Patents

Literature

96results about How to "Avoid interconnection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

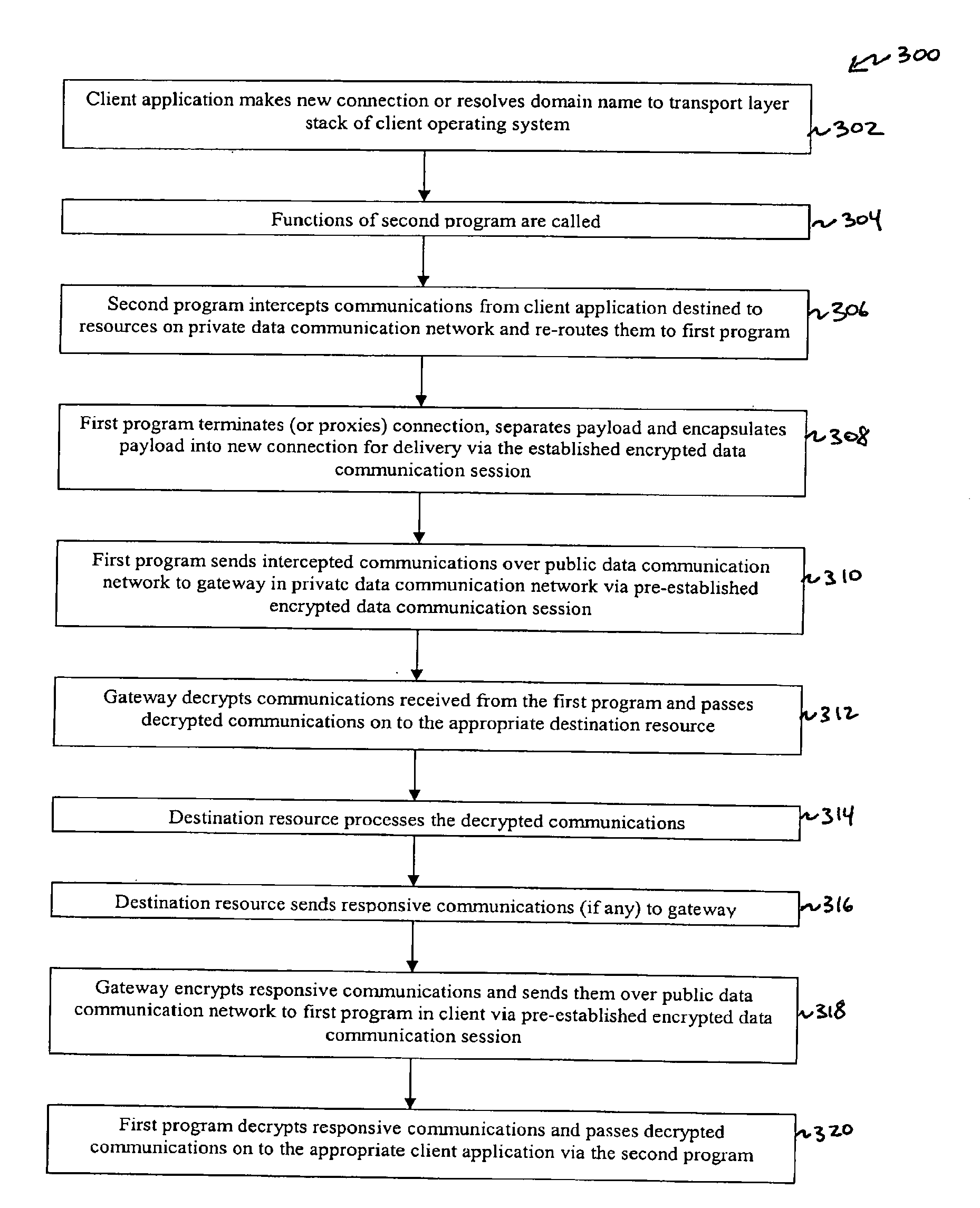

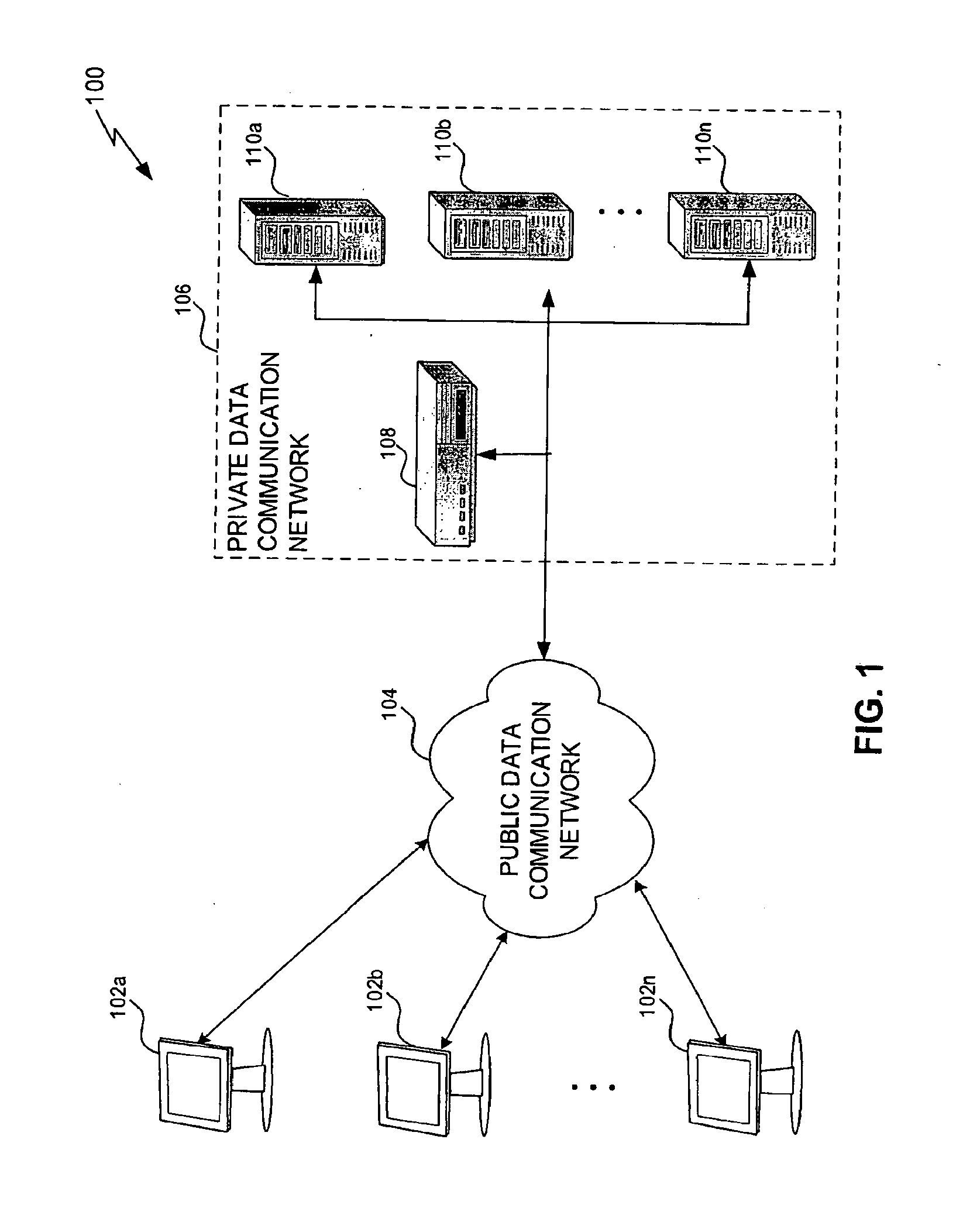

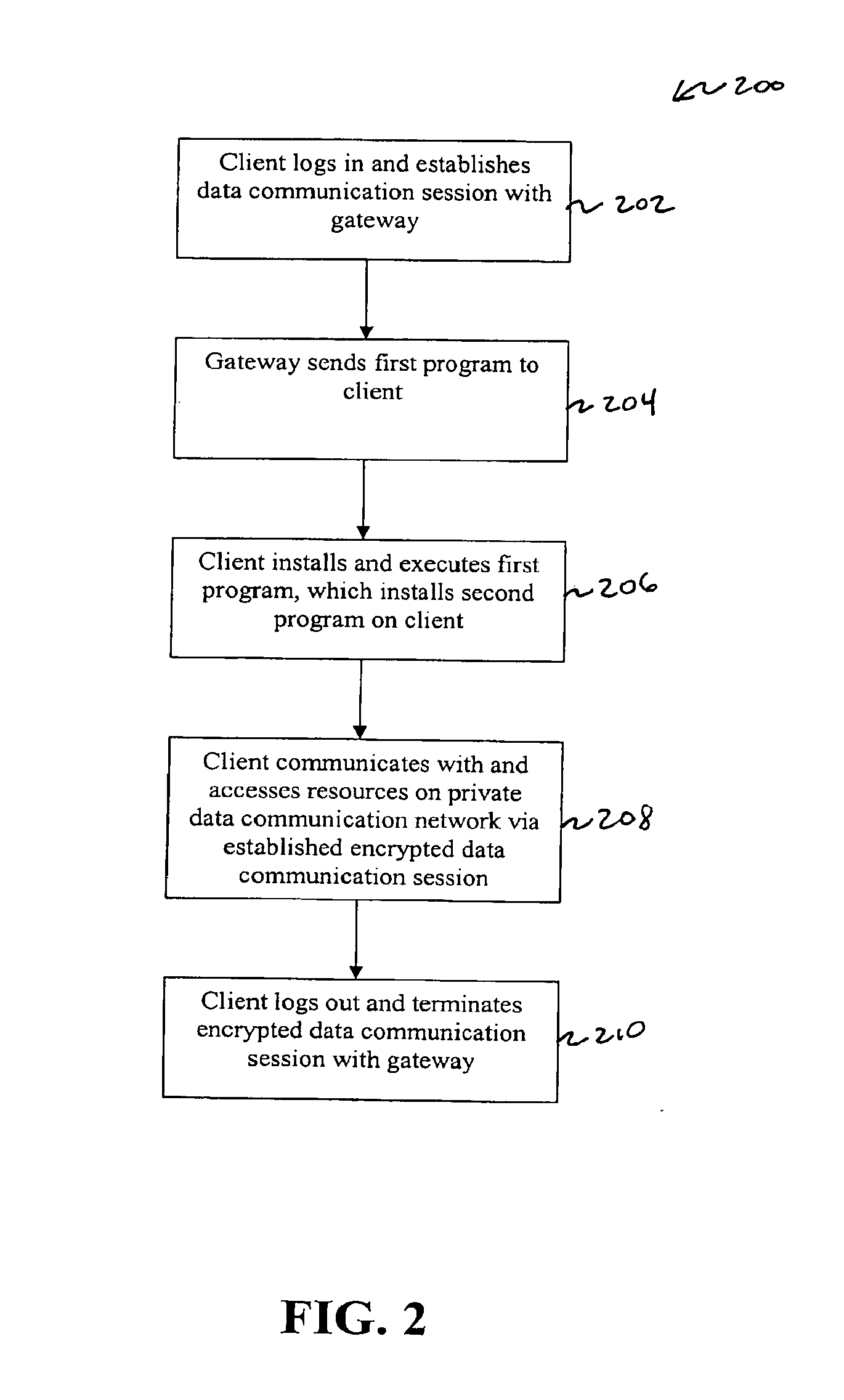

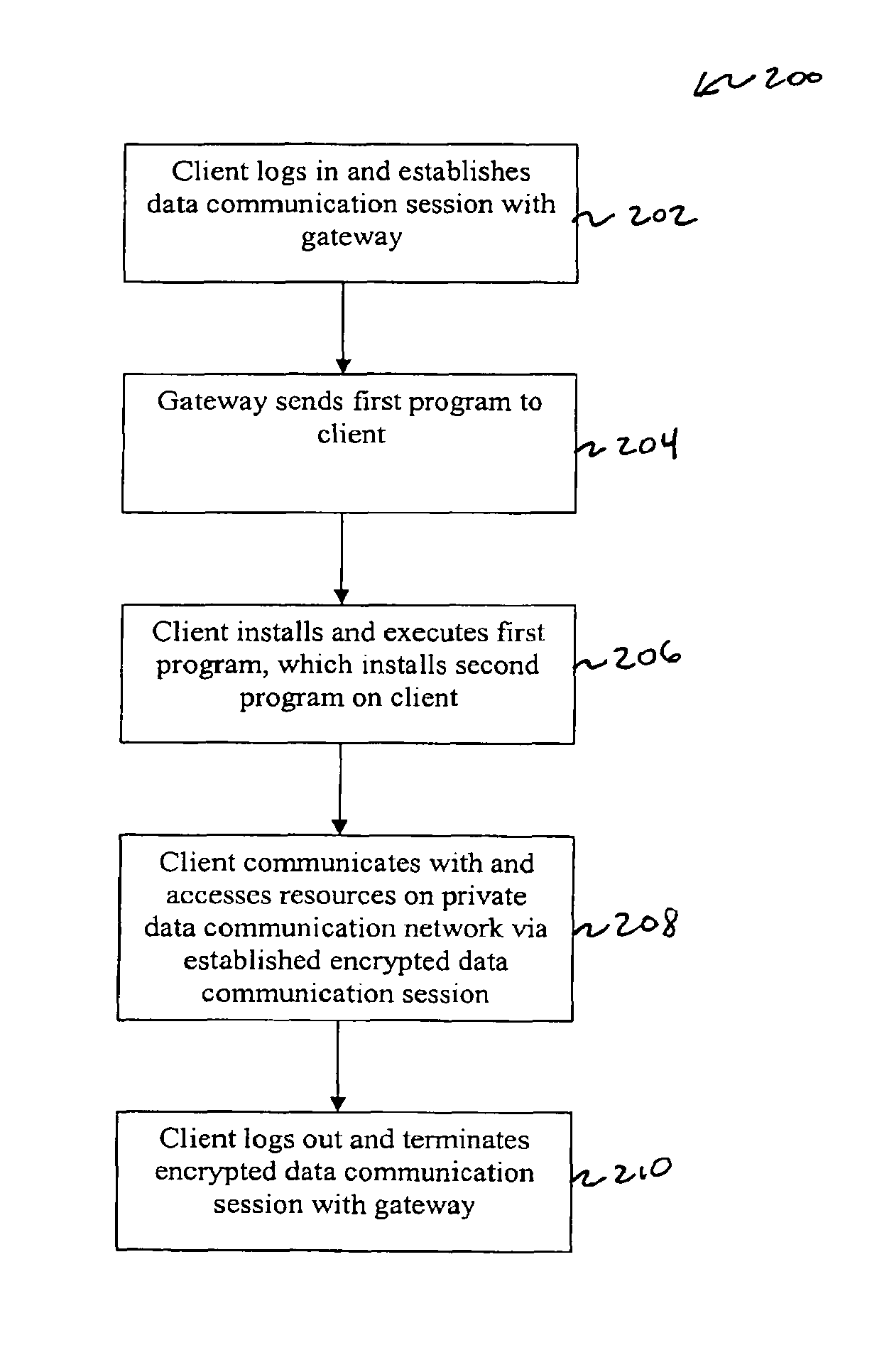

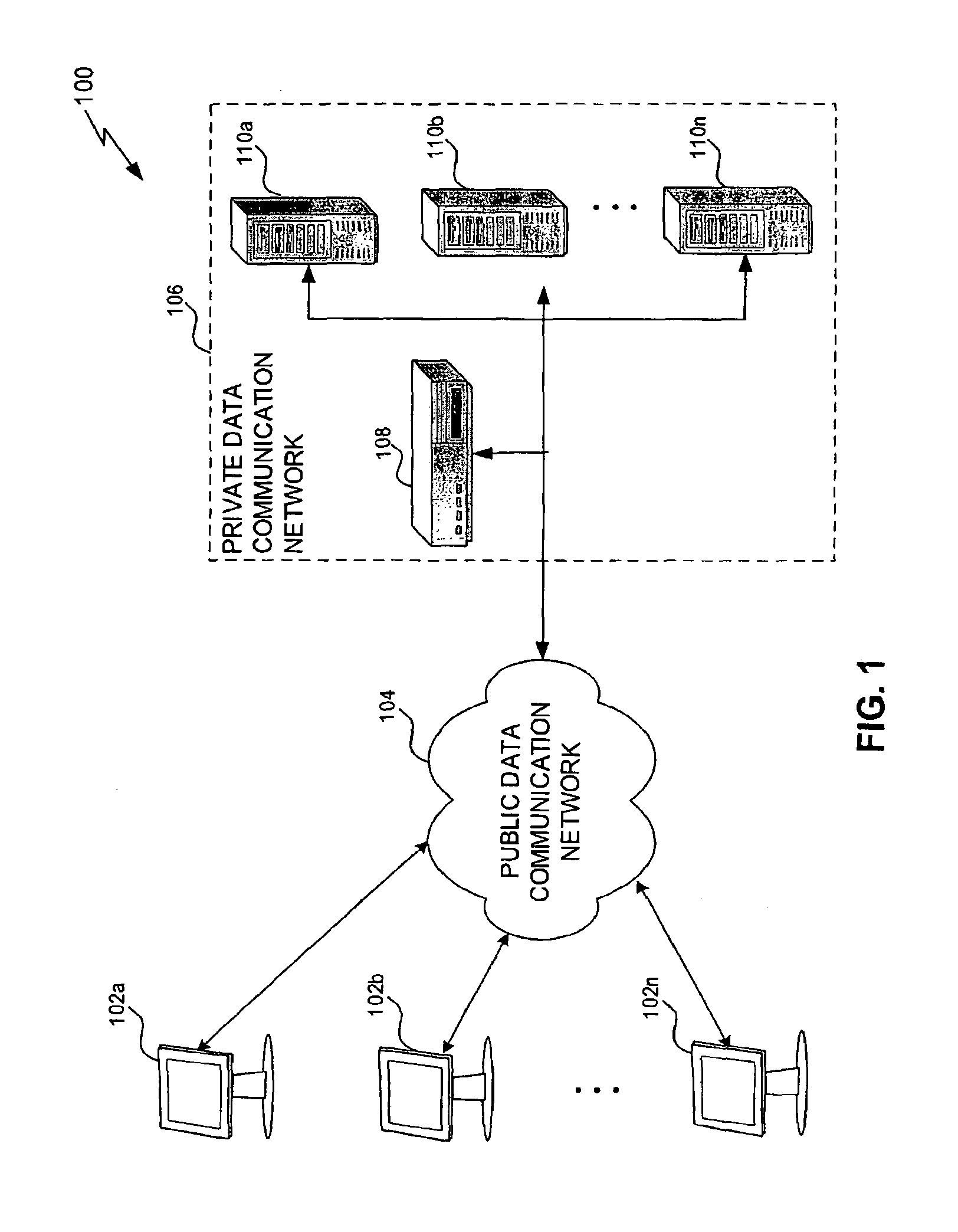

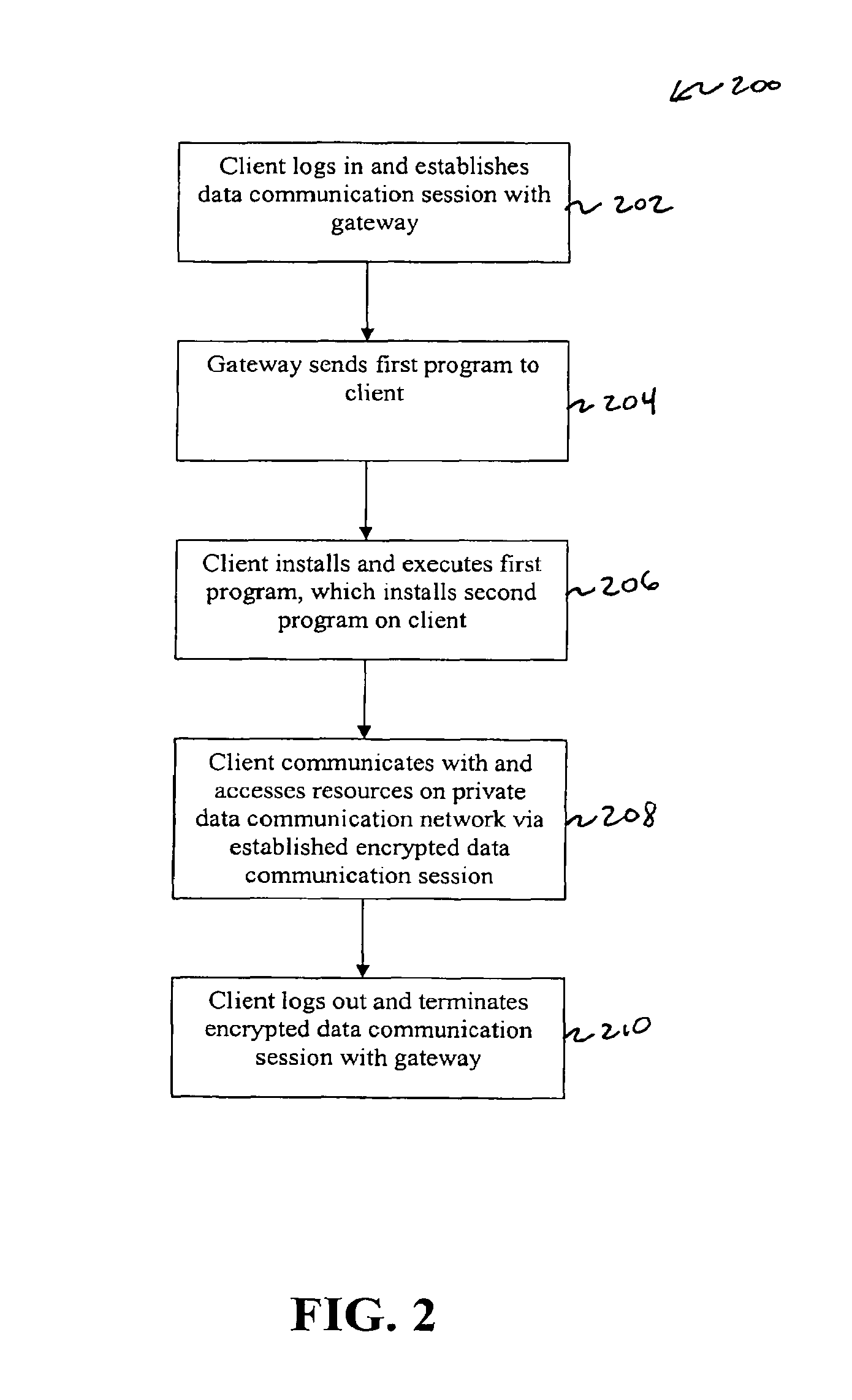

System and method for establishing a virtual private network

ActiveUS20100241846A1Improve network securityFor further processingData switching by path configurationMultiple digital computer combinationsPrivate networkClient-side

A system and method for establishing a virtual private network (VPN) between a client and a private data communication network. An encrypted data communication session, such as a—Secure Sockets Layer (SSL) data communication session, is established between a gateway and the client over a public data communication network. The gateway then sends a programming component to the client for automatic installation and execution thereon. The programming component operates to intercept communications from client applications destined for resources on the private data communication network and to send the intercepted communications to the gateway via the encrypted data communication session instead of to the resources on the private data communication network.

