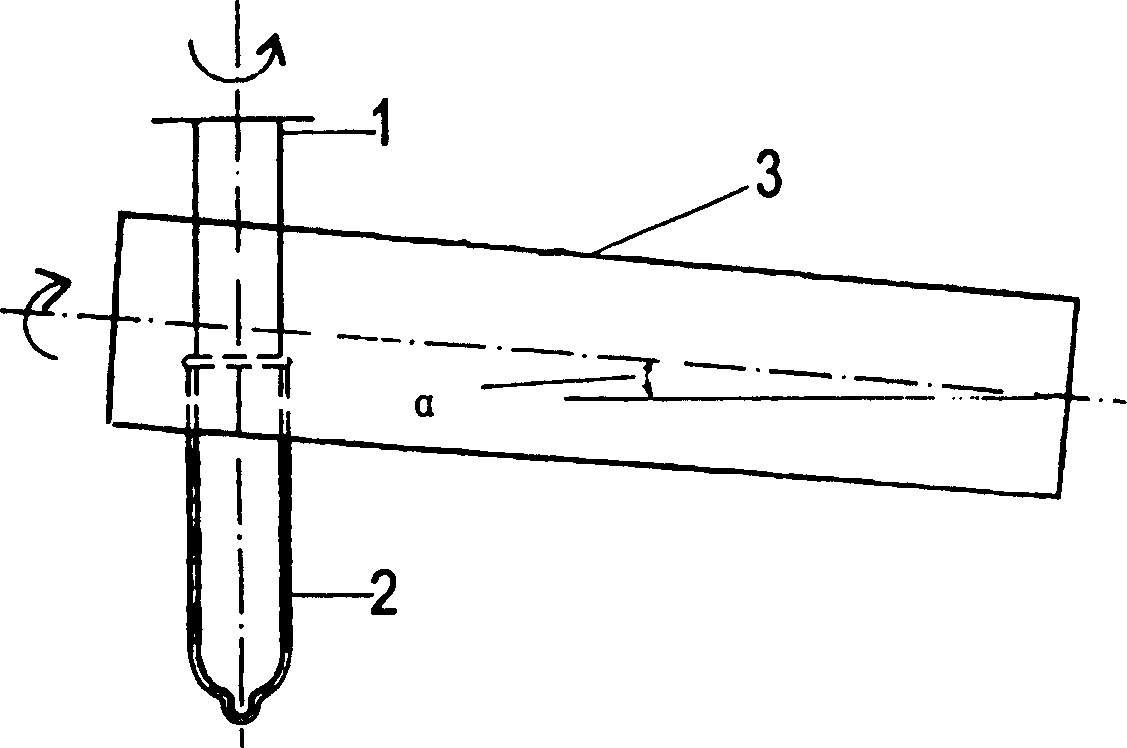

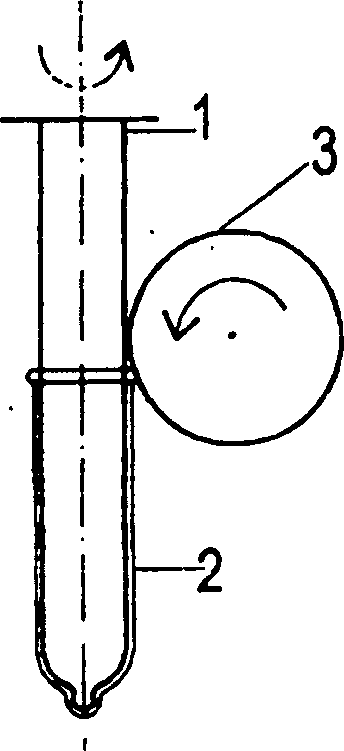

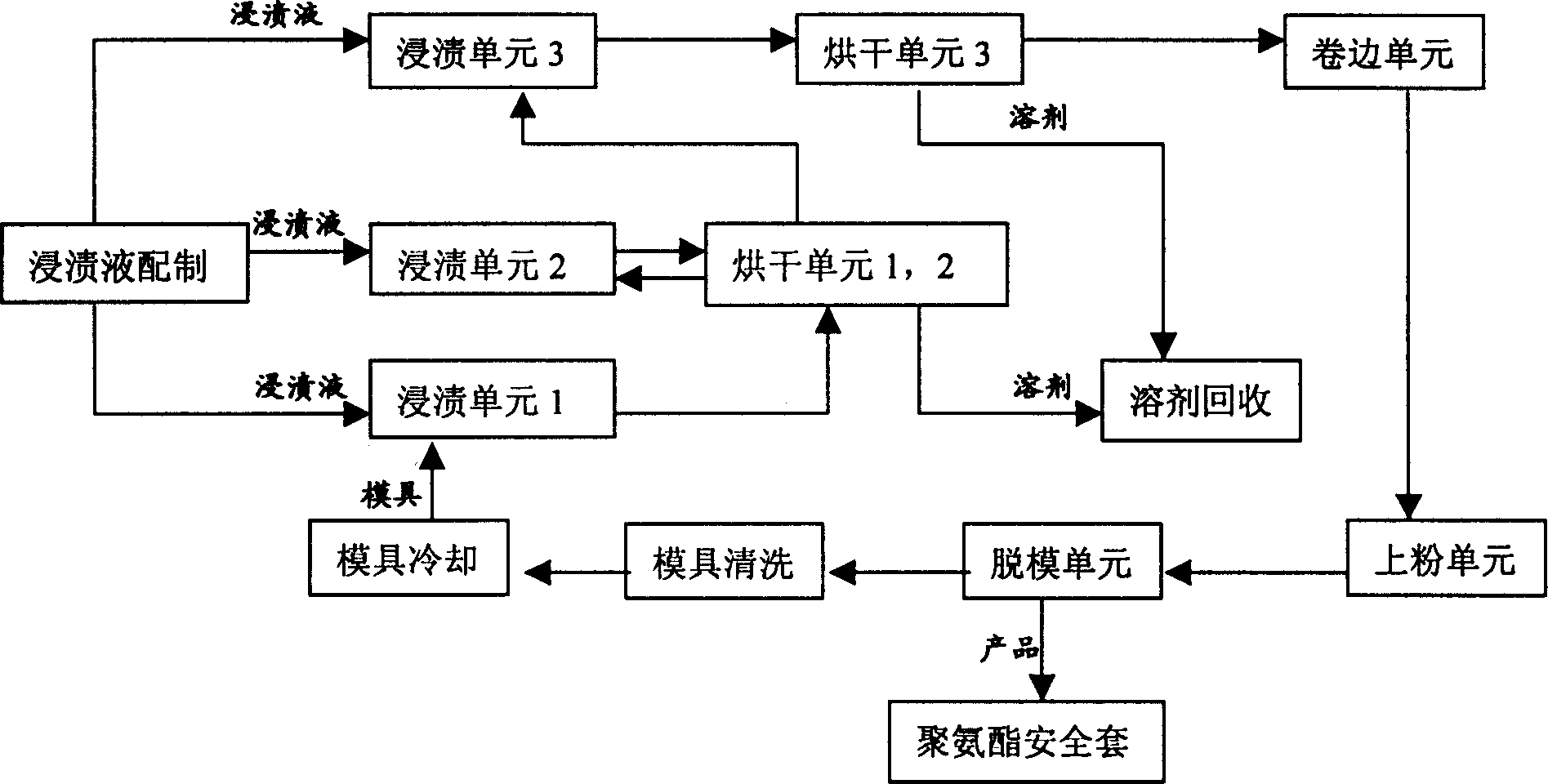

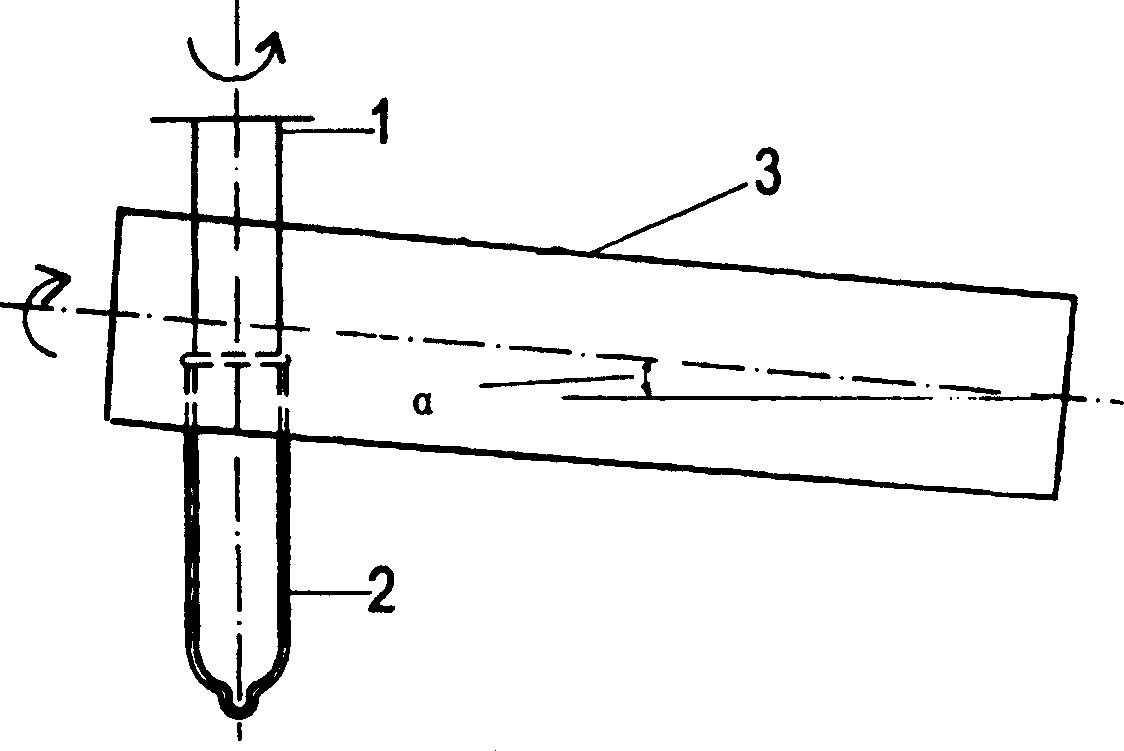

Polyurethane condom producing process

The polyurethane condom producing process includes dissolving polyurethane grains in organic solvent, filtering, soaking mold after being treated specially in the solution to form, drying, rolling hem, powdering, demolding and other steps. The polyurethane condom product has excellent performance and the process is complete, easy to roll hem and demold and high in production efficiency.

Owner:SICHUAN BOAO BIOLOGICAL MATERIAL

Preparation technology of waterproof roll material with long serivce life

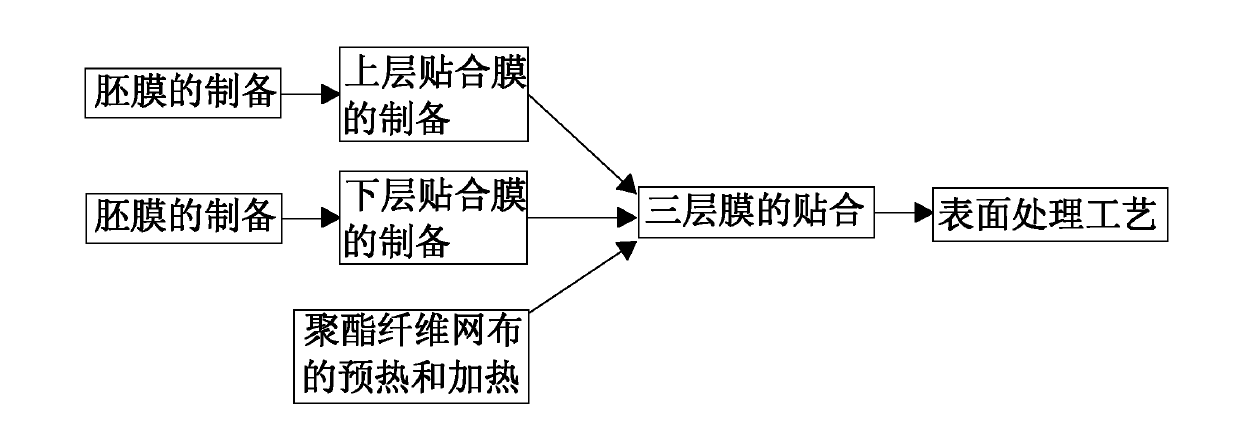

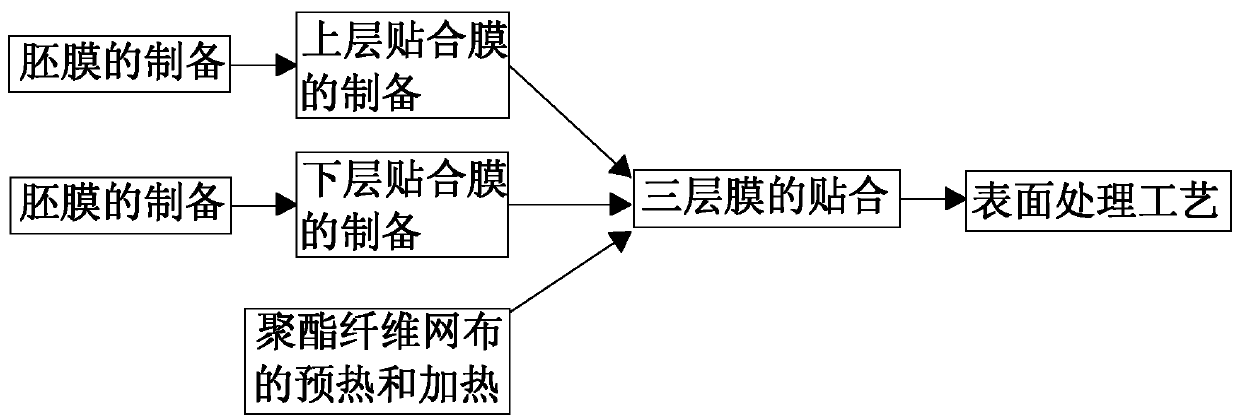

InactiveCN102168383AComplete workmanshipPlay a protective effectSynthetic resin layered productsLaminationWeather resistanceMechanical engineering

A preparation technology of a waterproof roll material with long service life includes the following steps: 1) preparation of a blank membrane, 2) preparation of an upper layer adhesive membrane, 3) preparation of a lower layer adhesive membrane, 4) preheating and heating of mesh, 5) preheating and heating of the upper and the lower layer adhesive membranes, 6) adhesion of the three layers of membranes, and 7) surface treatment. The reasonable preparation technology is adopted, and the technology is more complete, scientific and reasonable; the upper and the lower surfaces of a product are respectively coated with a surface treatment layer which not only plays roles in pollution prevention and product protection, but also achieves pollution-prevention self-cleaning effects in virtue of rain water; meanwhile, the thickness of the product prepared by the technology achieves 2.5-3.0cm, the increase in the thickness of the product improves the product durability and uvioresistant capability, thereby enhancing the waterproof effect of the product and prolonging the service life of the product.

