Patents

Literature

199results about How to "Accurate quality control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

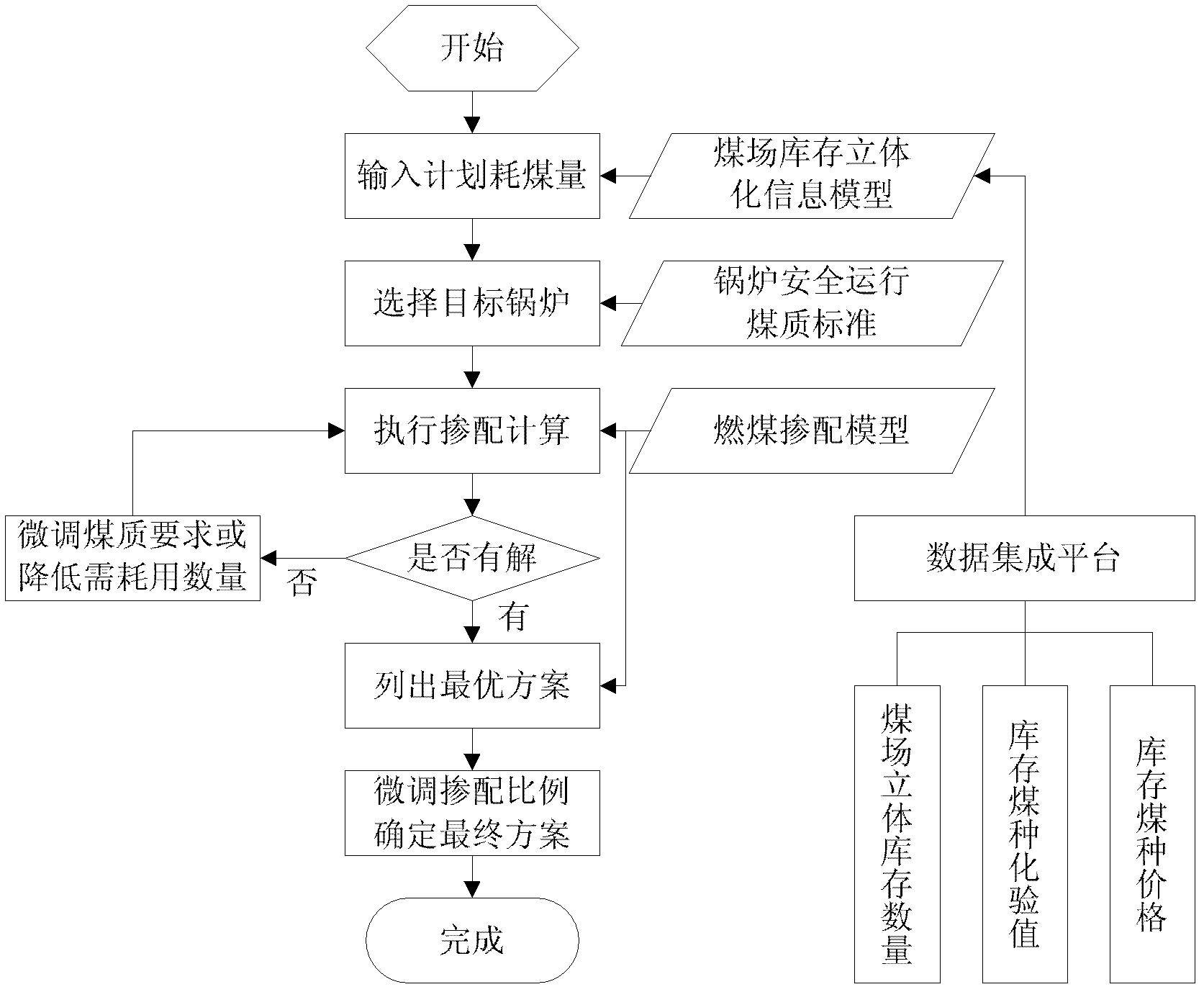

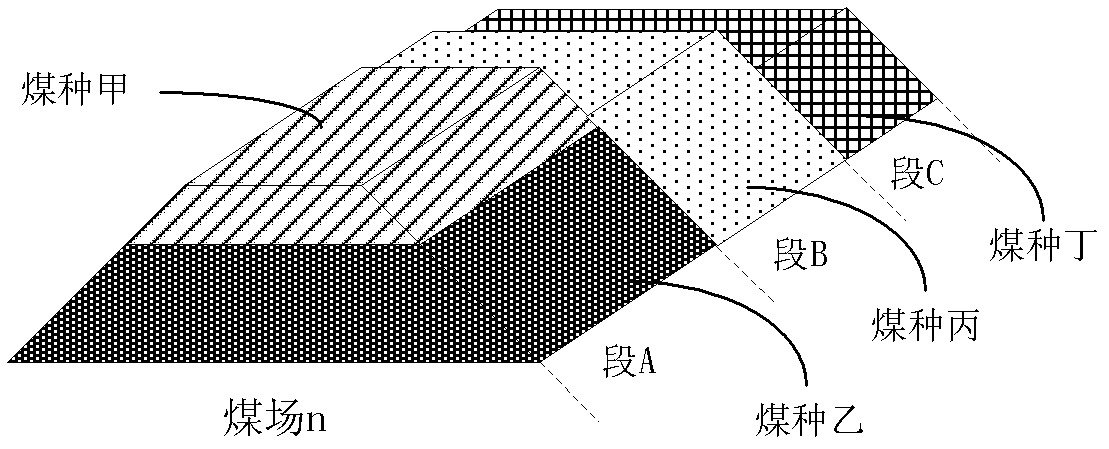

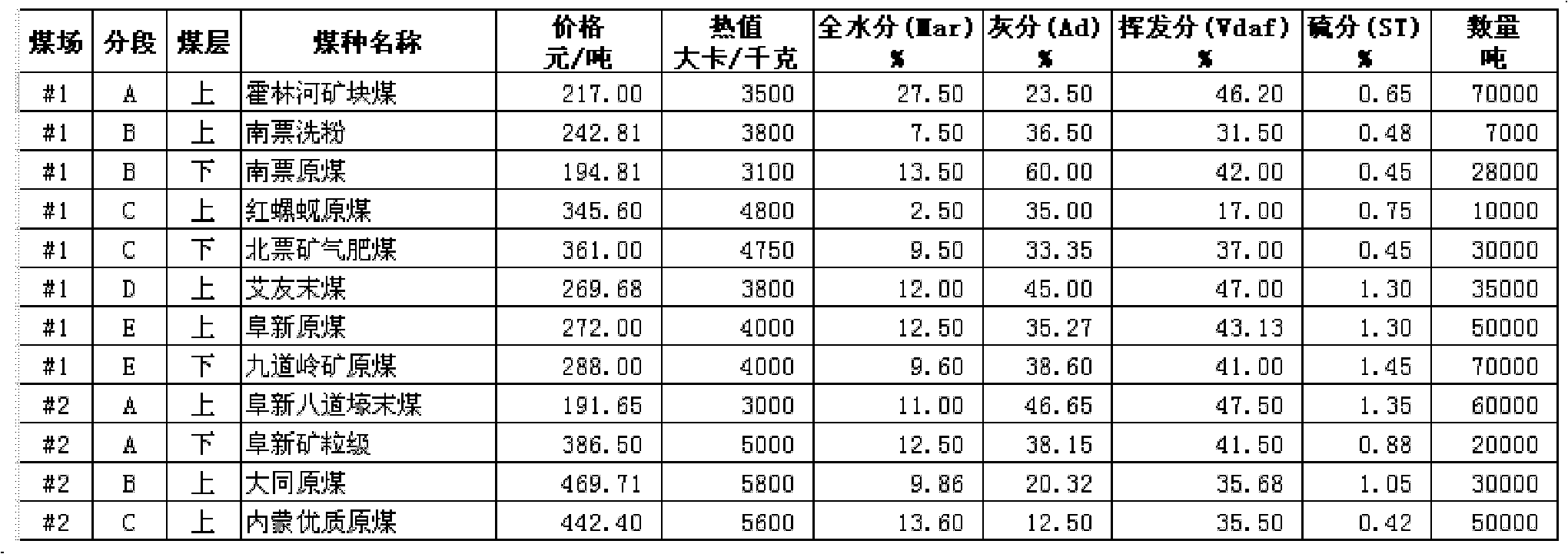

Fire coal blending method of thermal power plants

InactiveCN102592249AGuaranteed safe burningReduce the price per unit of energy consumptionData processing applicationsInformation repositoryCombustion

The invention discloses a fire coal blending method of thermal power plants, which belongs to the technical field of thermal power generation and automation and includes: building a coal yard inventory three-dimensional information model database according to coal yard inventory information; building a boiler combustion standard information base according to requirements of each boiler on coal quality and boiler self influence factors; generating a constraint condition according to the boiler combustion standard information base and the coal yard inventory three-dimensional information model database, and building a fire coal economical objective function to obtain a fire coal blending model; and calculating all fire coal blending proportion schemes when the boilers consume standard coal with a set quantity according to the fire coal blending model, and selecting a scheme with topmost layer coal as the optimum scheme. The fire coal blending method is most economical, reduces unit energy consumption price and improves economic benefit of power generation enterprises under the premise of ensuring boiler safe combustion.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

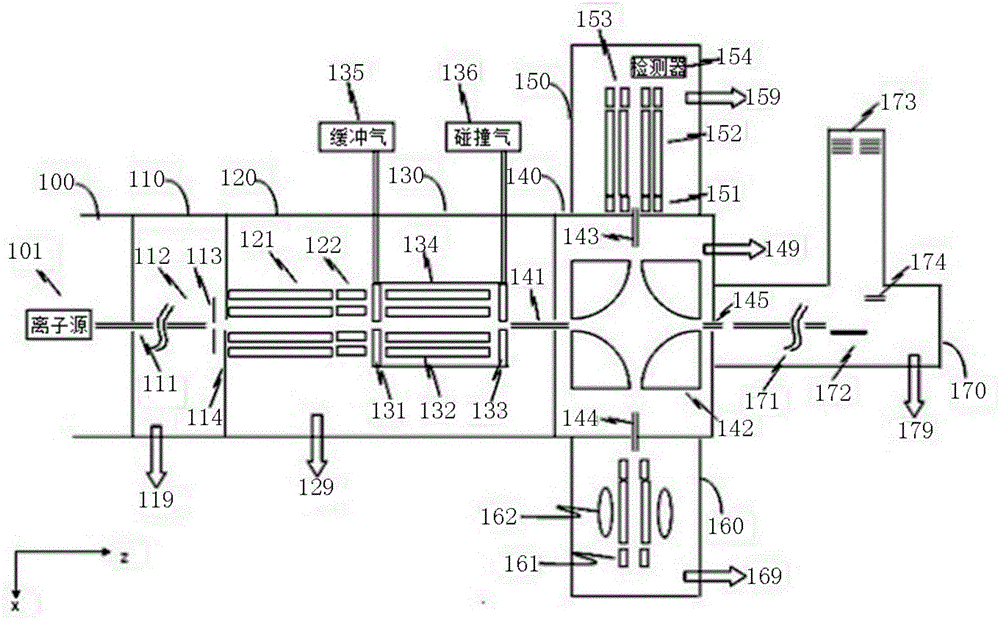

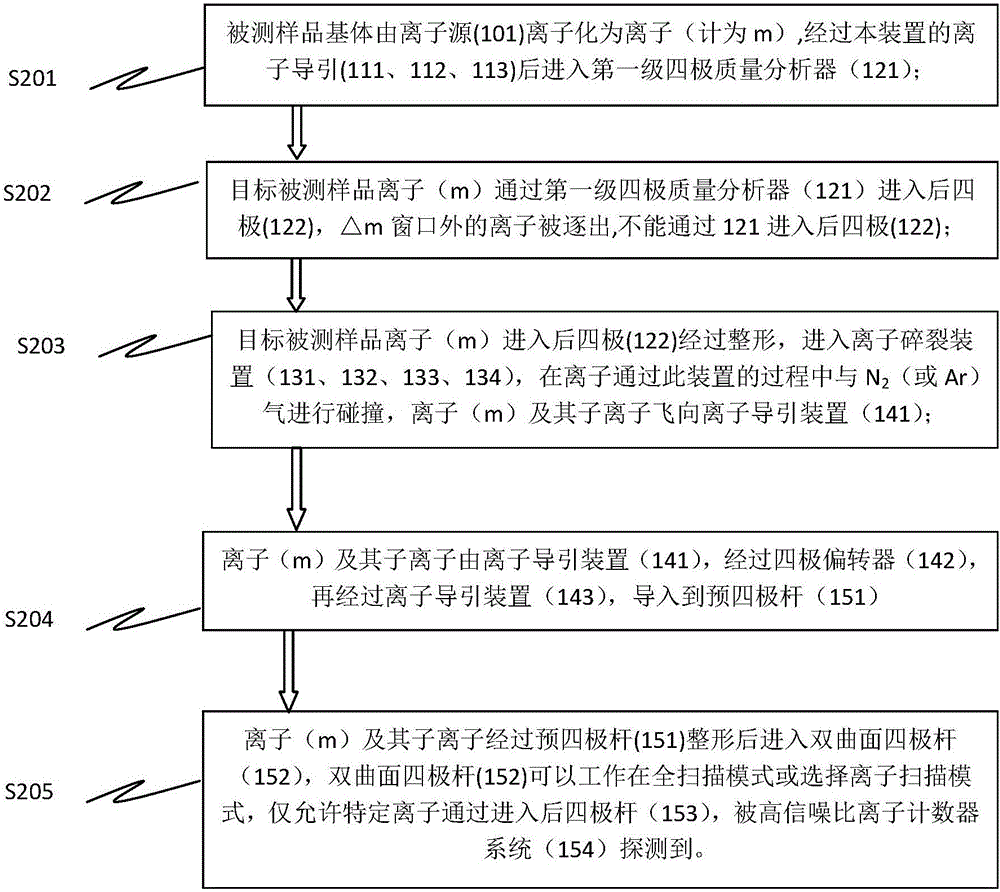

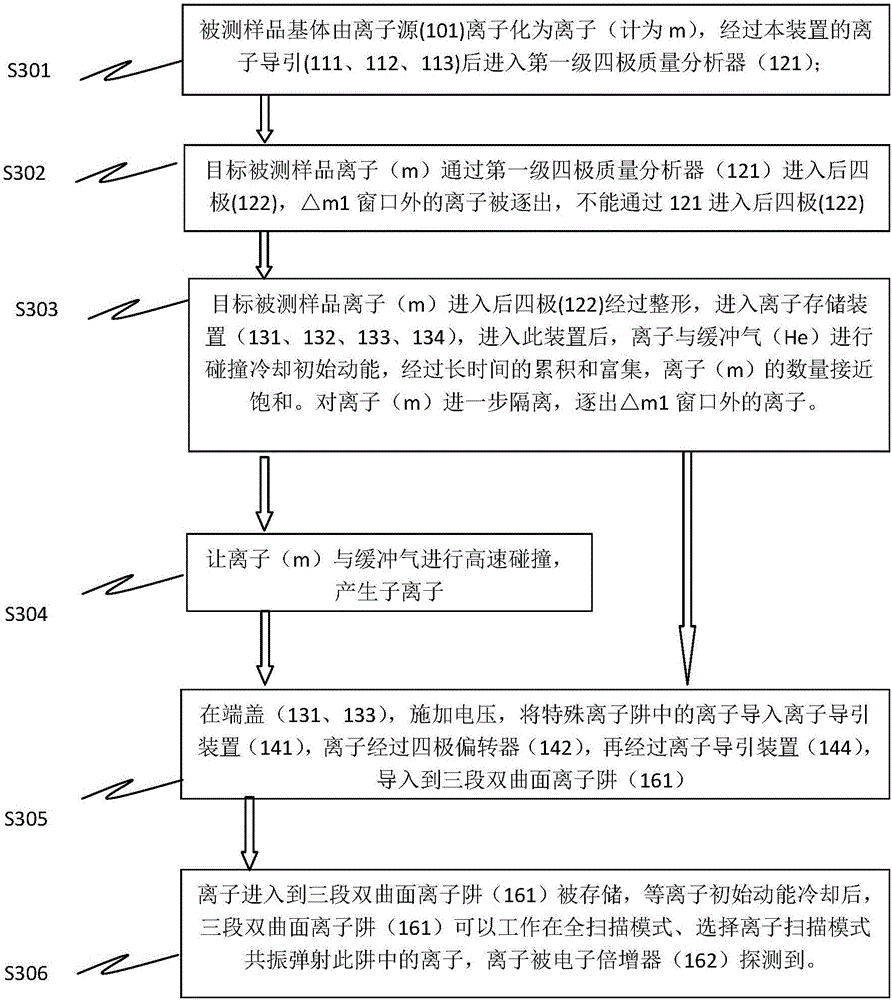

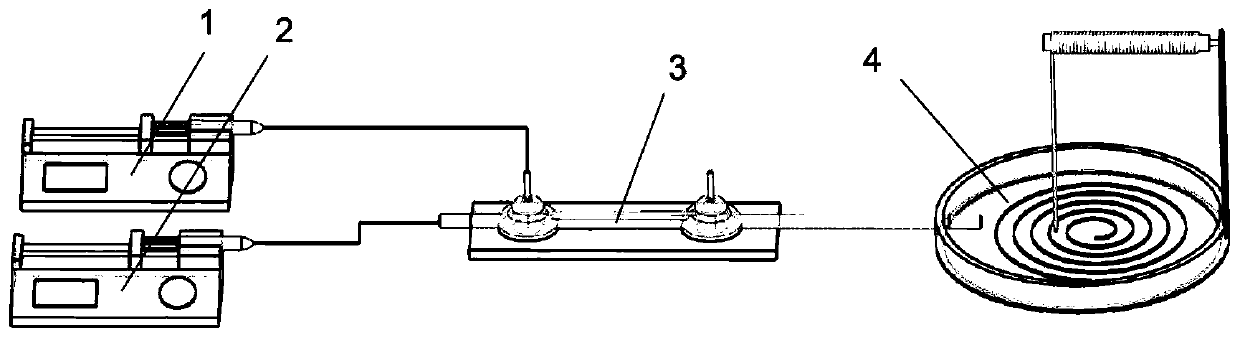

Novel series-parallel connection mass spectrum device system as well as parameter adjustment method and using method thereof

ActiveCN106169411AEasy to getReduce lossesStability-of-path spectrometersMaterial analysis by electric/magnetic meansGuidance systemMass analyzer

The invention provides a novel series-parallel connection mass spectrum device system. The system comprises mass spectrum necessary basic subsystems, such as a set of quadrupole mass filter system, a special quadrupole rod / linear ion trap mass analyzer system, an ion guidance system, a quadrupole deflector, a hyperbolic quadrupole rod mass analyzer and ion counter system, a low air pressure linear ion trap mass spectrometer and electron multiplier system, a flight time mass spectrum system, a multi-path gas flow control system, a vacuum gauge, a multi-section differential motion vacuum system and the like. Furthermore, the invention provides a method for operating above systems to perform quantitative analysis in a triplet quadrupole rod mode, qualitative analysis in a quadrupole filtering medium combined high / low air pressure ion trap mode, and quick / high-mass precision analysis in a quadrupole filtering combined flight time mass spectrum mode on ultra-trace materials in a complex matrix, a method for utilizing an effective combination of three different mass analyzers to achieve optimal ion optical parameter adjustment and a method for performing high-precision qualitative and quantitative analysis on the ultra-trace materials.