Owner:CITRIX SYST INC

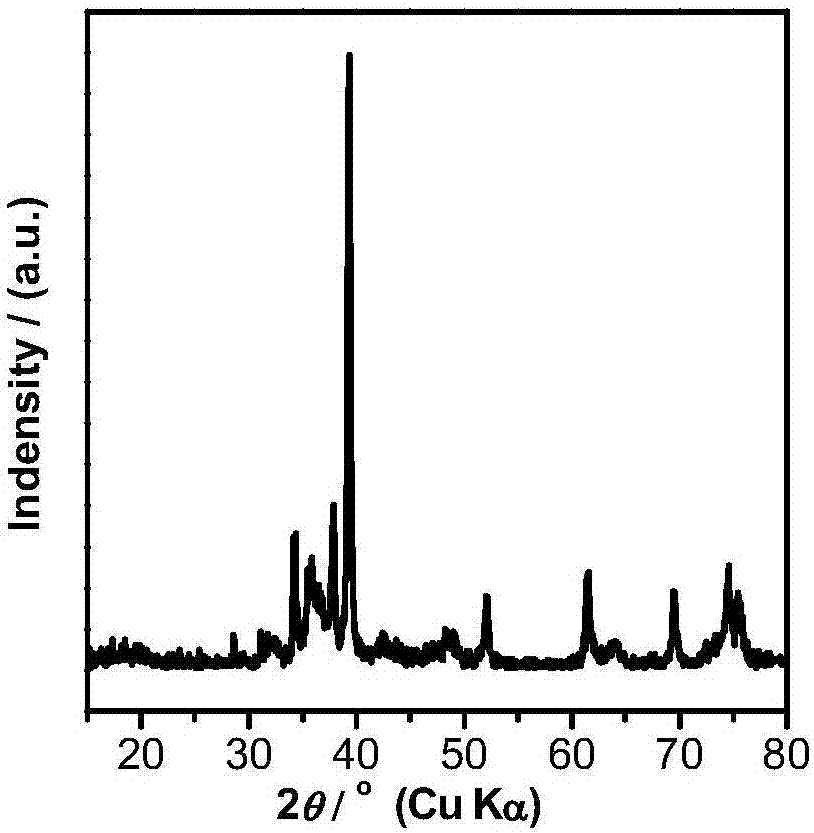

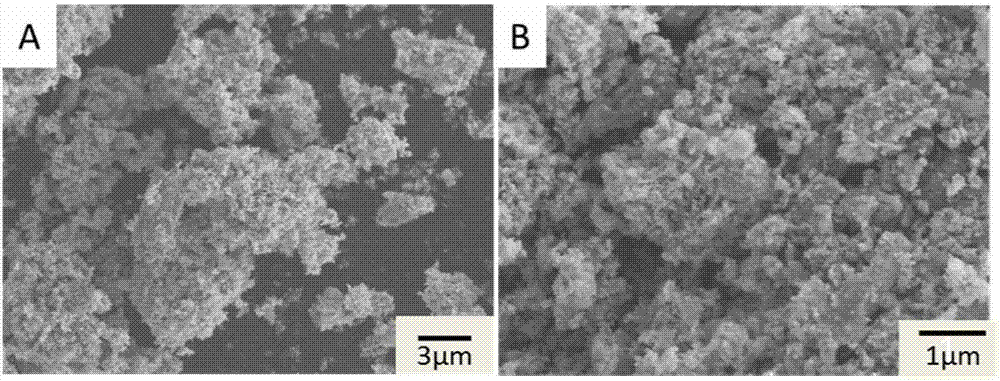

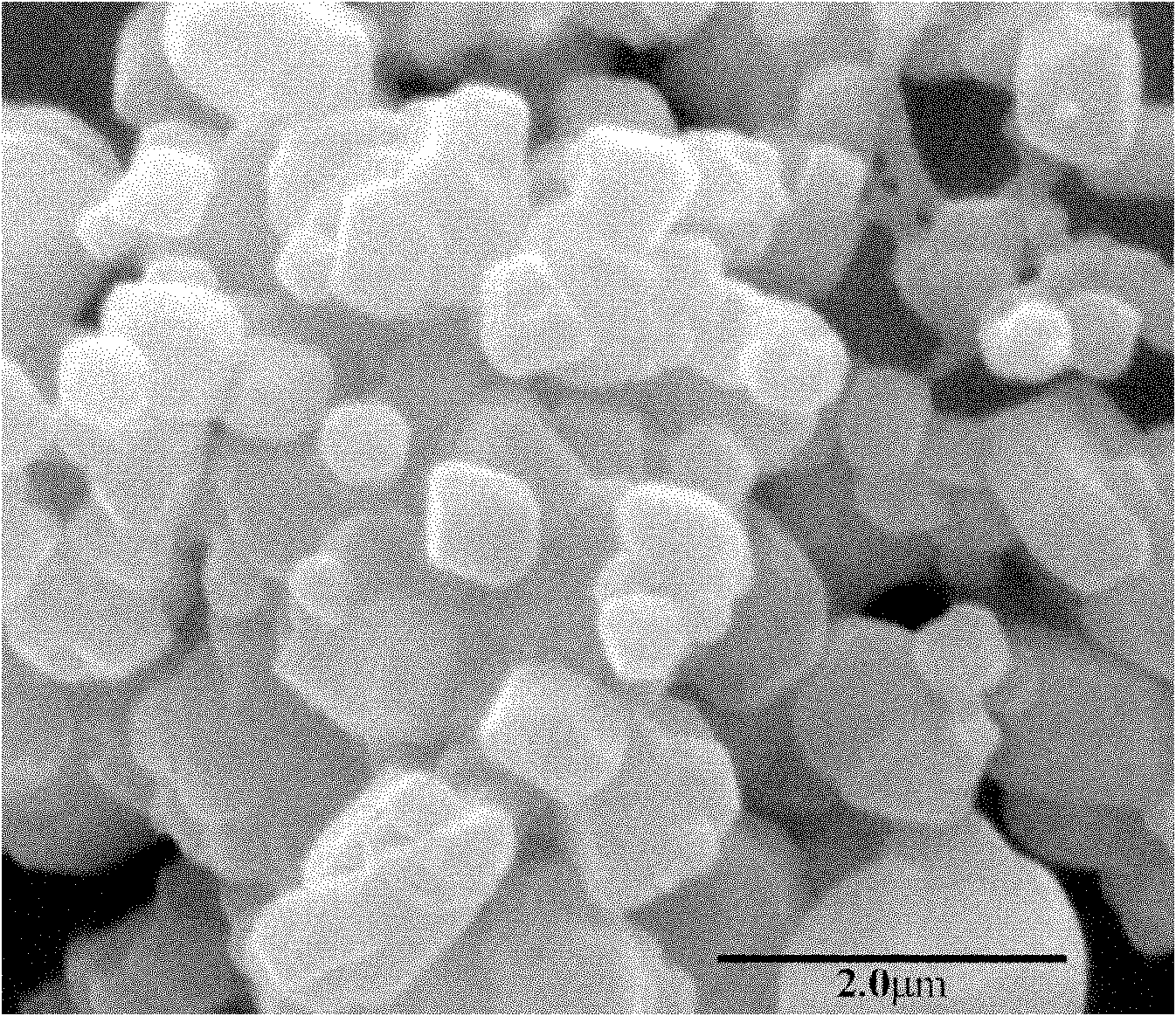

Preparation method of micro-nano molybdenum carbide powder

InactiveCN107352543AGuaranteed to dissolveAvoid contactTungsten/molybdenum carbideMicro nanoMolybdate

The invention discloses a preparation method of micro-nano molybdenum carbide powder. The preparation method comprises the specific steps that an organic precursor serves as a carbon source, molybdate serves as a molybdenum source, fused salt serves as a reaction medium, high-temperature processing, washing and drying are conducted in sequence in an air environment, and the micro-nano molybdenum carbide powder is prepared. The preparation method is quick in reaction speed, and the reaction time is effectively shortened. Besides, the fused salt exists between the generated solid-phase molybdenum carbide particles in the reaction process, so that the mutual bonding between the particles can be stopped, and the agglomeration phenomenon can be reduced. In the method, no special atmospheric conditions are needed, the micro-nano molybdenum carbide material can be prepared at a relatively low temperature; the process is simple, the preparation conditions are mild, and a large scale of production is easy to achieve.

Owner:DONGGUAN UNIV OF TECH

Al-based alloy sputtering target and manufacturing method thereof

InactiveUS20090242394A1Low resistivityImprove heat resistanceCellsVacuum evaporation coatingAlloyHardness

The present invention provides an Al—(Ni, Co)—(Cu, Ge)—(La, Gd, Nd) alloy sputtering target capable of decreasing a generation of splashing in an initial stage of using the sputtering target, preventing defects caused thereby in interconnection films or the like and improving a yield and operation performance of an FPD, as well as a manufacturing method thereof. The invention relates to an Al-based alloy sputtering target which is an Al—(Ni, Co)—(Cu, Ge)—(La, Gd, Nd) alloy sputtering target comprising at least one member selected from the group A (Ni, Co), at least one member selected from the group B (Cu, Ge), and at least one member selected from the group C (La, Gd, Nd) wherein a Vickers hardness (HV) thereof is 35 or more.

Owner:KOBELCO RES INST +1

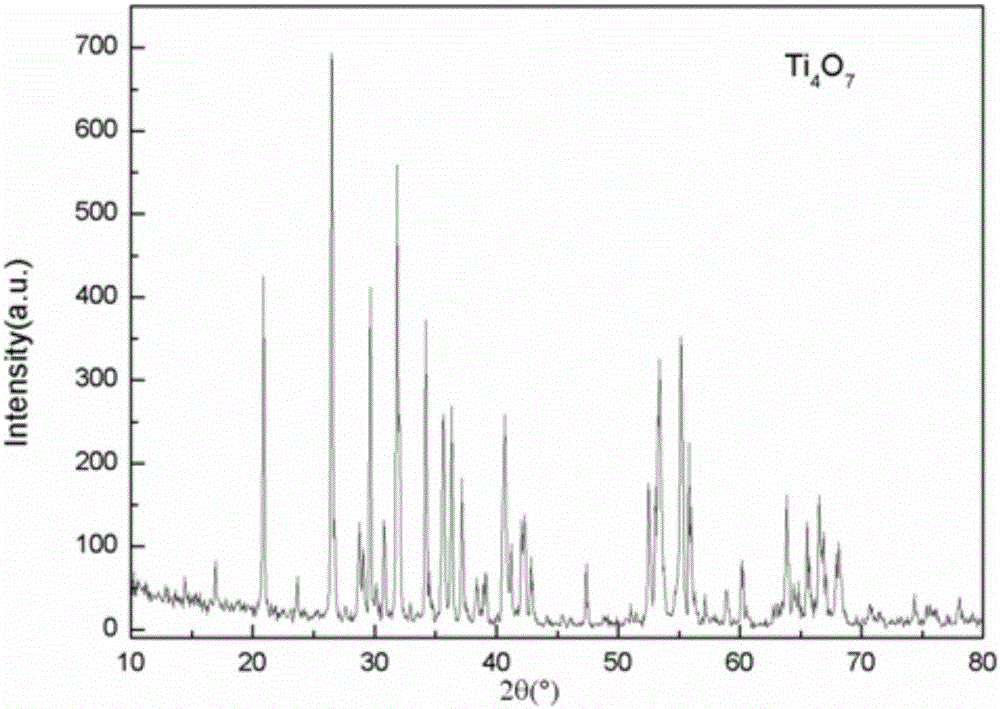

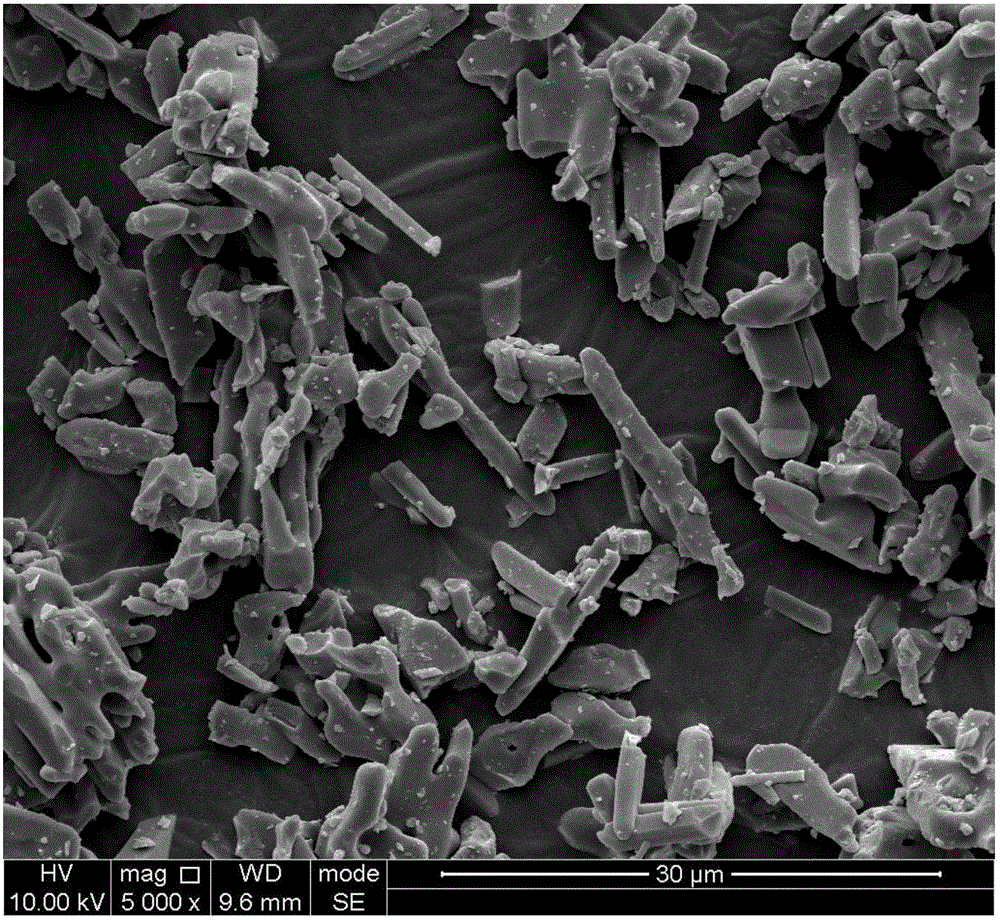

Rod-like titanium protoxide powder and preparation method thereof

The invention relates to a rod-like titanium protoxide powder and a preparation method thereof, wherein the titanium protoxide powder is Ti3O5 powder, Ti4O7 powder, Ti5O9 powder, Ti6O11 powder, Ti7O13 powder, Ti8O15 powder or Ti9O17 powder. The preparation method comprises: (1) material preparing, wherein raw materials comprise titanium dioxide powder, a carbon reducing agent and a chlorine salt, and according to the chemical formulas of each titanium protoxide powder and the chemical reactions among the used raw materials, the mold ratios of the raw materials for preparing various titanium protoxide powders are calculated; (2) material mixing and drying; (3) sintering, wherein the mixed powder obtained in the step (2) is loaded into a heating furnace, heating is performed at a heating speed of 5-15 DEG C / min under a flowing inert gas to achieve a temperature of 700-1300 DEG C, a reduction reaction is performed for 2-8 h at the temperature of 700-1300 DEG C, and cooling is performed along with the furnace to a room temperature after the reduction time is achieved; and (4) washing and drying, wherein the titanium protoxide-salt mixed powder obtained in the step (3) is washed with deionized water 3-10 times, and then drying is performed to obtain the rod-like titanium protoxide powder.