Owner:思嘉环保材料科技(上海)有限公司

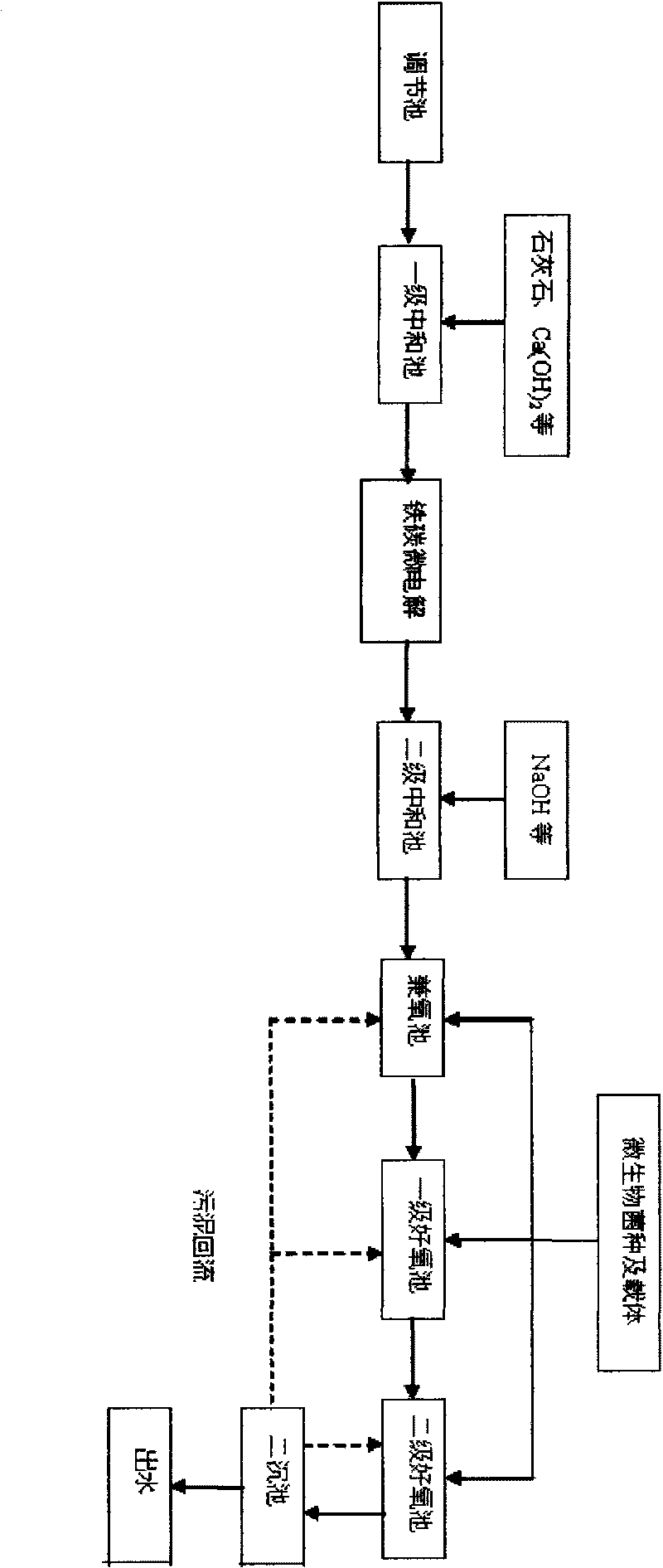

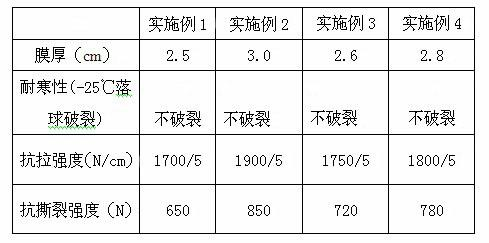

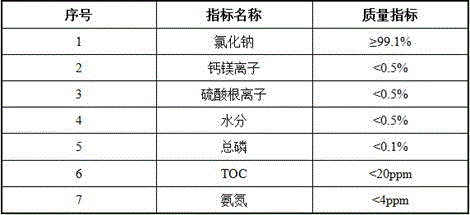

Technology for using organic contaminated high salinity wastewater to produce industrial refined salt

ActiveCN106495384AComplete workmanshipRealize resource utilizationWater contaminantsMultistage water/sewage treatmentResource utilizationEvaporation

The invention discloses a technology for using organic contaminated high salinity wastewater to produce industrial refined salt. The technology comprises the steps of conducting pretreatment and oil removal on the organic contaminated high salinity wastewater, afterwards, leading the pretreated organic contaminated high salinity wastewater into a secondary evaporation crystallizer in a multiple-effect evaporative crystallization system to be subjected to multiple-effect evaporation, obtaining risky waste salt particles after multiple-effect evaporation dewatering, leading the risky waste salt particles into a multi-stage ring kiln to be subjected to thermal desorption treatment, removing organic matter in the risky waste salt and obtaining solid particles, conducting dissolution and impurity removal on the solid particles, removing carbon dregs, phosphorous, ammonia nitrogen and calcium and magnesium in the solid particles to obtain a saline solution, leading the saline solution again into a primary evaporation crystallize in the multiple-effect evaporative crystallization system, and obtaining the industrial refined salt after evaporative crystallization. According to the technology for using the organic contaminated high salinity wastewater to produce the industrial refined salt, the technology is intact, resource utilization of the organic contaminated high salinity wastewater can be directly achieved, a set of evaporative crystallization device is saved, the problem of waste gas treatment in thermal desorption of the risky waste salt is effectively solved; meanwhile, the whole technological process is simple and automation of an operation can be achieved.

Owner:NANJING GW ENVIRONMENT ENG

Production process for door curtain material

ActiveCN101509202AReduce invasionInhibit migrationLiquid surface applicatorsSynthetic resin layered productsFiberPolyester

The invention provides a process for producing a door curtain material, which comprises delivery of polyester fiber grey cloth, double-face coating treatment, pre-plasticizing and gelling, planishing and cooling, primary coating of a horizontal coating head, plasticizing treatment, cooling and shaping, secondary coating of the horizontal coating head, plasticizing treatment, embossing, cooling, winding, surface treatment and preparation. The process combines net sandwich cloth coating and surface treatment process, is complete relatively to common coating processing, can process a vertical coating, a surface layer and a bottom layer, reduces the intrusion of ultraviolet rays on the coating by adopting the surface treatment process on the one hand, can prevent plasticizing agent from being transferred to the surface of a product on the other hand so as to achieve the antifouling effect and achieve the aim of self-cleaning by means of rainwater; and the product has good air tightness and superior abrasion-resisting property, is suitable for outdoor application, and has long service life and remarkable economic benefit.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

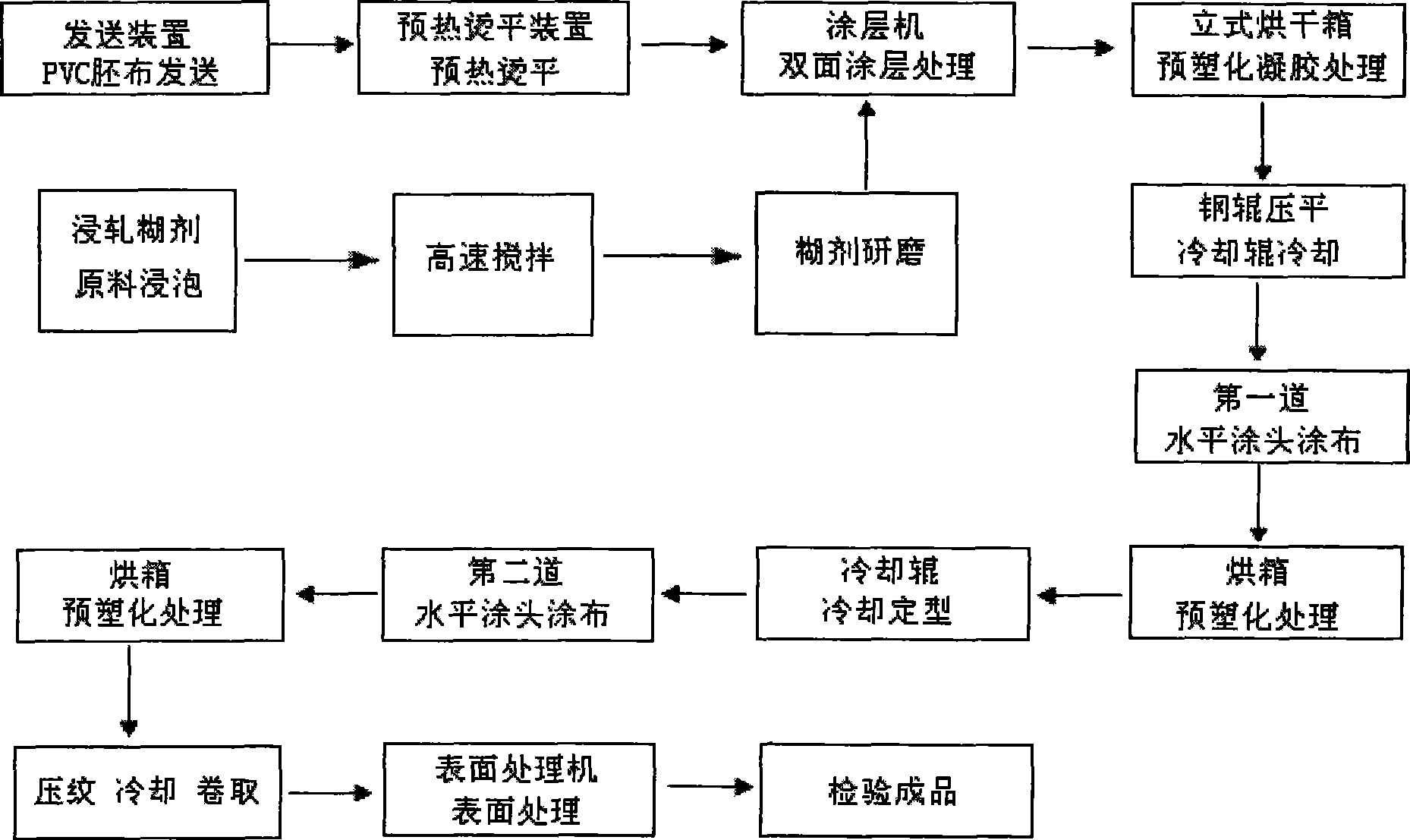

Effervescent tablets contg. Astragalus root and fructus ligustric lucidi for strengthening the body resistance, and its prepn. art

ActiveCN1723986AComplete workmanshipEasy extractionPill deliveryImmunological disordersMedicineLactose

A Chinese medicine in the form of effervescent tablet for strengthening human body resistance is proportionally prepared from the extracts of astragalus root and lucid ligustrum fruit, lactose, rebaudiose, tartaric acid, sodium dicarbonate, poly ethanediol and magnesium stearate. Its preparing process is also disclosed.

Owner:湖南华宝通制药有限公司

Polyurethane condom producing process

The polyurethane condom producing process includes dissolving polyurethane grains in organic solvent, filtering, soaking mold after being treated specially in the solution to form, drying, rolling hem, powdering, demolding and other steps. The polyurethane condom product has excellent performance and the process is complete, easy to roll hem and demold and high in production efficiency.

