Manual hole digging pile quality control device and application method thereof

A technology of manual hole-digging piles and control devices, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problems of large steel tape measurement errors, large errors, and large deviations in results, and achieve significant economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

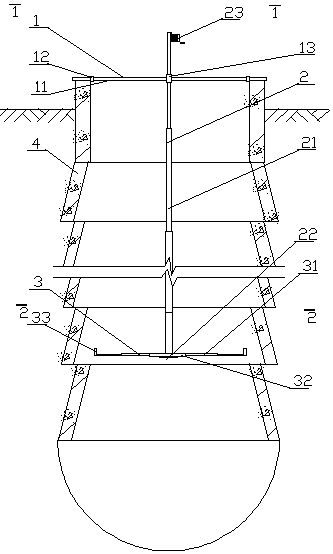

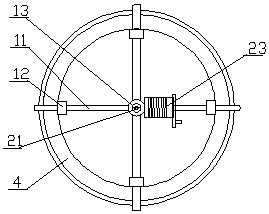

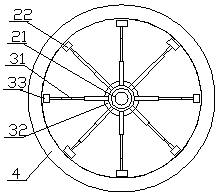

[0026] A certain project uses manual excavation piles with diameters of 800mm, 1m, 1.2m, 1.5m, 1.8m, 2m, 2.5m, and 3m. Figure 1 to Figure 3 The quality control device for manual hole-digging piles shown controls the hole-forming quality and ensures the hole-forming accuracy of the pile holes;

[0027] The manual digging pile quality control device is composed of a horizontal positioning frame 1, a central positioning rod 2, and a pile aperture detection ruler 3; The positioning rod 2 is parallel and concentric with the center of the manual digging pile; the pile aperture detection ruler 3 is located in the hole of the manual digging pile and is perpendicular to the center line of the manual digging pile; the horizontal positioning frame 1 is concentric and vertical to the center positioning rod 2 Intersect, concentric and parallel with the pile aperture detection ruler 3; the upper end of the center positioning rod 2 is vertically intersected and consolidated with the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com