Owner:SICHUAN UNIV

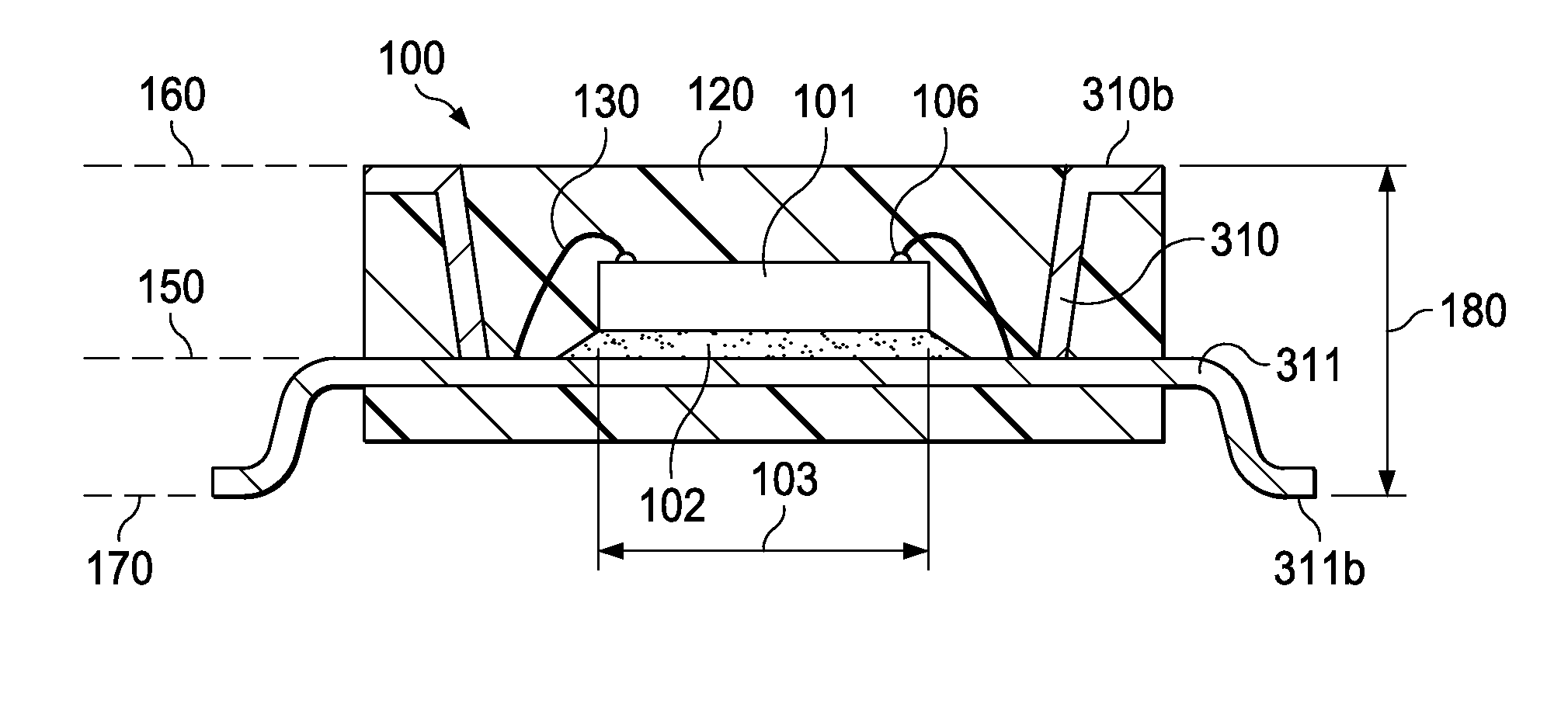

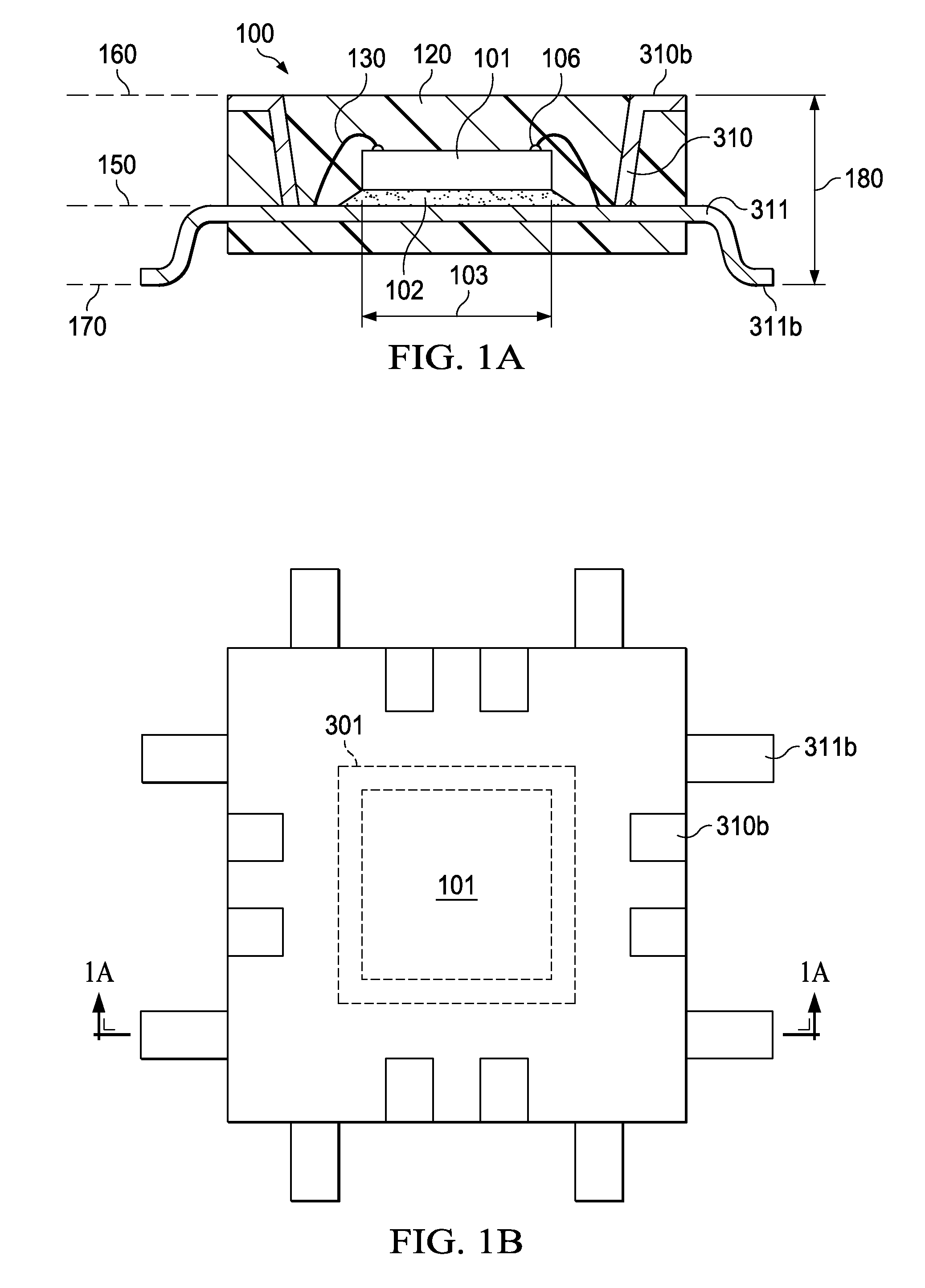

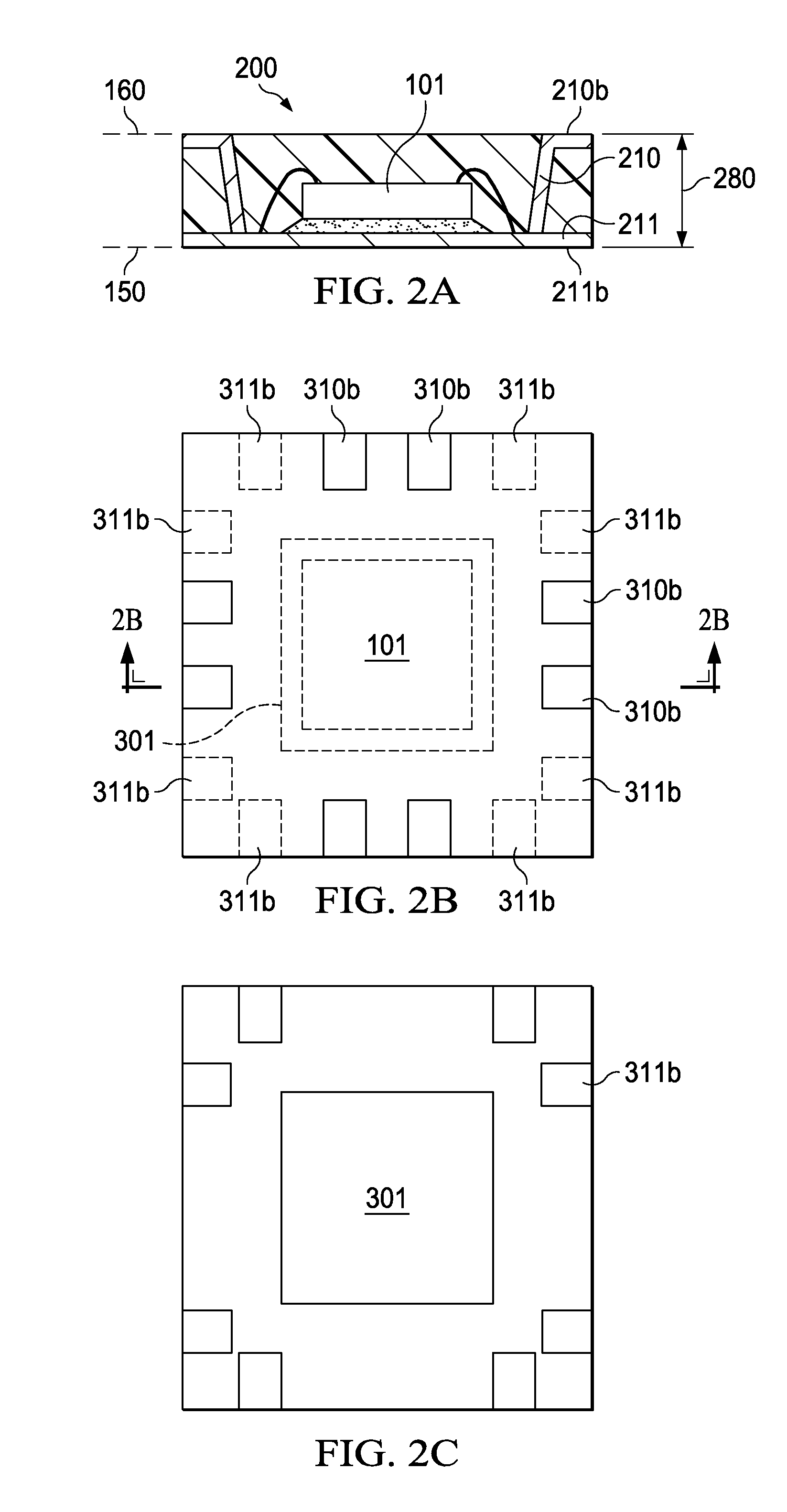

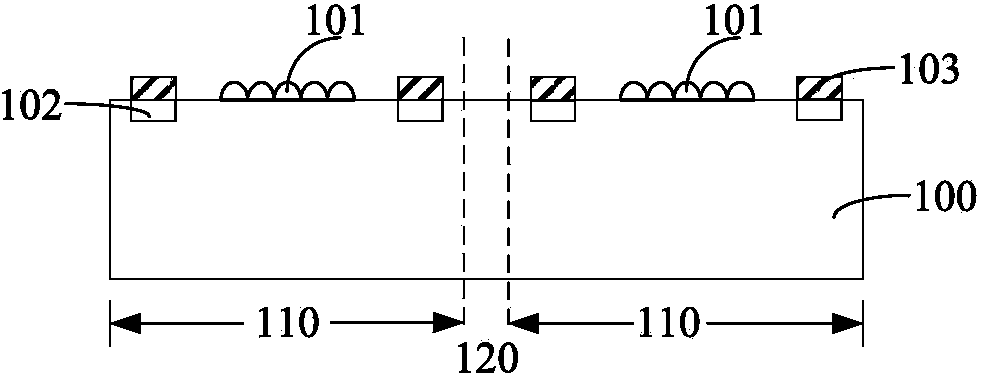

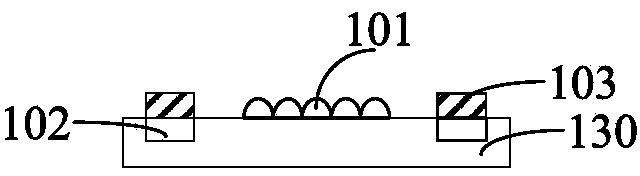

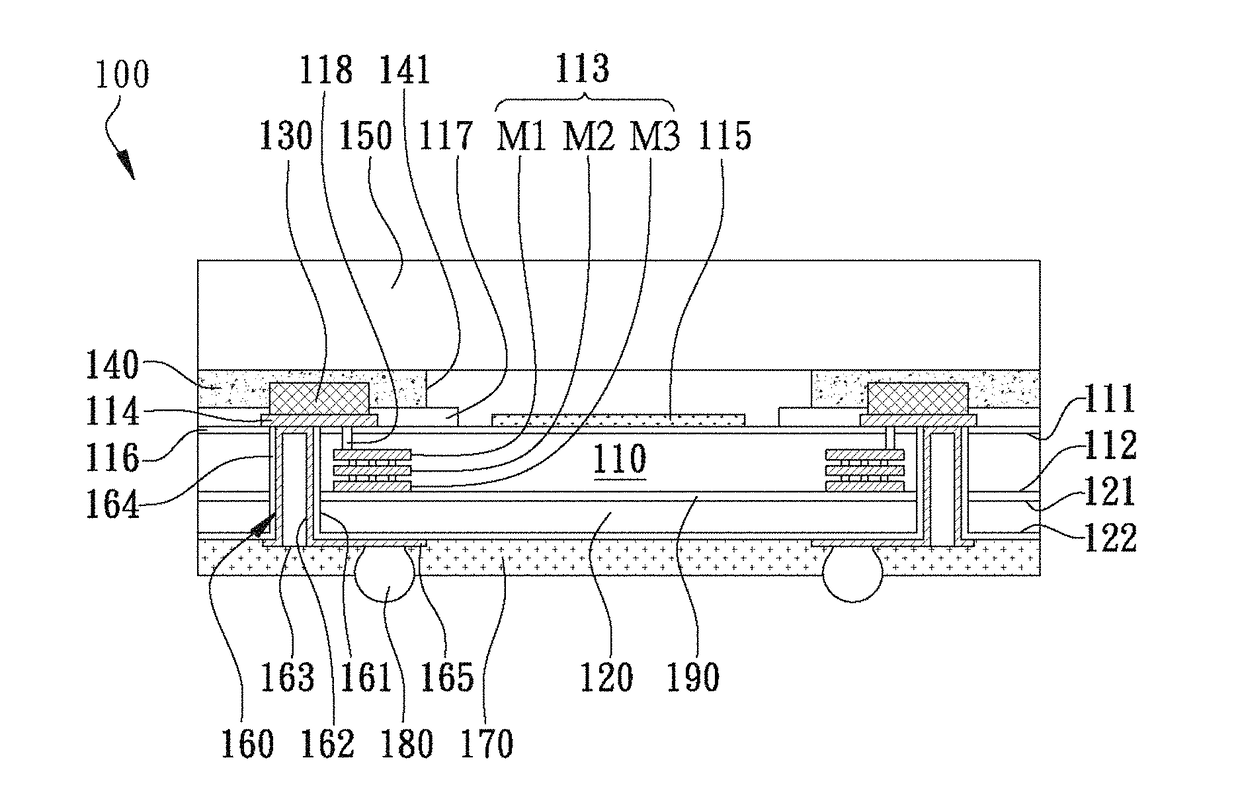

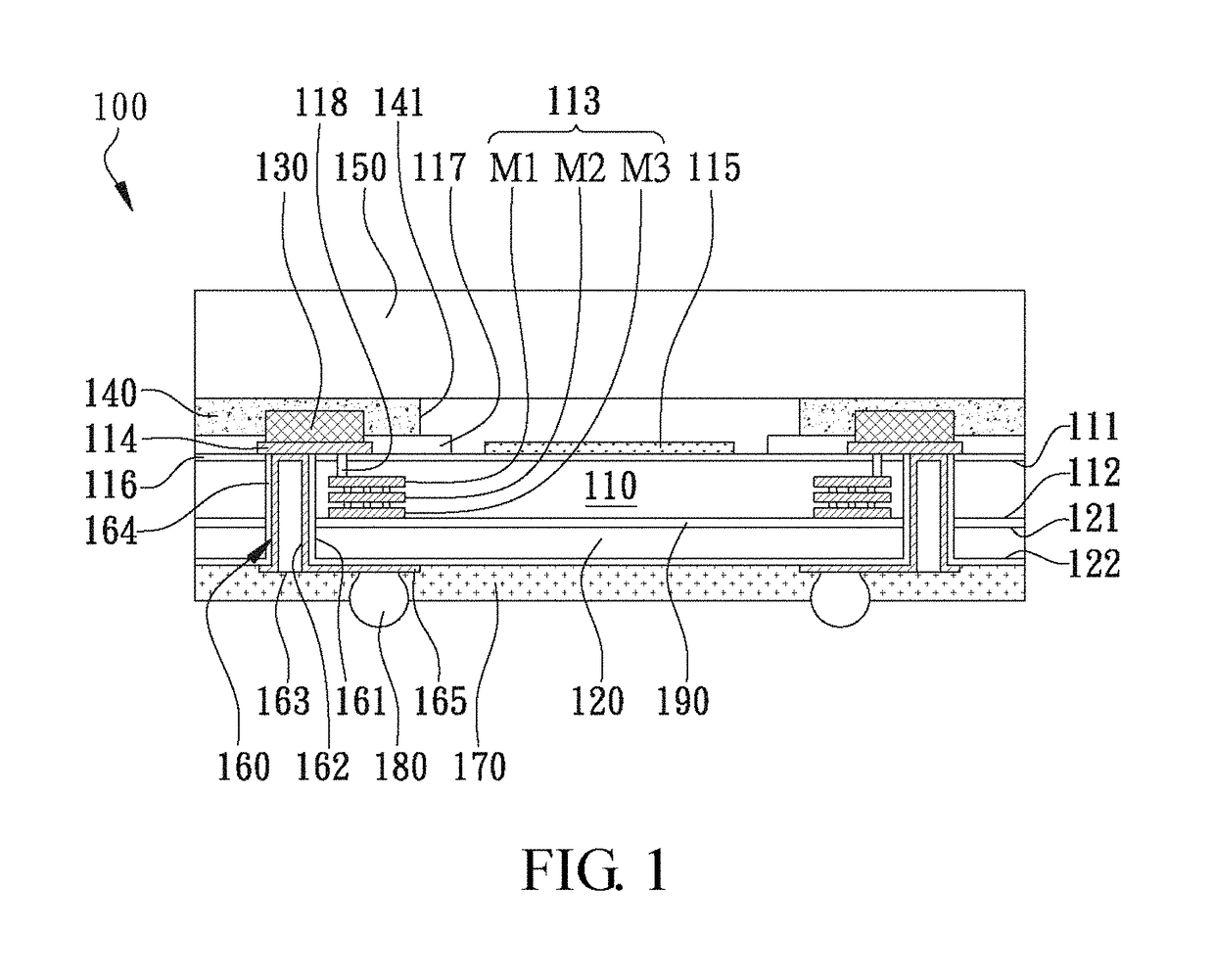

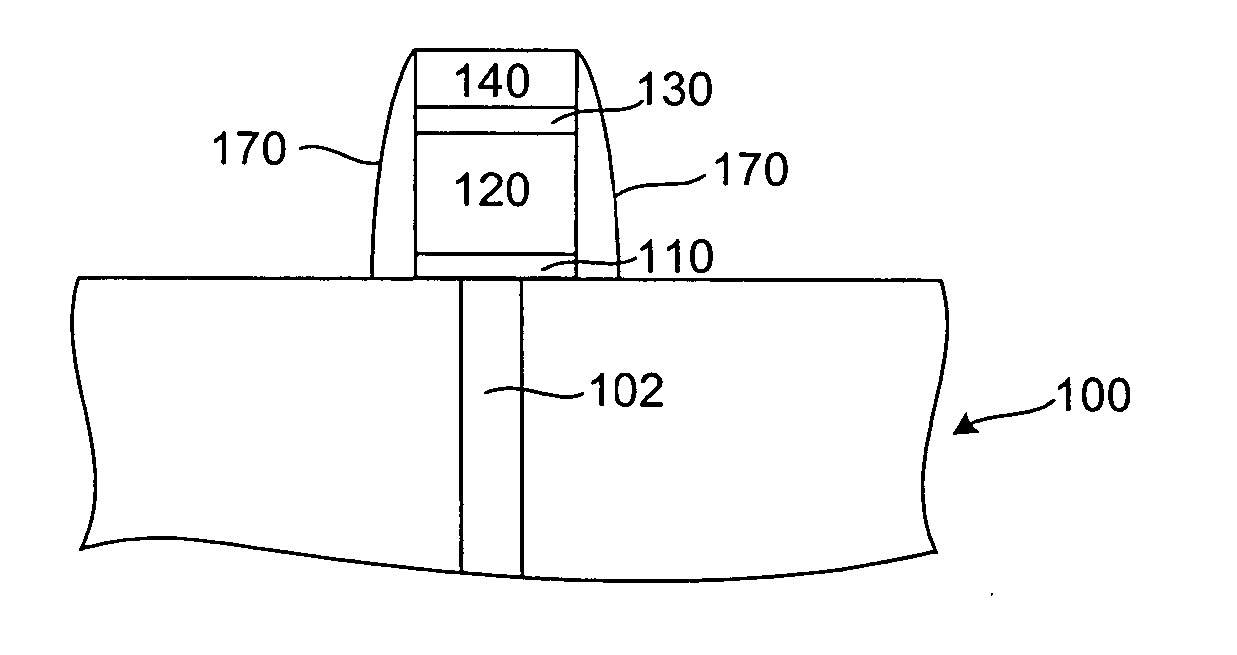

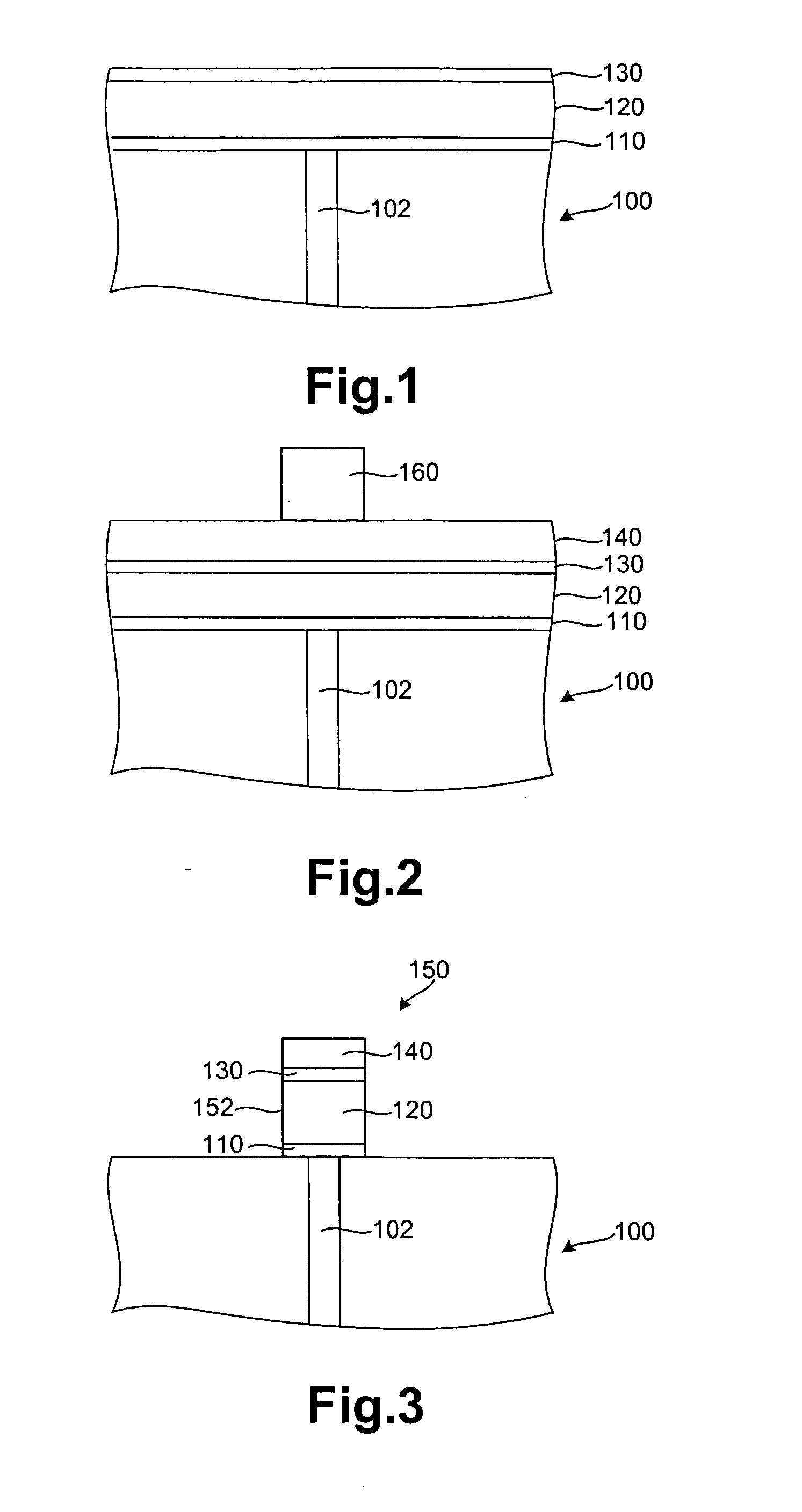

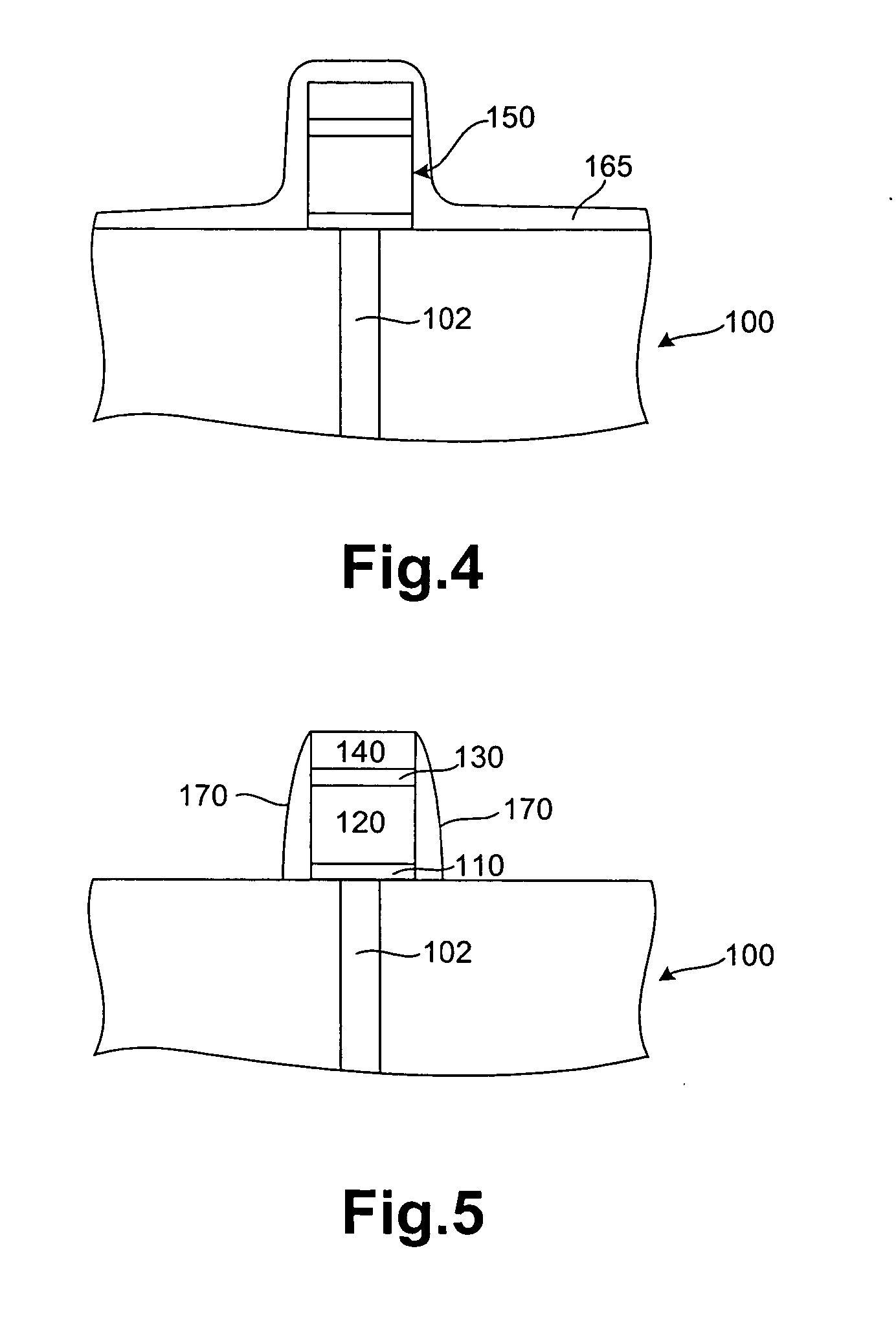

Leadframe-Based Semiconductor Package Having Terminals on Top and Bottom Surfaces

InactiveUS20140210062A1Avoid interconnectionAvoid noiseSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

A semiconductor device (100) with a leadframe having first (310) and second (311) leads with central and peripheral ends, the central ends in a first horizontal plane (150). The first leads have peripheral ends (310b) in a second horizontal plane spaced (160) from the first plane and the second leads having peripheral ends in a third horizontal plane (170). A semiconductor chip (101) is connected to the central lead ends. A package (120) encapsulates the chip and the central ends of the first and second leads, leaving the peripheral ends of the first and second leads un-encapsulated, wherein the packaged device has lead ends as terminals on the second and third horizontal plane.

Owner:TEXAS INSTR INC

System and method for establishing a virtual private network

ActiveUS8261057B2Improve network securityFor further processingData switching by path configurationMultiple digital computer combinationsPrivate networkClient-side

A system and method for establishing a virtual private network (VPN) between a client and a private data communication network. An encrypted data communication session, such as a—Secure Sockets Layer (SSL) data communication session, is established between a gateway and the client over a public data communication network. The gateway then sends a programming component to the client for automatic installation and execution thereon. The programming component operates to intercept communications from client applications destined for resources on the private data communication network and to send the intercepted communications to the gateway via the encrypted data communication session instead of to the resources on the private data communication network.

Owner:CITRIX SYST INC

Silicon carbide powder and preparation method thereof

InactiveCN102491333AControl reaction processLow reaction temperatureNanotechnologySilicon carbideCarbide siliconReaction temperature

The invention specifically relates to silicon carbide powder and a preparation method thereof. According to a technical scheme, the preparation method comprises the following steps of: uniformly mixing 5-20 percent by weight of nano-silicon dioxide or silica micro-powder, 0.5-2.5 percent by weight of carbon black or amorphous graphite powder, 70-88 percent by weight of an alkali metal chloride and 5-15 percent by weight of aluminum powder serving as raw materials; putting the uniformly-mixed raw materials into a tubular electric furnace, raising the temperature to 800-1,000 DEG C at the temperature raising rate of 4-10 DEG C per minute under the atmosphere of argon, and preserving heat for 2-10 hours; and putting an obtained product into nitric acid of which the concentration is 2-5 mol / L for soaking for 3-8 hours, filtering, cleaning with deionized water till the pH value of a cleaning solution is 7.0, and drying at the temperature of 110 DEG C for 8-24 hours to obtain silicon carbide powder. The method has the characteristics of low reaction temperature, simple process, controllable synthesis process, low production cost, and the like; and the prepared silicon carbide powder has the characteristics of high crystallization, high product purity, freeness from an impure phase and powder particle size of 50-200 nanometers.

Owner:WUHAN UNIV OF SCI & TECH

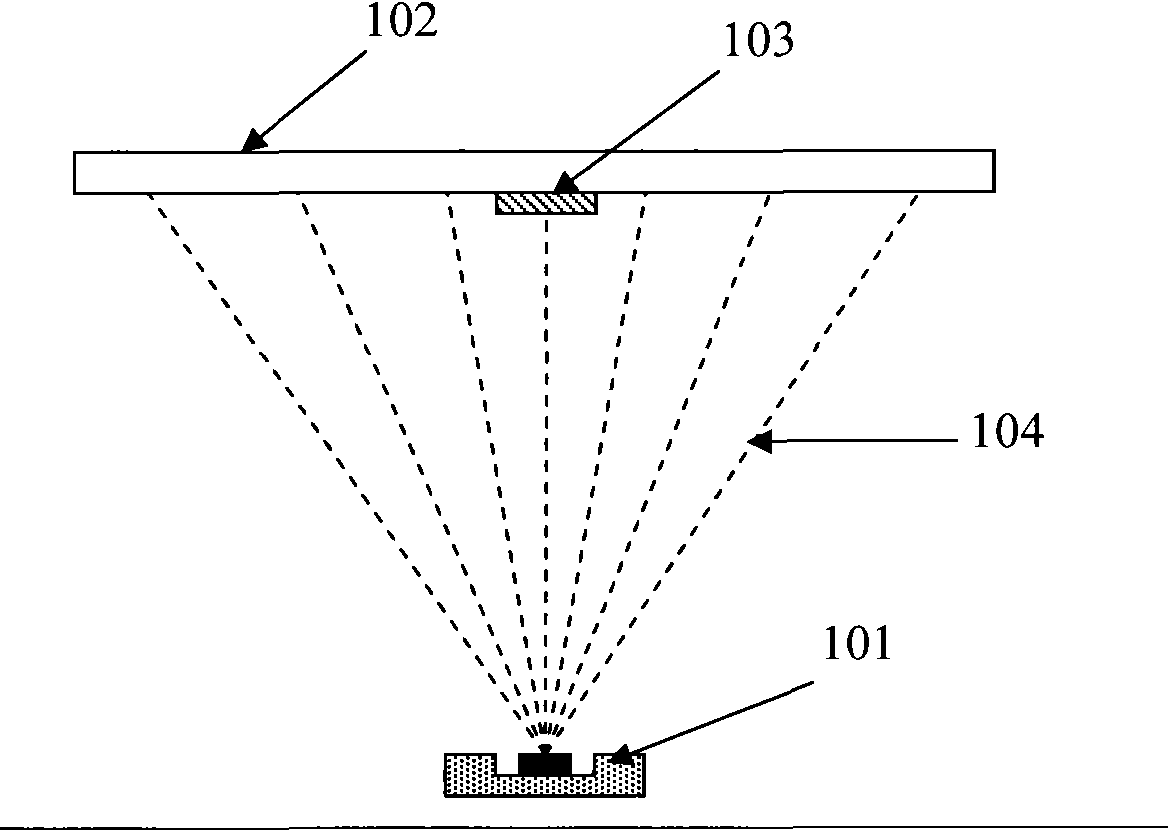

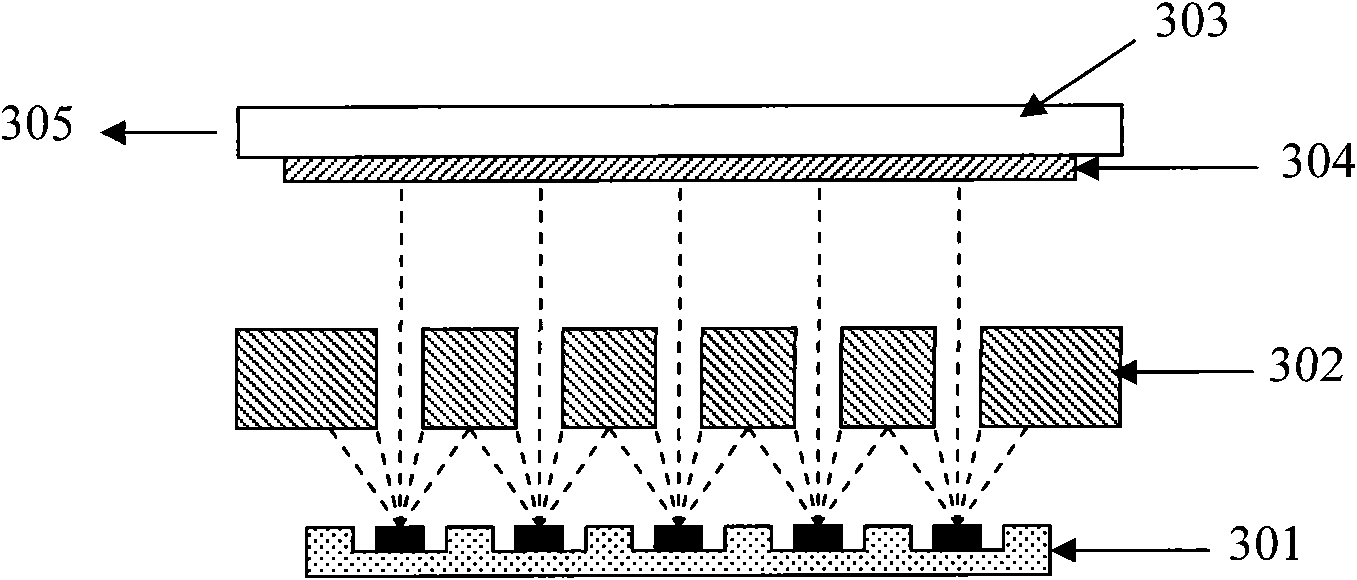

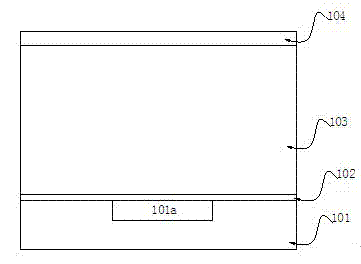

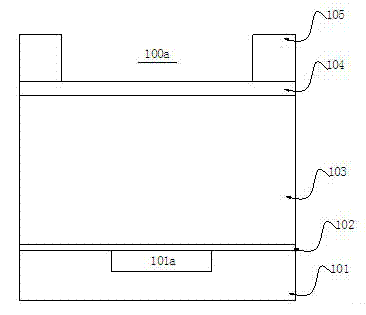

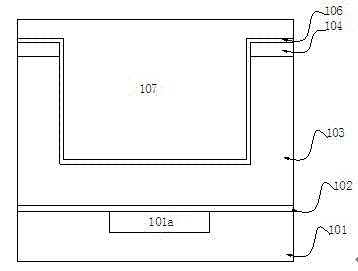

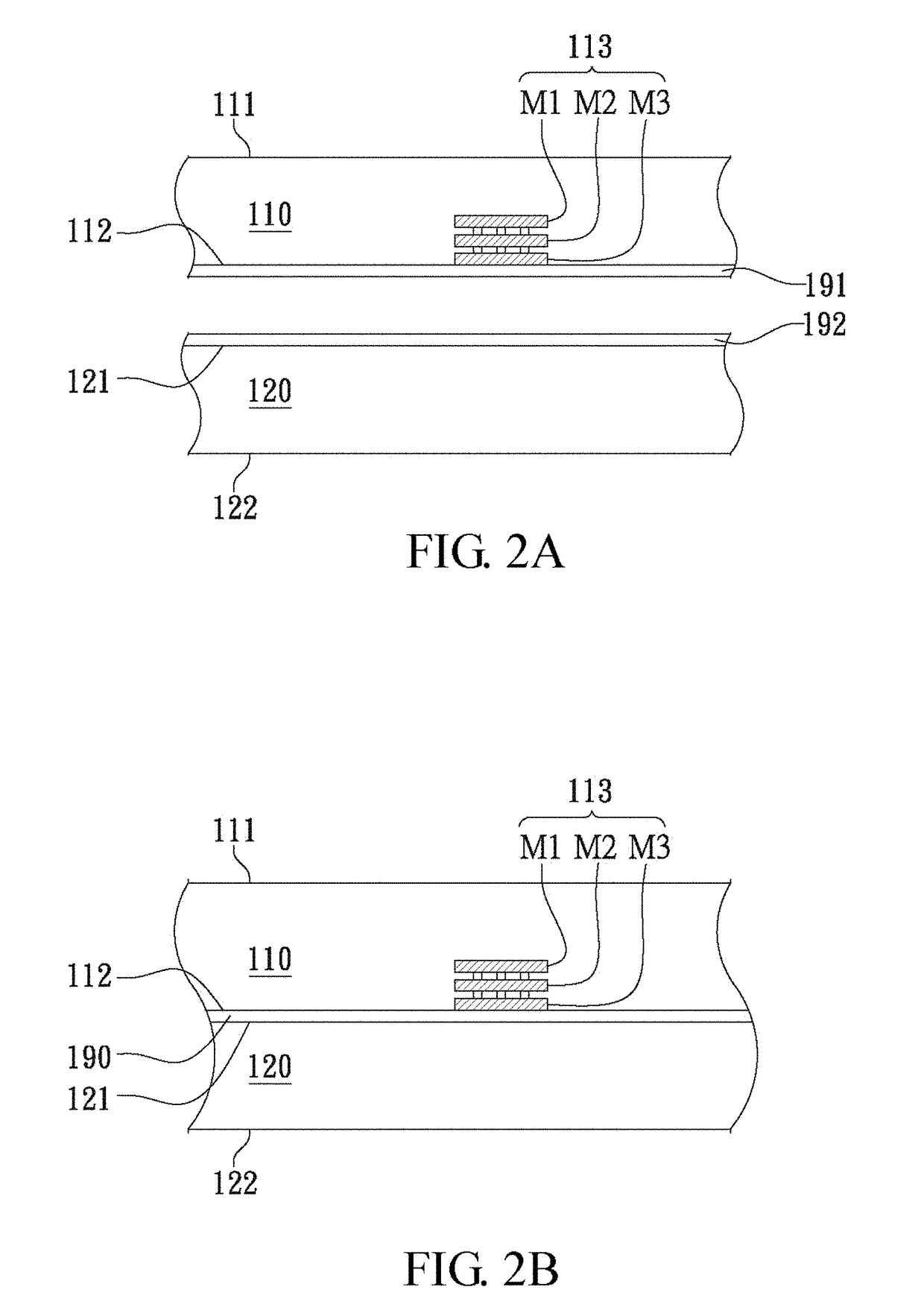

Image sensor module and forming method thereof

InactiveCN103956371AExcellent structural performanceReduce design difficultyRadiation controlled devicesImage sensorEngineering

The invention discloses an image sensor module and a forming method of the image sensor module. The image sensor module comprises a PCB substrate, a metal layer, an image sensing chip, a signal processing chip and welding protrusions. The PCB substrate is provided with a hole penetrating through the PCB substrate, the metal layer is arranged on the surface of the PCB substrate, the image sensing chip is inversely arranged above the PCB substrate, the image sensing chip is provided with an image induction area and a bonding pad surrounding the image induction area which is arranged above the hole, the bonding pad is electrically connected with the metal layer, the signal processing chip is inversely arranged above the PCB substrate, the signal processing chip is electrically connected with the metal layer, and the welding protrusions are arranged on the surface of the metal layer. The packaging performance of the image sensor module is improved, and the production cost of the image sensor module is reduced.

