Patents

Literature

184results about How to "Guaranteed to dissolve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

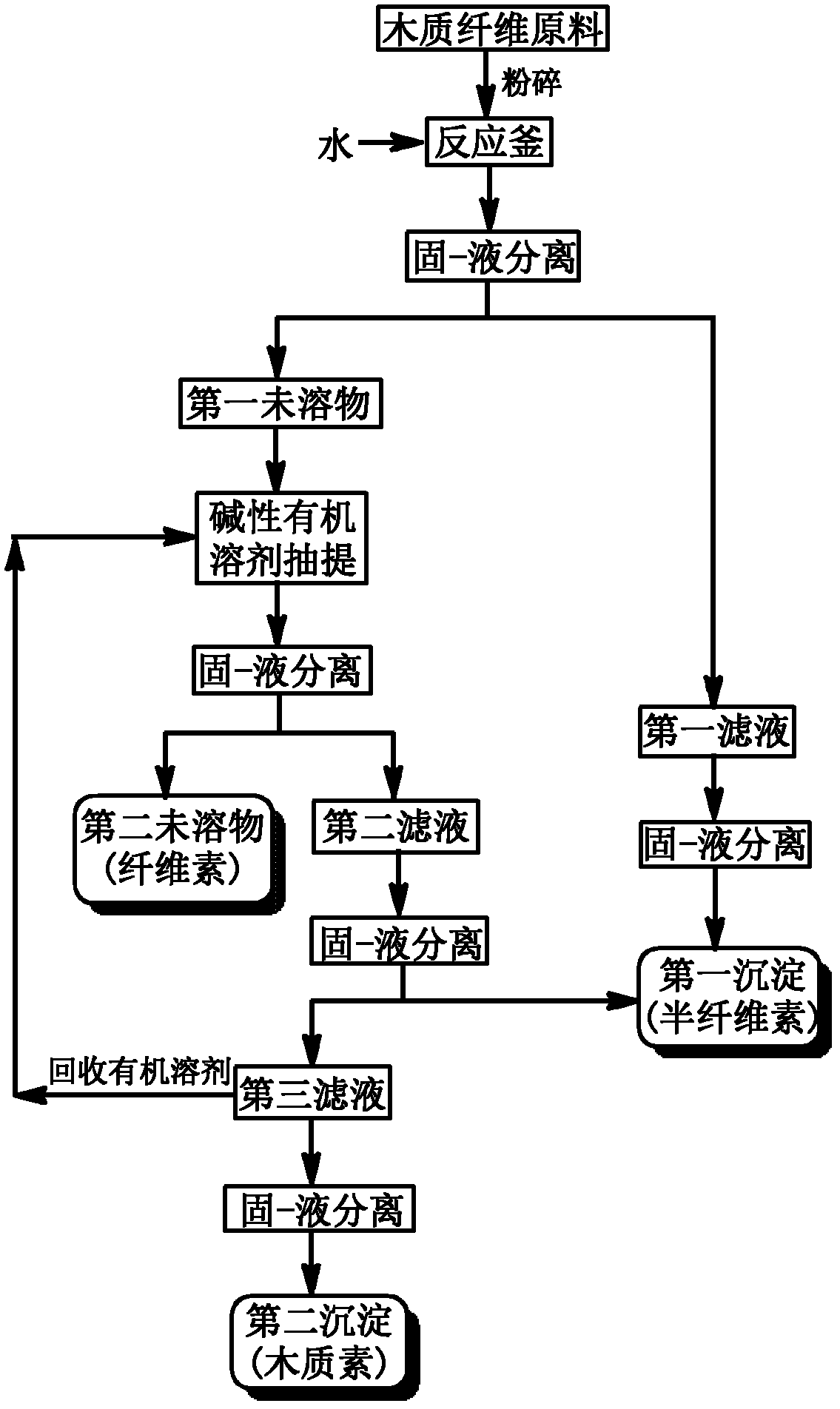

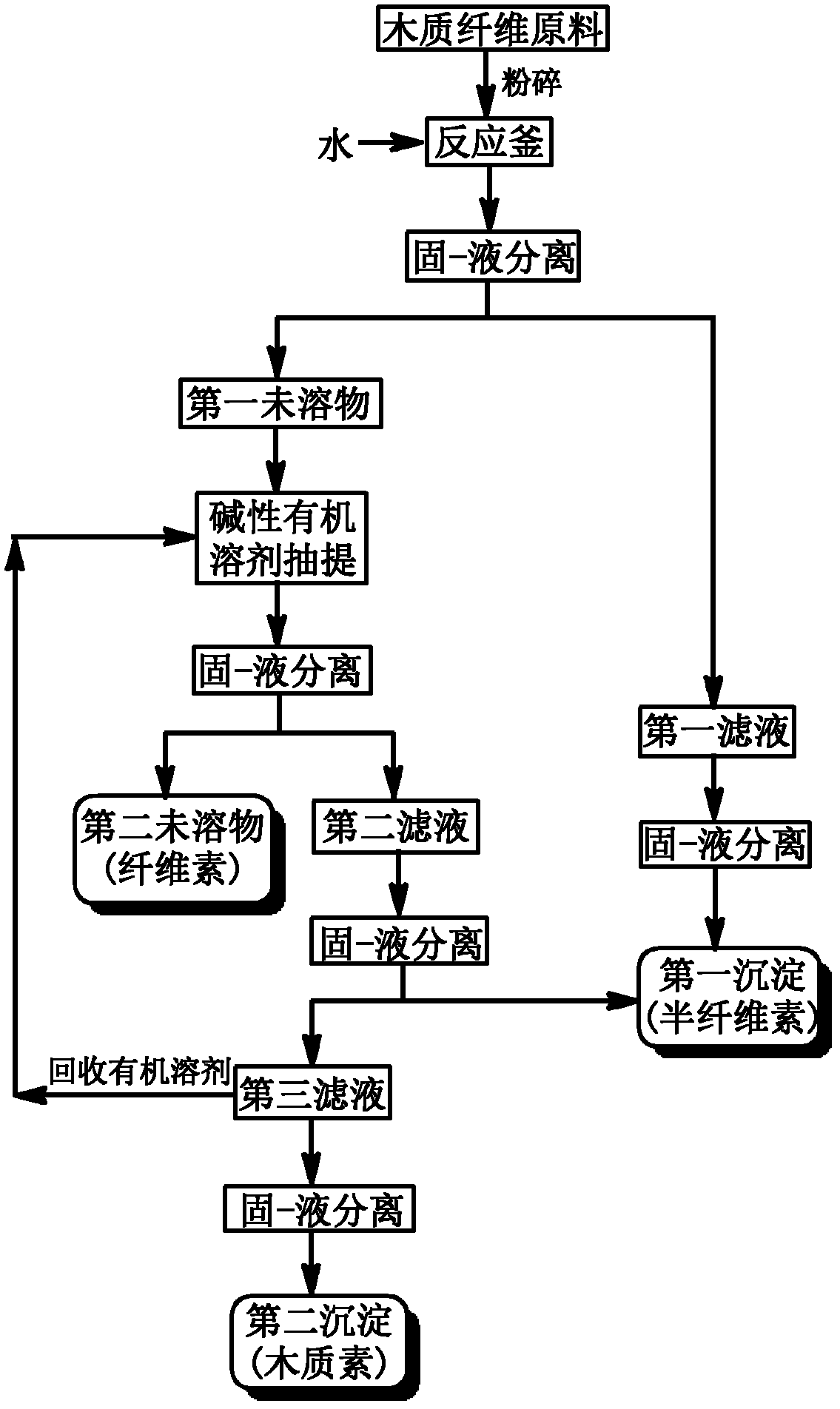

Method of extracting hemicellulose, cellulose and lignin from wood fiber raw materials

The invention relates to a method of extracting hemicellulose, cellulose and lignin from wood fiber raw materials and belongs to the field of utilization and technology of biomass resources of agriculture and forestry. In the method, the hemicellulose is extracted from the wood fiber raw materials by using hot water, then the lignin is extracted by using alkaline organic solvent under mild conditions; and residual ingredients rich in the cellulose are further used for enzyme hydrolysis to prepare fermentable sugar solution, thereby achieving full-ingredient utilization of the hemicellulose, cellulose and lignin in the biomass resources of the agriculture and forestry. The method has simple process, and is environmentally friendly, the organic solvent can be recycled, thereby promoting the development of the green agriculture and forestry, and the method has wide social and economic benefits.

Owner:BEIJING FORESTRY UNIVERSITY

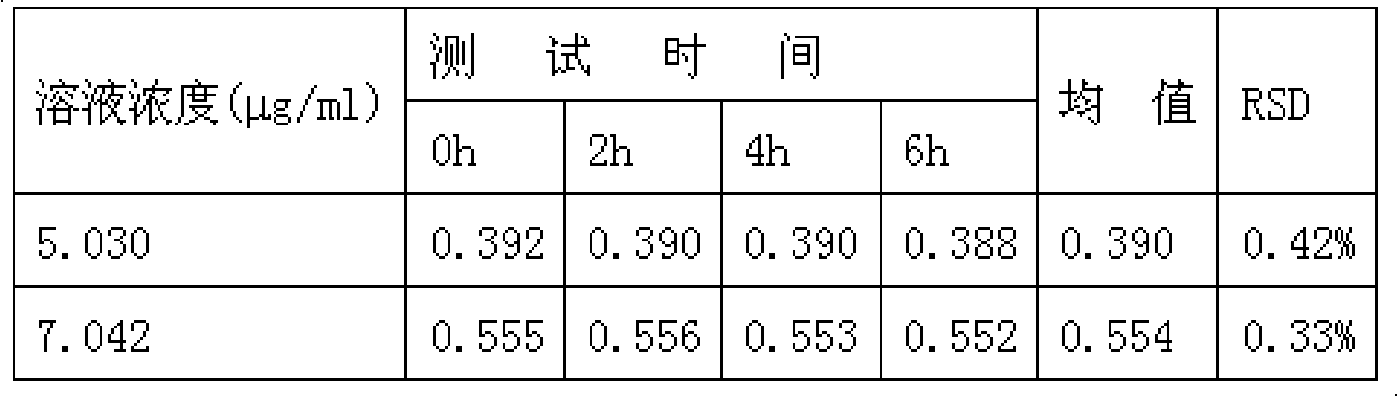

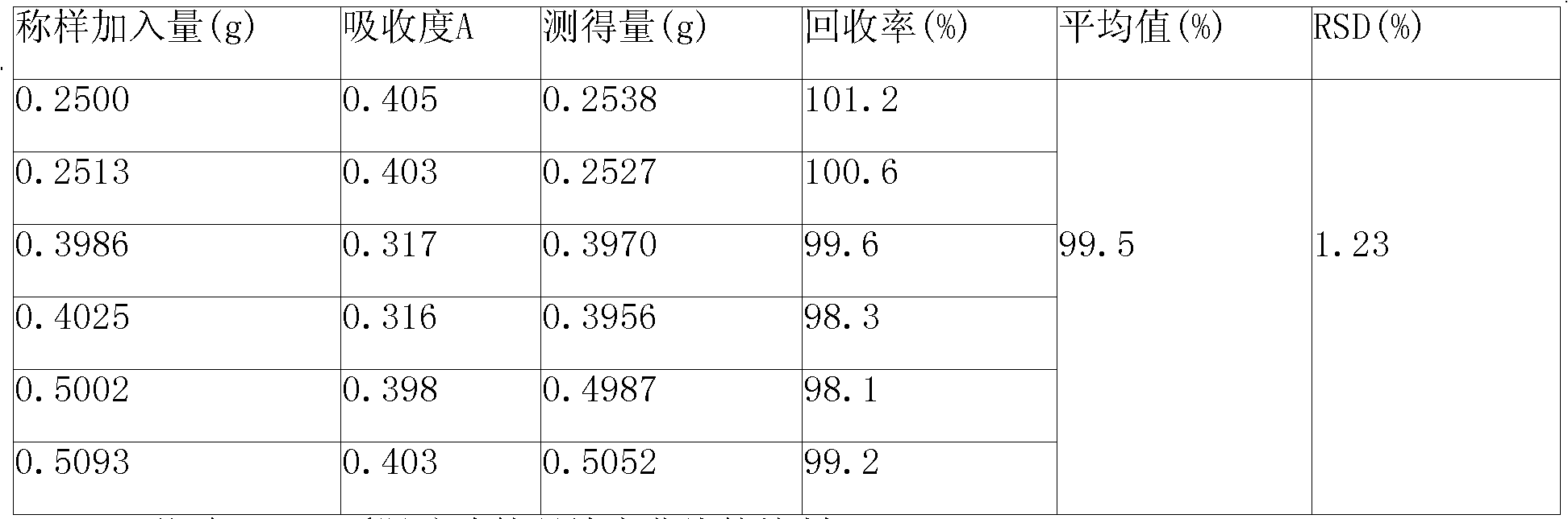

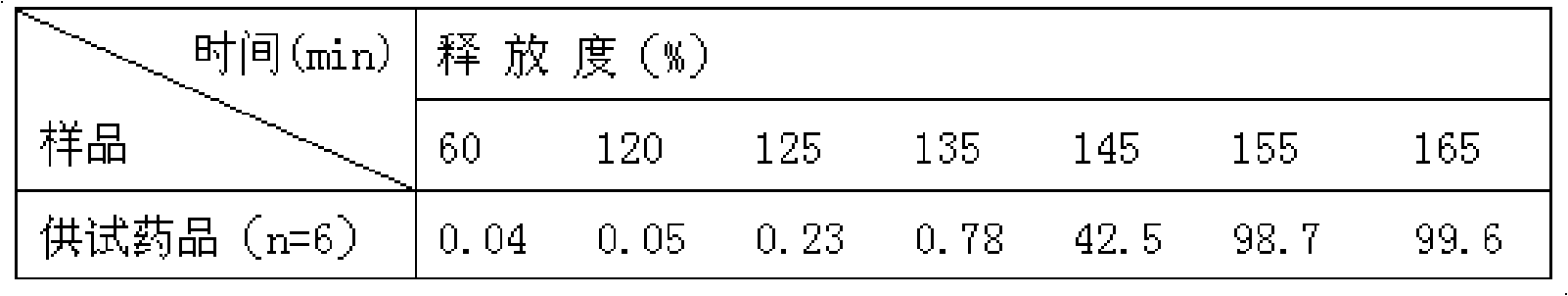

Metformin hydrochloride enteric-coated tablets quality control method

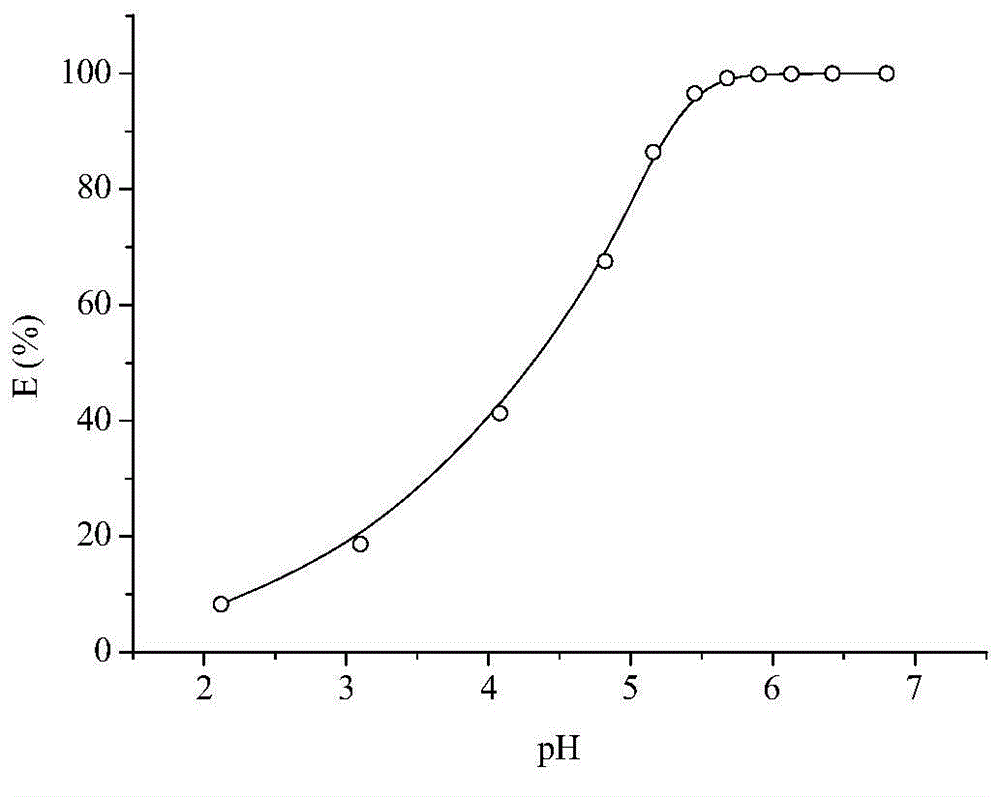

ActiveCN101339178AFacilitated releaseGuaranteed to dissolveComponent separationColor/spectral properties measurementsPhosphateMetformin Hydrochloride

The invention discloses a quality control method of metformin hydrochloride enteric coated tablet, comprising the aspects of character, identification, examination and content measurement; wherein, release examination comprises the release quantity examination of acid in hydrochloric acid solution of 0.1 mol / l and the release quantity examination in phosphate buffer with the pH value of 6.8; the examination of relevant substances comprises the following steps: dicyandiamide is taken as reference, sulfonic group cation exchange bonded silica is taken as filler, ammonium dihydrogen phosphate solution of 1.7 percent with the pH value of 3 is mobile phase and the high performance liquid chromatography is used for examining the relevant substances. The invention controls the release quantity of the metformin hydrochloride enteric coated tablet in gastric juice strictly, reduces the adverse reaction of patients effectively, improves the release quantity of the metformin hydrochloride enteric coated tablet in the buffer solution (simulated intestinal juice) and ensures the dissolution of the enteric coated tablet in the intestinal juice effectively; the invention also adds the examination of dicyandiamide impurity under the examination item and enhances the safety of the medicine.