Owner:SICHUAN BOAO BIOLOGICAL MATERIAL

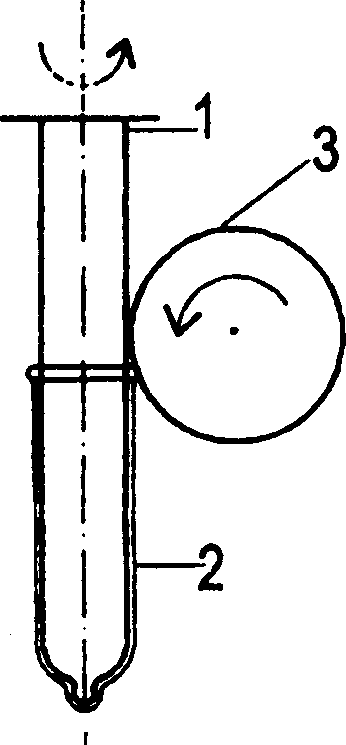

Sludge treatment process and system

ActiveCN104261645AComplete workmanshipReduction and RecyclingSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisWater contentChemistry

The invention discloses a sludge treatment process which comprises the following steps: (1) sterilizing sludge so as to kill microorganisms in the sludge; (2) dewatering and drying the sterilized sludge so as to reduce the water content of the sludge; (3) separating the dried sludge, carrying out high temperature plasma treatment on the separated sludge, and burning separated smoke; (4) carrying out sludge-smoke separation on smoke generated by reburning treatment, carrying out high temperature plasma treatment on the separated sludge again, and purifying and cooling the separated smoke. The invention further discloses a sludge treatment system capable of carrying out the sludge treatment process. The sludge treatment system comprises a sterilizing device, a dewatering device, a drying device, a plasma gasifying or plasma vitrifying device and a purifying device. The sludge treatment system can realize harmless, reducing and resourceful treatment for the sludge and does not generate secondary pollution, is safe and reliable, and can realize thorough treatment for the sludge.

Owner:山东博润环保科技有限公司

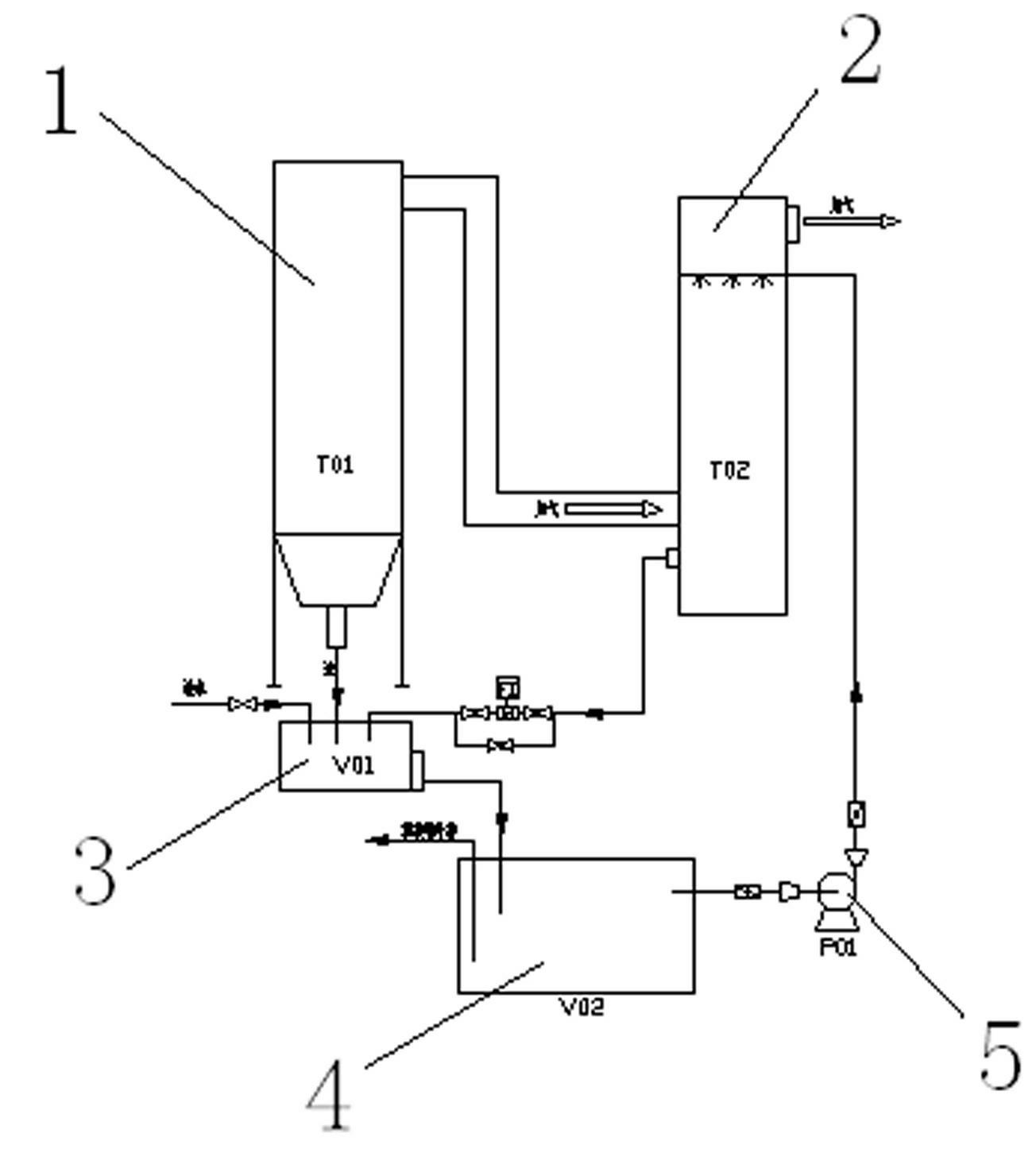

Electric arc furnace vacuum magnesium smelting system and magnesium smelting method thereof

The invention discloses an electric arc furnace vacuum magnesium smelting system. The electric arc furnace vacuum magnesium smelting system is characterized by comprising a grinding system, a preheating-decomposition system, a calcination system, a secondary heating system, a vacuum reaction system and a condensate collection system which are sequentially connected with one another. A magnesium smelting method of the electric arc furnace vacuum magnesium smelting system comprises the following stages: preliminary preparation; electric arc furnace vacuum magnesium smelting; and startup and shutdown after reaction completion. The electric arc furnace vacuum magnesium smelting system and the magnesium smelting method disclosed by the invention have the advantages that magnesium-containing powder obtained after grinding, decomposition and heating is subjected to vacuum treatment in a molten pool where iron is molten into liquid iron, and then argon gas is injected and high-temperature magnesium powder is sprayed, so that magnesium steam is generated after reduction; after collection and condensation, the magnesium steam turns into liquid magnesium to form rough magnesium; then, a magnesium ingot is cast through refining; the production process is reasonable, compact, matching in equipment, complete in technology, rapid in reaction process, short in time and high in production efficiency; and the production cost is reduced by 1 / 3 or above.

Owner:狄保法

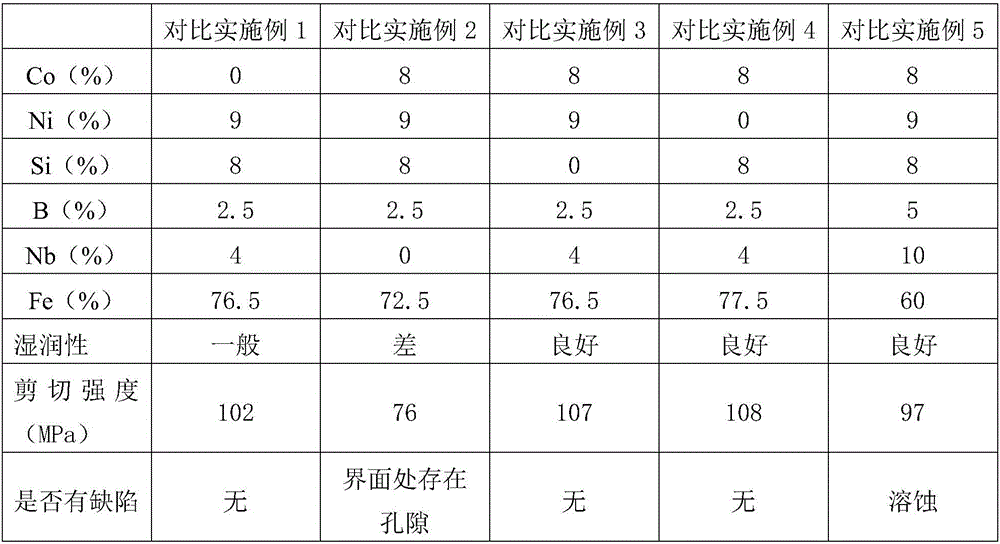

High temperature Fe-based solder for brazing 50Mo-50Re alloy and preparation method thereof, and brazing process

ActiveCN106271209AHigh melting pointHigh melting temperatureWelding/cutting media/materialsSoldering mediaMo elementSolid solution

The invention discloses a high temperature Fe-based solder for brazing 50Mo-50Re alloy and preparation method thereof, and brazing process. The solder includes the components with following weight ratios: Co 4wt%-9wt%, Ni 3wt%-12wt%, Si 3wt%-8wt%, B 0wt%-3wt%, Nb 3wt%-5wt%, and the balance Fe. The preparation method for the high temperature Fe-based solder comprises the following steps: mixing Fe particles, Si particles, B particles, Co particles, Ni particles and Nb particles evenly in proportion, making the solder into foil strip shape with a thickness ranging from 20-50Mum by using vacuum induction melting furnace and high vacuum spinning machine. The temperature for brazing the solder ranges from 1060-1160 DEG C, and the melting temperature of the solder keeps extremely high to ensure the high temperature performance of a weld. The solder is molten uniformly. The use of solder foil is conducive to promoting the diffusion of alloy elements in soldered connection process, and the solder foil is conducive to promoting element diffusion in soldered connection process. Solid solution can be generated by Fe element and Mo element; Co element and Nb element can promote the diffusion of Mo element and Re element in a brazing seam, so as to form a wide diffusion layer. The performance of the brazing seam is improved.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

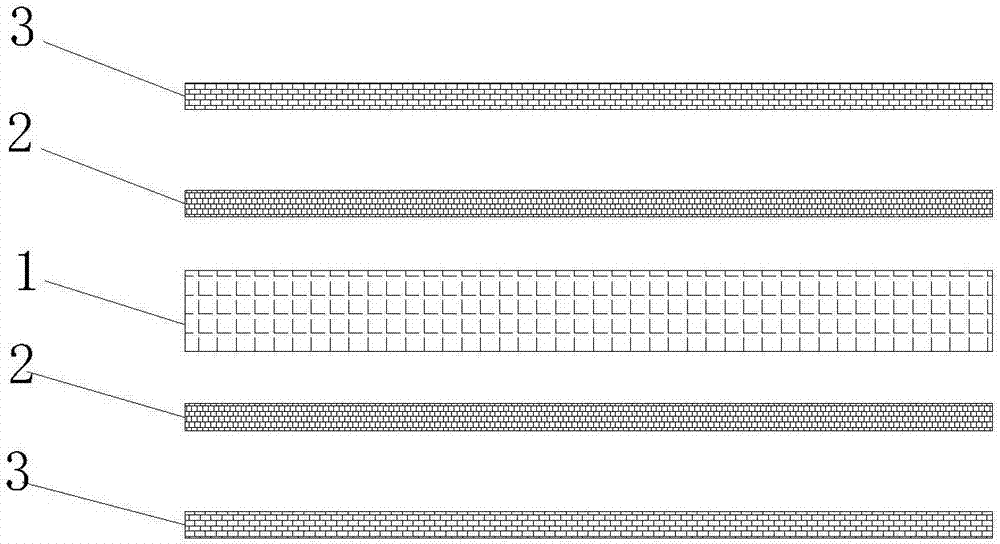

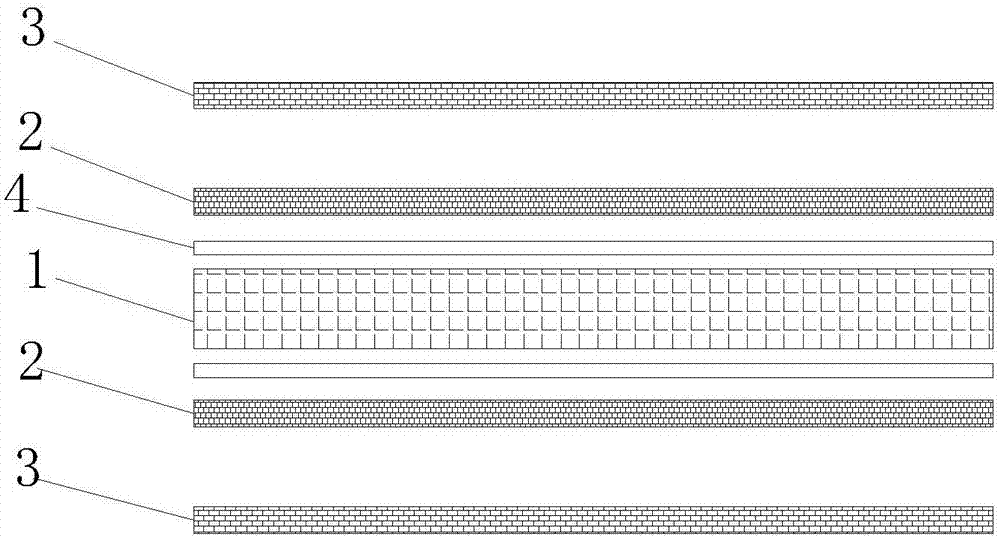

Laminating machine convenient to install and maintain

InactiveCN102092167AComplete workmanshipQuality improvementLamination ancillary operationsLaminationBrickCopper wire

The invention relates to a laminating machine convenient to install and maintain, which comprises a heating workbench and an upper cover, wherein the upper cover consists of an upper chamber, a silica gel plate and an upper chamber sealing ring which are combined in turn; a laid battery pack is arranged on the tabletop of the workbench of the laminating machine; the upper cover is pressed down, so that the upper cover is closely combined with the edge of the heating workbench, and a vacuum chamber is formed between the upper cover and the heating workbench; a lower chamber sealing ring is arranged at the periphery of the heating workbench so as to seal the vacuum chamber; an electric heating device and a temperature control device are arranged in the heating workbench, aluminium silicate light bricks coated with teflon cloth are paved under the heater, the size of the light bricks is equal to the area of a hot plate, and the thickness of the light bricks is about 5 centimeters; the heater is positioned between the hot plate and the aluminium silicate, a lead of the heater is welded with a small section of copper wire to connect a screw of a bakelite plate, and the screw is communicated with the outside; and the welding mode is brass soldering. The installation and fixation of a thermoelectric couple are mainly described; and because the laminating machine is high in vacuum degree of installation mode, long in service life and convenient to maintain, the laminating machine is suitable to be widely applied to a solar battery assembly process.

