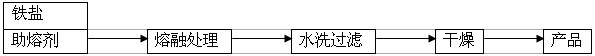

Method for preparing micaceous iron oxide by molten salt growth method

A technology of mica iron oxide and molten salt method, which is applied in the direction of iron oxide, iron oxide/iron hydroxide, etc., which can solve the requirements of volatile, small particle size of mica iron oxide, high pressure vessel temperature resistance, pressure resistance and corrosion resistance Very strict and other issues, to achieve the effect of shortening the reaction time, lowering the synthesis temperature, and increasing the diffusion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

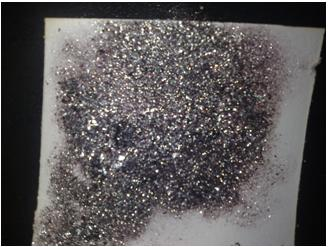

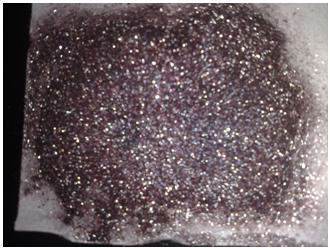

[0043] 10g iron source ferrous ammonium sulfate (FeSO 4 (NH 4 ) 2 SO 4 ·6H 2 O), 8.80gNa 2 SO 4 , 2.53gK 2 SO 4 Mix and grind evenly, put it into a corundum crucible, put the reaction mixture into a reaction furnace, and the temperature controller will raise the temperature at a rate of 5°C / min, the temperature will reach 800°C, keep the temperature for 30 minutes, preheat treatment; continue to heat up to 950°C and keep warm After 6 hours, the program cools down. After cooling to room temperature, transfer the product to a beaker, add 90ml of deionized water, stir and fully wash in a water bath at about 90°C to dissolve the sintered flux in water, and then wash it with a large amount of deionized water after suction filtration. to remove residual ions. The obtained filter cake was dried in a drying oven at 100 °C for about 1 h. After drying, the structure of the filter cake is loose, and the flaky mica iron oxide product is finally obtained. The obtained micaceous ...

Embodiment 2

[0045] 7g iron source ferrous sulfate FeSO 4 ·7H 2 O, 2.24gNaCl, 2.85gKCl are mixed and ground evenly, put into a porcelain crucible, put the reaction mixture into a reaction furnace, the temperature controller is programmed to heat up at a rate of 5°C / min, the temperature reaches 800°C, and the temperature is maintained for 30 minutes, preheating ;Continue to heat up to 900°C for 6 hours, then program to cool down. After cooling to room temperature, the product appeared as a spatter covering all inner surfaces of the crucible. Transfer the product to a beaker, add 90ml of deionized water, and stir in a water bath at about 90°C to fully wash with water to dissolve the sintered flux in water, and then wash with a large amount of deionized water after suction filtration to remove residual ions. The obtained filter cake was dried in a drying oven at 100 °C for about 1 h. After drying, the structure of the filter cake is loose, and the flaky mica iron oxide product is finally o...

Embodiment 3

[0047] 7g iron source ferrous sulfate (FeSO 4 ·7H 2 O), 8.80gNa 2 SO 4 , 2.53gK 2 SO 4 Mix and grind evenly, put it into a corundum crucible, put the reaction mixture into a reaction furnace, and the temperature controller will raise the temperature at a rate of 5°C / min, the temperature will reach 800°C, keep the temperature for 30 minutes, preheat treatment; continue to heat up to 950°C and keep warm After 6 hours, the program cools down. After cooling to room temperature, transfer the product to a beaker, add 90ml of deionized water, stir and fully wash in a water bath at about 90°C to dissolve the sintered flux in water, and then wash it with a large amount of deionized water after suction filtration. to remove residual ions. The obtained filter cake was dried in a drying oven at 100 °C for about 1 h. After drying, the structure of the filter cake is loose, and the flaky mica iron oxide product is finally obtained. The obtained micaceous iron oxide particles have a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com