Owner:贵州天安药业股份有限公司

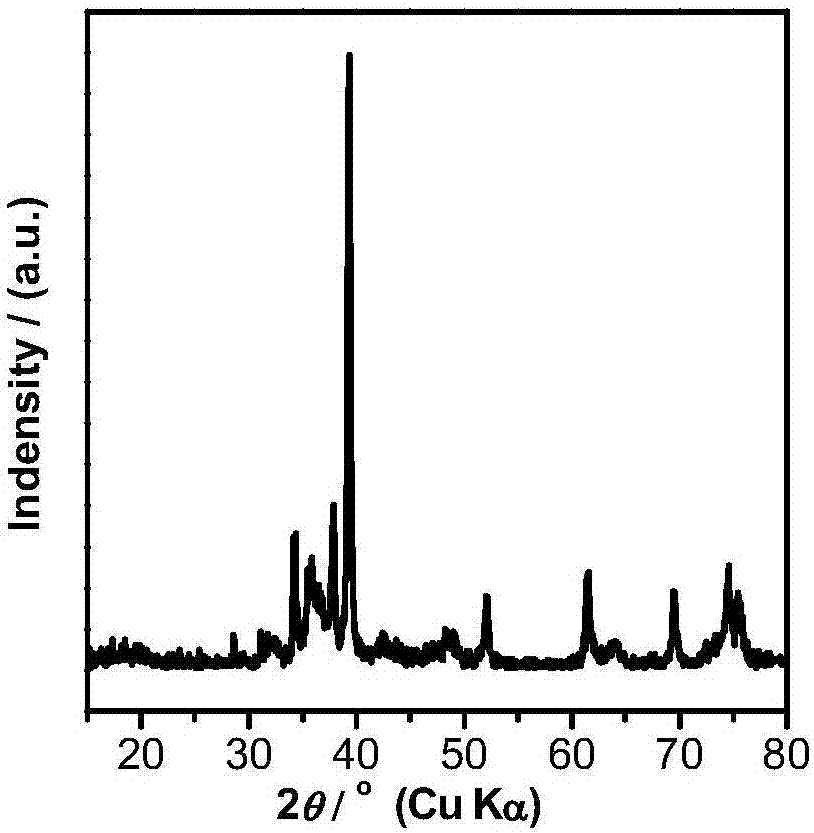

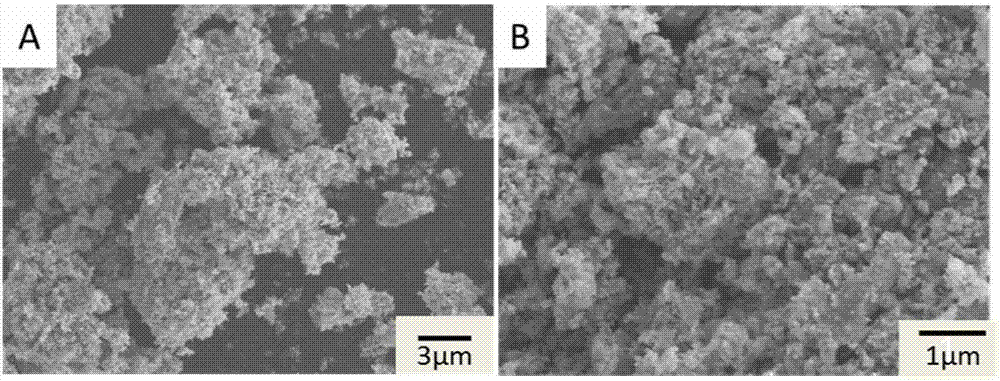

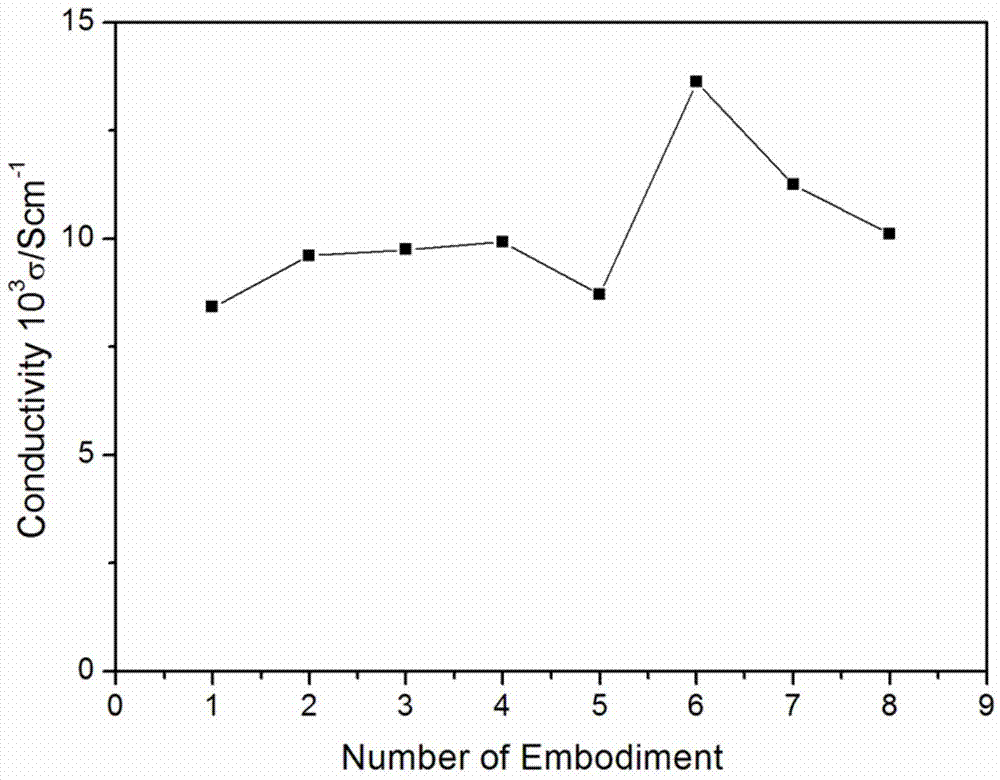

Preparation method of micro-nano molybdenum carbide powder

InactiveCN107352543AGuaranteed to dissolveAvoid contactTungsten/molybdenum carbideMicro nanoMolybdate

The invention discloses a preparation method of micro-nano molybdenum carbide powder. The preparation method comprises the specific steps that an organic precursor serves as a carbon source, molybdate serves as a molybdenum source, fused salt serves as a reaction medium, high-temperature processing, washing and drying are conducted in sequence in an air environment, and the micro-nano molybdenum carbide powder is prepared. The preparation method is quick in reaction speed, and the reaction time is effectively shortened. Besides, the fused salt exists between the generated solid-phase molybdenum carbide particles in the reaction process, so that the mutual bonding between the particles can be stopped, and the agglomeration phenomenon can be reduced. In the method, no special atmospheric conditions are needed, the micro-nano molybdenum carbide material can be prepared at a relatively low temperature; the process is simple, the preparation conditions are mild, and a large scale of production is easy to achieve.

Owner:DONGGUAN UNIV OF TECH

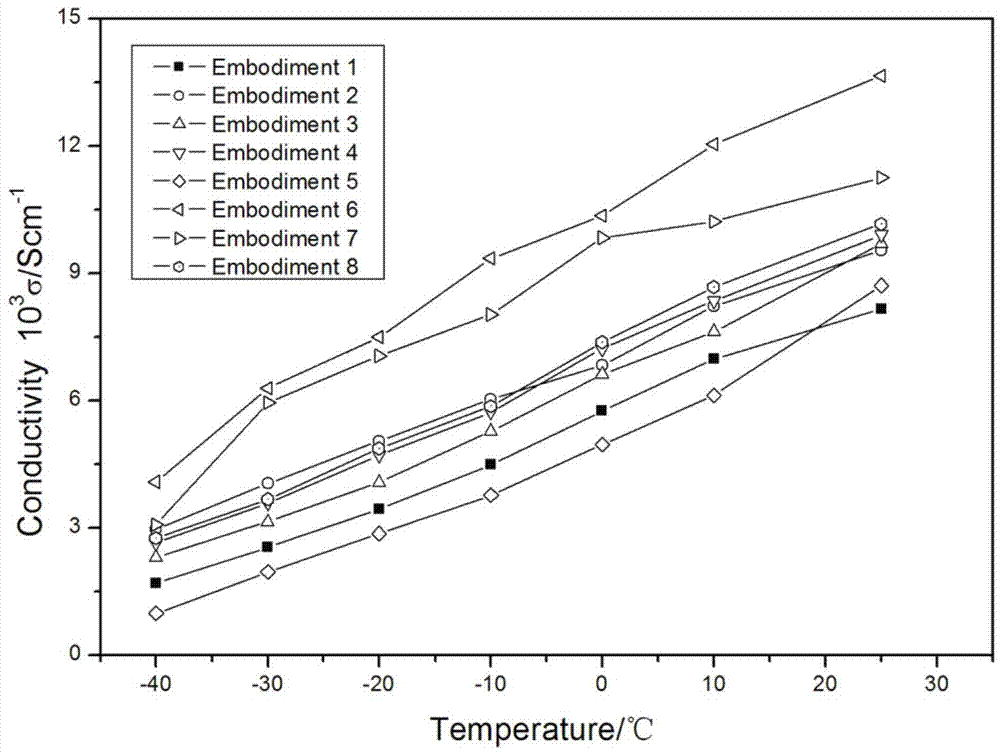

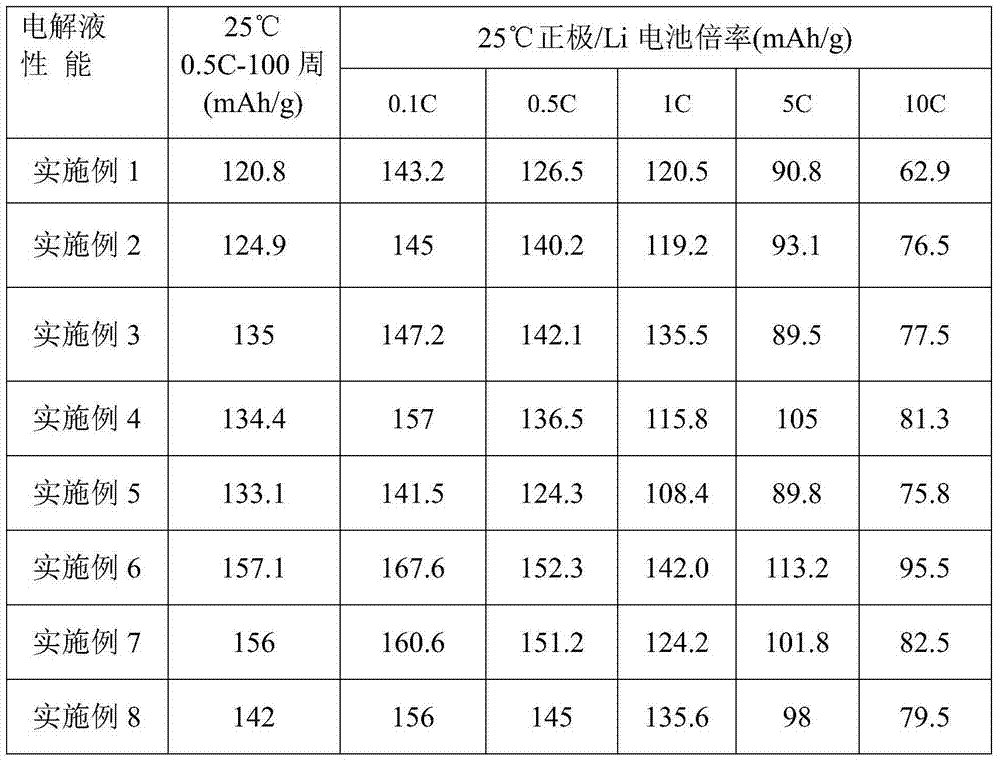

Low-temperature electrolyte of lithium iron phosphate battery

InactiveCN103500850AEasy to buyFair priceSecondary cellsOrganic electrolytesLithium vanadium phosphate batteryLithium iron phosphate

The invention relates to a low-temperature electrolyte of a lithium iron phosphate battery. The low-temperature electrolyte includes the following solvents of, by volume, 30%-45% of carbonic ester solvent, 50%-65% of carboxylic ester solvent and 4%-10% of additive. The solvents contain solute lithium, the lithium is LiPF6 or a combination of the LiPF6 and LiBF4, and the concentration of the lithium is 0.8-1.4mol / L. The low-temperature electrolyte is a nonaqueous electrolyte, through optimization of kinds and proportioning combination of the solvents of the electrolyte, low-viscosity carbonic ester and low-melting-point carboxylic ester are selected and used, the freezing point at low temperature is lowered, and low-temperature conductivity is increased. According to the low-temperature electrolyte, the lithium of the electrolyte is optimized, the low-temperature additive is selected preferably, normal-temperature circulation ratio performance of the electrolyte is maintained, and meanwhile, the low-temperature capacity retention ratio of the lithium iron phosphate battery and the ratio performance of the lithium iron phosphate battery are improved. The commercial application requirements of the electrolyte can be met, the low-temperature performance of the electrolyte is improved particularly, and therefore the electrolyte is suitable for aerospace and plateau alpine environment.