Owner:SHANGHAI SHENKE TECH

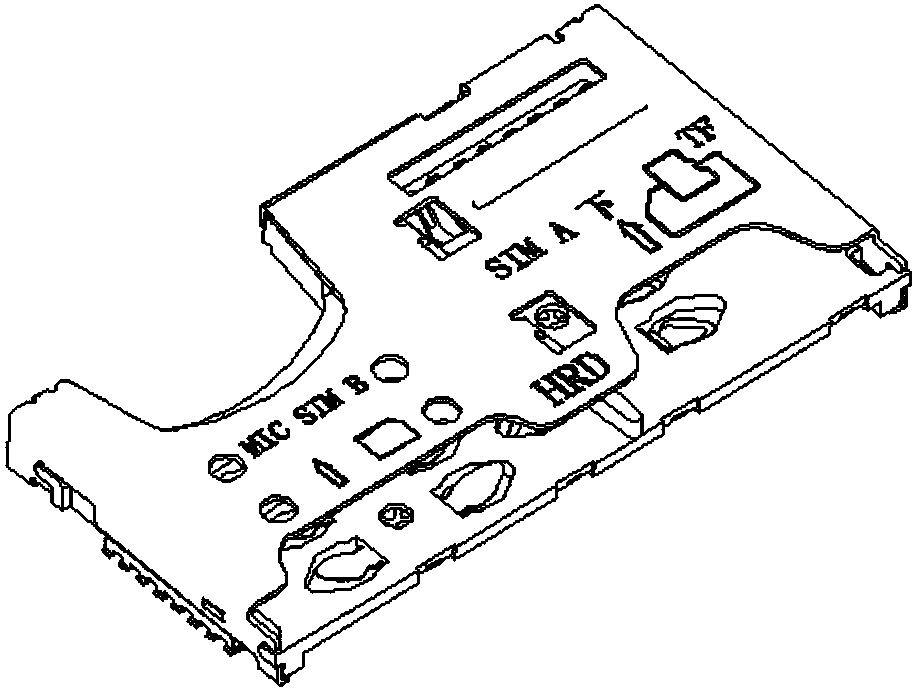

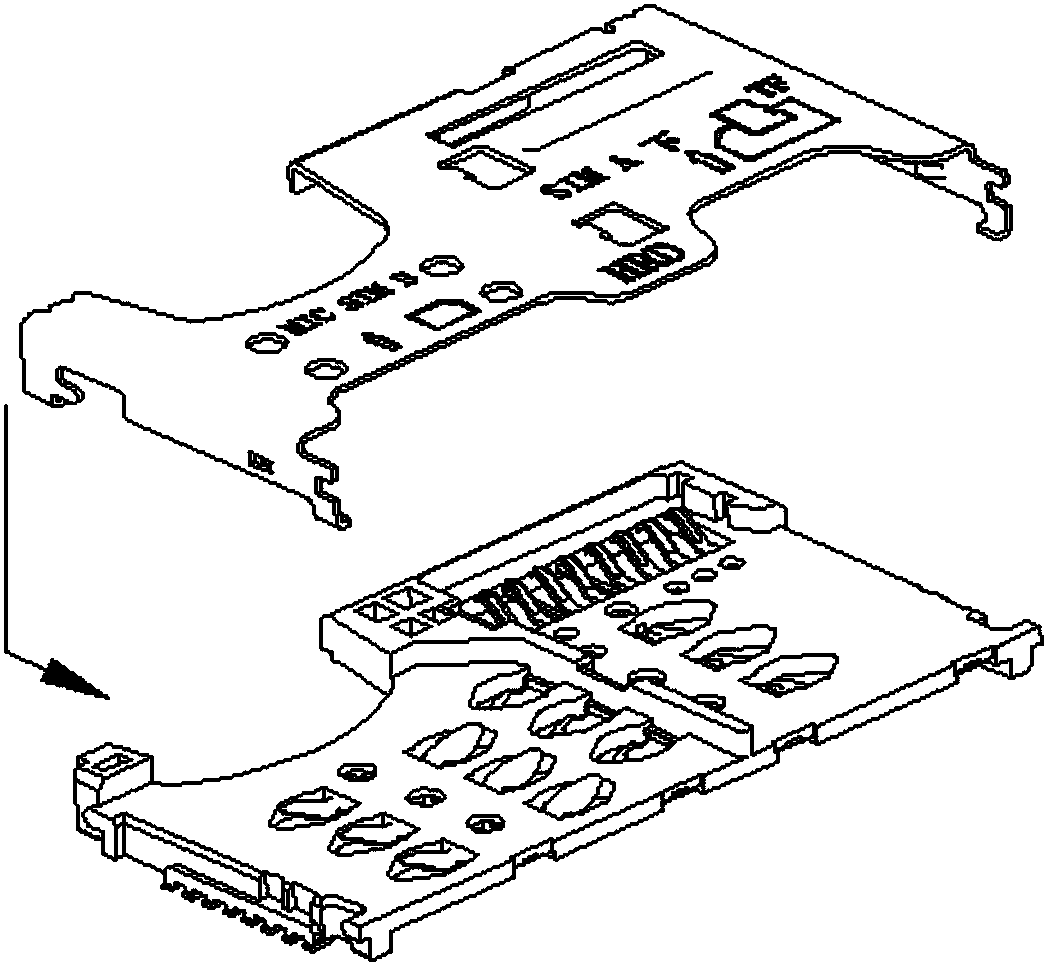

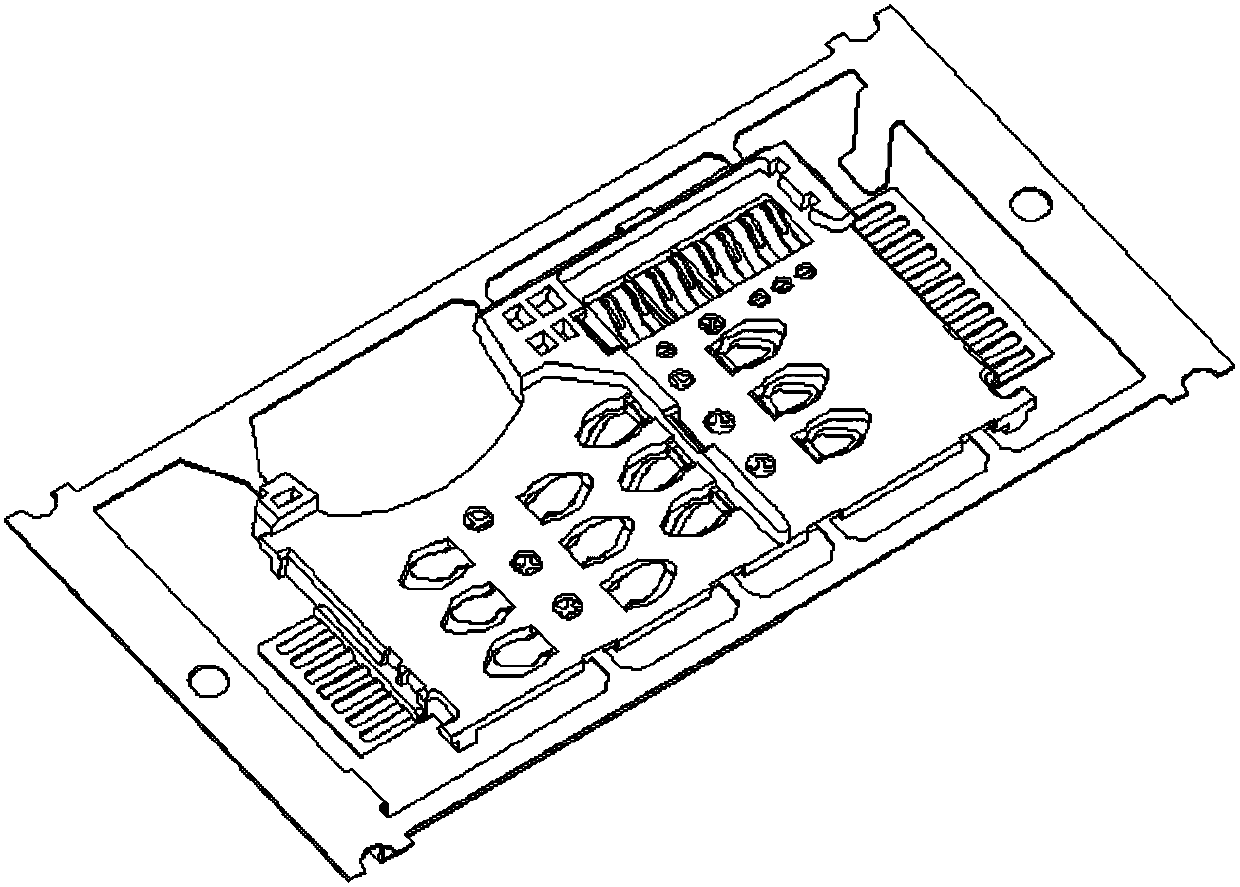

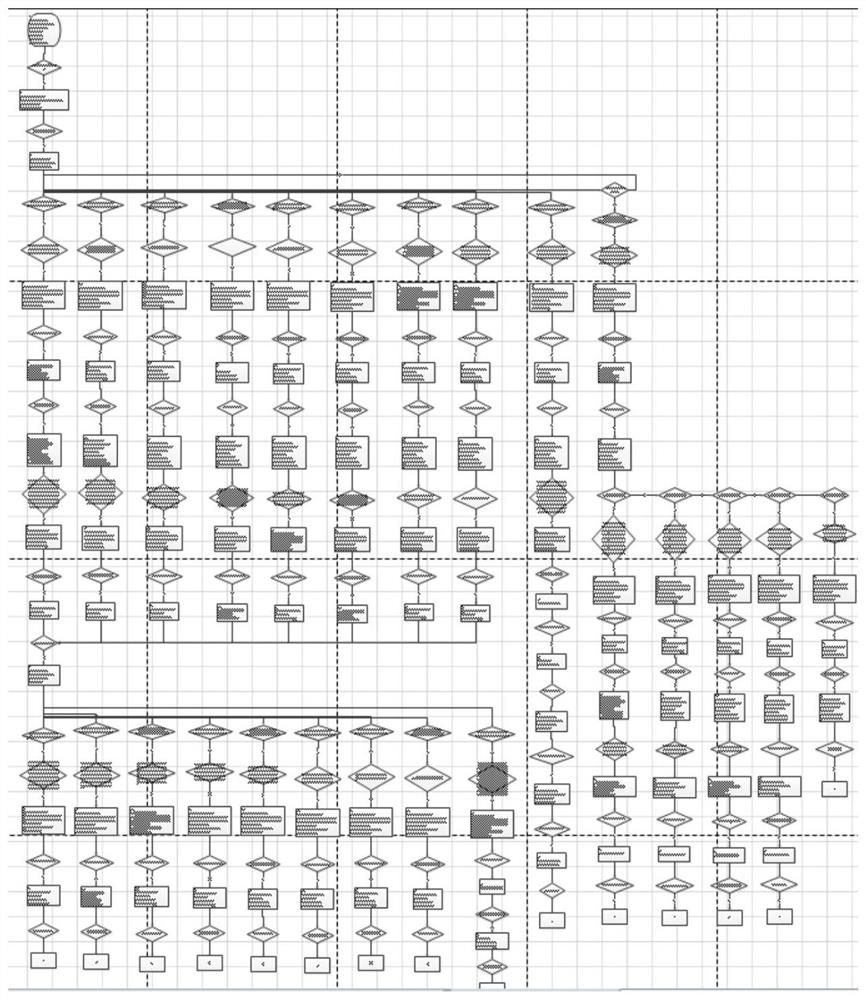

Automatic assembling and detecting equipment and process method for mobile phone card seat

PendingCN107717373ATimely exclusionIncrease productivityMeasurement devicesAssembly machinesProduction lineProcess integration

The invention relates to an automatic assembling and detecting equipment and a process method for a mobile phone card seat. The automatic assembling and detecting equipment comprises a first working cabinet and a second working cabinet, the first working cabinet is provided with a main body feeding and detecting device, a shell feeding device and an automatic assembling device, and the second working cabinet is provided with a finished product transferring device, a finished product detecting device and a taping and packaging device; and the main body feeding and detecting device and the shellfeeding device are connected with the automatic assembling device, the automatic assembling device is sequentially connected with the finished product detecting device and the taping and packaging device through the finished product transferring device, and each device is connected with a controller device and a display device. According to the automatic assembling and detecting equipment for themobile phone card seat, five procedures and the mobile phone card seat are integrated into a production line is realized, the five procedures are main body feeding and detecting, shell feeding, automatic assembling, finished product transferring and detecting, and taping and packaging, the production efficiency and the passing rate of products and the automation control level of the whole equipment are improved; and in addition, the automatic assembling and detecting equipment is compact in structure, complete in process, high in safety, and low in labor cost.