Owner:CHINA WAFER LEVEL CSP

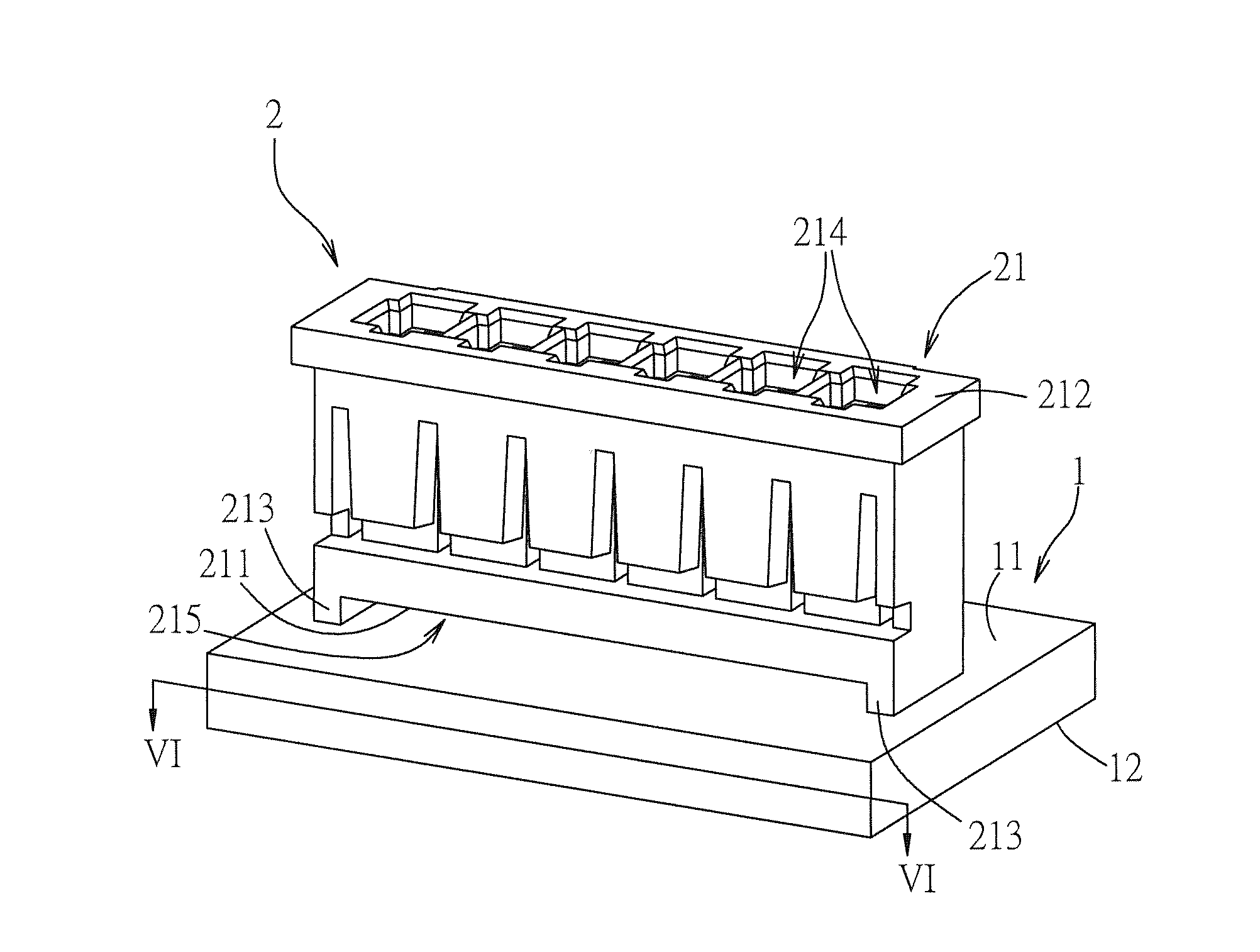

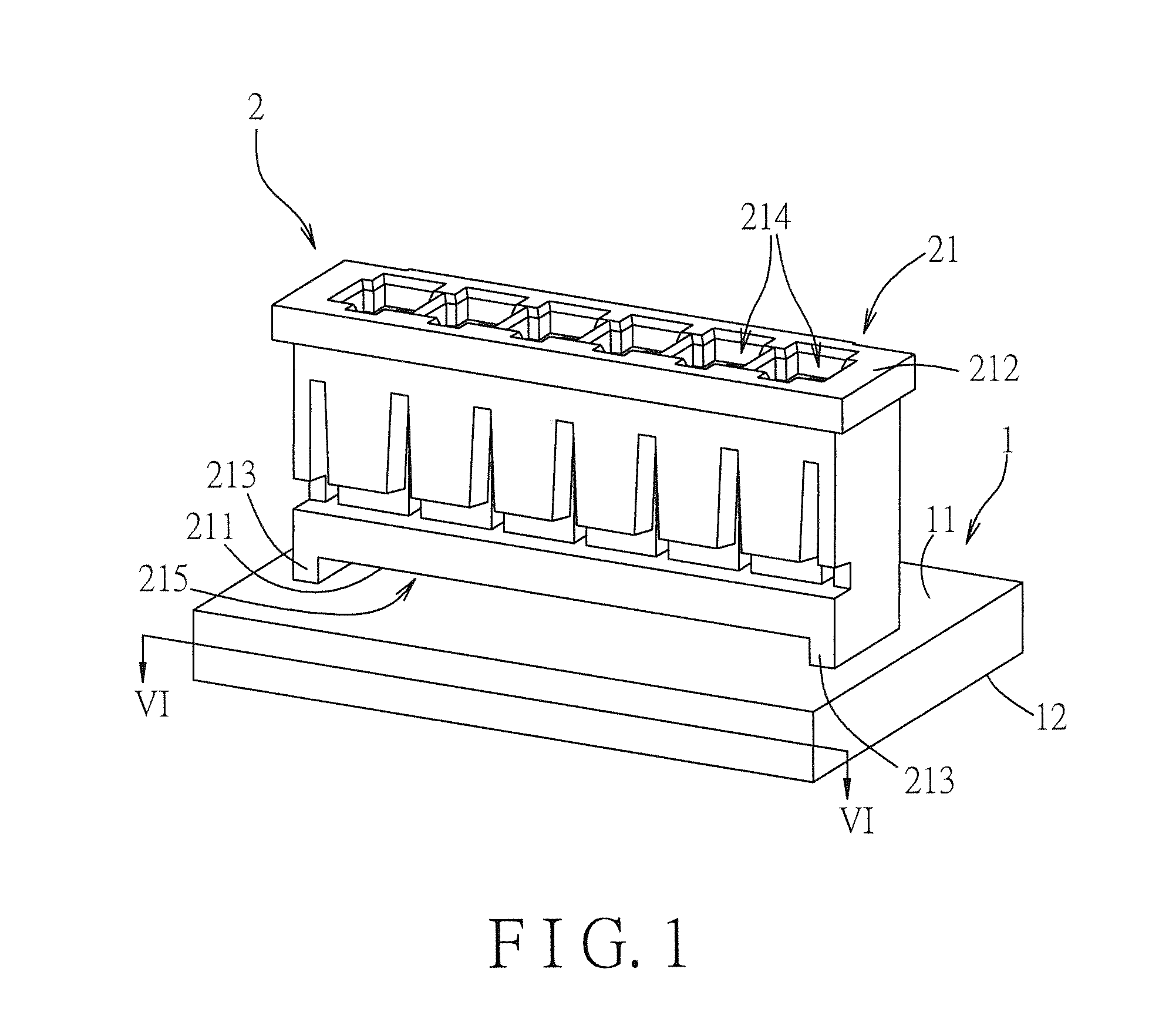

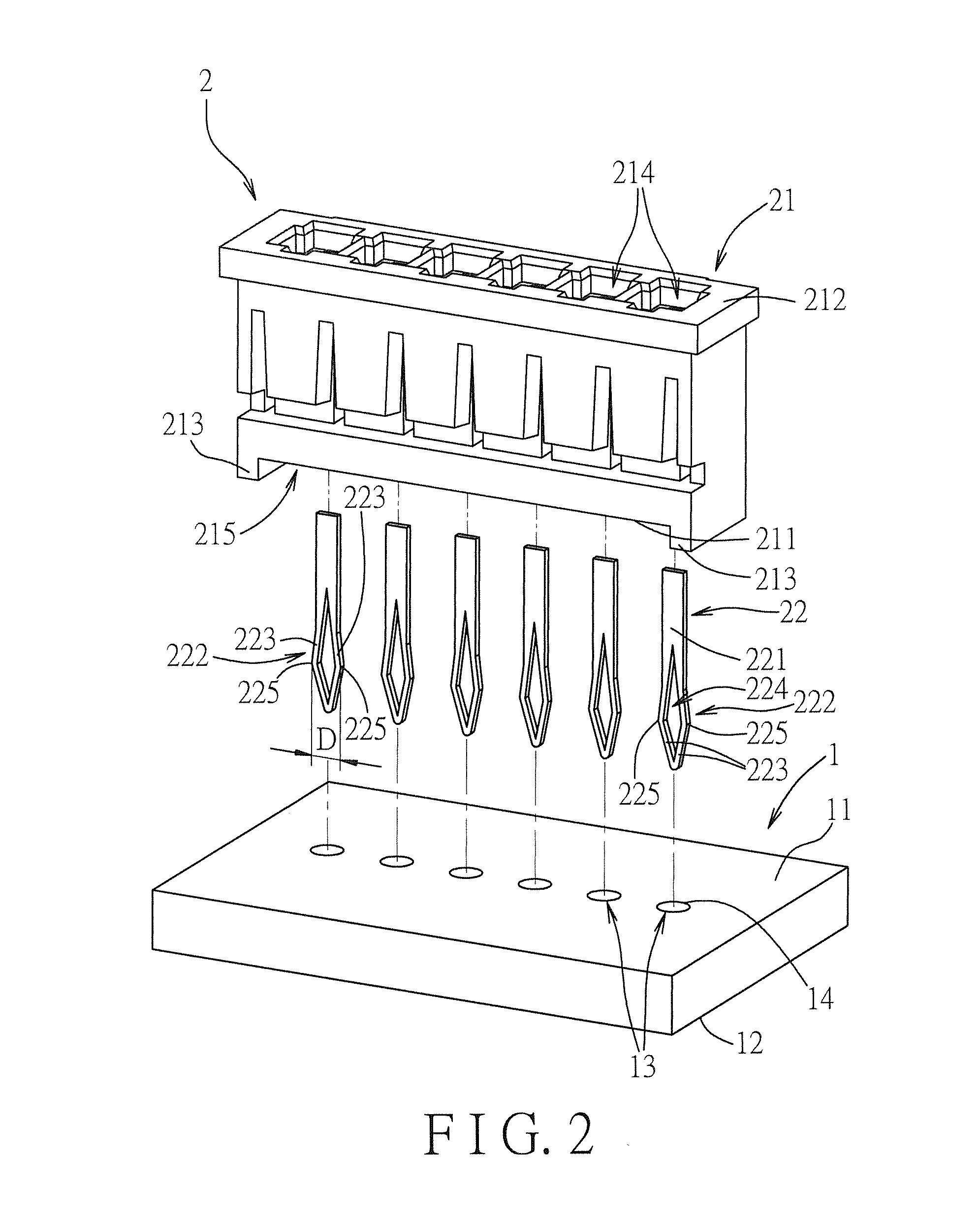

Electrical connector and assembly of the electrical connector and a circuit board

InactiveUS20150044889A1Increase the amount of fluidAvoid it happening againSoldered/welded conductive connectionsPrinted circuit aspectsElectrical connectorPlenum space

An electrical connector includes an insulating body having a bottom surface, a receiving groove formed in the bottom surface, and at least one support block projecting downwardly from the bottom surface for connection with a circuit board and cooperating with the bottom surface to define a venting space that communicates with the receiving groove and a solder hole in the circuit board. A conductive terminal includes a first positioning portion extending into and positioned in the receiving groove, and a second positioning portion connected to the first positioning portion and extending through the venting space and adapted to be positioned in the solder hole.

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

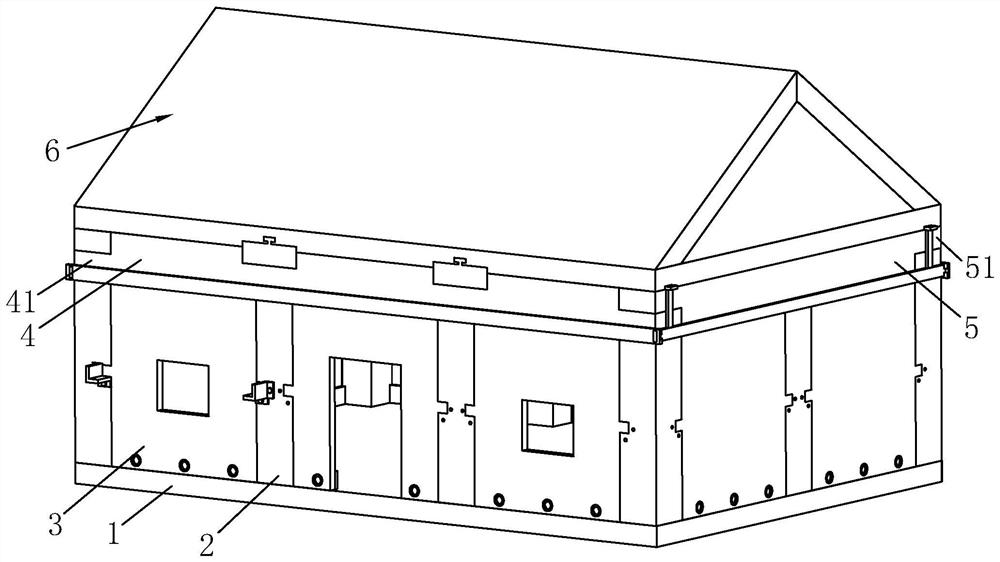

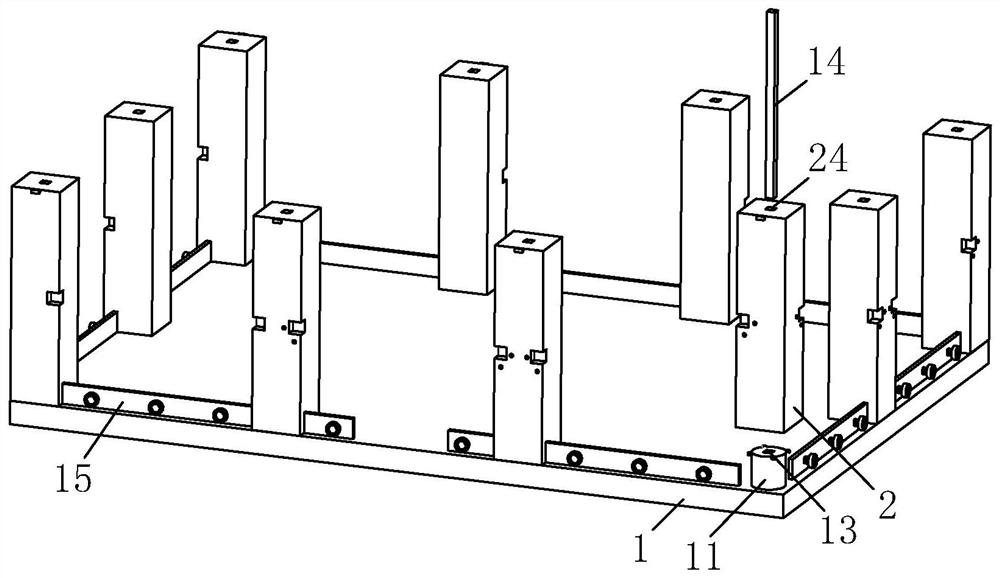

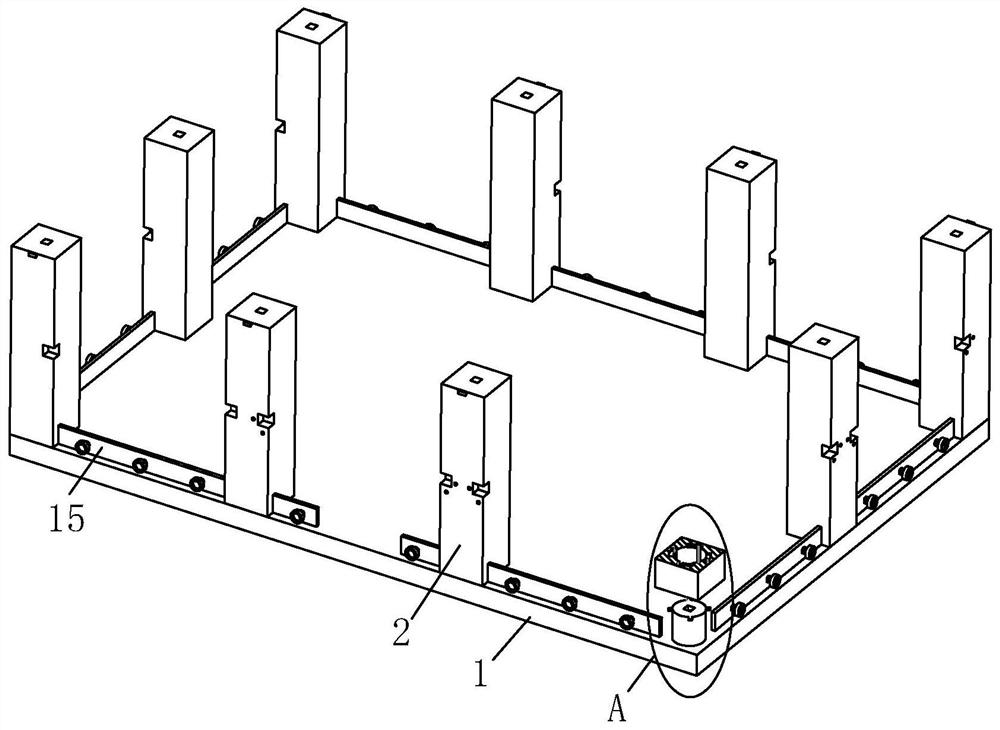

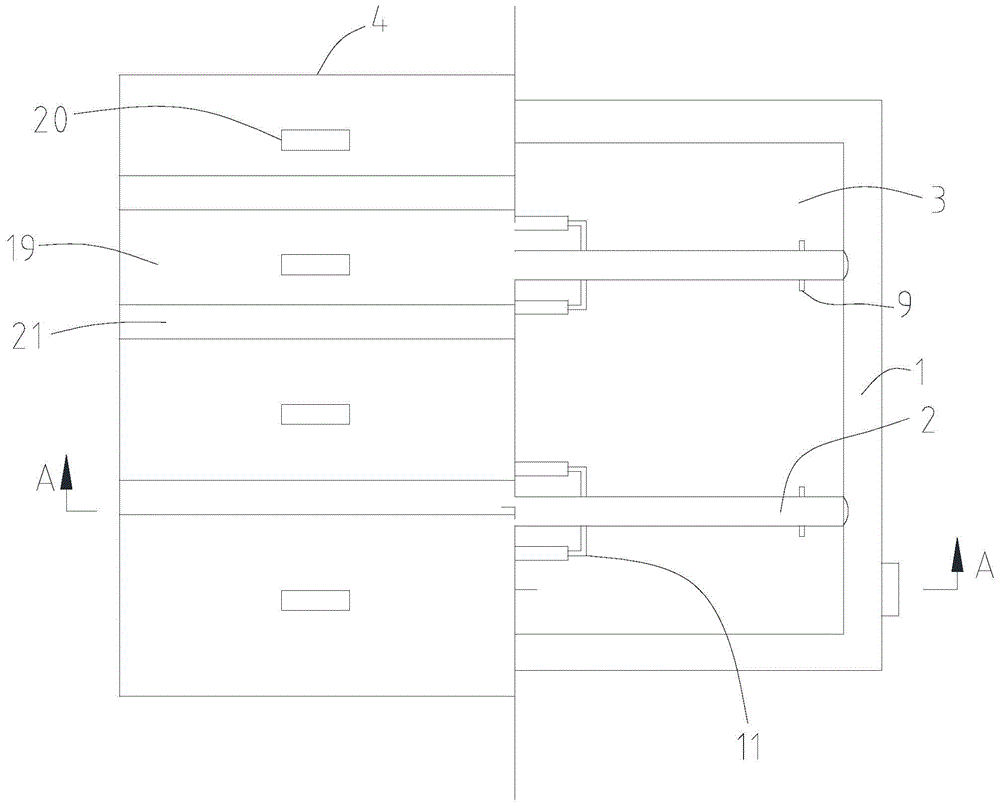

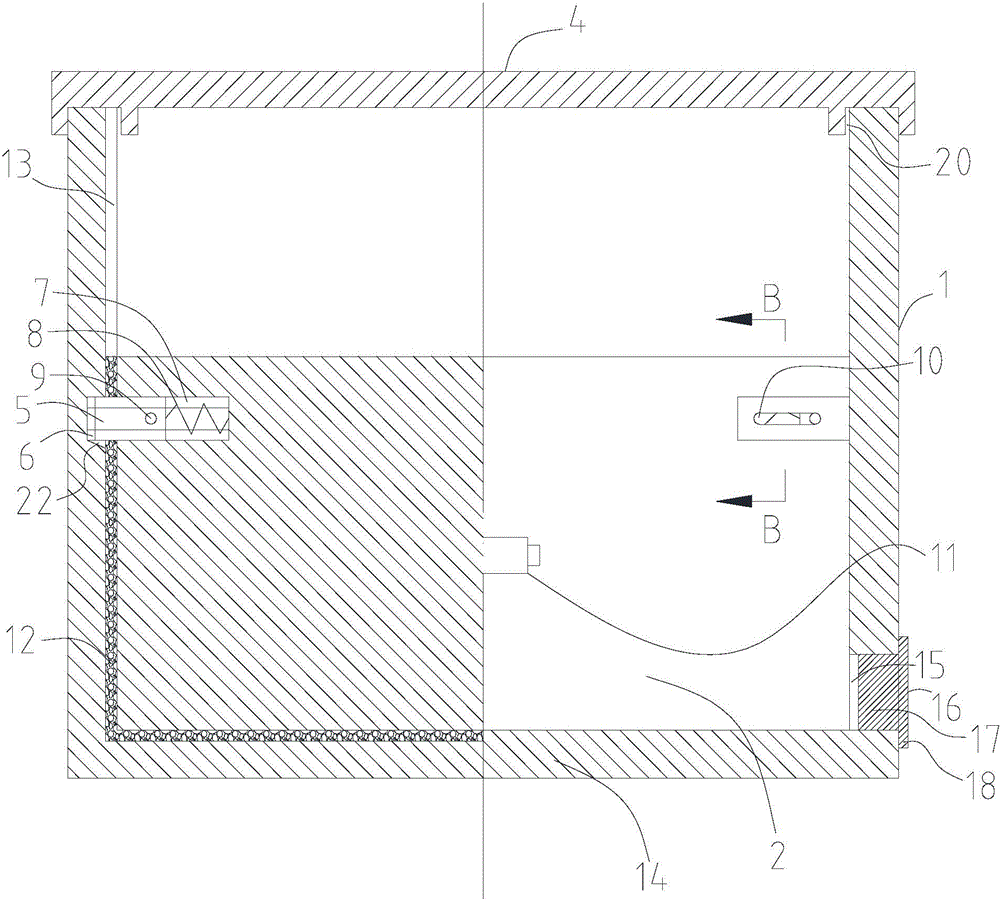

Prefabricated house building and construction method thereof

ActiveCN112012345AEasy to installImprove efficiencyBuilding material handlingHouse buildingWall plate

The invention relates to the technical field of house construction, in particularly to a prefabricated house building and a construction method thereof. According to key points of the technical scheme, a plurality of positioning columns are arranged at the top of a base, first limiting structures are arranged between positioning holes and the positioning columns, second limiting structures are arranged between supporting columns and the positioning columns, wallboards are arranged between the supporting columns, mounting structures are arranged between the wallboards and the supporting columns, first cross beams and second cross beams are arranged at the tops of the supporting columns, the two ends of the first cross beams are connected with first matching ends, the two ends of the secondcross beams are connected with second matching ends, third limiting structures are arranged between the first cross beams and the supporting columns, fourth limiting structures are arranged between the first matching ends and the second matching ends, a roof is arranged at the tops of the first cross beams and the tops of the second cross beams, and fifth limiting structures are arranged between the roof and the first cross beams. The prefabricated house building has the advantages of being convenient to install, high in efficiency and low in cost.