Owner:SHANDONG UNIV

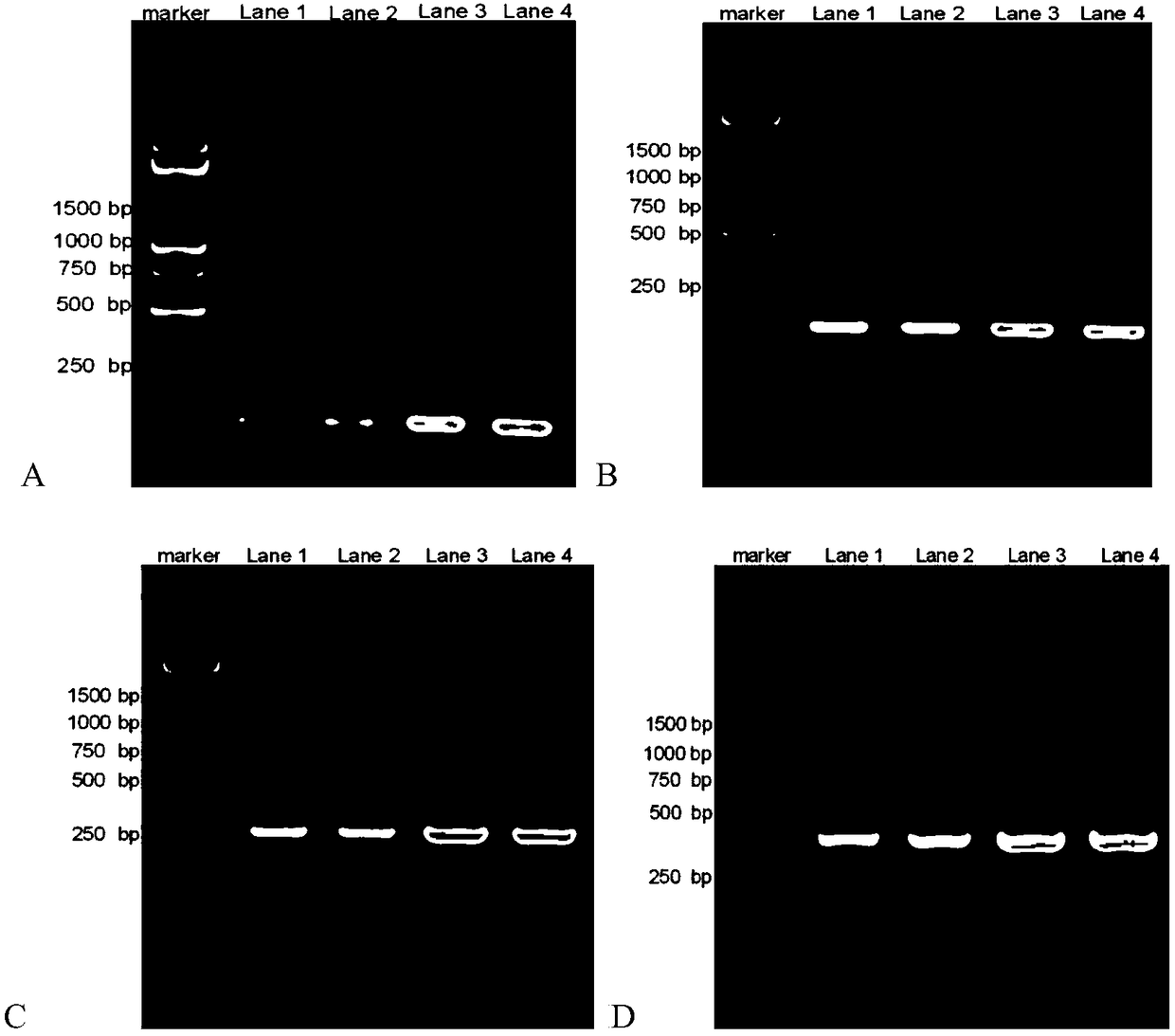

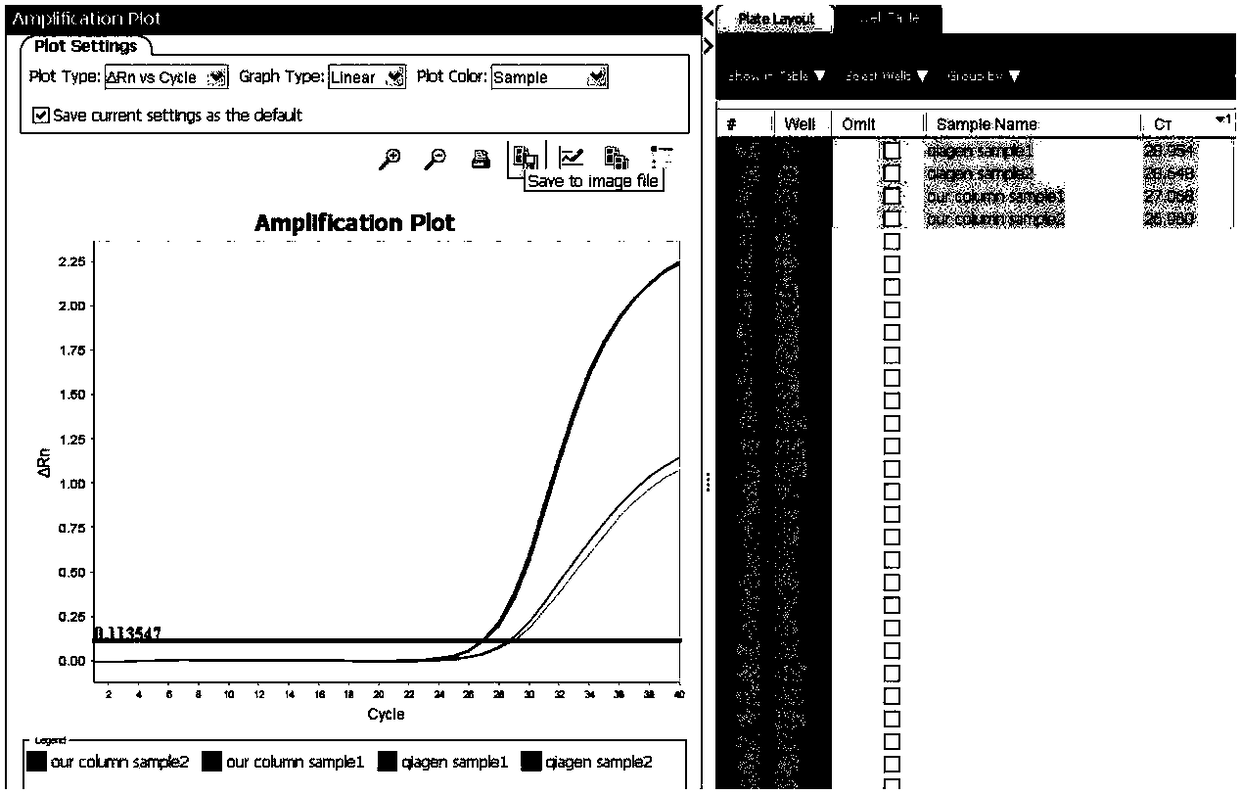

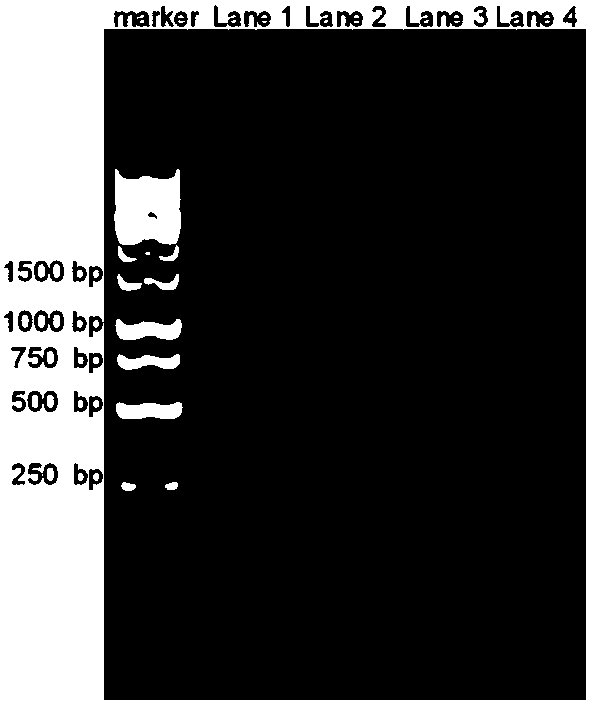

Silica gel absorption column extraction kit and method for free DNA (Deoxyribonucleic Acid) and RNA (Ribonucleic Acid) of blood plasma or blood serum

InactiveCN108070584AGuaranteed unobstructedGuaranteed to dissolveMicrobiological testing/measurementDNA preparationAbsorption columnBlood plasma

The invention discloses a silica gel absorption column extraction kit and method for free DNA (Deoxyribonucleic Acid) and RNA (Ribonucleic Acid) of blood plasma or blood serum and relates to the fieldof molecular biology. The kit comprises proteinase K, isopropyl alcohol, absolute ethyl alcohol and threefold-distilled water, and further comprises a lysis solution containing a nucleic acid separation accelerant, an adsorption solution containing a nucleic acid adsorption accelerant and a washing solution; the method is mainly carried out by utilizing the kit. By adopting the kit provided by the invention, the free DNA and RNA in the blood plasma or the blood serum can be rapidly and completely released, and denatured protein keeps a dissolved state; under the action of the adsorption solution, the free DNA and RNA are efficiently adsorbed on a silica gel absorption column; after the silica gel absorption column is washed by the washing solution, the free DNA and RNA with relatively high purity and concentration are obtained.

Owner:江苏然科生物技术有限公司

Cotton, wood and bamboo composite pulp phase-change microcapsule viscose and preparation method thereof

ActiveCN102839440AUniform particle sizeLittle impact on viscose quality and spinnabilityArtificial filaments from viscoseArtifical filament manufactureMethacrylate methylPolymer chemistry

The invention relates to cotton, wood and bamboo composite pulp phase-change microcapsule viscose and a preparation method thereof, belonging to the viscose field. The phase-change microcapsule comprises 80-250 parts of methyl methacrylate, 80-150 parts of phase change paraffin, 2.5-6 parts of an emulsifying agent, 0.5-1.5 parts of azo initiator, and 300-400 parts of deionized water. According to the invention, cotton, wood and bamboo composite pulp is used for preparing spun-viscose for producing the cotton, wood and bamboo composite pulp phase-change microcapsule viscose, and steps such as alkali steeping, aging, yellowing, dissolving and the like during the viscose production process are optimized. The microcapsule disclosed by the invention has a uniform grain size, is suitable for producing composite viscose and capable of remarkably improving the quality of the viscose and the spinnability with small influence; moreover, the prepared viscose not only has a natural moisturizing and ventilating effect of composite bamboo pulp fiber, but also has the function of accumulating heat and adjusting temperature.

Owner:CHENGDU GRACE FIBER

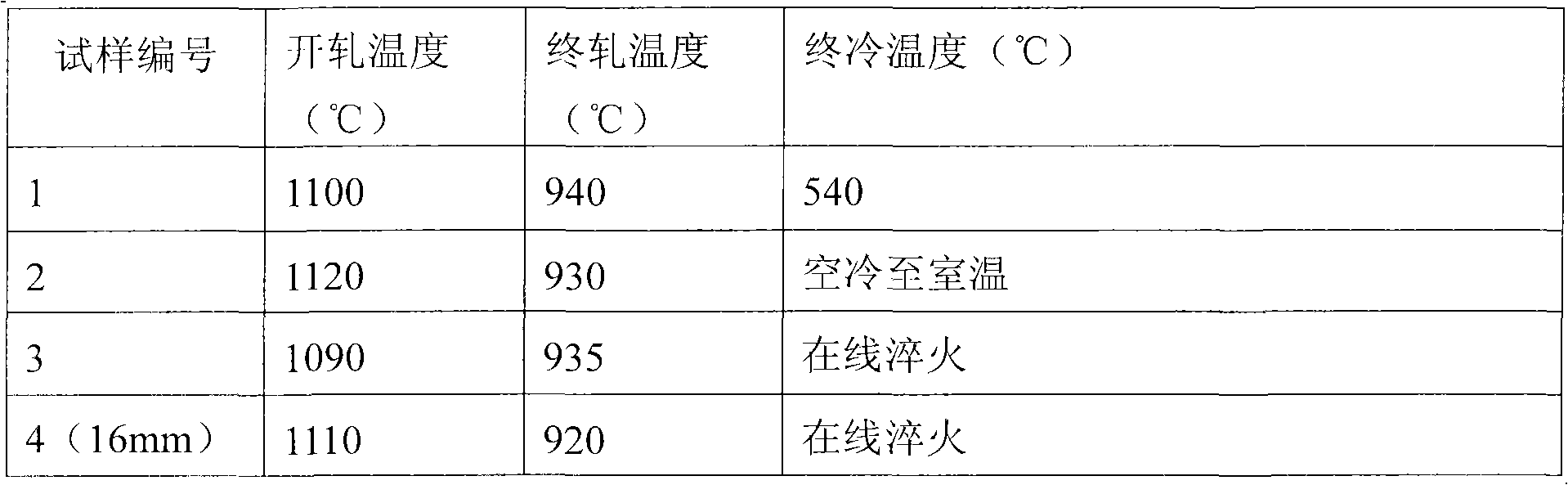

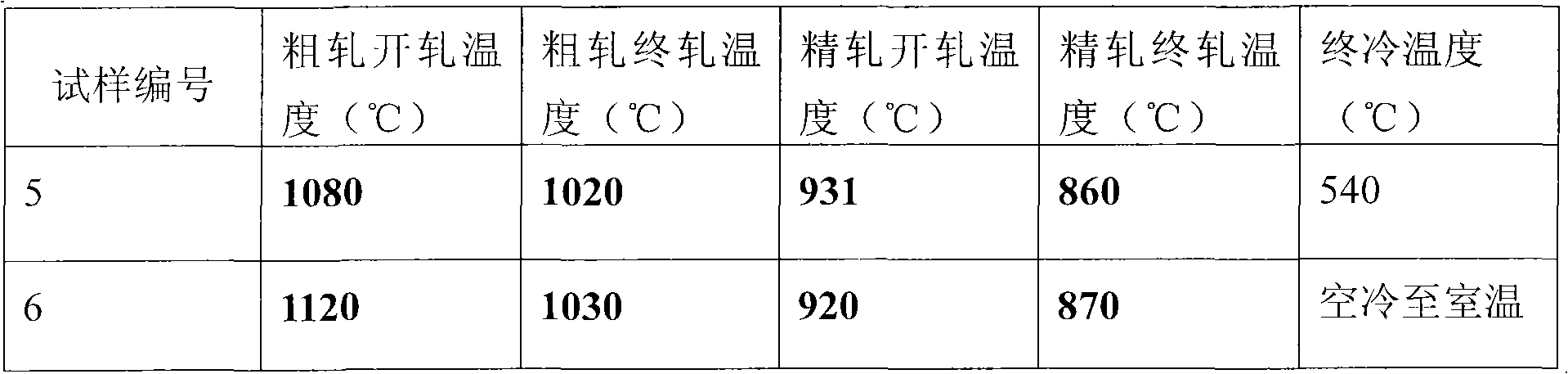

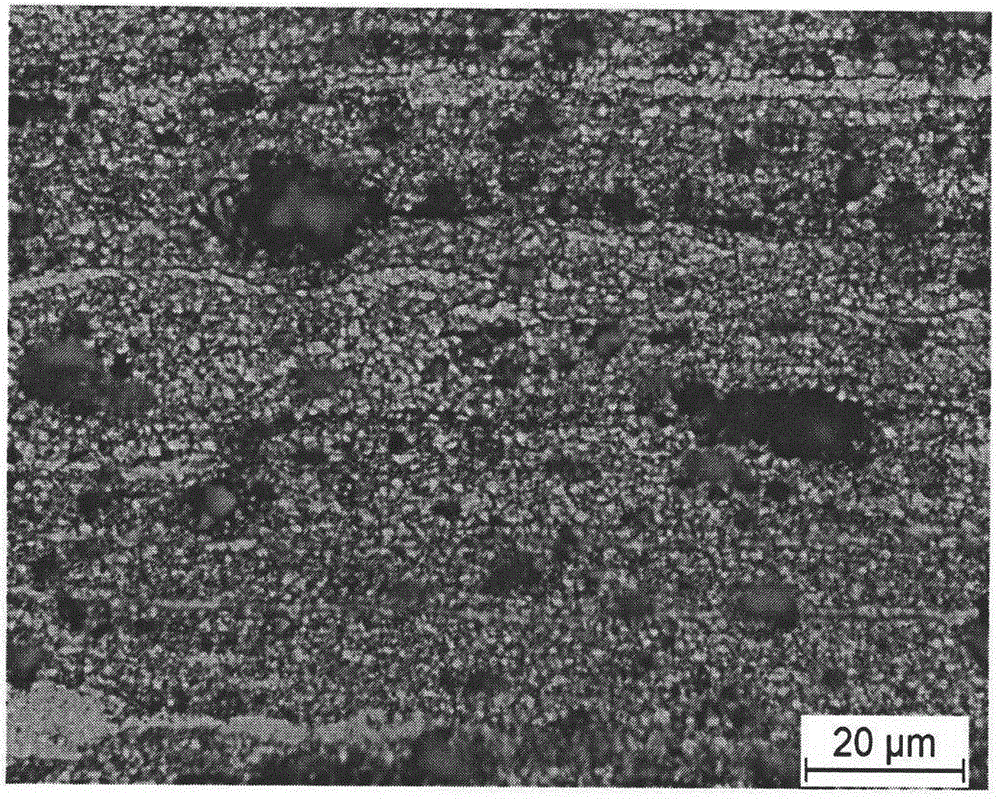

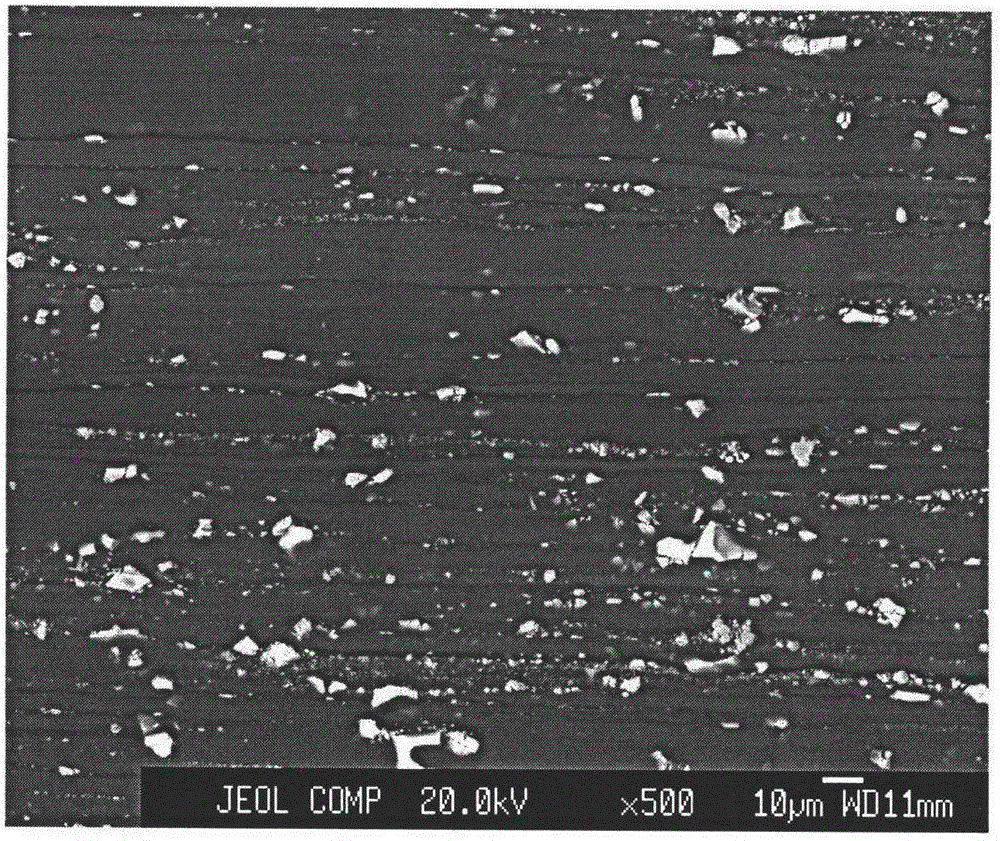

Method for manufacturing low-cost super-high intensity steel plate with yield strength of over 960 MPa for wide process operation window