Owner:鸿日达科技股份有限公司

Method for preparing mica iron oxide by hydrothermal reaction and crystallizing

InactiveCN100390072CReliable methodComplete workmanshipPigmenting treatmentFerric oxidesSulfateWhite powder

The present invention provides preparation process of mica iron oxide with controllable particle size and color. Ferrous sulfate as the side product of titanium white powder production is used as the material, and through dissolving and purifying, oxidation, creating precursor, hydrothermal reaction and crystallization in controlled conditions, and post-treatment, mica iron oxide with controllable particle size and color is prepared. The mica iron oxide product is in regular hexagonal sheet shape and has particle size of 40-180 micron and color regulated through altering the crystal growth promoter adding amount, medium concentration, temperature and time in the hydrothermal reaction and crystallization stage.

Owner:XIANGTAN UNIV

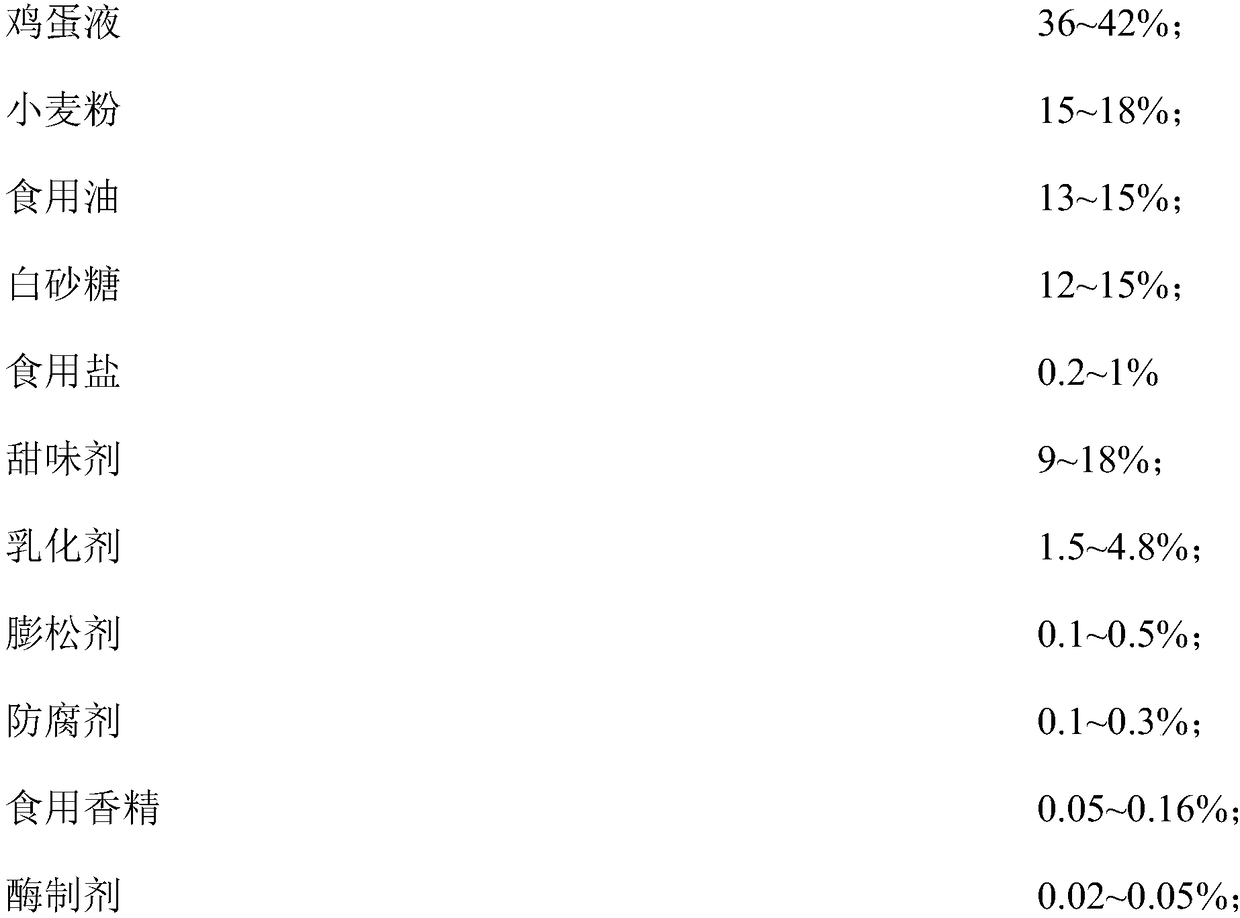

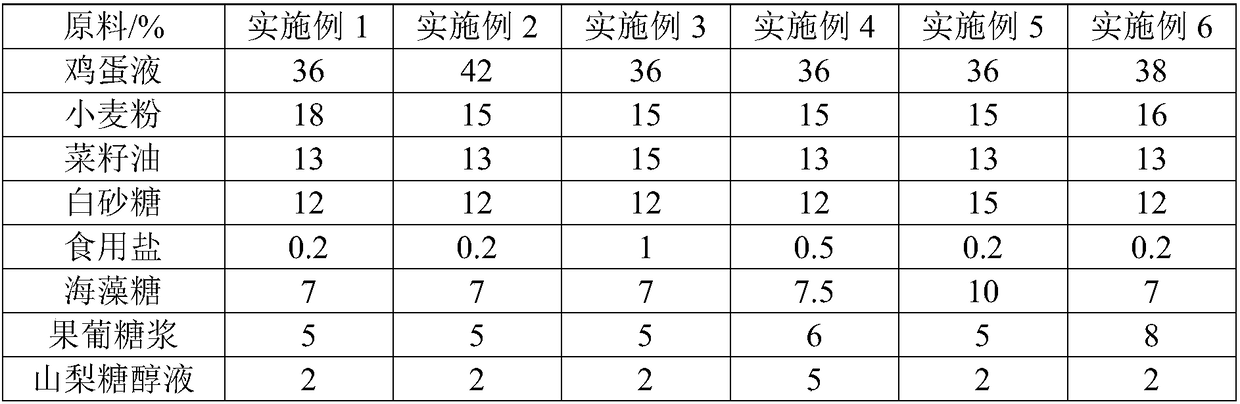

Enzyme-modified soft and smooth breakfast/meal replacement cake and making method thereof

InactiveCN108541737AIncrease moisture contentSoft tasteDough treatmentPre-baking dough treatmentGlucono delta-lactoneEdible oil

The present invention provides an enzyme-modified soft and smooth breakfast / a meal replacement cake and a making method thereof. The cake includes the following raw materials in percentages by mass: 36-42% of egg liquid; 15-18% of wheat flour; 13-15% of edible oil; 12-15% of white granulated sugar; 0.2-1% of table salt; 9-18% of sweeteners; 1.5-4.8% of emulsifiers, 0.1-0.5% of swelling agent, 0.1-0.3% of preservative and 0.1-0.2% of edible essence; wherein the preservative is composed of glucono-delta-lactone, glyceryl monostearate and sodium dehydrogenate. The cake is high in water content, soft in mouthfeel and long in shelf life. The making method is complete in process, hygienic and environmentally-friendly.