Owner:广东锦恒建筑有限公司

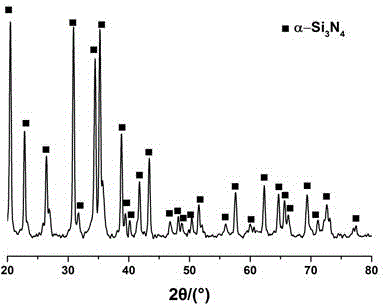

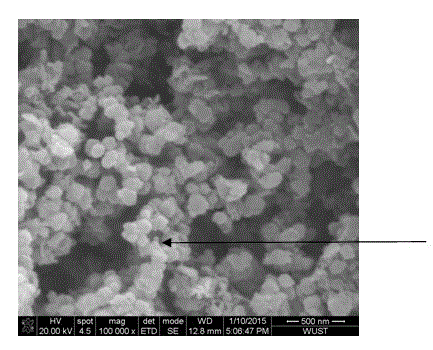

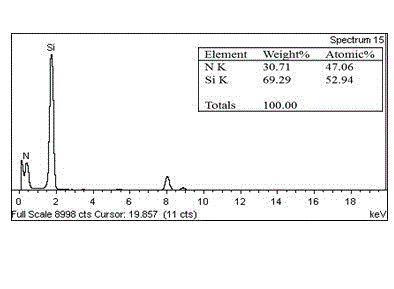

Single-phase alpha-Si3N4 micropowder and preparation method thereof

The invention relates to a single-phase alpha-Si3N4 micropowder and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps: uniformly mixing 5-30 wt% of simple substance silicon powder, 15-45 wt% of solid nitrogen source and 40-80 wt% of halide powder to prepare a mixture; putting the mixture into an electric tube furnace, heating to 1000-1300 DEG C at the heating rate of 2-10 DEG C / minute in a nitrogen atmosphere, and keeping the temperature for 2-6 hours; repeatedly washing the product with deionized water until no white precipitate appears when respectively titrating with AgNO3 and Ca(NO3)2 solutions; and finally, drying at 110 DEG C for 10-24 hours to obtain the single-phase alpha-Si3N4 micropowder. The preparation method has the characteristics of low reaction temperature, low cost, simple synthesis technique, controllable process, high yield and wide industrialization prospects. The particle size of the prepared single-phase alpha-Si3N4 micropowder is 100-500nm; and the single-phase alpha-Si3N4 micropowder has the advantages of no impurity phase, high activity, small particle aggregation and uniform particle size distribution.

Owner:WUHAN UNIV OF SCI & TECH

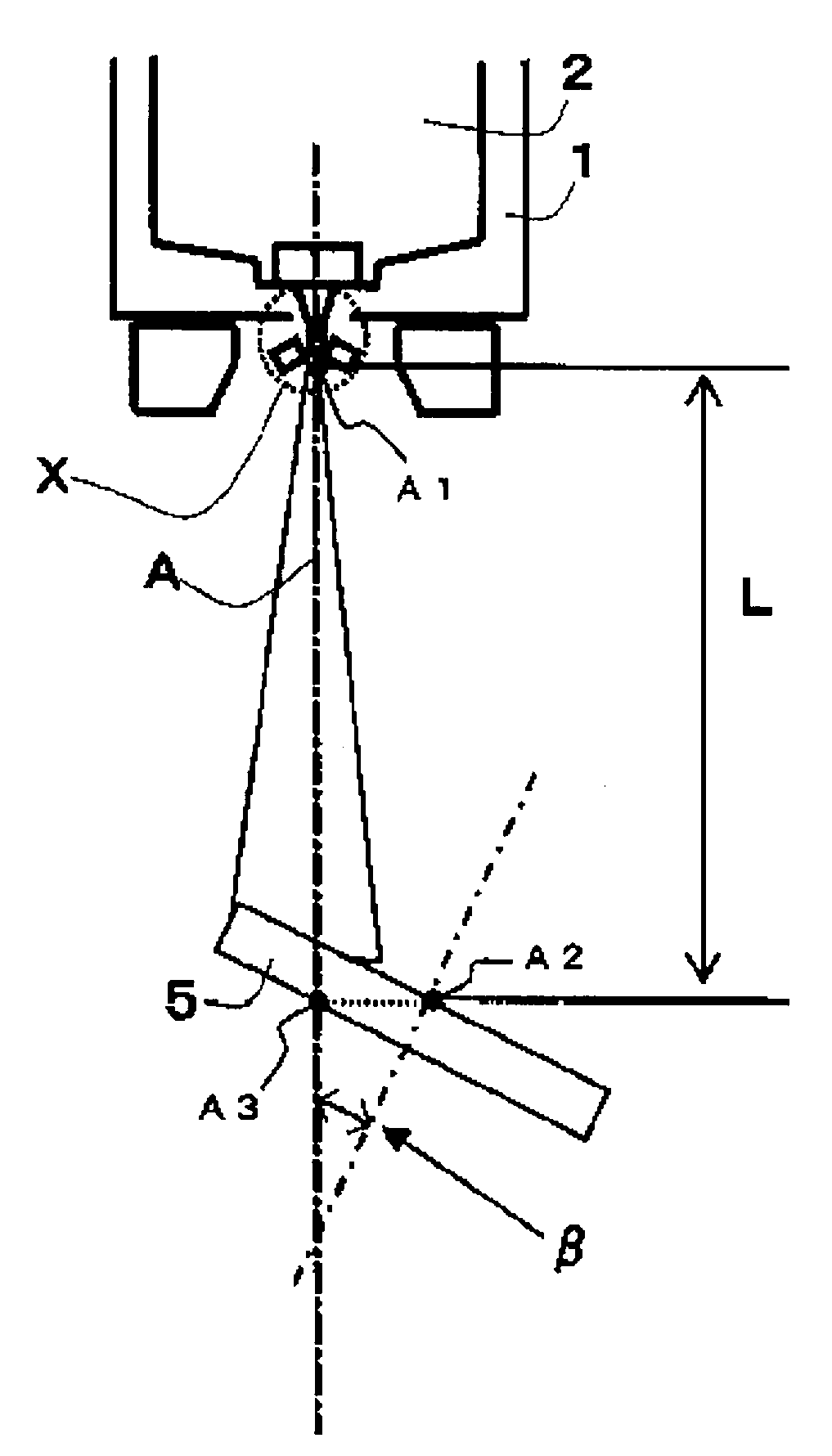

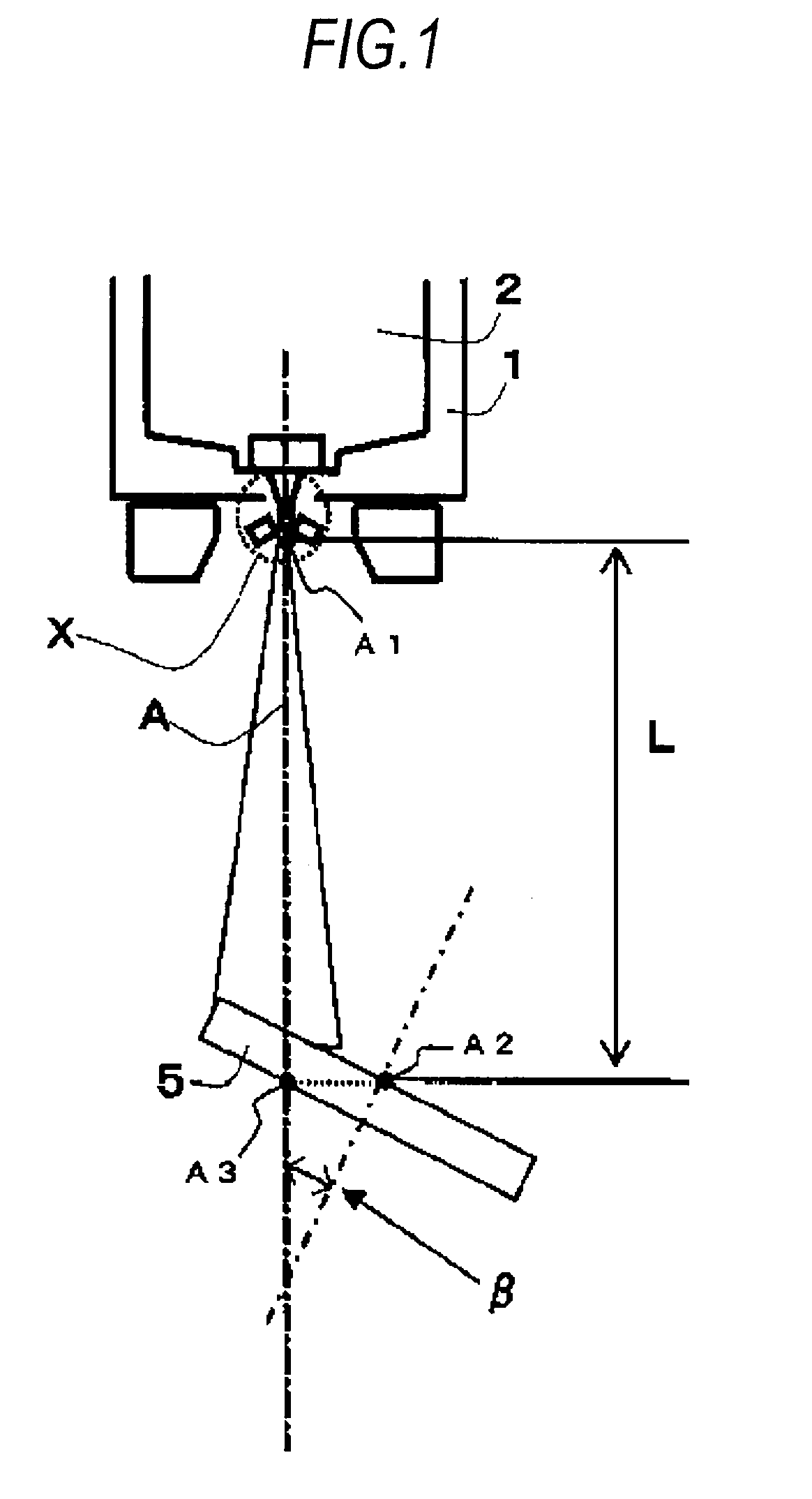

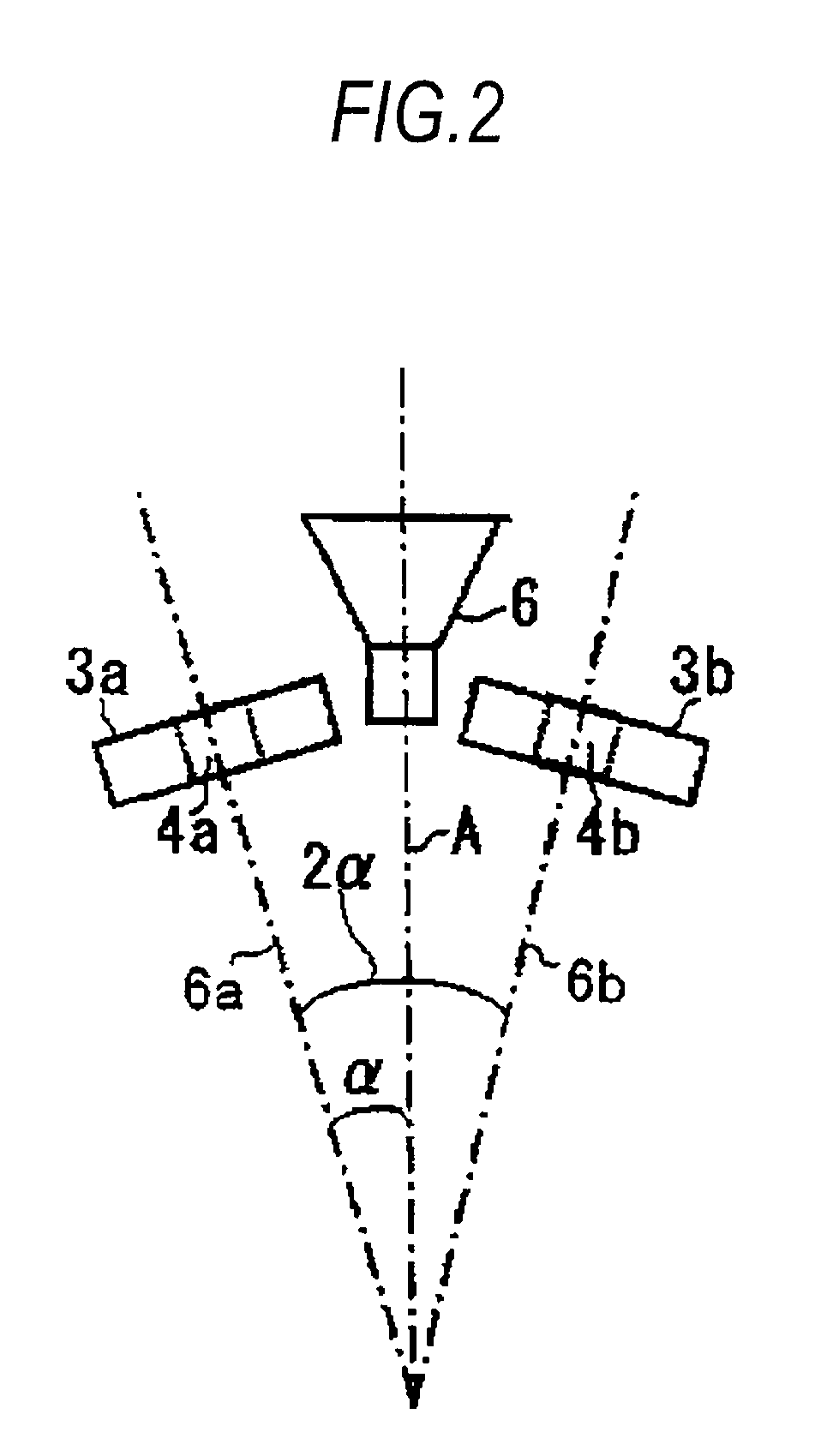

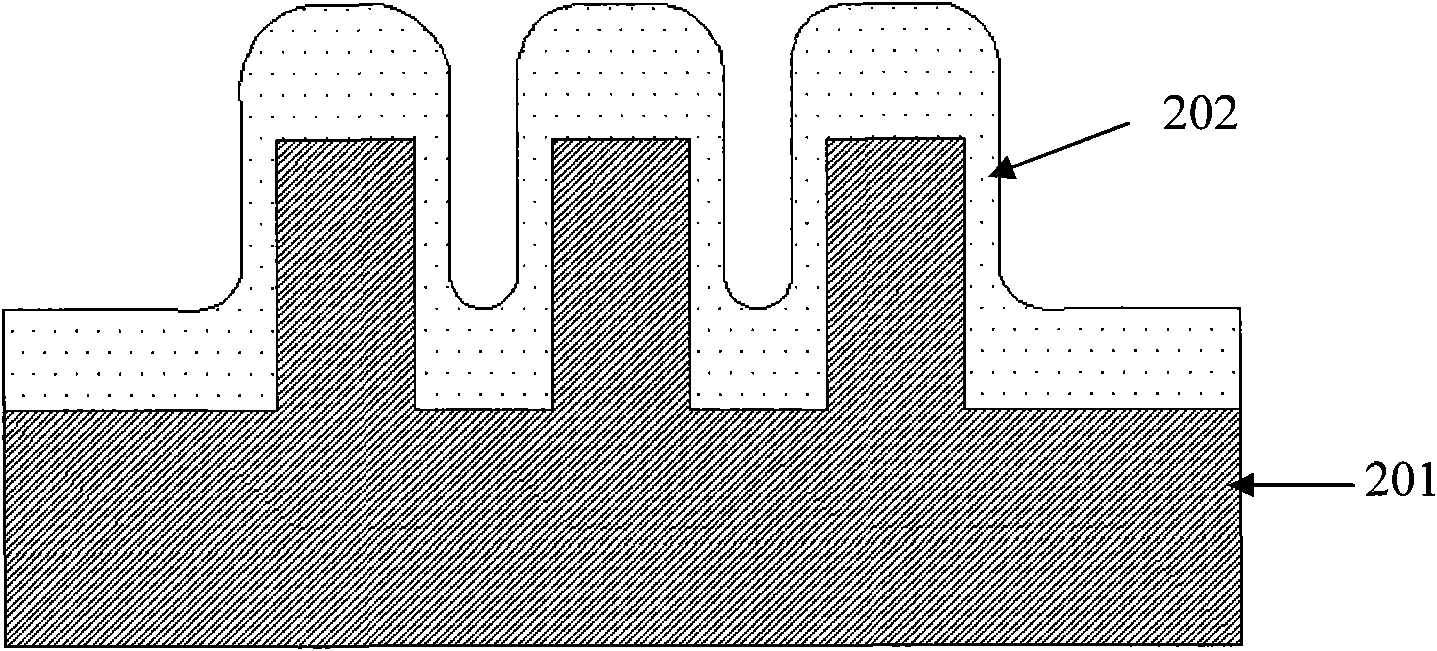

Continuous vertical hot evaporation metal film coating method

InactiveCN101845610AReduce or eliminate sidewall depositionAvoid interconnectionVacuum evaporation coatingPolarising elementsSurface reliefWidth ratio

The invention discloses a novel continuous vertical hot evaporation metal film coating method. Metal film materials are coated on samples above a hot evaporation source in a vapor deposition way through a hot evaporation source at the bottom. The invention is characterized in that a slit type straightening device is arranged between the hot evaporation source and a sample conveying mechanism, divergent metal molecules sent from the hot evaporation source are filtered, and metal molecule flows vertically facing substrate materials of samples are formed, wherein the depth-to-width ratio of the slit of the straightening device is smaller than a half of the depth-to-width ratio of a surface relief sculpture structure of the substrate materials of the samples. In the application and the implementation of the invention, only the metal molecules flying approximately in the vertical direction are allowed to be deposited on the surface of substrate materials, so the invention is favorable for reducing or eliminating the side wall deposition of the surface relief sculpture structure on substrate materials, avoids the interconnection of the top of the relief sculpture structure and metal films at the bottom, and enhances double-layer metal wire grating structures required by the metal wire grating formation polarization technology.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Method for constructing sequencing library based on blood samples, and uses of method in determination of fetal genetic abnormality

ActiveCN105400864AAvoid interconnectionReduce economic costsBioreactor/fermenter combinationsBiological substance pretreatmentsGENETIC ABNORMALITYNucleic acid sequencing

The present invention provides a method for constructing a sequencing library based on blood samples, a nucleic acid sequencing method, a method for determining fetal genetic abnormality in a sample, an apparatus for constructing a sequencing library based on blood samples, a nucleic acid device, and a system for determining fetal genetic abnormality in a sample.

Owner:北京六合华大基因科技有限公司 +1

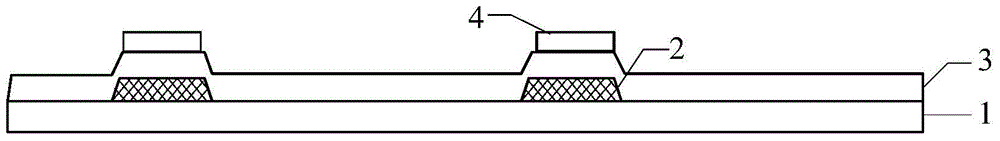

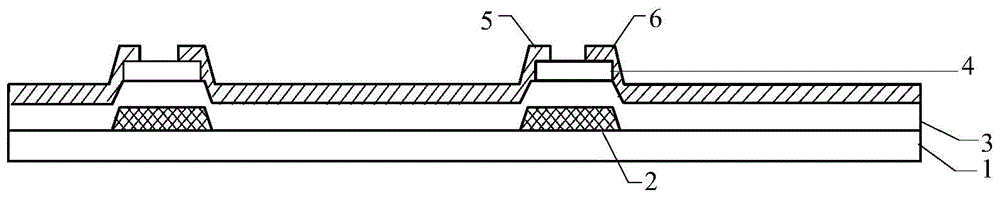

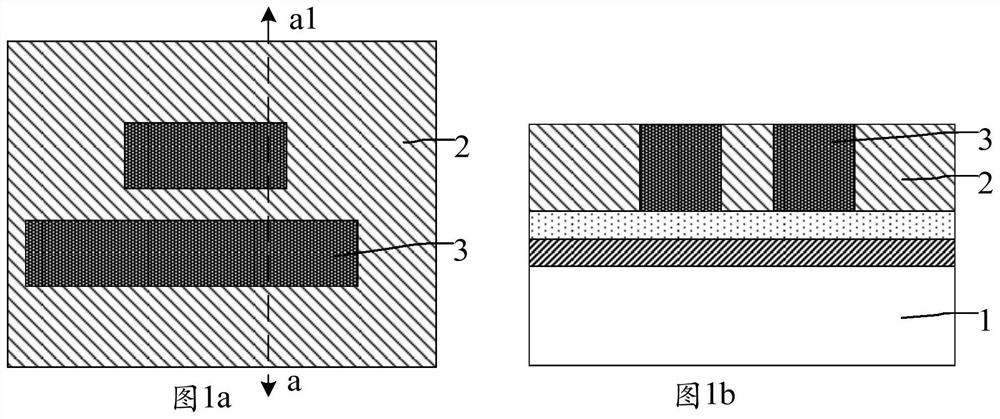

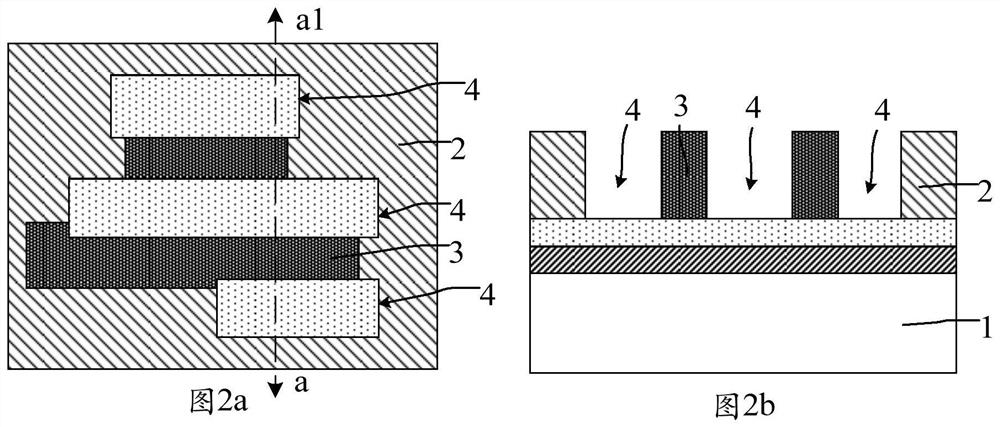

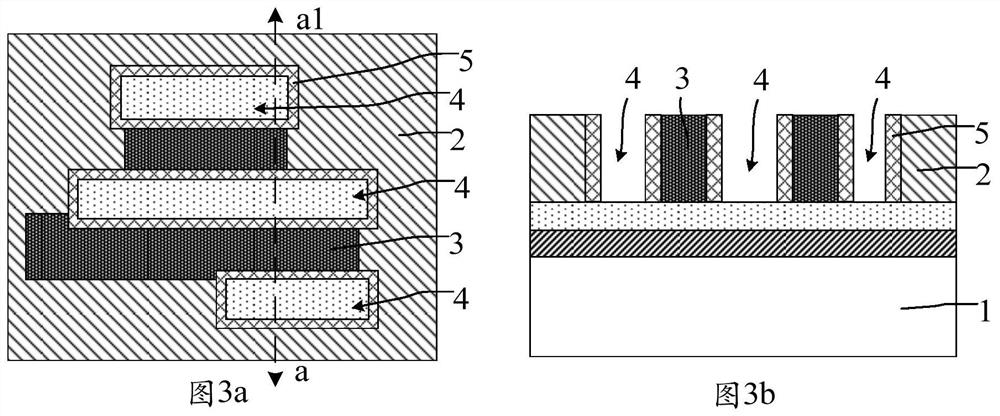

Array substrate and fabrication method thereof and display panel

ActiveCN104103583AAvoid interconnectionImprove featuresSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerOptoelectronics

The invention provides an array substrate and a fabrication method thereof and a display panel. The array substrate comprises a plurality of thin film transistors, and the fabrication method of the array substrate comprises the steps of: S1, providing the substrate, wherein sources and drains of the thin film transistors are formed on the substrate; S2, forming an insulation layer on the substrate, wherein the insulation layer comprises interval regions and a plurality of strip electrode regions, two arbitrary adjacent strip electrode regions are separated by the interval regions; S3, forming interval layers above the interval regions of the insulation layer; S4, forming patterns containing strip electrodes above the strip electrode regions of the insulation layer; and S5, stripping the interval layers above the interval regions. By the array substrate and the fabrication method thereof, the strip electrodes can be prevented from being connected to one another due to etching residue, and product feature is further improved.