ActiveCN101935810ALow costGuaranteed to dissolveTemperature control deviceHeat treatment process controlMetallurgyHigh intensity

The invention relates to a super-high intensity steel plate with yield strength of over 960 MPa. The steel plate comprises the following chemical constituents in percentage by weight: 0.12 to 0.14 percent of C, 0.3 to 0.4 percent of Si, 1.45 to 1.6 percent of Mn, less than or equal to 0.01 percent of P, less than or equal to 0.002 percent of S, 0.02 to 0.04 percent of Al, 0.38 to 0.42 percent of Cr, 0.28 to 0.32 percent of Ni, 0.35 to 0.41 percent of Cu, 0.35 to 0.45 percent of Mo, 0.015 to 0.025 percent of Ti, 0.02 to 0.03 percent of Nb, 0.0012 to 0.002 percent of B, less than or equal to 0.004 percent of N, less than or equal to 0.002 percent of O and the balance of iron and inevitable impurities. Production methods include conventional rolling and thermo-mechanical control process (TMCP) rolling.

Owner:SHANDONG IRON & STEEL CO LTD +1

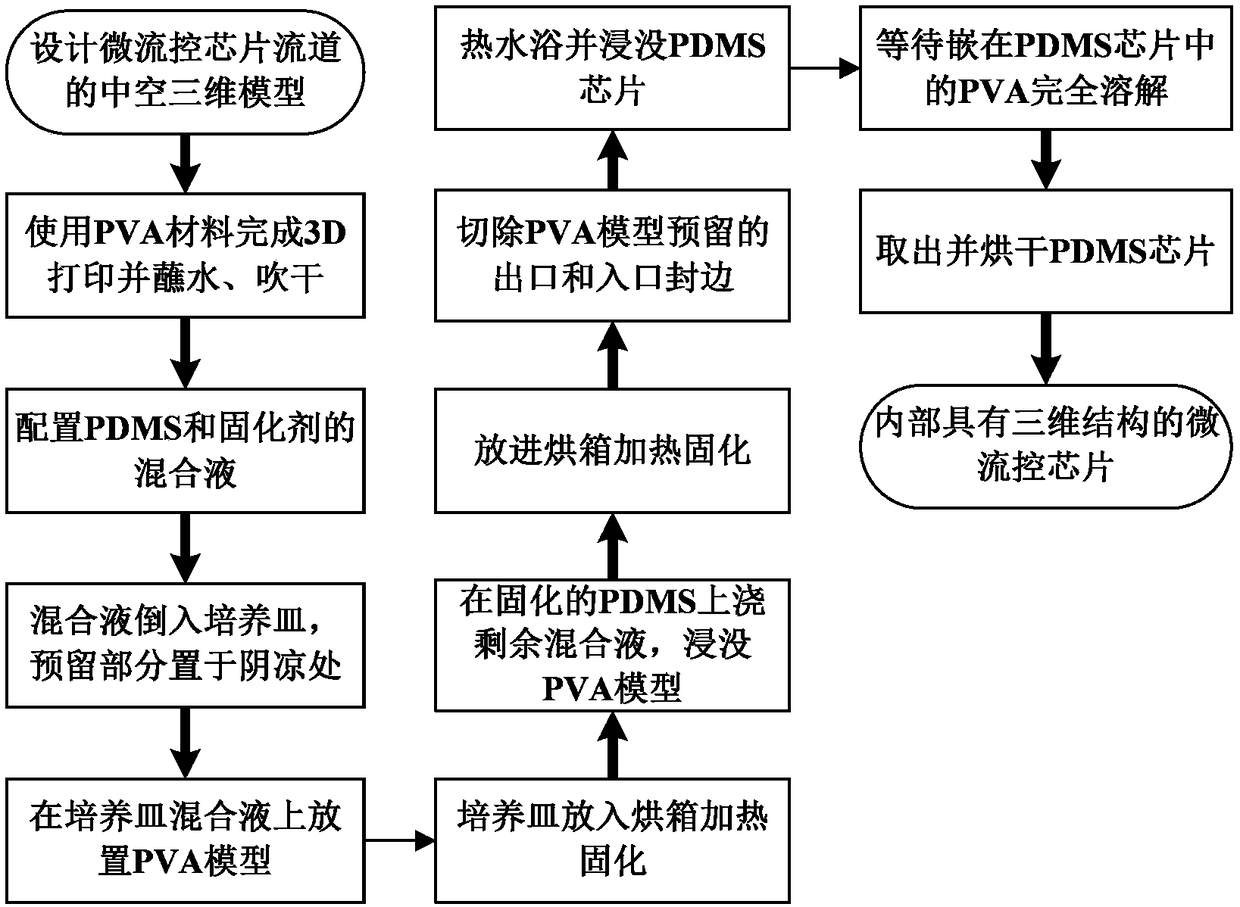

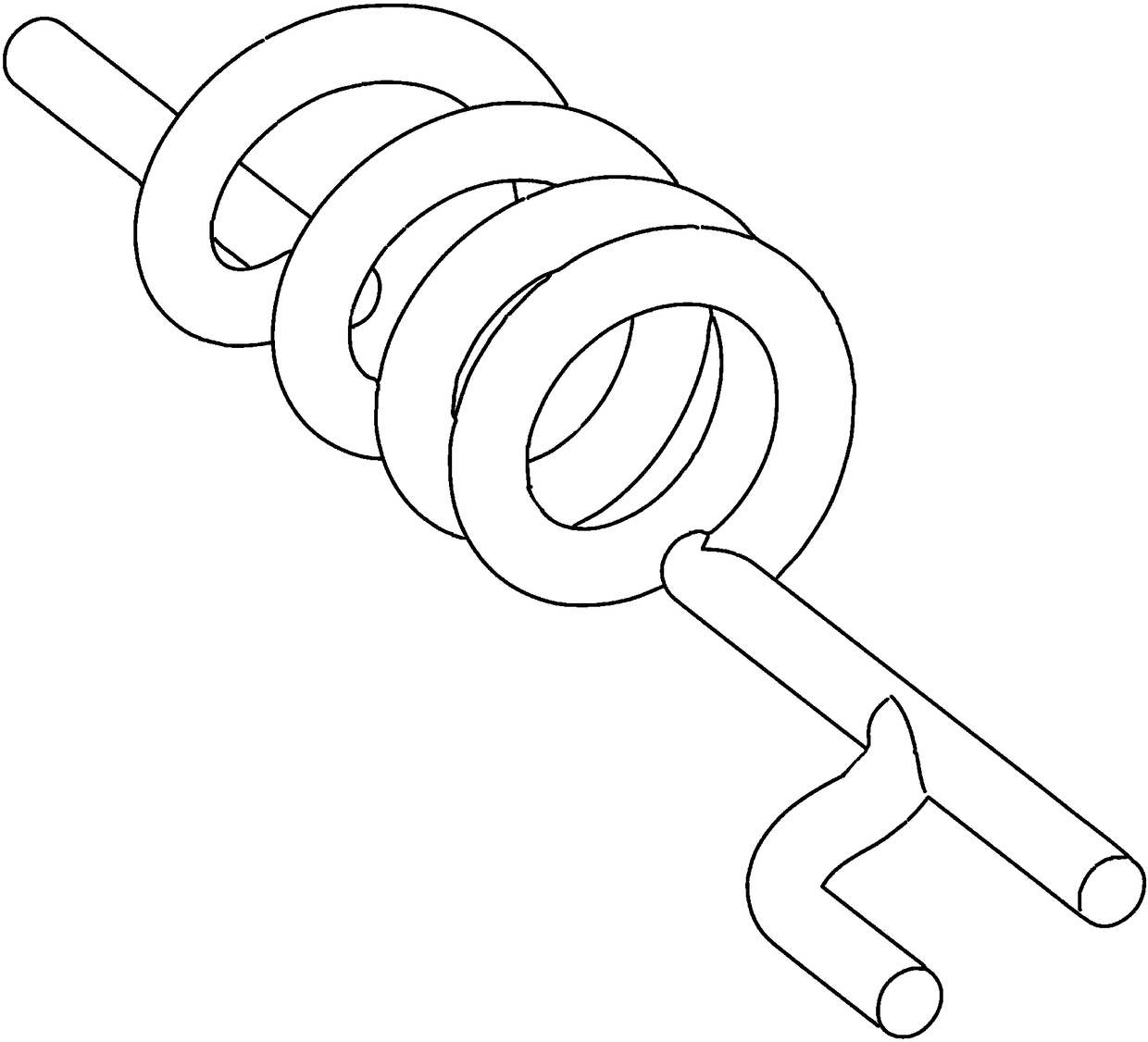

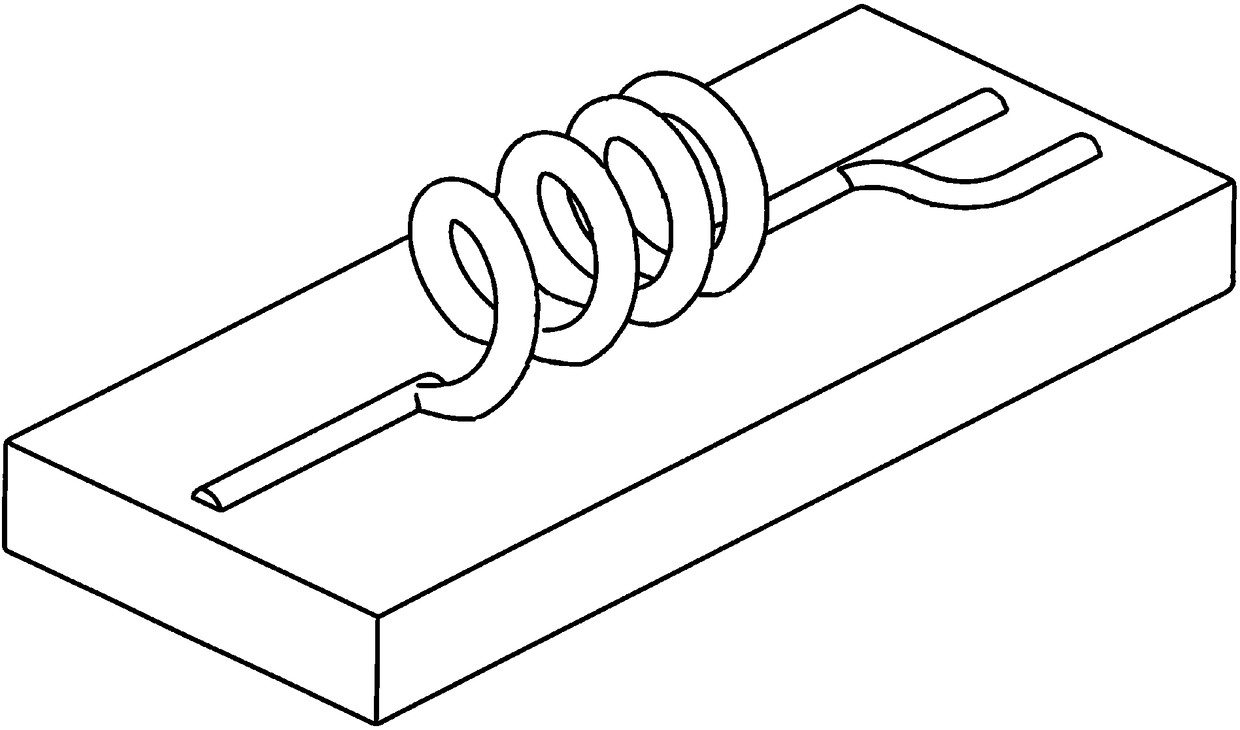

Method for preparing three-dimensional microfluidic chip

InactiveCN108554467AGuaranteed to dissolveReduce surface roughnessLaboratory glasswaresMicrofluidic chipWater soluble

The invention discloses a method for preparing a three-dimensional microfluidic chip, and belongs to the technical field of microfluidics. Water-soluble materials are selected, and a hollow model of internal three-dimensional passageways of the microfluidic chip is processed based on a 3D printing technology; the coarse degree of the outer surface of the hollow model is reduced through dipping andrapid drying process; secondary pouring is conducted on polydimethylsiloxane, after curing is conducted, reserved edge banding of the outlet and inlet of the hollow structure is cut, and the water-soluble materials are dissolved by using hot water bathing to obtain the microfluidic chip with a three-dimensional passageway structure and a smooth inner wall surface. The method has the advantages oflow implementing difficulty, simple procedures, low cost and the like, the prepared three-dimensional microfluidic chip has a highly complicated three-dimensional structure, the coarse degree of theinner surface of the three-dimensional microfluidic chip is low, and the visibility degree is high.

Owner:BEIJING UNIV OF TECH

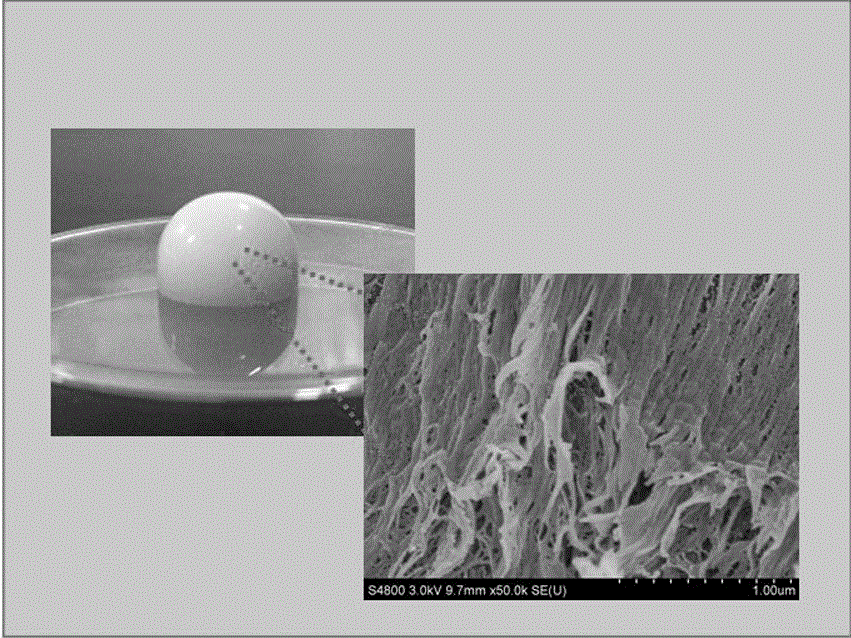

Nano-fibrosis silk fibroin gel and preparation method thereof

ActiveCN106310380AGuaranteed to dissolveProtect fibril structureProsthesisOrganic solventBiocompatibility Testing

The invention relates to a nano-fibrosis silk fibroin gel and a preparation method of the nano-fibrosis silk fibroin gel. Silk is degummed and then dissolved in salt-formic acid to obtain a silk fibroin solution; a silk fibroin-salt-formic acid solution is injected into a mould; the mould placed with the silk fibroin solution is immersed in an organic solvent or an aqueous solution, and stood for a certain time to form the silk fibroin gel. The preparation method disclosed by the invention is simple in preparation method, short in process, convenient to operate and easy for realization of batch production. The silk fibroin gel prepared by the invention has a natural bionic nanometer fibrillar structure, and is adjustable in mechanical properties and good in biocompatibility.