Owner:DONGGUAN HUAMEI FOOD

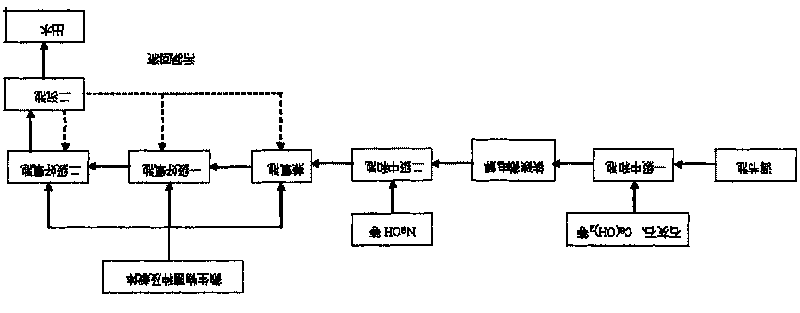

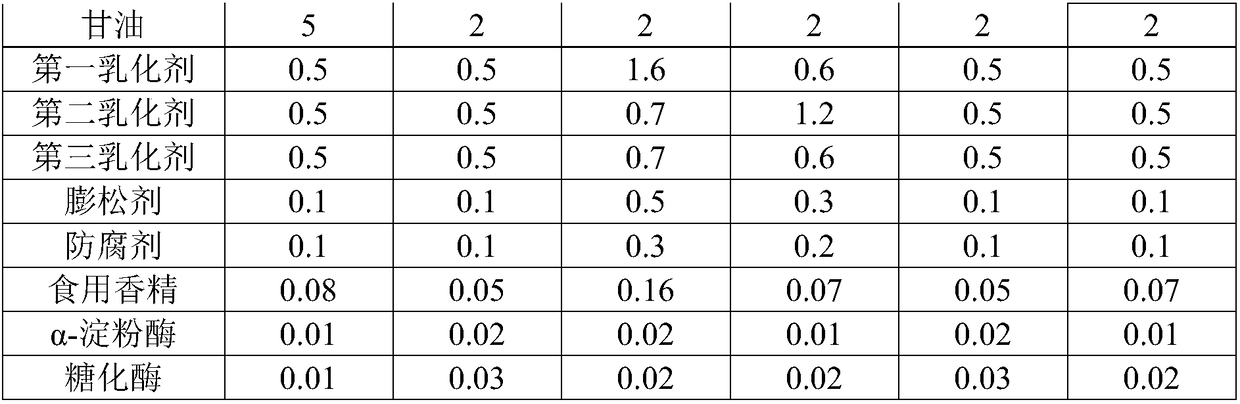

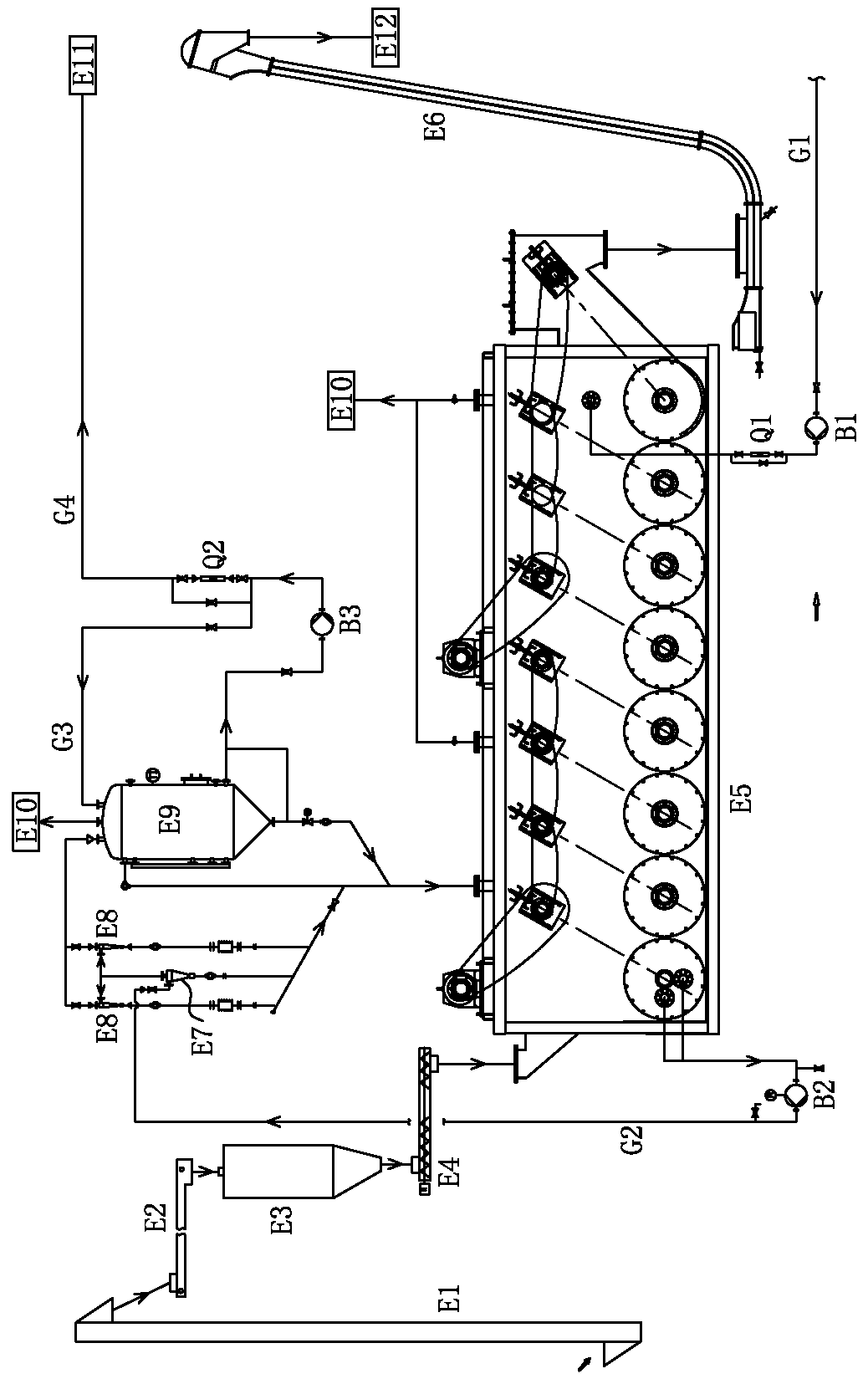

Soybean protein concentrate preparation system

PendingCN109836472AComplete workmanshipEasy to separatePeptide preparation methodsVegetable proteins working-upEvaporationEconomic benefits

The present invention relates to a soybean protein concentrate preparation system. An outlet of a raw material temporary storage bin is connected with a solid material inlet of an extractor via a quantitative packing auger, a wet meal outlet of the extractor is connected with an inlet of a wet meal conveyor, an inlet of a new solvent pump is connected with a fresh solvent tube, an outlet of the new solvent pump is connected with a new solvent inlet of the extractor, a concentrated liquid outlet of the extractor is connected with an inlet of a concentrated extract extracting pump, an outlet ofthe concentrated extract extracting pump is connected with an inlet of a first-stage hydrocyclone via a mixed liquid conveying tube, a light phase outlet of the first-stage hydrocyclone is connected with an inlet of a second-stage hydrocyclone, a light phase outlet of the second-stage hydrocyclone is connected to an inlet of a solution temporary storage tank, and bottom parts of the first-stage and second-stage hydrocyclones and solution temporary storage tank are connected to a return port of the powder extractor; and a lower outlet of the solution temporary storage tank is connected with anextract evaporation recovery system via a temporary storage tank transfer pump. The soybean protein concentrate preparation system saves equipment investment, utilizes all powder wastes and greatly improves economic benefits.

Owner:MYANDE GRP CO LTD

Preparation method of high-protein and low-fiber biological nutrition maize straw forage grass

InactiveCN103156059AHigh nutritional valueImprove palatabilityAnimal feeding stuffFiberBiotechnology

The invention discloses a preparation method of high-protein and low-fiber biological nutrition maize straw forage grass. In the production process of the preparation method, two parts, namely comprehensive mechanical processing and biological modulation are accomplished together. The preparation method comprises the following steps of: crushing maize straw, winnowing the crushed maize straw to take hulls and leaves, and carrying out microbial fermentation on the crushed maize straw to obtain high-quality straw forage grass. Compared with the unprocessed maize straw, the processed and modulated forage grass has the advantages of obviously enhancing the total nutrient content, enhancing the crude protein by 40% and reducing low fibers by about 30%, and has the advantages of favorable palatability, high nutritive value and favorable feeding effect. Moreover, the preparation method is suitable for large-scale and specialized production.

Owner:HEILONGJIANG PROVINCE RUJIA AGRI SCI & TECH DEV CO LTD

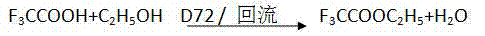

Synthesis method of ethyl trifluoroacetate

ActiveCN104710308ANo production costNo pollution in the processOrganic compound preparationCarboxylic acid esters preparationAfter treatmentTrifluoroacetic acid

A synthesis method of ethyl trifluoroacetate comprises the steps: with trifluoroacetic acid and ethanol as raw materials, with strong acidic cation exchange resin as a catalyst, at a temperature of 40-50 DEG C and at normal pressure, dropwise adding ethanol and maintaining for 20 minutes, heating up and refluxing to separate out a water and ethanol mixture, and making the reaction completed; after collecting a crude product, continuing to use the kettle bottom catalyst and ethanol; adding water to the collected crude product to wash ethanol, stratifying to obtain ethyl trifluoroacetate with the yield of more than 95%; and refluxing to separate out dilute ethanol, and rectifying to obtain 95% ethanol for repeated use. The method omits a drying tower and a filtration device used in a conventional process; ethanol recovered from the reaction can be repeatedly used after treatment, the production cost is effectively reduced, and the method has the advantages of simple operation process, environmental protection, energy saving and no pollution; because price difference between trifluoroacetic acid and ethyl trifluoroacetate is not large, requirements on the product yield and cost are higher; and the method is complete and standardized in process, convenient to operate and suitable for industrialized production, and can effectively improve the purity and yield of the product.