Owner:NAT INST OF METROLOGY CHINA

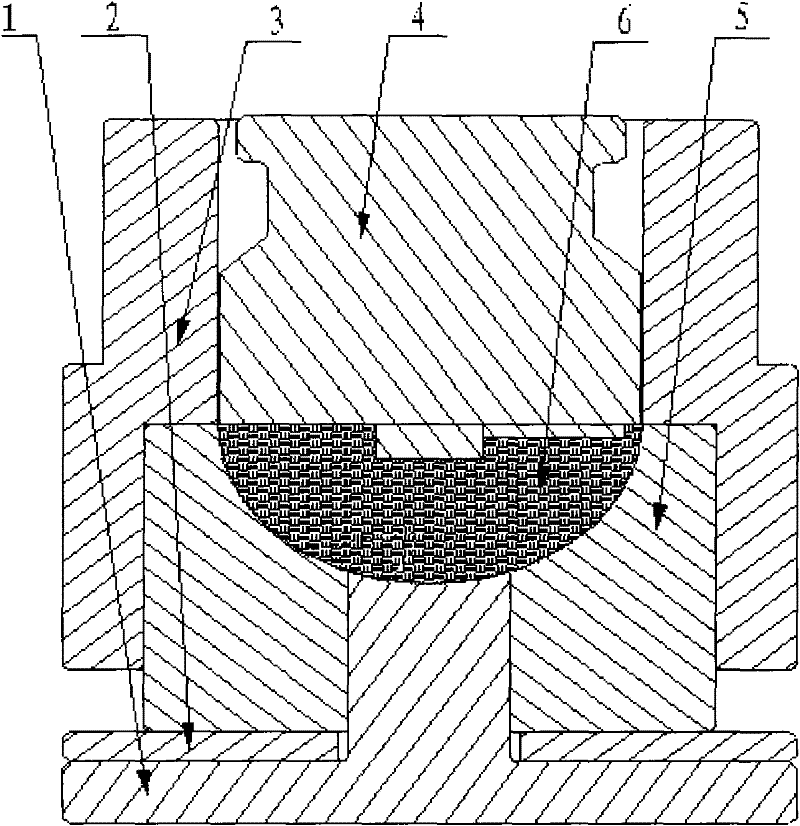

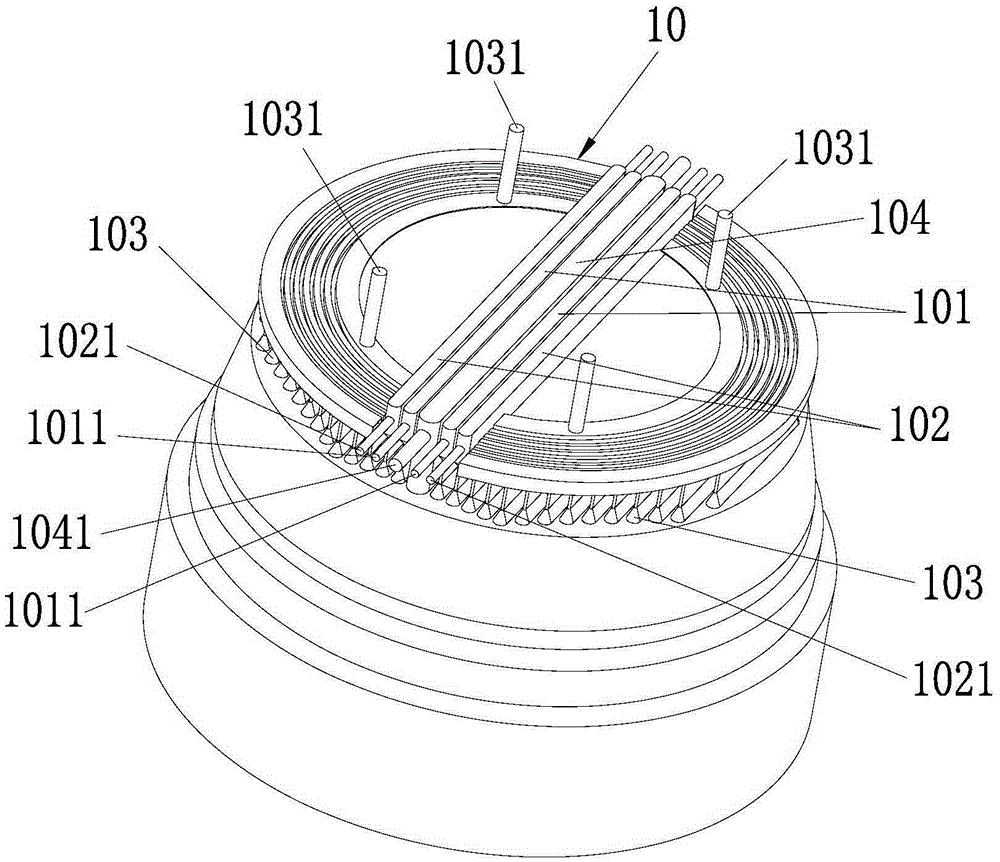

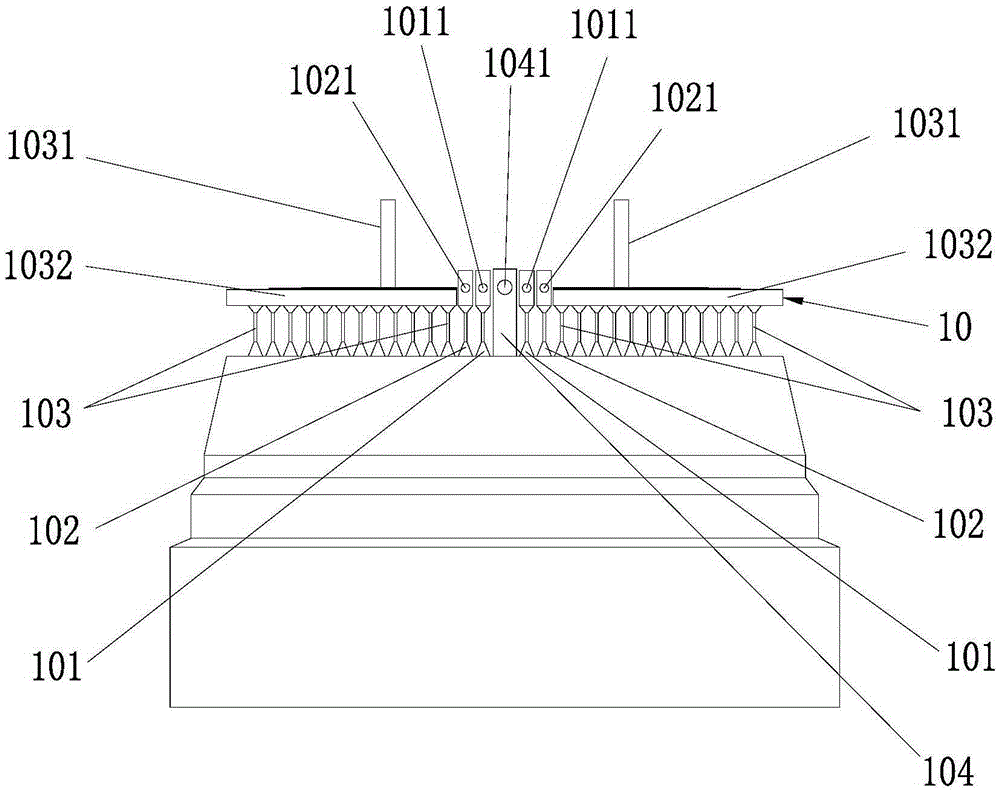

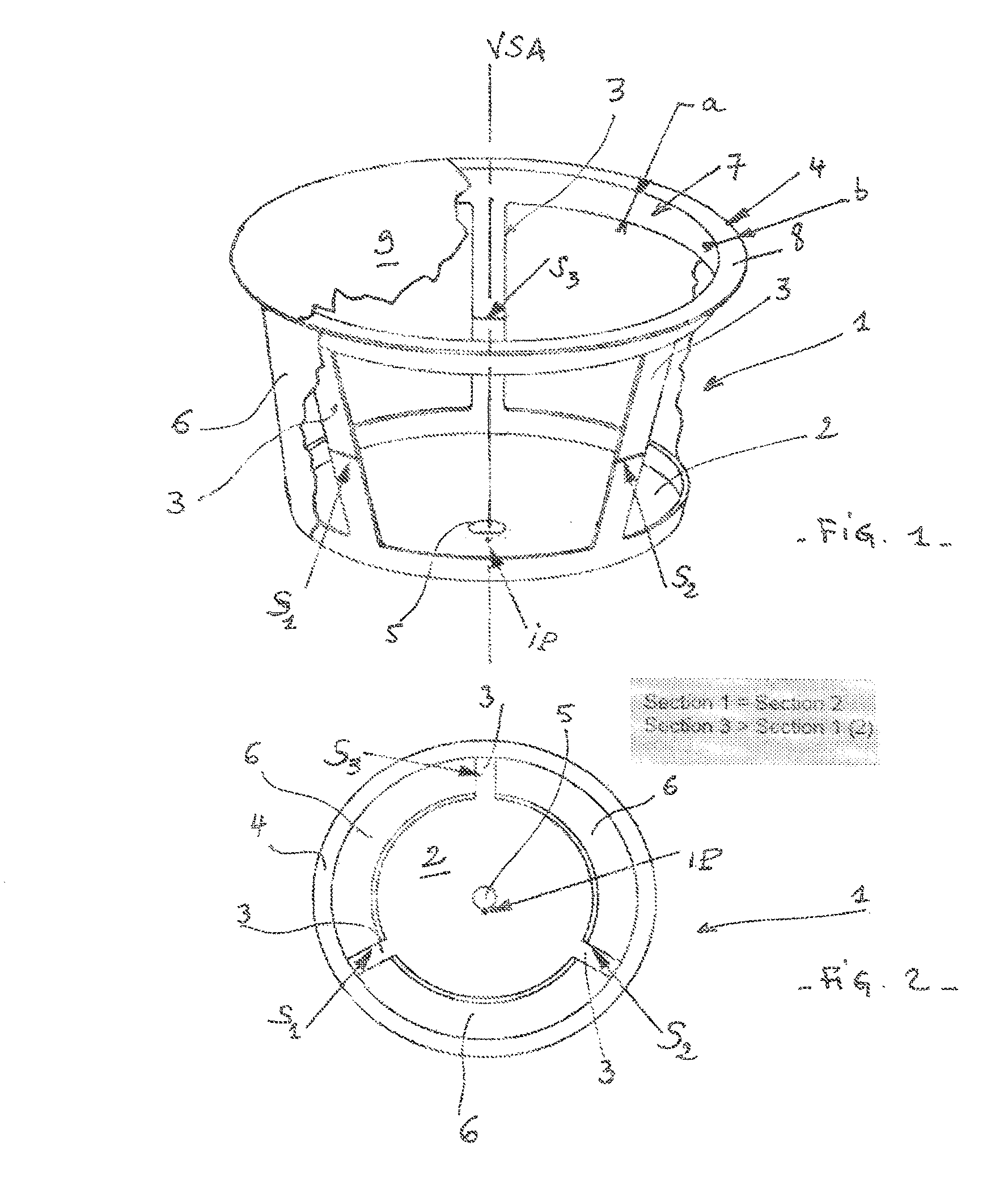

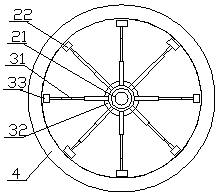

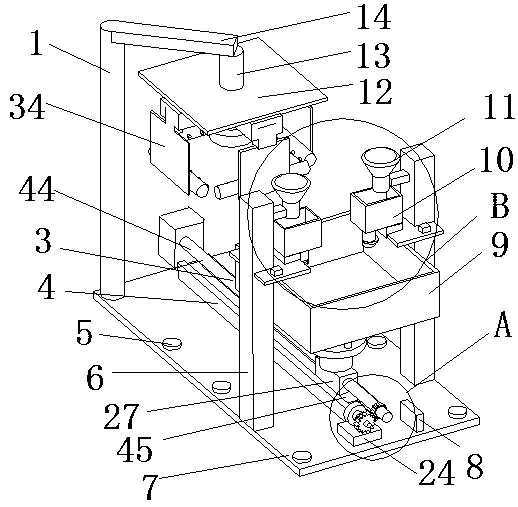

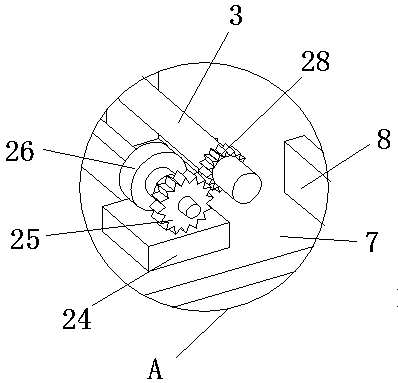

Mold for pressing hemispherical grain

InactiveCN102295496AAccurate shapeAccurate quality controlExplosive working-up apparatusEngineeringGasket

The invention discloses a mould for pressing a semi-sphere grain, and the mould is used for solving the problem that the semi-sphere grain can not be pressed in the prior art. The mould consists of a withdrawing module (1), a gasket (2), a guide sleeve (3), a punch (4) and a base (5), wherein the gasket (2) is placed on the working surface at one end, provided with an ejector rod, of the withdrawing module (1), and the base (5) is sleeved on the ejector rod of the withdrawing module (1), so as to constitute a complete semi-sphere inner cavity; one end, larger in inner diameter, of the guide sleeve (3) is sleeved on the base (5), and one end, smaller in inner diameter, of the guide sleeve (3) is matched with the punch (4); and the distance between the upper and lower end surfaces of the punch (4) is equal to that from the end surface of one end, smaller in inner diameter, of the guide sleeve (3) to the inner diameter variation part of the guide sleeve (3). The mould disclosed by the invention is used for pressing explosive, and the pressed semi-sphere grain is intact in shape without lathe work. The mould disclosed by the invention is suitable for military explosive and is also applicable to civil explosive or industrial explosive which has requirement in sphere.

Owner:XIAN MODERN CHEM RES INST

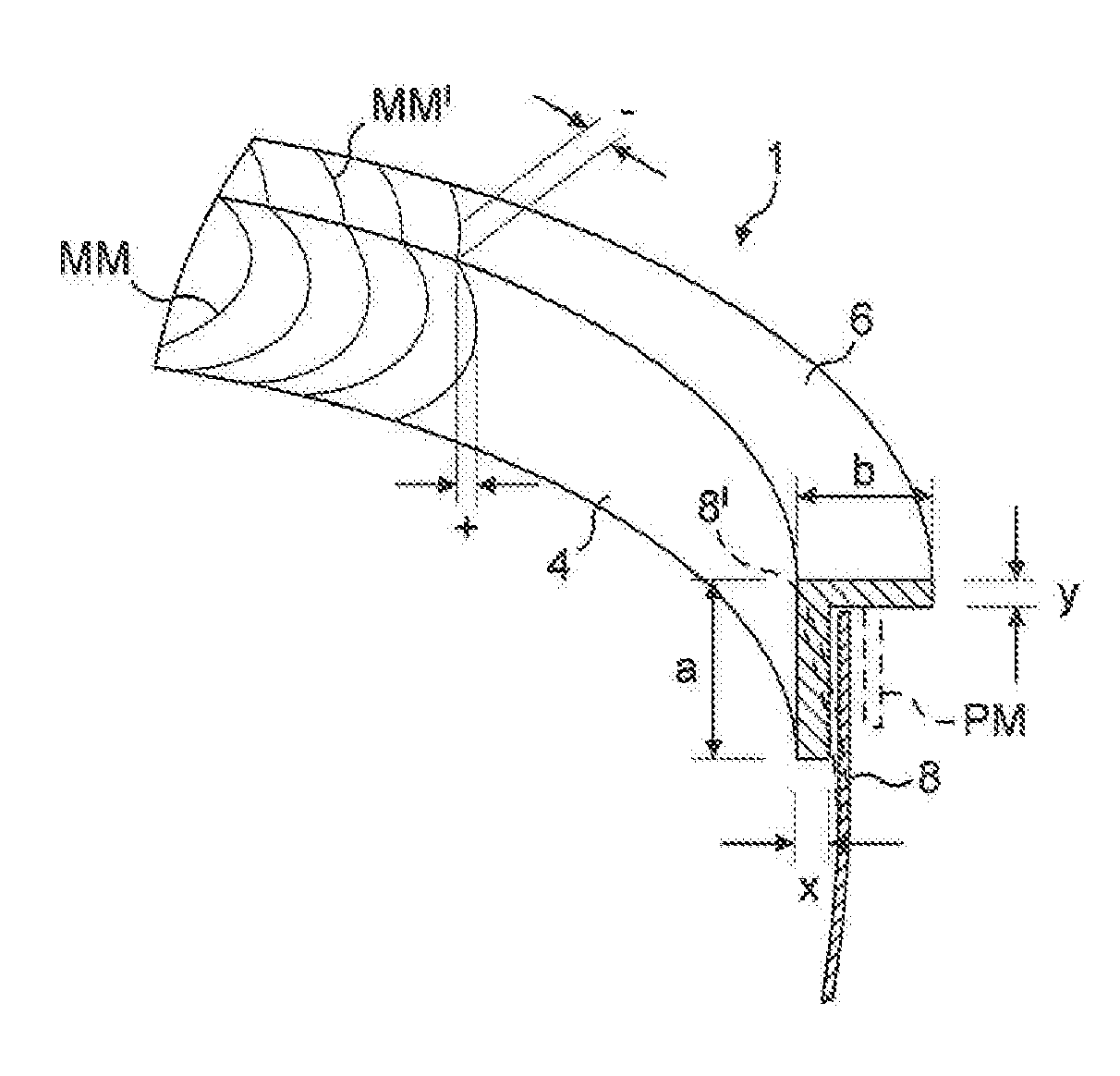

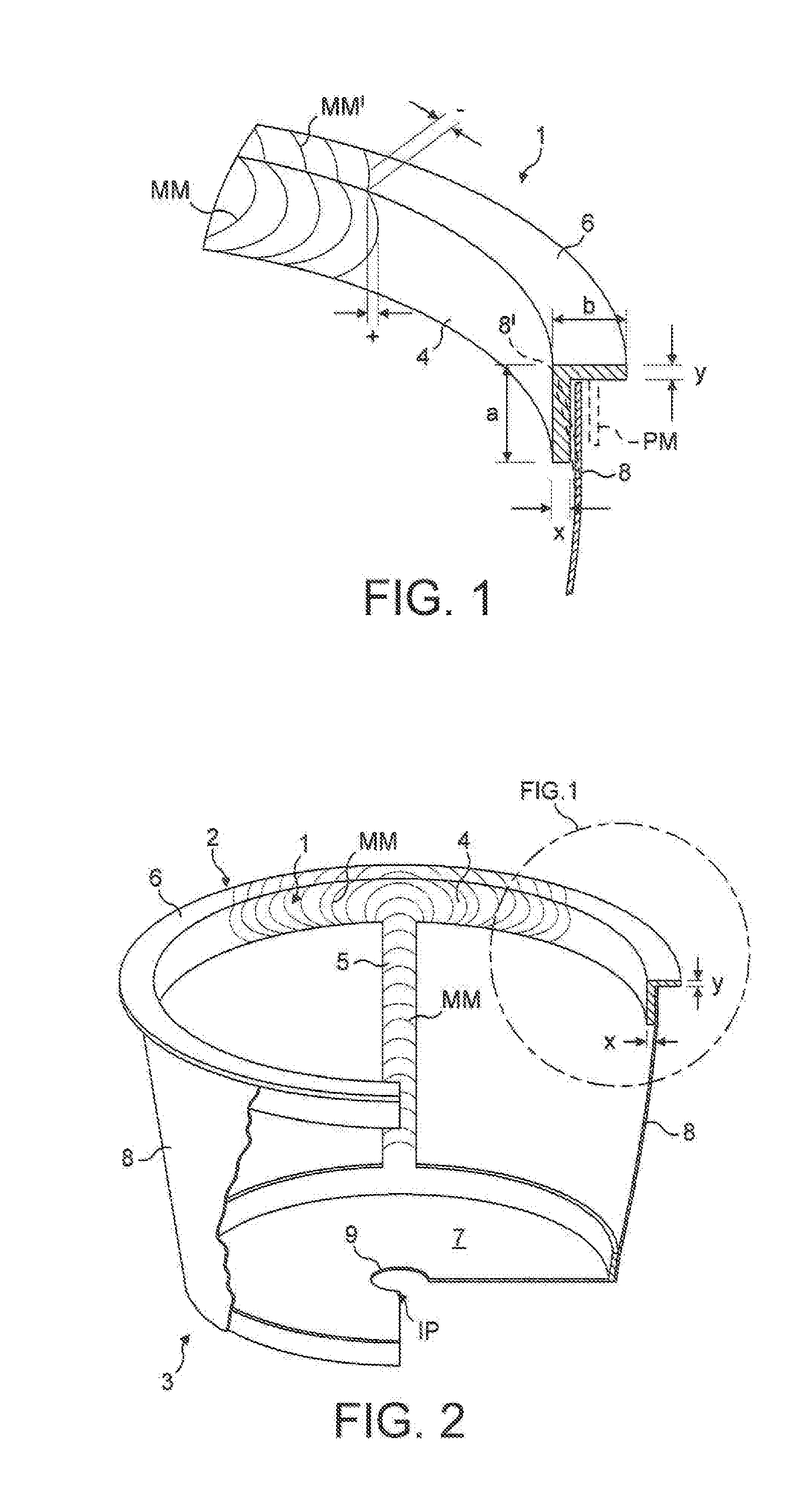

In-mould labelled container

InactiveUS20130139700A1Promote wettingEasy disposalWrappersFlexible elementsEngineeringMechanical engineering

The present invention concerns a container, preferably a capsule for use in a food preparation machine, comprising: (i) a structure with a lower side, at least one substantially vertical pillar extending from the lower side, said pillar being linked to a circular upper frame, said circular upper frame having a substantially L-shaped cross-section with a first circular portion disposed vertically to which the pillar is linked, said vertical portion being linked at its upper side to a second horizontal circular portion forming a peripheral edge, said first vertical portion having a height a and a thickness x, said second horizontal portion having a width b and a thickness y, (ii) a label attached to the lower side, pillar and outer surface of the upper circular frame's vertical portion, thus forming an envelope that defines capsule side walls. According to the invention, x is superior to y, and xa is superior to yb.

Owner:NESTEC SA

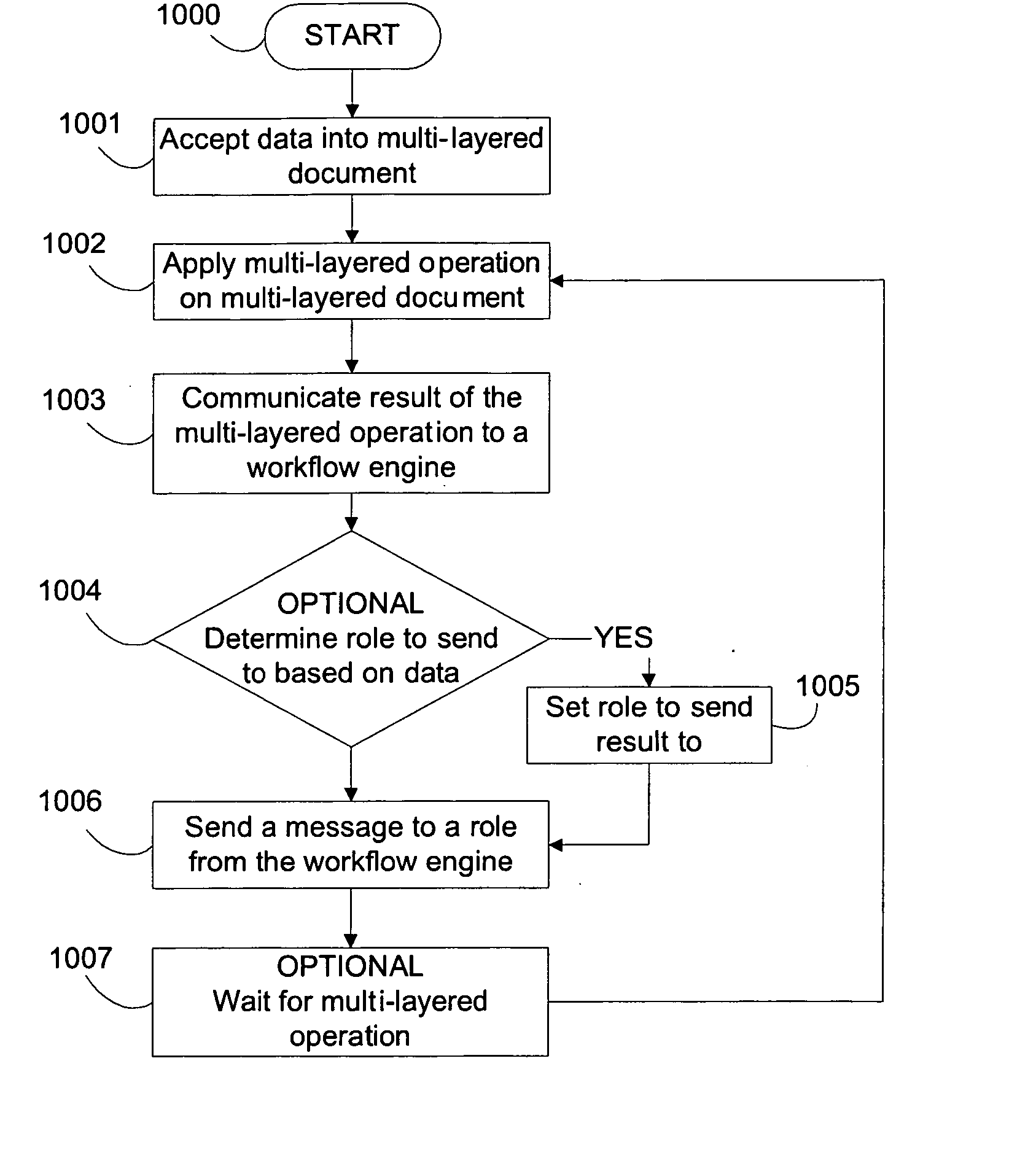

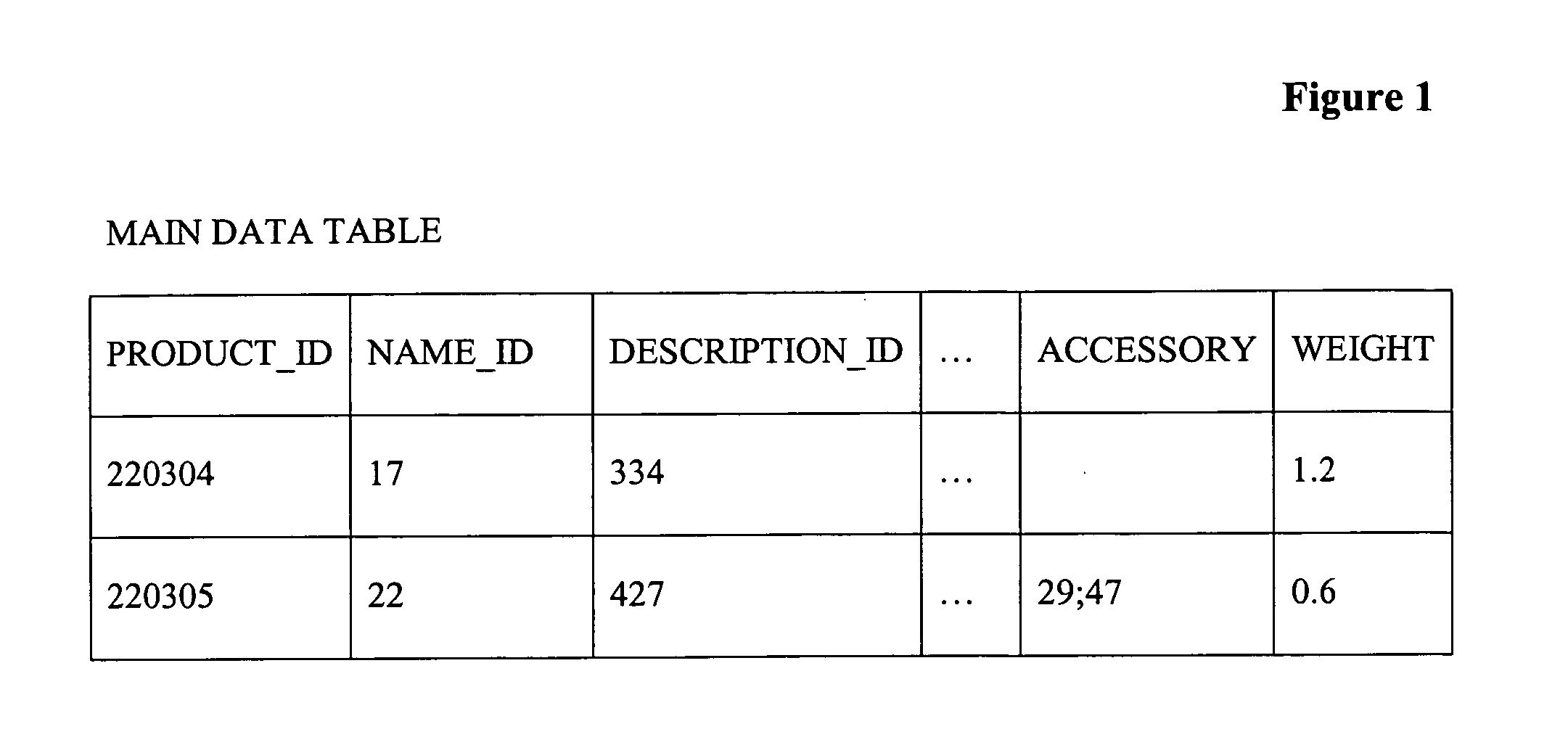

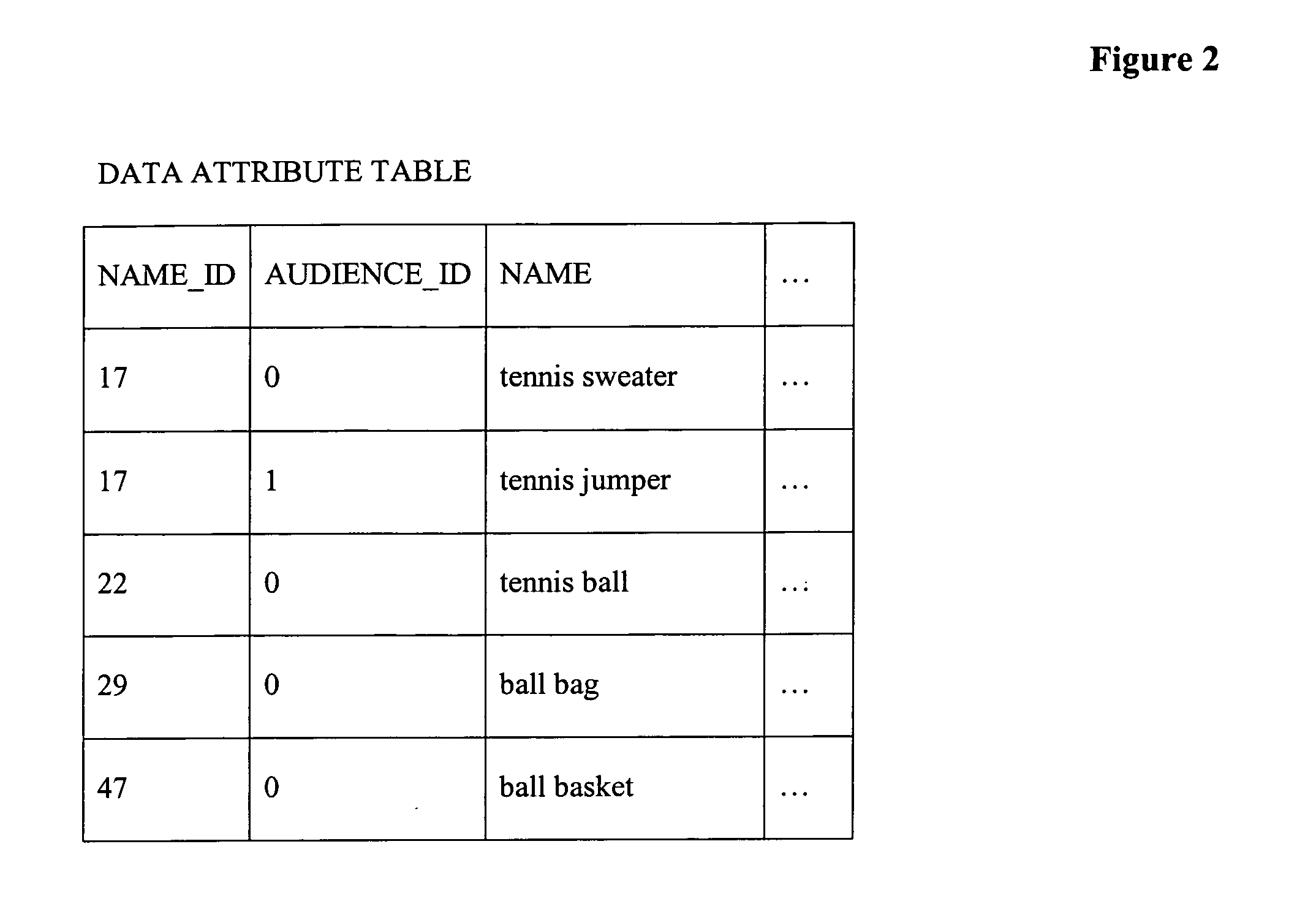

Method for enforcing group oriented workflow requirements for multi-layered documents

ActiveUS20070067728A1Accurate quality controlShorten cycle timeOffice automationSpecial data processing applicationsData integrityPaper document

Methods for enforcing group oriented workflow requirements for multi-layered documents. Embodiments allow results of multi-layered operations to dictate the flow of tasks that occur on a multi-layered document. Flow is directed to roles and may be directed by the data values operated on in addition to multi-layered operation results. The system enables the workflow enabled creation and maintenance of multi-layered documents that minimize repeated data to ensure the highest possible data integrity when targeting a publication at multiple audiences. When a publication is changed and requires maintenance, use of a defined workflow for updating the publication ensures consistency in each publication. Embodiments may comprise performance metrics for monitoring and benchmarking publication processes.