Owner:宁波芸生纺织品科技有限公司

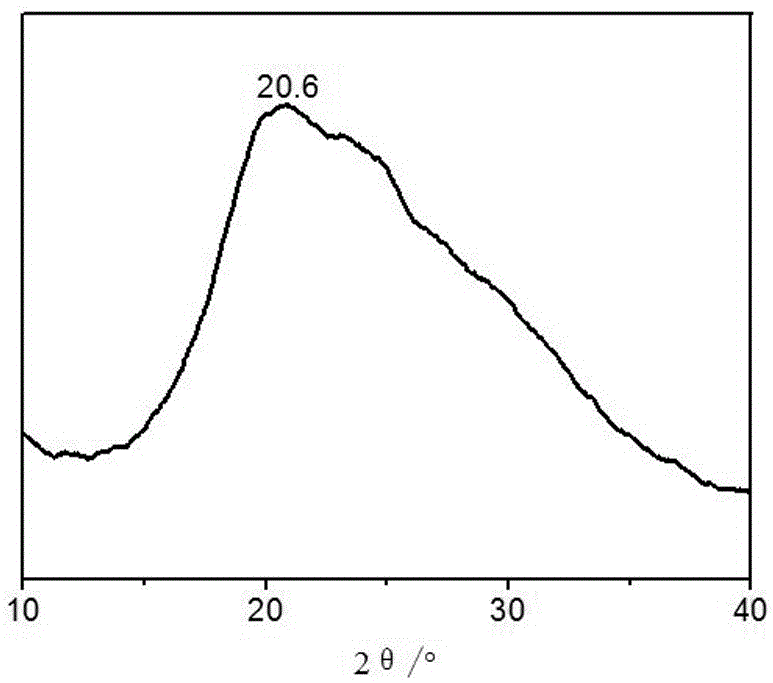

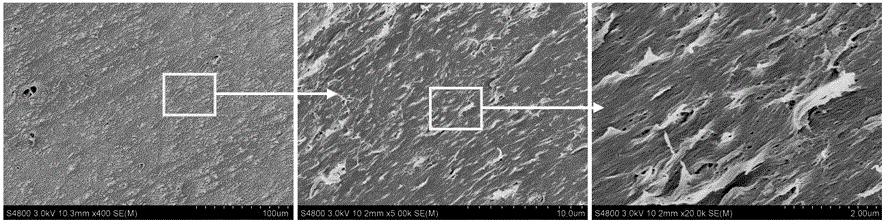

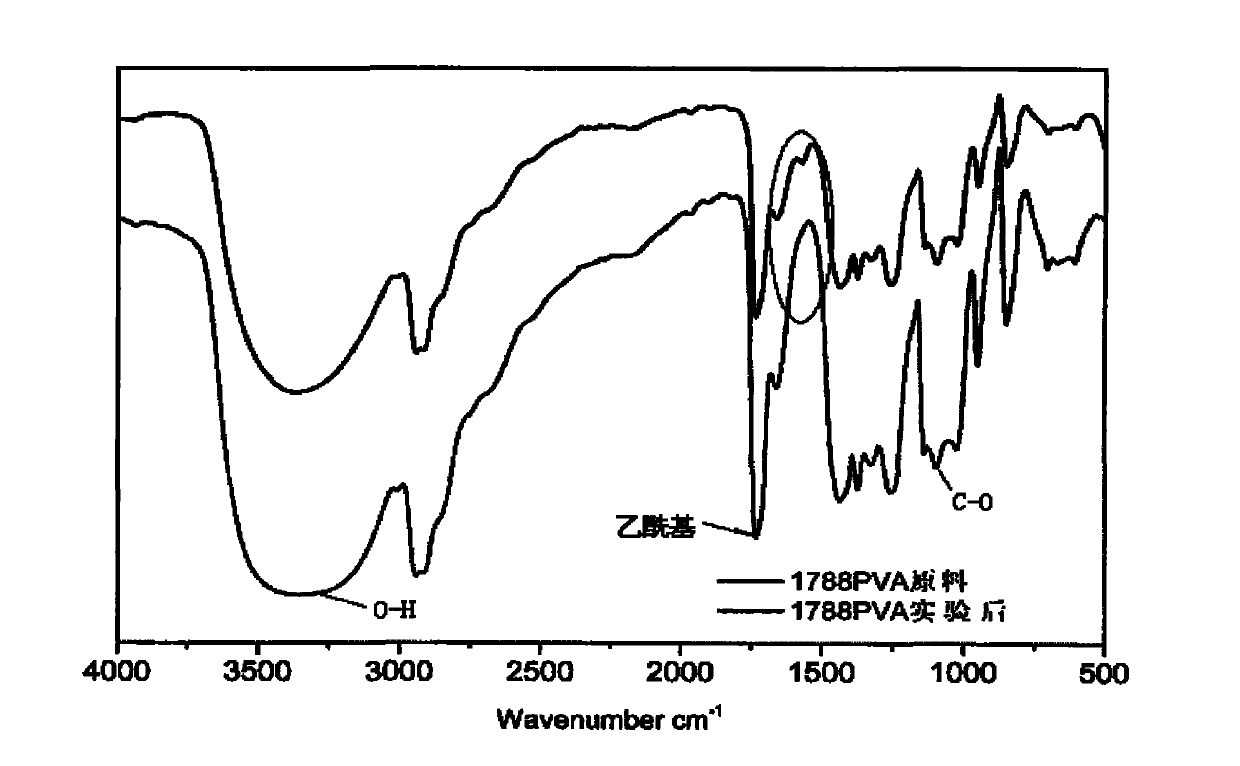

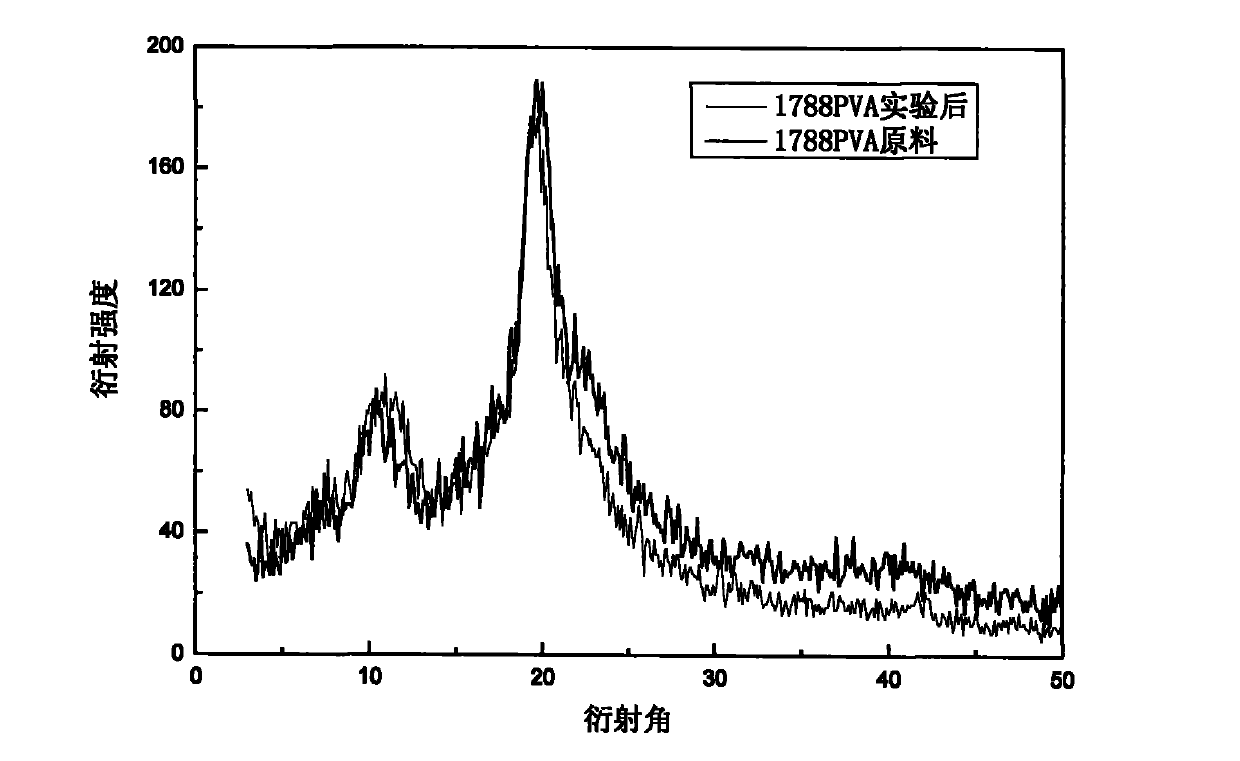

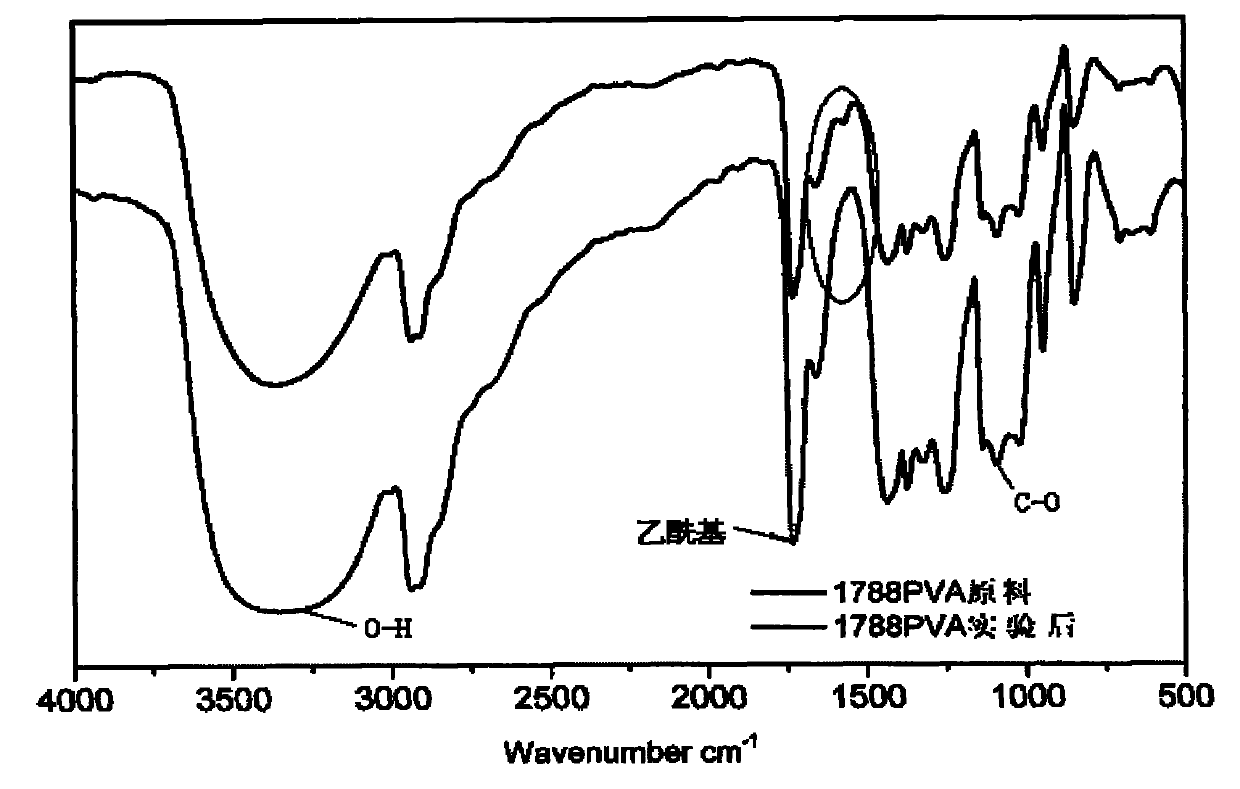

Purification method of polyvinyl alcohol

The invention relates to a purification method of polyvinyl alcohol obtained by alkali catalysis on polyvinyl acetate. In the method, a solution in which polyvinyl alcohol is undissolved or difficult to be dissolved while residues of polyvinyl alcohol are soluble is taken as a solvent, and purification on polyvinyl alcohol is carried out. The invention requires no modification on the traditional mature and complete industrialized PVA preparation process, thus being beneficial to implementation of industrialization, and ash content of the polyvinyl alcohol purified by the method in the invention is close to or less than 0.1%; and the solvent required in the process for preparing polyvinyl alcohol from polyvinyl acetate by hydrolysis or the product obtained by the process is taken as a solvent for purification treatment of polyvinyl alcohol, the produced waste liquor can be merged into the original waste liquor recovery and purification system, the cost is effectively reduced, and the separation of the polyvinyl alcohol after being purified is convenient.

Owner:CHINA PETROCHEMICAL CORP +2

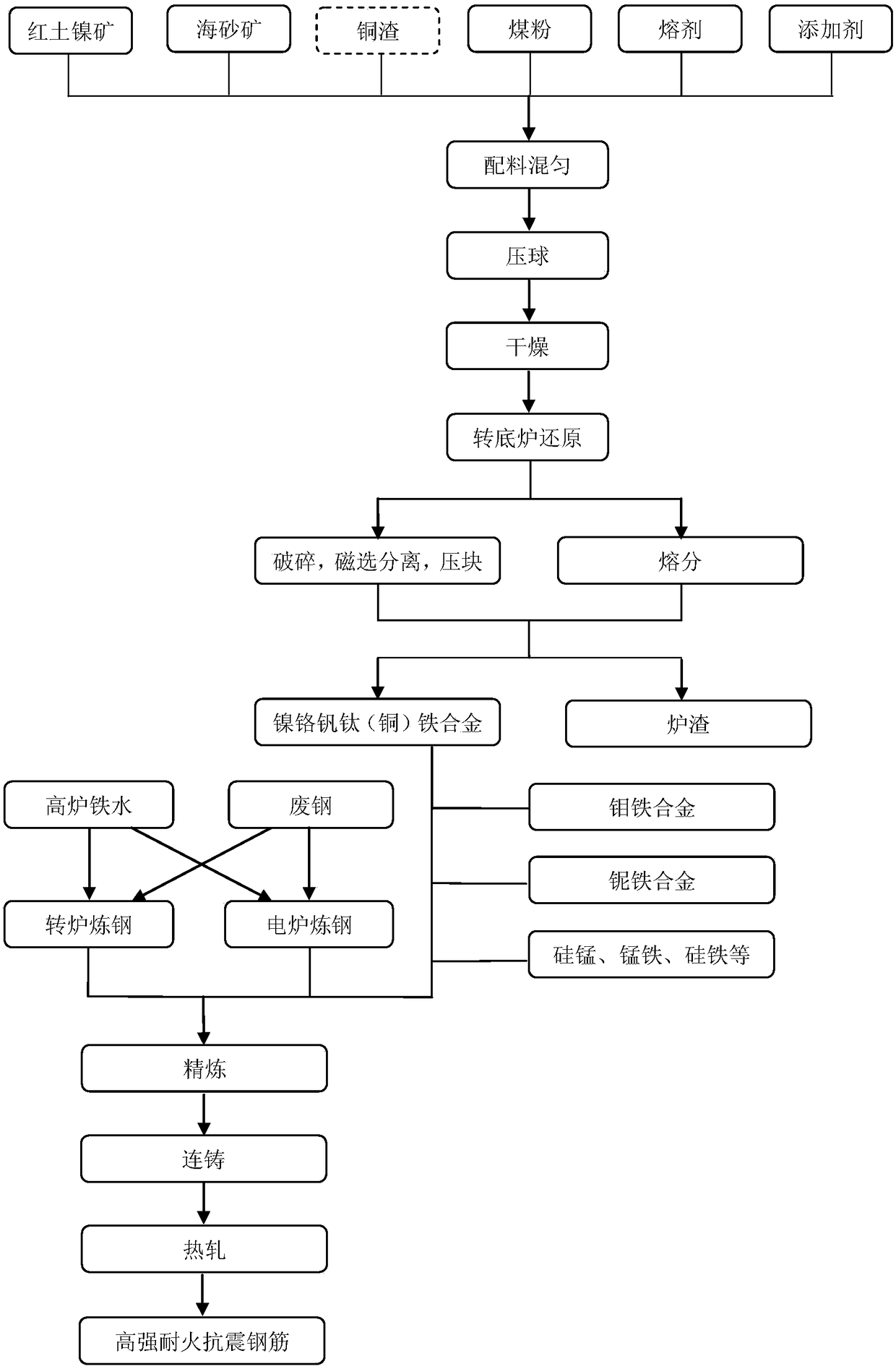

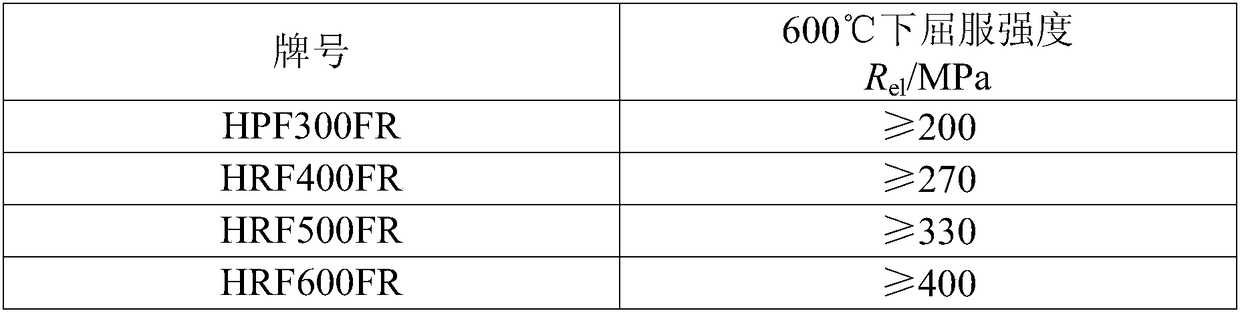

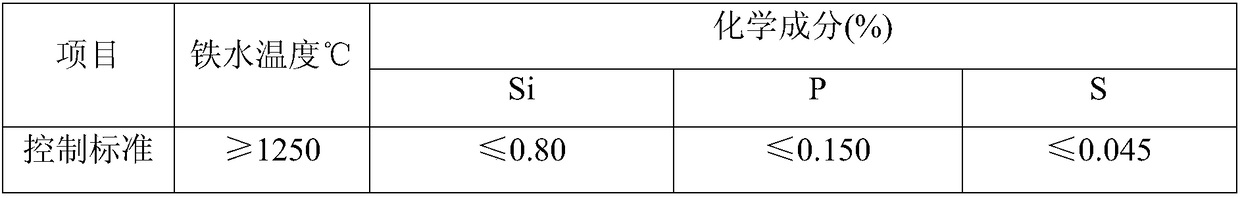

High-strength refractory anti-seismic steel bar and low-cost preparation cost thereof