Owner:TRUST CROP PROTECTION TECH CO LTD

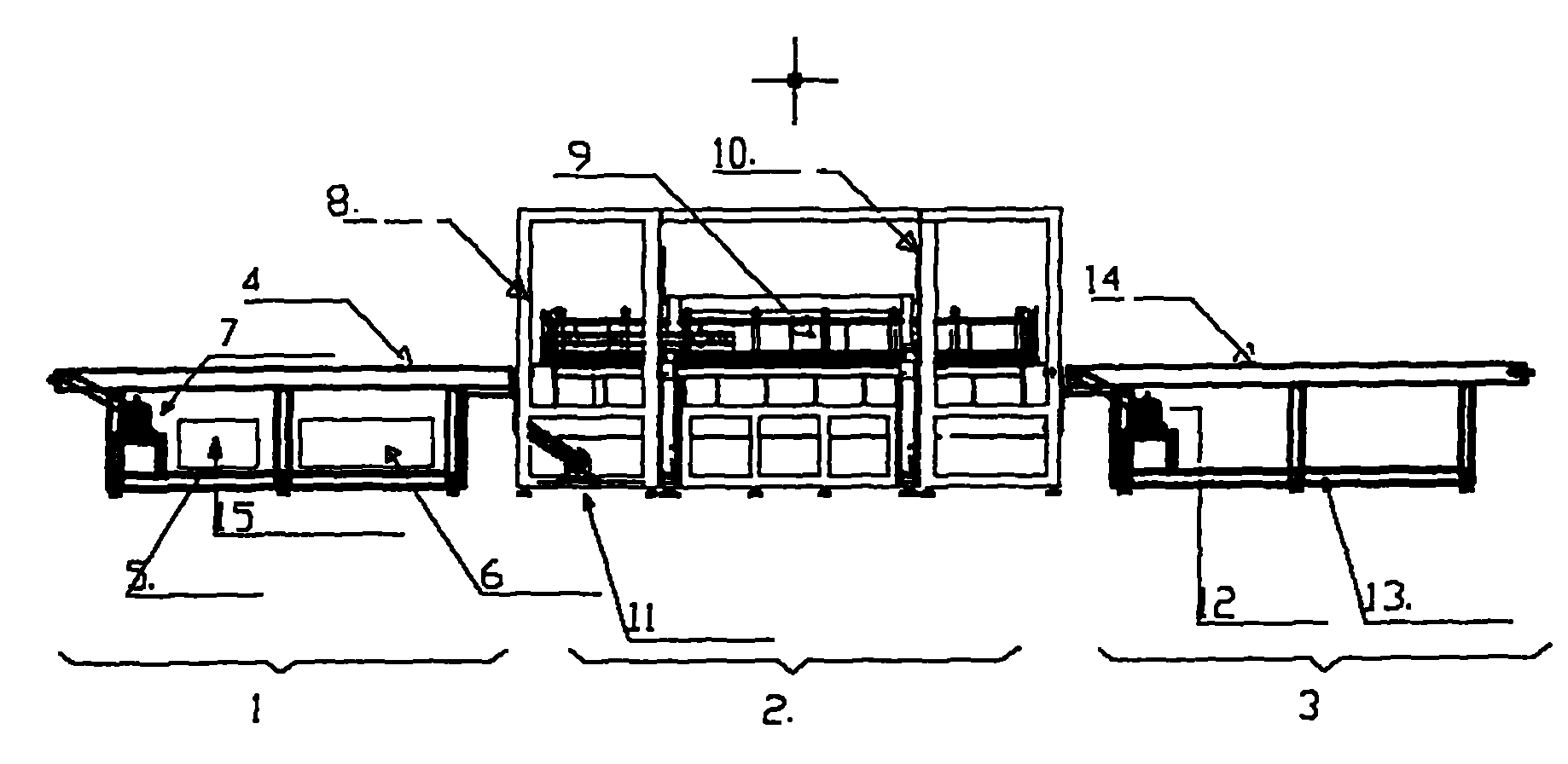

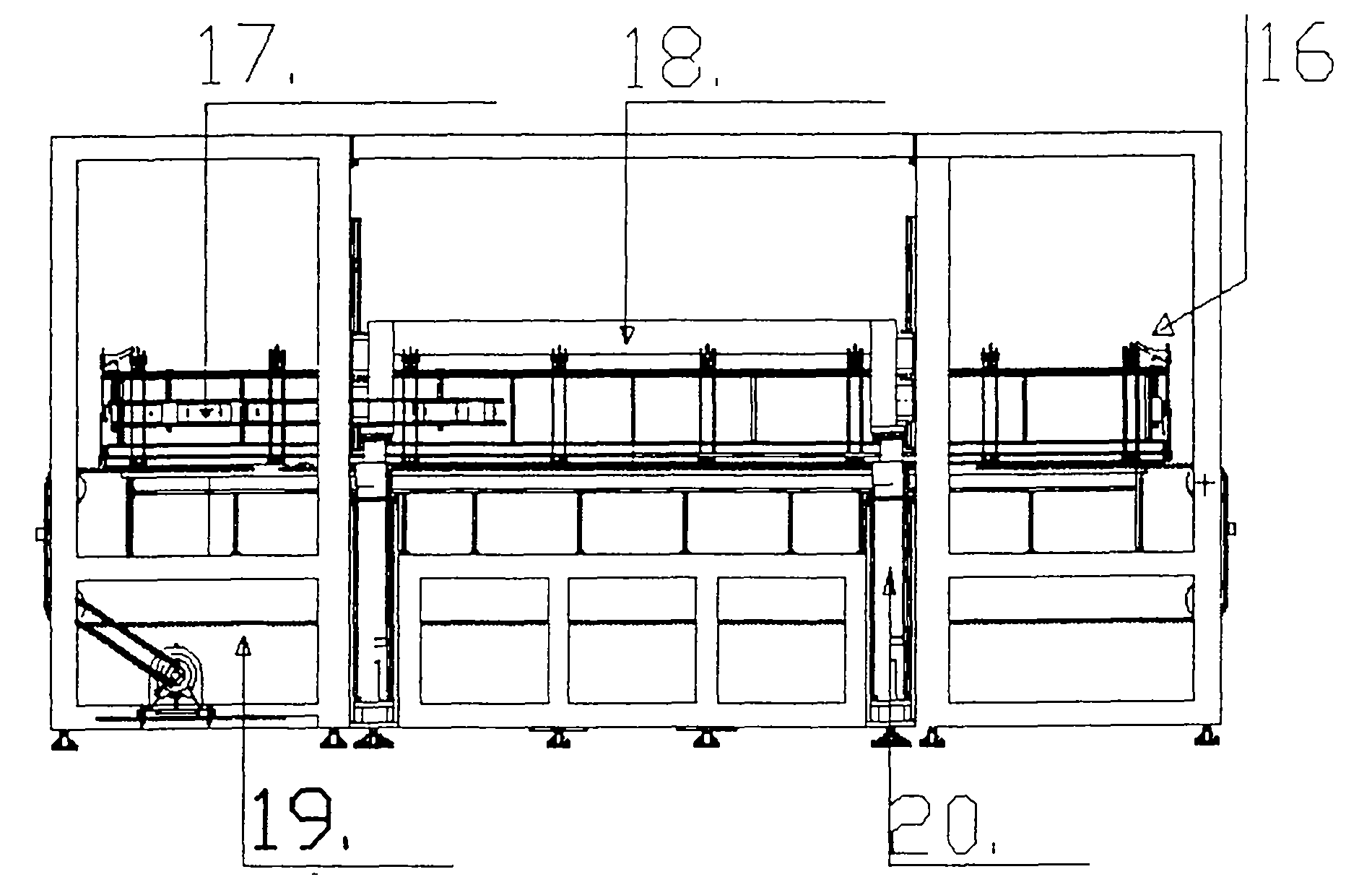

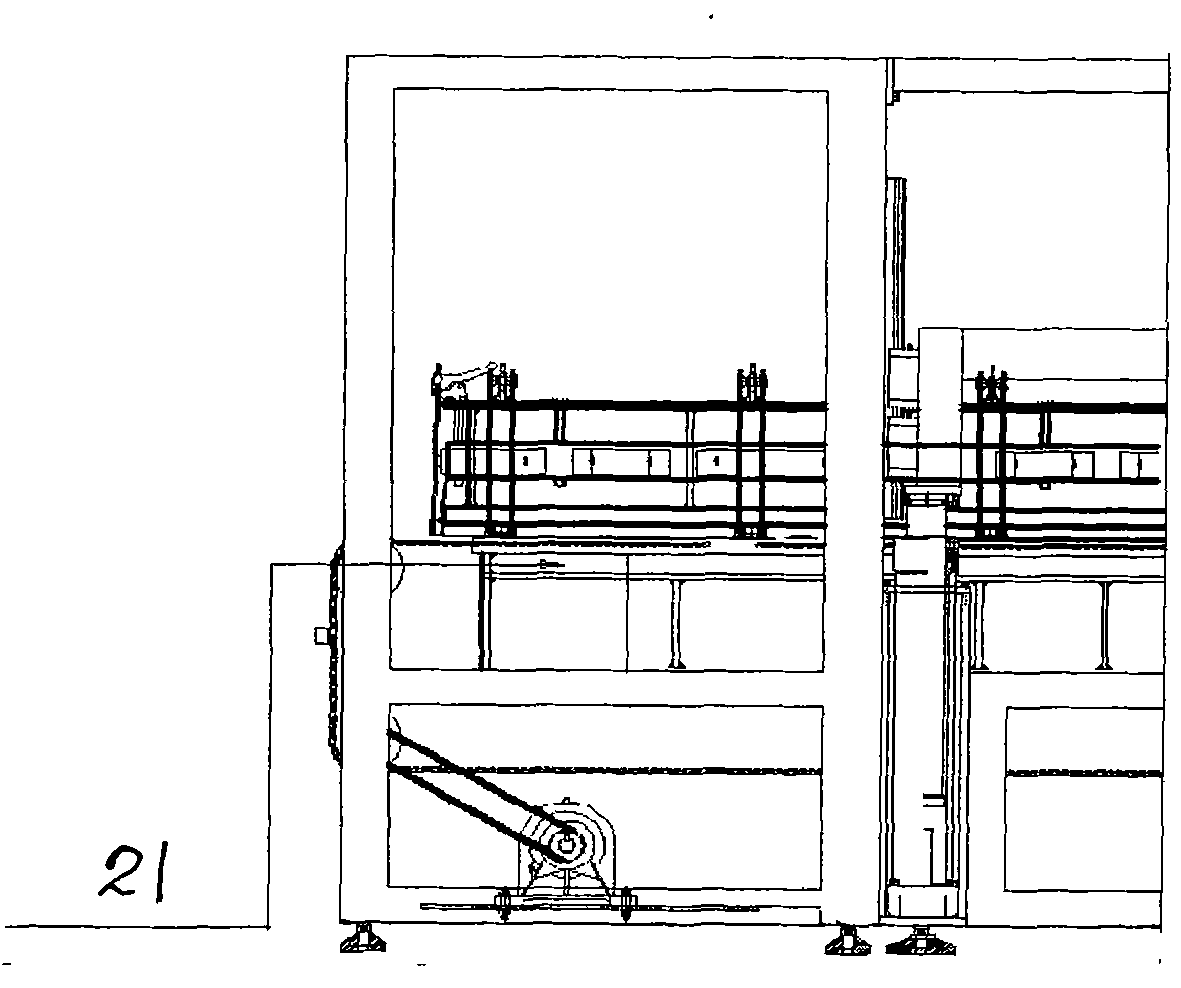

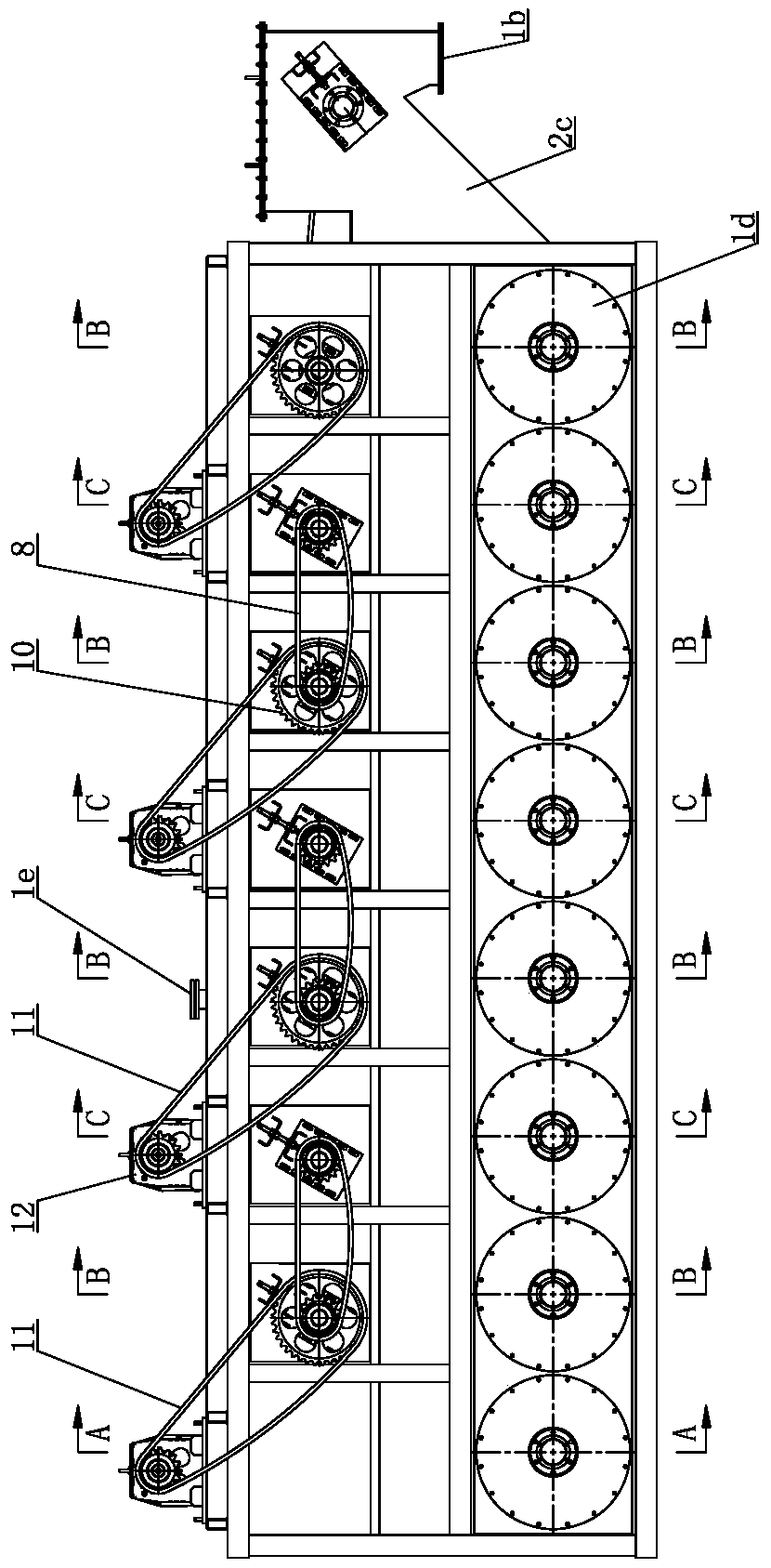

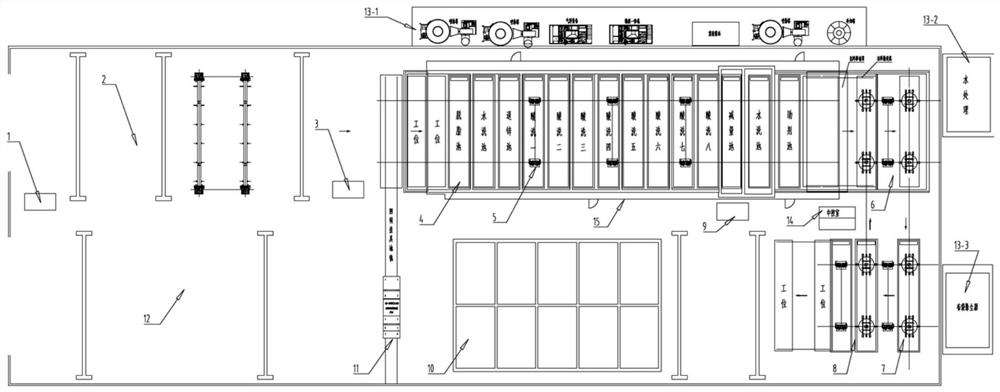

N-type hot galvanizing dual-purpose automatic production line system layout and implementation method

PendingCN111967768AImprove operational efficiencyLow running costHot-dipping/immersion processesRegistering/indicating quality control systemsInformation processingWater circulation