Owner:BOE TECH GRP CO LTD +1

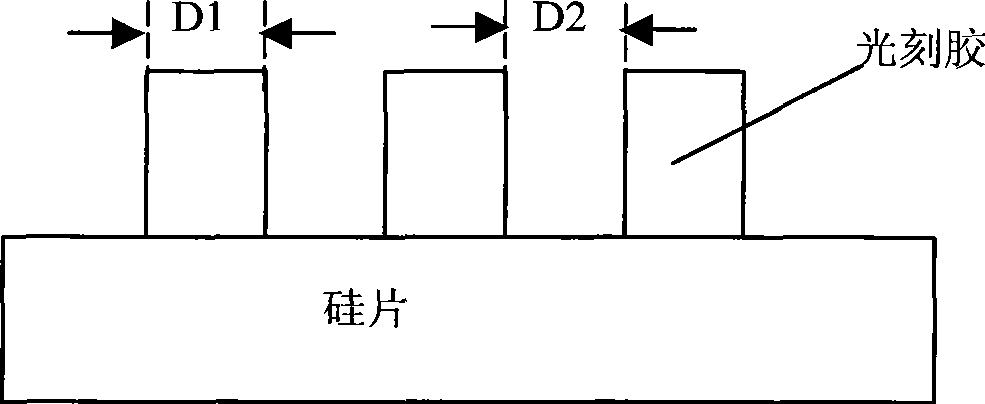

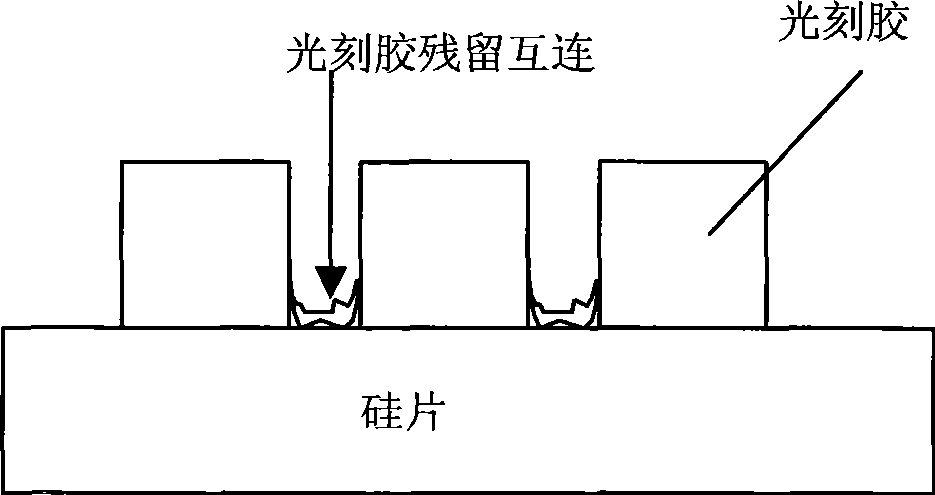

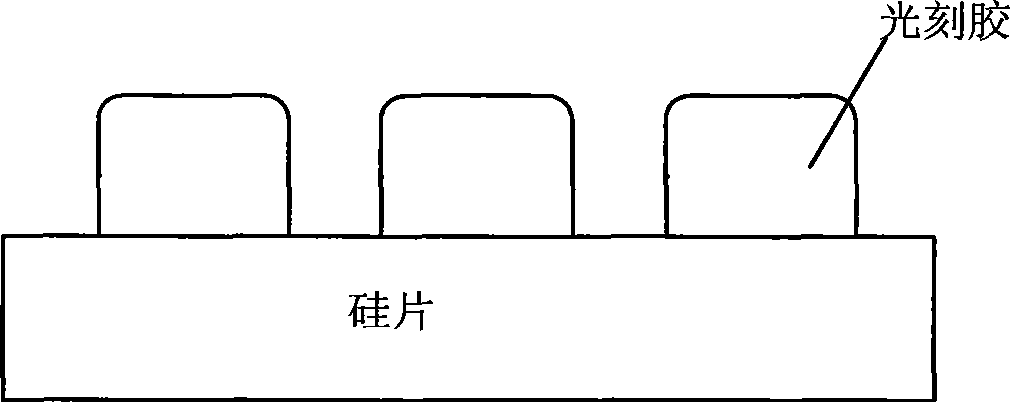

Photoetching development method

InactiveCN101446765ASmall feature sizeLarge feature sizeSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusPhotoresistSemiconductor

The invention discloses a photoetching development method, comprising the steps of exposing and hard curing; the characteristic sizes of exposed photoresist patterns are less than target value; the hard curing temperature in the hard curing process is increased, so that the characteristic sizes of the gaps of hard-cured photoresist patterns are controlled in the target value range. The method effectively prevents the photoresist remaining in the gaps of the photoresist patterns to form photoresist residuals interconnection in the development process; the hard curing temperature in the hard curing process is increased, and the photoresist is softened, so that the characteristic sizes of the hard-cured photoresist patterns are larger, and the characteristic sizes of the gaps of photoresist patterns are controlled in the target value range. The invention can be widely used for the manufacturing of semiconductor devices.

Owner:SHANGHAI HUA HONG NEC ELECTRONICS

Integration method of dual Damascus

InactiveCN102446822AAvoid leakage currentReduce control difficultySemiconductor/solid-state device manufacturingIntegrated approachDrain current

The invention discloses an integration method of dual Damascus, and the integration method uses a Damascus manufacturing process of digging trenches before vias. The method comprises the following steps: firstly depositing a metal hard mask when the vias are formed, thus effectively avoiding generating drain current and interlinkage between adjacent vias; reducing control difficulty of key sizes of the vias in an advanced copper process, improving the performance and reliability of a semiconductor device; and the technical process is simple and easy to control, and the method is suitable for popularizing application.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

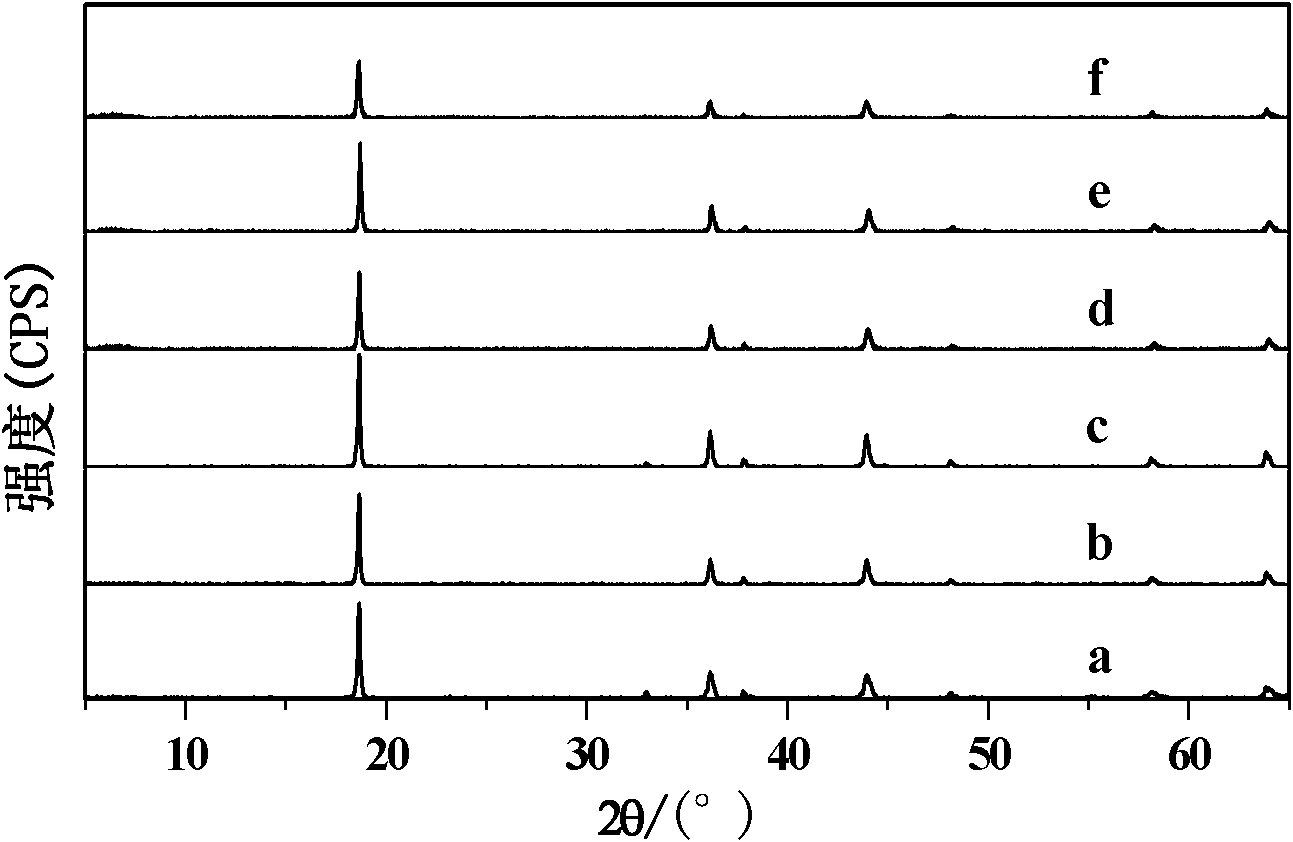

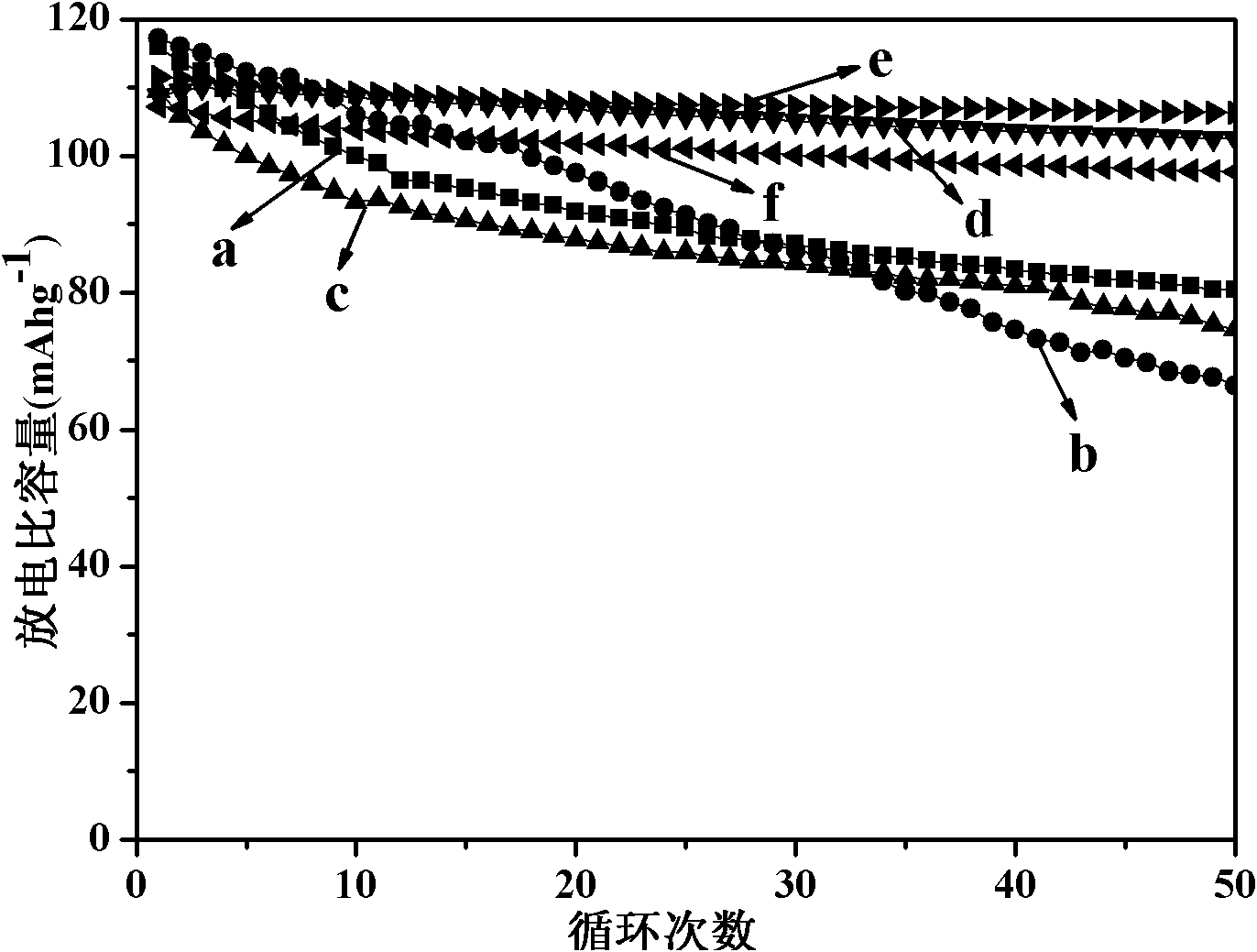

Method for preparing lithium manganate battery cathode material

InactiveCN101950802ADiffusion is fastThe group ratio is accurateCell electrodesLithium chlorideManganese

The invention discloses a method for preparing a lithium manganate battery cathode material. The method comprises the following steps of: melting a mixture of molten salt and a reactant through heating, and cooling, washing, filtering and drying to obtain the lithium manganate battery cathode material according to the stoichiometric ratio of a chemical formula LiCoxMn2-xFyO4-y, wherein x is more than or equal to 0 and less than or equal to 0.1, and v is more than or equal to 0 and less than or equal to 0.1; manganese metal powder is taken as a manganese source; lithium nitrate or lithium chloride is taken as a lithium source; and KCl is taken as a cosolvent. A lithium manganate product prepared by adopting the method has the advantages of good crystallization, stable electrochemical performance, high charging and discharging capacity, excellent cycle performance, less preparation process, simple process, low equipment requirement, cheap raw material price, and low cost and can be industrially produced.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

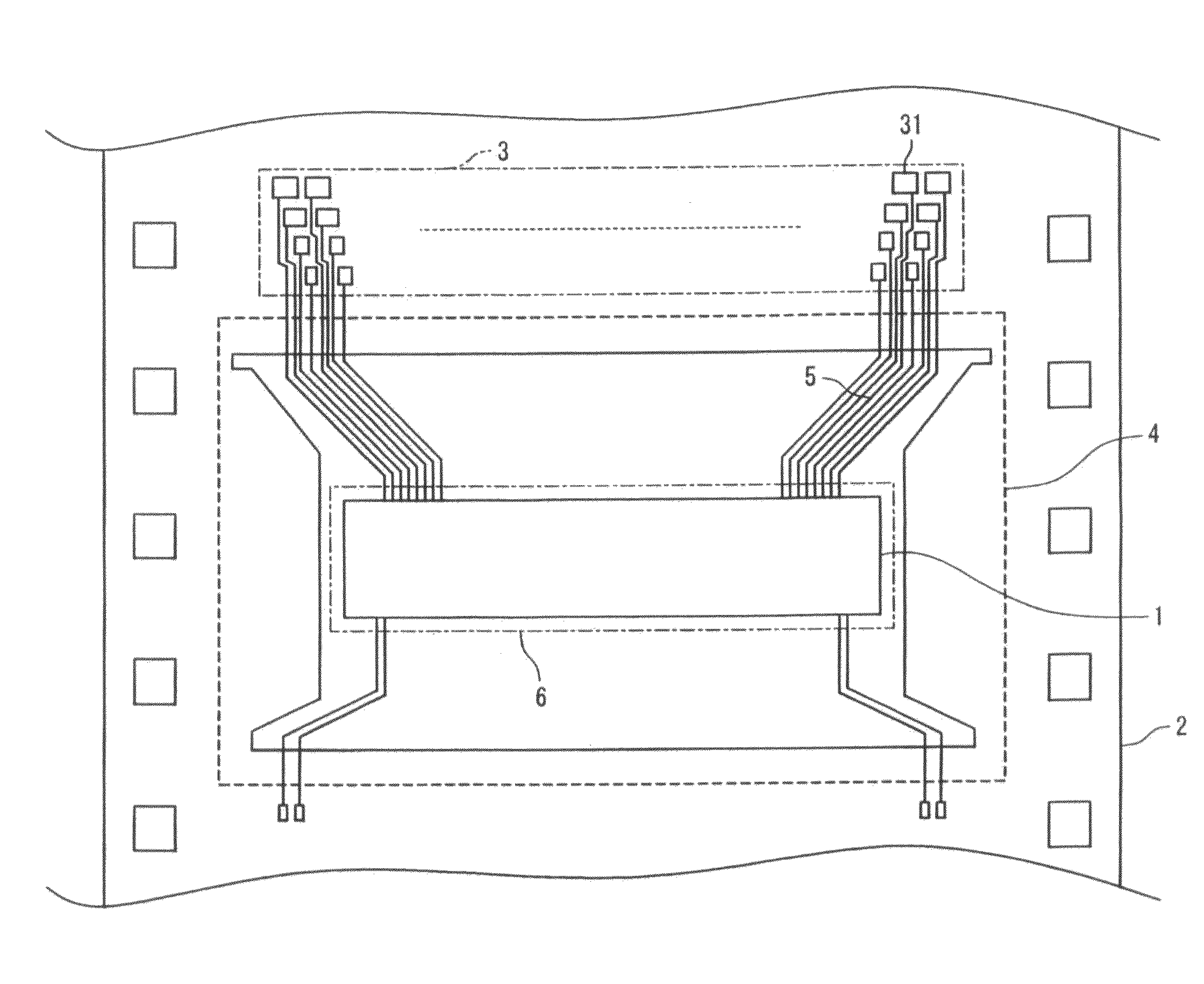

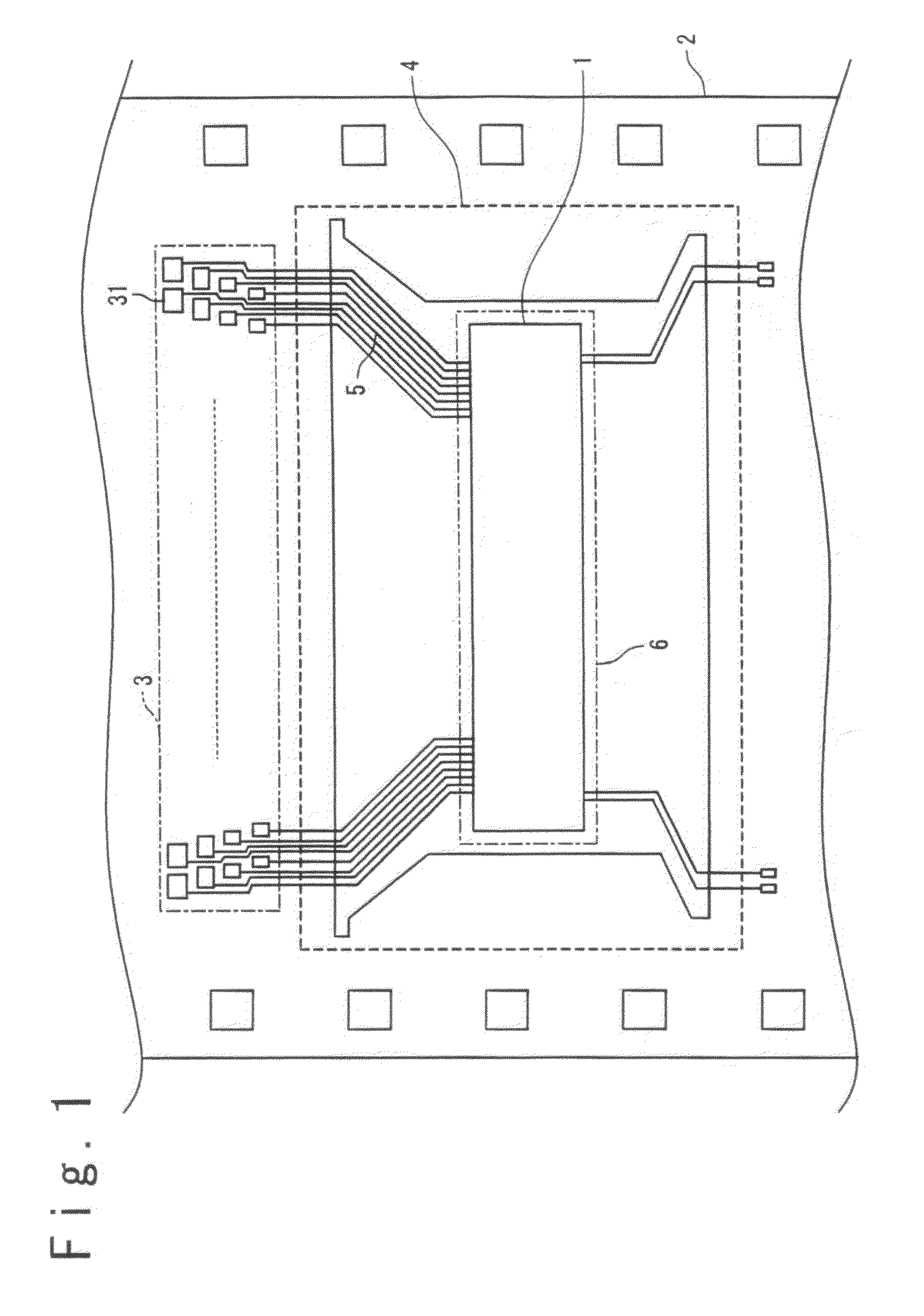

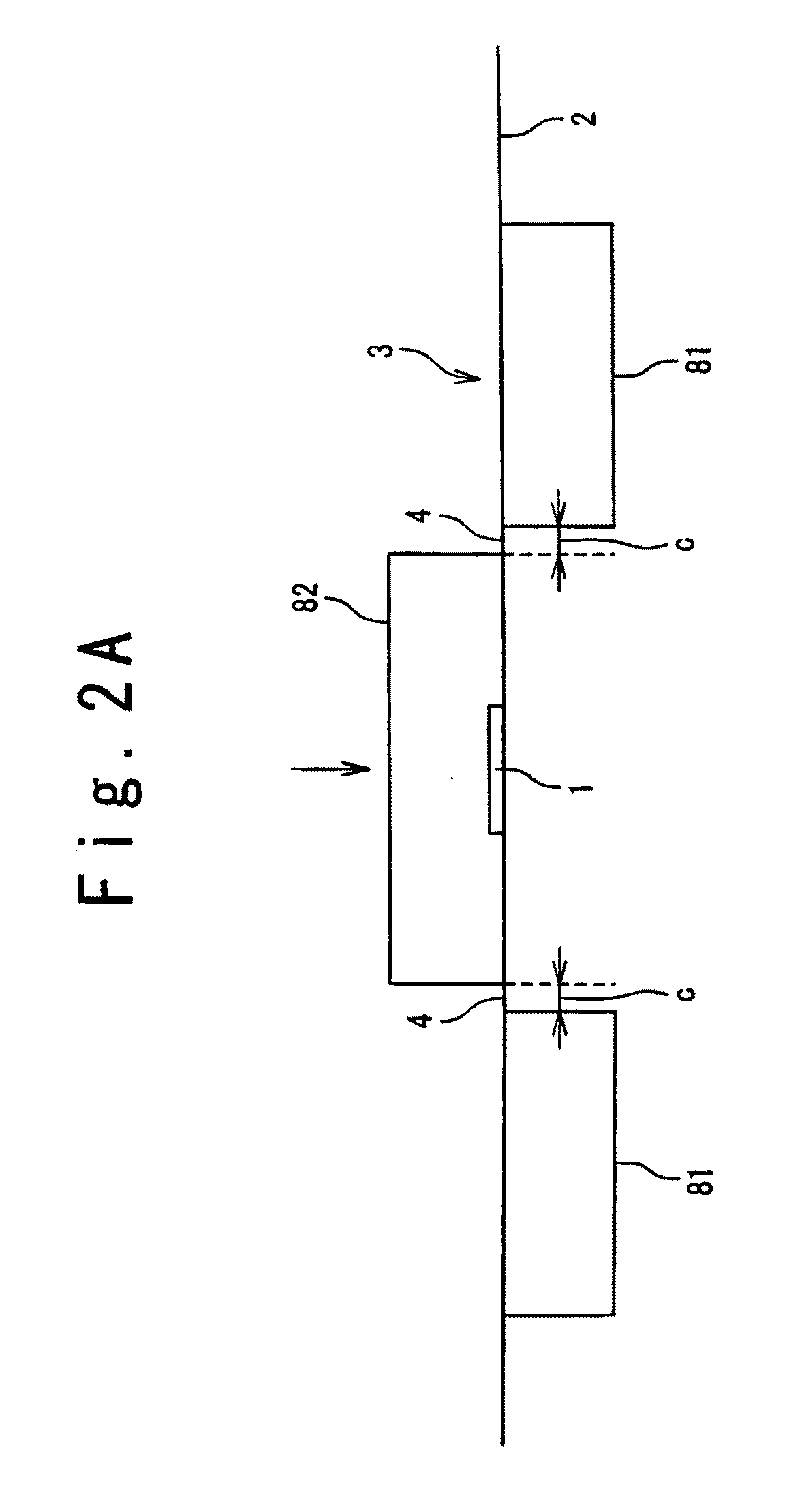

Tape carrier package, individual tape carrier package product, and method of manufacturing the same

InactiveUS20100295045A1Avoid interconnectionAvoid conductionSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsInterconnectionElectrical and Electronics engineering

A tape carrier package includes: a tape base; and interconnections formed on the tape base and extending to intersect a cutting line. At least a slit is formed along each of the interconnections, to intersect the cutting line and to divide the interconnection into a plurality of interconnection elements.