Owner:SAP AG

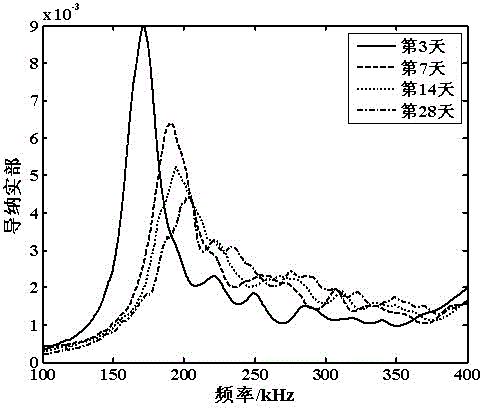

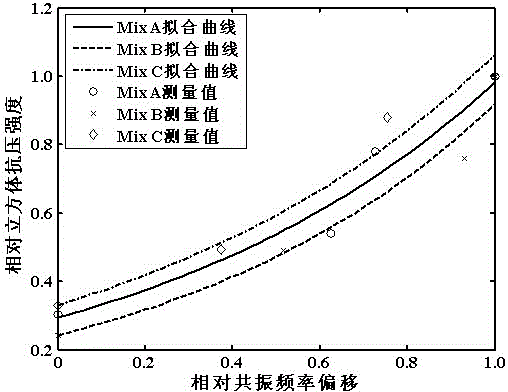

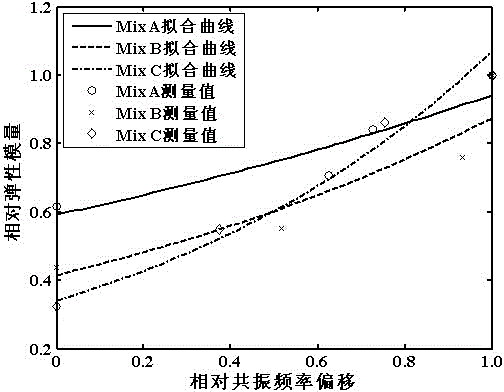

Monitoring method for solidification process of concrete test blocks on basis of piezoelectric impedance method

InactiveCN104165907AAccurate quality controlQuick monitoringMaterial resistanceElastic modulusElectricity

The invention relates to a monitoring method for the solidification process of concrete test blocks on the basis of a piezoelectric impedance method. The monitoring method comprises the step of extracting a resonance-frequency offset index and root-mean-square offset index in piezoelectric admittance signals of piezoelectric ceramic stuck on the concrete test blocks to monitor the change of the compressive strength and the elastic modulus of the concrete test blocks in the solidification process. The monitoring method provides a new path for monitoring the compressive strength and the elastic modulus of the concrete test blocks in the solidification process in real time. Compared with the prior art, the monitoring method has the advantages that fast monitoring can be realized, and the compressive strength and the elastic modulus of the concrete test blocks can be fast obtained under the condition without a pressure machine, so that the quality of the concrete in the casting process is accurately controlled.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

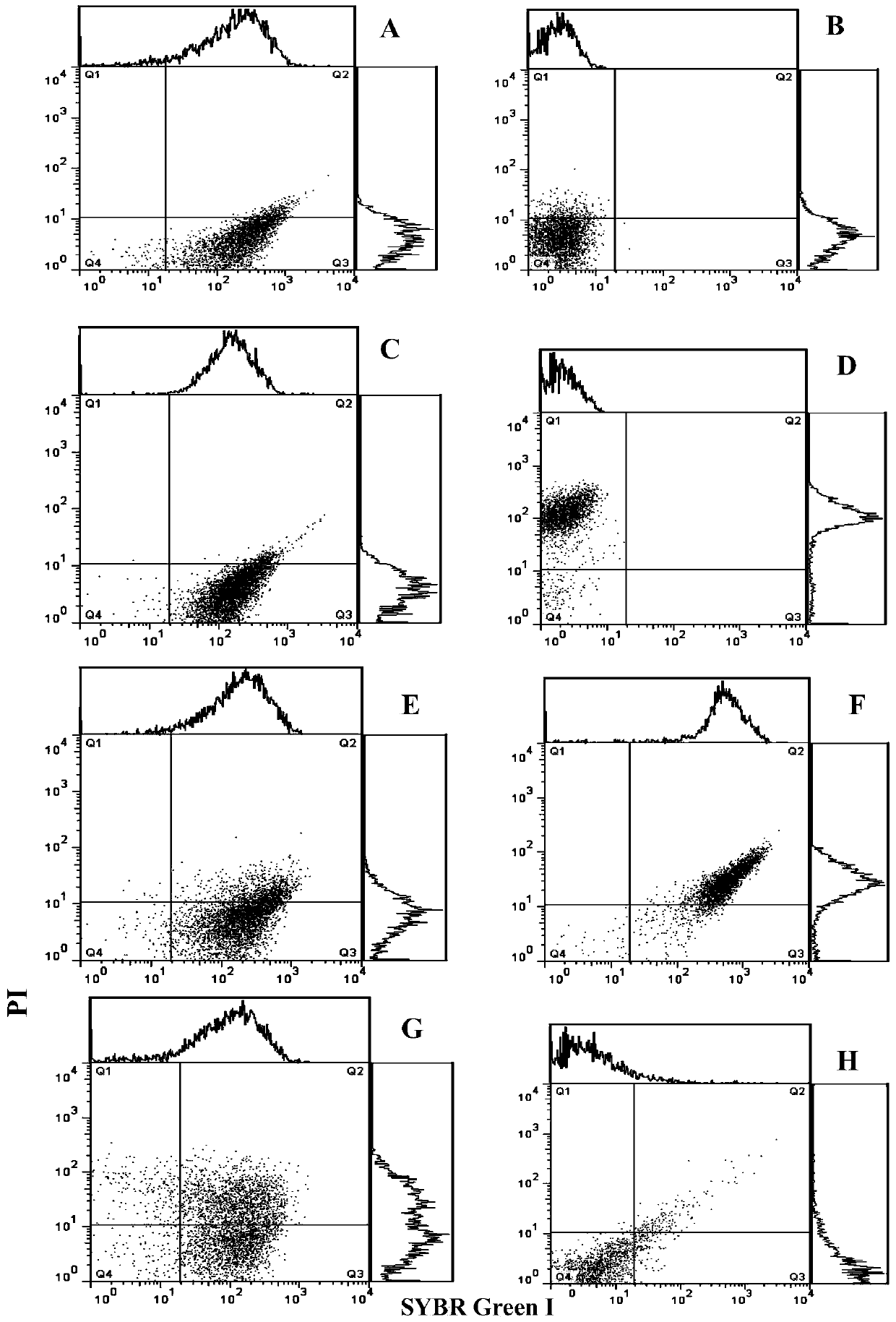

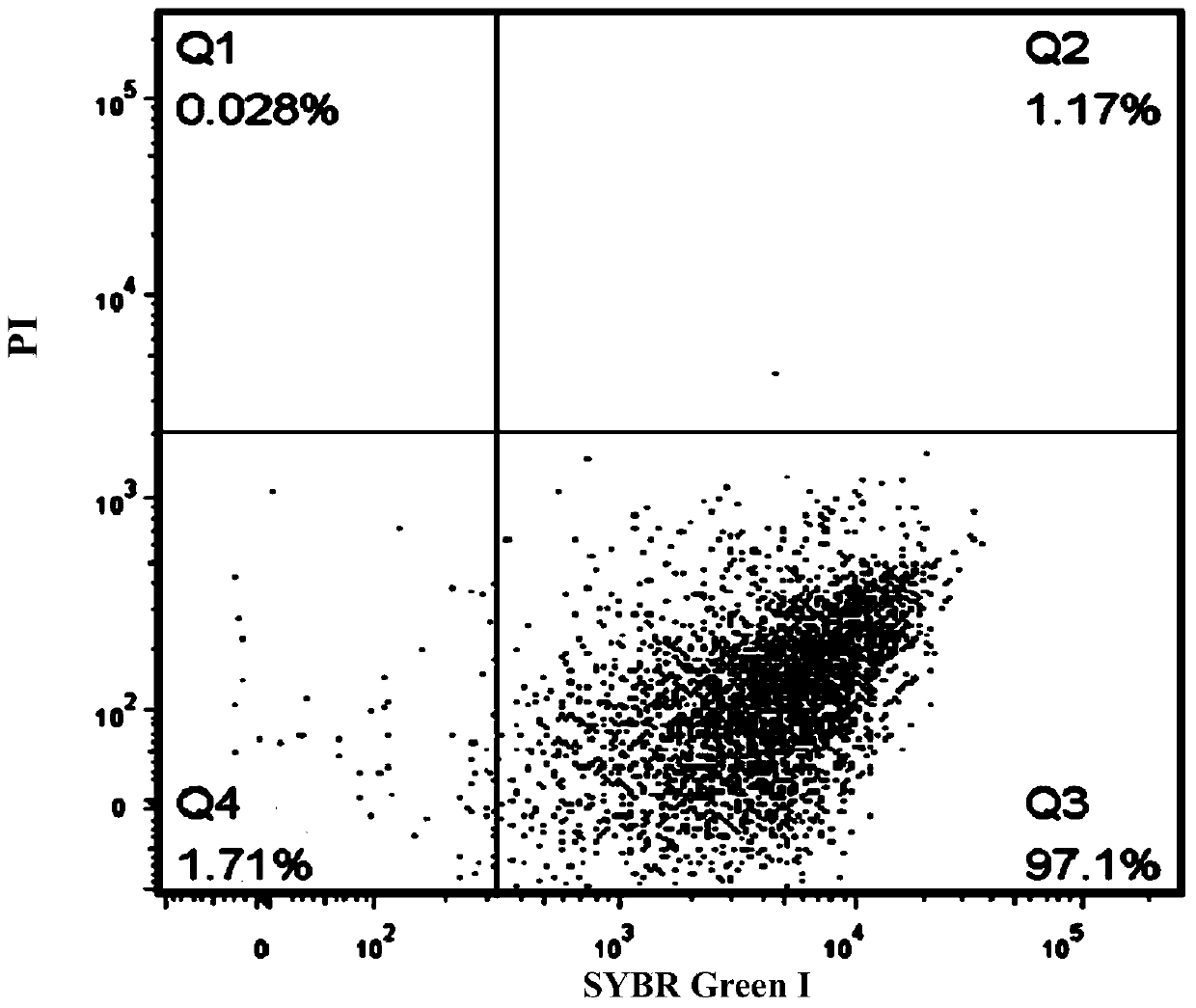

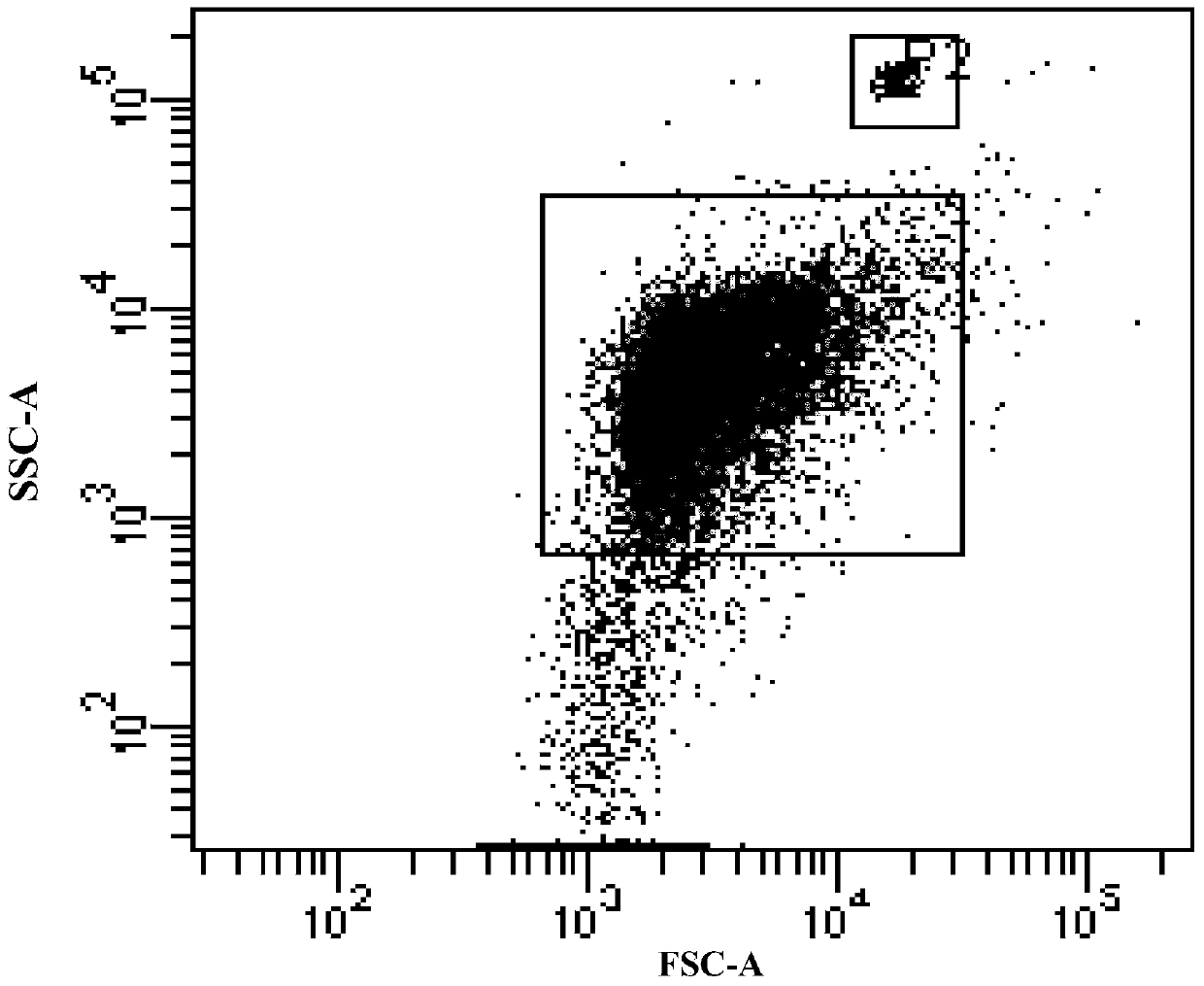

Application of flow cytometry method to vaccine production real-time monitoring

ActiveCN104198357ASave operating timeObvious superiorityIndividual particle analysisBiotechnologyVaccine Production

The invention discloses the application of a flow cytometry method to vaccine production real-time monitoring. The application is to apply the flow cytometry method to the vaccine production process, and monitor the viable bacteria count in real time during the vaccine production process. The application comprises the steps of dyeing bacterial cell through fluorescent dye, detecting the change of bacteria fluorescence signals through a flow cytometer, and obtaining an FCM diagram with at least two types of the following parameters by measuring the change of the bacteria fluorescence signals: viable bacteria count, dead bacteria count and total bacteria count, obtaining the ratio of the viable bacteria count according to the FCM diagram, obtaining the concentration of target bacteria solution through an absolute counting method, and obtaining the viable bacteria amount and the dead bacteria amount of target bacteria according to the ratio of the viable bacteria count and the concentration of the target bacteria solution. The invention provides a convenient, rapid and reliable bacterial activity monitoring method for the vaccine production process and is convenient and easy, the operation time is only 30 minutes, and the quality of the vaccine production process can be accurately controlled.

Owner:INST OF ANIMAL HEALTH GUANGDONG ACADEMY OF AGRI SCI

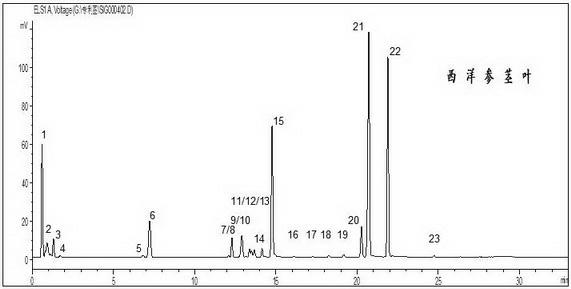

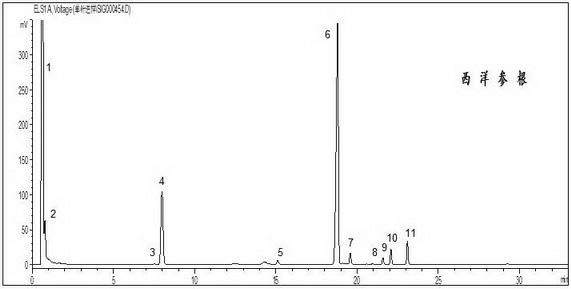

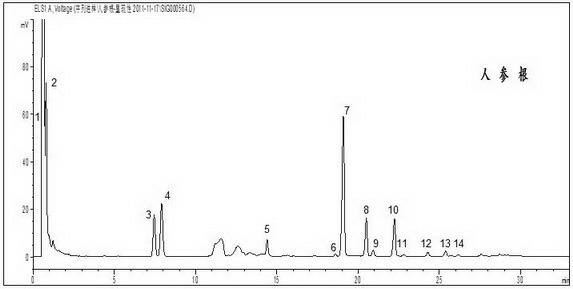

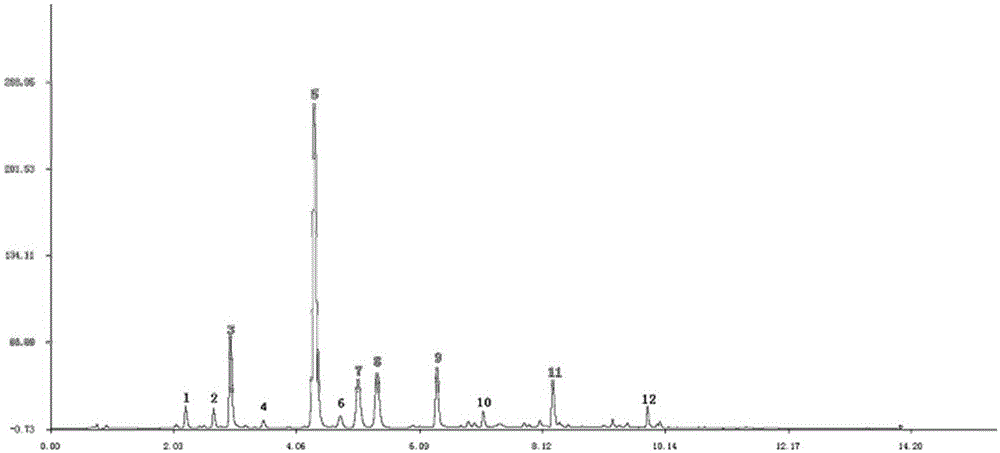

Method for constructing finger-print chromatogram for ginsenosides-containing crude drugs and preparations

InactiveCN102621264AAccurate quality controlEnsure Stability and ConsistencyComponent separationDrugMedicinal herbs

The invention provides a method for constructing a finger-print chromatogram for ginsenosides-containing crude drugs and preparations and relates to a construction method for constructing the ultra high performance liquid chromatography for preparations of American ginseng and American ginseng stem leaf drugs as well as American ginseng and American ginseng stem leaf extractives and a standard finger-print chromatogram thereof. The finger-print chromatogram obtained through the invention can be used for comprehensively controlling the quality of the drugs, ginsenosides extractives extracted from the drugs, and extractive preparations; and the preparations include solid preparations and liquid preparations, such as injections, granules, tablets, capsules, drinks, mixtures and oral liquids.