Owner:徐州瑞马智能技术有限公司

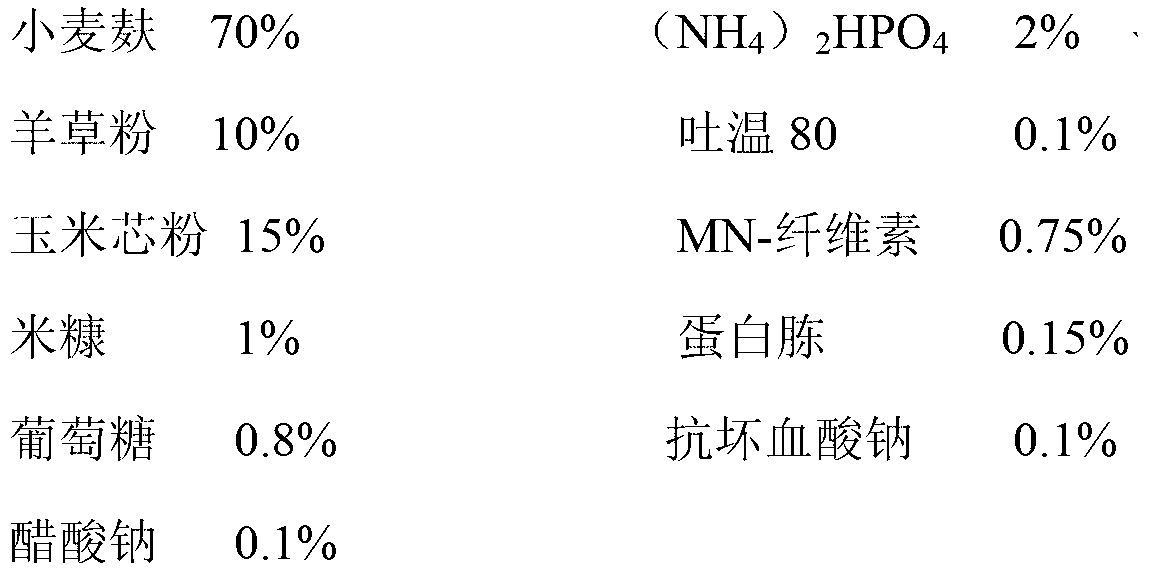

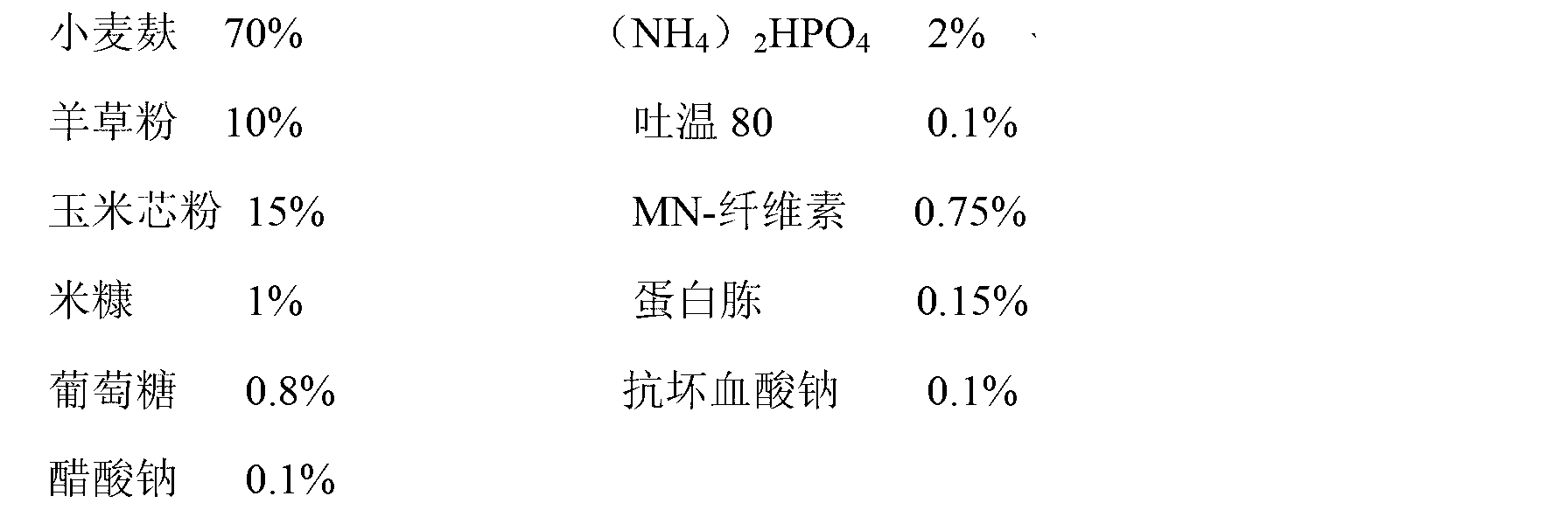

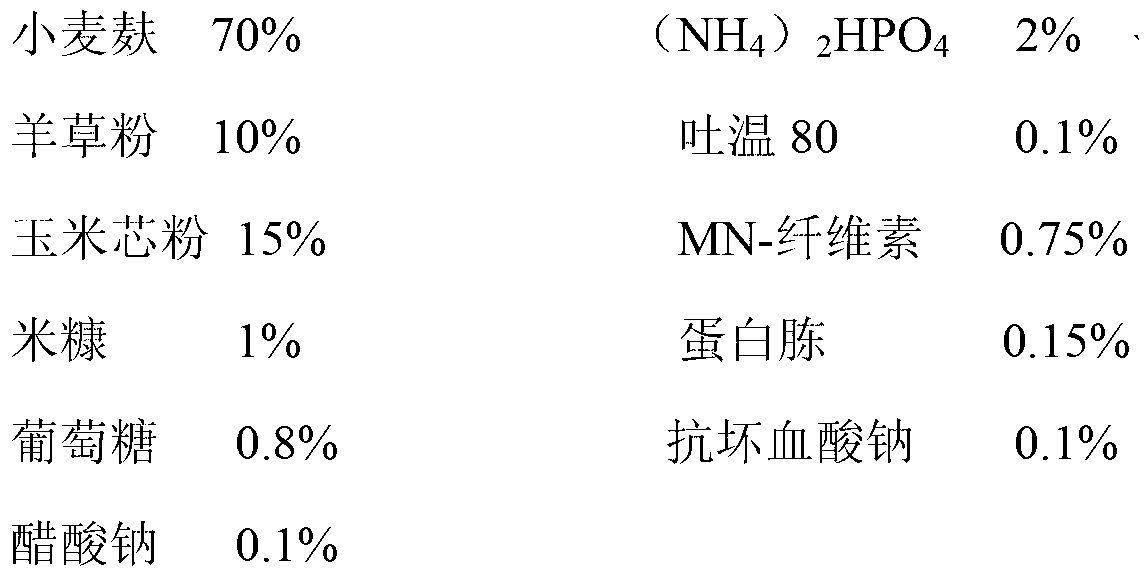

Pleurotus eryngii culture medium and pleurotus eryngii cultivation method

InactiveCN108293601ASimple methodImprove qualityCalcareous fertilisersAnimal corpse fertilisersFiberPotassium

The invention relates to a pleurotus eryngii culture medium and a pleurotus eryngii cultivation method. The culture medium comprises the following raw materials: 50-60 parts of wood chips, 25-30 partsof corncobs, 17-20 parts of bran, 3-5 parts of corn flour, 3-5 parts of soybean meal powder, 1-3 parts of calcium carbonate, 1-3 parts of lime, 2-4 parts of crustacean powder, 3-5 parts of mulberry twigs and 3-5 parts of carrot particles. The pleurotus eryngii cultivation method comprises the following steps: 1, mixing materials; 2, carrying out bagging; 3, carrying out sterilization; 4, carryingout cooling; 5, carrying out inoculation; 6, carrying out fungus germination; 7, carrying out transferring; 8, carrying out mushroom acceleration; 9, carrying out sporocarp development; and 10, carrying out harvesting and processing. The method provided by the invention is convenient and quick, the cultivated pleurotus eryngii can be put into the market in a short time, and expensive raw materials and complex processes are not needed. The pleurotus eryngii cultivated by the method has good quality and high nutritional value, contains rich proteins, carbohydrates, fat, fibers and minerals suchas potassium, phosphorus, calcium, iron and the like, and also contains vitamins B, C and the like.

Owner:绿美食用菌科技发展江苏有限公司

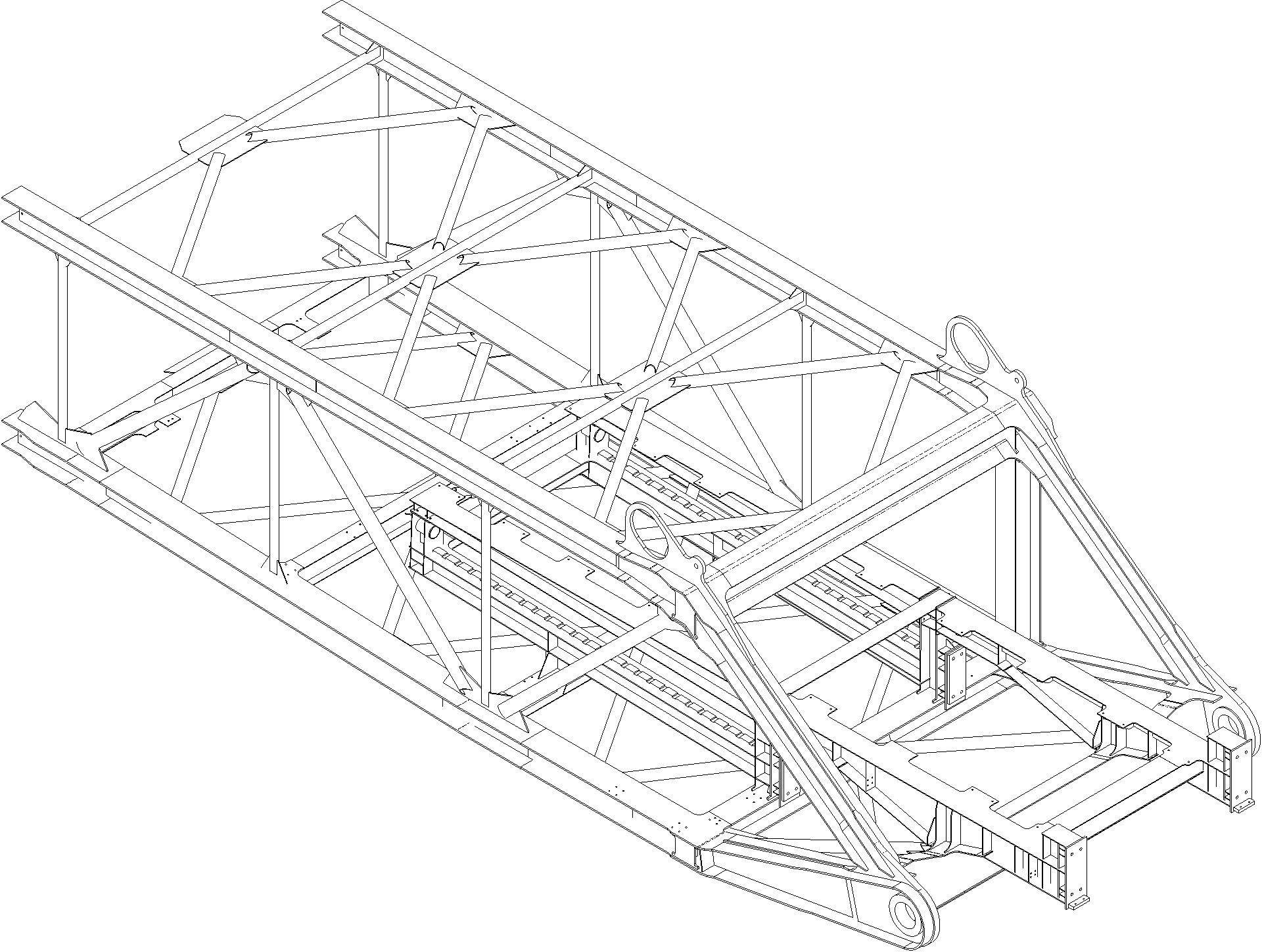

Method for processing material piling and taking machine track by using tools

InactiveCN101850493ASolve the accuracy problemExact fitWelding/cutting auxillary devicesAuxillary welding devicesPosition toleranceMachining

The invention relates to a method for processing a material piling and taking machine track by using tools and belongs to the technical field of machining. The method for processing the material piling and taking machine track comprises the following technical steps of: (1) performing rough machining on a track blank, namely eliminating deformation caused when a material is heated in a blanking process; (2) performing split processing, namely machining and welding alternatively and welding the track with a corresponding frame by using a welding tool I when frames are not assembled together; (3) performing finish machining on the track, namely performing finish machining on the track until the track meet the requirements of size, roughness and form and position tolerance; and (4) performing assembly and welding, namely using a welding tool II and a welding tool III to ensure relative position accuracy and welding four independent frames on which the track is positioned. The method has the advantages of simple process, time saving and labor saving properties, low manufacturing cost, reliable positioning, simple, convenient and rapid operation, easy grasping for users, high processing efficiency, high processing accuracy, high product quality and the like.

Owner:TIANJIN SERI MACHINERY EQUIP

Flue gas desulfurization process for small-sized heating or short-running-cycle boiler

InactiveCN102120128AWide variety of sourcesLow priceDispersed particle separationChemical reactionSlag

The invention relates to a desulfurization technology, in particular to a flue gas desulfurization process for a small-sized heating or short-running-cycle boiler, wherein the process provided by the invention is used for realizing desulfurization of a coal-fired boiler. In the method, limestone powder and coal are mixed and then added in a hearth, wherein the quantity rate of calcium to sulfur is 1.3-1.5; the sulfur dioxide generated by coal burning and the limestone powder are subjected to chemical reaction in the hearth so as to complete the main desulfurization process, the solid generated by reaction and slag are flushed to a desulfurization sedimentation basin together; the sulfur dioxide generated by residue sulfur elements enters a desulfurizing tower along with the flue gas; and the precipitated slag is cleared in the desulfurization sedimentation basin, the slurry containing lime at the upper part of the desulfurization sedimentation basin is fed into the desulfurizing tower by a desulfurization circulating pump and is in contact with the flue gas upstream from the lower part of the desulfurization sedimentation basin to be subjected to the desulfurization reaction again, the slurry after reaction falls in the bottom of the tower and overflows to a flushing tank through an overflow port, and finally the total sulfur elements are completely removed and collected.

Owner:SHANXI GERUI ENVIRONMENTAL PROTECTION EQUIP

Yeast culture extruding granulation and fermentation process taking distiller grains as raw materials

InactiveCN105146106AClear compositionHigh nutritional valueFood processingAnimal feeding stuffProduct inspectionYeast

The invention relates to a yeast culture extruding granulation and fermentation process taking distiller grains as raw materials. A technological process of the yeast culture extruding granulation and fermentation process comprises the following steps: (1) preparing materials; (2) activating strains; (3) inoculating and mixing; (4) controlling the temperature and fermenting; (5) carrying out enzymolysis to break walls; (6) granulating: preparing yeast culture particles by adopting a screw rod extruding manner; (7) drying: controlling the temperature of the yeast culture particles at 45-75 DEG C and drying for 12-36 hours to obtain finished products; and (8) carrying out post-treatment on the products: checking the products and packaging after qualification to obtain finished products. According to the yeast culture extruding granulation and fermentation process provided by the invention, distiller grain rice husks do not need to be removed; the products are obtained by adopting extruding granulation and low-temperature drying methods; after the materials are fermented for the first time, the viable count of yeast is more than or equal to 10*10<8>cfu / g of dry materials, the content of small peptides in a yeast culture is more than or equal to 10% and the wall breaking rate of the yeast is more than or equal to 80%; and the yeast culture extruding granulation and fermentation process has a complete process, a short production period and a relatively high nutritional value.

Owner:江苏益元泰生物技术有限公司

Double-sided floor and manufacturing method thereof

InactiveCN107139550ASimple structureGood value for moneyLayered product treatmentLaminationPaymentEngineering

The invention discloses a double-sided floor and a manufacturing method thereof. The invention is simple in structure, convenient and practical, green and environmentally friendly, waterproof and non-slip, sound-absorbing and flame-retardant, and cost-effective. , different pattern and same color, different pattern and different color and other combinations, this kind of double-sided structure, even if one side is defective due to dirt and impurities in the production process, there is another side that can be used, effectively improving the production yield and product quality; During the paving operation, customers can choose the same color pavement or different color embellished pavement according to their preferences, so that customers can obtain a variety of pavement combination effects for the same purchase price.

Owner:ANHUI YOSEMITE PLASTIC TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com