The invention relates to a low-cost preparation method of a high-strength refractory anti-seismic steel bar, and further discloses the high-strength refractory anti-seismic steel bar. The low-cost preparation method comprises the steps that 1, laterite nickel ore, marine placer and pulverized coal are dried, crushed, levigated and screened to obtain mixed particles; 2, a fusing agent of slaked lime and an additive of syrup are added into the mixed particles to obtain a to-be-reacted material; 3, the to-be-reacted material is subjected to ball pressing treatment to obtain a pellet; 4, the pellet is subjected to direct reduction-magnetic separation or smelting separation treatment to obtain an alloy; and 5, the alloy and ferromolybdenum or ferrocolumbium are added into molten steel, and LF refining, continuous casting and rolling are conducted to obtain the high-strength refractory anti-seismic steel bar. According to the low-cost preparation method of the high-strength refractory anti-seismic steel bar and the high-strength refractory anti-seismic steel bar, compared with separate use of the laterite nickel ore or the marine placer or copper slag, the reduction cost is greatly reduced, and an obtained nickel chromium vanadium titanium copper iron alloy can be directly used for low-cost production of the high-strength refractory steel bar; and the laterite nickel ore, the marineplacer and the copper slag are reasonably utilized, and energy saving and emission reducing are facilitated.

Owner:钢研晟华科技股份有限公司

Preparation method for cellulose-based composite aerogel with high adsorption performance

InactiveCN107159163AEvenly dispersedImprove adsorption capacityOther chemical processesWater contaminantsFreeze-dryingLithium bromide

The invention discloses a preparation method for a cellulose-based composite aerogel with high adsorption performance. The preparation method comprises the following steps: dissolving dopamine powder in an aqueous lithium bromide solution with a concentration of 50 to 80%; then adding microcrystalline cellulose powder, wherein a weight ratio of dopamine to microcrystalline cellulose is 1: 0.75 to 1: 1.5; placing the obtained mixture in an oil bath with a temperature of 120 DEG C, dissolving microcrystalline cellulose for 40 min or so under stirring at a speed of 50 to 100 r / min and allow dopamine to undergo auto-polymerization so as to form polydopamine; and slowly cooling a solution obtained in the previous step at room temperature and then carrying out freeze drying so as to form the polydopamine / cellulose-based composite aerogel. The composite aerogel provided by the invention has excellent performance in adsorption of the positive dye methylene blue, and the preparation method is simple in process.

Owner:SOUTHWEST JIAOTONG UNIV

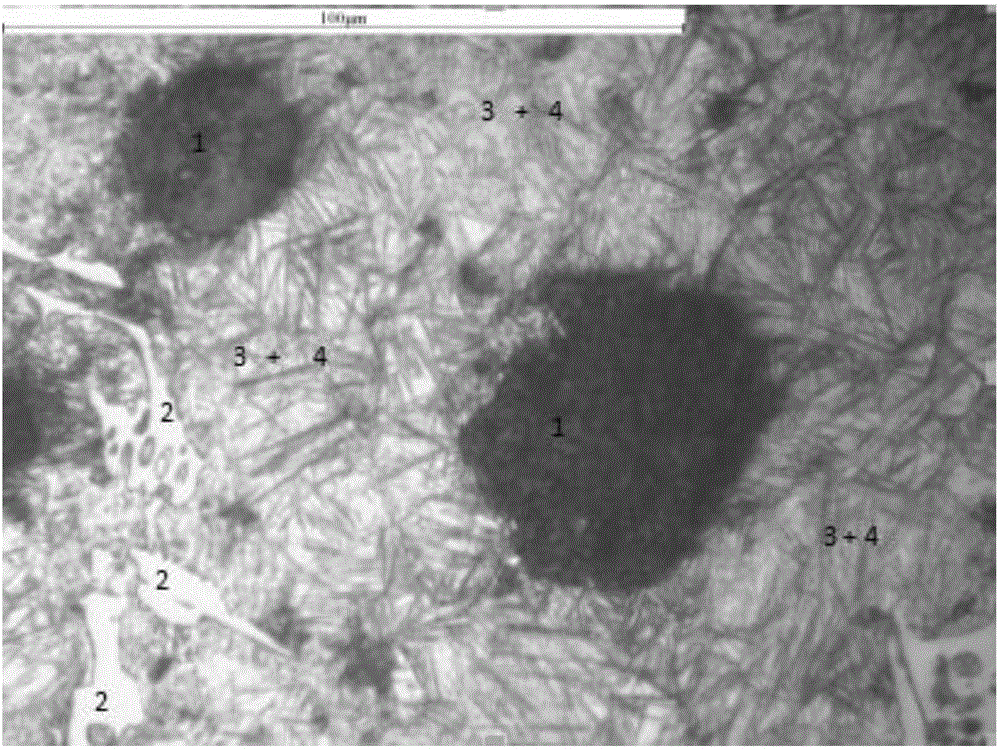

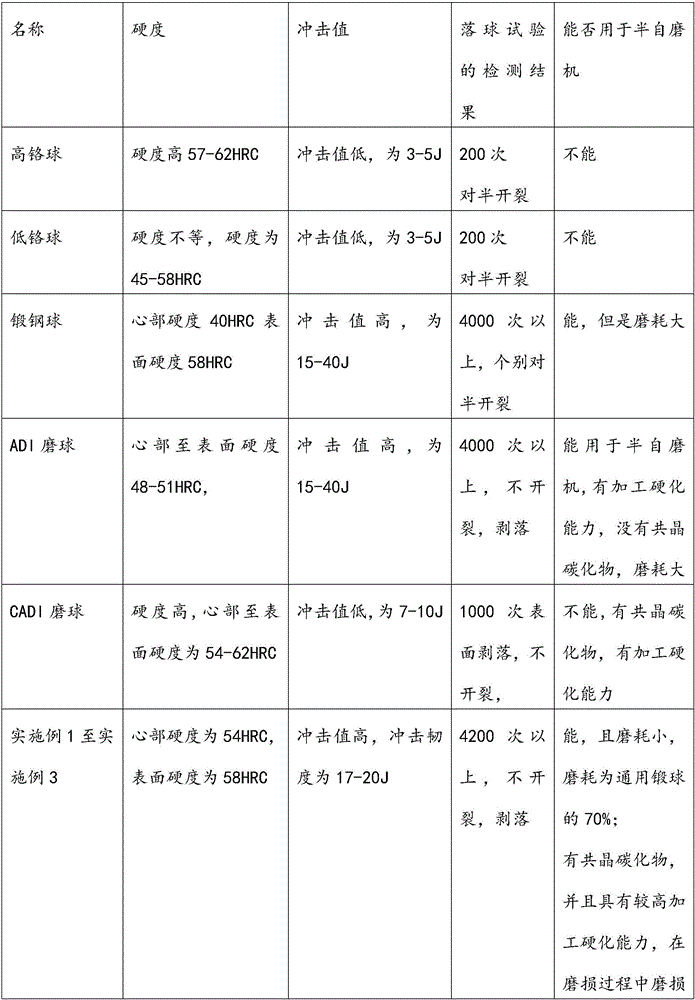

Spheroidal graphite ausferrite cast iron grinding ball suitable for being used in semi-automatic grinding machine and preparation process

The invention relates to a spheroidal graphite ausferrite cast iron grinding ball suitable for being used in a semi-automatic grinding machine and a preparation process. The spheroidal graphite ausferrite cast iron grinding ball is prepared from the following components in percentage by mass: 3.2 to 3.9 percent of carbon, 2.30 to 2.93 percent of silicon, 0.96 to 2.80 percent of manganese, 0.21 to 0.90 percent of chromium, 0.11 to 0.60 percent of copper, 0.10 to 0.80 percent of molybdenum, 0.10 to 0.68 percent of vanadium, 0.10 to 0.78 percent of titanium, 0.01 to 0.09 percent of niobium, greater than or equal to 0 and less than 0.05 percent of phosphorus, greater than or equal to 0 and less than 0.03 percent of sulfur, 0.03 to 0.05 percent of magnesium, 0.02 to 0.03 percent of rare earth elements and the balance of iron. The preparation process comprises the following steps: firstly, performing casting forming to prepare a cast grinding ball; secondly, performing thermal treatment on the cast grinding ball to prepare the spheroidal graphite ausferrite cast iron grinding ball. The hardness of the heart part of the spheroidal graphite ausferrite cast iron grinding ball disclosed by the invention is 54 HRC, and the surface hardness is 58 HRC; the impact toughness is 17 to 20 J / cm2; furthermore, the spheroidal graphite ausferrite cast iron grinding ball is higher in processing hardening capacity; in a wear process, a worn layer is processed to be hardened, so that the hardness can be up to 62 to 64 HRC, and the wear amount is 70 percent of that of a general forged ball.

Owner:CHENGDE RONGMAO CAST STEEL +1

Selective etching solution for metal tungsten and copper

The invention discloses an etching solution capable of selectively etching metal copper and metal tungsten. The etching solution comprises an oxidant, an organic acid, a chelating agent, a pH regulator and a copper etching inhibitor. According to the selective etching solution for the metal copper and the tungsten disclosed by the invention, the low etching rate of the metal copper can be guaranteed while the metal tungsten is efficiently etched, and etching of the metal copper is avoided to the maximum extent. In the etching process, the pH regulator such as imidazole stabilizes the pH value of the etching solution, and large fluctuation of the pH value of the etching solution is avoided, so that large fluctuation is caused to the etching rate and the etching stability of metal copper and tungsten; the chelating agent and copper ions generated in the etching solution rapidly form coordination bonds to be chelated, and decomposition of an oxidizing agent hydrogen peroxide and stability of a hard etching solution caused by accumulation of the copper ions in the etching solution are avoided; in the etching process of copper ion etching inhibitors such as aminotetrazole, etching of copper ions is inhibited, and high-selectivity etching of metal tungsten relative to copper is guaranteed.