Owner:JILIN ACAD OF TRADITIONAL CHINESE MEDICINE

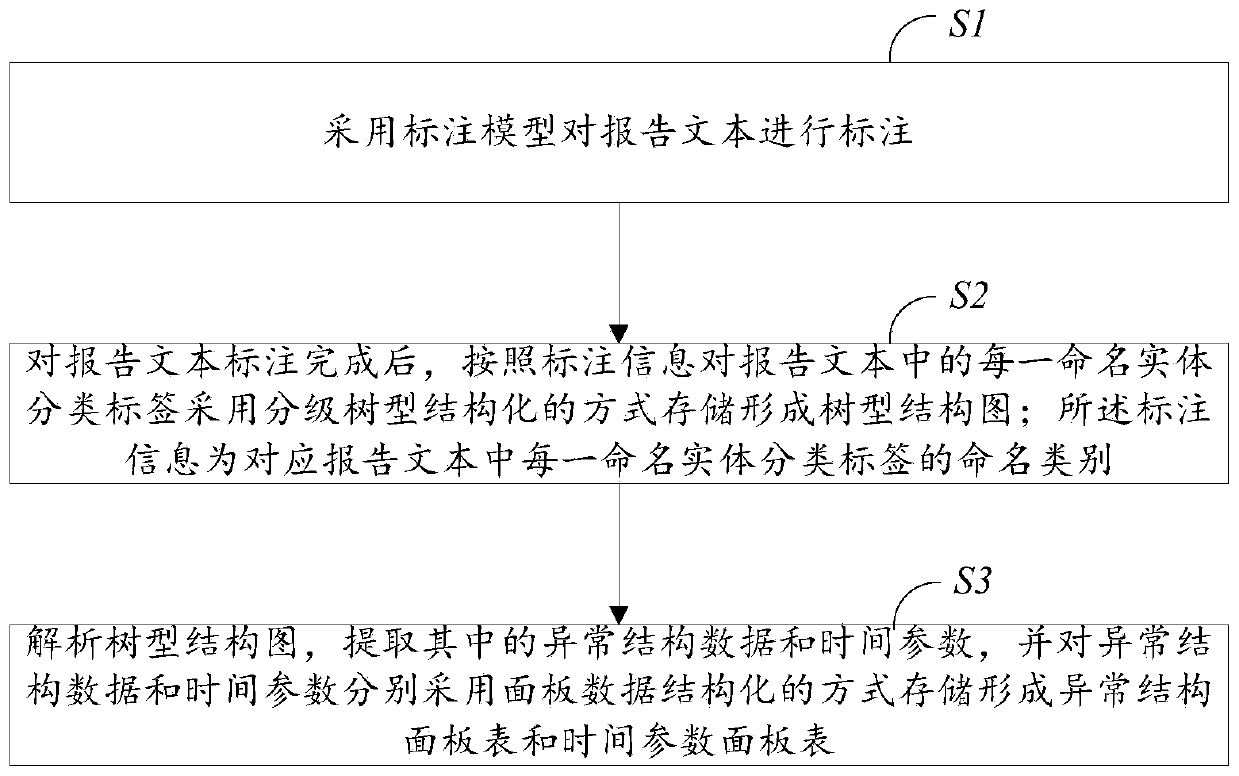

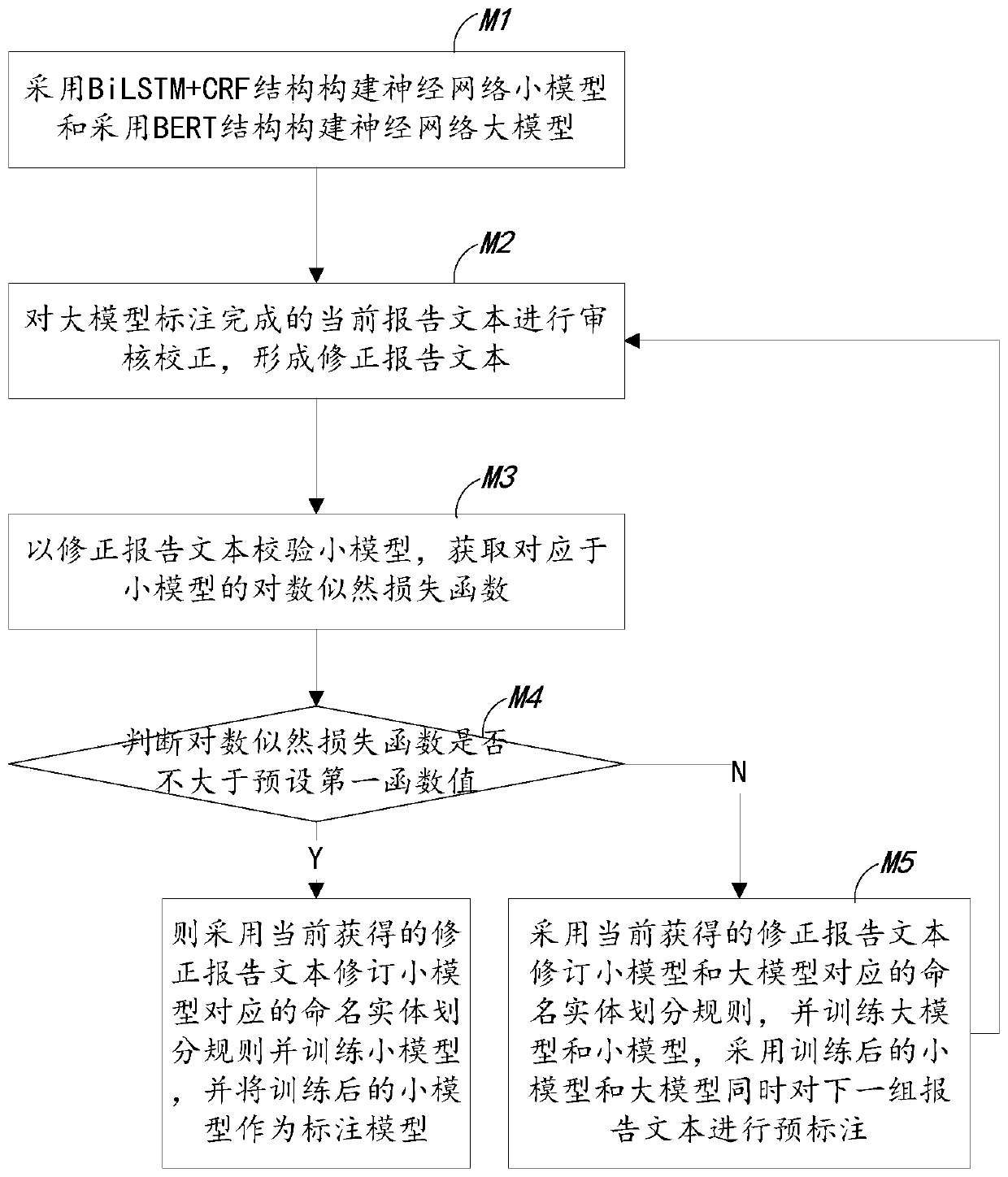

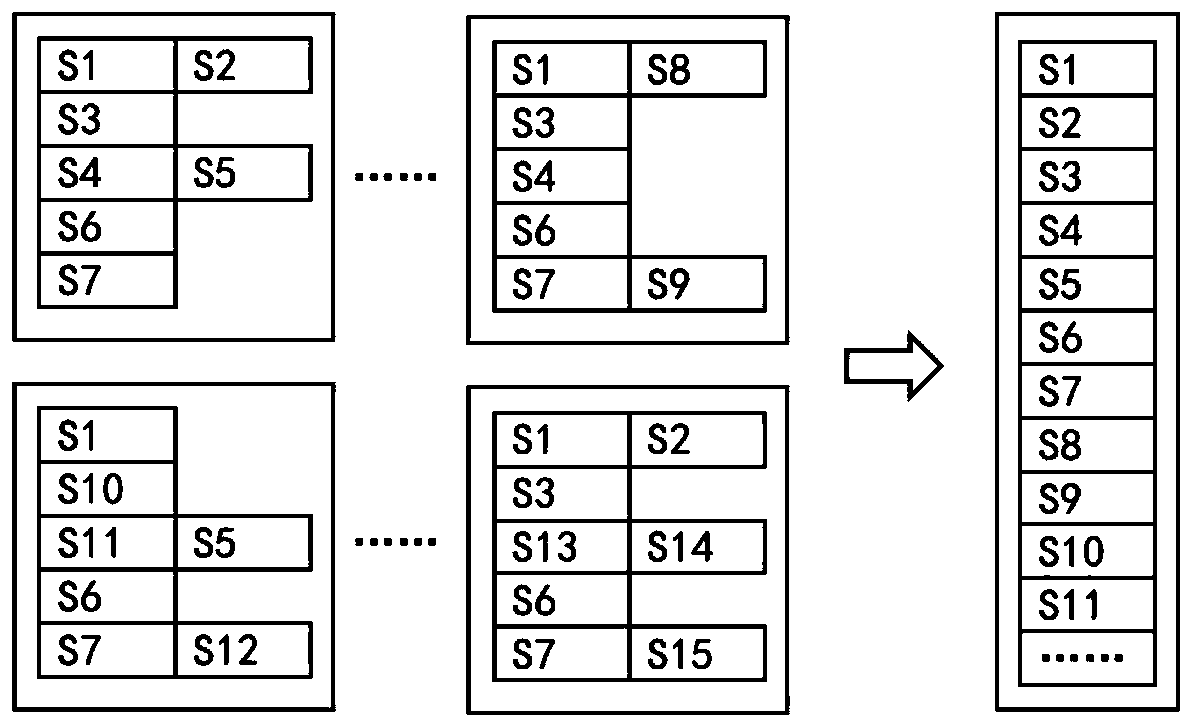

Capsule endoscopy report text structuring method and device and medium

ActiveCN111026799AAccurate quality controlSemantic analysisMedical imagesG i endoscopyVideo capsule endoscopy

Owner:安翰科技(武汉)股份有限公司

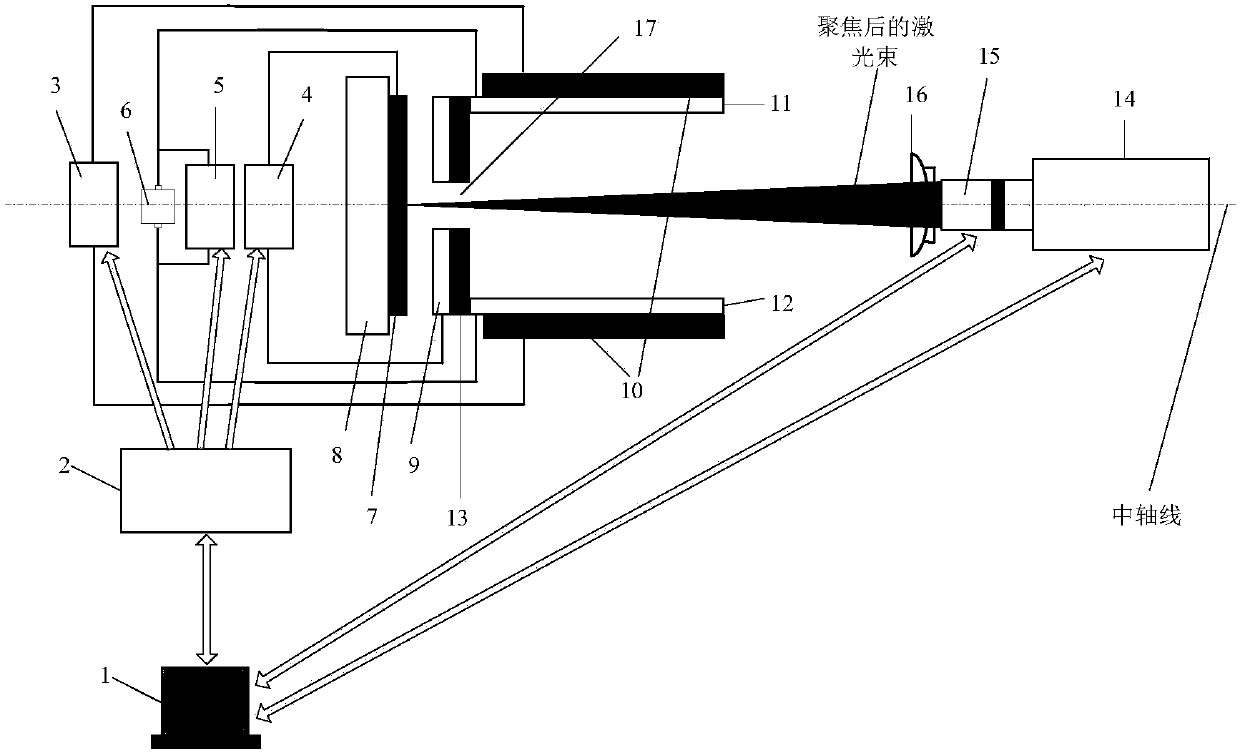

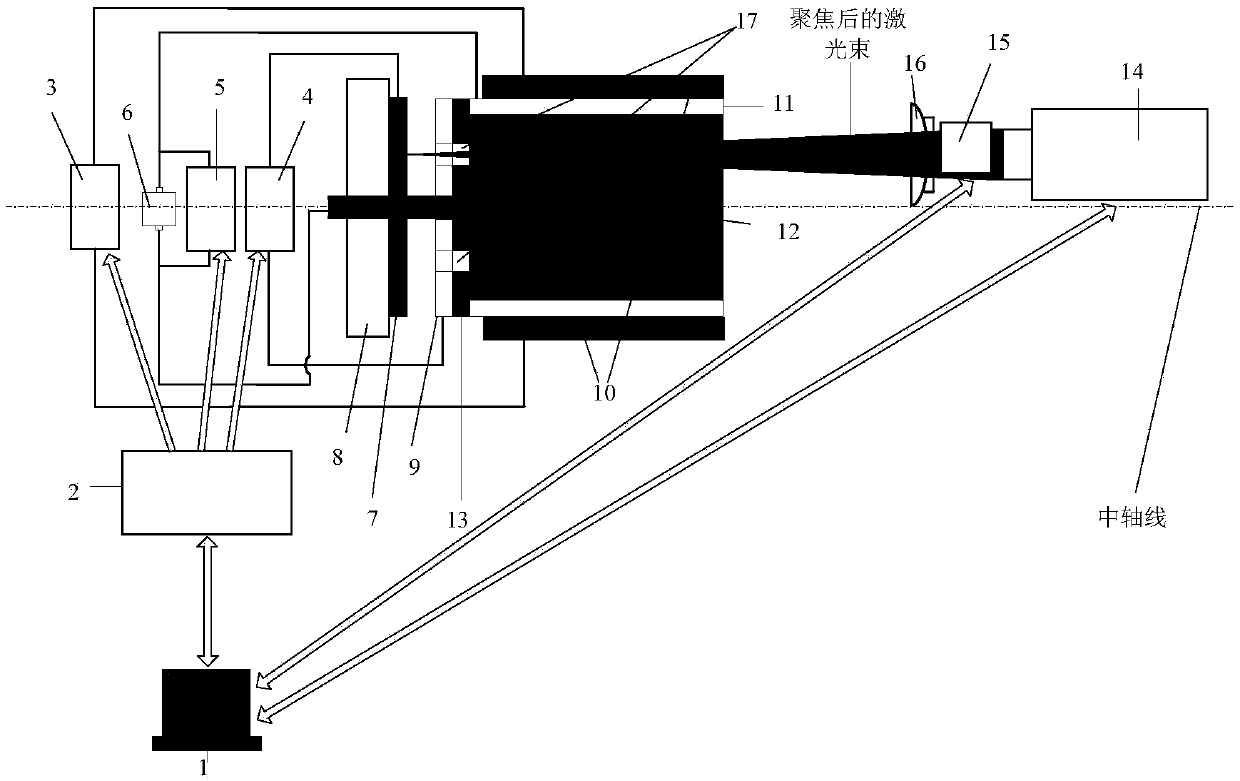

Reflecting type laser-electromagnetic field coupling thrustor

ActiveCN107939625AAccurate quality controlImprove propulsion efficiencyMachines/enginesUsing plasmaElectromagnetic field couplingThrust efficiency

The invention relates to a reflecting type laser-electromagnetic field coupling thrustor which comprises a laser system, an electromagnetic accelerating electrode assembly and a static electric fieldassembly. The electromagnetic accelerating electrode assembly comprises an electromagnetic accelerating cathode, an electromagnetic accelerating anode and an electromagnetic accelerating electrode power source; the static electric field assembly comprises a static electric field accelerating electrode, a working medium and a static electric field accelerating power source, the static electric field accelerating power source provides power for the working medium and the static electric field accelerating electrode, and a potential difference is formed between the working medium and the static electric field accelerating electrode to form a static electric field; laser plasmas generated by ablation of the working medium by laser beams enter the static electric field, when the laser plasmas accelerated by the static electric field move to the position between the electromagnetic accelerating cathode and the electromagnetic accelerating anode, discharge arcs can be induced to be generated,the laser plasmas are heated by the discharge arcs and are further ionized, the laser plasmas are sprayed out in an accelerated manner under the joint effect of lorentz force and aerodynamic force, and thrust is accordingly generated. The reflecting type laser-electromagnetic field coupling thrustor has the beneficial effects that the thrust is adjustable, the thrust efficiency is high, and the thrust density is large.