Owner:RENESAS ELECTRONICS CORP

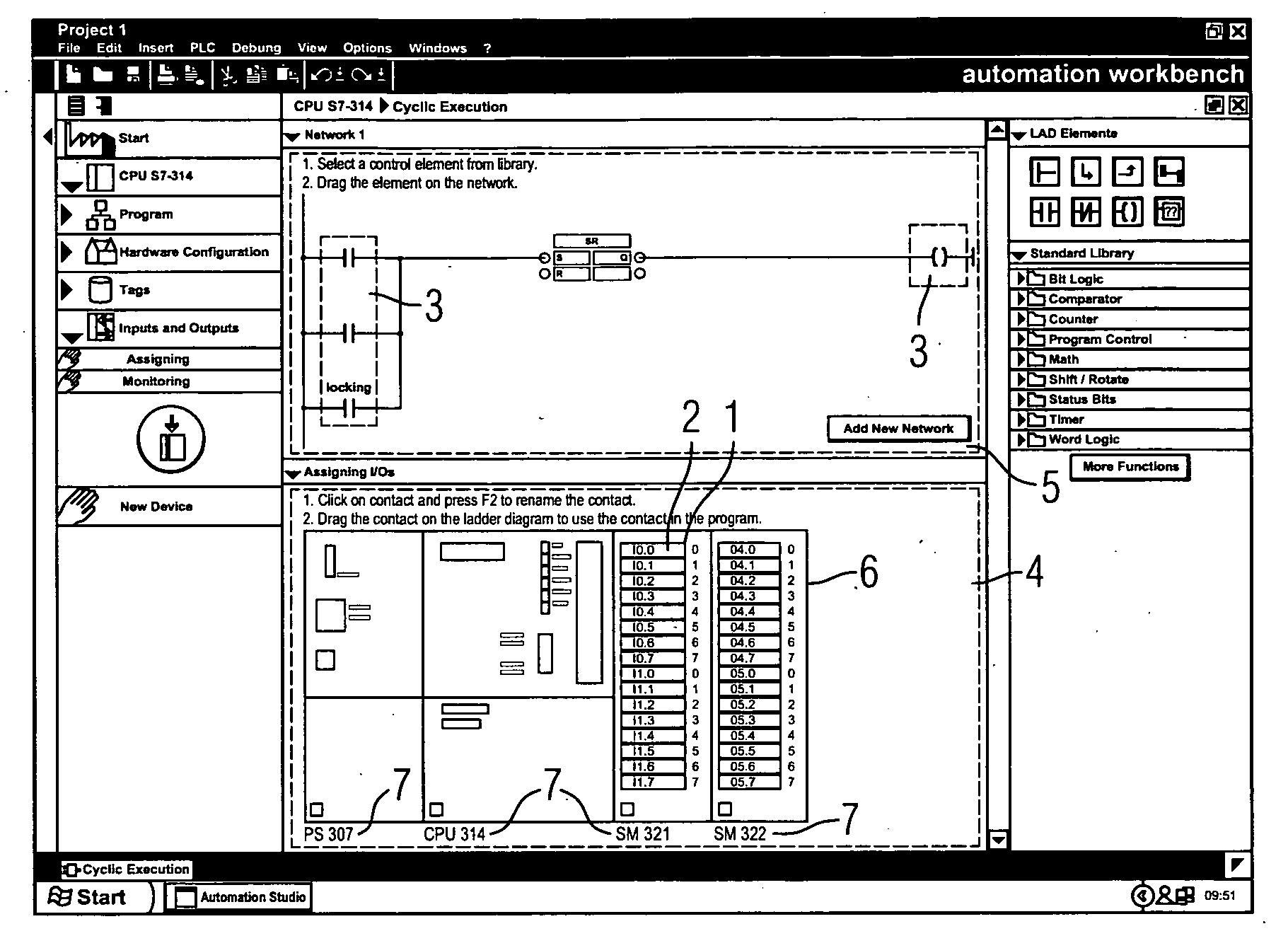

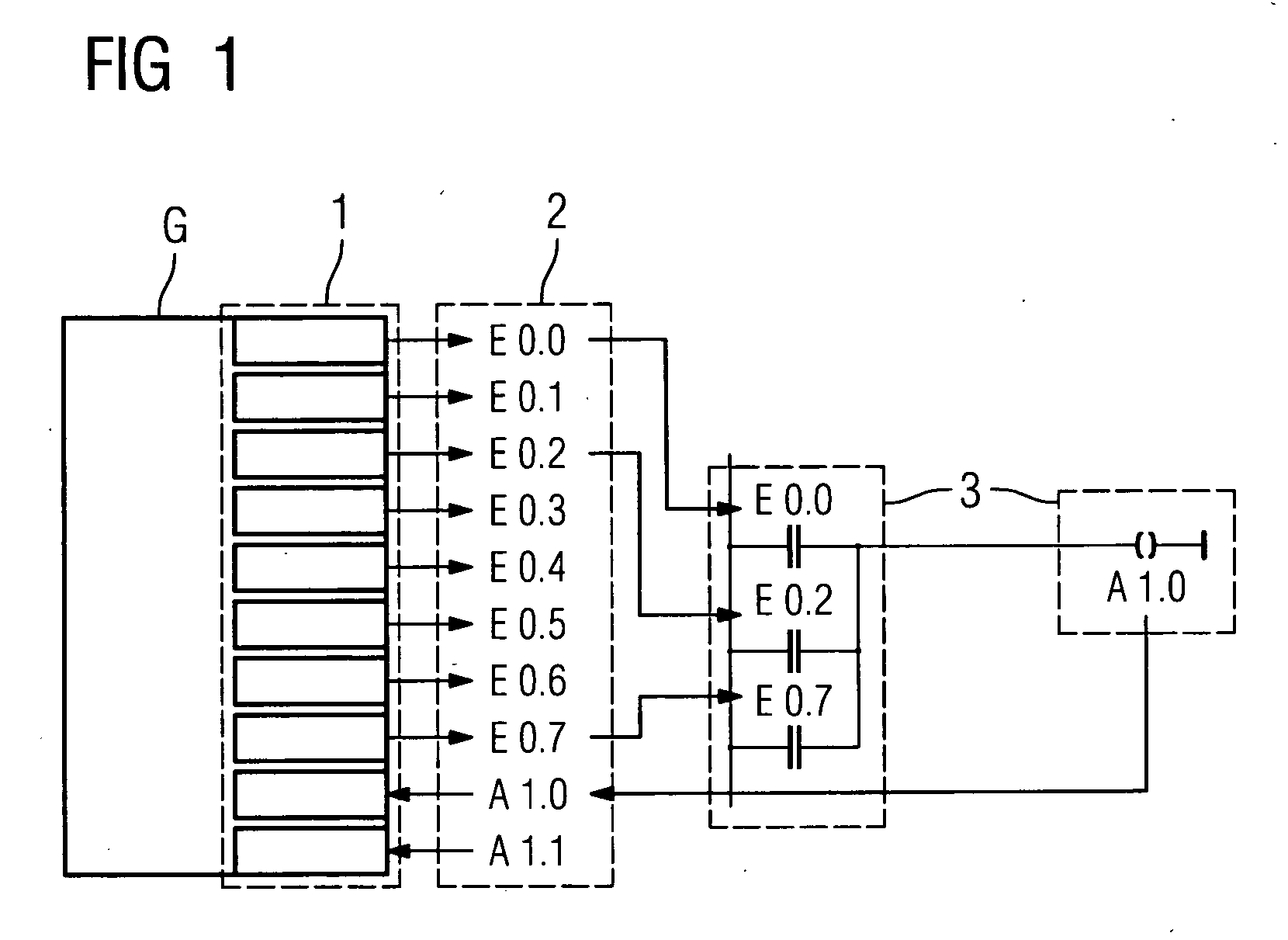

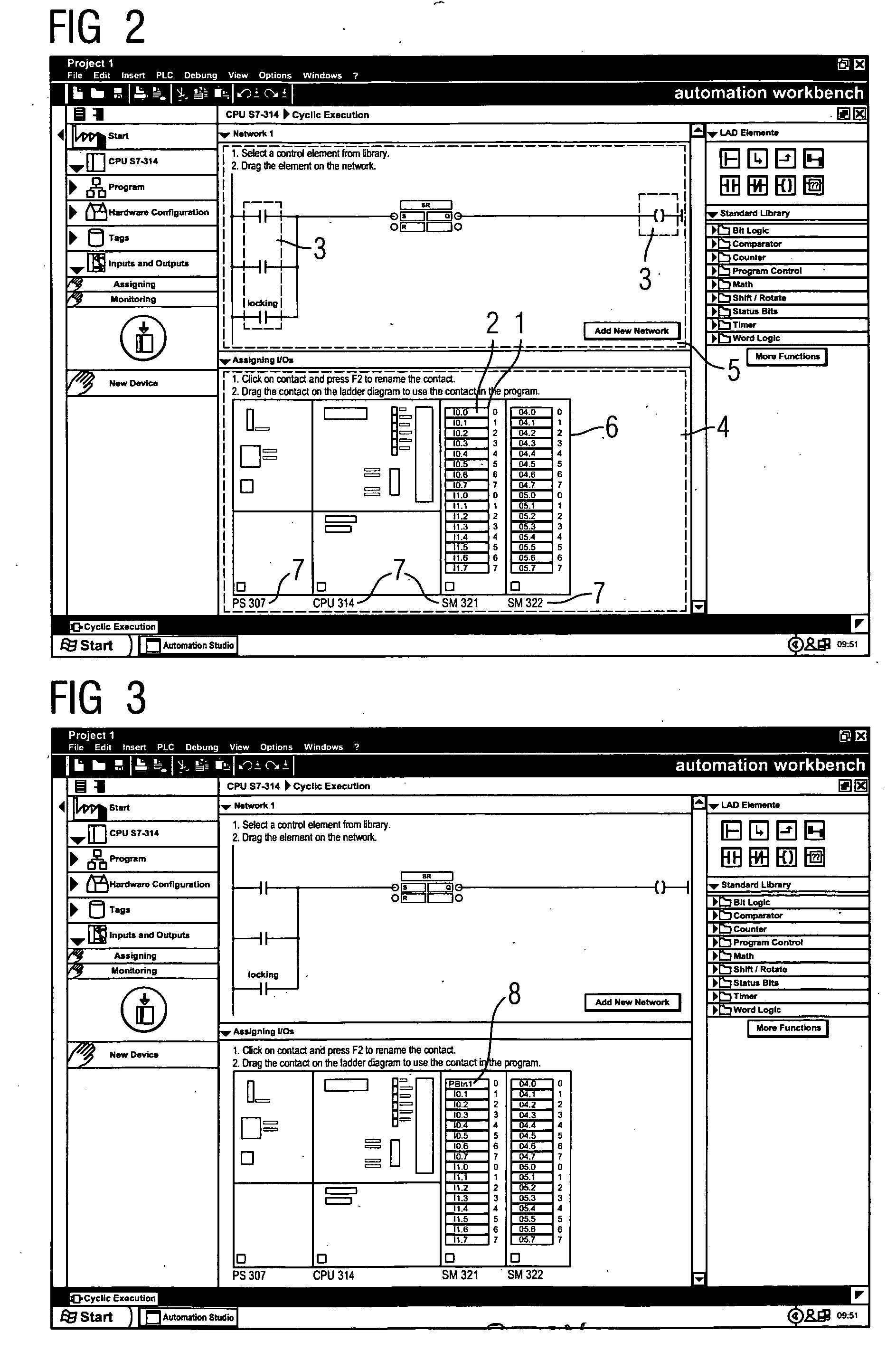

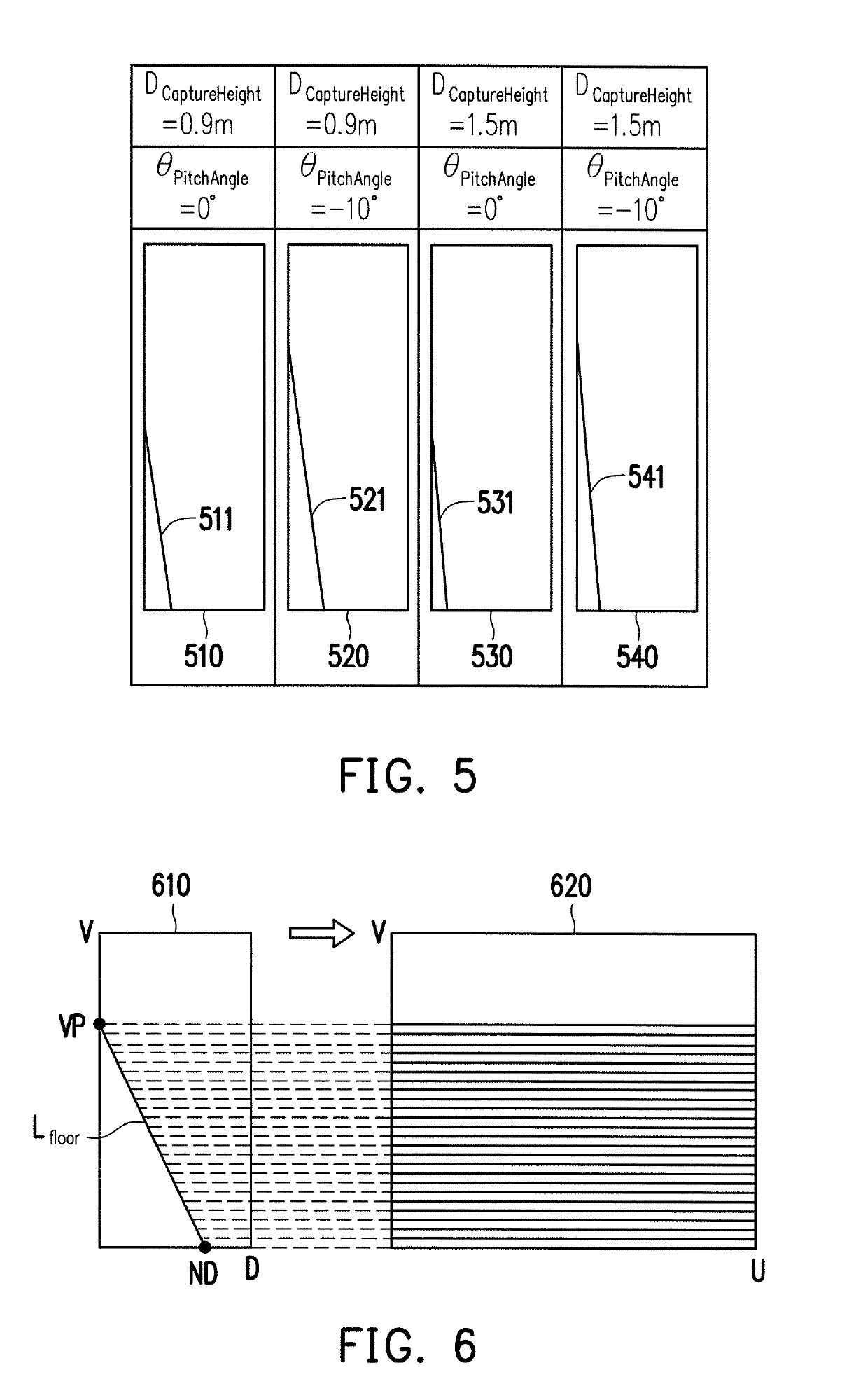

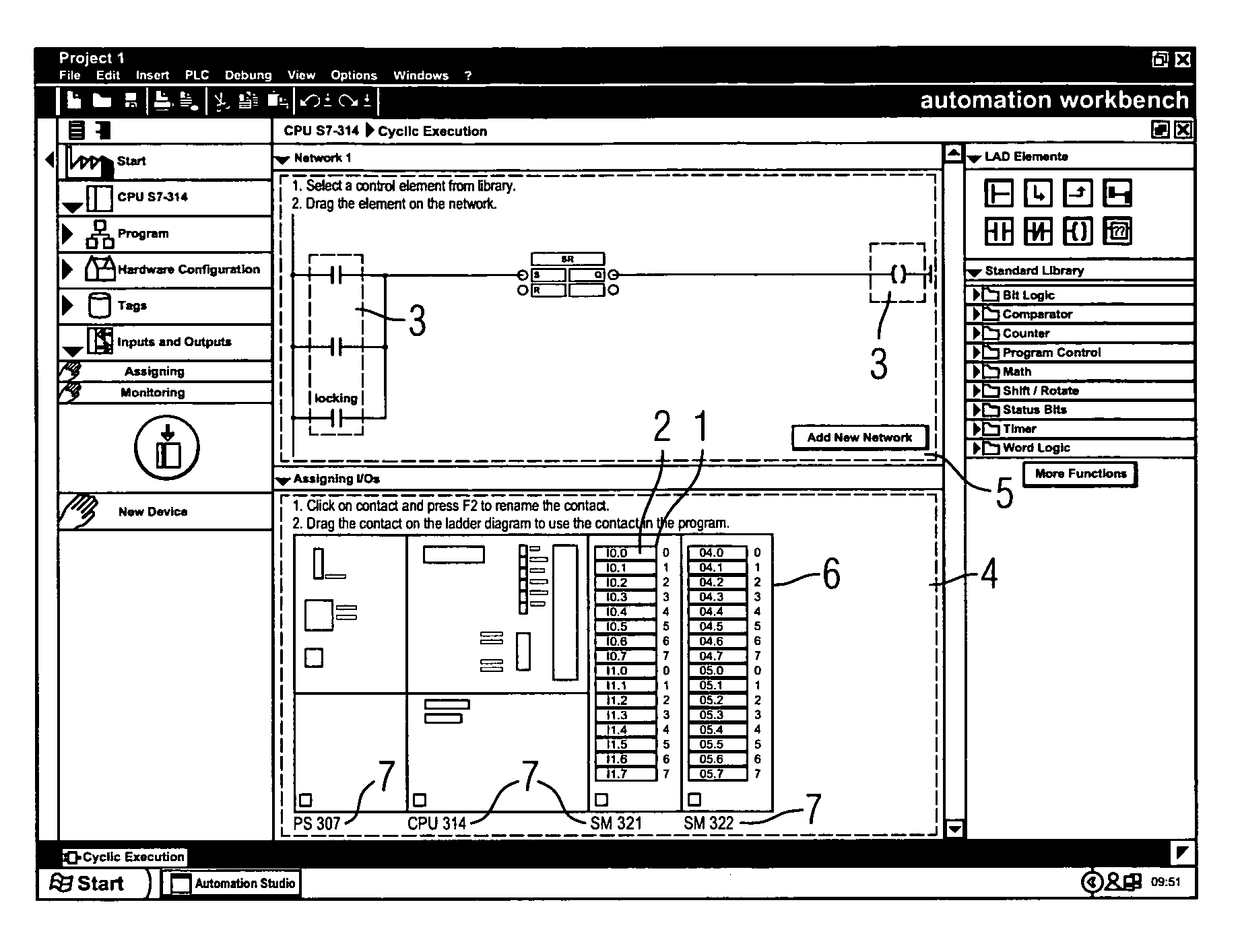

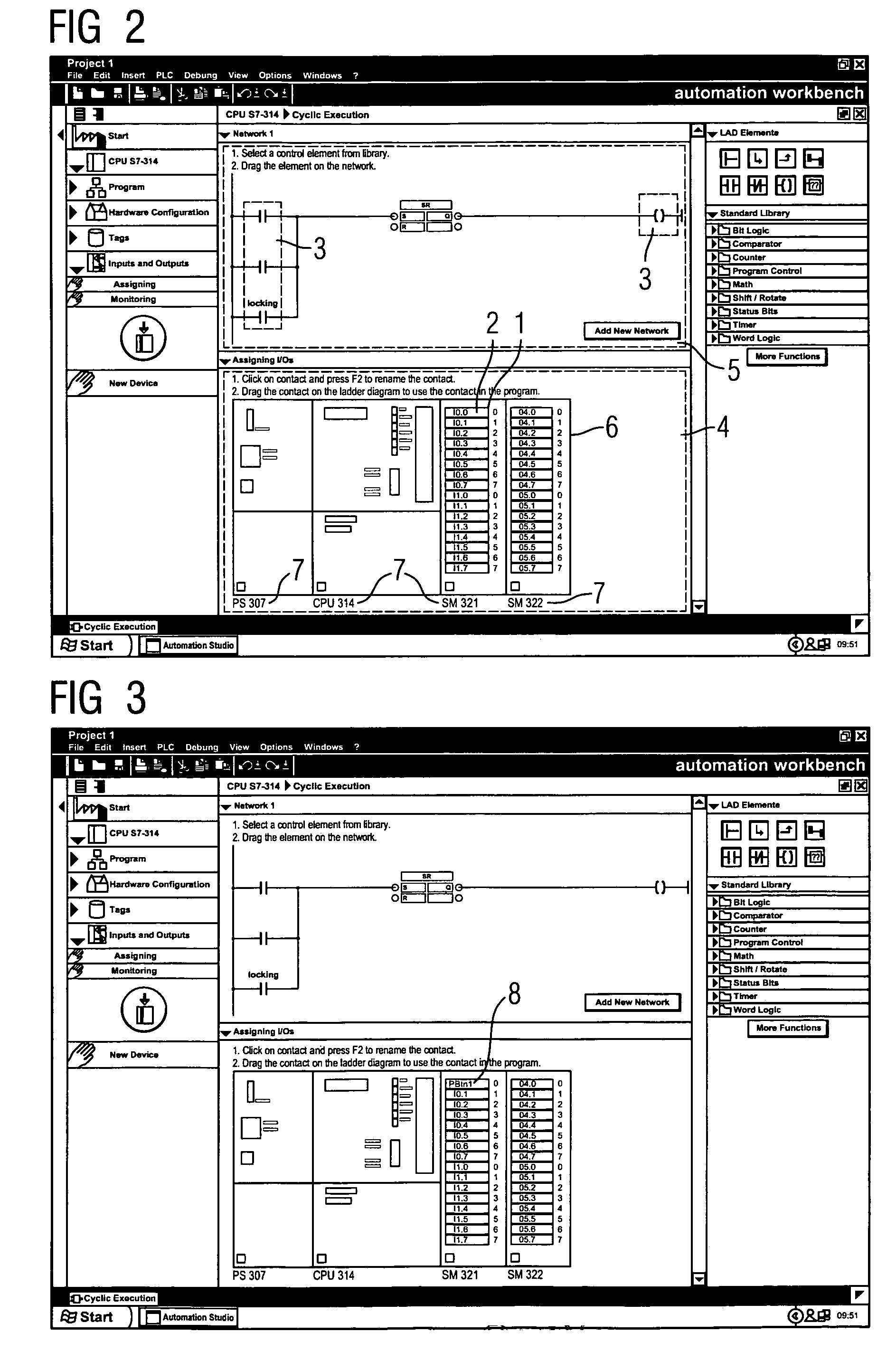

Graphical interconnection of hardware signals

ActiveUS20070067053A1Short timeCompetitive advantageComputer controlSimulator controlComputer hardwareGraphics

In one aspect, a system and a method for graphical interconnection of hardware signals of a device, especially of a controller device are provided. The object of the invention is to design the graphical interconnection in a simple manner so that a user can perform this function intuitively and without knowledge of the address convention used in the engineering system. This object is achieved by the inventive system and by the inventive method by the hardware signals being interconnected graphically with program elements of a programming environment using drag & drop. A clean copy of the Abstract that incorporates the above amendments is provided herewith on a separate page.