Owner:湖北兴福电子材料股份有限公司

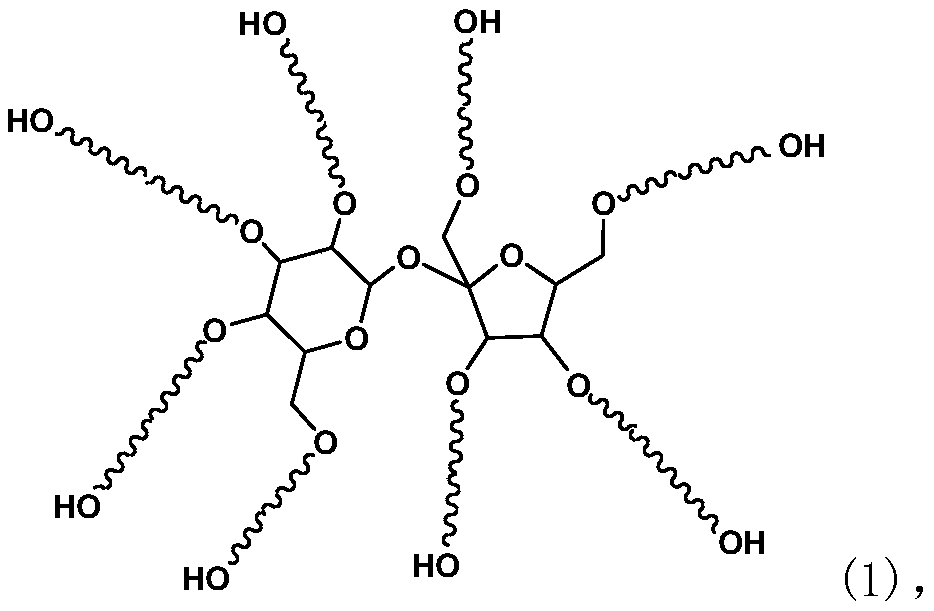

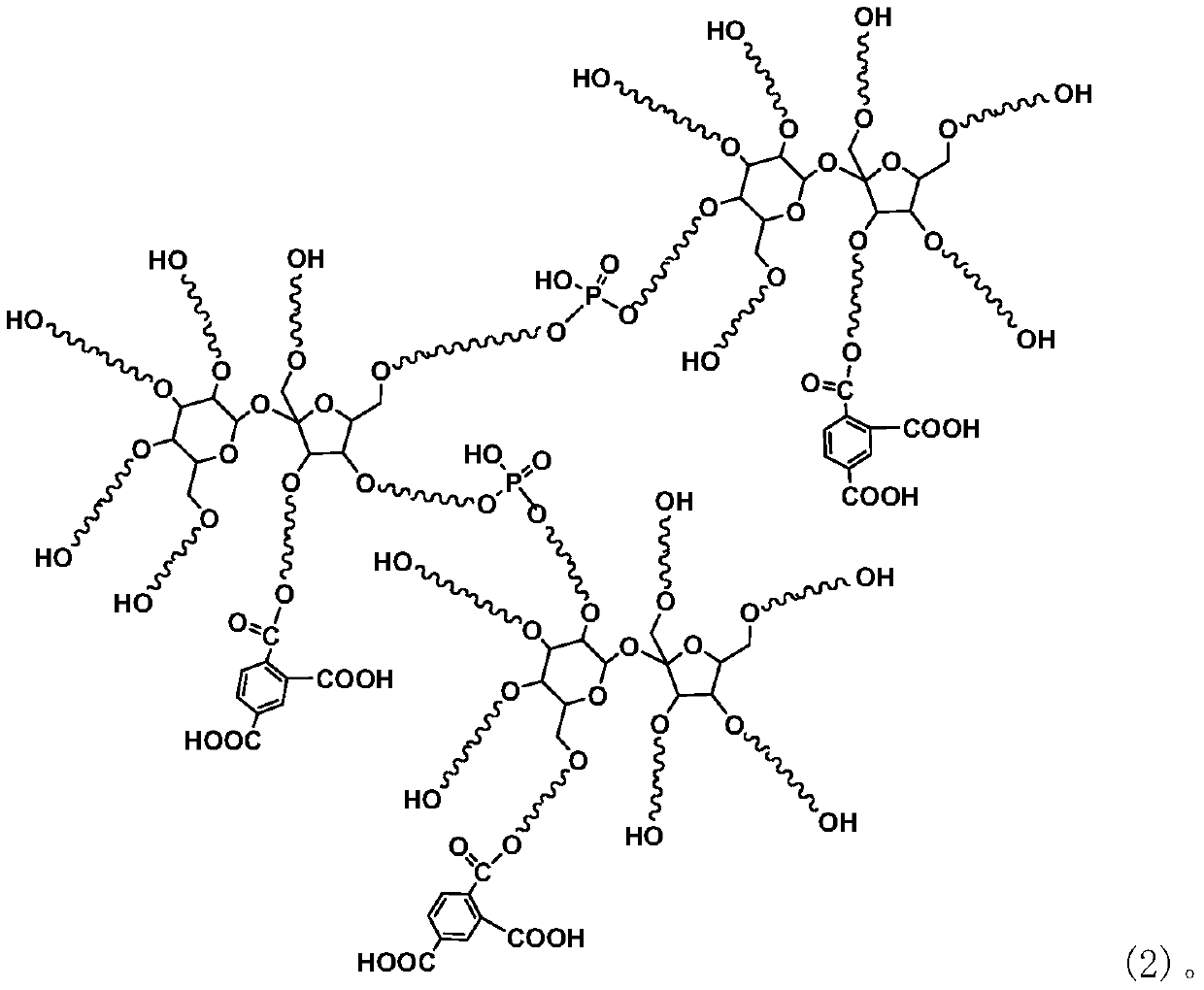

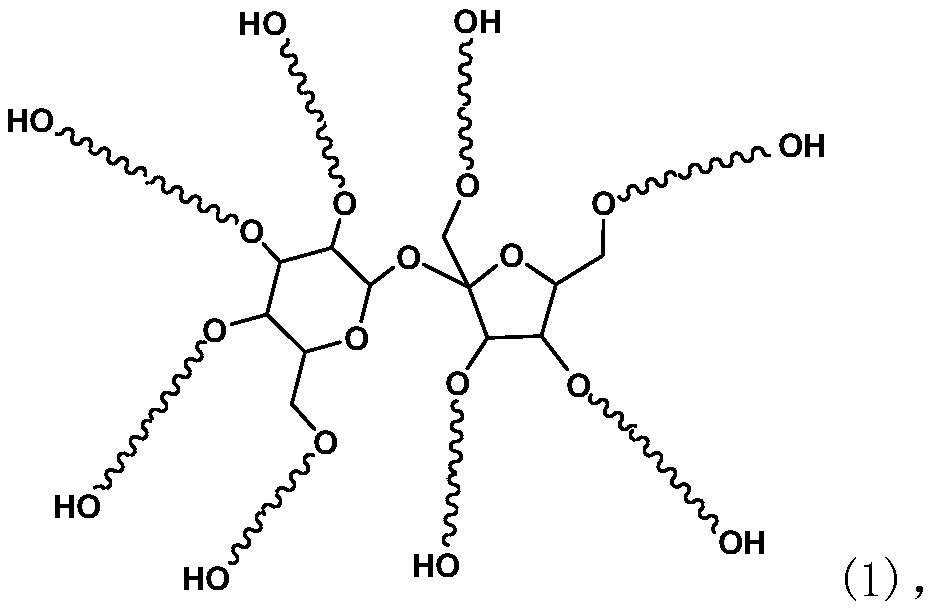

Saccharide-based water reducing agent and preparation method thereof

The invention discloses a saccharide-based water reducing agent and a preparation method thereof. The saccharide-based water reducing agent is of a hyperbranched structure, wherein firstly short polyether side chains with adjustable hydrophilicity and hydrophobicity are grafted to polyhydroxy saccharide monomers, then the hyperbranched structure is formed through cross-linking of a phosphate esterification reaction, and finally carboxylic acid adsorption groups are grafted to the tail ends of part of the polyether side chains through a carboxylic acid esterification reaction. According to theinvention, a short polyether side chain is introduced into hydroxyl of a saccharide monomer through ethoxylation reaction; the slow setting workability characteristic of the saccharide monomer is reserved, polyether prepared from the saccharide monomer introduced with the polyether side chain is easily flowing liquid at room temperature or after being heated, and the reaction efficiency and the reaction effect with a cross-linking agent, acid anhydride and the like are improved.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Method for measuring total iron content in fly ash

InactiveCN103472059AReduce concentrationImprove solubilityMaterial analysis by observing effect on chemical indicatorWater chlorinationPotassium dichromate

The invention provides a method for measuring total iron content in fly ash. The method comprises the steps that 1) a sample to be measured is weighed, concentrated hydrochloric acid, a sodium fluoride solution and a stannous chloride solution are added into the sample to be measured and are heated to dissolve the sample; 2) the stannous chloride solution is continuously dripped into the sample in the sample dissolving process until the test solution is faint yellow or colorless; 3) after the sample is dissolved completely, solid potassium permanganate is added into the sample, and the solution is boiled until the solution is reddish; 4) the stannous chloride solution is dripped into the test solution again to enable the test solution to return to be faint yellow, the volume of the solution is concentrated to be about 20mL, then 100mL of water is added into the solution, and the solution is cooled down; 5) sodium tungstate is used as an indicator, a titanium trichloride solution is dripped into the test solution to enable the test solution to return to be light blue, titration is immediately conducted by a potassium dichromate standard titration solution after the test solution is faded to be colorless from light blue, and the total iron content is computed according to the volume of wasted potassium dichromate standard titration solution. The method for measuring the total iron content in the fly ash eliminates interference of reducibility ions in the test solution, and improves accuracy.

Owner:武汉钢铁有限公司

Method for extracting radix codonopsis extract

InactiveCN106176878ASolve the problem of incomplete extractionLow boiling pointFood ingredient functionsPlant ingredientsWater bathsDistillation

The invention discloses a method for extracting radix codonopsis extract. The method comprises the steps that one part of radix codonopsis is placed in a drying box, radix codonopsis is dried till the water content of radix codonopsis is smaller than or equal to 5%, and grinding is carried out; electronic beams with the strength being 10 kGy are used for irradiation; radix codonopsis powder is added into 70% ethyl alcohol with the pH value being 5, water bath ultrasonic treatment is carried out for 5 min, stirring is carried out for 1 h, suction filtration is carried out, first filtrate and first filter residues are obtained, the first filtrate is subjected to rotary evaporation, and a mixture A is obtained; the first filter residues are placed in eight parts of organic solvent, water ultrasonic treatment is carried out for 5 min, stirring is carried out for 30 min, suction filtration is carried out, second filtrate is obtained and subjected to rotary evaporation, and a mixture B is obtained; second filter residues are added into 50 parts of deionized water, digesting is carried out for 10 min, the mixture is cooled to 30 DEG C, suction filtration is carried out, third filtrate is obtained, reduced pressure distillation is carried out, and a mixture C is obtained; the mixture A, the mixture B and the mixture C are placed in 15 parts of absolute ethyl alcohol, the mixture is placed in a water bath at the temperature of 50 DEG C, stirring is carried out for 20 min, the mixture is placed in a refrigerator, the temperature is below 5 DEG C, standing is carried out for 10 h, suction filtration is carried out, liquid is filtered out, and the radix codonopsis extract is obtained. According to the method, nutrient substances in radix codonopsis are efficiently and safely extracted.

Owner:周晗生

Process for producing D- copper-amine quaternary ammonium salt wood repellent

InactiveCN1500605AGuaranteed to dissolveReduce dosageWood impregnation detailsOrganic acidPreservative

The present invention relates to the field of timber preserving technology, and is especially the preparation process of D-type copper quaternary ammonium salt timber preservative. During its preparation, copper salt of organic acid is used as copper source and ammonium carbonate as source of carbonic radical ion, and the preparation process includes mixing ethanolamine, didecyl dimethyl ammonium chloride and ammonium carbonate, adding water, adding copper salt of organic acid and stirring. The D-type copper quaternary ammonium salt timber preservative has pH value of 9-11, effective components as high as 20 %, reduced packing and transport cost, high stability and no precipitate. Reducing the amount of ethanolamine while increasing the amount of ammonium carbonate can ensure the complete dissolution of copper, reduce the toxicity of product and reduce product cost.

Owner:DONGGUAN CITY TIANBAO WOOD PROTECTION TECH

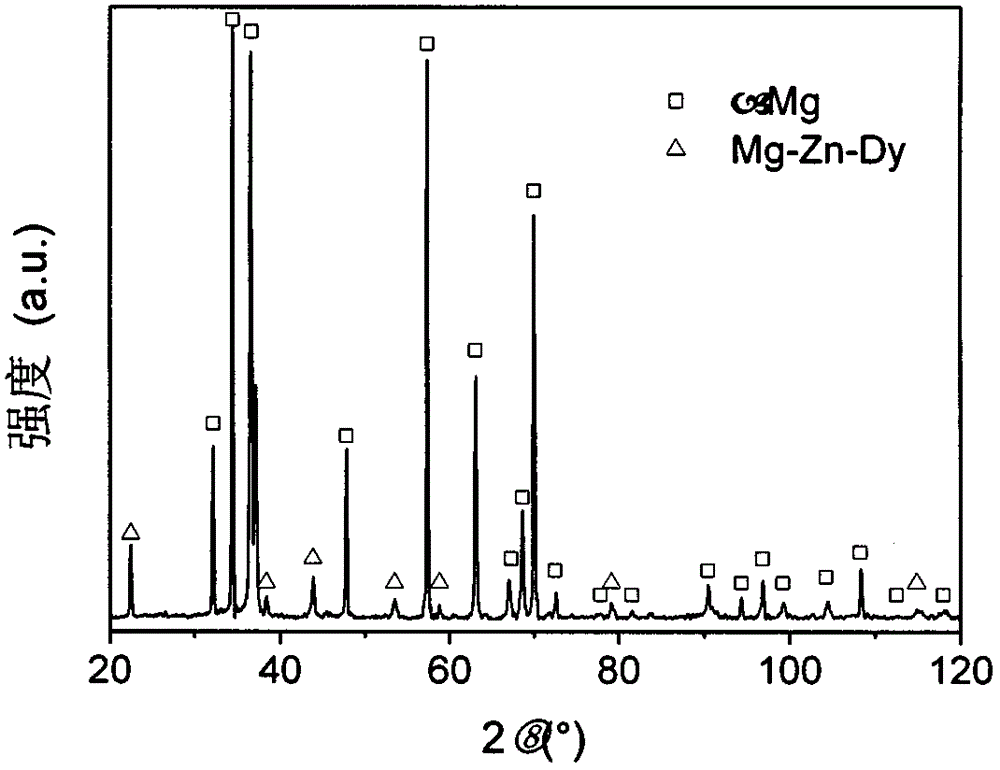

Deformed magnesium alloy and casting method and deformation processing method thereof

The invention relates to a deformed magnesium alloy and a casting method and a deformation processing method thereof. The deformed magnesium alloy comprises the following components in percentage by weight: 5.0 to 6.0 percent of Zn, 0.3 to 0.9 percent of Zr, 0.3 to 4.3 percent of Dy and the balance of Mg. The casting method for the magnesium alloy comprises the following steps of: raising the temperature to 730 DEG C under the protection of gas after Mg is melted, and adding Zn, a Mg-Zr intermediate alloy and a Mg-Dy intermediate alloy into a melt in sequence; adding a refining agent, stirring, raising the temperature to 750 to 760 DEG C, and standing for 30 minutes; and after the temperature of the melt is reduced to 715 DEG C, deslagging, and performing rapid solidification to obtain a casting blank. The deformation processing method for the magnesium alloy comprises the following steps of: performing homogenization treatment on the casting blank at the temperature of 400 DEG C, and performing forward extrusion under the conditions that the extrusion ratio is 40, extrusion temperature is 320 to 340 DEG C and extrusion speed is 1.5 to 2.5m / min. The defect of insufficient strength and plasticity of the conventional Mg-Zn-Zr series alloy is overcome, and the Mg-Zn-Zr-Dy alloy has a fine as-extruded structure and high room temperature and high temperature tensile mechanical properties.

Owner:GUANGDONG INST OF NEW MATERIALS

Novel process for preparation of glycine by using chloroacetic acid aqueous phase ammoniation method

InactiveCN105272865AOptimize feeding parametersHigh yieldOrganic compound preparationAmino-carboxyl compound preparationAcetic acidGlycine

The invention discloses a novel process for preparation of glycine by using a chloroacetic acid aqueous phase ammoniation method. The novel process comprises the following three processing steps: ammoniation reaction, purification of crude glycine, after-treatment of mother liquor. The process optimizes feeding parameters for preparation of the glycine by using the chloroacetic acid aqueous phase ammoniation method, and improves the purification method of the glycine, so yield of the glycine is significantly improved to 91% to 92% from original 84% to 86%; meanwhile, usage amount of methanol used for extraction is greatly reduced, wherein the usage amount of the methanol for production of per ton of the glycine is reduced by more than 25%, so treatment amount and treatment difficulty of the methanol mother liquid is significantly reduced; moreover, the novel process provided by the invention greatly reduces production cost and is significantly suitable for large-scale industrial production.

Owner:HEBEI DONGHUA JIHENG CHEM

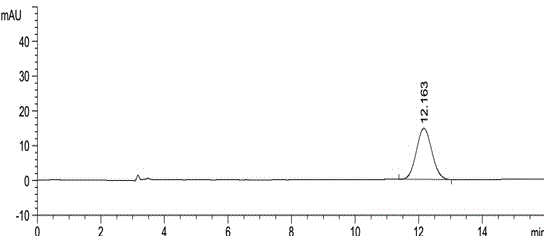

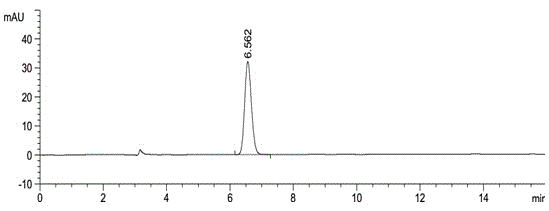

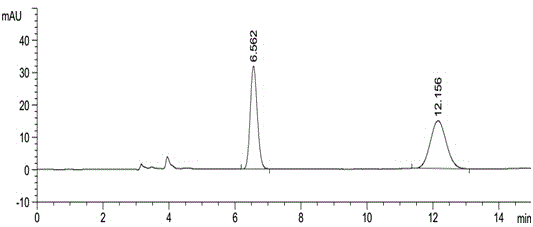

Method for using liquid chromatography to separate and measure apremilast and enantiomer thereof

ActiveCN104820028AAccurate quality controlAccurate separation detectionComponent separationAlkaneEnantiomer

The invention relates to a method for using a liquid chromatography to separate and measure apremilast and enantiomer thereof. The method includes that using spherical silica gel coated with chiral polymer at surface as a chiral chromatographic column, using alkane-different concentrations of polarity organic solvent as mobile phase, wherein the polarity organic solvent is composed of first organic solvent and second organic solvent, the alkane is selected from normal hexane, normal heptane, cyclohexane and methylene dichloride, the first organic solvent is isopropanol, and the second organic solvent is selected from methanol, ethanol and acetonitrile. The method for using the liquid chromatography to separate and measure the apremilast and enantiomer thereof solves the problem that the apremilast and enantiomer thereof are difficult to separate for the separation and measurement, and accordingly the controllable quality of the apremilast and the preparation thereof is guaranteed.

Owner:CHONGQING PHARMA RES INST

Middle-toughness high-formability heat-resisting magnesium alloy

The invention provides middle-toughness high-formability heat-resisting magnesium alloy. The middle-toughness high-formability heat-resisting magnesium alloy is characterized by comprising the following components in percentage by weight: 3.0-7.0% of Al, 0.5-3.0% of Sm, 0.3-0.75% of Bi and the balance of Mg. The tensile strength and the elongation percentage of the magnesium alloy in cast state at room temperature are respectively 220Mpa and 12.5%, and the tensile strength and the elongation percentage at 150 DEG C are respectively 162Mpa and 14.5%; under the same conditions, compared with AZ6l alloy, the magnesium alloy has the advantages that the tensile strength and the elongation percentage at room temperature are respectively increased by 7.3% and 127%, the tensile strength and the elongation percentage at 150 DEG C are respectively increased by 15.7% and 123%; and compared with the flowability of AZ9lD, the flowability of the magnesium alloy in cast state is increased by 36.6%. The tensile strength and the elongation percentage of the magnesium alloy in die-casting state at room temperature are respectively 285Mpa and 16.5%, and the flowability of the magnesium alloy in die-casting state is slightly lower than that of AZ91D alloy. The middle-toughness high-formability heat-resisting magnesium alloy has middle toughness, excellent forming property and excellent high-temperature performance and is suitable for industries such a rail transit, automobiles, sports equipment and 3C (computer, communication and consumer electronic).