Owner:NAT UNIV OF DEFENSE TECH

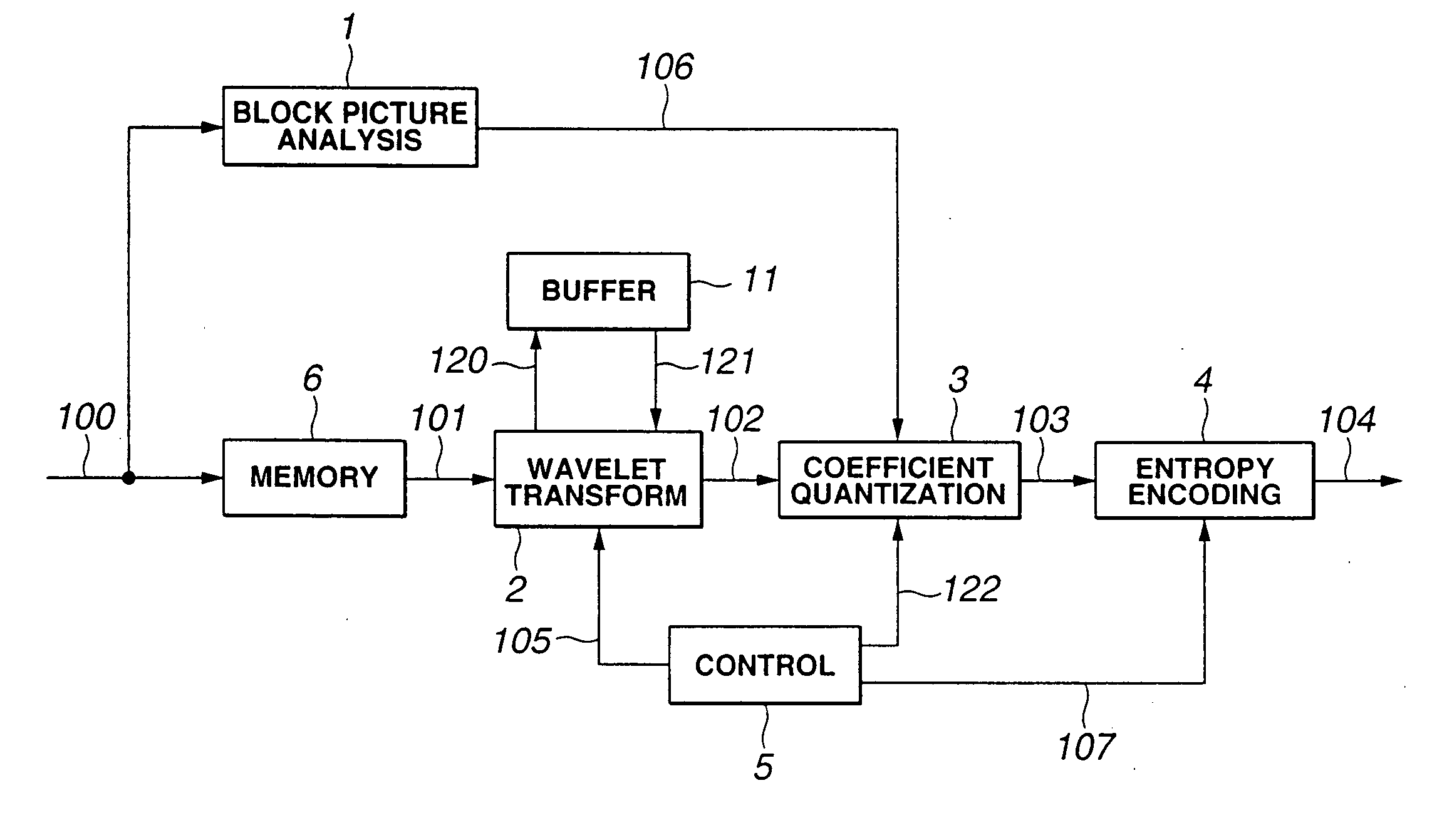

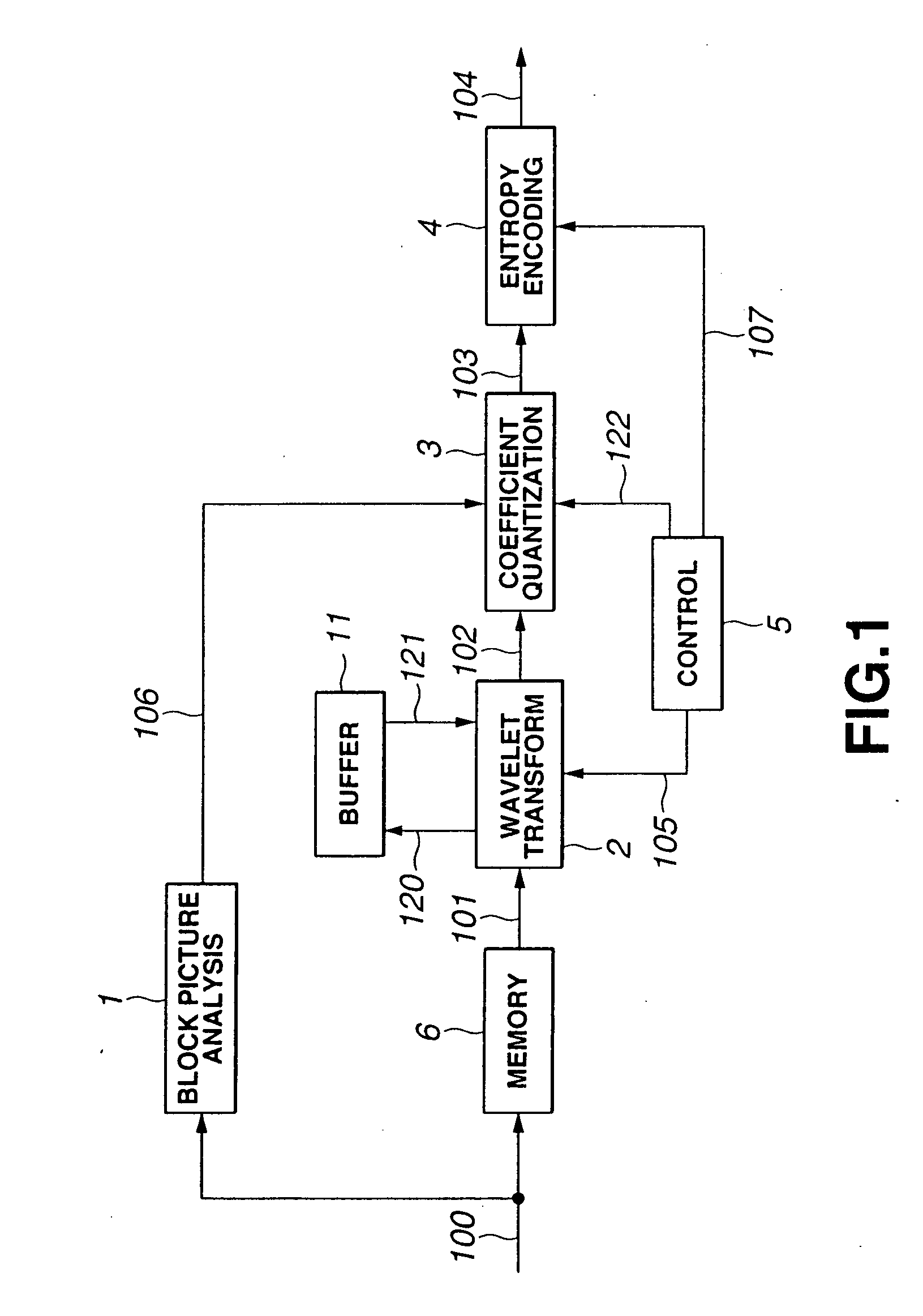

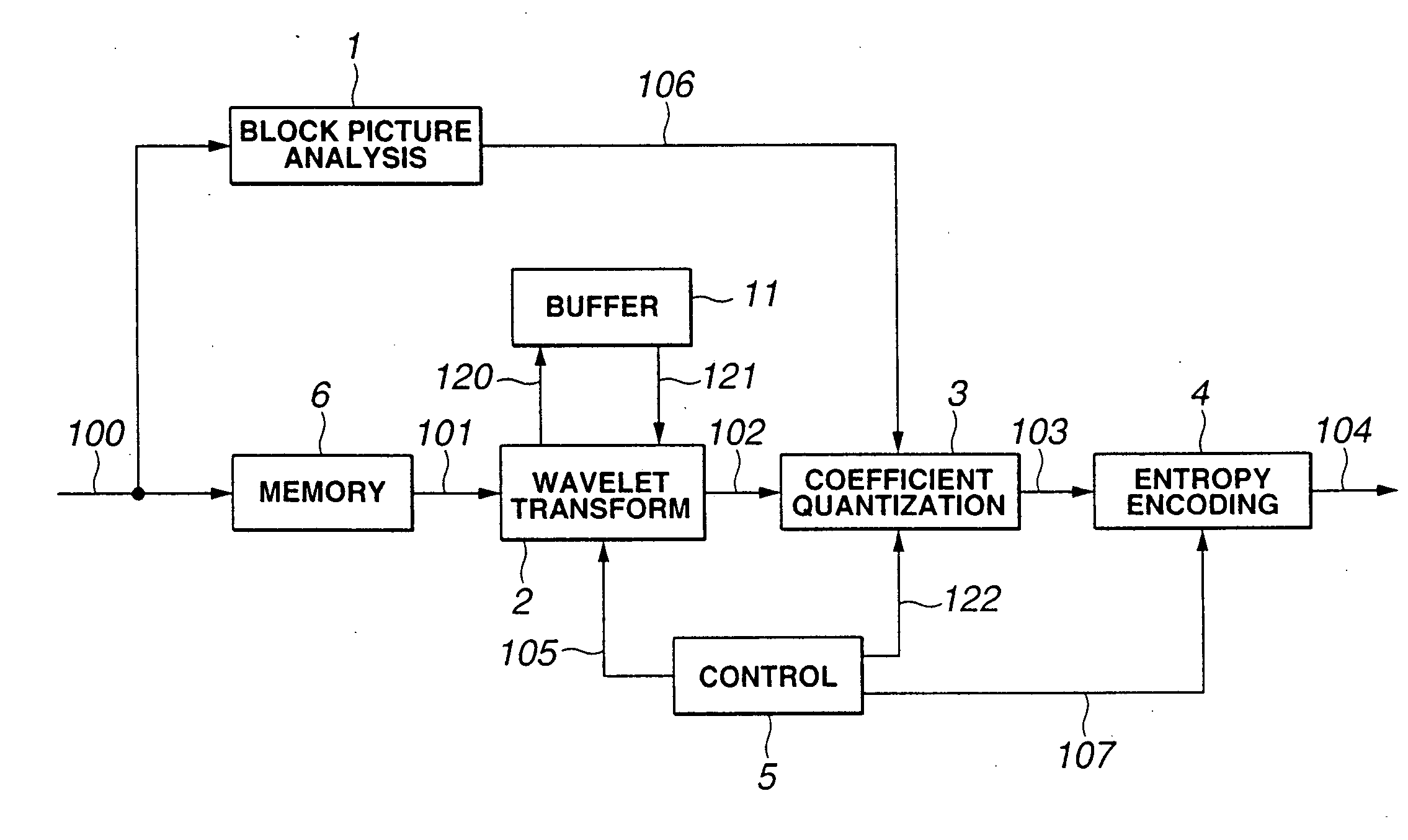

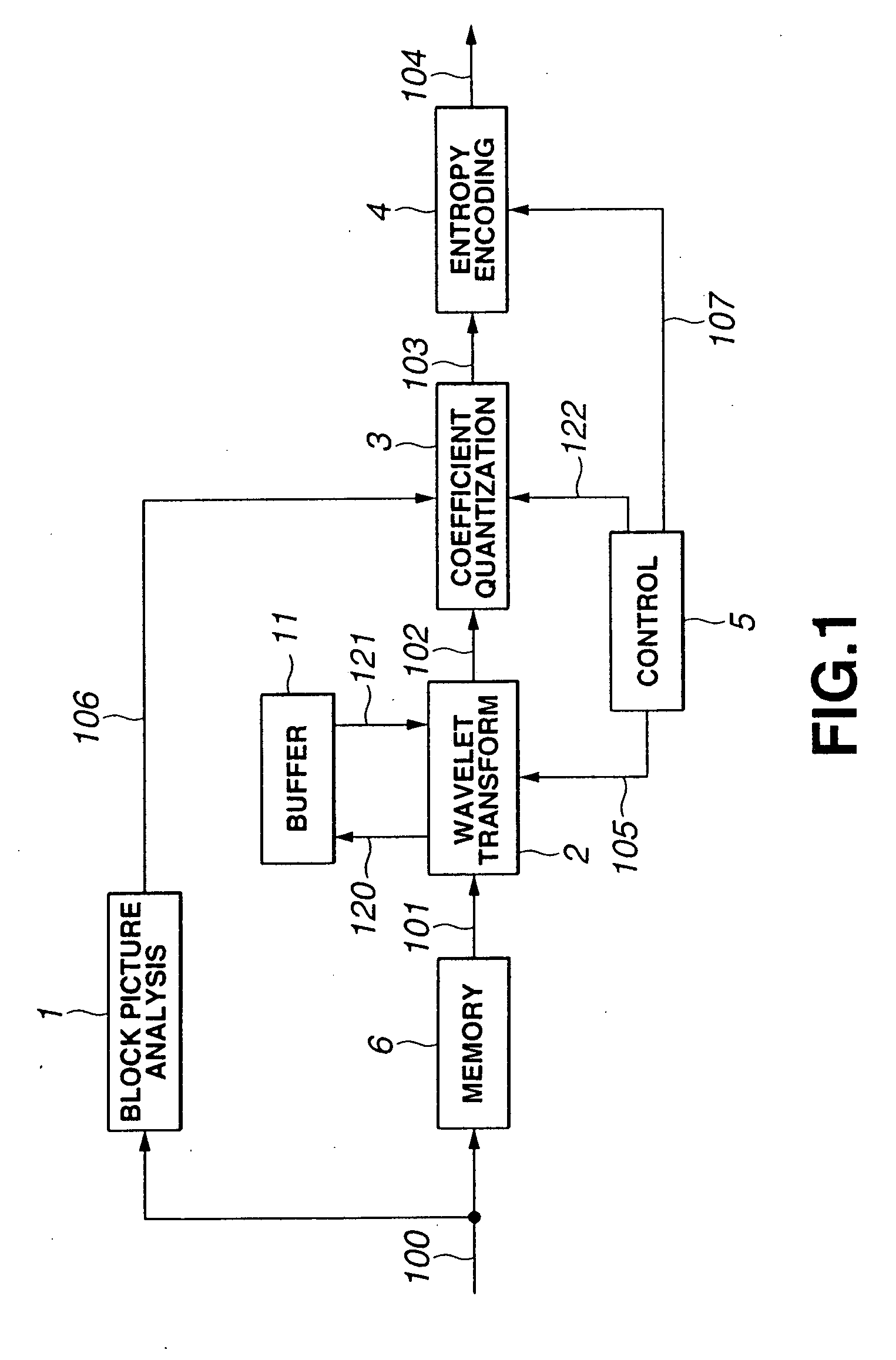

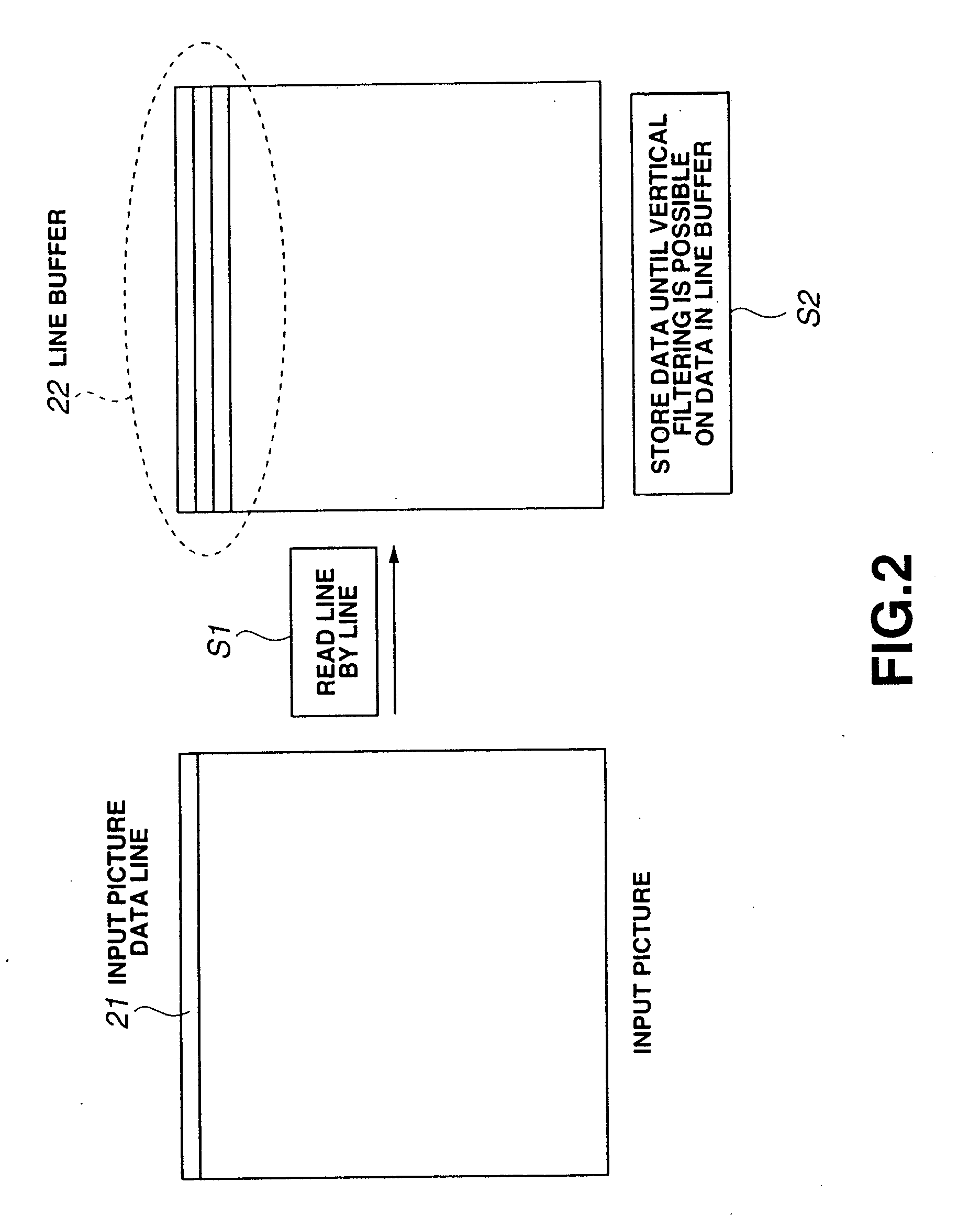

Block area wavelet transform picture encoding apparatus

InactiveUS20050265617A1Accurate quality controlImprove picture qualityCode conversionImage codingWeight coefficientQuality control

Owner:SONY CORP

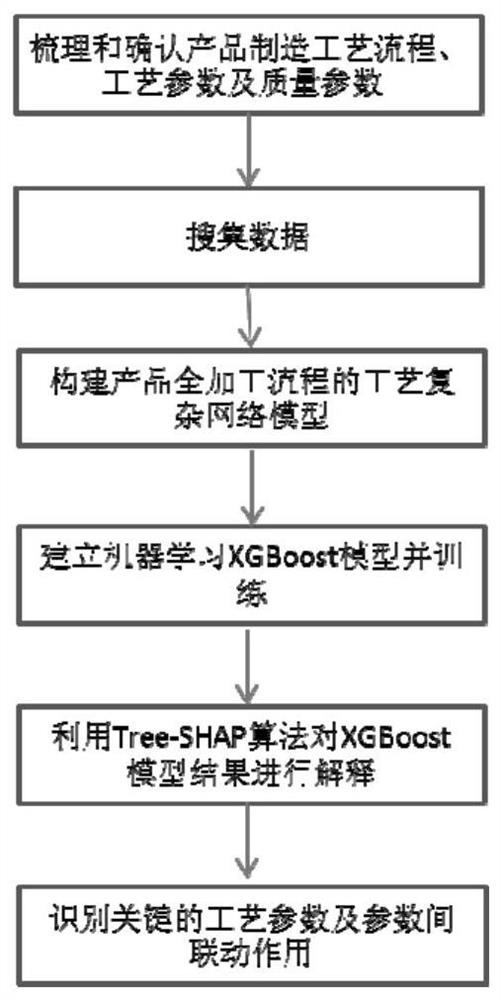

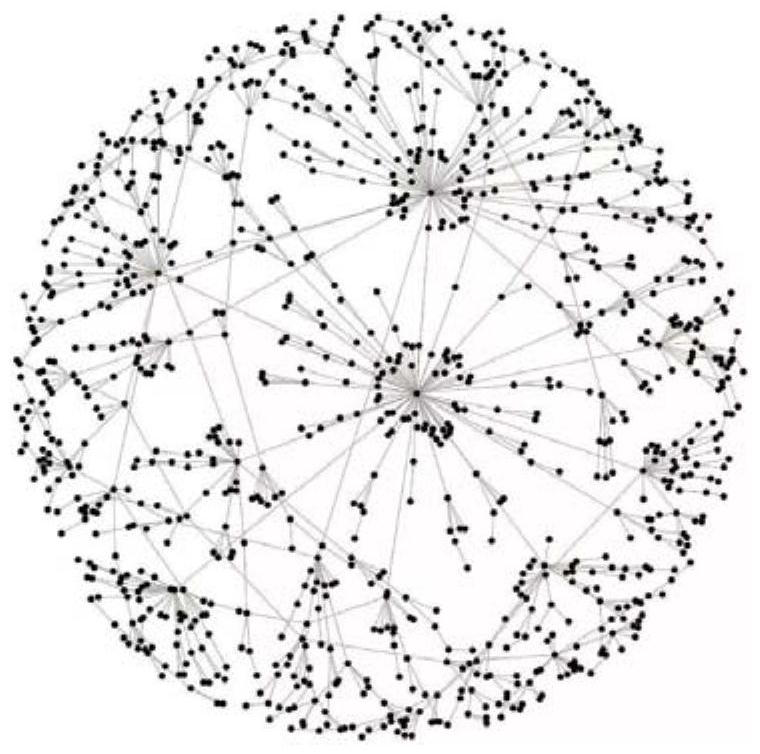

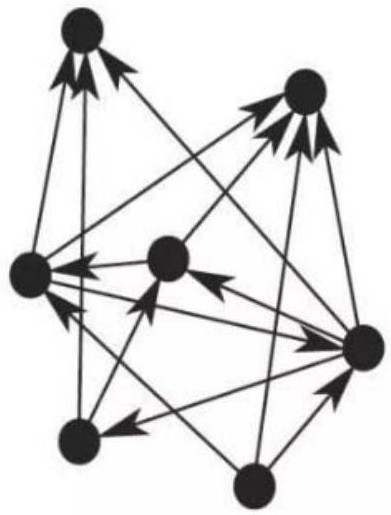

Product quality control method based on process network model and machine learning algorithm

PendingCN113469241AImprove product qualification rateAccurate quality controlCharacter and pattern recognitionMachine learningNetwork modelQuality control

The invention discloses a product quality control method based on a process network model and a machine learning algorithm. According to the method, product quality control is realized in a mode of fusing a product process complex network and a machine learning algorithm, namely, a quality transmission complex network is established based on a product process mechanism, a machine learning XGBoost model is established based on the quality transmission network and sample data and trained, and an SHAP algorithm model is established to analyze an XGBoost training result. Key process parameters influencing quality are quantitatively mined, and the linkage effect among the process parameters is accurately calculated. The method has the advantages that a product process mechanism and a big data analysis method are effectively combined, so that the problems of high dimension, strong nonlinearity and non-uniform sample distribution of industrial actual production data, which cannot be solved by a common statistical analysis method, are effectively solved, and the defect that a traditional product quality control method carries out qualitative description or only carries out product quality control for a single independent factor is overcome; and the method can comprehensively and quantitatively analyze the influence of complex process factors in the whole process of product processing on the final product quality and accurately calculate the linkage influence among the process factors to form a quality identification model based on process mechanism and data dual drive, and is large in processing data volume, high in speed and accurate in evaluation result.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

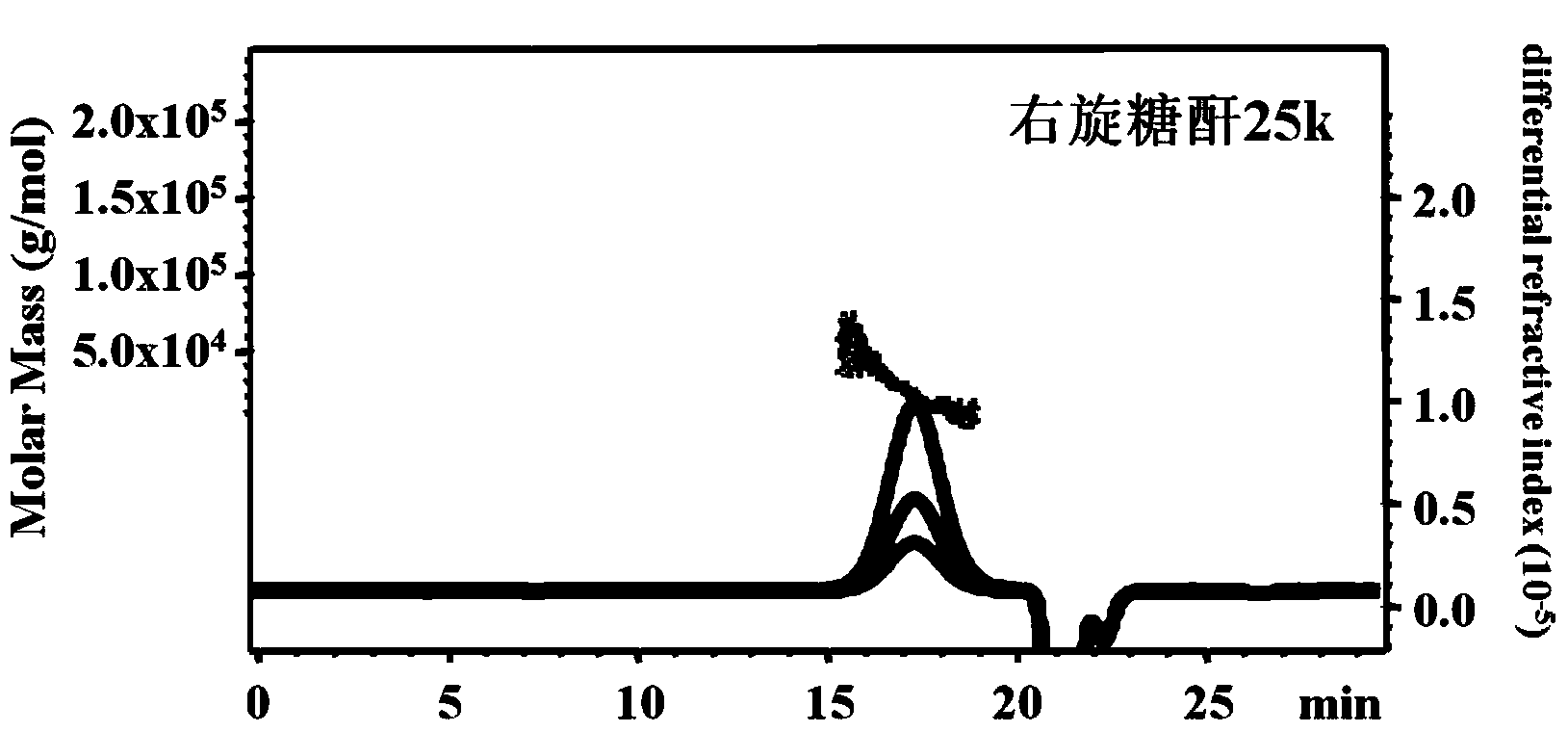

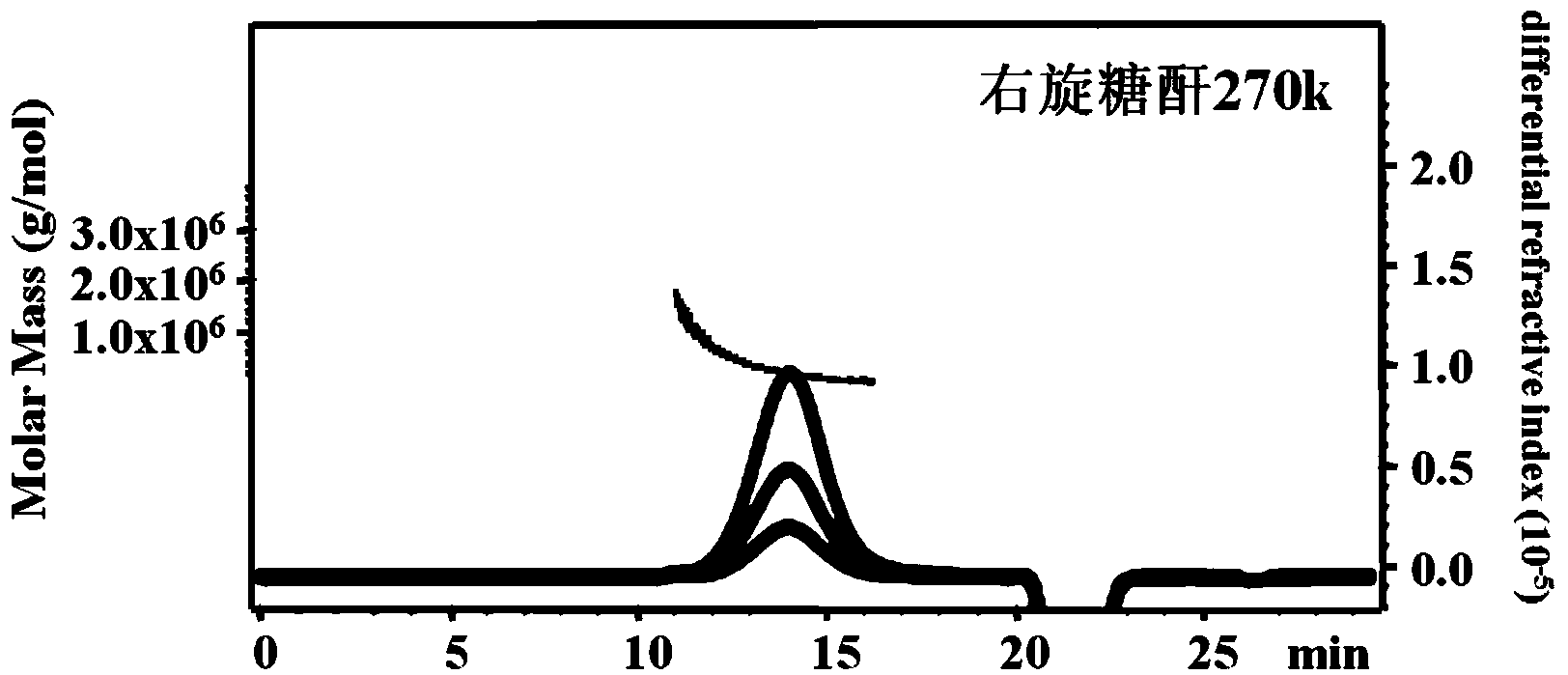

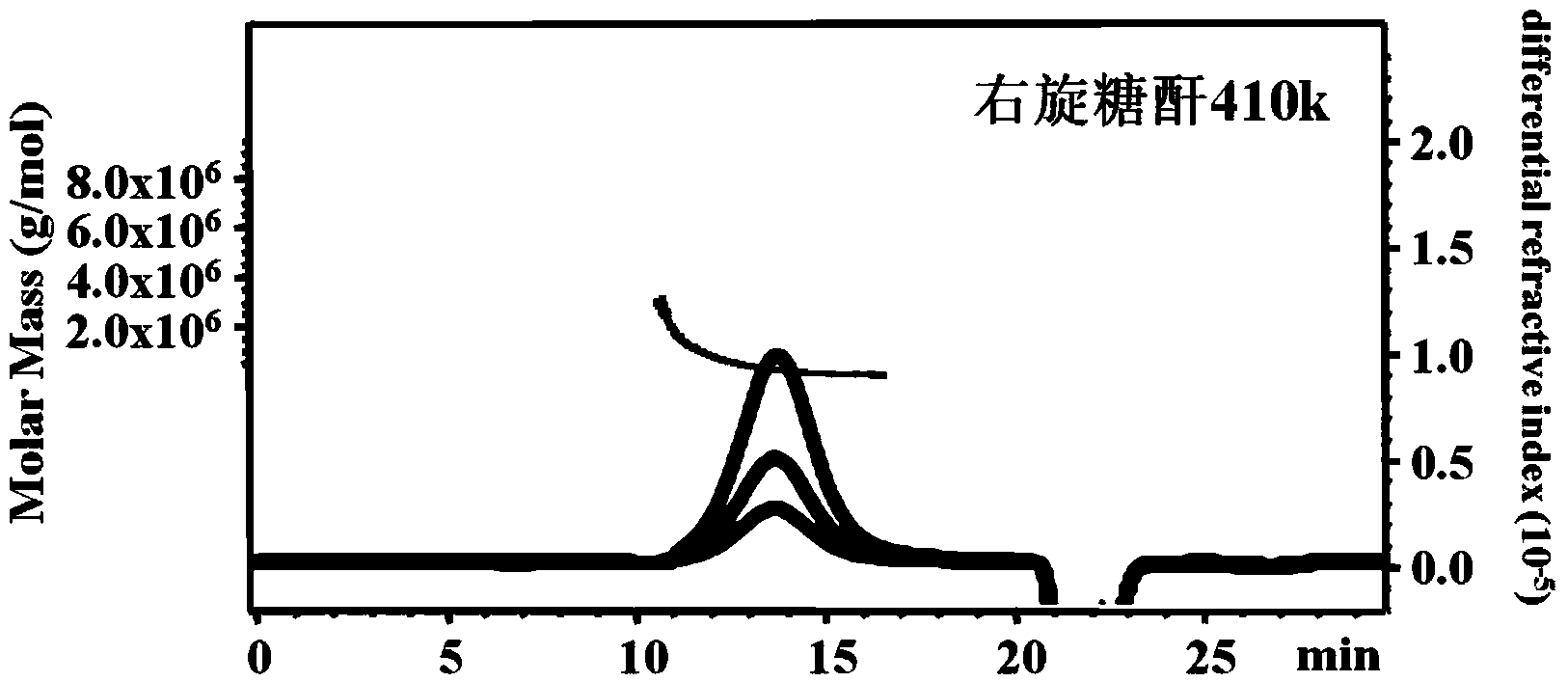

Method for quantifying polysaccharides and components of polysaccharides

ActiveCN103940940AHigh accuracy of resultsThe method is simpleComponent separationWeight distributionChemistry

The invention relates to the technical field of saccharide measurement and in particular relates to a method for quantifying polysaccharides and components of the polysaccharides. The method comprises the following steps: performing high performance size exclusion chromatography (HPSEC) or asymmetric field flow separation on a polysaccharide sample solution, analyzing by combining technologies of laser light scattering (LLS), refractive index (RI) and ultraviolet detection (UV), and calculating the contents of polysaccharides and components of the polysaccharides in a selected molecular weight distribution range through the dn / dc values of the polysaccharides and components of the polysaccharides measured by adopting the refractive index increment value (dn / dc) of 0.146mL / g (0.130-0.160mL / g) or a refractive index detection technology. The method can be used for measuring the content of the polysaccharides in plants and fungi and products of the polysaccharides, and the accurate, high-efficiency and simple method is provided for quality control on polysaccharide substances.

Owner:李绍平

MOCVD equipment spray head and vapour reaction control method thereof

InactiveCN105420691AQuality improvementInhibition of prereactionChemical vapor deposition coatingGas phaseShielding gas

The invention provides an MOCVD equipment spray head. The MOCVD equipment spray head comprises an MO source channel, a protective gas channel, an oxygen source channel, an observation channel and a reaction cavity, wherein an MO source gas and a protective gas directly reach the interior of the reaction cavity through the MO source channel and the protective gas channel respectively; an oxygen source gas is dispersed through a buffer cavity and then reaches the reaction cavity through the oxygen source channel; the protective gas channel is arranged between the MO source channel and the oxygen source channel; and the protective gas forms a gas wall in the reaction cavity so as to prevent pre-mixing of the MO source gas and the oxygen source gas in the reaction cavity before reaching a rotary base, thus the quality of film growth of MOCVD equipment is improved. According to the MOCVD equipment spray head provided by the invention, the thickness and the length of the gas wall can be controlled through controlling the flow rate of the protective gas, and the quality of film growth can be accurately controlled through designing the observation channel, the MO source channel, the protective gas channel and the oxygen source channel, so as to obtain a high-quality film.