Owner:SIEMENS AG

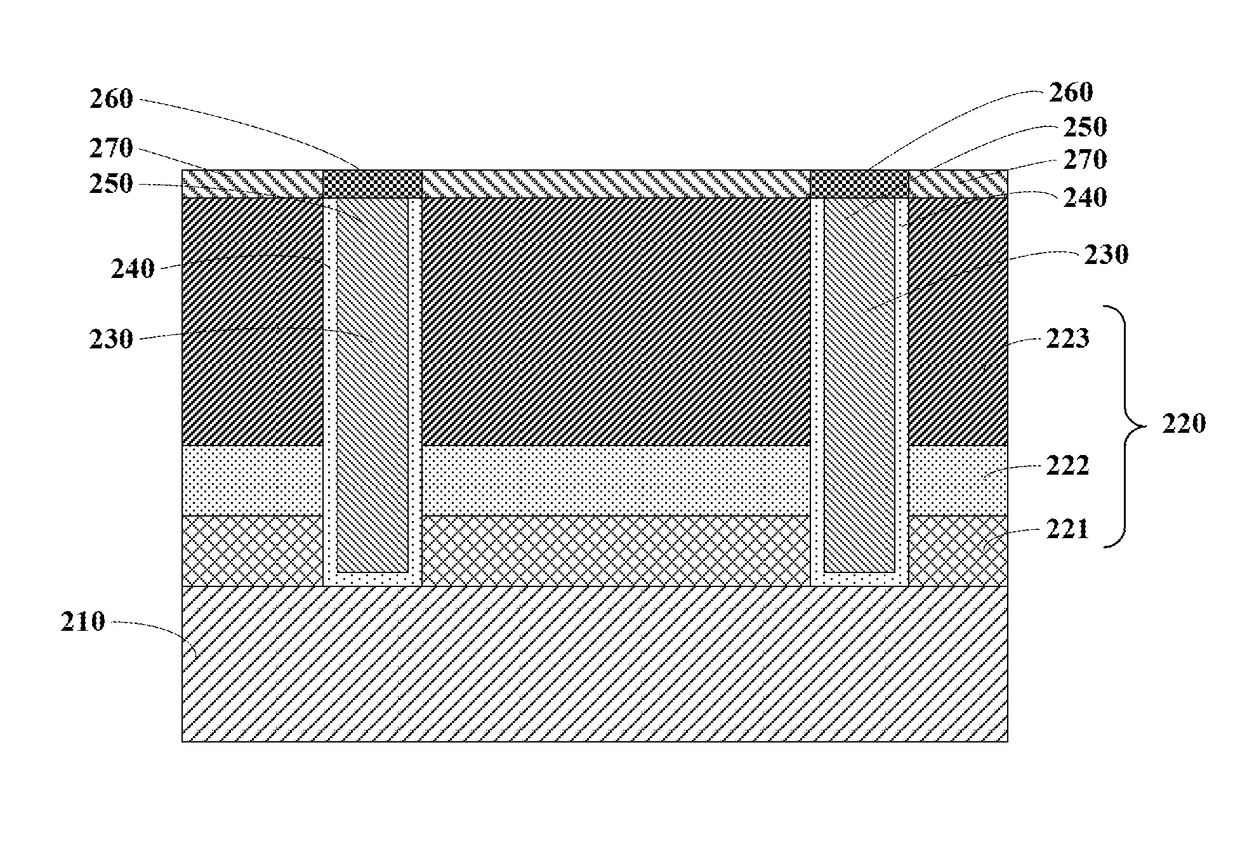

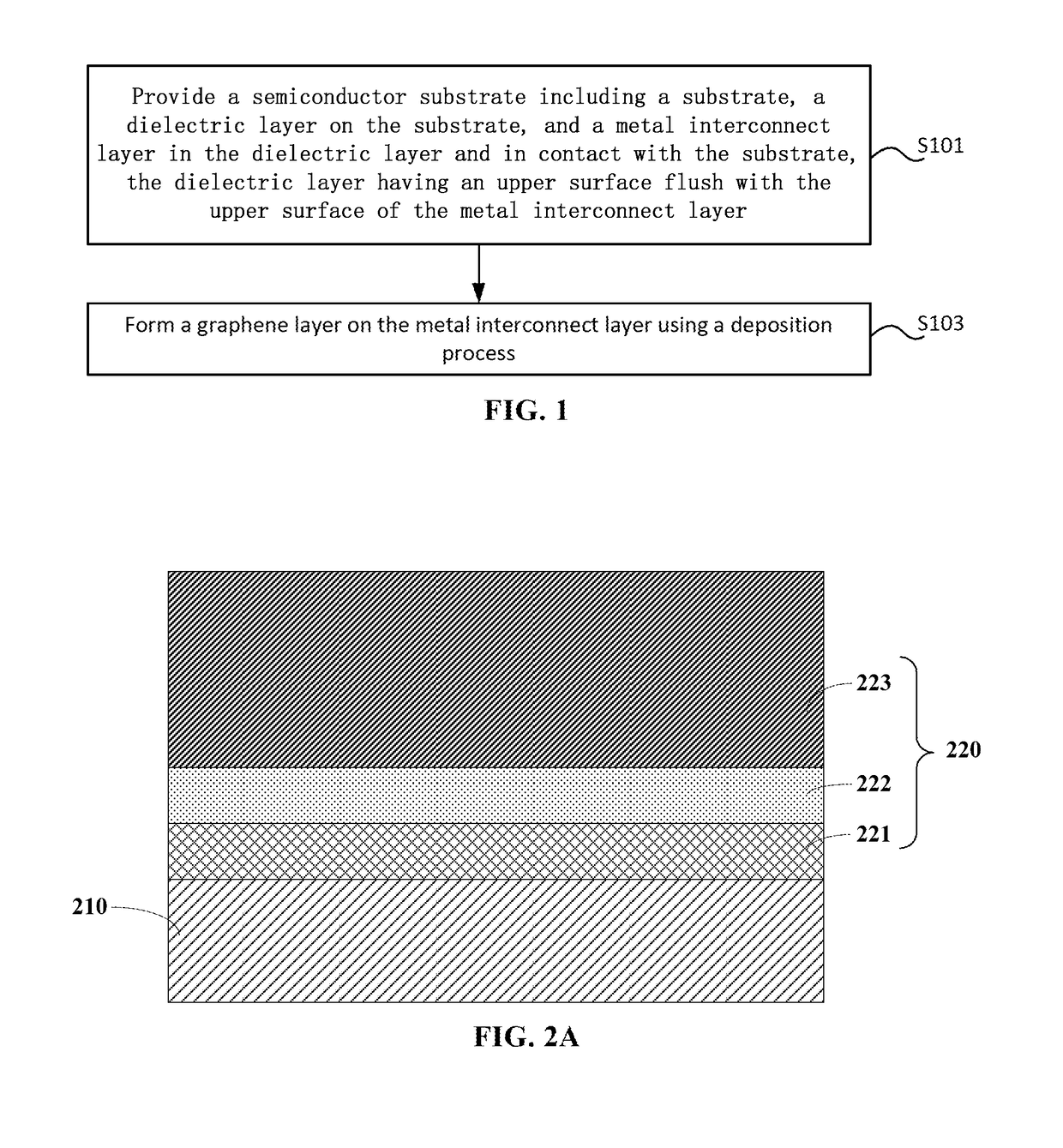

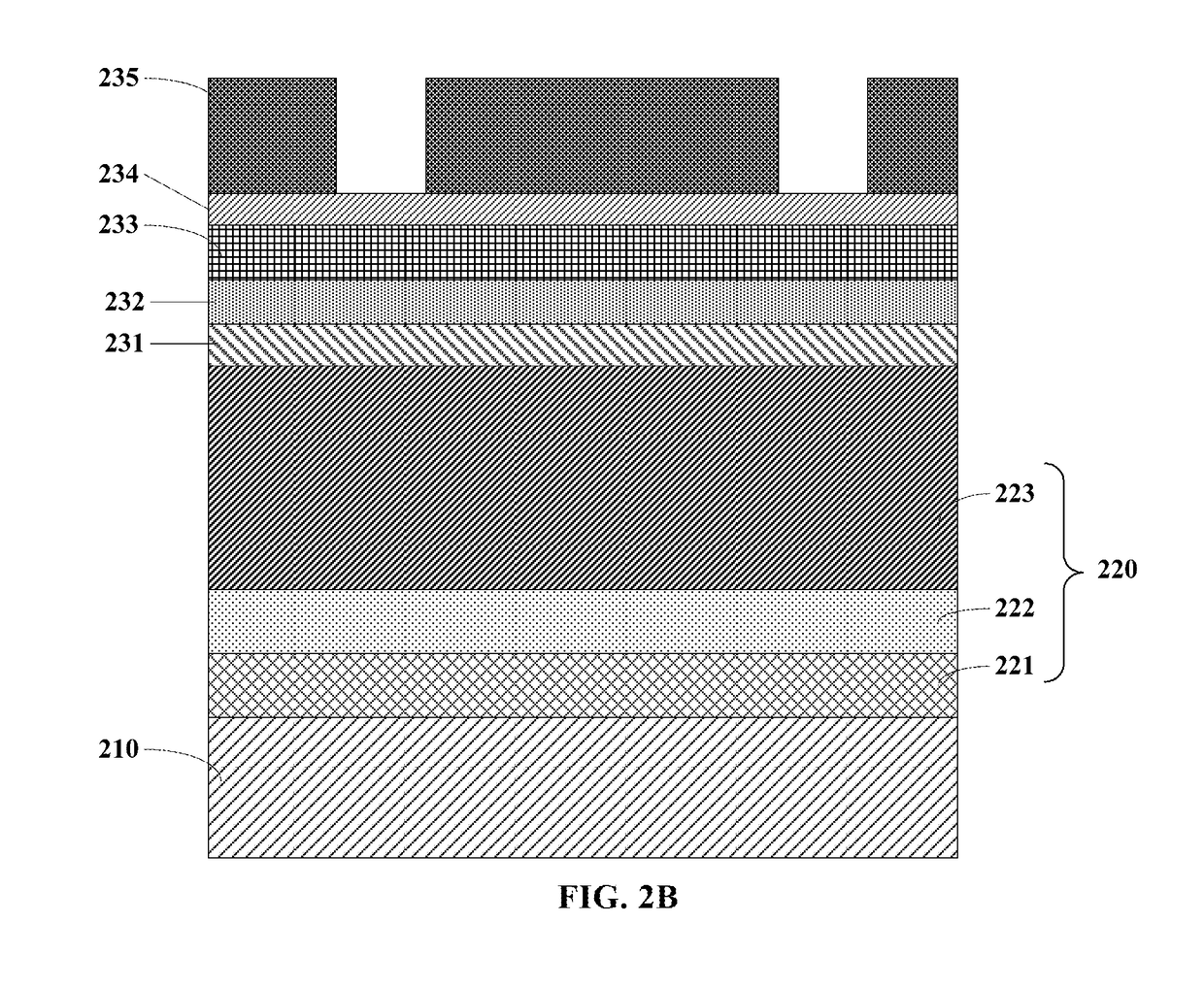

Method for capping Cu layer using graphene in semiconductor

ActiveUS9929096B2Extension of timeImprove equipment reliabilitySemiconductor/solid-state device detailsSolid-state devicesMetal interconnectOxygen

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Wafer level chip scale package having continuous through hole via configuration and fabrication method thereof

ActiveUS20170256471A1Avoid interconnectionAvoid pollutionSemiconductor/solid-state device detailsSolid-state devicesEngineeringMetal

A wafer level chip scale package (WLCSP) has a device chip, a carrier chip, an offset pad, a conductive spacing bump and a through hole via (THV). The device chip is attached to the carrier chip. The offset pad is disposed on a first surface of the device chip. The conductive spacing bump is formed on the offset pad. The through hole via includes a through hole and a hole metal layer. The through hole penetrates through the carrier chip and the device chip, and the hole metal layer is formed in the through hole and in contact with the offset pad.

Owner:POWERTECH TECHNOLOGY

Cooling water tank for machine tool

InactiveCN104084839AImprove isolationEasy to disassemble and operateMaintainance and safety accessoriesSewageSettling basin

The invention relates to machine tool accessories, in particular to a cooling water tank for a machine tool. According to the cooling water tank for the machine tool, partition plates are inserted in a tank body so that when the tank body is cleaned, the partition plates can be directly taken down, and then the tank body can be cleaned. In addition, a water outlet is arranged, so that when the tank body is cleaned, sewage in the tank is discharged easily, and the tank body is very conveniently cleaned. Moreover, due to the fact that handles, connection blocks and sealing gaskets are arranged, the partition plates are very conveniently mounted and dismounted, the partitioning effects of the partition plates are very good at the same time, different settling basins are effectively prevented from being communicated with one another, and the settling effect of the settling basins is improved.

Owner:ZHEJIANG LEKELAI MACHINERY

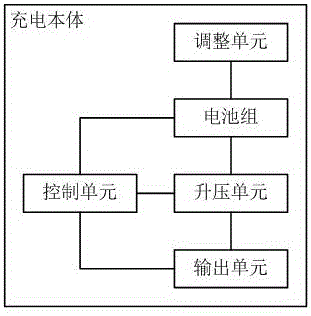

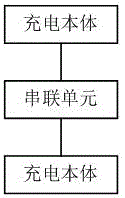

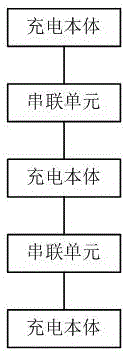

Intelligent sustainable power system based on complementation of wind, light, storage and mains supply

InactiveCN106253447AImprove reliabilityImprove power supply efficiencyElectric powerCharging/discharging current/voltage regulationCharged bodyEngineering

The invention provides an intelligent sustainable power system based on complementation of wind, light, storage and mains supply. The power supply system comprises at least one charging body which is internally provided with a control unit, a boosting unit, a battery pack and an output unit, wherein the control unit is used for controlling the boosting of the battery pack through the boosting unit and then outputting through the output unit, and the charging body also comprises an adjusting unit; the battery pack is provided with a plurality of battery groups, the adjusting unit is provided with a plurality of selective switches used for selecting the connection relationship for the battery groups so as to adjust the output of the output unit. Due to the adoption of the scheme, through the arrangement of the adjusting unit, the connection relationship for the battery groups is selected, so that output voltage or output current of the power system for charging can be adjusted, and the power system has an extremely high market application value.

Owner:SHENZHEN AIYIRUI TECH CO LTD

Semiconductor structure and forming method thereof

PendingCN112713087AIncreased etch resistanceReduce the probability of misetchingSemiconductor/solid-state device manufacturingSemiconductor structureEngineering

The invention discloses a semiconductor structure and a forming method thereof. The forming method comprises the steps of providing a substrate, and forming a to-be-etched layer on the substrate, forming a core layer and a plurality of sacrificial layers located in the core layer on the to-be-etched layer, and enabling the sacrificial layers to be arranged at intervals, removing part of the core layer between the adjacent sacrificial layers to form a first groove penetrating through the core layer, and exposing the sacrificial layers from the side wall of the first groove, carrying out first ion doping treatment on the core layer of the side wall of the first groove, wherein the first ion doping treatment is suitable for increasing the etching resistance of the core layer of the side wall of the first groove, forming a side wall on the side wall of the first groove, after first ion doping processing and side wall forming are carried out, removing the sacrificial layer, forming a second groove penetrating through the core layer, and isolating the second groove and the first groove by a side wall, and etching the to-be-etched layers at the bottoms of the first groove and the second groove by taking the core layer and the side walls as masks. According to the embodiment of the invention, the probability that the core layer on the side wall of the first groove is mistakenly etched in the step of removing the sacrificial layer is reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

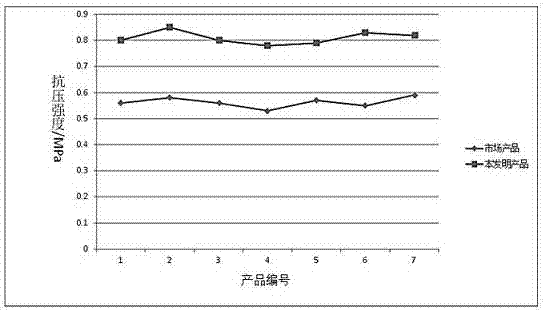

Preparation method for foam glass with high compressive strength

InactiveCN107500552AHigh compressive strengthAvoid breakingGlass shaping apparatusFoaming agentThenardite

The invention relates to a preparation method for foam glass with high compressive strength, belonging to the technical field of building materials. The foam glass comprises the following raw materials by weight: 90-94% of waste glass abrasive powder, 1.00-1.50% of a raw material additive, 0.5-2.0% of sodium hexametaphosphate, 1.0-3.0% of borax, 0.4-0.8% of thenardite, 1.5-4% of calcium carbonate, 1.8-1.9% of a foaming agent, 0.6-0.8% of a foam stabilizer, 0.2-0.4% of a flux and 0.1-0.2% of a reinforcing agent. The preparation method comprises the following steps: sufficient grinding in a conical ball mill; and melting, foaming and cooling in an electromagnetic induction heater. The foam glass prepared by using the method has high compressive strength, uniform stomatal structure, small density and low thermal conductivity.

Owner:LUDONG UNIVERSITY

Method for forming aluminum-containing interconnect

InactiveUS20050020059A1Prevent interconnection shortAvoid interconnectionSemiconductor/solid-state device manufacturingTitanium nitrideContact region

A method for forming an aluminum-containing interconnect is provided. The method includes providing a substrate with a contact region. A first barrier layer, an aluminum-containing conductive layer, and a second barrier layer are sequentially formed over the substrate, and then patterned to form an aluminum-containing interconnect. The aluminum-containing interconnect is electrically coupled to the contact region and has a sidewall exposed. A barrier spacer is formed on the sidewall of the aluminum-containing interconnect by using a material selected from a group consisting of titanium, titanium nitride, and the combination thereof.

Owner:NAN YA TECH

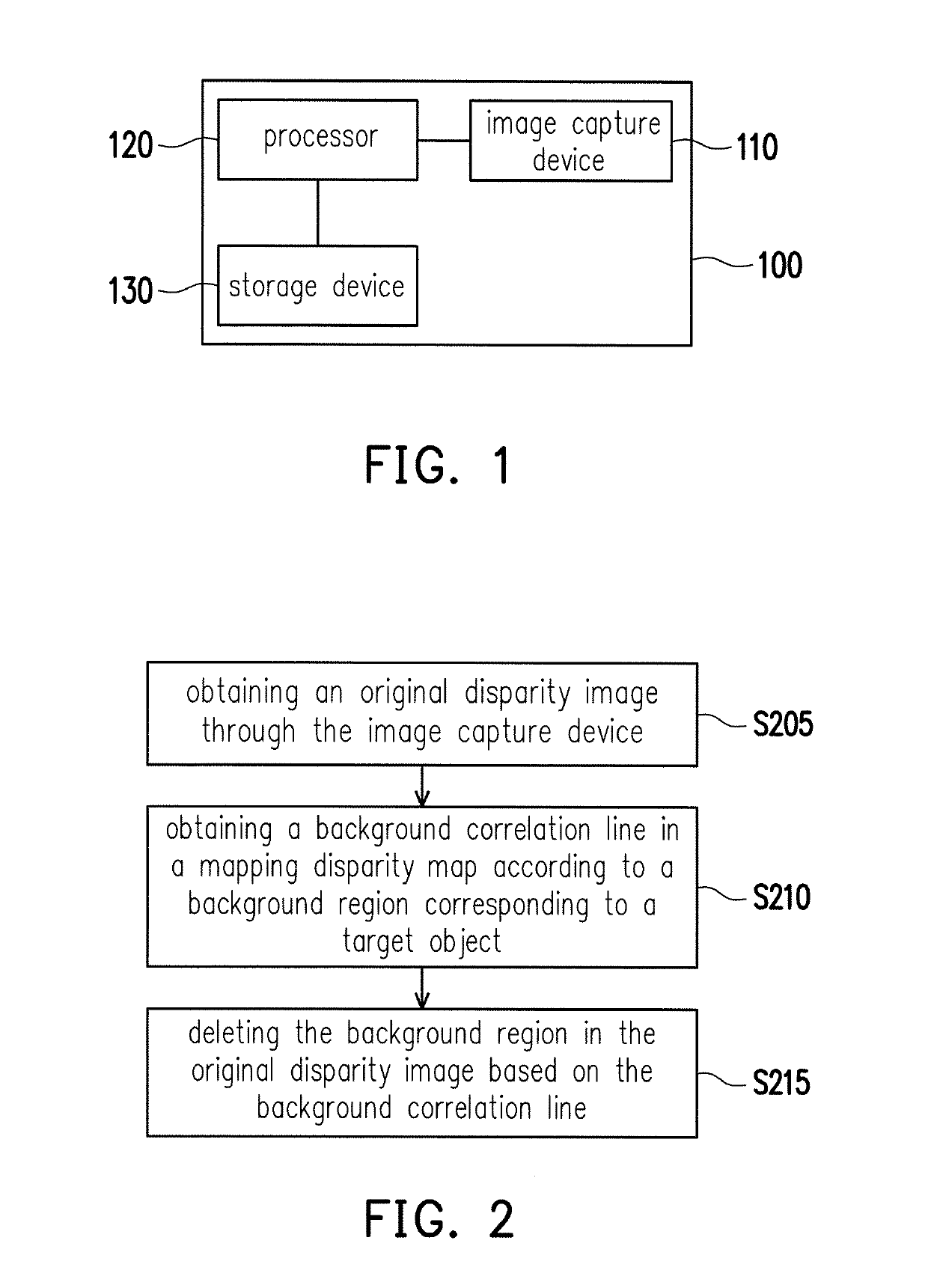

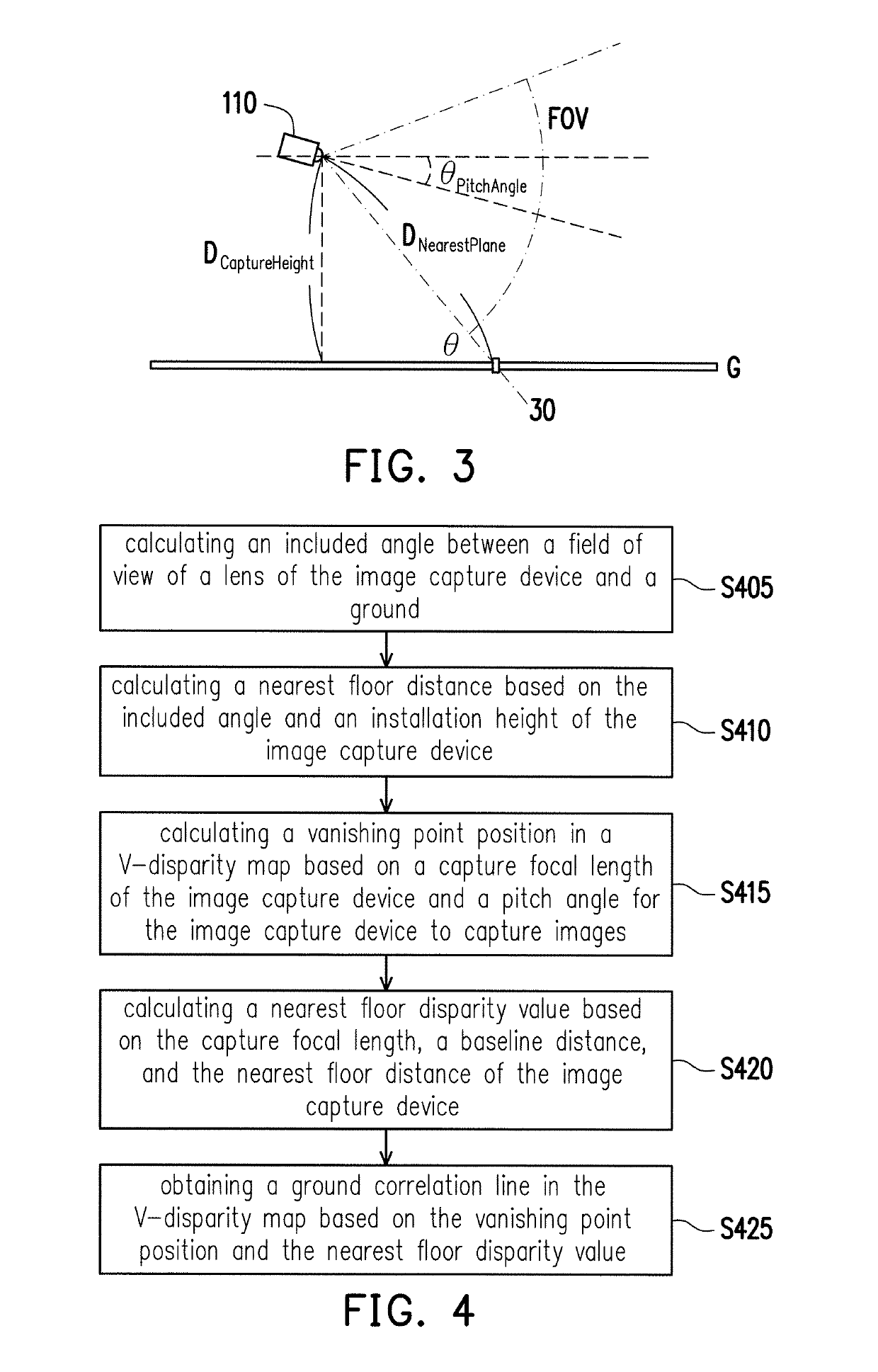

Image processing method, image processing device and computer readable storage medium

ActiveUS20190102895A1Improve accuracyAvoid interconnectionImage enhancementImage analysisImage basedImage capture

An image processing method, an image processing device, and a computer readable storage medium are provided. An original disparity image is obtained through an image capture device. A background correlation line is obtained in a mapping disparity map according to a background region corresponding to a target object. The background region is deleted in the original disparity image based on the background correlation line.

Owner:WISTRON CORP

Graphical interconnection of hardware signals

ActiveUS8683364B2Short timeCompetitive advantageComputer controlSimulator controlGraphicsComputer hardware

A system and a method for graphical interconnection of hardware signals of a device, (e.g., a controller device) are provided. The graphical interconnection can now be implemented in a simple manner so that a user can perform this function intuitively and without knowledge of the address convention used in the engineering system. This may be achieved by the inventive system and by the inventive method by the hardware signals being interconnected graphically with program elements of a programming environment using drag & drop features in a graphical user interface.

Owner:SIEMENS AG

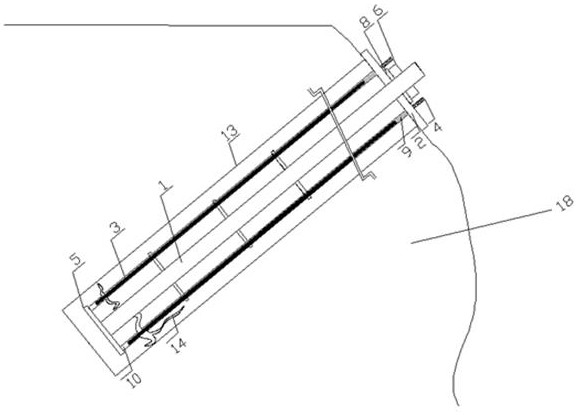

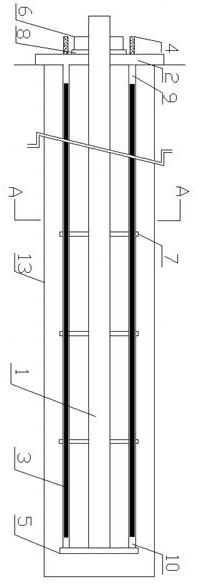

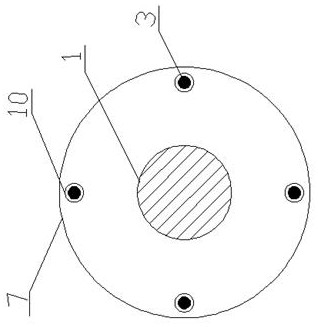

Self-feedback stratum information and multi-time repairing anchoring structure and anchoring and repairing method

ActiveCN112064635AReduce air pressureRepair grouting in timeIn situ soil foundationBulkheads/pilesSlurryPipe

The invention discloses a self-feedback stratum information and multi-time repairing anchoring structure and an anchoring and repairing method. The self-feedback stratum information and multi-time repairing anchoring structure comprises a hollow anchor rod, wherein the bottom of an anchoring section of the anchor rod is fixedly connected with a circular base plate; a plurality of annular fixing rings are arranged on a rod body of the anchor rod at intervals in a sleeving mode; a plurality of third circular holes are formed in the fixing rings; a free section of the anchor rod penetrates through a porous arched base plate; the porous arched base plate is fixed to the rock wall surface; pipes penetrate through the third circular holes and second circular holes in the same axis correspondingly; a rubber film column is installed in each pipe; the rubber film columns are filled with gas; anchor holes are filled with slurry injected through the anchor rod and solidified; the outer walls of the rubber film columns make close contact with the solidified slurry after the pipes are pulled out; and pressure sensors are installed inside the rubber film columns and are in signal connection witha controller. According to the self-feedback stratum information and multi-time repairing anchoring structure and the anchoring and repairing method, the anchoring structure and a stratum are linked,stratum deformation information can be automatically fed back, later repairing of the stratum through the anchoring structure is facilitated, the structure is simple, and multi-time repairing can beachieved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

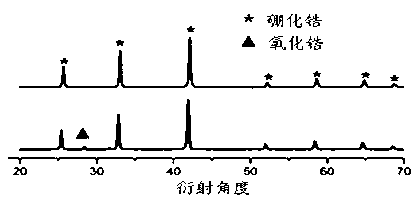

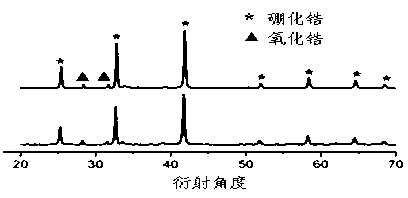

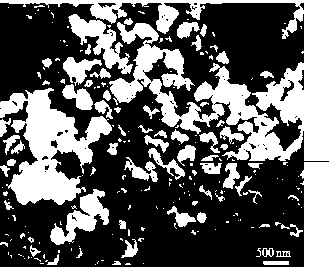

Zirconium boride ultrafine powder and preparation method thereof

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com