Owner:GUANGDONG INST OF NEW MATERIALS

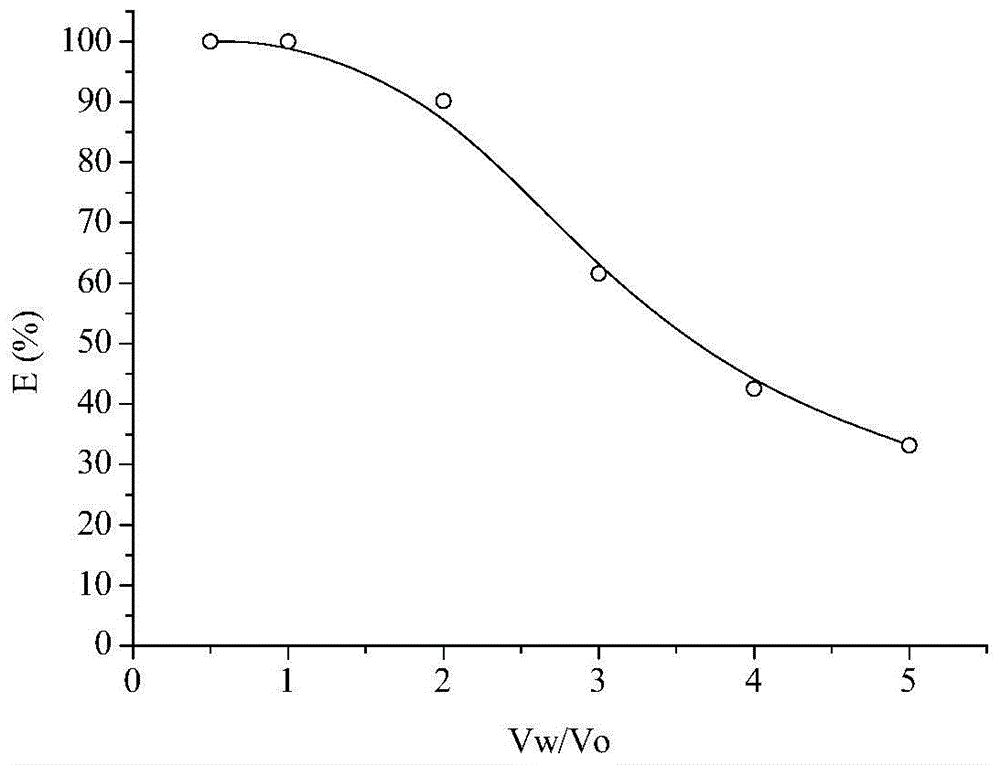

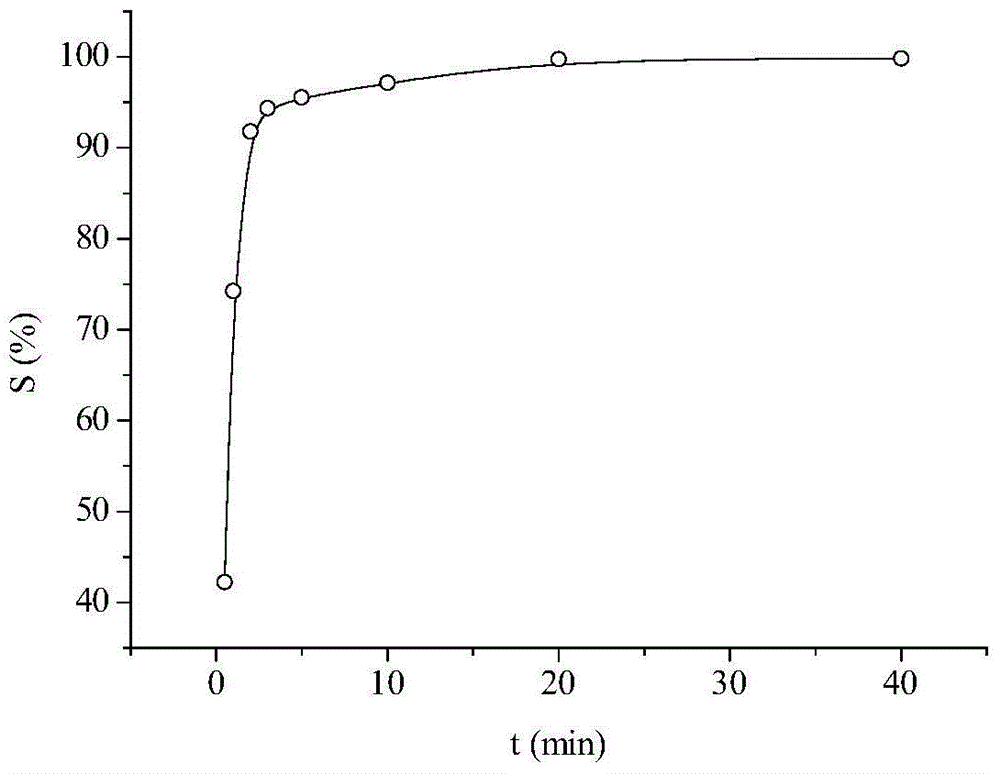

Method for treating chemical nickel plating concentrated waste liquid by solvent extraction method and ion exchange method

ActiveCN104962888AFast extractionImprove extraction efficiencyLiquid/solution decomposition chemical coatingLiquid solutions solvent extractionLiquid wasteIon exchange

The invention discloses a method for treating a chemical nickel plating concentrated waste liquid by a solvent extraction method and an ion exchange method. The method comprises adjusting a chemical nickel plating concentrated waste liquid concentration to 6-7 by NaOH, fully mixing the waste liquid subjected to pH adjustment and an extractant, carrying out standing for two phase layering, separating the two phases to obtain organic and water phases, wherein the water phase is a nickel-free solution and the organic phase is a loading organic phase, fully mixing sulfuric acid and the above organic phase, carrying out standing for two phase layering, separating the two phases to obtain a water phase and an organic phase, wherein the water phase is a nickel sulfate solution and the organic phase is an extractant, treating the nickel-free solution by an alkalescent anion exchange resin column to remove hypophosphite, carrying out cooling to precipitate sodium sulfate crystals, and adding nickel sulfate and hypophosphite into the sodium sulfate crystals to obtain a regenerated chemical nickel plating liquid for direct chemical nickel plating. The method has the advantages of high extraction efficiency, environmental friendliness, simple operation, low cost and high economic value.

Owner:SOUTHEAST UNIV

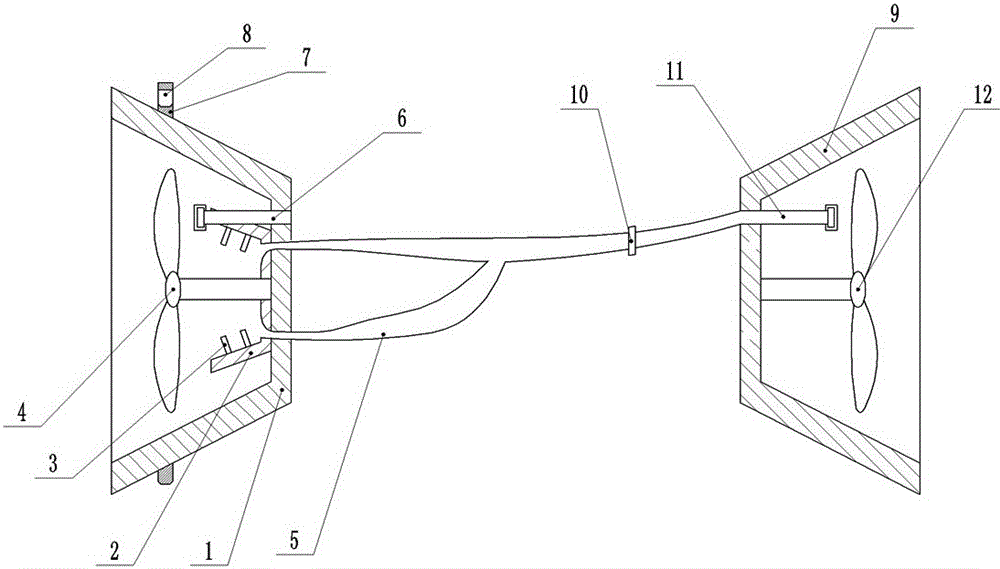

Double-face paint spraying device

ActiveCN106733359AAvoid pollutionAvoid harmSpraying apparatusPretreated surfacesOrganic solventLacquer

The invention belongs to the technical field of spraying devices, and particularly discloses a double-face paint spraying device. The double-face paint spraying device further comprises a first paint spraying gun and further comprises a second paint spraying cover. An air blowing fan and a second paint spraying gun are arranged in the second paint spraying cover, and the second paint spraying gun corresponds to the air blowing fan. A first paint spraying cover is arranged on one side of the second paint spraying gun, and a recycling cover and the first paint spraying gun are arranged at the bottom in the first paint spraying cover. A recycling pipeline is arranged at the bottom of the recycling cover and comprises a gas recycling part connected with the recycling cover, and a paint mist dissolving part connected with the second paint spraying gun. A gas flow switch is arranged at the junction of the gas recycling part and the paint mist dissolving part. The end, located in the recycling cover, of the gas recycling part is provided with a one-way valve. An organic solvent filled with dissolved paint mist is arranged in the paint mist dissolving part. An air suction fan is arranged in the recycling cover and provided with a control switch. Compared with the prior art, through the technology, the paint mist can be recycled, the problem of pollution can be solved, and meanwhile the paint spraying efficiency is improved.

Owner:MINGFENG DOORS

Medium-carbon low-alloy martensitic steel and smelting method thereof

The invention discloses medium-carbon low-alloy martensitic steel and a smelting method thereof. The medium-carbon low-alloy martensitic steel comprises, by mass, 0.25%-0.40% of C, 0.20%-0.40% of Si, 0.15%-0.20% of Cu, 0.45%-0.55% of Mg, 0.20%-0.60% of Mn, 0.60%-0.80% of Cr, 0.40%-0.80% of Ni, 0.04%-0.06% of Ti, 0-0.025% of P, 0-0.025% of S, 0.33%-0.53% of Si, and the balance impurities with the allowed quantity being 0.06% or below. The medium-carbon low-alloy martensitic steel disclosed by the invention has the characteristics that hardness and low plasticity are good, a cold plastic deformation forming process can be adopted conveniently, the weldability is good and the heat treatment decarburizing tendency is small and further has the advantages of being capable of obtaining a source conveniently, low in cost and the like.

Owner:孙仁

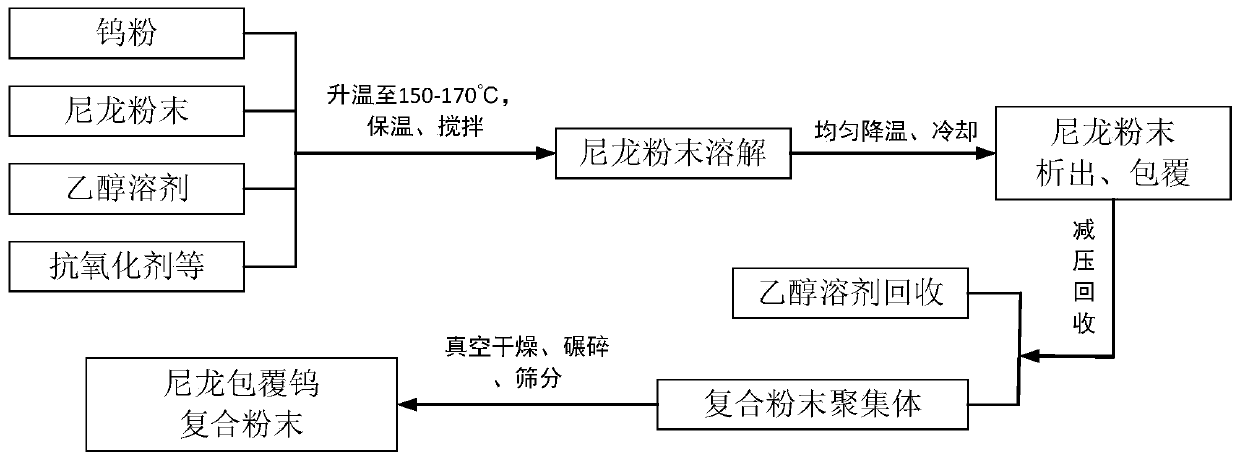

Nylon-coated metal tungsten radiation-shielding composite material and preparation method thereof

The invention discloses a nylon-coated metal tungsten radiation-shielding composite material and a preparation method thereof. The preparation method comprises the steps: mixing nylon, tungsten powder, an ethanol solvent and other substances in a reaction kettle, performing heating until complete dissolution of the nylon, then controlling temperature lowering precisely so as to precipitate the nylon and coat the precipitated nylon on the surface of tungsten powder particles, opening the reaction kettle, performing filtration, collecting the ethanol solvent so as to obtain nylon-coated tungsten composite powder aggregate, and performing drying, stirring, dispersion, powder flow guiding and other post-treatment so as to obtain the nylon-coated tungsten composite powder which is suitable for selective laser sintering forming. The nylon powder is nylon powder specific for 3D printing, has reliable performance and stable selective laser sintering forming. The nylon-coated metal tungsten radiation-shielding composite material has excellent performance, good fluidity and a good nylon coating effect, requirements of forming in an SLS process are met fully, and molding of a structural member with excellent radiation shielding performance, no toxicity, environmental protection and good mechanical properties can be achieved through a selective laser sintering process.

Owner:SOUTH CHINA UNIV OF TECH

Rose flower beer and preparation method thereof

The invention discloses rose flower beer and a preparation method thereof. The preparation method of the rose flower beer comprises the steps of extracting dried rose flowers to obtain rose flower extract, crushing barley malt, carrying out gelatinization on purple sweet potatoes to obtain gelatinized mash, saccharifying the barley malt and the gelatinized mash, filtering sweet mash and washing atrough to obtain wort, boiling the wort, sizing the wort and carrying out cyclotron precipitation, cooling and oxygenating, inoculating, fermenting and carrying out cold storage, filtering, filling and sterilizing. The rose flower beer is prepared by taking the purple sweet potatoes as one of the raw materials, thus obtaining the nutrient components of the purple sweet potatoes and the appearancewith bright color. The rose flower extract is added in the boiling stage of the wort, the effective components in the dried rose flowers are enabled to be dissolved by boiling at high temperature, androse flower cell liquid is added in a filtration stage, so that the efficient utilization of the rose flower cell liquid is realized, the excellent flavor and efficacy of the rose flower beer are ensured, and the flavor and quality of the final beer product are ensured. The obtained rose flower beer product has good efficiency, has the nutritional and health care functions of the purple sweet potatoes and the rose flowers, and has the effects of moisturizing skin, maintaining beauty and keeping young, and the like.

Owner:倪氏国际玫瑰产业股份有限公司

Radix polygonati officinalis plantation method

InactiveCN106922356AAbsorb evenlyReduce antagonismBioloigcal waste fertilisersSewage/sludge fertilisersPolygonum odoratumOfficinalis

The invention discloses a radix polygonati officinalis plantation method. The method comprises steps of preparing fertilizer packs each including components such as farmyard manures, lotus pond mud, vegetable dregs, oil meals and bean cakes, mixing the components to support an annular fertilizer pack, digging plantation caves, evenly scattering 80-mesh fine earth on the bottoms of the plantation caves, placing a fertilizer pack in each plantation cave, preserving a gap for placing radix polygonati officinali seedlings in the middle of the fertilizer pack, transplanting the prepared radix polygonati officinalis seedlings to the gaps of the plantation caves, filling fine earth to the plantation caves to fulfill the gaps between the roots of the radix polygonati officinalis seedlings and the fertilizer pack, watering the surround of the seedlings and watering 1,600 to 1,800 ml water for each seedling, and watering in the same way for each plant between the December of the current-planted year to the February of the next year. Antagonism between ions during absorption of,nutrient elements can be obviously reduced, so contents of various metal elements can be improved.

Owner:贵州黔峰百草科技发展有限公司

Sea cucumber decoction piece processing technology

InactiveCN102599559AReduce the temperatureShorten the timeFood preparationSea cucumberQuick freezing

The invention relates to a sea cucumber decoction piece processing technology. The technology comprises the following main steps of primary cooking, soaking, intermediate finishing, secondary cooking, secondary soaking, quick freezing, slicing, drying and packaging. The sea cucumber decoction piece processing technology provided by the invention is applicable to be processed by adopting different containers, the phenomenon that skin of the sea cucumber can be weathered after sea cucumber is placed for a long time or the sea cucumber is placed for a long time when being defrosted is avoided, and freshness of the sea cucumber decoction piece product is guaranteed.

Owner:冯玉萍

Water-soluble biological humic acid fertilizer

InactiveCN110668873ALarge poresDissolve fastAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSodium bicarbonateMicrobial agent

The invention belongs to the technical field of fertilizers, and particularly relates to a water-soluble biological humic acid fertilizer. The fertilizer comprises, by weight, potassium nitrate, ammonium nitrate, monoammonium phosphate, urea, humic acid, amino acid chelated medium and trace elements, a composite microbial agent, organic matters, sodium sulfate decahydrate, boric acid, magnesium sulfate monohydrate, biostimulant, an anti-caking agent and sodium bicarbonate. The sodium bicarbonate and a plant pigment are added when the water-soluble fertilizer is prepared, and the sodium bicarbonate enables a semi-finished water-soluble fertilizer to be fully mixed and fermented, so the water-soluble fertilizer has large pores, and can be quickly dissolved in water when being put into water,the plant pigment can be blended into water along with the dissolution of the water-soluble fertilizer, and when the water-soluble fertilizer is applied, the water contains the dissolved water-soluble fertilizer, and certainly contains the plant pigment, thereby whether the water-soluble fertilizer is applied or not can be judged according to whether the plant pigment exists or not.

Owner:吴娟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com