Owner:SUN YAT SEN UNIV

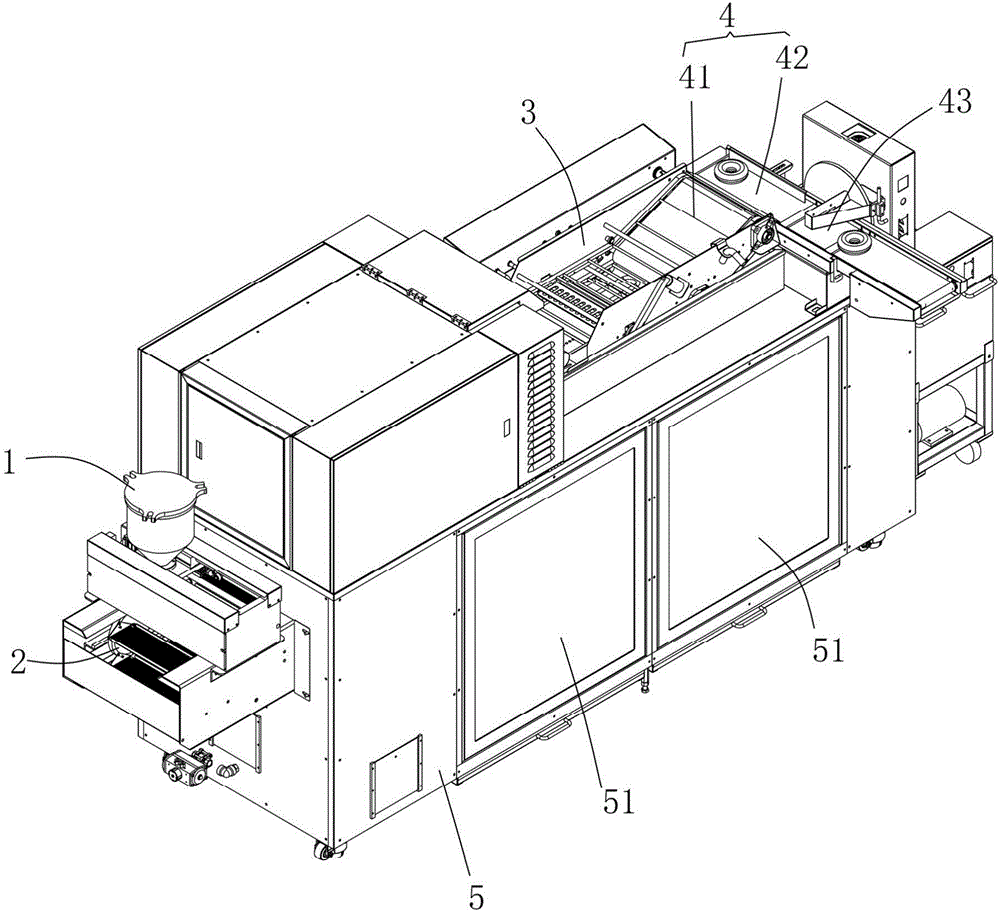

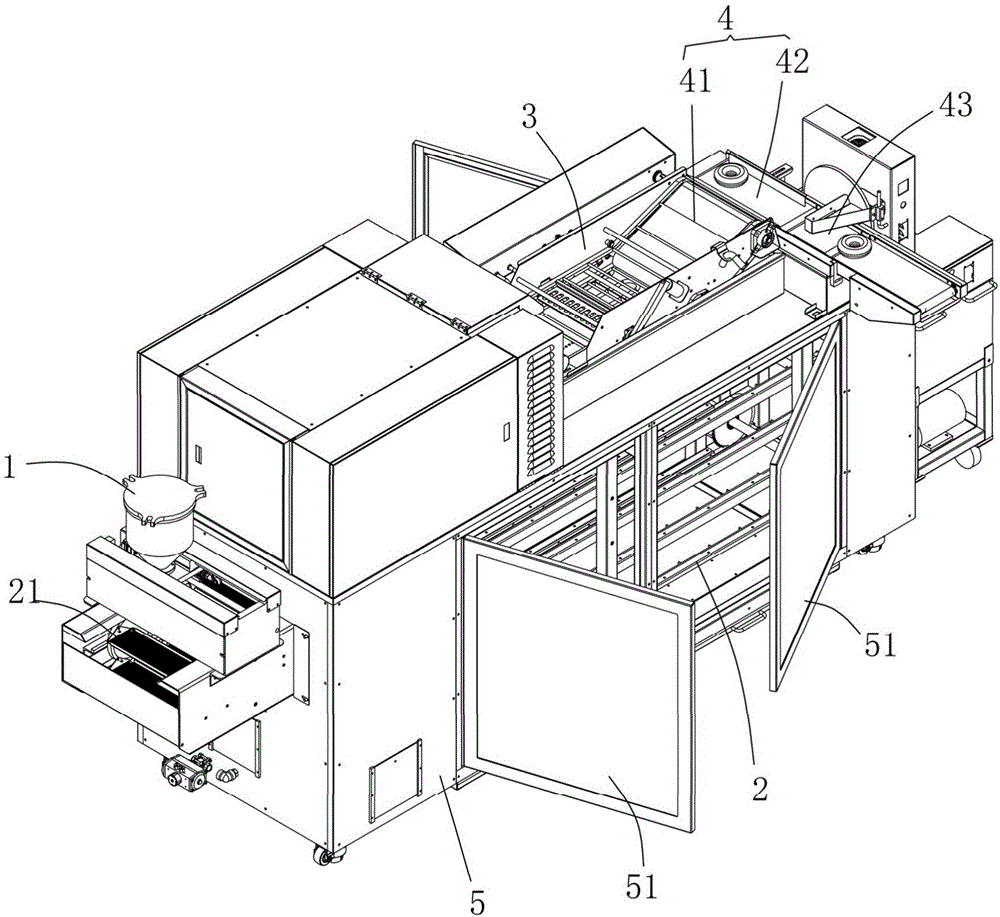

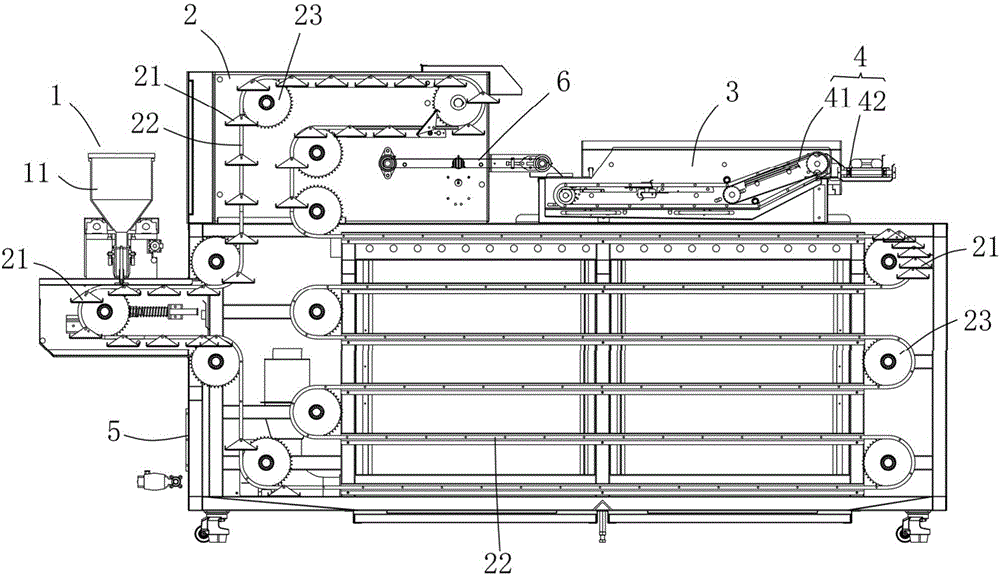

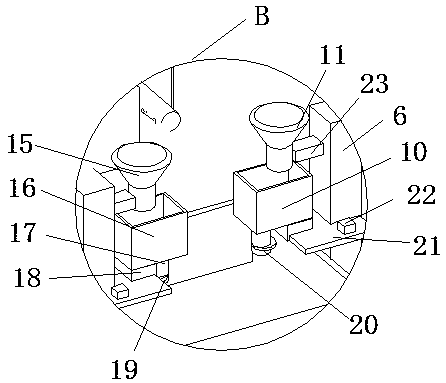

Automated donut production apparatus

InactiveCN106577901AImprove work efficiencySave human effortOil/fat bakingDough shaping and cutting apparatusQuality controlContinuous production

The invention relates to the technical field of food processing, in particular to an automated donut production apparatus, comprising an extrusion forming unit, a fermenting unit, a frying unit and a discharging unit; the extrusion forming unit extrudes dough into donut bases; the fermenting unit receives the donut bases extruded by the extrusion forming unit and provides a fermenting environment and time to ferment the donut bases; the frying unit receives the fermented donut bases discharged by the fermenting unit and fries the donut bases to form finished donuts; the frying unit features side turning frying during frying of the donut bases; the discharging unit discharges the donuts fried by the frying unit. The automated donut production apparatus provides automated continuous production of extrusion forming, fermenting and frying for donuts, provides precise quality control, and ensures perfection of finished products; the automated donut production apparatus has high operating efficiency, reduced labor consumption and reduced production cost.

Owner:汕头市煜丰机械有限公司

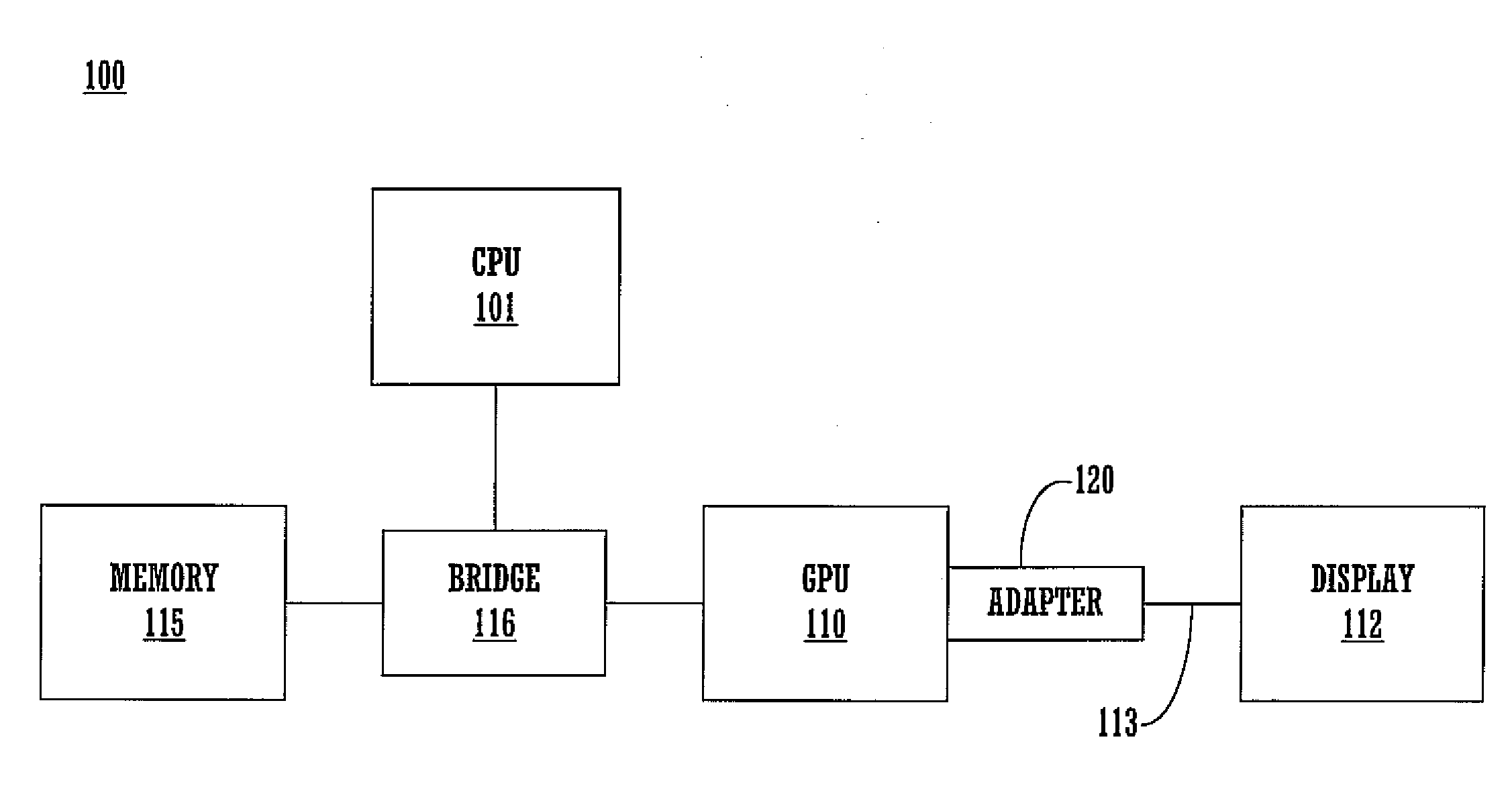

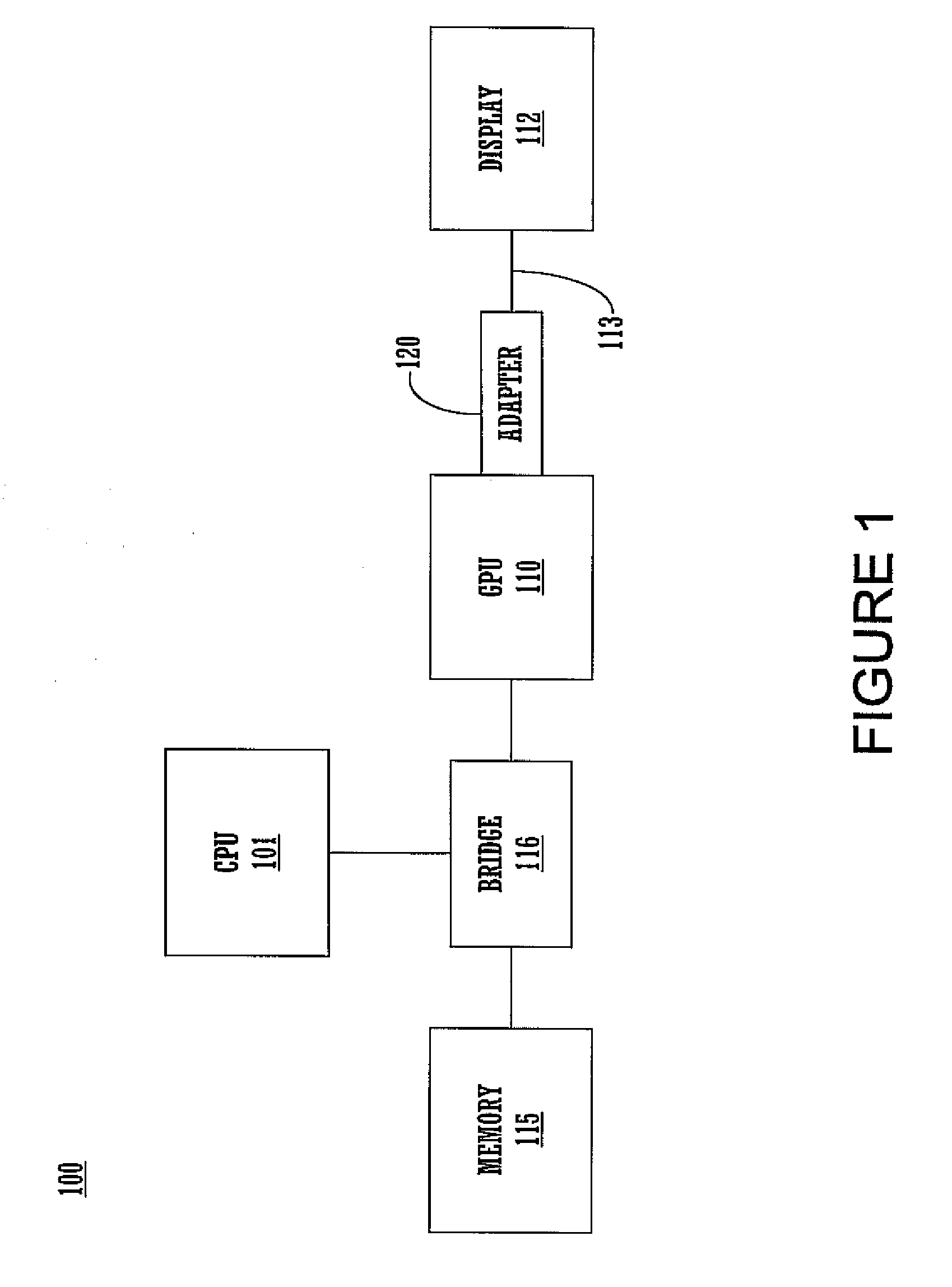

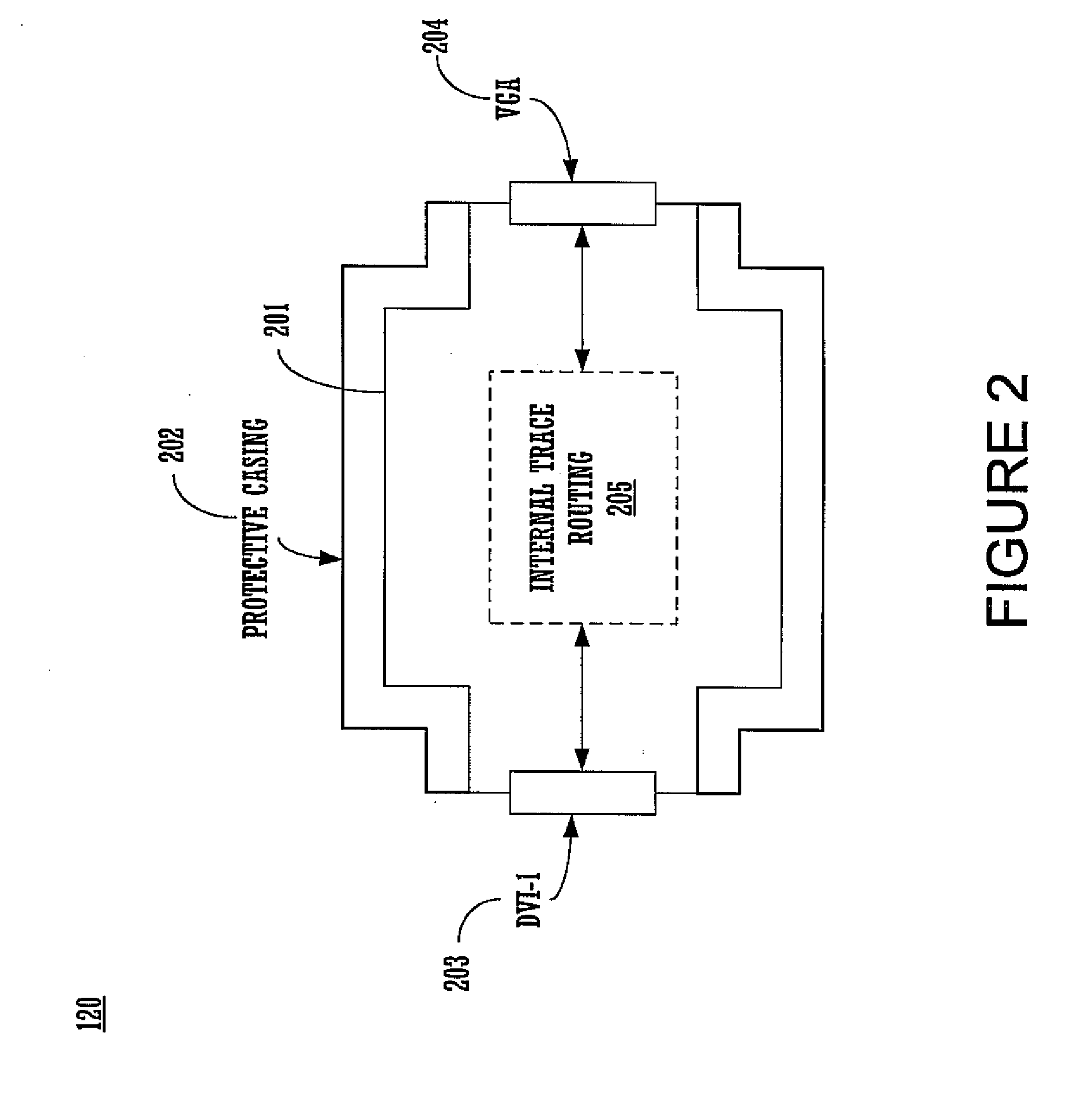

Controlled impedance display adapter

ActiveUS20080174595A1Improves EMI shieldingLow costElectric discharge tubesCoupling device detailsEngineeringPrinted circuit board

A display adapter for a digital connector and an analog connector. The display adapter includes a PCB (printed circuit board). A first connector and a second connector are both mounted on the PCB. The first connector and second connectors can be VGA, DVI-I, DVI-D, or HDMI format. The PCB is configured to communicatively couple video signals between the first connector having one format and the second connector having a different format.

Owner:NVIDIA CORP

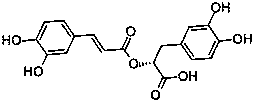

Quantitative quality control method of herbal tea product

InactiveCN103808829AEffective quality controlAccurate quality controlComponent separationFlos chrysanthemiGLYCYRRHIZA EXTRACT

The invention discloses a quantitative quality control method of a herbal tea product, the herbal tea is the product prepared by using mesona chinensis, plumeria rubra, microcos paniculata, flos chrysanthemi, honeysuckle, selfheal and liquorice as raw materials, and the aim of effectively controlling the product quality is achieved by quantitatively determining three feature components in the product: tanshinol, (alpha)-3-carboxy-alpha-hydroxybenzene propanoic acid and rosmarinic acid. The method can be used for performing content determination and quantitative quality control on the herbal tea product and a raw material extract so as to effectively guarantee the quality and stability of the produced herbal tea, thereby well guaranteeing the safety of vast consumer. The quantitative quality control on three components of the herbal tea product adopts the high performance liquid chromatography, the content ranges of the three feature components including tanshinol, (alpha)-3-carboxy-alpha-hydroxybenzene propanoic acid and rosmarinic acid in qualified raw material extract are respectively 0.01wt-45wt%, the content range of each component in the quality herbal tea beverage product is respectively 0.1-5000microgram / mL.

Owner:HUNAN NORMAL UNIVERSITY +1

Fully-automatic brick tea forming equipment

ActiveCN106900890AAccurate quality controlImprove qualityPre-extraction tea treatmentClimate change adaptationBrickRobotic arm

The invention relates to fully-automatic brick tea forming equipment which is matched with a press machine (135) during use and comprises a weighing component (127), a steaming component (128), a mechanical arm demolding component (129), a mold component (130), a template conveying and discharging component (131) and an electric control system; an outlet of the weighing component (127) corresponds to an inlet of the steaming component (128); an outlet of the steaming component (128) corresponds to a feeding port of the mold component (130); the mechanical arm demolding component (129) is respectively matched with the template conveying and discharging component (131). The fully-automatic brick tea forming equipment provided by the invention has the benefits that the quality control of raw materials is accurate, a steaming effect is good, uniform and consistent, the quality of a finished brick is good, the pressing process is accurate to control, and a fully-automatic demolding effect is good.

Owner:INST OF FRUIT & TEA HUBEI ACAD OF AGRI SCI

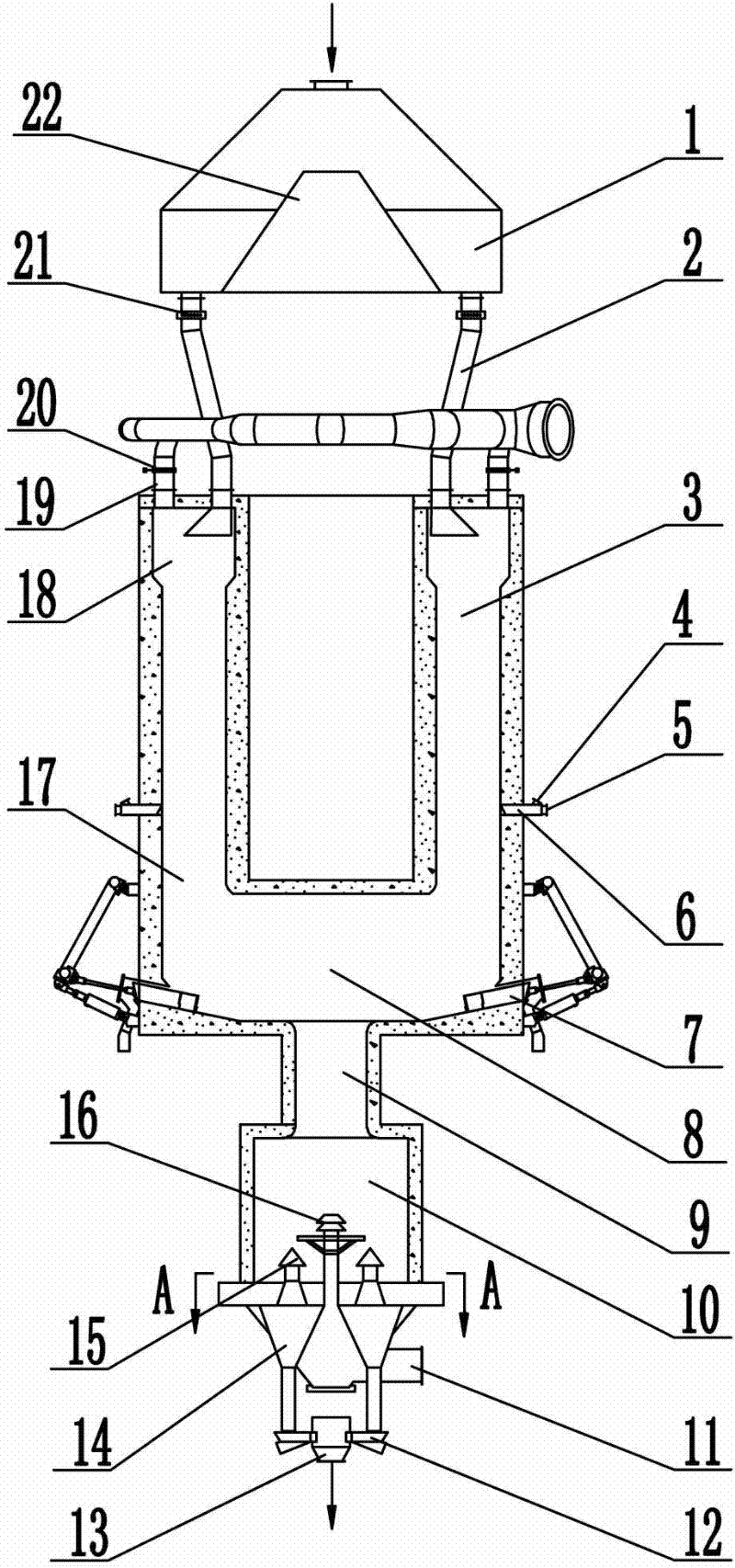

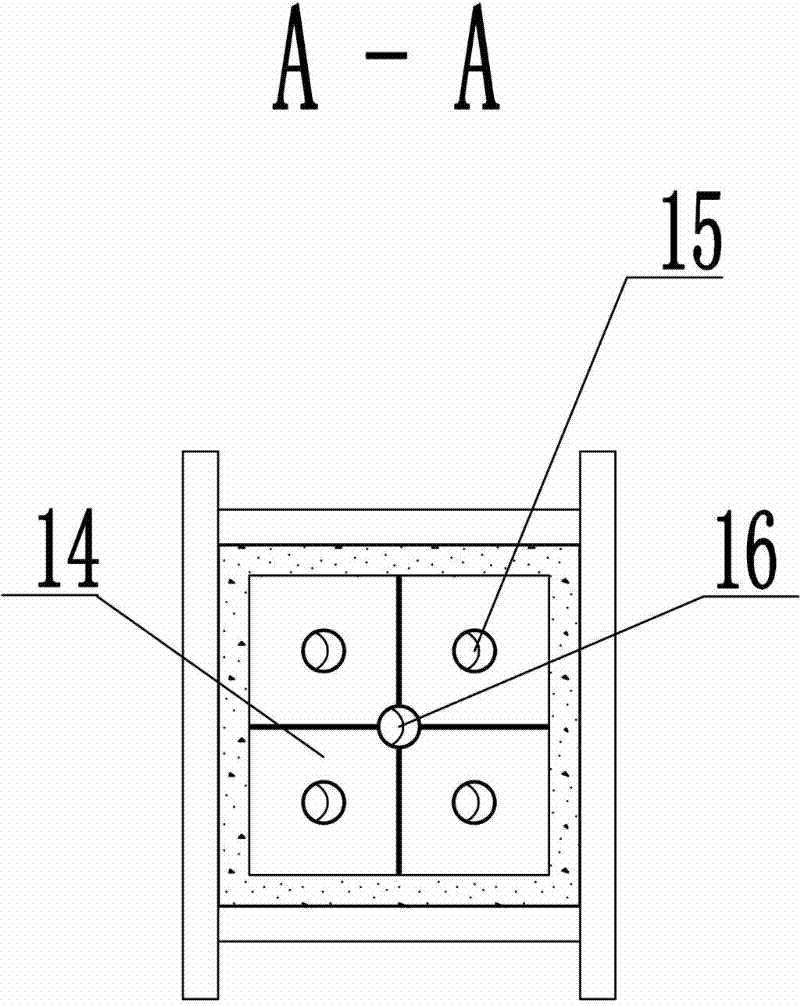

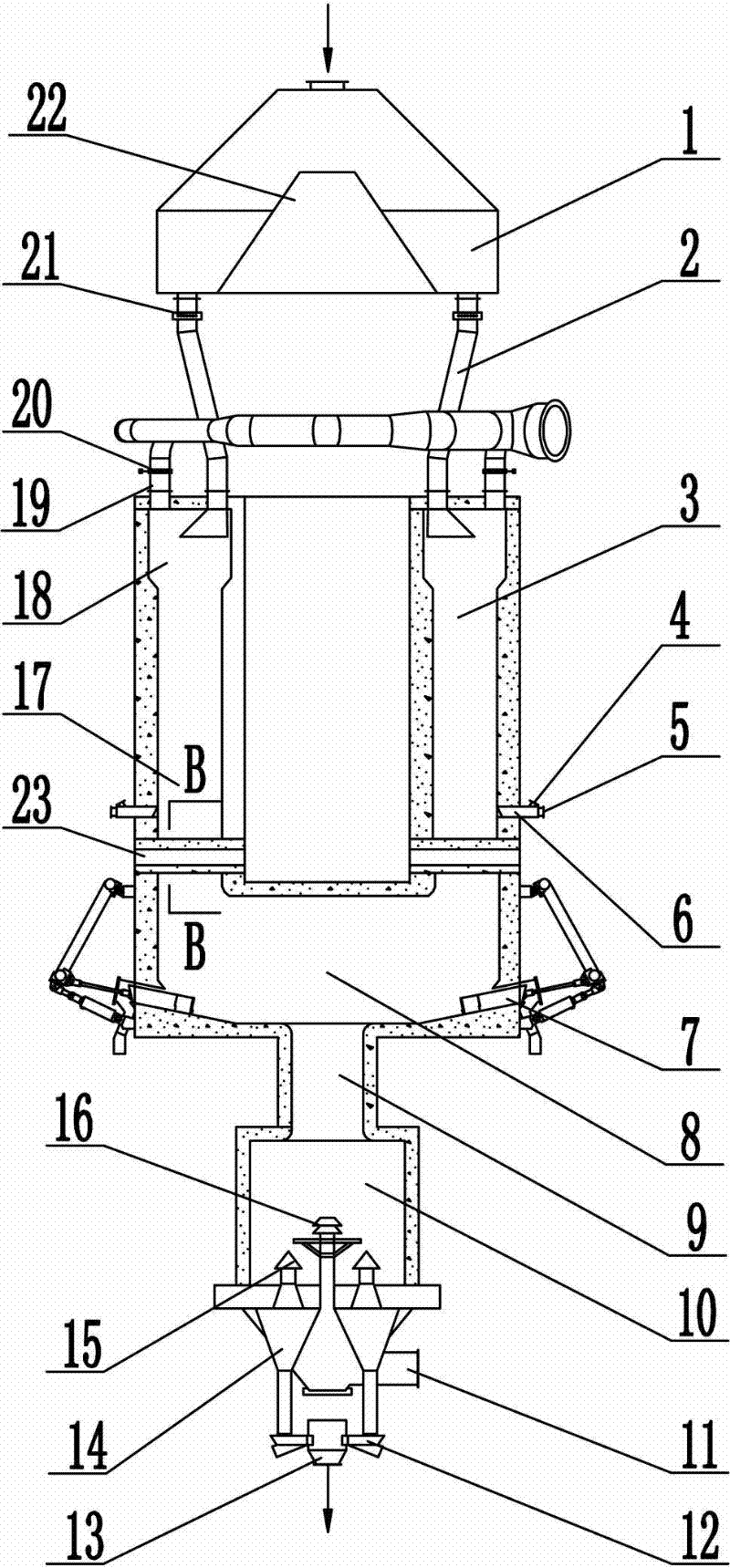

Calcinating shaft kiln comprehensively utilizing heat energy unit temperature field

InactiveCN102374769AReasonable structural designEven air distributionVertical furnacesAirflowEngineering

The invention provides a calcinating shaft kiln comprehensively utilizing heat energy unit temperature field and solves the problems of the existing shaft kiln that product quality is low and heat consumption is high. The calcinating shaft kiln comprises a feeding bin, a feeding pipe, a calcinating chamber and a cooling chamber. According to the technical key points of the invention, each discharge port of a top loop shunting feeding bin is connected with the feed inlet of the respective independent unit temperature field material calcinating activate chamber through a feed air lock pipe; each chamber is internally provided with one unit temperature field combustor, the bottom of each chamber is communicated with a material integrative energy integration chamber, and is communicated with the proportion gas flow strengthening cooling chamber through a material diffusing heat exchange region, the lower part of the balance gas flow strengthening cooling chamber provided with a center cooling nozzle button and a chamber cooling nozzle button is connected with the discharging air lock device. The calcinating shaft kiln has reasonable structure design, and can be controlled accurately in material preheating, calcination and cooling process; each unit temperature field has the advantages of small calcinating region, strong flame ejection penetrating power, uniform temperature distribution in the temperature field, good product quality and low heat rate.

Owner:鞍山市华杰石灰工业设计研究有限公司

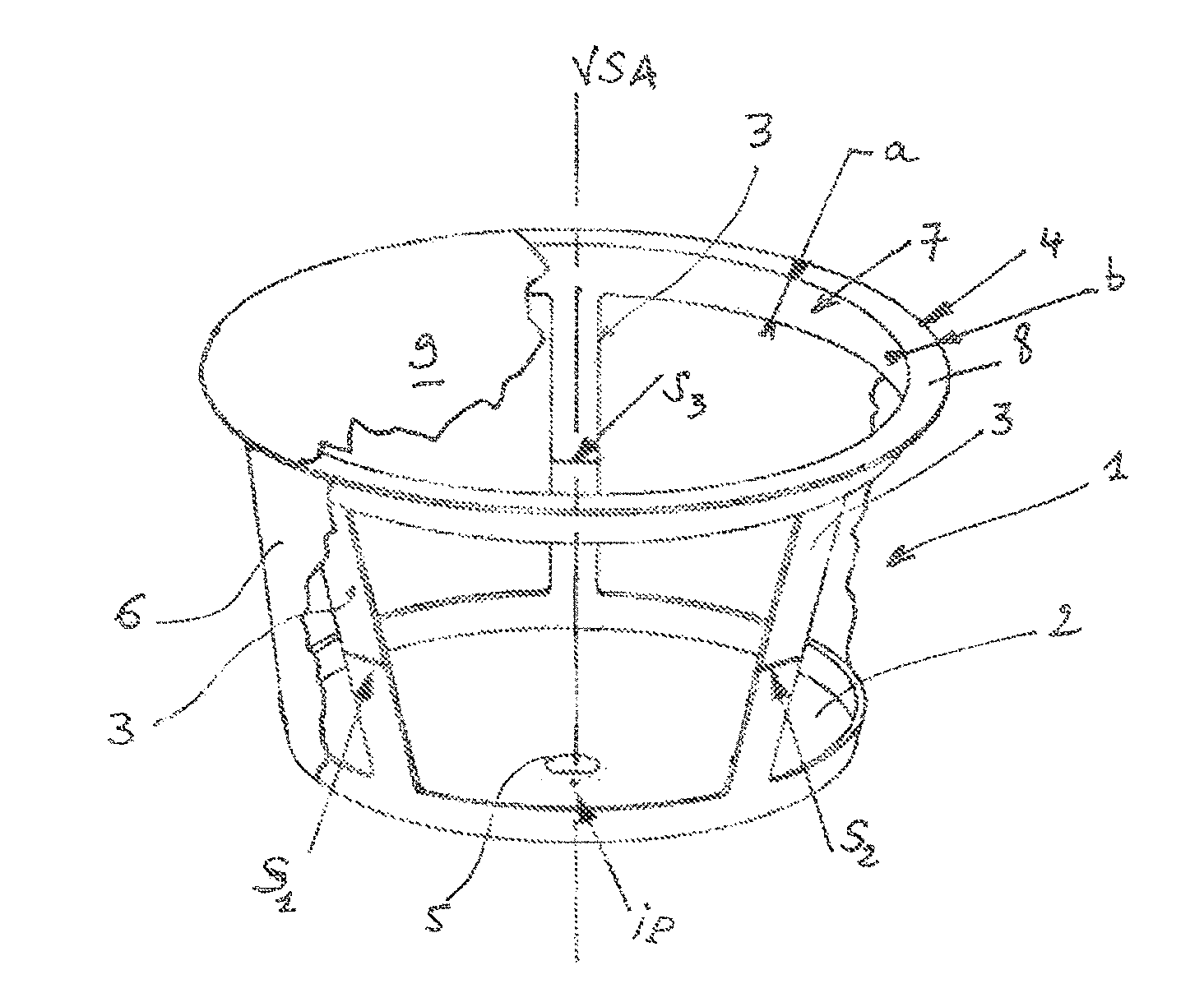

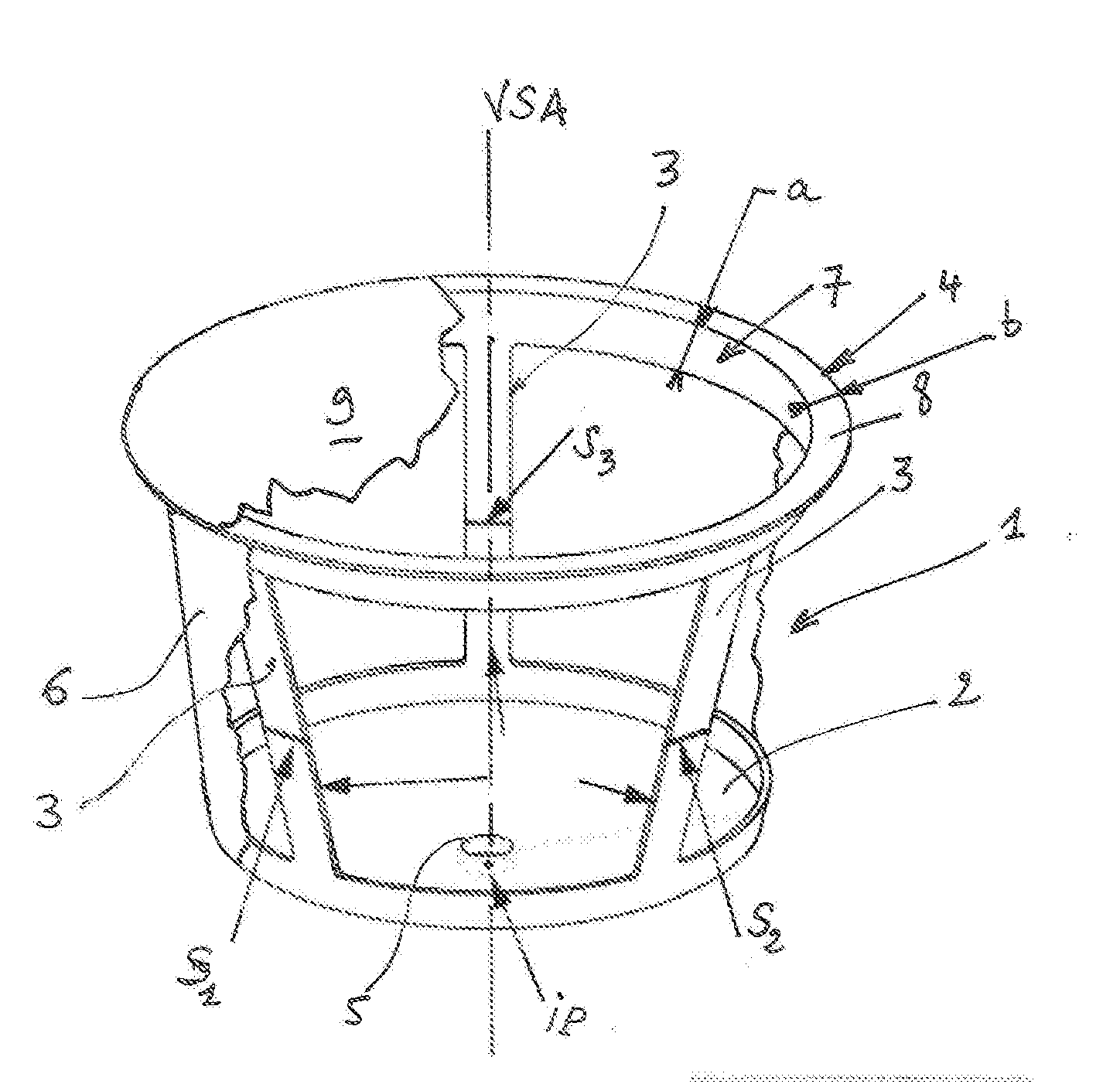

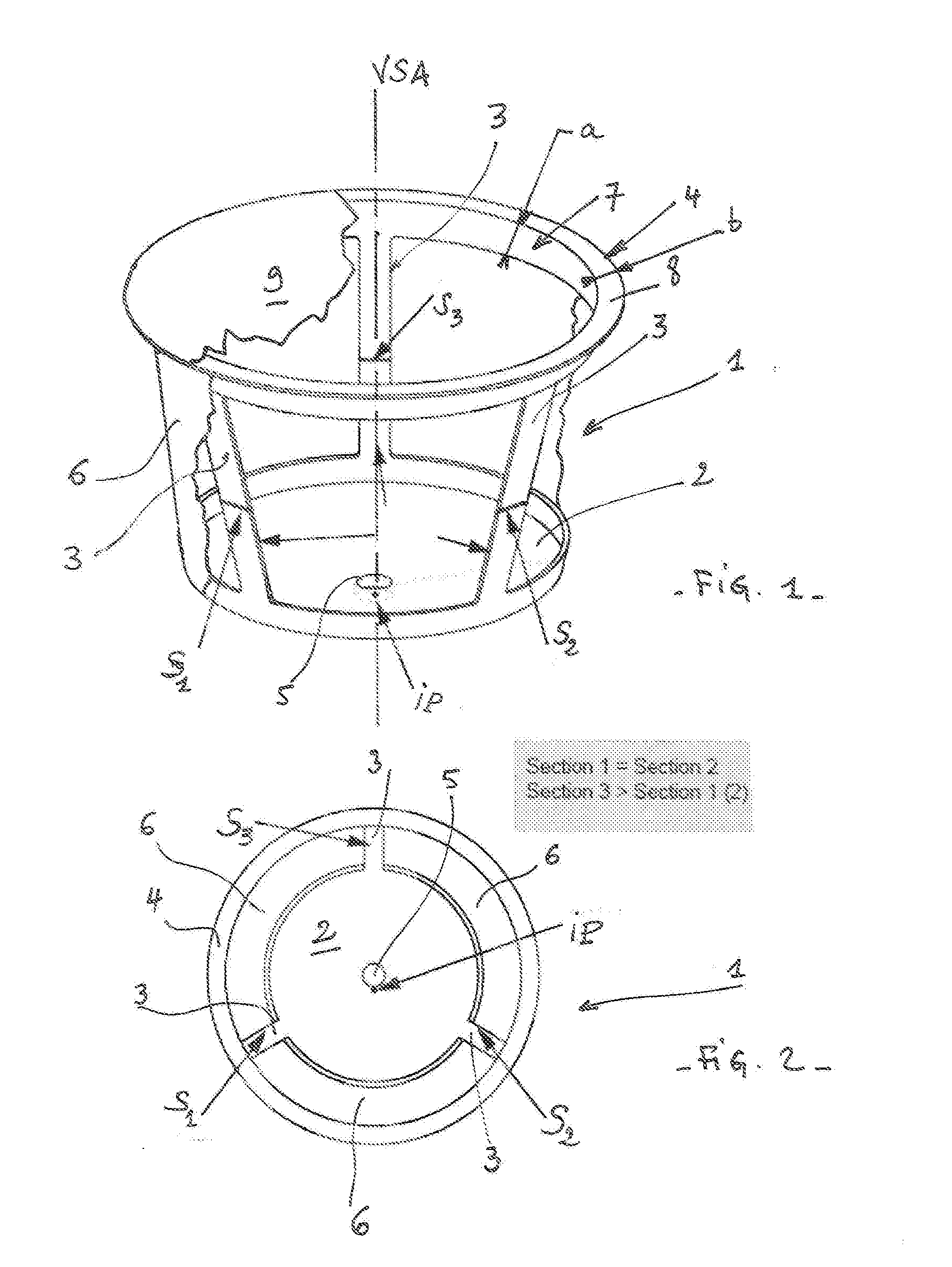

In-mould labelled container

InactiveUS8833235B2Easy disposalEasy to recycleWrappersContainer/bottle contructionInjection pointBiomedical engineering

The present invention concerns an injection-molded capsule for use in a food preparation machine, said capsule for use in a food preparation machine comprising: (i) a structure (1) with a lower side (2), at least three pillars (3) extending from the lower side and linked to a circular upper frame (4) which defines the surroundings of the capsule top side, the pillars (3) having cross-sections S1, S2 and S3, the lower side (2) being a solid wall that comprises a dispensing opening (5) and is centered across the vertical symmetry axis VSA of said capsule, and (ii) a label (6) attached to the outer surface of the lower side (2), pillars (3) and upper circular frame (4), thus forming an envelope that defines capsule side walls, characterized in that the injection point IP of the capsule is off-centered in the vicinity of said dispensing opening (5), opposed the pillar (3) having a cross-section S3 relatively to the axis VSA, and in that S1=S2 and S3>S1.

Owner:SOC DES PROD NESTLE SA

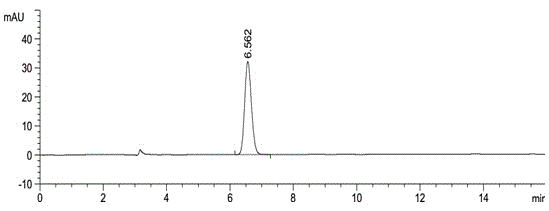

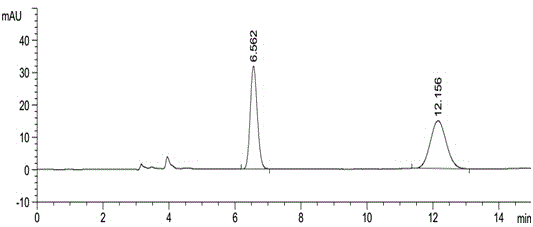

Method for using liquid chromatography to separate and measure apremilast and enantiomer thereof

ActiveCN104820028AAccurate quality controlAccurate separation detectionComponent separationAlkaneEnantiomer

The invention relates to a method for using a liquid chromatography to separate and measure apremilast and enantiomer thereof. The method includes that using spherical silica gel coated with chiral polymer at surface as a chiral chromatographic column, using alkane-different concentrations of polarity organic solvent as mobile phase, wherein the polarity organic solvent is composed of first organic solvent and second organic solvent, the alkane is selected from normal hexane, normal heptane, cyclohexane and methylene dichloride, the first organic solvent is isopropanol, and the second organic solvent is selected from methanol, ethanol and acetonitrile. The method for using the liquid chromatography to separate and measure the apremilast and enantiomer thereof solves the problem that the apremilast and enantiomer thereof are difficult to separate for the separation and measurement, and accordingly the controllable quality of the apremilast and the preparation thereof is guaranteed.

Owner:CHONGQING PHARMA RES INST

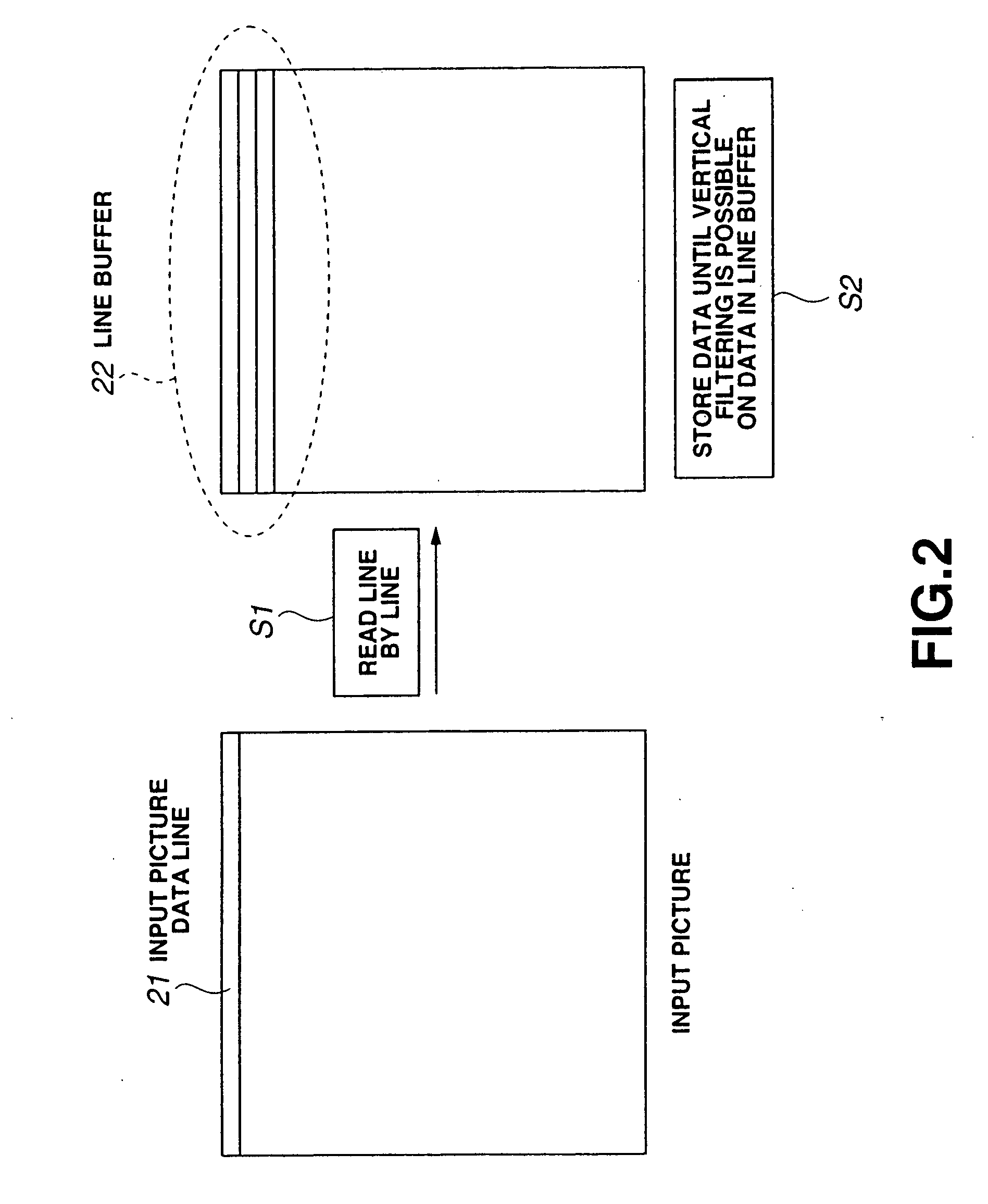

Block area wavelet transform picture encoding apparatus

InactiveUS20050259880A1Accurate quality controlImprove picture qualityCode conversionImage codingQuality controlWavelet transform

In wavelet transform encoding, high-quality encoding is to be realized by enabling picture quality control from one fractional area to another. An input picture 100 is read out in an amount corresponding to a number of lines required for wavelet transform and buffered in a memory unit 6. The input picture then is wavelet transformed in a wavelet transform unit 2 and quantized in a coefficient quantizing unit 3. In quantizing wavelet transform coefficients, the wavelet transform coefficients are multiplied by weighting coefficients from one sub-band to another. The weighting coefficients are determined using the analysis information of a specified block area in a picture, such as motion information and texture fineness information. This enables fine quantization control in terms of a picture block as a unit.

Owner:SONY CORP

In-mould labelled container

InactiveUS20130146495A1Promote wettingEasy disposalWrappersLaminationBiomedical engineeringFood preparation

The present invention concerns an injection-molded capsule for use in a food preparation machine, said capsule for use in a food preparation machine comprising: (i) a structure (1) with a lower side (2), at least three pillars (3) extending from the lower side and linked to a circular upper frame (4) which defines the surroundings of the capsule top side, the pillars (3) having cross-sections S1, S2 and S3, the lower side (2) being a solid wall that comprises a dispensing opening (5) and is centered across the vertical symmetry axis VSA of said capsule, and (ii) a label (6) attached to the outer surface of the lower side (2), pillars (3) and upper circular frame (4), thus forming an envelope that defines capsule side walls, characterized in that the injection point IP of the capsule is off-centered in the vicinity of said dispensing opening (5), opposed the pillar (3) having a cross-section S3 relatively to the axis VSA, and in that S1=S2 and S3>S1.

Owner:SOC DES PROD NESTLE SA

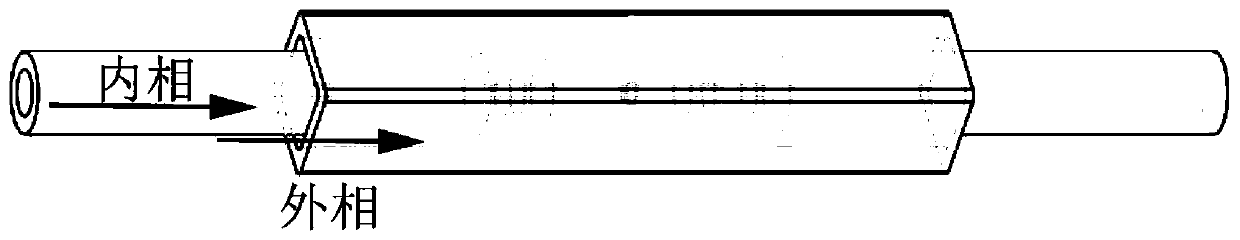

Method for preparing fiber with thermal insulation function based on microfluidic technology

ActiveCN110016725AWith heat preservation functionAccurate quality controlMonocomponent protein artificial filamentFilament/thread formingFiberDevice form

The invention discloses a method for preparing fiber with a thermal insulation function based on the microfluidic technology. According to the method, a glass tube is used for preparing a microfluidiccontrol device, the device is composed of a cylindrical inner tube body and a square outer tube body, a phase change material is injected through the inner tube body, and a cross-linkable fiber solution is injected through the outer tube body. The phase change material in the microfluidic control device forms dispersed droplets under the shearing action of an external phase fiber solution, then the fiber solution is crosslinked and dried to obtain functional fiber with nodes, and the nodes are filled with the phase change material. When the temperature rises, the phase change material absorbsheat, when the temperature is reduced, the phase change material releases heat, and the thermal insulation function is achieved. The diameter of the fiber and the number and size of the nodes can beadjusted by changing the flow rates of the internal and external phases, the technology is simple in preparation process, and the prepared fiber can be used for heat preservation and energy storage and for cooling and heat dissipation and has broad application prospects.

Owner:绍兴钠钇光电有限公司

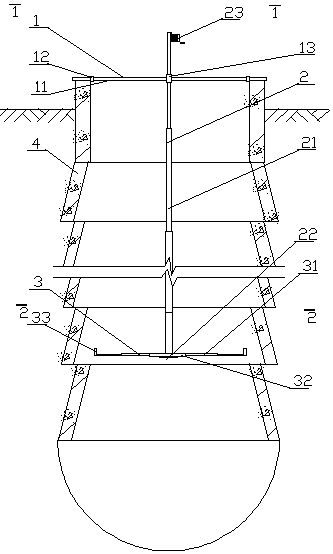

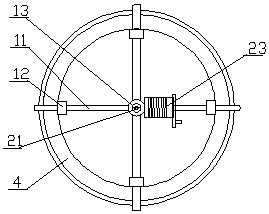

Manual hole digging pile quality control device and application method thereof

InactiveCN107907031AGood economic benefitsAccurate control of concentricityMechanical diameter measurementsBulkheads/pilesQuality controlEngineering

The invention discloses a quality control device and a use method for artificially digging piles. The device is composed of a horizontal positioning frame, a central positioning rod and a pile aperture detection ruler; The center line of the hole pile is vertical; the center positioning rod is parallel and concentric with the center of the artificial hole pile; Concentric and perpendicularly intersecting; the upper end of the central positioning rod is perpendicularly intersected and consolidated with the horizontal positioning frame, and the lower end is perpendicularly intersected and consolidated with the pile aperture detection ruler; the invention is beneficial to accurately control the center displacement during the construction process of artificial excavation piles. , pile diameter, pile concentricity, pile hole verticality quality, can also be used as a quality inspection tool, economical and practical, with significant economic benefits.

Owner:宋功业

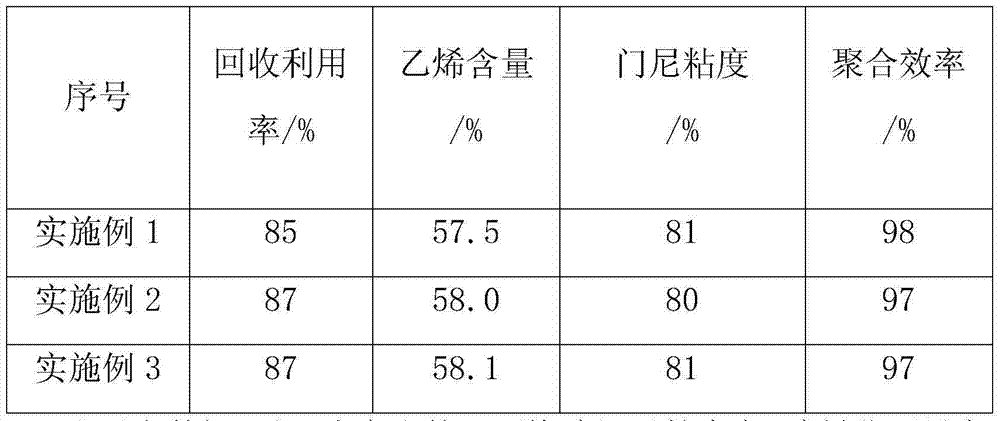

Production technology of ethylene propylene rubber

InactiveCN103539882AIncrease concentrationHigh reuse rateChemical recyclingPolymer scienceThermal insulation

The invention discloses a production technology of ethylene propylene rubber and relates to the field of rubbers. The production technology of the ethylene propylene rubber comprises five technological processes, namely polymerization, removal of a catalyst, recycling of a monomer and a solvent, coagulation as well as dehydration and drying. According to the production technology of the ethylene propylene rubber, a catalyst (described in the specification) is adopted in the polymerization process, a reaction speed is greatly increased, a full liquid phase thermal insulation reaction is adopted in the polymerization process, namely reaction heat is used for warming a polymerization kettle in a thermal insulation manner, optimal design of the polymerization kettle can meet reactant mixing requirement, a liquid-liquid filling reaction system can accurately control parameters of the polymerization technological process and product quality, concentration of a polymer glue solution is high, quantity of a cycle solvent is low, efficiency of recycled steam and recycling rate of the solvent are high, the polymerization kettle is small in volume but high in production intensity, conversion per pass is high, raw materials and a cycle monomer do not need to be refined, content of residual catalyst in the product is low, qualified rate of a product is high, consumption of the raw materials and the catalyst is low, and content of a vanadium catalyst in sewage is low. The production technology of the ethylene propylene rubber is good, high in production elasticity and low in investment.

Owner:ANHUI TONGFENG RUBBER & PLASTIC IND

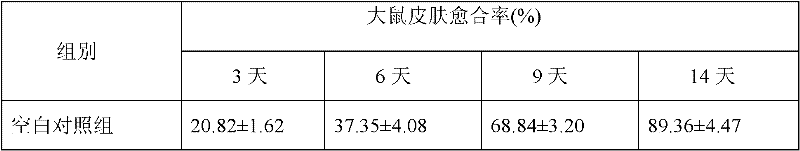

Sodium humate skin external preparation for promoting wound healing

InactiveCN102225072AStrong anti-inflammatoryStrong anti-exudationAerosol deliveryInanimate material medical ingredientsWound healingExternal application

The invention discloses a sodium humate skin external preparation for promoting wound healing, which is a gel formulation, a film formulation, a film-forming formulation or an ointment formulation of sodium humate in addition with pharmaceutically-acceptable adjuvant materials. In terms of the mass fraction, the content of sodium humate is 0.1% to 20%. The sodium humate skin external preparation disclosed by the invention has strong effects of relieving the inflammation, reducing the exudation, promoting the regeneration of capillary vessels and increasing the generation of collagen, and can significantly reduce the time of wound healing and promote wound healing. The application range of sodium humate in the medicine field is increased, and the blank of sodium humate skin external preparations is filled in. The sodium humate skin external preparation is available in various forms for external application, such as a gel, a film, a film-forming agent and an ointment. The sodium humate skin external preparation has the characteristics of relatively-definite components, quick onset of action, stable property and accurate quality control, and is convenient to be used in the clinic and selected by patients.

Owner:XI AN JIAOTONG UNIV

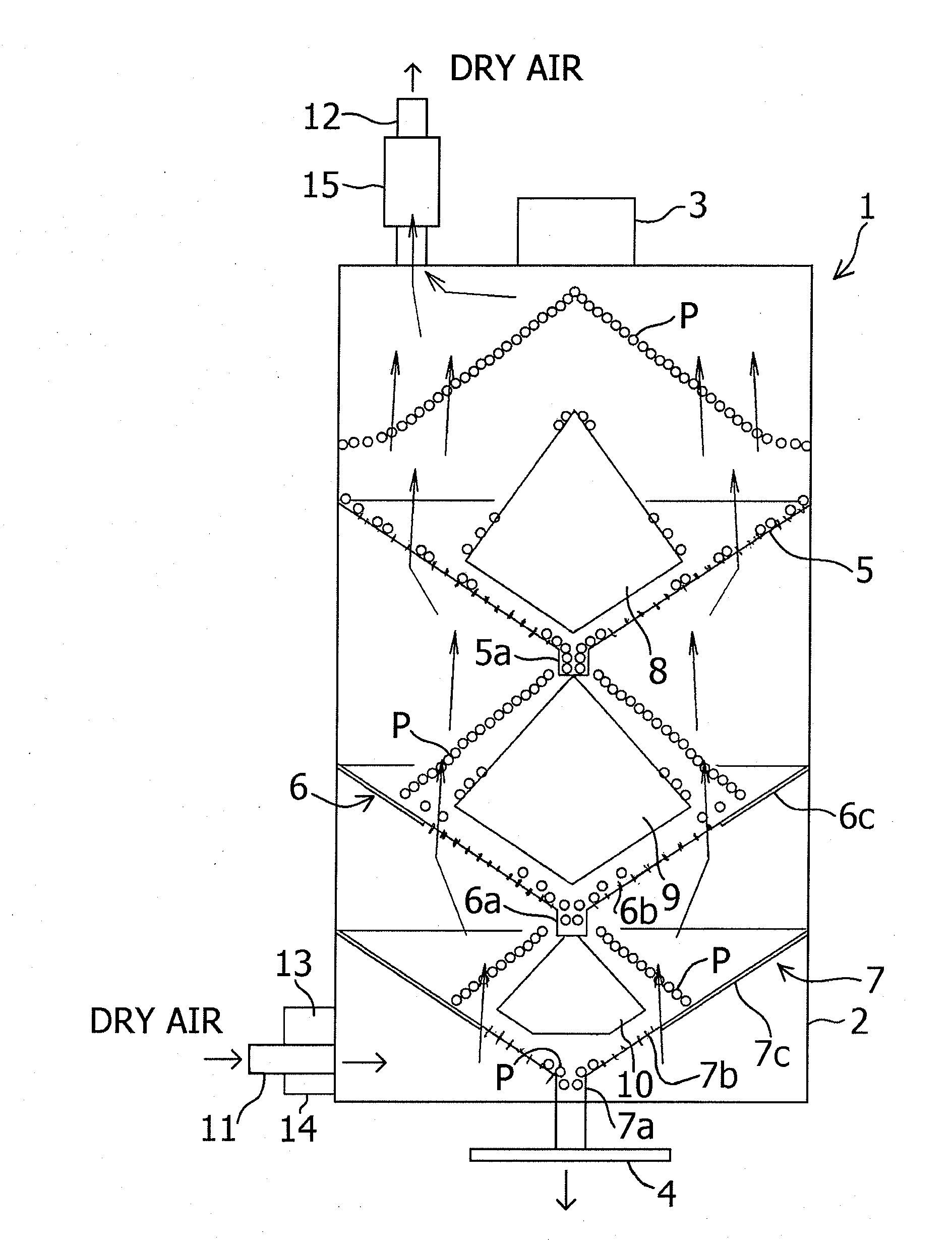

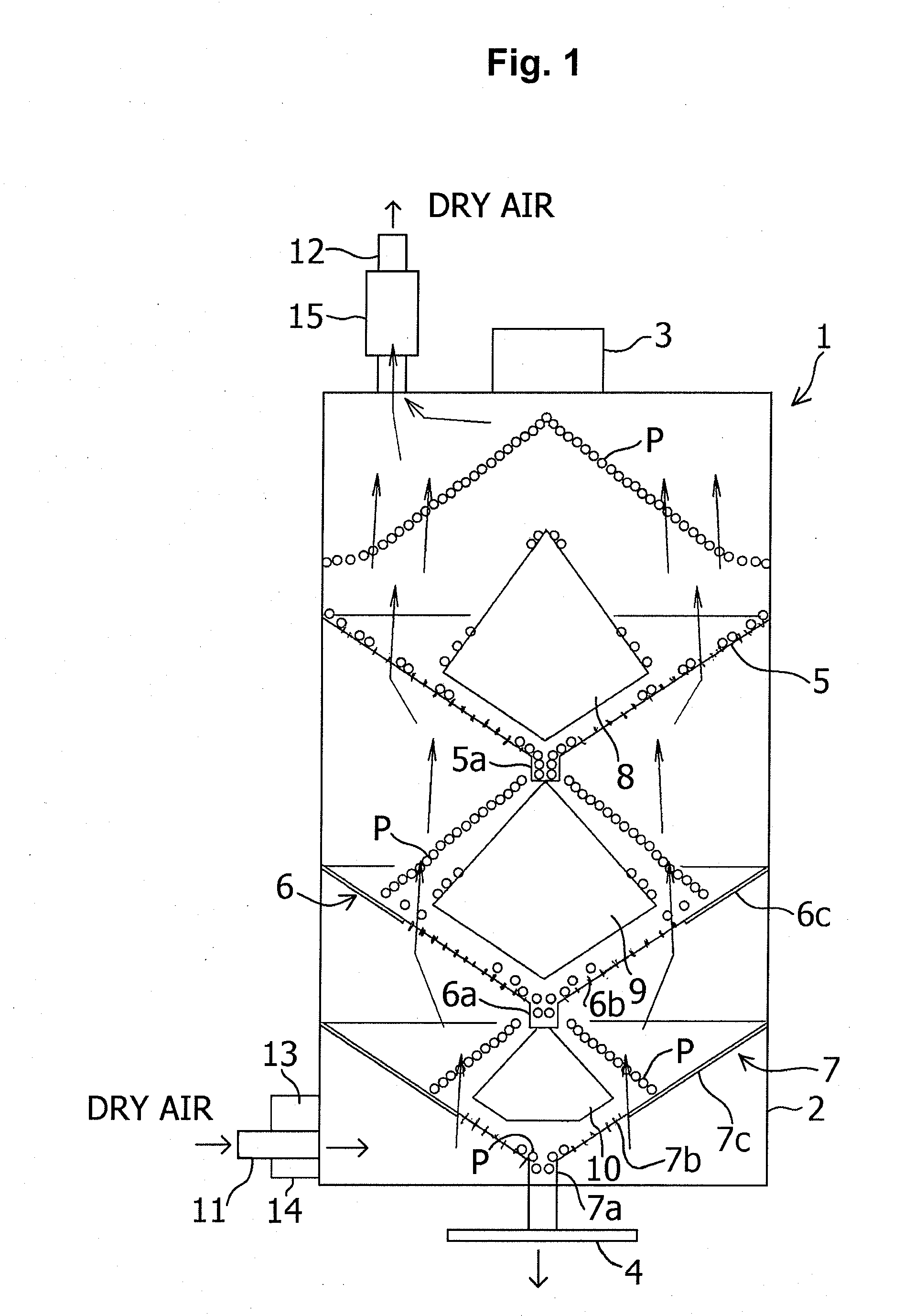

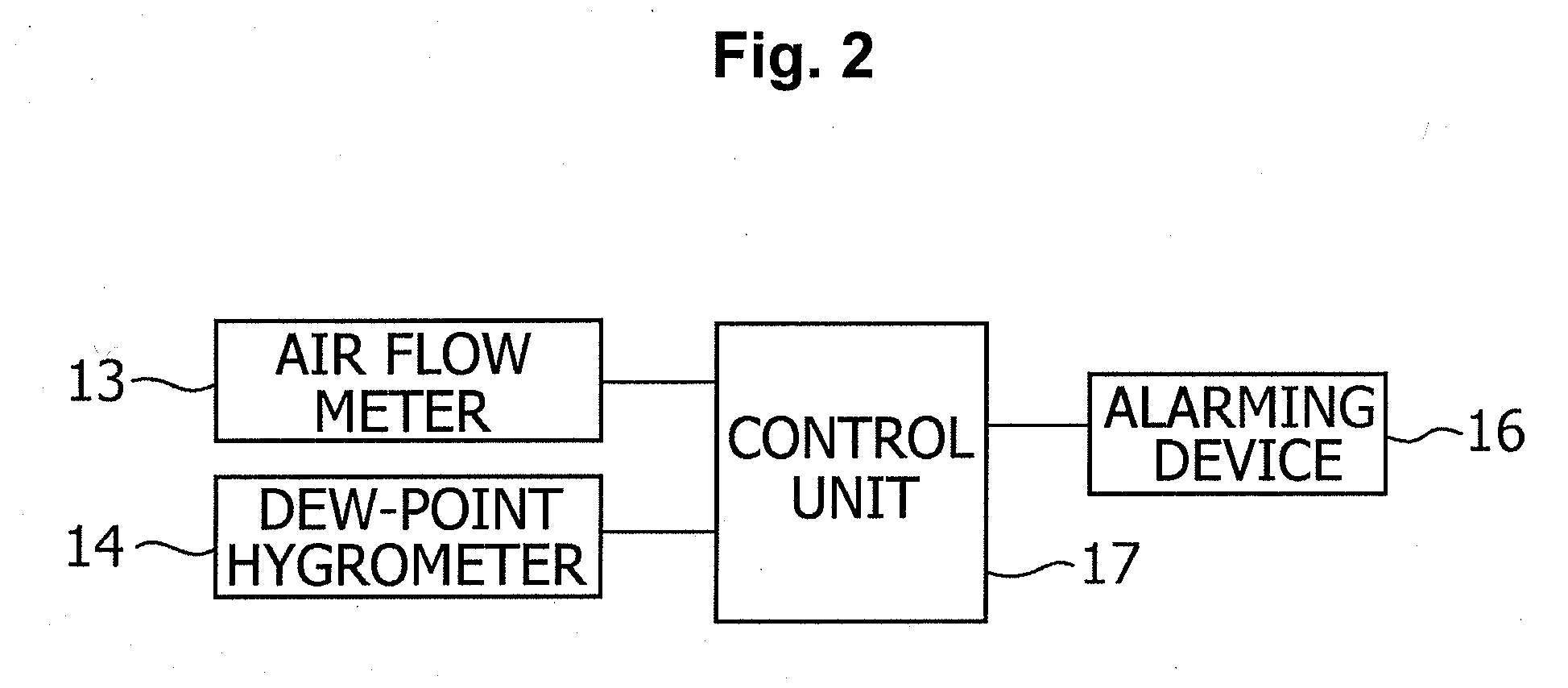

Drying hopper

InactiveUS20100107434A1Shorten drying timeSimple configurationDrying machinesDrying timeMechanical engineering

Owner:SYSKO

Dough kneading device for flour-made food processing

ActiveCN108617724AAccurate quality controlEasy to cleanMixing/kneading structural elementsMixing/kneading with rollersEngineeringSingle chip

The invention discloses a dough kneading device for flour-made food processing. The dough kneading device comprises a base and is characterized in that a transverse slide guide rail is arranged in themiddle of the upper surface of the base, a third fixing plate is arranged on the left side of the slide guide rail, a screw is rotatably connected to the right side of the third fixing plate througha bearing, square support columns are arranged at the front end and the rear end of the right side of the upper surface of the base, a second connecting rod is arranged on the inner side of the upperend of each square support column, a liquid feeding hopper is arranged on the front second connecting rod, a flour feeding hopper is arranged on the rear second connecting rod, and a single-chip microcomputer is arranged on the right side of the upper surface of the base. The dough kneading device has the advantages that the device is provided with an electronic weighing device and an electronic counter, the weight of needed flour and water can precisely controlled, the flour and the water can be automatically mixed according to a certain proportion, production efficiency is increased, dough does not need secondary processing during use, a dough kneading bin can move by the slide guide rail below the dough kneading bin, the kneaded dough can be conveniently taken out, and the dough kneading bin can be conveniently cleaned.

Owner:安徽品滋味食品股份有限公司

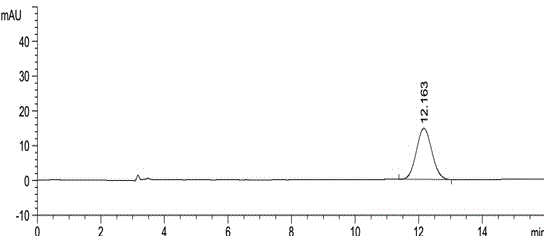

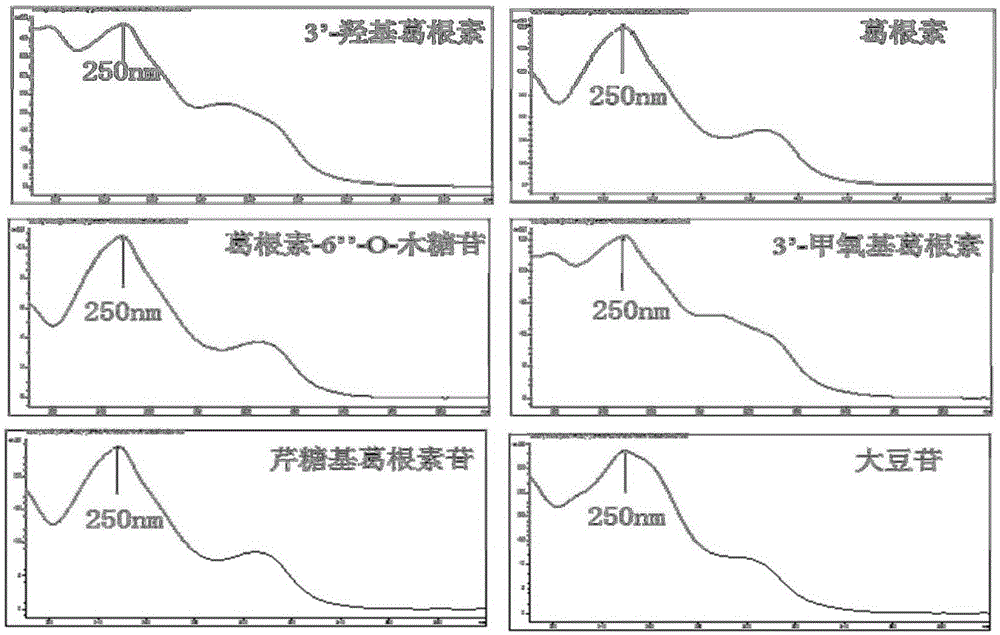

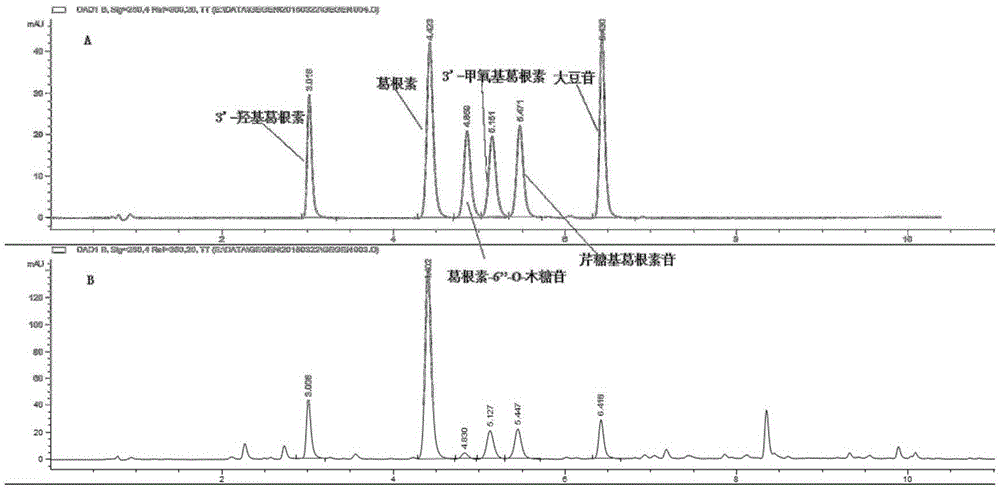

UPLC method for detecting components in radix puerariae, radix puerariae extract and radix puerariae-containing preparation

ActiveCN106370763AAccurate quality controlShorten the timeComponent separationMedicinal herbsPuerarin

The present invention provides a UPLC method for qualitatively and quantitatively detecting the contents of six components such as 3'-hydroxy puerarin, puerarin, puerarin-6"-O-xyloside, 3'-methoxy puerarin, mirificin and daidzin in radix puerariae, radix puerariae extracts and radix puerariae-containing preparations by adopting puerarin as a reference substance. The UPLC method comprises: preparing a reference substance solution and a testing sample solution, and carrying out gradient elution by adopting 0.1% acetic acid as a mobile phase A and adopting acetonitrile as a mobile phase B, wherein the detection wavelength is 250 nm, the chromatographic column is SB-C18, RRHD 1.8 [mu]m, 2.1*100 mm, the column temperature is 31 DEG C, the flow rate is 0.4 mL / min, and the injection volume is 1 [mu]L; comparing the obtained chromatogram with a radix puerariae herb finger print, wherein the main peak is puerarin, and other components are corresponding to various peaks in a one-to-one manner so as to identify the herb; and calculating the contents of the six components in the radix puerariae by combining relative calibration factors (the relative calibration factor of 3'-hydroxy puerarin is 1.253, the relative calibration factor of puerarin is 1.000, the relative calibration factor of puerarin-6"-O-xyloside is 1.422, the relative calibration factor of 3'-methoxy puerarin is 1.297, the relative calibration factor of mirificin is 1.332, and the relative calibration factor of daidzin is 1.030) and the peak area of puerarin in the contrast solution.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com